Lakeshore 336 User Manual

User’s Manual

Model 336

Temperature Controller

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

Methods and apparatus disclosed and described herein have been developed solely on company funds of

Lake Shore Cryotronics, Inc. No government or other contractual support or relationship whatsoever has existed

which in any way affects or mitigates proprietary rights of Lake Shore Cryotronics, Inc. in these developments.

Methods and apparatus disclosed herein may be subject to U.S. Patents existing or applied for.

Lake Shore Cryotronics, Inc. reserves the right to add, improve, modify, or withdraw functions, design modifications,

or products at any time without notice. Lake Shore shall not be liable for errors contained herein or for incidental or

consequential damages in connection with furnishing, performance, or use of this material.

Rev. 1.9 P/N 119-048 7 December 2015

sales@lakeshore.com

service@lakeshore.com

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

| www.lakeshore.com

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: THREE (3) YEARS

1.Lake Shore warrants that products manufactured by Lake Shore (the

"Produ ct") will be f ree from def ects in materials and workmanship for

three years from the date of Purchaser's physical receipt of the Product (the "Warranty Period"). If Lake Shore receives notice of any such

defects during the Warranty Period and the defective Product is

shipped freight prepaid back to Lake Shore, Lake Shore will, at its

option, either repair or replace the Product (if it is so defective) without charge for parts, service labor or associated customary return

shipping cost to the Purchaser. Replacement for the Product may be

by either new or equivalent in performance to new. Replacement or

repaired parts, or a replaced Product, will be warranted for only the

unexpired portion of the original warranty or 90 days (whichever is

greater).

2.Lake Shore warrants the Product only if the Product has been sold

by an authorized Lake Shore employee, sales representative, dea ler or

an authorized Lake Shore original equipment manufacturer (OEM).

3.The Product may contain remanufactured parts equivalent to new

in performance or may have been subject to incidental use when it is

originally sold to the Purchaser.

4.The Warranty Period begins on the date the Product ships from Lake

Shore’s plant.

5.This limited warranty does not apply to defects in the Product

resulting from (a) improper or inadequate installation (unless OT&V

services are performed by Lake Shore), maintenance, repair or calibration, (b) fuses, software, power surges, lightning and non-rechargeable batteries, (c) software, interfacing, parts or other supplies not

furnished by Lake Shore, (d) unauthorized modification or misuse, (e)

operation outside of the published specifications, (f ) improper site

preparation or site maintenance (g) natural disasters such as flood,

fire, wind, or earthquake, or (h) damage during shipment other than

original shipment to you if shipped through a Lake Shore carrier.

6.This limited warranty does not cover: (a) regularly scheduled or ordinary and expected recalibrations of the Product; (b) accessories to the

Product (such as probe tips and cables, holders, wire, grease, varnish,

feedthroughs, etc.); (c) consumables used in conjunction with the

Product (such as probe tips and cables, probe holders, sample tails,

rods and holders, ceramic putty for mounting samples, Hall sample

cards, Hall sample enclosures, etc.); or, (d) non-Lake Shore branded

Products that are integrated with the Product.

7. To the extent allowed by applicable law, this limited warranty is the

only warranty applicable to the Product and replaces all other warranties or conditions, express or implied, including, but not limited to,

the implied warranties or conditions of merchantability and fitness

for a particular purpose. Specifically, except as provided herein, Lake

Shore undertakes no responsibi lity that the products will be fit for any

particular purpose for which you may be buying the Products.

Any implied warranty is limited in duration to the warranty period. No

oral or written information, or advice given by the Company, its

Agents or Employees, shall create a warranty or in any way increase

the scope of this limited warranty. Some countries, states or provinces

do not allow limitations on an implied warranty, so the above limitation or exclusion might not apply to you. This warranty gives you specific legal rights and you might also have other rights that vary from

country to country, state to state or province to province.

8.Further, with regard to the United Nations Convention for International Sale of Goods (CISC,) if CISG is found to apply in relation to this

agreement, which is specifically disclaimed by Lake Shore, then this

limited warranty excludes warranties that: (a) the Product is fit for the

purpose for which goods of the same description would ordinarily be

used, (b) the Product is fit for any particular purpose expressly or

impliedly made known to Lake Shore at the time of the conclusion of

the contract. (c) the Product is contained or packaged in a manner

usual for such goods or in a manner adequate to preserve and protect

such goods where it is shipped by someone other than a carrier hired

by Lake Shore.

9. Lake Shore disclaims any warranties of technological value or of

non-infringement with respect to the Product and Lake Shore shall

have no duty to defend, indemnify, or hold harmless you from and

against any or all damages or costs incurred by you arising from the

infringement of patents or trademarks or violation or copyrights by

the Product.

10.THIS WARRANTY IS NOT TRANSFERRABLE. This warranty is not

transferrable.

11.Except to the extent prohibited by applicable law, neither Lake

Shore nor any of its subsidiaries, affiliates or suppliers will be held liable for direct, special, incidental, consequential or other damages

(including lost profit, lost data, or downtime costs) arising out of the

use, inability to use or result of use of the product, whether based in

warranty, contract, tort or other legal theory, regardless whether or

not Lake Shore has been advised of the possibility of such damages.

Purchaser's use of the Product is entirely at Purchaser's risk. Some

countries, states and provinces do not allow the exclusion of liability

for incidental or consequential damages, so the above limitation may

not apply to you.

12.This limited warranty gives you specific legal rights, and you may

also have other rights that vary within or between jurisdictions where

the product is purchased and/or used. Some jurisdictions do not allow

limitation in certain warranties, and so the above limitations or exclusions of some warranties stated above may not apply to you.

13.Except to the extent allowed by applicable law, the terms of this

limited warranty statement do not exclude, restrict or modify the

mandatory statutory rights applicable to the sale of the product

to you.

Model 336 Temperature Controller

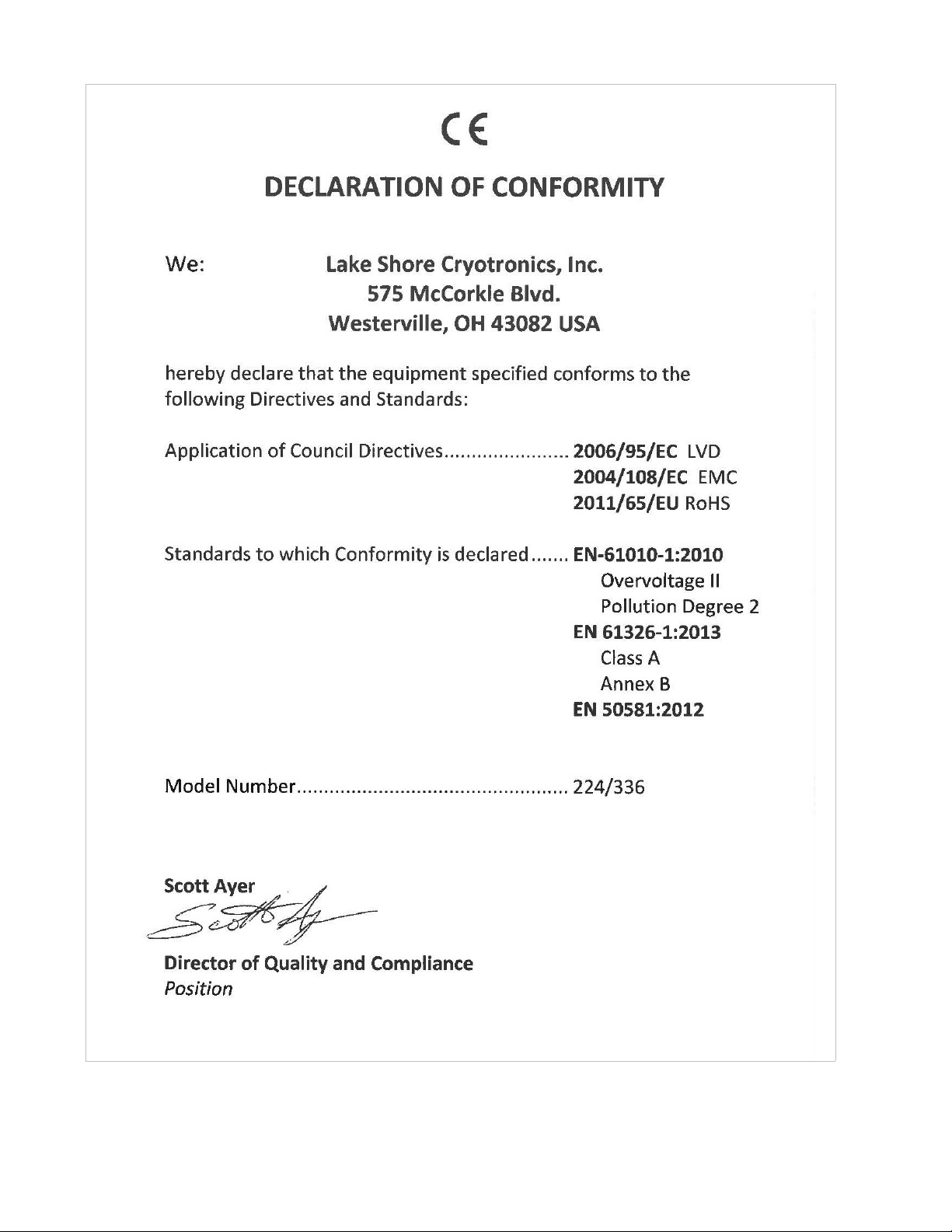

CERTIFICATION

Lake Shore certifies that this product has been inspected and tested

in accordance with its published specifications and that this product

met its published specifications at the time of shipment. The accuracy and calibration of this product at the time of shipment are traceable to the United States National Institute of Standards and

Technology (NIST); formerly known as the National Bureau of Standards (NBS).

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 336 firmware is as

free of errors as possible, and that the results you obtain from the

instrument are accurate and reliable. However, as with any computer-based software, the possibility of errors exists.

In any important research, as when using any laboratory equipment,

results should be carefully examined and rechecked before final conclusions are drawn. Neither Lake Shore nor anyone else involved in

the creation or production of this firmware can pay for loss of time,

inconvenience, loss of use of the product, or prop erty damage caused

by this product or its failure to work, or any other incidental or consequential damages. Use of our product implies that you understand

the Lake Shore license agreement and statement of limited warranty.

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States copyright law and international treaty provisions. To maintain the warranty, the code contained in the firmware must not be modified. Any

changes made to the code is at the user's risk. Lake Shore will assume

no responsibility for damage or errors incurred as result of any

changes made to the firmware.

FIRMWARE LICENSE AGREEMENT (continued)

Under the terms of this agreement you may only use the Model 336

firmware as physically installed in the in strument. Archival copies are

strictly forbidden. You may not decompile, disassemble, or reverse

engineer the firmware. If you suspect there are problems with the

firmware, return the instrument to Lake Shore for repair under the

terms of the Limited Warranty specified above. Any unauthorized

duplication or use of the Model 336 firmware in whole or in part, in

print, or in any other storage and retrieval system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers and sellers claim designations used to distinguish their products as trademarks. Where those designations

appear in this manual and Lake Shore was aware of a trademark

claim, they appear with initial capital letters and the ™ or ® symbol.

Alumel™ and Chromel™ are trademarks of

Conceptech, Inc., Corporation

Apiezon™ is a registered trademark of M&I Materials, Ltd.

CalCurve™, Cernox™, SoftCal™, Rox™, Curve Handler™ are trademarks of Lake Shore Cryotronics, Inc.

Java™ is a registered trademark of Sun Microsystems, Inc.

of Santa Clara, CA

LabVIEW® is a registered trademark of National Instruments.

Mac® is a registered trademark of Apple, Inc., registered in the U.S and

other countries.

Microsoft Windows®, Excel®, and Windows Vista® are registered

trademarks of Microsoft Corporation in the United States and other

countries.

Stycast® is a trademark of Emerson & Cuming.

WinZip™ is a registered trademark of Nico Mak of Connecticut.

Copyright 2009 - 2015 Lake Shore Cryotronics, Inc. All rights reserved. No portion of this manual may be

reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the express written permission of Lake Shore.

| www.lakeshore.com

Model 336 Temperature Controller

Electromagnetic Compatibility (EMC) for the Model 336 Temperature Controller

Electromagnetic Compatibility (EMC) of electronic equipment is a growing concern worldwide. Emissions of and

immunity to electromagnetic interference is now part of the design and manufacture of most electronics. To qualify

for the CE Mark, the Model 336 meets or exceeds the requirements of the European EMC Directive 89/336/EEC as a

CLASS A product. A Class A product is allowed to radiate more RF than a Class B product and must include the following warning:

WARNING:This is a Class A product. In a domestic environment, this product may cause radio interference in which

case the user may be required to take adequate measures.

The instrument was tested under normal operating conditions with sensor and interface cables attached. If the

installation and operating instructions in the User's Manual are followed, there should be no degradation in EMC

performance.

This instrument is not intended for use in close proximity to RF Transmitters such as two-way radios and cell

phones. Exposure to RF interference greater than that found in a typical laboratory environment may disturb the

sensitive measurement circuitry of the instrument.

Pay special attention to instrument cabling. Improperly installed cabling may defeat even the best EMC protection.

For the best performance from any precision instrument, follow the grounding and shielding instructions in the

User's Manual. In addition, the installer of the Model 336 should consider the following:

D Shield measurement and computer interface cables.

D Leave no unused or unterminated cables attached to the instrument.

D Make cable runs as short and direct as possible. Higher radiated emissions are possible with long cables.

D Do not tightly bundle cables that carry different types of signals.

| www.lakeshore.com

Model 336 Temperature Controller

i

Table of Contents

Chapter 1

Introduction

Chapter 2

Cooling System Design and

Temperature

Control

1.1 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Sensor Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.2 Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.3 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.4 Configurable Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.5 Three Option Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Sensor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Model 336 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.1 Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.2 Sensor Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.3 Thermometry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.4 Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.4.1 Heater Outputs (Outputs 1 and 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.4.2 Unpowered Analog Outputs (Outputs 3 and 4) . . . . . . . . . . . . . . . . . . . . . .10

1.3.5 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.6 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.7 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4 Safety Summary and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.2 Temperature Sensor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.2.1 Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.2 Sensor Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.3 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.4 Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.5 Sensor Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Sensor Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.3.1 Precision Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.2 SoftCal™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.3 Sensors Using Standard Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.4 Curve Handler™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.1 Mounting Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.2 Sensor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.3 Thermal Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.4 Contact Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.5 Contact Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.6 Lead Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.7 Lead Soldering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4.8 Thermal Anchoring Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4.9 Thermal Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 Heater Selection and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.1 Heater Resistance and Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.2 Heater Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.3 Heater Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.4 Heater Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.6 Consideration for Good Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.6.1 Thermal Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6.2 Thermal Lag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6.3 Two-Sensor Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6.4 Thermal Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

| www.lakeshore.com

2.6.5 System Non-Linearity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.7 PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7.1 Proportional (P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7.2 Integral (I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7.3 Derivative (D). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.7.4 Manual Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.8 Manual Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.8.1 Setting Heater Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.8.2 Tuning Proportional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.8.3 Tuning Integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.8.4 Tuning Derivative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.9 Autotuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.10 Zone Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.11 Thermoelectric Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 3

Installation

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2 Inspection and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3 Rear Panel Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4 Line Input Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.1 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.2 Line Fuse and Fuse Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.3 Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.4.4 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5 Diode/Resistor Sensor Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5.1 Sensor Input Connector and Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5.2 Sensor Lead Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5.3 Grounding and Shielding Sensor Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5.4 Sensor Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5.5 Four-Lead Sensor Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5.6 Two-Lead Sensor Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5.7 Lowering Measurement Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.6 Capacitance Sensor Inputs (Model 3061) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.6.1 Wiring, Guarding and Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.7 Thermocouple Sensor Inputs (Thermocouple Model 3060) . . . . . . . . . . . . . . . . . . . . . . . 37

3.7.1 Sensor Input Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.7.2 Thermocouple Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.7.3 Grounding and Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.8 Heater Output Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.8.1 Heater Output Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.8.2 Heater Output Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.8.3 Heater Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.8.4 Heater Output Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.8.5 Powering Outputs 3 and 4 Using an External Power Supply . . . . . . . . . . . . . . . . 39

3.8.5.1 Choosing a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.8.5.2 Power Supply Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.8.5.3 Connecting to the Model 336 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.8.5.4 Programming Voltages Under 10 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chapter 4

Operation

Model 336 Temperature Controller

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.1.1 Understanding Menu Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2 Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.1 Keypad Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.1.1 Direct Operation Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.1.2 Menu/Number Pad Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.2.2 Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.2.3 General Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.3 Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

iii

4.3.1 Display Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.3.1.1 Four Loop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3.1.2 All Inputs Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3.1.3 Input Display Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

4.3.1.4 Custom Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.3.2 Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.4 Input Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.4.1 Diode Sensor Input Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.4.2 Positive Temperature Coefficient (PTC) Resistor Sensor Input Setup . . . . . . . 52

4.4.3 Negative Temperature Coefficient (NTC) Resistor Sensor Input Setup . . . . . . 52

4.4.4 Range Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.4.5 Thermal Electromotive Force (EMF) Compensation . . . . . . . . . . . . . . . . . . . . . . . . .53

4.4.6 Thermocouple Sensor Input Setup (Model 3060 Only) . . . . . . . . . . . . . . . . . . . . . . 54

4.4.6.1 Internal Room Temperature Compensation . . . . . . . . . . . . . . . . . . . . . . . . .54

4.4.6.2 Internal Room Temperature Compensation Calibration Procedure 54

4.4.7 Capacitance Sensor Input Setup (Model 3061 Only) . . . . . . . . . . . . . . . . . . . . . . . .55

4.4.7.1 Range Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.4.7.2 Temperature Coefficient Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4.7.3 Control Channel Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4.8 4-Channel Scanner Input Setup (Model 3062 Only) . . . . . . . . . . . . . . . . . . . . . . . .56

4.4.8.1 Type and Range Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4.4.8.2 Update Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.4.9 Curve Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.4.10 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.4.11 Input Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.4.12 Temperature Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.4.13 Preferred Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.4.14 Max/Min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.5 Output and Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.5.1 Heater Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.5.1.1 Max Current and Heater Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.5.1.1.1 User Max Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.5.1.2 Power Up Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.5.1.3 Heater Out Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.5.1.4 Output Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.5.1.4.1 Closed Loop PID Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.5.1.4.2 Zone Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5.1.4.3 Open Loop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

4.5.1.5 Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5.1.5.1 Control Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.5.1.5.2 Proportional (P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.5.1.5.3 Integral (I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.5.1.5.4 Derivative (D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.5.1.5.5 Manual Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.5.1.5.6 Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.5.1.5.7 Setpoint Ramping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

4.5.1.5.8 Heater Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.5.1.5.9 ALL OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.5.2 Unpowered Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.5.2.1 Warm Up Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.5.2.2 Monitor Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.6 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

4.6.1 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

4.6.2 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

4.6.3 IEEE-488 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

4.6.3.1 Remote/Local . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.7 Locking and Unlocking the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

| www.lakeshore.com

Chapter 5

Advanced

Operation

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2 Autotune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.3 Zone Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.4 Bipolar Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.5 Warm Up Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.5.1 Warm Up Percentage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.5.2 Warm Up Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.6 Monitor Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.6.1 Monitor Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.6.1.1 Polarity and Monitor Out Scaling Parameters . . . . . . . . . . . . . . . . . . . . . . . 79

5.7 Alarms and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.7.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.7.1.1 Alarm Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.7.1.2 Alarm Latching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.7.2 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.8 Curve Numbers and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.8.1 Curve Header Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.8.2 Curve Breakpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.9 Front Panel Curve Entry Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.9.1 Edit Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.9.1.1 Edit a Breakpoint Pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.9.1.2 Add a New Breakpoint Pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.9.1.3 Delete a Breakpoint Pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.9.1.4 Thermocouple Curve Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.9.2 View Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.9.3 Erase Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.9.4 Copy Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.10 SoftCal™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.10.1 SoftCal™ With Silicon Diode Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.10.2 SoftCal™ Accuracy With DT-400 Series Silicon Diode Sensors . . . . . . . . . . . . 89

5.10.3 SoftCal™ With Platinum Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.10.4 SoftCal™ Accuracy With Platinum Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.10.5 SoftCal™ CalibrationCurve Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter 6

Computer

Interface Operation

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.2 IEEE-488 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.2.1 Changing IEEE-488 Interface Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.2.2 Remote/Local Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.2.3 IEEE-488.2 Command Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.2.3.1 Bus Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.2.3.2 Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.2.3.3 Device Specific Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.2.3.4 Message Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.2.4 Status System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.2.4.1 Condition Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.2.4.2 Event Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.2.4.3 Enable Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.2.4.4 Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.2.4.5 Service Request Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.2.4.6 Reading Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.2.4.7 Programming Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.2.4.8 Clearing Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.2.5 Status System Detail: Status Register Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.2.5.1 Standard Event Status Register Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.2.5.2 Operation Event Register Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.2.6 Status System Detail: Status Byte Register and Service Request . . . . . . . . . . 101

6.2.6.1 Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Model 336 Temperature Controller

v

6.2.6.2 Service Request Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.2.6.3 Using Service Request (SRQ) and Serial Poll . . . . . . . . . . . . . . . . . . . . . . . 102

6.2.6.4 Using Status Byte Query (*STB?) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.2.6.5 Using the Message Available (MAV) Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.2.6.6 Using Operation Complete (*OPC) and

Operation Complete Query (*OPC?) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.3 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.3.1 Physical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.3.2 Hardware Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.3.3 Installing the USB Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.3.3.1 Installing the Driver From Windows® Update in

Windows 7 and Vista® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.3.3.2 Installing the Driver From Windows® Update in Windows® XP . . . 105

6.3.3.3 Installing the Driver From the Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.3.3.3.1 Download the driver: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.3.3.3.2 Extract the driver: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.3.3.3.3 Manually install the driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6.3.3.4 Installing the USB Driver from the Included CD . . . . . . . . . . . . . . . . . . . 107

6.3.4 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.3.4.1 Character Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.3.4.2 Message Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.3.5 Message Flow Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.4 Ethernet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.4.1 Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.4.1.1 Network Address Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.4.1.2 Network Addresss Configuration Methods . . . . . . . . . . . . . . . . . . . . . . . . 110

6.4.1.3 DNS Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

6.4.2 Viewing Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.4.2.1 LAN Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.4.2.2 MAC Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.4.2.3 Viewing Network Configuration Parameters and

DNS Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.4.3 TCP Socket Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.4.4 Embedded Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.4.4.1 Connecting to the Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.4.4.2 Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.5 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.5.1 Embedded Curve Handler™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.5.2 Ethernet Firmware Updater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

6.5.3 Instrument Configuration Backup Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6.5.4 Embedded Chart Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.5.4.1 Configuration Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.5.4.2 Starting Data Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.5.4.3 Chart Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.5.4.4 Utilities Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.5.4.5 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

6.5.4.6 Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

6.6 Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

6.6.1 Interface Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Chapter 7

Options and

Accessories

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.2 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.3 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.5 Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

7.6 Input Option Card Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

| www.lakeshore.com

Chapter 8

Service

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.2 USB Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.2.1 New Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.2.2 Existing Installation No Longer Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.2.3 Intermittent Lockups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.3 IEEE Interface Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.3.1 New Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.3.2 Existing Installation No Longer Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.3.3 Intermittent Lockups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.4 Fuse Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.5 Line Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.6 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

8.7 Factory Reset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

8.7.1 Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

8.7.2 Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

8.8 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

8.9 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

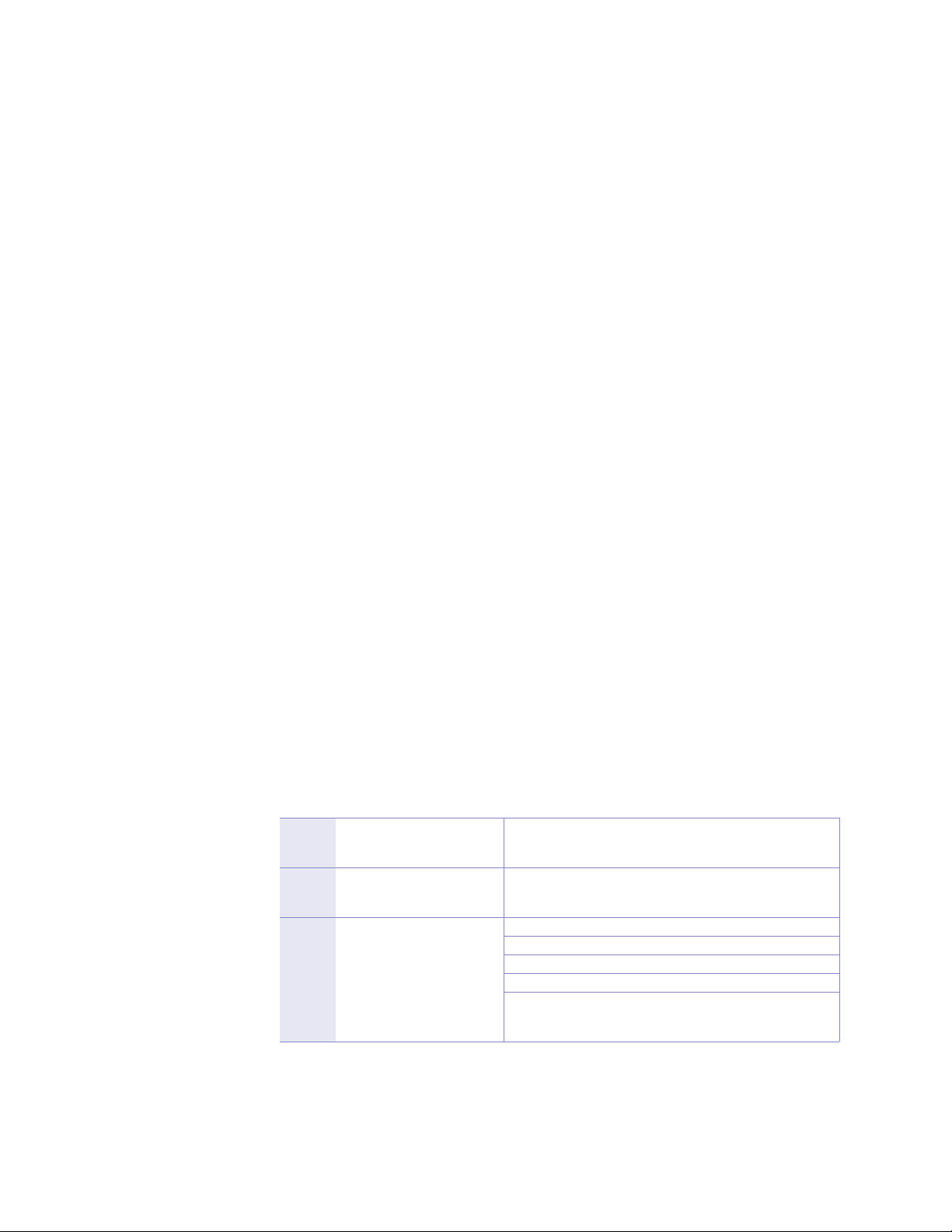

8.10 Rear Panel Connector Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

8.10.1 IEEE-488 Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

8.11 Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

8.11.1 Identification of Electrostatic Discharge Sensitive Components . . . . . . . . 161

8.11.2 Handling Electrostatic Discharge Sensitive Components . . . . . . . . . . . . . . . . 162

8.12 Enclosure Top Remove and Replace Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

8.13 Firmware Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

8.13.1 Updating the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

8.13.2 Record of Updates Made to the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

8.14 Technical Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

8.14.1 Contacting Lake Shore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

8.14.2 Return of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

8.14.3 RMA Valid Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

8.14.4 Shipping Charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

8.14.5 Restocking Fee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Appendix A

Temperature Scales

Appendix B

Handling Liquid

Helium and

Nitrogen

Appendix C

Curve Tables

A.1 Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

A.2 Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

A.3 Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

B.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

B.2 Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

B.3 Handling Cryogenic Storage Dewars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

B.4 Liquid Helium and Nitrogen Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

B.5 Recommended First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

C.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Model 336 Temperature Controller

1 . 1 P r o d u c t D e s c r i p t i o n 1

Chapter 1: Introduction

FIGURE 1-1 Model 336 front view

1.1 Product Description

Features:

D Operates down to 300 mK with appropriate NTC RTD sensors

D Four sensor inputs and four independent control outputs

D Two PID control loops: 100 W and 50 W into a 50 ) or 25 ) load

D Autotuning automatically collects PID parameters

D Automatically switch sensor inputs using zones to allow continuous measure-

ment and control from 300 mK to 1505 K

D Custom display setup allows you to label each sensor input

D Ethernet, USB, and IEEE-488 interfaces

D Supports diode, RTD, and thermocouple temperature sensors

D Sensor excitation current reversal eliminates thermal EMF errors for

resistance sensors

D

±10 V analog voltage outputs, alarms, and relays

The first of a new generation of innovative temperature measurement and control

solutions by Lake Shore, the Model 336 temperature controller comes standard

equipped with many advanced features promised to deliver the functionality and

reliable service you’ve come to expect from the world leader in cryogenic thermometry. The Model 336 is the only temperature controller available with four sensor

inputs, four control outputs, and 150 W of low noise heater power. Two independent

heater outputs providing 100 W and 50 W can be associated with any of the four sensor inputs and programmed for closed loop temperature control in proportional-integral-derivative (PID) mode. The improved autotuning feature of the Model 336 can be

used to automatically collect PID parameters, so you spend less time tuning your controller and more time conducting experiments.

The Model 336 supports the industry’s most advanced line of cryogenic temperature

sensors as manufactured by Lake Shore, including diodes, resistance temperature

detectors (RTDs) and thermocouples. The controller’s zone tuning feature allows you

to measure and control temperatures seamlessly from 300 mK to over 1,500 K by

automatically switching temperature sensor inputs when your temperature range

goes beyond the usable range of a given sensor. You’ll never again have to be concerned with temperature sensor over or under errors and measurement continuity

issues. Alarms, relays, and ±10 V analog voltage outputs are available to help automate secondary control functions.

| www.lakeshore.com

2 cHAPTER 1: Introduction

Another innovative first from Lake Shore, the ability to custom label sensor inputs

eliminates the guesswork in remembering or determining the location to which a

sensor input is associated. As we strive to maintain increasingly demanding workloads, ease of use and the ability to stay connected from anywhere in the world are

critical attributes. With standard Ethernet, USB, and IEEE-488 interfaces and an intuitive menu structure and logic, the Model 336 was designed with efficiency, reliable

connectivity, and ease of use in mind. While you may need to leave your lab, Ethernet

ensures you’ll always be connected to your experiments. The new intuitive front

panel layout and keypad logic, bright graphic display, and LED indicators enhance the

user friendly front panel interface of the Model 336.

In many applications, the unparalleled feature set of the Model 336 allows you to

replace several instruments with one, saving time, money and valuable laboratory

space. Delivering more feedback, tighter control, and faster cycle times, the

Model 336 keeps up with increasingly complex temperature measurement and control applications. It is the ideal solution for general purpose to advanced laboratory

applications. Put the Model 336 temperature controller to use in your lab and let it

take control of your measurement environment.

1.1.1 Sensor Inputs

The Model 336 offers 4 standard sensor inputs that are compatible with diode and

RTD temperature sensors. The field installable Model 3060 thermocouple input

option provides support for up to two thermocouple inputs by adding thermocouple

functionality to inputs C and D.

Sensor inputs feature a high-resolution 24-bit analog-to-digital converter; each

input has its own current source, providing fast settling times. All four sensor inputs

are optically isolated from other circuits to reduce noise and to provide repeatable

sensor measurements. Current reversal eliminates thermal electromotive force

(EMF) errors in resistance sensors. Nine excitation currents facilitate temperature

measurement and control down to 300 mK using appropriate negative temperature

coefficient (NTC) RTDs. Autorange mode automatically scales excitation current in

NTC RTDs to reduce self heating at low temperatures as sensor resistance changes by

many orders of magnitude. Temperatures down to 1.4 K can be measured and controlled using silicon or GaAlAs diodes. Software selects the appropriate excitation current and signal gain levels when the sensor type is entered via the instrument front

panel. The unique zone setting feature automatically switches sensor inputs,

enabling you to measure temperatures from 300 mK to over 1,500 K without interrupting your experiment.

The Model 336 includes standard temperature sensor response curves for silicon

diodes, platinum RTDs, ruthenium oxide RTDs, and thermocouples. Non-volatile

memory can also store up to 39 200-point CalCurves for Lake Shore calibrated temperature sensors or user curves. A built-in SoftCal™ algorithm can be used to generate curves for silicon diodes and platinum RTDs that can be stored as user curves.

Temperature sensor calibration data can be easily uploaded and manipulated using

the Lake Shore curve handler software.

1.1.2 Temperature Control

Model 336 Temperature Controller

Providing a total of 150 W of heater power, the Model 336 is the most powerful temperature controller available. Delivering very clean heater power, it precisely controls

temperature throughout the full scale temperature range for excellent measurement

reliability, efficiency, and throughput. Two independent PID control outputs supplying 100 W and 50 W of heater power can be associated with any of the four standard

sensor inputs. Precise control output is calculated based on your temperature setpoint and feedback from the control sensor. Wide tuning parameters accommodate

most cryogenic cooling systems and many high-temperature ovens commonly used

in laboratories. PID values can be manually set for fine control, or the improved

1 . 1 . 3 I n t e r f a c e 3

autotuning feature can automate the tuning process. Autotune collects PID parameters and provides information to help build zone tables. The setpoint ramp feature

provides smooth, continuous setpoint changes and predictable setpoint approaches

without the worry of overshoot or excessive settling times. When combined with the

zone setting feature, which enables automatic switching of sensor inputs and scales

current excitation through 10 different preloaded temperature zones, the Model 336

provides continuous measurement and control from 300 mK to 1505 K.

Control outputs 1 and 2 are variable DC current sources referenced to chassis ground.

Output 1 can provide 100 W of continuous power to a 25 ) load or 50 W to a 50 ) or

25 ) load. Output 2 provides 50 W to 25 ) or 50 ) heater loads. Outputs 3 and 4 are

variable DC voltage source outputs providing two ±10 V analog outputs. When not in

use to extend the temperature controller heater power, these outputs can function as

manually controlled voltage sources.

Temperature limit settings for inputs are provided as a safeguard against system

damage. Each input is assigned a temperature limit, and if any input exceeds that

limit, all control channels are automatically disabled.

1.1.3 Interface

The Model 336 is standard equipped with Ethernet, universal serial bus (USB) and

parallel (IEEE-488) interfaces. In addition to gathering data, nearly every function of

the instrument can be controlled through a computer interface. You can download

the Lake Shore curve handler software to your computer to easily enter and manipulate sensor calibration curves for storage in the instrument’s non-volatile memory.

Ethernet provides the ability to access and monitor instrument activities via the

internet from anywhere in the world. The USB interface emulates an RS-232 serial

port at a fixed 57,600 baud rate, but with the physical plug-ins of a USB. It also allows

you to download firmware upgrades, ensuring the most current firmware version is

loaded into your instrument without having to physically change anything.

Each sensor input has a high and low alarm that offer latching and non-latching operation. The 2 relays can be used in conjunction with the alarms to alert you of a fault

condition and perform simple on/off control. Relays can be assigned to any alarm or

operated manually.

The ±10 V analog voltage outputs on outputs 3 and 4 can be configured to send a voltage proportional to temperature to a strip chart recorder or data acquisition system.

You may select the scale and data sent to the output, including temperature or

sensor units.

bSensor input connectors

cTer mi na l b lo ck

dEthernetinterface

e USB interface

FIGURE 1-2 Model 336 rear panel

f IEEE-488 interface

g Line input assembly

h Output 2 heater

i Output 1 heater

j Thermocouple

option inputs

| www.lakeshore.com

4 cHAPTER 1: Introduction

1.1.4 Configurable Display

1.1.5 Three Option Cards

The Model 336 offers a bright, graphic liquid crystal display with an LED backlight

that simultaneously displays up to 8 readings. You can show all 4 loops, or if you need

to monitor 1 input, you can display just that one in greater detail. Or you can custom

configure each display location to suit your experiment. Data from any input can be

assigned to any of the locations, and your choice of temperature or sensor units can

be displayed. For added convenience, you can also custom label each sensor input,

eliminating the guesswork in remembering or determining the location to which a

sensor input is associated.

FIGURE 1-3 Displays showing four loop mode, input display mode and custom display mode

Field installable input option cards can expand your sensor selection to include silicon diodes (like DT-670), capacitance sensors or thermocouples. Once installed, the

option input can be selected and named from the front panel like any other input

type. These option cards further expand the application versatility of the Model 336

temperature controller by allowing specialized sensors to be switched in and out to

achieve specific measurement objectives.

For example, addition of the thermocouple input option enables continuous measurement to 1000 K and above. Alternatively, the capacitance sensor option card

enables a magnetics-impervious capacitance temperature sensor to be temporarily

switched in for elimination of magneto-resistive effects while taking low temperature sample measurements under high or changing fields. The 4-channel scanner

option card enables use of additional sensors for supplemental monitoring.

1.2 Sensor Selection

Silicon diodes are the best choice for general cryogenic use from 1.4 K to above room

temperature. Diodes are economical to use because they follow a standard curve and

are interchangeable in many applications. They are not suitable for use in ionizing

radiation or magnetic fields.

Cernox™ thin-film RTDs offer high sensitivity and low magnetic field-induced errors

over the 0.3 K to 420 K temperature range. Cernox sensors require calibration.

Platinum RTDs offer high uniform sensitivity from 30 K to over 800 K. With excellent

reproducibility, they are useful as thermometry standards. They follow a standard

curveabove 70 K and are interchangeable in many applications.

Model 336 Temperature Controller

1 . 2 S e n s o r S e l e c t i o n 5

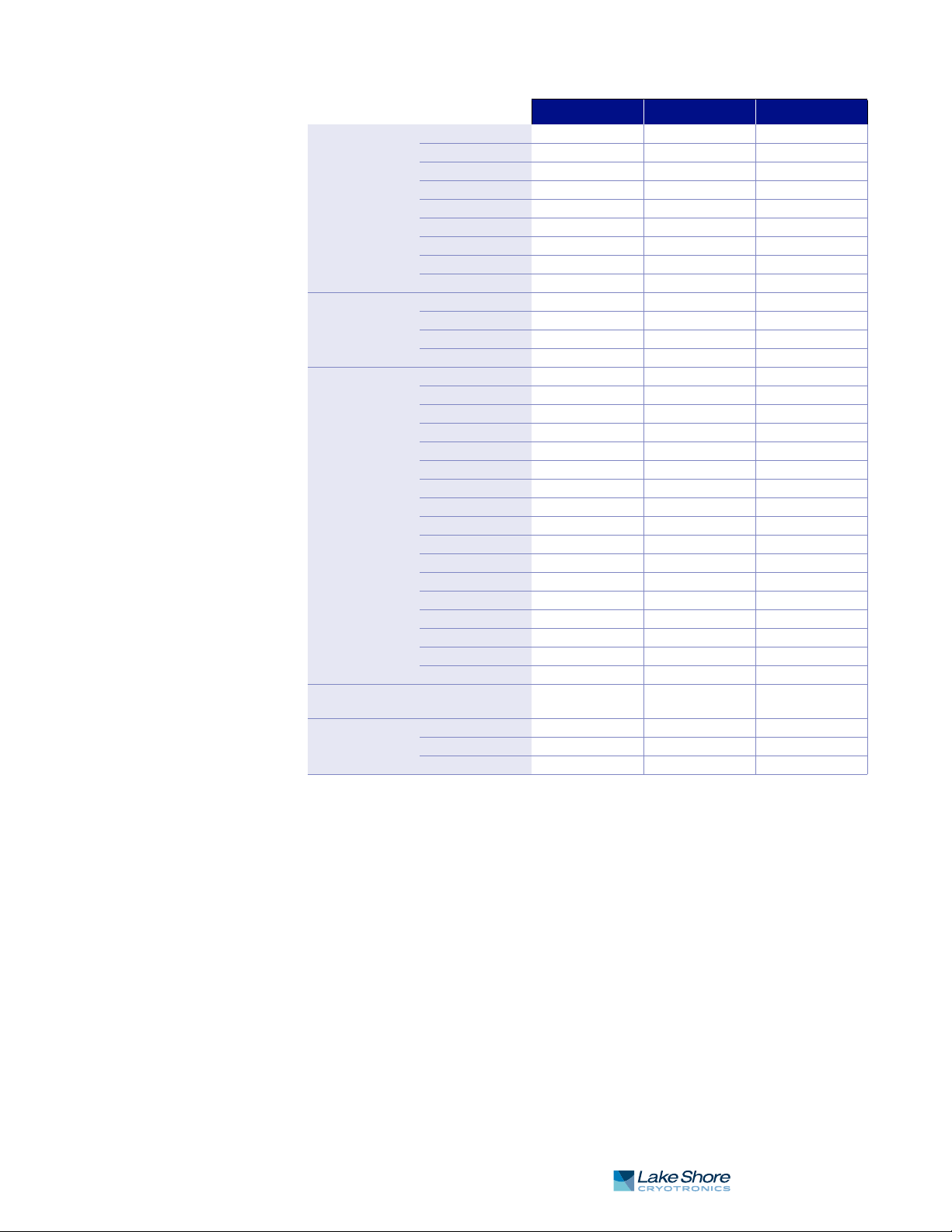

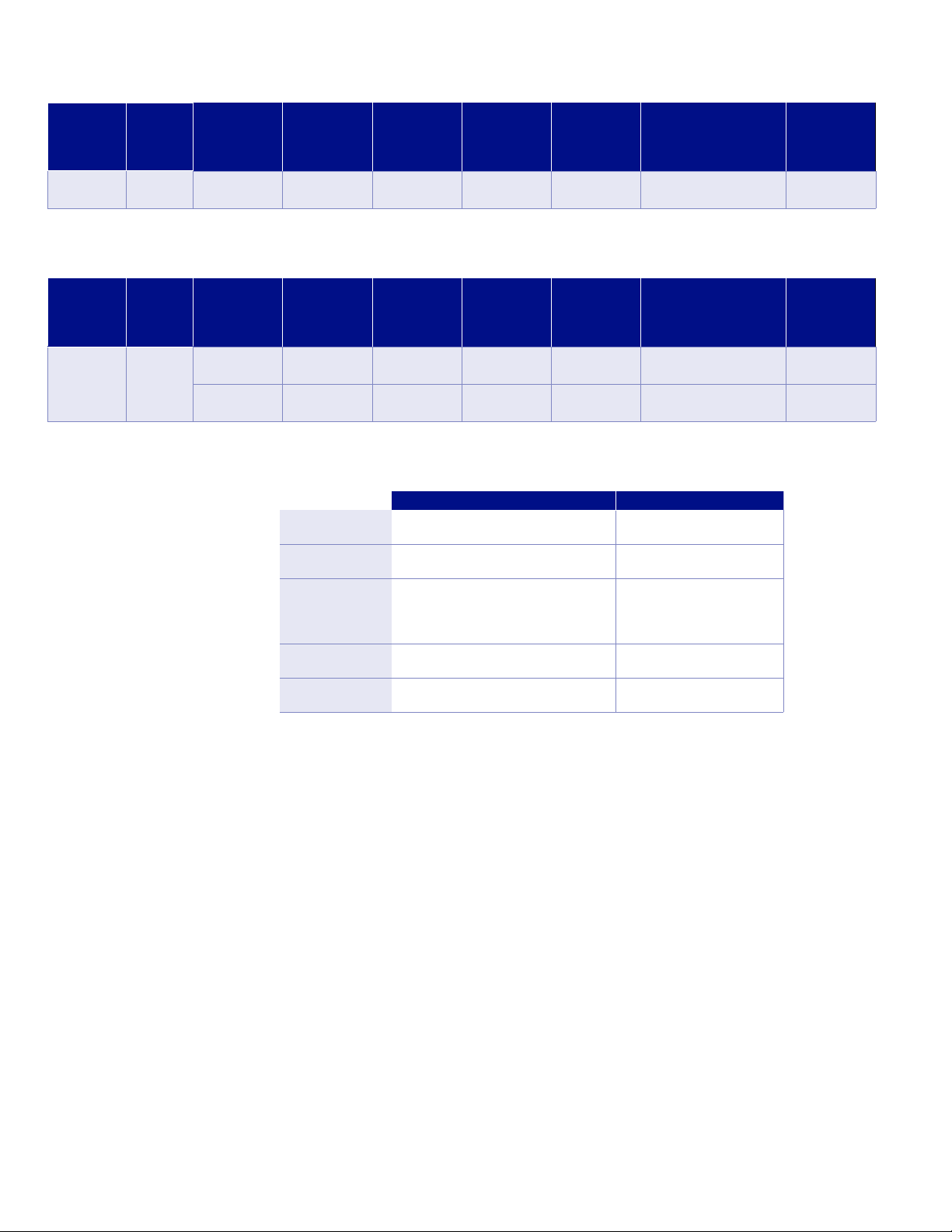

Model Useful Range Magnetic Field Use

Diodes

(3062)

Positive Temperature

Coefficient RTDs

Negative

Temperature

Coefficient RTDs

Capacitance

3061

Thermocouples

3060

1

Non-HT version maximum temperature: 325 K

2

Low temperature limited by input resistance range

3

Low temperature specified with self-heating error: " 5 mK

Silicon Diode DT-670-SD 1.4 K to 500 K T # 60 K & B " 3 T

Silicon Diode DT-670E-BR 30 K to 500 K T# 60 K & B " 3 T

Silicon Diode DT-414 1.4 K to 375 K T # 60 K & B " 3 T

Silicon Diode DT-421 1.4 K to 325 K T # 60 K & B " 3 T

Silicon Diode DT-470-SD 1.4 K to 500 K T # 60 K & B " 3 T

Silicon Diode DT-471-SD 10 K to 500 K T # 60 K & B " 3 T

GaAlAs Diode TG-120-P 1.4 K to 325 K T > 4.2 K & B " 5 T

GaAlAs Diode TG-120-PL 1.4 K to 325 K T > 4.2 K & B " 5 T

GaAlAs Diode TG-120-SD 1.4 K to 500 K T > 4.2 K & B " 5 T

100 ) Platinum PT-102/3 14 K to 873 K T > 40 K & B " 2.5 T

100 ) Platinum PT-111 14 K to 673 K T > 40 K & B " 2.5 T

Rhodium-Iron RF-800-4 1.4 K to 500 K T > 77 K & B " 8 T

Rhodium-Iron RF-100T/U 1.4 K to 325 K T > 77 K & B " 8 T

Cernox™ CX-1010 0.3 K to 325 K

Cernox™ CX-1030-HT 0.3 K to 420 K

Cernox™ CX-1050-HT 1.4 K to 420 K

Cernox™ CX-1070-HT 4 K to 420 K

Cernox™ CX-1080-HT 20 K to 420 K

1

T > 2 K & B " 19 T

1, 3

1

1

1

T > 2 K & B " 19 T

T > 2 K & B " 19 T

T > 2 K & B " 19 T

T > 2 K & B " 19 T

Germanium GR-200A-100 0.3 K to 100 K Not recommended

Germanium GR-200A-250 0.5 K to 100 K Not recommended

Germanium GR-200A/B-500 1.4 K to 100 K Not recommended

Germanium GR-200A/B-1000 1.4 K to 100 K Not recommended

Germanium GR-200A/B-1500 1.4 K to 100 K Not recommended

Germanium GR-200A/B-2500 1.4 K to 100 K Not recommended

Carbon-Glass CG R-1-500 1.4 K to 325 K T > 2 K & B " 19 T

Carbon-Glass CGR-1-1000 1.7 K to 325 K

Carbon-Glass CGR-1-2000 2 K to 325 K

Rox™ RX-102 0.3 K to 40 K

2

T > 2 K & B " 19 T

2

3

T > 2 K & B " 19 T

T > 2 K & B " 10 T

Rox™ RX-103 1.4 K to 40 K T > 2 K & B " 10 T

Rox™ RX-202 0.3 K to 40 K

3

T > 2 K & B " 10 T

CS-501 1.4 K to 290 K T>4.2 K & B " 18.7 T

Type K 9006-006 3.2 K to 1505 K Not recommended

Type E 9006-004 3.2 K to 934 K Not recommended

Chromel-AuFe 0.07% 9006-002 1.2 K to 610 K Not recommended

TABLE 1-1 Sensor temperature range

| www.lakeshore.com

6 cHAPTER 1: Introduction

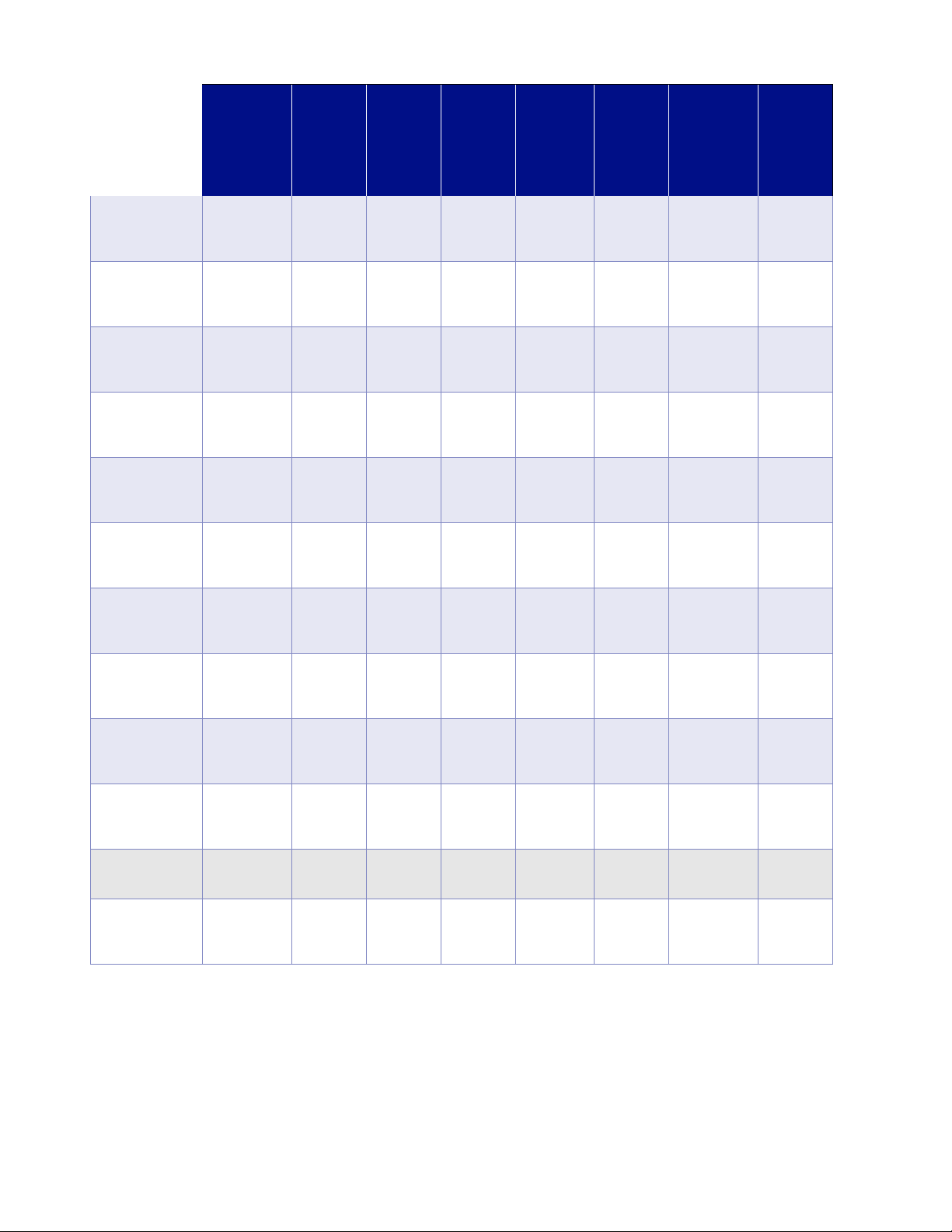

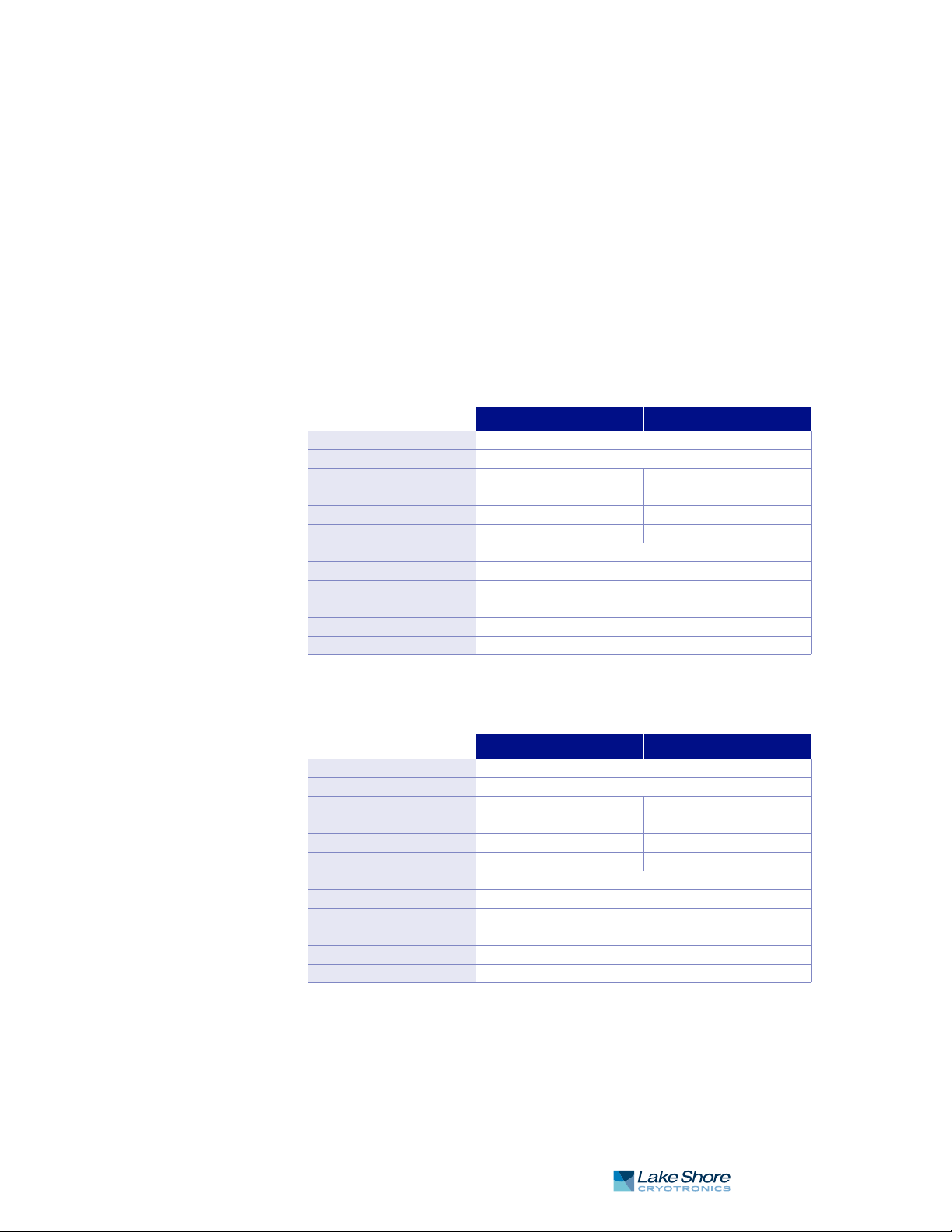

Example

Lake Shore

Tem p er a t u r e

Sensor

1.4 K

77 K

300 K

500 K

1.4 K

77 K

300 K

475 K

1.4 K

77 K

300 K

475 K

Silicon Diode

Silicon Diode

GaAlAs Diode

DT-670-CO-13

with 1.4H

calibration

DT-470-SD-13

with 1.4H

calibration

TG-120-SD

with 1.4H

calibration

30 K

100 ) Platinum RTD

500 ) Full Scale

PT-103 with 14J

calibration

77 K

300 K

500 K

0.3 K

0.5 K

4.2 K

300 K

1.4 K

6

4.2 K

77 K

420 K

0.35 K

1.4 K

4.2 K

100 K

1.8 K

4.2 K

10 K

100 K

1.4 K

4.2 K

77 K

300 K

0.5 K

1.4 K

4.2 K

40 K

Cernox™

Cernox™

Germanium

Germanium

Carbon-Glass

Rox™

CX-1010-SD

with 0.3L

calibration

CX-1050-SD-HT

with 1.4M

calibration

GR-300-AA

with 0.3D

calibration

GR-1400-AA

with 1.4D

calibration

CGR-1-500

with 1.4L

calibration

RX-102A-AA

with 0.3B

calibration

4.2

Capacitance CS-501

77

200

Thermocouple

50 mV

Typ e K

3060

4

Typical sensor sensitivities were taken from representative calibrations for the sensor listed

5

Control stability of the electronics only, in an ideal thermal system

6

Non-HT version maximum temperature: 325 K

7

Accuracy specification does not include errors from room temperature compensation

75 K

300 K

600 K

1505 K

Nominal

Resistance/

Volta ge

1.664 V

1.028 V

0.5597 V

0.0907 V

1.6981 V

1.0203 V

0.5189 V

0.0906 V

5.391 V

1.422 V

0.8978 V

0.3778 V

3.660 )

20.38 )

110.35 )

185.668 )

2322.4 )

1248.2 )

277.32 )

30.392 )

26566 )

3507.2 )

205.67 )

45.03)

18225 )

449 )

94 )

2.7 )

15288 )

1689 )

253 )

2.8 )

103900 )

584.6 )

14.33 )

8.55 )

3701 )

2005 )

1370 )

1049 )

6.0 nF

9.1 nF

19.2 nF

-5862.9 µV

1075.3 µV

13325 µV

49998.3 µV

Typ i ca l

Sensor

Sensitivity

-12.49 mV/K

-1.73 mV/K

-2.3 mV/K

-2.12 mV/K

-13.1 mV/K

-1.92 mV/K

-2.4 mV/K

-2.22 mV/K

-97.5 mV/K

-1.24 mV/K

-2.85 mV/K

-3.15 mV/K

0.191 )/K

0.423 )/K

0.387 )/K

0.378 )/K

-10785 )/K

-2665.2 )/K

-32.209 )/K

-0.0654 )/K

-48449 )/K

-1120.8 )/K

-2.4116 )/K

-0.0829 )/K

-193453 )/K

-581 )/K

-26.6 )/K

-0.024 )/K

-26868 )/K

-862 )/K

-62.0 )/K

-0.021 )/K

-520000 )/K

-422.3 )/K

-0.098 )/K

-0.0094 )/K

-5478 )/K

-667 )/K

-80.3 )/K

-1.06 )/K

27 pF/K

52 pF/K

174 pF/K

15.6 µV/K

40.6 µV/K

41.7 µV/K

36.006 µV/K

TABLE 1-2 Typical sensor performance

Measurement

Resolution :

Temperature

4

Equivalents

0.8 mK

5.8 mK

4.4 mK

4.7 mK

0.8 mK

5.2 mK

4.2 mK

4.5 mK

0.2 mK

16 mK

7 mK

6.4 mK

1.1 mK

0.5 mK

5.2mK

5.3 mK

8.5 µK

26 µK

140 µK

23 mK

20 µK

196 µK

1.9 mK

18 mK

4 µK

41 µK

56µK

6.3 mK

28 µK

91 µK

73 µK

7.1 mK

13 µK

63 µK

4.6 mK

16 mK

41 µK

128µK

902 µK

62 mK

74 mK

39 mK

12 mK

26 mK

10 mK

10 mK

11 mK

Electronic

Accuracy:

Temperature

Equivalents

±13 mK

±76 mK

±47 mK

±40 mK

±13 mK

±69 mK

±45 mK

±38 mK

±7 mK

±180 mK

±60 mK

±38 mK

±13 mK

±10 mK

±39 mK

±60 mK

±0.1 mK

±0.2 mK

±3.8 mK

±339 mK

±0.3 mK

±2.1 mK

±38 mK

±338 mK

±48 µK

±481 µK

±1.8 mK

±152 mK

±302 µK

±900 µK

±1.8 mK

±177 mK

±0.1 mK

±0.8 mK

±108 mK

±760 mK

±0.5 mK

±1.4 mK

±8 mK

±500 mK

NA

7

±0.25 K

7

±0.038 K

7

±0.184 K

7

±0.73 K

Temperature

Accuracy

including

Electronic

Accuracy,

CalCurve and

Calibrated Sensor

±25 mK

±98 mK

±79 mK

±90 mK

±25 mK

±91 mK

±77 mK

±88 mK

±19 mK

±202 mK

±92 mK

±88 mK

±23 mK

±22 mK

±62 mK

±106 mK

±3.6 mK

±4.7 mK

±8.8 mK

±414 mK

±5.3 mK

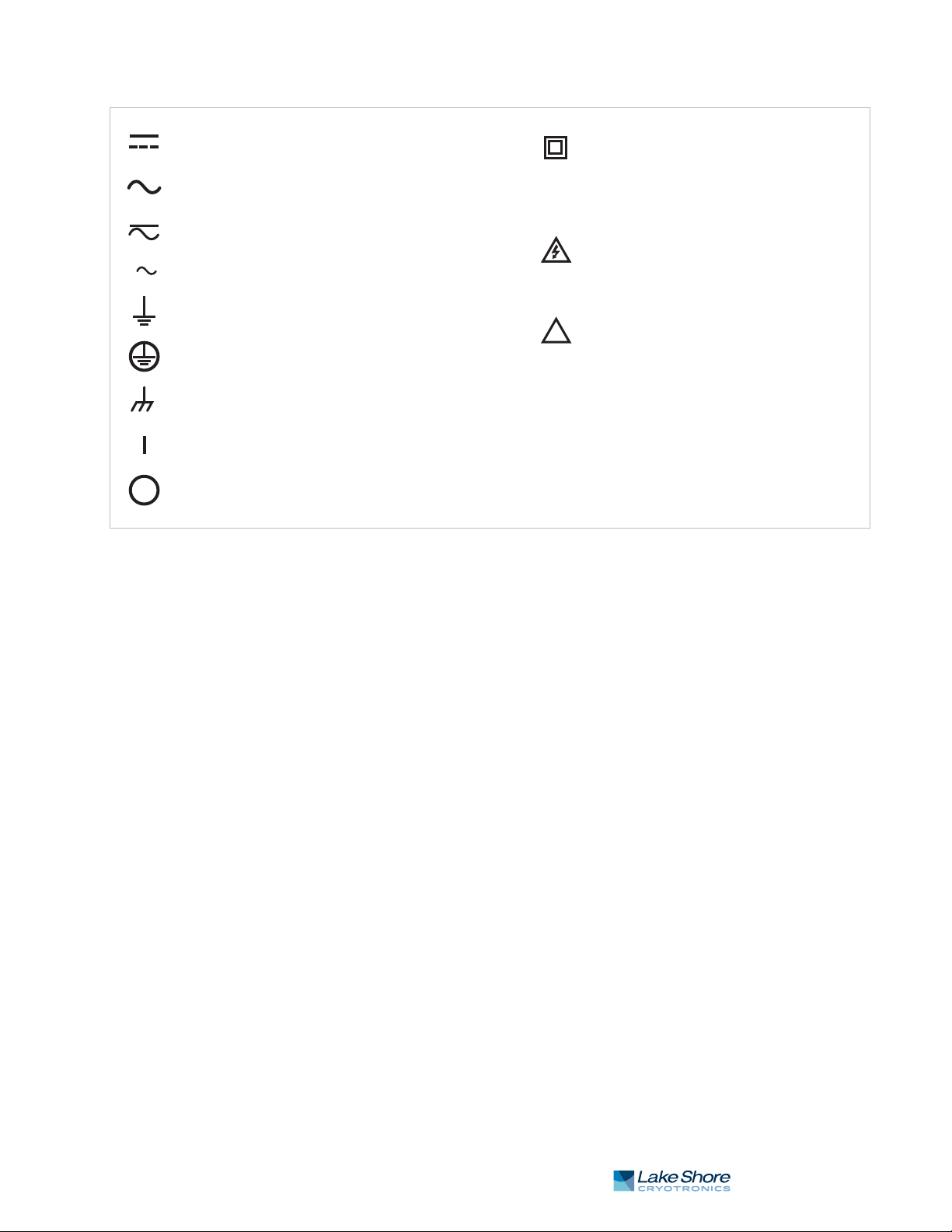

±7.1 mK