La germania LUEP02-90-S, LUE02-90-S, LUE41-90-S, LUE02-90-W User Manual

MODELS

LUEP02-90-S, LUE02-90-W, LUE02-90-S,LUE41-90-S

LUEP02-90-S

LUE02-90 W

LUE02-90 -S

LUE41-90-S

UPRIGHT COOKERS

Installation instructions

User instructions

This cooker is approved for use with Natural and Propane gases

Leave instructions with the owner

Contents

Contents 2-3

General information 4-5

❍ Introducing your new cooker

❍ Notes on disposal

❍ Before connecting your new cooker

❍ Safety considerations

Installation instructions 6-7

❍ Statutory regulations

❍ Gas supply

❍ Electrical supply

❍ Instructions

❍ Vertical clearances

❍ Overhead clearances

❍ Side clearances to vertical surface

❍ Installation

❍ Overall dimensions (with legs adjusted to

180mm)

Gas and electric connection 8-9

❍ Electrical connection

❍ Gas regulator

❍ If using flexible connection

❍ If using copper connection

❍ Gas connection

❍ Gas inlet - Nat Gas & LPG

❍ Gas inlet with different leg heights - mm

❍ Energy consumption

❍ Test the operation of the cooker before leaving

❍ For service to this appliance

Support legs 10

❍ Method of fixing screw-in type legs

❍ Method of fixing push-on type legs

❍ Height adjustment of legs

Anti-tilt restraint 11

Upstand installation 12

Hob & control panel lay-out 13

❍ LUEP02-90-S, LUE02-90-S/W and

LUE41-90-S

Cooktop burner operation 14-15

❍ First time use

❍ Cooktop burner operation

❍ Ignition - models LUEP02-90-S and

LUE02-90-S

2

❍ Ignition - model LUE41-90-S

❍ Cooktop burner adjustments

❍ Ventilation

❍ Minute minder

❍ Use of cooktop burners

Oven/grill operation 16-18

❍ Accessories

❍ First time use

❍ Cooling fan operation

❍ Thermostat and function selector control knobs

❍ Oven heat distribution

❍ Oven functions

❍ Switching the oven ON

❍ Grill operation

❍ Shelf positions

Description of oven functions 19-21

❍ Oven light

❍ Conventional cooking

❍ Upper element

❍ Lower element

❍ Radiant grilling

❍ Fan grilling

❍ Fan forced cooking

❍ Defrosting

Oven cooking tips 21

Electronic control functions -

LUE02-90-S only 22-23

❍ Setting time of day

❍ Oven will not switch on/to clear a program

❍ Manual operation

❍ Manual operation with timer

❍ Semi-automatic operation with end cooking

❍ Automatic operation with end cooking

❍ To clear a program

Trouble shooting chart 24-25

Cooking chart 26

Cleaning 27-28

❍ Cleaning hob

❍ Cleaning oven interior

❍ Cleaning oven shelf supports

❍ Cleaning oven glass door

❍ Replacing the oven light

Service information 29-37

❍ To remove the glass lid (for cookers fitted

with glass lid)

❍ To remove the upstand (for cookers fitted with

an upstand)

❍ Access to the under hob area

❍ To replace the gas control valves or gas

manifold

❍ To replace thethermostat

❍ To remove the side panels

❍ To replace the function selector control

❍ To replace the electronic control box

❍ To replace a cooktop burner electronic spark

ignitor

❍ To replace a cooktop safety shut off

thermocouple

❍ To replace the underhob cooling fan

❍ To remove the oven door

❍ To replace the oven door inner glass panel

❍ To replace the oven door outer glass panel

❍ To replace the oven door hinges

❍ To replace the oven fan

❍ To replace the electronic programmer

❍ To replace the minute minder

❍ To replace the element around the fan

❍ To replace the top element

❍ To replace the bottom element

❍ Final check

❍ Data plates

❍ Wiring diagrams - LUEP02-90-S

❍ Wiring diagrams - LUE02-90-S/W and

LUE41-90-S

Notes 38-39

3

Important information

Introducing your new cooker

We thank you and congratulate you on your choice.

These instructions cover four cooker models:

These carefully designed products, manufactured with the highest

quality materials, have been carefully tested to satisfy all your

cooking demands.

We therefore request that you read and follow these easy

instructions which will allow you to obtain excellent results right

from the start.

All cookers feature a gas hotplate containing 5 cooktop burners,

including one central wok burner. The multi-function ovens are

fitted with a cooking fan and self cleaning linings.

The cooker’s data plate is accessible even with the cooker fully

installed. It is positioned on the inside of the oven door, centre

bottom. A copy of the data plate is also reproduced on page

35 of this booklet. Always quote the details from it to identify

the appliance when ordering spare parts or requesting a service.

Note: Pictures and graphics in this manual cover all four models

and may vary in minor details from your cooker.

Notes on disposal

❍ Old appliances still have some residual value. An

environmentally friendly method of disposal will ensure that

valuable raw materials can be recovered and used again.

❍ Before you dispose of your old appliance, make sure that it

has been rendered inoperable.

❍ Your new cooker was protected by suitable packaging while

it was on its way to you. All materials used for this purpose

are environmentally friendly and suitable for recycling.

White enamel hob

Stainless steel hob

LUEP02-90-S ✔ ✔✔ ✔ ✔✔✔

LUE02-90-W ✔✔ ✔ ✔ ✔✔

LUE02-90-S ✔✔✔✔✔✔

LUE41-90-S ✔✔✔✔✔✔

4

Glass lid

Electronic ignition

Upstand

Push button ignition

Minute minder

Flame failure

Electronic timer

Cooling fan

Self cleaning linings

Do not spray aerosols in

vicinity of this appliance

while it is operation.

Where this appliance is

installed in a marine

environment or in

caravans, for safety

reasons it shall not be

used as a space heater.

This appliance is not

intended for use by

young children or infirm

persons without

supervision. Young

children should be

supervised to ensure

they do not play with

this appliance.

Warning:

Accessible parts will

become hot when in use.

To avoid burns or scalds

children should be kept

away.

Please make a contribution to protecting the environment by

disposing of the packaging appropriately.

Before connecting your new cooker

❍ Before using your new cooker, please read these ‘Instructions

for Use’ carefully. They contain important information

concerning your personal safety as well as on use and care

of the oven.

❍ Please keep the operating and installation instructions in a

safe place; this important documentation may also be of use

to a possible subsequent owner.

❍ Do not use the cooker if it is damaged in any way.

❍ Installation and connection of the cooker should be

performed according to the instructions and connection

diagram provided, and should be entrusted to a licensed

specialist. In the event of a damage that occurs as a result of

improper connection, the warranty will be void.

❍ Our appliances meet the applicable safety regulations for

electrical appliances, Repairs may be performed only by

customer service engineers trained by the manufacturer.

Inexpert repairs may entail serious injury to you, the user.

Safety considerations

❍ Never leave the appliance unattended when cooking with

fat or oil. It could ignite if overheated.

❍ In case of a defect, switch off at the mains.

❍ Do not clean the oven with steam or high pressure cleaners.

❍ Ensure that the power cord does not get caught in the hot

oven door. The plastic insulation could melt.

❍ Do not use loose greaseproof paper in the oven (e.g. when

heating the oven). The paper could be drawn to the fan and

damage the fan and the element.

❍ Do not insert a baking sheet or aluminium foil sheet at the

bottom of the oven. A heat build-up could result and cooking

times and temperatures could change or enamel could be

damaged.

❍ Do not pour water on the hot oven floor. Damage to enamel

could result.

❍ Always place a baking tray below a roast to prevent juices

from dripping on the oven lining.

❍ Do not place heavy items on the oven door when open as

this may result in damage to the door hinges.

❍ To ensure correct cooking the oven door must close properly.

Keep the door sealing surfaces clean at all times.

5

Installation instructions

Statutory regulations

This appliance shall be installed in accordance with the

manufacturer’s installation instructions, local gas fitting

regulations, municipal building codes, electrical wiring

regulations, AS 5601 the Australian Standard for gas installations.

Refer also to AS 5601 for pipe sizing tables.

Gas supply

Check that the data plate shows the appliance is suitable for the

available gas supply. The data plate is located on the inside of

the oven door, centre bottom. A copy of the data plates is

reproduced on page 35 of this booklet.

Electrical supply

Both models require connection to a 15 Amp wall socket.

Instructions

1. The model number and the type of appliance, gas pressure

and gas type are found on the inside of the oven door, centre

bottom. A copy of the data plates is reproduced on page 35

of this booklet.

2. The appliance requires connection to a 240 V, 50 Hz

electric supply. The power point must be installed by an

authorized person.

3. Before commencing any work, make sure that the power point

switches are turned off and the three in plug is removed.

4. If the appliance cannot be adjusted to perform correctly

contact Sampford & Staff or your local gas utility. For service

contact telephone number refer page 9 of this booklet.

5. Instruct the user in the operation of the appliance before

leaving.

Vertical clearances:-

The cooker shall be installed so that a vertical clearance of at

least 600 mm is maintained between its burners and any

combustible material, and where this is not practicable, the

underside of any combustible material less than 600 mm above

the burner shall be protected by noncombustible millboard at

least 6 mm thick which is covered with sheet metal not less than

0.4 mm thick, or shall be protected by an equivalent material,

extending at least 225 mm beyond the sides of the cooker.

Overhead clearances:-

Range hoods and exhaust fans shall be installed in accordance

with the manufacturer’s instructions. However, in no case shall

the clearance between the top of the highest burner of the

6

cooking appliance and the underside of a range hood be less

than 600mm, or an overhead exhaust fan, 750 mm.

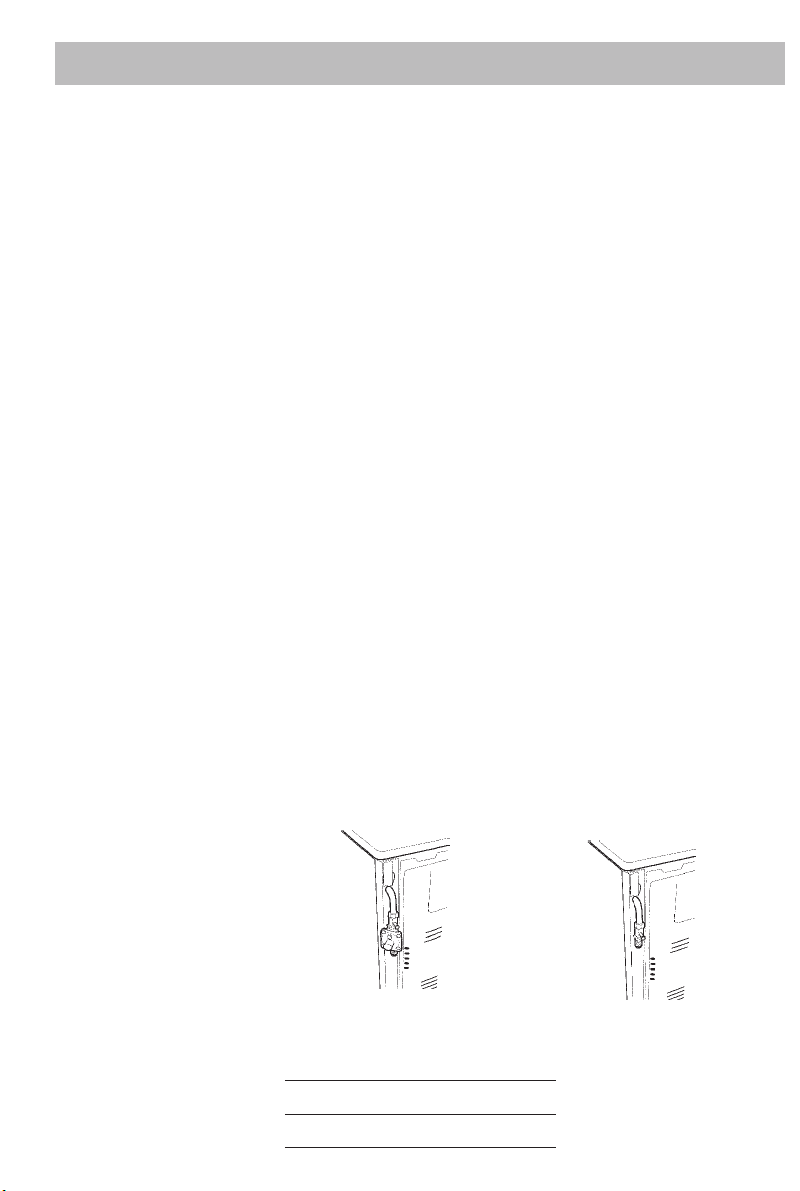

Side clearances to vertical surface:-

If the distance measured from the periphery of the nearest burner

to any vertical combustible surface, is less than 200 mm, the

surface shall be protected in accordance with clause 5.12.1.1

and 5.12.1.2 of AS 5601.

Installation

Make sure the minimum clearances to combustible materials are

maintained during the installation including adequate space for

the operation and servicing of the cooker. For height limitations

use the dimensions as shown in the drawing.

Note:

For stainless steel cookers fitted with an upstand an optional

glass lid is available.

Part no: LL01-90-S.

For height limitations use dimensions with lid as shown in

drawing.

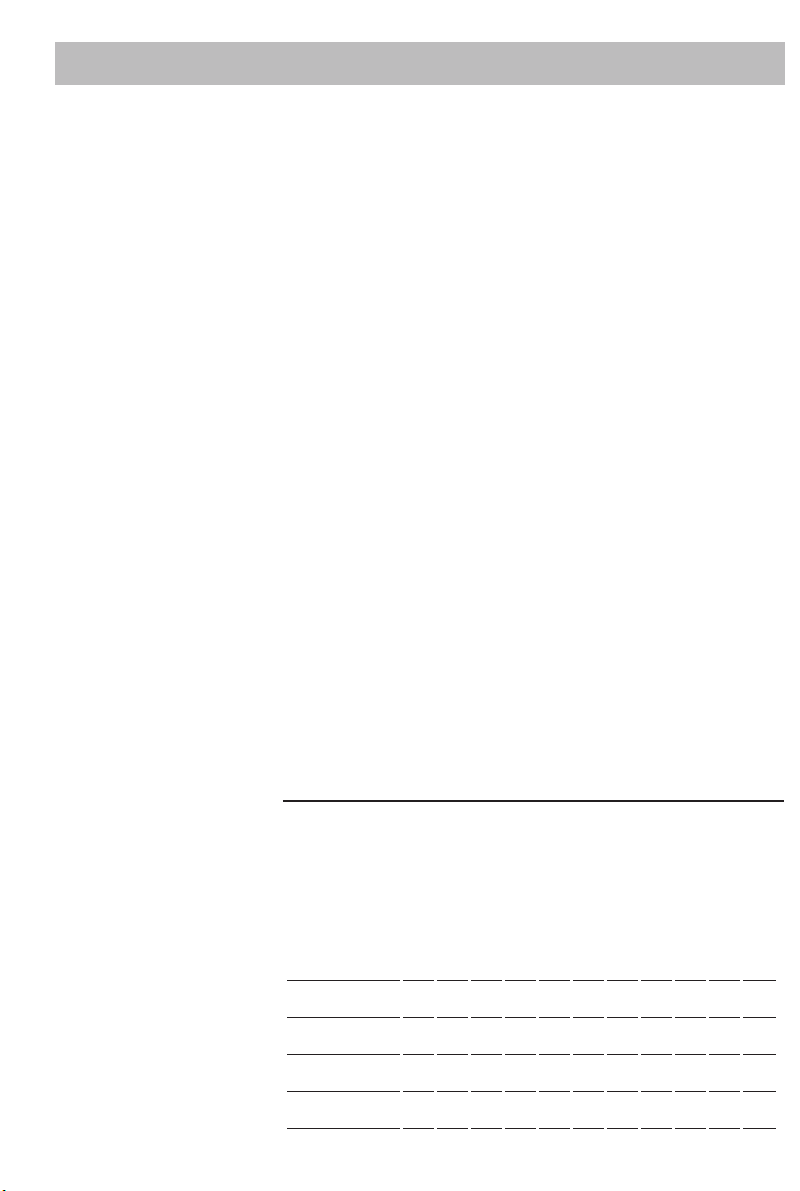

Overall dimensions (with legs adjusted to 180mm)

Height over hob: 910 mm

Height over upstand: 980 mm

Height over lid: 1510 mm (LUE02-90-W)

Width: 895 mm

Depth: (incl. oven door

handle & knobs): 660 mm

Depth: (flush with oven door): 610 mm

7

Gas and electric connection

Electrical connectioni

The electric lead and plug are for connection onto a 15 Amp

socket. A 15 Amp socket is to be within 1 m of the appliance.The

lead is situated at the left hand side of the cooker.

Gas regulator

The gas connection is via 1/2” compression. Connect the cooker

to the gas supply and check for gas soundness.

If using a flexible connection

This appliance is approved for connection by a CLASS B hose.

Connection is in compliance with AS 5601, clause 5.12.1.8.

If using copper connection

To allow cooker to be moved forward for service make a loop in

the copper tube before connecting onto regulator.

Gas connection

The cooker must be connected to the gas supply with upstream

connection of an isolation valve in accordance with the

respectively valid requlations. We recommend that the isolation

valve be fitted prior to the cooker to enable isolation of the

cooker from the gas supply. The valve must be easily accessable

at all times.

To find out the factory set gas type, see label at rear of cooker.

The gas connection is via 1/2” compression. Connect the cooker

to the gas supply and check for gas soundness. NEVER use a

naked flame to check for gas leaks.

Gas inlet (mm)- Nat gas Gas inlet (mm)- LPG

From RH rear side: 35 mm¢ From RH rear side: 35mm¢

Up from floor: 600 mm¢ Up from floor: 685 mm¢

Gas inlet with different leg heights - mm

Min NG: 585 LP: 670

Ref NG: 600 LP: 68 5

Max NG: 620 LP: 705

8

Energy consumption

Burners Gas type Pressure (kPa) Injector (mm) Mj/hr Watts

Small Natural 1.0 0.90 3.85 -

LPG 2.75 0.54 3.25 Medium Natural 1.0 1.18 7.12 (x2) LPG 2.75 0.70 5.75 Large Natural 1.0 1.55 12.5 -

LPG 2.75 0.92 11.25 Wok Natural 1.0 1.65 13.1 -

LPG 2.75 0.95 13.1 Oven/Grill 3000 W

Test the operation of the cooker before leaving

Note: These burners have no aeration adjustment.

Check correct operation of the ignitions system and operation of

burners individually and in combination. Burner flames should

be clear blue, with no yellow tipping. If the burners show any

abnormality check that the burners are correctly located. If

satisfactory performance can not be obtained, contact Sampford

& Staff or the local gas utility. For service contact number refer

below.

Important

Before leaving instruct the owner in the use of the cooker.

It should be expressly noted that we cannot accept any liability

for direct or indirect damage caused by wrong connection or

improper installation. When being repaired, the appliance must

always be disconnected from the mains supply; if required, notify

our customer service.

This appliance is imported

and distributed by:

For service to this appliance

For service to this appliance please contact:

Sampford & Staff P/L

52-70 Sparks Avenue

Fairfield, Vic, 3078

Phone: 1300 727 421

Fax: 1300 727 425

Email: service@sampford.com.au

9

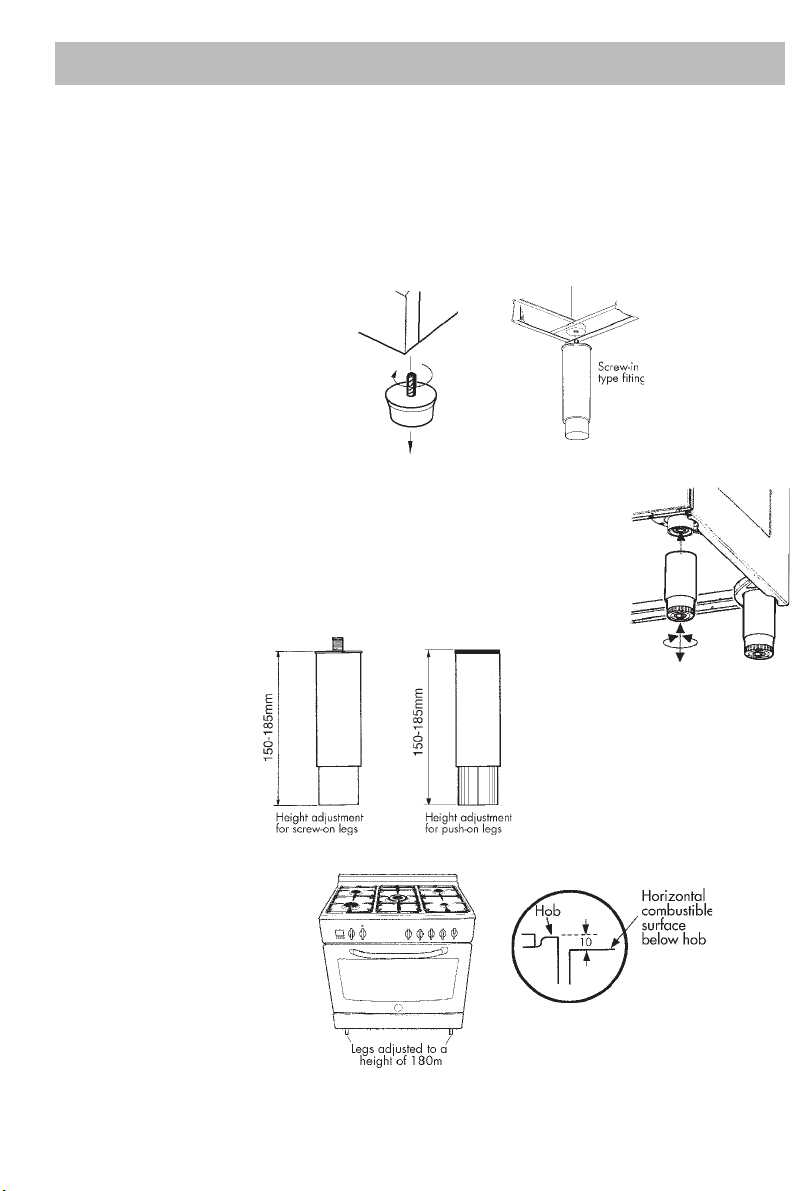

Support legs

The cooker is supplied with four support legs. The legs are fitted

to the cooker with two alternative methods of fixing, either screwin type legs or push-on type legs.

Method of fixing the screw-in type legs

Before fitting legs remove the four transit supports. (One for each

corner). 4 support legs are supplied separately and are fitted

on location to the four corners of the lower support frame.

Method of fixing push-on type legs

Transit supports are left in situe. Each leg is

pushed firmly over the transit support.

Height adjustment of legs

Each leg is adjusted by screwing the lower

section in or out as required for fitting to a

900 mm

standard

bench height. For lower bench

tops adjust height as required. The

adjustment range for the leg is

150 - 285mm. With the legs

adjusted to a height of 180mm

the cooker hob is located 10mm

above a horizontal combustible

surface, ref AS 5601 Fig 5.1.

10

If the legs are not used and the cooker is mounted onto a plinth,

fit transit legs to allow for clearance.

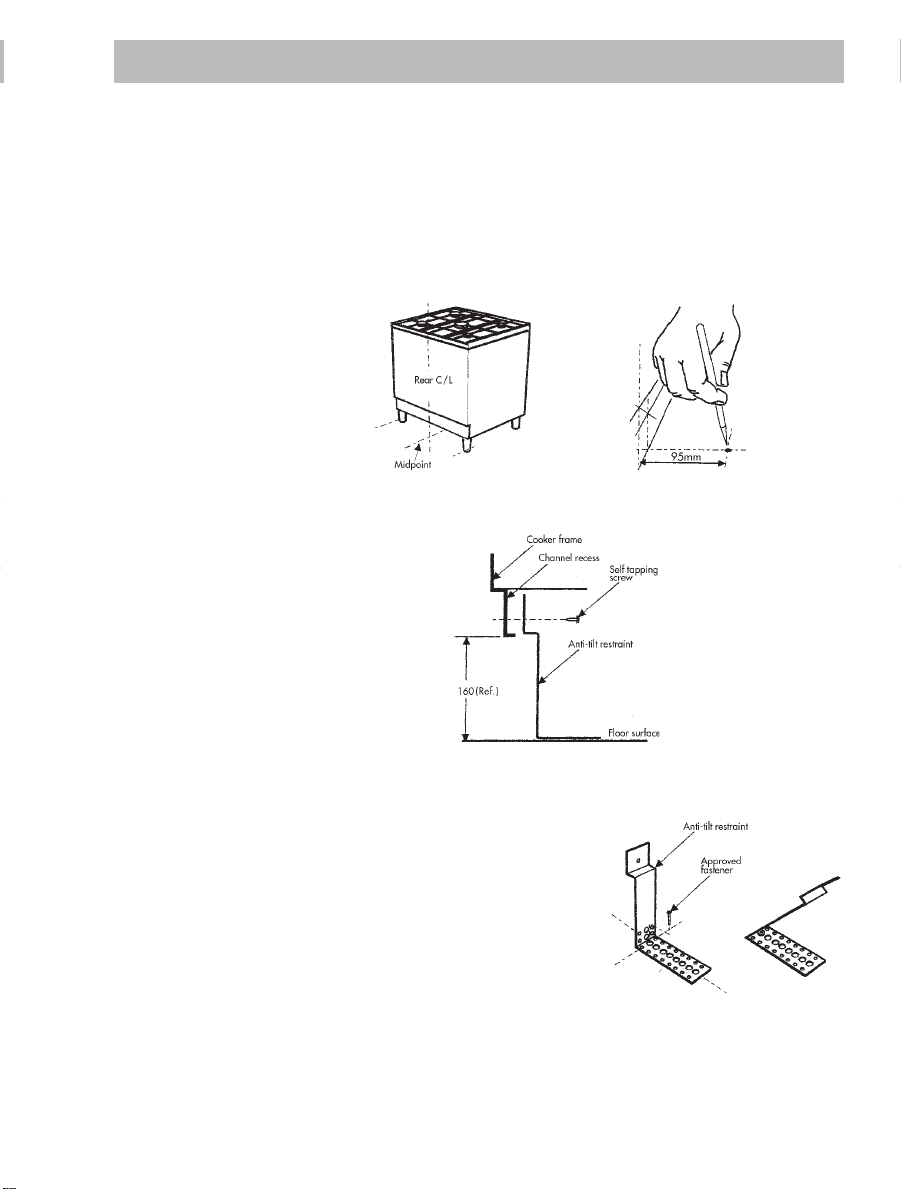

Anti-tilt restraint

Once legs are adjusted to the correct height, fit the anti-tilt

restraint bracket.

1. Locate cooker in desired position and mark rear leg

positions.

2. Remove cooker and locate the mid point of the cooker at the

rear and on the floor, measure out from the wall 95mm to

mark the position of the fixing hole.

3. Measure height under channel recess to floor.

4. Bend anti-tilt restraint bracket (supplied) at 90° as measured.

5. Fix restraint bracket to floor

at position marked. Use the

hole closest to the bend for

fixing.

Note: For concrete floors, an

anchor is provided. For

other construction, use a

suitable fastener.

Bend bracket forward to

clear cooker base.

6. Relocate the cooker into the correct position and from the

underside front, bend anti-tilt bracket up and into channel

recess at cooker base. Fix into position with self tapping

screw provided.

11

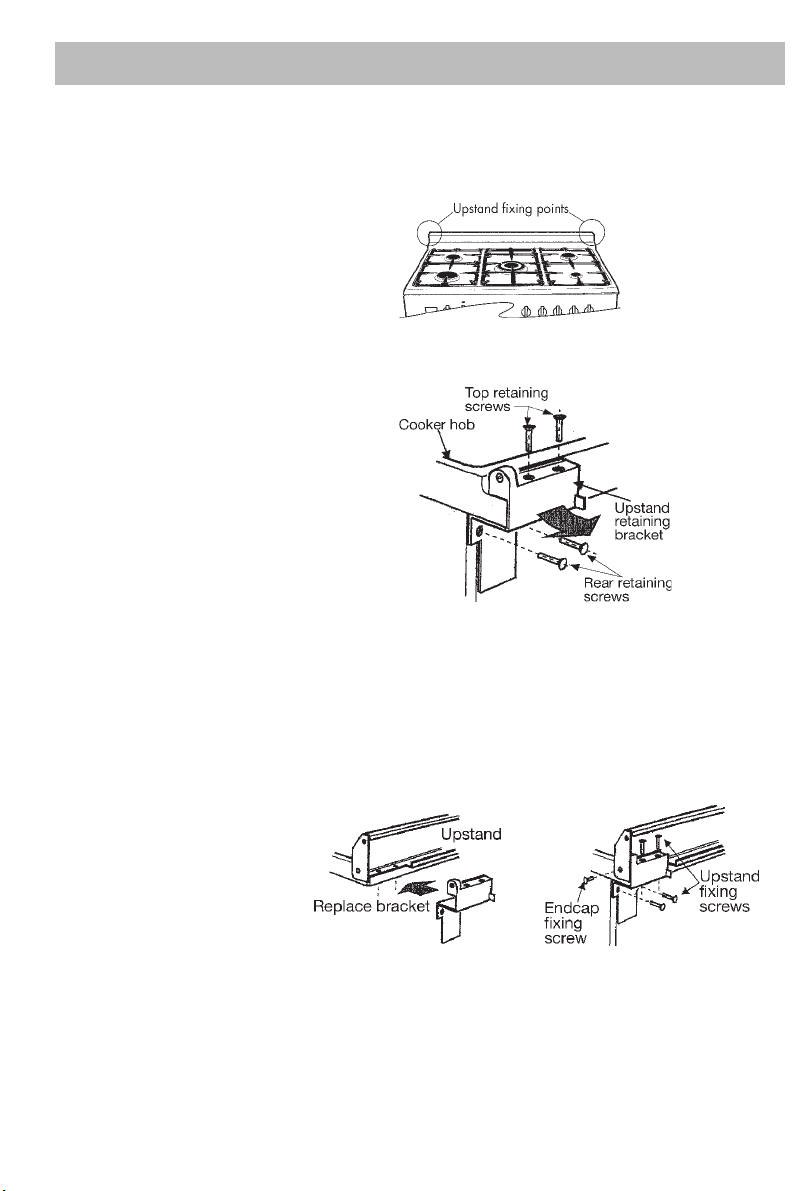

Upstand installation

All stainless steel hob models are fitted with an upstand. The

upstand is packaged at the top rear of the cooker.

The upstand is fixed along the rear of the cooker hob. Fixing

points for locating the upstand are at either end of the hob.

1. Remove the upstand retaining brackets either side of the hob

by removing the top and rear fixing screws in each bracket.

3. Peel away protective film from the underside of the upstand

and locate onto the cooker top.

4. Line up the bracket holes with the upstand fixing holes.

Relocate the upstand brackets and secure with the retaining

screws.

5. Remove the remaining protective film from the upstand and

secure end caps using M4 CSK screws, one each end.

12

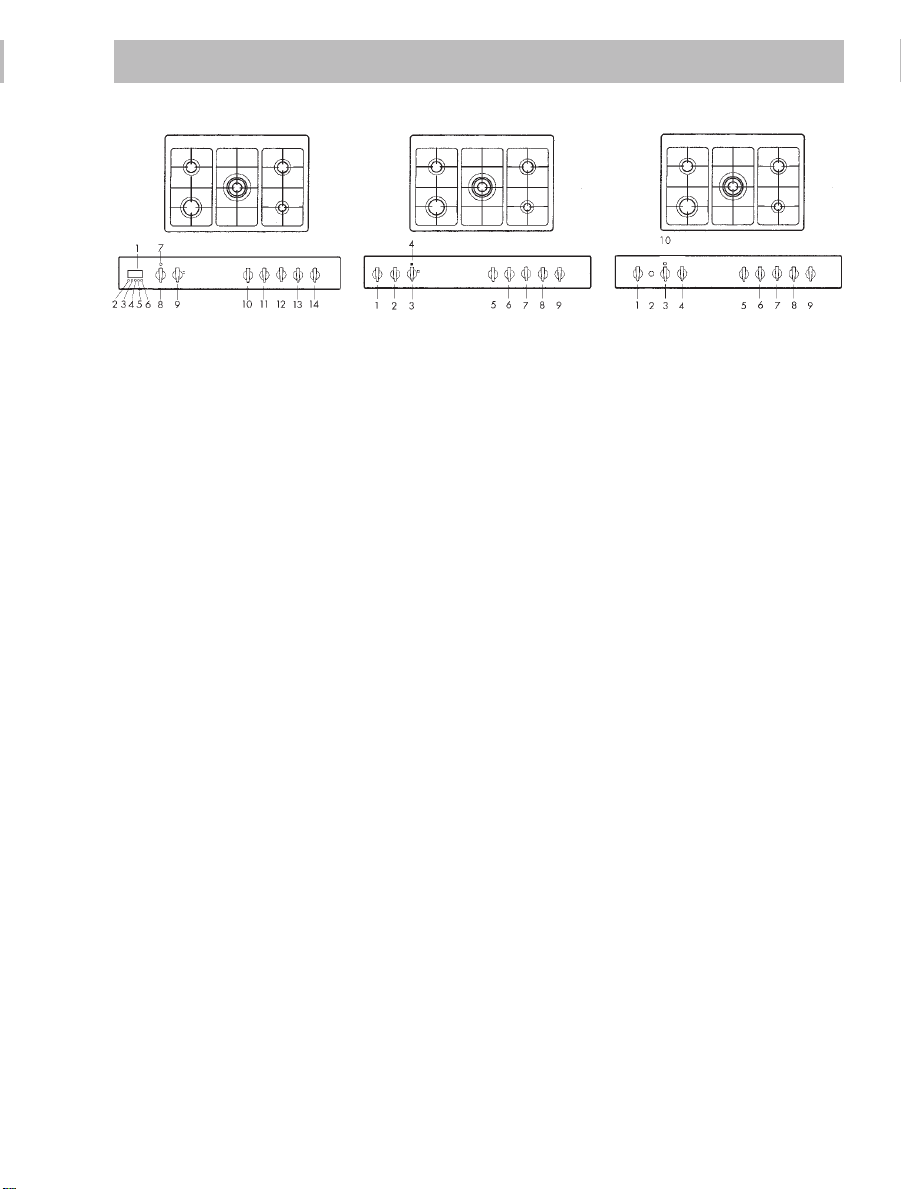

Hob & control panel lay-out

LUEP02-90-S

1. Electronic clock

2. Timer button

3. Duration of cooking

button

4. End of cooking button

5. Advance time button

6. Reduce time button

7. Thermostat indicator

light

8. Thermostat control knob

9. Function selector

control knob

10.Left front burner control

knob

11. Left rear burner control

knob

12.Central (wok) burner

control knob

13.Right rear burner

control knob

14.Right front burner

control knob

LUE02-90-S/W

1. Minute minder

2. Thermostat control

knob

3. Function selector

control knob

4. Thermostat indicator

light

5. Left front burner control

knob

6. Left rear burner control

knob

7. Central (wok) burner

control knob

8. Right rear burner

control knob

9. Right front burner

control knob

LUE41-90-S

1. Minute minder

2. Spark ignition button

3. Thermostat control

knob

4. Function selector

control knob

5. Left front burner

control knob

6. Left rear burner control

knob

7. Central (wok) burner

control knob

8. Right rear burner

control knob

9. Right front burner

control knob

10.Thermostat indicator

light

13

Loading...

Loading...