Project

Item No.

Quantity

blaSt ChilleR/FReezeR

Model RR2FS-160, Model SR2FS-160, Model 2R2FS-160

RR-SR – Roll-in Blast Chiller without Condensing Unit

2FS-160 – Roll-in Blast Chiller/Blast Freezer

StandaRd FeatuReS

• Unit assembled at installation site

• Inside and outside casing of 304 stainless steel

• Top and back panel in treated steel

• Injected polyurethane foam insulation, 3-1/8" thick, 0% CFC

• 3/4" insulated ground with access ramp. 304 stainless steel coating

• Internal safety door release

• Hinges: ramp hinges (location specified on order)

• Scraper seal at the bottom of the door

• Stainless steel front framework with anti-condensing system

• Coved internal corners with radius 1/2"

• 1-1/4" wide magnetic door seals with anti-dirt, anti-impact

rounded profile and tool-free removal

• Smooth, sealed control panel

• Baseboards for floor adjustment

• Easy maintenance

CapaCity

• Accomodates trollies 30" x 37" x 73" (WxDxH)

• Blast chilling capacity of 145°F, to 40°F, “to core” within 1 hr. 50 mins.

RR: 353 lbs.

SR: 485 lbs.

• Blast freezing capacity of 145°F, to 0°F, “to core” within 4 hrs. 30 mins.

SR: 353 lbs.

Multi-point FRigipRobe

• A stainless steel probe with four temperature sensors monitors

core temperature of product

• Frigiprobe electronically assists blast chilling and freezing of products

accurately regardless of quantity, weight, or thickness

• Blast freezing or chilling is automatically stopped once “core”

temperature is reached (0°F to +40°F)

• Blast chilling mode can limit air temperature at the surface to

32°F to prevent surface icing

eleCtRoniC ContRol

• Blast chilling or freezing controlled with Timer Mode or

Frigiprobe Mode

• Timer Mode remembers last time settings

• Temperature maintained after blast chilling or freezing

optionS & aCCeSSoRieS

Audible alarm

Stainless Steel backside

Set of 6 rolls of paper for printer

Fan stops with door open

• Automatic control of defrosting cycle

• Audible signal at start and end of cycle with remote report feature

• Remote alarm signal (output 12 Vdc)

• Temporary self-repair of probes and quick diagnosis of anomalies

• Temperature display in °F or °C.

Control panel display

• Control panel at 63" off the floor.

• Alternating digital display of core temperature and time at start of cycle

(Frigiprobe mode)

• Alternating digital display of internal temperature and time remaining

before end of cycle (Timer mode)

• Lights indicating functions in progress

Communication board and printer

• Serial type RS 232 C port and parallel port, enabling unit to be connected

to a PC, to a data processing network or to a printer

• Built-in printer for recording temperature and duration of cycles

ReFRigeRation

Similar for both models

• R404A refrigerant

• Four 11-7/8" diameter fans, mounted on a pivoting stainless steel panel

for easy maintenance

• Two evaporators with fitted thermostatic expansion valve

• Solenoid valve on the liquid line

• Refrigeration circuit with light nitrogen pressure

eleCtRiCal deFRoSting

• Defrosting with six 1,700 BTU/hr. heaters made of 304 stainless steel

• Safety thermostat for de-icing heaters on each evaporator

(3M) 7/07 Printed in U.S.A.

FR004

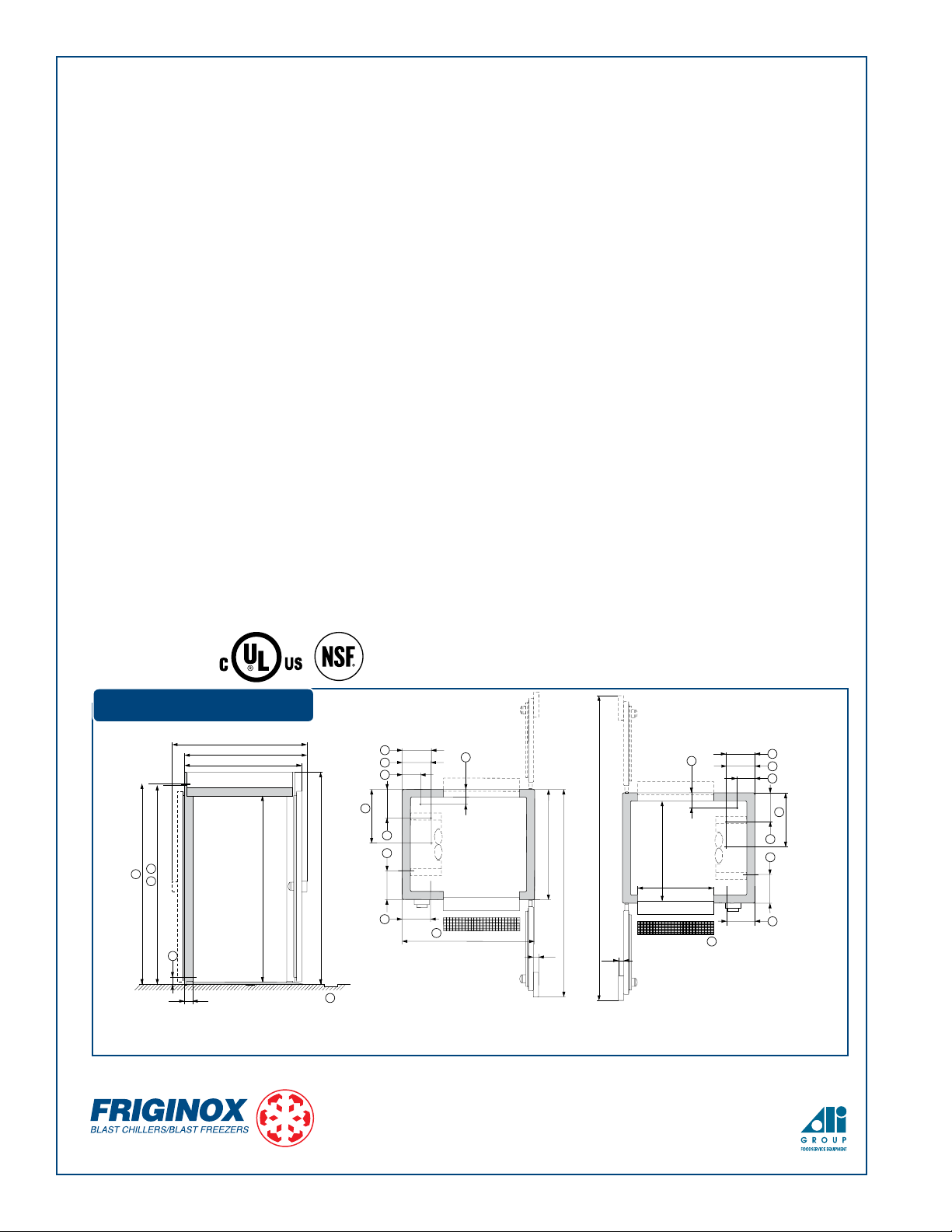

D

1

D

D

1

D

E

B

B

B

B

6"

11

-3

/8

"

18

-1

/2

"

7-

1

/8"

43

-1

/4"

81

-1

/2

" single acces

s

11"

11"

11

"

11

"

52

"

2"

To

p

Vi

ew

D'

D

D'

D

E

B

B

BB

6"

30"

11-3/8"

18-1/2"

7-1/8"

37-7/8"

119-3/4" double access

11"

11"

11"

11"

2"

Top View

E

D

D1

A

B

48-1/8"

46-1/8"

3"

3-1/8"

83-7/8"

74-1/4"

78-1/2"

79"

Front View

53" pass through version

diSaSSeMbled unit paRtS

• Evaporators, evaporator fans, electrical box, electronic control, control

panel are totally assembled on panels and connected. This is called

evaporator block.

• All electrical and control wiring pre-wired. Only the front frame heater

needs to be connected in the electrical box on the site. Other panels

delivered flat.

• Biggest piece measurements (unpacked):

Evaporator block (WxHxD): 43-5/8" x 84-1/8" x 25-5/8"

–

Door (WxHxD): 36-1/4" x 75-1/4" x 7-7/8"

–

• Biggest piece net weights:

Evaporator block: 331 lb.

–

Door: 78 lb.

–

RequiReMent

General

• Wall Clearance

Top: 15-3/4"

–

Sides: 2-3/4"

–

• Ventilation of premises if temperature is higher than 100°F,

taking into account the unit’s heat emission

• Keep away from sources of heat

• Install gutter and siphoning tube

Electrical - Evaporator

• Electrical power supply must conform to regulation

• Voltage: 208-240V / 60 / 1, with ground

• Installed power: 4,000 W - 7.3 A

• Amps: 15 A

• Breakers: 20 A

RR2FS-160

(without condensing unit)

Remote condensing unit

Compressor unit with crankcase heater

–

Condenser (air or water cooled)

–

Liquid receiver, liquid indicator, and drier-filter

–

High pressure controller safety device

–

Condenser pressure controller

–

Electrical box for power supply and all protections for the condensing unit

–

• Remote condensing unit needs to have “pump down” capability

• Refrigerating capacity:

Evaporation temperatures 32°F: 58,000 BTU/hr.

Evaporation temperatures -4°F: 25,000 BTU/hr.

SR2FS-160

(without condensing unit)

Remote condensing unit

Compressor unit with crankcase heater

–

Condenser (air or water cooled)

–

Liquid receiver, liquid indicator, and drier-filter

–

High pressure controller safety device

–

Condenser pressure controller

–

Oil separator if semi-hermetic compressor unit

–

Electrical box for power supply and all protections for the condensing unit

–

• Remote condensing unit needs to have “pump down” capability

• Refrigerating capacity:

Evaporation temperatures -4°F: 82,000 BTU/hr.

Evaporation temperatures -40°F: 36,000 BTU/hr.

• Consult installer for remote condensing unit requirements

appRovalS

RR-SR 2FS-160

A. Electrical power supply

B. De-icing water runoff

D. Liquid line

D1. Suction line

E. Duct

FRiginox – uSa

PO Box 4129 Winston-Salem, NC 27105

800/551-8795 • Ph: 336/661-0257

Fax: 336/661-9546

sales@moffat.com www.friginoxusa.com

Due to an ongoing value analysis program at Friginox, specifications contained in this catalog are subject to change without notice.

FRiginox – Canada

P.O. Box 301, Jordan Station, Ontario L0R 1S0

800/263-5798 • Ph: 905/562-4195

Fax: 905/562-4618

sales@moffat.com www.friginoxusa.com

Loading...

Loading...