1

Ladan

Wood gasification boiler

Instruction for use, installation and assembly of

boiler.

2

General description:

We are introducing you the ecological wood gasification boiler of the output 18, 25, 40, 60,

80kW. The hot-water boiler is designed for heating of apartment, family house, guest house,

smaller industrial workshop and similar object. The boiler is designed for burning of wood only.

Any dry wood can be used for burning, mainly logs till 550-1000 mm length. Also wood of higher

humidity can be used but then the nominal output is reduced and burning time prolonged. Due to

its large feed hopper you can avoid the most demandable operation of preparation and cutting the

wood into smaller pieces. It’s recommended to feed fire with logs of approx. diameter 10-15 cm.

The ashes is only 1-2 % from amount of used wood (cleaning approx. once a week maximum) In

consideration of very low level harmfull pollutants production the operation of wood gasification

boiler is very ecological.

Wood gasification boilers are well-tested and easy to use. The boiler is produced from the special

boiler sheet steel of thickness – 6 mm inner part and 4mm outer part. Fireproof shaped pieces

inside the boiler are made from a special heatproof material, so the pieces are highly heat resistant,

high strength and provide long service life. The body of the boiler is made as weldment of steel

plates. It includes a feed hopper with a heatproof shaped piece that has an oblong opening (nozzle)

for transit of flue gas. Under the nozzle there is a combustion space formed with the ceramic

shaped pieces. In the rear part of the boiler there are vertical flue tubes which in the upper part go

to the collecting channel with a make fire flap. Rear part of the collecting channel is fitted with an

eduction pipe for connecting to the chimney. In the front of boiler is situated a blowing ventilator

with regulation flap for air inlet. The boiler body is insulated by mineral wool Nobasil of

thickness 20mm which is located between the body and jacketing.

Primary and secondary air is preheated and in optimal ratio distributed into the combustion

chamber and nozzle.

Wood gasification boilers are completely different from the current solid fuel boilers. The priciple

of burning is based on the gasification at high temperature (approx. 1100 °C).

Wood burning gas is supported by a blowing ventilator which blows primary air into the

combustion chamber and secondary air injection into the nozzle. This combustion system is very

economical while saving approx. 40% of fuel. Boiler operation requires the minimum attendance

due to automatic operation of the boiler. Hopper contents is sufficient for about 8 to 12 hours

operation at medium power. At minimum output level the boiler is operational even up to 24

hours. All this provides the digital microprocessor control measures.

3

Technical parameters:

Type of boiler

LADAN

18

25

40

60

80

Boiler output

kW

18

25

40 60 80

Feed hopper capacity

dm3

75

113

180

250

360

Door dimension /h-w/

mm

270x450

270x450

270x450

370x570,

270x570

370x570,

270x570

Prescribed chimney draught

Pa

10

23

23

28

32

Test overpreassure

bar 4 4

4

4

4

Max. working overpressure

bar 2 2

2

2

2

Boiler weight

kg

360

430

465

620

735

Diameter of flue connection

mm

160

160

178

178

178

Boiler height

mm

1280

1280

1490

1490

1490

Boiler width

mm

595

595

595

715

715

Boiler depth

mm

855

1055

1055

1380

1626

Shielding of electric parts

IP

21

21

21

21

21

Electrical input

W

70

70

70

140

140

Hydraulic loss of boiler at 10k

mbar

0,21

0,31

0,54

0,84

1,12

CO emission class

4 4

4

4

4

Boiler efficiency

%

90

Temp. of flue gas in

nominal output

°C

148

146

144

162

168

Flow of flue gas

kg/s

0,018

0,02

0,035

0,054

0,072

Maximum noise level

dB

57

57

57

57

57

Specified fuel

wood

Water content max.

20%

Average fuel consumption

kg/h

5,5

7,6

9,5

11,8

14,6

Recommended fuel size

mm

150

150

150

150

150

Max. length of logs

mm

350

550

550

800

1000

Water volume in boiler

l

55

75

93

113

132

Voltage

V/Hz

230/50

230/50

230/50

230/50

230/50

Range of temperature

of heating

°C

60 - 90

60 - 90

60 - 90

60-90

60-90

Min. water temperature in service

°C

60

60

60

60

60

Operation temperature of water

°C

80 - 90

80 - 90

80 - 90

80-90

80-90

Safety valve Danfoss BVTS

• temperature of inlet water

• pressure of inlet water

• opening temperature

°C

Bar

°C

Max. 15

2

95

4

Protection of Boiler against overheating.

ATTENTION: According to the EN 303-5 standard the Safety cooling circuit against the boiler

overheating must not be used for other purposes than to protect boiler against overheating.

5

1. Drain valve Danfoss - BVTS, ¾“

2. Submersible case with temperature-sensitive element

3. Safety cooling heat exchanger

4. Drain to sump

5. Boiler

6. Inlet of cold water

Valve Danfoss – BVTS is on the outlet of the cooling circuit of which sensor is placed at the side

part of a boiler and protects the boiler against overheating. When boiler water temperature

increases above 95°C, cooling circuit is filled up with tap water that takes the extra heat away. In

case of boiler overheating and opening of Danfoss – BVTS valve there must be secured the

permanent drain of heated water from the boiler cooling circuit into spillway.

Valve at the cold water inlet into the boiler cooling circuit must be permanently open and the

boiler cooling circuit must be connected to the functioning distribution of cold water (e.g. cold tap

water network) of temperature 10-15°C and operating overpressure 2-6 bar.

In case of thermostatic valve Danfoss – BVTS opening the circulation of cooling water through

the cooling circuit is not guaranteed it is a risk of boiler damage ! In such case the boiler

warranty is invalid.

Valve DANFOSS is not a part of a boiler!!!

6

Dimension scheme:

Boiler sketch

7

8

Boiler operation:

Before making fire it is necessary:

- familiarize with the attendance of electronic boiler regulation

- check water pressure in the central heating system

- check if the boiler is connected to the mains

Making fire in the boiler

- set the heating temperature

- select the fan speed

- through the upper door insert paper, chips, small pieces of wood and to the rest of feeding

champer add more logs

- chimney flap must be opened!

- fire up the paper and close feeding door

- open the lower door and let the fuel approximately 20 min. flare

- after 20 min. close the lower door and chimney flap

- push down „K„ button to get run the burning mode

Refilling a loading chamber

- stop the fan by pressing „K“ button

- open the chimney flap

- CAREFULLY! open the feeding (upper) doors

- refill the fuel

- close the upper door and chimney flap

- press button „K„ to return to the previous state of the boiler

Warning

Be careful not to get any fuel during the refilling between the chimney flap and the flange. It

would make impossible to close flap correctly.

Cleaning the boiler:

When using dry wood and optimum fuel gasification the combustion chamber and heat

exchanger get sooted minimally. However, when using wet wood the walls of combustion

chamber can be covered with a layer of tar and the boiler does not have an adequate efficiency.

We remove the tar in combustion chamber once a week by burning with ajar feeding door

and chimney flap. If there is a lot of ash in the feeding chamber it is necessary to remove it. The

ash and dust in the combustion chamber should be removed regularly every 3-5 days.

Tubes of the heat exchanger should be cleaned once a month. Before cleaning the heat exchanger

it is necessary to remove cover of heat exchanger thereby creating access to the tube heat

exchanger. The heat exchanger tubes are to be cleaned with a special brush.

Cleaning the air inlet:

Clean air conduit of primary and secondary air is an essential condition for efficient combustion

in the boiler. It is recommended to clean the air conduit minimally once per heating season.

9

After removing a fan and air inlet cover we can see the two tubes that lead air into the nozzle and

to two holes at the upper door. These holes should be cleaned with a small brush and vacuum

cleaner. Turn on the fan and check by hand the clearness of air.

Put the cover of air inlet and fan back. Then it is necessary to set up the shutter of the secondary

air. We screw the shutter to stop with a screwdriver and then turn counter-clockwise 1-2 turns.

Before the summer season starts, we totally clean the boiler loading chamber, combustion

chamber and tubes in the heat exchanger.

Maintenance and repair of the boiler:

During operation of the boiler it is necessary to check the water pressure in the system, door

tightness, chimney shutter tightness, heat exchanger cover tightness and the right fan operation. It

is recommended to have the boiler checked by a professional service worker once before the

beginning of the heating season. Especially to check the correct function of the safety valve,

temperature sensor, emergancy thermostat and regulation.

Door tightness:

The door is attached to the boiler in three points. Two hinges and one door handle.

In case of door leakage it is possible to screw in the door handle but also draw close the hinges.

Chimney shutter tightness:

At cleaning of the heat exchanger it is necessary to clean also seating surface of the shutter and

shutter itself.

Running the fan:

Fan cleanness is one of the conditions for reliable operation of boiler. The fan should be checked

and serviced.

Draught of chimney:

Flue draught must have the specified value 23 Pa.

- Small flue draught shortens the service life of the boiler – creating tar inside the

boiler, condensation and smoke during the fuel loading.

Solution: insert the chimney, put a special extension on the chimny or use

a suction fan in chimney.

- Strong flue draught of chimney increases the consumption of fuel, higher heat loss

in the chimney, lower boiler efficiency and lower boiler output.

Solution: install a throttle valve between the flue and boiler.

10

Problems solution

Defect Cause/Remedy

Boiler has a lower output as it was

a new one

- Clean up air inlet system

- Clean up blades of fan

- Use dry wood

Afterclosing the flue shutter the boiler

burns for a while and then smoke

- Insufficient quantity of primary air

- Clean up the primary air inlet

- Check the shutter opening behind the fan

In combustion chamber arebigger

pieces of unburnt logs.

- Nozzle opening Increased

- Change the nozzle

- Set the air inlet into a closed position and turn

3 turns back from the closed position.

Smoke escape over the closed door.

- set up the door, check the tightness of the

door

- Change the sealing cord of the door

Flue shutter does not open.

- Flue shutter is sticked with tar

- Increase the boiler temperature

- Use the dry wood

- Open flue shutter manually

After opening the upper door and

chimney shutter the boiler room is full

of smoke

- Low flue draught

- The flue diameter should be bigger than the

diameter of boiler flue connection. It is

recommended 200mm.

- Chimney heigth should be minimum 8m

- Assembly suction fan

- Increase the chimney heigth

Boiler does not seal

- Contact service worker or dealer

Failure of electronic regulation

- Contact service worker or dealer

11

Scheme of boiler Ladan 25 kW:

1. Electronic regulation 14. Thermometer

2. Upper door 15. Thermal fuse / emergency thermostat /

3. Pull rod of chimney shutter 16. Water output socket

4. Loading chamber 17. Upper back cover

5. Conduit of primary air 18. Make a fire flap

6. Fan shutter 19. Cover of heat exchanger

7. Fan 20. Flue branch

8. Fireproof nozzle 21. Heat exchanger tubes

9. Covering of secondary air 22. Fireproof concrete

10. Door handle 23. Secondary air

11. Fireclay shaped bricks 24. Combustion chamber

12. Lower door 25. Direction of flue gas

13. Upper front cover 26. Return water socket

27. Filler hole

12

Picture of thermal sensor and emergency thermostat:

1. Upper metal sheet of the boiler

2. Socket of outlet water 2“

3. Temperature sensor

4. Emergency thermostat /in case the temperature is higher than

110 °C the fan turns off /

13

Scheme of loading chamber:

Length of chamber is 590-1000 mm

Loading chamber

14

Assembly regulations

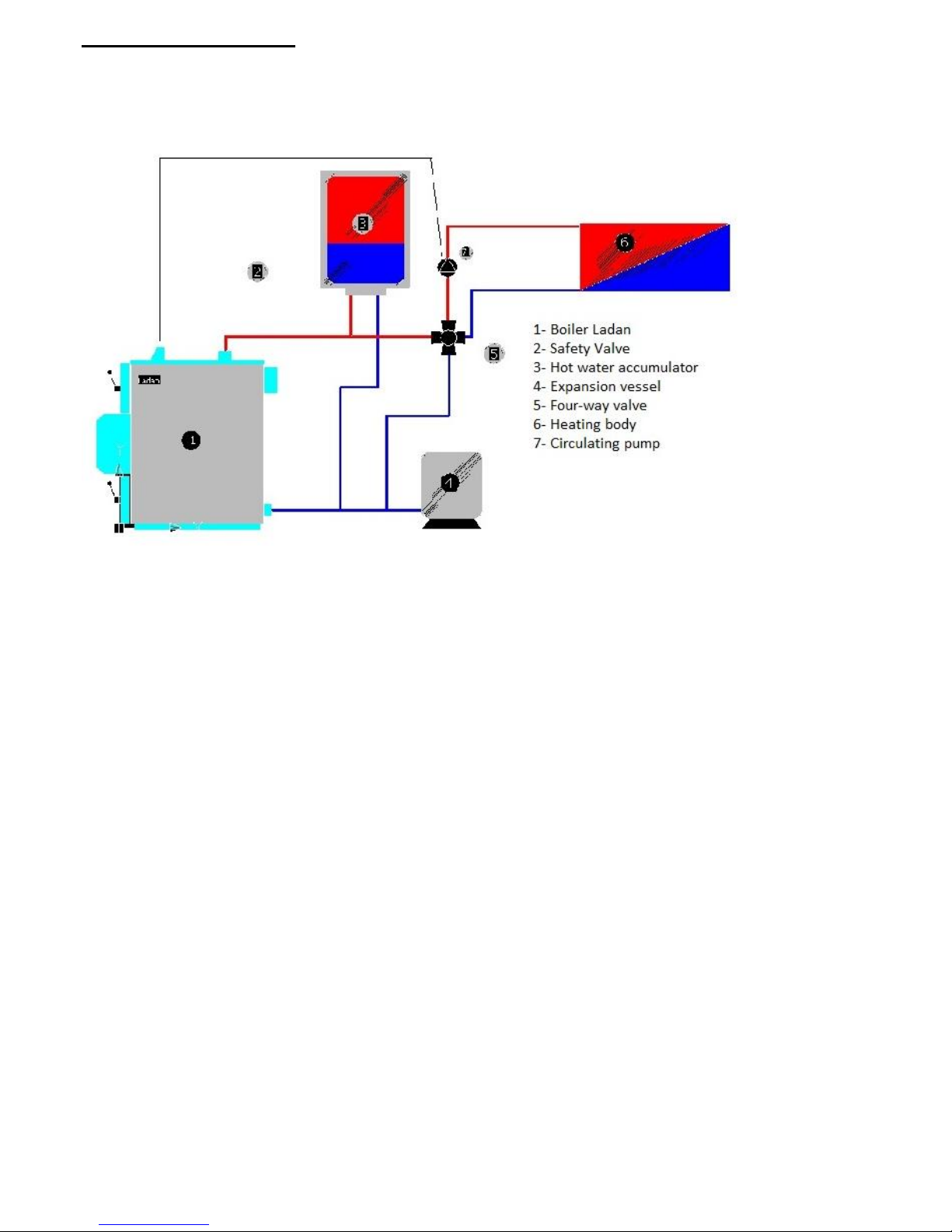

Basic connection scheme of boiler Ladan into the central heating system

The boiler should be connected into the central heating system of which the capacity is

appropriate to the boiler output.

The boiler must be connected to the flue by the shortest way. Other appliances must not be

attached to the same flue. It is not recommended a permanent connection with water supply

through the filling up valve so that in case of valve untightness the pressure might increase. Max.

overpressure is 0,2 MPa.

Boiler room must have a good ventilation.

Assembly of boiler can be done by specialists in compliance with the valid local standards.

Minimum return water temperature at the inlet to the boiler is 60 °C.

It is recommended the boiler is fitted together with the accumulation tank which must correspond

to the standard EN 303-5.

The boiler must be installed together with four-way valve /duomix/. The valve secures that return

water temperature is not less than 60° and protect the boiler against the low temperature

corrosion.

15

Installation instruction

Place a boiler on the fireproof thermally isolated floor overhung boiler floor plan at least 500mm

on the each side.

It is necessary to keep at least minimum specified safety distances of external boiler outlines and

exhaust pipe from any combustible and medium combustible material in distance min. 800 mm.

Examles of combustibility:

Combustibility grade B: very hardly combustible materials / plasterboard .../

Combustibility grade C1: hardly combustible materials / lignit boards, sawdust boards .../

Combustibility grade C2: medium combustible materials / wood - oak, alder, larch, spruce,

fiberboards .../

Combustibility grade C3: easily combustible materials/ wood- beech, ashen, poplar, fiberboards,

cork, foils, polystyrene, polyethylene, asphald board, celulose materials .../

The boiler is necessary to install in accordance with standards valid in the country of installation.

Safety instructions:

On the boiler and to his safety distance it is prohibited to put any combustible item and materials.

Before you start to work with some changes related the boiler enviroments / manipulation with

combustible materials, etc. / it is necessary to shutdown the boiler and wait till the boiler burns

out. The boiler operation must be according his parameters and the boiler can not be overloaded.

At the ash removing it is necessary to use safety tools /gloves., etc../ to take away and store the

ash in the fireproof tanks.

Attendance instructions:

The boiler can be operated only by person who is older than 18 years old, mentally and healthy

capable and familiarized with the Manual for operation. During boiler operation it is necessary to

check impeccable boiler state.

Instructions for liquidation of the product after its lifetime:

The product should be liquidated by selling to a scrap-material dealer. The wrapping should be

liquidated in the same way.

16

Certificate of warranty.

Type of boiler .......................................................................... LADAN

Production number ..................................................................

Checked by : ............................................................................

Sell-by-date: .............................................................................

..................................................

Stamp and signature

Instructions for customers and conditions of guarantee:

- Producer is not responsible for damage during transportation of the product.

- Warranty period is 24 month from the date of ex-factory.

- Warranty is valid only if the boiler was installed into the heating system by specialized

company.

- Warranty is valid only if body of the boiler was connected into the system together with

four-way valve / duomix/ or other mixing valve.

- Producer is not responsible for incorrect boiler operation due to incorrect boiler connection

into the system.

Guarantee:

Guarantee does not include:

- the consumable material like door seal, heat exchanger seal, fan seal, fireproof nozzle,

fireproof brickwork and bricks.

- faults caused by the customer

- faults caused by an incorrect operation and maintenance, if boiler was used for other purpose

than defined or unprofessional care.

Loading...

Loading...