La Germania TUS96C61LBX, AMS96C71LBNE, AMS96C71LBCR, AMS96C71BX, AMS96C71BVI Installation Manual

...

INSTALLATION, MAINTENANCE

AND USE INSTRUCTIONS FOR

FREE-STANDING COOKERS

90x60 cm

APPLY DATA LABELS

GIANT OVEN

3100248

1

READ THE INSTRUCTION BOOKLET BEFORE INSTALLING AND USING THE APPLIANCE.

It is important that you retain these ins tructio ns, pr oof of pur chase as well as o ther impo rtant do cume nts about this

product for future reference.

The manufacturer will not be responsible for any damage to property or to persons caused by incorrect installation

or improper use of the appliance.

Due to continual product development, Bertazzoni Group reserves the right to alter specifications and

appearances without notice.

THIS APPLIANCE HAS BEEN DESIGNED FOR DOMESTIC USE ONLY

TO BE INSTALLED BY AN AUTHORISED PERSON

CONTENTS

SECTION Page

WARNINGS 3

LOCAL AUTHORITY REQUIREMENTS 4

IMPORTANT INFORMATION FOR INSTALLING AND SERVICING THE APPLIANCE 5

APPLIANCE GAS CONNECTION 7

SUPPORT LEGS AND BACKGUARD INSTALLATION 9

ANTI-TIL DEVICE 10

CONVERTION TO A DIFFERENT TYPE OF GAS 12

APPLIANCE ELECTRIC CONNECTION 14

INSTALLATION CHECKLIST 15

APPLIANCE USE AND MAINTENANCE 16

TROUBLESHOOTING 30

DISPOSAL INFORMATION 30

2

WARNINGS:

1. This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience or kno wledge, unless they have been given supervis ion or instruction concerning

the use of the appliance by a person responsible for their safet y. Children should be supervised to ensure that they

do not play with the appliance.

2. DO NOT USE OR STORE FLAMMABLE MATERIALS IN THE APPLIANC STORAGE DRAWER OR NEAR THIS

APPLIANCE. DO NOT SPRAY AEROSOLS IN THE VACINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE. This appliance is not suitable for use with aftermarket lids or covers.

4. WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT OR IN CARAVANS, IT SHALL NOT

SPACE HEATER.

5. After removing the packaging, make sure to check if there is any damage to the appliance. If there is an y damage,

never attempt to use the appliance and immediately contac t your a ut horis ed Service C e ntre. As pack agin g materials

can be dangerous to children, they need to be collected immediately and put out of reach.

6. In certain circumstances electrical appliances may be a safety hazard. T he unit MUST be connected to the e lectrical

supply before operation to enable the electronic ignition to work. T he electrical connection must be accessible after

installation. The appliance must be electrically isolated before any maintenance can be performed.

7. Do not place heavy objects on this appliance (cookto p or door), use for storage or as a cutting surface, as sharp

edges can damage the surface. This appliance is designed for cooking o nly. If any damage such as chips or cracks

are seen in the glass, turn off all control knobs and do not use until the appliance has been inspected by an

authorised service person or replaced.

8. This appliance is designed for domestic household use onl y and for the cooking of domestic food products. Use as a

commercial appliance will void the warranty. It should not to be used outdoors and must be full y install ed. Do not use

the appliance until fully installed. If this appliance is installed on a base, measures must be taken to prevent the

appliance from slipping from the base.

9. Damage can occur to b ench tops if pots and pans are able to overlap the bench top. This can res ult in heat being

transferred to the bench top. Ensure that correct sized pots & pans are used. Refer to guide in instructions.

10. Do not allow pot handles or utensils to be plac ed near gas burners in operation, as they can cause the handles to

become hot to touch. Always turn handles away when small ch ildren are near by. It is recommended that chil dren are

kept away from the cooktop at all times.

11. Do not leave the cooktop while cooking with solid or liquid oils. There may be flaming up in conditions of extreme

heating. Never pour water onto the flames occurring from oil. Immediately turn the cooktop off and cover the pa n

with a lid or fire blanket in order to smother the flame.

12. If the electrical supply c ord is damaged, either when being installed or after installation, it must be r eplaced by the

manufacturer, its service agent or similarly qualified persons in order to prevent a hazard.

13. The appliance is not intended to be operated by means of an external timer or separate remote control system.

14. Electrical c onnection must be made as per local wiring rules and regulations.. Do not disconnect the a ppliance with

wet hands or bare feet, and do not disconnect the power cord with extreme force. If the electrical supply is restricted,

means of all-pole disconnection must be accessible and in corporated i n the fixe d wiring in acc ordance with the wiring

rules.

15. Ensure that the kitchen is well ventilated or mechanical ventilation is in use while cooking on the appliance.

16. The cooktop and oven will become hot during and directly after use. Do not touch any components during this time, as

they may be hot and can cause burns. To avoid burns young chi ldren should be kept awa y. Care should be taken to

avoid touching heating elements inside the oven.

17. Cleaning may only be commenced on the appliance once it has cooled down and is turned off. Failure to clean

properly can damage the unit. Do not use a steam jet or any other high pressure cleaning equ ipment to clean the

appliance.

18. Do not use harsh abrasive cleaners or sharp metal scrapers to clean the glass surface as they can scratch the

surface, which may result in the glass shattering. Clean the glass using a w arm damp cloth (e.g. dishcloth).

19. When the appliance is not being used, the knobs must be kept in the ‘OFF’ position.

20. The applia nce must be installed and put into operati on by an authorised person under the conditions provid ed by the

manufacturer in this manual. The manufacturer cannot be held responsible for an y damage that might occur due to

faulty installation. Do not modify this appliance.

21. Use the anti-tilt kit to prevent the appliance from accidentally falling over.

BE USED AS A

3

LOCAL AUTHORITY REQUIREMENTS

Before installation, unpack all parts from carton, remove all internal packaging and check for da mage. Check Gas Type and

specifications plate placed on the rear of the unit, alternatively there is a second label supplied. All gas fitting work, service

and repairs can only be performed by an authorised person in accordance with AS/NZS 5601 and local gas regulations.

Failure to comply with this condition will void the warranty. Always unplug the appliance before carrying out any maint enance

operations or repairs. The walls of the units must not be higher than worktop and m ust be capable of resisting temperatures

of 65⁰K(65°C Above Amb.Temp. ) or higher. Do not install the ap pliance near flammable materials (eg. curtains). The final

act of any installation or gas type conversion must be the f ull testing of this appliance, which includes leak testing, ign ition of

each burner and the functionality of the burners separately and together.

Keep all the dangerous packing parts (polystyrene foam, bags, cardboard, staples, etc.) away from children.

Any walls of the adjacent furniture pieces and the wall behind the cooker must be mad e of heat-resistant material that can

withstand a minimum temperature of 65°K(65°C Above Amb.Temp. )

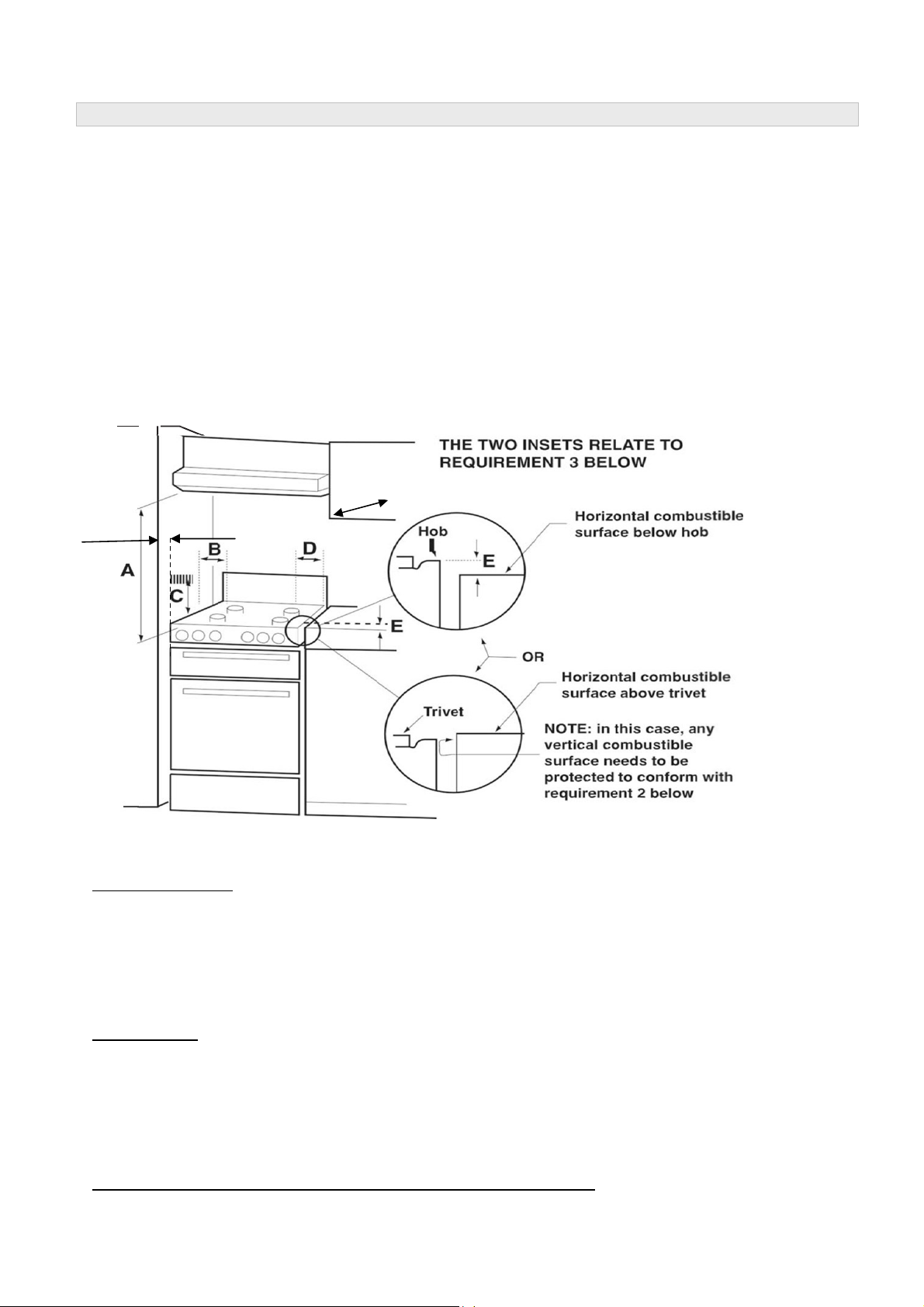

Clearance above and around domestic cookers

REQUIREMENTS

1. Overhead clearances

Range hoods and exhaust fans shall be installed in accor dance with the manufacturer’s instructions. However, in no case

shall the clearance between the highest part of the hob of the cooking appliance and a range hood or an overhea d exaust

fan be less than 700 mm .

Any other downward facing combustible surface less than 700 mm above the highest part of the hob shall be pr otected for the

full width and depth of the cooking surface area in accordan ce with clause 5.12.1.2. However, in no case shall the clearance to

any surface be less than 450mm.

The maximum depth of wall cabinet above the cooking shall be 400 mm.

2. Side clearances

Where B, measured from the periphery of the near est burner to any vertical combustible surface, is less than 2 00 mm, the

surface shall be protected in accordance with Clause 5.12.1.2 to a height C of not less than 200 mm a bove the level of the

backguard for the full width of the cooking surface area. Where the cooking appliance is fitted with a “splash back”, protection

of the rear wall is not required.

The appliance can be installed bet ween two walls. A single sidewall that exceeds the height of the work surface is possible.

This must be at a minimum distance of 70 mm from the edge of the cooker.

3. Additional requirements for Freestandin g and Elevated Cooking Appliances

Where D, the distance from the periphery of the nearest burner to a horizontal c ombustible surface is less than 200 mm, then

E shall be 10 mm or more, or the horizontal surface shall be above the trivet. See inserts above.

– (Measurement A)

– (Measurements B & C)

400mm max.

Fig. 01

– (Measurements D & E)

4

IMPORTANT INFORMATION FOR INSTALLING AND SERVICING THE APPLIANCE

The cooker can be installed separately, as a freestanding unit, or between kitchen units or between a kitchen unit and the wall.

This appliance is not connected to devices which exhaust combustion products.

Special attention must be focused on the prescriptions described below regarding room aeration and ventilation.

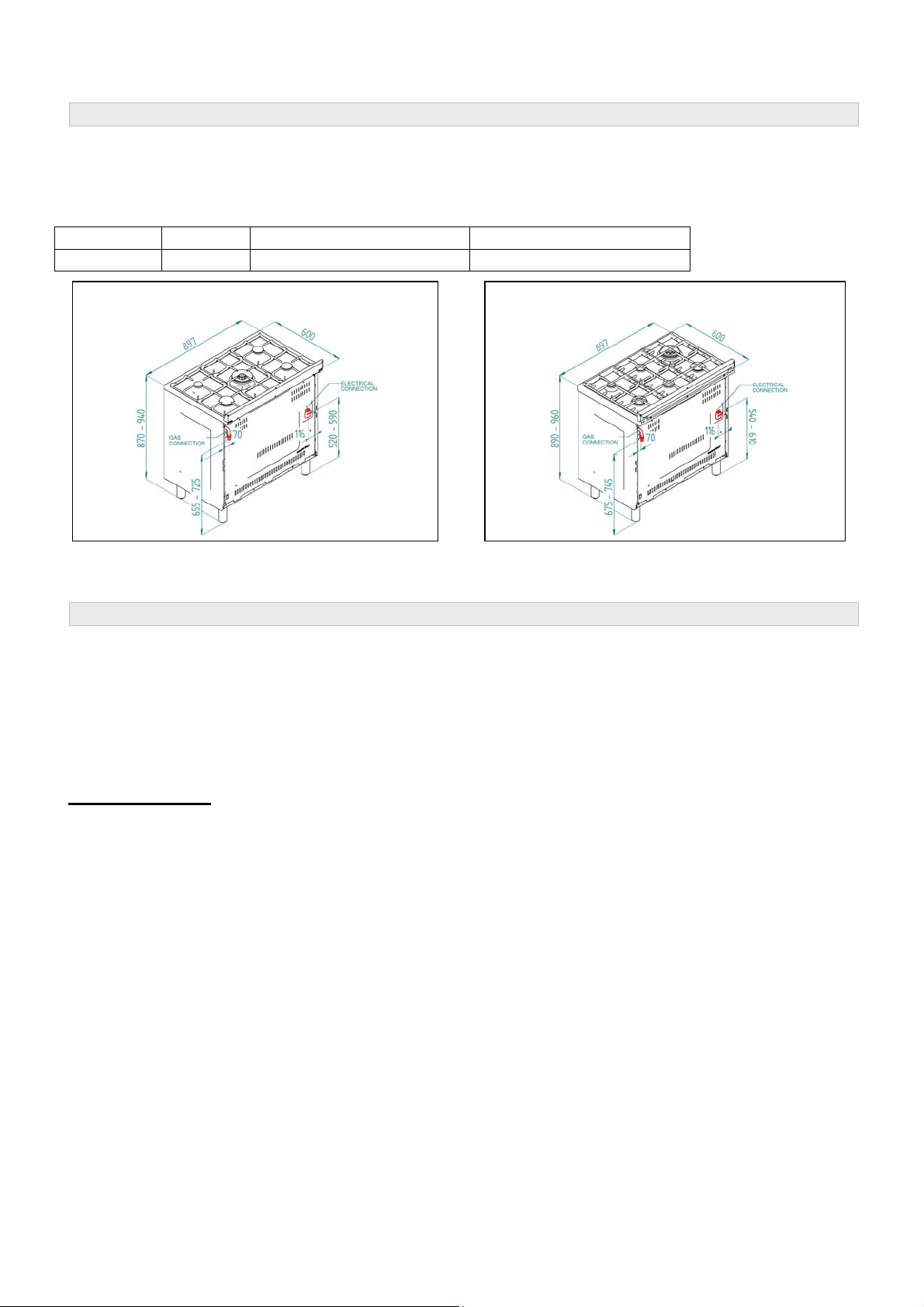

The dimensions of the appliance are listed below:

LENGTH DEPTH HEIGHT with worktop stamped HEIGHT with worktop welded

897mm 600mm adjustable 870-940mm adjustable 890-960mm

Fig.2 Fig.3

Cooker with worktop stamped Cooker with worktop welded

APPLIANCE SERVICING

IMPORTANT!

ALL SERVICING AND MAINTENANCE ARE TO BE COMPLETED BY THE MANUFACTURER’S AUTHORISED

PERSONNEL ONLY.

Before carrying any servicing operation disconn ect the appliance from gas and electric supply and extra app liance from final

installation place in order to have access to the appliance for proper servicing intervention.

GAS CONVERSION

WARNING!

Before carrying out this operation, disconnect the appliance from gas and electricity.

Gas conversion shall be conducted by a factory-trained professional.

Call the customer service hotline to identify a factory-trained professional near your home.

The gas conversion procedure for this range includes differents steps:

1. Pressure regulator

2. Surface burners

3. Main oven burner

4. Visual checks prior to closure of oven bottom panel

5. Adjustment of minimum setting

The conversion is not completed if all 5 steps have not been concluded properly.

Before performing the gas conversion, locate the package containing the replacement nozzle shipped with every range.

IMPORTANT: Each nozzle has a number indicating its flow diameter printed on the body. Consult the table on pa ge 20 for

matching nozzles to burners. Save the nozzles removed from the range for future use.

STEP 1: PRESSURE REGULATOR.

For NG or ULPG installation ref. to fig. 7 and chapter ‘Appliance gas connection’ at pag 7

STEP 2: SURFACE BURNERS

For surface burners conversion ref to table 1 chapter ‘Adaption to various types of gas’ at page 8 and chapter

‘Conversion to different types of gas’ at page 12

STEP 3: MAIN OVEN BURNER

For main oven burner conversion ref to table 1 chapter ‘Adaption to various types of gas’ at page 8 and chapter

‘Conversion to different types of gas’ at page 12

5

STEP 4: VISUAL CHECKS

The following visual check must be performed to ensure that the conversion has been carried out properly and without

damage to other components of the range. Verify that the flame of the oven b urner be completely blue and with regular

aspect as shown below.

CONNECTION OF THERMOCOUPLE TO THERMOSTAT

The thermocouple for oven burner is connected to the magnet. Tight gently the connection.

The tip of the spark plug or thermocouple must fully overlap at least the first gas emission hole of the burner.

After performing all these visual checks, reinstall the bottom panel of the oven c ompartment and proceed to setting the

minimum for each burner.

STEP 5: MINIMUM FLAME ADJUSTMENT

WARNING!

These adjustments should be made only for use of the appliance with Natural g as. For use with ULPG, the choke screw

must be fully turned in a clockwise direction.

Surface burners

Light one burner at a time and set the knob to the MINIMUM position (small flame). Remove the knob.

The range is equipped with a safety valv e. Using a small-size slotted screwdriver, locat e the choke valve on the va lve body

and turn the choke screw to the right or left until the burner flame is adjusted to desired minimum.

Make sure that the flame does not go out when switching quickly from the MAXIMUM to the MINIMUM position.

Oven burner

Set the oven temperature control knob to the MAXIMUM setting. Close the oven door and operate t he oven for at least 10

minutes. Set the knob to the MINIMUM setting. Remove the knob. With a slotted screwdriver turn the choking screw (bypass screw at the left side of the thermostat bar) and, while observing the flame at the same time through the bottom oven

porthole, evaluate the consistency of the flame so it remains on when switching quickly from MINIMUM to MAXIMUM

setting.

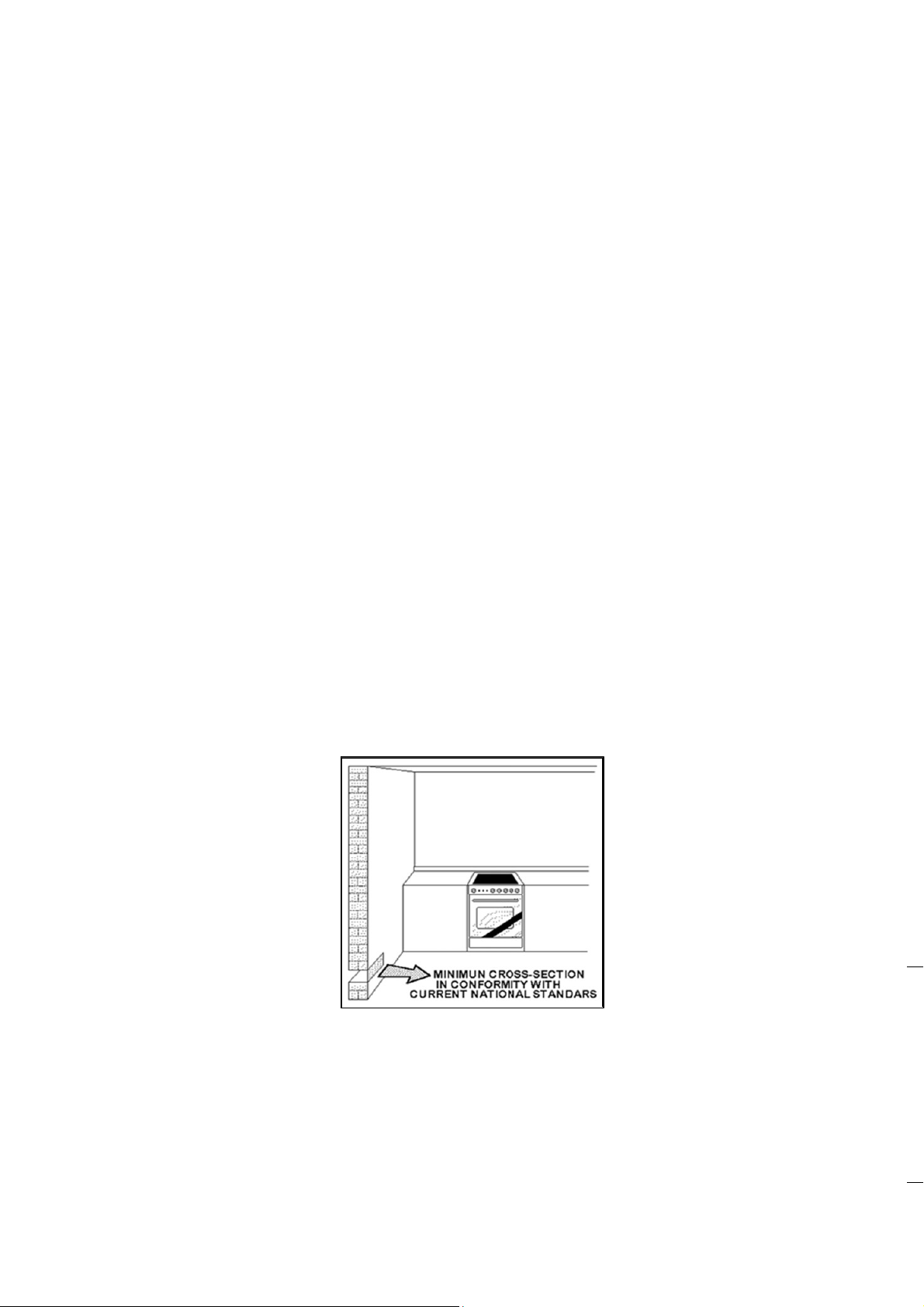

Room Ventilation

To ensure that the appliance operates correctly, the room where it is installed must be conti nuously ventilated. The room

volume should not be less than 25m3 and the quantity of air should be based on the r egular combustion of gas and on the

ventilation of the room. Natural air will flow through permanent openings in the walls of the room to be ventilated. These

openings will be connected with the outside environment and should have a minimum cross-section defined by current

national standards regarding room ventilation (Fig. 04).

These openings should be built so that they cannot be clogged.

Indirect ventilation is also permitted by taking air from the rooms adjacent to the one to be ventilated.

Fig. 04

Location and Aeration

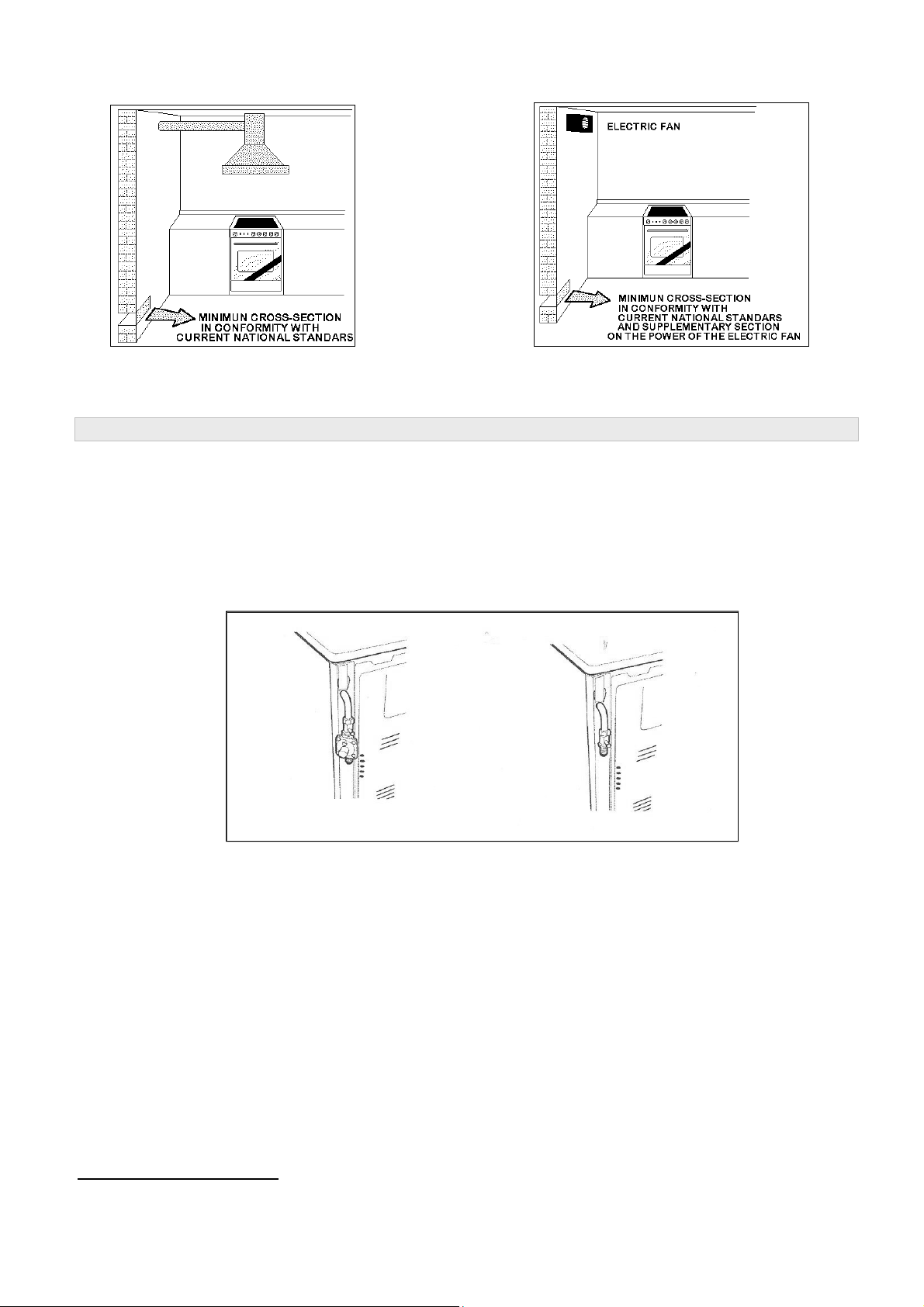

Gas cooking appliances must always evacuate the c ombustion products by means of hoods connected to chimneys, flues or

directly outside (Fig. 05). If a hood cannot be installed It is possible to use a fan installed on a window or directly facing

outdoors, to be operated together with the appliance ( Fig. 06), provided that there is strict compliance with the ventilation

regulations.

6

Fig. 05 Fig. 06

APPLIANCE GAS CONNECTION

IMPORTANT: This appliance must be installed by an authorised person.

WARNING: DO NOT MODIFY THIS APPLIANCE

If the appliance cannot be adjusted to perform correctly, contact the service department.

This appliance utilises a threaded 1/2" gas male fitting.

To connect the appliance to the gas network with a flexible hose, a supplemental hose nipple fitting is needed which is

supplied with the appliance. (Fig. 07)

Fig. 07

Gas inlet positions with different leg heights – mm

Gas inlet (mm) - Nat gas Gas inlet (mm) – ULPG

From RH rear side: 70 mm From RH rear side: 70mm

Up from floor cooker with worktop stamped: 655 - 725mm Up from floor cooker with worktop stamped: 570 - 640mm

Up from floor cooker with worktop welded: 675 - 745mm Up from floor cooker with worktop welded: 590 - 660mm

Gas Regulator

The gas connection is via 1/2" tapered thread. Connect the cook er to the ga s supply and te st for leaks. NEVER use a n aked

flame to check for gas leaks.

Natural Gas: Gas regulator supplied with the appliance must be installed.

ULPG: Test point adaptor to be fitted and checked at time of installation.

Using a flexible connection

This appliance is approved for connection with a flexible hose, which complies with the AS/NZS 1869 (AGA

Approved), 10mm ID, class B or D, between 1-1.2m long. Connection shall be in compliance with AS560 1.

When installing the hose restraint device, the appliance anchor point is the rear panel

7

.

Using a Copper Pipe connection

The cooker must be connected to the gas supply with upstream connection of an isola tion valve in accordance with the

respectively valid regulations. We recommend that the isolation valve be fitted prior to the cooker to enab le isolation of th e

cooker from the gas supply. The valve must be easily accessible at all times.

To find out the gas type factory settings, see label on the rear of the appliance.

TABLE N°1

Adaption to various types of gas

Burners Gas type Pressure

Small Natural

(kPa)

1.00

Injector

(mm)

0.90 4.00 0.30 regulated

Mj/hr By-pass size

(mm)

Small ULPG 2.75 0.54 4.00 0.30

Medium Natural 1.00 1.18 7.00 0.36 regulated

Medium ULPG 2.75 0.70 7.00 0.36

Large Natural 1.00 1.55 11.50 0.52 regulated

Large ULPG 2.75 0.92 11.50 0.52

Wok Natural 1.00 1.80 14.50 0.65 regulated

Wok ULPG 2.75 1.02 14.50 0.65

Wok 2way Natural 1.00

Wok 2way ULPG 2.75

Ex.1.80

int.0.80

Ex. 1.02

int. 0.50

17.50

17.50

Ext. 0.65 reg.

int. 0.34 reg.

Ext. 0.65

int. 0.34 reg.

Oven Natural 1.00 1.95 16.50 0.62 regulated

Oven ULPG 2.75 1.10 16.50 0.62

Test the operation of the cooker before leaving

Note: These burners have no aeration adjustment.

Check correct operation of the ignitions system and operation of the regulator and operation of the bur ners individ ually and

in combination. Burner flames should be clear b lue, with no yello w tipping. If the burner s show any abnormalit y check that

the burners are correctly located. If satisfactory performance cannot be obtained, contact Bertazzoni Group service.

Important

Before leaving instruct the owner in the use of the cooker it should be e xpressl y noted th at we cannot a ccept any lia bilit y for

direct or indirect damage caused by wrong connection or improper installation. When being repaired, the appliance must

always be disconnected from the mains supply; if required, notify our customer service.

TABLE N°2: GAS BURNER DIMENSION

Burner Dimension (mm)

Auxiliary Ø 50

Semi-rapid Ø 70

Rapid Ø 95

Wok Ø 125

Wok 2 ways Ø 135

8

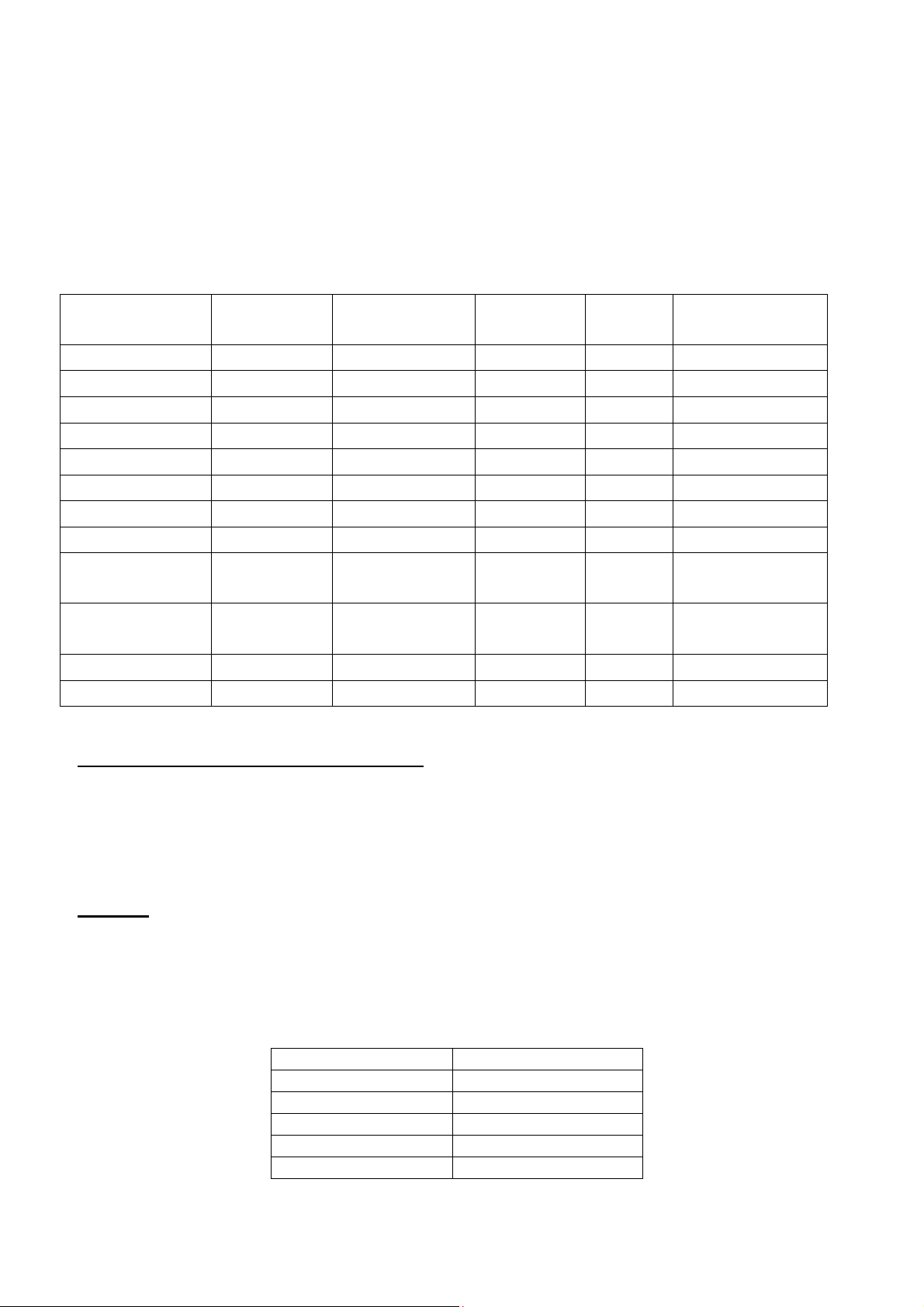

SUPPORT LEGS AND BACKGUARD INSTALLATION

The cookers are supplied with four transit supports (one for each corner).

Four support legs are supplied separately and are fitted on location to the four corners of the lower support frame. Each

support leg is pushed over the relevant transit support until flush with the support frame.

Each leg is adjusted by screwing the lowe r section in or out as required for fitting to a 900mm be nch height. For lower

bench tops adjust the height of the legs to 180mm so the hob is located 10mm above the horizontal combustible surf ace,

ref. AS/NZS 5601.

Fig. 08

Legs should be installed with the appliance close to its final destination, as

the legs are not designed for excessive force and will snap off if too much side

force is exerted on them (dragging along or angled too much). When fitting, try

to keep the appliance as close to a horizontal position as possible. Use of a

pallet jack is recommended.

If the legs are not used and the cooker is mounted onto a plint h, four transit

supports allow for clearance.

With the legs fitted, the backguard supplied with the appliance can be fitted.

Follow the instructions shown in Fig. 09.

ATTENTION: TAKE CARE DO NOT OBSTRUCT THE OUTLET

OPENINGS ON THE BACKGUARD; THEY MUST BE

UNOBSTRUCTED FOR PROPER OPERATION

Fig 09

9

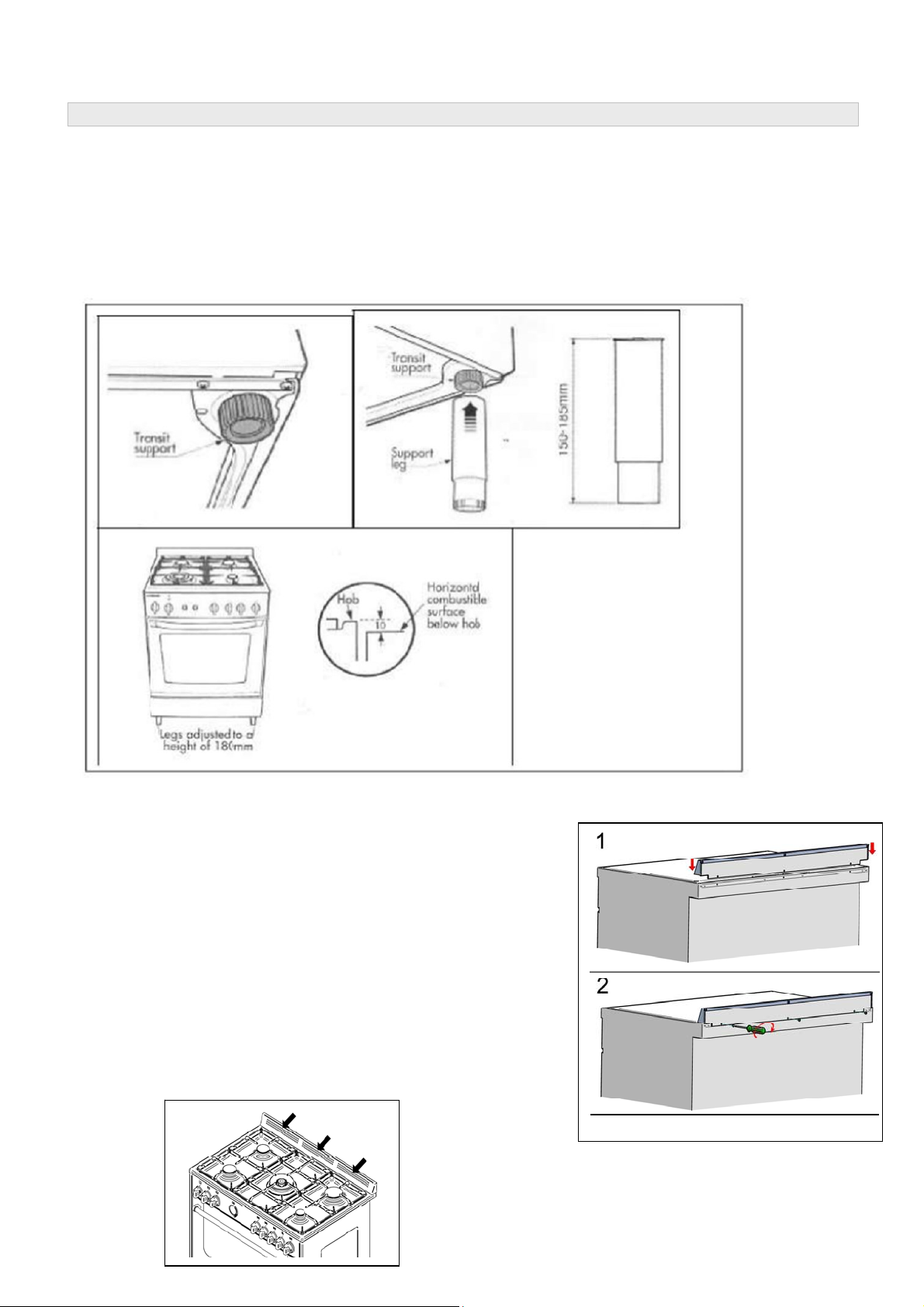

ANTI-TILT DEVICE AND STRAIN RELIEF FLEXIBLE HOSE BEVICE

ANTI-TILTING CHAIN/HOSE RESTRAINING CHAIN

A chain must be fitted by the installer within 50mm of the hose connection point to prevent strain on the hose

when the cooker is pulled forward. The chain should restrict the appliance moveme nt to no more than 80%

of the hose length. After the chain is installed, check that there is no strain on the hose or gas connections

when the cooker is pulled as far forward as the chain allows.

The cooker is also supplied with two chains which are connected to the rear left and right of the appl iance.

The chains should be connected to the wall directly behind the chains as low as possible t o prevent the

appliance from tilting forward. If the appliance is installed between two cupboards, drill a hole on each side of

the cupboards, pass the chains through the holes and anchor the chains within each cupboard. Ensure the

chain connections are strong enough to support the weight of the appliance and taught to prevent it from

tilting forward.

WARNING! In order to prevent accidental tipping of the appliance, for example a child climbing onto the

open oven door, the stabilising means must be installed. Ensure the chains are correctly anchored to prevent

the appliance from tilting forward and to prevent strain on the hose when the cooker is pulled forward.

MAKE SURE THE ANTI-TILTING CHAINS ARE TAUGHT WHEN ANCHORED AND ANTI TILT

RESTRAINT IS INSTALLED TO PREVENT THE APPLIANCE TILTING

Please refer to the next two pages for examples of incorrect and correct chain installation.

Accidental tipping

Chains are provided as a preventative

measure against accidental tipping.

These chains must be fitted as part of

the installers compliance. Failure for

your installer to fit chains in

accordance with the relevant

installation code will make the

installation of your upright cooker noncompliant and class an illegal

installation.

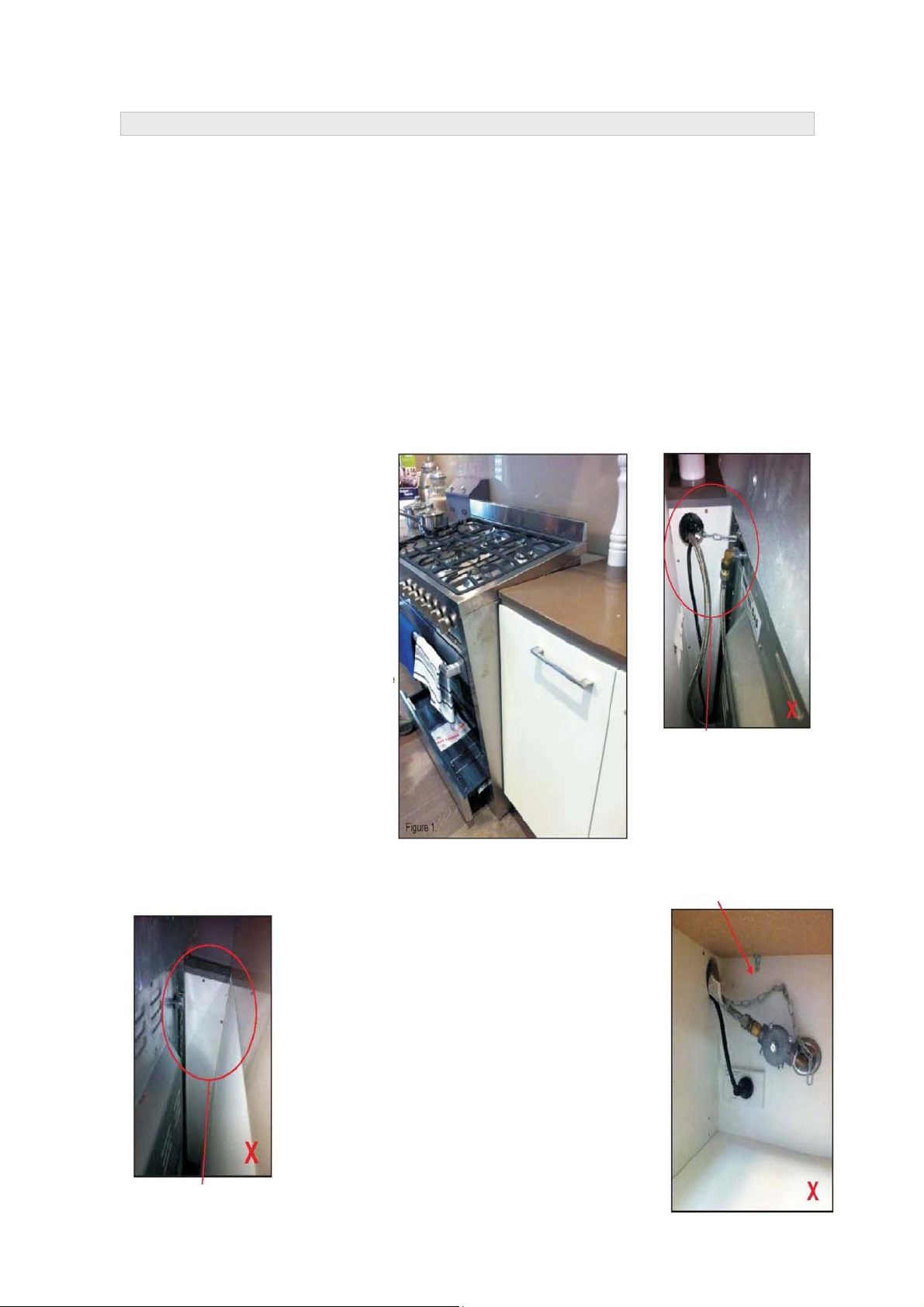

Incorrect installation

The photographs on this page are of

one single kind of incorrect installation

(although there are many)which does

not have the chains sufficiently

secured, figure 1. Shows an example

of how far forward an oven can tip

when not secured properly. Note:

Correct installation is part of the

installer compliance.

Left Side of oven,

chain not attached

Unfortunately the example on this page is the way

many installers are installing uprights. This may

believe that they are using the correct method by

putting the chain through a hole into the adjacent

cabinet and screwing the chain to the back wall but it

will not work if not properly.

Putting the chain into the adjacent cabinet is the

preferred method, provided there is no slackness in

the chain.

Some installations only have a single chain affixed.

Both chains must be fixed as part of the installers

compliance. Failure to fix both chains will make the

installation non compliant

10

Hole in cabinet too

large, allowing the

upright oven to tilt

forward.

Loose Chain

Loading...

Loading...