DealerSales@LagunaTools.com

+1 (800) 861 4637

Fusion 2 Tablesaw

MTSF236110175-0130

MTSF252110175-0130

© 10/2017, Laguna Tools, Inc.

Fusion 2 Tablesaw

MTSF2

© 10/2017, Laguna Tools, Inc.

Max Blade Diameter 10"

Arbor Diameter 5/8"

Arbor Speed 4500 RPM

Max Dado Diameter 10"

Max Dado Width 13/16"

Rip Capacity, with Fence 36" Right, 17" Left (52” Option)

Maximum Depth of Cut @ 90° 3 1/8"

Maximum Depth of Cut @ 45° 2 1/8"

Blade Tilt 45° Left, 3° Arbor Adjustment

Table Dimension, with Extensions (LxWxth.)27"L x 44"W x 1-1/2"th. (cm: 68.58, 111.76, 3.81)

Extension Wing Dimesnsion (LxW) 27"L x 12"W (cm: 68.58, 30.48)

Mitre Slot 3/4" to 1" T

Fence Type Sliding Cam Action Fully Adjustable

Fence Face Dimensions (LxWxth.) 33-3/8"L x 2-1/2"W x 1/2"th. (cm: 84.77, 6.35, 1.27)

Throat Plate Type Professional Square Zero Clearance

Throat Plate Dimensions (LxWxth.) 14-5/8"L x 4-1/16"W x 1/2"th. (cm: 37.15, 10.32, 1.27)

Floor to Table Height 34-3/4" (88.27cm)

Phase 1PH

Voltage 115V (Installed) / 230V*

Motor Type TEFC Capacitor Start AC Induction

Horsepower 1-3/4 HP

Motor Speed 3450 RPM

Cycle 60 Hz.

Full Load Amperage 14 Amp. / 7 Amp.

Start Capacitor 200 µF-U

Run Capacitor 35 µF-U

Switch Type Magnetic

Power Transfer Single V-Ribbed Bando 142J FJ

Power Cord 6 Ft. 14 AWG

Power Plug Included N5-15

NEMA Breaker Recommendation 20 Amp.

Notes *230V option will require the purchase of 230V switch.

Foot Print (LxW) 18-1/2"L x 19"W (cm: 45.72, 48.26)

Overall Dimensions (LxWxH) 39-3/4"L x 65-1/2"W x 38"H (cm: 100.01, 166.37, 96.52)

Shipping Dimensions (LxWxH) 29-3/4"L x 46-5/8"W x 42-5/8"H (cm: 75.57, 118.43, 108.27)

Net Weight (No Accessories) 240 Lbs. (108.86 Kgs.)

Shipping Weight 310 Lbs. (136.08 Kgs.)

Dust Collection: Outlet Dia. 4"

Dust Collection: CFM Min. Req. 500 CFM

MTSF236110175-0130

MTSF252110175-0130

MTSF3362203-0130

MTSF3522203-0130

Setup & maintenancE Manual

2072 Alton Parkway Irvine, CA 92606 U.S.A.

www.lagunatools.com - dealersales@lagunatools.com

p. 1-800.234.1976 - f. 1-949.474.0150

@lagunatools

Fusion Tablesaw

© 10/2017, Laguna Tools, Inc.

Fusion Tablesaw

Dear Woodworker

Thank you for your purchase and welcome to the Laguna Tools group of discriminating woodworkers. I understand that you have a choice of

where to purchase your machines and appreciate the confidence you have in our products.

Every machine sold by Laguna Tools has been carefully designed and well thought through from a woodworker’s perspective. I cut on our

bandsaws, lathers, table saws, combination machines, and CNC Routers. Through my hands-on experience, I work hard to make our

machines better. I strive to give you machines that inspire you to create works of art. Machines that are a joy to run and work on. Machines that

encourage your performance.

Today, we offer high performance machines with innovative solutions that meet the needs of woodworkers and their ever-evolving craft. I

started Laguna Tools as a woodworker, I still am. Thank you again for becoming a Laguna Tools customer.

Sincerely,

Torben Helshoj - President and Founder of Laguna Tools. Imagination, Innovation, and invention at work.

Registration

To get the most out of your Laguna Tools purchase, we have a registration page set up on Lagunatools.com. Registering your tool will be

helpful later if you ever need to warranty any defective part or component of your new machine or order replacement or consumable parts.

Please follow the link below to register your purchase.

https://lagunatools.com/policies/warranty

Warranty

New woodworking machines sold by Laguna Tools carry a one-year warranty effective from the date of shipping. Machines sold through

dealers must be registered with Laguna Tools within 30 days of purchase to be covered by this warranty. Laguna Tools guarantees all new

machine sold to be free of manufacturers’ defective workmanship, parts and materials. We will repair or replace, without charge, any parts

determined by Laguna Tools, Inc. to be a manufacturer’s defect. We require that the defective item/part be returned to Laguna Tools with the

complaint. Any machines returned to Laguna Tools must be returned with packaging in the same manner in which it was received. If a part or

blade is being returned it must have adequate packaging to ensure no damage is received during shipping. In the event the item/part is

determined to be damaged due to lack of maintenance, cleaning or misuse/abuse, the customer will be responsible for the cost to replace the

item/part, plus all related shipping charges. This limited warranty does not apply to natural disasters, acts of terrorism, normal wear and tear,

product failure due to lack of maintenance or cleaning, damage caused by accident, neglect, lack of or inadequate dust collection,

misuse/abuse or damage caused where repair or alterations have been made or attempted by others.

Laguna Tools, Inc. is not responsible for additional tools or modifications sold or performed (other than from/by Laguna Tools, Inc.) on any

Laguna Tools, Inc. woodworking machine. Warranty maybe voided upon the addition of such described tools and/or modifications, determined

on a case-by-case basis. Normal user alignment, adjustment, tuning and machine settings are not covered by this warranty. It is the

responsibility of the user to understand basic woodworking machinery settings and procedures and to properly maintain the equipment in

accordance with the standards provided by the manufacturer. Parts, under warranty, are shipped at Laguna Tools, Inc.’s cost either by

common carrier, FEDEX ground service or a similar method. Technical support to install replacement parts is primarily provided by phone, fax,

e-mail or Laguna Tools Customer Support Website. The labor required to install replacement parts is the responsibility of the user. Laguna

Tools is not responsible for damage or loss caused by a freight company or other circumstances not in our control. All claims for loss or

damaged goods must be notified to Laguna Tools within twenty-four hours of delivery. Please contact our Customer Service Department for

more information. Only new machines sold to the original owner are covered by this warranty.

For all Warranty claims, please call: 1-800-332-4094

© 10/2017, Laguna Tools, Inc.

2

Fusion Tablesaw

Table of Contents

Dear Woodworker ................................................................................................................................................................................................... 2

Registration ............................................................................................................................................................................................................. 2

Warranty .................................................................................................................................................................................................................. 2

Fusion 3 Tablesaw Specifiactions ........................................................................................................................................................................... 4

Fusion 2 Tablesaw Specifiactions ........................................................................................................................................................................... 6

General safety ......................................................................................................................................................................................................... 8

Tool Overview ....................................................................................................................................................................................................... 10

Controls............................................................................................................................................................................................................. 10

Receiving & Unpacking ......................................................................................................................................................................................... 11

Inventory ........................................................................................................................................................................................................... 11

Setup ..................................................................................................................................................................................................................... 12

Overview ........................................................................................................................................................................................................... 12

General Setup ................................................................................................................................................................................................... 12

Installing/ Removing the Throat Plate ............................................................................................................................................................... 13

Installing/ Removing Riving knife ...................................................................................................................................................................... 14

Installing/removing the blade guard .................................................................................................................................................................. 14

Installing/removing the blade ............................................................................................................................................................................ 15

Adjustments .......................................................................................................................................................................................................... 16

Fence Adjustments ........................................................................................................................................................................................... 16

Throat Plate Adjustments.................................................................................................................................................................................. 18

Adjusting the Motor belt tension........................................................................................................................................................................ 18

Adjusting the Tilt limits of the arbor ................................................................................................................................................................... 18

Trouble Shooting ................................................................................................................................................................................................... 20

Wiring Diagram: Fusion F2 110V/220V ................................................................................................................................................................. 21

Wiring Diagram: Fusion F3 220V .......................................................................................................................................................................... 22

Parts Diagrams ..................................................................................................................................................................................................... 23

Fence Assembly ............................................................................................................................................................................................... 23

Mitre Gauge, Blade Guard ................................................................................................................................................................................ 24

Motor and Trunnion........................................................................................................................................................................................... 25

Cabinet ............................................................................................................................................................................................................. 26

F3 Cabinet ........................................................................................................................................................................................................ 27

Parts List ............................................................................................................................................................................................................... 28

© 10/2017, Laguna Tools, Inc. 3

Fusion Tablesaw

NAME & MODEL

Advertised Name

Fusion 3 Tablesaw

Short Name

F3

BASE SKU(S)

MTSF3362203-0130

SHORT SKU

MTSF3

UPC Stock Model

MTSF3362203-0130

w/ 52" Rip

MTSF3522203-0130

NCLUDED WITH PURCHASE

Professional Square Zero Clearance Throat Plate (pre-installed)

10" 40T Blade (pre-installed)

Riving Knife (pre-installed)

Mitre Gauge (ships in tool holder)

Tool Holder (pre-installed)

Fence

Blade Guard

Tool and Accessory holder

Installation and Adjustment Tools

Phase

1PH

Voltage

230V

Motor Type

TEFC Capacitor Start AC Induction

Horsepower

3 HP

Motor Speed

3450 RPM

Cycle

60 Hz.

Full Load Amperage

14 Amp.

Start Capacitor

300 µF-U

Run Capacitor

50 µF-U

Switch Type

Magnetic with Overload Protection

Power Transfer

Single V-Ribbed Bando 142J FJ

Power Cord

6 Ft. 14 AWG

Power Plug Included

N6-15

NEMA Breaker Recommendation

30 Amp.

Foot Print (LxW)

20"L x 20-1/2"W (cm: 50.8, 52.07)

Overall Dimensions (LxWxH)

39-3/4"L x 65-1/2"W x 38"H (cm: 100.01, 166.37, 96.52)

Shipping Dimensions (LxWxH)

29-3/4"L x 46-5/8"W x 42-5/8"H (cm: 75.57, 118.43, 108.27)

Net Weight (No Accessories)

300 Lbs. (136.08 Kgs.)

Shipping Weight

370 Lbs. (163.293 Kgs.)

Dust Collection: Outlet Dia.

4"

Dust Collection: CFM Min. Req.

550 CFM

Sound Emissions

N/A

TABLESAW SPECIFIC

Max Blade Diameter

10"

Arbor Diameter

5/8"

Arbor Speed

4500 RPM

Max Dado Diameter

10"

Max Dado Width

13/16"

Rip Capacity, with Fence

36" Right, 17" Left (52" option)

Maximum Depth of Cut @ 90°

3 1/8"

Maximum Depth of Cut @ 45°

2 1/8"

Blade Tilt

45° Left, 3° Arbor Adjustment

Table Dimension, with Extensions

(LxWxth.)

27"L x 44"W x 1-1/2"th. (cm: 68.58, 111.76, 3.81)

Extension Wing Dimension (LxW)

27"L x 12"W (cm: 68.58, 30.48)

Fusion 3 Tablesaw Specifiactions

ELECTRICAL

GENERAL

© 10/2017, Laguna Tools, Inc.

4

Fusion Tablesaw

Mitre Slot

3/4" to 1" T

Fence Type

Sliding Cam Action Fully Adjustable

Fence Face Dimensions (LxWxth.)

33-3/8"L x 2-1/2"W x 1/2"th. (cm: 84.77, 6.35, 1.27)

Throat Plate Type

Professional Square Zero Clearance

Throat Plate Dimensions (LxWxth.)

14-5/8"L x 4-1/16"W x 1/2"th. (cm: 37.15, 10.32, 1.27)

Floor to Table Height

34-3/4" (88.27cm)

warning: Read the entire manual before plugging in your new Laguna Tools machine.

© 10/2017, Laguna Tools, Inc. 5

Fusion Tablesaw

NAME & MODEL

Advertised Name

Fusion 2 Tablesaw

Short Name

F2

BASE SKU(S)

MTSF236110175-0130

SHORT SKU

MTSF2

UPC Stock Model

MTSF236110175-0130

w/ 52" Rip

MTSF252110175-0130

NCLUDED WITH PURCHASE

Professional Square Zero Clearance Throat Plate (pre-installed)

10" 40T Blade (pre-installed)

Riving Knife (pre-installed)

Mitre Gauge (ships in tool holder)

Tool Holder (pre-installed)

Fence

Blade Guard

Tool and Accessory holder

Installation and Adjustment Tools

Phase

1PH

Voltage

115V (Installed) / 230V*

Motor Type

TEFC Capacitor Start AC Induction

Horsepower

1-3/4 HP

Motor Speed

3450 RPM

Cycle

60 Hz.

Full Load Amperage

14 Amp. / 7 Amp.

Start Capacitor

200 µF-U

Run Capacitor

35 µF-U

Switch Type

Magnetic

Power Transfer

Single V-Ribbed Bando 142J FJ

Power Cord

6 Ft. 14 AWG

Power Plug Included

N5-15

NEMA Breaker Recommendation

20 Amp.

Notes:

*230V option will require the purchase of 230V switch.

Foot Print (LxW)

18-1/2"L x 19"W (cm: 45.72, 48.26)

Overall Dimensions (LxWxH)

39-3/4"L x 65-1/2"W x 38"H (cm: 100.01, 166.37, 96.52)

Shipping Dimensions (LxWxH)

29-3/4"L x 46-5/8"W x 42-5/8"H (cm: 75.57, 118.43, 108.27)

Net Weight (No Accessories)

240 Lbs. (108.86 Kgs.)

Shipping Weight

310 Lbs. (136.08 Kgs.)

Dust Collection: Outlet Dia.

4"

Dust Collection: CFM Min. Req.

500 CFM

Sound Emissions

N/A

TABLESAW SPECIFIC

Max Blade Diameter

10"

Arbor Diameter

5/8"

Arbor Speed

4500 RPM

Max Dado Diameter

10"

Max Dado Width

13/16"

Rip Capacity, with Fence

36" Right, 17" Left

Maximum Depth of Cut @ 90°

3 1/8"

Maximum Depth of Cut @ 45°

2 1/8"

Blade Tilt

45° Left, 3° Arbor Adjustment

Table Dimension, with Extensions

(LxWxth.)

27"L x 44"W x 1-1/2"th. (cm: 68.58, 111.76, 3.81)

Extension Wing Dimension (LxW)

27"L x 12"W (cm: 68.58, 30.48)

Fusion 2 Tablesaw Specifiactions

ELECTRICAL

GENERAL

© 10/2017, Laguna Tools, Inc.

6

Fusion Tablesaw

Mitre Slot

3/4" to 1" T

Fence Type

Sliding Cam Action Fully Adjustable

Fence Face Dimensions (LxWxth.)

33-3/8"L x 2-1/2"W x 1/2"th. (cm: 84.77, 6.35, 1.27)

Throat Plate Type

Professional Square Zero Clearance

Throat Plate Dimensions (LxWxth.)

14-5/8"L x 4-1/16"W x 1/2"th. (cm: 37.15, 10.32, 1.27)

Floor to Table Height

34-3/4" (88.27cm)

warning: Read the entire manual before plugging in your new Laguna Tools machine.

© 10/2017, Laguna Tools, Inc. 7

Fusion Tablesaw

Work area

Tool Use

Caution:

Use only manufacturer recommended

harm.

warning

serious injury to the operator and bystanders.

General safety

: Read all safety considerations. Failure to follow this set of guidelines can result in unwarranted damage to the machine and

KEEP ALL CHILDREN AND UN-INFORMED PERSONS AWAY FROM

THE MACHINE. Do not allow bystanders to touch the machine or power

chord. All but the operator should be away from the work area while the

machine is under use.

KEEP WORK AREA CLEAN. A clutter area can limit the range of machine

and cause serious injury to the operator.

MAKE SURE THE WORK AREA IS CHILD-PROOF AND UNACCESABLE

TO UNTRAINED PERSONS. Use padlocks where accessible and keep all

machine unplugged when not in use.

DO NOT KEEP OR PLACE TOOLS IN OUTDOOR OR DAMPM

ENVIRONMENTS. Never operate the tool under wet or damp conditions.

Exposing this product to those environments may result in damage to the

tool. Do not use tool in the presence of flammable liquids or gasses.

Personal Safety

KNOW YOUR MACHINE. Read and understand the owner’s manual and labels affixed to the tool. Learn its application and limitations as well as the specific potential hazards peculiar to this tool.

DRESS PROPERLY. Do not wear loose clothing or jewelry. Do not wear gloves that can be caught in the cutter-head or power feed or any part of the machine. Tie up or wear protective coverings to contain long hair.

USE SAFTEY GOGGLES. Some machines require additional face shield than offered by safety goggles alone. Know your machine and the proper PPE to use.

USE EAR PROTECTION. Some machines operate at very high noise levels. To prevent damage to ears, be sure to use ear protection allways.

GUARD AGAINST ELECTRIC SHOCK. Prevent all bodily contact with grounded surfaces and parts of the machine that pose electrical threats.

DO NOT OVER REASCH THE CUTTER HEAD OR STAND ON THE MACHINE. Serious injury can occur from mishandling this tool. Keep proper footing on the floor at all times.

AVOID ACCIDENTAL STARTING FOR MACHINES WITHOUT MAGNETIC OR AUTOMATIC SHUT-OFF SWITCHES. Make sure the tool is in the off position prior to plugging it in.

KEEP GUARDS IN PLACE. Machine parts like riving knifes, blade guard, cutter-head guards, feather boards, push sticks, ect. are designed to minimize possible injury. Keep them in place unless when a safer means of operation is available.

BE ALERT ALWAYS AND GIVE 100% OF YOUR ATTENTION TO THE OPERATION OF THIS TOOL. Failure to do so can result in serious injury to both the operator and bystanders.

DO NOT RELY ON GUARDS. The operator of this tool is 100% responsible for his/her own safety. The guards and safety components sold with this machine are not enough to ensure safety.

CHECK FOR DAMAGED PARTS. Before every use of this tool, makes sure

the machine or any components of the machine are not damaged or at the

mercy of being damaged. If a damaged part is discovered, stop immediately

put the machine out of service until the part is replaced. Parts can be

ordered directly from Laguna Tools at 1-800-234-1976.

DO NOT FORCE TOOL. The tool is designed to operate at a certain rate. Forcing the workpiece beyond that rate will do an inadequate job and may case damage or harm to the operator.

USE THE CORRECT TOOL FOR THE JOB. Know the limitations and capabilities of your new purchase. Do not try to fit a square peg in a round hole.

SECURE THE WORK PIECE. For all woodworking and metalworking applications, the workpiece should be secured correctly by the operator and appropriate clamps and vises. Always use a clamp or vise when available, it is safer than using your hands.

FEED DIRECTION. If feed rate is applicable, then there is only one direction of feed rate for the tool. Do not force the workpiece in the wrong feed direction.

KEEP CUTTERHEADS SHARP. Never operate this machine with unsharpened cutter heads or blades. Operating under these conditions greatly increase the chance of kickback and overloads.

NEVER LEAVE TOOL RUNNING UNATTENDED. Do not leave the tool until it comes to a complete stop. When unattended, unplug the tool.

warning:

Contact Laguna Tools or a Competent repair service.

warning:

replacement parts. All others may cause damage or harm.

All repairs should be done by trained repairmen.

Use only Laguna tools or compatible and marked

accessories. Some accessories may cause damage or

Kickback

A kickback occurs when the blade or cutter head is forced into biting the

work-piece and forces it against the initial feed direction. This happens

when the workpiece binds between the saw blade or cutter head and a

stationary object (fence). KICKBACKS CAN USUALLY BE AVOIDED BY

FOLLOWING THESE GUIDELINES:

a. Make sure the fence is always parallel to the saw blade.

b. Keep the sawblade or cutter heads sharp. Replace or

sharpening anti-kickback pawls when points become dull.

c. Keeping guards, spreaders and anti-kickback pawls in place and

operating properly. The spreader must be in alignment with the

sawblade and the pawls must stop a kickback once it has

started. Check action prior to use.

d. NEVER use a workpiece that is twisted or warped or does not

have a straight edge to guide along the rip fence.

e. NEVER releasing the work until you have pushed it all the way

past the sawblade or cutter head.

f. Using the appropriate push stick or push blocks.

g. NEVER confine the cut-off piece when ripping or cross cutting.

h. When ripping, apply the feed force to the section of the

workpiece between the sawblade and the rip fence.

i. Never process multiple loose workpieces.

© 10/2017, Laguna Tools, Inc.

8

Fusion Tablesaw

Electrical

A.W.G CORD SIZE

TOOLS

RATING

VOLTS

CORD LENGTH IN FEET

120

25

50

100

150

240

50

100

200

-

3-6

16 ga.

16 ga.

16 ga.

14 ga.

6-8

18 ga.

16 ga.

14 ga.

12 ga.

8-10

16 ga.

14 ga.

12 ga.

12 ga.

10-12

14 ga.

14 ga.

12 ga.

10 ga.

12-16

14 ga.

12 ga.

10 ga.

8 ga.

16-20

12 ga.

12 ga.

8 ga.

-

RULINGS

warning:

Before connecting this tool to a power supply

(receptacle, outlet, etc.) make sure that the voltage supplies is

warning:

Some dust created by power sanding, sawing,

Crystalline silica from bricks, cement, and other masonry

are specifically designed to filter out microscopic particles.

General Safety and Rulings

DISCONECT THE POWER FIRST. Always disconnect machine from power

supply BEFORE adjusting, changing tooling, or servicing machine.

USE A QUALIFIED ELECTRICIAN FOR ALL ELCETRICAL

CONNECTIONS. Failure to do so may result in damage to the tool and

electrical shock to the operator and bystanders.

POWER PLUGS. Your machine may not come with a power plug because

of the variance in power receptacles. Consult with a local electrician prior to

purchasing a power plug.

EXTENSION CORDS. Consult with or use a qualified electrician prior to

sizing extension cords for use with this machine. Repair any damaged

extension cords when discovered. The following table should only serve as

guidelines.

AMPERAGE

Note: The smaller the AWG gauge (ga.) size, the wider the cord.

GROUNDING

In the event of a malfunction, properly grounding the tool provides a path for

the electrical build up or charge to dissipate in a safe manner.

DO NOT MODIFY THE PLUG. Do not remove any of the prongs attached

to the proper plug for the machine.

USE ONLY 3 WIRE EXTENSION CHORDS. Some extension cords only

have two wires, which does not allow for groundings.

ONLY USE ADAPTER WHEN ABOSLUTLY NECESSARY. The following

diagram should only serve as guidelines, consult a qualified electrician if in

doubt.

the same that is specified on the nameplate of the tool.

Also make sure that the power supply is equipped with the

appropriate breaker and plug according to your local electrical

code.

IF IN DOUBT, DO NOT PLUG IN THE MACHINE. Using this

tool with a voltage different than that stated on the nameplate

can damage the electrical components of this machine and

will not be covered by a warranty.

grinding, drilling and other construction activities contain

chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead from lead based paint.

•

products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do

this type of work. To reduce your exposure to these

chemicals, work in a well-ventilated area and work with

approved safety equipment, such as face or dust masks that

© 10/2017, Laguna Tools, Inc. 9

Fusion Tablesaw

1. Start/ Stop Control Switch

6. Cabinet with integrated mobility kit.

7. Arbor Height adjustment control

12. Dust Extraction outlet.

Controls

Start/ EZ acess Stop

Arbor Hieght Control & Tilt guage.

Arbor Tilte control

Fence clamp lock

The on/off switch turns the machine on

with the use of a padlock as shown.

The Arbor height control adjusts the

Behind the Control is the tile Gauge.

7

8

11

12

1

2 3 4

5

6

9

10

Tool Overview

Your new Laguna Tools machine is comprised of different components to make a long lasting and precise piece of machinery that will help you

with your next project. Understanding your new machine and the comprising components will make you a better craftsman.

The basic components of the table saw are:

2. Rip Fence

3. Fence Front Guide

4. Fence Rear Guide

5. Table with Mitre Slots

8. Arbor Tilt adjustment control

9. Throat Plate

10. Blade

11. Accessories and Holder

and off. It also holds the reset switch in

the event of overload. It can be locked

© 10/2017, Laguna Tools, Inc.

10

height of the blade. Centered in the

control is the height adjustment lock.

The tilt control, located on the

right of the cabinet, adjust the tilt

of the arbor. Center is the tilt lock.

`

The fence clamp securely locks

the fence anywhere on the rail

by a cam action mechanism.

Fusion Tablesaw

caution

persons when lifting the tool into position and moving th

into position.

warning:

To avoided set-up Problems and to prevent

setup section prior to proceed to set up the machine.

tech tip

or

Use a drill or a screws driver with a #2 Philips head bit and remove the

bottom screws from the carton. These screws may be discarded.

Tech tip:

friction under operation. Rust can be removed with WD-40.

Box 1 contents

Box 2 contents

Box 3 contents

Pre-Installed on machine

Fence

PTSF236110175-0130-1-1

Rear Rail 2

PTSF236110175-0130-127.5

Rear Rail 1

PTSF236110175-0130-127.5

Throat Plate

PTSF236110175-0130-6

Push Stick

PTSF236110175-0130-130

Front Rail 2

PTSF236110175-0130-127.6

Front Rail 1

PTSF236110175-0130-127.6

Riving Knife

PTSF236110175-0130-27

Blade Guard

PTSF236110175-0130-2-1

Hardware kit

-

10” Blade

PTSF236110175-0130-33

Install Tools

-

Mitre Gauge

PTSF236110175-0130-3

Fence Hooks*

PTSF236110175-0130-118

Mobility Wheels

PTSF236110175-0130-115

*Fence storag e h ooks may be pre-installed.

Tool Storage

PTSF236110175-0130-120

Wing (2)

PTSF236110175-0130-4

Note:

Note:

Note:

2.

1 2 3

4

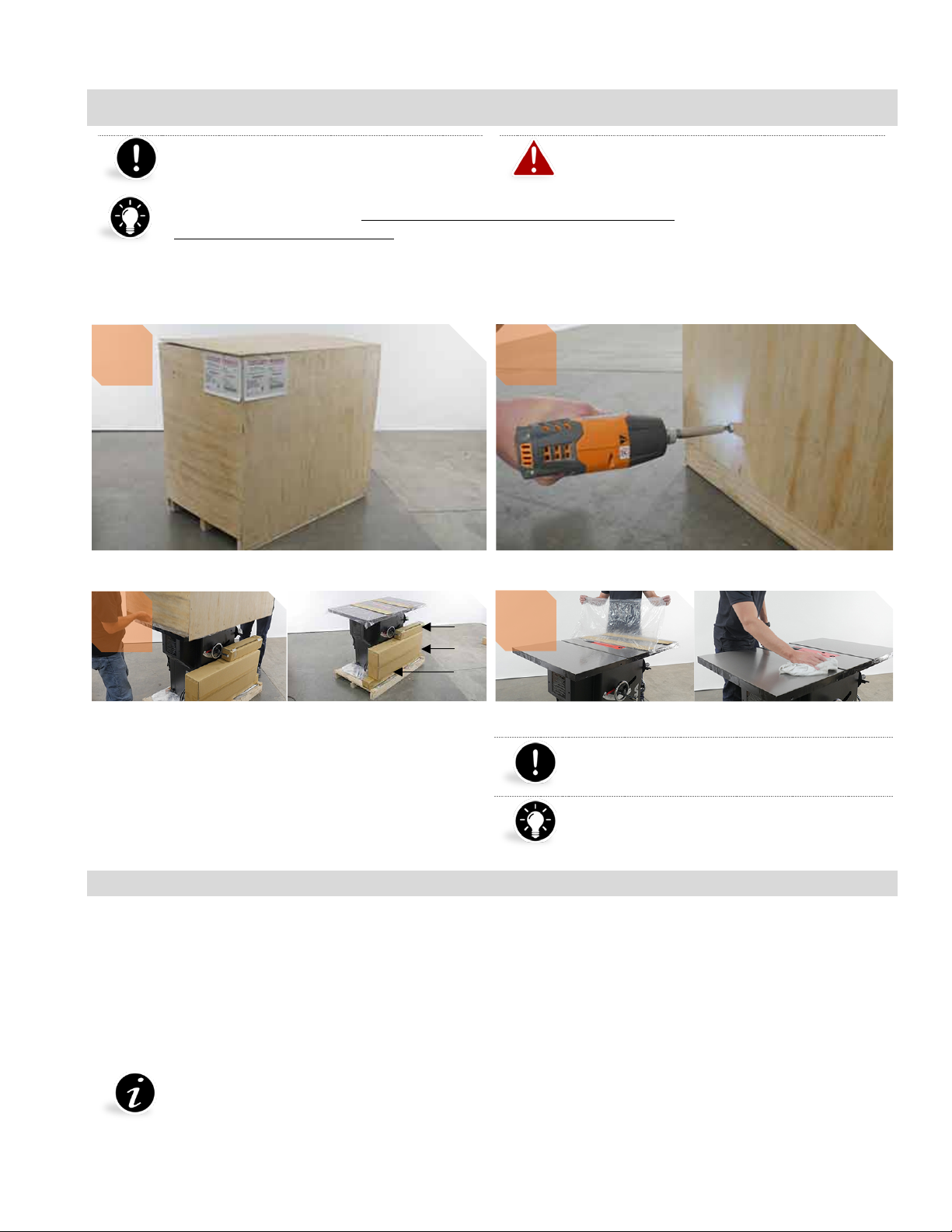

Receiving & Unpacking

:

Your new Laguna tools machine is heavy. Use 2

e tool

:

A Setup video is available at lagunatools.com/classic-machinery/tablesaws/f2-fusion/

www.youtube.com/watch?v=FOPstZ61uFs

If any damage has occurred as a result of shipment, notify the transportation company as soon as possible and ask them to make an

immediate inspection. Ask for a damage or loss report. Also notify your distributer for any loss or damage during shipment. See enclosed

warranty statement on page 1 of this manual.

potential damage to the machine, read through the entire

This is how the machine is shipped from the factory.

1.

3.

Use two persons to lift the carton away from the palet. There should

be three packages along with the tablesaw. From top to bottom as

shown:

1. Smaller fence rail sections, Hardware Kit

2. Fence, install tools, push stick, blade guard assembly,

3. Longer fence rail sections.

NOTE: The throat plate, riving knife, and 10” are pre-installed in the machine.

The mitre guage, and balde changing tool are positioned in the tool holder

located on the right side of the cabinet.

Inventory

Peel back the protected vinyl plastic and wipe away the Oil with a

waste rag.

caution:

An oily rag left unattended can be a serious fire

hazard. Discard in an appropriate manner.

To help keep your table top clean and to prevent or

clean any rust, we recommend waxing your tabletop with an

appropriate wax rubbing compound. This will also reduce

The Rear Rail part number comprises of 2 pieces, 1 and 2

The Front Rail part number comprises of 2 pieces, 1 and 2 with end Caps.

For safety Reasons, This Machine is not s old with a tape-rule for the left side of the blade. It is not a missing part.

© 10/2017, Laguna Tools, Inc. 11

Fusion Tablesaw

warning

adjustments with the saw connect

1.

2.

3.

4.

5.

6. 7. 8. 9.

10.

11.

1 2 3

4

12.

Setup

Your new machine has been mostly assembly from the certified ISO 91001 certified factory where it was made. Some parts must be

assembled by the purchaser. Please read all steps first before proceeding with step one.

: Do not connect to a power supply until the setup is complete. DO NOT Perform any of the following steps, installations, or

ed to the power source.

Overview

General Setup

Use the supplied wrench and Alan key to loosely fasten (2) bolts,

lock washers, washers, and nuts to the short rear fence guide and

the back left of the table. STOP BEFORE TIGHTENTING: Keep

bolts loose until entire rail assembly is in place to properly level rail.

To level the rear fence with the table top, place a ridged straight

edge on top of the rails. Apply downward force at both arrow

indicators and simultaneously tighten the bolts with the supplied

Allen key and wrench.

© 10/2017, Laguna Tools, Inc.

12

Repeat Step 1 for the longer rear fence section with (3) bolts, lock

washers, washers, and nuts. Use the assembly diagram in step 1.

Note: If the Fence Hooks are not yet installed, now is a good time to do so.

Note: The blade guard and fence should not be installed for this step.

Loosely fasten the (5) square headed bolts, (5) washers, and (5)

nuts. A couple revolutions of the bolt will be tight enough. Prepare to

insert the (2) aluminum front rail sections.

Fusion Tablesaw

handle is in the open, unlocked, position prior to installing.

Information:

This machine is shipped with a zero-

already in the saw.

Information:

This concludes the general setup of this

with the blade, and other important topics.

warning:

Make Sure the rip fence is always parallel to

section to adjust the fence.

5 6 7 9 8

10

11

12

Insert the long Front Rail. STOP BEFORE TIGHTENING: Keep

these bolts loose until the entire rail assembly is in place to properly

level the rail.

Align the pins and insert holes of the two front rail pieces and firmly

push together.

Insert the short Front Rail into the first square head bolt.

IMPORTANT: Insert the switch assembly before joining the two

Front Rail pieces. STOP BEFORE TIGHTENING

Align the entire front rail section with the “Blade Notching” on the

measuring tape.

Install the fence by placing the front end first. Be sure that the

This step may take 2 persons. To level the front rail sections to the

table top use a ridge straight edge atop the loosely fit rail sections.

Apply downward force to the straight edge while keeping the two

sections firmly together. Simultaneously fasten down the bolts.

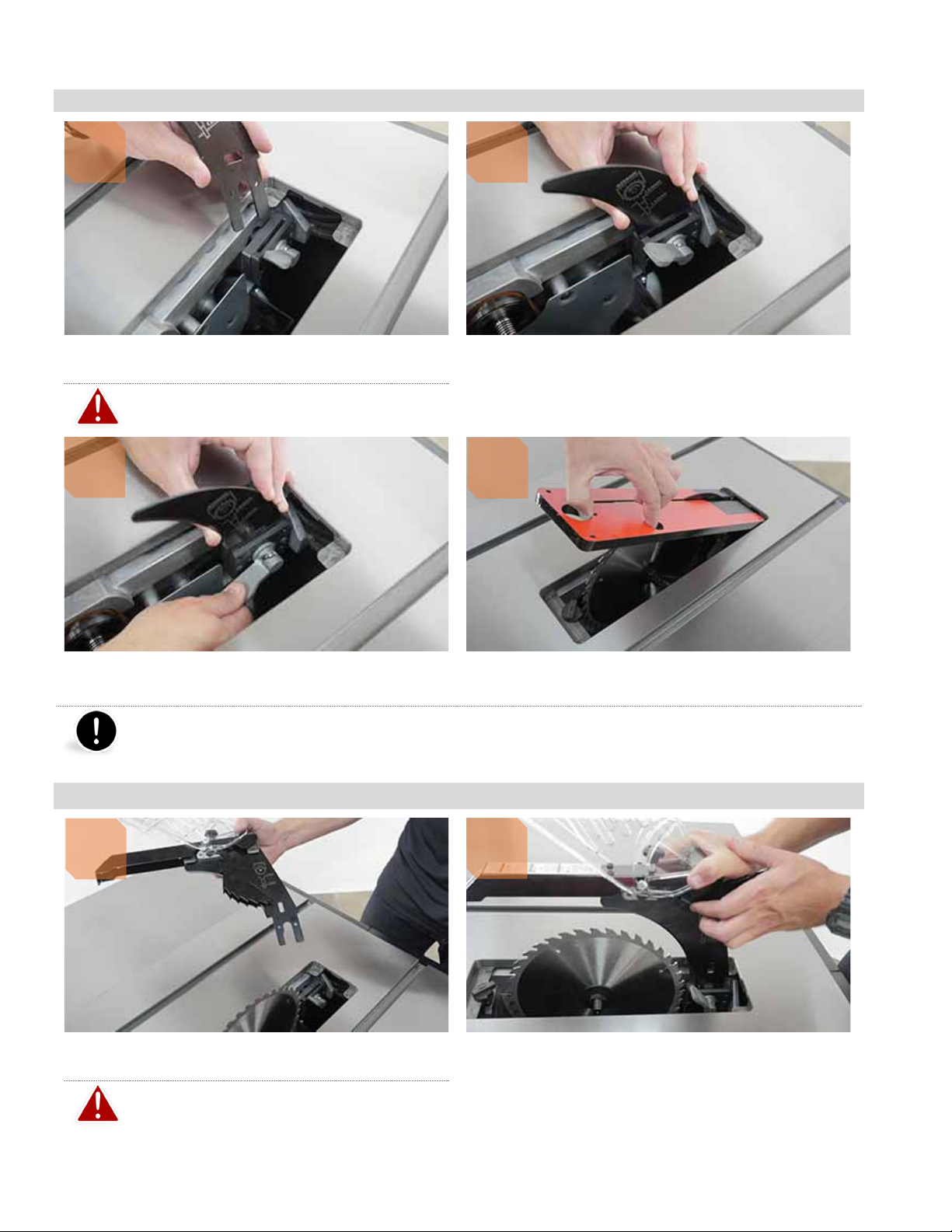

Installing/ Removing the Throat Plate

WARNING: MAKE SURE SAW IS UNPLUGED. To remove or

install the throat plate, first set it to the unlock position. Then, insert

the rear end first and tilt the other end down into position.

© 10/2017, Laguna Tools, Inc. 13

To level the tablesaw with the ground, use the two leveling casters.

The knobs on the right lock the mobility of the saw.

clearance throat plate that has already been cut at the

factory. Because of this, there may be some residue

tool. In addition, there is an ‘Adjustments’ section that

goes over how to adjust the scale, fence for alignment

the saw blade before rip cutting, see the Adjustments

Fusion Tablesaw

lock with the thumb of your right hand.

caution:

Make sure to inspect the riving knife frequently. Do not operate with a bent or knicked riving knife. Replacement riving

of the knife.

1 4 3 2 1

2

Installing/ Removing Riving knife

With the throat plate removed, and the cam lock mechanism in the

open position (pulled up), insert the riving knife into the slot.

warning:

removing, installing, or adjusting any accessories.

Keep firm hold of the riving knife with left hand and engage the cam

knifes can be purchased from Laguna tools. Only use the riving knife with sawblades satisfying the stated conditions on the side

Make Sure the saw is unplugged prior to

Installing/removing the blade guard

Position the riving knife against the left inside of the casing and push

down. Make sure the knife is positioned correctly and seated in the

bottom of the casing. Keep right hand free for next step.

Re-Install the throat plate – do not forget to lock the throat plate.

With the throat plate removed, and the cam lock mechanism in the

open position (pulled up), insert the blade guard into the slot.

warning:

removing, installing, or adjusting any accessories.

© 10/2017, Laguna Tools, Inc.

14

Make Sure the saw is unplugged prior to

Hold up the pawls and position the blade guard against the left

inside of the casing and push down. Make sure the guard is

positioned correctly and seated in the bottom of the casing. Grasp

the pawls with one hand, leaving the other hand free to activate the

cam action lock.

Fusion Tablesaw

the throat plate.

warning:

No piece of safety equipment is enough to

precautions prior to operation.

warning:

Never operate with a broken or damaged

spread, riving knife, blade guard, or throat plate. Inspect

components regularly.

loosen.

5 4 3 3 4 2 1

Activate the cam action lock.

Installing/removing the blade

Grasp the pawls up out of the way to re-insert the throatplate. Lock

ensure safety. 100% of your attention is required when

operation this machine. Never lose focus on what you

are doing and understand all warning labels and safety

warning:

guard that is fit for the saw blade in use.

Only use a riving knife, spreader, or blade

Unplug the tablesaw! Raise the Blade to the highest position.

Remove the throat plate. Remove blade guard, riving knife, or

splitter.

Use the supplied blade changing tool (located in tool holder upon

shipment) to release the 5/8” arbor nut. Counter Clockwise to

© 10/2017, Laguna Tools, Inc. 15

With the blade in the highest position, engage the blade lock by

pressing in with left thumb. Simultaneously, slowly, rotate the blade

until the lock engages.

When re-installing the blade, make sure the flange is on as shown

above.

Fusion Tablesaw

FITTING THE FENCE

caution:

The fence can also be used on the left side of

ADJUSTING THE SCALE (Rule)

Adjust the scale to the zero position and re tighten the screws.

warning

1

2 3 2 1 4

Adjustments

Your Laguna Tools machine come fully adjusted form the factory, but it is good practice to double check these adjustments and make sure the

tool is in safe operating condition.

: Disconnect the saw from the power source when making any adjustments or performing any maintenance.

Fence Adjustments

While hold the fence and the cam lock, raise the cam lock to

engage the open position. Insert the fence frame into the front rail.

The fence can slide freely on any position to the right of the blade.

the blade but use extreme caution. There is not a scale

on the left side of the blade because of the safety

concerns. Practice safe woodworking at all times.

With the blade in a high position, bring the fence close but not

touching the blade.

Tech tip:

blade and the fence to ensure good distance.

© 10/2017, Laguna Tools, Inc.

16

Use a folded piece of paper between the

Use a #2 Philips head driver to loosen (but do not remove) the

transparent scale reader.

Fusion Tablesaw

ADJUSTING THE FENCE GLIDE BUSHINGS

Making THE FENCE PARRELEL TO THE BLADE.

warning:

It is not guaranteed that the fence will be

fence parallel to the saw blade prior to operation.

warning:

fence that is un-parallel to the blade will

in damage or injury.

1 2 3 4 1 2 3

TO adjust the front bushings, use the included Alan key to raise or

lower the nylon bushings that make contact with the front fence rail.

parallel to the saw blade form the factory. Make sure

to make all the required adjustment to make the

To adjust the rear bushing, Loosen the hex nut that locks the height

position of the bushing. Adjust the position and tighten the hex nut.

Take the fence out of position and flip it on its back side to access

the cat screws that push the nylon supports in/out.

Use the included Allen Key to adjust the depth of each nylon

support. Do small increments and check.

© 10/2017, Laguna Tools, Inc. 17

greatly increase the chance of kickback and can result

Fusion Tablesaw

With the throat plate still in position, use a straight edge and lay it

caution:

Make sure the throatplate is lower than the

kickback.

to approximately 2" above table.

adequate to put enough tension on the belt.

caution:

From the factory, the tilt limits a pre-set to be

to set the tilt limits to 0 and 45 degrees.

1

Belt Adjustment Bolt

1 2 1

Tilt adjustment screw

2

Throat Plate Adjustments

Adjusting the Motor belt tension

crossed the plate and table. Use the included Allen key to make

appropriate adjustments.

cast iron table. Having the throat plate higher at any

position can interfere with the workpiece feed and

cause injury or harm and increase the chance of

To access the motor, remove the motor housing cover using a #2

Philips head driver. There are 4 screws in total holding on the motor

cover.

IMPORTANT: Set blade to 0° on tilt scale, then raise or lower blade

Adjusting the Tilt limits of the arbor

To access the left side tilt limit adjustment screw, remove the motor

housing cover using a #2 Philips head driver. There are 4 screws in

total holding on the motor cover.

between 0 and 45 degrees tilt to the left. Adjusting this

limit will slightly increase or decrease that amount

which may cause zero clearance throat plate or fence

to interfere. Adjusting these limits should only be done

To adjust the belt, Set blade to 0° on tilt scale, then raise or lower

blade to approximately 2" above table. Loosen the belt adjustment

bolt. With the bolt loose, Raise or lower the motor so that the belt is

tight. DO NOT OVERTIGHTEN BELT , the weight of the motor is

Locate the tilt adjustment screw. Drive the screw into the threaded

die to expand the tilt range slightly.

© 10/2017, Laguna Tools, Inc.

18

Fusion Tablesaw

Tilt adjustment screw

To access the right-side tilt adjustment screw, remove the tool

storage using a #2 Philips head driver. There are 4 screws in total

holding on the tool storage box.

Locate the tilt adjustment screw. Drive the screw into the threaded

die to expand the tilt range slightly.

© 10/2017, Laguna Tools, Inc. 19

Fusion Tablesaw

Behavior

Possible Cause

Possible Solution

1. Switch disabling key not installed.

1. Insert switch disabling key into ON/OFF switch.

1. Feed rate/cutting speed too fast.

1. Decrease feed rate/cutting speed.

1. Motor or component loose.

1. Inspect/replace damaged bolts/nuts, and re-tighten

Trouble Shooting

Machine will not start or

continues to trip the breaker.

Machine trips the overload, or

feel underpowered during

operation.

Machine is excessively loud or

is experiencing much vibration.

2. Blown fuse.

3. Wall circuit breaker tripped.

4. Power supply switched OFF or at fault.

5. Plug/receptacle at fault/wired wrong.

6. Motor connection wired wrong.

7. Wiring open/has high resistance.

8. Motor ON/OFF switch at fault.

9. Start capacitor at fault.

10. Motor at fault.

2. Workpiece material unsuitable for machine.

3. Workpiece crooked; fence not aligned.

4. Machine undersized for task; wrong blade.

5. Run capacitor at fault.

6. Belt is slipping.

7. Motor wired incorrectly.

8. Plug/receptacle at fault.

9. Pulley/sprocket slipping on shaft.

10. Motor bearings at fault.

11. Contactor not energized/has poor contacts.

12. Motor overheated.

13. Motor at fault.

2. Blade at fault.

3. Belts worn or loose.

4. Pulley loose.

5. Motor mount loose/broken.

6. Machine incorrectly mounted.

7. Arbor pulley loose.

8. Arbor bearings at fault.

9. Motor bearings at fault.

2. Replace fuse/ensure no shorts.

3. Ensure circuit size is correct/replace weak breaker.

4. Ensure power supply is on/has correct voltage.

5. Test for good contacts; correct the wiring.

6. Correct motor wiring connections.

7. Check/fix broken, disconnected, or corroded wires.

8. Replace switch.

9. Test/replace if faulty.

10. Test/repair/replace.

2. Only cut wood; ensure moisture is below 20%.

3. Straighten or replace workpiece; adjust fence.

4. Use correct blade; reduce feed rate or depth of cut.

5. Test/repair/replace.

6. Tension/replace belt.

7. Wire motor correctly.

8. Test for good contacts/correct wiring.

9. Replace loose pulley/shaft.

10. Test/repair/replace.

11. Test all legs for power/replace if faulty.

12. Clean motor, let cool, and reduce workload.

13. Test/repair/replace.

with thread locking fluid.

2. Replace warped/bent blade; re-sharpen dull blade.

3. Tension/replace belt

4. Realign/replace shaft, pulley, setscrew, and key.

5. Tighten/replace.

6. Tighten mounting bolts; relocate/shim machine.

7. Retighten/replace arbor pulley.

8. Replace arbor housing bearings; replace arbor.

9. Test by rotating shaft; grinding/loose shaft requires

bearing replacement.

© 10/2017, Laguna Tools, Inc.

20

Fusion Tablesaw

Information:

to Wire this saw to

A 220v power supply, a new 220v switch assembly is required. Please call Laguna tools customer service to order parts: 1

Wiring Diagram: Fusion F2 110V/220V

The Fusion 2 tablesaw Comes wires for 110\115V from the factory with a 110V Switch assembly. In order

© 10/2017, Laguna Tools, Inc. 21

-800-234-1979.

Fusion Tablesaw

omes wires for a 230V power supply with a 230V industrial strength contactor switch. This saw will

Wiring Diagram: Fusion F3 220V

Information:

not operate on 110V, and replacements parts are not available to make this possible.

The Fusion 3 tablesaw C

© 10/2017, Laguna Tools, Inc.

22

Fusion Tablesaw

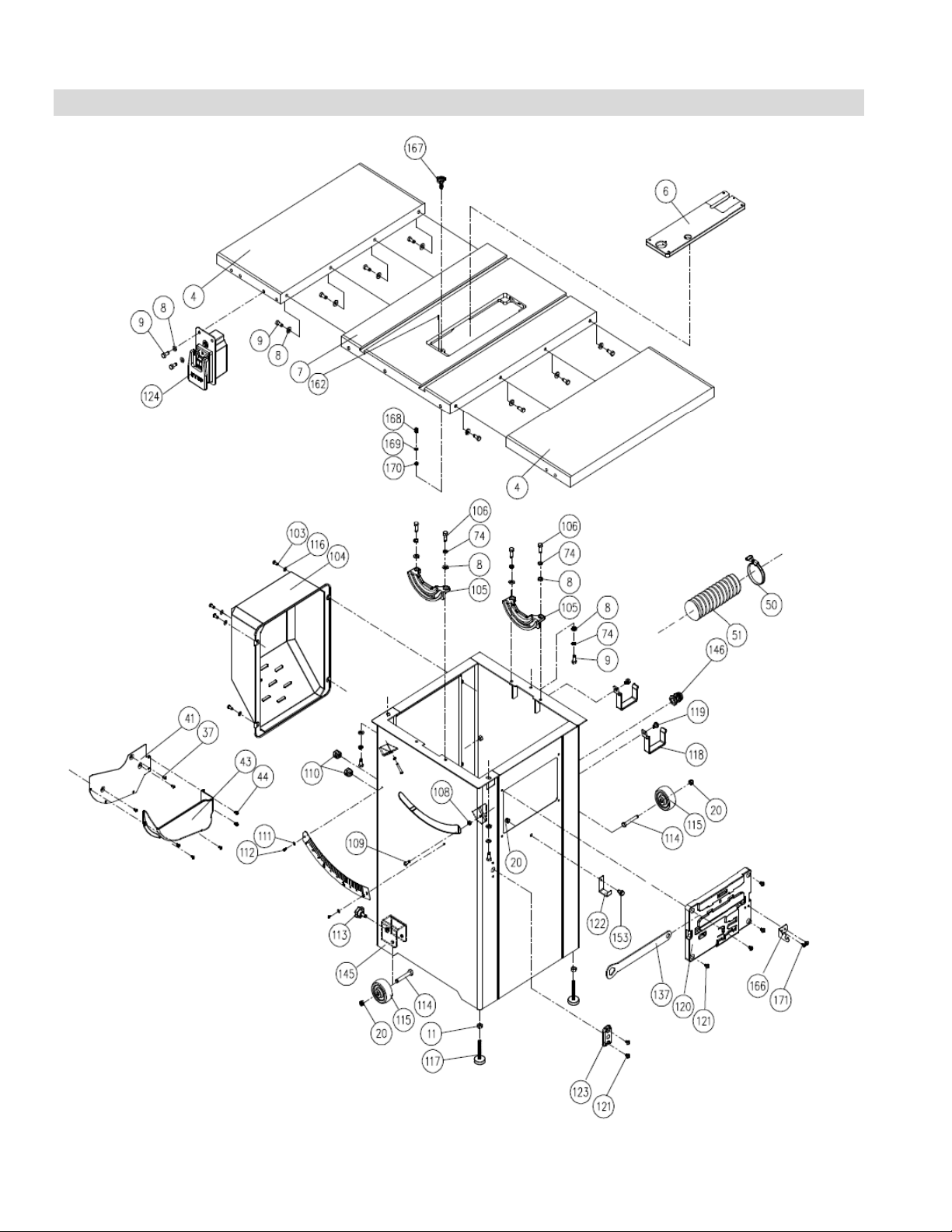

Parts Diagrams

Fence Assembly

© 10/2017, Laguna Tools, Inc. 23

Fusion Tablesaw

Mitre Gauge, Blade Guard

© 10/2017, Laguna Tools, Inc.

24

Fusion Tablesaw

Motor and Trunnion

© 10/2017, Laguna Tools, Inc. 25

Fusion Tablesaw

Cabinet

© 10/2017, Laguna Tools, Inc.

26

Fusion Tablesaw

F3 Cabinet

© 10/2017, Laguna Tools, Inc. 27

Fusion Tablesaw

Key

Laguna Tools Part Number

Part Decryption

Notes

Q'ty

1

PTSF236110175-0130-1-1

Rip Fence Assembly

1

1

PTSF236110175-0130-1

52" Rail Assembly

1

CAP Screw w/ Spring

Washer

1.2

PTSF236110175-0130-1.2

Flat Washer

8.5*16*2.0t

6

1.3

PTSF236110175-0130-1.3

Hex Nut

M8*1.25P(13B*6.5H)

6

1.4

PTSF236110175-0130-1.4

Square Bolt

M8*1.25P*20

3

1.6

PTSF236110175-0130-1.6

Rear rail

1

1.7

PTSF236110175-0130-1.7

Front Rail Assembly

52"

2

PTSF236110175-0130-2-1

Blade Guard Assy

1

2

PTSF236110175-0130-2

Right Table Assembly

1

CAP Screw w/ Spring

Washer

2.10

PTSF236110175-0130-2.10

Steel Tube

2

2.2

PTSF236110175-0130-2.2

Flat Washer

8.5*16*2.0t

8

2.3

PTSF236110175-0130-2.3

Hex Nut

M8*1.25P(13B*6.5H)

10

2.4

PTSF236110175-0130-2.4

Square Bolt

M8*1.25P*20

4

2.5

PTSF236110175-0130-2.5

Leveling foot

2

2.7

PTSF236110175-0130-2.7

PDF Table

1

2.8

PTSF236110175-0130-2.8

Brace

4

2.9

PTSF236110175-0130-2.9

Self-Tapping screw

8

3

PTSF236110175-0130-3

Miter Gauge Assembly

1

4

PTSF236110175-0130-4

Extension Table

2

6

PTSF236110175-0130-6

Table Insert Assembly

1

7

PTSF236110175-0130-7

Table

1

8

PTSF236110175-0130-8

Flat Washer

8.5*16*2.0t

19

9

PTSF236110175-0130-9

Hex. screw

M8*1.25P*20

13

10

PTSF236110175-0130-10

Up-down Bracket

1

10

PTSF3362203-0130-10

Up-down Bracket

for F3 10” Tablesaw

for MTSF3362203-0130

1

11

PTSF236110175-0130-11

Hex Nut

M8*1.25P(13B*6.5H)

4

12

PTSF236110175-0130-12

Spring

1

12

PTSF3362203-0130-12

Spring

for F3 10” Tablesaw

for MTSF3362203-0130

1

13

PTSF236110175-0130-13

Cap Screw

M8*1.25P*20

5

14

PTSF236110175-0130-14

Motor Assy

1.75HP*110V*60HZ*1PH

1

14

PTSF236110175-0130-14-1

Motor Assy

1.75HP*220V*60HZ*1PH

1

3HP*230V*60HZ*1PH for

MTSF3362203-0130

15

PTSF236110175-0130-15

Flat Washer

10*20*3.0t

1

16

PTSF236110175-0130-16

Spring Washer

10.2*18.5

1

17

PTSF236110175-0130-17

Hex. screw

M10*1.5P*30

1

18

PTSF236110175-0130-18

Motor Fixing Shaft

1

19

PTSF236110175-0130-19

Anit-loose Nut

M10*1.5P(17B*12H)

1

20

PTSF236110175-0130-20

Anit-loose Nut

M8*1.25P(13B*9H)

4

21

PTSF236110175-0130-21

Retaining Ring

STW-14

1

22

PTSF236110175-0130-22

Bracket for Riving Knife

1

23

PTSF236110175-0130-23

Cap Screw

M8*1.25P*16

2

24

PTSF236110175-0130-24

Spring

1

25

PTSF236110175-0130-25

Bushing

1

26

PTSF236110175-0130-26

Block

1

27

PTSF236110175-0130-27

Riving Knife

1

28

PTSF236110175-0130-28

SET Lock screw

M6*1.0P*8

5

Parts List

1.1 PTSF236110175-0130-1.1

2.1 PTSF236110175-0130-2.1

M8*1.25P*20/8.2*15.4 3

M8*1.25P*20/8.2*15.4 4

14 PTSF3362203-0130-14 Motor Assy for F3 10” Tablesaw

© 10/2017, Laguna Tools, Inc.

28

1

Fusion Tablesaw

29

PTSF236110175-0130-29

Round Head Screw

M5*0.8P*16

2

30

PTSF236110175-0130-30

Pin

1

31

PTSF236110175-0130-31

Fixing Knob

1

32

PTSF236110175-0130-32

Lock Handle

1

33

PTSF236110175-0130-33

Sawblade

10''*40T

1

34

PTSF236110175-0130-34

Sawblade clamp

1

35

PTSF236110175-0130-35

Nut

TW5/8"-12(in)

1

Round Head Socket Lock

Screw

38

PTSF236110175-0130-38

Upper Trunnion

1

38

PTSF3362203-0130-38

Upper Trunnion

for F3 10” Tablesaw

for MTSF3362203-0130

1

40

PTSF236110175-0130-40

Locking CAP screw

M8*1.25P*20

2

41

PTSF236110175-0130-41

Fixing Plate

1

43

PTSF236110175-0130-43

Dust Hood

1

44

PTSF236110175-0130-44

Pan Head Screw

M5*0.8P*8

5

46

PTSF236110175-0130-46

Arbor Lock Handle

1

47

PTSF236110175-0130-47

Spring

1

48

PTSF236110175-0130-48

Retaining Ring

ETW-9

2

50

PTSF236110175-0130-50

Clamp

I.D.60-80mm(O.D.)

1

51

PTSF236110175-0130-51

Dust Hose

2.5”(O.D.)*800mm

1

52

PTSF236110175-0130-52

Anit-loose Nut

M10*1.5P(17B*8H)

1

53

PTSF236110175-0130-53

Flat Washer

10.3*23*2.0t

1

54

PTSF236110175-0130-54

Retaining Ring

RTW-35

1

55

PTSF236110175-0130-55

Ball Bearing

2

56

PTSF236110175-0130-56

Spacer

1

57

PTSF236110175-0130-57

Fixed Plate

1

58

PTSF236110175-0130-58

Poly V-Belt 135J7

1

59

PTSF236110175-0130-59

Arbor

1

60

PTSF236110175-0130-60

Hex. screw

M6*1.0P*16

1

61

PTSF236110175-0130-61

Flat Washer

6.2*20*3.0t

1

62

PTSF236110175-0130-62

Flat Washer

6.4*16*1.6t

1

63

PTSF236110175-0130-63

Lead Screw

1

64

PTSF236110175-0130-64

Retaining Ring

STW-16

1

65

PTSF236110175-0130-65

Key 4*4*8

2

66

PTSF236110175-0130-66

Washer

1

67

PTSF236110175-0130-67

Bearing 51100

2

68

PTSF236110175-0130-68

Trunnion

1

69

PTSF236110175-0130-69

Bevel Gear

2

70

PTSF236110175-0130-70

Flat Washer

6.4*16*1.0t

1

71

PTSF236110175-0130-71

Anit-loose Nut

M6*1.0P(10B*5H)

2

72

PTSF236110175-0130-72

Column

2

73

PTSF236110175-0130-73

Cap Screw

M8*1.25P*35

2

74

PTSF236110175-0130-74

Spring Washer

8.2*15.4

14

75

PTSF236110175-0130-75

Flat Washer

10*20*1.5t

1

76

PTSF236110175-0130-76

Bushing

1

77

PTSF236110175-0130-77

SET Screw

M5*0.8P*5

2

78

PTSF236110175-0130-78

Plate

1

79

PTSF236110175-0130-79

Spring Pin 6*16

2

80

PTSF236110175-0130-80

Pointer

1

Round Head Lock Screw

w/Washer

82

PTSF236110175-0130-82

Shaft

1

83

PTSF236110175-0130-83

Bushing

1

84

PTSF236110175-0130-84

Handwheel

2

37 PTSF236110175-0130-37

M5*0.8P*12 6

81 PTSF236110175-0130-81

© 10/2017, Laguna Tools, Inc. 29

M5*0.8P*12/5*10.5*1.0t 1

Fusion Tablesaw

84

PTSF3362203-0130-84

Handwheel Assembly

for F3 10” Tablesaw

for MTSF3362203-0130

2

85

PTSF236110175-0130-85

Fixing Knob

2

86

PTSF236110175-0130-86

Worm Gear Box

1

87

PTSF236110175-0130-87

Worm Gear

1

88

PTSF236110175-0130-88

Ball Bearing 6201

1

89

PTSF236110175-0130-89

Retaining Ring

RTW-32

1

90

PTSF236110175-0130-90

Gear

1

91

PTSF236110175-0130-91

Flat Washer

5.5*22*2.0t

1

92

PTSF236110175-0130-92

Hex. screw

M5*0.8P*12

1

93

PTSF236110175-0130-93

Cap Screw

M8*1.25P*45

2

94

PTSF236110175-0130-94

Worm Shaft

1

95

PTSF236110175-0130-95

Set Screw

M6*1.0P*6

3

96

PTSF236110175-0130-96

Key 4*4*20

1

97

PTSF236110175-0130-97

Ball Bearing 6005

1

98

PTSF236110175-0130-98

Retaining Ring

STW-25

1

99

PTSF236110175-0130-99

Retaining Ring

STW-13

1

100

PTSF236110175-0130-100

Retaining Ring

RTW-47

1

101

PTSF236110175-0130-101

Shaft

1

102

PTSF236110175-0130-102

Bushing

1

103

PTSF236110175-0130-103

Pan Head Screw

M6*1.0P*16

4

104

PTSF236110175-0130-104

Motor Cover

1

105

PTSF236110175-0130-105

Trunnion Support

2

106

PTSF236110175-0130-106

Hex. screw

M8*1.25P*25

4

108

PTSF236110175-0130-108

Hex Nut

M6*1.0P(10B*5H)

2

109

PTSF236110175-0130-109

Hex. screw

M6*1.0P*25

2

110

PTSF236110175-0130-110

Strain Relief

SB7R-1

1

111

PTSF236110175-0130-111

Flat Washer

4.3*10*1.0t

2

112

PTSF236110175-0130-112

Pan Head Screw

M4*0.7P*8

2

113

PTSF236110175-0130-113

Knob

5/16"-18NC*3/4"

2

114

PTSF236110175-0130-114

Hex. screw

M8*1.25P*60

2

115

PTSF236110175-0130-115

Wheel

2

116

PTSF236110175-0130-116

Flat Washer

6.3*13*1.0t

4

117

PTSF236110175-0130-117

Leveling foot

2

118

PTSF236110175-0130-118

Slide Shelf

2

119

PTSF236110175-0130-119

Hex Screw w/Washer

M8*1.25P*12/(13B*6.5H)

2

120

PTSF236110175-0130-120

Storage Box

1

Round Head Screw

w/Washer

122

PTSF236110175-0130-122

Fix Plate

1

123

PTSF236110175-0130-123

Worm Shaft Bracket

1

120V CSA for MTSF236110175-

0130

220V CSA for MTSF236110175-

0130

3HP*220V for for MTSF3362203-

0130

127

PTSF236110175-0130-127

36" Rail Assembly

1

CAP Screw w/ Spring

Washer

127.2

PTSF236110175-0130-127.2

Flat Washer

8.5*16*2.0t

6

127.3

PTSF236110175-0130-127.3

Hex Nut

M8*1.25P(13B*6.5H)

6

127.4

PTSF236110175-0130-127.4

Square Bolt

M8*1.25P*20

3

127.5

PTSF236110175-0130-127.5

Rear rail

1

127.6

PTSF236110175-0130-127.6

Front Rail Assembly

36"

1

130

PTSF236110175-0130-130

Push Sticks

1

121 PTSF236110175-0130-121

124 PTSF236110175-0130-124 Magnetic Switch Assy

124 PTSF236110175-0130-124-1 Magnetic Switch Assy

124 PTSF3362203-0130-124 Magnetic Switch Assy for F3 10” Tablesaw

127.1 PTSF236110175-0130-127.1

© 10/2017, Laguna Tools, Inc.

30

M6*1.0P*10/6*13.2*1.0t 6

1

1

1

M8*1.25P*20/8.2*15.4 3

Fusion Tablesaw

133

PTSF236110175-0130-133

Hex. Wrench

2.5mm

1

134

PTSF236110175-0130-134

Hex. Wrench

6mm

1

135

PTSF236110175-0130-135

Open Wrench

8*10

1

136

PTSF236110175-0130-136

Open Wrench

11*13

1

137

PTSF236110175-0130-137

Arbor Wrench

1

145

PTSF236110175-0130-145

Stand

1

145

PTSF3362203-0130-145

Stand

for F3 10” Tablesaw

for MTSF3362203-0130

1

146

PTSF236110175-0130-146

Strain Relief

PGA13.5-11B

1

147

PTSF236110175-0130-147

Bushing

for MTSF236110175-0130 only

4

148

PTSF236110175-0130-148

#N/A

1

150

PTSF236110175-0130-150

Handle

for MTSF236110175-0130 only

2

151

PTSF236110175-0130-151

Set screw

M5*0.8P*12

2

152

PTSF236110175-0130-152

Key 4*4*12

2

153

PTSF236110175-0130-153

Hex Screw w/Washer

M8*1.25P*16/(13B*6.5H)

1

154

PTSF236110175-0130-154

Adjusting Bushing

1

155

PTSF236110175-0130-155

Set screw

M5*0.8P*5

1

159

PTSF236110175-0130-159

Retaining Ring

STW-10

1

160

PTSF236110175-0130-160

O-Ring P11

1

162

PTSF236110175-0130-162

Spring Pin 3*10

1

166

PTSF236110175-0130-166

Hook

1

167

PTSF236110175-0130-167

Knob

1

168

PTSF236110175-0130-168

Spring

1

169

PTSF236110175-0130-169

Flat Washer

5.2*12*1.5t

1

170

PTSF236110175-0130-170

Anit-loose Nut

M5*0.8P(8B*6H)

1

171

PTSF236110175-0130-171

Round Head Screw

M5*2.12P*12

2

*125

PTSF236110175-0130-*125

Power Cord

SJT14AWG*3C*2550mm

1

1.7.1

PTSF236110175-0130-1.7.1

Front Rail

1

1.7.2

PTSF236110175-0130-1.7.2

Scale 52"

1

1.7.3

PTSF236110175-0130-1.7.3

End Cap - Left

1

1.7.4

PTSF236110175-0130-1.7.4

End Cap - Right

1

1.7.5

PTSF236110175-0130-1.7.5

Round Head Screw

M4*1.59P*12

4

52" Rail with Right Table

Assy

OP PTSF236110175-0130-OP

1

© 10/2017, Laguna Tools, Inc. 31

Laguna Tools is not responsible for errors or omissions.

Specications subject to change. Machines may be shown with optional accessories.

© 2017, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the registered trademarks of Laguna Tools, Inc. All rights reserved.

MTSF236110175-0130

tt

MTSF252110175-0130

Precision ground mirrored tabletop.

Quick release blade attachments.

Integrated mobility and storage.

Quick blade changes with the push

button blade lock.

Single poly V-Ribbed belt and double

sealed large bearings.

Reliable totally enclosed fan cooled

AC Induction motor.

Shrouded dust control

and powder coated body.

The new Laguna F2 and F3 Table Saws are unlike any saw on the market.

Having the same quality demands earned through the original fusion table saw,

the new fusion line will not only impress but exceed the expectations you have

come to expect from Laguna. With a completely redesigned trunnion and arbor

controls that focus on buttery smooth movements, continuous accuracy, and

longevity of the saw - we are sure this is the saw that will give you the perfect rip

cut for many years.

Newly designed precision arbor mounted directly to cabinet top. Height adjustment moves straight up easily with mechanical assist. Arbor tilt is now on 2:1

ratio gear box. The new Laguna Arbor is Sturdy and built to last.

Designed for user adjustability. From the jointless fence to the right of the blade, to

the newly designed throat plate, every accessory and control is adjustable to ensure

the saw is accurate.

Optional Accessories

MTSF2

52” Rip Assembly

MTSFUSION52RIP-0130

Canadian made 10” saw

blades

AT00210060

AT00110060

AT00810050

Visit LagunaTools.com for more

Designed in california

2072 Alton Parkway Irvine, CA 92606 U.S.A.

www.lagunatools.com - dealersales@lagunatools.com

p. 1-800.234.1976 - f. 1-949.474.0150

Loading...

Loading...