La Cornue Grand-Papa 135, GM2-EE 123, GM2-GE 120, GM2-EE 173, GM2-EE 120 Installation Manual

...Page 1

1

Dear Customer,

Thank you for purchasing a La Cornue cooker. We hope that you will really enjoy

preparing delicious meals with it.

The aim of this installation guide is to familiarise you with the potential of a

professional quality appliance designed for domestic use and to facilitate its upkeep.

Above all, a La Cornue cooker is manufactured from noble and pure materials. The

specific choices for certain components, such as brass for the burners and cast-iron for

the hotplate, correspond to technicality and professional performance requirements

which are not attainable with other materials or protective treatments. We are very

much attached to the authenticity of our cookers and we are convinced that you will

appreciate them even more as you use them.

We recommend you follow the advice provided in the “Instructions for Use” brochure;

this will ensure that you are satisfied with your cooker for a long time.

Thank you for placing your trust in us.

Xavier Dupuy

President and Managing Director

Page 2

2

©2007 - LA CORNUE – Installation Guide for Europe - “Cornuchef” Range.

Novemeber 2007 - A.K.

Page 3

3

Installation Guide - “Cornuchef” Range

WARNING

T

his appliance must be installed by a qualified professional in accordance with the

current regulations in the country where the appliance is installed and must only be

used in a well ventilated area. Read the guides before installing and using this

appliance.

Appliance categories (see pt. 1.2, page 14 “Installation”):

- Class 1: Free-standing cooking appliance not normally in direct contact with the kitchen

units or the surrounding walls.

-Class 2: Cooking appliance that can be integrated between two kitchen units, whose walls

can be in direct contact with the surrounding units. This type of appliance can be in

contact with only one kitchen unit during installation.

- Class 2 / Sub-Class 1: Class 2 appliance that can be free-standing or installed so that the

side panels are accessible.

Before installing the appliance, ensure that the local gas supply conditions (gas type and

pressure) and the adjustment of the appliance are compatible.

The adjustment conditions for this appliance are indicated on the label at the back of the

hob and on the test certificate.

This appliance is not intended to be connected to a ventilation system or a ventilation shaft

for combustion products. It should be installed and connected in accordance with the

current regulations, and special attention should be paid to the applicable ventilation

regulations.

The use of a gas cooking appliance results in the production of heat and moisture in the

room where it is installed. Ensure that the room is well ventilated: keep natural ventilation

holes open or install a mechanical ventilation device (mechanical extractor hood).

Prolonged or intensive use of the appliance may call for additional ventilation, e.g. by

opening a window, or for more effective ventilation, by increasing the power of the

mechanical ventilation system installed.

The parts that are protected by the manufacturer must not be manipulated by the installer

or the user.

Please note:

The accessible parts may be hot when the oven is being used: keep young children at a safe

distance.

All of our cooking appliance belong to Class 1 and Class 2 / Sub-Class 1 and are designed for domestic use

only. They meet the requirements of the 90/396/CEE European Directive (“Gas Appliances”) and the

72/73/CEE European Directive (“Low Voltage Directive”), both amended by the 93/68/CEE Directive.

Page 4

4

Installation Guide - “Cornuchef” Range

WARNING ..................................................................................................... 3

DESCRIPTION ............................................................................................... 5

1. General description ................................................................................... 5

2. Hob configurations .................................................................................... 6

3. Energy power and gas flow rates .............................................................. 7

4. Power ratings for the electrical elements ............................................... 7

COOKER “GRAND - MAMAN 90” ................................................................. 8

1. Dimensions ................................................................................................. 8

2. Connections ................................................................................................ 8

3. Energy power ............................................................................................. 9

COOKER “GRAND - PAPA 135” .................................................................... 10

1. Dimensions ................................................................................................10

2. Connections .............................................................................................. 10

3. Energy power ............................................................................................ 11

HOBS ............................................................................................................ 12

1. Dimensions hob “Grand-Maman 90” ....................................................... 12

2. Connections hob “Grand-Maman 90” ....................................................... 12

3. Dimensions hob “Grand-Papa 135” .......................................................... 12

4. Connections hob “Grand-Papa 135” ......................................................... 13

5. Energy power hobs “Grand-Maman 90” and “Grand-Papa 135” .............13

BEFORE DELIVERY ..................................................................................... 14

1. Safety requirements ................................................................................. 14

2. Electrical supply ....................................................................................... 15

3. Gas supply ................................................................................................ 16

4. Installation ............................................................................................... 16

CONNECTIONS ............................................................................................ 17

1. Electrical connections .............................................................................. 17

2. Gas connection ........................................................................................ 18

IGNITION - ADJUSTMENTS ........................................................................ 19

1. Starting the appliance .............................................................................. 19

2. Replacing the oven light .......................................................................... 23

3. Changing the injectors ............................................................................. 24

4. Adjusting the low settings ........................................................................25

5. Injectors table ........................................................................................... 26

WARRANTY ................................................................................................. 27

CONTENTS

Page 5

5

Installation Guide - “Cornuchef” Range

DESCRIPTION General description

DESCRIPTION

1. GENERAL DESCRIPTION

The range of "CORNUCHEF" cooking appliances consists of 4 models:

- Cooker “Grand-Maman 90” (model GM2, width: 90cm).

- Cooker “Grand-Papa 135” (model GP2, width: 135cm).

- Hob “Grand-Maman 90” (model TM2, width: 90cm).

- Hob “Grand-Papa 135” (model TP2, width: 135cm).

Each of the cooker or hot top models includes several sub-models, depending on the chosen hot top and its combination with the oven.

The cookers in the "CORNUCHEF" range consist of:

- a thermostatically-controlled electric or gas oven;

- one hot top bounded at the rear by a stainless steel skirting creating a gap between the

cooker and the wall, thus ensuring the removal of burnt gases and smells.

The "Grand-Papa" stove is equipped with a 45 cm wide electric steam oven, located to the

right of the oven, which is used to warm plates.

Page 6

DESCRIPTION

6

Installation Guide - “Cornuchef” Range

Hob configurations

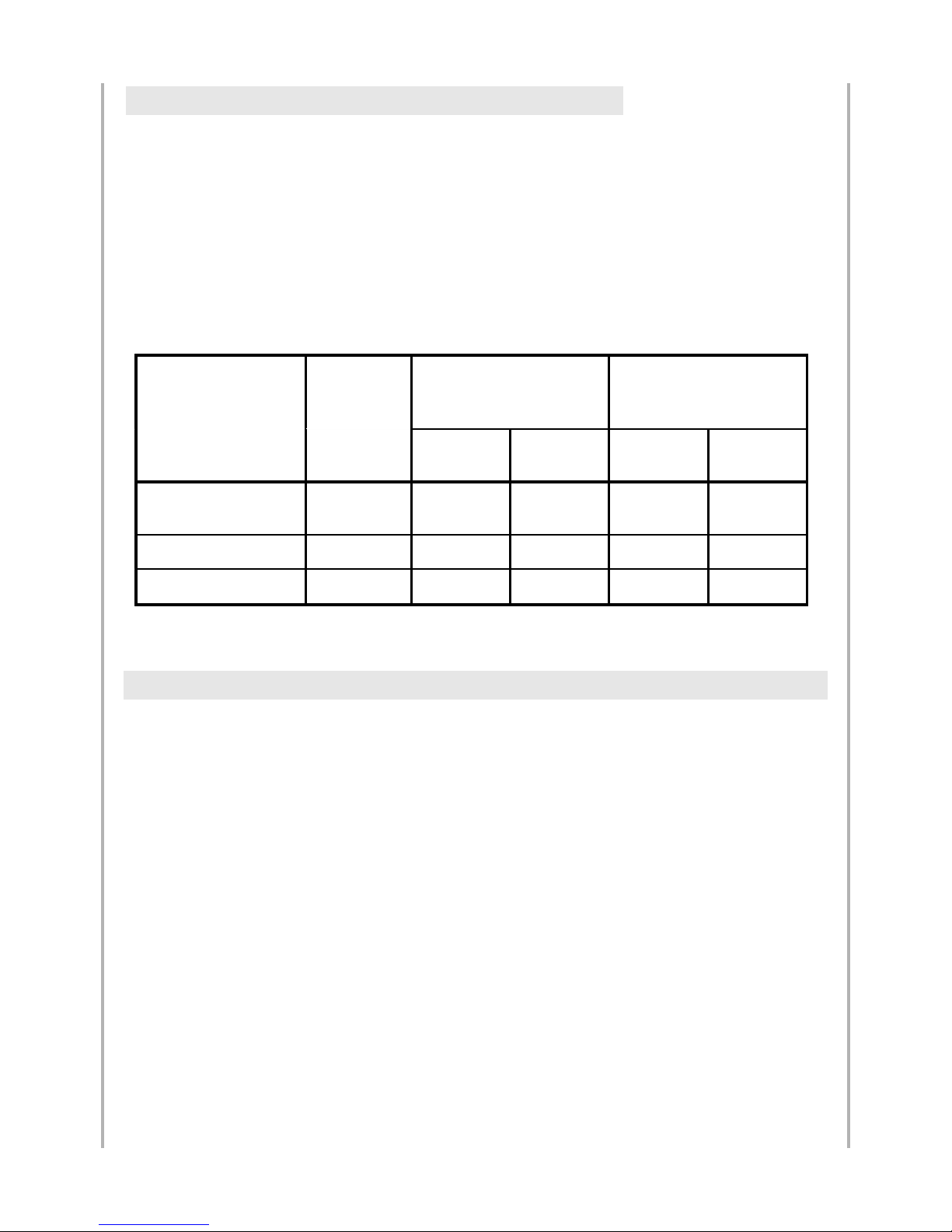

2. HOB CONFIGURATIONS

2 gas burners (small burner at the rear)

1 single gas burner

2 gas burners

2 gas burners (small burner at the rear)

1 gas hotplate

2 gas burners

2 gas burners (small burner at the rear)

1 single gas burner

2 electric ceramic plates

2 gas burners (small burner at the rear)

1 single gas burner

2 electric induction plates

2 gas burners (small burner at the rear)

1 gas hotplate

2 electric ceramic plates

2 gas burners (small burner at the rear)

1 gas hotplate

2 electric induction plates

2 electric ceramic plates

1 electric hotplate

2 electric ceramic plates

2 electric induction plates

1 electric hotplate

2 electric induction plates

123

124

2 gas burners (small burner at the rear)

1 single gas burner

1 small electric teppan-yaki

120

174

129

173

179

989

484

ALL GAS

MIXED (GAS AND ELECTRIC)

ALL ELECTRIC

2 electric ceramic plates

1 small electric teppan-yaki

2 electric ceramic plates

2 electric induction plates

1 small electric teppan-yaki

2 electric induction plates

909

404

ALL ELECTRIC WITH TEPPAN-YAKI

Page 7

7

Installation Guide - “Cornuchef” Range

DESCRIPTION Energy power

All of our appliances belong to Category II and are designed for gases from the second and

third groups.

The gas used can be either natural gas, propane or butane, depending on availability. Refer

to pages 24 – 26 for information about adapting your cooker or your hob to the various

types of gas.

The tables below summarise for each gas type and for each burner the heat flow rate

(energy power in kW, Maximum Heat Power) and the volume flow rate (in m3/hour) or

the mass flow rate (in kg/hour) of useful gas.

Large vaulted electric oven (74/84 litres, large volume) ......................................... 6 000 W

3 500 W oven floor + 2 500 W vault

Grill in large vaulted gas oven ..............................................................................… 2 500 W

Baking stone ............................................................................................................ 3 000 W

Oven light ..................................................................................................................... 25 W

Ignition for small and large vaulted gas ovens .............................................................. 25 W

Automatic ignition for gas burners ............................................................................... 25 W

Warming cupboard, width: 450 mm ....................................................................… 1 750 W

Electric ceramic hob, Ø 145 mm .............................................................................. 1 200 W

Electric ceramic hob, Ø 195 mm (2 zones) .............................................................. 1 800 W

Round electric plate, Ø 180 mm .............................................................................. 2 000 W

Round electric plate, Ø 220 mm .............................................................................. 2 000 W

Electric hotplate ..........……………………………..................................................... 1 300 W

(small, dimensions: 284 x 476 mm)

Small “La Cornue” Teppan-Yaki .................................................….......................... 1 600 W

Induction plates (2 burners) ................................................................................… 3 600 W

3. ENERGY POWER AND GAS FLOW RATES

4. POWER RATINGS FOR THE ELECTRICAL ELEMENTS

Burner

Nominal heat

flow

Volume flow rate (m

3

/ hour)

Mass flow rate (kg / hour)

(Maximum

Heat Power in

kW)

Natural Gas

G20, 20 mbar

Natural Gas

G25 20 mbar

Propane

G31 37 mbar

Butane

G30 29 mbar

Gas hobs:

- large burner

- small burner

3

1,7

0,29

0,16

0,33

0,19

0,21

0,12

0,22

0,12

Hotplate

3

0,29

0,33

0,21

0,22

Large vaulted gas oven

(74/84 l)

6,5

0,62

0,72

0,46

0,47

Page 8

8

Installation Guide - “Cornuchef” Range

Dimensions, connections GRAND-MAMAN 90

Mixed gas/electric cooker

All-electric cooker

2. COOKER CONNECTIONS

GRAND - MAMAN 90

220 480 200

900

950

80

575

40

50

900

40

50

650

140

140

200

200

100

100

125

125

140

140

Rear view

200

200

Rear view

CABLE 2

CABLE 1

CABLE 1

1. C

OOKER DIMENSIONS

TERMINAL

BLOCK 1

TERMINAL

BLOCK 2

CABLE 2 & 3

TERMINAL

BLOCK 1

TERMINAL

BLOCK 2 & 3

GAS INLET

MALE G 1/2 CONNECTION

GAS INLET

MALE G 1/2 CONNECTION

Cooker weight: 110 - 150 kg. depending on the model

Page 9

9

Installation Guide - “Cornuchef” Range

GRAND-MAMAN 90 Gas and electric Power

GRAND - MAMAN 90

3. POWER FOR GAS AND ELECTRIC COOKERS

Page 10

10

Installation Guide - “Cornuchef” Range

Dimensions, connections GRAND-PAPA 135

Mixed gas/electric cooker

All-electric cooker

2. COOKER CONNECTIONS

GRAND - PAPA 135

1350

480

200

220

Cooker weight: 180 - 220 kg. depending on the model

950

80

575

40

50

900

40

50

650

140

140

200

200

100

100

125

125

140

140

Rear view

200

200

Rear view

CABLE 2

CABLE 1

CABLE 1

GAS INLET

MALE G 1/2

CONNECTION

1. C

OOKER DIMENSIONS

TERMINAL

BLOCK 1

TERMINAL

BLOCK 2

CABLE 2 & 3

TERMINAL

BLOCK 1

TERMINAL

BLOCK 2 & 3

GAS INLET

MALE G 1/2 CONNECTION

Page 11

11

Installation Guide - “Cornuchef” Range

GRAND-PAPA 135 Gas and electric Power

GRAND - PAPA 135

3. POWER FOR GAS AND ELECTRIC COOKERS

* PLEASE NOTE: For 2 cables and a 400 V a.c. 3N power supply (3 Ph + N + T)

- 1 cable is 400 V a.c., 3-PHASE

- 1 cable is 230 V a.c., SINGLE-PHASE

Page 12

12

Installation Guide - “Cornuchef” Range

Dimensions, connections HOBS 90 & 135

Mixed gas/electric hob

All-electric hob

2. HOB

“GRAND

-MAMAN 90” CONNECTIONS

HOBS 90 & 135

250

200

40

650

50

Rear view

Rear view

CABLE 2

CABLE 1

CABLE 1

GAS INLET

MALE G 1/2 CONNEC-

TION

1. H

OB “GRAND

-MAMAN 90” DIMENSIONS

TERMINAL

BLOCK 1

TERMINAL

BLOCK 2

TERMINAL

BLOCK 1

GAS INLET

MALE G 1/2 CONNECTION

200

900

Hob weight: 70 - 90kg. depending on the model

250

200

40

650

50

3. HOB “GRAND-PAPA 135” DIMENSIONS

1350

200

Hob weight: 80 - 100kg. depending on the model

Page 13

Mixed gas/electric hob

All-electric hob

13

Installation Guide - “Cornuchef” Range

HOBS 90 & 135

HOBS 90 & 135

TT--22----00EE 112233 1133,,77 11,,3322 11,,5511 00,,9966 11 2255 11

0,1 0,5 _ _ _

TT--22----00EE 117733 1133,,77 11,,3322 11,,5511 00,,9966 11 2255 11

0,1 0,5 _ _ _

TT--22----00EE 112200 77,,77 00,,7744 00,,8855 00,,5544 00,,5566 11662255 11

71___

TT--22----00EE 112244 77,,77 00,,7744 00,,8855 00,,5544 00,,5566 33002255 11

13,5 1,5 _ _ _

TT--22----00EE 112299 77,,77 00,,7744 00,,8855 00,,5544 00,,5566 33662255 11

16 1,5 _ _ _

TT--22----00EE 117744 77,,77 00,,7744 00,,8855 00,,5544 00,,5566 33002255 11

13,5 1,5 _ _ _

TT--22----00EE 117799 77,,77 00,,7744 00,,8855 00,,5544 00,,5566 33662255 11

16 1,5 _ _ _

TT--22----00EE 448844 00 00 00 00 00 77330000 11

32 4 1 13 1,5

TT--22----00EE 998899 00 00 00 00 00 88550000 22

21,5 2,5 / 1,5 1 16 1,5

TT--22----00EE 440044 00 00 00 00 00 77660000 22

20 2,5 / 1,5 1 13 1,5

TT--22----00EE 990099 00 00 00 00 00 88880000 22

23 2,5 / 1,5 1 16 1,5

Propane Gas

G31 - 37

mbar

GGAASS SSUUPPPPLLYY

IINNFFOORRMMAATTIIOONN

Butane Gas

G30 - 29

mbar

Mass Flow

Rate

k g/hour

Volume F low

Rate

m3/hour

MMoo ddeell

HHEEAATT FFLL OOWW

kkWW MMHHPP

Natural gas

G20 - 20

mbar

Natural gas

G25 - 20

mbar

Current

(A)

EELLEECCTTRRIICC SSUUPPPPLLYY IINNFFOORRMMAATTIIOONN

Current

(A)

Nominal

cable

section

mm

2

Nominal

cable

section

mm

2

TToottaall ppoowweerr iinn

WWaattttss

Number of

cables

440000 VV aa..cc .. 33NN

ppooww eerr ssuuppppllyy

((33 PPhh ++ NN ++ TT))

Number of

cables

223300 VV aa..cc ..

ppooww eerr ssuuppppllyy

((11 PPhh ++ NN ++ TT))

4. HOB “GRAND-PAPA 135” CONNECTIONS

Rear view

Rear view

CABLE 2

CABLE 1

CABLE 1

GAS INLET

MALE G 1/2 CONNEC-

TION

TERMINAL

BLOCK 1

TERMINAL

BLOCK 2

TERMINAL

BLOCK 1

GAS INLET

MALE G 1/2 CONNECTION

Dimensions, connections

5. P

OWER FOR GAS AND ELECTRIC HOBS

Page 14

14

Installation Guide - “Cornuchef” Range

Safety requirements BEFORE DELIVERY

In order to be able to install your appliance as soon as it is delivered, you will have to check

that the layout of your kitchen and your gas and electricity supplies are ready for it.

1.1. V

entilation

It is essential that the room where the “La Cornue” cooker or hob will be installed has

excellent ventilation, i.e. to the outside for vapour and burnt gases and a fresh air inlet.

Do not use an air recycling system.

A flow rate of at least 4 cubic metres per hour of fresh air per kW of gas heat power is

necessary to ensure the supply of combustion air.

The gas regulations also require high and low ventilation to be installed in the room where

a gas appliance will be installed.

The external ventilation system must consist of fixed aerators or flipping glass panes as

well as vapour aspirators or extractor hoods.

We strongly advise you to use an extractor hood.

Recommended power:

- 700 cubic metres per hour or 10 – 15 times the volume of the air in the room

each hour.

"La Cornue" can propose you models of customized hoods in materials matching your

cooker or extractors that can be integrated into a hood manufactured by the user.

The ventilation hood has to be built with inflammable materials.

For optimum efficiency, the fresh air inlet for renewing the air extracted by the hood must

be located either directly at the back of the appliance or within a 2 – 3m. radius, at ground

level.

1.2. Installation (see following page)

As the oven and the hob are particularly well insulated, the appliance can be built-in

without any need for any special precautions with regard to the surroundings. However,

if the cooker or the hob is installed against a wall, the hottest parts (the strip between 60

and 95cm. from the floor, and the surface between the hob and the extractor hood) must

be protected with a stainless steel plate (credenza) or ceramic tiles.

Ceramic cardboard with a minimum thickness of 20mm. must be installed under

the hob to insulate the units placed underneath.

1. SAFETY REQUIREMENTS

BEFORE DELIVERY

Page 15

15

Installation Guide - “Cornuchef” Range

BEFORE DELIVERY Electrical Supply

MINIMUM DISTANCE FROM THE KITCHEN UNITS (in mm.)

Voltage: 230V a.c., single-phase + neutral + ground

400V a.c. 3N, three-phase + neutral + ground.

Safety:

The electrical supply must necessarily be grounded and must be equipped with a circuit

breaker protection compatible with the appliance’s power rating. In high-risk regions, an

additional protection against natural electrical phenomena (lightning) must be used.

Power:

It is advisable to check whether the power rating of your electrical installation provides

you with sufficient power for your model, taking into account any electrical appliances

you have already installed. Refer to the tables for each of the models for the total power

and current ratings.

Due to the power of La Cornue appliances, a simple plug and socket connection is not

recommended: the electrical connection should consist of a flexible cord without a plug,

directly connected to the circuit breaker outlet by means of a junction box with terminal

blocks, preferably of the anti-shearing type.

Only all-gas hobs with only hob burner ignition can be connected with an ordinary 3-pin

plug.

2. E

LECTRICAL S

UPPLY

300 300

0

0

0

330

450

A

A

minimum 750

recommandé 900

RECOMMENDED 900

MINIMUM 750

Page 16

16

Installation Guide - “Cornuchef” Range

Gas supply BEFORE DELIVERY

The gas installation must comply with the current regulations in the country

where the appliance will be installed.

Reminder of the main obligations with regard to gas installations:

The gas must be supplied via a rigid metallic pipe, terminated by an easily accessible

manual shutoff valve.

This valve must be positioned, taking into account that the gas inlet on the appliance is

situated:

· on the left of the cooker or the hob.

· at the level of the work area (on the bottom left) for hobs.

See the drawings on the specific presentation pages for each model for details about the

connections.

When your cooker or your hob is built-in between two kitchen units, the shut-off valve

must be accessible through an appropriate cut-out in the back of the kitchen unit.

It is forbidden to use flexible rubber hoses with a collar fastening to supply gas to gas

appliances.

When all of the work has been carried out on your gas supply network, perform a

functional test before connecting the appliance; this will ensure that no metallic burrs can

enter the appliance’s gas supply pipe and thus obstruct the burners or the gas taps.

In order to ensure that the hob is perfectly horizontal, especially on old flooring, we advise

you to install your cooker on a wooden or cement base and your hob on a perfectly

horizontal kitchen unit, the height of which will allow you to bring the hob to a level in

accordance with its environment or your own requirements.

Each cooker is equipped with adjustable feet that allow you to compensate for differences

in the floor level.

REMINDER: Ceramic cardboard with a minimum thickness of 20mm. must be

installed under the hob to insulate the units placed underneath.

4. INSTALLATION

3. GAS SUPPLY

Page 17

17

Installation Guide - “Cornuchef” Range

CONNECTIONS Electrical connections

" La Cornue " appliances are supplied with 1 – 3 flexible cords, P/N: H07 RN-F, consisting

of 3 or 5 wires, approximately 1.5m long, ready to be connected to a single-phase or 3phase + neutral power supply, depending on the indications specified on the order form

(see the table corresponding to each model for the power ratings).

All of the electricity supply circuits must be disconnected before accessing the

connection terminal boxes.

REMINDER: the appliance should be connected to the main power supply via terminal

blocks (preferably of the anti-shearing type) and not by means of simple plugs.

Insert the cable below the hot air outlets at the back of the oven, never in front of them.

Should your appliance be connected to a different type of power supply at a later date, in

some cases (please contact our technical department before) it will be possible to change

the cabling accordingly, according to the following instructions:

- Unscrew the protection plate from the back of the appliance in order to access the

connection terminal block(s) to which the various heating elements are connected (if

there are 2 supply cables on the cooker, there are also 2 connection terminal blocks).

230V – single-phase 400V – 3-phase

- For a single-phase 230V power supply, shunt the P1, P2 and P3 terminals, and

then connect the cable wires as follows:

- neutral (blue wire) to N

- the phase (red or brown wire) to P1

- the ground to T (yellow / green)

- For a 3-phase 400V power supply, remove the shunt from the P1, P2 and P3

terminals, and then connect the cable wires as follows:

- neutral (blue wire) to N

- the three other wires (red or brown) to the P1, P2 and P3 terminals.

- the ground to T (yellow / green)

Ensure that the cross-section of the electrical cables corresponds to that

indicated in the tables in the general description for each appliance

1. ELECTRICAL CONNECTIONS

CONNECTIONS

T = Ground

N = Neutral

Ph1 = Phase 1

Ph2 = Phase 2

Ph3 = Phase 3

Page 18

18

Installation Guide - “Cornuchef” Range

Gas connections CONNECTIONS

Our appliances are supplied with injectors corresponding to the type of gas supply specified

in your order (natural gas, butane or propane). These injectors should only be changed if

a different type of gas is used.

See page 26 for the table summarising the injectors to be used for each type of gas, the

country of installation and injector replacement instructions.

If no particular instructions are specified in the order, the appliance is equipped with

injectors for natural gas G20 (pressure: 20 mbar.).

The type of gas for which the appliance is equipped is indicated on a label at the back of

the hob, close to the gas supply pipe and on the test certificate supplied with the appliance.

The cooker or the hob is connected to the gas supply via a male threaded connector with

G ½ thread (previous reference: 15/21).

The previously installed shutoff valve can be connected via a rigid metallic pipe installation

or by means of certified (TFEM) flexible hoses equipped with a mechanical union.

The pipes must be fully accessible and placed so that they cannot be affected by fire or

deteriorated by the combustion gases, the hot parts of the appliances or by hot products

overflowing. They must not be crushed or kinked.

Recommended hose: certified TUBOGAZ for the gas type used.

It is forbidden to connect our gas appliances with flexible hoses mounted on hose

tailpieces.

Refer to the drawings on the description pages for each appliance type for

information about the exact location of the gas and electricity outlets on your

appliance.

If a sealing compound has to be used, we recommend using LOCTITE 542.

For appliances operating with BUTANE / PROPANE gas, use two cylinders with an

automatic reversing switch or an outdoor tank, and a standard pressure reducing valve

adapted to your model’s total flow rate (see tables on pages 9 – 36) and the pressure of the

gas used.

We advise you to use a pressure reducing valve with a minimum of 2 kg/hour for the hobs

and a pressure reducing valve with a minimum of 3kg/hour for the cookers.

As a general rule, an additional safety margin corresponding to 20 – 30% of the appliance’s

maximum flow rate has to be respected.

The pressure reducing valve should be placed more than 2 m. from the appliance to

guarantee constant pressure from the gas supply.

2. GAS CONNECTION

Page 19

19

Installation Guide - “Cornuchef” Range

IGNITION – ADJUSTMENTS Starting the appliance

The gas burners on our “Cornuchef” range appliances are fitted with safety thermocouples:

if a burner shuts off for any reason, the gas supply for that burner is automatically stopped.

1.1. Gas bur

ners with electric ignition

All of our appliances are originally equipped with automatic gas burner

ignition.

To ignite a gas burner, press the control knob and turn it to the left to

the “high flame” position.

The burner is automatically ignited. Keep the knob pressed for 5 – 10

seconds (the safety thermocouple may take longer to react the first

time).

The sparking noise means that the ignition system is operating

normally.

· Low setting: this is achieved by rotating the knob fully to the left or to the bottom.

· Shutoff: bring the knob back to its vertical position by rotating it to the right.

1.2. Hotplate with electric ignition

Ignition identical to that for gas burners.

Gas hotplate

INITIAL IGNITION

Defuse any trapped air from the gas network, starting with each of the burners on

the cooktop. Once this is done, the gas oven can then be ignited. However, if the

safety device for the oven is activated (red indicator ON), press the reset button

above the red indicator to repeat the procedure.

1. STARTING THE APPLIANCE

IGNITION – ADJUSTMENTS

Page 20

20

Installation Guide - “Cornuchef” Range

Starting the appliance IGNITION – ADJUSTMENTS

1.3. Round ceramic plates

To heat a ceramic plate with a single burner (diameter: 145

mm.), turn the knob towards the right or towards the left to

the desired position:

- 1 corresponds to the lowest position,

- 6 corresponds to the highest position,

- 0 corresponds to the shutoff position.

To heat the central burner of a ceramic plate with a double

burner and 2 zones (diameter: 195 mm.), you just have to

rotate the double-circuit simmerstat clockwise.

To ignite the 2 (outer and central) burners, turn the knob towards the right to the sign oo

(see the figure shown opposite) until you hear a click from the microswitch that will light

the peripheral element.

The two burners reach the maximum temperature in this position. You can then set the

temperature of the double burner by turning the control knob to any position between 6

and 1.

Note: it is impossible to only ignite the outer burner.

Please note: if the surface is cracked/fractured, immediately disconnect the appliance or the relevant

part of the supply.

1.4. Induction plates

The 180 mm or 210 mm cooking zone adapts itself and

automatically recognizes the diameter of the pan used (120

- 250 mm) and therefore evenly distributes the heat in the

pan, thus ensuring that all of the food is cooked at the same

temperature.

Your hob’s heat settings range from 200 - 2 400 Watts for the small

burner (180 mm diameter) or

200 - 2 800 Watts for the large burner (210 mm diameter).

The maximum power for the two burners is 3 600 Watts.

You can set the power for the front burner or the back burner by turning the control knob

to the positions 1 – 6.

To stop your hob, turn the knob to the position 0 and the indicator light will then turn off.

The indicator lights provide two types of information:

1. Normal operation

When the generator is working properly, the indicator light is always on. The indicator

light flashes when not enough power can be generated. When the two indicator lights are

on, the generator is providing the two inductors with the required power.

2. Dysfunction

If the indicator light blinks as soon as the burner is turned on, that means that there is no

pan on the burner or that the pan is not suitable for an induction hob.

Please note: if the surface is cracked/fractured, immediately disconnect the appliance or the relevant

part of the supply.

0

3

1

2

4

5

6

0

3

1

2

4

5

6

single burner

double burner

0

3

1

2

4

5

6

Page 21

21

Installation Guide - “Cornuchef” Range

IGNITION – ADJUSTMENTS Starting the appliance

1.5. Electric hotplate

To heat the electric hotplate, turn the control knob towards the right

or towards the left to the desired position:

- 1, corresponds to the lowest power,

- 6, corresponds to the highest power,

- 0, corresponds to the shutoff position.

1.6. Electric T

eppan-Yaki (Japanese grill)

- Small model: 284 x 478 mm, power: 1 600 W

- Large model: 419 x 478 mm, power: 2 200 W

The electric Teppan-Yaki is equipped with thermostatcontrolled heating elements; the control knob allows you to

adjust the temperature from 50°C (position 1) to 250°C

(position 6).

Turn the thermostat knob to the desired temperature; the

green light indicates that the appliance is heating.

The green indicator light is turned off when the desired temperature

is reached; you can then add the food that you want to grill.

After use, return the thermostat knob to the position “0” (shutoff)

1.7. Round electric plates (option in r

eplacement of the ceramic plates)

Depending on the model, your cooking appliance may be equipped

with one or two groups of two electric round plates – one with a

diameter of 18cm. and the other with a diameter of 22cm., with a

maximum power of 2 000 W each.

To heat an electric plate, press on the corresponding control

knob and turn it towards the right to the desired position:

- 1, corresponds to the lowest temperature,

- 3, corresponds to the highest temperature,

- 0, corresponds to the shutoff position.

1.8. Gas oven with electr

onic ignition

The simmerstat (C) switches on the heating element on the vault of the

oven (grill), the thermostat (B) switches on the gas ramp.

The simmerstat and the thermostat are both equipped with indicator lights.

Oven ignition:

Turn the oven thermostat (B) to the desired temperature.

The electronic temperature regulation system allows you to control the

temperature entirely automatically; it is therefore entirely normal that the

flames ignites itself and turns itself off to keep the oven at the desired

temperature

0

3

1

2

4

5

6

1

2

3

0

C

B

G

Page 22

Note:

The red indicator in the bottom part of the control box indicates any operational defects

related to oven ignition. If this indicator is ON, check that the gas shutoff valve is set to the

open position and the cooker is well supplied with gas, then press the button (G) above

the indicator light.

Before using the oven for the first time or if it has not been used for a long period of time,

you have to press this button several times to defuse any trapped air from the gas circuit.

If this phenomenon persists, contact our after-sales department or your dealer.

1.9. Electric oven

The simmerstat (C) activates the heating element in the vault of the

oven (grill); the thermostat (B) activates the heating element under the

oven floor. The simmerstat and the thermostat are both equipped with

an indicator light.

Oven ignition:

- Position the selector switch (D) on the “oven floor” position (in

bottom).

- Then turn the oven thermostat (B) to the desired temperature and the

simmerstat to the corresponding preheating power.

- After preheating (between 15 and 20 minutes depending on the

temperature required), set the cooking mode for the food to be cooked.

- You can then place your food in the oven.

Caution: The lever of the selector switch (D) can be positioned in bottom or top. The position "oven

floor" is in bottom, the position "baking stone" is in top. If you do not have the option "baking stone"

in your electric oven, never position the lever of the selector switch in top.

1.10. Grill Function (gas and electric ovens)

Your oven is equipped with an electric grill controlled separately from the heating element

on the oven floor.

- Position the simmerstat (C) on the desired power setting.

- After preheating (between 5 and 10 minutes depending on the temperature), set the

cooking mode for the food to be cooked.

- You can then place in the grill the food that requires grilling.

When using the “grill” function, you should leave the oven door ajar and pull the

hob drip tray towards the front as far as the (F) mark.

In this position, the oven light is on to allow you to keep an eye on the food cooking.

22

Installation Guide - “Cornuchef” Range

Starting the appliance IGNITION – ADJUSTMENTS

baking stone

oven floor

C

B

D

Page 23

23

Installation Guide - “Cornuchef” Range

IGNITION – ADJUSTMENTS Starting the appliance

1.11. Baking stone function (option for electric ovens)

The “baking stone” option

consists of:

a refractory stone, a 3000W

electric heating element and

a stainless steel bread spatula.

To start using your “baking

stone”, you must follow

these instructions:

- Remove the cover from the

baking stone heating element

plug (at the back of the

oven).

- Attach the heating element

by inserting it into the

corresponding plug.

- Place the “shelf” grill in the

centre of the oven (2nd level) and then place the baking stone on the grill.

- Position the selector switch (D) to the “baking stone” position (in top) and the thermostat

(B) to the desired temperature.

- After preheating (between 10 and 15 minutes depending on the desired temperature),

you can then place your food to cook in the oven.

The baking stone can also be preheated by setting the selector switch (D) to the “oven floor” position

(in bottom) and the thermostat (B) to about 220°C. After preheating (between 15 and 20 minutes),

position the selector switch to the “baking stone” position in top and place the food to cook in the oven.

After cooking on the baking stone, leave it in the oven to cool down. Then, remove the

stone and the heating element from the oven, and replace the plug cover on the plug at

the back of the oven.

The light is located on the side at the top of the oven; it is

automatically switched on when the oven door is opened.

Please note: disconnect your oven before interfering with

the light to prevent any risk of an electrical shock and to

allow the appliance to cool down (if necessary).

Remove the protection glass and then unscrew the

damaged light.

Refit a new light and the protection glass.

2. REPLACING THE OVEN LIGHT

cover

plug

stone

heating

element

Grill on the

2nd level

Page 24

IGNITION – ADJUSTMENTSOven light - Injectors

24

Installation Guide - “Cornuchef” Range

Technical characteristics of the light:

- 25W - 230V - 240V

- 300°C - E14 base

The part numbers of the injectors for the various burners and the gas oven (see their

locations on the photographs below) differ depending on the type of gas used and the

country of installation.

The injectors of gas burner and hotplate are replaced according to the following sequence:

1. Remove the brisk heat grill, then the pan.

2. Remove the cap of the burner.

3. Unscrew the injector from the top using a standard 7 mm box spanner. Install the new

injector and screw it down completely.

4. Place the cap of the burner taking care to place it correctly on the body of the burner.

5. Place the pan, then the grill or the fire plate.

Injector for gas oven

3. CHANGING THE INJECTORS

Injector

Burner cap

GAS BURNER AND HOTPLATE

1

2

Page 25

25

Installation Guide - “Cornuchef” Range

InjectorsIGNITION – ADJUSTMENTS

The injectors for gas oven are always replaced in the following sequence:

1- Screw the adjusting cone (2) and insert it into the mixing tube in order to free

sufficient space for unscrewing the injector.

2- Unscrew the injector (1) with a 7mm flat wrench.

3- Install the injector (1) corresponding to the new type of gas and tighten it.

4- Ignite the burner and adjust the air inlet (see the table opposite for the primary

air adjustment) by screwing or unscrewing the adjusting cone (2) until you obtain a

slightly blue flame showing no separation; separation of the flame is an indication that

there is too much air.

5- Then block the adjusting cone (2) with the blocking washer.

Once you have changed the injectors, it is a good idea to adjust the low settings for the

hob burners (see Section 4).

Only the low settings for the gas hob burners and the hotplate can be adjusted with the

following procedure:

1. Remove the control knobs by unscrewing the screw that keeps them in position;

2. Remove the cock cover by using a screwdriver as a lever: the cover is clipped on to the

hob;

3. Re-install the control knob of the burner that you want to adjust; ignite the burner, then

rotate the knob to "low" setting;

4. After removing the control knob again, rotate the split screw on the cock body with a

screwdriver, to the left to increase the flow rate, to the right to reduce it. Make sure that

the resulting flame at the lowest setting is sufficiently strong to heat the

thermocouple.

5. Re-install the knob to turn the burner off;

6. In case of gas change, it can be necessary to replace the reduced flow adjustment screw

(by-pass) by a different reference screw (see table page 26).

7. Re-install the cover and the control knobs by screwing the appropriate screws.

Once the appliance has been adapted to a different type of gas or to a pressure

other than those for which it was previously set, the new settings will have to be

indicated in place of the previous settings, and a new gas information label will

be supplied with the new injectors.

Any sealing will have to be replaced.

4. ADJUSTING THE LOW SETTINGS

Page 26

26

Installation Guide - “Cornuchef” Range

Injectors IGNITION – ADJUSTMENTS

All the adjustments and replacement of injectors or bypass screws must be

carried out by a qualified professional.

The part numbers of the injectors for the various hot top burners (see locations on the

diagram page 24) differ, depending on the type of gas and country of installation.

The following table defines which injector, bypass screw and burner cap should be used if

the type of gas is changed or if you move.

5. INJECTORS TABLE

AT, CH, DK,

ES, FI, GB,

GR, IE, IT,

PT, SE

40

“Flat”

Matt black

NATURAL

II

NNJJEECCTTOORRSS

((mmaarrkkiinnggss))

BByyppaassss rreedduu--

cceedd ffllooww aaddjjuusstt--

mmeenntt ssccrreeww

BBuurrnneerr

ccaapp

Legend

Burners: P.BR. - small burner ( 65.7 mm), G.BR. - large burner ( 94.8 mm)

Countr

y:

142

200

4

Country

Gas

Category

index

Type of

gas

G20 20 LU

108

P.BR. G.BR

Oven

P.BR. G.BR.

32

40138

210

4

200

4

109 32

G20 / G25

2E

G25 25 NL2L

Pressiure

(mbar)

Primary air

adjustment of

the oven (mm)

20 / 25 BE, FR2E+

G20 202H

“Flat”

Matt black

40142108 32

G20 20 DE

34151

230 4

117 25

20 DE

2ELL

G25

BE, CH, ES,

FR, GB, GR,

IE, IT, PT

4092

125 4

71 32

G30/G31 28-30/373+

DK, FI, NL,

NO, SE

4092

125 4

71 32

G30 303B/P

AT, CH, DE,

LU

34

“Flat”

Matt black

BUTANE - PROPANE

80

110

2

63 25

G30 503B/P

AT: Austria

DE: Germany

FI: Finland

GR: Greece

LU: Luxembourg

PT: Portugal

BE: Belgium

DK: Denmark

FR: France

IE: Ireland

NL: Netherlands

SE: Sweden

CH: Switzerland

ES: Spain

GB: United Kingdom

IT: Italy

NO: Norway

Page 27

27

Installation Guide - “Cornuchef” Range

Following receipt of full payment for our

goods, our appliances are guaranteed for

three years from the invoice date against

any structural faults and any material

defects. This warranty excludes improper

use of the appliance or a non-compliant

installation. Intervention and travel costs

will be billed in this event.

If our goods were to dysfunction, the

buyer then has to contact us once he has

ensured that it is not due to a noncompliant installation or abnormal use

in order to decide with us how the

appliance should be repaired. The

appliance should be cleaned and clean

prior to any intervention.

Any complaints with regard to the state,

the presentation, the non-compliance of

our goods should be addressed to our

headquarters by recommended letter

within a maximum of eight days

following delivery.

The application of the warranty will be

subject to LA CORNUE SA receiving a

certificate stating that the material has

been installed by a professional in

accordance with the current technical

and safety standards.

Under this warranty, the seller shall

replace at no cost the parts recognized as

faulty by its technical department. This

warranty covers all labour costs with the

exception of freight charges.

The warranty period specified above

shall not be extended if faulty parts need

to be replaced.

This warranty shall cease to apply

- if the operational defect is the result of

an unauthorized intervention on the

appliance;

- if the faulty operation is due to normal

wear and tear of the appliance or from

negligence or insufficient maintenance

by the buyer;

- if the faulty operation is due to acts of

Nature.

LA CORNUE SA shall not be held legally

responsible in these three cases.

The seller’s guarantee and his

responsibility for products shall be

limited to repairs to any defects as

stipulated in the above conditions.

As expressly agreed between the

contracting parties, the seller’s

responsibility in the event of an

operational fault shall be limited to the

above provisions, especially with regard

to concealed defects as well as material

and immaterial damage.

In all cases, the buyer may not suspend

payment if he lodges a complaint about

the quality of the goods.

WARRANTY (3 YEARS)

After-Sales Department:

- Covered by the warranty:

tel: +33 (0)1 34 48 36 15 fax: +33 (0)1 34 48 52 31

- Not covered by the warranty (appliance older than three years):

tel: +33 (0)1 47 37 56 00 fax: +33 (0)1 47 39 10 49

Page 28

28

Installation Guide - “Cornuchef” Range

HEADQUARTERS AND WORKSHOP

14, rue du Bois du Pont - Z.I. Les Béthunes

95310 SAINT OUEN L’AUMONE

POSTAL ADDRESS:

BP 99006 - 95070 Cergy Pontoise Cedex

FRANCE

Tel: +33 (0)1 34 48 36 36

Fax: +33 (0)1 34 64 32 65

www.la-cornue.com

e-mail : a.table@la-cornue.com

Loading...

Loading...