Lake Shore 218S, 218, 218E User Manual

User’s Manual

Model 218

Temperature Monitor

Includes Coverage For:

Model 218S and Model 218E

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

Internet Addresses:

sales@lakeshore.com

service@lakeshore.com

Visit Our Website:

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake

Shore Cryotronics, Inc. No government or other contractual support or relationship whatsoever has existed which in

any way affects or mitigates proprietary rights of Lake Shore Cryotronics, Inc. in these developments. Methods and

apparatus disclosed herein may be subject to U.S. Patents existing or applied for. Lake Shore Cryotronics, Inc.

reserves the right to add, improve, modify, or withdraw functions, design modifications, or products at any time

without notice. Lake Shore shall not be liable for errors contained herein or for incidental or consequential damages in

connection with furnishing, performance, or use of this material.

Revision 2.2 P/N 119-007 03 July 2012

Lake Shore Model 218 Temperature Monitor User’s Manual

1. Lake Shore warrants that this Lake Shore product (the “Product”) will

be free from defects in materials and workmanship for the Warranty

Period specified above (the “Warranty Period”). If Lake Shore receives

notice of any such defects during the Warranty Period and the Product

is shipped freight prepaid, Lake Shore will, at its option, either repair

or replace the Product if it is so defective without charge to the owner

for parts, service labor or associated customary return shipping cost.

Any such replacement for the Product may be either new or equivalent

in performance to new. Replacement or repaired parts will be

warranted for only the unexpired portion of the original warranty or 90

days (whichever is greater).

2. Lake Shore warrants the Product only if it has been sold by an

authorized Lake Shore employee, sales representative, dealer or

original equipment manufacturer (OEM).

3. The Product may contain remanufactured parts equivalent to new in

performance or may have been subject to incidental use.

4. The Warranty Period begins on the date of delivery of the Product or

later on the date of installation of the Product if the Product is installed

by Lake Shore, provided that if you schedule or delay the Lake Shore

installation for more than 30 days after delivery the Warranty Period

begins on the 31st day after delivery.

5. This limited warranty does not apply to defects in the Product resulting

from (a) improper or inadequate maintenance, repair or calibration, (b)

fuses, software and non-rechargeable batteries, (c) software,

interfacing, parts or other supplies not furnished by Lake Shore, (d)

unauthorized modification or misuse, (e) operation outside of the

published specifications or (f) improper site preparation or

maintenance.

6. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE

ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTY OR CONDITION, WHETHER WRITTEN OR ORAL,

IS EXPRESSED OR IMPLIED. LAKE SHORE SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY, SATISFACTORY QUALITY AND/OR

FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE PRODUCT. Some countries, states or provinces do not allow

limitations on an implied warranty, so the above limitation or

exclusion might not apply to you. This warranty gives you specific

legal rights and you might also have other rights that vary from

country to country, state to state or province to province.

7. TO THE EXTENT ALLOWED BY APPLICABLE LAW, THE

REMEDIES IN THIS WARRANTY STATEMENT ARE YOUR

SOLE AND EXCLUSIVE REMEDIES.

8. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE

LAW, IN NO EVENT WILL LAKE SHORE OR ANY OF ITS

SUBSIDIARIES, AFFILIATES OR SUPPLIERS BE LIABLE FOR

DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR

OTHER DAMAGES (INCLUDING LOST PROFIT, LOST DATA

OR DOWNTIME COSTS) ARISING OUT OF THE USE,

INABILITY TO USE OR RESULT OF USE OF THE PRODUCT,

WHETHER BASED IN WARRANTY, CONTRACT, TORT OR

OTHER LEGAL THEORY, AND WHETHER OR NOT LAKE

SHORE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. Your use of the Product is entirely at your own risk.

Some countries, states and provinces do not allow the exclusion of

liability for incidental or consequential damages, so the above

limitation may not apply to you.

LIMITED WARRANTY STATEMENT

WARRANTY PERIOD: ONE (1) YEAR

LIMITED WARRANTY STATEMENT (Continued)

9. EXCEPT TO THE EXTENT ALLOWED BY APPLICABLE LAW,

THE TERMS OF THIS LIMITED WARRANTY STATEMENT DO

NOT EXCLUDE, RESTRICT OR MODIFY, AND ARE IN

ADDITION TO, THE MANDATORY STATUTORY RIGHTS

APPLICABLE TO THE SALE OF THE PRODUCT TO YOU.

CERTIFICATION

Lake Shore certifies that this product has been inspected and tested in

accordance with its published specifications and that this product met its

published specifications at the time of shipment. The accuracy and

calibration of this product at the time of shipment are traceable to the

United States National Institute of Standards and Technology (NIST);

formerly known as the National Bureau of Standards (NBS).

FIRMWARE LIMITATIONS

Lake Shore has worked to ensure that the Model 218 firmware is as free

of errors as possible, and that the results you obtain from the instrument

are accurate and reliable. However, as with any computer-based software,

the possibility of errors exists.

In any important research, as when using any laboratory equipment,

results should be carefully examined and rechecked before final

conclusions are drawn. Neither Lake Shore nor anyone else involved in

the creation or production of this firmware can pay for loss of time,

inconvenience, loss of use of the product, or property damage caused by

this product or its failure to work, or any other incidental or consequential

damages. Use of our product implies that you understand the Lake Shore

license agreement and statement of limited warranty.

FIRMWARE LICENSE AGREEMENT

The firmware in this instrument is protected by United States copyright

law and international treaty provisions. To maintain the warranty, the

code contained in the firmware must not be modified. Any changes made

to the code is at the user’s risk. Lake Shore will assume no responsibility

for damage or errors incurred as result of any changes made to the

firmware.

Under the terms of this agreement you may only use the Model 218

firmware as physically installed in the instrument. Archival copies are

strictly forbidden. You may not decompile, disassemble, or reverse

engineer the firmware. If you suspect there are problems with the

firmware, return the instrument to Lake Shore for repair under the terms

of the Limited Warranty specified above. Any unauthorized duplication

or use of the Model 218 firmware in whole or in part, in print, or in any

other storage and retrieval system is forbidden.

TRADEMARK ACKNOWLEDGMENT

Many manufacturers claim designations used to distinguish their products

as trademarks. Where those designations appear in this manual and Lake

Shore was aware of a trademark claim, they appear with initial capital

letters and the ™ or

Apiezon

®

is a trademark of Biddle Instruments.

®

symbol.

CalCurve™, Carbon-Glass™, Cernox™, Duo-Twist™, Quad-Lead™,

Quad-Twist™, Rox™, SoftCal™, and Thermox™ are trademarks of

Lake Shore Cryotronics, Inc.

Chromel™ and Alumel™ are trademarks of Hoskins Manufacturing

Company.

Formvar™ is a trademark of Monsanto Chemical Company.

®

MS-DOS

and Windows® are trademarks of Microsoft Corp.

NI-488.2™ is a trademark of National Instruments.

PC, XT, AT, and PS-2 are trademarks of IBM.

®

Stycast

is a trademark of Emerson & Cuming.

®

Teflon

is a trademark of DuPont De Nemours.

Copyright © 1998 – 2004, 2009 and 2012 by Lake Shore Cryotronics, Inc. All rights reserved. No portion of this manual

may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the express written permission of Lake Shore.

A

Lake Shore Model 218 Temperature Monitor User’s Manual

DECLARATION OF CONFORMITY

We: Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville OH 43082-8888 USA

hereby declare that the equipment specified conforms to the following

Directives and Standards:

Application of Council Directives: .............................. 73/23/EEC

89/336/EEC

Standard to which Conformity is declared: ................ EN 61010-1:2001

Overvoltage II

Pollution Degree 2

EN 61326 A2:2001

Class A

Annex B

Model Number: .......................................................... 218

Ed Maloof

Printed Name

Vice President of Engineering

Position

B

Lake Shore Model 218 Temperature Monitor User’s Manual

Electromagnetic Compatibility (EMC) for the Model 218 Temperature Monitor

Electromagnetic Compatibility (EMC) of electronic equipment is a growing concern worldwide.

Emissions of and immunity to electromagnetic interference is now part of the design and manufacture

of most electronics. To qualify for the CE Mark, the Model 218 meets or exceeds the generic

requirements of the European EMC Directive 89/336/EEC as a CLASS A product. A Class A product

is allowed to radiate more RF than a Class B product and must include the following warning:

WARNING: This is a Class A product. In a domestic environment, this product may

cause radio interference in which case the user may be required to take

The instrument was tested under normal operating conditions with sensor and interface cables

attached. If the installation and operating instructions in the User’s Manual are followed, there should

be no degradation in EMC performance.

Pay special attention to instrument cabling. Improperly installed cabling may defeat even the best

EMC protection. For the best performance from any precision instrument, follow the grounding and

shielding instructions in the User’s Manual. In addition, the installer of the Model 218 should consider

the following:

• Leave no unused or unterminated cables attached to the instrument.

• Make cable runs as short and direct as possible.

• Do not tightly bundle cables that carry different types of signals.

• Add the clamp-on ferrite filters (Part Number 9009-020) included with the connector kit to the

sensor input cables near the instrument rear panel.

adequate measures.

C

Lake Shore Model 218 Temperature Monitor User’s Manual

TABLE OF CONTENTS

Chapter/Paragraph Title Page

1 INTRODUCTION .................................................................................................................................... 1-1

1.0 GENERAL ........................................................................................................................... 1-1

1.1 MODEL 218 FEATURES .................................................................................................... 1-3

1.2 MODEL 218 SPECIFICATIONS ......................................................................................... 1-4

1.3 SAFETY .............................................................................................................................. 1-6

1.3.1 Handling Liquid Helium and Liquid Nitrogen ................................................................... 1-6

1.3.2 Safety Summary .............................................................................................................. 1-7

1.3.3 Safety Symbols ................................................................................................................ 1-7

2 SENSOR CONSIDERATIONS ............................................................................................................... 2-1

2.0 GENERAL ........................................................................................................................... 2-1

2.1 TEMPERATURE SENSOR SELECTION ........................................................................... 2-1

2.1.1 Temperature Range ......................................................................................................... 2-1

2.1.2 Sensor Sensitivity ............................................................................................................ 2-1

2.1.3 Environmental Conditions ................................................................................................ 2-1

2.1.4 Measurement Accuracy ................................................................................................... 2-2

2.1.5 Sensor Package .............................................................................................................. 2-2

2.2 CALIBRATED SENSORS ................................................................................................... 2-2

2.2.1 Traditional Calibration ...................................................................................................... 2-2

2.2.2 SoftCal™ .......................................................................................................................... 2-2

2.2.3 Standard Curves .............................................................................................................. 2-3

2.2.4 CalCurve™ ...................................................................................................................... 2-4

2.3 SENSOR INSTALLATION .................................................................................................. 2-4

2.3.1 Mounting Materials .......................................................................................................... 2-4

2.3.2 Sensor Location ............................................................................................................... 2-4

2.3.3 Thermal Conductivity ....................................................................................................... 2-4

2.3.4 Contact Area .................................................................................................................... 2-5

2.3.5 Contact Pressure ............................................................................................................. 2-5

2.3.6 Lead Wire ......................................................................................................................... 2-6

2.3.7 Lead Soldering ................................................................................................................. 2-6

2.3.8 Heat Sinking Leads .......................................................................................................... 2-6

2.3.9 Thermal Radiation ........................................................................................................... 2-6

2.3.10 Thermal EMF Compensation with Voltage Excitation ..................................................... 2-6

3 INSTALLATION ..................................................................................................................................... 3-1

3.0 GENERAL ........................................................................................................................... 3-1

3.1 INSPECTION AND UNPACKING ....................................................................................... 3-1

3.2 REPACKAGING FOR SHIPMENT ..................................................................................... 3-1

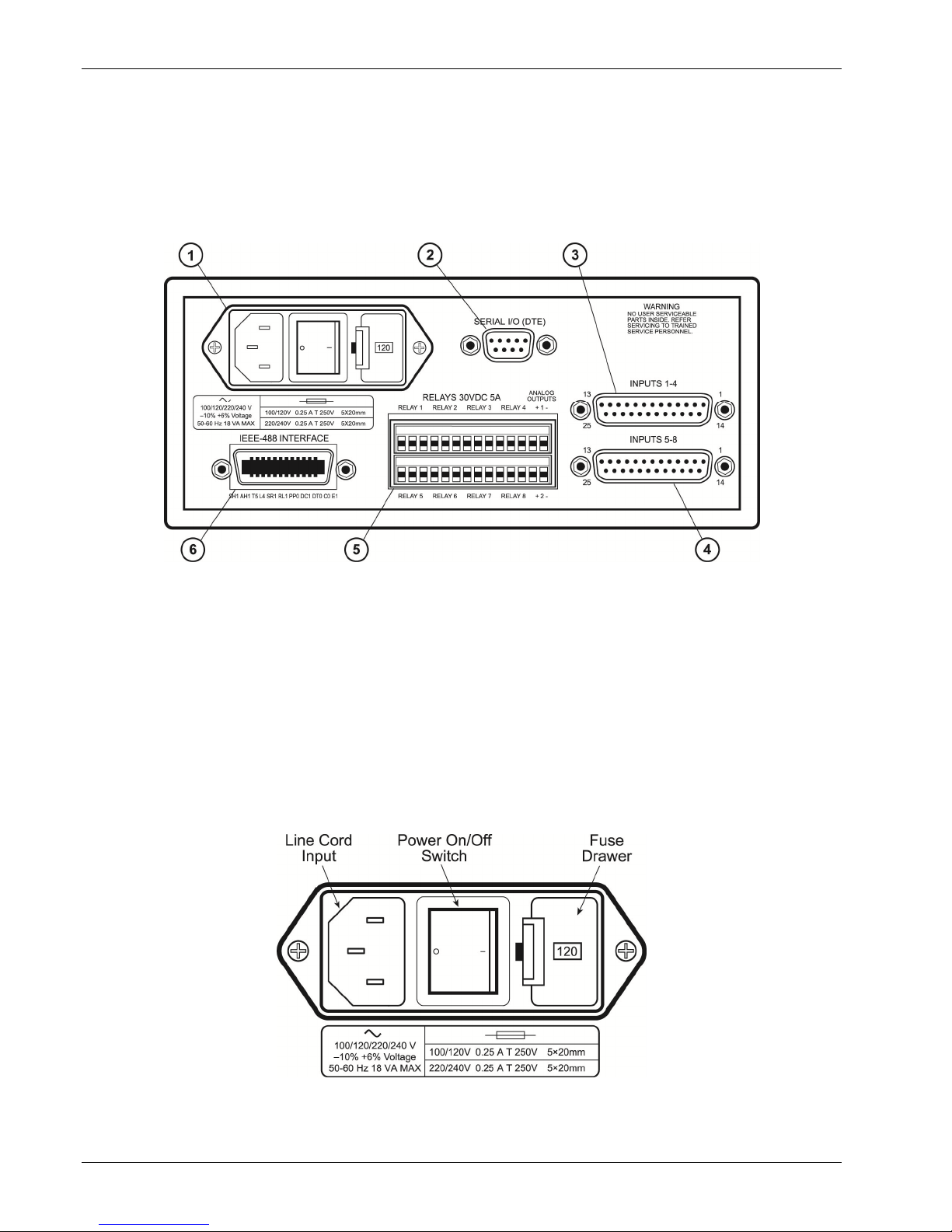

3.3 REAR PANEL DEFINITION ................................................................................................ 3-2

3.3.1 Line Input Assembly ........................................................................................................ 3-2

3.3.2 Sensor Inputs ...........................................................................................................

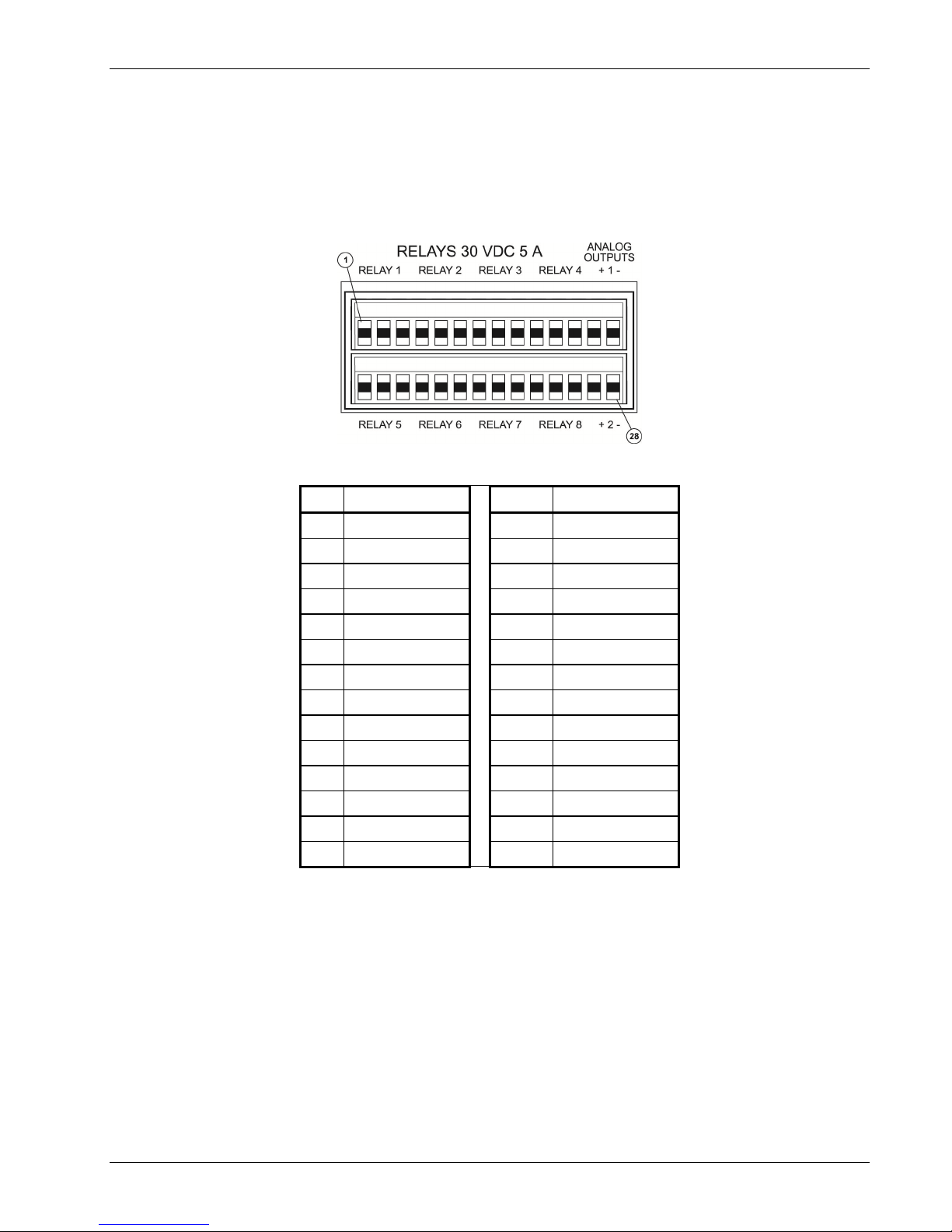

3.3.3 Terminal Block (Model 218S ONLY) ............................................................................... 3-7

3.3.4 Computer Interfaces ........................................................................................................ 3-8

4 OPERATION .......................................................................................................................................... 4-1

4.0 GENERAL ........................................................................................................................... 4-1

4.1 DISPLAY SCREEN DESCRIPTION ................................................................................... 4-1

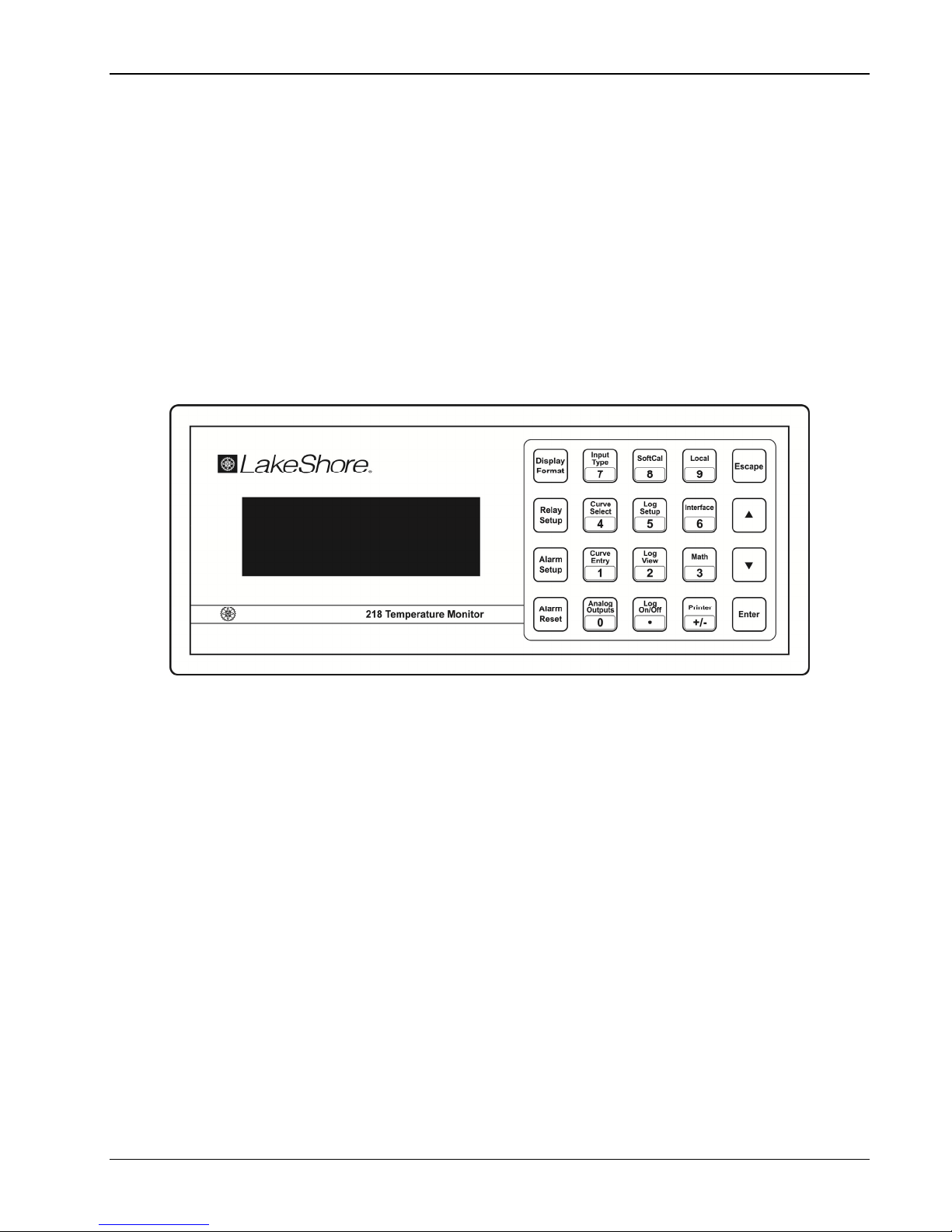

4.2 KEYPAD DESCRIPTION .................................................................................................... 4-3

4.2.1 General Keypad Operation .............................................................................................. 4-4

4.3 TURNING POWER ON ....................................................................................................... 4-4

4.4 DISPLAY SETUP ................................................................................................................ 4-4

........ 3-4

Table of Contents i

Lake Shore Model 218 Temperature Monitor User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

4.5 INPUT TYPE........................................................................................................................ 4-5

4.5.1 Optimizing the Update Rate ............................................................................................. 4-7

4.6 CURVE SELECT ................................................................................................................. 4-7

4.7 MATH ................................................................................................................................... 4-8

4.7.1 Max/Min ............................................................................................................................ 4-8

4.7.2 Linear ................................................................................................................................ 4-9

4.7.3 Filter ................................................................................................................................ 4-10

4.8 ANALOG OUTPUTS (MODEL 218S ONLY) ..................................................................... 4-11

4.8.1 Example of Low and High Analog Parameter Setting .................................................... 4-13

4.9 ALARMS SETUP AND OPERATION ................................................................................ 4-13

4.10 ALARM RESET ................................................................................................................. 4-15

4.11 RELAY SETUP (MODEL 218S ONLY) ............................................................................. 4-15

4.12 LOCKING THE KEYPAD ................................................................................................... 4-16

4.13 RESETTING MODEL 218 TO DEFAULTS ....................................................................... 4-16

5 SPECIAL FEATURES ............................................................................................................................ 5-1

5.0 GENERAL ............................................................................................................................ 5-1

5.1 FRONT PANEL CURVE ENTRY......................................................................................... 5-1

5.1.1 Curve Header Parameters ............................................................................................... 5-1

5.1.2 Curve Breakpoints ............................................................................................................ 5-2

5.1.3 Editing An Existing Curve ................................................................................................. 5-2

5.1.4 Entering A New Curve ...................................................................................................... 5-3

5.1.5 Erasing User Curves ........................................................................................................ 5-4

5.1.6 Viewing Standard Curves ................................................................................................. 5-4

5.1.7 Copying Curves ................................................................................................................ 5-4

5.2 SOFTCAL™ ......................................................................................................................... 5-5

5.2.1 SoftCal™ and Silicon Diode Sensors ............................................................................... 5-6

5.2.2 SoftCal™ Accuracy with Silicon Diode Sensors .............................................................. 5-7

5.2.3 SoftCal™ and Platinum Sensors ...................................................................................... 5-7

5.2.4 SoftCal™ Accuracy with Platinum Sensors ..................................................................... 5-8

5.2.5 Creating a SoftCal™ Calibration Curve ........................................................................... 5-8

5.3 DATA LOGGING ................................................................................................................. 5-9

5.3.1 Log Setup ......................................................................................................................... 5-9

5.3.2 Starting and Stopping Data Log ..................................................................................... 5-11

5.3.3 Viewing Logged Data ..................................................................................................... 5-11

5.3.4 Line Power Loss ............................................................................................................. 5-11

5.4 PRINTING .......................................................................................................................... 5-12

5.4.1 Printer Support ............................................................................................................... 5-12

5.4.2 Printer Connector and Cable .......................................................................................... 5-13

5.4.3 Printer Operation ............................................................................................................ 5-13

6 REMOTE OPERATION .......................................................................................................................... 6-1

6.0 GENERAL ............................................................................................................................ 6-1

6.1 IEEE-488 INTERFACE ........................................................................................................ 6-1

6.1.1 IEEE-488 Interface Settings ............................................................................................. 6-2

6.1.2 IEEE-488 Command Structure ......................................................................................... 6-2

6.1.3 Status Registers ............................................................................................................... 6-3

6.1.4 Example IEEE Setup and Program .................................................................................. 6-5

6.1.5 Notes On Using the IEEE Interface .................................................................................. 6-5

ii Table of Contents

Lake Shore Model 218 Temperature Monitor User’s Manual

TABLE OF CONTENTS (Continued)

Chapter/Paragraph Title Page

6.2 SERIAL INTERFACE .......................................................................................................... 6-8

6.2.1 Physical Connection ........................................................................................................ 6-8

6.2.2 Hardware Support ............................................................................................................ 6-8

6.2.3 Character Format ............................................................................................................. 6-9

6.2.4 Message Strings .............................................................................................................. 6-9

6.2.5 Message Flow Control ................................................................................................... 6-10

6.2.6 Changing Baud Rate ..................................................................................................... 6-10

6.2.7 Serial Interface Basic Programs .................................................................................... 6-11

6.2.8 Troubleshooting ............................................................................................................. 6-16

6.3 IEEE-488/Serial Interface Commands .............................................................................. 6-16

7 SERVICE ................................................................................................................................................ 7-1

7.0 GENERAL ........................................................................................................................... 7-1

7.1 GENERAL MAINTENANCE PRECAUTIONS .................................................................... 7-1

7.2 ELECTROSTATIC DISCHARGE ........................................................................................ 7-1

7.2.1 Identification of Electrostatic Discharge Sensitive Components ..................................... 7-1

7.2.2 Handling Electrostatic Discharge Sensitive Components ............................................... 7-2

7.3 FUSE DRAWER .................................................................................................................. 7-2

7.4 LINE VOLTAGE SELECTION ............................................................................................. 7-2

7.5 FUSE REPLACEMENT ...................................................................................................... 7-3

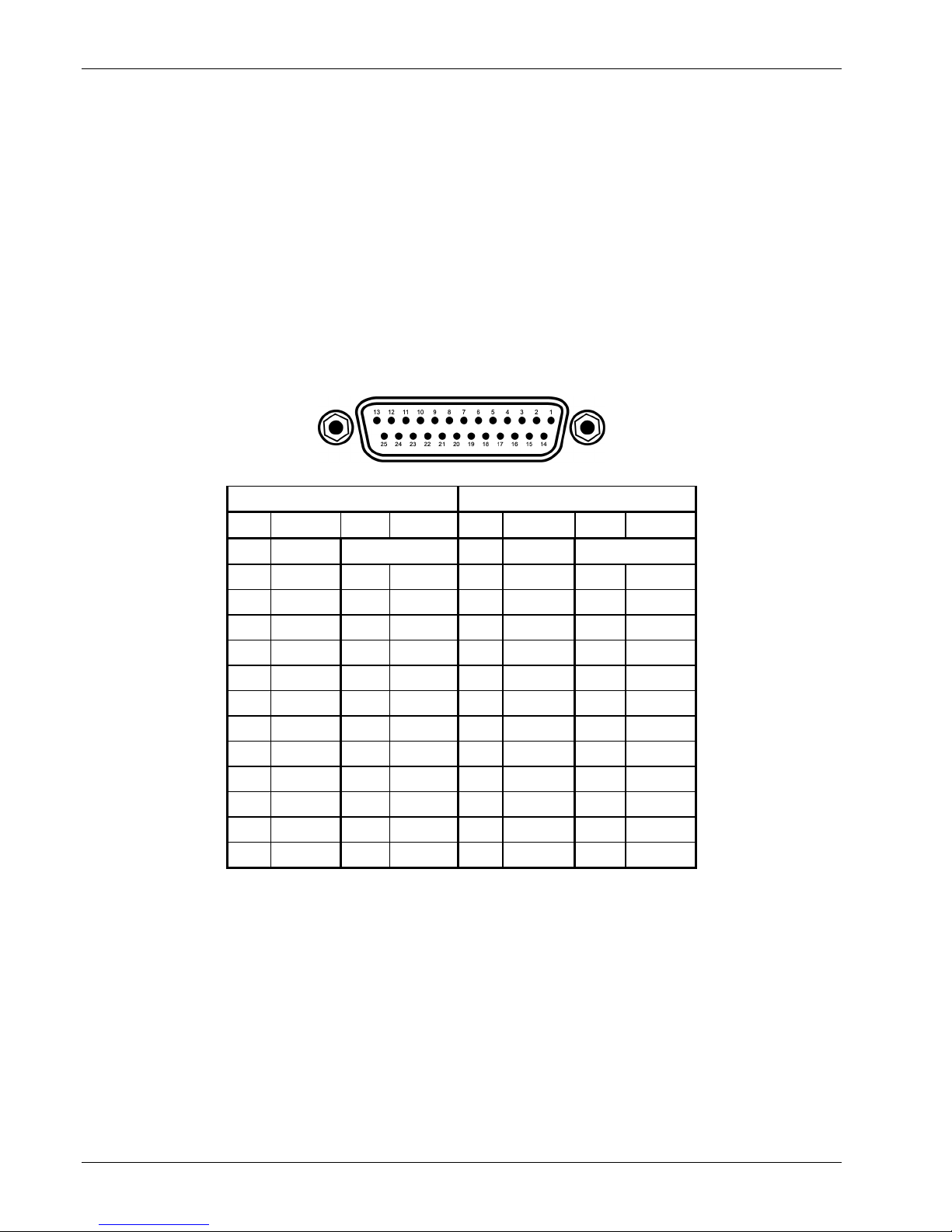

7.6 SENSOR INPUT CONNECTOR AND PINOUT ................................................................. 7-3

7.7 TERMINAL BLOCK (MODEL 218S ONLY) ........................................................................ 7-4

7.8 IEEE-488 INTERFACE CONNECTOR ............................................................................... 7-5

7.9 SERIAL INTERFACE CABLE AND ADAPTERS ................................................................ 7-6

7.10 TOP OF ENCLOSURE REMOVE AND REPLACE PROCEDURE .................................... 7-7

7.11 EPROM AND NOVRAM REPLACEMENT ......................................................................... 7-8

7.12 ERROR MESSAGES .......................................................................................................... 7-8

7.13 CALIBRATION PROCEDURE .......................................................................................... 7-10

7.13.1 Required Equipment List ............................................................................................... 7-10

7.13.2 Sensor Input Calibration Setup ...................................................................................... 7-10

7.13.3 Clear Calibration ............................................................................................................ 7-10

7.13.4 A/D Linearity Calibration ................................................................................................ 7-10

7.13.5 Zero Calibration ............................................................................................................. 7-11

7.13.6 2.5 Volt Input Gain Calibration ....................................................................................... 7-11

7.13.7 7.5 Volt Input Gain Calibration ....................................................................................... 7-11

7.13.8 10 µA Current Source Calibration .................................................................................. 7-11

7.13.9 250 Ω Input Gain Calibration ......................................................................................... 7-12

7.13.10 500 Ω Input Gain Calibration ......................................................................................... 7-12

7.13.11 7.5 kΩ Input Gain Calibration ........................................................................................ 7-12

7.13.12 5 kΩ Input Gain Calibration ........................................................................................... 7-13

7.13.13 Calibrate Input Group B ................................................................................................. 7-13

7.13.14 Analog Output Calibration and Test (Model 218S Only) ............................................... 7-13

7.13.15 Calibration Specific Interface Commands ..................................................................... 7-14

8 ACCESSORIES ...................................................................................................................................... 8-1

8.0 GENERAL ........................................................................................................................... 8-1

8.1 MODELS ............................................................................................................................. 8-1

8.2 OPTIONS ............................................................................................................................ 8-1

8.3 ACCESSORIES .................................................................................................................. 8-1

APPENDIX A – CURVE TABLES ................................................................................................................ A-1

Table of Contents iii

Lake Shore Model 218 Temperature Monitor User’s Manual

LIST OF ILLUSTRATIONS

Figure No. Title Page

1-1 Cryogenic Storage Dewar ............................................................................................................... 1-5

2-1 Silicone Diode Sensor Calibrations and CalCurve™ ...................................................................... 2-3

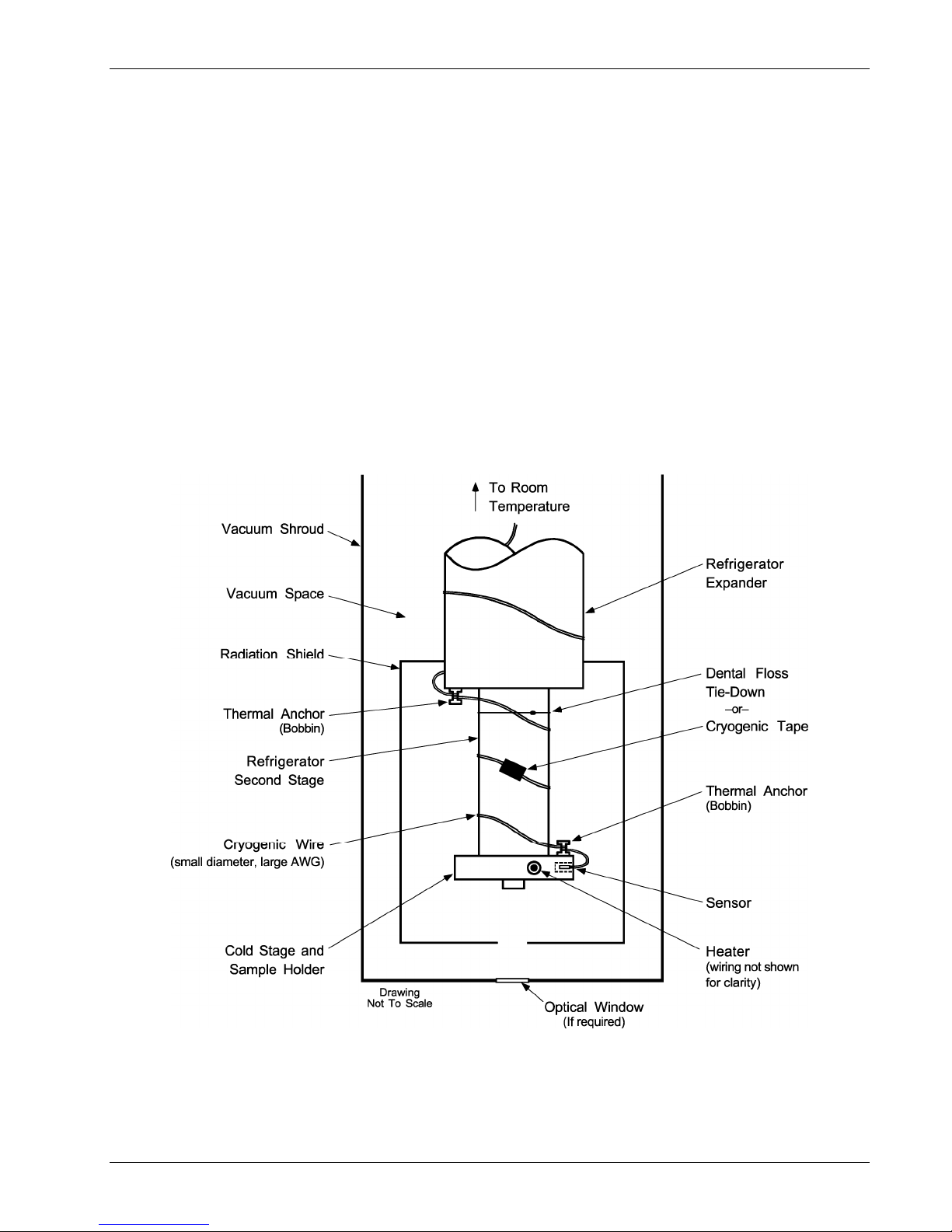

2-2 Typical Sensor Installation in a Mechanical Refrigerator ................................................................ 2-5

3-1 Model 218 Rear Panel .................................................................................................................... 3-2

3-2 Line Input Assembly ........................................................................................................................ 3-2

3-3 Model 218 Input Connector Pinouts ............................................................................................... 3-4

3-4 Terminal Block Connectors ............................................................................................................. 3-7

4-1 Model 218 Front Panel .................................................................................................................... 4-1

4-2 Model 218 Normal Display Screen Format ..................................................................................... 4-2

4-3 Example of Low and High Analog Parameter Setting .................................................................. 4-13

5-1 SoftCal™ Temperature Ranges for Silicon Diode Sensors ............................................................ 5-6

5-2 SoftCal™ Temperature Ranges for Platinum Sensors ................................................................... 5-7

5-3 Serial Port Details ......................................................................................................................... 5-13

6-1 Typical National Instruments GPIB Configuration from IBCONF.EXE ........................................... 6-7

7-1 Fuse Drawer .................................................................................................................................... 7-2

7-2 Power Fuse Access ........................................................................................................................ 7-2

7-3 Model 218 Input Connector Pinouts ............................................................................................... 7-3

7-4 Terminal Block Connectors ............................................................................................................. 7-4

7-5 IEEE-488 Rear Panel Connector Details ........................................................................................ 7-5

7-6 Serial Port Pinouts .......................................................................................................................... 7-7

7-7 Location of Internal Components .................................................................................................... 7-9

8-1 Model RM-1/2 Rack-Mount Kit ........................................................................................................ 8-3

8-2 Model RM-2 Dual Rack-Mount Kit .................................................................................................. 8-4

LIST OF TABLES

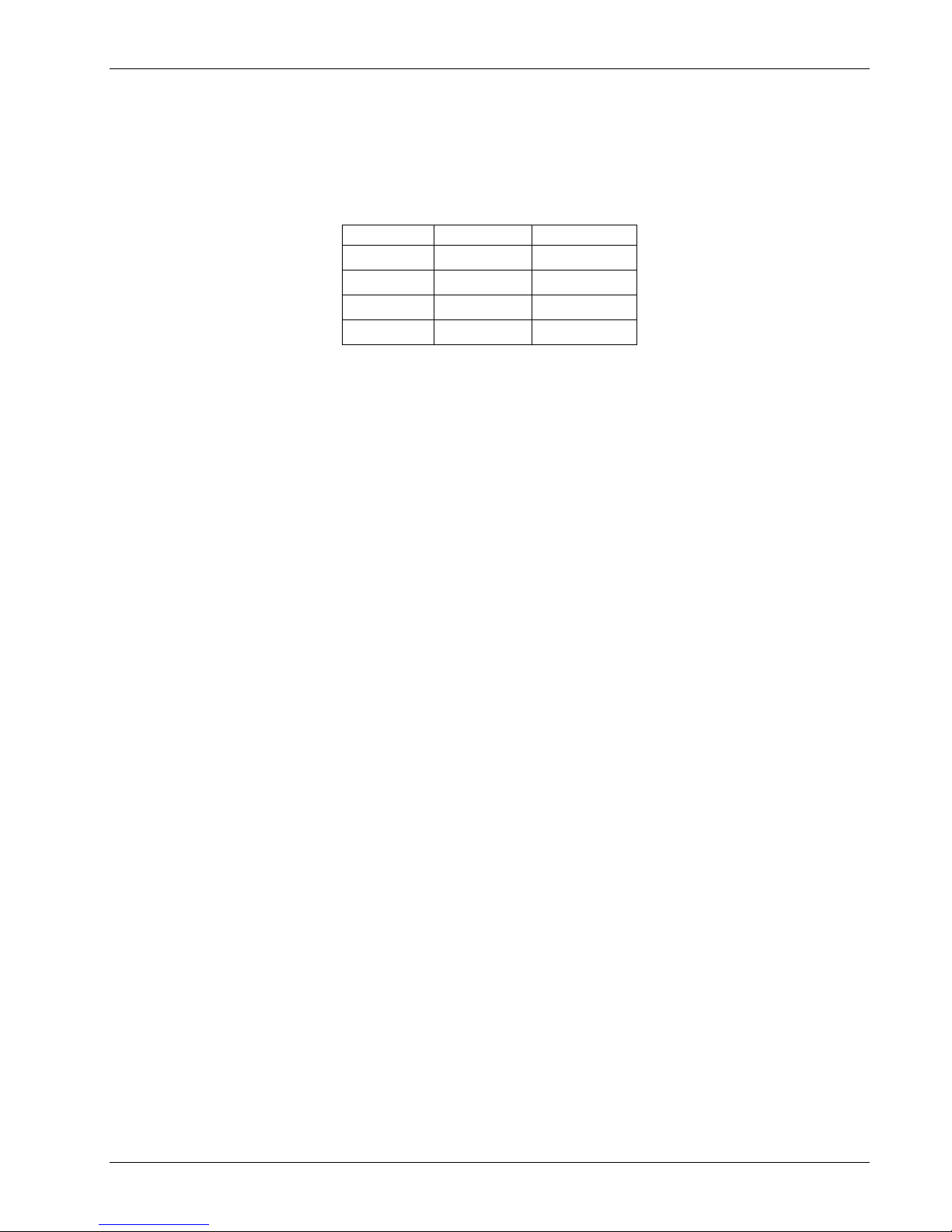

Table No. Title Page

1-1 Supported Lake Shore Sensors ...................................................................................................... 1-1

1-2 Model 218 Sensor Input Performance Chart .................................................................................. 1-4

3-1 AC Line Input Definitions ................................................................................................................ 3-3

4-1 Sensor Input Type Display Messages ............................................................................................ 4-6

4-2 Sensor Configuration Update Rates ............................................................................................... 4-7

4-3 Standard Curves Included in the Model 218 ................................................................................... 4-7

4-4 Model 218 Parameter Defaults ..................................................................................................... 4-16

5-1 Recommended Curve Parameters ................................................................................................. 5-1

5-2 Storage Capability Based on Readings per Record ....................................................................... 5-9

5-3 Serial Printer Interface Specifications ........................................................................................... 5-12

6-1 Sample BASIC IEEE-488 Interface Program .................................................................................. 6-6

6-2 Serial Interface Specifications ......................................................................................................... 6-9

6-3 Serial Interface Program Control Properties ................................................................................. 6-12

6-4 Visual Basic Serial Interface Program .......................................................................................... 6-13

6-5 Quick Basic Serial Interface Program ........................................................................................... 6-14

6-5 Model 218 Interface Commands by Function ............................................................................... 6-17

A-1 Standard DT-470 Diode Curve ...................................................................................................... A-1

A-2 Other Standard Diode and Platinum Curves ................................................................................. A-2

A-3 Standard DT-670 Diode Curve ...................................................................................................... A-2

iv Table of Contents

Lake Shore Model 218 Temperature Monitor User’s Manual

CHAPTER 1

INTRODUCTION

1.0 GENERAL

The Model 218 is an eight input temperature monitor that can be used with diode or resistive

temperature sensors. The measurement input was designed for the demands of cryogenic temperature

measurement. The monitor’s low noise, high resolution and wide operating range make it ideal for

noncryogenic applications as well.

There are two versions of the Model 218, the Model 218S and Model 218E. Both versions have the

same sensor measurement and display capabilities but include different interfaces.

The Model 218S has many interface features intended for system integration and automated data

collection that make it useful for cryogenic and noncryogenic applications. The Model 218S includes

two computer interfaces, IEEE-488 and serial. Data logging memory and printer capability are included

to help automate data collection. Two analog voltage outputs, an alarm feature and eight relays

enhance system integration.

The Model 218E is configured to have a lower selling price but maintains the same level of

performance. It includes a serial computer interface, data logging memory and printer capability. The

alarm feature is also present on the Model 218E, but there are no relays. The 218E has all the features

and specifications of the 218S except IEEE-488 interface, analog voltage outputs and relays.

Introduction 1-1

Lake Shore Model 218 Temperature Monitor User’s Manual

Table 1-1. Supported Lake Shore Sensors 1

Type Model Temp. Range

Diodes

Silicon Diode DT-670-SD 1.4 K to 500 K

Silicon Diode DT-670E-BR 30 K to 500 K

Silicon Diode DT-414 1.4 K to 375 K

Silicon Diode DT-421 1.4 K to 325 K

Silicon Diode DT-470-SD 1.4 – 475 K

Silicon Diode DT-471-SD 10 K to 500 K

GaAIAs Diode TG-120-PL 1.4 K to 325 K

GaAIAs Diode TG-120-PL 1.4 K to 325 K

GaAIAs Diode TG-120-SD 1.4 K to 500 K

Positive Temperature Coefficient RTDs

100 Ω Platinum

100 Ω Platinum

PT-102/3 14 K to 873 K

PT-111 14 K to 673 K

Rhodium-Iron RF-800-4 1.4 K to 500 K

Rhodium-Iron RF-100T/U 1.4 K to 325 K

Negative Temperature Coefficient RTDs2

Cernox™ CX-1010 2 K to 325 K4

Cernox™ CX-1030-HT 3.5 K to 420 K

Cernox™ CX-1050-HT 4 K to 420 K

3,6

Cernox™ CX-1070-HT 15 K to 420 K3

Cernox™ CX-1080-HT 50 K to 420 K3

Germanium GR-200A/B-1000 2.2 K to 100 K4

Germanium GR-200A/B-1500 2.6 K to 100 K4

Germanium GR-200A/B-2500 3.1 K to 100 K4

Carbon-Glass CGR-1-500 4 K to 325 K5

Carbon-Glass CGR-1-1000 5 K to 325 K5

Carbon-Glass CGR-1-2000 6 K to 325 K5

Rox™ RX-102A 1.4 K to 40 K5

1 Sensors sold separately.

2 Single excitation current may limit the low temperature range of NTC resistors

3 Non-HT version maximum temperature: 325 K

4 Low temperature limited by input resistance range

5 Low temperature specified with self-heating error: < 5 mK

6 Low temperature specified with self-heating error: < 12 mK

3,6

1-2 Introduction

Lake Shore Model 218 Temperature Monitor User’s Manual

1.1 MODEL 218 FEATURES

PTC Resistor Measurements

The Model 218 can read up to eight 100 Ω, 1000 Ω PTC (positive temperature coefficient) or any

other PTC resistive sensors using their standard curves or individual calibrations. Platinum RTDs are

known for their wide range of operation and uniform sensitivity. The Model 218 can read Platinum

RTDs to achieve temperature readings greater than 1000 K (727 °C). Platinum RTDs sold by Lake

Shore are limited to 800 K (527 °C).

Diode Measurements

The Model 218 can read up to eight Lake Shore DT-470 or any other diode temperature sensor.

Diode sensors are easily interchangeable and provide a wide measurement range from 1.4 to 475 K.

Many diodes like the DT-470 follow a standard temperature response curve that may eliminate the

need for costly or time consuming individual calibration. The convenient SoftCal™ feature can be

used to improve the accuracy of less expensive DT-470 sensors.

NTC Resistor Measurements

The Model 218 can read up to eight NTC (negative temperature coefficient) resistor sensors using

their standard curves or individual calibrations. NTC resistor sensors are typically used in specialized

applications such as magnetic and radiation environments. In some applications, the constant current

excitation of the 218 may limit the useful range of NTC resistor sensors (refer to Table 1-2).

Configurable Sensor Inputs

The Model 218 has eight constant current sources (one for each input) that can be configured for a

variety of sensors. The inputs can be configured from the front panel or via computer interface and

are grouped in two sets of four. Each set of four inputs are configured for the same sensor type (i.e.

all 100 Ω Platinum or all Silicon Diodes, etc.).

Sensor Input Reading Capability

The Model 218 has two high resolution A/D converters to increase its update rate. It can read sensor

inputs more quickly than other scanning monitors because it does not have to wait for current source

switching. The result is 16 new readings per second allowing all inputs to be read twice each second.

Inputs can be turned off to obtain a higher reading rate on fewer sensors. All readings can be read

out of the instrument with the IEEE-488 interface. The serial interface can also be used to read all

readings if it is operated efficiently. The display is updated twice each second.

Temperature Response Curves

The Model 218 has standard temperature sensor response curves for silicon diodes and platinum

RTDs. It can support a wide variety of temperature sensors that do not have a standard curve

because a unique 200 point user curve can be stored for each of the eight inputs. CalCurves™ for

Lake Shore calibrated sensors can be stored as user curves. User curves can be entered from the

front panel or with a computer interface. The built in SoftCal™ algorithm can also be used to generate

improved curves for DT-470 diodes and platinum RTDs that are stored as user curves.

Configurable Display

The eight display locations on the Model 218 are user configurable. These locations can be used to

display a single readout for each of the eight inputs or for more than one readout for fewer inputs.

Sources for readout data are temperature units, sensor units and results of the math function. Input

number and data source are always displayed for convenience.

Introduction 1-3

Lake Shore Model 218 Temperature Monitor User’s Manual

1.2 MODEL 218 SPECIFICATIONS

Thermometry

Number of Inputs: 8

Input Configuration: Two groups of four. Each group must contain same input type

Measurement Type: Four-lead differential

Excitation: Eight constant current sources

Supported Sensors (temp. range): Silicon Diode, GaAlAs Diode, RTDs: 100 Ω Platinum, 1000 Ω Platinum,

Germanium, Carbon Glass, Cernox, ROX

Accuracy/Resolution: Refer to Table 1-2

Maximum Update Rate: 16 readings per second total

Standard Curves: DT-470, DT-670, CTI-C, DT-500D, PT-100, PT-1000

User Curves: Room for eight (one per input). 200 point maximum for each

Soft Cal™: Improves accuracy of DT-470 diode to ±0.25 K from 30 K to 375 K. Improves

accuracy of Platinum RTDs to ±0.25 K from 70 K to 325 K. Stored as user curves

Math: Maximum, Minimum, and Linear Equation

Filter: Averages 2 to 64 input readings

Front Panel

Display: 4 line by 20 character backlit LCD display

Number of input displays: 1 to 8

Display Units: K, C, V, Ω

Display Update Rate: All displayed inputs twice in one second

Temperature Display Resolution: 0.001° between 0° to 99.999°, 0.01° between 100°

Sensor Units Display Resolution: Sensor dependent, to 5 digits

Display Annunciators: Remote (R), Alarm (A), Data Logging (D), Max (>), Min (<), Linear (/)

Keypad: 20-Key membrane, numeric and specific functions

Front Panel Features: Front panel curve entry and keypad lock-out

Interface

IEEE-488.2 Interface (218S Only): SH1,AH1,T5,L4,SR1,RL1,PP0,DC1,DT0,C0,E1

Serial Interface: RS-232C Electrical, DE-9 Connector, 9600 BAUD

Printer Capability: Support for serial printer through serial interface. Used with Data Log parameters

Alarms:

Number: 16 – High and low for each input

Data Source: Temperature, sensor units, linear equation

Settings: Units, High Setpoint, Low Setpoint, Deadband, Latching or Non-Latching,

Audible on or off

Actuators: Display annunciator, beeper, relays (218S)

Relays (218S Only):

Number: 8

Contacts: Normally Open (NO), Normally Closed (NC), and Common (C)

Contact Rating: 30 VDC at 5 A

Operation: Each input may be configured to actuate any or all of the 8 relays. Relays

may be activated on high, low, or both alarms for any input, or manually

Corrected Analog Output (218S):

Scale: User selected

Range: ±10 V

Resolution: 1.25 mV

Accuracy: ±2.5 mV

Minimum Load: 1 kΩ

Data Logging

Readings: 1

to 8 per record

Operation: Store Data Log records in memory or send them to the printer. Users may

display, print, or retrieve stored data by computer interface

Data memory: Maximum of 1500 single reading records, non-volatile

General

Ambient Temperature: 15 to 35 °C at rated accuracy. 10 to 40 °C at reduced accuracy

Power Requirement: 100, 120, 220, 240VAC, +6% –10%, 50 or 60Hz, 18 VA

Size: 217 mm W × 90 mm H × 317.5 mm D (8.5 × 3.5 × 12.5 in.), half rack

Weight: 3 kilograms (6.6 pounds)

Approval: CE Mark (contact Lake Shore for availability)

to 999.99°, 0.1° above 1000°

1-4 Introduction

Lake Shore Model 218 Temperature Monitor User’s Manual

Introduction 1-5

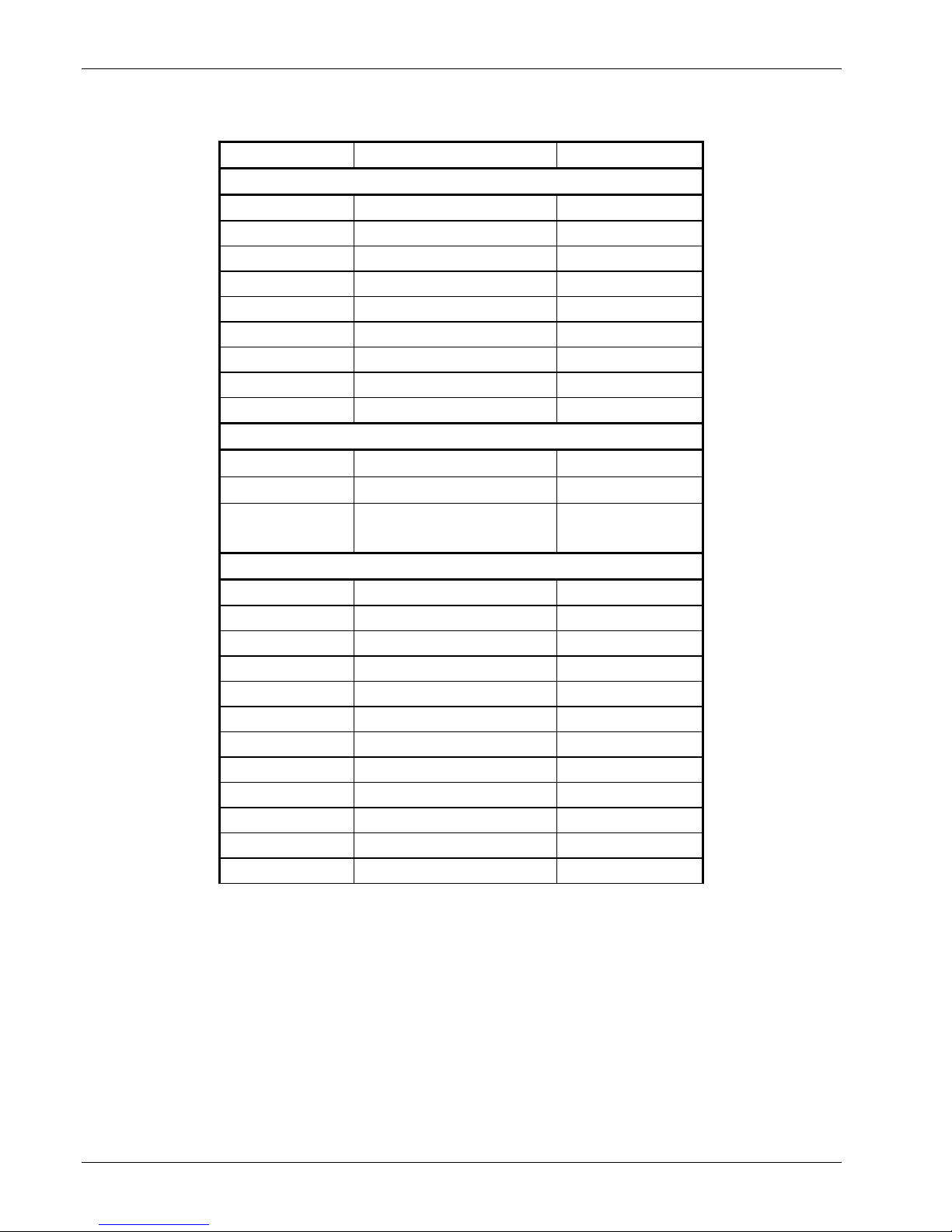

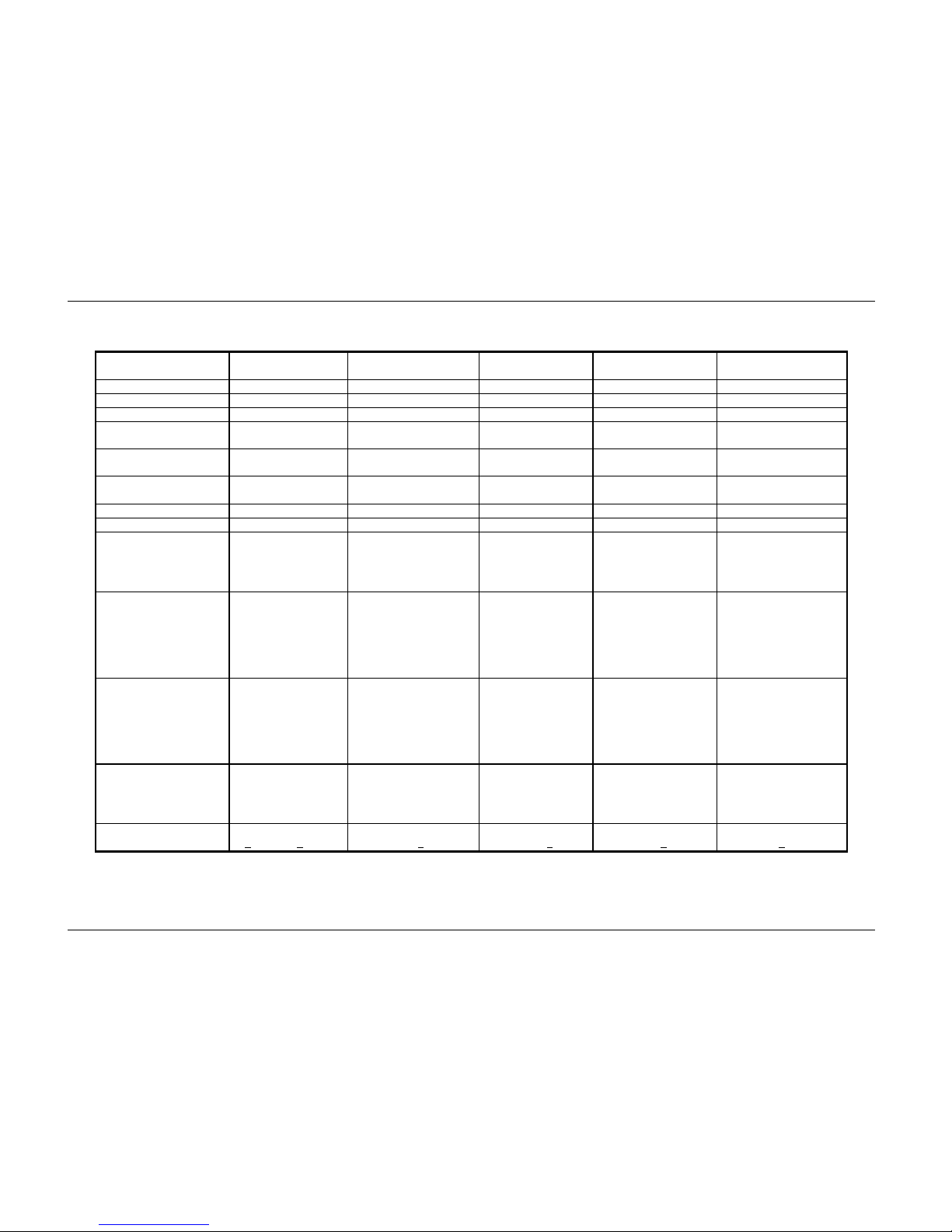

Table 1-2. Model 218 Sensor Input Performance Chart

Sensor Type Silicon Diode GaAlAs Diode

100

Ω Platinum RTD

500

Ω Full Scale

1000

Ω Platinum RTD Cernox™ RTD

Temperature Coefficient Negative Negative Positive Positive Negative

Sensor Units Volts (V) Volts (V) Ohms (Ω) Ohms (Ω) Ohms (Ω)

Input Range 0 to 2.5 V 0 to 7.5 V 0 to 500 Ω 0 to 5000 Ω 0 – 7500 Ω

Sensor Excitation

(Constant Current)

10 µA ±0.01% 10 µA ±0.01% 1 mA ±0.3% 1 mA ±0.3% 10 µA ±0.01%

Display Resolution

(Sensor Units)

100 uV 100 uV 10 m

Ω 100 mΩ 100 mΩ

Example LSCI Sensor

DT-470-CO-13 with

1.4H Cal.

TG-120SD with 1.4H Cal. PT-103 with 14J Cal. PT-10012 with 1.4J Cal. CX-1050-SD with 4L Cal.

Temperature Range 1.4 – 475 K 1.4 – 475 K 30 – 800 K 30 – 800 K 3.5 – 400 K

Standard Sensor Curve LSCI Curve 10 Requires Calibration DIN 43760 Scaled from DIN 43670 Requires calibration

Typical Sensor

Sensitivity

-30 mV/K at 4.2 K

-1.9 mV/K at 77 K

-2.4 mV/K at 300 K

-2.2 mV/K at 475 K

-180 mV/K at 10 K

-1.25 mV/K at 77 K

-2.75 mV/K at 300 K

-2.75 mV/K at 475 K

0.19

Ω/K at 30 K

0.42

Ω/K at 77 K

0.39

Ω/K at 300 K

0.35

Ω/K at 675 K

0.33

Ω/K at 800 K

1.9

Ω/K at 30 K

4.2

Ω/K at 77 K

3.9

Ω/K at 300 K

3.3

Ω/K at 800 K

-770

Ω/K at 4.2 K

-1.5

Ω/K at 77 K

-0.1

Ω/K at 300 K

Measurement Resolution:

Sensor Units

Temperature Equivalence

20 uV

1 mK at 4.2 K

11 mK at 77 K

10 mK at 300 K

10 mK at 475 K

20 uV

1 mK at 10 K

16 mK at 77 K

10 mK at 300 K

10 mK at 475 K

2 m

Ω

10.6 mK at 30 K

10 mK at 77 K

10 mK at 300 K

10 mK at 675 K

10 mK at 800 K

20 m

Ω

10.6 mK at 30 K

10 mK at 77 K

10 mK at 300 K

10 mK at 800 K

50 m

Ω

1 mK at 4.2 K

33.3 mK at 77 K

500 mK at 300 K

Electronic Accuracy:

Sensor Units

Temperature Equivalence

±160 uV ±0.01% RDG

±11 mK at 4.2 K

±138 mK at 77 K

±88 mK at 300 K

±77 mK at 475 K

±160 uV ±0.02% RDG

±6 mK at 10 K

±300 mK at 77 K

±150 mK at 300 K

±110 mK at 475 K

±0.004

Ω ±0.02% RDG

±25 mK at 30 K

±18 mK at 77 K

±70 mK at 300 K

±162 mK at 675 K

±187 mK at 800 K

±0.06

Ω ±0.04% RDG

±40 mK at 30 K

±33 mK at 77 K

±135 mK at 300 K

±370 mK at 800 K

±0.1

Ω ±0.04% RDG

±1 mK at 4.2 K

±88 mK at 77 K

±1.144 K at 300K

Temperature Accuracy

including electronic

accuracy, CalCurve™

and calibrated sensor

±31 mK at 4.2 K

±193 mK at 77 K

±138 mK at 300 K

±177 mK at 475 K

±21 mK at 10 K

±390 mK at 77 K

±140 mK at 300 K

±210 mK at 475 K

±45 mK at 30 K

±38 mK at 77 K

±105 mK at 300 K

±262 mK at 675 K

±287 mK at 800 K

±60 mK at 30 K

±53 mK at 77 K

±170 mK at 300 K

±470 mK at 800 K

±9 mK at 4.2 K

1

±138 mK at 77 K

1

±1.284 K at 300K

1

Magnetic Field Use

Recommended for

T > 60 K & B < 3 T

Recommended for

T > 4.2 K & B < 5 T

Recommended for

T > 40 K & B < 2.5 T

Recommended for

T > 40 K & B < 2.5 T

Recommended for

T > 2 K & B < 19 T

1

Specified accuracy includes no effects of thermal EMF voltages. An error of 3 mΩ results from ea ch 1 µV of thermal EMF voltage. In well-designed systems, thermal EMF voltage should b e less than 10 µV.

2

No longer available from Lake Shore.

Lake Shore Model 218 Temperature Monitor User’s Manual

1.3 SAFETY

1.3.1 Handling Liquid Helium and Liquid Nitrogen

Liquid Helium (LHe) and liquid nitrogen (LN

the Model 218. Although LHe and LN

2

) may be used in conjunction with

2

are not explosive, there are certain

safety considerations when handling them.

1.3.1.1 Handling Cryogenic Storage Dewars

Operate all cryogenic containers (dewars) in accordance with manufacturer

instructions. Safety instructions are normally posted on the side of each

dewar. Keep cryogenic dewars in a well-ventilated place, protected from the

weather, and away from heat sources. Figure 1-1 shows a typical cryogenic

dewar.

MAGNETIC

LIQUIDLIQUID

HELIUMHELIUM

UPRIGHT

NON-

KEEP

NON-

FLAMMABLE

1.3.1.2 Liquid Helium and Nitrogen Safety Precautions

Transfer LHe and LN

and operate storage dewar controls in accordance

2

with manufacturer/supplier instructions. During transfer, follow all safety

precautions written on the storage dewar and recommended by the

manufacturer.

WARNING: Liquid helium is a potential asphyxiant and can cause rapid suffocation

without warning. Store and use in an adequately ventilated area. DO NOT

vent the container in confined spaces. DO NOT enter confined spaces where

gas may be present unless area is well-ventilated. If inhaled, remove to fresh

air. If not breathing, give artificial respiration. If breathing is difficult, give

oxygen. Get medical attention.

WARNING: Liquid helium can cause severe frostbite to exposed body parts. DO NOT

touch frosted pipes or valves. For frostbite, consult a physician

immediately. If a physician is unavailable, warm the affected parts with

water that is near body temperature.

Two essential safety aspects of handling LHe are adequate ventilation and eye and skin protection.

Although helium and nitrogen gases are non-toxic, they are dangerous because they replace air in

a normal breathing atmosphere. Liquid helium is an even greater threat because a small amount of

liquid evaporates to create a large amount of gas. Store and operate cryogenic dewars in open,

well-ventilated areas.

When transferring LHe and LN2, protect eyes and skin from accidental contact with liquid or the

cold gas issuing from it. Protect eyes with full face shield or chemical splash goggles; safety

glasses (even with side shields) are inadequate. Always wear special cryogenic gloves (Tempshield

Cryo-Gloves

®

or equivalent) when handling anything that is, or may have been, in contact with the

liquid or cold gas, or with cold pipes or equipment. Wear long sleeve shirts and cuffless trousers

long enough to prevent liquid from entering shoes.

Figure 1-1. Cryogenic

Storage Dewar

1.3.1.3 Recommended First Aid

Post an appropriate Material Safety Data Sheet (MSDS) obtained from the manufacturer/distributor

at every site that stores and uses LHe and LN

and first aid.

If a person exhibits symptoms of asphyxia such as headache, drowsiness, dizziness, excitation,

excessive salivation, vomiting, or unconsciousness, remove to fresh air. If breathing is difficult, give

oxygen. If breathing stops, give artificial respiration. Call a physician immediately.

If exposure to cryogenic liquids or cold gases occurs, restore tissue to normal body temperature

(98.6 °F) by bathing it in warm water not exceeding 105 °F (40 °C). DO NOT rub the frozen part,

either before or after rewarming. Protect the injured tissue from further damage and infection and

call a physician immediately. Flush exposed eyes thoroughly with warm water for at least

15 minutes. In case of massive exposure, remove clothing while showering with warm water. The

patient should not drink alcohol or smoke. Keep warm and rest. Call a physician immediately.

Introduction 1-7

. The MSDS specifies symptoms of overexposure

2

1.3.2 Safety Summary

Observe these general safety precautions during all phases of instrument operation, service, and

repair. Failure to comply with these precautions or with specific warnings elsewhere in this manual

violates safety standards of design, manufacture, and intended instrument use. Lake Shore

Cryotronics assumes no liability for Customer failure to comply with these requirements.

The Model 218 protects the operator and surrounding area from electric shock or burn, mechanical

hazards, excessive temperature, and spread of fire from the instrument. Environmental conditions

outside of the conditions below may pose a hazard to the operator and surrounding area.

• Indoor use.

• Altitude to 2000 m.

• Temperature for safe operation: 5 to 40 °C.

• Maximum relative humidity: 80% for temperature up to 31 °C decreasing linearly to 50% at 40 °C.

• Power supply voltage fluctuations not to exceed ±10% of the nominal voltage.

• Overvoltage category II.

• Pollution degree 2.

Ground The Instrument

To minimize shock hazard, connect the instrument chassis and cabinet to an electrical ground.

The instrument is equipped with a three-conductor AC power cable. Plug the power cable into an

approved three-contact electrical outlet or use a three-contact adapter with the grounding wire

(green) firmly connected to an electrical ground (safety ground) at the power outlet. The power jack

and mating plug of the power cable meet Underwriters Laboratories (UL) and International

Electrotechnical Commission (IEC) safety standards.

Ventilation

The instrument has ventilation holes in its top and bottom covers. Do not block these holes when

the intrument is turned on.

Do Not Operate In An Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any

electrical instrument in such an environment constitutes a definite safety hazard.

Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Refer component replacement and

internal adjustments to qualified maintenance personnel. Do not replace components with power

cable connected. Always disconnect power and discharge circuits before touching them.

Do Not Substitute Parts Or Modify Instrument

Do not install substitute parts or perform any unauthorized modification to the instrument. Return

the instrument to an authorized Lake Shore Cryotronics, Inc. representative for service and repair to

ensure that safety features are maintained.

Cleaning

Do not submerge instrument. Clean only with a damp cloth and mild detergent. Exterior only.

Lake Shore Model 218 Temperature Monitor User’s Manual

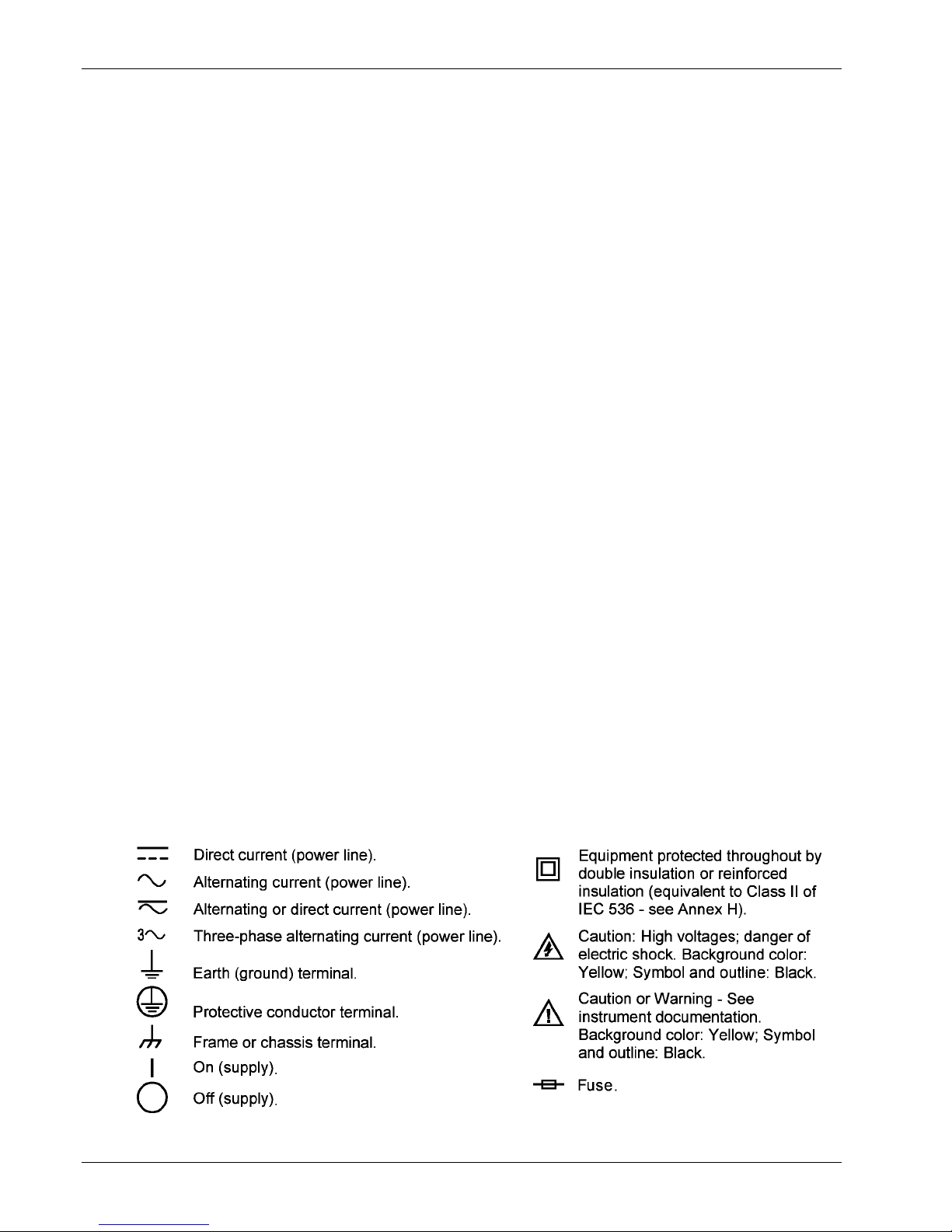

1.3.3 Safety Symbols

1-8 Introduction

Lake Shore Model 218 Temperature Monitor User’s Manual

CHAPTER 2

SENSOR CONSIDERATIONS

2.0 GENERAL

Selecting the proper sensor is vital to good temperature monitoring. This chapter covers Temperature

Sensor Selection in Paragraph 2.1, Calibrated Sensors in Paragraph 2.2, and Sensor Installation in

Paragraph 2.3. This chapter describes cryogenic applications, but many ideas apply to other

temperature measurements.

2.1 TEMPERATURE SENSOR SELECTION

This section covers general information about sensor selection. Find additional information on

temperature sensor characteristics and selection in the Lake Shore Temperature Measurement and

Control Catalog.

2.1.1 Temperature Range

The experimental temperature range must be known when choosing a sensor. Some sensors can be

damaged by temperatures that are too high or too low. Manufacturer’s recommendations should

always be followed. Sensor sensitivity is also dependent on temperature and can limit a sensors

useful range. It is important not to specify a range larger than necessary. If an experiment is being

done at liquid helium temperature and a very high sensitivity is needed for good measurement

resolution, that same resolution may not be required to monitor warm up to room temperature. Two

different sensors may be required to tightly cover the range from helium to room temperature, but

lowering the requirement on warm up may allow a less expensive, one sensor solution.

Another thing to consider when choosing a temperature sensor is that instruments like the Model 218

are not able to read some sensors over their entire temperature range. Lake Shore sells calibrated

sensors that operate down to 50 mK, but the Model 218 is limited to operation above 1 K in its

standard configuration.

2.1.2 Sensor Sensitivity

Temperature sensor sensitivity measures how much a sensor signal changes when the temperature

changes. It is important because so many measurement parameters relate to it. Resolution, accuracy,

and noise floor depend on sensitivity. Many sensors have different sensitivities at different

temperatures. For example, platinum sensor sensitivity is good at higher temperatures, but drops

sharply below 30 K. It may be difficult to determine if a sensor has adequate sensitivity over the

experimental temperature range. Table 1-2 lists sensor sensitivity translated into temperature

resolution and accuracy at different points. This is typical sensor response and can be used as a

guide to choose a sensor for the Model 218.

2.1.3 Environmental Conditions

Environmental factors such as high vacuum, magnetic field, corrosive chemicals, or even radiation

may limit effectiveness of some sensors. Lake Shore offers sensor packages that withstand

environmental factors found in typical cryogenic cooling systems.

Magnetic field experiments are very common. Field dependence is an important selection criteria for

temperature sensors used in these experiments. Table 1-2 states the field dependence of most

common sensors. The Lake Shore Temperature Measurement and Control Catalog includes detailed

field dependence tables along with specific data on other environmental factors when available.

Sensor Considerations 2-1

Lake Shore Model 218 Temperature Monitor User’s Manual

2.1.4 Measurement Accuracy

Temperature measurements have several sources of error. Account for errors induced by both the

sensor and the instrumentation when computing accuracy. The instrument has measurement error in

both reading the sensor signal and calculating a temperature using a temperature response curve.

Error results from the sensor comparison to a calibration standard; the sensor temperature response

shifts with time and repeated thermal cycling. Instrument and sensor makers specify these errors, but

some things help maintain good accuracy. For example, choose a sensor with good sensitivity in the

most critical temperature range, as sensitivity minimizes the effect of most error sources. Install the

sensor properly (Paragraph 2.3). Recalibrate the sensor and instrument periodically. Use a sensor

calibration appropriate for the accuracy requirement.

2.1.5 Sensor Package

There are many types of sensor packages which generally determine sensor size, thermal and

electrical contact to the outside, and sometimes limit temperature range. Some sensors may be

purchased as bare chips without a package. When different packages are available for a sensor,

consider the sensor mounting surface and how to heat sink the leads.

2.2 CALIBRATED SENSORS

It can be difficult to choose the right sensor, calibrate it, translate calibration data into a temperature

response curve understandable to the Model 218, and load the curve into the instrument. Lake Shore

offers a variety of calibration and curve loading services to fit different accuracy requirements and

budgets: Traditional Calibration in Paragraph 2.2.1, SoftCal™ in Paragraph 2.2.2, Standard Curves in

Paragraph 2.2.3, and the Lake Shore CalCurve™ Service in Paragraph 2.2.4.

2.2.1 Traditional Calibration

Calibration compares a sensor with an unknown temperature response to an accepted standard.

Lake Shore temperature standards are traceable to the U.S. National Institute of Standards and

Testing (NIST) or the National Physical Laboratory in Great Britain. These standards allow

Lake Shore to calibrate sensors from 50 mK to above room temperature. Calibrated sensors are

more expensive than uncalibrated sensors.

Calibrated temperature sensors are the most accurate available from Lake Shore. Errors from sensor

calibration are almost always smaller than error contributed by the Model 218. The Lake Shore

Temperature Measurement and Control Catalog has complete accuracy specs for calibrated sensors.

Calibrated sensors include measured test data printed and plotted, coefficients of a Chebychev

polynomial fitted to the data, and two tables of data points used as interpolation tables optimized for

accurate temperature conversion. The smaller table, called a breakpoint interpolation table, fits into

instruments like the Model 218 where it is called a temperature response curve. Install a curve into a

Model 218 through a CalCurve™ (Paragraph 2.2.4) or manually through the instrument front panel.

Note instrument specifications before ordering calibrated sensors. A calibrated sensor is required

when a sensor does not follow a standard curve if the user wishes to display in temperature.

Otherwise the Model 218 operates in sensor units like ohms or volts. The Model 218 may not work

over the full temperature range of some sensors. The Model 218 is limited to operation above 1 K or

more even with sensors that can be calibrated to 50 mK.

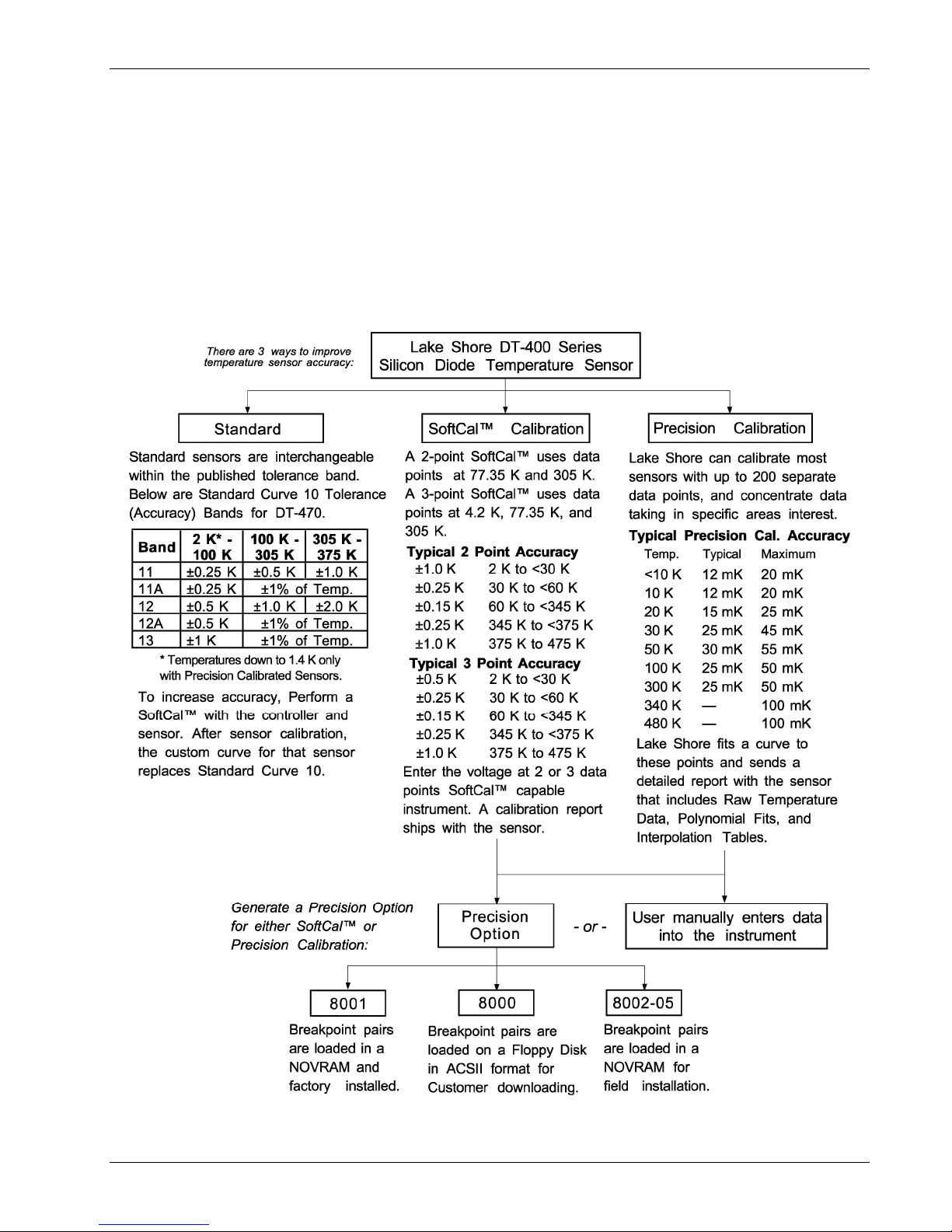

2.2.2 SoftCal™

SoftCal™ is a good solution for applications that do not require the accuracy of a traditional

calibration. The SoftCal™ algorithm uses the predictability of sensors that follow a standard curve to

improve individual sensor accuracy. A few known temperature points are required to perform

SoftCal™.

Lake Shore sells SoftCal™ calibrated sensors that include both the large interpolation table and the

smaller breakpoint interpolation table. A CalCurve™ (refer to Paragraph 2.2.4) or front panel curve

entry (refer to Paragraph 5.2) may be required to get the breakpoint table into a Model 218 where it is

called a temperature response curve.

2-2 Sensor Considerations

The Model 218 also performs SoftCal™ calibration. The user provides 1, 2, or 3 known temperature

reference points. Calibration range and accuracy depend on these points (Paragraph 5.2).

2.2.3 Standard Curves

Some types of sensors behave very predictably and a standard temperature response curve can be

created for them. Standard curves are a convenient and inexpensive way to get reasonable

temperature accuracy. Sensors with a standard curve are often used when interchangeability is

important. Some individual sensors are selected for their ability to match a published standard curve

and sold at a premium, but in general these sensors do not provide the accuracy of a calibrated

sensor. For convenience, the Model 218 has several standard curves included in firmware.

Lake Shore Model 218 Temperature Monitor User’s Manual

C-218-2-1.eps

Figure 2-1. Silicon Diode Sensor Calibrations and CalCurve™

Sensor Considerations 2-3

Lake Shore Model 218 Temperature Monitor User’s Manual

2.2.4 CalCurve™

The CalCurve™ service provides the user with a convenient way to get the temperature response

curve from Lake Shore’s calibrated sensors into instruments like the Model 218. It can be performed

at the factory when calibrated sensors and instruments are ordered together. The factory installed

CalCurve™ option is Model 8001 and should be ordered with the calibrated sensor.

A CalCurve™ can be done in the field when additional or replacement sensors are installed. Curve

data is loaded into some type of non-volatile memory that is installed into the instrument by the user.

In the case of the Model 218, the curve is loaded into a non-volatile memory chip which can be

installed into the instrument. The field installed version is a Model 8002 and it should be ordered with

the calibrated sensor.

Customers that have an RS-232C or IEEE-488 interface have another option in loading curves from

calibrated sensors. A Model 8000 includes the curve and a download program on a disk. The down

load program is a good idea if sensors are changed often. The Model 8000 should also be ordered

with the calibrated sensor.

2.3 SENSOR INSTALLATION

This section covers Mounting Materials in Paragraph 2.3.1, Sensor Location in Paragraph 2.3.2,

Thermal Conductivity in Paragraph 2.3.3, Contact Area in Paragraph 2.3.4, Contact Pressure in

Paragraph 2.3.5, Lead Wire in Paragraph 2.3.6, Lead Soldering in Paragraph 2.3.7, Heat Sinking Leads

in Paragraph 2.3.8, Thermal Radiation in Paragraph 2.3.9, and Thermal EMF Compensation with

Voltage Excitation in Paragraph 2.3.10.

For more detailed information, Lake Shore sensors ship with installation instructions that cover that

specific sensor type and package. The Lake Shore Temperature Measurement and Control Catalog

includes an installation section as well. Lake Shore also offers a line of cryogenic accessories. Many of

the materials discussed are available through Lake Shore and can be ordered with sensors or

instruments.

2.3.1 Mounting Materials

The high vacuum used to insulate cryostats is one consideration in choosing sensor mounting

materials. Choose materials with a low vapor pressure so they do not evaporate or out-gas and spoil

the vacuum insulation. Metals and ceramics do not have this problem, but greases and varnishes

must be checked. Another consideration is temperature extremes most sensors are exposed to. The

linear expansion coefficient of a material becomes important when temperature changes are so large.

Never try to permanently bond materials with linear expansion coefficients that differ by more than

three. Use a flexible mounting scheme or the parts will break apart, potentially damaging them. The

thermal expansion or contraction of rigid clamps or holders could crush fragile samples or sensors

that do not have the same coefficient.

2.3.2 Sensor Location

Positioning a sensor is less problematic if the entire load and sample holder are at the same

temperature. Unfortunately, this not the case in many systems. Temperature gradients (differences in

temperature) exist because there is seldom perfect balance between the cooling source and heat

sources. Even in a well-controlled system, unwanted heat sources like thermal radiation and heat

conduction through mounting structures can cause gradients. For best accuracy, position sensors

near the sample, so that little or no heat flows between the sample and sensor.

2.3.3 Thermal Conductivity

Thermal conductivity is the ability of heat to flow through a material. Copper and aluminum have good

thermal conductivity, while stainless steel does not. Non-metallic, electrically-insulating materials like

alumina oxide and similar ceramics have good thermal conductivity, while G-10 epoxy-impregnated

fiberglass does not. Sensor packages, cooling loads, and sample holders should have good thermal

conductivity to reduce temperature gradients. Surprisingly, connections between thermally conductive

mounting surfaces often have very poor thermal conductivity. Thermal conductivity can change with

temperature. Do not assume a heat sink grease that works well at room temperature and above will

do the same job at low temperatures.

2-4 Sensor Considerations

Lake Shore Model 218 Temperature Monitor User’s Manual

2.3.4 Contact Area

Thermal contact area greatly affects thermal conductivity because a larger area has more opportunity

to transfer heat. Even when the size of a sensor package is fixed, thermal contact area can be

improved with the use of a gasket material. A soft gasket material forms into the rough surface being

mated to increase the area of the two surfaces that is in contact. Good gasket materials are soft, thin

and have good thermal conductivity themselves. They must also withstand the environmental

extremes. Indium foil and cryogenic grease are examples.

2.3.5 Contact Pressure

When sensors are permanently mounted, the solder or epoxy used to hold the sensor acts as both

gasket and adhesive. Permanent mounting is not a good solution for everyone because it limits

flexibility and can potentially damage sensors. Much care should be taken not to over heat or

mechanically stress sensor packages. Less permanent mountings require some pressure to hold the

sensor to its mounting surface. Pressure will greatly improve the action of gasket material to increase

thermal conductivity and reduce thermal gradients. A spring clamp is recommended so that different

rates of thermal expansion don’t increase or decrease pressure with temperature change.

C-218-2-2.bmp

Figure 2-2 Typical Sensor Installation in a Mechanical Refrigerator

Sensor Considerations 2-5

2.3.6 Lead Wire

Different types of sensors come with different types and lengths of electrical leads. In general a

significant length of lead wire must be added to the sensor for proper heat sinking and connecting to

a bulk head connector at the vacuum boundary. The lead wire must be a good electrical conductor,

but a poor thermal conductor, or heat will transfer down the leads and change the temperature

reading of the sensor. Small 30 to 40 AWG wire made of an alloy like phosphor bronze is much better

than copper wire. Thin wire insulation is preferred and twisted wire should be used to reduce the

effect of RF noise if it is present. The wire used on the room temperature side of the vacuum

boundary is not critical so copper cable is normally used.

2.3.7 Lead Soldering

When additional wire is soldered to short sensor leads, care must be taken not to overheat the

sensor. A heat sink such as a metal wire clamp or alligator clip will heat sink the leads and protect the

sensor. Leads should be tinned before bonding to reduce the time that heat is applied to the sensor

lead. Solder flux should be cleaned after soldering to prevent corrosion.

2.3.8 Heat Sinking Leads

Sensor leads can be a significant source of error if they are not properly heat sinked. Heat will

transfer down even small leads and alter the sensor reading. The goal of heat sinking is to cool the

leads to a temperature as close to the sensor as possible. This can be accomplished by putting a

significant length of lead wire in thermal contact with every cooled surface between room temperature

and the sensor. Lead wires can be adhered to cold surfaces with varnish over a thin electrical

insulator like cigarette paper. They can also be wound onto a bobbin that is firmly attached to the cold

surface. Some sensor packages include a heat sink bobbin and wrapped lead wires to simplify heat

sinking.

Lake Shore Model 218 Temperature Monitor User’s Manual

2.3.9 Thermal Radiation

Thermal (black body) radiation is one of the ways heat is transferred. Warm surfaces radiate heat to

cold surfaces even through a vacuum. The difference in temperature between the surfaces is one

thing that determines how much heat is transferred. Thermal radiation causes thermal gradients and

reduces measurement accuracy. Many cooling systems include a radiation shield. The purpose of the

shield is to surround the load, sample, and sensor with a surface that is at or near their temperature

to minimize radiation. The shield is exposed to the room temperature surface of the vacuum shroud

on its outer surface, so some cooling power must be directed to the shield to keep it near the load

temperature. If the cooling system does not include an integrated radiation shield (or one cannot be

easily made), one alternative is to wrap several layers of super-insulation (aluminized mylar) loosely

between the vacuum shroud and load. This reduces radiation transfer to the sample space.

2.3.10 Thermal EMF Compensation with Voltage Excitation

Sensors used at low temperatures must operate with little power dissipated in the sensor. To keep

power low, the voltage across the sensor is kept low. Two major problems occur when measuring

small DC voltages. The first is external noise entering the measurement through the sensor leads

which is discussed with sensor setup. The second is the presence of thermal EMF voltages,

sometimes called thermocouple voltages, in the lead wiring. Thermal EMF voltages appear whenever

there is a temperature gradient across a piece of voltage lead. They can be canceled in the

measurement with a similar temperature gradient in the other voltage lead. Thermal EMF voltages

must exist because the sensor is almost never the same temperature as the instrument. Minimize

them by careful wiring, verifying voltage leads are symmetrical in the type of metal used and how they

are joined, and by keeping unnecessary heat sources away from the leads. Even in a well designed

system, thermal EMF voltages can be an appreciable part of a low voltage sensor measurement.

The Model 218 has no thermal correction algorithm. Other instruments automatically reverse the

current source polarity and average the positive and negative sensor readings to cancel the thermal

EMF voltage. Account for thermal EMF errors when estimating Model 218 measurement accuracy.

2-6 Sensor Considerations

Lake Shore Model 218 Temperature Monitor User’s Manual

CHAPTER 3

INSTALLATION

3.0 GENERAL

This chapter covers general Model 218 installation instructions: Inspection and Unpacking in

Paragraph 3.1, Repackaging for Shipment in Paragraph 3.2, and Rear Panel Definition in

Paragraph 3.3.

3.1 INSPECTION AND UNPACKING

Inspect shipping containers for external damage. Make all claims for damage (apparent or concealed)

or partial loss of shipment in writing to Lake Shore within five (5) days from receipt of goods. If damage

or loss is apparent, please notify the shipping agent immediately.

Open the shipping containers. Use the packing list included with the system to verify receipt of the

instrument, sensor, accessories, and manual. Inspect for damage. Inventory all components supplied