Page 1

Operation Manual

Oil-Air Cooling Unit OL 4503

Version 2.0

Page 2

Laird Technologies GmbH

Borsigstrasse 1

D-24568 Kaltenkirchen

www.lairdtech.com

Protection Notice

Dissemination as well as copying of this document, utilization or posting of its contents is not permitted

unless formally granted. Violations entail claims for compensation. All copyrights, including rights due to

patent grant or registration of a utility model or design, are reserved.

All product names used in this manual are trademarks of the corresponding manufacturers.

Technical modifications subject to change.

Page 3

Table of Contents

3

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

Table of Contents

1 About this Manual ............................................................................................................................ 6

1.1 Terms of Guarantee .............................................................................................................................6

1.2 Contact Information ..............................................................................................................................7

2 Product Identification ....................................................................................................................... 8

2.1 Unit Specifications ................................................................................................................................8

2.2 Identification Plate ................................................................................................................................8

3 Safety Regulations ........................................................................................................................... 9

3.1 Hazard classes ......................................................................................................................................9

3.2 Safety Symbols .....................................................................................................................................9

3.3 Hints for Safe Operation .................................................................................................................. 10

3.3.1 Prevent Hazards ..................................................................................................................................................... 10

3.3.2 Hints Regarding the Electrical Equipment .............................................................................................................. 10

3.3.3 Environmental Issues .............................................................................................................................................. 11

3.3.4 Protective Clothing .................................................................................................................................................. 11

3.4 Safety Equipment .............................................................................................................................. 11

3.4.1 Safety and Signalling Equipment included in the Unit ............................................................................................ 11

3.4.2 Guards ..................................................................................................................................................................... 12

3.4.3 Caution Label .......................................................................................................................................................... 13

3.5 In Case of Accidents ......................................................................................................................... 13

4 Product Description ....................................................................................................................... 14

4.1 Intended Use ...................................................................................................................................... 14

4.2 Non-Conformity with the Intended Use........................................................................................ 14

4.3 Unit Components ............................................................................................................................... 15

4.4 Specifications ...................................................................................................................................... 16

4.5 Setting-up Requirements ................................................................................................................. 17

4.5.1 Installation Location................................................................................................................................................. 17

4.5.2 Environmental Conditions ....................................................................................................................................... 17

4.5.3 Infrastructure ........................................................................................................................................................... 17

5 Transport .......................................................................................................................................... 18

5.1 Safety Indications for Transport and Setting-up ........................................................................ 18

5.2 Transportation of the unit ................................................................................................................. 18

5.3 Unpacking ............................................................................................................................................ 18

Page 4

Table of Contents

4

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

6 Initial Operation ............................................................................................................................... 19

6.1 Safety Indications Related to Initial Operation ........................................................................... 19

6.2 Setting to Work ................................................................................................................................... 19

6.2.1 Placement ............................................................................................................................................................... 19

6.2.2 Cooling Circuit Connection and Filling .................................................................................................................... 20

6.2.3 Electrical Connections ............................................................................................................................................ 22

6.2.4 Carrying out Setting-to-Work .................................................................................................................................. 23

6.3 Daily Start-up ...................................................................................................................................... 23

6.4 Setting-to-Work after Storage ......................................................................................................... 23

7 Controlling the Unit ........................................................................................................................ 24

7.1 Safety Indications for Controlling the Unit ................................................................................... 24

7.2 Switching on the Unit ....................................................................................................................... 24

7.3 Switching off the Unit ....................................................................................................................... 24

7.4 Settings ................................................................................................................................................. 25

7.4.1 Pressure Setting on the Angle-type Safety Valve .................................................................................................. 25

7.4.2 Setting the Thermostat............................................................................................................................................ 26

8 Disruptions ....................................................................................................................................... 27

8.1 Disrupt Operation ............................................................................................................................... 27

8.1.1 Trouble Shooting ..................................................................................................................................................... 27

9 Maintenance and Cleaning ......................................................................................................... 28

9.1 Maintenance Schedule ................................................................................................................... 28

9.2 Cleaning of Heat Exchanger ........................................................................................................... 28

9.3 Refilling of Coolant ............................................................................................................................. 28

9.4 Cleaning of Unit Casing ................................................................................................................... 29

10 Repair ............................................................................................................................................... 29

11 Dismounting, Disposal, Storage ................................................................................................. 30

11.1 Temporary Placing out of Operation ............................................................................................. 30

11.2 Re-packaging the Unit ...................................................................................................................... 30

11.3 Storing the Unit ................................................................................................................................... 30

11.4 Disposal ................................................................................................................................................ 31

11.5 Disposal of Operating Materials ..................................................................................................... 31

11.6 Return of the Unit to LAIRD ............................................................................................................ 31

12 Wear Parts and Spare Parts ....................................................................................................... 32

Page 5

Table of Contents

5

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

Addendum ............................................................................................................................................. 34

Performance chart ....................................................................................................................................... 34

Flow scheme ................................................................................................................................................. 35

Wiring diagram .............................................................................................................................................. 36

History of Changes

Date

Index

Reason for Change

Name

Page

29-Nov-13

1.0

First version

Edom/Pfeiffer

06-Jul-15

2.0

Spare part numbers changed

Dany/Bitenaite

p. 33

Page 6

About this Manual

Terms of Guarantee

6

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

1 About this Manual

This document is the English translation of the original Operation Manual in German language for the Oil-Air

Cooling Unit OL 4503 (called unit in the following). It is based on German safety regulations. In your country

other regulations may apply.

This Operational Manual addresses the needs of the user of the unit. Its intention is to allow the safe

operation of the unit. Thus, it should be read carefully and be kept in a space accessable for the users of the

unit at any time.

All chapters of this Operation Manual can be read independently and thus can be used for look-up purposes.

1.1 Terms of Guarantee

General sale and delivery terms of LAIRD apply. The buyer accepts these terms, at the latest when signing

the contract of purchase.

The particular terms of guarantee and duration of guarantee of the unit in question can be taken from the

contract documents as well as from the order confirmation.

Warranty claims and liability are excluded in case of one of the following situations:

Use of the unit in an unintended way

Inaccurate installation, putting into service, operation, repair or maintenance of the product by people

that are not fully authorized

Use of the product despite of defect, wrongly implemented or non-functional safety devices or

protective gear

Unauthorized or forbidden modifications by the user concerning the electrical equipment of the unit

Unauthorized or forbidden modifications by the user concerning the mechanical structure of the unit

Unauthorized or forbidden modifications by the user concerning the operating parameters

Use of unauthorized tools

Use of unauthorized operating supplies

Exceedance of mandatory maintenance intervals

Cases of disaster caused by foreign matter influence or act of nature beyond control

PLEASE NOTE

Any form of unintended use of the unit and any structural change caused by the user without prior

authorization in written form by LAIRD will lead to the termination of warranty as well the termination of the

declaration of conformation and will free LAIRD from product liability. This concern includes safety devices

as well.

In case of authorized changes or when adding optional equipment it is the sole responsibility of the customer

to assure the accurate implementation of the safety devices required.

Page 7

About this Manual

Contact Information

7

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

1.2 Contact Information

If you have questions with respect to this unit please use the contact information given below. Always

communicate the following:

Your name and address

Name of contact at your address

Product data as on identification plate: Type of unit, serial number and year of manufacture

Company contact:

Mail:

Laird Technologies GmbH

Borsigstrasse 1

D-24568 Kaltenkirchen

Deutschland

Internet:

http://www.lairdtech.com

E-Mail:

info-lcs@lairdtech.com

Phone:

+49 4191 9993-0

Fax:

+49 4191 9993-33

Page 8

Product Identification

Unit Specifications

8

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

2 Product Identification

2.1 Unit Specifications

Manufacturer

Laird Technologies GmbH

Type of product

Oil-air cooler

Type of unit

OL 4503

Article number

1264.00

Table 1: Unit specifications

2.2 Identification Plate

The identification plate is attached on the top of the coolant container below the unit cover.

Fig. 1: Position of identification plate

1

Identification plate

Fig. 2: Unit specific identification plate

1

Unit type

2

Article number

3

Serial number

4

Electrical specification

5

Date of manufacture

1

1

2

4

3

5

Page 9

Safety Regulations

Hazard classes

9

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

3 Safety Regulations

3.1 Hazard classes

In this document safety instructions are using standardized representation and symbols. Depending on the

probability of their incidence and the severeness of consequences three hazard classes are used.

DANGER

Reference to direct danger for humans.

Inobservance will lead to irreversible injuries or exitus.

CAUTION

Reference to noticeable danger for humans or possible damage to property.

Inobservance may lead to reversible injuries or to damage to property.

3.2 Safety Symbols

In this Operation Manual concrete safety instructions are given in order to point out unpreventable residual

risks when operating the unit. These risks include danger for

Human beings

The unit and other equipment

The environment

The safety symbols used in this manual are indicated below. The main reason for their use is to point the

reader to the safety instruction given in the text field beside.

Symbol

Meaning

Warning with respect to general danger or damage to property

Warning with respect to electrical hazard

Table 2: Warning signs

Symbol

Meaning

This symbol indicates the requirement of wearing safety gloves

This symbol indicates the requirement of disconnecting from mains.

Table 3: Signs giving orders

Page 10

Safety Regulations

Hints for Safe Operation

10

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

3.3 Hints for Safe Operation

PLEASE NOTE

Conduct inspections on a regular time base

This will ensure that the appropriate measures will be carried out indeed.

The unit is operation save. It was built according to the state-of-the-art.

Despite this the unit could cause hazards if it

is used in a way it was not intended for

is used improperly

is operated under unsuitable conditions

3.3.1 Prevent Hazards

Hazards can be prevented by safety-conscious and anticipatory behaviour of staff.

Everybody working with the unit should keep the following in mind:

Make this Operation Manual available for everybody at the operation site of the unit in a complete and

perfectly readable state!

Use the unit exclusively for what it was intended!

The unit must be operational and errorfree. Check the condition of the unit before working with it and

within a regular time frame.

Make sure that nobody can injure himself by any part of the unit!

Any disruption or recognizable change concerning the unit should be reported to the responsible

person.

Stick to accident prevention regulations as well as any regional regulations!

3.3.2 Hints Regarding the Electrical Equipment

DANGER

Danger to life through electrical shock when working on the electrical equipment of the unit!

Switch off the unit before starting your work!

Disconnect the unit from mains by pulling the mains plug!

Verify that the installation is dead (volt-free)!

Carry out earthing or short circuiting!

When working on electrical installations the following principles should be observed:

Works on the electrical installations may only be accomplished by qualified electrical staff!

When connecting electrical equipment to mains regional regulations have to be observed. Be aware of

the wiring diagram information.

The unit is powered by electricity. Electrical shock hazard exists, if the electrical installations are

defective or the insulation fails during operation.

When switched-off the unit is not disconnected from mains. This is only the case when the mains plug

is pulled.

Any changes regarding the control elements of the unit can have an influence on the save operation.

All intended changes must be authorized by the manufacturer.

After the implementation of a change the operativeness of the safeguards must be verified.

Page 11

Safety Regulations

Safety Equipment

11

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

No unauthorized changes on the unit are allowed. All intended changes must be authorized by the

manufacturer.

3.3.3 Environmental Issues

Environmentally concious and anticipatory behaviour of staff avoids environmentally hazardous impacts.

The following principles apply for environmentally conscious behaviour:

Environmentally hazardous substances must not get into the soil or into the drains. They should be

kept in appropriate containers.

Environmentally hazardous substances must be brought to utilization or disposal according to regional

regulations.

When dealing with working fluids always keep aware of the safety data sheet of the corresponding

manufacturer.

3.3.4 Protective Clothing

When doing a job that leads to contact of the skin with the coolant (e.g. filling-up of the coolant container):

Wear safety gloves made of PVC, neoprene or nitrile rubber

3.4 Safety Equipment

PLEASE NOTE

The safety equipment listed below must be integrated in the local control environment by the customer,

unless otherwise noted. These tasks must be carried out solely by trained experts. All information required

can be taken from the wiring diagram shown in the addendum.

Safety equipment must not be modified, removed or taken out of operation. All parts of the safety equipment

must be accessible at all times.

3.4.1 Safety and Signalling Equipment included in the Unit

The unit is equipped with safety equipment at critical spots:

The filling level of the coolant container is indicated in an inspection glass.

The circulated oil amount is controlled by a flow control device (flow switch) that must be integrated in

the potential-free safety circuit of the device that is to be cooled.

The oil temperature is controlled by a thermostat. When the oil temperature exceeds the maximum

setpoint this is indicated by the potential-free safety circuit.

The maximum pump pressure is limited by an angle-type safety valve that bypasses the oil stream

when the pressure pre-set is exceeded.

Page 12

Safety Regulations

Safety Equipment

12

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

Fig. 3: Safety equipment

1

Thermostat

2

Flow control device (flow switch)

3

Angle-type safety valve

4

Inspection glass, level indicator

3.4.2 Guards

Direct access to hazardous parts or areas of the unit is restricted by the unit cover. The cover may only be

removed for the purpose of maintenance or repair works and shall be replaced prior to taking the unit back to

operation. The cover is fixed by four screws which can be unscrewed using a metric AF10 wrench.

Fig. 4: Guard

1

Unit cover

1

2

3

4

1

Page 13

Safety Regulations

In Case of Accidents

13

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

3.4.3 Caution Label

Danger spots on the unit are indicated corresponding to German safety regulation BGV A8 "Sicherheits- und

Gesundheitsschutzkennzeichnung am Arbeitsplatz"

Caution labels on the unit must be easily readable at all times. Illegible caution labels must be exchanged

without delay.

Fig. 5: Caution labels on the unit

1

Hint for using the correct cap on oil filler

3.5 In Case of Accidents

Should you or an other person be injured when working with the unit:

Stay calm!

Give first aid!

Call the company’s first-aider without exception!

First aid at accidents with oil

The unit employs oil as a coolant in a closed-loop configuration. In case of damage oil can leak from the

circuit and cause hazards.

Long term or repeated contact with skin without appropriate cleaning may obstruct the skin pores and

may lead to irregularities as oil acne or folliculitis.

When exposed to oil always observe the safety data sheet of the manufacturer.

1

Page 14

Product Description

Intended Use

14

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

4 Product Description

4.1 Intended Use

The oil-air cooler OL 4503 is used for the cooling of an oil circuit. Oil circulates between the cooling unit and

the device to be cooled. The oil is recooled by an air-cooled heat exchanger. The maximum cooling capacity

depends on the ambient air temperature (see page 16 ).

The unit is exclusively intended for use in industrial and commercial environments.

The intended use also includes the observance and following of all hints given in this Operation Manual.

4.2 Non-Conformity with the Intended Use

Operation of the unit under improper operational conditions is not permitted, since otherwise the operation

safety can not be granted.

When using the unit in a way not compliant with the intended use, hazardous situations may occur.

Operation of the unit is not permitted under the following conditions:

The unit is used for a purpose other than the one it is intended for.

The unit or parts of it are damaged, the electrical installation is not correct or the insulation is broken.

Protective or safety equipment is not functional or defect, improperly installed or missing.

The unit is not working properly.

The unit was modified without authorization or modified in a way that is not permitted.

Controlling devices were modified in a way that is not permitted.

Operational parameters were changed in a way that is not permitted.

Operation in areas exposed to explosion hazards.

Operation with cooling media not according to specification.

Use of unauthorized tools.

Exceedance of the compulsary maintenance intervals.

PLEASE NOTE

The manufacturer is not liable for damage occuring when using the unit in a way it was not intended.

When using the unit in a way it was not intended for, the manufactorer’s waranty given by LAIRD will

expire.

Page 15

Product Description

Unit Components

15

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

4.3 Unit Components

Additional information can be retrieved from the flow scheme shown in the addendum. The unit consists of

the following main components:

Fig. 6: Main components

1

Cooling circuit

2

Coolant container

3

Sheet-metal hood

Cooling Circuit

In the cooling circuit the coolant (i.e. the oil) is driven by the pump to the device that is to be cooled and back

via the return flow. The heat is dissipated into the ambient air by an air-cooled heat exchanger. Exceedance

of the maximum pump pressure is prevented by a bypass circuit.The oil temperature is controlled by an

electronic thermostat. Oil throughput is controlled by a flow control device.

Fig. 7: Main components

1

Stop valve

2

Fan 3 Oil drain screw

2

1

3

1

3

2

Page 16

Product Description

Specifications

16

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

4.4 Specifications

Dimensions and weight

Length:

650 mm

Width:

350 mm

Height:

750 mm

Weight:

49.6 kg (empty)

Coolant capacity:

23 liters (Shell Diala S3-ZXIG)

Table 4: Dimensions and weight

Performance data

Cooling capacity:

4500 Watts at 22.8 K difference between the

oil outlet temperature and the ambient air

temperature

Pump capacity:

> 22 lpm at 3.5 bar

Mains voltage:

230 VAC 10% 50/60 Hz

Power input:

785 Watts (P

max

; 230 V; 50 Hz)

1058 Watts (P

max

; 230 V; 60 Hz)

Table 5: Performance data

Environmental conditions

Operating temperature:

-10°C ... +40°C

Storage temperature:

-25°C ... +70°C

Relative humidity:

20% … 90%

Table 6: Environmental conditions

Settings

Flow control device

14.0 ± 0.3 lpm

Thermostat

55 ± 3 °C

Maximum pressure

9.0 +0.5/-0.2 bar

Table 7: Settings

Page 17

Product Description

Setting-up Requirements

17

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

4.5 Setting-up Requirements

4.5.1 Installation Location

The location must be even.

When choosing the installation location the following must be kept in mind: the flow of the cooling air

must not be restricted, forward and back flow connections must be easily accessable and all hoses

must be installed without sharp bends.

4.5.2 Environmental Conditions

CAUTION

Risk of damage through unsuitable environmental conditions!

Damage to the unit and corrosion damage may result and are not covered by manufacturer’s

liability.

The unit is only authorized for use in indoor environments.

The unit must not be stored or operated in agressive, humid environments.

The unit must not be stored or operated outdoor.

Pay attention to the environmental conditions as given in the specifications on page 16.

4.5.3 Infrastructure

The following infrastructure is required for connecting the unit:

Parameter

Rated value

Operating voltage

230 VAC

Table 8: Required infrastructure

Page 18

Transport

Safety Indications for Transport and Setting-up

18

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

5 Transport

5.1 Safety Indications for Transport and Setting-up

CAUTION

Risk of injury by lifting the unit!

The weight of the unit is more than 50 kg.

Do not lift the unit manually.

Always use proper auxiliary means such as a forklift or a jack lift.

CAUTION

Risk of damage by improper transportation!

Transport the unit in upright position.

Do not tilt the unit or expose it to impacts.

5.2 Transportation of the unit

The unit is delivered shrinked in foil on a transportable pallet. Leave the unit on the pallet until bringing it into

service. Use a forklift or jacklift for transportation to the installation location.

5.3 Unpacking

Remove the foil before setting up the unit.

Inspect the unit with regard to:

Damage caused by transportation

Completeness of delivery

Lift the unit with a forklift or jack lift off the transportable pallet.

Dispose of the packaging material in accordance with regional regulations

PLEASE NOTE

LAIRD advises to keep the transportable pallet for later transportation of the unit.

Page 19

Initial Operation

Safety Indications Related to Initial Operation

19

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

6 Initial Operation

6.1 Safety Indications Related to Initial Operation

CAUTION

Danger of malfunction caused by faulty connections during initial operation!

Before switching on the unit make sure that:

All safety equipment of the unit is implemented and functional.

All connections were properly made.

Nobody is endangered by the start-up of the unit.

Please follow the rules in chapter Safety Regulations on page 9.

6.2 Setting to Work

6.2.1 Placement

Fig. 8: Minimum clearance for air entrance and air exit

1

Ventilation grid

1) Move the unit to its installation location as mentioned in chapter 5.2

2) Place the unit in a way that air entrance and air exit are not obstructed. Wall clearance must not be less

than 0.5 m, otherwise cooling capacity may be restricted

PLEASE NOTE

In case of storage of the unit at temperatures lower than 5°C or higher than 40°C for longer periods please

wait 3 hours prior to initial operation to allow for temperature adjustment.

1

min. 0.5 m

min. 0.5 m

1

Page 20

Initial Operation

Setting to Work

20

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

6.2.2 Cooling Circuit Connection and Filling

CAUTION

Risk of damage by using improper cooling hoses!

This may lead to damage to persons, damage to the unit or corrosion damage.

When choosing cooling hoses pay attention to sufficient burst strength and compatibility with coolant.

Only use cooling hoses without any signs of damage.

The cooling hoses are connected to the unit by means of screwed hose nipples.

Oil inlet and oil outlet are indicated with respective symbols.

Fig. 9: Labelling of oil inlet and oil outlet

PLEASE NOTE

When operating the unit make sure only to use the operation coolant container cap. This cap allows for

pressure equilibrium in the cooling system (breathing). Save the transportation cap for later transportation

purposes (e.g. when sending the unit back for repair).

Oil Inlet

Oil Outlet

Page 21

Initial Operation

Setting to Work

21

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

Fig. 10: Operation cap, transportation cap, filler plug of coolant container

1

Operation cap

2

Transportation cap

3

Filler plug of coolant container

1) Unscrew the four screws of the unit cover using a metric AF10 wrench and remove the cover.

2) Remove the caps from the hose nipples of oil inlet and oil outlet.

3) Connect a hose to the hose nipples for oil inlet and oil outlet and secure it with a hose clamp,

respectively.

4) Connect the hoses to the corresponding nipples of the device to be cooled.

PLEASE NOTE

When connecting the cooling hoses pay attention to flow direction. Follow the documentation released by

the manufacturer of the device to be cooled.

5) Remove the transportation cap on the coolant container using an appropriate wrench.

6) Fill the coolant container with oil up to a filling level indicated roughly in the center of the inspection glass.

Use a funnel in order not to moisten any current-carrying components with oil

7) Close the coolant container using the operation cap supplied on delivery.

1

2

3

Page 22

Initial Operation

Setting to Work

22

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

6.2.3 Electrical Connections

DANGER

Danger to life by electrical shock when working on the electrical equipment of the unit!

Switch off the unit before starting your work!

Disconnect the unit from mains by pulling the mains plug!

Verify that the installation is dead (volt-free)!

Carry out earthing or short-circuiting!

CAUTION

Risk of damage through improper connections!

Improper integration of the unit into the safety circuit of the device to be cooled will lead to the

inoperativeness of the safety equipment listed in chapter 3.4.

All required connections must be incorporated according to the wiring diagram shown in the addendum.

Ensure that all connected safety equipment is properly functioning!

All tasks should be carried out only by expert staff.

PLEASE NOTE

The unit is delivered without a mains cable. The electrical connection as well as the integration into the

safety circuit of the device to be cooled are the customer’s responsibility and must be accomplished by

expert staff.

Information required can be taken from the specifications listed on page 16 and the wiring diagram

available in the addendum.

After implementing the mains cable connect the unit to mains by inserting the mains plug.

Page 23

Initial Operation

Daily Start-up

23

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

6.2.4 Carrying out Setting-to-Work

CAUTION

Lack of coolant may destroy the pump!

Operate the unit only when the filling level of the coolant container is correct!

Check the filling level of the coolant container regularly!

After connecting the cooling circuit, filling the coolant container and finishing the electrical connection follow

the steps below for the setting-to-work of the unit:

1) Open the stop valve.

2) Let the unit run for about 1 minute in order to de-aerate the pump.

3) Switch off the unit.

4) Close the stop valve.

5) Let the unit run for about 10 minutes in order to fill and de-aerate the cooling circuit.

6) Switch off the unit.

7) Check the filling level using the inspection glass. Fill up oil, if required, until a liquid level in the center of

the inspection glass. Use a funnel in order not to moisten any current-carrying components with oil.

8) Remount the unit cover.

DANGER

Danger to life by electrical shock caused by improperly mounted grounding washer!

Mount the grounding washer at the position of one of the four screws securing the unit cover!

Make sure that the screws are properly tightened!

This is to make sure that the grounding washer cannot get loose by vibrations during operation which could

lead to the situation of the unit cover carrying current.

9) Switch on the unit again and check the compliance with the operational parameters.

The unit is ready for use.

6.3 Daily Start-up

Switch on the unit about 1 minute prior to using the equipment that is to be cooled.

6.4 Setting-to-Work after Storage

Setting-to-work after storage will have to follow the same procedures as required for initial operation (see

chapter 6.2).

Page 24

Controlling the Unit

Safety Indications for Controlling the Unit

24

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

7 Controlling the Unit

The unit is controlled by using the controls of the equipment that is to be cooled.

All alarm and error signalling is only indicated on the control panel of the equipment that is to be cooled.

7.1 Safety Indications for Controlling the Unit

CAUTION

Lack of coolant may destroy the pump!

Operate the unit only when the oil filling indication on the coolant container is correct!

Check the oil filling indication regularly!

Also pay attention to the hints given in the chapter Safety indications on page 9.

7.2 Switching on the Unit

The unit is ready for switching on.

1) Switch on the unit about 1 minute prior to operation of the device to be cooled using the appropriate

control of that device.

2) Check the compliance with the required operational data according to the specifications listed on page

16.

The unit is running.

7.3 Switching off the Unit

1) Switch off the unit using the control of the device to be cooled.

2) Close all valves that may exist along the hoses running to and from the unit

The unit is out of operation.

Page 25

Controlling the Unit

Settings

25

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

7.4 Settings

The angle-type safety valve and the thermostat are set to the specified values by the manufacturer. Should

any modification be required, please follow the steps indicated below.

Fig. 11: Angle-type safety valve

1

Cover nut

2

Counter nut

3

Adjusting screw

4

Wrench to be used here for fixation

7.4.1 Pressure Setting on the Angle-type Safety Valve

PLEASE NOTE

A small amount of oil may leak from the valve.

The unit is switched off.

1) Loosen cover nut using a metric AF36 wrench and dismount. Use second wrench of the same size at

point 4 in Fig. 10 for holding the valve in place.

2) Loosen counter nut by turning it anticlockwise (use a AF36 wrench).

3) Set adjusting screw to the pressure value required:

Screwing in will increase the pressure setpoint.

Screwing out will decrease the pressure setpoint.

4) Tighten counter nut by turning it clockwise.

5) Re-install cover nut and tighten.

Pressure setting is accomplished.

6) Operate unit and check pressure.

If the intended pressure value is not yet reached, repeat the whole procedure.

1

2 3 2

4

Page 26

Controlling the Unit

Settings

26

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

7.4.2 Setting the Thermostat

Fig. 12: Thermostat

1

Knob of thermostat

Increase the temperature setpoint

1) Turn the knob clockwise.

The switch-off temperature is set to a higher value.

Decrease the temperature setpoint

1) Turn the knob counter-clockwise.

The switch-off temperature is set to a lower value.

1

Page 27

Disruptions

Disrupt Operation

27

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

8 Disruptions

8.1 Disrupt Operation

The most common reason for disrupt operation of the unit is improper maintenance. Maintenance should be

carried out regularly according to the maintenance intervals defined in chapter 9.

In case of disruption start with checking the follwing:

fan polluted or blocked?

coolant polluted?

Low coolant contents because of leakage, evaporation or an extended cooling circuit with long hoses?

More help can be found in the following paragraph.

In case you do not succeed in identifying the problem cause by means of this manual please contact the

service department of LAIRD.

8.1.1 Trouble Shooting

For trouble shooting you may rely on the follwing:

Alarm and error signalling within the safety circuit of the device to be cooled

Wiring diagram

Flow scheme

Trouble shooting table (see below)

Problem

Possible reason

Countermeasure

The unit does not start

Mains cable

plugged in?

Insert mains plug→ page 22

The unit is running, but

cooling capacity is not

available or too low

External hoses

sharply bent?

Pay attention to smooth bends when hoses are

connected

Unit properly

located?

Clearance to walls not less than 0.5 m → page 19

Coolant hoses

connected?

Connect hoses considering flow direction→ page 20

Is there flow in

cooling circuit?

Flow is signalled potential-free by the safety

equipment of the unit and can be visualized in the

range of controls of the device to be cooled.

Fan turning?

Cover the ventilation grid next to the fan with a sheet

of paper. If the paper is sucked and hold by the air

flow, the fan works properly

Ambient

temperature too

high?

Check specifications →page 16

Noisy unit

Contents in coolant

container low.

Refill coolant

Table 9: Trouble shooting list

Page 28

Maintenance and Cleaning

Maintenance Schedule

28

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

9 Maintenance and Cleaning

Diligent maintenance is the prime factor for assuring an error-free and efficient operation of the unit.

Operating personnel can perform these tasks when properly trained.

9.1 Maintenance Schedule

Device

Activityt

Interval

Criteria

Tools

Performer

Heat Exchanger

Clean

Minimum weekly

(if required, daily)

Plate fins and

ventilation grids

not polluted

AF10 wrench,

compressed-air,

vaccum cleaner

Operating

personnel

Coolant container

Check filling

Weekly

Coolant indication

in the center of

inspection glass

Funnel, measuring

cup

Operating

personnel

Coolant quality

Inspect

visually

Weekly

Absence of

cloudiness or

floating particles

Inspection glass

on coolant

container

Operating

personnel

Table 10: Maintenance schedule

9.2 Cleaning of Heat Exchanger

Cooling capacity is reduced to a large extend, if the heat exchanger is polluted. The heat exchanger must be

checked for pollution regularly and be cleaned, if required.

For cleaning the heat exchanger follow these steps:

1) Switch off the unit.

2) Unscrew the four screws holding the unit cover with a AF10 wrench and remove the cover.

3) Clean the heat exchanger using compressed air opposite to the direction of air entrance into the unit

(i.e. from the inside out).

4) Remove any pollution from the ventilation grids using a vacuum cleaner.

5) Remount the unit cover.

The unit is ready for operation.

9.3 Refilling of Coolant

Since the cooling circuit is an open circuit, evaporation of coolant may occur. Thus the filling level of the

coolant container has to be checked regularly, and coolant might have to be refilled as described in chapter

6.2.2 on page 20.

Page 29

Repair

Cleaning of Unit Casing

29

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

9.4 Cleaning of Unit Casing

CAUTION

Risk of damage due to the use of improper cleansing material!

When using aggressive or abrasive cleaning agents corrosion may occur as result of a damaged

paint film.

For cleaning the device casing only use mild cleaning agents (e.g.dish washing detergents)!

Use clean and lintless cloth for cleaning!

Regularly remove dirt from the casing of the unit to prevent corrosion damage and clogging of the air grids.

Pay attention that all the labels at the unit are always clean and legible.

10 Repair

PLEASE NOTE

Do not carry out any repair work on the unit. Send the unit back to the LAIRD service department (for

contact see page 7).

Page 30

Dismounting, Disposal, Storage

Temporary Placing out of Operation

30

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

11 Dismounting, Disposal, Storage

11.1 Temporary Placing out of Operation

For placing the unit out of operation for maintenance or repair follow the steps below:

1) Switch off the unit.

2) Close all valves that may be incorporated in the cooling circuit.

3) Disconnect all hoses to and from the unit.

4) Place a collection container of sufficent volume (23 liters minimum) close to the drain screw.

5) Loosen the drain screw with a 10 mm Allen key and remove it.

6) Let the coolant container run empty into the collection container. To empty the coolant container

completely the unit must be tilted.

PLEASE NOTE

The coolant has to be collected and disposed of according to applicable regulations.

7) Re-attach the drain screw and clean the unit.

The unit is placed out of operation.

11.2 Re-packaging the Unit

In order to prevent spilling of residual coolant from the coolant container during transport the transport cap

must be attached.

The unit has been switched off, emptied (see chaper 11.1) and the unit cover has been

removed.

1) Remove the operation cap from the coolant container.

2) Attach the transport cap.

3) Remount the unit cover.

4) Put the protection caps on the hose clamps.

5) Lift the unit with a forklift or jacklift and place the transportable pallet under it.

6) Enclose the unit including the transportable pallet with shrinking foil and shrink the foil tight.

The unit is ready for transportation.

11.3 Storing the Unit

The storage area must be even and the unit should not stand on an edge or other obstructive object.

The environmental conditions for storage of the unit or parts of it can be found in the specification paragraph

on page 16.

Page 31

Dismounting, Disposal, Storage

Disposal

31

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

11.4 Disposal

The unit was manufactured mainly from recycable material.

Make sure the components of the unit end up at a qualified company for disposal and recycling.

Contact LAIRD for take back of end-of-life units (see company contact on page 7) or ask a company

destined for disposal and recycling.

11.5 Disposal of Operating Materials

The operating materials of the unit can be hazardous to the environment and to health.

Make sure the operating materials are disposed of or recycled according to local regulations.

Also, the safety specifications of the coolant manufacturer must be obeyed.

11.6 Return of the Unit to LAIRD

PLEASE NOTE

Declaration of decontamination

Before re-shipment of the unit a declaration of decontamination must be sent to LAIRD.

Page 32

Wear Parts and Spare Parts

Return of the Unit to LAIRD

32

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

12 Wear Parts and Spare Parts

Spare parts must comply with the technical specifications defined by LAIRD. Original LAIRD parts are

subject to strict obligations and fulfill these requirements.

LAIRD does not provide warranty service in case of damages caused by the use of spare parts made by

manufacturers other than LAIRD.

PLEASE NOTE

Identification data concerning the unit and spare parts

The type of unit and the article number can be found on the identification plate of the unit. The

corresponding numbers shown in drawings 12 and 13 as well as the part description are listed in the spare

part list (table 11).

Please direct your inquiries and orders to LAIRD (contact see page 7) with the following detailed information:

Type of unit

Article number

Serial number

Part description

Quantity

Shipping details

Fig. 13: Spare part overview part 1

3

10

9

7

6

2

8

1

Page 33

Wear Parts and Spare Parts

Return of the Unit to LAIRD

33

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

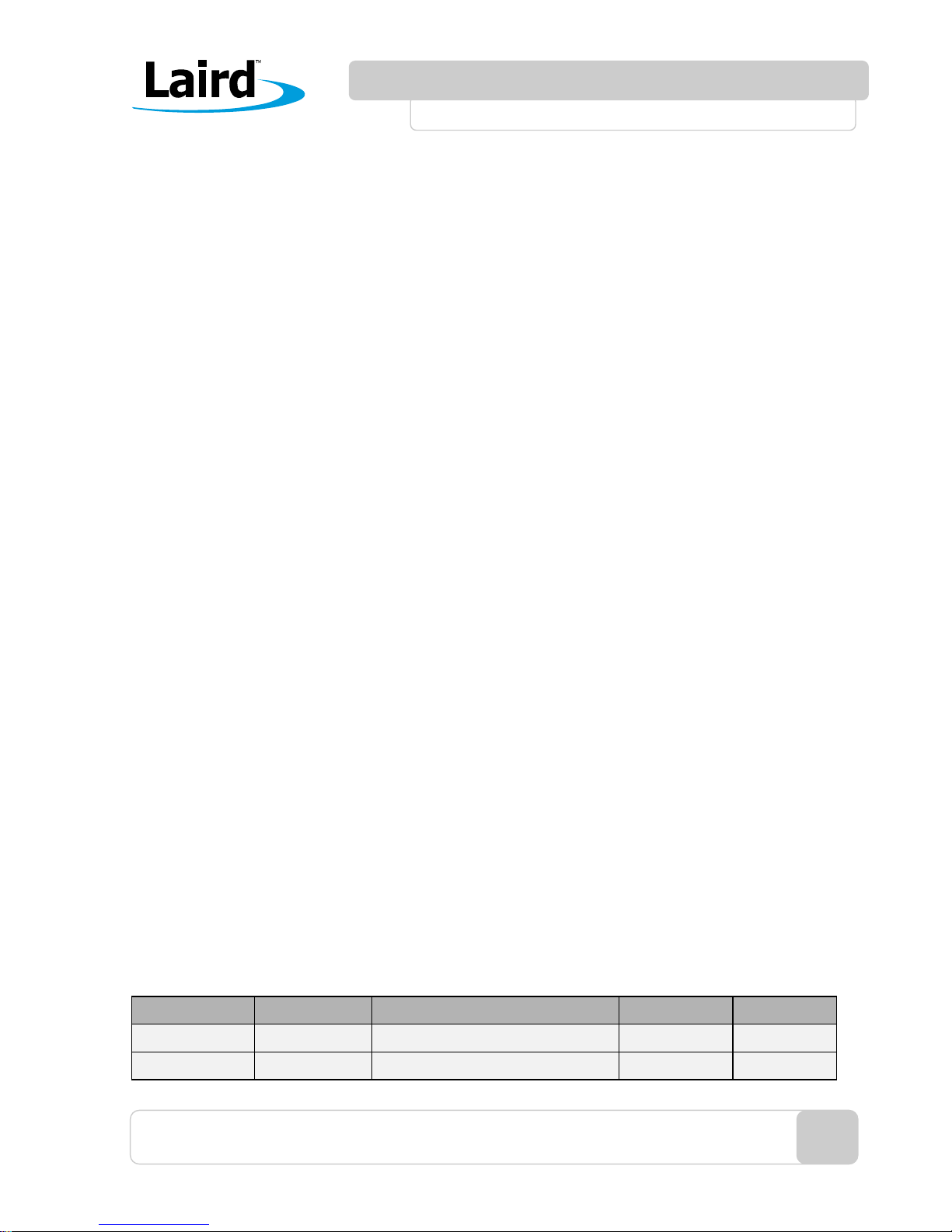

Fig. 14: Spare part overview part 2

Pos.

Qty

Description

Article No.

1 1 Motor pump unit KA1-26-230-2

95205237.00

2 1 Thermostat AMFS-13

95160001.00

3 1 Axial fan S4E 330-AP 18-31

95251655.00

4 1 Starter capacitor for fan

95290709.00

5 1 Starter capacitor for pump

95290735.00

6 1 Stop valve ¼“

96521001.00

7 1 Angle-type safety valve

96121014.00

8 1 Inspection glass

93300201.00

9 1 Flow switch

95140572.00

10 1 Control head for flow switch

95140567.00

Table 11: Spare parts

4

5

Page 34

Addendum

Performance chart

34

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

Addendum

Performance chart

Cooling capacity versus difference between entering air and supplied coolant temperatures

Leistungsdiagramm OL 4503

10

15

20

25

30

2,5 3 3,5 4 4,5 5 5,5 6 6,5

Leistung (KW)

D

t Temp. Lufteintritt / Öl-Vorlauf (°C)

Page 35

Addendum

Flow scheme

35

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

Flow scheme

Page 36

Addendum

Wiring diagram

36

Laird Technologies GmbH

Operation Manual (Translation)

Date: 06-Jul-2015

Version: 2.0

Oil-Air Cooling Unit OL 4503

1264.00

Wiring diagram

Loading...

Loading...