Lainox Naboo Compact CVEN061, Naboo Compact CVES061, Naboo Compact CBEN061, Naboo Compact CBES061, Naboo Compact COEN061 Owner's Manual

...Page 1

Compact by Naboo

Compact by Sapiens

Heart

Gas-Fired or Electric

Combi Oven/Steamer

OWNER'S

MANUAL

90028771rev00

Page 2

2

90028771rev00

Page 3

FOR YOUR SAFETY

Do not store or use

gasoline or other

flammable vapors or

liquids in the vicinity of

this or any other appliance.

FOR SAFE AND EFFICIENT OPERATION OF THIS EQUIPMENT, THIS MANUAL MUST BE

RETAINED BY THE OWNER/USER FOR FUTURE REFERENCE.

GAS LEAK INSTRUCTIONS

Post in a prominent

location, instructions to

be followed in the event of

user smelling gas.

This information shall be

obtained by consulting the

local gas supplier.

WARNING

Improper installation,

adjustment, alteration

service or maintenance

can cause property

damage, injury or death.

Read the installation,

operating and maintenance

instructions thoroughly

before installing or

servicing this equipment.

WARNINGS

WARNING

DEATH, INJURY, AND EQUlPMENT DAMAGE could result from improper installation

of the Oven/Steamer, or from installation of a unit damaged during shipment or

storage. Either of these conditions could also void the equipment warranty. DO

NOT INSTALL a Oven/Steamer suspected of damage.

Install the Oven/Steamer according to the policies and procedures outlined in this

manual.

WARNING

NEVER EXCEED 14”/355.6 mm WATER COLUMN (1/2 psi) GAS PRESSURE.

If the gas supply pressure exceeds 14”/355.6 mm water column, a pressure

regulating valve must be installed in the gas supply plumbing to reduce the gas

pressure to less than 14”/355.6 mm water column.

WARNING

Using water not within the limits specified in this manual could void or adversely

affect the warranty coverage of the Oven/Steamer.

WARNING

The flooring directly under this unit must be made of non-combustible material.

WARNING

CAUTION - To reduce the risk of the fire, the appliance is to be installed in non-

combustibile surroundings only, with no combustibile material within 18 inches of

the sides, front, or rear of the appliance or within 40 inches above the appliance.

The appliance is to be mounted on floors of noncombustibile construction with

noncombustibile flooring and surface finish and with no combustibile material

against the underside, or on no combustibile material against the undrside. Such

construction shall in all cases extend not less than 12 inches beyond the equipment

on all sides.

3

90028771rev00

Page 4

WARNINGS

WARNING

All clearance requirements above, below, and around the unit are the same

for combustible or non-combustible locations.

Maintain at least 20”/500 mm clearance on the right of the unit.

Maintain at least 10”/254 mm clearance at the rear of the unit.

Maintain at least 40”/1000 mm clearance above the unit.

WARNING

Malfunctions and equipment damage may result from improper mounting.

Malfunctions and/or damage resulting from improper mounting are not covered

by the equipment warranty. The Oven/Steamer MUST BE LEVEL BOTH FRONT TO

BACK AND SIDE TO SIDE in all mounting arrangements.

Equipment damage may result from shifting the Oven/Steamer more than 3° out of

level while power is turned on.

WARNING

INJURY AND EQUIPMENT DAMAGE could result from improper lifting. Refer to the

appropriate dimension and check the weight of the unit being installed.

Use enough workers with experience of lifting heavy equipment to place the

Oven/Steamer on the supporting surface.

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE could result from improper installation

of the drain outlet lines.

Improper installation of these lines could void the Oven/Steamer warranty.

The following restrictions are critical to the safety of personnel and equipment, and

must not be violated under any circumstances.

Do not connect the drain line into PVC pipe, or any other drain material

that cannot sustain 180 °F/82 °C.

Do not connect drains from any other equipment to the Oven/Steamer drain line.

Do not connect the drain outlet extension line directly to a floor drain or sewer line.

Do not block drain vents at the top of the unit (

).

4

90028771rev00

Page 5

WARNINGS

WARNING

DO NOT TRY TO LIGHT THE BURNERS OR PILOT WITH A FLAME.

THERE IS NO PILOT TO LIGHT OR ADJUST.

Ovens/Steamers have electronic ignition systems which automatically light the

burners, sense the flame, and control gas flow. This provides both precise burner

control and safety ignition and shutdown features.

DEATH, INJURY OR EQUIPMENT DAMAGE may result from an improperly adjusted

gas control and ignition system. Do not alter any adjustments on this electronic

control or solenoid valve. If adjustment is required, contact an authorized service

center. The Manufacturer is in no way responsible for the operation or safety of this

equipment if the controller, valve, or igniter probe are adjusted by anyone other

than a authorized service representative.

WARNING

Equipment damage and faulty operation will result if the gas, water, or electrical

supplies fall below requirements. This may be caused by other equipment on the

same supply lines. During all tests, adjustments, and inspection of the Oven/

Steamer, turn on all equipment drawing on the same supply lines.

WARNING

DO NOT ATTEMPT TO START OR OPERATE a Oven/Steamer during

a power outage. Critical safety circuits are not energized, and serious injury to

personnel or damage to equipment may result.

DEATH, INJURY, AND EQUIPMENT DAMAGE could result from improper operation

of the Oven/Steamer.

Be sure oven/steamer has been installed correctly according to the installation

instructions in Chapter 2 before starting operation.

5

90028771rev00

Page 6

WARNINGS

WARNING

For these appliances, the state of the metal components in direct contact with the

source of heat must be checked. It is therefore advisable to make an annual visual

check on the combustion chamber.

This precaution is sufficient to prevent any irreparable damage to the appliance.

WARNING

Steam leaks around the door, cooking compartment flooding, reduced cooking

performance, and compartment implosion can be caused by a blocked drain or

drain screen. Inspect and clean the drain and drain screen before each use.

Never operate the steamer without the screen in place.

WARNING

Do not use flammable cleaning agents to clean the Oven/Steamer, or in the vicinity

of this appliance.

WARNING

Avoid any operation which leads to cooking salt being deposited on the steel

surfaces of the oven. Should this happen, clean thoroughly and immediately.

WARNING

Before using your new appliance clean out the oven carefully. Do not use acids

or corrosive cleaners, wire wool or brushes to clean either the oven cavity or the

appliance cabinet (use warm water with a suitable detergent).

WARNING

Inside of oven/steamer stays hot for a long time. Be careful when cleaning inside

oven/steamer compartment.

WARNING

Oven cleaners are caustic and if wrongly used can irritate the skin and eyes.

Always follow the Manufacturer’s instructions to the letter.

6

90028771rev00

Page 7

WARNINGS

WARNING

Let rinse water drain through compartment drain opening. If water does not drain

freely, drain lines must be cleaned before cooking again. Clogged or slow drains

are dangerous because hot water can collect in compartment and spill out when

opening compartment door.

WARNING

DEATH, INJURY, OR EQUIPMENT DAMAGE may result from improper service or

maintenance practices. Always turn the main power switch to OFF for any unit before

starting service, maintenance or repairs.

WARNING

Steam leaks around the door, cooking compartment flooding, reduce cooking

performance, and compartment implosion can be caused by a blocked compartment

vent, or a blocked drain or drain screen. Inspect and clean the compartment vent,

drain and drain screen before each use.

Never operate the oven/steamer without the screen in place.

WARNING

The liquid phosphoric acid in descaling can be harmful if not handled properly.

Follow these basic safety rules for handling and using acid.

Wear protective clothing when mixing or applying chemical cleaners. Wear rubber

gloves, mask and approved cup-type goggles.

Avoid breathing fumes. If liquid comes in contact with skin, flush immediately with

large quantities of cold water. Remove contaminated clothing.

If chemical contacts eyes, flush with cold water for a minimum of 15 minutes.

Get immediate medical attention.

If chemical is swallowed or ingested, follow instructions on the chemical container.

Get immediate medical attention.

WARNING

DEATH, INJURY, OR ELECTRIC SHOCK can occur by touching electrical

components and wires inside the access panel when the main power switch is in

the ON position. NEVER REMOVE THE SERVICE ACCESS PANEL.

Allow only Authorized Service Representatives to perform service, maintenance,

and repairs that require the removal of the service access panel(s).

7

90028771rev00

Page 8

WARNINGS

WARNING

DEATH, INJURY, OR ELECTRIC SHOCK can occur by touching electrical,

components and wires inside the access panel when the main power switch is in

the ON position. NEVER REMOVE THE SERVICE ACCESS PANEL.

Allow only Authorized Service Representatives to perform service, maintenance,

and repairs that require the removal of the service access.

WARNING

This appliance has more than one power supply connection point. Disconnect the

power supply before replacing fuses.

ONLY FOR DOUBLE STACK VERSION

WARNING

WHEN APPLIANCE IS PROVIDED WITH CASTERS

-RISK OF ELECTRIC SHOCK-

APPLIANCE MUST BE SECURED TO BUILDING STRUCTURE.

SEE INSTALLATION INSTRUCTION

NOTICE

When this appliance is installed with casters, it must be installed with the casters

supplied, a connector complying with either ansi z21.69-csa 6.16 and a quick-

disconnect device complying with ansi z21.41-csa 6.9.

it must also be installed with restraining means to guard against transmission of

strain to the connector, as specified in the appliance manufacturer’s instruction.

The casters with brake must be on the front of the appliance

8

90028771rev00

Page 9

PROTECTING WARRANTY COVERAGE

The warranty printed to the left specifies the owner/user’s responsibility for proper

installation, operation and maintenance of the Combi Unit.

If these responsibilities are not met, the Limited Warranty and/or Extended Limited

Warranty coverage may be adversely affected.

The following table is provided to assist the owner/user in meeting these responsibilities. In

addition, the warranty advantages of installing a Steamer Gard water treatment system are

explained after the table.

The Warranty Protection Table lists installation, operation, and maintenance factors that

have in the past adversely affected warranty coverage.

The owner/user of a Combi Unit should pay particular attention to these factors to protect

his warranty coverage.

This table is not a comprehensive list of the owner/user’s responsibilities.

The Steamer are intended for use only by professionally trained personnel.

To meet his responsibilities, the owner/user must supplement this guide with any additional

actions consistent with the operation of steam generating food preparation equipment by a

trained professional.

9

90028771rev00

Page 10

TABLE OF CONTENTS

Chapter Page

CHAPTER 1. PRODUCT IDENTIFICATION 12

MODEL NUMBER 12

PRODUCT TAGS 12

IDENTIFICATION PLATE 12

OVEN MODELS AND VERSION 13

TECHNICAL DATA 14

CHAPTER 2. INSTALLATION INSTRUCTIONS 15

INTRODUCTION 15

INSTALLATION POLICIES 15

INSTALLATION OVERVIEW 16

INSTALLATION DIAGRAM NOTES 19

INSTALLATION DIAGRAMS 20

PREPARATION FOR INSTALLATION 33

Unpacking and Inspection 33

Shipping Damage Instructions 33

Protecting The Oven / Steamer 33

Electric Power Requirements 34

Gas Supply Requirements 34

Water Quality Requirements 34

Softened, Treated, or Filtered Water 35

Water Supply System 36

Selecting The Operating Location 36

INSTALLATION INSTRUCTIONS 38

Position and Level the Oven/Steamer 38

Leg Mounting and Leveling 39

Assembly 39

Positioning and Leveling 40

Appliance equipped with casters 41

Install and Connect the Free Air Vented Drain Lines 42

Exhaust Port Ventilation 45

Install Electric Power Line 46

Connect Electrical Line 47

Install and Connect Water Supply Lines 48

Testing Water Supply Lines 50

Install and Connet Gas Supply Lines 50

Testing Gas Supply Lines and Burner Controls 51

Pressure Testing The Gas Supply Lines 51

Testing the Automatic Gas Valve and Burner Control System 52

Start-Up Check List 54

Initial Operation and Cleaning 56

Lighting Instructions 57

Shutdown Instructions 57

10

90028771rev00

Page 11

TABLE OF CONTENTS

CHAPTER 3. PREVENTIVE MAINTENANCE AND TROUBLESHOOTING 58

INTRODUCTION 58

MAINTENANCE RECORDS 58

DAILY MAINTENANCE 59

Blowdown Steam Generator 59

Cleaning 59

Inspect the Cooking Compartment Vent 59

WEEKLY MAINTENANCE 59

Clean Drain 59

Descale Steam Generator 60

Health Hazard Data, effects of Overexposure 60

Emergences and First aid Procedures 60

Troubleshooting notes 63

11

90028771rev00

Page 12

The Manufacturer assigns two product identification numbers to each Oven/Steamer:

a model number and a serial number. The model number identifies the product

characteristics. The serial number identifies the individual unit (Figure 1-1).

MODEL NUMBER

This manual covers all models (for capacit in units): each model electric or gas-fired with

or without steam generators.

Each character of a model number identifies a characteristic of the oven/steamer.

The model number begins with CBE.. (with steam generator, “E” means electric) or

CVG.. / CVE.. or COE.. (without steam generator, “E” or “G” means electric or gas-fired),

followed by a number for capacity in units. This manual covers all standard features and

options available on the Oven/Steamer models listed above.

Other than selection of options, there are presently no significant design, parts, or

operating differences among oven/steamers with the same model number.

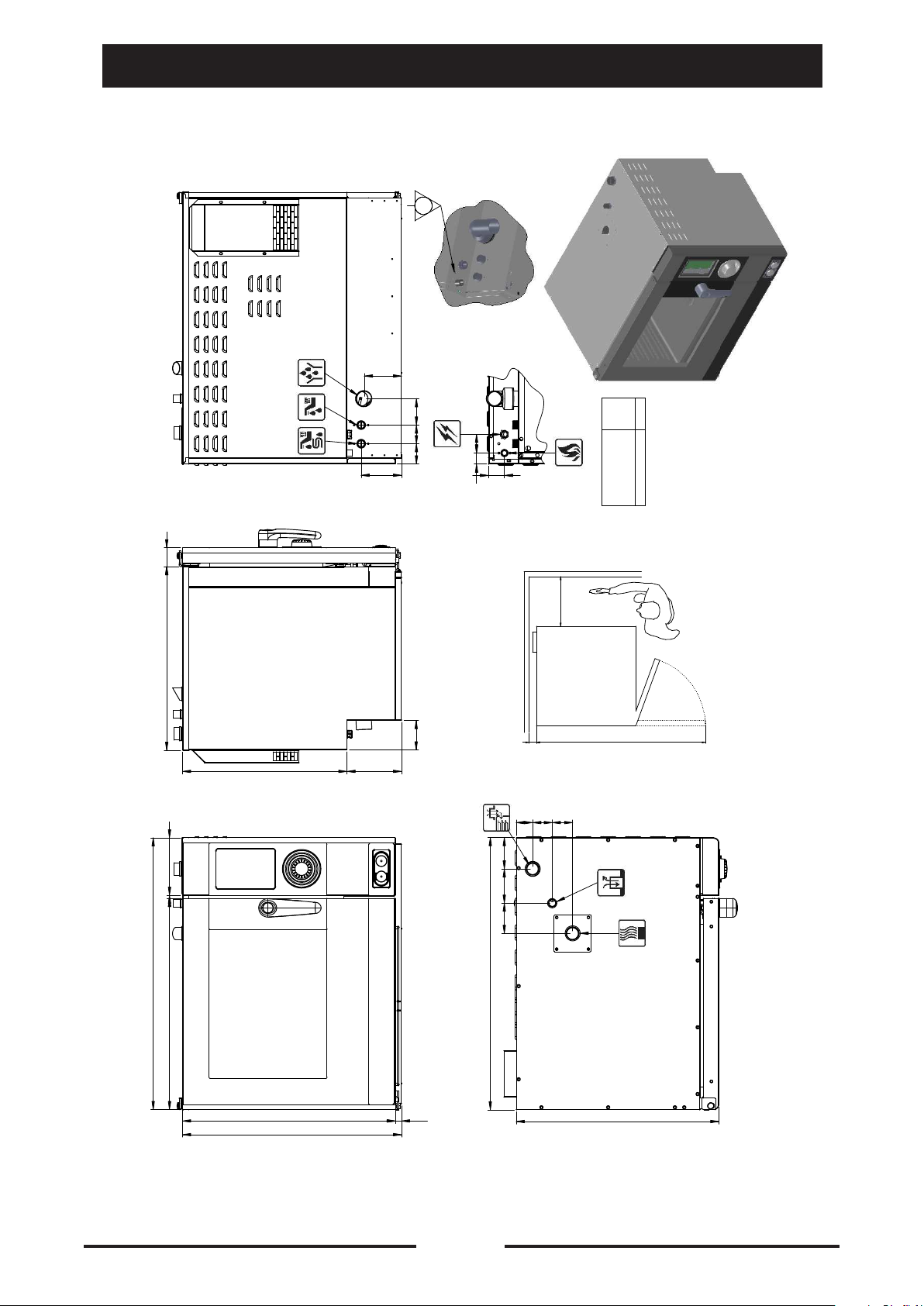

Figures 1-2 illustrate the models and identify the major components.

CHAPTER 1. PRODUCT IDENTIFICATION

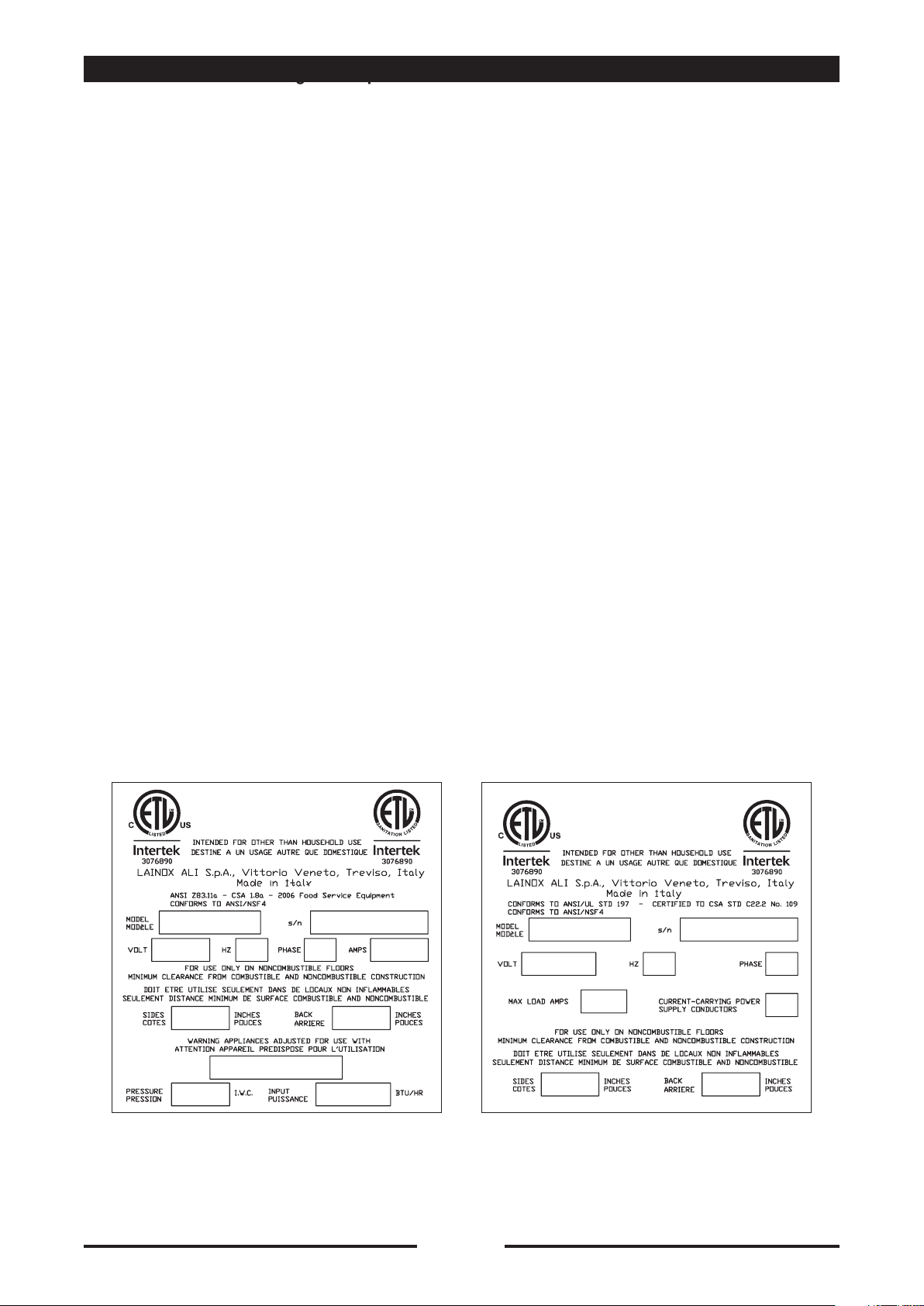

PRODUCT TAGS

Before shipping, each single unit is furnished with different tags which give you

information on appliance operation. These tags are located on the lower right side of the

unit close to the identification plate.

IDENTIFICATION PLATE

Figure 1-1 illustrates typical Identification Plates.

The plate is located on the right side of each unit as illustrated in Figures 2-1.

The Identification Plate lists the model number, gas supply requirement, power

requirements, and wiring requirements of each Oven/Steamer.

Figure 1-1. Identification Plate

12

90028771rev00

Page 13

OVEN MODELS AND VERSIONS

MODELS

CVGN 061

gas rating power BTU 29.000 (8,5 kW)

CVGS 061

MODELS

CVEN061 /CBEN061

CVEN061 /CBEN061

COEN026

COES026

COEN061

COES061

COEN101

COES101

rating power kW 8,25

rating power kW 5,25

rating power kW 7,75

rating power kW 15,5

COMPARTMENT CAPACITY

6 trays 12”x20”x21/2” max. recommended load 53 lbs. of food

COMPARTMENT CAPACITY

6 trays 12”x20”x21/2” max. recommended load 53 lbs. of food

6 trays 12”x14”x21/2” max. recommended load 36 lbs. of food

6 trays 12”x20”x21/2” max. recommended load 53 lbs. of food

10 trays 12”x20”x21/2” max. recommended load 88 lbs. of food

13

90028771rev00

Page 14

TECHNICAL DATA

Model

CVGN061 / CVGS061 BTU 29.000 - kW 8 4

Model

CVEN061 / CVES061

CBEN061 / CBES061

COEN026 / COES026 5,25

COEN061 / COES061 7,75

COEN101 / COES101 15,5

Nominal Rating

BTU/kW

Power Rating

kW

8,25

Consumption

Amps

Voltage

AC 208V

3 AC 208V

3 AC 480V

AC 208V

3 AC 208V

3 AC 480V

AC 208V

3 AC 208V

3 AC 480V

3 AC 208V

3 AC 480V

Water Pressure

kPa/Psi

200 500 kPa

35 60 Psi

Max load

V

Amps

40

30

13

25

16

7

37

23

10

46

20

Consumption

softened water

max. Liter/hr

8

Consumption

softened water

max. Liter/hr

8

8

8

8

8

8

8

8

8

8

8

Connecting wires type: use copper wires only.

*

14

14

90028771rev00

90028771rev00

Page 15

CHAPTER 2. INSTALLATION INSTRUCTIONS

This manual and several components are packaged inside the during shipment. To

access these packages, the shipping crate has been disassembled.

Discard the shipping crate and protect the from dirt and damage during storage, site

preparation, and installation as described in “Protecting The Oven/Steamer.

WARNING

DEATH, INJURY, AND EQUlPMENT DAMAGE could result from improper installation

of the Oven/Steamer, or from installation of a unit damaged during shipment or

storage. Either of these conditions could also void the equipment warranty.

DO NOT INSTALL a Oven/Steamer suspected of damage.

Install the Oven/Steamer according to the policies and procedures outlined in this

manual.

INTRODUCTION

This chapter is a guide for installation of the Oven/Steamer models identified in Chapter

1. This guide is for use by qualified professionals, and does not include all procedures

and precautions in the common domain of licensed plumbers, pipe fitters, and

electricians, or experienced food service equipment installers.

This guide must be used in conjunction with professional experience and a thorough

understanding of the local and national utility, construction and sanitation codes; the

most prominent of which are listed in the Installation Policies section below.

Before starting installation, the owner and the installer should read through this chapter

and thoroughly understand and agree upon:

• The installation policies of The Manufacturer as stated in Installation Policies.

• An installation plan based on the Installation Overview and Installation Check List.

• Responsibility for feed water quality and its testing as described in Preparation For

Installation, Water Quality Requirements.

INSTALLATlON POLICIES

• The Oven/Steamer must be installed by qualified plumbing and electrical personnel,

working to all applicable national and local codes. Equipment installation must comply

with the Basic Plumbing Code of the Building Officials and Code Administrators

International, Inc. (BOCA), the National Fuel Gas Code, ANSI Z223.1-(latest edition) or

the Natural Gas Installation Code CAN/CGA-B149.1 or the propane Installation Code

CAN/CGA-B149.2, the National Electric Code, ANSI/NFPA No. 70-(latest edition) or the

Canadian electrical code, CSA 22.1, and the Food Service Sanitation Manual of the Food

and Drug Administration (FDA).

15

90028771rev00

Page 16

CHAPTER 2. INSTALLATION INSTRUCTIONS

• All models of the Oven/steamers comply with the applicable standards for

manufacturers. Included among those certification agencies are: etl and NSF.

• The Oven/Steamers are certified for safe operation only when permanently installed in

accordance with local and/or national codes.

Many local codes exist, and it is the responsibility of the owner and installer to comply

with these codes.

• In no event shall the Manufacturer assume any liability for damage or injury

resulting from installations which are not in strict compliance with the Installation

Instructions and the codes cited above. Specifically, The Manufacturer will not

assume any liability for damage or injury resulting from improper installation of

equipment, including, but not limited to, temporary or mobile installations.

INSTALLATION OVERVIEW

Installation of the Oven/Steamer is presented in two parts: preparation and installation.

The Installation Check List, Table 2-1, lists the major tasks to be performed in a

recommended sequence. Each item references the instructions for starting the task.

Complete the preparation tasks in sequence, and then the installation tasks.

Installation requirements may vary from site to site; adapt the check list accordingly.

Schematic Installation Diagram, Figure 2.1, illustrates the utility lines and connections

required to install the Oven/Steamer.

The Dimension Drawings, Fig. 2-2, show the required utility connection points,

dimensions, and clearances for each model.

16

90028771rev00

Page 17

TABLE 2-1. INSTALLATION CHECK LIST

TASK PAGE

REFERENCE

PREPARATION

Unpack, inspect, and protect the unit. 33

Check electric power requirements. 34

Check gas power requirements. 34

Test supply water quality. 34

Select water treatment system. 36

Select operating location. 36

INSTALLATION

Position and level steamer. 38

Assemble packaged components. 38

Install and connect drain line. 43

Connect exhaust flue diverter. 44

Install and connect electrical line. 47

Install and connect water supply lines. 49

Test water supply lines. 50

Install and connect gas supply lines 50

Test gas supply lines. 51

Perform start-up checks. 55

17

90028771rev00

Page 18

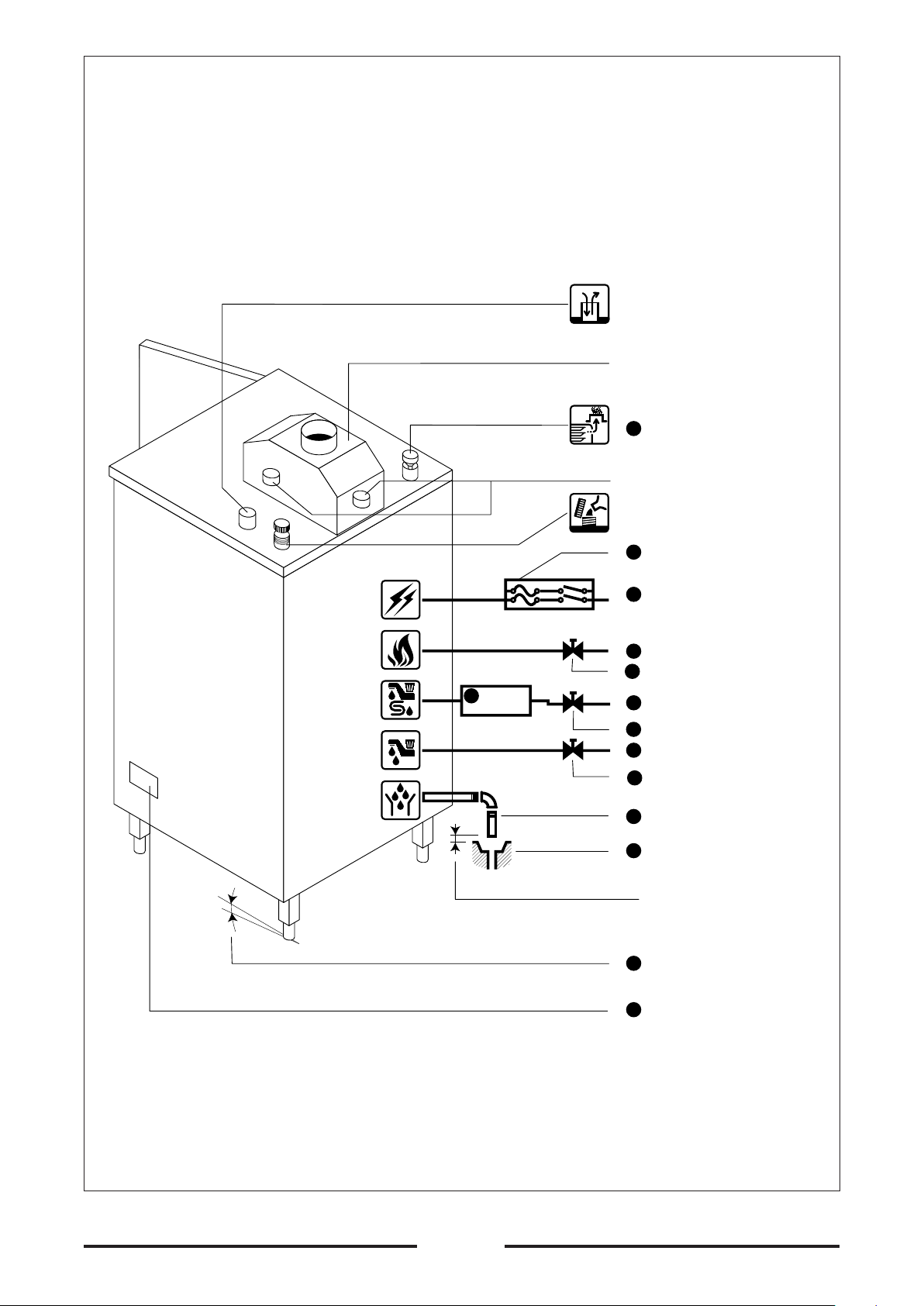

CONNECTION

ELECTRICAL

SUPPLY

SAFETY VENT HOLE

(DO NOT BLOCK)

FLUE DIVERTER

10

DRAIN EXHAUST VENT

(DO NOT BLOCK)

CONNECTIONS: EXHAUST FROM

OVEN AND STEAM GENERATOR

INLET FOR DESCALING SOLUTION

(OPEN FOR DESCALING ONLY)

MAIN POWER SWITCH AND

2

FUSE BOX

1

MAIN ELECTRIC POWER

SUPPLY

3∞

CONNECTION

GAS SUPPLY

CONNECTION

Steam Generator and

Humidifier Supply

CONNECTION

Steam Condenser and

Steam Generator rinsing

Supply

CONNECTION

Free Air Vented Drain

6

STEAMER

GUARD

11

MAIN GAS SUPPLY

12

MAIN MANUAL GAS SHUT-OFF

VALVE

4

HOT (MAX 122 ∞F/50 ∞C) COLD

SOFTENED WATER SUPPLY

7

WATER SUPPLY SHUT-OFF VALVE

UNTREATED NORMAL COLD

5

WATER SUPPLY

7

WATER SUPPLY SHUT-OFF VALVE

DRAIN LINE

8

9

FLOOR DRAIN

25 mm / 1 INCH

CLEARANCE MINIMUM

(only for version "D")

LEVELING

3

IDENTIFICATION PLATE

1

18

90028771rev00

Figure 2-1

Page 19

INSTALLATION DIAGRAM NOTES

1-

The Product Identification Plate located on the right side service panel specifies the

electric power requirements.

2-

For each unit, the installer must provide a ground connection and a separate fused

disconnect switch.

3-

Catastrophic damage will result from shifting the more than 3° out of level while power is

turned on at the unit’s main power switch.

4-

The unit must have an untreated cold water supply NOT HOT, and a HOT (max.

122 °F/50 °C) cold softened water supply.

5-

The softened water supply must meet the quality requirements of Table 2-2, and the

pressure requirements on installation diagrams (Fig. 2-2).

6-

A Steamer Gard system is recommended when water quality does not meet the Table 2-2

requirements.

7-

A manual water shut-off valve must be installed between the main softened water supply

and the steamer supply line. Refer to Figures 2-8 and 2-9 for recommended component

arrangements. A manual water shut-off valve must be installed between the main

untreated main water supply and the steam condenser supply line.

8-

The drain line: use a heat-resistant plastic pipe (not flexible), installed without loops

or kinks and no longer than 2 meters with a slope of no less than 4 degrees, or realize

a drain line with a gravity flow away from the Oven. Drain line must not be connected

to the drain lines of any other equipment. In compliance with current standards, the

drainage piping must not be connected in a straight line.

9-

It is advisable to interpose a funnel (see drawing) to facilitate flow. DO NOT REDUCE

THE DRAIN LINE DIAMETER. DO NOT INSTALL A TRAP ON THE DRAIN LINE.

10-10-

Never block the drain exhaust vent and at the top of the Oven.

WARNING

NEVER EXCEED 14”/355.6 mm WATER COLUMN (1/2 psi) GAS PRESSURE.

If the gas supply pressure exceeds 14”/355.6 mm water column, a pressure

regulating valve must be installed in the gas supply plumbing to reduce the gas

pressure to less than 14”/355.6 mm water column.

11-11-

A main manual gas shut-off valve must be installed between the main gas supply and the

Oven/Steamer gas supply line.

12-

Refer to figures 2-1 for the recommended component arrangements.

19

90028771rev00

Page 20

INSTALLATION

DIAGRAMS

20

90028771rev00

Page 21

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

CVGN/S061 (inch)

CVGN061 / CVGS061 / inch

2,36

23

ø2"ø3/4

ø3/4

5

AC 120V

2,56 2,36 3

5,12

4

1,42 2,36

2

0,3 51,2

ø1/2

19,7

7 21

2 2

ø1-1/2"

3

ISO 228.1

R 1/2"

EN10226

DK

EE-LV-LT-MT-SK-SI-HR

IT-LU-NO-NL-PT-GB-SE

DE-AT-BE-ES-FI-FR-GR-IE

CH-HU-CZ-BG-CY-PL-TR

34,45

7,28

26,77 0,39

26,97 0,79

27,76

ø1"

4 3,98 4

ø1,5"

34,45

26

21

90028771rev00

Page 22

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

CVGN/S061 (US)

CVGN061 / CVGS061 / mm

120

60

590

185 680

10

ø3/4 ø50

ø3/4

AC 120V

130

65 60 85

95

36 60

52

6,5 1300

ø1/2

500

175 530

ø40

65 63 53

ISO 228.1

R 1/2"

EN10226

DK

EE-LV-LT-MT-SK-SI-HR

IT-LU-NO-NL-PT-GB-SE

DE-AT-BE-ES-FI-FR-GR-IE

CH-HU-CZ-BG-CY-PL-TR

101 110 97

ø25

875

705

20 685

22

90028771rev00

ø40

875

650

Page 23

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

CVEN/S061 (inch)

CVEN061 / CVES061 / inch

23 2,36

ø2"ø3/4

ø3/4

21 7

5

AC 208V

3AC 208V

3

2,56 2,36

5,12

4

3AC 480V

1,42 2,36

ø1-1/2"

2,05

0,3 51,2

2 2

19,7

34,45

7,28

0,39 26,77

3,98

4

ø1"

34,45

26,97

27,76

0,79

26

23

90028771rev00

Page 24

ø3/4 ø50ø3/4

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

CVEN/S061 (US)

CVEN061 / CVES061 / mm

120

3AC 480V

AC 208V

3AC 208V

60

590

185 680

10

530

175

130

65 60 85

95

36 60

ø40

52

500

6,5 1300

53 63

101

110

ø25

875

705

20 685

24

90028771rev00

875

650

Page 25

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

CBEN/S061 (inch)

CBEN061 / CBES061 / inch

23 2,36

ø2"ø3/4

ø3/4

21 7

5

3AC 480V

AC 208V

3AC 208V

2,36

5,12

2,56 3

4

1,42 2,36

ø1-1/2"

2,04

0,3 51,2

2

2

19,7

34,45

7,28

0,39

26,77

3,98 4

ø1"

9,13

34,45

26,97

27,76

0,79

1,34

26

25

90028771rev00

Page 26

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

CBEN/S061 (US)

CBEN061 / CBES061 / mm

590 60

ø50ø3/4

ø3/4

530 175

120

130

85

65 60

95

AC 208V

3AC 208V

3AC 480V

36 60

ø40

51,75

500

6,5 1300

53 63

875

185 680

10

685

705

20

26

90028771rev00

875

101

110

ø25

232

34

650

Page 27

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

COEN/S026 (inch)

COEN026 / COES026 / inch

5

3 3,31 2,36

ø1-1/2"ø3/4 ø3/4

1,67

6

2,41

1,97 22,6

20,08

3AC 208V

3

28,54

6

2

20,08

1,6

1,2

2

ø1-1/2"ø1-1/4"

6,69

26,38

35

0,83 0,75

3,15

25

27

90028771rev00

Page 28

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

COEN/S026 (US)

COEN026 / COES026 / mm

121

50 575

ø3/4 ø3/4 ø40

155

725 155

60 80

84

84

42,5

61,3

3AC 208V

50

510

880

670

21 19 170

28

90028771rev00

510

40

30

50

80

ø30 ø40

625

Page 29

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

COEN/S061 (inch)

COEN061 / COES061 / inch

5

3

ø1-1/2"ø3/4ø3/4

1,97

29,53

3,31 2,36

6

1,67

2,41

3AC 208V

3

28,54

6

2

20,08

20,08

26,38 0,75 6,69

35

0,83

1,6

1,2

1,97

3,15

ø1-1/2"ø1-1/4"

31

29

90028771rev00

Page 30

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

COEN/S061 (US)

COEN061 / COES061 / mm

121

80

ø3/4 ø40ø3/4

50

750

725

155

155

84 60

84

42,5

61,3

3AC 208V

50

510

170

510

19

880

670

21

40

30

50

80

ø40ø30

800

30

90028771rev00

Page 31

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

COEN/S101 (inch)

COEN101 / COES101 / inch

5

3

ø3/4 ø1-1/2"ø3/4

2

29,53

3,31 2,36

6

1,67

2,41

3AC 208V

3

37,99

6

2

20,08

20,08

35,83

44

0,83 0,75 6,69

1,6

1,2

2

3,15

ø1-1/2"ø1-1/4"

31

31

90028771rev00

Page 32

Los datos tecnicos indicados en el presente catalogo no son vinculantes. La empr esa se reserva el derecho de efectuar modificationes sin previo aviso.

I dati riportati sul presente documento sono da ritenersi non vincolanti. L'azienda si riserv a di apportare modifiche tecniche in qualsiasi momento.

The specification shown in this document are to be considered non binding. The company res erves the right to make technical change at any moment.

Die auf dieser Unterlage angegebenen technishen Daten sind als unverbinlich anzusehen. Die Firma behält sich das Rec ht vor zu jeder zeit technische Änderungen vorzunehmen.

Les données techniques sur ce document ne doivent pas être cons idérées contraigrantes. La societé se réserve le droit d'apporter des modification techniques à tout moment.

COEN/S101 (US)

COEN101 / COES101 / mm

121

80

750 50

965

ø3/4 ø3/4 ø40

155

155

60

84

84

42,5

61,3

3AC 208V

50

510

1120

21 910 19 170

32

90028771rev00

510

40

30

50

80

ø30 ø40

800

Page 33

PREPARATION FOR INSTALLATION

Select and prepare the operating location before permanently positioning the unit. Protect

the unit and packaged components during site preparation. Do not select the operating

location or start installation before checking the electric power, gas, and water quality

requirements to assure proper drainage, ventilation, and safety.

UNPACKING AND INSPECTION

The is packed in a wooden shipping crate. The fat filter is packed in a separate box.

Additional components, not assembled at the factory are packaged inside the Oven/Steamer

cooking Compartment. These are:

Owner’s Manual Flue Diverter (optional)

Wire Shelves Legs (optional)

After disassembling the shipping crate, visually inspect the for damage.

Before unpacking the separate components, inspect their shipping cartons for damage.

If the cartons are not damaged, unpack them and inspect the components for damage or loss.

• If the and its separate components are delivered in good condition, close

and reseal all the component packages. Then proceed to Protecting The Oven/Steamer.

• If any shipping carton appears damaged, refer to the Shipping Damage Instructions below.

• If the or any of the components have suffered shipping damage or loss,

refer to the Shipping Damage Instructions below.

Shipping Damage Instructions

If shipping damage or loss is discovered or suspected, observe the following guidelines in

preparing a shipping damage claim.

• Write down a description of the damage or the reason for suspecting damage as soon as

it is discovered. This will help in filling out the claim forms later.

• As soon as damage is discovered or suspected, notify the carrier that delivered the

shipment.

• Arrange for a carrier representative to examine the damage.

• Fill out all appropriate claim forms and have the examining carrier sign and date each form.

PROTECTING THE OVEN / STEAMER

While running power and supply lines to the operating location, remove the and components

from the immediate work area. To maintain them in good, clean condition and prevent loss

or damage:

1-

Leave the packaged components inside the cooking compartment.

2-

Keep the fat filter and together to prevent loss.

Keep the clean by covering it with a plastic tarp or drop cloth.

3-

4-

Do not store other items on top of the machine.

33

90028771rev00

Page 34

PROTECTING THE OVEN / STEAMER

Electric Power Requirements

The characteristics of the electric power supply must match the power requirements

specified on the Oven/Steamer product identification plate.

The plate is secured to the outside of the right-side access panel as illustrated in Figure

2-2.Gas Supply Requirements

WARNING

NEVER EXCEED 14”/355.6 mm WATER COLUMN (1/2 psi) GAS PRESSURE.

If the gas supply pressure exceeds 14”/355.6 mm water column, a pressure

regulating valve must be installed in the gas supply plumbing to reduce the gas

pressure to less than 14”/355.6 mm water column.

• Natural gas pressure must be between 4.5”/101.6 mm -14”/355.6 mm water column.

• Propane gas supply pressure must be between 11”/304.8 mm - 14”/355.6 mm water column.

WATER QUALITY REQUIREMENTS

Cold or hot water (max. 122 °F/50 °C) for steam generator and humidifier.

WARNING

Using water not within the limits specified in this manual could void or adversely

affect the warranty coverage of the Oven/Steamer.

As with any steam generating equipment, poor water quality degrades Oven/Steamer

performance. If feed water is low in Total Dissolved Solids (TDS) and free of particulate

matter, the steam generator, heating element, and valves of the Oven/Steamer will give

years of trouble-free service with a minimum of maintenance.

In some areas, even potable tap water contains a variety of impurities that can cause

costly problems in steam generating equipment.

Of primary concern are mineral salts and other impurities which remain behind as lime or

scale deposits during the steam generating process. These deposits have caused many

components to fail, including heating elements, probes, and solenoid valves.

Of equal importance is the decrease in heat transfer efficiency caused by lime and scale

deposits. Decreased heat transfer increases water and power consumption. Use of the

in areas with poor water quality requires installation of a Steamer Gard water treatment

system or increased frequency of maintenance, cleaning, and descaling.

Check the quality of supply water before starting construction of the water supply lines.

If a water treatment system must be installed to achieve acceptable water quality, install

it before connecting the water supply lines to the Oven/Steamer.

34

90028771rev00

Page 35

WATER QUALITY REQUIREMENTS

Contact a local water treatment specialist for an on-the-premises water analysis.

The recommended minimum feed water quality requirements for the Oven/Steamer are

listed in Table 2-2.

Table 2-2. Minimum Supply Water Quality Requirements

Total Dissolved Solids less than 60 parts per million

Silica less than 13 parts per million

Alkalinity less than 0 parts per million

Chloride less than 30 parts per million

pH factor greater than 7.5

Softened, Treated, or Filtered Water

Do not use softened or chlorinated water in the steam generator.

If the water supply is treated or softened either by the water company or on the

premises, it may contain chlorine or various salts.

These additives are damaging to the steam generator. Salts used to soften water cause

rapid scale buildup, and increased corrosion.

The hardness of the water has to be from 1 ÷ 4 degrees Clark (1 to 6 fH/0.5 and 2.8

dH). Some water treatment plants kill bacteria in the water by adding chlorine.

When heated in the steam generator, chlorinated water rapidly dissolves generator walls

and heater elements. In extreme cases, poisonous and highly corrosive chlorine gas is

released in the steam generator. Installing a high volume water filtering system removes

most of the salts used for water softening. Contact a local water treatment specialist or

the local water company for assistance with chlorinated water.

Always connect an untreated cold water supply to the steam quenching and boiler

rinsing water supply line. DO NOT USE HOT WATER.

The oven/steamer will not function properly or within design safety limits if hot or

warm water is supplied.

35

90028771rev00

Page 36

WATER SUPPLY SYSTEM

Select a water supply system that fulfills the following elements: the two different

inlet water supplies (softened and untreated) must provide a minimum dynamic

pressure of 35 psi (2.4 kg/cm2) and a maximum static pressure of 60 psi (4.1 kg/

cm2). If the static pressure exceeds 60 psi, a pressure regulator must be installed

in the supply lines. Refer to page 33 for detailed pressure and fitting requirements,

and for the recommended plumbing layouts.

If analysis shows that the supply water is NOT within the required limits, install a

Steamer Gard water treatment system. Figure 2-6 on page 33 illustrates a treated water

supply arrangement.

If analysis shows that the supply water is NOT within the required limits, and it is not

possible to install a Steamer Gard water treatment system, plan on increasing the

frequency of maintenance, cleaning, and descaling beyond that recommended in the

maintenance schedule (Chapter 4).

SELECTING THE OPERATING LOCATION

For safe and efficient operation, observe the following criteria when selecting an

operating location for the Oven/Steamer.

WARNING

The flooring directly under this unit must be made of non-combustible material.

1-

Do not install these units in areas where combustibles are stored or may accumulate.

The surrounding area must be clear of combustibles, including the space under the unit.

2-

A proper air supply for combustion and ventilation air is critical for safe, efficient

operation of Oven/Steamers. The area around the oven/steamer must have adequate

ventilation for gas-fired-appliances.

Air openings around the unit should not be blocked; provide adequate clearance for

proper air flow to combustion chamber.

3-

The vents for combustion and ventilation air are on the right side of the unit. Do not

block these air vents. Do not install any heat producing equipment near the air vents of

the unit.

WARNING

All clearance requirements above, below, and around the unit are the same

for combustible or non-combustible locations.

Maintain at least 20”/500 mm clearance on the right side of the unit.

Maintain at least 10”/254 mm clearance at the rear of the unit.

36

90028771rev00

Page 37

4-

The dimension drawings (Figure 2-2) specify all dimensions and clearances required for

proper operation and service of each Oven/Steamer covered in this manual.

5-

The service access panel is on the right side of the unit. Select an operating location that

allows access to the right side of the unit for service.

6-

CBE models have electric steam generators

Units have from two to four exhaust ports on the top (see on the dimensions drawing).

A chimney, flue plenum, or exhaust hood should be close enough to extend an exhaust

duct to these ports.

7-

The location selected must be capable of supporting the operational weight of the unit,

including the weight of water and food.

The Oven/Steamer operating weights are listed on the dimension drawings.

8-

The floor surface under the unit must be level and continuous with the flooring in front

of the unit. The cart must roll smoothly into the for ease of operation and maintenance of

the door-to-cart compartment seal.

37

90028771rev00

Page 38

INSTALLATION INSTRUCTIONS

After selecting and preparing the Oven/Steamer operating location, the oven/steamer

can be positioned and installed. When installation is complete, perform all start-up

checks to verify proper installation and operation.

POSITION AND LEVEL THE OVEN/STEAMER

NOTE: If there is not enough clearance behind the to install the drain, electrical, and

water lines, skip this procedure and continue with Install and Connect the Free Air

Vented Drain Lines. After installing all necessary drain, electrical, and water lines,

return to these instructions and install the unit.

The is positioned and leveled twice. First level the main unit in position.

Then place the roll-in cart in the cooking chamber, and adjust the unit level to match the

roll-in cart.

WARNING

Malfunctions and equipment damage may result from improper mounting.

Malfunctions and/or damage resulting from improper mounting are not covered by

the equipment warranty. The MUST BE LEVEL BOTH FRONT TO BACK AND SIDE TO

SIDE in all mounting arrangements.

Equipment damage may result from shifting the Oven/Steamer more than 3° out of

level while power is turned on.

Adjustable Leveling Legs only if present

The supporting legs of the Oven/Steamer are 12 inch/304.8 mm long when the adjustable

feet are fully retracted. The adjustable feet can be extended approximately 2 inches/50.8

mm. This extension provides the 4 inch/101.6 mm space below the unit required by NSF

sanitary standards, and a means of leveling the oven/steamer.

ASSEMBLY

1-

Check that the feet are fully retracted into the legs. Do not overtighten. The feet should

easily screw in and out using fingers only.

WARNING

INJURY AND EQUIPMENT DAMAGE could result from improper lifting. Refer to the

appropriate dimension and check the weight of the unit being installed.

Use enough workers with experience of lifting heavy equipment to place the on the

supporting surface.

2-

Be sure electric power is turned off at the main power switch. Place the on the left

side.

38

90028771rev00

Page 39

3-

Refer to figure 2-3 and bolt the legs to the Oven/Steamer frame. All four legs must be

installed for proper mounting of the unit.

4-

Place the oven/steamer upright on its four legs.

Figure 2-3. Leg Bolts

Oven placed on counters, if placed on a plane different from the one suggested by

the producer, must be sealed (see point A, fig. X) along all it’s perimeter with silicon

approved by NSF (type GE – red, aluminum ore transparent coloured silicones, series

RTV), on the plane. The above said is not valid if oven is equipped with feet, supplied

upon specific request.

Positioning and Leveling

1-

Check that all Unpacking and Inspection tasks are complete.

Thoroughly clean the floor area that will support the unit.

2-

Using a level, determine and mark the highest corner of the floor area that will support

the leveling legs.

WARNING

INJURY AND EQUIPMENT DAMAGE could result from improper lifting. Refer to the

appropriate dimension and check the weight of the unit being installed.

Use enough workers with experience of lifting heavy equipment to place the on the

supporting surface.

3-

Roll the cart out of the cooking compartment, and move the into position and level it.

4-4-

Extend the adjusting foot of the leg in the highest corner (marked in step 3), until that

corner of the unit is four inches above the supporting surface.

5-

Using a level, adjust the other three legs until the is level both front to back and side to

side.

39

90028771rev00

Page 40

POSITION AND LEVEL THE OVEN/STEAMER

For free-standing models, the appliance needs to be levelled: small differences in level

of the supporting surface can be eliminated with the adjustable feet (by screwing or

unscrewing them). A significantly uneven or sloping stance can affect the operation of the

oven adversely.

40

90028771rev00

Page 41

APPLIANCE EQUIPPED WITH CASTERS

ELECTRIC

• Adequate means must be provided to limit the movement of the appliance without

depending on or the transmitting stress to the electrical conduit.

• The appliance shall be installed using flexible conduit.

GAS-FIRED

• The installation shall be made with a connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69 – CSA 6.16, and a QuickDisconnect Devices for Use With Gas Fuel, ANSI Z21.41 – CSA 6.9.

• Adequate means must be provided to limit the movement of the appliance without

depending on the connector and the quick-disconnect device or its associated piping

to limit the appliance movement.

Locations were the restraining means may be attached to the appliance

BACK SIDE

41

90028771rev00

Page 42

INSTALL AND CONNECT THE FREE AIR VENTED DRAIN LINES

The drain outlets and the drain vent at the top of the unit and must be free air

vented to equalize the pressure in the with the atmosphere.

Generating steam causes pressure to increase in the unit; cold water flow into the

condenser creates a vacuum (low pressure) in the condenser. Without a free airvent, either

high or low pressure in the compartment will cause malfunction or damage.

• Pressure build up in the steamer will cause steam and hot water leakage around the door.

• A vacuum will implode the steamer and cause permanent physical damage.

Refer to Figure 2-4, and the dimension drawings (Figure 2-2). The drain outlet

discharges exhaust steam and hot condensate from the oven/steamer.

The drain exhaust vents ( and ) and a 1 inch/25 mm minimum clearance between the

drain opening and floor provide the with free air venting.

Furnishing and installing the drain lines and fittings is the responsibility of the owner and/or

installer. Figure 2-4 illustrates a drain layout recommended by the Manufacturer.

The drain line: Use a heat-resistant plastic pipe (not flexible), installed without loops or

kinks and no longer than 2 metres with a slope of no less than 4 degrees, or realize a drain

line with a gravity flow away from the unit. Drain line must not be connected to the drain

lines of any other equipment. In compliance with current standards, the drainage piping

must not be connected in a straight line.

42

90028771rev00

Page 43

%

CONNECT THE FREE AIR VENTED DRAIN LINES

Figure 2-4. Recommended

Drain Layout

SAFETY EXHAUST VENT

(DO NOT BLOCK)

DRAIN EXHAUST VENT

(DO NOT BLOCK)

INLET FOR

DESCALING SOLUTION

STEAM GENERATOR

Min. 4

1" (25,4 mm).

Max. 200 cm

Draining

The water is drained off by gravity through a heat-resistant pipe DN 50 (2”), maximum

length 2 m, installed at an angle of no less than 4°.Mean temperature of the drain water:

180°F/82°C.

It is imperative to fit a drain cup to ensure a minimum air drop of 1” (25 mm). between the

appliance’s plastic drain elbow and drain line. A direct connection is not permissible.

WARNING

The drain line must be outside the perimeter of the oven. It is prohibited to reduce

the drain diameter.

43

90028771rev00

Page 44

INSTALL AND CONNECT THE FREE AIR VENTED DRAIN LINES

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE could result from improper installation

of the drain outlet lines.

Improper installation of these lines could void the warranty.

The following restrictions are critical to the safety of personnel and equipment, and

must not be violated under any circumstances.

Do not connect the drain line into PVC pipe, or any other drain material

that cannot sustain 180 °F/82 °C.

Do not connect drains from any other equipment to the Oven/Steamer drain line.

Do not connect the drain outlet extension line directly to a floor drain or sewer line.

Do not block drain vents at the top of the unit (

1-

The drain lines must be installed in compliance with the Basic Plumbing Code of the

Building Officials and Code Administrators International, Inc. (BOCA), and the Food

Service Sanitation Manual of the Food and Drug Administration (FDA).

2-

The total length of pipe and number of bend fittings required to reach the open drain

determines the pipe size used to extend the drain line to an open drain.

• If the drain outlet extension requires twelve feet or less of pipe, and no more than two

elbows are required, use 2” / 50 mm pipe and fittings.

).

3-

The drain line must have a gravity flow from the drain outlet to the floor drain. Do not

install a trap in the drain line.

4-

Free air venting requires a minimum of 1”/25.4 mm clearance between the end of the

drain line and the top of the floor drain.

5-

Do not connect the steamer drain to drains or plumbing of any other equipment.

If drains of two or more units are connected together:

• Low pressure can develop, causing an implosion and physical collapse of the

Oven/Steamer.

• Drainage from another unit can flow back into compartment of Oven/Steamer.

6-

When assembling the drain pipes and fittings, apply a hardening type pipe sealant

to the threads, and thread them together FINGER TIGHT ONLY. DO NOT USE A WRENCH.

44

90028771rev00

Page 45

EXHAUST PORT VENTILATION

Stack connection

pipe

Adaptor

Damper

Suction hood

Figure A Figure B

Hood filter

Ducted

ceiling

NOTE: In case oven equipped with canopy is installed under a commercial ventilation

hood, respect minimum distance “D” between canopy and commercial ventilation hood

D = “d” x 1.25 = 1.25 times canopy port diameter.

Appliance suitable for connection to a flue gas vent when used with draft hood (provided

as optional).

Appliance to be installed under a ventilation hood when draft hood is not provided.

1-

Refer to exhaust ports 1 (steam generator) and 2 (chamber) on the appropriate dimension

drawings. These ports must be vented to an exhaust flue by the Flue Diverter.

2-

A ductwork connection must comply with all local and national codes for venting gas-fired

appliances. After sizing and positioning the collars secure them tightly to the exhaust ports.

3-

Fit the flue diverter using 4 fixing screws for this purpose.

4-

The oven can also be installed without the flue diverter under a commercial ventilation

hood (see Figure B).

When venting to an exhaust hood, the hood must be sized to the ventilation requirements of

the Oven/Steamer installed.

45

90028771rev00

Page 46

EXHAUST PORT VENTILATION

EXHAUST PORT VENTILATION

• Do not connect these ports directly to a forced draft exhaust system or canopy.

• Respect the maximum distance between the flue diverter and canopy (Figure A).

• Excess draft through the flue reduces the oven’s efficiency and may affect cooking

times.

5-

Do not block for any reasons the ports or reduce their dimensions.

INSTALL ELECTRIC POWER LINE

Furnishing and installing the electrical power lines switches, fuse box connectors and

accessories is the responsibility of the owner and/or installer.

Figure 2-5 illustrates an electrical layout recommended by the Manufacturer.

When installing the electrical power lines and accessories, observe the following

instructions.

1-

Install the electrical power and ground lines in accordance with local codes and/or the

National Electric Code, ANSI/NFPA No. 70-(latest edition) (USA), or the Canadian Electrical

Code, CSA C22.1.

2-

Refer to the electrical schematic diagram that was shipped with the unit, and also sticked

up on to the right side access panel (inside).

3-

Install the proper size disconnect switch, circuit breaker or fuses, and wire and conduit to

conform to all local codes and the national codes cited above (see Technical Data pag. 13).

4-

Install a separate disconnect switch and fuses or breakers sized to meet the line amps

required by the Oven/Steamer (see see Technical Data pag. 13).

The fuses or breakers may be an integral part of the disconnect switch or in a separate

fuse box. Install the disconnect switch for easy access as needed for emergency shutdown.

Throughout the remainder of this manual the fused disconnect switch is referred to as the

main power switch.

5-

There should be a sufficient length of flexible conduit between the Oven/Steamer connector

and the wall so the unit can be moved for service.

6-

Each must be electrically grounded by the installer in accordance with the National Electric

Code, ANSI/NFPA No. 70-(latest edition), or the Canadian Electrical Code, CSA C22.1.

46

90028771rev00

Page 47

INSTALL ELECTRIC POWER LINE

MAIN POWER SWITCH

Oven/Steamer

AND FUSE BOX

Electrical Supply

CONNECTION

Location Detailed

on

Dimension Drawing

MAIN ELECTRIC

POWER SUPPLY

Figure 2-5. Recommended Electrical Layout

7-

The characteristics of the electric power supply must match the power requirements specified

on the product identification plate.

The plate is located on the right side of the unit in the bottom left corner. Also refer to the

electrical schematic diagram that was shipped with the unit, included at the end of this

manual.

CONNECT ELECTRICAL LINE

Refer to the electrical schematic diagram and connect the electrical lines to the terminal block

inside the right side access panel as described below. Copies of the electrical schematic

diagrams are included at the end of this manual and a copy was shipped with the unit and also

stuck on the right side access panel (inside).

1-

Remove the right side access panel by removing the screws that hold it in place. Save the

screws.

2-

Refer to the electrical schematic diagram that was shipped with the unit.

3-

Mechanically secure the flexible conduit to the electrical access hole.

4-

The terminal block and ground connection are near the center of the side opening. Connect the

wires to the terminal block and ground connector accordingly.

5-

The oven/steamer must be electrically grounded by the installer in accordance with the

National Electric Code, ANSI/NFPA No. 70-(latest edition), or the Canadian Electrical Code,

CSA C22.1.

6-

If no further work inside the side panel is required at this time, such as plumbing and leak

checks, secure the right side access panel with the mounting screws.

47

90028771rev00

Page 48

INSTALL AND CONNECT WATER SUPPLY LINES

Furnishing and plumbing the water supply lines is the responsibility of the owner and/or

installer. This section explains the plumbing layouts recommended by the Manufacturer.

When installing and connecting the water supply lines to the Oven/Steamer, observe the

following guidelines and instructions.

1-

The Oven/Steamer has compression fittings at the back of the unit for connection to the

water supply lines. The steam generator and humidifier fitting (

is 3/4” IPS and the condenser and boiler rinsing fitting (

IPS.

2-

Always connect untreated COLD water supply to the Oven/Steamer condenser/boiler rinsing

water supply line. DO NOT USE HOT WATER. The Oven/Steamer will not function properly or

within design safety limits if hot or warm water is supplied.

3-

Do not connect the to a softened or treated water supply which adds chlorine or chloride

salts to the water. Refer to the Softened, Treated, or Filtered Water instructions on page 21

for details.

on dimension drawing)

on dimension drawing) is 3/4”

4-

Supply water must have a minimum dynamic pressure of 35 psi (2,4 kg/cm2) and a maximum

static pressure of 60 psi (4.1 kg/cm2). Water pressure greater than 60 psi will cause damage

to the solenoid valves. Local water pressure can be 100 psi or more.

If possible, check supply pressure at non-peak demand time. A local water company can

assist in this check. If static pressure exceeds 60 psi water, a pressure regulator must be

installed in the supply lines. For best results, set the regulator for 50 psi dynamic pressure.

5-

Refer to the recommended plumbing layouts in Figures 2-6 and 2-7, and install the water

supply lines and fittings in accordance with all local and national codes.

While constructing and installing the water supply lines, pay particular attention to the

following requirements and recommendations.

WARNING

This equipament is to installed with adeguate BACKFLOW that complies with

FEDERAL, STATE, OR LOCAL CODES having jurisdiction

Oven/Steamer

AIR/WATER COLUMN

(IF REQUIRED)

MAIN WATER

SHUT-OFF VALVE

PRESSURE REDUCER

(IF REQUIRED)

AIR/WATER COLUMN

(IF REQUIRED)

MAIN WATER

SHUT-OFF VALVE

PRESSURE REDUCER

(IF REQUIRED)

MAIN UNTREATED

COLD

WATER SUPPLY

SOFTENED COLD/HOT

(MAX 122 ϒF/50 ϒC)

WATER SUPPLY

CONDENSER

STEAM GENERATOR

RINSING

STEAM GENERATOR

FILLING UP

HUMIDIFIER

40-MESH STRAINER

WATER CONNECTION

ON DIMENSION

DIAGRAM

40-MESH STRAINER

WATER CONNECTION

ON DIMENSION

DIAGRAM

CHECK VALVE

CHECK VALVE

Figure 2-6. Water Supply Lines without a water trattament system

48

90028771rev00

Page 49

INSTALL AND CONNECT WATER SUPPLY LINES

CHECK VALVE 40-MESH STRAINER

AIR/WATER COLUMN

STEAM GENERATOR

FILLING UP

HUMIDIFIER

STEAMERGARD

WATER TREATMENT

SYSTEM

WATER CONNECTION

ON DIMENSION

DIAGRAM

MAIN WATER

SHUT-OFF VALVE

PRESSURE REDUCER

(IF REQUIRED)

Figure 2-7. Water Supply Lines water trattament system

a. Apply pipe dope or teflon tape to any threaded connection

b. When installing a water supply system without a water trattament system, we

recommends the plumbing layout illustrated in Figure 2-6.

• Install a single water line from the main untreated cold water supply to the water

solenoid valve outside the for the condenser and the steam generator rinsing.

• Install a single water line from the main softened cold/hot (max. 122 °F/50 °C) water

supply to the water solenoid valve outside the for the steam generator filling up and

humidifier.

c. When installing a water supply system with a water trattament system, we recommends

the plumbing layout illustrated in Figure 2-7.

Install a single water line from the untreated main cold/hot (max. 122 °F/50 °C) water

supply to the water solenoid valve before the water trattament system.

• The water supply line from the water trattament system connects to the steam generator

fill and humidifier connection.

• The cold water supply to the condenser and steam generator rinsing connection can be

untreated

d.

Use 3/4” lines for the steam generator/humidifier,and condenser and

steam generator rinsing lines respectively.

If larger lines are used, a pressure regulator must be installed in the supply line to

maintain the pressure specified in step 4.

e. Install a manual water valve between the main cold water supply line and the

Oven\Steamer lines.

f. The National Sanitation Foundation (NSF) requires installation of a check-valve in all

supply lines in accordance with and as required by local plumbing codes.

The recommended locations for check valves are shown in the recommended plumbing

layouts.

g. We recommends installing a 40-mesh water strainer at the locations shown in the

recommended plumbing layouts.

(IF REQUIRED)

UNTREATED

MAIN COLD/HOT

MAX 122 ϒF/50 ϒC

WATER SUPPLY

49

90028771rev00

Page 50

INSTALL AND CONNECT WATER SUPPLY LINES

6-

Construct all supply lines up to the point of installing the strainer(s). Before connecting

the strainer(s), flush the water supply line(s). Then install the strainer(s) at the indicated

location(s).

• Make sure the arrow on the strainer body points in the direction of flow into the

oven/steamer fittings.

• Install the strainer so the access nut points down.

• If the remaining water lines and/or water trattament system are not installed and

connected immediately after flushing, temporarily cap the strainer outlet(s) to prevent

blockage.

7-

Construct the remainder of the water supply lines but do not connect them to the Oven/

Steamer.

a. If the Oven/Steamer is installed with a water trattament system, refer to figure 2-7, and

the water trattament system manual for detailed instructions.

• The 40-mesh strainer must be installed at the water trattament system inlet.

• A check valve must be installed between the water trattament system and the

Oven/Steamer steam generator inlet.

• The line from the water trattament system must connect to the Oven/Steamer 3/4” steam

generator inlet.

b. If the Oven/Steamer is installed without a water trattament system, refer to Figure 2-6.

Note that the tee is installed after the check valve and strainer to reduce the number

of fittings and amount of piping required.

Before connecting the water supply lines to the Oven/Steamer, flush the lines.

Then connect the water supply lines to the at the locations shown in the appropriate

dimension drawing (Figure 2-2).

TESTING WATER SUPPLY LINES

1-

Check all connections for proper tightness.

2-

Remove the right side access panel to inspect water connections inside the steamer.

3-

Open the water supply valves.

4-

Check all lines and connections for leakage, both inside and outside the oven/steamer.

If no other inspections are being made at this time, replace the right side access panel.

INSTALL AND CONNECT GAS SUPPLY LINE

Furnishing and installing the gas supply lines, valves, regulators, and accessories is

1-

the responsibility of the owner and/or installer. When installing the gas supply lines and

accessories, observe the following instructions.

Install the gas supply lines in accordance with local codes and/or the National Fuel Gas

Code, ANSI Z223.1-(latest edition), the Natural Gas Installation Code CAN/CGA-B148.1 and

Propane Installation Code CAN/CGA-B148.2.

2-

Use 1/2 inch gas supply piping and fittings. Refer to the appropriate dimension drawing for

pressure data and connection locations.

Refer to Figure 2-8 for recommended layout of the gas supply lines.

50

90028771rev00

Page 51

INSTALL AND CONNECT GAS SUPPLY LINES

Oven/Steamer

PRESSURE REGULATING

VALVE (IF REQUIRED)

AUTOMATIC GAS VALVE

IN

BURNER CONTROL SYSTEM

GAS SUPPLY CONNECTION

ON DIMENSION DIAGRAM

MAIN GAS

SHUT-OFF VALVE

MAIN GAS SUPPLY

DRIP LEG

Figure 2-8. Recommended Gas Supply Line Layout

3-

Install a manual shut-off valve between the gas supply line and the Oven/Steamer gas

connection ( on dimension drawing).

4-

Install a sediment trap (drip leg) in the gas supply line, then connect gas supply piping to the

steam generator gas valve piping.

5-

If natural gas pressure exceeds 14”/355,6 mm water column, a pressure regulating valve

must be installed in the gas supply plumbing to reduce the pressure to within the limits

specified in Gas Supply Requirements.

6-

If Propane gas is supplied, use a gas pipe joint compound which is resistant to Propane gas.

TESTING GAS SUPPLY LINES AND BURNER CONTROLS

After initial installation, both the gas lines and burner controls should be inspected for proper

installation and tested for leaks and proper operation. After service or repair, the components

affected should be inspected and tested for leaks and proper operation.

Pressure Testing The Gas Supply Lines

The gas lines leading to the Oven/Steamer can be tested immediately after installation, or

during the Start-Up Checks. Do not supply gas to these lines until they have been tested.

When testing these lines observe the following.

1-

Remove the right side access panel. Check all internal and external connections for proper tightness.

2-

Refer to Figure 2-8, and set-up the Oven/Steamer automatic gas valve according to the test

pressure being used. The same pressure criteria apply when testing lines prior to the manual

gas shut-off valve.

• The appliance and its individual shut-off valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of

14”/355.6 mm water column (1/2 psi or 3.45 kPa).