Page 1

Neo

EVERYTHING IS POSSIBLE NOW

USA

CAN

EN

Page 2

2

Page 3

Neo,

YOUR USEFUL SPACE.

BLAST CHILLING +194°F TO +37°F

SHOCK FREEZING +194°F TO 0°F

THAWING 0°F TO +37°F

5-STEP RETARDER PROOFING

SLOW COOKING UP TO +185°F

HOLDING AT SERVING TEMPERATURE +149°F

3

Page 4

Slow Cooking

Automatic

Cooking only

Cooking

+

Chilling

10 Nov 201610:15

Back

185°F

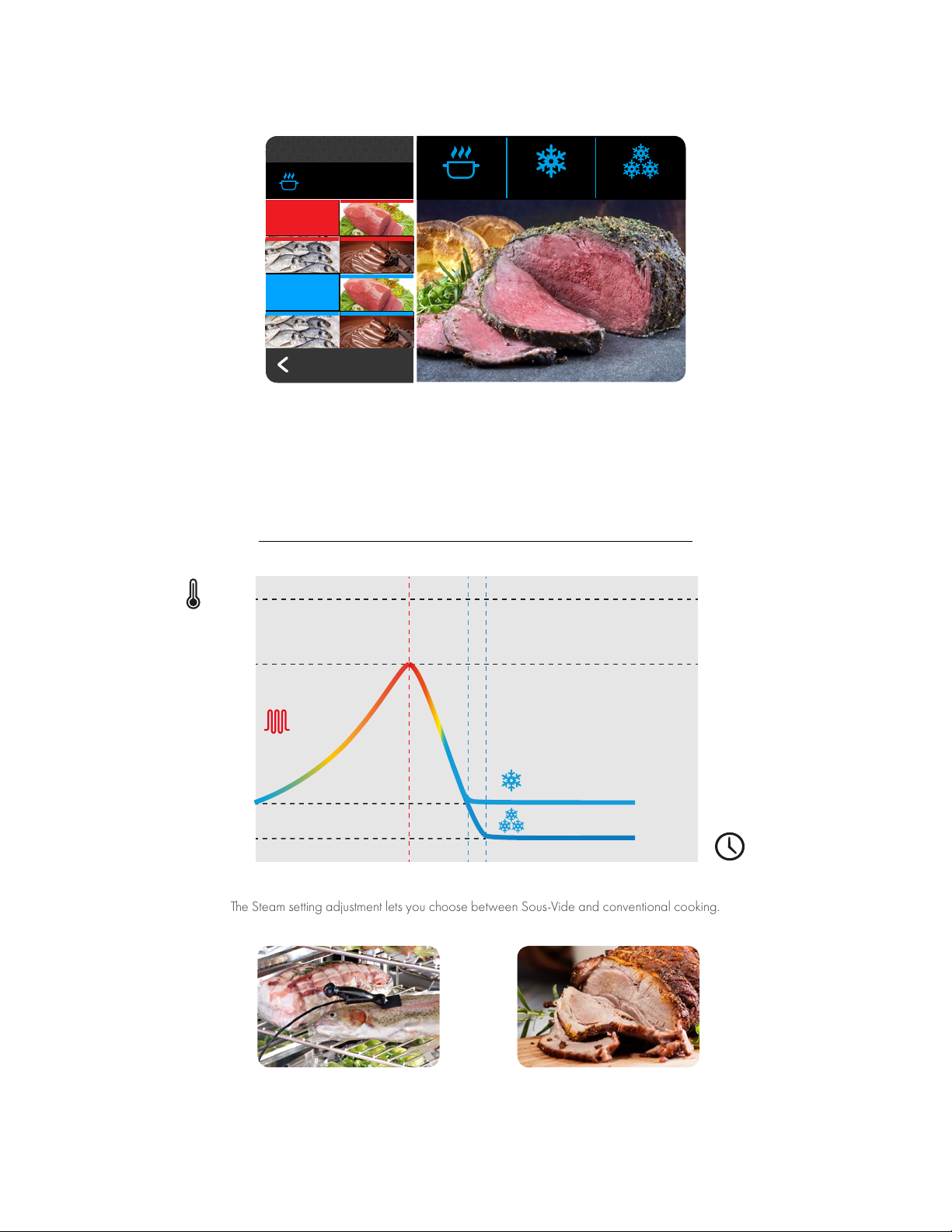

The Steam setting adjustment lets you choose between Sous-Vide and conventional cooking.

85°C

Cooking Blast Chilling Shock Freezing

TRUE COOK AND CHILL

WITH Neo.

149°F

65°C

COOKING

BLAST

37°F

3°C

-18°C

0°F

CHILLING

SHOCK

FREEZING

PRESERVING

+37°F

PRESERVING

0°F

4

Page 5

Neo

EVERYTHING AT YOUR FINGER TIPS.

AUTOMATIC USE MODE

Many recipes are categorized by type: meat, fish, vegetable, pasta, baking, breads, and creams.

Making it easy to identify which function to use.

ADVANCED USE MODE

Based on your needs, the chosen operation can be configured by modifying the cavity

temperature, Core Temperature, fan speed and time (duration) settings.

USER FRIENDLY

The interface is simple and intuitive thanks to icon driven menus.

CUSTOMIZABLE RECIPES (My recipes)

You have the possibility to create groups of recipes customized to your preferences.

TOUCH SCREEN CONTROLS

7” High Definition, capacitive color screen, with touch screen functions.

USB PORT

Upload and download recipes.

Download HACCP data.

5

Page 6

Blast Chilling

Back

10 Nov 201610:15

Blast chilling to the core of a product produces a thermal shock, this prevents the bacterial

proliferation that causes food to age, so food retains quality longer.

BLAST CHILLING

+194°F TO +37°F

ADVANTAGES:

- PREPARATION IN ADVANCE

Blast Chilling allows preparation to be planned and

prepared in advance increasing productivity.

- SHELF LIFE

Food can be safely kept fresh for 4-5 days

and in full compliance with HACCP standards.

- CONSISTENT QUALITY

By preserving the optimum moisture and limiting the amount of liquid lost,

food stays as soft as if it had just come out of the oven.

- ECONOMIC ADVANTAGES

6

Food cost is constantly under control by minimizing waste. Food is viable for service for

a longer duration of time and less shrinkage occurs from moisture loss.

- BETTER SERVICE

You can more effectively organize your time and work flow to increase the speed

and efficiency of service without Sacrificing quality.

Page 7

Shock Freezing

Back

10 Nov 201610:15

A standard freezer freezes food slowly allowing the formation of macro crystals in liquids which damage the cellular structure

and subsequently cause the loss of consistency and product quality then deteriorates during thawing.

NEO, however, rapidly lowers the core temperature of any food to 0°F with the formation of micro crystals which do not damage

the structure of the product. This means that a top quality product is still viable after thawing as well.

SHOCK FREEZING

+194°F TO 0°F

ADVANTAGES:

- PREPARATION IN ADVANCE

Shock freezing allows work to be organized for advanced preparation,

separating the preparation phase from the plating phase.

Essential, for example, when preparing ice cream or baked goods.

- CONSISTENT QUALITY

Less shrinkage is realized because liquids are preserved, so food maintains its taste,

color and texture and keeps its nutritional value.

- ECONOMIC ADVANTAGES

An extended or more varied menu is now possible with NEO.

Products can be purchased when they are in season, cost less, or in greater quantities;

all of which can be preserved perfectly and used for food preparation all year round.

With no waste and no extra costs

.

7

Page 8

START

small

size

medium

size

large

size

Advanced Mode

Thawing

Automatic

Back

10 Nov 201610:15

Being able to check and decide on the thawing of a product with a specific function means retaining the integrity of taste,

nutrition, and texture optimizing inventory control and avoiding unnecessary waste.

THAWING

0°F TO +37°F

ADVANTAGES:

- THE RIGHT TIME

Quick thawing at a controlled temperature reduces waiting times for preparation stages,

and guarantees the quality and sanitation of the food, whether raw, par-cooked or frozen.

≤ 1.97”

≤ 50 mm

68°F

60’

1.97” ÷ 3.94”

50 ÷ 100 mm

77°F

240’

> 3.94”

> 100 mm

SMALL PORTIONS MEDIUM PORTIONS LARGE PORTIONS

- SAFE FOODS

Thawing takes place in complete safety and in full compliance with the HACCP standard the

micro crystals of moisture are returned to their natural state, leaving a superior product.

It is the ideal function for any product to be served raw or cold, such as fish

or baked items because it does not damage the molecular structure.

- CONSISTENT QUALITY

- ECONOMIC ADVANTAGES

This means that you can slack semi-processed or finished products in relatively short amounts of time

8

with the highest quality and just the right quantities required, optimizing food costs.

86°F

360’

Page 9

Leavening

Leavening Retarder

Automatic

Back

Manual

10 Nov 201610:15

Controlled proofing is used for bread and baking mixes

by managing the temperature, moisture and timing.

PROOFING AND RETARDING

5-STEP RETARDER PROOFING

86°F

30°C

32°F

0°C

14°F

-10°C

BLOCK

variable duration

ACTIVATION RISING

ADVANTAGES:

- ADVANCED PREPARATION

Baked or bread products can be worked right through to their final phase and before baking,

they can be retarded or delayed for cooking at a later time.

DELAY BAKINGSTORAGE

- GUARANTEED QUALITY

Thanks to the exclusive manual proofing function with moisture management,

a high standard of quality is obtained.

- ECONOMIC ADVANTAGES

With delayed preparation, night shifts may be eliminated. The flexibility of producing “Just in Time” is the best way

to optimize resources, manage time and respond to the variables in requests.

No added costs for surplus semi-processed preparations

- BETTER SERVICE

The major advantage is that products are available for cooking immediately in the event of unexpected emergencies.

9

Page 10

Slow Cooking

Automatic

Cooking only

Cooking

+

Chilling

10 Nov 201610:15

Back

COOK AND CHILL

NEO can be used without a problem even after hours.

Your kitchen can work 24 hours a day without a break.

UP TO +185°F

ADVANTAGES:

- ADVANCED PREPARATION.

After the day shift, it can be used when the kitchen is idle, overnight for slow cooking.

It can be programmed for +37°F Blast chilling or 0°F Shock freezing after cooking.

- QUALITY

Slow cooking protects not only the flavor and taste, but also the succulence and tenderness,

especially of large portions of meat with excellent results.

- ECONOMIC ADVANTAGES

A measurable reduction in shrinkage means an economic advantage which

is extremely important in sales by weight (delicatessens and butchers).

More portions equal enhanced earnings.

10

- BETTER SERVICE

The flexibility of this function means you can organize your work better,

since you always have an important kitchen aid on hand to help you.

This cycle can be used in bakeries too for melting chocolate or candying fruit.

Page 11

65°C

Advanced Mode

Phase 1

Phase 2

HOLD

Back My recipes

Cookbook

10 Nov 201610:15

TEMPERATURE HOLDING

Another exclusive function of NEO is in addition to cooking at low temperatures,

it can be used to hold food at serving temperature throughout serving hours.

+149°F

+149°F

ADVANTAGES:

- QUALITY

The exclusive functionality of NEO guarantees the highest quality

in full compliance with the HACCP standard.

- ECONOMIC ADVANTAGES

The economic advantage lies in the availability, with no additional costs, of a holding cabinet.

- BETTER SERVICE

It is an essential aid for improving organization and preparation.

There is nothing worse than working hard to find the best ingredients and transforming them

into a dish that is then served to the customer at the wrong temperature.

11

Page 12

Neo,

SIMPLIFYLING THE USE OF ACCESSORIES

- HEATING THE CORE PROBE

A practical solution for removing the core probe after a Shock freezing cycle to 0°F.

AUTOMATIC DEFROSTING

Function for automatically defrosting the cavity.

- PRECHILLING

A dedicated icon for this useful function before starting a blast chilling or Shock freezing cycle.

- DRYING

Using a drying cycle is recommended before you start cooking delicate products, such as meringues, at low temperature.

It is also important to prevent the formation of molds and unpleasant odors after cleaning.

- ANISAKIS KILLER -4°F

A dedicated program with a specific icon for activating a sanitization cycle for fish that is to be eaten raw.

- CONTINUOUS CYCLE/MULTI-LEVEL

With the Continuous Cycle function, you can activate the multi-level function on the display with the

possibility of choosing up to eight timers and assigning the holding time in the cavity on each level.

- WASHING THE CAVITY

NEO can be equipped with a quick-fit, practical shower head fitting (optional) for washing the cavity.

12

Page 13

Neo,

FOR ALL NEEDS.

THE RANGE

A range for a system that completes and multiplies

functions at all levels of the catering sector.

051/054 081/084 121/ 124 161/ 164 122

Distance

Models Capacity

NEOG051

NEOG054

NEOG081

NEOG084

NEOG121

NEOG124

NEOG161

NEOG164

NEOG122

NEOG… = For gastronomy and pastry

5 x GN 1/1

5 x GN 1/1

5 x 26 x 18”65[2.56]

9 x GN 1/1

8 x GN 1/1

8 x 26 x 18”65[2.56]

12 x GN 1/1

12 x GN 1/1

12 x 26 x 18”65[2.56]

17 x GN 1/1

16 x GN 1/1

16 x 26 x 18”65[2.56]

12 x GN 2/1

btw

Layers

mm / [inch]

60

[2.36]

60

[2.36]

60

[2.36]

60

[2.36]

60

[2.36]

Blast chilling

capacity in 90'

+194°F > +37°F

bs / [Kg]

L

40 / [18] 26 / [12] 1,430 500

40 / [18] 26 / [12] 1,052 500

55 / [25] 35 / [16] 2,108 1,000

55 / [25] 35 / [16] 1,745 1,000

79 / [36] 53 / [24] 4,807 1,600

79 / [36] 53 / [24] 1,680 1,600

121 / [55] 79 / [36] 7,061 1,600

121 / [55] 79 / [36] 2,495 1,600

159 / [72] 106 / [48] 9,986 1,600

Shock freezing

capacity in 240'

+194°F > 0°F

bs / [Kg]

L

Cooling

power

(1) - (W)

Heating

power

(W)

External dimensions

W x D x H mm / [inch]

790 x 720 x 850

[31.1 x 28.3 x 33.5]

850 x 760 x 850

[33.5 x 29.9 x 33.5]

790 x 820 x 1320

[31.1 x 32.3 x 52.0]

850 x 850 x 1320

[33.5 x 33.5 x 52.0]

790 x 820 x 1800

[31.1 x 32.3 x 70.9]

850 x 850 x 1800

[33.5 x 33.5 x 70.9]

790 x 820 x 1950

[31.1 x 32.3 x 76.8]

850 x 850 x 1950

[33.5 x 33.5 x 76.8]

1100 x 1050 x 1800

[43.3 x 41.3 x 70.9]

Cooling

power

abosorption

(2) - (kW)

1.1 0.6 5.5

1.1 0.7 5.5

1.4 1.1 6 .1

1.8 1.2 7. 4

3.2 1.8 7. 4

2.7 1.8 12.4

4.5 1.9 9.2

4.0 1.9 16.8

6.0 1.9 13.8

Heating

power

absorption

(kW)

(1) T.evap.= -13°F / T.cond.= +113°F

(2) T.evap.= +5°F / T.cond.= +131°F

Consumption

(Amps)

Power supply

voltage

1ph / 208V / 60 Hz

1ph / 208V / 60 Hz

1ph / 208V / 60 Hz

1ph / 208V / 60 Hz

3ph / 208V / 60 Hz

3ph / 208V / 60 Hz

3ph / 208V / 60 Hz

3ph / 208V / 60 Hz

3ph / 208V / 60 Hz

13

Page 14

Neo

USAGE

• Blast chilling +194 / +37°F

• Schock freezing +194 / 0°F

• Thawing 0 / +37°F

• 5-step retarder proofing

• Slow cooking at low temperatures up to +185°F

• Holding at serving temperature at +149°F

OPERATION

• 7” high definition, capacitive, colour screen (LCD - TFT - IPS) with

choice of “Touch Screen” functions. All the processes are displayed

with specific icons for each type of food, meat, fish, baked items, etc.

and activated by touching the icon.

• Multi-point heated core probe, (4 detection points)

• USB connection for Upload and Download

• Automatic defrosting cycles

• Integrated recipe book “My recipes”

• Cell pre-cooling

• Drying

• Continuous cycle

FEATURES

CLEANING MAINTENANCE

• Manual washing with external, quick-fit shower head (optional)

CONTROLS AND SAFETY

• Standard fitted water inlet valve

• Thermal protection to safeguard the compressor.

• Microswitch cuts off the internal fan when the door is opened.

CONSTRUCTION

• External side panels and top in AISI 304 18/10 stainless steel.

• Door in AISI 304 18/10 stainless steel.

• Inner lining with rounded corners in AISI 304 18/10 stainless steel.

• Leak-proof inner floor.

• High-density expanded polyurethane insulation (about 2.62 lb/ft

thickness 2.36”, HCFC-free.

• Anti-condensation heating element on the body below the magnetic

seal stop.

• Full width, horizontal ergonomic handle and magnetic seals on all

four sides of the door.

• Patented system for injecting humidity into the cell.

•

Removable guide rail supports in AISI 304 18/10 stainless steel.

• Removable, L-shaped guide rails in AISI 304 18/10 stainless steel,

can be slotted in every 0.59”.

3

COOLING UNIT CONSTRUCTION

• Electric fans with indirect flow onto the food.

• Sealed compressor.

• R452A refrigerant gas.

• High performance evaporator with multiple gas injection points

• Copper-aluminium evaporating and cataphoretic paint coating with

non-toxic epoxy resin.

• Copper condensing coil with high heat yield aluminium fins.

• Patented hot gas defrost system.

• Energy-free, defrosting and condensation evaporation system

ADDITIONAL ACCESSORIES

),

• Kit of swivel wheels with brake

14

Page 15

15

Page 16

LA90034060 - USA/CAN EN - 11/2017 - 0000

LAINOX ALI S.p.A.

Via Schiaparelli 15

Z.I. S. Giacomo di Veglia

31029 Vittorio Veneto (TV) · Italy

Tel +39 0438 9110

Fax +39 0438 912300

lainox@lainox.com

www.lainox.com

an Ali Group Company

The information contained in this document is to be considered non-binding. Lainox ALI S.p.A. reserves the right to make changes at any time without prior warning

The Spirit of Excellence

Loading...

Loading...