Page 1

Time

OUT1

OUT2

OUT3

LON LON LON LON

P=20P=0 P=30 P=50 P=70 P=50 P=30 P=20 P=0

LOF LOF LOF LOF

OFF

OFF

OFF

ON

ON

ON

CM=PO

OC1=20

OC2=30

OC3=50

OC4=0

Fig.4 Control by optimisation of the available power

Load

start

Neutral

zone

Load

stop

t<LOF

SP+DBH

Pressure

SP+DBL

SP

SP

SP+PB

Pressure

Time

Control dueto

integral action

PWM

0%

100%

Fig.5 PWM output control

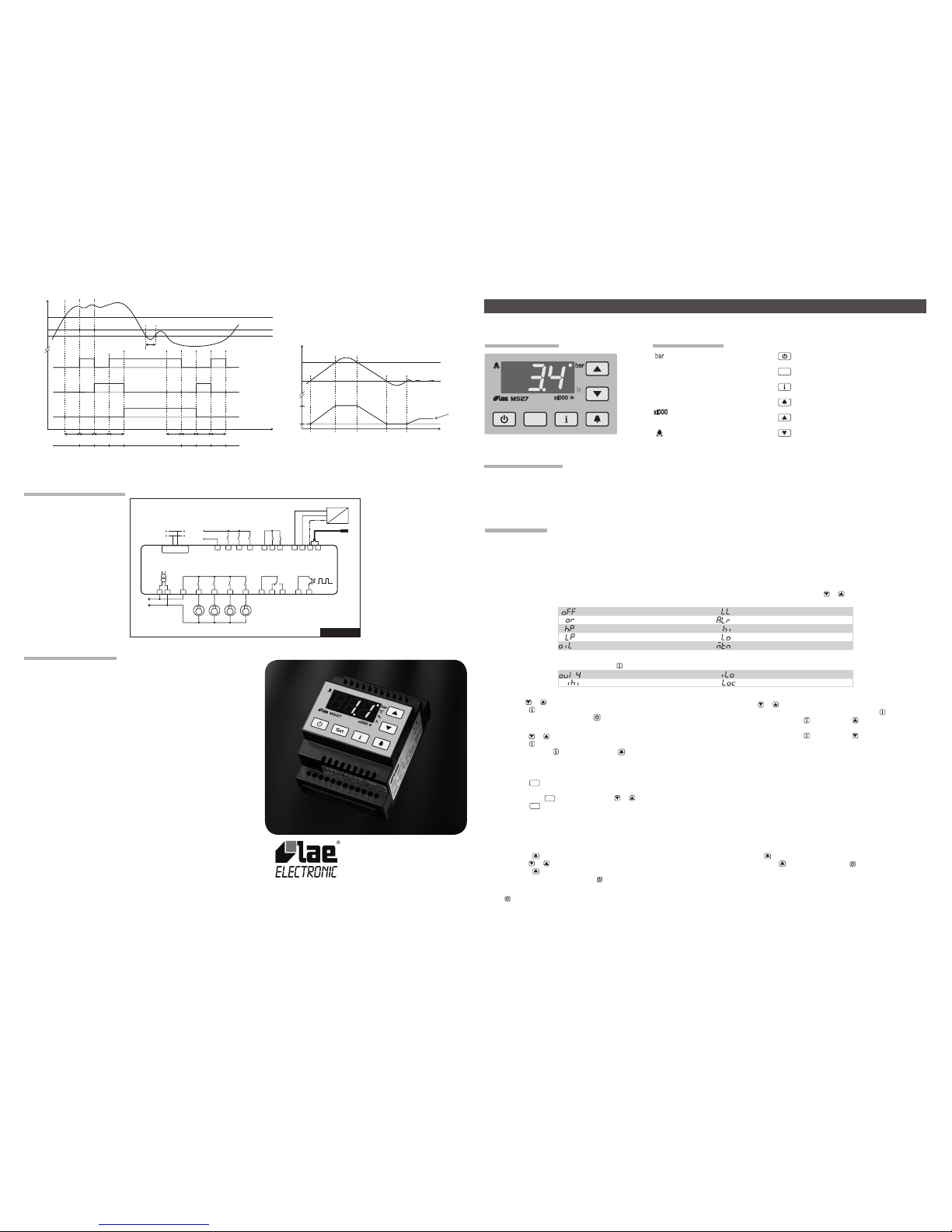

WIRING DIAGRAMS

1234

115÷230Vac

DI3COM COMDI5DI4 DI1DI2 2-T

NTC10K

1-P

MS27-1SE-B

Power

Supply

L

N

dataI/O

RS485

PC comm.

5(1)A

5(1)A

A

B

5(1)A 5(1)A 7(2)A 0...100%

ALR PWM

OUT4OUT3OUT2OUT1

I

P

0/4-20mA

GND

+12Vdc

24

5

421

20 1918

98

2211 12

23

14

1317 1615

763

2

1

TECHNICAL DATA

Power supply

MS27…E 230Vac±10%, 50/60Hz, 3W

MS27…U 115Vac±10%, 50/60Hz, 3W

Relay outputs

OUT1…OUT4 5(1)A

Alarm 7(2)A

Pressure input

type: 0/4…20mA

range: -1.0…45.0bar

resolution: 0.1bar

Temperature input

type: NTC10K (LAE SN4…)

range: -50.0…120.0°C

resolution: 0.5°C (-20.0…80.0); 1°C out of that range

Operating conditions

-10 … +50°C; 15…80% r.H.

CE (Reference norms)

EN60730-1; EN60730-2-9;

EN55022 (Class B);

EN50082-1

Front Protection

IP55

VIA PADOVA, 25

31046 ODERZO /TV /ITALY

TEL. +39 - 0422 815320

FAX +39 - 0422 814073

www.lae-electronic.com

E-mail: sales@lae-electronic.com

OPERATION

DISPLAY

Parameter INP selects the input used for control.

INP ■ =1-P: Input 1-P (0/4…20mA) is used to control pressure. In the setup the parameters relating to the variable to be controlled (SPL, SPH, SP,…) are

expressed in bar. In normal mode, the display shows the pressure measured in bar, or the corresponding temperature in °C, calculated according to the

refrigerant gas used (see REF). Input 2-T is disabled.

INP ■ =2-T: Input 2-T (NTC10K) is used for temperature control. In the setup the parameters relating to the variable to be controlled (SPL, SPH, SP,…) are

espressed in °C. In normal mode the display shows the temperature measured in °C, or the corresponding pressure calculated in bar. Input 1-P is disabled.

In normal mode it’s also possible to display the percentage of available power used. To modify the type of display, press or .

The following indications may also appear:

Controller in stand-by Low refrigerant level alarm

Over range or probe failure Generic alarm

High pressure alarm

High measured value alarm

Low pressure alarm Low measured value alarm

Low compressor oil alarm Periodic maintenance warning

INFO MENU

To have access to the info menu, press button . The available info is:

...

Output 1..4 state / hours of operation Min input value measured.

Max. input value measured. Keypad state (lock)

Access to menu and information displayed.

With button ■ or select the data to be displayed;

Press button ■ to display the value;

To exit from the menu, press button ■ or wait for 10seconds

Display of hours of operation of out1…out4 outputs

With button ■ or select the output;

Display the ON/OFF state of output by pressing button ■ ;

While holding down button ■ , press button to display the hours of

operation (multiplied by 1000); the “h” LED blinks.

While holding down button ■ , press button to display the hours of

operation; the “h” LED is lit.

Warning: the hours of operation of stages are not stored, ‘---‘ is ■

displayed.

Reset of hours of operation of out1…out4 outputs and of IHI, ILO recordings

With buttons ■ or select the data to be reset;

Press button ■ to display the value;

While keeping button ■ pressed, use button .

SETPOINT (display and modication of desired pressure/temperature value)

Press button ■

Set

for at least half second, to display the setpoint value;

If the second setpoint has been enabled (see ■ DI1, DI2), before its value appears, the display shows “2SP”;

By keeping button ■

Set

pressed, use button or to set the desired value (adjustment is within the minimum SPL and the maximum SPH limit).

When button ■

Set

is released, the new value is stored.

ALARM MENU

The last nine alarms can be displayed in the alarm menu, from the most recent AL1, to the least recent AL9.

Access to menu and display of stored alarm.

Press button ■ ;

With button ■ or select the data to be displayed;

Press button ■ to display the alarm type;

To exit from the menu, press button ■ or wait for 10 sec.

Reset of all stored alarm.

Press button ■ to display the type of any alarm in the list;

By keeping button ■ pressed, press button for 1 second, until the

inscription ‘non’ appears.

STAND-BY

Button when pressed for 3 seconds, allows the controller to be put on a standby or output control to be resumed (with SB=YES only).

KEYPAD LOCK

The keypad lock avoids undesired, potentially dangerous operations, which might be attempted when the controller is operating in a public place. In the INFO

menu, set parameter LOC=YES to inhibit all functions of the buttons. To resume normal operation of keypad, adjust setting so that LOC=NO.

INSTALLATION

The controller, size 71x97x61 mm (WxHxD), is to be secured to a DIN rail in such a position as to ensure that no liquid inltrates causing serious damage ■

and compromising safety.

Make sure that electrical connections comply with the paragraph “wiring diagrams”. To reduce the effects of electromagnetic disturbance, keep the sensor ■

and signal cables well separate from the power wires.

Connect a pressure transmitter with output 0/4..20mA to input 1-P. Whenever control takes place through temperature, connect an NTC10K probe (part No. ■

LAE SN4…) to input 2-T.

%

°C

h

Set

Pressure display in bar

°C

Temperature display in °C

%

Percentage of use of available power

h

Hours of operation (LED lit)

h

Thousands of hours of operation

(LED blinking)

Alarm

Stand-by button

Set

Setpoint button

Info button

Alarm display button

Increase button

Decrease button

Fig.1 - Front Panel

Thank you for having chosen an LAE electronic product. Before installing the instrument, please read this instruction booklet carefully in order to ensure safe

installation and optimum performance.

MS27 INSTRUCTIONS FOR USE

DESCRIPTION

INDICATIONS

Page 2

CONTROL

OUTPUT CONFIGURATION

Outputs are congured with parameters OC1, OC2, OC3, OC4. Parameter OCx controls the operation of output OUTx: OCx=1…100 indicates the power in

percentage over the total power, of the compressor connected to OUTx. With OCx= -1, output OUTx is associated to a stage, which is active when the relay is

closed. With OCx= -2, output OUTx is associated to a stage, which is active when the relay is open. With OCx=0, output OUTx is not used for control.

Warning: the output associated to the compressor motor must always be wired in the terminals located before the terminals where the outputs controlling the

stages are. Example: in a system with two compressors of different power (the rst with 60% of total power, the second with 40%), each compressor having a

stage, the conguration of outputs is as follows: OC1 = 60, OUT1 is connected to the motor of compressor 1 of power equal to 60% of total power. OC2 = -1,

OUT2 is connected to the stage of compressor 1, the stage is active when the relay is closed. OC3 = 40, OUT3 is connected to the motor of compressor 2 of

power equal to 40% of total power. OC4 = -1, OUT4 is connected to the stage of compressor 2.

CONTROL ALGORITHM

Parameter CM provides the control algorithm.

CM ■ =ROT: rotation of outputs of equal power. This algorithm minimises the number of starts/stops per hour of each load. When the system calls for more power,

the output which has been off for longer will be activated. When demand for power decreases, the output which has been on for longer will be switched off. When

an output remains active for more than LRT minutes, the controller looks for an inactive output fullling the requirements to be activated (less hours of operation,

minimum off time elapsed,…) and the rotation of the two outputs will take place. In this way, an equal sharing of the total operation time among all loads will be

achieved (see Fig. 2). Note:the compressor rotation algorithm assumes that compressors have got an equal power. In this case, parameter OCx is used only to

dene if output OUTx either controls a compressor or a stage. So, if the value is positive, it will have no effect on OCx, regardless of what you program. Example:

in a system consisting of four compressors, each will have a power equal to 25% of the total value, regardless of the value programmed to OCx.

CM ■ =SEN: sequential activation of the enabled outputs. The outputs are switched on/off with xed sequence, from output 1 to output 4 (see Fig. 3).

CM ■ =PO: optimisation of the available power. The controller combines the outputs in such a way as to obtain a ne control, both in case of calls for more

power and less power. Example: OC1=10, OC2=20, OC3=30, OC4=50. If a capacity of 90 is required, outputs OUT1, OUT3, OUT4 (10+30+50) are switched

on. If a capacity of 50 is required, outputs OUT2 and OUT3 (20+30) are switched on (see Fig. 4).

CONFIGURATION PARAMETERS

To get access to the parameter conguration menu, press button ■

Set

+ for 5 seconds;

with button ■ or select the parameter to be modied;

press button ■

Set

to display the value;

by keeping button ■

Set

pressed, use button or to set the desired value;

when button ■

Set

is released, the newly programmed value is stored and the following parameter is displayed;

to exit from the setup, press button ■ or wait for 30 seconds.

Note: re-programming some parameters causes a complete re-conguration of the controller operation. So please put the controller on stand-by, if you have

to modify the parameters relating to the output conguration or the selection of the control algorithm.

(In the parameter description, we refer to ‘pressure control’. In case of temperature based control, please replace the word ‘pressure’ with ‘temperature’ and

‘bar’ with ‘°C’).

PAR RANGE DESCRIPTION

INP 1-P, 2-T Input selection for control

1-P: input 1-P is used for pressure control; input 2-T is disabled.

2-T: input 2-T is used for temperature control; input 1-P is disabled.

INP=1-P

MPI 0MA, 4MA Min. current input range.

0MA: input 0…20mA; 4mA: input 4…20mA

RLO -1.0…RHI bar Min. scale range.

RLO takes the minimum value measured by the transmitter (corresponding to 0/4mA).

RHI RLO...45.0bar Max. scale range.

RHI takes the maximum value measured by the transmitter (corresponding to 20mA).

OS1 -12.0..12.0bar Probe offset

REF 404,507,22,134 Refrigerant used. It allows Pressure - Temperature conversion.

404=R404A, 507=R507, 22=R22, 134=R134A

SPL RLO…SPH Minimum limit for SP and 2SP setting

SPH SPL…RHI Maximum limit for SP and 2SP setting

SP SPL...SPH Main setpoint, indicates the pressure to be maintained.

2SP SPL...SPH Alternate Setpoint.

Pressure refence point is 2SP if DI1 (DI2) = 2SP and the corresponding input is active.

DBL -10.0...0.0bar Lower neutral zone.

The state of outputs remains unchanged as long as pressure is within the band SP+DBL

and SP+DBH.

DBH 0.0...10.0bar Higher neutral zone.

LON 0...250s Load start delay.

Pressure must remain higher than SP+DBH for LON seconds before the next load is switched on.

LOF 0...250s Load stop delay.

Pressure must remain lower than SP+DBL for LOF seconds before the next load is switched off.

SON 0...250s Stage start delay.

Pressure must remain higher than SP+DBH for SON seconds before the next stage is switched on.

SOF 0...250s Stage stop delay.

Pressure must remain lower than SP+DBL for SOF seconds before the next stage is switched off.

PB 0...20.0bar Proportional band (PWM output control, see Fig. 5).

Zone above setpoint in which the PWM output is activated proportionally.

Example: pressure < SP, PWM=0%; pressure=SP+PB/2, PWM=50%; pressure>SP+PB, PWM=100%.

IT 0...250s Integral action time (control of PWM output, see Fig. 5).

The greater the IT value, a more stable control takes place.

CM ROT,

SEN,

PO

Selection of control algorithm.

ROT: rotation of equal power outputs. SEN: sequential activation of outputs.

PO: optimisation of available power.

OC1,

OC2,

OC3,

OC4

-2...100 Control of output 1, 2, 3, 4.

1…100: power (percentage of total) of the load connected to output OUTx (x=1, 2, 3, 4);

0: output OUTx not used;

-1: output OUTx connected to a stage, which is activated when the contact is closed.

-2: output OUTx connected to a stage, which is activated when the contact is open.

MLS 0...30min Minimum off time of loads.

Minimum time which must elapse between when the load is switched off and when it’s switched on again.

LRT 0...120min Time of forced rotation of loads (only with CM=ROT).

This parameter, if greater than 0, provides the operation time of a load after which the controller takes into

account the possibility of rotation of two outputs.

DPU 0...120min Start delay.

Delay between the time when the controller is switched on when the outputs are activated, in order for the

compressor crankcases to warm up.

SCD 0...100 % Down Scaling.

It indicates the maximum per cent power usable during an alarm with enabled down scaling action.

ALA RLO...AHA Low value measured alarm threshold.

AHA ALA...RHI High value measured alarm threshold.

AID 0...120min High/Low alarm delay.

D1M

D2M

NON,

SBY,

2SP,

ALR

Function of digital input DI1, DI2.

NON: input disabled;

SBY: when input DI1 (DI2) is active, the controller is put on a stand-by.

2SP: when input DI1 (DI2) is active, the control setpoint is 2SP.

ALR: when input DI1 (DI2) is active, the controller detects a generic alarm which causes the display to show

ALR, to load to be switched off and control to be stopped. When the alarm is over, the controller resumes output

control automatically (automatic reset).

D1C

D2C

OPN,

CLS

Activation of digital input DI1, DI2.

OPN: active input is open;

CLS: active input is closed

DxM NON,HP, LP,

OIL, LL, ALR

Function of digital input DI3, DI4, DI5.

NON: input disabled. HP: high pressure alarm. LP: low pressure alarm. OIL: low compressor oil level. LL: low

refrigerant level alarm. ALR: generic alarm.

DxC OPN, CLS Activation of digital input DI3, DI4, DI5 (see D1C).

DxD 0...120min Activation delay of alarm DI3, DI4, DI5.

The digital input must remain in the activation condition for this time before the alarm is detected.

DxA DSP,

SAR,

SMR

Reaction following alarm DI3, DI4, DI5.

DSP: alarm display.

SAR: in addition to the alarm displayed, a down scaling (SCD) is activated and control is stopped. When the

alarm is over, the controller resumes output control automatically (automatic reset).

SMR: in addition to alarm displayed, all loads are switched off and control is stopped. When the alarm is over,

control is resumed but only after the alarm has been acknowledged by pressing button (manual reset).

MTC 0...600

(x100hours)

Maintenance.

When the operation hours of any load achieve this value, a maintenance warning will ash on display. To eliminate

this warning, after performing maintenance, rest the hour counters as described in paragraph “info menu”.

SB NO/YES Stand-by button enabling.

TLD 1...30min Delay for min / max input loggin.

SND NO/YES Alarm buzzer enabling

ADR 1...255 MS27 address for PC communication.

OPERATION EXAMPLES

SP

SP+DBH

Pressure

Time

SP+DBL

OUT1

OFF for10min

OUT2

OFF for7min

OUT3

OFF for15min

LON LON LON

LOF

t<LOF

LOF LOF

CM=ROT

OC1=33

OC2=33

OC3=33

OC4=0

OFF

OFF

OFF

ON

ON

ON

Fig.2 Control by rotationof outputs of equal power

Load

start

Neutral

zone

Load

stop

Time

OUT1

OUT2

OUT3

LON LON LON

LOF LOF LOF

OFF

OFF

OFF

ON

ON

ON

CM=SEN

OC1=20

OC2=30

OC3=50

OC4=0

Fig.3 Control bysequential activation of outputs

Load

start

Neutral

zone

Load

stop

t<LOF

SP+DBH

Pressure

SP+DBL

SP

Loading...

Loading...