Lakeshore 332 User Manual

User’s Manual

Model 332

Temperature Controller

LakeShore

Control

Setpoint

Zone

Input

Display

Setup

Setting

PID/

MHP

Setup

Curve

Entry

1 234 5+/

6 789 0

Format

Math

Alarm

Analog

Output

332 Temperature Controller

Remote/

Local

Interface

Escape

Enter

Control A

Control B

Auto

Tune

Loop

Tune

Ramp

Heater

Range

Heater

Off

Remote

Alarm

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

E-mail Addresses:

sales@lakeshore.com

service@lakeshore.com

Visit Our Website At:

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake Shore Cryotronics, Inc.

No government or other contractual support or relationship whatsoever has existed which in any way affects or mitigates proprietary

rights of Lake Shore Cryotronics, Inc. in these developments. Methods and apparatus disclosed herein may be subject to U.S. Patents

existing or applied for. Lake Shore Cryotronics, Inc. reserves the right to add, improve, modify, or withdraw functions, design

modifications, or products at any time without notice. Lake Shore shall not be liable for errors contained herein or for incidental or

consequential damages in connection with furnishing, performance, or use of this material.

Revision: 1.7 P/N 119-034 14 May 2009

Lake Shore Model 332 Temperature Controller User’s Manual

1. Lake Shore warrants that this Lake Shore product (the

“Product”) will be free from defects in materials and

workmanship for the Warranty Period specified above (the

“Warranty Period”). If Lake Shore receives notice of any such

defects during the Warranty Period and the Product is shipped

freight prepaid, Lake Shore will, at its option, either repair or

replace the Product if it is so defective without charge to the

owner for parts, service labor or associated customary return

shipping cost. Any such replacement for the Product may be

either new or equivalent in performance to new. Replacement or

repaired parts will be warranted for only the unexpired portion of

the original warranty or 90 days (whichever is greater).

2. Lake Shore warrants the Product only if it has been sold by an

authorized Lake Shore employee, sales representative, dealer

or original equipment manufacturer (OEM).

3. The Product may contain remanufactured parts equivalent to

new in performance or may have been subject to incidental use.

4. The Warranty Period begins on the date of delivery of the

Product or later on the date of installation of the Product if the

Product is installed by Lake Shore, provided that if you schedule

or delay the Lake Shore installation for more than 30 days after

delivery the Warranty Period begins on the 31st day after

delivery.

5. This limited warranty does not apply to defects in the Product

resulting from (a) improper or inadequate maintenance, repair or

calibration, (b) fuses, software and non-rechargeable batteries,

(c) software, interfacing, parts or other supplies not furnished by

Lake Shore, (d) unauthorized modification or misuse, (e)

operation outside of the published specifications or (f) improper

site preparation or maintenance.

6. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE

ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTY OR CONDITION, WHETHER WRITTEN OR

ORAL, IS EXPRESSED OR IMPLIED. LAKE SHORE

SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTIES OR

CONDITIONS OF MERCHANTABILITY, SATISFACTORY

QUALITY AND/OR FITNESS FOR A PARTICULAR PURPOSE

WITH RESPECT TO THE PRODUCT. Some countries, states

or provinces do not allow limitations on an implied warranty, so

the above limitation or exclusion might not apply to you. This

warranty gives you specific legal rights and you might also have

other rights that vary from country to country, state to state or

province to province.

7. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE

REMEDIES IN THIS WARRANTY STATEMENT ARE YOUR

SOLE AND EXCLUSIVE REMEDIES.

8. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE

LAW, IN NO EVENT WILL LAKE SHORE OR ANY OF ITS

SUBSIDIARIES, AFFILIATES OR SUPPLIERS BE LIABLE FOR

DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR

OTHER DAMAGES (INCLUDING LOST PROFIT, LOST DATA

OR DOWNTIME COSTS) ARISING OUT OF THE USE,

INABILITY TO USE OR RESULT OF USE OF THE PRODUCT,

WHETHER BASED IN WARRANTY, CONTRACT, TORT OR

OTHER LEGAL THEORY, AND WHETHER OR NOT LAKE

SHORE HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. Your use of the Product is entirely at your

own risk. Some countries, states and provinces do not allow the

exclusion of liability for incidental or consequential damages, so

the above limitation may not apply to you.

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: ONE (1) YEAR

LIMITED WARRANTY STATEMENT (Continued)

9. EXCEPT TO THE EXTENT ALLOWED BY APPLICABLE LAW,

THE TERMS OF THIS LIMITED WARRANTY STATEMENT DO

NOT EXCLUDE, RESTRICT OR MODIFY, AND ARE IN

ADDITION TO, THE MANDATORY STATUTORY RIGHTS

APPLICABLE TO THE SALE OF THE PRODUCT TO YOU.

CERTIFICATION

Lake Shore certifies that this product has been inspected and

tested in accordance with its published specifications and that this

product met its published specifications at the time of shipment.

The accuracy and calibration of this product at the time of

shipment are traceable to the United States National Institute of

Standards and Technology (NIST); formerly known as the National

Bureau of Standards (NBS).

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 332 firmware is

as free of errors as possible, and that the results you obtain from

the instrument are accurate and reliable. However, as with any

computer-based software, the possibility of errors exists.

In any important research, as when using any laboratory

equipment, results should be carefully examined and rechecked

before final conclusions are drawn. Neither Lake Shore nor anyone

else involved in the creation or production of this firmware can pay

for loss of time, inconvenience, loss of use of the product, or

property damage caused by this product or its failure to work, or

any other incidental or consequential damages. Use of our product

implies that you understand the Lake Shore license agreement and

statement of limited warranty.

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States

copyright law and international treaty provisions. To maintain the

warranty, the code contained in the firmware must not be modified.

Any changes made to the code is at the user’s risk. Lake Shore will

assume no responsibility for damage or errors incurred as result of

any changes made to the firmware.

Under the terms of this agreement you may only use the Model

332 firmware as physically installed in the instrument. Archival

copies are strictly forbidden. You may not decompile, disassemble,

or reverse engineer the firmware. If you suspect there are

problems with the firmware, return the instrument to Lake Shore for

repair under the terms of the Limited Warranty specified above.

Any unauthorized duplication or use of the Model 332 firmware in

whole or in part, in print, or in any other storage and retrieval

system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers and sellers claim designations used to

distinguish their products as trademarks. Where those

designations appear in this manual and Lake Shore was aware of

a trademark claim, they appear with initial capital letters and the ™

®

or

symbol.

CalCurve™, Carbon-Glass™, Cernox™, Duo-Twist™, High-

Temperature Cernox™, Quad-Lead™, Quad-Twist™, Rox™,

SoftCal™, and Thermox™ are trademarks of Lake Shore

Cryotronics, Inc.

MS-DOS

®

and Windows/95/98/NT/2000® are trademarks of

Microsoft Corp.

NI-488.2™ is a trademark of National Instruments.

PC, XT, AT, and PS-2 are trademarks of IBM.

Copyright © 2002 – 2009 by Lake Shore Cryotronics, Inc. All rights reserved. No portion of this manual may

be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the express written permission of Lake Shore.

A

Lake Shore Model 332 Temperature Controller User’s Manual

DECLARATION OF CONFORMITY

We: Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville OH 43082-8888 USA

hereby declare that the equipment specified conforms to the following

Directives and Standards:

Application of Council Directives: .............................. 73/23/EEC

89/336/EEC

Standards to which Conformity is declared: .............. EN61010-1:2001

Overvoltage II

Pollution Degree 2

EN61326 A2:2001

Class A

Annex B

Model Number: .......................................................... 332

Ed Maloof

Printed Name

Vice President of Engineering

Position

B

Lake Shore Model 332 Temperature Controller User’s Manual

Electromagnetic Compatibility (EMC) for the Model 332 Temperature Controller

Electromagnetic Compatibility (EMC) of electronic equipment is a growing concern worldwide.

Emissions of and immunity to electromagnetic interference is now part of the design and manufacture

of most electronics. To qualify for the CE Mark, the Model 332 meets or exceeds the requirements of

the European EMC Directive 89/336/EEC as a CLASS A product. A Class A product is allowed to

radiate more RF than a Class B product and must include the following warning:

WARNING: This is a Class A product. In a domestic environment, this product may

cause radio interference in which case the user may be required to take

The instrument was tested under normal operating conditions with sensor and interface cables

attached. If the installation and operating instructions in the User’s Manual are followed, there should

be no degradation in EMC performance.

This instrument is not intended for use in close proximity to RF Transmitters such as two-way radios

and cell phones. Exposure to RF interference greater than that found in a typical laboratory

environment may disturb the sensitive measurement circuitry of the instrument.

Pay special attention to instrument cabling. Improperly installed cabling may defeat even the best

EMC protection. For the best performance from any precision instrument, follow the grounding and

shielding instructions in the User’s Manual. In addition, the installer of the Model 332 should consider

the following:

• Shield measurement and computer interface cables.

• Leave no unused or unterminated cables attached to the instrument.

• Make cable runs as short and direct as possible. Higher radiated emissions are possible with

long cables.

• Do not tightly bundle cables that carry different types of signals.

adequate measures.

C

Lake Shore Model 332 Temperature Controller User’s Manual

TABLE OF CONTENTS

Chapter/Paragraph Title Page

1 INTRODUCTION .................................................................................................................................................... 1-1

1.0 GENERAL ......................................................................................................................................... 1-1

1.1 PRODUCT DESCRIPTION ............................................................................................................... 1-2

1.2 SENSOR SELECTION GUIDE .......................................................................................................... 1-4

1.3 SPECIFICATIONS ............................................................................................................................. 1-8

1.4 SAFETY SUMMARY ....................................................................................................................... 1-11

1.5 SAFETY SYMBOLS ........................................................................................................................ 1-12

2 COOLING SYSTEM DESIGN ................................................................................................................................. 2-1

2.0 GENERAL ......................................................................................................................................... 2-1

2.1 TEMPERATURE SENSOR SELECTION .......................................................................................... 2-1

2.1.1 Temperature Range ....................................................................................................................... 2-1

2.1.2 Sensor Sensitivity .......................................................................................................................... 2-1

2.1.3 Environmental Conditions .............................................................................................................. 2-2

2.1.4 Measurement Accuracy ................................................................................................................. 2-2

2.1.5 Sensor Package ............................................................................................................................. 2-2

2.2 CALIBRATED SENSORS ................................................................................................................. 2-2

2.2.1 Traditional Calibration .................................................................................................................... 2-2

2.2.2 SoftCal™........................................................................................................................................ 2-3

2.2.3 Standard Curves ............................................................................................................................ 2-3

2.2.4 CalCurve™ .................................................................................................................................... 2-3

2.3 SENSOR INSTALLATION ................................................................................................................. 2-5

2.3.1 Mounting Materials ......................................................................................................................... 2-5

2.3.2 Sensor Location ............................................................................................................................. 2-5

2.3.3 Thermal Conductivity ..................................................................................................................... 2-5

2.3.4 Contact Area .................................................................................................................................. 2-5

2.3.5 Contact Pressure ........................................................................................................................... 2-6

2.3.6 Lead Wire....................................................................................................................................... 2-6

2.3.7 Lead Soldering ............................................................................................................................... 2-7

2.3.8 Heat Sinking Leads ........................................................................................................................ 2-7

2.3.9 Thermal Radiation .......................................................................................................................... 2-7

2.4 HEATER SELECTION AND INSTALLATION .................................................................................... 2-7

2.4.1 Heater Resistance and Power ....................................................................................................... 2-7

2.4.2 Heater Location .............................................................................................................................. 2-8

2.4.3 Heater Types ................................................................................................................................. 2-8

2.4.4 Heater Wiring ................................................................................................................................. 2-8

2.5 CONSIDERATIONS FOR GOOD CONTROL ................................................................................... 2-8

2.5.1 Thermal Conductivity ..................................................................................................................... 2-8

2.5.2 Thermal Lag ................................................................................................................................... 2-8

2.5.3 Two-Sensor Approach ................................................................................................................... 2-9

2.5.4 Thermal Mass ................................................................................................................................ 2-9

2.5.5 System Nonlinearit y ....................................................................................................................... 2-9

2.6 PID CONTROL .................................................................................................................................. 2-9

2.6.1 Proportional (P) ............................................................................................................................ 2-10

2.6.2 Integral (I)..................................................................................................................................... 2-10

2.6.3 Derivative (D) ............................................................................................................................... 2-10

2.6.4 Manual Heater (MHP) Output ...................................................................................................... 2-10

2.7 MANUAL TUNING ........................................................................................................................... 2-12

2.7.1 Setting Heater Range .................................................................................................................. 2-12

2.7.2 Tuning Proportional ...................................................................................................................... 2-12

2.7.3 Tuning Integral ............................................................................................................................. 2-13

2.7.4 Tuning Derivative ......................................................................................................................... 2-13

2.8 AUTOTUNING ................................................................................................................................. 2-13

2.9 ZONE TUNING ................................................................................................................................ 2-14

Table of Contents i

Lake Shore Model 332 Temperature Controller User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

3 INSTALLATION ...................................................................................................................................................... 3-1

3.0 GENERAL ......................................................................................................................................... 3-1

3.1 INSPECTION AND UNPACKING ...................................................................................................... 3-1

3.2 REPACKAGING FOR SHIPMENT .................................................................................................... 3-1

3.3 REAR PANEL DEFINITION ............................................................................................................... 3-2

3.4 LINE INPUT ASSEMBLY ................................................................................................................... 3-3

3.4.1 Line Voltage ................................................................................................................................... 3-3

3.4.2 Line Fuse and Fuse Holder ............................................................................................................ 3-3

3.4.3 Power Cord .................................................................................................................................... 3-3

3.4.4 Power Switch ................................................................................................................................. 3-4

3.5 DIODE/RESISTOR SENSOR INPUTS .............................................................................................. 3-4

3.5.1 Sensor Input Connector and Pinout ............................................................................................... 3-4

3.5.2 Sensor Lead Cable ........................................................................................................................ 3-4

3.5.3 Grounding and Shielding Sensor Leads ......................................................................................... 3-5

3.5.4 Sensor Polarity ............................................................................................................................... 3-5

3.5.5 Four-Lead Sensor Measurement ................................................................................................... 3-5

3.5.6 Two-Lead Sensor Measurement .................................................................................................... 3-6

3.5.7 Lowering Measurement Noise........................................................................................................ 3-6

3.6 THERMOCOUPLE SENSOR INPUTS .............................................................................................. 3-7

3.6.1 Sensor Input Terminals .................................................................................................................. 3-7

3.6.2 Thermocouple Installation .............................................................................................................. 3-7

3.6.3 Grounding and Shielding ................................................................................................................ 3-7

3.7 HEATER OUTPUT SETUP ............................................................................................................... 3-8

3.7.1 Loop 1 Output ................................................................................................................................ 3-8

3.7.2 Loop 1 Heater Output Connector ................................................................................................... 3-8

3.7.3 Loop 1 Heater Output Wiring ......................................................................................................... 3-8

3.7.4 Loop 1 Heater Output Noise .......................................................................................................... 3-9

3.7.5 Loop 2 Output ................................................................................................................................ 3-9

3.7.6 Loop 2 Output Resistance .............................................................................................................. 3-9

3.7.7 Loop 2 Output Connector ............................................................................................................... 3-9

3.7.8 Loop 2 Heater Protection ............................................................................................................... 3-9

3.7.9 Boosting the Output Power ............................................................................................................ 3-9

3.8 ANALOG OUTPUT .......................................................................................................................... 3-10

3.9 RELAYS .......................................................................................................................................... 3-10

3.10 INITIAL SETUP AND SYSTEM CHECKOUT PROCEDURE .......................................................... 3-11

4 OPERATION ........................................................................................................................................................... 4-1

4.0 GENERAL ......................................................................................................................................... 4-1

4.1 FRONT PANEL DESCRIPTION ........................................................................................................ 4-1

4.1.1 Keypad Definitions ......................................................................................................................... 4-1

4.1.2 Annunciators .................................................................................................................................. 4-3

4.1.3 General Keypad Operation ............................................................................................................ 4-3

4.1.4 Display Definition ........................................................................................................................... 4-4

4.1.5 Heater Bar Definition ...................................................................................................................... 4-4

4.2 TURNING POWER ON ..................................................................................................................... 4-5

4.3 DISPLAY FORMAT AND SOURCE (UNITS) SELECTION ............................................................... 4-5

4.4 INPUT SETUP ................................................................................................................................... 4-7

4.4.1 Diode Sensor Input Setup .............................................................................................................. 4-7

4.4.2 Platinum Resistor Sensor Input Setup ........................................................................................... 4-8

4.4.3 NTC RTD Sensor Input Setup ........................................................................................................ 4-8

4.4.3.1 Thermal EMF Compensation ...................................................................................................... 4-9

4.4.4 Thermocouple Sensor Input Setup ............................................................................................... 4-10

4.4.4.1 Room-Temperature Compensation .......................................................................................... 4-10

4.4.4.2 Room-Temperature Calibration Procedure ............................................................................... 4-11

4.5 CURVE SELECTION ....................................................................................................................... 4-12

ii Table of Contents

Lake Shore Model 332 Temperature Controller User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

4.5.1 Diode Sensor Curve Selection ..................................................................................................... 4-13

4.5.2 Resistor Sensor Curve Selection ................................................................................................. 4-13

4.5.3 Thermocouple Sensor Curve Selection ....................................................................................... 4-13

4.6 TEMPERATURE CONTROL ........................................................................................................... 4-14

4.6.1 Control Loops ............................................................................................................................... 4-14

4.6.2 Control Modes .............................................................................................................................. 4-15

4.6.3 Tuning Modes .............................................................................................................................. 4-15

4.7 CONTROL SETUP .......................................................................................................................... 4-15

4.8 MANUAL TUNING ........................................................................................................................... 4-17

4.8.1 Manually Setting Proportional (P) ................................................................................................ 4-17

4.8.2 Manually Setting Integral (I) ......................................................................................................... 4-17

4.8.3 Manually Setting Derivative (D) .................................................................................................... 4-18

4.8.4 Setting Manual Heater Power (MHP) Output ............................................................................... 4-18

4.9 AUTOTUNE (Closed-Loop PID Control) .......................................................................................... 4-19

4.10 ZONE SETTINGS (Closed-Loop Control) ....................................................................................... 4-20

4.11 SETPOINT....................................................................................................................................... 4-23

4.12 RAMP .............................................................................................................................................. 4-23

4.13 HEATER RANGE AND HEATER OFF ............................................................................................ 4-24

4.14 MATH .............................................................................................................................................. 4-26

4.14.1 Max/Min ....................................................................................................................................... 4-26

4.14.2 Linear ........................................................................................................................................... 4-27

4.14.3 Filter ............................................................................................................................................. 4-28

4.15 ALARMS AND RELAYS .................................................................................................................. 4-29

4.15.1 Alarms .......................................................................................................................................... 4-29

4.15.2 Relays .......................................................................................................................................... 4-31

4.16 ANALOG OUTPUT .......................................................................................................................... 4-32

4.16.1 Analog Output In Input Mode ....................................................................................................... 4-32

4.16.2 Analog Output In Manual Mode ................................................................................................... 4-34

4.16.3 Analog Output In Loop 2 Mode .................................................................................................... 4-35

4.17 LOCKING AND UNLOCKING THE KEYPAD .................................................................................. 4-35

4.18 DISPLAY BRIGHTNESS ................................................................................................................. 4-36

4.19 REMOTE/LOCAL ............................................................................................................................ 4-36

4.20 INTERFACE .................................................................................................................................... 4-36

4.21 DEFAULT VALUES ......................................................................................................................... 4-37

5 ADVANCED OPERATION ..................................................................................................................................... 5-1

5.0 GENERAL ......................................................................................................................................... 5-1

5.1 CURVE NUMBERS AND STORAGE ................................................................................................ 5-1

5.1.1 Curve Header Parameters ............................................................................................................. 5-1

5.1.2 Curve Breakpoints ......................................................................................................................... 5-2

5.2 FRONT PANEL CURVE ENTRY OPERATIONS .............................................................................. 5-2

5.2.1 Edit Curve ...................................................................................................................................... 5-4

5.2.1.1 Thermocouple Curve Considerations ......................................................................................... 5-5

5.2.2 Erase Curve ................................................................................................................................... 5-6

5.2.3 Copy Curve .................................................................................................................................... 5-6

5.3 SOFTCAL™ ...................................................................................................................................... 5-7

5.3.1 SoftCal With Silicon Diode Sensors ............................................................................................... 5-7

5.3.2 SoftCal Accuracy With Silicon Diode Sensors ............................................................................... 5-8

5.3.3 SoftCal With Platinum Sensors ...................................................................................................... 5-9

5.3.4 SoftCal Accuracy With Platinum Sensors ...................................................................................... 5-9

5.3.5 SoftCal Calibration Curve Creation .............................................................................................. 5-10

6 COMPUTER INTERFACE OPERATION ................................................................................................................ 6-1

6.0 GENERAL ......................................................................................................................................... 6-1

6.1 IEEE-488 INTERFACE ...................................................................................................................... 6-1

6.1.1 Changing IEEE-488 Interface Parameters ..................................................................................... 6-2

Table of Contents iii

Lake Shore Model 332 Temperature Controller User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

6.1.2 IEEE-488 Command Structure ....................................................................................................... 6-2

6.1.2.1 Bus Control Commands ............................................................................................................. 6-2

6.1.2.2 Common Commands .................................................................................................................. 6-3

6.1.2.3 Device Specific Commands ........................................................................................................ 6-3

6.1.2.4 Message Strings ......................................................................................................................... 6-3

6.1.3 Status Registers ............................................................................................................................. 6-4

6.1.3.1 Status Byte Register and Service Request Register .................................................................. 6-4

6.1.3.2 Standard Event Status Register and Standard Event Status Enable Register ........................... 6-4

6.1.4 IEEE Interface Example Programs ................................................................................................. 6-5

6.1.4.1 IEEE-488 Interface Board Installation for Visual Basic Program ................................................ 6-5

6.1.4.2 Visual Basic IEEE-488 Interface Program Setup ........................................................................ 6-7

6.1.4.3 IEEE-488 Interface Board Installation for Quick Basic Program ............................................... 6-10

6.1.4.4 Quick Basic Program ................................................................................................................ 6-10

6.1.4.5 Program Operation ................................................................................................................... 6-13

6.1.5 Troubleshooting ............................................................................................................................... 6-13

6.2 SERIAL INTERFACE OVERVIEW .................................................................................................. 6-14

6.2.1 Physical Connection ..................................................................................................................... 6-14

6.2.2 Hardware Support ........................................................................................................................ 6-14

6.2.3 Character Format ......................................................................................................................... 6-15

6.2.4 Message Strings .......................................................................................................................... 6-15

6.2.5 Message Flow Control ................................................................................................................. 6-16

6.2.6 Changing Baud Rate .................................................................................................................... 6-16

6.2.7 Serial Interface Example Programs .............................................................................................. 6-17

6.2.7.1 Visual Basic Serial Interface Program Setup ............................................................................ 6-17

6.2.7.2 Quick Basic Serial Interface Program Setup ............................................................................ 6-20

6.2.7.3 Program Operation ................................................................................................................... 6-21

6.2.8 Troubleshooting ........................................................................................................................... 6-21

6.3 COMMAND SUMMARY .................................................................................................................. 6-22

6.3.1 Interface Commands (Alphabetical Listing) .................................................................................. 6-24

7 OPTIONS AND ACCESSORIES ............................................................................................................................ 7-1

7.0 GENERAL ......................................................................................................................................... 7-1

7.1 MODELS ........................................................................................................................................... 7-1

7.2 OPTIONS .......................................................................................................................................... 7-1

7.3 ACCESSORIES ................................................................................................................................. 7-2

7.4 MODEL 3003 HEATER OUTPUT CONDITIONER ............................................................................ 7-4

8 SERVICE ................................................................................................................................................................ 8-1

8.0 GENERAL ......................................................................................................................................... 8-1

8.1 ELECTROSTATIC DISCHARGE ....................................................................................................... 8-1

8.1.1 Identification of Electrostatic Discharge Sensitive Components ..................................................... 8-1

8.1.2 Handling Electrostatic Discharge Sensitive Components ............................................................... 8-1

8.2 LINE VOLTAGE SELECTION ........................................................................................................... 8-2

8.3 FUSE REPLACEMENT ..................................................................................................................... 8-2

8.4 REAR PANEL CONNECTOR DEFINITIONS .................................................................................... 8-3

8.4.1 Serial Interface Cable Wiring ......................................................................................................... 8-5

8.4.2 IEEE-488 Interface Connector ....................................................................................................... 8-6

8.5 TOP OF ENCLOSURE REMOVE AND REPLACE PROCEDURE .................................................... 8-7

8.6 FIRMWARE AND NOVRAM REPLACEMENT .................................................................................. 8-7

8.7 LOOP 2 / ANALOG OUTPUT RANGE SELECTION ......................................................................... 8-8

8.8 JUMPERS ......................................................................................................................................... 8-8

8.9 ERROR MESSAGES ......................................................................................................................... 8-9

8.10 CALIBRATION PROCEDURE ......................................................................................................... 8-11

8.10.1 Equipment Required for Calibration ............................................................................................. 8-11

8.10.2 Diode/Resistor Sensor Input Calibration ...................................................................................... 8-12

8.10.2.1 Sensor Input Calibration Setup and Serial Communication Verfication .................................... 8-12

iv Table of Contents

Lake Shore Model 332 Temperature Controller User’s Manual

Chapter/Paragraph Title Page

8.10.2.2 10 µA Current Source Calibration and 1 µA, 100 µA, 1 mA Output Verfication ........................ 8-12

8.10.2.3 Diode Input Ranges Calibration ................................................................................................ 8-13

8.10.2.4 Resistive Input Ranges Calibration .......................................................................................... 8-14

8.10.3 Thermocouple Sensor Input Calibration ....................................................................................... 8-15

8.10.3.1 Sensor Input Calibration Setup ................................................................................................. 8-15

8.10.3.2 Thermocouple Input Ranges Calibration .................................................................................. 8-16

8.10.4 Analog Output Calibration ............................................................................................................ 8-17

8.10.4.1 Analog Output Calibration ........................................................................................................ 8-17

8.10.5 Calibration Specific Interface Commands .................................................................................... 8-18

APPENDIX A – GLOSSARY OF TERMINOLOGY ........................................................................................................ A-1

APPENDIX B – TEMPERATURE SCALES .................................................................................................................. B-1

APPENDIX C – HANDLING OF LIQUID HELIUM AND NITROGEN ............................................................................ C-1

APPENDIX D – CURVE TABLES ................................................................................................................................. D-1

LIST OF ILLUSTRATIONS

Figure No. Title Page

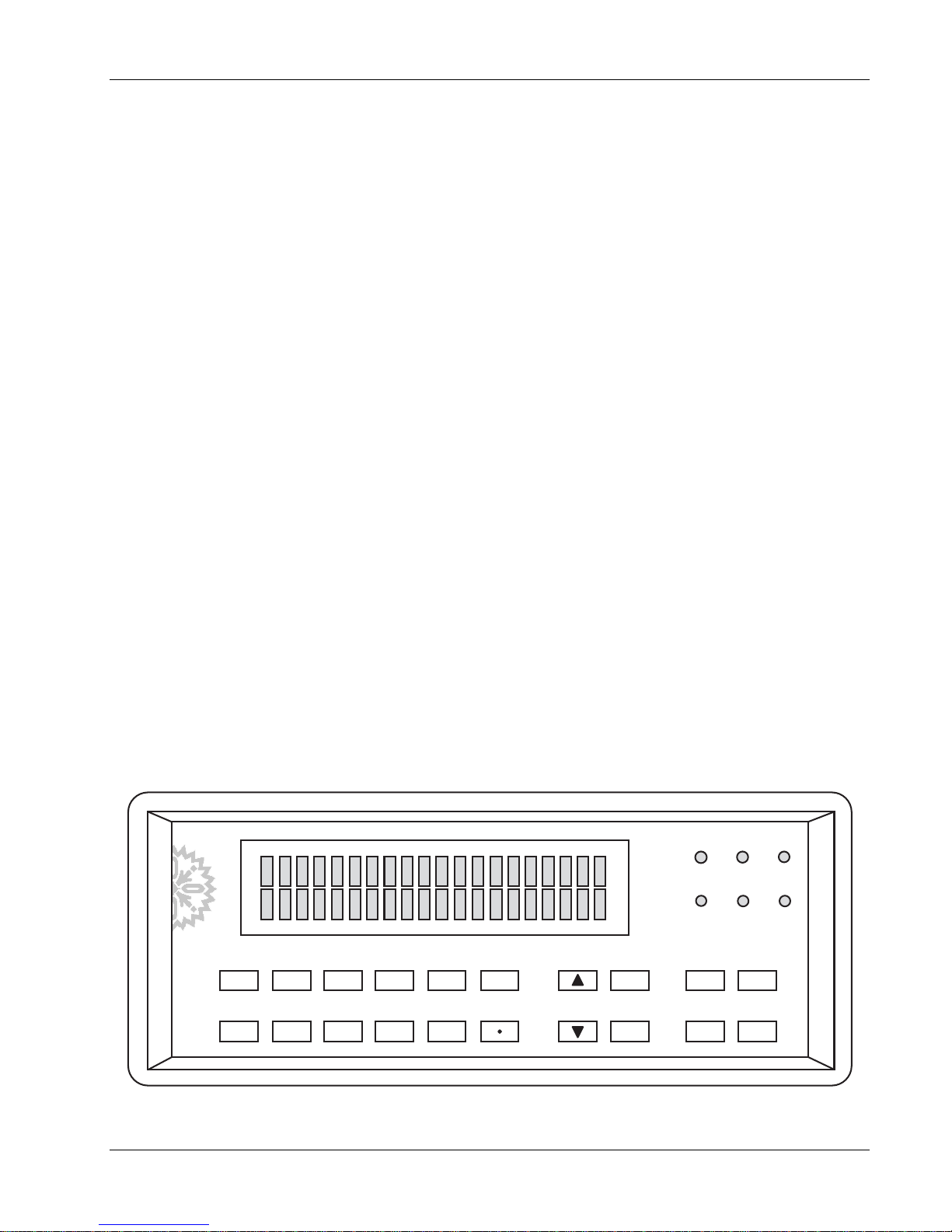

1-1 Model 332 Temperature Controller Front Panel ........................................................................................... 1-1

2-1 Silicon Diode Sensor Calibrations and CalCurve ......................................................................................... 2-4

2-2 Typical Sensor Installation In A Mechanical Refrigerator ............................................................................. 2-6

2-3 Examples of PID Control ............................................................................................................................ 2-11

3-1 Model 332 Rear Panel .................................................................................................................................. 3-2

3-2 Line Input Assembly ..................................................................................................................................... 3-3

3-3 Diode/Resistor Input Connector ................................................................................................................... 3-4

3-4 Thermocouple Input Definition and Common Connector Polarities .............................................................. 3-7

3-5 RELAYS and ANALOG OUTPUT Terminal Block ...................................................................................... 3-10

4-1 Model 332 Front Panel ................................................................................................................................. 4-1

4-2 Display Definition ......................................................................................................................................... 4-4

4-3 Heater Bar Definition .................................................................................................................................... 4-4

4-4 Display Format Definition ............................................................................................................................. 4-5

4-5 Record of Zone Settings ............................................................................................................................. 4-22

4-6 Deadband Example .................................................................................................................................... 4-29

4-7 Relay Settings ............................................................................................................................................ 4-31

5-1 SoftCal Temperature Ranges for Silicon Diode Sensors .............................................................................. 5-8

5-2 SoftCal Temperature Ranges for Platinum Sensors..................................................................................... 5-9

6-1 GPIB Setting Configuration .......................................................................................................................... 6-6

6-2 DEV 12 Device Template Configuration ....................................................................................................... 6-6

6-3 Typical National Instruments GPIB Configuration from IBCONF.EXE........................................................ 6-11

7-1 Model 3507-2SH Cable Assembly ............................................................................................................... 7-3

7-2 Model 3003 Heater Output Conditioner ........................................................................................................ 7-4

7-3 Model RM-1/2 Rack-Mount Kit ..................................................................................................................... 7-5

7-4 Model RM-2 Dual Rack-Mount Kit ................................................................................................................ 7-6

8-1 Power Fuse Access ...................................................................................................................................... 8-2

8-2 Sensor INPUT A and B Connector Details ................................................................................................... 8-3

8-3 HEATER OUTPUT Connector Details .......................................................................................................... 8-3

8-4 RELAYS and ANALOG OUTPUT Terminal Block ........................................................................................ 8-4

8-5 RS-232 Connector Details ............................................................................................................................ 8-4

8-6 IEEE-488 Rear Panel Connector Details ...................................................................................................... 8-6

8-7 Location of Internal Components ............................................................................................................... 8-10

B-1 Temperature Scale Comparison .................................................................................................................. B-1

C-1 Typical Cryogenic Storage Dewar ................................................................................................................ C-1

TABLE OF CONTENTS (Continued)

Table of Contents v

Lake Shore Model 332 Temperature Controller User’s Manual

LIST OF TABLES

Table No. Title Page

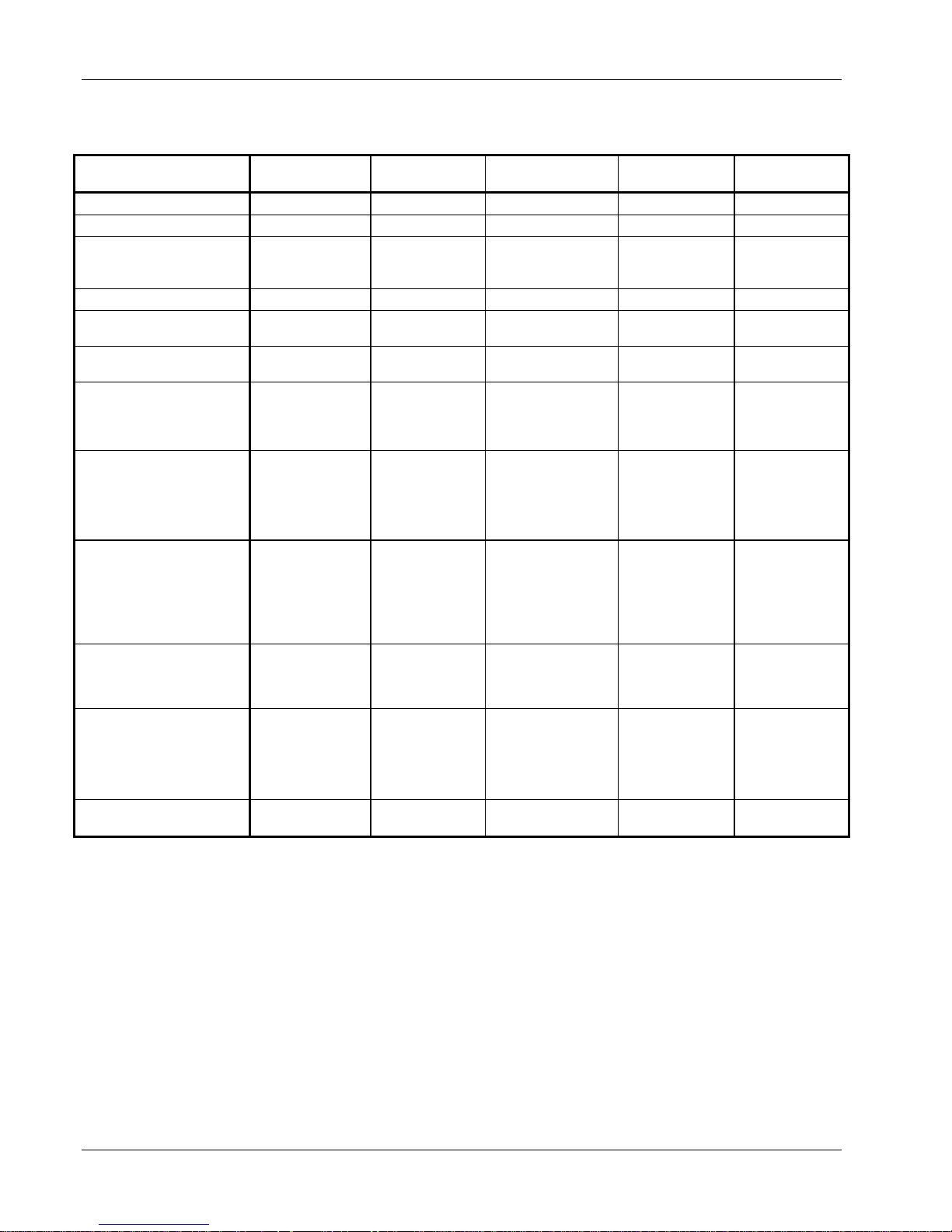

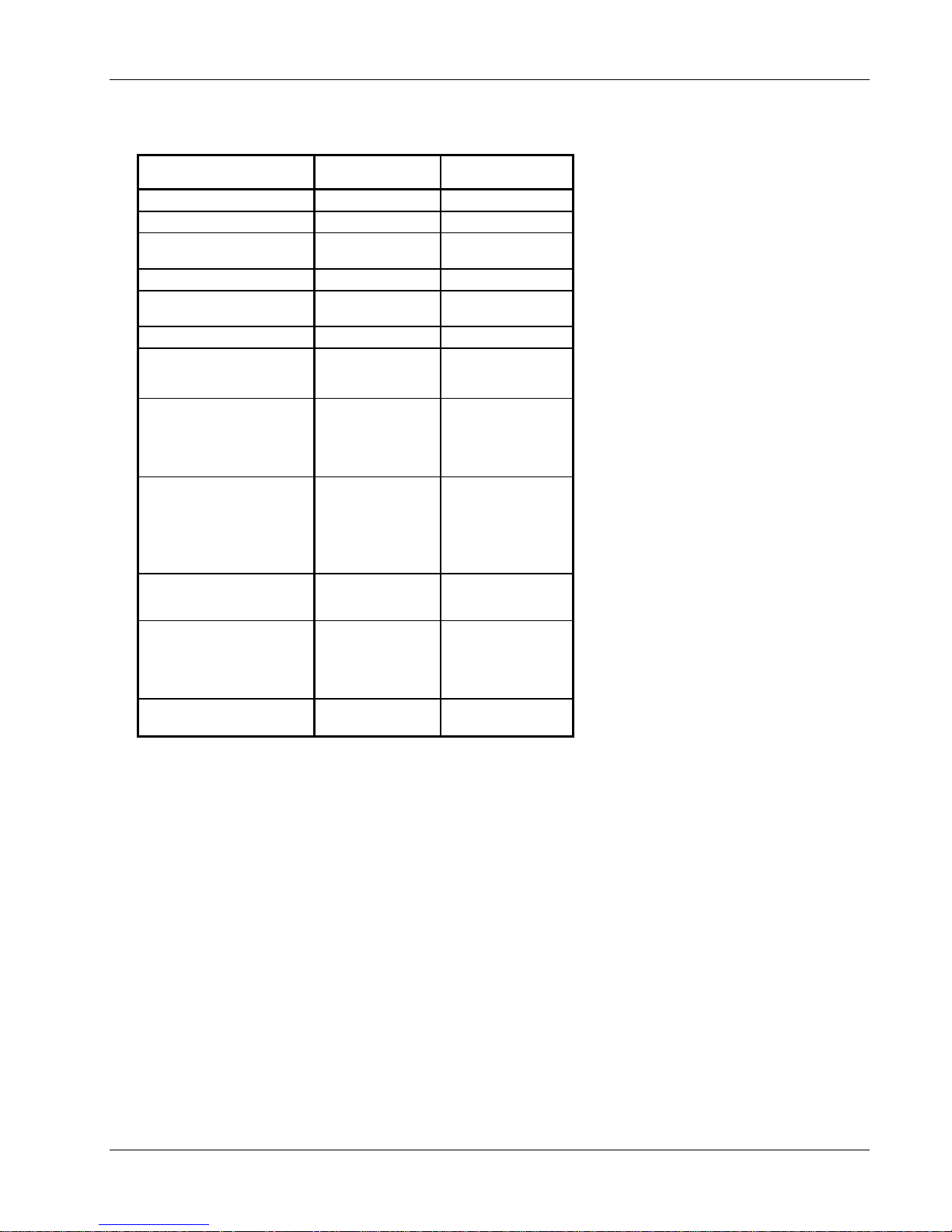

1-1 Temperature Range of Typical Lake Shore Sensors .................................................................................... 1-4

1-2 Model 332 Sensor Input Performance Chart ................................................................................................ 1-5

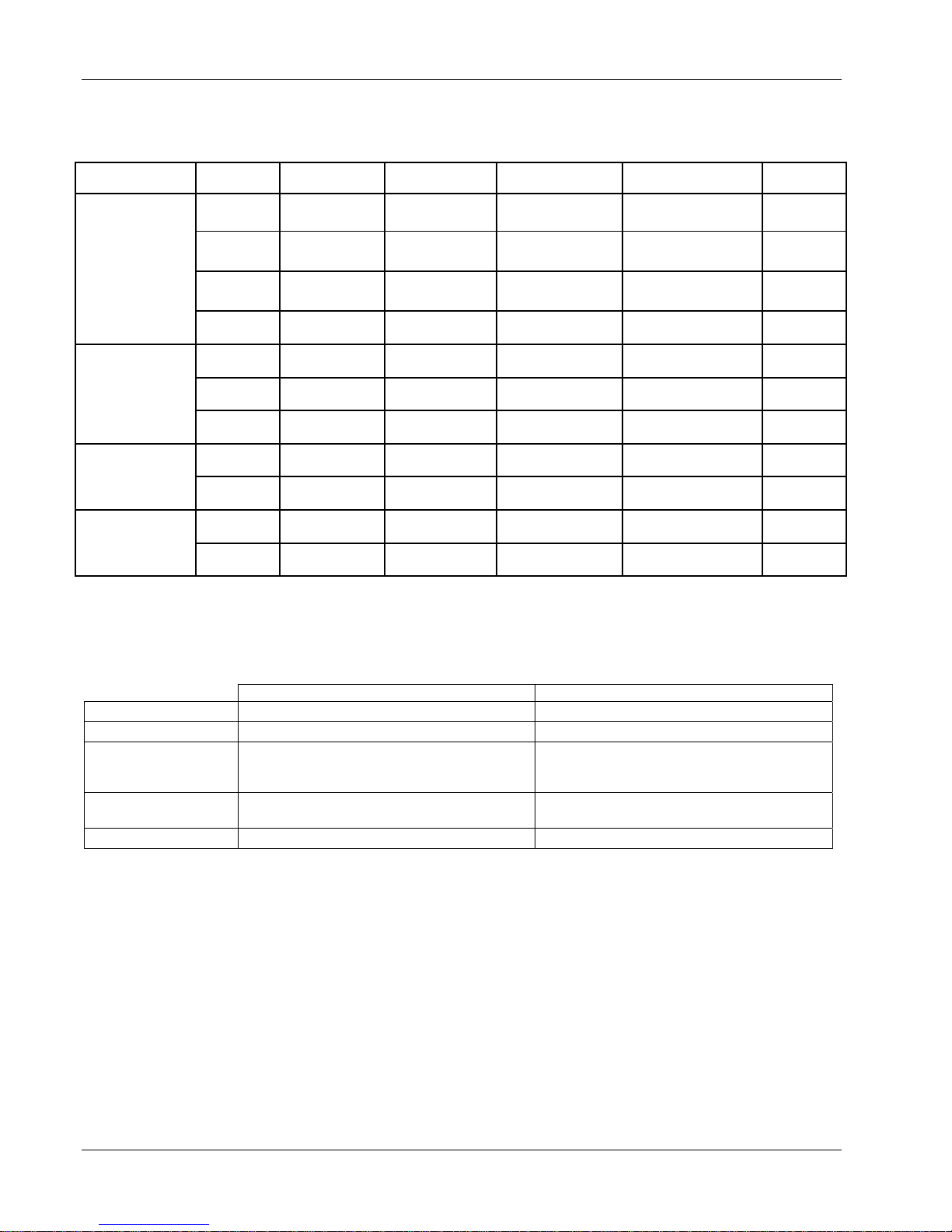

1-3 Model 332 Input Specifications ..................................................................................................................... 1-8

4-1 Sensor Input Types ...................................................................................................................................... 4-7

4-2 Sensor Curves ............................................................................................................................................ 4-12

4-3 Comparison of Control Loops 1 and 2 ........................................................................................................ 4-14

4-4 Linear Equation Configuration .................................................................................................................... 4-27

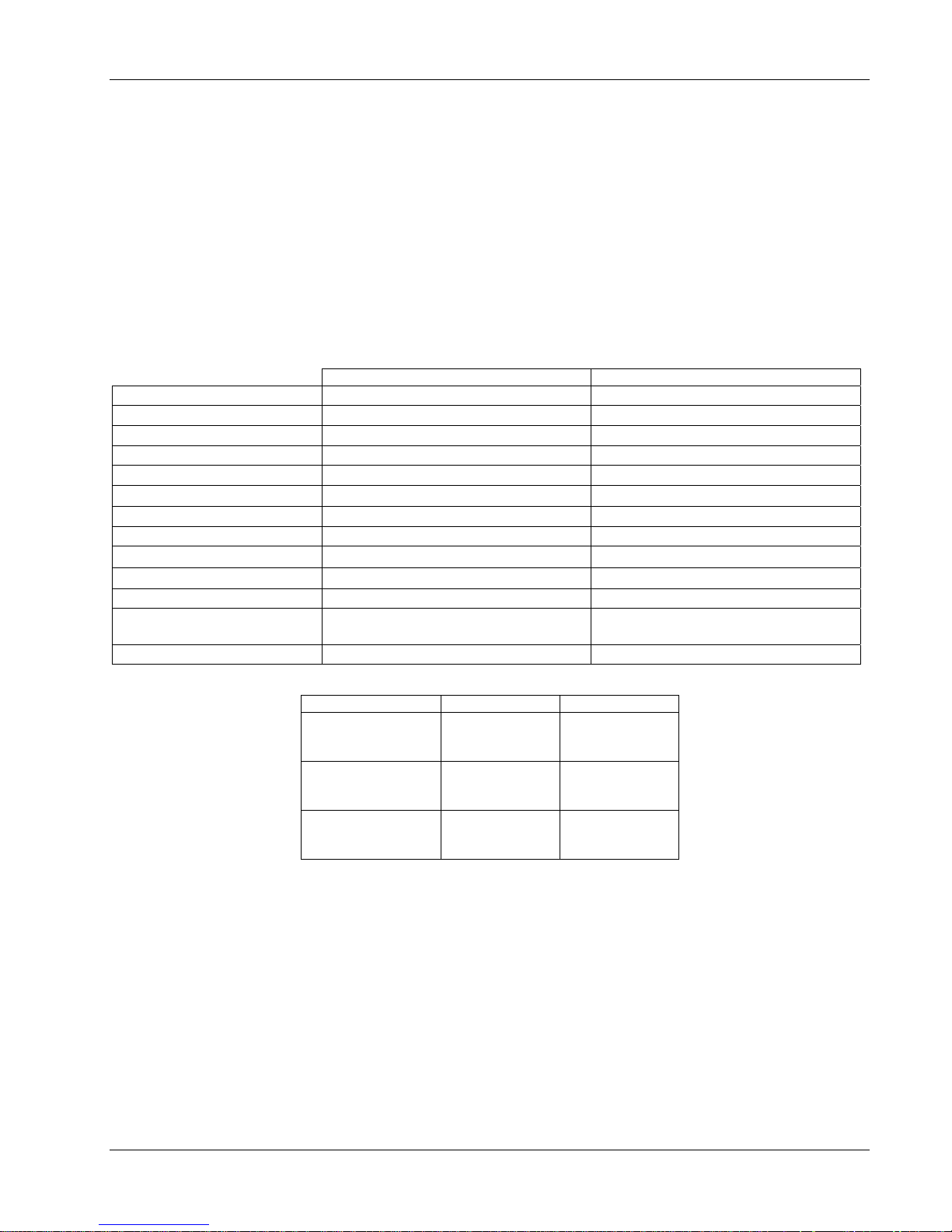

4-5 Default Values ............................................................................................................................................ 4-38

5-1 Curve Header Parameters ............................................................................................................................ 5-3

5-2 Recommended Curve Parameters ............................................................................................................... 5-3

6-1 IEEE-488 Interface Program Control Properties ........................................................................................... 6-8

6-2 Visual Basic IEEE-488 Interface Program .................................................................................................... 6-9

6-3 Quick Basic IEEE-488 Interface Program ................................................................................................... 6-12

6-4 Serial Interface Specifications .................................................................................................................... 6-15

6-5 Serial Interface Program Control Properties ............................................................................................... 6-18

6-6 Visual Basic Serial Interface Program ........................................................................................................ 6-19

6-7 Quick Basic Serial Interface Program ......................................................................................................... 6-20

6-8 Command Summary .................................................................................................................................. 6-23

8-1 Calibration Table for Diode Ranges ........................................................................................................... 8-14

8-2 Calibration Table for Resistive Ranges ...................................................................................................... 8-15

8-3 Calibration Table for Thermocouple Ranges .............................................................................................. 8-16

B-1 Temperature Conversion Table .................................................................................................................... B-2

C-1 Comparison of Liquid Helium and Liquid Nitrogen ...................................................................................... C-1

D-1 DT-470 Silicon Diode Curve ........................................................................................................................ D-1

D-2 DT-670 Silicon Diode Curve ........................................................................................................................ D-2

D-3 DT-500 Series Silicon Diode Curves ........................................................................................................... D-2

D-4 PT-100/-1000 Platinum RTD Curves ........................................................................................................... D-3

D-5 RX-102A Rox™ Curve ........................................................................................................

D-6 RX-202A Rox™ Curve ................................................................................................................................ D-5

D-7 Type K Thermocouple Curve ....................................................................................................................... D-6

D-8 Type E Thermocouple Curve ....................................................................................................................... D-7

D-9 Type T Thermocouple Curve ....................................................................................................................... D-8

D-10 Chromel-AuFe 0.03% Thermocouple Curve ................................................................................................ D-9

D-11 Chromel-AuFe 0.07% Thermocouple Curve .............................................................................................. D-10

........................ D-4

vi Table of Contents

Lake Shore Model 332 Temperature Controller User’s Manual

CHAPTER 1

INTRODUCTION

1.0 GENERAL

This chapter introduces the Model 332 Temperature Controller. The Model 332 was designed and

manufactured in the United States of America by Lake Shore Cryotronics, Inc. The Model 332

Temperature Controller is a microprocessor-based instrument with digital control of a variable current

output. The Model 332 features include the following.

z Two Sensor Inputs Supporting:

– Diodes

– Positive Temperature Coefficient (PTC) Resistance Temperature Detectors (RTDs)

– Negative Temperature Coefficient (NTC) RTDs

– Thermocouples

z Five Tuning Modes:

– Autotuning P

– Autotuning PI

– Autotuning PID

– Manual

– Zone (10 Temperature Zones)

z Two Temperature Control Loops:

– Loop 1 – 50 W Output

– Loop 2 – 10 W Output

z Bright Large-Character Display:

– 2 Row by 20 Character Vacuum Fluorescent Display

– Display of Sensor Temperature in K, °C, or sensor units in volts, ohms

z Serial Interface

z IEEE-488 Interface

z Model 330 Command Emulation Mode

z Relays

LakeShore

Control

Setup

Zone

Setting

1 234 5+/

Setpoint

PID/

MHP

6 789 0

C332-1-1.eps

Figure 1-1. Model 332 Temperature Controller Front Panel

Introduction 1-1

Input

Setup

Curve

Entry

Display

Format

Math

Alarm

Analog

Output

332 Temperature Controller

Remote/

Local

Interface

Escape

Enter

Control A

Control B

Auto

Tune

Loop

Tune

Ramp

Heater

Range

Heater

Remote

Alarm

Off

Lake Shore Model 332 Temperature Controller User’s Manual

1.1 PRODUCT DESCRIPTION

The Lake Shore Model 332 Temperature Controller creates a new standard for high-resolution

temperature measurement in an easy-to-use temperature controller. The Model 332 offers high

resolution with negative temperature coefficient (NTC) resistance temperature detectors (RTDs) to

temperatures as low as 1 K. The Model 332 includes a 50 W heater output on the first control loop

and 10 W on the second control loop. This provides greater flexibility in applications that require a

second heater.

Sensor Inputs

Automatic scalable excitation current allows the Model 332 to support Cernox™ and other NTC RTDs

to temperatures as low as 1 K. At higher temperatures, where resistance is low and concerns for sensor

self-heating are minimal, the Model 332 provides an excitation current of 1 mA for a better signal to

noise ratio and high-measurement resolution. At low temperature, where resistance is high (up to

Ω), the Model 332 provides an excitation current of 1 µA to minimize sensor self-heating and

75 k

self-heating induced error. Excitation currents of 10 µA and 100 µA are also available. Manual control of

the excitation range is available, making it possible to fix the input range. The Model 332 also uses

current reversal to eliminate thermal electromotive force (EMF) errors.

The Model 332 Temperature Controller features two inputs, with a high-resolution 24-bit analog-todigital converter and separate current source for each input. Sensors are optically isolated from other

instrument functions for quiet and repeatable sensor measurements. Sensor data from each input can

be read up to ten times per second, with display updates twice each second.

Standard temperature response curves for silicon diodes, platinum RTDs, and many thermocouples are

included. Up to twenty 200-point CalCurves™ for Lake Shore calibrated sensors or user curves can be

loaded into non-volatile memory via computer interface or the instrument front panel. A built-in

SoftCal™ algorithm can also be used to generate curves for silicon diodes and platinum RTDs, for

storage as user curves.

Sensor inputs are factory configured and compatible with either Diode/RTD or Thermocouple sensors.

The choice of 2 Diode/RTD inputs, 1 Diode/RTD input and 1 Thermocouple input, or 2 Thermocouple

inputs must be specified at time of order. The configuration cannot be changed in the field. The

software selects the appropriate excitation current and signal gain levels when the sensor type is

entered via the instrument front panel.

The Diode/RTD input configuration is compatible with most diode and negative and positive

temperature coefficient RTDs. Current reversal eliminates thermal EMF errors for resistor sensors.

The Thermocouple input configuration is compatible only with thermocouple sensors. Roomtemperature compensation is included for any type of thermocouple in use. Temperature response

curves for many types of thermocouples are included. Temperature response curves may be entered

as user curves for other thermocouples.

The Lake Shore SoftCal algorithm for silicon diode and platinum RTD sensors is a good solution for

applications that need more accuracy than a standard sensor curve but not traditional calibration.

SoftCal uses the predictability of a standard curve to improve the accuracy of an individual sensor

around known temperature reference points.

Temperature Control

For the greatest flexibility in temperature control, the Model 332 has two independent, proportionalintegral-derivative (PID) control loops that drive two heater outputs of 50 W and 10 W.

A PID control algorithm calculates control output based on temperature setpoint and feedback from the

control sensor. Wide tuning parameters accommodate most cryogenic cooling systems and many small

high-temperature ovens. Control output is generated by a high-resolution digital-to-analog converter for

smooth, continuous control. A manual control mode is also included.

1-2 Introduction

Product Definition (Continued)

Lake Shore Model 332 Temperature Controller User’s Manual

Loop 1 heater output is a well-regulated variable DC current source. Heater output is optically isolated

from other circuits to reduce interference and ground loops. Heater output can provide up to 50 W of

continuous power to a resistive heater load and includes two lower ranges for systems with less cooling

power. Heater output is short-circuit protected to prevent instrument damage if the heater load is

accidentally shorted.

The Model 332 has a second control loop called Loop 2. The Loop 2 output is a single-range, variable

DC voltage source that can vary from 0 V to +10 V. The output can source up to 1 A of current

providing a maximum of 10 W of heater power. The output is short protected so the instrument is not

harmed if the heater load is accidentally shorted.

The setpoint ramp feature allows smooth continuous changes in setpoint and also makes the

approach to a setpoint temperature more predictable. The zone feature can automatically change

control parameter values for operation over a large temperature range. Values for ten different

temperature zones can be loaded into the instrument, which will select the next appropriate value on

setpoint change.

The Model 332 AutoTune feature simplifies the tuning process. With its own measurements of system

characteristics and based on characteristics of typical cryogenic systems, the AutoTune function

computes proportional, integral, and derivative setting values. The AutoTune function only tunes one

control loop at a time. Because setting an inappropriate heating range is potentially dangerous to some

loads, the Model 332 AutoTune feature does not attempt to automate that step of the tuning process.

Interface

Most functions on the instrument front panel can also be performed via computer interface. The

Model 332 is equipped with a parallel IEEE-488 interface as well as a serial RS-232C interface.

Maximum reading rates can be achieved with either interface.

High and low alarms for each input can be used in latching mode, requiring user intervention before

alarms reset. Alarms can also be used in conjunction with relays in non-latching mode, where alarms

automatically reset when the activation condition ends, to perform simple on-off control functions. Relay

assignments are configurable so that one relay may be assigned to each input or both assigned to a

single input for high/low control.

The analog voltage output can be configured to send a voltage proportional to temperature or data

acquisition system. The user may select the scale and data sent to the output, including temperature,

sensor units, or linear equation results. Under manual control, the analog voltage output can also serve

as a voltage source for any other application.

Also included is a Model 330 command emulation mode for drop-in interchangeability with Model 330

Temperature Controllers in existing systems.

Configurable Display

The Model 332 includes a bright vacuum fluorescent display that simultaneously displays up to four

readings. Frequently used functions can be accomplished from the instrument front panel with one or

two keystrokes. Display data includes input and source annunciators for each reading. Each of the four

display locations may be configured by the user. Data from either input may be assigned to any of the

four locations. The user's choice of temperature, sensor units, and maximum, minimum, or linear

equation results can be displayed. Heater range and control output as current or power can also be

continuously displayed numerically or as a bar graph for immediate feedback on control operation.

Introduction 1-3

Lake Shore Model 332 Temperature Controller User’s Manual

1.2 SENSOR SELECTION GUIDE

The Lake Shore Temperature Measurement and Control Catalog contains complete information on

selecting the appropriate Lake Shore Temperature Sensor for your application. A list of sensors that

may be used with the Model 332 is provided in Table 1-1. This paragraph provides a brief guideline

covering sensors commonly used with the Model 332. Typical performance specifications can be found

in Table 1-2. If a specific sensor model is not included in the table, use the sensitivity of the sensor at

the desired temperature to calculate temperature equivalence for your sensor.

Silicon Diodes are the best choice for general cryogenic use from 1.4 K to 500 K. Economical to use

because they follow a standard curve and are interchangeable in many applications, silicon diodes

are not suitable for use in ionizing radiation or magnetic fields.

GaAlAs Diodes offer high sensitivity from 1.4 K to above room temperature, with better sensitivity than

silicon diodes at temperatures below 25 K. They are useful in moderate magnetic fields. GaAlAs

diodes require calibration.

Platinum RTDs offer high uniform sensitivity from 30 K to over 800 K, with excellent reproducibility,

they are useful as a thermometry standard. They follow a standard curve above 70 K and are

interchangeable in many applications, but are not useful at cryogenic temperatures below 20 K.

Cernox™ and High-Temperature Cernox RTDs offer excellent sensitivity over a wide range of

temperatures, with resistance to strong magnetic fields and ionizing radiation. Cernox sensors

require calibration.

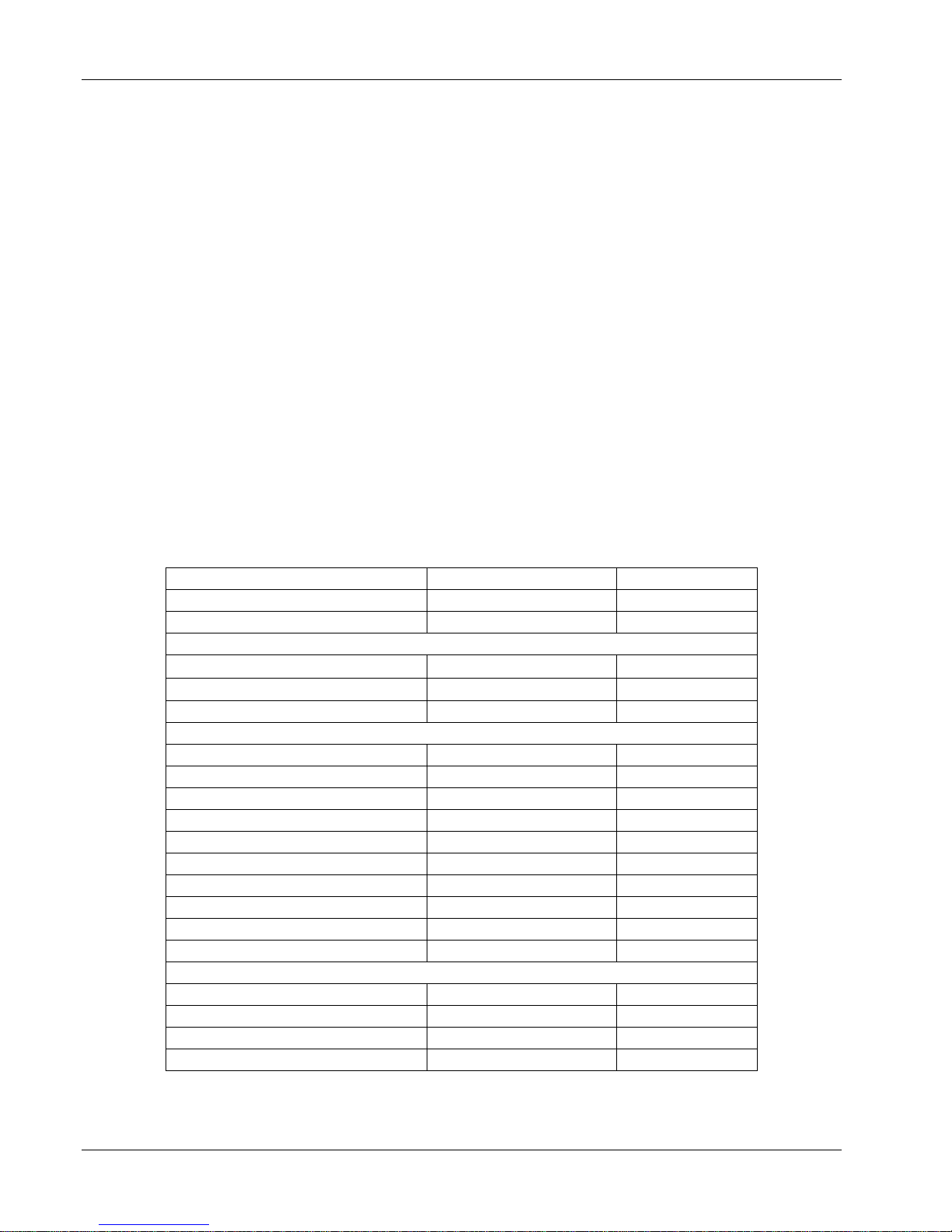

Table 1-1. Temperature Range of Typical Lake Shore Sensors

*

Diodes Model Useful Range

Silicon Diodes DT-670 1.4 – 500 K

GaAlAs Diode TG-120 1.4 – 475 K

Positive Temperature Coefficient (PTC) RTDs

100 Ω Platinum RTD PT-100, 250 Ω full scale

100 Ω Platinum RTD PT-100, 500 Ω full scale

30 – 675 K

30 – 800 K

Rhodium-Iron RTD RF-800-4 1.4 – 400 K

Negative Temperature Coefficient (NTC) † RTDs

Germanium RTD GR-200A-1500 1.4 – 100 K

Germanium RTD GR-200A-1000 1.4 – 100 K

Germanium RTD GR-200A-250 1 – 40 K

Carbon-Glass™ RTD CGR-1-500 3 – 325 K

Cernox™ RTD CX-1050 AA or SD 2– 325 K

Cernox™ RTD CX-1030 AA or SD 1 – 325 K

High-Temperature Cernox™ RTD CX-1030-SD-HT 1 – 420 K

Rox™ Ruthenium Oxide RTD RX-102A 1 – 40 K

Rox™ Ruthenium Oxide RTD RX-202A 1 – 40 K

Rox™ Ruthenium Oxide RTD RX-103A 1.4 – 325 K

Thermocouples

Chromel versus AuFe 0.07% Model 9006-002 1.4 – 610 K

Type E Model 9006-004 3.2 – 930 K

Type K Model 9006-006 3.2 – 1500 K

Type T Model 9006-008 3.2 – 670 K

* Sensors sold separately.

† Excitation current may limit the low temperature range of NTC resistors.

1-4 Introduction

Lake Shore Model 332 Temperature Controller User’s Manual

Sensor Selection Guide (Continued)

Rox™ RTD thick film sensors are useful in low temperature applications in magnetic fields, with a very

low incidence of magnetic field errors. Each model adheres to a single resistance versus

temperature curve. The Rox Models RX-102A and RX-202A are useful to temperatures as low as

50 mK, with accuracy to within ±5 mK at 50 mK; the RX-202A also offers an upper temperature

range to 300 K. The Model 332 configured with Rox RTDs should only be used down to 1 K.

Thermocouples offer uniform sensitivity over a wide temperature range and measure the highest

temperatures possible with the Model 332. While many types are inexpensive and standard curves

are available, thermocouples are less accurate than other sensors. Repeatability is highly

dependent upon installation.

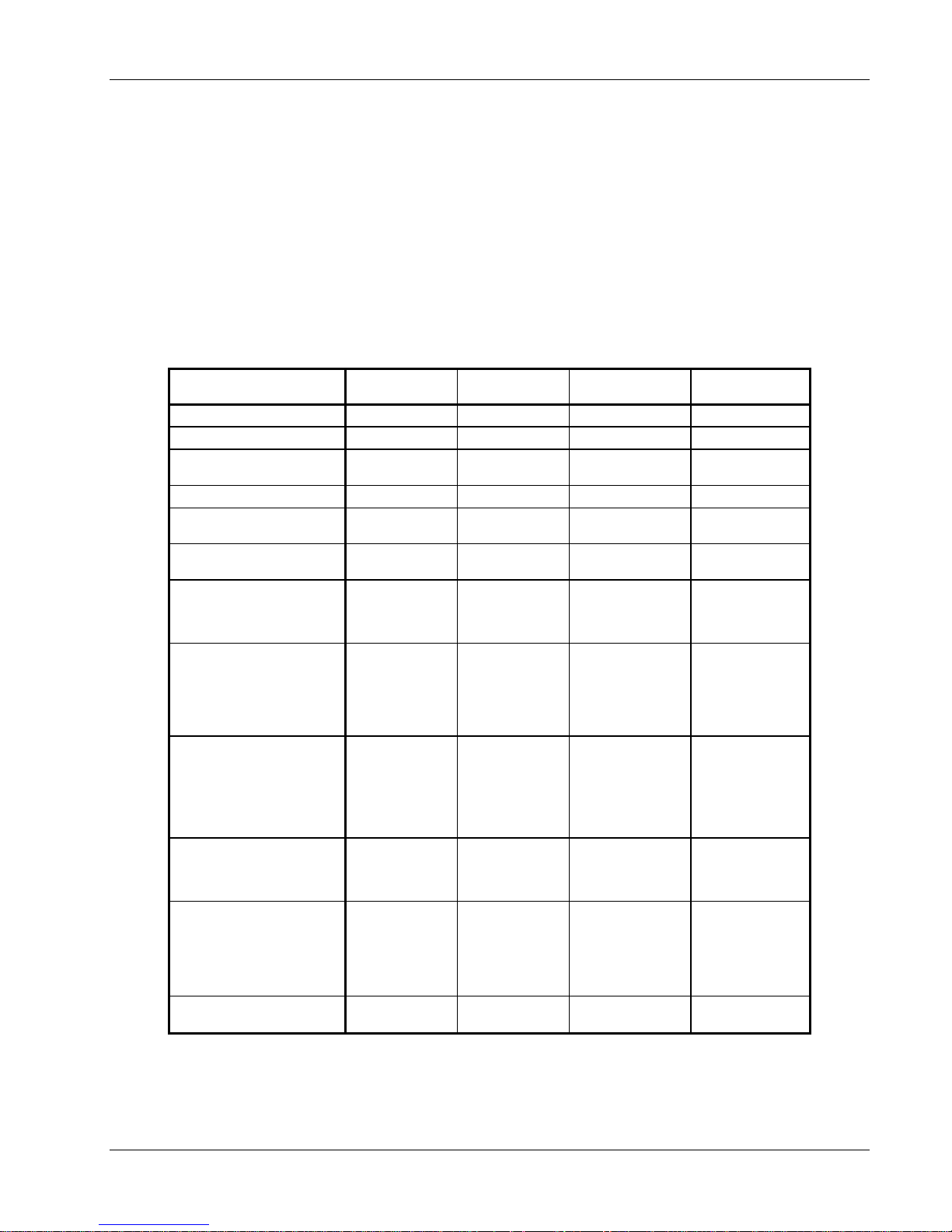

Table 1-2. Model 332 Typical Sensor Performance Chart

Sensor Type Silicon Diode GaAlAs Diode

Temperature Coefficient Negative Negative Positive Negative

Input Range 0 – 2.5 V 0 – 7.5 V

Sensor Excitation*

(Constant Current)

Display Resolution (Sensor Units) 100 µV 100 µV

Example Lake Shore Sensor

Standard Sensor Curve

Typical Sensor Sensitivity †

Measurement Resolution:

Sensor Units

Temperature Equivalence

Electronic Accuracy:

Sensor Units

Temperature Equivalence

Temperature Accuracy including

electronic accuracy, CalCurve

and calibrated sensor

Control Stability:

Sensor Units

Temperature Equivalence

Magnetic Field Use

10 µA ±0.05% 10 µA ±0. 05% 1 mA 10 µA ±0.05%

DT-470-SD-13 with

1.4H calibration

Curve 10 Requires calibrated

–31.6 mV/K at 4.2 K

–1.73 mV/K at 77 K

–2.3 mV/K at 300 K

–2.12 mV/K at 475 K

10 µV

0.3 mK at 4.2 K

5.8 mK at 77 K

4.4 mK at 300 K

4.7 mK at 475 K

±80 µV ±0.005%

of reading

±5 mK at 4.2 K

±75 mK at 77 K

±47 mK at 300 K

±40 mK at 475 K

±26 mK at 4.2 K

±130 mK at 77 K

±107 mK at 300 K

±100 mK at 475 K

±20 µV

±0.6 mK at 4.2 K

±11 mK at 77 K

±8.4 mK at 300 K

±9 mK at 475 K

Recommended for

T ≥ 60 K & B ≤ 3 T

TG-120-SD with

1.4H calibration

sensor

–210 mV/K at 4.2 K

–1.25 mV/K at 77 K

–2.85 mV/K at 300 K

–3.15 mV/K at 475 K

20 µV

0.1 mK at 4.2 K

16.0 mK at 77 K

7.1 mK at 300 K

6.3 mK at 475 K

±80 µV ±0.01%

±3 mK at 4.2 K

±180 mK at 77 K

±60 mK at 300 K

±38 mK at 475 K

±20 mK at 4.2 K

±255 mK at 77 K

±180 mK at 300 K

±123 mK at 475 K

±40 µV

±0.2 mK at 4.2 K

±32 mK at 77 K

±14 mK at 300 K

±13 mK at 475 K

Recommended for

T > 4.2 K & B ≤ 5 T

of reading

100 Ω Platinum RTD

500 Ω Full scale

0 – 500 Ω 0 – 7500 Ω

10 mΩ 100 mΩ

PT-103 with

14J calibration

DIN 43760 Requires calibrated

0.19 Ω/K at 30 K

0.42 Ω/K at 77 K

0.39 Ω/K at 300 K

0.36 Ω/K at 800 K

2 mΩ

10.6 mK at 30 K

4.8 mK at 77 K

5.2 mK at 300 K

5.6 mK at 800 K

±0.004 Ω ±0.01%

of reading

±23 mK at 30 K

±14 mK at 77 K

±39 mK at 300 K

±95 mK at 800 K

±48 mK at 30 K

±39 mK at 77 K

±84 mK at 300 K

±195 mK at 800 K

±4 mΩ

±22 mK at 30 K

±9.5 mK at 77 K

±10 mK at 300 K

±11 mK at 800 K

Recommended for

T > 40 K & B ≤ 2.5 T

Rox™

RX-102A-AA with

0.3E calibration

sensor

–80 Ω/K at 4.2 K

–4 Ω/K at 20 K

–1.06 Ω/K at 40 K

40 mΩ

<1 mK at 4.2 K

10 mK at 20 K

38 mK at 40 K

±0.10 Ω ±0.04%

of reading

±8.1 mK at 4.2 K

±134 mK at 20 K

±491 mK at 40 K

±24.1 mK at 4.2 K

±238 mK at 20 K

±705 mK at 40 K

±80 mΩ

±1 mK at 4.2 K

±20 mK at 20 K

±76 mK at 40 K

Recommended for

T > 2 K & B ≤ 10 T

* Current reversal eliminates thermal EMF voltage errors for resistor sensors.

†

Typical sensor sensitivities were taken from representative calibrations for the sensor listed.

Introduction 1-5

A

A

A

A

A

Lake Shore Model 332 Temperature Controller User’s Manual

Table 1-2. Model 332 Typical Sensor Performance Chart (Continued)

Sensor Type

Germanium

GR-200A-1500

Temperature Coefficient Negative Negative Negative Negative Negative

Input Range AutoRange AutoRange AutoRange AutoRange AutoRange

Sensor Excitation*

(Constant Current)

75 mV max

4 ranges from 75 Ω -

75 kΩ

Display Resolution (Sensor Units) 5 digits 5 digits 5 digits 5 digits 5 digits

Example Lake Shore Sensor

Standard Sensor Curve

GR-200A-1500

with1.4D calibration

Requires calibrated

sensor

–64200 Ω/K at 1.4 K

Typical Sensor Sensitivity †

Measurement Resolution:

Sensor Units

Temperature Equivalence

Electronic Accuracy:

Sensor Units

Temperature Equivalents

Temperature Accuracy including

electronic accuracy, CalCurve

and calibrated sensor

Control Stability:

Sensor Units

Temperature Equivalence

Magnetic Field Use

–668 Ω/K at 4.2 K

–0.078Ω/K at 77 K

uto Range

see Table 1-3

4

<10 µK at 1.4 K

30 µK at 4.2 K

3.8 mK at 77 K

3

1

Auto Range

see Table 1-3

4

±0.2 mK at 1.4 K

±1 mK at 4.2 K

±38 mK at 77 K

±6 mK at 1.4 K 4

±6 mK at 4.2 K

±128 mK at 77 K

3

1

3

1

±80 mΩ

±20 µK at 1.4 K

±60 µK at 4.2 K

±7.6 mK at 77 K

4

3

1

Not Recommended Not Recommended

Germanium

GR-200A-250

75 mV max

4 ranges from 75 Ω -

75 kΩ

GR-200A-250 with

0.3D calibration

Requires calibrated

sensor

–8450 Ω/K at 1 K

–68.9 Ω/K at 4.2 K

–0.054 Ω/K at 77 K

uto Range

see Table 1-3

<10 µK at 1 K

40 µK at 4.2 K

5.5 mK at 77 K

Auto Range

see Table 1-3

±0.2 mK at 1 K

±2 mK at 4.2 K

±47 mK at 77 K

±6 mK at 1 K

±7 mK at 4.2 K

±137 mK at 77 K

±80 mΩ

±20 µK at 1 K

±80 µK at 4.2 K

±11 mK at 77 K

3

2

1

3

2

1

3

2

1

3

2

1

4 ranges from 75 Ω -

CX-1070-SD with

Requires calibrated

–17600 Ω/K at 4.2 K

–-969 Ω/K at 10 K

–8.26 Ω/K at 77 K

–0.419 Ω/K at 300 K

uto Range

see Table 1-3

<10 µK at 4.2 K

<100 µK at 10 K

3.6 mK at 77 K

7.2 mK at 300 K

Auto Range

see Table 1-3

±1 mK at 4.2 K

±3 mK at 10 K

±28 mK at 77 K

±128 mK at 300 K

±7 mK at 4.2 K

±11 mK at 10 K

±78 mK at 77 K

±268 mK at 300 K

±80 mΩ

±20 mK at 4.2 K

±7.2 mK at 77 K

±14.4 mK at 300 K

Recommended for

T > 2 K & B ≤ 19 T

Cernox™

CX-1070

75 mV max

75 kΩ

1.4L calibration

sensor

4

3

2

2

4

3

2

4

3

2

4

2

Cernox™

CX-1050

75 mV max

4 ranges from 75 Ω -

75 kΩ

CX-1050-SD with

1.4L calibration

Requires calibrated

sensor

–-42800 Ω/K at 2 K

–2290 Ω/K at 4.2 K

–2.15 Ω/K at 77 K

–0.131 Ω/K at 300 K

uto Range

see Table 1-3

<10 µK at 2 K

<10 µK at 4.2 K

1.2 mK at 77 K

2.3 mK at 300 K

Auto Range

see Table 1-3

±0.3 mK at 2 K

±1 mK at 4.2 K

±30 mK at 77 K

±130 mK at 300 K

2

±6 mK at 2 K

±7 mK at 4.2 K

±80 mK at 77 K

±270 mK at 300 K

2

4

3

2

1

4

3

2

1

4

3

2

1

Cernox™

CX-1030

75 mV max

4 ranges from 75 Ω -

75 kΩ

CX-1030-SD with

1.4L calibration

Requires calibrated

sensor

–-8670 Ω/K at 1.4 K

–138 Ω/K at 4.2 K

–-.828 Ω/K at 77 K

–0.067 Ω/K at 300 K

uto Range

see Table 1-3

<10 µK at 1.4 K

20 µK at 4.2 K

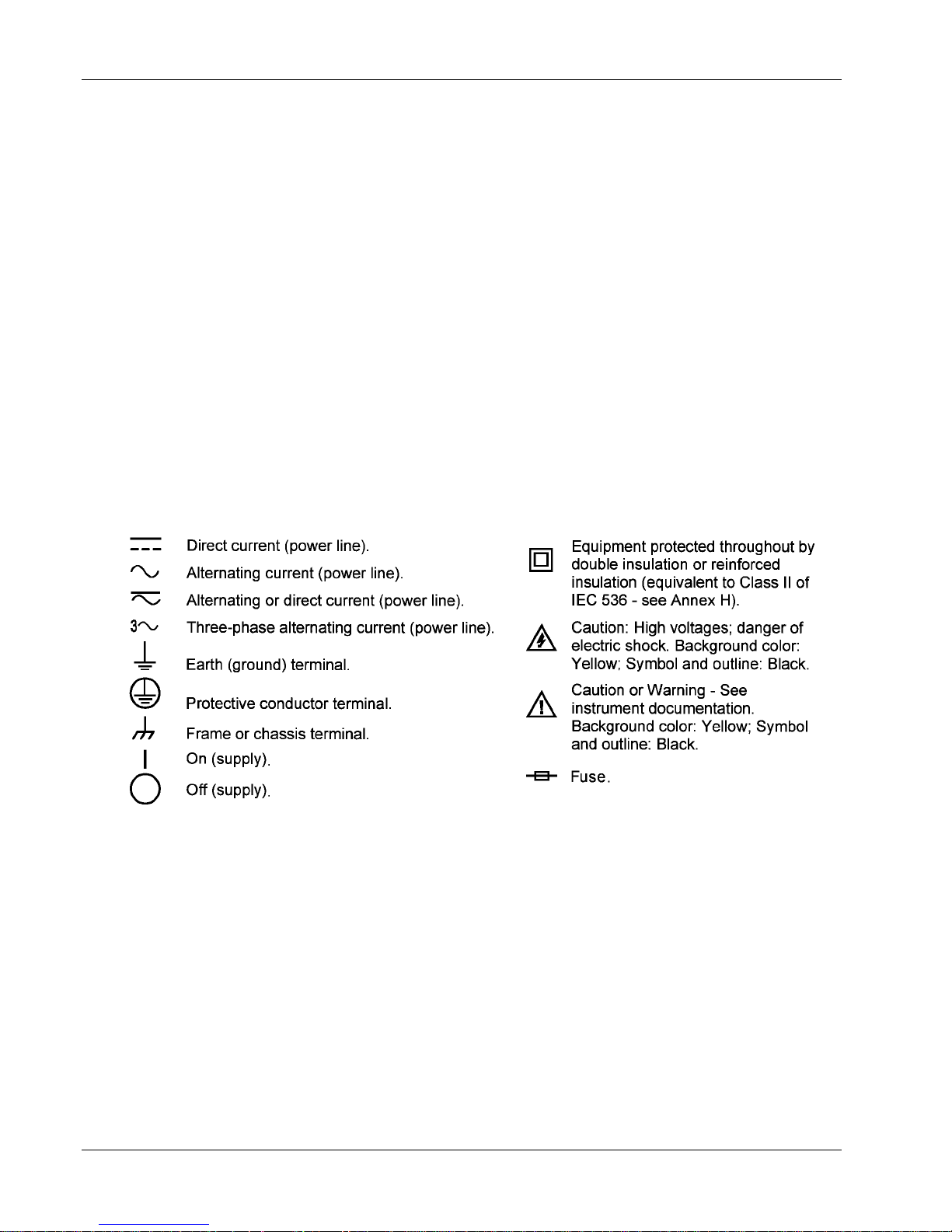

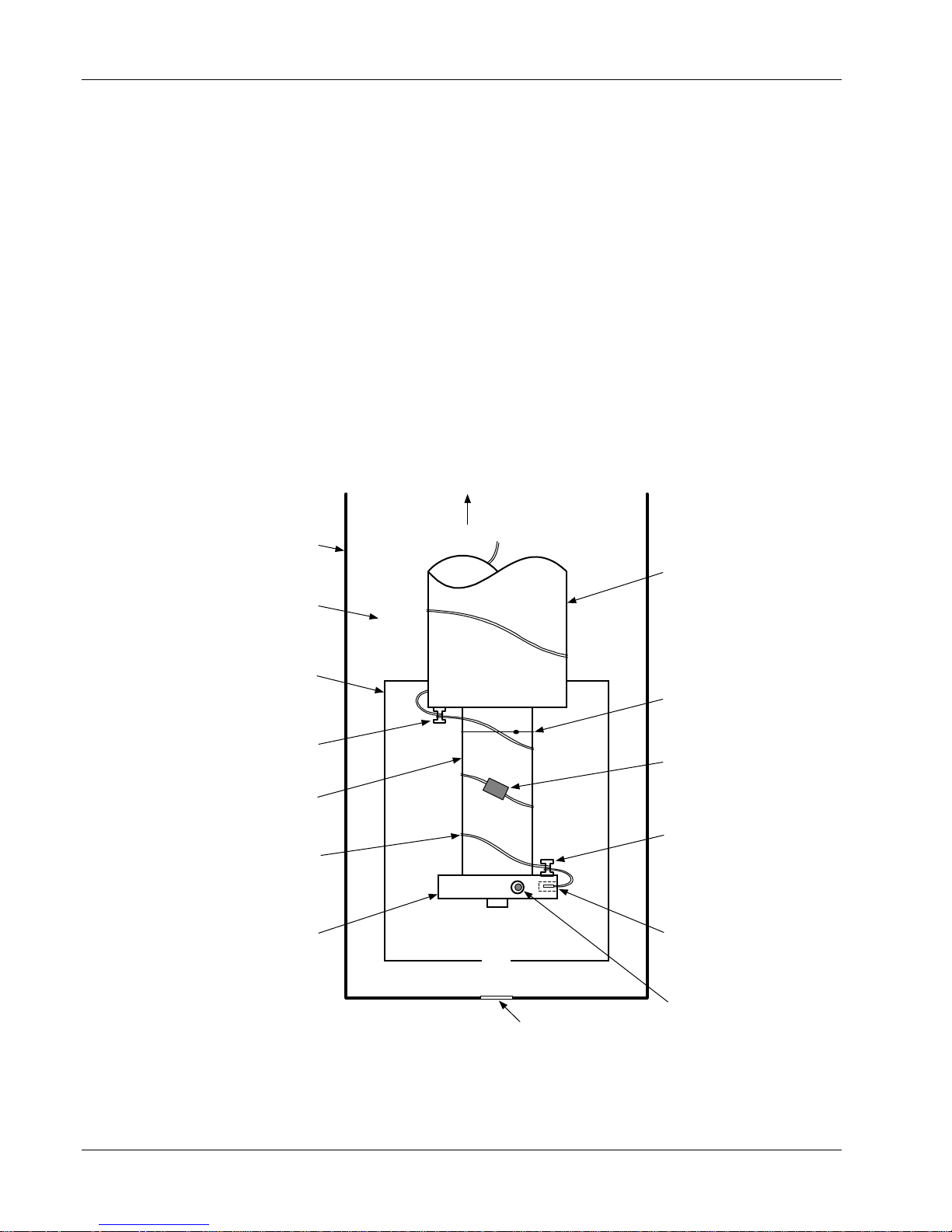

3.6 mK at 77 K