La Germania TUS95L61LDX, TUS96C71BX, TUS95L71DX Installation Manual

INSTALLATION, AND USE INSTRUCTIONS

FOR COOKERS

90x60 cm

READ THE INSTRUCTION BOOKLET BEFORE INSTALLING AND USING THE APPLIANCE.

GIANT OVEN

310201

The manufacturer will not be responsible for any damage to property or to persons caused by incorrect installation or

improper use of the appliance.

The manufacturer is not responsible for any inaccuracies, due to printing or transcription errors, co ntained in this booklet. In

addition, the appearance of the figures reported is also purely indicative.

The manufacturer reserves the right to make changes to its products when considered necessary and useful, without affecting

the essential safety and operating characteristics.

THIS APPLIANCE HAS BEEN DESIGNED FOR NON-PROFESSIONAL DOMESTIC USE.

INSTRUCTION FOR INSTALLER/INSTALLER TECHNICAL MANUAL

APPLIANCE GAS CONNECTION

Installation must be done by authorised installation staff.

Before connecting the appliance to the gas network, make sure that the data on the label attached to the food warmer

drawer or on the back of the cooker are compatible with what is indicated for the gas distribution netwo rk.

A label in the food warmer drawer (or on the back) of the appliance indicates the appliance adjustment conditions: type

of gas and operating pressure.

IMPORTANT: This appliance must be installed in compliance with current national standards in force and used only in

a well-ventilated room.

WARNING: It should be recalled that the appliance utilises a threaded 1/2" gas cylindrical male fitting according to UNIISO 228-1.

To connect the appliance to the gas network with a flexible rubber hose, a supplemental hose nipple fitting is needed

(see Fig. 1) which is supplied with the appliance.

ADAPTATION TO DIFFERENT TYPES OF GAS

Before performing any maintenance operation, disconnect the appliance from the gas supply and electricity network.

REPLACING THE NOZZLES TO OPERATE WITH ANOTHER TYPE OF GAS:

Follow the instructions below to change the burner nozzles on the work surface:

1) Pull out the plug from the electric outlet to avoid any type of electric contact.

2) Remove the grids from the work surface (Fig. 2).

3) Remove the burners (Fig. 2).

4) Unscrew the nozzles using a 7 mm spanner, and replac e them (Fig. 3) with those needed for the new type of gas according

to what is indicated in Table 1.

Follow the instructions below to change the oven burner nozzle:

1) Remove the oven level (Fig. 4-5).

2) Loosen the screw V and pull out the burner from the support being careful not to damage the ignition plug and the

thermocouple (Fig. 6).

3) Unscrew the nozzle R (Fig. 6) using a 7 mm spanner and replace it with the nozzle nee ded for the ne w type of gas accordi ng

to what is indicated in Table 2 or in Table 3.

Follow the instructions below to change the grill burner nozzle:

1) Loosen the screw at the end of the grill burner and pull out the burner from the support being careful not to damage the

ignition plug and the thermocouple (Fig. 7).

2) Unscrew the nozzle C (Fig. 7) using a 7 mm spanner and replace it with the nozzle nee ded for the ne w type of gas accordi ng

to what is indicated in Table 2 or in Table 3.

WARNING: After completing the above-mentioned replacements, th e technician must adjust the burners, a s described

in the paragraph below, seal any adjustment and pre-adjustment devices and apply the label on the

appliance, to replace the existing one, corresponding to the new gas adjustment. This label is contained in

the spare nozzle bag.

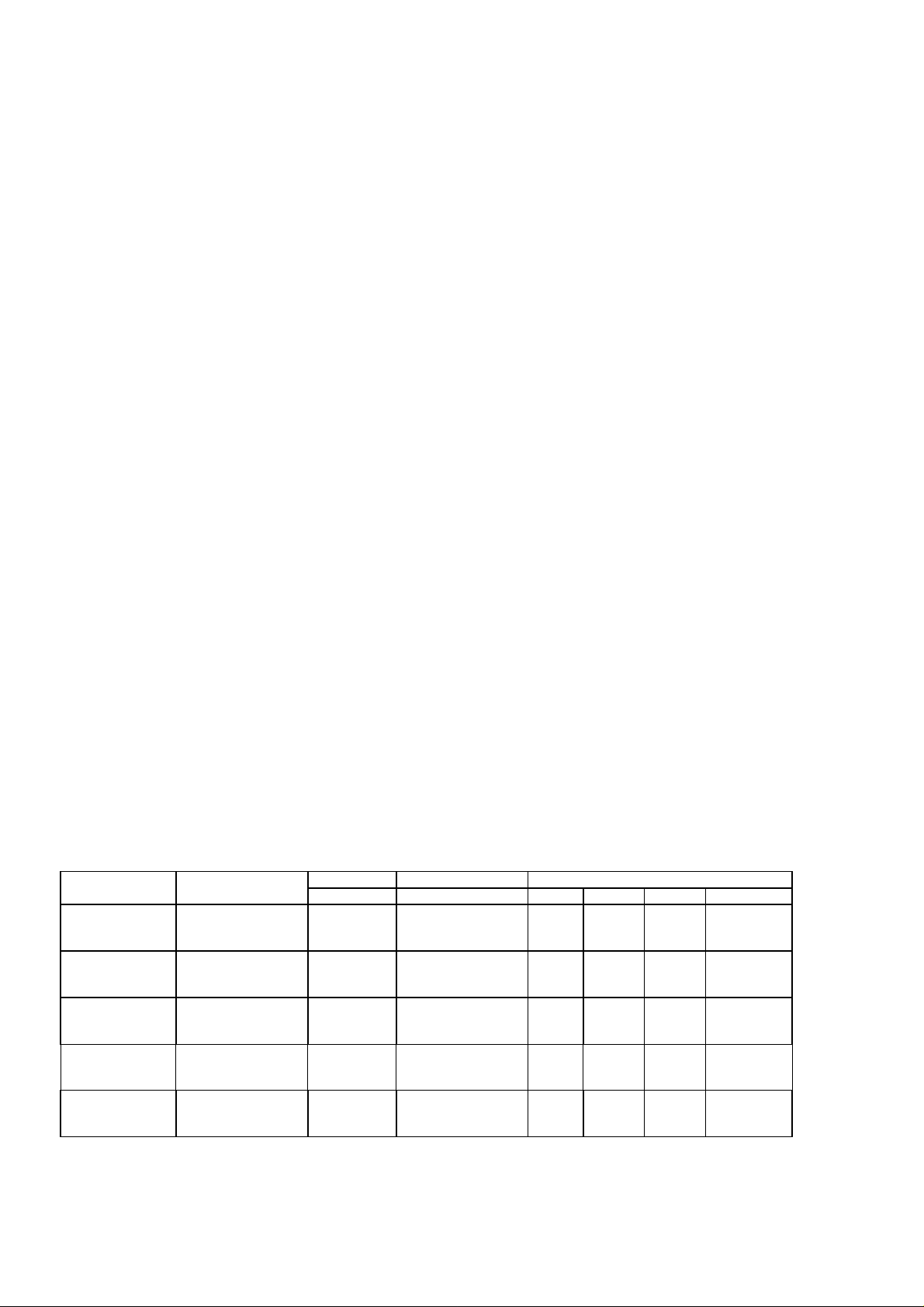

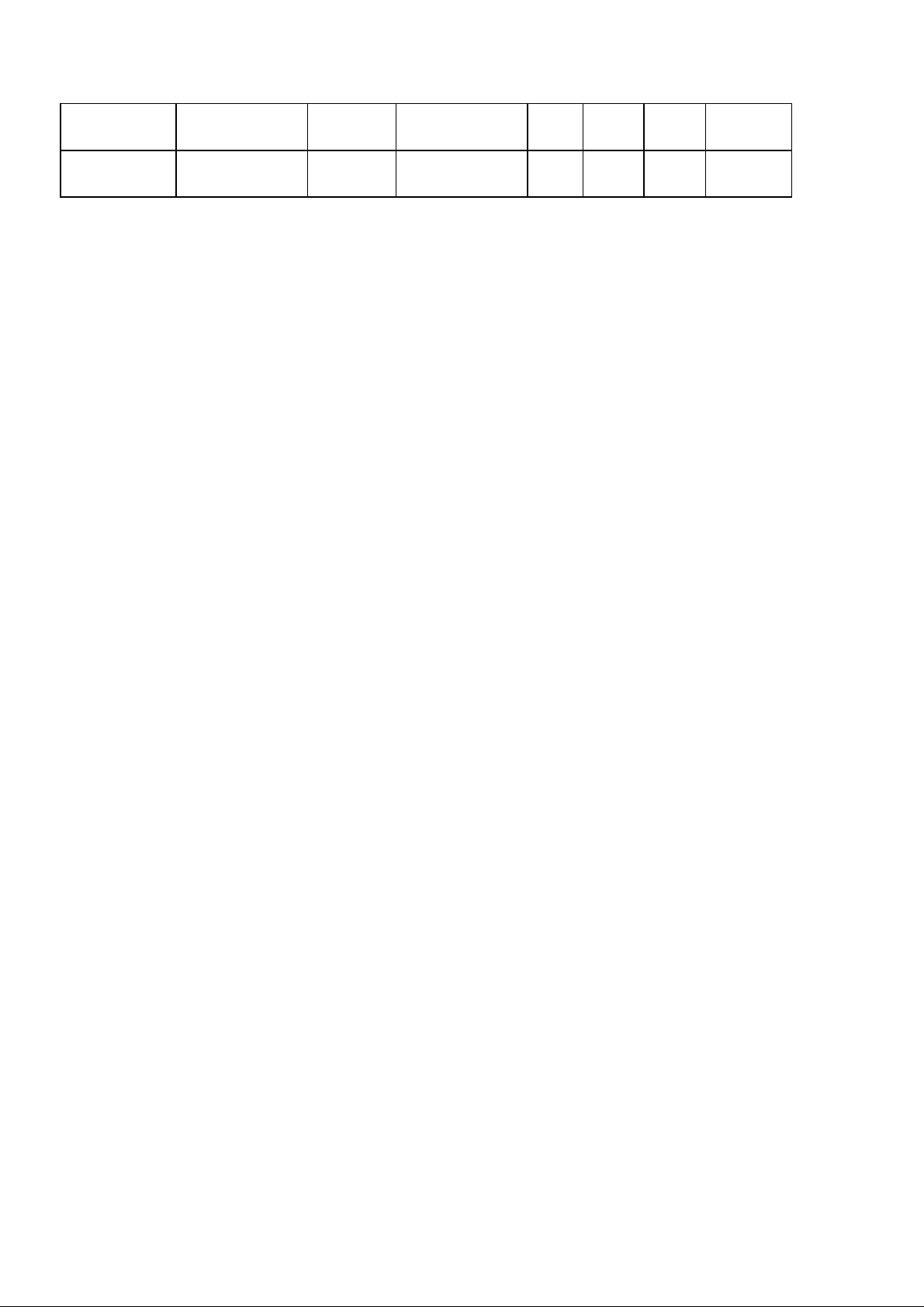

Table 1

Burner Types of gas Pressure Nozzle diameter Rater capacity

mbar 1/100 mm. g/h l/h kW kcal/h

Auxiliary Natural G20 20 72 - 95 1 860

Butane G30 28-30 50 73 - 1 860

Propane G31 37 50 71 - 1 860

Semi-rapid Natural G20 20 97 - 167 1,75 1505

Butane G30 28-30 65 127 - 1,75 1505

Propane G31 37 65 125 - 1,75 1505

Rapid Natural G20 20 115 - 286 3 2580

Butane G30 28-30 85 218 - 3 2580

Propane G31 37 85 214 - 3 2580

Fish Natural G20 20 120 - 276 2,9 2494

Butane G30 28-30 85 211 - 2,9 2494

Propane G31 37 85 207 - 2,9 2494

Double Natural G20 20 135 - 334 3,5 3010

Ring Butane G30 28-30 95 254 - 3,5 3010

Propane G31 37 95 250 - 3,5 3010

2

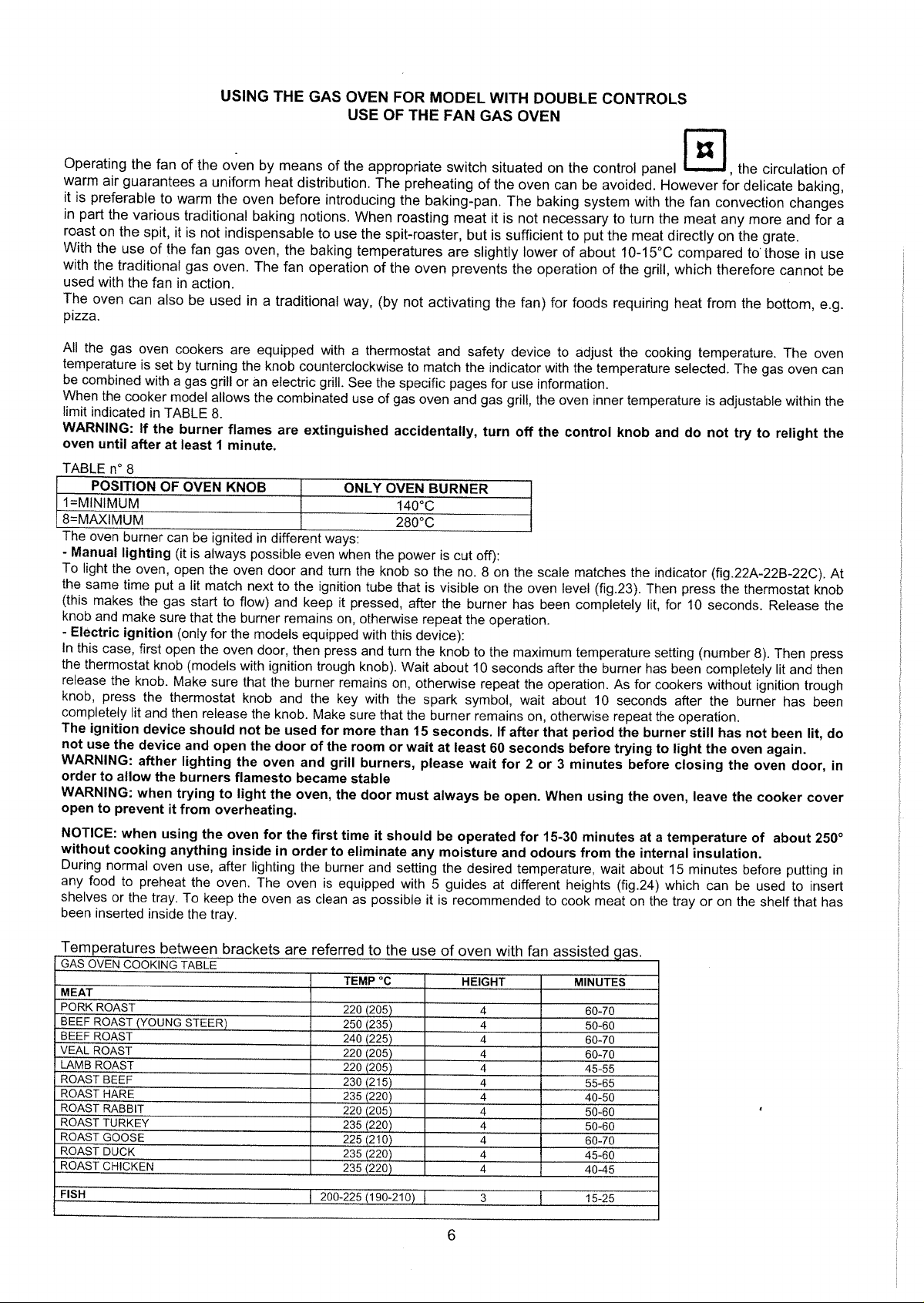

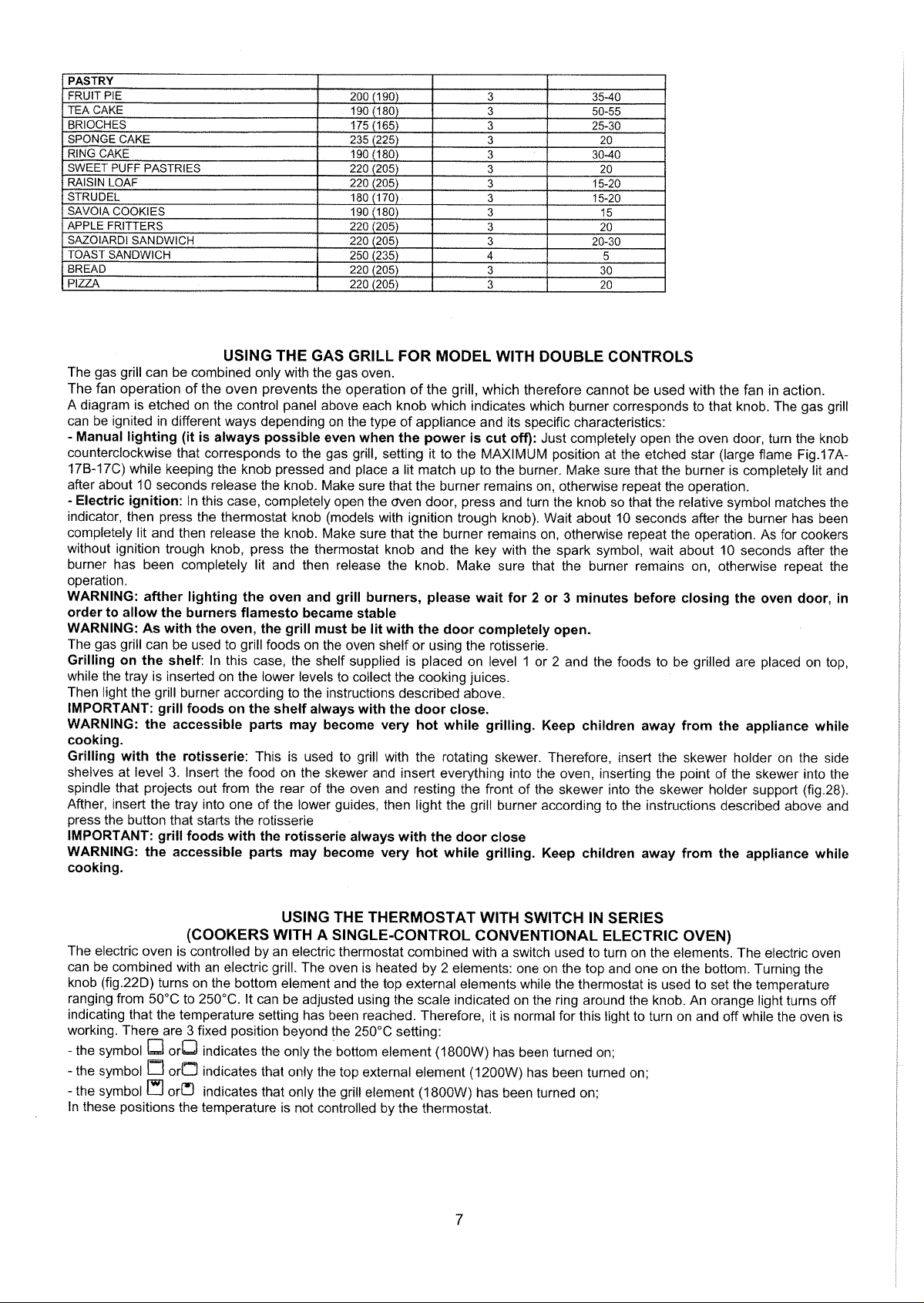

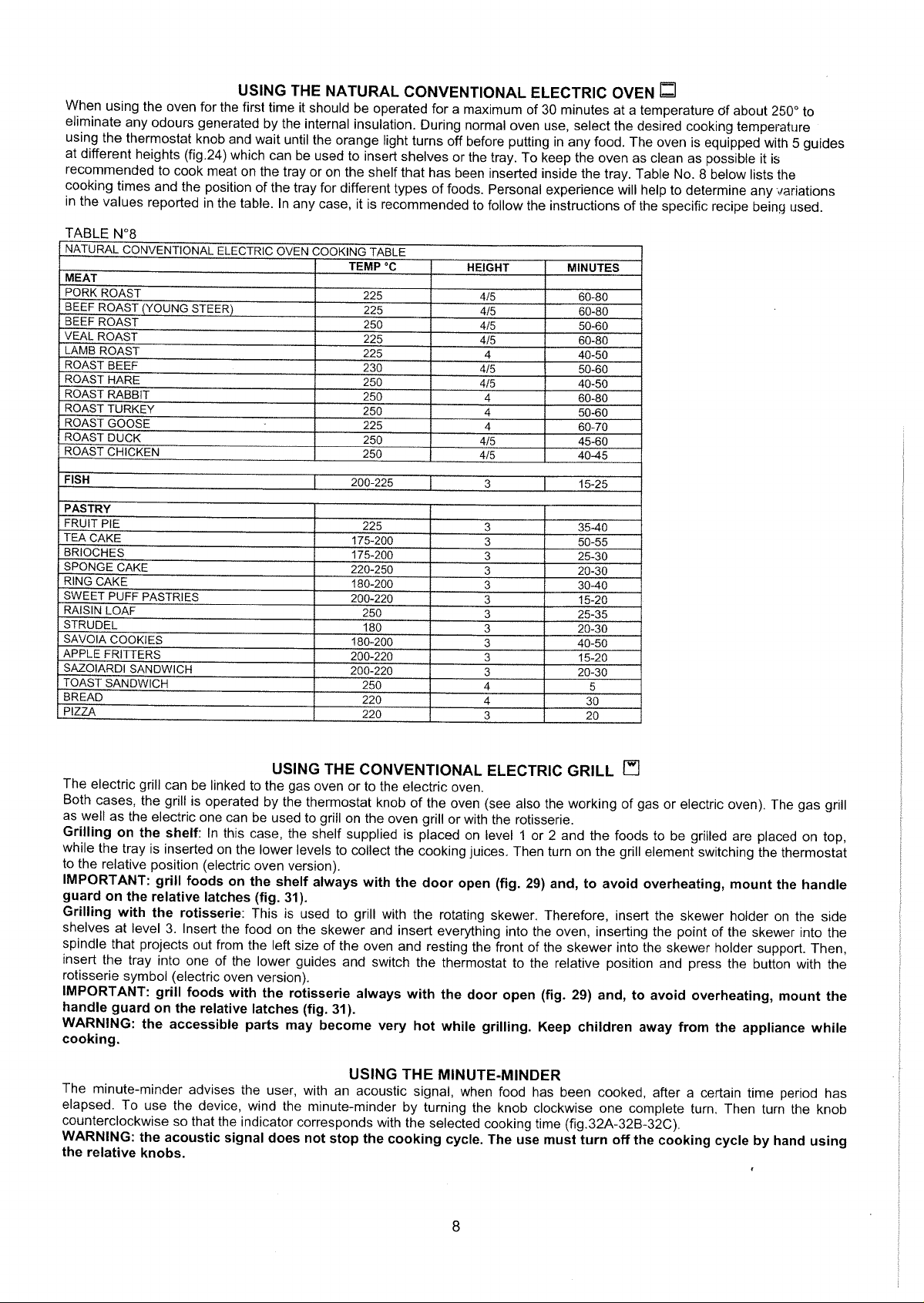

Table 2 (model with gas oven and gas grill with double controls)

Oven Natural G20 20 135 - 352 3,7 3182

Butane G30 30 90 269 - 3,7 3182

Propane G31 37 90 264 - 3,7 3182

Grill Natural G20 20 115 - 191 2 1720

Butane G30 30 68 145 - 2 1720

Propane G31 37 68 143 - 2 1720

BURNER ADJUSTMENT

Burner "MINIMUM" adjustment:

Work surface burner adjustment: follow the instructions below to adjust the work surface burner minimum:

1) Light the burner and set the knob to the MINIMUM position (small flame).

2) Remove the knob of the valve that is press fit on the rod of that valve.

3) If the cooker is not equipped with safety valves on the surface burners, insert a small slotted scre wdriver into the hole on the

valve rod (Fig. 10) and turn the choke screw to the right or left until the burner flame is adjusted to minimum. If the cooker is

equipped with safety valves, the choke valve is not located in the rod hole, but on the valve body (see fig. 11).

4) Make sure that the flame does not go out when switching quickly from the MAXIMUM to the MINIMUM position.

Oven burner adjustment: follow the instructions below to adjust the minimum:

1) Light the burner setting the knob to the MAXIMUM position.

2) Close the oven door and operate the oven for at least 10 minutes.

3) Set the knob to the MINIMUM position (corresponding to 120°) and then remove it.

4) With a slotted screwdriver turn the choking screw (see figure 12) and, while observing the flame at the same time through th e

cooker porthole, evaluate the consistency of the flame so it remains on when switching quickly from the MINIMUM to the

MAXIMUM position.

Grill burner adjustment: follow the instructions below to adjust the minimum:

1) Light the burner setting the knob to the MAXIMUM position.

2) Close the oven door and operate the oven for at least 10 minutes.

3) Set the knob to the MINIMUM position (small flame) and then remove it.

4) If the cooker is not equipped with safety valves on the surface burners, insert a small slotted scre wdriver into the hole on the

valve rod (Fig. 10) and turn the choke screw to the right or left, while observing the flame at the same time through the cooker

porthole, evaluate the consistency of the flame so it remain s on when switching quickly from the MINIMUM to the MAXIMUM

position. If the cooker is equipped with safety valves, the choke valve is not located in the rod hole, but on the valve body (see

figure 11).

WARNING: The above-mentioned adjustment should be made only with natural gas burners, while for those operating

with liquid gas the screw must be locked at the end in a clockwise direction.

WARNING: For the model with single grill burner, the grill burner always operates at maximum and therefore no

minimum adjustment is required.

APPLIANCE ELECTRIC CONNECTION:

The electric connection must comply with the current legal standard s and regulations.

Before making the connection, check that:

- The system electrical rating and the current outlets are adequate for the maximum power output of the appliance (see the label

applied to the bottom of the casing).

- The outlet or the system is equipped with an efficient ground connection in accordance with the current legal standards and

regulations. The company will not be responsible for the non-compliance with these instructions.

When the connection to the power supply network is made using an outlet:

- If the power cord is supplied without a plug, apply a standard plug that is suitable for the load indicated on the label. Connect

the wires according to the diagram shown in FIG.13 and check that:

letter L (phase) = brown wire;

letter N (neutral) = blue wire;

ground symbol = green-yellow wire;

- The power cord must be positioned so that an overtemperature of 75 K will not be reached at any point.

- Do not use reductions, adapters or splitters since they might cause false contacts and lead to dangerous overheating.

When the connection is made directly to the electric network:

- Insert an omnipolar circuit-breaker between the appliance and the network which is sized for the appliance load with a

minimum opening between the contacts of 3 mm.

- Remember that the ground wire must not be interrupted by the circuit-breaker.

- As an alternative, the electric connection can also be protected by a high-sensitivity residual current circuit-breaker.

- It is highly recommended to attach the special green-yellow ground wire to an efficient ground system.

3

USER MANUAL

r

WARNING:

Oven and grill burners shall not be used simultaneously

WARNING: In case of gas smell, a defect of the oven or any problem, disconnect the gas supply and electricity network.

Contact the After Sales Service for check/maintenance.

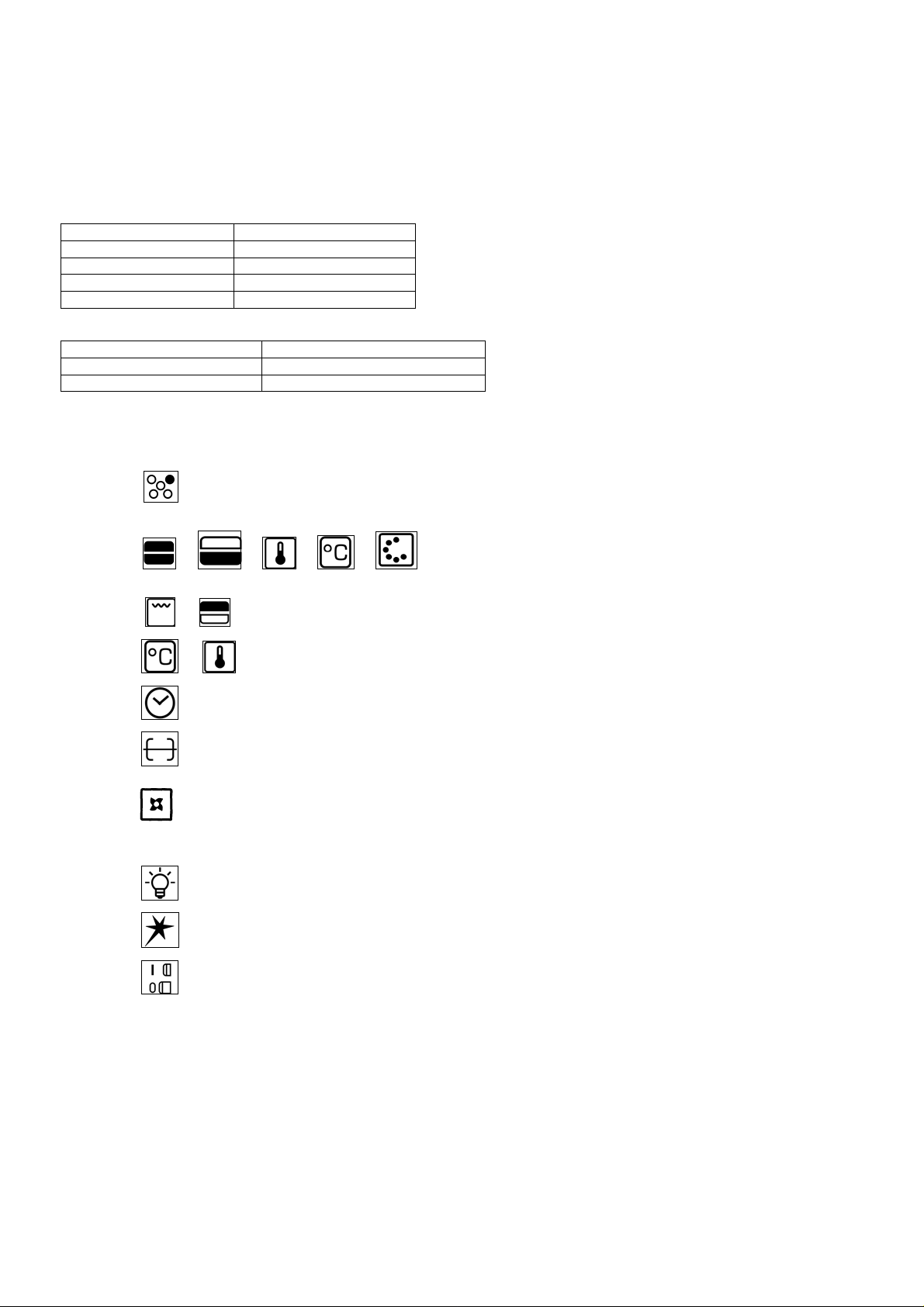

GAS BURNER DIMENSION

Dimension (mm)

Burne

Auxiliary Ø 50

Semi-rapid Ø 70

Rapid Ø 95

Ultra-rapid Ø 130

ELECTRIC HOTPLATES DIMENSION

TYPE DIMENSION

Hot plate rapid type Ø 145 (front centre) 1500W

Hot plate rapid type Ø 180 (rear centre) 2000W

CONTROL PANEL DESCRIPTION

On the control panel, small symbols show the function of each knob o r key. Here as follows are the several controls

that a cooker can have:

the symbol shows the disposition of burners on the worktop, the full dot identifies the burner in object (in this case the

rear burner on the right).

the symbol or or or or shows the running of any oven (gas oven, gas oven with gas grill, gas

oven with electric grill, static oven, 9 positions switch)

the symbol or shows the grill (gas grill, electric grill)

the symbol or shows the electric thermostat for electric fan oven

the symbol shows the minute minder

the symbol shows the operating key for the rotisserie (only gas oven)

the symbol sho ws the oven fan working button as to allow the oven to o perates with fan assisted gas. The fan operation

of the oven prevents the operation of the electric grill, which therefore cannot be used with the fan in action.

the symbol shows the ignition key for the oven light (all except the electric fan oven)

the symbol shows the push-button for burner ignition

the symbol shows if keys are in position “on” or “off”

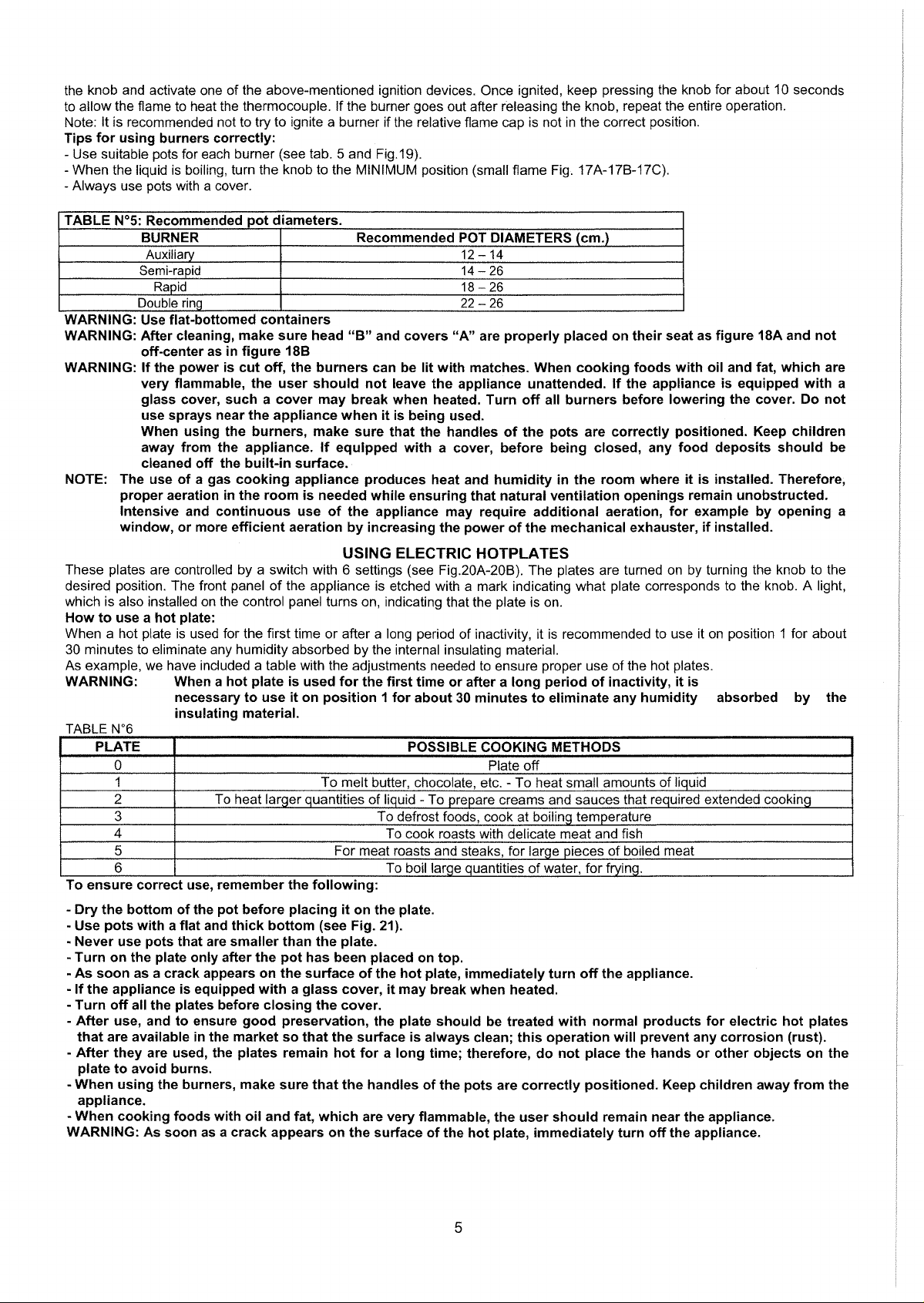

USING BURNERS

A diagram is etched on the control panel abo ve each knob which in dicates which burner corresponds to that knob. The burners

can be ignited in different ways depending on the type of appliance and its specific characteristics:

- Manual lighting (it is always possible even when the power is cut off): Turn the knob counterclockwise that corresponds

to the burner selected, setting it to the MAXIMUM position at t he etched star (large flame Fig.17A-17B-17C) and place a lit

match up to the burner.

- Electric ignition: Turn the knob counterclockwise that corresponds to the burner selected, setting it to the MAXIMUM position

(large flame Fig. 17A-17B-17C) and keep on pressing the knob in corr espondence of th e ignition symbol marke d with a star (for

cookers equipped with ignition trough knob) or press the igni tion button marked with a st ar and release it as soo n as the burne r

has ignited.

- Burner ignition equipped with safety device (thermocouple)(fig.16): Press and turn the knob counterclockwise that

corresponds to the burner selected, setting it to the MAXIMUM position at the etched star (large fl ame F ig. 17A-1 7B-17 C), press

4

Loading...

Loading...