Laguna Tools SmartShop MCNC-LTL-CO2-MU-2012-40, SmartShop MCNC-LTL-CO2-MU-2420-40, SmartShop MCNC-LTL-CO2-MU-2420-80 User Manual

SmartShop Laser | MU

MCNC-LTL-CO2-MU-2012-40

ltl-CO2-MU-2420-40

ltl-CO2-MU-2420-80

LAGUNA TOOLS

17101 Murphy Ave.

Irvine, California 92614

Ph: 800.234.1976

www.lagunatools.com

Model Numbers MCNC-LTL-CO2-MU-2012-40

ltl-CO2-MU-2420-40

ltl-CO2-MU-2420-80

© 2017, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the registered trademarks of Laguna Tools, Inc. All rights reserved.

Directory

2.2 Equipment Composition............................................................................................ 7

2.2.1 Equipment Composition................................................................................. 8

2.2.2 Transmission System......................................................................................... 9

2.2.3 Optical System................................................................................................. 10

2.2.4 Control System.................................................................................................11

2.2.5 Peripheral equipment....................................................................................... 12

2.3 Front of the Machine...................................................................................................15

3.Equipment Installation........................................................................................................... 16

3.1Preparation before Installation.....................................................................................16

3.1.1 Site Preparation.............................................................................................16

3.1.2 Personnel Preparation................................................................................... 16

3.1.3 Tool Preparation............................................................................................16

3.1.4 Other Preparation.......................................................................................... 17

3.2 Installation procedure..........................................................................................................17

3.2.1 Package of Laser Tube.................................................................................................. 17

3.2.2 Installation of Laser Tube................................................................................ 17

3.2.3 Water Pump Installation...................................................................................18

3.2.4 Exhaust Fan Installation................................................................................20

3.2.5 Air Pump Installation....................................................................................20

3.3Ground Line Connection..............................................................................................21

4 Equipment Debugging........................................................................................................... 21

4.1Inspection before Debugging.......................................................................................22

4.1.1Boot Process..............................................................................................................22

Power On:..........................................................................................................................22

4.1.2 Test Running................................................................................................. 22

4.2 Laser Debugging.........................................................................................................22

4.2.1 Output of the Laser Tube................................................................................. 22

4.2.2 Laser Path Debugging......................................................................................23

4.2.3Test Processing..................................................................................................28

5. Simple operating instructions................................................................................................29

5.1 Simple operating instructions..................................................................................... 29

5.2Data line using operation............................................................................................. 31

5.2.1 Parameter Matching......................................................................................... 32

5.2.2 Make simple pictures&Set picture layers........................................................37

5.2.3 Set working mode......................................................................................... 39

5.2.4 Download files................................................................................................. 40

5.2.5 Equipment Operation............................................................................................... 41

5.3 U-disk Operation.................................................................................................................43

6. Rotary Processing..........................................................................................................................45

6.1 Electrical Installation.......................................................................................................... 45

6.1.1 Rotary Connection................................................................................................... 45

6.2 Software Operation............................................................................................................. 46

6.2.1 Software Setting.......................................................................................................47

6.2.2 Cutting Test.............................................................................................................. 50

7. Equipment maintenance and repair...............................................................................................54

8. CO2 Laser Tubes of Glass Usage Considerations................................................................ 56

Preface

Thank you for choosing our products. We will provide you with

comprehensive after-sales service and solutions, please keep this

instruction booklet and other attachments for your better use later.

This statement only applied to our standard equipment, for special

ordered Machine, please read the attached documentation.

The Manual is going to show you the work Principle, methods of

installation, operation, troubleshooting, transport and storage and

maintenance. If it’s your first time to use this product, please read this

information carefully before installation and use.

For quick and efficient using this equipment, the user should meet

conditions as below:

A. Operator requires a certain amount of computer expertise to edit the

graphics software ,For Example:

Coreldraw,Photoshop ,Autocad and other CAD software.

B. Operators have a certain knowledge of optics and electrical related

equipment repair and maintenance

C. Confirmed that the operator is familiar with the equipment operating

procedures before starting the and do as it’s instruction.

Apologized that due to the constantly product updated,maybe somewhere

is different with your products.

Brief Introduction of Laser Engraving Machine

1. Safety knowledge

1.1 Basic Information

● Make sure that the operator is trained before operating the machine.

● In order to avoid unnecessary loss,the operator is prohibited from

leaving and must observe the machine at all the times when it under

working.

1.2 Optical Security

Our Equipment Adopts the Fourth Laser that the wavelength is 10.6μm,

Recommended that the operator wear the accredited laser protective

glasses.

Even wear the laser protective glasses and do not look directly at the laser

beam or any reflection of the laser beam.

1.3 Electricity Security

Observe the machine nameplate carefully such as power and voltage

requirement before you access the power supply.

Without our permission,please do not disassemble the electrical parts

yourself .Especially do not touch the laser power supply ,laser tube when

it s working because of its lethal voltage,the danger still exists even

power outage.

1 Hazard

a wide variety of potentially dangerous substances that produced by the

plastic materials when processing can be removed by the ventilation

systems,if the smoke or the smell is too big ,the gas mask is needed.

2 Other hazards

For security purposes,Equipment modification is strictly prohibited

without the manufacturer agreement.

2. Equipment Brief Introduction

Equipment adopted the high-precision transmission shaft and servo-drive

can be realized fast and smooth carving.Non-Metal materials can be cut

or engraved by the high efficiency laser tube.

※※※一※※※※一※※

Machine Series :

BCL:

bodor cutting laser

BML:

bodor marking laser

Working area

:

0503:500mm×300mm

0605:600mm ×500mm

1006: 1000mm×600mm

1309: 1300mm×900mm

1610: 1600mm×1000mm

… ……

Model description

:

M: Mini Series

X: Standard Series

B :Laser Cutting Bed

FB:Fiber Laser Cutting Series

YB/YT:YAG Laser Cutting Series

FP:Fiber Marking Series

additional devices

1-1 Machine Model Description

Example:BCL1309XU means working area:1300mm×900m with up-down system.

2.1 Nameplate Introduction

The nameplate fixed on the right rear of the device which can get more

equipment information.No randomly change or demolition.

2.2 Equipment Composition

Machine Appearance or the some details are different because of the

model or Machine improvement.Specific to the material object as the

standard.

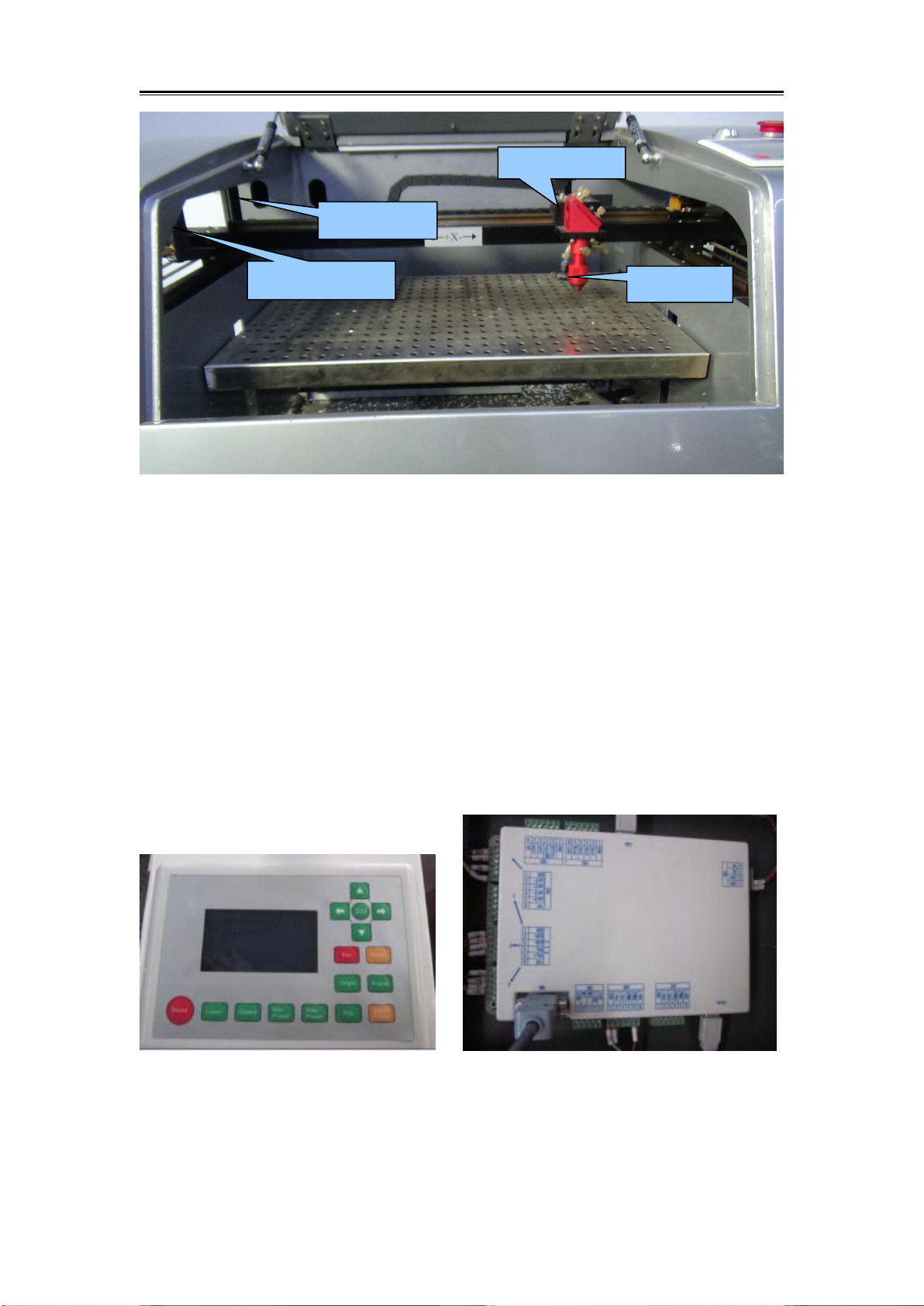

Liner Guide

Laser Head

Slider

Belt

Red Dot System

Nozzle Connector

Unique Equipment Number

2.2.1 Equipment Composition

Laser

Machine

Machine

Body

Transmis

sion

System

Optical

System

Control

System

Peripheral

equipment

Tool Box

1

2

3

4

Picture 1: Machine body:body、transom、upper shield,Up&Down table

1-Liner Guide 2-Laser head 3-Slider 4-Belts 5-Stainless Steel Working

Table 6-Photoelectric switch 7-Nozzle Connector 8-Red Dot System

2.2.2 Transmission System

8

5

6

7

Motor

Transom

Transmission Shaft

Picture 2: Transmission System is Composed of Motor ,Driver ,

Transmission Shaft,Liner Guide,Slider,Belt.

2.2.3 Optical System

Note: Laser tube must be handled with care during installation;High

Voltage and Cathode lines should be tense properly;Water inlet on the

upper and outlet on the below(Reci Tube);Ensure that no bubble inside

the tube;Evenly Strength on both sides when fix the laser tube on the

Basement.Make sure it Solid and not crushed.

Liner Guide

Belts

Slider

Belt

Picture 3:Optical System :Three Reflectors and Focal Lens Device

2.2.4 Control System

Control Systems are different because of the machine model,Specific to

the material object as the standard!

Our control systems as below :Leetro

、

Ruida

Ruida Control Panel Ruida Control Card

First Reflector

Second Reflector

Third Reflector

Focal Lens

Leetro Control Panel Leetro Control Card

Picture 4: Control System:Control pane, Control Car,Computer

Control Card

Power Supply

Laser Power Supply

Data Line

Driver

Relay

2.2.5 Peripheral equipment

Picture 5: Peripheral equipment:Water Pump,Exhaust Fan ,Air Pump

2.2.6 Tool Box

Exhaust Fan Socket

Water Pump

Air Pump

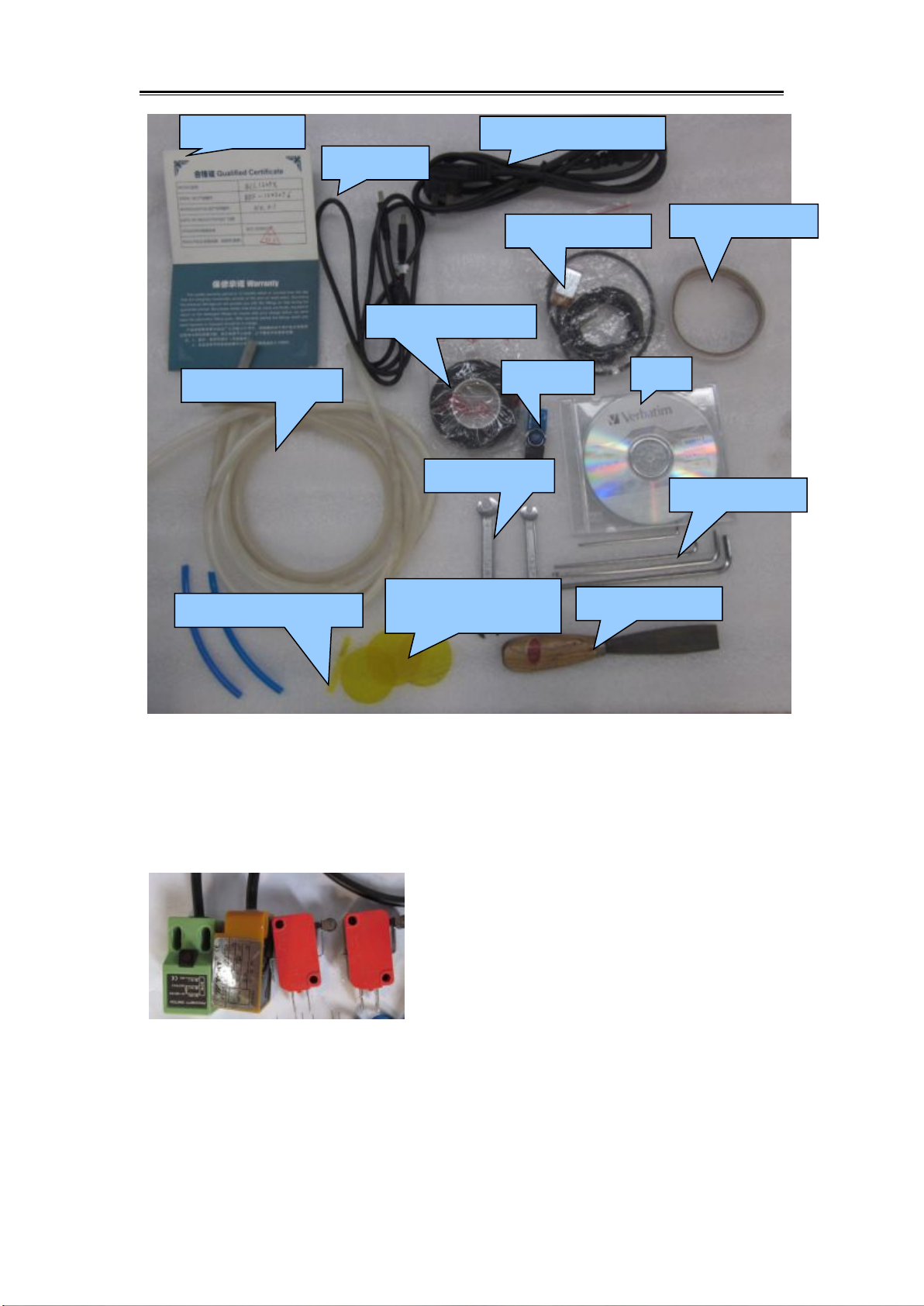

Picture 6 Tool Box

Note:Tool Box is different because of the machine model,Specific to the

material object as the standard.!

Limit switches :Proximity switches and Micro switches

Certification

Data line

Power Supply Line

Limit Switch

Adhesive Tape

High pressure tape

U Disk

CD

Water/Air Pump

Fork wrench

Laser Path

Allen wrench

Focus Distance Block

shovel blade

shovel blade Usage Focus Distance Block Usage

Picture 7 Shovel Blade Focus Distance Block

2.3 Front of the Machine

Picture 8:Control Panel

Focal Distance Block

On/Off button

Emergency Stop

Control Panel

Picture 9: Machine Power Supply Socket

3.Equipment Installation

3.1Preparation before Installation

3.1.1 Site Preparation

Equipment should be set in dry environment without electromagnetism

and high-strength electricity, without pollution's disturbance and effect.

Temperature of working environment is 10-38℃, humidity is 10-90%,

AC 220V±10%, 50HZ,resistance to ground should be smaller than 5Ώ.

3.1.2 Personnel Preparation

The operator must master the main point of installation. Otherwise, the

damage of machine parts will not in our scope of protection.

Three-hole Strip

Ground Line Connector

Fuse

Power Supply Connector

Water inlet

Water Outlet

Air Pump Connector

3.1.3 Tool Preparation

There is tool box with this machine. Besides, multimeter and screw driver

and other detection tools are needed.

3.1.4

Other Preparation

Purified water for water chiller, power strip, pipe for discharge smoke,

sample material, etc.

3.2 Installation procedure

3.2.1 Package of Laser Tube

In case of damage during transportation or outside force, the tube is

packed with sponge. And two ends of tube are sealed with zip lock bag to

prevent the mirror from pollution or scratch. Finally, the tube is built up

with sponge supports to prevent tube have direct contact with

surrounding.

3.2.1.2 Open the carton box, take out the laser tube. Both hands hold the

middle of the tube; take off the sponge supports; take off the packing

sponge; take off the zip lock bag. Then inspect whether the tube is intact.

If tube have any defect, please take photo and send to Bodor for

confirmation.

Attention: It needs as least two person when remove the package. Handle

the tube with care.

3.2.2 Installation of Laser Tube

Open the back cover. You can see two white laser basement, two water

pipes, and black color low-voltage line and red color high-voltage line.

Picture 10:Laser Tube Installation

3.2.2.1

Use Allen wrench M3 take off the screws that fix the laser tube and

remove the upper parts.

Put the low voltage side of the laser tube on the basement that nearby the

First reflector mirror.

Put back the basement upper parts and fix the screws.connect the high

voltage socket and water inlet and outlet pipe.Fix the laser tube well as

Picture 10.

Notice:

●Distance is 2cm between the laser Output and the first reflection mirror.

●Do not too tense to crush the laser tube.

●Solid connect the water inlet pipe to prevent the water leakage.

●Laser Tube inside water flow from the high pressure side to low

pressure side,start to work without bubbles

High Voltage

Basement

Low-Voltage

Water Outlet

Water Inlet

Water Flow Direction

3.2.3 Water Pump Installation

Picture 11 Water Pump

▲Find one container, fill in purified water or distilled water.

▲Put the water pump into this container.

▲Connect the water pump Outlet with the machine water inlet by water

pipe.

Picture 11 Water Pump Installation

Notice

:

● Laser Tube inside water flow from the high pressure side to low

pressure side,Or broken the laser tube.

● When powered on, the bubble in the tube can be removed by extruding

the water pipe or turning the laser tube.

Water Outlet

● Do not touch high voltage lines during working or shut down the

machine for a while,or may cause an electric shock and threaten safety.

3.2.4 Exhaust Fan Installation

Picture 13: Exhaust Fan Connection

Attention ,Exhaust fan is different because the model,Specific to the

material object as the standard.

Exhaust Fan

Air Pipe

Clamp

3.2.5 Air Pump Installation

Connect the Silicone with the machine air connector by a shorten air

pipe.please ensure the laser head blow works fine when power on the

machine.as the upper picture.

Air Pump(compressor)plays an important role in the whole system,the air

filter is necessary for the high pressure gas to prevent that the pollution of

the focal lens and thus effect the engraving.or it will broken the focal

lens.keep the air pipe connector unobstructed :on one hand can keep the

focal lens cleaning ,on the other hand ,to prevent the processed material is

subjected to high-temperature combustion.

3.3Ground Line Connection

The Laser Machine is very strict with ground line connection. Your local

electric system must be meet the local electric security standard.

L : 220V Live line; Phase line

N : Zero Line, compose the electric system together with phase line

E: Grounding line, resistance to ground should be less than 4 Ω

Attention:

Nonstandard grounding may lead to high failure rate and other security

accident. All these are not in the range of Bodor's protection.

4 Equipment Debugging

4.1Inspection before Debugging

Before power on, please inspect and make sure all electric wire terminals

are intact. And move the laser head and X axis beam to make sure they

are smooth enough. Power on when everything is ok.

4.1.1Boot Process

Power On:

Connect the Power supply lines→turn the Emergency stop→press the

green button

Power off:

Press green button→emergency stop→disassemble power supply lines

4.1.2 Test Running

Use the direction key on control panel to test whether laser head can

move normally after power on, whether beam have any noise,each device

can work properly. Debug the laser path is all works properly.

4.2 Laser Debugging

Laser Debugging divided into two sections:output of laser tube and Laser

Path Debugging

4.2.1 Output of the Laser Tube

After the equipment power on, please make sure the water flow direction

is from high-tension terminal (red line) to low-tension terminal (black

line); inlet and outlet water pipe and electric line connect properly. Most

importantly, be sure there is no bubble in the tube.

Next, stick one acrylic block on the first reflection mirror, press the

"Laser" button on control panel to test whether there is laser out of tube.

If there is no facula or weak light, then you need check whether you have

set the ammeter on the max value, or whether the water chiller is

connected in right way. If still have no light from tube, then there may be

some defect of laser tube or laser power supply. Now, you need to have

simple test of this device or take some photo to Bodor for quality

confirmation.

4.2.2 Laser Path Debugging

The laser path is debugged OK before shipment. While there may be

displacement of laser path during long time transportation. So it's better

to debug the laser path again for security.

Laser Fundamental Diagram as below:

Optical system consists of a laser tube, 3 reflection mirrors, 1 focus lens,

a laser head and red dot position system.

Laser shoot out from the laser tube, reflected by first, second, third

reflection mirror, and then reaches the working table through focus lens.

Finally reach on the work table.

Actually ,the working principle is through multi-reflecting and focusing

to achieve the best cutting and engraving effect.During this period ,there

will be no laser if the screws are loosen.

4.2.2.1 Needed Parts for Debugging:

Laser Path Adjustment block,Adhesive Tape, Focal Distance

Block,Shovel Blade,Pliers.

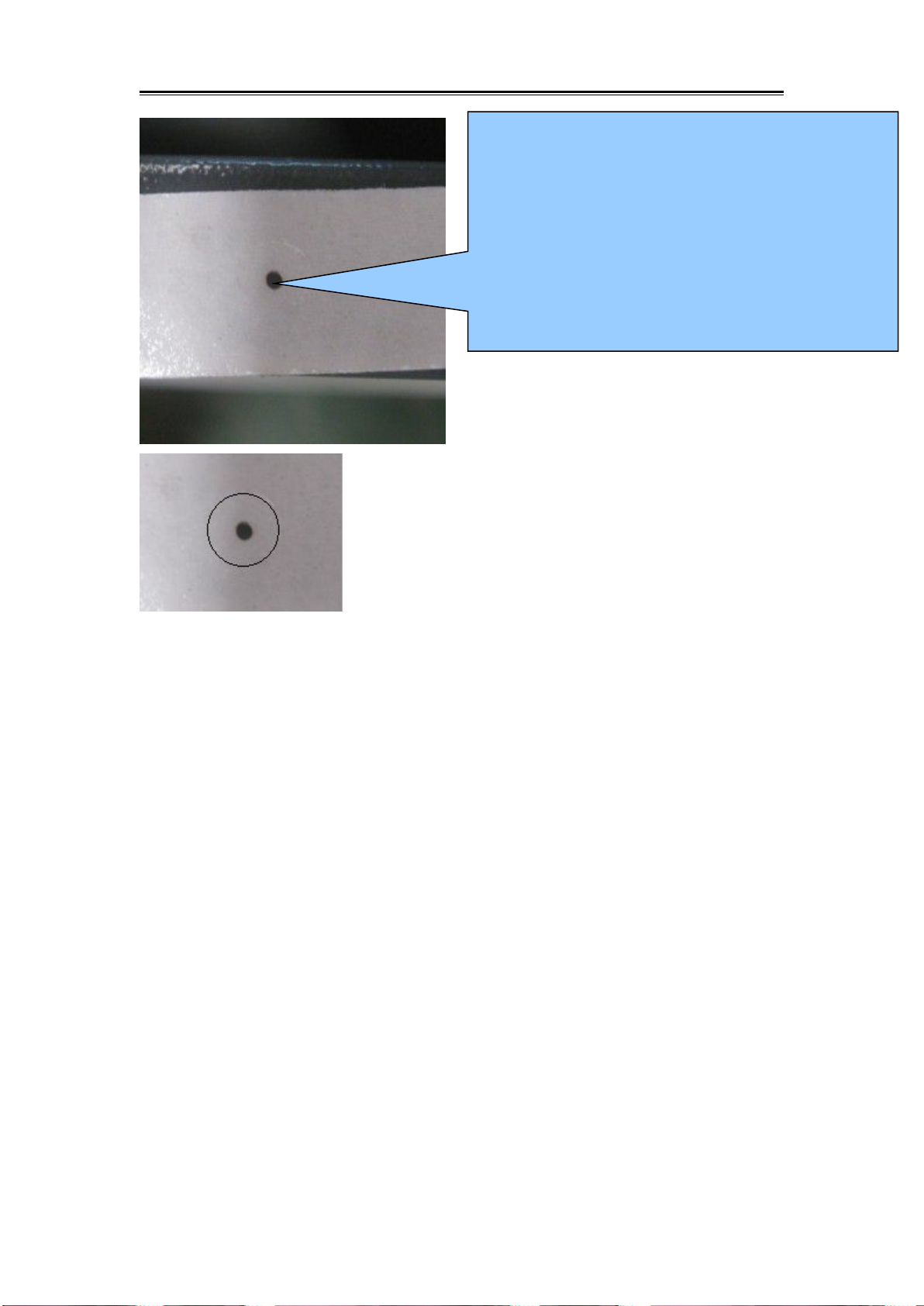

4.2.2.2 Laser Path Debugging Steps

Work Principle:Put the reflected Facula as the point,and then put it in

the center through by adjusting the position of the laser tube.

Detailed Steps:

Laser shoot out from the laser tube, reflected by first, second, third

reflection mirror, and then reaches the working table through focus lens.

Finally reach on the work table.

It's working theory is through multi-reflecting and focusing, to achieve

the best cutting and engraving effect. If light path isn't adjusted properly,

it may destroy laser tube, reflectors, lens and so on. Please re-adjust the

light path if it tilts. Following steps for your reference:

No.2 Screw

Before adjusting the laser, outlet of laser tube

and circular hold on laser head should be

consistent.

The laser beam should shoot on on the right

side of the central point of the mirror. It's

better for reflection.

Adjusting method: adjust first mirror bracket.

2

From the first reflector to second reflector, the laser beam should

be fell on the same point from both nearest and farthest position to

the first reflector.

Upper--please adjust No.1 screw;

Lower--please adjust No.1 and No.2 screw;

Left—please adjust No.2 screw;

Right—please adjust No.1 and No.2 screw.

No.2 Screw

No.3 Screw

If light on same point and not on right

side of the center, please adjust

No.11,12,13 screw.

No.11 Screws (Two)

No.12 Screws (Two)

No.13 Screws (Two)

No.1 Screw

No.23 Screw

No.21 Screw

No.22 Screw

No.11 Screws (Two)

Accordingly, from second reflection mirror to

third reflection mirror, laser should fall on the

same upper side of the center slightly.

Upper—adjust No.21 screw;

lower—adjust No.21,22 screw;

Left—adjust No.22 screw;

Right—adjust No.21,23 screw.

If light is on same point and not on

upper side of the center slightly:

Left or Right -- you need to adjust

No.11 screw;

Upper / lower -- please adjust the

position of laser tube.

No.31 Screw

No.33 Screw

No.32Screw

put a double sides adhesive tape on the

outlet of the laser head, take left hand side

as left, right hand, right;laser tube side, front

and people where we stand, backside. Just

as picture shows

Picture A

Attention:

Laser is invisible light but can do harm to human body. Please keep away

from the laser path when debugging. The operator must master the basic

knowledge of laser machine.

4.2.3Test Processing

After debugging of light path, put the working material on the working

table, then spin the laser head clockwise(overlooking the laser head), to

make it stay in the focal length height. After adjusting the focal length,

then anticlockwise the lens cone nut. Then move the laser head to the

designated spot, finally open software to design patterns you need, set the

processing way, speed and power. Download and name it, then machine

could cut or engrave the files as you command. Take following picture as

a reference.:

Notice:Only need to operate the control panel if there is Auto Focus

System.

The Facula should be in the center of the

outlet as Picture A

If not:

Left -- adjust No.32 screw;

Right -- adjust No.31 and 33 screw;

Front -- adjust No.32 and 33 screw;

Back -- adjust No.31 and 32 screw.

5. Simple operating instructions

Before operation, please electrify the equipment, then connect the

machine USB and computer USB with USB data line.

5.1 Simple operating instructions

A. Double click on ‘RDCAMSetup6.exe’ in the disk then indicate the

dialog box as below:

B. Click【Install】button. Installation interface shows up as below:

C. Click Firstly. The following dialog box shows up.

D. After confirming USB data line is connected well, click “ok”.The

following dialog box shows up.

E. After installing USB drive, click

to install software.

After that, the following dialog box will show up and indicate that the

software has been installed successfully.

Esc:

F.After finishing all installations, click【

】

to end up installation process.

The user may need to install some different software (install external

software while installing LaserWork). So after finishing all installations,

the dialog box cannot close automatically. The user can end up

installation by clicking

【

】button.

5.2Data line using operation

Before operation, the machine has been started. All accessories such as

water chiller and pump can function well

5.2.1 Parameter Matching

Different machines have different versions.

The purpose of reading parameters is to match “Supplier Parameter” and

“User Parameter” in main board with parameters in software.

Double Click the Software“RDWorksV8”

Click the “Vendor Setting” in the “File”as below:

Insert the Password“rd8888” :

Click “Read”after enter into the interface:

Click “user” as shown in the following picture.Click”Read”:

Attention: if changing main board or parameters, please first go through

“Read” Then find parameters of CD or U disk and go through “Open”

and“Read

In the U disk or CD along with the machine, find the file folder named by

machine serial number.

You can check“CHANGJIA.RDVSet”after open it

:

Click Open

Files of

Machine with

After opening it,“Insert Succeed shows up.

Click “User” as shown in the following picture.According to the

supplier’s setting mode, follow the sequence of read—open—write to

import user parameters.

Click Open

After importing parameters of the supplier and user, close the software.

Reopen the software, you can use it normally.

5.2.2 Make simple pictures&Set picture layers

A .In the software, choose “Rectangle”and draw a simple square. Then

modify the size

B. Click “TEXT”.

Click once in the drawing zone.In the dialog box, edit text and click

“OK”button.

Modify the Size

Select the Color Layer after finish the text.:

Color Layer Area

Download Here

5.2.3 Set working mode

Select the Power and Speed according to the materials.(take the

parameter sheet as reference)

5.2.4 Download files

Click “Download”,Name the file and

confirm “ok”

5.2.5 Equipment Operation

On the main board, press”File”

Find your file, press”Enter”

Put your processing object in a right position, adjust a proper focal

distance.

“Origin”-- “Frame”--“Start-Pulse”

5.3 U-disk Operation

(same as Data Line Operation will not be illustrate again)

After set parameters of “Power” “Speed” “Processing Mode”save the file

into U-disk.

Origin

Start-Pulse

Connect U-disk into U-FLASH.

Choose “Read U disk” , Press “Enter”,

Choose your file which need to be processed, choose “Copy to Memory”,

Press”Enter”.

(Notice: the file name you will process should not be the same as your

previous imported file in the main board, if so, U-disk file will not

allowed to import again, you need to change another name then import it

into the main board)

Find the your imported file, then start/cut.

Save To U

File

6. Rotary Processing

6.1 Electrical Installation

6.1.1 Rotary Connection

Place the rotary on the working table and keep flatness.

Unplug the aviation plug that connected with driver.

Connect the male connector on driver with female connector on the

rotary.

6.2 Software Operation

Start up: Reset machine with Metal. Click the limited switch on Y-axis

TWO TIMES to help it reset. Pictures as followed:

6.2.1 Software Setting

Open the software”RDWorks”, File--Vendor Setting--Vendor Parameter

Password: rd8888--OK

Press “Read”, then close the dialog box.

NOTICE: RECORD ALL INITIAL PARAMETERS BEFORE THE

FOLLOWING MODIFICATION.

It has to be recovered when not use rotary.

In the right side of software, choose “ User”--Press “Read”

In the following “Cut Parameters” with red frame, REMOVE A ZERO,

like: 200.00-20.00, 3000.000-300.00, 20.000-2.000, 400.000-40.000,

3000.000-300.00, refer as followed:

Press “Write”

6.2.2 Cutting Test

“Circle pulse” will be changed according to the diameter of processing

object. Formula in the following:

Actual Pulse= {theoretic pulse * theoretic length}/actual length

Illustration: engrave a 20mm line on the bottle (diameter=65mm)

(1) Output--check the box “ enable rotate engrave”--Circle Pulse:

1000--Diameter: 65mm, refer to the following:

Noted: a. The box “enable rotate engrave” should be checked.

b. Diameter: processing object’ s diameter

(2)Draw a 20mm line in the software, parameter setting: suggest “max

speed=15mm/s”, “ max power=15%”, download.

(3) Stick a pare tape on the surface of processing object.

(4) Set right rotary, adjust the processing object in a right position, pull

laser head just above the processing object.

Notice: Direction of rotary confirmation:

Press Direction Button on the control panel, if the direction of rotary

wheel is apposite with the button on control panel, that is correct. If is not,

the engraving image will be mirror image, Then turn the rotary 90 degree.

(5) Adjust proper focal distance then start engraving

(6) Measure the length of line

Through measurement, the length is 16.5mm, it is not matched with

previous setting parameter 20mm, so the circle pulse (10000) is not

correct.

(7) Revise circle pulse, and figure out the following according to

formula:

Actual pulse={10000*20}/16.5=12121

Then fill this value and diameter into the following parameter setting:

Notice:

A. The direction of rotary will influence the engraving effect, if direction

is wrong, the engraving image will reverse.

B. When you do not use rotary, don’t forget set the parameters into initial,

and removed the check of “enable rotate engrave ” .

7. Equipment maintenance and repair

7.1 Daily maintenance

Equipment's working environment could not be too scurviness. If

temperature is higher than 30℃, lower than 18℃, and if there is too

much dust, with severe air pollution, then the machine could be badly

damaged, failure rate goes up steadily. Various electric parts are easily

damaged under wet environment.

7.2Water tank's change and clean(suggest to change water and clean

water tank per week)

Attention: before machine starts to work, be sure that laser tube is full of

water and without bubble.

Recycling water's quality and temperature could affect laser tube's

lifespan directly. We suggest to use pure water, and control the water

under 35

℃。

If it's higher than 35, then need to change recycling water, or

add ice to water(we suggest customers choose water chiller, or use two

water tanks)

Clean water tank: firstly, switch off electric power, take off the water-inlet

water tube to let water inside laser tube go to water tank. Open water tank,

take out water pump, clean dirt on it. After cleaning water tank, changing

new recycling water, put back the water pump. Connecting water tube on

pump to water-inlet gate, and other joints. Connect electric power to

water pump separately for 2-3 minutes(make laser tube be full of

recycling water).

7.3Exhaust fan's clean

After long term's using of exhaust fan, it would accumulate much solid

dust, which could make exhaust fan produce big noise and it is also not

good for eliminating wasted air and smell. When it occurs that exhaust

fan is not good enough to suck and eliminate air, firstly close the power,

take off air-in and out tubes, remove dust inside, bottom up the exhaust

fan, roll fan blades inside until it's totally cleaned. Finally, set up the

exhaust fan.

6.4 Reflectors' and lens' clean(suggest to clean before working

everyday, equipment should be under power off situation)

There are 3 reflectors and 1 lens on Laser equipment(the first reflector is

set on emission exit of laser tube, mean on the laser equipment's

upper-left side, the second reflector is on the left side of transom, the

third one is on the top side of laser head, lens is inside in lens cone), laser

beam is transmitted through these reflectors and lens. It's easily for

mirrors to smear dust and other dirt, which could result in laser's loss or

mirrors' damage. The first and second reflector needn't have to be taken

off when do cleaning. Take lens wiping paper with leaner to wipe

reflectors from center to edge. The third one and lens need to take off

from lens frame and clean them with same way, and put back after

finishing.

Attention:①wipe the reflectors and lens softly, do not damage their

surface coating film;②handle gently during wiping to avoid falling

down;③the convexity side must be arranged downward.

6.5 Guide rail's clean (suggest clean half a month, power off operation)

As key parts, guide rail and straight line axis play role of guiding and

supporting. In order to guarantee higher processing precision, higher

requirement for guide rail's guiding accuracy and straight line axis'

moving stability. During processing, the material processed can produce

much corrosive dust and smog. After long term acceleration of these dust

and smog on guide rail and straight line axis, equipment's working

precision can be affected and can also form corrosive spot on them, thus

shorten machine's lifespan. For maintaining equipment's normal and

stable work, make sure the products' processing quality, please do well in

guide rail and straight line axis' daily maintenance.

Attention:For cleaning guide rail, please prepare dry cotton cloth,

lubricating oil(sewing machine oil can be adopted).

6.5 Light path's examination

Laser engraving equipment's optical system consists of reflectors'

reflection and lens' focusing. In light path, lens doesn't exist excursion,

however, the three reflectors are fixed through machinery, so possibility

for excursion can be big. Generally speaking, the light path could be

skewing, we suggest users to test it before everyday working.

6.6 Slide block's maintenance

Slide block is one of key parts. It's role is to guide and support, same as

guide rail and straight line axis. In order to guarantee it's normal work,

lubricating oil must be added periodically.

8. CO2 Laser Tubes of Glass Usage Considerations

8.1 Before using, please connect the water pump/chiller first, adopts

lower side in and higher sider out principle, adjust water-outlet tube's

position, guarantee cooling water is full of cooling tube. There should be

not any bubble inside the laser tube, then power on.Requirement: cooling

water should adopt software(distilled water or pure water), and frequently

pay attention to cooling water's temperature, should be within 12-30℃. It

should not be too low or too high, especially in summer. Once water's

temperature is too high, should change cooling water in time or stop the

equipment for some time. Cold area should guarantee water should not be

freeze, especially when machine stops working, cooling water must not

stay inside in laser tube in case there is any frozen cooling water to cause

explosion.(Specially attention: users who use AC, cooling water tank

must connect with ground)

8.2 The two supporting points should be on the 1/4 point on the laser tube,

and guarantee water-flow at the level of 2L-4L per minute, or the effect is

not good, which could lead to mode hopping, light spot becomes several,

thus result in power going down. Cooling water's water-outlet tube must

be submerged in water, or there will occur laser tube is not filled totally

with water when power off and on.

8.3 Pay attention to protect laser tube's exit side, to avoid smog sputtering

on the exit surface and pollute the it, or power will be lower down. The

mirror on exit side can not be cleaned with cotton ball and other tools, or

it's power will be severe affected. Correct methods for cleaning this

mirror:

●

once the mirror is polluted, do not open the laser tube

● obliquely blow mirror's surface

● use pure alcohol compressed by cylinder needle to spray the mirror

surface

● open the laser after alcohol volatilizing totally

If above methods have no effects, professional stuff need to use cotton to

clean it's surface from center to edge vortically with cotton ball dipped in

alcohol. The best way is to protect mirror from pollution. Special

attention: don't use ACETONE to clean the mirror.

8.4 During the debugging, through adjusting laser tube's supporting

position or rotating laser tube's direction to reach the best effect, then fix

the laser tube.

8.5 Must pay attention: avoid dust acceleration on high voltage electrode,

keep dry. Be away from metals as much as possible in case any fire

hazard. In order to protect high voltage sheath from dust, please entangle

plastic wrap on it.

8.6 During using of laser tube, there should be no scale inside laser tube

in case to cause water plugging, thus affect cooling effect. Once there is

any scale, use 20% diluted hydrochloric acid clean it.

8.7 Laser tube belongs to glass products, fragile. Avoid local stress when

arranging laser tube.

8.8 To use laser tube properly, save laser power. Laser tube's best power

is 80% of rated power.

9. Common troubleshooting

Symptoms

Problem analysis

Processing method

No laser beam

during working

1. Firstly, check if laser tube itself works

normally(the exit of laser),if it works

normally

Test if mirrors are damaged

or not, light path is skewing.

2. The exit of laser tube has no laser, then

check if water recycling works

normally(see if water flow is smoothly), if

no water flow or it's not smoothly

clean water pump, dredge

water tube

3. Water recycles normally, then check if

laser power guiding light is bright or not,

fan rotates or not, if not

Laser power goes bad, need

to change laser power

4. Press "laser", if there is no light

Laser power or laser tube has

problem

5. If there is light

Water protector goes bad,

need to change

6. If short circuit water protector, there is

still no light

Main board or wiring board

has problem, need to change

Scanning

becomes

shallow

1. Check working light's intensity and

speed, if speed is too fast, intensity is

small, water temperature is too high

Enlarge light's intensity,

lower down speed, change

recycling water

2. Check depth of crisperding, and see if

it's normal, if it's normal,

Increasing graphics resolution

or scanning precision

3. Crisperding is still shallow, or both

occasionally,

Check if Mirrors are dirty or

damaged, light path is

skewing

4. Connect ampere meter, if it can reach

20MA, but the depth is still shallow

Laser tube aging, need to

change laser tube

Laser is not

stable,

sometimes has,

sometimes does

not

1. Check if the mirrors are too dirty or if

they are damaged, light path is skewing or

not

Clean or change mirrors,

adjusting light path

2. Mirrors' light path is normal, then check

if water recycling is normal or not, if it is

not normal,

Clean or change water pump,

dredge water tube

3. Water cycling is normal, it's may water

protector's problem

Change water protector

4. If problems remain, main board, laser

power, laser tube, all possible to lead to

this phenomenon

Change all part above

alternately, and check the

reason

Output

patterns, but

the size is not

right

1. Check "Coreldraw" and see if Graph

Plotter unit is 1016 when it outputs PLT

1016Change graph plotter's

unit to 1016

2. See if resolution ratio is right or not

Recount resolution ratio

Equipment

reset abnormal

1.The direction is right when reset, but

reaches the vertex,the transom can not

stop(if new machine, please check main

board's parameter first, if it's right)

Check if it's stuck during

moving, main board, tool

sensor problem, change

2.Transom resets normally, laser head

doesn't move, maybe tensioner get stuck or

motor axis break, parameter is wrong

Change tensioner or small

motor, modify parameter,

check motor line's clip

3.Contrary to transom's movement, and

strike the side

Main board parameter is

wrong. Stop the machine and

modify main board

parameter. Re-down load

configuration

4.Drivers or Motors' problem

Change drivers or motors

Equipment stop

engraving, skip

engraving or

disordered

engraving

1.Check equipment's grounding situation,

and check grounding line is standard or

not(resistance to ground should not be

bigger than 5Ώ)

Modify grounding line to

reach standard requirement.

2.Check if the original pattern has mistake,

such as pattern is cross, leaking, or lack

something

Correct mistakes in patterns

3.If other patterns don't have this problem,

only some one has such problem

Patterns and date mismanage,

need to make working sketch

again

4.Problem remains

Maybe it's computer's serial

port, engraver's main board's

problem

Appendix 1

After-sale warranty of Laser Engraving Cutting Machines

First of all, thank you very much for purchasing a Bodor product. In

order to guarantee the smooth processing of after-sales service, we will

make the following announcements:

General principles

1. We are responsible for the maintenance of facilities which are

within the Warranty conditions.

2. Users must keep the machine's integrity and independence during

operation. In the following situation, our company will not take any direct,

indirect or joint liability. Futhermore, if any equipment is damaged or

there are any losses in either economic or reputation to our company due

to the following situation, we, Bodor company, reserve the right to

investigate any legal liability.

1) Using the equipment in an environment that it was not designed

for..

2) Altering the machines privately, including, adding parts, reducing

parts, dismounting, using another brand's parts, etc.

3) Human damage or doing operations and maintenance without

following the requirements in the instructions.

4) Damage caused by movement or transportation.

On condition of not influencing the machine's performance, our

company reserves the right to change the product's specifications and

name the products before informing the customer.

Our company is responsible for the quality and performance of the

machine we sell. However, we are not responsible for other indirect

obligations and responsibilities.

Detailed Principles

Equipment Warranty: 2 years. Calculated from the production date in

machine’s nameplate.Specific details are as below:

2 .Laser module Warranty:

(1)RF Tube’s and fiber module’s warranty: 1 year

(2)Standard CO2 Glass Laser Tube’s warranty: 40w ~ 80w: 4

months ;100w ~ 150w: 6 months.Warranty of related laser power supply

is one year.

(3)RECI Laser Tube’s warranty: 10 months .Warranty of related laser

power supply is one year.

(P.S. Laser module’s warranty date calculated from the production

date in laser module tag. CO2 Laser Tube is suggested to be used in

nonmetal and opaque materials’ engraving and cutting,and should be keep

clean. Improper use will cause the front lens to breakdown. Any

breakdown of the front lens and an incomplete laser tube will not be

guaranteed.

3.The warranty does not include consumable parts, such as glass mirrors,

belts, switches, gas nozzles ,foots/wheels, keys/press boards, etc.

4.Warranty of peripheral devices (if the machine has them):

Warranty of peripheral devices is 1 year, calculated from the production

date in the device’s tag. Maintained by device’s manufacturers as

standard,Our company assist maintenance. Peripheral devices including

water-chillers, fans, air pumps, water pumps etc.(If the machine has

them).

Accessories repair and shipping cost

Within the warranty period:

For free repair or replacement of accessories, the buyer should bear

the shipping costs from their local place to our company if it needs to

tested, repaired or replaced.

If the failure cause by the parts quality after testing(non human

factors and use environment etc.), it will be repaired or replaced free of

charge, and Bodor company will bear the return shipping cost. If the

failure doesn’t cause by the parts quality, the buyer should pay the repair

fees and round-trip shipping cost.

P.S. The repaired parts should be returned to our factory. if the buyer is

in arrears of spare parts, Bodor company will cancel the warranty terms

of the machine).

Outside the warranty period:

The buyer should paid for repairs and round-trip shipping.

Door to Door Service Policies

Bodor supplies door to door services all over the world. Charging

standards and service processes are as below:

(A). Charging standards:

1. Technician visa fees, domestic travel expenses (including

transportation cost occurred during handling documents);

2. Training and maintenance fees: $100/day/person(take the time of

landing and starting off of plane in customer’s country as standard);

3. International round-trip tickets (reserved and paid by the buyer, and

supply the e-ticket information to our company );

4. Abroad accommodation(arranged and paid by the buyer)

(B).Overseas training/maintenance processes:

1. Bodor company will calculate the fees of item 1 and item 2 above,

and then inform the buyer. After the buyer pays the fees, Bodor company

will arrange for the technician to apply for a visa.

2. We will inform the buyer after the technician gets the visa. The

buyer should supply the round-trip ticket information mentioned above in

item 3, and arrange accommodation from item 4 after the technician

arrives.

3. Only after getting the approval of Bodor company, the buyer can

apply for an extension for the training and maintenance.The buyers

should pay for the“extend training and maintenance service fees”before

the start of the extend service.

Appendix 2

Reference Parameter Setting List for Cutting/Engraving:

40W PARAMETER SETTING

Thickness(mm)

Speed

(mm/s)

Max Power

(%)

Min Power (%)

Acrylic

3mm

10~15

50~75

50~70

6mm

4~5

65-80

65~75

8mm

2~5

60~80

65~75

Cloth/ Paper

1mm

100

25

22

Leather

2mm

100

35

30

MDF (WOOD/PAPER)

3mm

306055

6mm

107065

9mm

38075

Glass

300~600

18-65

Interval 0.03-0.1

Acrylic

300-600

18-65

Interval0.03-0.1

Double-color board

30-50

40~50

Cutting

Double-color board

300~600

23~30

Interval0.03-0.1

80W PARAMETER SETTING

Material

Thickness

Speed

Working Max

Power(%)

Corner Min

Power (%)

Usage

Remarks

Acrylic

3mm

10-20

40-70

35-70

Cutting

6mm

5-10

70-80

65-80

Cutting

8mm

28075-80

Cutting

Lower than

the focal

Block

0.5mm

10mm

1-28075-80

Cutting

Lower than

the focal

block 1mm

Cloth/ Paper

0.5mm

100-400

20-50

20-50

Cutting

Leather

0.5mm

100-400

35-50

35-50

Cutting

Double-color

board

1.5mm

30-50

45-55

Cutting

Marble

300-600

25-75

Engraving

Interval

0.03-0.1

Acrylic

300-600

25-75

Engraving

Interval

0.03-0.1

Wood

300-600

25-75

Engraving

Interval

0.03-0.1

Double-color

board

300-600

25-75

Engraving

Interval

0.03-0.1

Notice:

Above parameters are just for your reference, please change accordingly

based on your materials.

Loading...

Loading...