CNC Lathe 3-Axis

Manual

LAGUNA TOOLS

2072 Alton Parkway

Irvine, California 92606

Ph: 800.234.1976

www.lagunatools.com

Model Number: MCNC Lathe 1000-0233

© 2018, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the registered trademarks of Laguna Tools, Inc. All rights reserved.

Table of Contents

Page Number

Safety Rules 4

Warranty 5

Noise Emission 6

Specification Sheet 6

Receiving Your CNC Lathe 6

Introduction to Your CNC Lathe 6

Parts of CNC Lathe 7

Additional Instructions for the Use of the CNC 10

Where to Locate Your CNC Lathe 10

Unpacking Your CNC Lathe 11

Assembly and Operation 12

Maintenance 17

Troubleshooting 18

3

Safety Rules

As with all machinery, there are certain hazards involved with the

operation and use. Using it with caution will considerably lessen the

possibility of personal injury. However, if normal safety precautions are

overlooked or ignored, personal injury to the operator may result. If

you have any questions relative to the installation and operation, do not

use the equipment until you have contacted your supplying distributor.

Read carefully before operating the machine.

1. Keep the working area clean and be sure adequate lighting is available.

2. Do not wear loose clothing, gloves, bracelets, necklaces or ornaments.

Wear face, eye, respiratory and body protection devices as indicated

for the operation or environment.

3. Be sure that the power is disconnected from the machine before

tools are serviced or an attachment is to be fitted or removed.

4. Never leave the machine with the power on.

5. Do not use dull, gummy or cracked cutting tools.

6. Be sure that the keys and adjusting wrenches have been removed

and all the nuts and bolts are secured.

4

Limited Warranty

New machines and accessories sold by Laguna Tools carry a one-year warranty

effective from the date of shipping. Machines sold through dealers must be registered

with Laguna Tools within 30 days of purchase to be covered by this warranty. Laguna

Tools guarantees all new machines and accessories sold to be free of manufacturers’

defective workmanship, parts and materials. We will repair or replace, without charge,

any parts determined by Laguna Tools, Inc. to be a manufacturer’s defect. We require

that the defective item/part be returned to Laguna Tools with the complaint. Any

machines returned to Laguna Tools must be returned with packaging in the same

manner in which it was received. If a part or blade is being returned it must have

adequate packaging to ensure no damage is received during shipping. In the event the

item/part is determined to be damaged due to lack of maintenance, cleaning or

misuse/abuse, the customer will be responsible for the cost to replace the item/part,

plus all related shipping charges. This limited warranty does not apply to natural

disasters, acts of terrorism, normal wear and tear, product failure due to lack of

maintenance or cleaning, damage caused by accident, neglect, lack of or inadequate

dust collection, misuse/abuse or damage caused where repair or alterations have been

made or attempted by others.

Laguna Tools, Inc. is not responsible for additional tools or modifications sold or

performed (other than from/by Laguna Tools, Inc.) on any Laguna Tools, Inc.

machine. Warranty maybe voided upon the addition of such described tools and/or

modifications, determined on a case-by-case basis.

Software purchased through Laguna Tools Inc. is not covered under this warranty

and all technical support must be managed through the software provider. Software is

non-refundable.

Normal user alignment, adjustment, tuning and machine settings are not covered by

this warranty. It is the responsibility of the user to understand basic machinery

operation, settings and procedures and to properly maintain the equipment in

accordance with the standards provided by the manufacturer.

Parts, under warranty, are shipped at Laguna Tools, Inc.’s cost either by common

carrier, FEDEX ground service or a similar method. Technical support to install

replacement parts is primarily provided by phone, fax, e-mail or Laguna Tools

Customer Support Website. The labor required to install replacement parts is the

responsibility of the user.

Laguna Tools is not responsible for damage or loss caused by a freight company or

other circumstances not in our control. All claims for loss or damaged goods must be

notified to Laguna Tools within twenty-four hours of delivery. Please contact our

Customer Service Department for more information.

Only new machines sold to the original owner are covered by this warranty.

For warranty repair information, call 1-800-332-4094.

Noise Emission

Notes concerning noise emission

Given that there exists a relationship between noise level and exposure times, it

is not precise enough to determine the need for supplementary precautions. The

factors affecting the true level of exposure to operators are clearly the amount of

time exposed, the characteristics of the working environment, other sources of

dust and noise, etc. For example, adjacent machines may affect the level of

ambient noise. It is possible that exposure level limits will vary from country to

country.

Specification Sheet

Spindle Motor

Spindle RPM 5,000 - 24,000 RPM Spindle

Controller Laguna HHC (Hand Held Controller)

Volts One phase machine 220v /30 amp

Ball Screw on Vertical Axis Yes

Rack and Pinion on Horizontal

Axis

Maximum Diameter 8"

Maximum Travel Length 46" or 72"

Machine Foot Print 73"L x 24"D x 65"H

Receiving Your Machine

Note: It is probable that your machine will be delivered by a third party. Before

you unpack your new machine, you will need to first inspect the packing, invoice,

and shipping documents supplied by the driver.

Ensure that there is no visible damage to the packing or the machine. You need

to do this prior to the driver leaving. All damage must be noted on the delivery

documents and signed by you and the delivery driver. You must then contact the

seller, Laguna Tools, within 24 hours.

3HP 3 Phase Industrial Induction Spindle,

Liquid Cooled

Yes

Introduction to CNC Lathe

The CNC Lathe is designed to give you years of safe service. Read this owner’s

manual in its entirety before assembly or use.

The advantage of the CNC machine is that it can, in most cases, fully machine

the complete job without it being removed from the Lathe so that you have

finished parts of high accuracy that are totally repeatable.

It can also produce intricate carvings with the purchase of the relevant software.

It is possible to reduce the amount of different machines in the shop, as the CNC

Lathe will perform a multiple of functions and is a must for serious woodworkers.

6

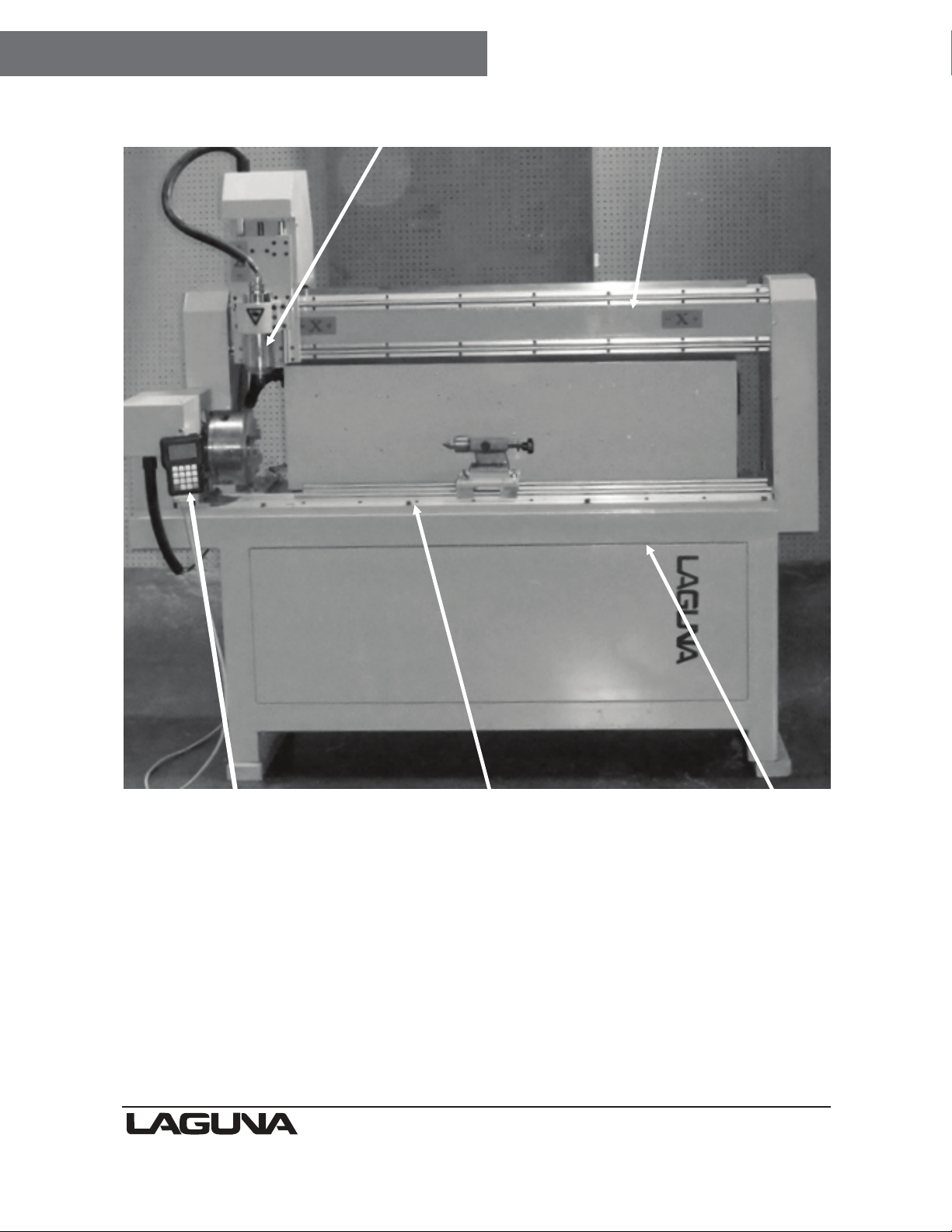

Parts of the CNC Machine

Router Spindle

Gantry

Hand-held controller

Note: Some of the photographs in the manual may not be identical to your

machine, but the principle that they show is the same for your machine.

Laguna Tools operates a constant improvement program, and changes to

machines are ongoing.

Bed

The bed of the machine consists of a heavy steel frame that supports linearbearing

rods. The tail stock slides along the rods and can be clamped in any

position to suit the job at hand.

Bed

Frame

7

Gantry

The gantry runs along the back of the lathe

and supports the linear bearing rods. The

router spindle moves along the rods on linear

bearings. It is moved along the length of the

gantry rack and pinion that is controlled by the

machine controller.

Frame

The frame is a heavy welded construction that

supports all the other parts of the machine.

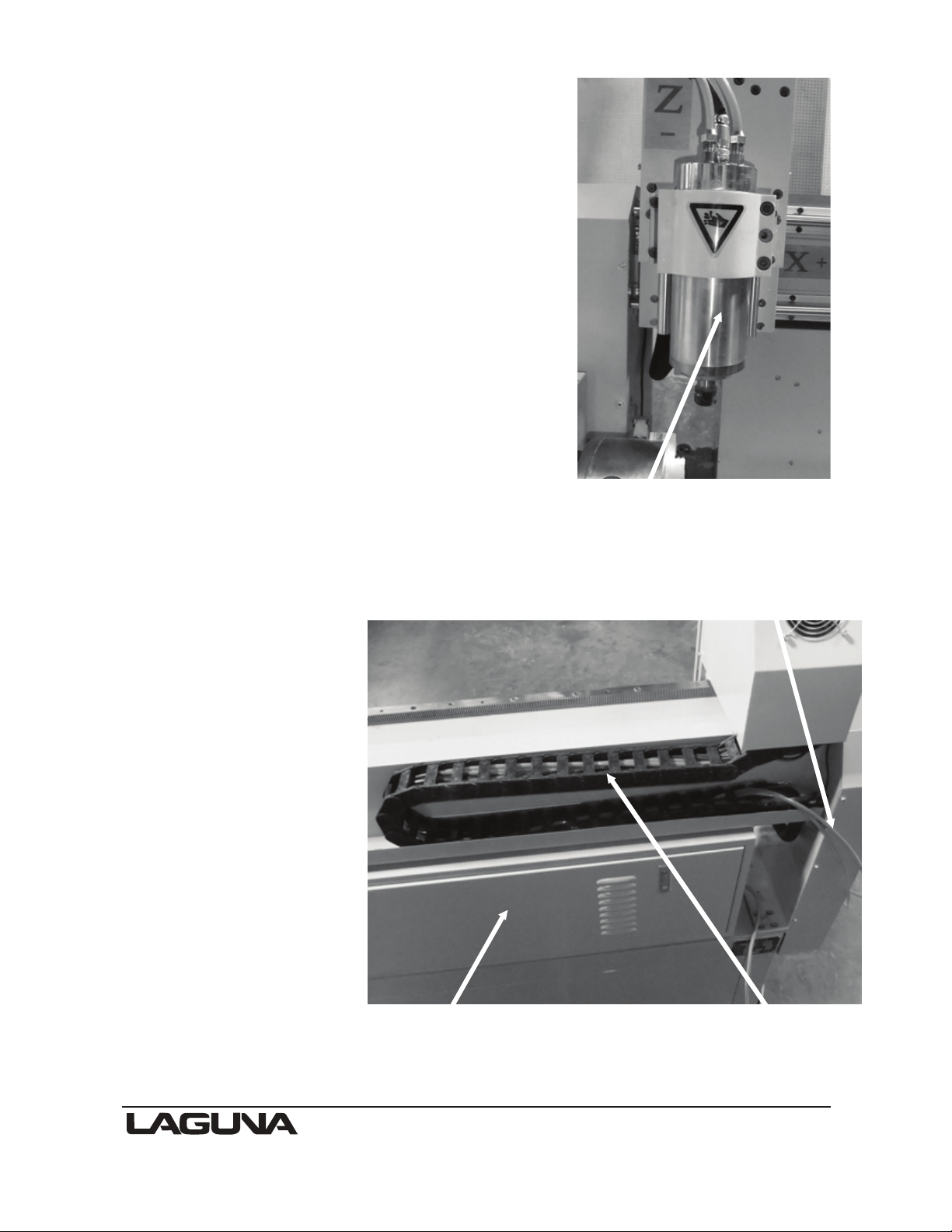

Router Spindle

The router spindle is moved vertically by a

precision ball screw system that is controlled

by the machine controller.

Note: If the spindle is run without cooling,

it could be damaged and fail.

Caterpillar track

The caterpillar track runs at the

back of the lathe and contains all

the electrical cables and the

motor water pipes.

Electrical cabinet

The electrical cabinet is

located at the back of

the lathe and contains all

the control equipment.

Water pump

The water pump provides

coolant for the router

spindle motor.

Running the router

spindle without the

cooling pump running

can lead to

spindle bearing

failure.

Router spindle

Motor water pipes

Electrical cabinet Caterpillar track

8

Tail stock

The tail stock runs on liner bearing rods. The tail stock slides along the rods and

can be clamped in any position to suit the job at hand.

Chuck drive

The chuck is driven through a right-angled

drive and is under the control of the on-board

computer.

Spindle vertical movement

The spindle is moved vertically by a motor that

rotates a precision ball screw.

The vertical movement is limited by a home

proximity switch.

Spindle clamp Spindle adjustment

Tail stock clamp Linear bearing rods

Spindle drive [cover

removed]

Tail stock clamp

Chuck drive shown with the

cover removed

Z Home limit switch

Precision ball screw for the Z axis

9

Machine data plate

The machine data plate is located at the

back of the machine and contains all the

machine information.

Hand-held controller

The hand held controller controls all

functions of the lathe.

Note: See separate manual for the

operation of the hand held controller..

Additional instructions

for the use of the CNC

Like all machines, there is danger associated with the machine. Injury is

frequently caused by lack of knowledge or familiarity. Use this machine with

respect. If normal safety precautions are overlooked or ignored, serious personal

injury may occur. As the CNC lathe is under the control of the onboard machine

controller, it is important that you are clear of the cutter when operating the

machine.

Where to locate your Machine

Before you unpack your machine, select the area where you will use your

machine. There are no hard-and-fast rules for its location, but below are a few

guidelines.

1. There should be an area around the machine suitable for the length of wood

that you will be machining.

Controller

2. Adequate lighting. The better the lighting, the more accurate and safely you

will be able to work

3. Solid floor. You should select a solid flat floor, preferably concrete or

something similar.

4. Close to power source and dust collection.

10

Unpack the machine

To unpack your machine, you will need tin snips, knife and a wrench.

1. Using the tin snips, cut the banding that is securing the machine to the pallet

(if fitted).

WARNING: EXTREME CAUTION MUST BE USED BECAUSE THE

BANDING WILL SPRING AND COULD CAUSE INJURY.

2. Remove the box from the CNC machine (if fitted) and any other packaging

material. The parts ordered with the machine will be packed on or inside the

machine.

Note: The machine is heavy, and if you have any doubt about the described

procedure, seek professional assistance. Do not attempt any procedure that you

feel is unsafe, or that you do not have the physical capability of achieving.

3. Use a forklift with sufficient lifting capacity and forks that are long enough to

reach the complete width of the machine.

4. Remove the securing bolts that attach the machine to the pallet (if fitted).

5. Approaching the machine from the front, lift the machine on the frame, taking

care that there are no cables or pipes in the area of the forks.

6. Move the machine to the required position and lower gently to the floor.

7. Level the machine so that the lathe is not rocking and the machine is level in

both directions using a spirit level.

11

Assembly and Operation

Cleaning the machine

Clean off any protection grease with WD40 or something similar.

The machine has steel parts that if not protected will rust, lubricate with WD40 or wax.

Use 30wt motor oil or lithium white grease lubricant or equivalent to lubricate the ball

screws. Wipe off any excess to reduce dirt and dust acumination.

Assembling the hand-held controller

Note: See separate manual for the operation of the hand-held controller.

Memory stick socket

Connection cable

Fit the cable to the controller and ensure that the screws are finger tight. The

USB printer cable port is used to connect the controller direct into your computer.

Note: The connection port socket and plug only fit one way, so ensure that the

plug is the correct way up prior to assembling.

Cabinet socket

Hand held controller

Controller cable fitted to cabinet socket

12

Electrical connections for the machine

The main power cable and has no plug fitted, as it will be dependant on your

insterlation. Ensure that when installing the electrical supply to the machine, 220v

single phase is supplied.

It is recommended that you use a 30-amp breaker.

Note: When wiring the machine to your electrical system, keep your cable as

short as possible, and the cable should not be allowed to run along the floor, as

this will cause a trip hazard.

The second cable has a female electrical socket for connection to the water pump.

Note: A qualified electrician must carry out the electrical installation.

Water-cooled spindles

Water-cooled spindles will be provided with a 220-volt spindle-cooling pump.

The submersible pump needs to be submerged in a minimum 5-gallon

reservoir of water (the bigger the water tank the better).

Never run the spindle without cooling,

or the spindle will be damaged or destroyed. (WITHOUT WATER FLOWING

THROUGH THE SPINDLE, THE SPINDLE WILL OVERHEAT AND FAIL.)

Connecting the water pipes to the machine

There are two water tubes that come out of the machine. These are used to

provide cooling for the liquid-cooled router spindle.

Note: The water pump design may vary from the one shown.

Fitting the water pipe

Note: Never run the motor without the cooling being connected, or the

motor could be damaged.

You will connect one tube to the water pump, and the other will be placed in the

water container for the return water. It is not important which pipe is used as the

return.

Fit the pipe fitting to the pump.

Connect one of the coolant pipes to the water pump by pushing it into the connector.

Lightly pull on the pipe to ensure that it is connected correctly. Fill a container about

3/4 full with clean water. If the pipe needs to be removed from the pump, press the

outer ring into the fitting and gently pull the pipe out of the fitting.

Water pump

Pipe fitting

13

Note: You will need to provide a coolant tank with a minimum capacity of 5

gallons. If the shop temperature is high, the tank size will need to be larger. If

your shop is likely to be subject to freezing temperatures, antifreeze must be

added to the cooling water.

Lower the water pump into the container, ensuring that it is the correct way up

(water inlet lowest) and place the water return pipe into the container.

The logical position for the water container is close to the machine, as the water

pipes exit the machine at the back. Once the assembly is complete and the water

pump electrical connection has been made, lift the water return pipe up and

check that the water is flowing.

Place the lid onto the container to keep dust and dirt out of the container.

Check the container periodically, as the water will evaporate.

Note: If the spindle is run without cooling, it could be damaged and fail. It is

strongly suggested that the water pump is run for at least 5 minutes after

the spindle is switched off to remove residual heat.

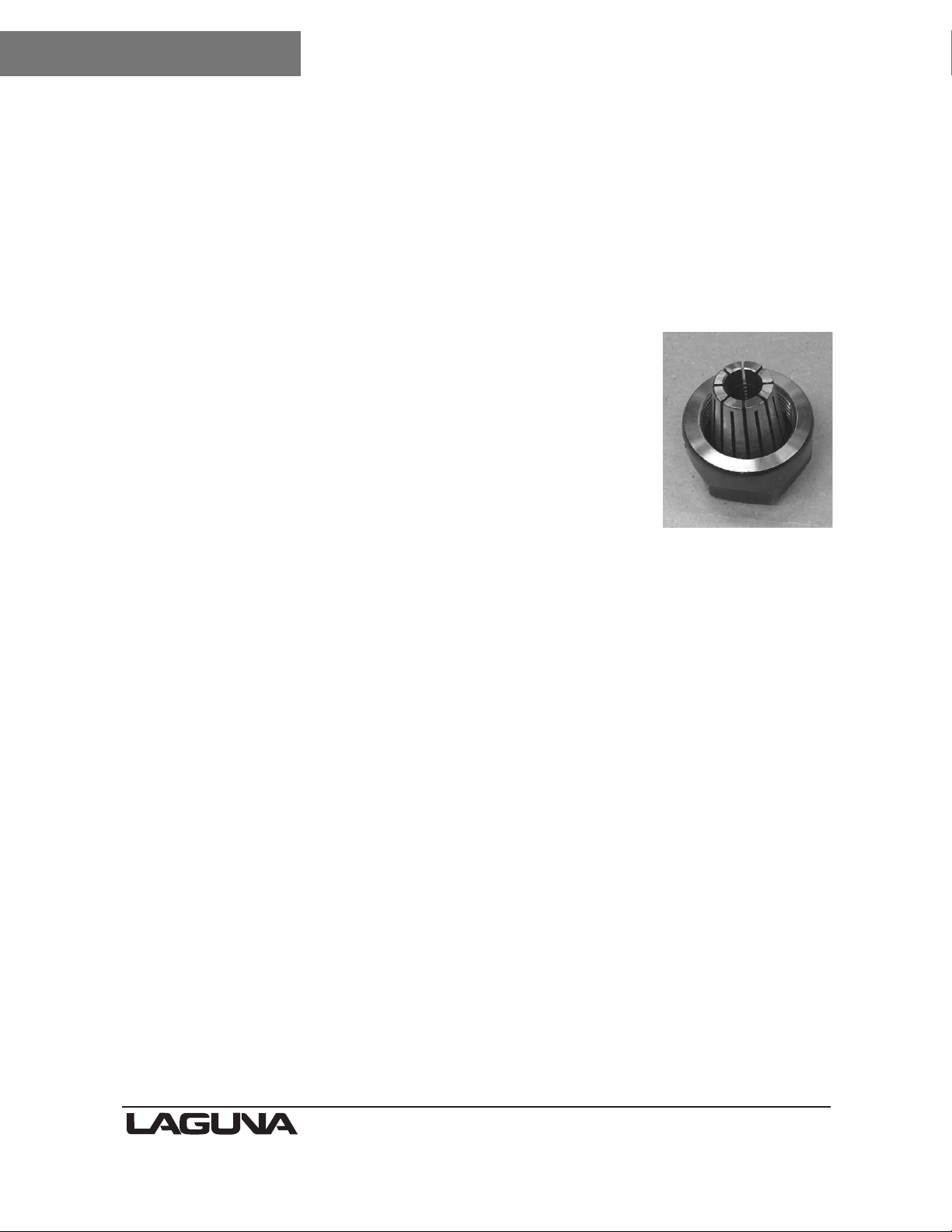

Fitting the router bit into the router head

Note: Before changing or fitting the router bit,

always disconnect the power to the machine.

Note: Collets and spindle collet hole must be

cleaned regularly. Ensure that the slots in the

collets are free of sawdust, as sawdust builds

up and will stop the collet compressing. If the

collet or spindle hole is not clean, the router

bit may not run true, and this will affect the

performance of your machine.

Spindle nut Collet

1. Select a pointed router bit and its relevant collet.

2. Fit the collet into the spindle nut. Press the collet into

the spindle nut until it snaps into place.

Note: The router bit must not be fitted into the collet until

the collet has been fitted into the spindle nut. With the

router bit fitted into the collet, the collet cannot compress

and snap into the spindle nut.

The face of the collet and the face of the spindle nut will

be close to flush.

Note: To remove the collet, hold the spindle nut and

press the collet on the side. The collet will compress and

pop out. Do not try to remove the collet while a cutter is

fitted, as the collet will not compress and pop out.

3. Fit the spindle nut and collet assembly onto the

spindle thread by hand.

4. Press the bit into the collet, but note that the flute of

the router bit must not be inside the collet and should be

a minimum of 1/16" outside the collet. Hold the router

spindle with the supplied wrench and tighten the collet

with a second wrench. Do not over tighten.

Note: Use this process for all other router bits that you need to fit but you will

have to change the collet if the shank of the router bit is a different size.

Tightening the spindle nut

Collet fitted to

spindle nut

14

Types of router bits

There are five basic types of router bits: straight, up

shear, down shear, combination (also called

compression), and form tools (round over, ogee, etc.).

1. Straight Router Bits

These are the standard router bits that are commonly

used with handheld routers and are readily available at

home centers.

2. Up Shear Router Bits

These bits have flutes that are spiraled upward (a standard twist drill is an

example of this type of bit). This bit design removes the chips from the kerf but

has a tendency to chip the top surface, especially veneers or melamine surfaces.

Ball nose router bits are a variation of the up shear bit design but have a

radiused end. These bits are typically used for 3-D surfacing applications.

3. Down Shear Router Bits

These bits are similar to the up shear but with an opposite spiral that actually

tends to pack the chips into the kerf. These bits prevent chipping the material

surface, especially with veneers or melamine surfaces.

Router bits

4. Combination (Compression) Router Bits

These bits combine the advantages of both up shear and down shear designs.

The top section of the tool is down shear to prevent chipping the top surface of

the material, and the lower part of the bit is up shear to prevent chipping the

bottom surface of the material.

Combination Router Bits are the preferred configuration for machining veneered

plywood as well as melamine-surfaced product. A variation of the bit is called the

“mortising compression” router bit. With this bit, the up shear portion of the bit is

less than 1/4" in length so that the bit can be used on 1/4" veneered plywood and

for dados.

5. Form Router Bits

Form Router Bits typically are available in standard profiles such as round over,

ogee, etc. Router bits that have a shape associated with them would be classified

with this group.

15

DO’S AND DON’TS

1. DO verify water level in the spindle reservoir.

2. DO lubricate all ball screws & linear guilds every 8 hours of run time. Use 30w oil

or lithium white grease lubricant or equivalent to lubricate the ball screws. Wipe

off any excess to reduce dirt and dust acumination.

3. DO keep your collets clean, as fine dust builds up and they get tight.

4. When doing carving work, it is necessary to use a much larger volume of water

for the spindle-cooling reservoir & lubricating the Z-axis more often.

5. DO NOT ever, under any circumstances, reach over the table or obstruct the

movement of the gantry while the machine is powered or running a program.

6. ALWAYS Turn off main power prior to changing tooling or working on the spindle.

7. ALWAYS remove main power prior to working on or servicing the spindles

water pump and or reservoir.

8. The E-STOP button MUST be out before turning on the main power (twist and

it will pop out).

Turning on the machine

Note: Before you turn on the machine, remove all

tools and other objects from the machine.

Release the emergency stop by twisting

clockwise, and it will pop out.

Press the green start button that will turn power

on to the machine.

Pressing the green button will also power the

controller and the display will light up.

The screen will display “All axis home”

Make sure that the machine is clear of

obstructions and press the green Origin/OK

button.

The router head will move to the home position.

Note: Home is a mechanical position that is a

constant that is determined by switches on each

of the axes.

X+ = Across (from left-to-right when standing in front of the machine).

Y+ = Length (from front-to-back when standing in front of the machine).

Z+ = vertical (up).

By pressing HIGH LOW / 0 and MENU / - the display will change to AX=0, AY=0,

and AZ=0. (note: you can’t set a origin if the display is at AX, AY, AZ)

Emergency stop button

Start button

When the X, Y and Z have an A in front, this denotes that the dimensions

displayed are in reference to the machine’s home position. When the X, Y, and Z

values are displayed with a number (1-9), this indicates the dimensional

relationship of the machine from the machine origin.

16

Maintenance

As with any machine, to ensure optimal performance you must

conduct regular maintenance.

Daily checks

1. Clean the machine and lubricate unpainted surfaces

with a wax or WD40. Wipe off any excess and buff

with a dry polishing cloth. This will reduce the likelihood

of rust forming.

2. Check cutter teeth for chips and dullness.

3. Generally inspect the machine for damage and loose

or worn parts.

4. Collets and spindle collet hole must be cleaned

regularly. Ensure that the slots in the collets are free of

sawdust, as sawdust builds up and will stop the collet

compressing. If the collet or spindle hole is not clean, the

router bit may not run true, and this will affect the

performance of your machine.

Weekly checks

1. Clean the cutters.

2. Check cutter teeth for chips and dullness.

3. Generally inspect the machine for damage and loose or worn parts.

4. Check the dust extraction for blockages and any large bits that could cause

blockages.

Collet fitted to

spindle nut

17

Troubleshooting

Machine will not start

1. Check that the start switch is being pressed full in.

2. Check that the red stop switch is fully out.

3. Check that the electrical power cord is plugged into the power outlet.

4. Check that the electrical supply is on (reset the breaker).

5. With the power disconnected from the machine, check that the wiring to the

plug is correct. Check that the rubber insulation is stripped enough and is not

causing a bad connection. Check that all the screws are tight.

The machine will not stop

This is a very rare occurrence, as the machine is designed to fail-safe. If it should

occur and you cannot fix the fault, seek professional assistance. The machine

must be disconnected from the power and never run until the fault has been

rectified.

1. Internal breaker faulty. Replace the breaker.

Motor tries to start but will not turn

1. With the power disconnected from the machine, try to turn the spindle by hand.

If the spindle will not turn, check the reason for the jamming.

2. Motor faulty. Replace the motor.

3. Spindle was run without coolant. Replace the motor.

Motor overheats

The motor is designed to run hot, but should it overheat, it has an internal

thermal overload protector that will shut it down until the motor has cooled, and

then it will reset automatically. If the motor overheats, wait until it has cooled and

restart. If the motor shuts down consistently, check for the reason. Typical

reasons are dull cutting tools, no water in the coolant tank, blockage in the

coolant pipe and excessive ambient temperature.

Squeaking noise

1. Check the bearings.

Spindle slows down during a cut

1. Dull cutting tools. Replace the tool or have it re-sharpened.

2. Feeding the wood too fast. Slow down the feed rate.

Machine vibrates

1. Machine not level on the floor. Re-level the machine, ensuring that it has no

movement.

18

2072 Alton Parkway. Irvine, CA 92606

Ph: 800.234.1976 | www.lagunatools.com

Laguna Tools is not responsible for errors or omissions.

Specifications subject to change. Machines may be shown with optional accessories.

© 2018, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the

registered trademarks of Laguna Tools, Inc. All rights reserved.

Loading...

Loading...