L-Acoustics WST K2 Rigging Manual

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

1 / 52

®

enclosure

RIGGING MANUAL

VERSION 1.0

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

2 / 52

DANGER

This symbol indicates a potential risk of harm to an individual or damage to the product.

It can also notify the user about instructions that must be strictly followed to ensure safe installation or

operation of the product.

OBLIGATION

This symbol notifies the user about instructions that must be strictly followed to ensure proper installation or

operation of the product.

EQUIPMENT

This symbol indicates the equipment, tools, and spare parts required to perform a procedure.

INFORMATION

This symbol notifies the user about complementary information or optional instructions.

®

enclosure

RIGGING MANUAL

VERSION 1.0

SAFETY INSTRUCTIONS

1. Read this manual

2. Follow all SAFETY INSTRUCTIONS as well as DANGER and OBLIGATION warnings

3. Never incorporate equipment or accessories not approved by L-ACOUSTICS

4. Read all the related PRODUCT INFORMATION documents before exploiting the system

The product information document is included in the shipping carton of the related system component.

5. Work with qualified personnel for rigging the system

Installation should only be carried out by qualified personnel that are familiar with the rigging techniques and

safety recommendations outlined in this manual.

6. Ensure personnel health and safety

During installation and set-up personnel must wear protective headgear and footwear at all times. Under no

circumstances personnel is allowed to climb on a loudspeaker assembly.

7. Respect the Working Load Limit (WLL) of third party equipment

L-ACOUSTICS® is not responsible for any rigging equipment and accessories provided by third party

manufacturers. Verify that the Working Load Limit (WLL) of the suspension points, chain hoists and all additional

hardware rigging accessories is respected.

®

8. Respect the maximum configurations and the recommended safety level

For safety issue, respect the maximum configurations outlined in this manual. To check the conformity of any

configuration in regards with the safety level recommended by L-ACOUSTICS®, model the system in

SOUNDVISION and refer to the warnings in Mechanical Data section.

9. Be cautious when flying a loudspeaker array

Always verify that no one is standing underneath the loudspeaker array when it is being raised. As the array is

being raised, check each individual element to make sure that it is securely fastened to the adjacent element.

Never leave the array unattended during the installation process. As a general rule, L-ACOUSTICS® recommends

the use of safety slings at all times.

10. Be cautious when ground-stacking a loudspeaker array

Do not stack the loudspeaker array on unstable ground or surface. If the array is stacked on a structure, platform,

or stage, always check that the latter can support the total weight of the array. As a general rule, L-ACOUSTICS®

recommends the use of safety straps at all times.

11. Take into account the wind effects on dynamic load

When a loudspeaker assembly is deployed in an open air environment, wind can produce dynamic stress to the

rigging components and suspension points. If the wind force exceeds 6 bft (Beaufort scale), lower down and/or

secure the loudspeaker array.

SYMBOLS

The following symbols are used in this document:

K2_RM_EN_0 .5

w w w . l -a c o us t i cs .c o m

3 / 52

WELCOME TO L-ACOUSTICS®

Thank you for choosing the L-ACOUSTICS® K2 WST® system.

This document contains essential information on rigging the system properly and safely. Carefully read this document in

order to become familiar with these procedures.

As part of a continuous evolution of techniques and standards, L-ACOUSTICS® reserves the right to

change the specifications of its products and the content of its documents without prior notice.

Please check the L-ACOUSTICS® web site on a regular basis to download the latest document and software updates:

www.l-acoustics.com.

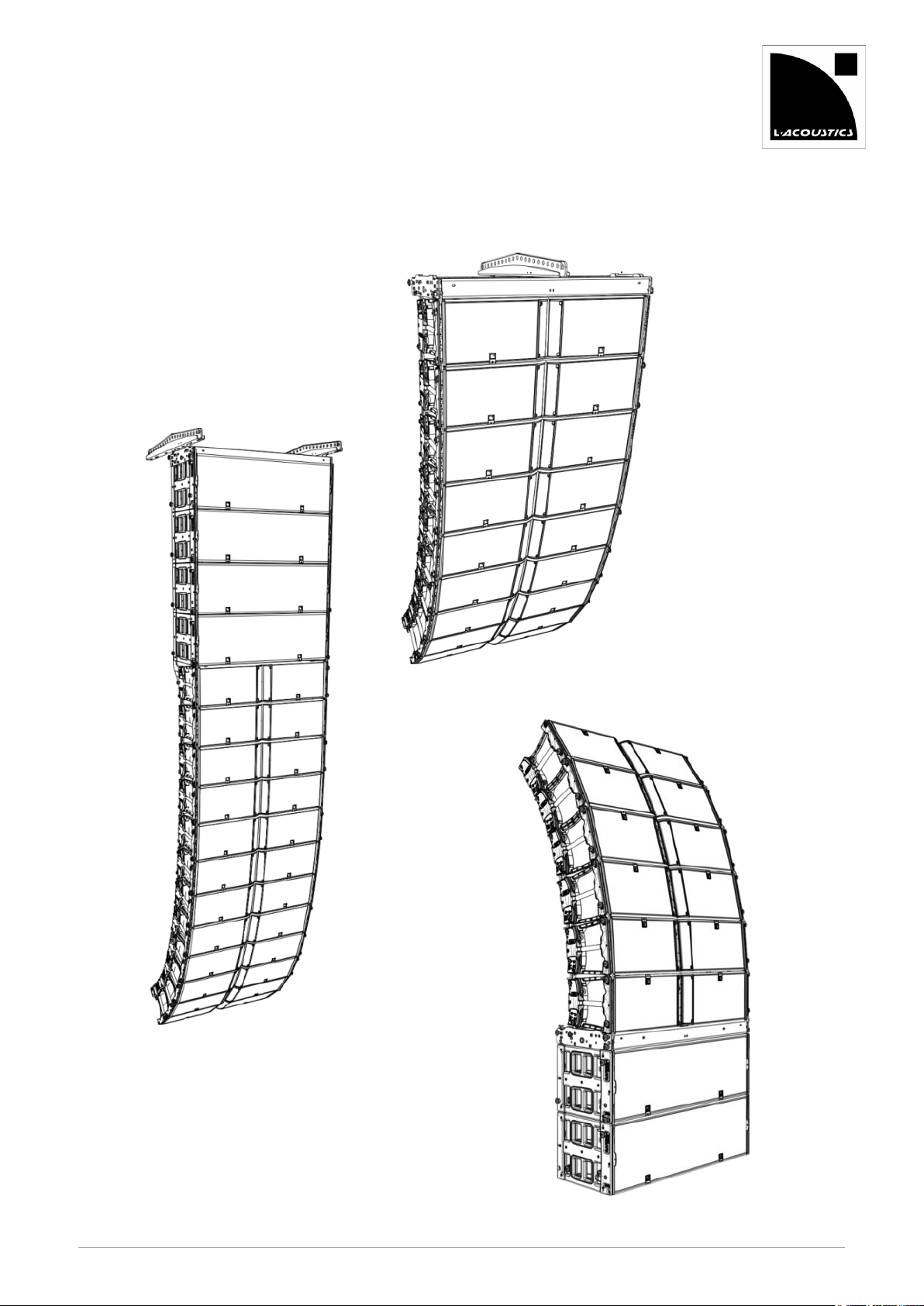

K2 WST® SYSTEM

The L-ACOUSTICS® K1 system has achieved international recognition and is today the prime choice of engineers for

the largest stadium tours and outdoor festivals. Its sonic performance, its fully integrated system package and its rider

friendliness are considered as the industry benchmarks. With K2, L-ACOUSTICS® offers K1 performance in a rescaled

package. The K2 system flexibility makes it suited to both permanent installation and touring applications, from theatre

to stadium productions.

The main system components are as follows:

• K2, full-range element, with adjustable horizontal directivity, operating from 35 Hz to 20 kHz

• K1-SB, low-frequency element, reinforcing LF contour down to 30 Hz or LF throw down to 35 Hz

• SB28, low-frequency element, extending the operating bandwidth down to 25 Hz

• LA4X/LA8 amplified controllers or LA-RAK, touring rack fitted with three LA8

The 3-way quad amplified design, the transducers resources are among the characteristics giving K2 an exceptional

ability to perform in many applications and with a record-breaking performance/weight ratio. Any on-site deployment

can be easily and quickly achieved thanks to an extremely ergonomic, fast and captive rigging system.

A K2 line source utilizes the unrivalled characteristics of Wavefront Sculpture Technology®. Inter-element angles can be

set with laser like accuracy up to a generous 10˚, allowing the optimization of the vertical coverage with SPL smoothly

spread across the audience. Horizontally, the K2 coverage pattern can be adjusted to sector and match any audience or

specific room geometries. Four different settings are possible: two symmetric (70° or 110°) and two asymmetric (90° as

35°/55° or 55°/35°).

Thanks to its full range capability, the K2 enclosure can be deployed as a standalone line source. For applications

demanding extreme LF impact (contour mode), or maximized LF projection (throw mode), K2 can be arrayed with its

dedicated and flyable K1-SB LF extension. The K2 system can also address applications with demanding infrasonic

reproduction when combined to the SB28 subwoofer. Before installation, any system configurations can be acoustically

and mechanically modeled with SOUNDVISION 3D simulation software.

For touring applications, K2 can be associated to the LA-RAK, a universal distribution platform for power, audio signals

and network which facilitates cross rental between rental companies. LA-RAK houses three LA8 amplified controllers

and can be flown onto a K2 array. Other applications can feature LA8 amplified controllers. For high-end installation

projects, K2 can also be driven by the LA4X amplified controller. The scheme authorizes fully discrete DSP treatment

per section and maximum power headroom for the best possible sonic performance.

Thanks to dedicated factory presets, the LA8/LA4X amplified controller constitutes an extremely advanced and precise

drive system for the enclosures. All L-ACOUSTICS® amplified controllers feature the L-DRIVE, a thermal and overexcursion protection circuit.

Up to 253 LA8/LA4X amplified controllers can be connected together via the Ethernet-based L-NET protocol. The LA

NETWORK MANAGER software allows online remote control and monitoring of all the connected units, via a userfriendly and intuitive graphic interface, and features the Array Morphing EQ. This exclusive tool allows the engineer to

quickly adjust the tonal balance of the system to reach a reference curve or to ensure consistency of the sonic

signature.

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

4 / 52

®

enclosure

RIGGING MANUAL

VERSION 1.0

CONTENTS

1 RIGGING SYSTEM 5

1.1 Loudspeaker enclosure ............................................................................................................................................................... 5

1.2 Rigging elements .......................................................................................................................................................................... 5

1.3 Software application .................................................................................................................................................................... 5

1.4 Accessories .................................................................................................................................................................................. 5

2 MECHANICAL SAFETY 7

2.1 Mechanical limits ......................................................................................................................................................................... 7

2.2 Assessing mechanical safety ......................................................................................................................................................... 7

3 RIGGING SYSTEM DESCRIPTION 8

3.1 Elements for enclosure rigging .................................................................................................................................................... 8

3.2 Elements for storage and transportation ..................................................................................................................................... 9

3.3 Elements for flying ..................................................................................................................................................................... 10

3.4 Elements for LA-RAK rigging ..................................................................................................................................................... 12

4 SYSTEM SETUP 14

4.1 Ground-stacking ........................................................................................................................................................................ 14

4.2 Flying ......................................................................................................................................................................................... 15

5 SUBSET PROCEDURES 17

Preparing a block of 4 K2 ..................................................................................................................................... 17 PROCEDURE A.

Preset the inter-enclosure angles ......................................................................................................................... 19 PROCEDURE B.

Stacking K2 on K2-BUMP .................................................................................................................................... 20 PROCEDURE C.

Attaching K2-BAR on K2-BUMP .......................................................................................................................... 23 PROCEDURE D.

Attaching a block of four K2 under K2-BUMP ..................................................................................................... 25 PROCEDURE E.

Attaching a block of four K2 under K2 ................................................................................................................. 27 PROCEDURE F.

Attaching a block of four K2 under a K1 system element .................................................................................... 31 PROCEDURE G.

Attaching K1 or K1-SB under K2-BUMP ............................................................................................................. 36 PROCEDURE H.

Stacking LA-RAK on K2-BUMP ............................................................................................................................ 37 PROCEDURE I.

APPENDIX A: PICKUP POINTS GUIDELINES 41

APPENDIX B: INSTALLING A LASER INCLINOMETER 45

APPENDIX C: SPECIFICATIONS 46

K2 .................................................................................................................................................................................................. 46

K1-SB .................................................................................................................................................................................................. 47

K2-BUMP .............................................................................................................................................................................................. 48

K2-BUMP-FLIGHT ................................................................................................................................................................................ 48

K2-BAR ................................................................................................................................................................................................. 49

K2-LINK ................................................................................................................................................................................................ 49

K2-RACKMOUNT ................................................................................................................................................................................ 50

K1-DELTA............................................................................................................................................................................................. 51

K2-CHARIOT ........................................................................................................................................................................................ 51

K2_RM_EN_0 .5

w w w . l -a c o us t i cs .c o m

5 / 52

1 RIGGING SYSTEM

K2

Full range enclosure, deployable in a variable curvature line source.

K1-SB

Dedicated subwoofer enclosure, deployable with K2.

K2-CHARIOT

Transport dolly for four K2 enclosures.

K2-BUMP

Rigging frame used to fly K2 line arrays. Designed to be compatible with K1 and K1-SB.

Provided with two bow shackles WLL 3.25 t.

K2-BAR

Rigging bar designed to provide a wider range of site angles for the K2-BUMP.

Provided with two bow shackles WLL 3.25 t.

K1-DELTA

Rigging plate designed to be used optionally with the K2-BUMP, to adjust the azimuth angle

of flown K2 / K1 / K1-SB arrays.

K2-BUMPFLIGHT

Flight-case dedicated to the rigging elements of the K2 system.

In order to be used as storage for the K2-BUMP it must be prepared using the foams

provided with the product.

K2-LINK

Rigging interface between K2 and K1 or K1-SB.

K2-RACKMOUNT

Rigging interface for stacking one or two LA-RAK on top of a K2 array flown with a K2BUMP.

K2-BPCHAIN

Adjustable sling used to prevent the chain bag of a climbing hoist being in front of a flown

array top enclosure.

LA-SLING2T

Chain sling with two-leg bridles used to implement bridle hangs.

SOUNDVISION

Proprietary 3D acoustical and mechanical modeling software.

K2CHARIOTCOV

Protective cover for transportation and storage

Other K2 SYSTEM components

All the other components of the system are presented in the K2 user manual, document intended to

describe the enclosure configurations and connection scheme.

The system approach developed by L-ACOUSTICS® consists in providing packaged solutions for loudspeaker systems

in order to guarantee the highest and most predictable level of performance at any step: modeling, installation, and

operation. An L-ACOUSTICS® loudspeaker system is the set of components available to form any loudspeaker system

based on one of the full-range loudspeaker enclosures afforded by L-ACOUSTICS®. It includes enclosures, rigging

accessories, loudspeaker cables, amplified controllers and software applications.

The main components involved in the rigging process of a K2 system are the following:

1.1 Loudspeaker enclosure

1.2 Rigging elements

1.3 Software application

1.4 Accessories

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

6 / 52

K2

K1-SB

LA-RAK

K2-BUMP

K2-BAR

K2-LINK

K1-DELTA

K2-RACKMOUNT

K2-CHARIOT

LA-SLING2T

K2-BPCHAIN

SOUNDVISION

®

enclosure

RIGGING MANUAL

VERSION 1.0

Main components involved in the K2 rigging process

K2_RM_EN_0 .5

w w w . l -a c o us t i cs .c o m

7 / 52

2 MECHANICAL SAFETY

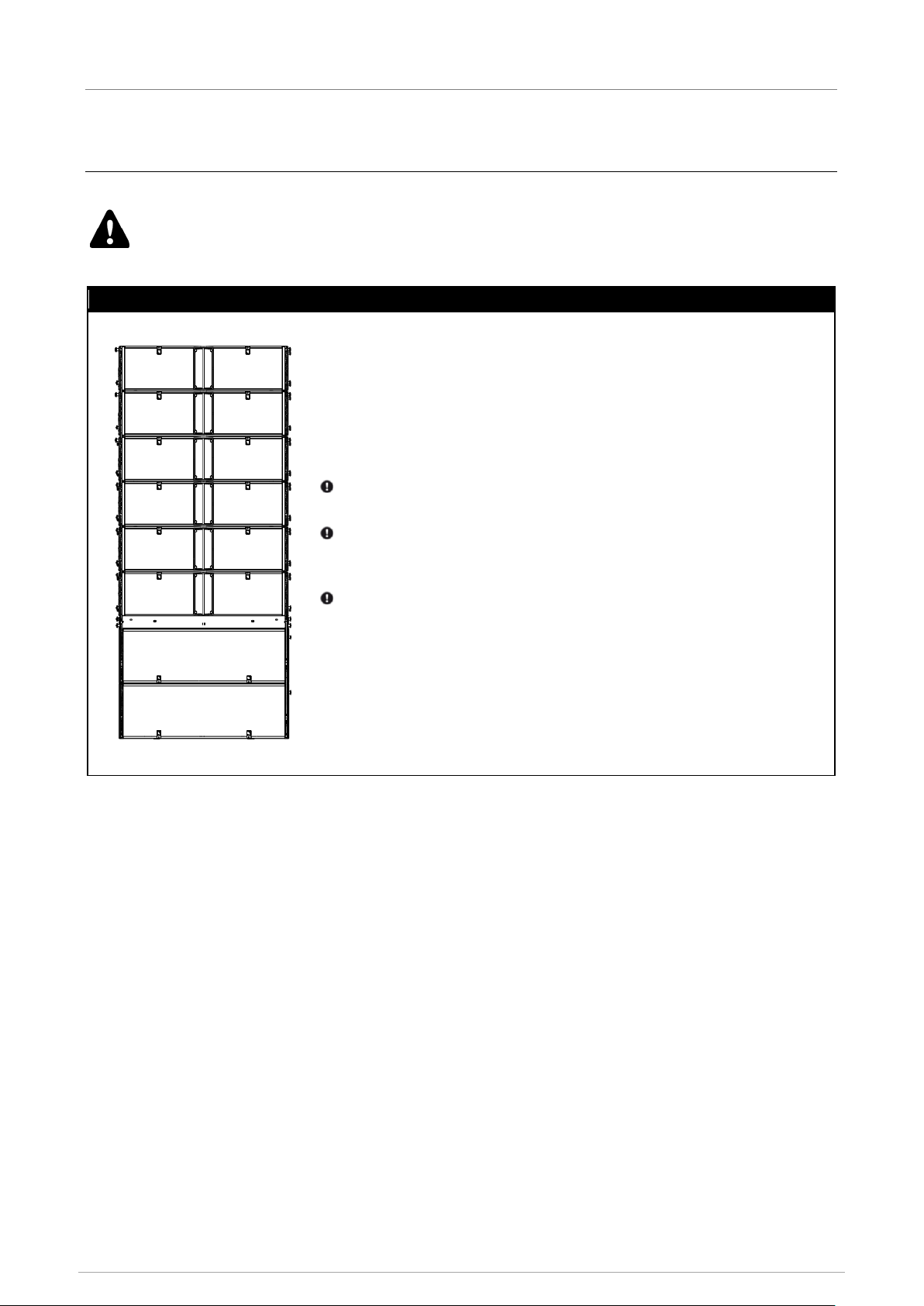

Ground-stacked

Safe limit

Maximum limit

K2 on K1-SB with K2-BUMP

4 K2

6 K2

Flown

Safe limit

Maximum limit

K2-BUMP

K2-BUMP + K2-BAR

16 K2

14 K2 + 2 LA-RAK

12 K1-SB + 1 LA-RAK

24 K2

24 K2 + 2 LA-RAK

16 K1-SB + 2 LA-RAK

K2-LINK under K1-BUMP

16 K2

24 K2

SOUNDVISION and mechanical safety

To deploy more elements than the safe limits, or when mixing different type of loudspeaker enclosures

within the same array, always model the system in SOUNDVISION before installation, and check the

Mechanical Data section for any stress warning or stability warning.

Rated working load limit (WLL) is not enough

The rated WLL is an indication of the element resistance to tensile stress. For complex mechanical systems

such as loudspeaker arrays, WLLs cannot be used per se to determine the maximum number of enclosures

within an array or to assess the safety of a specific array configuration.

Mechanical modeling with SOUNDVISION

The working load applied to each linking point, along with the corresponding safety factor, will depend on

numerous variables linked to the composition of the array (type and number of enclosures, splay angles)

and the implementation of the flying or stacking structure (number and location of flying points, site angle).

This cannot be determined without the complex mechanical modeling and calculation offered by

SOUNDVISION

Assessing the safety with SOUNDVISION

The overall safety factor of a specific mechanical configuration always corresponds to the lowest safety

factor among all the linking points. Always model the system configuration with the SOUNDVISION

software and check the Mechanical Data section to identify the weakest link and its corresponding working

load. By default, a stress warning will appear when the mechanical safety goes beyond the recommended

safety level.

Safety of ground-stacked arrays in SOUNDVISION

For ground-stacked arrays, a distinct stability warning is implemented in SOUNDVISION. It indicates a

tipping hazard when the array is not secured to the ground, stage or platform. It is user responsibility to

secure the array and to ignore this warning.

Consideration must be given to unusual conditions

SOUNDVISION calculations are based on usual environmental conditions. A higher safety factor is

recommended with factors such as extreme high or low temperatures, strong wind, prolonged exposition

to salt water, etc. Always consult a rigging specialist to adopt safety practices adapted to such a situation.

2.1 Mechanical limits

The K2 rigging system complies with 2006/42/EC: Machinery Directive. It has been designed following the guidelines of

BGV-C1.

2006/42/EC: Machinery Directive specifies a safety factor of 4:1 against the rupture. The limits specified in the tables

below correspond to deployments with a safety factor of 4:1 or higher. Refer to SOUNDVISION for the safety factor

of a specific deployment.

The safe limit gives the maximum number of elements for which the safety factor is always compliant with the

2006/42/EC: Machinery Directive, regardless of the other deployment parameters (site angles, inter-enclosure angles,

etc.).

The maximum limit gives the maximum number of elements for which the safety factor can be compliant with the

2006/42/EC: Machinery Directive, when the other deployment parameters provide the best mechanical conditions.

2.2 Assessing mechanical safety

In order to assess the actual safety of any array configuration before implementation, refer to the following warnings:

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

8 / 52

®

enclosure

RIGGING MANUAL

VERSION 1.0

3 RIGGING SYSTEM DESCRIPTION

K2 enclosures can be ground-stacked and flown independently (K2-BUMP) or in combination with K1 system elements

(K1, K1-SB, or K1-BUMP).

The K2-BUMP is designed to be directly compatible with K1 and K1-SB. The K2 enclosure rigging system requires the

K2-LINK interface to be compatible with the K1 rigging system.

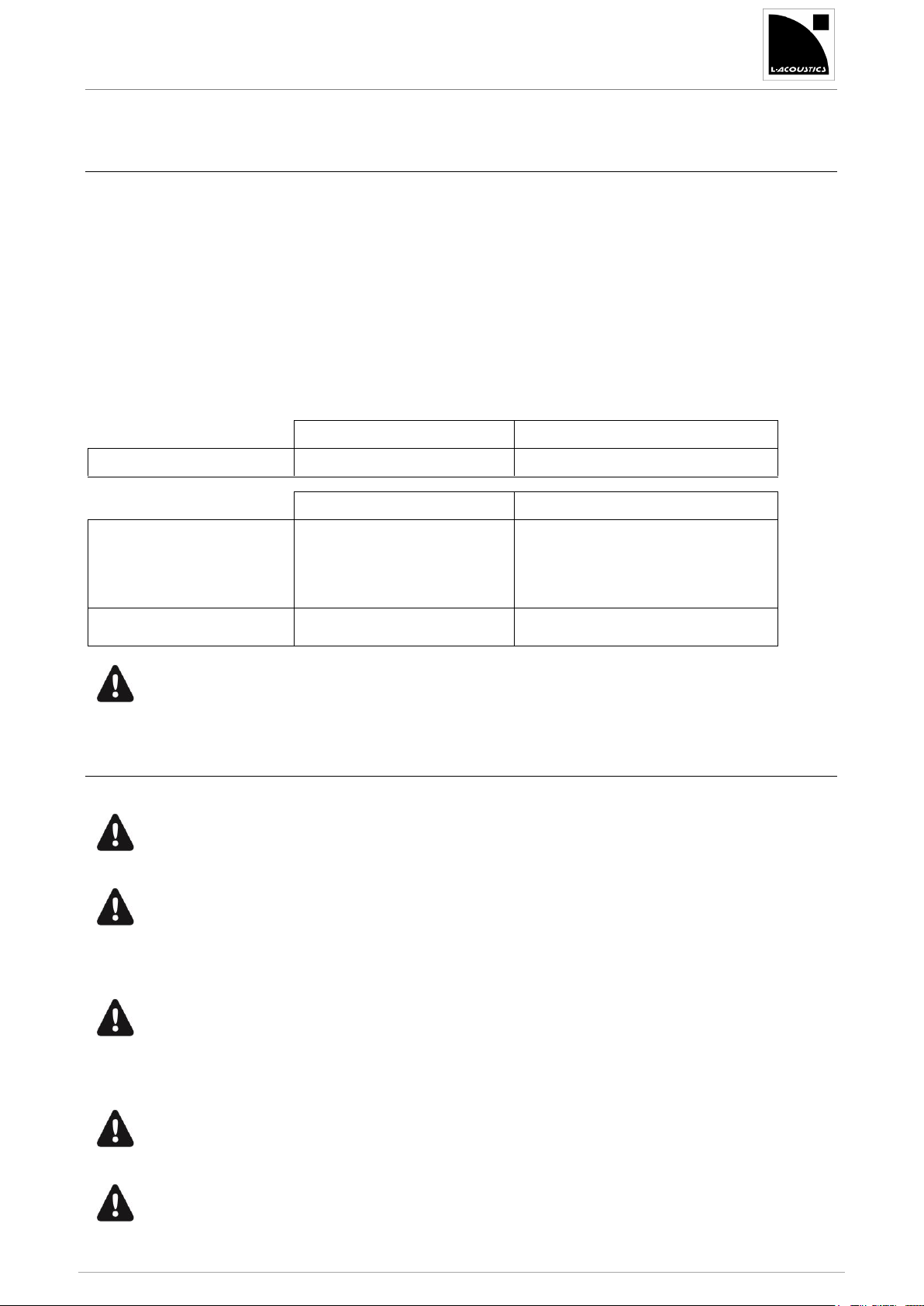

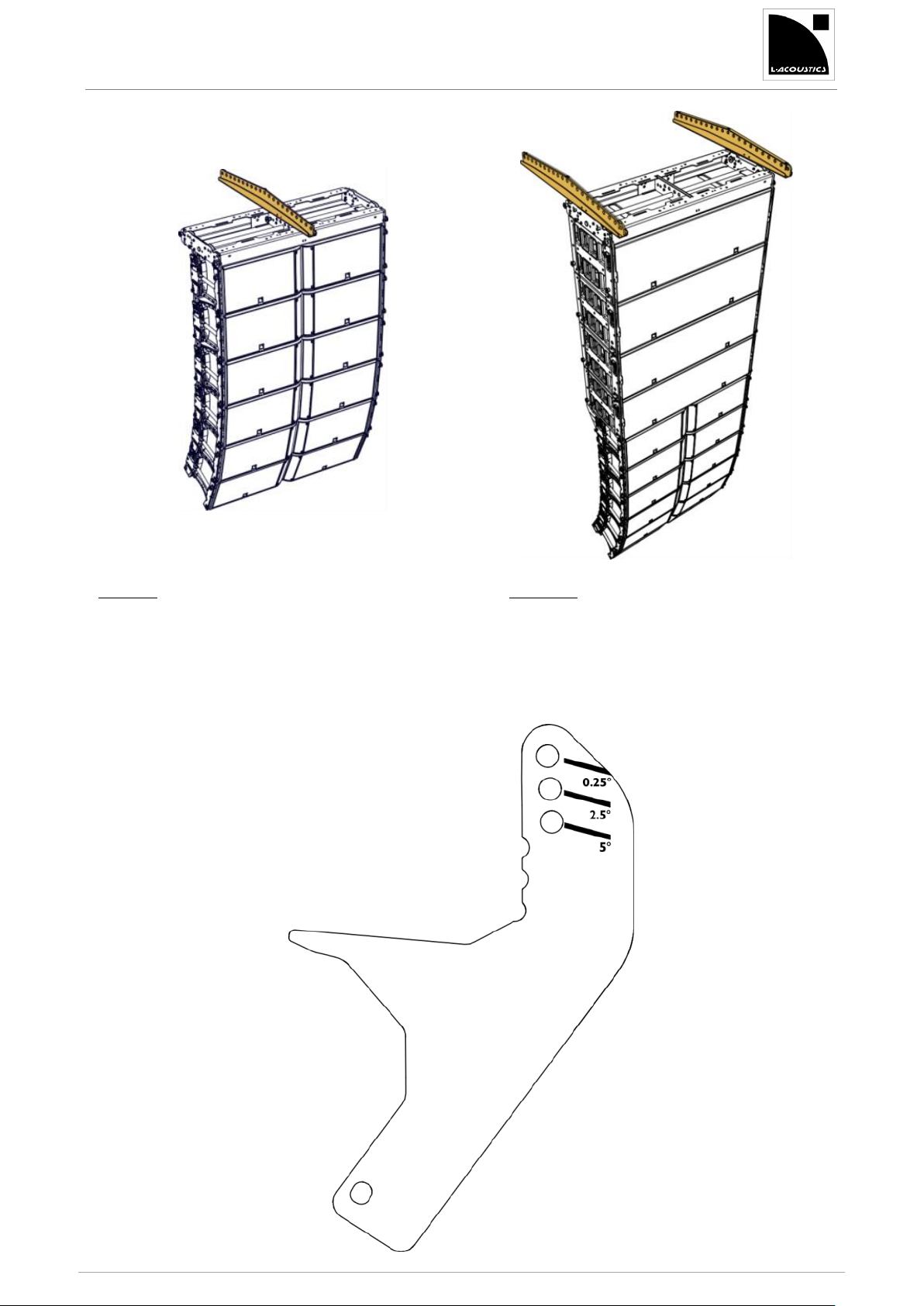

3.1 Elements for enclosure rigging

On both sides, the K2 enclosure integrates two arms to connect to another element of the rigging system, such as an

enclosure or to a flying frame.

At the front, a rotating arm provides a fixed point around which the enclosure can freely rotate until its

connection at the rear.

At the rear, a sliding arm allows the inter-element angle setting and the inter-element rear connection.

The angles between adjacent enclosures are secured by an automatic system that is activated in advance and locks itself

during the stacking and lifting procedures.

K2_RM_EN_0 .5

w w w . l -a c o us t i cs .c o m

9 / 52

3.2 Elements for storage and transportation

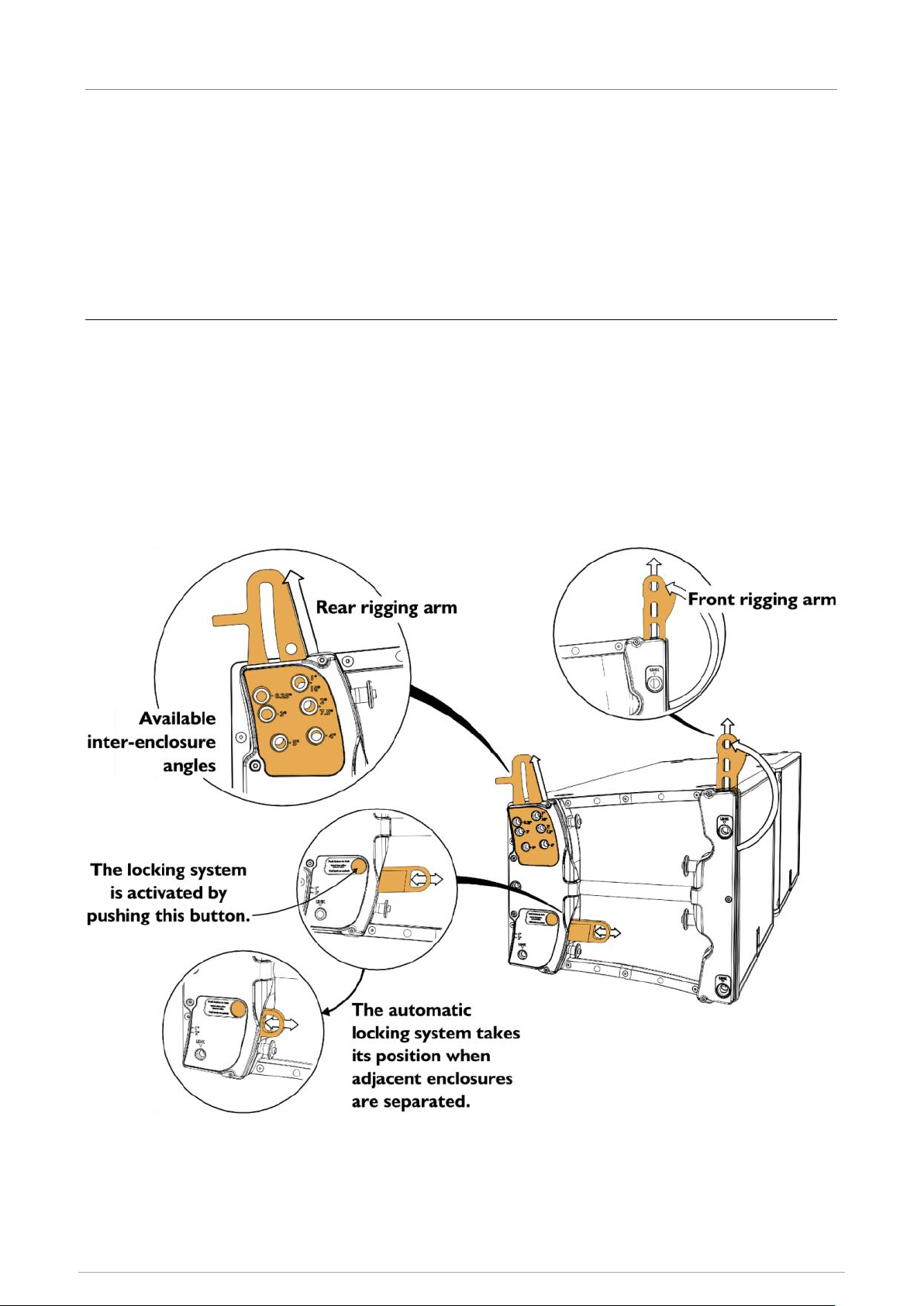

TIPPING HAZARD

If the enclosures are not pinned at 10°, they can separate at the back, causing the stack to tip over.

The K2-CHARIOT is designed for the transportation and storage of blocks of four K2 enclosures.

During transportation the blocks must have an inter-enclosure angle of 10° to avoid any separation of the enclosures.

This angle must be set using the enclosure rear rigging arm pin. The automatic locking system must remain unloaded.

The K2-CHARIOT rear rigging arm must be at its -15° site angle position.

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

10 / 52

With K1-SB and a single motor the hole no 2 provides a 0° site angle.

®

enclosure

RIGGING MANUAL

VERSION 1.0

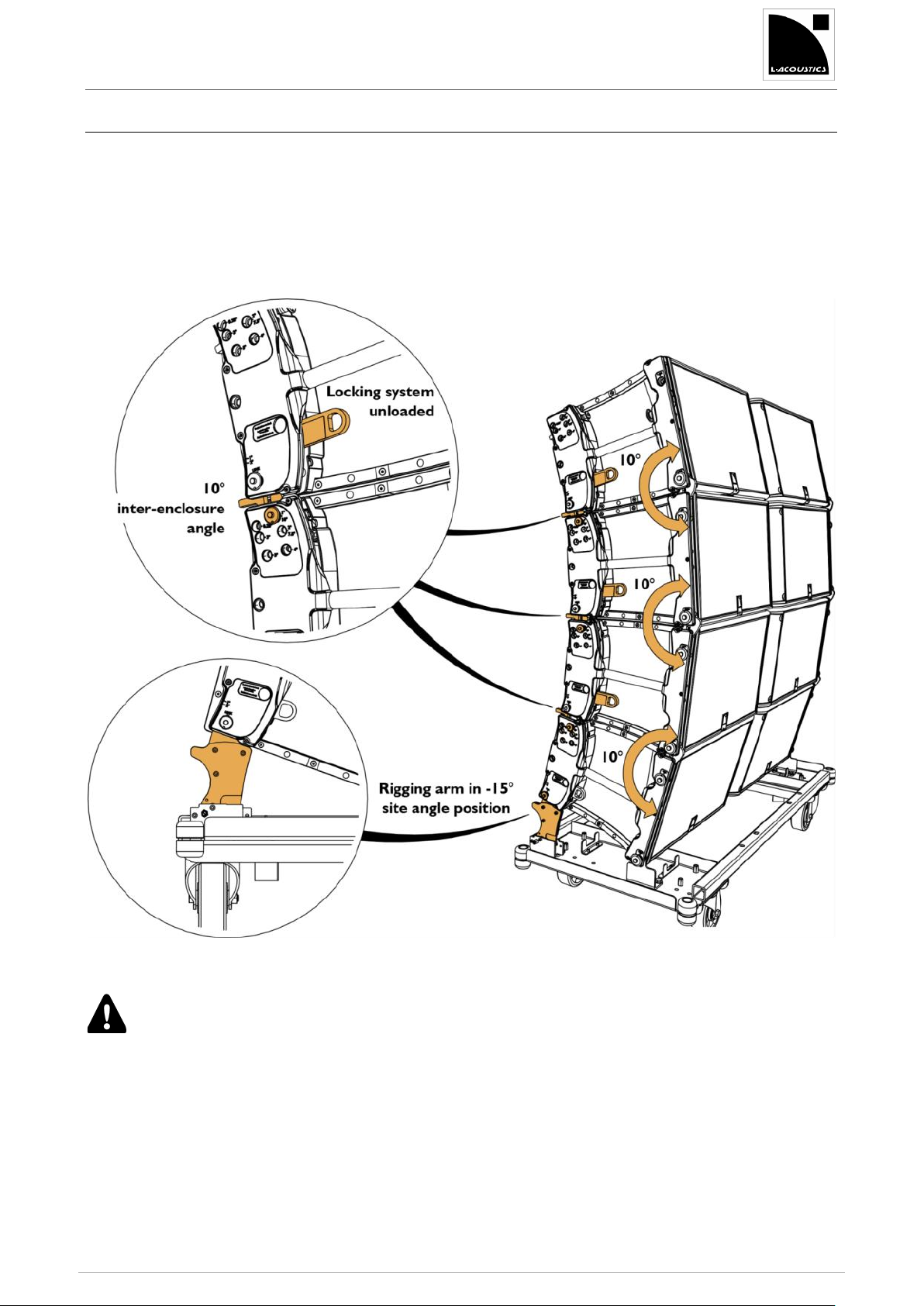

3.3 Elements for flying

The K2-BUMP is designed for flying line arrays of K2, K1 or K1-SB enclosures. 4 holes are available on the central bar

of the K2-BUMP. Refer to your SOUNDVISION model to know which holes to use.

By adding a K2-BAR to the K2-BUMP, the site angle range can be increased. 21 holes are available on the K2-BAR

which can be attached to the K2-BUMP as a rear or a front extension and in position A or B, thus offering a total of 84

discrete positions for pick-up points.

The rear extension is suited to downwards and front extension to upwards site angles.

K2_RM_EN_0 .5

w w w . l -a c o us t i cs .c o m

11 / 52

Standard: One K2-BAR attached in the center of K2-BUMP

Alternative: Two K2-BAR attached on the sides

The K2 system can be flown under a K1 system element, K1, K1-SB or K1-BUMP. The K2-LINK is designed to make

the rigging systems compatible.

It provides three holes and therefore three angles between the top K2 enclosure and the bottom K1 element: 0.25°,

2.5° and 5°.

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

12 / 52

1 LA-RAK : 2 rails : 2 K2-BAR

2 LA-RAK : 4 rails : 1 K2-BAR

®

enclosure

RIGGING MANUAL

VERSION 1.0

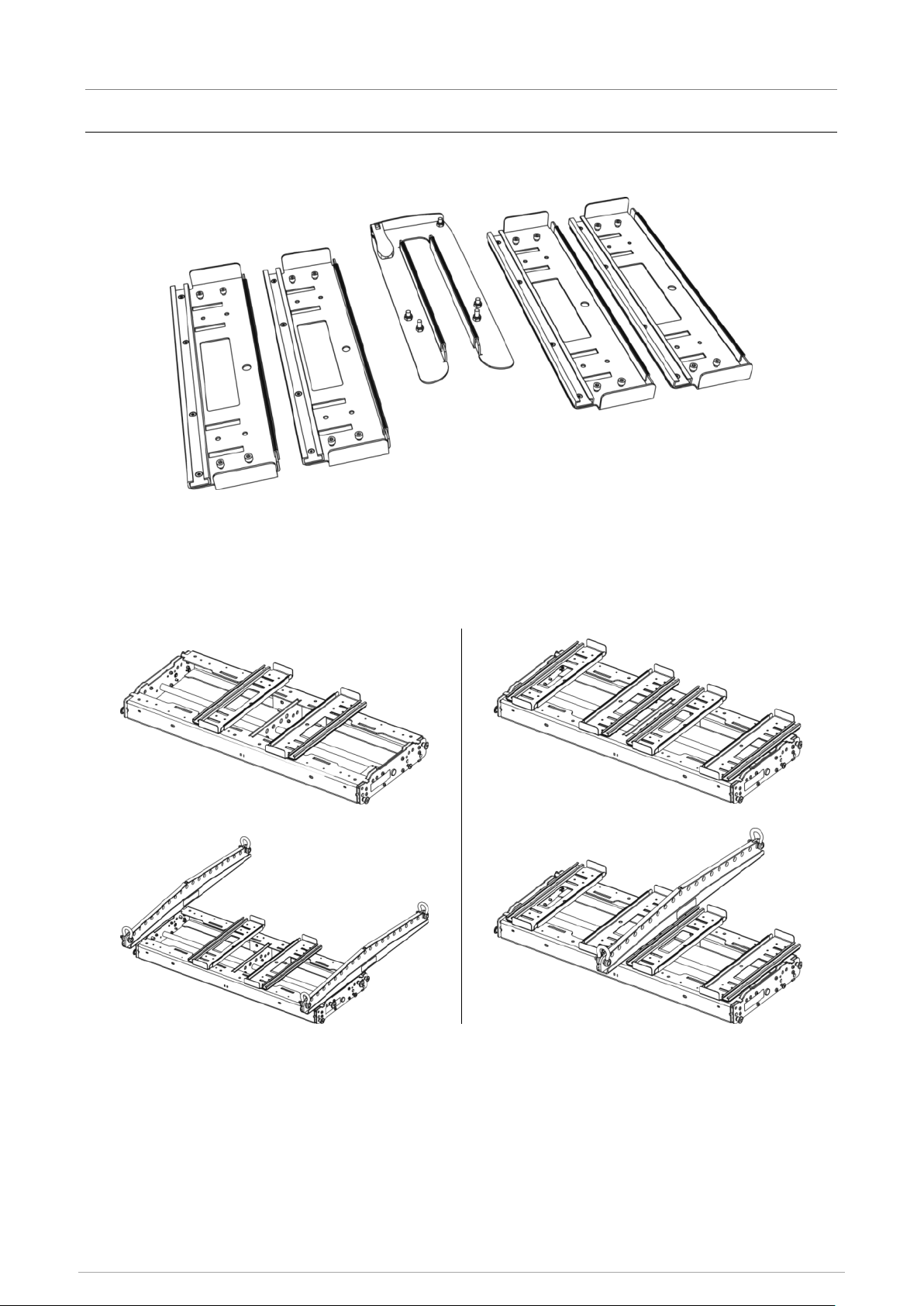

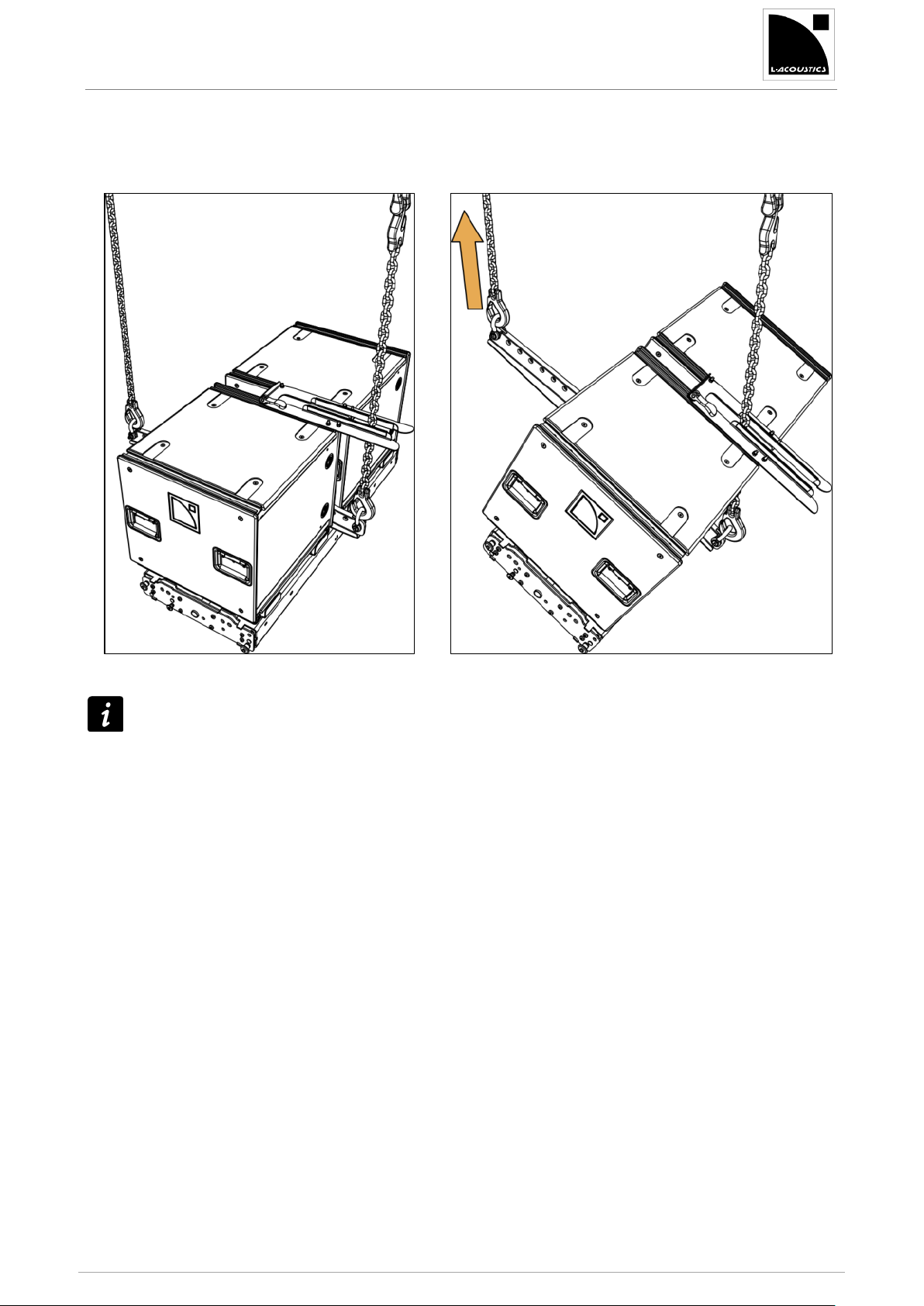

3.4 Elements for LA-RAK rigging

The K2-RACKMOUNT is designed to stack one or two LA-RAK on top of a flown array.

It is composed of four rails and a stabilizer.

The rails are screwed on the K2-BUMP. Their number and position depend on the number of racks.

The K2-RACKMOUNT must be used along with either one or two K2-BAR.

K2_RM_EN_0 .5

w w w . l -a c o us t i cs .c o m

13 / 52

When two racks are mounted side by side, the stabilizer is used to prevent the assembly from tipping or toppling over.

0° site angle

30° positive site angle

Refer to APPENDIX A: PICKUP POINTS GUIDELINES for more information.

The stabilizer traps one of the chains used to lift the assembly.

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

14 / 52

Final check

After the setup, always verify no yellow labels are visible on the front and on both sides of the array.

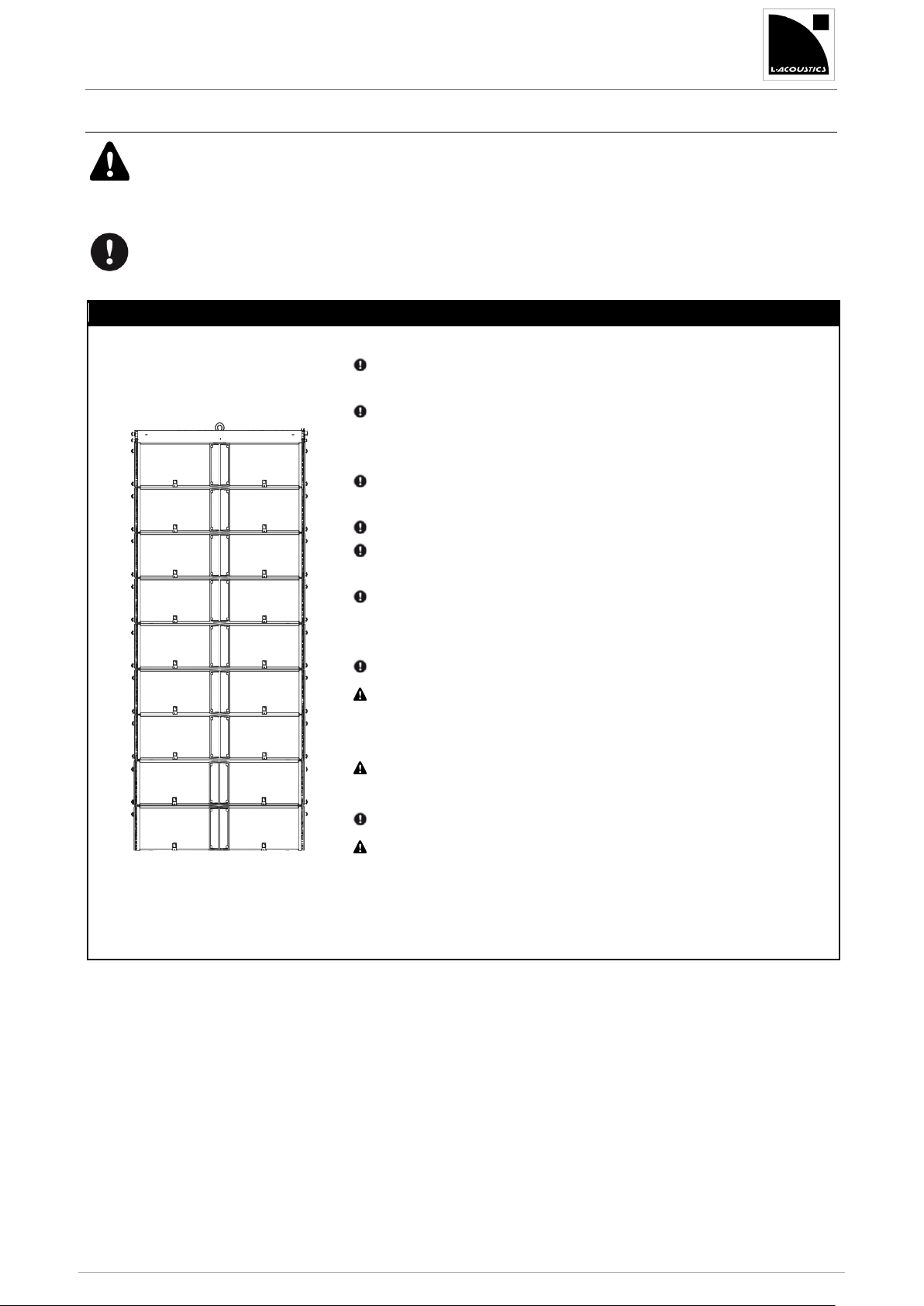

K2 enclosures on K1-SB

Stack as many K1-SB enclosures as necessary.

Refer to the K1 rigging manual to set up the K1-SB part of the array.

Position and attach a K2-BUMP on the K1-SB stack

Refer to PROCEDURE H.

Position and attach an upside down K2 on the K2-BUMP and add as many K2

enclosures on top of the first one.

Refer to PROCEDURE C.

®

enclosure

RIGGING MANUAL

VERSION 1.0

4 SYSTEM SETUP

4.1 Ground-stacking

K2_RM_EN_0 .5

w w w . l -a c o us t i cs .c o m

15 / 52

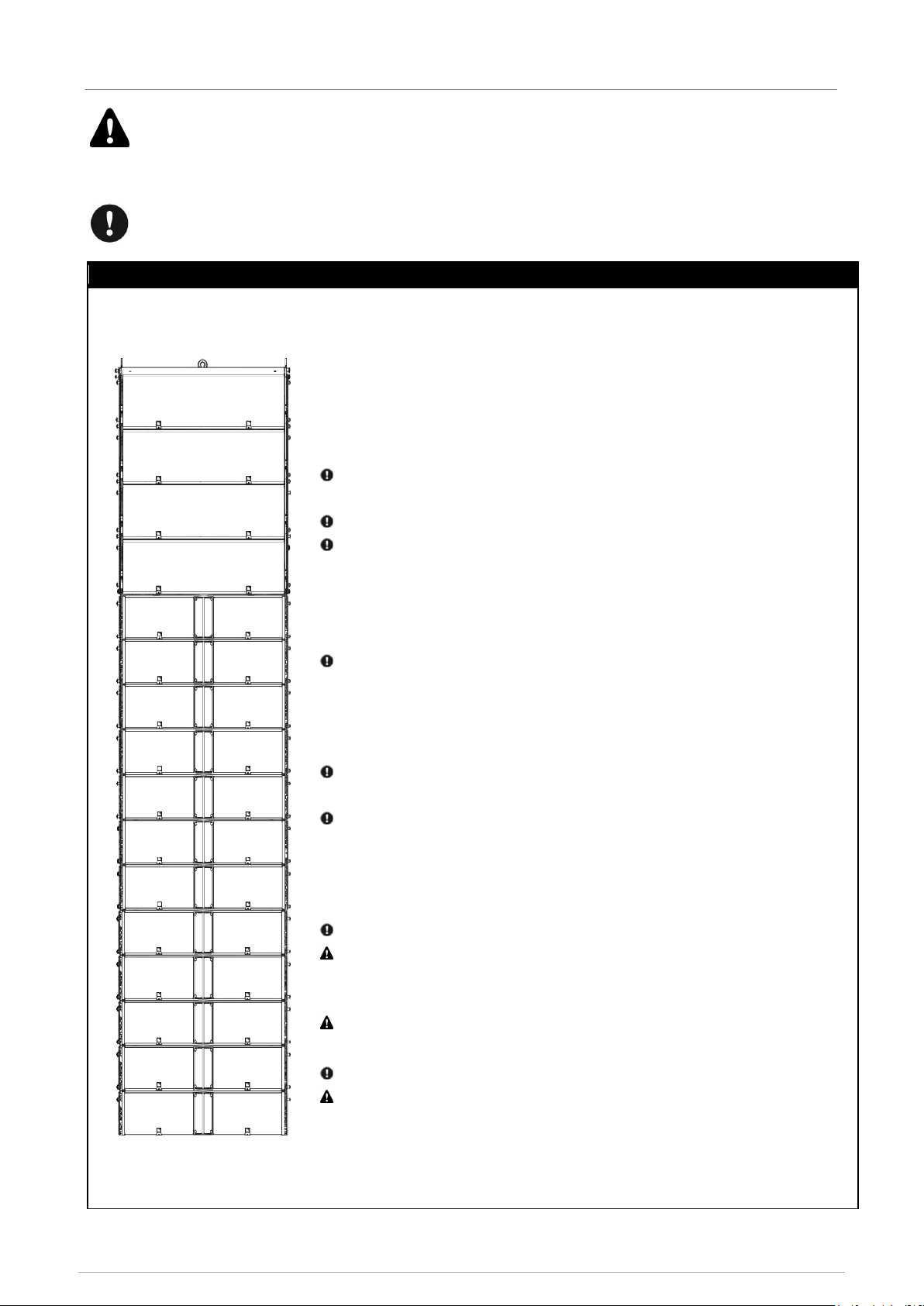

4.2 Flying

Final check

After the setup, always verify no yellow labels are visible on the front and on both sides of the array.

At least one motor for each K2-BAR

When using two K2-BAR, do not implement a bridle between the bars.

Before setup, choose a flying option

Refer to SOUNDVISION modeling and to 3.3 Elements for flying (p. 2).

K2 enclosures under K2-BUMP

Prepare all the blocks of 4 K2 necessary to build the array.

If a block is not already built, refer to PROCEDURE A.

Preset the inter-enclosures angles.

Refer to PROCEDURE B.

Place an open a K2-BUMPFLIGHT under the motor.

If necessary, attach one or two K2-BAR to the K2-BUMP.

Refer to PROCEDURE D.

If necessary, stack one or two LA-RAK on the K2-BUMP.

Refer to PROCEDURE I.

Refer to APPENDIX A: when stacking only one LA-RAK.

Attach the shackles.

Refer to SOUNDVISION for the number and position of the shackles.

Lift the assembly so you can position a block of four K2 under it.

Attach the block of four K2 to the K2-BUMP

Refer to PROCEDURE E.

Verify that the rear rigging arms are secured by pins and that no yellow

label is visible on the front.

Lift the assembly so you can position a block of four K2 under it.

Verify that no yellow label is visible on both sides of the array.

Attach the block of four K2 enclosures to the bottom of the array.

Refer to PROCEDURE F.

Verify that the rigging arms at the back are secured by pins and that no

yellow label is visible on the front.

Repeat the last two steps until the array is complete.

Raise the array to its final trim height.

Adjust site and azimuth angles.

K2 WST

K2_RM_EN_1 .0

w w w . l -a c o us t i cs .c o m

16 / 52

Final check

After the setup, always verify no yellow labels are visible on the front and on both sides of the array.

When using two K2-BAR, do not implement a bridle between the bars. Always use at least two motors. Refer

to APPENDIX A: PICKUP POINTS GUIDELINES.

Before setup, choose a flying option

Refer to SOUNDVISION modeling and to 3.3 Elements for flying (p. 2).

K2 enclosures under K1-SB

K1-SB array setup

Refer to your SOUNDVISION model to define which flying frame to use.

If you are using the K1-BUMP:

Refer to the K1 rigging manual to set up the K1-SB part of the array.

Or if you are using the K2-BUMP:

Place an open a K2-BUMPFLIGHT under the motor.

If necessary, attach one or two K2-BAR to the K2-BUMP.

Refer to PROCEDURE D.

If necessary, stack one or two LA-RAK on the K2-BUMP.

Refer to PROCEDURE I.

Refer to APPENDIX A: when stacking only one LA-RAK.

Attach the shackles.

Refer to SOUNDVISION for the number and position of the shackles.

Lift the assembly so you can position a block of K1-SB under it.

Attach the K1-SB block to the K2-BUMP.

Refer to PROCEDURE H.

Repeat the last two steps until the K1-SB array is complete.

K2 array setup

Prepare all the blocks of 4 K2 necessary to build the array

If a block is not built already, refer to PROCEDURE A.

Preset the inter-enclosures angles.

Refer to PROCEDURE B.

K1-SB and K2 arrays connection

Lift the K1-SB array so you can position a block of four K2 under it.

Using two K2-LINK interfaces, attach the block of K2 under the K1-SB array.

Refer to PROCEDURE G.

Verify that the rear rigging arms are secured by pins and that no yellow label is

visible on the front.

Lift the array so you can position a block of four K2 under it.

Verify that no yellow label is visible on both sides of the array.

Attach the block of four K2 to the bottom enclosure of the array.

Refer to PROCEDURE F.

Verify that the rear rigging arms are secured by pins and that no yellow label is

visible on the front.

Repeat the last two steps until the array is complete.

Raise the array to its final trim height.

Adjust site and azimuth angles.

®

enclosure

RIGGING MANUAL

VERSION 1.0

Loading...

Loading...