Page 1

AlberTine 36

Dual Fuel Range

AlberTine

User Guide

&

Installation & Service Instructions

U109956-13

Page 2

Page 3

WARNING!

If the information in these instructions is not followed exactly, a re or

explosion may result, causing property damage, personal injury or death.

DO NOT store or use gasoline or other ammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

DO NOT try to light any appliance.

DO NOT touch any electrical switch.

DO NOT use any phone in your building.

Follow the gas supplier’s instructions.

If you cannot reach your gas supplier, call the re department.

Installation and service must be performed by a qualied installer, service

agency or the gas supplier.

WARNING!

The anti-tip device supplied with this range must be installed when the appliance is installed. This will reduce the risk of

tipping of the appliance from abnormal usage or by excessive loading of the oven door.

WARNING!

• A CHILD OR ADULT CAN TIP THE RANGE AND BE KILLED.

• INSTALL ANTI-TIP BRACKET PACKED WITH RANGE - SEE INSTALLATION

INSTRUCTIONS.

ArtNo.030-0030 - RM tipping

warning symbols

• A CHILD OR ADULT CAN TIP THE RANGE AND BE KILLED

• ENGAGE THE RANGE TO THE ANTITIP DEVICE SEE INSTALLATION

INSTRUCTIONS.

• REENGAGE THE ANTITIP DEVICE IF THE RANGE IS MOVED.

• FAILURE TO DO SO CAN RESULT IN DEATH OR SERIOUS BURNS TO

CHILDREN OR ADULTS.

Page 4

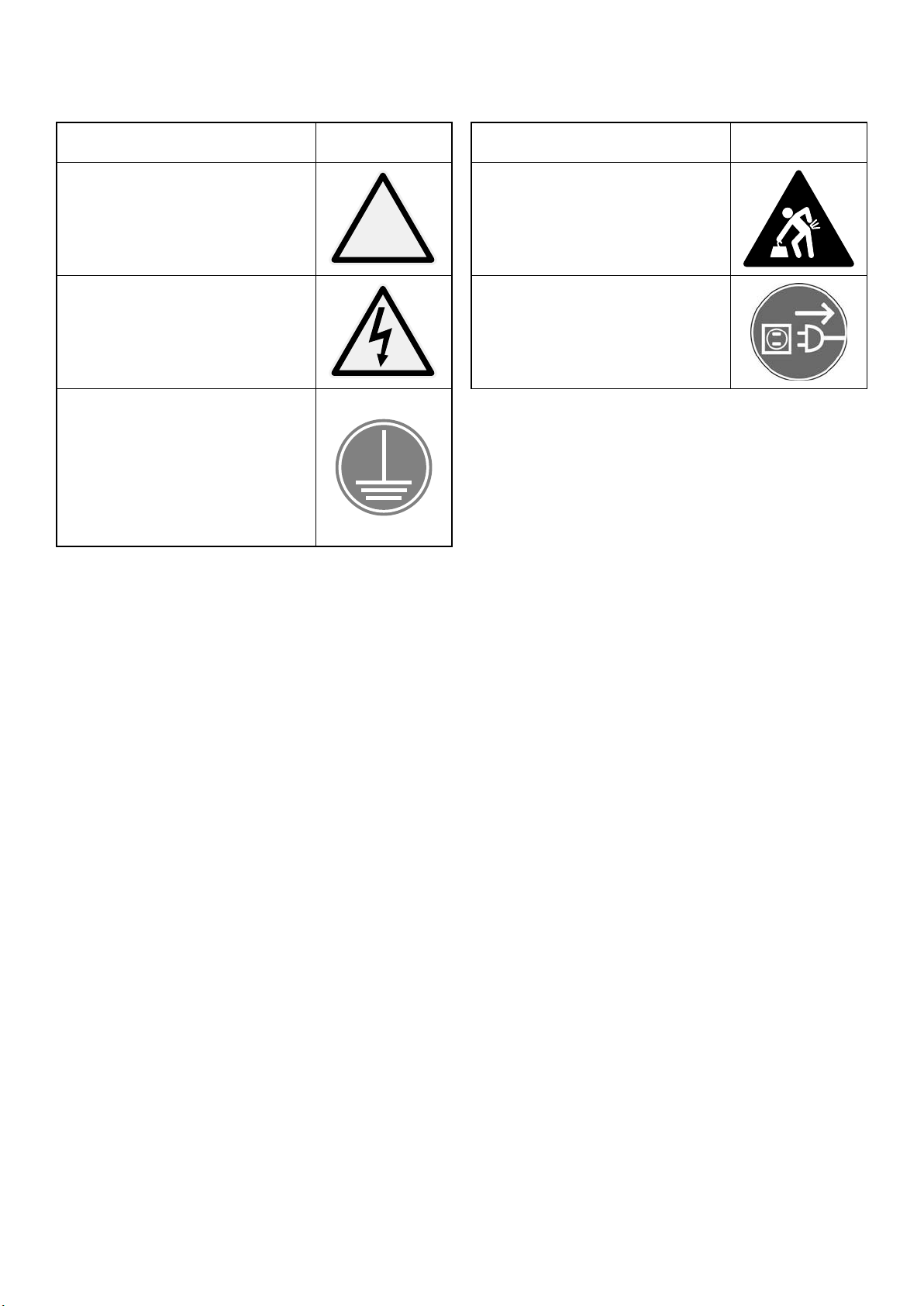

The following symbols are related to safety and are used on the product and throughout this manual.

Meaning / Description Symbol

WARNING / CAUTION

An appropriate safety instruction

should be followed or caution taken if

a potential hazard exists.

DANGEROUS VOLTAGE

To indicate hazards arising from

dangerous voltages.

PROTECTIVE EARTH GROUND

To identify any terminal which

is intended for connection to an

external conductor for protection

against electric shock in case of a

fault, or the terminal of a protective

earth (ground) electrode.

!

Meaning / Description Symbol

HEAVY

This product is heavy and reference

should be made to the safety

instructions for provisions of lifting

and moving.

DISCONNECT MAINS SUPPLY

Disconnect incoming supply before

inspection or maintenance.

Page 5

Contents

1. Important safety information 1

2. Range overview 5

Cooktop burners 5

Cleaning 6

The multifunction oven 6

Operating the oven 7

Steam 8

General oven tips 9

Accessories 9

3. Oven cooking guide 11

4. Cleaning your range 13

Essential information 13

Control panel and oven doors 14

Cleaning brass parts (some models only) 14

Ovens 14

5. Troubleshooting 15

6. Installation Instructions 17

7. Service and parts 19

8. Installation safety instructions 20

9. Installation 22

Positioning the range 24

Moving the range 25

Removing the door 25

Lowering the two rear rollers 25

Installing the ue grille 26

Leveling 26

Anti-tip device 26

Fitting the anti-tip device 26

Wall xing 26

Side panel extension kit 27

11. Gas connection 28

12. Conversion to LP Gas 30

13. Electrical connection 34

14. Final tting and checks 39

Assemble the range 39

Range operational checks 40

Customer care 40

How to move the range for servicing 40

Replacing the range 40

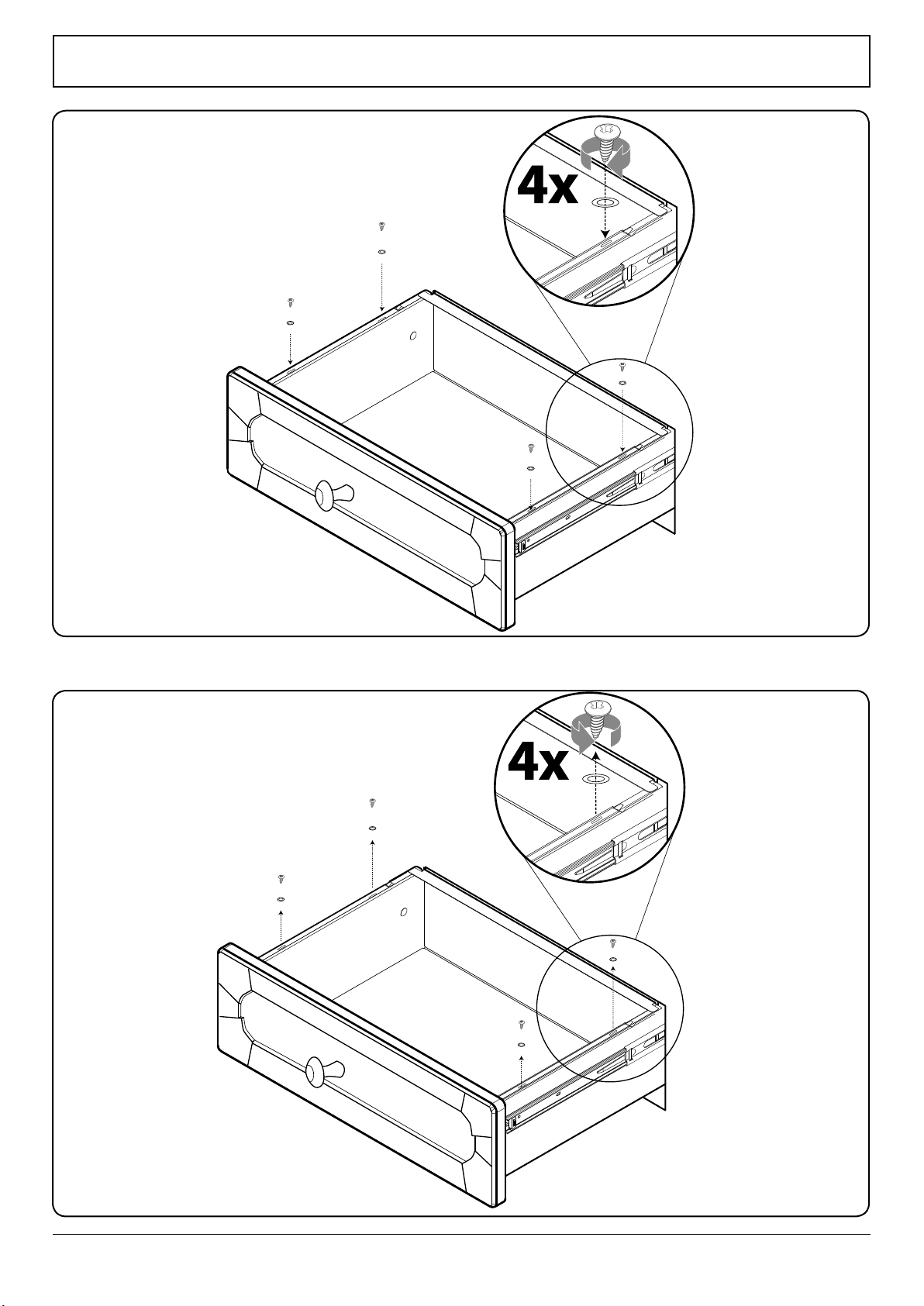

Fitting the drawer 41

Removing the drawer 41

15. Circuit diagram 42

16. Technical data 43

17. Warranty 44

Page 6

Page 7

1. Important safety information

Read all instructions before using this appliance. Save these

instructions for future reference.

Have your appliance properly installed and grounded by

a qualied technician. The installation must conform with

local codes, or in the absence of local codes, in accordance

with the National Fuel Gas Code, ANSI Z223. 1/NFPA 54 or, in

Canada, the Natural Gas and Propane Installation Code, CSA

B149. 1 and in addition the National Electrical Code NFPA 70

or the Canadian Electric Code, CSA C22. 1.

Install only as described in the installation section of this

book.

Ask your dealer to recommend a qualied technician and an

authorized repair service. Know how to disconnect the power

to the range at the circuit breaker or fuse box in case of an

emergency.

The anti-tip device supplied with this range must be installed

when the appliance is installed. This will reduce the risk of

tipping of the appliance from abnormal usage or by excessive

loading of the oven door or storage drawer.

Leaning, sitting or stepping on the doors or drawer of this

range can result in serious injuries and also cause damage to

the range. DO NOT allow anyone to climb, stand or hang on

any part of the range.

If the range is installed near a window, proper precautions

should be taken to prevent curtains from blowing over the

burners.

NEVER leave any items on the range cooktop. The

n

hot air from an oven vent may ignite ammable

items and may increase pressure in closed

containers, which may cause them to burst. Many

aerosol-type spray cans are EXPLOSIVE when

exposed to heat and may be highly ammable.

Avoid using or storing them near an appliance.

Many plastics will burn and most are damaged by heat. Keep

plastic items away from parts of the range that may become

warm or hot. DO NOT leave plastic items on the cooktop as

they may burn, melt or soften if left too close to a vent or a

lighted burner.

Storage should not be installed directly above a range. If

anything is stored above the range, it should be limited to

infrequently used items, which can be safely stored in an area

subjected to heat from a range. Temperatures may be unsafe

for some items such as volatile liquids, cleaners or aerosol

sprays.

Destroy the carton and plastic bags after unpacking the

range. NEVER allow children to play with packaging material.

Important safety notice and warning

Prior to connection, the power cord should be

n

inspected for any damage. In the event of damage

please consult your electrical installer.

You must provide adequate clearances between the

n

range and adjacent combustible surfaces. Refer to

Installation Instructions.

Save the installation instructions for the local

n

electrical inspector’s use.

In case of fire

DO NOT use water on grease res. NEVER pick

n

up a aming pan. Turn the controls o. Smother a

aming pan on a cooktop burner by covering the

pan completely with a well tting lid or baking tray.

Isolate the power source, where it is safe to do so. If

available, use a multipurpose dry chemical or foamtype re extinguisher.

If the re is in an oven pan, smother by closing the oven door.

Open doors and windows, or if a hood is installed, turn it on

to remove smoke and odor.

To prevent fire or smoke damage

Before using the range, make sure all the packing materials

have been removed.

Always keep the area around the range free from combustible

materials, gasoline, and other ammable vapors and liquids.

NEVER use this appliance as a space heater to heat

n

or warm the room. Doing so may result in carbon

monoxide poisoning and overheating of the oven.

NEVER cover any slots, holes or passages in the

n

oven bottom or cover an entire rack with materials

such as aluminum foil. Doing so blocks airow

through the oven and may cause carbon monoxide

poisoning. Aluminum foil linings may also trap heat,

causing a re hazard.

It is recommended that this appliance is serviced

n

annually by a qualied service engineer.

DO NOT repair or replace any part of the appliance

n

unless specically recommended in this User

Manual. Always consult a qualied service engineer.

All other servicing should be done only by a qualied

technician, this may reduce the risk of personal injury and

damage to the range.

NEVER modify or alter the construction of a range by

removing leveling legs, panels, wire covers, anti-tip brackets/

screws, or any other part of the product.

DO NOT leave children alone.

n

Babies, toddlers and young children should not be allowed

near the range at any time. They should NEVER be allowed to

sit or stand on any part of the appliance.

DO NOT allow children to climb or play around the range.

The weight of a child on an open door may cause the range

to tip, resulting in serious burns or other injury.

1

Page 8

Teach them not to play with controls or any other part of the

range.

NEVER store items of interest to children in the cabinets

above a range or on the backguard of a range; children

climbing on the range to reach them could be seriously

injured.

DO NOT use the oven for storage.

n

This instruction is based on safety considerations.

Flammable materials should not be stored in an oven, the

range storage drawer or near the cooktop burners. This

includes paper, plastic and cloth items, such as cookbooks,

plastic ware and towels, as well as ammable liquids. DO

NOT store explosives, such as aerosol cans, on or near the

appliance.

Flammable materials may explode and result in re or

property damage.

They might catch re if they touch a hot surface.

Use dry oven gloves when applicable – using damp gloves

might result in steam burns when you touch a hot surface.

NEVER operate the range with wet hands.

Important safety notice and

warning

The California Safe Drinking Water and Toxic Enforcement Act

of 1986 (Proposition 65) requires the Governor of California to

publish a list of substances known to the State of California to

cause cancer or reproductive harm, and requires businesses

to warn customers of potential exposures to such substances.

This appliance contains or produces a chemical or chemicals

which can cause death or serious illness and which are known

to the state of California to cause cancer, birth defects or

other reproductive harm.

To avoid the risk of electrical shock, personal injury,

n

or death, make sure your range has been properly

grounded and always disconnect it from the main

power supply before servicing.

DO NOT touch cooktop burners or areas near burners.

Gas burners may be hot even if they have been o for some

time. Areas near the gas burners may become hot enough

to cause burns. During and after use, DO NOT touch, or let

clothing touch or other ammable materials contact the

burners or areas near the burners until they have had enough

time to cool. These areas include the cooktop and rear vent.

DO NOT touch heating elements or interior surfaces

n

of ovens.

Oven heating elements may be hot though they are dark in

color. Interior surfaces of an oven may become hot enough

to cause burns. During and after use, DO NOT touch, or

let clothing or other ammable materials touch heating

elements or interior surfaces of oven until they have had

enough time to cool.

Other range surfaces that may become hot enough to cause

burns are the broiler compartment and oven vent at the rear

of the range.

Wear suitable clothing

NEVER wear loose-tting or hanging clothes while using the

range. Be careful when reaching for items stored in cabinets

over the cooktop. Flammable material could be ignited if

brought into contact with a burner ame or hot surface and

may cause severe burns.

Users of this appliance are hereby warned that the burning

of gas can result in low-level exposure to some of the listed

substances, including benzene, formaldehyde and soot, due

primarily to the incomplete combustion of natural gas or

liquid petroleum (LP) fuels. Properly adjusted burners will

minimize incomplete combustion.

Exposure to these substances can also be minimized by

properly venting with an open window or using a ventilation

fan or hood.

To reduce the risk from substances in the fuel or from fuel

combustion, make sure this appliance is installed, operated,

and maintained according to the instructions in this booklet.

Conversion

This appliance is supplied set for Natural gas. A conversion kit

for Propane gas is supplied with the range.

Be sure your range is correctly adjusted by a qualied service

technician or installer for the type of gas (Natural or LP) that is

to be used. See the Installation section of these instructions.

WARNING!

n

These adjustments must be made by a qualied

service technician in accordance with the

manufacturer’s instructions and all codes and

requirements of the authority having jurisdiction.

Failure to follow these instructions could result in

serious injury or property damage. The qualied

agency performing this work assumes responsibility

for the conversion.

User servicing

Use only dry potholders or oven

gloves

Moist or damp potholders on hot surfaces may result in

burns from steam. NEVER let a potholder touch hot heating

elements.

DO NOT use a towel or other bulky cloth in place of a glove.

DO NOT repair or replace any part of the appliance unless

specically recommended in the manual. All other servicing

should be referred to a qualied technician.

2

Page 9

Cooktop burners

Ovens

Quality of flames

On Natural Gas, the burners’ ames should be a blueish color

with, at most, a slightly yellowish fringe.

On Propane gas, the ames may be “softer”. The cooktop

burner ames may have a slightly yellowish tip.

If the ame burns with a long white tip, you should call for

service.

If the ame is distorted, check that the burner head is

correctly placed over the burner.

MAKE SURE THE FLOW OF COMBUSTION AND

n

VENTILATION AIR TO THE RANGE IS UNOBSTRUCTED.

Use the right size pan

This appliance is equipped with burners of dierent sizes.

Use utensils with at bottoms. DO NOT use unstable pans

and position the handles away from the edge of the cooktop.

Make sure the ames are under the pans. It is unsafe to let the

ames burn up the sides of the pan; the handle may get too

hot.

A proper relationship between the utensil and burner will

also improve eciency.

NEVER leave cooktop burners unattended at high

n

settings. Pans boiling over can cause smoking and

greasy spills may catch on re.

Protective Liners – DO NOT use aluminum foil to

n

line cooktop bowls or oven bottoms. Foil liners

may result in a risk of electric shock or re and will

damage the enamel nish. NEVER allow aluminum

foil to contact the heating elements.

DO NOT use hotplate protectors, foil or hotplate

n

covers of any description. These may aect the safe

use of your hotplate burners and are potentially

hazardous to health.

Glazed Cooking Utensils – Only certain types of

n

glass, glass/ceramic, ceramic, earthenware, or

other glazed utensils are suitable for range top

use without breaking due to the sudden change in

temperature.

Utensil handles should be turned inward and not

n

positioned over adjacent burners. If handles are

left over adjacent burners they will get hot and may

burn.

Use of aluminum pans may cause metallic marking

n

of the grates. This does not aect the durability of

the enamel and may be cleaned o with a metal

polish.

Use care when opening the door.

n

Let hot air and steam escape before removing or

n

replacing food.

NEVER heat unopened food containers. Pressure

n

buildup may make the container burst and cause

injury.

Keep oven vent ducts unobstructed.

n

Placement of oven racks

Always place oven racks in the desired location while

n

the oven is cool. If the rack must be moved while the

oven is hot, DO NOT let the potholder contact the

hot heating element in the oven.

WARNING!THIS APPLIANCE IS PROVIDED WITH

n

ROLLERS TO FACILITATE MOVEMENT DURING

INSTALLATION. THE RANGE SHOULD NOT BE MOVED

AFTER INSTALLATION.

General safety instructions

This appliance must be installed by a competent person in

accordance with the installation instructions. The installation

must comply with the relevant regulations and also the local

electricity supply company requirements.

This appliance is designed for domestic cooking only. Use for

any other purpose could invalidate any warranty or liability

claim.

The use of a gas cooking appliance results in the production

of heat and moisture in the room in which it is installed.

Make sure that the kitchen is well ventilated: keep natural

ventilation holes open or install a mechanical ventilation

device, (mechanical extractor hood).

Prolonged intensive use of the appliance may call for

additional ventilation, for example opening a window, or

more eective ventilation, for example increasing the level of

mechanical ventilation where present.

This appliance should not be installed with any

n

ventilation system that blows air downward toward

the gas cooking appliance. This type of ventilation

system may cause ignition and combustion

problems with the gas cooking appliance, resulting

in personal injury or unintended operation.

Ventilating systems that direct the air upwards can

be used.

The range should be serviced by a qualied service engineer

and only approved parts used. Have the installer show you

the location of the range circuit breaker. Mark it for easy

reference. Always allow the range to cool and then switch it

o at the circuit breaker before cleaning or carrying out any

maintenance work, unless specied otherwise in this guide.

All parts of the range become hot with use and will

n

retain heat even after you have stopped cooking.

3

Page 10

Take care when touching the range in order to

n

minimize the possibility of burns; always be certain

that the controls are in the OFF position and that it is

cool before attempting to clean the range.

Clean with caution. If a wet sponge or cloth is used to wipe

spills on a hot surface, be careful to avoid steam burns. Some

cleaners can produce noxious fumes if applied to a hot

surface.

Clean only parts listed in this guide.

In the interests of hygiene and safety, the range should be

kept clean at all times as a build up of fats and other food

stu could result in a re.

Always keep combustible wall coverings or curtains etc. a safe

distance away from your range.

DO NOT spray aerosols in the vicinity of the range

n

while it is in use.

DO NOT store or use combustible materials, or ammable

liquids in the vicinity of this appliance.

Take great care when heating fats and oils, as they will ignite

if they get too hot.

Use a deep fat thermometer whenever possible to prevent

overheating fat beyond the smoking point.

NEVER leave a deep fry pan unattended. Always

n

heat fat slowly, and watch as it heats. Deep fry pans

should be only a maximum of one third full of fat.

Filling the pan too full of fat can cause overspill

when food is added. If you use a combination of oils

or fats in frying, stir them together before heating,

or as the fats melt.

Foods for frying should be as dry as possible. Frost on frozen

foods or moisture on fresh foods can cause hot fat to bubble

up and over the sides of the pan. Carefully watch for spills or

overheating of foods when frying at high or medium high

temperatures. NEVER try to move a pan of hot fat, especially

a deep fry pan. Wait until the fat is cool.

When an oven is on, DO NOT use the top of the ue (the

round holes along the back of the range) for warming plates,

dishes, drying dish towels or softening butter.

When using an electrical appliance near the cooktop, be sure

that the cord of the appliance does not come into contact

with the cooktop.

Take care that no water seeps into the appliance.

Make sure that your kitchen is well ventilated at all times. Use

extractor fans or hoods when installed.

The range is designed for cooking foods only and must not

be used for any other purpose.

The oven should NOT be used for heating the kitchen, not

only does this waste fuel but the control knobs may become

overheated.

When the oven is on DO NOT leave the oven door open for

longer than necessary.

The specication of this range should not be altered.

This appliance is heavy, take care when moving it.

When the range is not in use, ensure that the control knobs

are in the OFF position.

4

Page 11

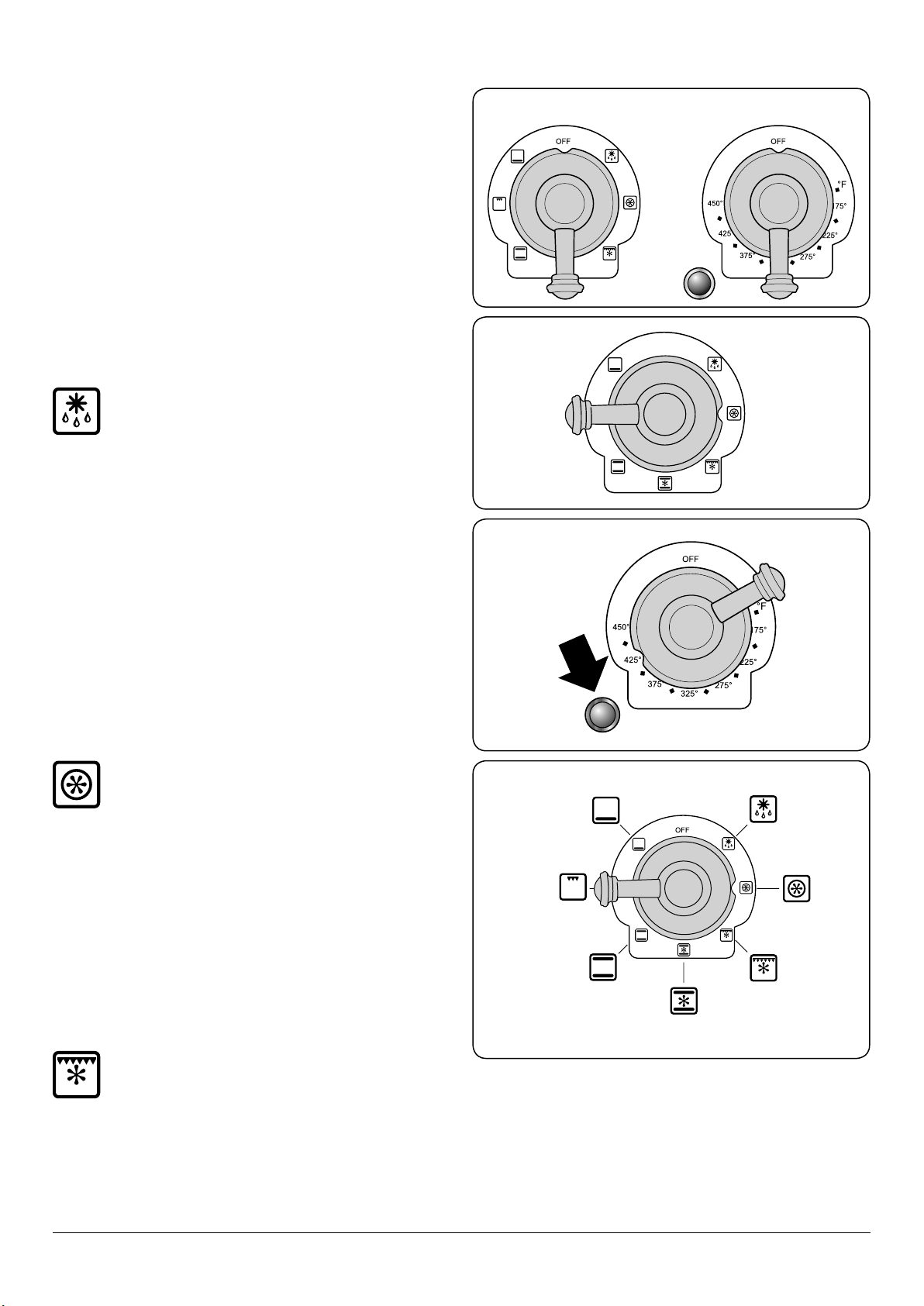

ArtNo.280-0007 - HP Knob Full

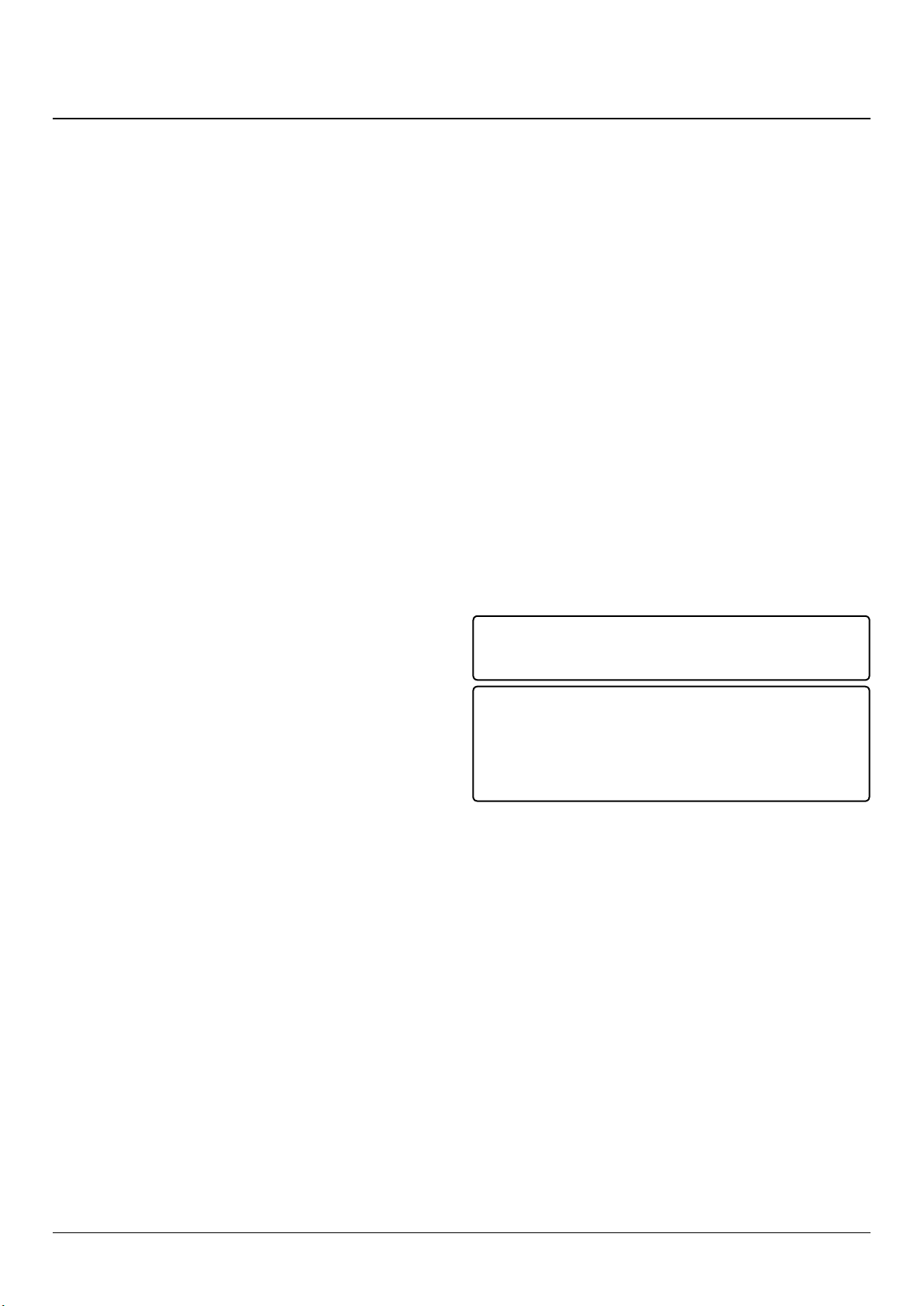

2. Range overview

The dual fuel single cavity range cooker has the following

features:

A. 5 hotplate burners

B. Control panel

C. Multifunction oven

D. Storage drawer

Cooktop burners

Note: Before using the cooktop make sure all burners are in

place and all the grates on the range are properly placed.

The drawing by each knob indicates which burner that knob

controls (Fig. 2.1).

Each burner has a special Flame Supervision Device (FSD) that

stops the ow of gas if the ame goes out.

To light a burner push in and turn the associated control knob

to the high position as indicated by ‘HI’ (Fig. 2.2).

Keep holding the knob pressed in to let the gas through to

the burner for about 4 seconds (Fig. 2.3). The igniter should

spark and light the gas.

When a cooktop burner knob is pressed in, sparks will be

made at every burner – this is normal. DO NOT attempt

to disassemble or clean around any burner while another

burner is on: an electric shock could result.

Fig. 2.1

Fig. 2.3

If, when you let go of the control knob, the burner goes out,

the safety device has not held in. Turn the control to the

OFF position and wait one minute, then try again this time

holding in the control knob for slightly longer.

Adjust the ame height to suit by turning the knob. On this

range the low position is beyond high, not between high and

o. The ‘LO’ marks the low position. Turn the knob towards it

after the contents of a pan have boiled (Fig. 2.4).

Make sure ames are under the pans. For safety reasons,

adjust the ames so that they DO NOT extend beyond the

edge of the cooking utensil. This instruction is based on

safety considerations (Fig. 2.5).

Pans and kettles with concave bases or down turned base

rims should not be used (Fig. 2.6).

Simmering aids, such as asbestos or mesh mats, are NOT

recommended. They will reduce burner performance and

could damage the grates (Fig. 2.7).

Avoid using unstable or misshapen pans that may tilt easily

and pans with a very small base diameter e.g. milk pans,

single egg poachers (Fig. 2.8).

The minimum pan diameter recommended is 7½” (19 cm) for

the outer burners and 10” (26 cm) for the center burner.

Fig. 2.2

Fig. 2.5

Fig. 2.4

Fig. 2.6 Fig. 2.7

ArtNo.311-0002 Pan with rim

Art No. 311-0003 Simmer aids

Fig. 2.8

If after lighting, a cooktop burner’s ame goes out, turn it

o and leave it for one minute before relighting it.

ArtNo.311-0004 T ipping wok

5

Page 12

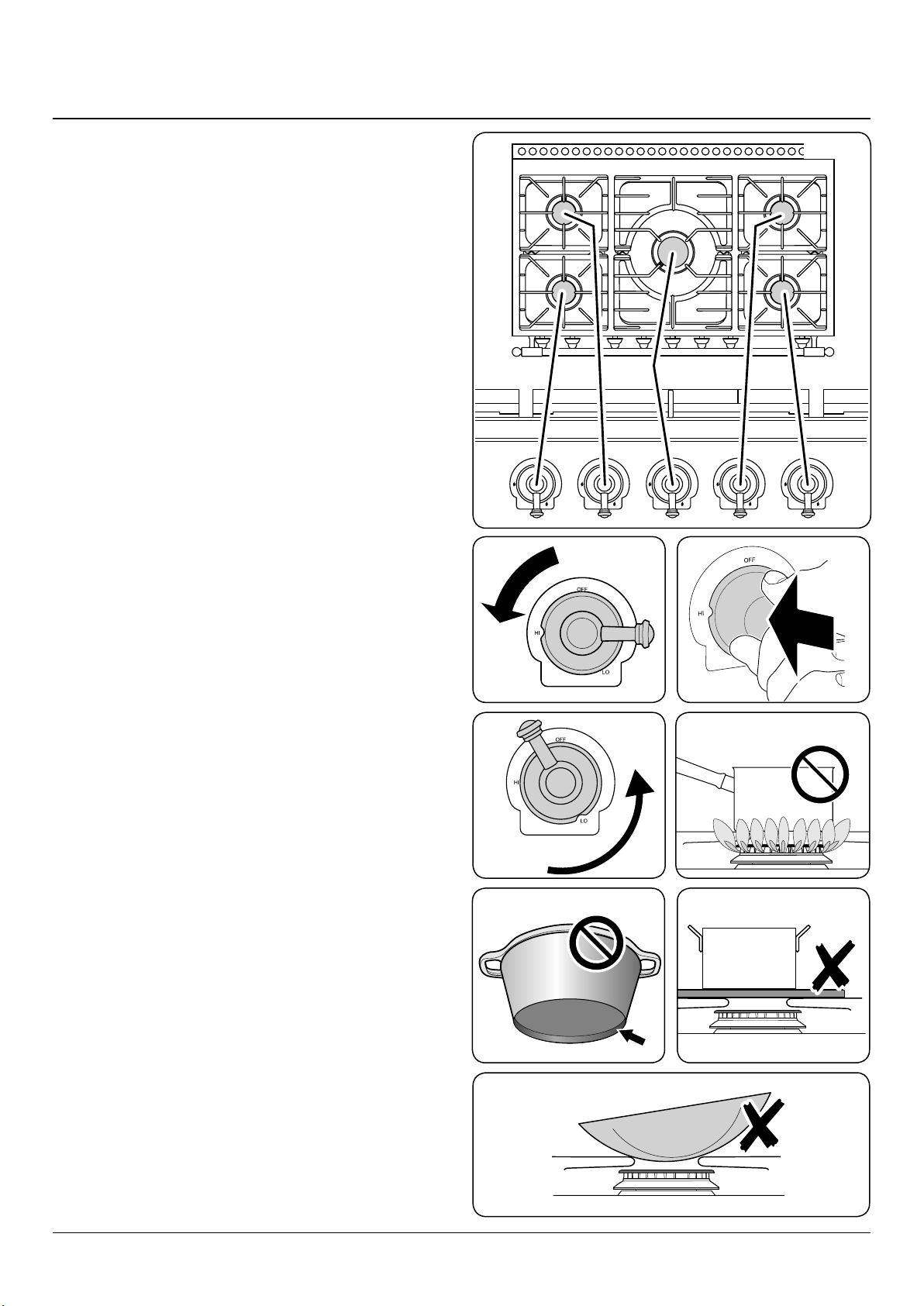

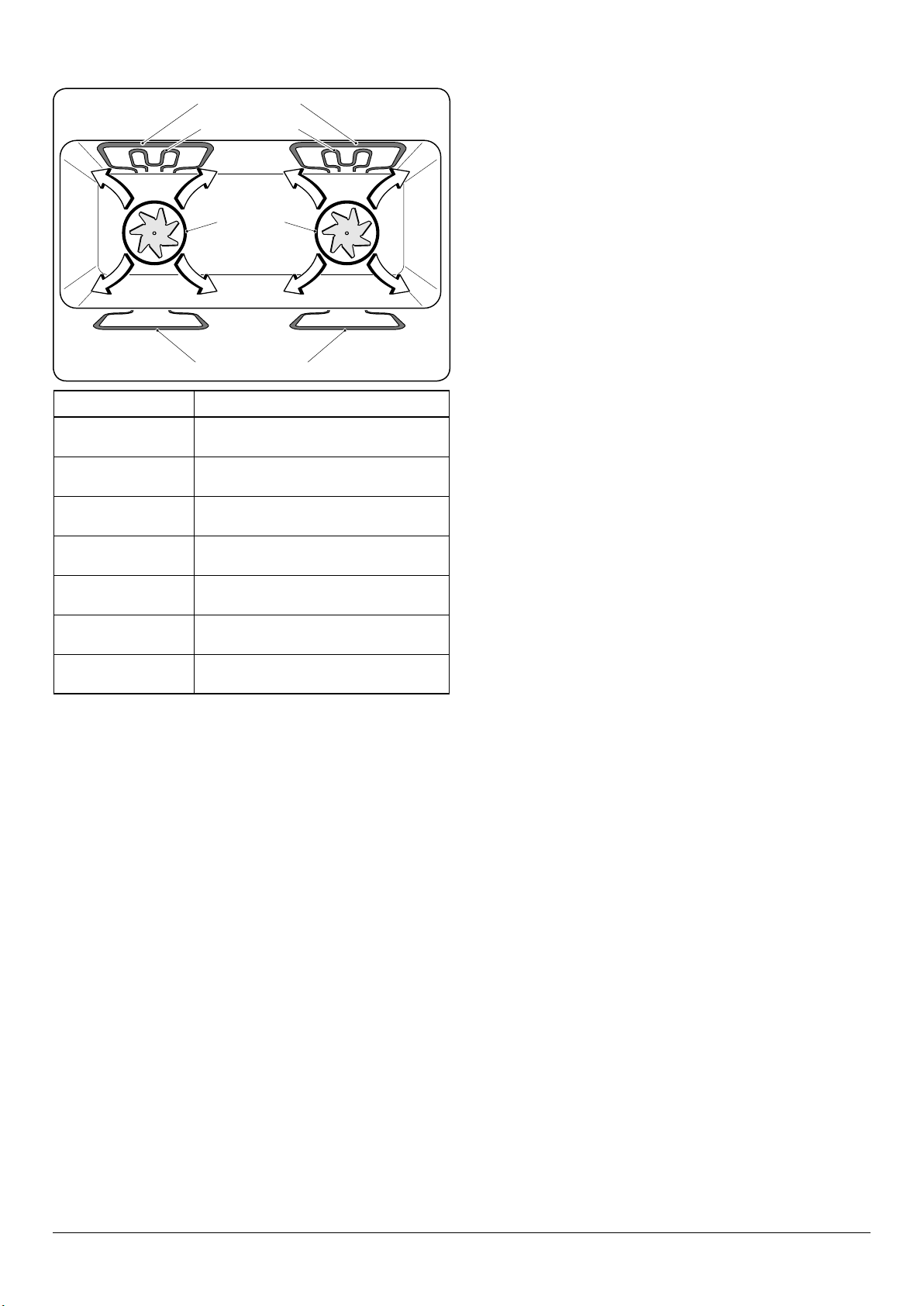

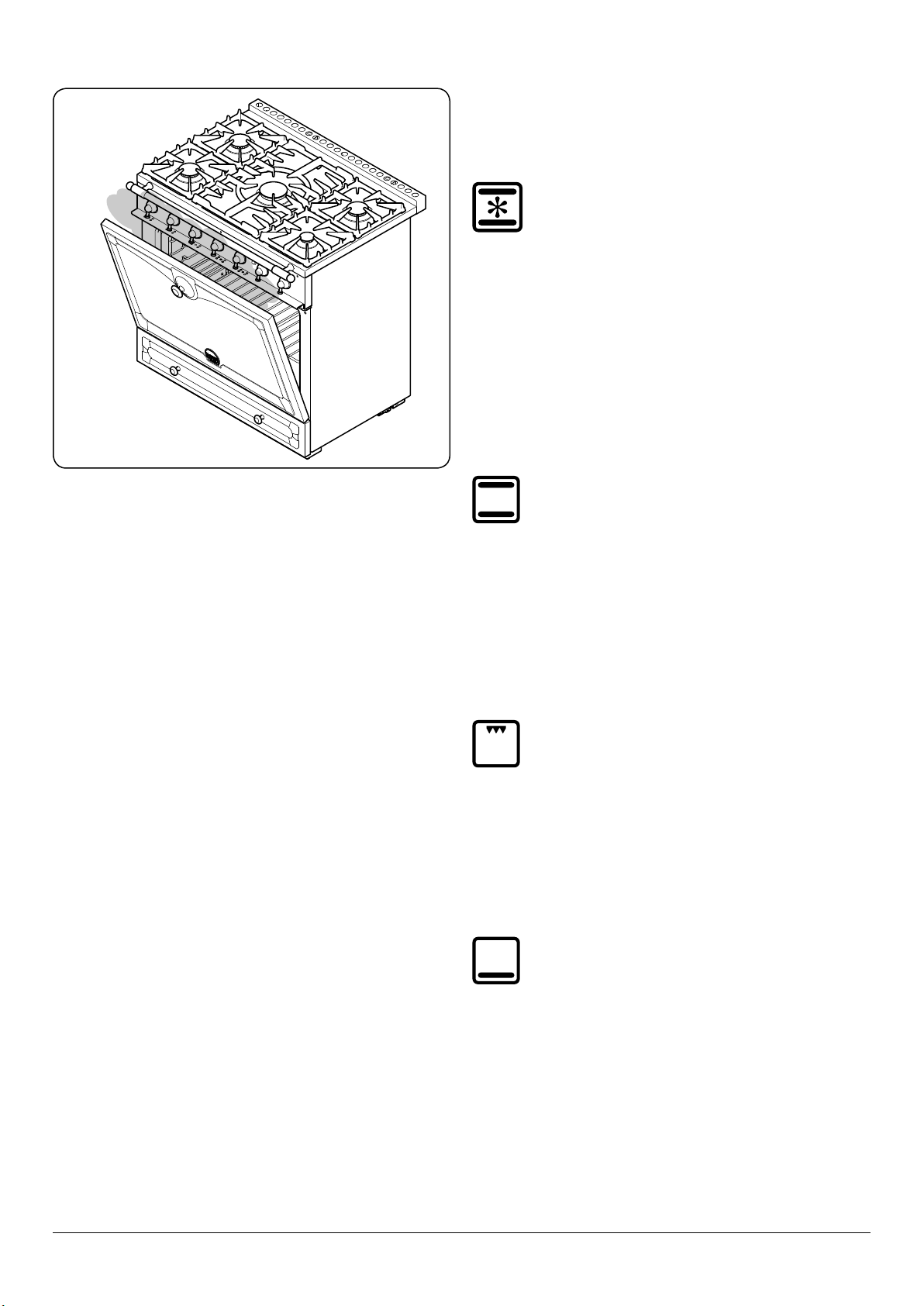

ArtNo.326-0001 - Albertine SC - MF oven elements

Base heat elements

Broiling elements

Convection

elements

Top heat elements

Fig. 2.9

Igniting cooktop burners without electricity

If there is a power failure the cooktop burners can be lit with

a match.

A. Hold a burning match ½” from the burner head, keeping

your hand as far horizontally away from the burner as

possible.

B. Push and turn the burner control knob to HI/lighting

position. As soon as the burner ame lights move your

hand away. With your other hand, keep holding the

knob pressed for a few seconds so that the burner safety

device can ‘sense’ the heat of the ame.

C. Turn the burner control knob to the OFF position when

you have nished using it.

Function Use

Thaw & serve

Convection oven

Convection

broiling

Convection

assisted

Conventional oven

Broiling/Browning

element

Warming

To thaw small items in the oven without heat

A full cooking function, even heat throughout,

great for baking

Broiling meat and sh with the door closed

A full cooking function good for roasting and

baking

A full cooking function for roasting and baking

in the lower half of the oven

To brown and crisp cheese topped dishes and

broiling meat

To crisp up the bases of quiche, pizza or pastry

Table 2.1

Cleaning

You can remove the burner head for cleaning; see the

‘Cleaning your Range’ section of these instructions.

Note: You should wipe the top surface of the range around

the cooktop burners as soon as possible after spills occur.

Note: Use of aluminum pans may cause metallic marking of

the grates. This does not aect the durability of the enamel

and may be cleaned o with a metal polish.

The multifunction oven

IMPORTANT: Before using the oven for the rst time, to

dispel manufacturing odors, turn the oven to 200 °C

(395 °F) in Convection Assisted mode and run for one hour.

To clear the smell make sure the room is well ventilated to

the outside air, by opening windows or turning on your

ventilation hood.

During use the appliance becomes hot. Care should be taken

to avoid touching the heating elements inside the oven.

The oven is a multifunction oven (Fig. 2.9). In addition to

convection elements around the fans, it is tted with extra

heating elements, in the top of the oven and under the oven

base. Take care to avoid touching the top elements when

placing or removing items from the oven.

The multifunction oven has 3 main cooking functions,

convection, convection assisted and conventional

cooking. These functions should be used to complete most

of your cooking.

The browning element and warming can be used in the

latter part of the cooking process to ne-tune the results to

your particular requirements.

Use convection broiling for all your broiling needs and thaw

and serve to safely thaw small items of frozen food.

Table 2.1 gives a summary of the multifunction modes.

The multifunction oven has many varied uses. We suggest

you keep a careful eye on your cooking until you are familiar

with each function. Remember, not all functions will be

suitable for all food types.

Please remember that all ranges vary – temperatures in your

new ovens may dier to those in your previous range.

6

Page 13

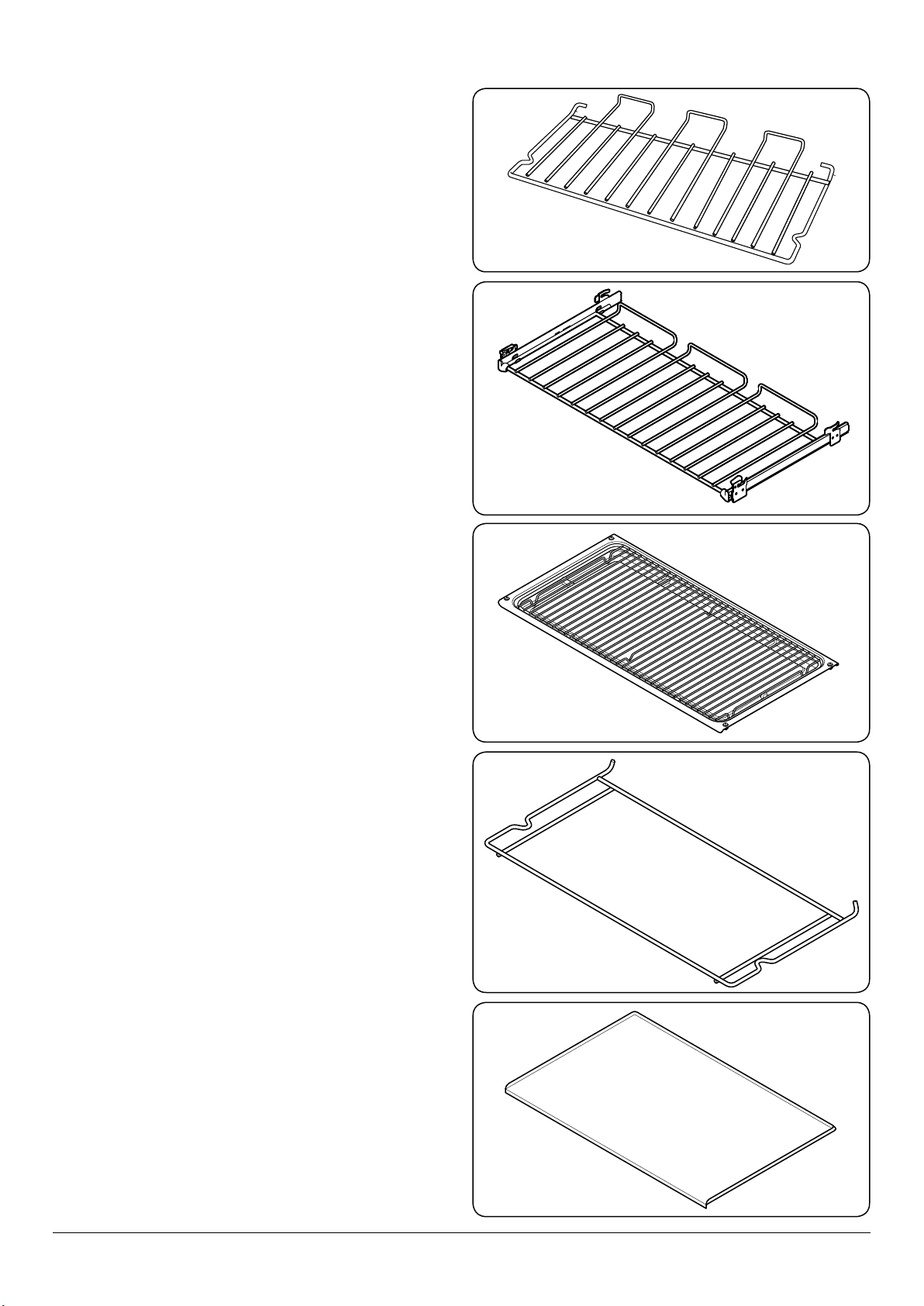

ArtNo.280-0012 - MF Knob Fan Oven

OFF

Operating the oven

The multifunction oven has two controls: a function selector

and a temperature setting knob (Fig. 2.10).

Turn the function selector control to a cooking function. Fig.

2.11 shows the control set for conventional oven cooking.

Turn the oven temperature knob to the temperature you

need. The oven heating light will glow until the oven has

reached the temperature you selected. It will then cycle on

and o during cooking as the oven maintains the selected

temperature (Fig. 2.12).

Fig. 2.10

Multifunction oven modes

Defrost

This function operates the fan(s) to circulate cold air

ArtNo.030-0017 - MF defrost symbol

as desserts, cream cakes and pieces of meat, sh and poultry

to be defrosted.

Thawing in this way speeds up the process and protects the

food from contamination. Pieces of meat, sh and poultry

should be placed on a rack, over a tray to catch any drips. Be

sure to wash the rack and tray after thawing.

Thaw with the oven door closed.

Large items, such as whole chickens and meat roasts should

not be thawed in this way. We recommend this be carried out

in a refrigerator.

Thawing should not be carried out in a warm oven. Ensure

that dairy foods, meat and poultry are completely thawed

before cooking.

Convection oven

ArtNo.030-0016 - MF Fan Oven Symbol

throughout, allowing you to cook large amounts quickly.

only. Make sure the temperature control is at 0° and

that no heat is applied. This enables small items such

This function operates the fans and the heating

element around them. The fans direct the heat

around the oven so that an even heat is produced

Fig. 2.11

ArtNo.280-0013 - MF Knob With Neon

Fig. 2.12

Fig. 2.13

Base heat Defrost

Convection oven cooking is particularly suitable for multirack cooking and is a good ‘all-round’ function. It may be

necessary to reduce the temperature by approximately 10 °C

(20 °F) for recipes previously cooked in a conventional oven.

If you wish to preheat the oven, wait until the indicator light

has gone out before inserting the food.

To cook on 3 levels, use racks 1, 3 and 5. If required, you can

uuse your broiler pan and rack as an extra level.

Convection broiling

This function operates the fan while the top element

ArtNo.030-0018 - MF Fan Grill Symbol

is on. It produces a more even, less erce heat than a

conventional broiler. For best results, place the food

to be broiled, on the grid in the pan provided. Thick pieces of

meat or sh are ideal for cooking in this way, as the circulated

air reduces the erceness of the heat from the broiler. The

oven door should be kept closed while cooking is in progress,

so saving energy. You will also nd that the food needs to be

watched and turned less than for normal broiling.

Browning &

broiling element

7

Conventional

oven

ArtNo.280-0016 - MF knob symbols

Convection assisted oven

Convection

oven

Convection

grilling & broiling

Page 14

Fig. 2.14

Rack levels 5 and 6 should be used depending on the size of

the food being cooked. For best results we recommend that

the grill pan is not located on the uppermost shelf.

Convection assisted oven

This function operates the fans, circulating air

heated by the elements at the top and the base of

ArtNo.030-0014 - Top & Bottom Fan Symbol

the oven. The combination of fan and conventional

cooking (top and base heat) makes this function ideal for

cooking large items that need thorough cooking, such as a

large meat roast. It is also possible to bake on two racks at

one time using racks 2 & 4, although they will need to be

changed over during the cooking time, as the heat at the top

of the oven is greater than at the base, when using this

function.

This is a fast intensive form of cooking; keep an eye on the

food cooking until you have become accustomed to this

function.

Conventional oven (Top and Base Heat)

This cooking function combines the heat from the

ArtNo.030-0015 - Top & Bottom Symbol

top and base of the oven. The heat at the top of the

oven is greater than the heat at the base, so the

oven will be hotter in the top half than the lower half.

Unless you are cooking food that requires fast intensive

cooking, we suggest you place it on a lower rack.

This cooking mode will take longer to preheat than

convection mode. If you wish to cook one more than one

rack at a time we recommend that you use the convection

function for an even heat thoughout the oven.

Browning/Broiling Element

This function uses the inner sections of the elements

in the top of the oven. It is a useful function for the

ArtNo.030-0019 - MF Top Element Symbol

browning or nishing of pasta dishes, vegetables in

sauce or lasagne, the item to be browned being already hot

before switching to the browning function.

Meat dishes can be broiled using the browning element,

through the cooking should be closely monitored, as the heat

at the top of the oven is greater than at the base when using

this function.

Warming

ArtNo.030-0020 - MF Bottom Element Symbol

This function uses the base element only. It will crisp

up your pizza or quiche base or nish o cooking the

base of a pastry case on a lower rack. It is also a

gentle heat, good for slow cooking of casseroles in the

middle of the oven or for plate warming.

The Browning and Warming functions are useful additions

to your oven, giving you exibility to nish o items to

perfection. With use, you will soon realize how these

functions can combine to extend your cooking skills.

Steam

When cooking foods with high water content (e.g. oven fries)

there may be some steam visible at the grille at the rear of the

cooktop. This is perfectly normal.

8

Page 15

General oven tips

IMPORTANT: Before using for the rst time, to dispel

manufacturing odors turn the ovens to 200 °C (395 °F) in

Convection Assisted mode and run for one hour. To clear the

smell, make sure the room is well ventilated to the outside air,

by opening windows for example.

Caution!

n

The inside door face is constructed with toughened

safety glass. Take care not to scratch the surface

when placing cookware on the glass panel.

DO NOT close the door against the oven racks.

Accidental damage may cause the door glass panel

to fracture.

The wire racks should always be pushed rmly to the back of

the oven.

Bakeware and meat pans should be placed level centrally

on the oven’s wire racks. Keep all trays and containers away

from the sides of the oven, as over browning of the food may

occur.

Always place baking sheets with the widest part across the

oven.

Fig. 2.15

Fig. 2.16

Cooking high moisture content foods can create a ‘steam

burst’, when the oven door is opened. When opening the

oven stand well back and allow any steam to disperse

(Fig. 2.14).

When the oven is on, DO NOT leave the door open for longer

than necessary, otherwise the knobs may get very hot.

Always leave a ‘ngers width’ between dishes on the same

rack. This allows the heat to circulate freely around them.

Cover meat when cooking to avoid fat splashes.

To reduce fat splashing when you add vegetables to hot fat

around a roast, dry them thoroughly or brush lightly with

cooking oil.

If you want to brown the base of a pastry dish, preheat the

baking sheet for 15 minutes before placing the dish in the

center of the sheet or use the base heat in the Multifunction

oven.

Where dishes may boil and spill over during cooking, place

them on a baking sheet.

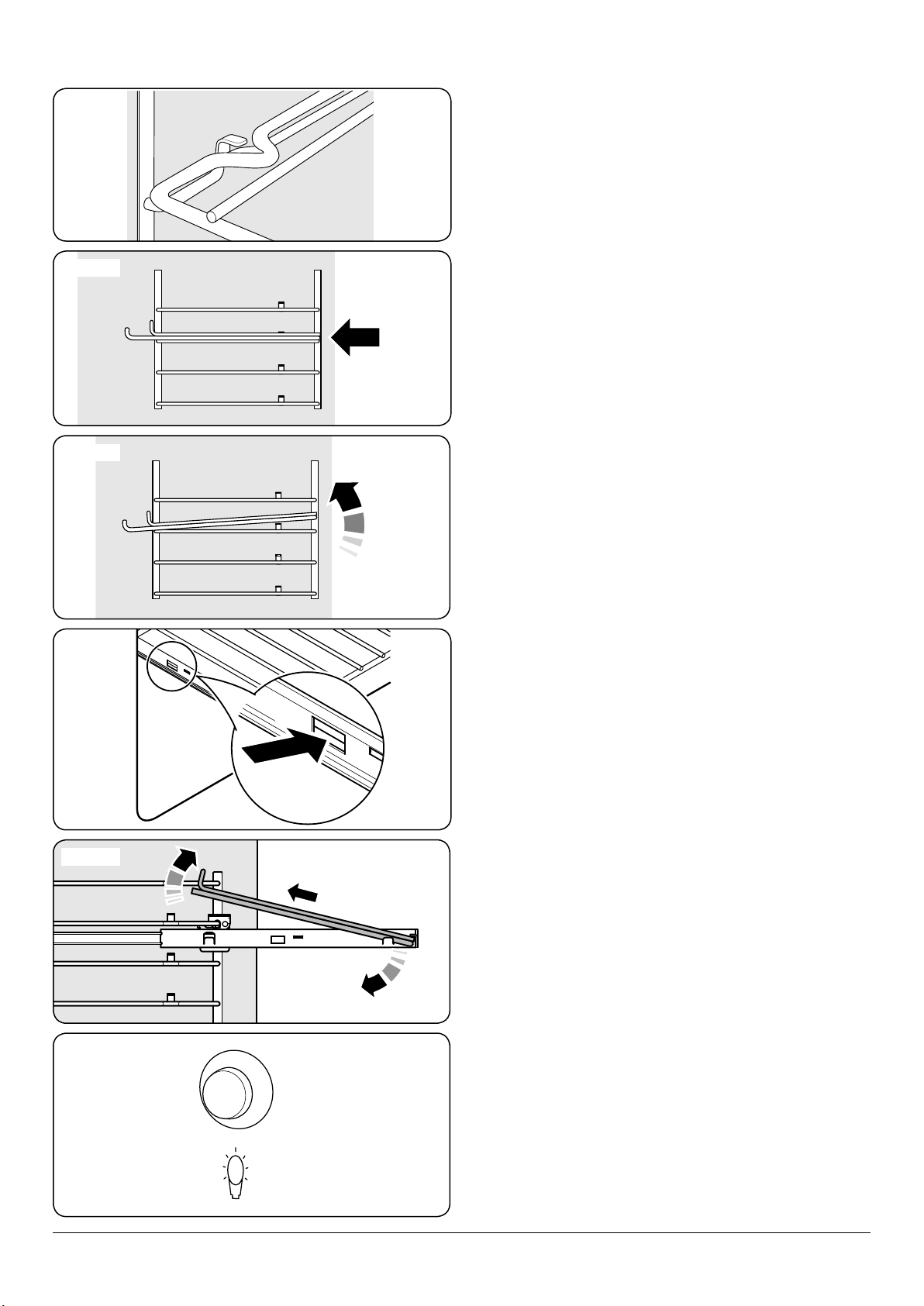

Accessories

Oven racks

Fig. 2.17

Fig. 2.18

Each oven is supplied with:

• 1 full width rack (Fig. 2.15)

• 1 telescopic rack with runners (Fig. 2.16)

• One broiler tray with grid (Fig. 2.17)

• One broiler tray rack (Fig. 2.18)

• And one pastry tray (Fig. 2.19).

Fig. 2.19

ArtNo.326-0005 - Pastry tray

9

Page 16

Fig. 2.20

Fig. 2.21

Fig. 2.22

Any shelf can be tted in any of the positions. The oven

shelves are retained when pulled forward but can be easily

removed and retted.

To remove and refit the racks

The rack has a small kink on either side (Fig. 2.20). To remove

the rack, line these up with the stops in the rack support (Fig.

2.21). Lift the rack upwards so that it will pass over the rack

stop and then pull it forwards (Fig. 2.22).

Ret in the reverse order, making sure to push it fully back.

To remove and refit the telescopic rack and runners

Slide the rack out on the runners. While holding one of the

runners securely, carefully lift the rear of the rack upwards:

the rack will spring clear of the central restraining tab. Repeat

for the opposite side of the rack.

Note: To aid the removal of the shelf you can insert a suitable

at tool through the opening in the side of the runners and

lever the rack clear (Fig. 2.23).

Tilt the front of the rack downwards and then lift clear of the

runners (Fig. 2.24).

Ret in the reverse order, making sure to push the rack down

onto the runner arms.

Fig. 2.23

Fig. 2.24

Oven light

Press the appropriate button to turn on the oven lights.

If one of the oven lights fail, turn o the range circuit breaker

before you change the bulb. See the ‘Troubleshooting’ section

for details on how to change an oven light bulb (Fig. 2.25).

Storage

The bottom drawer is for storing oven trays and other

cooking utensils. The drawer can be removed completely for

cleaning, etc.

It can get very warm, so DO NOT store anything in it,

n

which may melt or catch re.

Never store ammable materials in the drawer.

n

This includes paper, plastic and cloth items, such

as cookbooks, plastic ware and towels, as well as

ammable liquids.

DO NOT store explosives, such as aerosol cans, on or

n

near the appliance.

Flammable materials may explode and result in re

n

or property damage.

Fig. 2.25

ArtNo.320-0023

Oven light USA

10

Page 17

3. Oven cooking guide

Remember – not all modes will be suitable for all food types.

The oven control settings and cooking times given are

intended to be used only as a guide only. Individual tastes

may require the temperature to be altered to provide a

preferred result.

Food is cooked at a lower temperature in a convection oven

than in a conventional oven. When using recipes, reduce the

temperature by 20 °F (10 °C) and the cooking time by 5-10

minutes. The temperature in the convection oven is the same

throughout ensuring uniform results.

Fig. 3.1 shows the shelf positions.

The racks should not be placed directly one above the

other. When cooking on more than one rack always leave

at least one runner space between them. Place baking

sheets, individual cake tins or baking dishes centrally on the

oven rack. For best results preheat the oven until the oven

indicator light goes out.

For roast meats and poultry refer to the convection oven

guide – reduce cooking time slightly.

The broiling / browning feature can be used on full power

for browning or sealing items, or for toast. For meat dishes,

the thicker the meat, the lower the temperature setting you

should apply.

5

4

ArtNo.050-0019 - Albertine SC

- Shelf position

3

2

1

Fig. 3.1

Make sure meat and poultry is fully cooked before

n

serving.

11

Page 18

Cooking chart

ArtNo.030-0015 - Top & Bottom Symbol

Conventional

oven

Temperature

°F

Rack

position for

conventional

cooking

ArtNo.030-0016 - MF Fan Oven Symbol

Convection

oven

Temperature

°F

Approximate cooking time

Meat

Beef (no bone) 300 2 300 30-35 minutes per 1 lb + 30-35 minutes

375 2 375 20-25 minutes per 1 lb + 20-25 minutes

Lamb 300 2 300 30-35 minutes per 1 lb + 30-35 minutes

375 2 375 20-25 minutes per 1 lb + 20-25 minutes

Pork & veal 300 2 300 35-40 minutes per 1 lb + 35-40 minutes

375 2 375 25-30 minutes per 1 lb + 25-30 minutes

Poultry

Chicken 300 2 300 20-25 minutes per 1 lb + 20-25 minutes

375 2 375 15-20 minutes per 1 lb + 15-20 minutes

Turkey (slow cook) 300 2 300 25-30 minutes per 1 lb + 25-30 minutes

375 2 375 20 minutes per 1 lb + 20 minutes

Turkey (fast cook) 300 2 300 20 minutes per 1 lb + 20 minutes

375 2 375 15 minutes per 1 lb + 15 minutes

Duck/Duckling 300 2 300 20 minutes per 1 lb

Casserole 300 2 300 2-4 hours, according to recipe

Fish

350 2 350 Fillet 15-20 minutes; whole 15-20 minutes per 1 lb

350 2 350 Whole 10 minutes per 1 lb + 10 minutes

350 2 350 Steaks according to thickness

Desserts

Cup cake 325 2 325 20 minutes

Scone 375 2 375 15 minutes

Deep apple pie 350 2 350 45 minutes

Plate tart 350 2 350 45 minutes

Fruit cake 8” x 3.5” 275 2 275 1¾-2 hours

Pu pastry 400 2 400 15-40 minutes according to size

Angel food cake 325 2 325 50-60 minutes

Brownies 350 2 350 25-30 minutes

Muns 350 2 350 25-30 minutes

Cookies 350 2

350 15-20 minutes

Pound cakes 350 2 350 40-60 minutes

Bread

375 2 375 20-30 minutes

12

Page 19

4. Cleaning your range

Essential information

Before thorough cleaning, turn o the circuit breaker. Allow

the range to cool.

After cleaning remember to switch on the circuit breaker

before using the range.

Never use paint solvents, caustic cleaners, biological

n

powders, bleach, chlorine based bleach cleaners,

coarse abrasives or salt.

Do not mix dierent cleaning products – they may

n

react together with hazardous results.

Recommended cleaning materials are shown in Table 4.1.

Cleaning the range – Daily care

Cleaning the range is not a welcomed chore, but it has to be

done to maintain eciency and appearance. Remember it

is better to wipe up any spills as they occur, this will prevent

them burning on and becoming more dicult to remove

later.

Make sure the ow of combustion and ventilation air

n

to the range is unobstructed – for example by buildup of fats or grease.

If the ame is distorted, check that the burner head is

correctly placed over the burner base (Fig. 4.1).

If the ame burns with a long white tip you should call for

service.

Cleaning for spills

For spills and boil-overs that occur while cooking, as soon as

possible turn o the burner and allow it to cool. Do not clean

until the area is completely cooled down. Wipe up spills as

soon as possible.

Do not allow surplus water to seep into the range.

Cooktop burners

The burner heads and caps can be removed for cleaning.

Make sure they are absolutely dry before replacing.

Part Finish

Burner grates &

top of burner

heads

Burner base

Maintop top

Sides, toe-kick

Control panel

Oven interior

Door handles

Oven racks &

supports

Door inner

Outer door

and drawer

Brass trims

(some models

only)

Copper trims

(some models

only)

Oven Liner

Porcelain enamel

Aluminum

Stainless steel

Painted enamel

Porcelain enamel

or stainless steel

Porcelain enamel

Brass or plated

brass/plastic

Chrome

Porcelain enamel

Porcelain enamel

or stainless steel

Brass

Copper

ArtNo.050-0014 - Cleaning table USA

Porcelain Enamel

Recommended

cleaning method

Mildly abrasive cleaner such as

Bon Ami ® or Soft Scrub®.

Dishwasher.

As above.

Hot soapy water, non-abrasive

cleaner, soft cloth.

Hot soapy water and soft cloth.

Non-abrasive cleaner, soft cloth.

Branded oven cleaner suitable for

enamel surfaces such as Dawn

Power Dissolver®. Take care not to

damage the oven door seals.

Non-abrasive cleaner, hot soapy

water, soft cloth. Brass handles

can be cleaned with a gentle

brass polish.

Dishwasher. Hot soapy water and

scouring pad.

Mildly abrasive cleaner such as

Bon Ami ® or Soft Scrub® with a

soft cloth.

Multi-surface cleaner, soft cloth.

Non-abrasive cleaner, hot soapy

water, soft cloth. Gentle brass

polish.

Hot soapy water and soft cloth.

Mildly abrasive cleaner such as

Bon Ami ® or Soft Scrub® with a

soft cloth.

Table 4.1

When replacing burner head, ensure this locates properly

within the base (Fig. 4.2). If you look at the bottom of the

burner head you will see two ‘pips’; these t into the two

notches in the burner base (Fig. 4.3).

Check burner ports are not blocked. If blockage occurs,

remove stubborn particles using a piece of fuse wire.

Stainless steel main top

Lift away pots or pans from main top. Remove grates from

spillage area and carefully place in a sink of warm soapy

water. Wipe loose debris from main top. Avoid using any

abrasive cleaners including cream cleaners on brushed

stainless steel surfaces. For best results use a liquid detergent

cleaner. Rinse with cold water and thoroughly dry with

a clean, soft cloth. Make sure all parts are dry before

repositioning.

13

Page 20

ArtNo.311-0029 - Burner base & head alignment

ArtNo.311-0030 - Burner head fitting

Fig. 4.1

Fig. 4.2

A

ArtNo.311-0028 - Burner head off

B

C

Never use caustic or abrasive cleaners as these will

n

damage the surface.

Control panel and oven doors

Avoid using any abrasive cleaners including cream cleaners,

on brushed stainless steel surfaces. For best results use liquid

detergents.

The control panel and control knobs should only be cleaned

with a soft cloth wrung out in clean hot soapy water – but

take care that no surplus water seeps into the appliance. Wipe

with a clean dampened cloth then polish with a dry cloth. The

oven doors should only be cleaned with a soft cloth wrung

out in clean hot soapy water.

Cleaning brass parts (some models only)

Uncoated natural brass is used as part of the authentic nish

on some models and this may tarnish with age. To regain

a polished nish, these areas should be cleaned using a

gentle brass cleaner. Take care the cleaner does not aect

surrounding areas.

D

Ovens

The side panels can be removed for cleaning and for cleaning

behind them.

A – Burner head, B - Burner ring, C – Base

Fig. 4.3

Fig. 4.4 Fig. 4.5

ArtNo.281-0020 Removing the liner

Removing the oven linings

Remove the shelves rst. To remove the oven shelf supports

lift until clear of the two supporting holes and pull outwards

(Fig. 4.4).

Please note – there are specic liners for the left and right

hand side.

To remove the side panels, simply lift the panel and slide

forwards (Fig. 4.5).

Replacing the oven linings

To replace the liner the cut-out section must be at the top of

the liner. Slide the liner towards the back of the oven cavity.

When this is in place the shelf supports can be replaced. To

do this, rst insert the bottom of the support in the cut-out

followed by the two hooks at the top.

ArtNo.281-0019 - Removing the shelf support

14

Page 21

5. Troubleshooting

Cooktop ignition or cooktop burners faulty

Is the power on?

Are the sparker (ignition electrode) or burner holes blocked

by debris?

Are the burner heads correctly located? See the section

entitled ‘Cleaning’.

Remember that each cooktop burner has a special safety

device that stops the ow of gas if the ame goes out.

When lighting a cooktop burner the safety device has to be

overridden by holding in the control knob so that the gas

can ow. This allows the ame sensor to heat up and operate

the safety device. Keep holding the knob pressed in to let the

gas through to the burner for few seconds. The igniter should

spark and light the gas.

If, when you let go of the control knob, the burner goes out,

the safety device has not held in. Turn the control to the

OFF position and wait one minute, then try again this time

holding in the control knob for slightly longer.

Cooktop burners will not light

If only one or all the cooktop burners will not light, make sure

that the parts have been replaced correctly after wiping or

removing for cleaning.

Check that there is not a problem with your gas supply. You

can do this by making sure that other gas appliances you may

have are working.

Do the burners spark when you push in the control knob? If

not check the power is on.

Steam is coming from the oven

When cooking foods with a high water content (e.g. oven

fries) there may be some steam visible at the rear grille.

Take care when opening the oven door, as there may be a

momentary pu of steam when the oven door is opened.

Stand well back and allow any steam to disperse.

An oven fan is noisy

The sound of the oven fan may change as the oven heats up –

this is perfectly normal.

If there is an installation problem and I don’t get my

original installer to come back to fix it who pays?

You do. Service organizations will charge for their service if

they are correcting work carried out by your original installer.

It is in your interest to track down your original installer.

Power failure

In the event of a failure in the electrical supply, remember to

reset the clock to ensure that the timed oven continues to

operate.

Food is cooking too slowly, too quickly, or burning

Cooking times may dier from your previous oven. Check

that you are using the recommended temperatures and

rack positions. See the oven cooking guide section of the

instructions. The oven control settings and cooking times are

intended to be used only as a guide. Individual tastes may

require the temperature to be altered either way, to get the

results you want. Try cooking at a higher temperature setting.

The oven is not cooking evenly

If you are cooking a large item, be prepared to turn it round

during cooking.

If two racks are used, check that space has been left for the

heat to circulate. When a baking sheet is put into the oven,

make sure it is placed centrally on the rack.

Check that the door seal is not damaged.

A dish of water when placed on the rack should be the

same depth all over. (For example, if it is deeper at the back,

then the back of the range should be raised up or the front

lowered.)

If the range is not level arrange for your supplier to level it for

you.

Oven not coming on

Is the power on? Is the clock illuminated?

If not there may be something wrong with the power supply.

Is the range supply on at the circuit breaker?

Have you set a cooking function?

What cleaning materials are recommended for the

range?

See the ‘Cleaning’ section for a full list of recommended

cleaning materials.

We DO NOT recommend corrosive or caustic

n

cleaners as these may damage your range.

The knobs get hot when I use the oven, can I avoid this?

Yes, this is caused by heat rising from the oven, and heating

them up. DO NOT leave the oven door open.

The timed oven is not coming on when turned on

manually

Is the power on? Is the clock illuminated?

If not, there may be something wrong with the power supply.

Is the range supply on at the circuit breaker?

Has the time of day been set?

15

Page 22

Fig. 5.1

The timed oven is not coming on when automatic

cooking

Has the oven knob been left in the OFF position by mistake?

Oven temperature getting hotter as the range gets older

If turning the knob down has not worked or only worked for a

short time then you may need a new thermostat. This should

be installed by a service technician.

Fig. 5.2

Oven light is not working

The bulb has probably blown. You can buy a replacement

bulb (which is not covered under the guarantee) from most

electrical stores. Ask for a 40 W – 230 V halogen lamp (G9)

(Fig. 5.1).

Turn o the power at the circuit breaker.

Before removing the existing bulb, turn o the power supply

and make sure that the oven is cool. Open the oven door and

remove the oven shelves.

Unscrew the bulb cover by turning it a quarter turn, counterclockwise. It may be very sti (Fig. 5.2).

Pull the existing bulb to remove it. When handling the

replacement bulb, avoid touching the glass with your ngers,

as oils from your hands can cause premature failure. Push,

click in the replacement bulb.

Replace the bulb cover by turning it a quarter turn, clockwise.

Turn on the circuit breaker and check that the bulb now

lights.

16

Page 23

8. Installation Instructions

WARNING!

If the information in these instructions is not followed exactly, a re or

explosion may result, causing property damage, personal injury or death.

DO NOT store or use gasoline or other ammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

DO NOT try to light any appliance.

DO NOT touch any electrical switch.

DO NOT use any phone in your building.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

If you cannot reach your gas supplier, call the re department.

Installation and service must be performed by a qualied installer, service

agency or the gas supplier.

WARNING!

The anti-tip device supplied with this range must be installed when the appliance is installed. This will reduce the risk of

tipping of the appliance from abnormal usage or by excessive loading of the oven door.

WARNING!

• ALL RANGES CAN TIP. A CHILD OR ADULT CAN TIP THE RANGE AND BE KILLED.

• INSTALL ANTI-TIP BRACKET PACKED WITH RANGE - SEE INSTALLATION

INSTRUCTIONS.

ArtNo.030-0030 - RM tipping

warning symbols

• A CHILD OR ADULT CAN TIP THE RANGE AND BE KILLED

• ENGAGE THE RANGE TO THE ANTITIP DEVICE SEE INSTALLATION

INSTRUCTIONS.

• REENGAGE THE ANTITIP DEVICE IF THE RANGE IS MOVED.

• FAILURE TO DO SO CAN RESULT IN DEATH OR SERIOUS BURNS TO

CHILDREN OR ADULTS.

25

Page 24

The following symbols are related to safety and are used on the product and throughout this manual.

Meaning / Description Symbol

WARNING / CAUTION

An appropriate safety instruction

should be followed or caution taken if

a potential hazard exists.

DANGEROUS VOLTAGE

To indicate hazards arising from

dangerous voltages.

PROTECTIVE EARTH GROUND

To identify any terminal which

is intended for connection to an

external conductor for protection

against electric shock in case of a

fault, or the terminal of a protective

earth (ground) electrode.

!

Meaning / Description Symbol

HEAVY

This product is heavy and reference

should be made to the safety

instructions for provisions of lifting

and moving.

DISCONNECT MAINS SUPPLY

Disconnect incoming supply before

inspection or maintenance.

26

Page 25

INSTALLATION

Check the appliance is electrically safe and gas sound when you have nished.

9. Service and parts

Firstly, please complete the appliance details below and keep them safe for future reference – this information will enable us

to accurately identify the particular appliance and help us to help you. Filling this in now will save time and inconvenience

if you later have a problem with the appliance. It may also be of benet to keep your purchase receipt with this leaet. You

may be required to produce the receipt to validate a warranty eld visit.

Dealer’s Name and Address

Name of Appliance

Appliance Serial Number*

Fuel Type

Date of Purchase

Installer’s Name, Address and

Telephone No.

Date of Installation

* This information is on the appliance data badge.

If you have a problem

In the unlikely event that you have a problem with your appliance, please refer to rest of this booklet, especially the problem

solving section, rst to check that you are using the appliance correctly.

If you are still having diculty, please contact Tech Support at 800-223-3900 or email techsupport@agamarvel. com.

Please note

For warranty information or to register your AGA range, go to www.aga-ranges.com. You may also refer to the warranty

document provided with the appliance or contact Customer Service at 800-223-3900.

Out of warranty

We recommend that our appliances are serviced regularly throughout their life to maintain the best performance and

eciency. The frequency of service will depend on usage – for normal usage once a year should suce. Service work should

only be carried out by a suitably Authorized Person.

Spare parts

To maintain optimum and safe performance, we recommend that only genuine spare parts are used. DO NOT use re-

conditioned or unauthorized controls. Contact Order Desk at 800-223-3900 to order AGA spare parts or email orderdesk@

agamarvel. com.

27

Page 26

INSTALLATION

Check the appliance is electrically safe when you have nished.

10. Installation safety instructions

Regulations

Installation of this range must conform with local

n

codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/NFPA.54, latest

edition.

In Canada, installation must conform with the

n

current Natural Gas Installation Code, CAN/

CGA-B149. 1 or the current Propane Installation

Code, CAN/CGA-B149.2, and with local codes where

applicable.

In Canada, electrical grounding must be in

n

accordance with the current CSA C22.1 Canadian

Electrical Code Part 1 and/or local codes. See

‘Electrical Connection’ in this section.

CSA 1.1, latest edition and CAN/CGA-22.2 latest edition.

This range becomes hot in use, the cooktop burners produce

exhaust gases.

IMPORTANT

Observe all governing codes and ordinances.

n

The range must be properly grounded.

n

This appliance is heavy. Ensure you have the correct

facilities to complete the move. To nd the weight of

the appliance, refer to the "Technical data".

Refer to "Positioning the range".

n

Save these instructions for the local electrical

n

inspector’s use.

For your safety

DO NOT store or use combustible materials, gasoline or other

ammable vapors and liquids in the vicinity of this or any

other appliance.

If you smell gas,

• open windows.

Improper installation, adjustment, alteration,

n

service or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information, consult a qualied engineer.

NEVER reuse old exible connectors. The use of old

n

exible connectors can cause gas leaks and personal

injury. Always use NEW exible connectors when

installing a gas appliance.

IMPORTANT!

• Remove all packing material and literature from oven

before connecting gas and electrical supply to range.

• Have your range installed by a qualified installer.

• DO NOT install your range on a substrate that cannot

withstand 180 °F (82 °C).

• DO NOT install your range directly onto carpeting.

Ensure an appropriate, non-combustible, substrate is

installed prior to installing the range.

• Make sure the wall coverings around the range can

withstand heat generated by the range up to 200 °F

(93 °C).

• There must be a gap of at least 30’’ (762 mm) between

the top of the range and any combustible surface above

it.

• If a ventilating hood is installed above the range follow

the installation instructions supplied with the hood.

This type of ventilation system may cause ignition

n

and combustion problems with the gas cooking

appliance, resulting in personal injury or unintended

operation. Ventilating systems that direct the air

upwards can be used.

Items of interest to children should not be stored

n

above a range – children climbing on the range to

reach items could be seriously injured.

• DO NOT touch electrical switches.

• Extinguish any open flame.

• Immediately call your gas supplier.

28

Page 27

INSTALLATION

Check the appliance is electrically safe when you have nished.

Converting to propane gas

This appliance is supplied set for natural gas.

A conversion kit for Propane gas is supplied with the range.

The conversion must be performed by a qualied LP gas

installer. See the ‘Conversion’ section at the back of this

installation manual for more details.

For installation 5000 ft above sea level, the

n

appliance must be converted using high altitude kit

A065744. Contact your distributor.

Location of the range

The range may be installed in a kitchen/kitchen dining area

but NOT in a room containing a bath or shower.

The range is freestanding and should not be placed on a

separate base.

DO NOT locate the range where it may be subject to strong

drafts. Any openings beneath the range or behind the range

should be sealed.

The range should be positioned on a solid substrate.

Your range is heavy DO NOT place on soft oor

n

coverings, such as cushioned vinyl or carpeting.

Use care when moving the range on cushioned vinyl or

carpeted ooring.

When the oor covering ends at the front of the range, the

area that the range will rest on should be built up to the same

level or higher than the oor covering.

Also, make sure your oor covering will withstand

n

180°F. (See the Installation Safety Instructions

section).

(See the Installation Safety Instructions section).

n

29

Page 28

Check the appliance is electrically safe and gas sound when you have nished.

9. Installation

INSTALLATION

You will also need the following tools and equipment to

complete the range installation satisfactorily.

1. Multimeter

2. Electric drill

3. Masonry drill bit & anchors (only required if installing

the range on a stone or concrete oor)

4. Steel tape measure

5. Phillips head screwdriver

6. Flat head screwdriver

7. 2.5mm Allen key (supplied with the range)

8. Level

9. Open-end or adjustable wrench

10. Pencil and ruler

11. Pipe wrenches

12. 13 mm spanner or socket wrench

Additional materials you may need:

• Gas line shut-off valve.

• Pipe joint sealant or UL-approved pipe thread tape

with Teflon* that resists action of natural and LP gases.

*Teflon: Registered trademark of DuPont

• Flexible metal appliance connector (½’’ I.D.). A 5foot

length is recommended for ease of installation but

other lengths are acceptable. NEVER use an old

connector when installing a new range.

• Flare union adapter for connection to gas supply line

(¾’’ or ½’’ NPT x ½’’ I.D.).

• Flare union adapter for connection to pressure regulator

on range (½’’ NPT x ½’’ I.D.).

22

Page 29

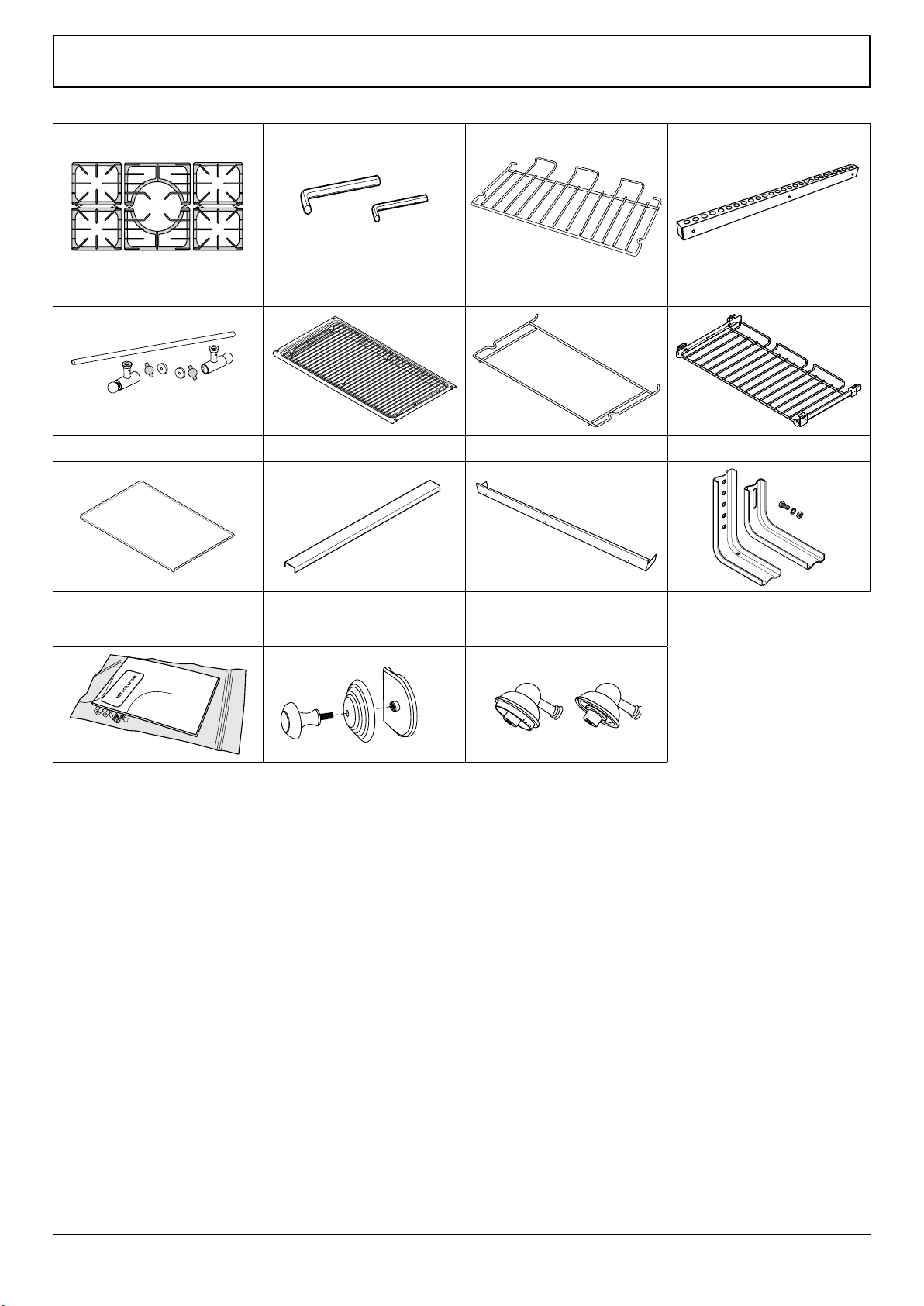

Checking the parts:

INSTALLATION

Check the appliance is electrically safe and gas sound when you have nished.

6 grates page 23

Hand rail and end pieces page

23

1 pastry tray

ArtNo.326-0005 - Pastry tray

Allen key 3 mm 2.5 mm 2 full capacity racks

Broiler tray and grid Broiler tray rack Telescopic rack with runners

Side extension kit

ArtNo.351-0001 - Side extension

panel USA

page 27 Toe kick page 23 Anti-tip device page 26

ArtNo.350-0007 - Plinth USA

Rear Flue Grille page 26

Conversion kit from natural gas to

propane gas (kit number A060048)

page 30

ArtNo.020-0019

Conversion Kit USA

2 sets of oven door knob parts

page 23

5 burner control knobs and 3 oven

control knobs page 23

23

Page 30

INSTALLATION

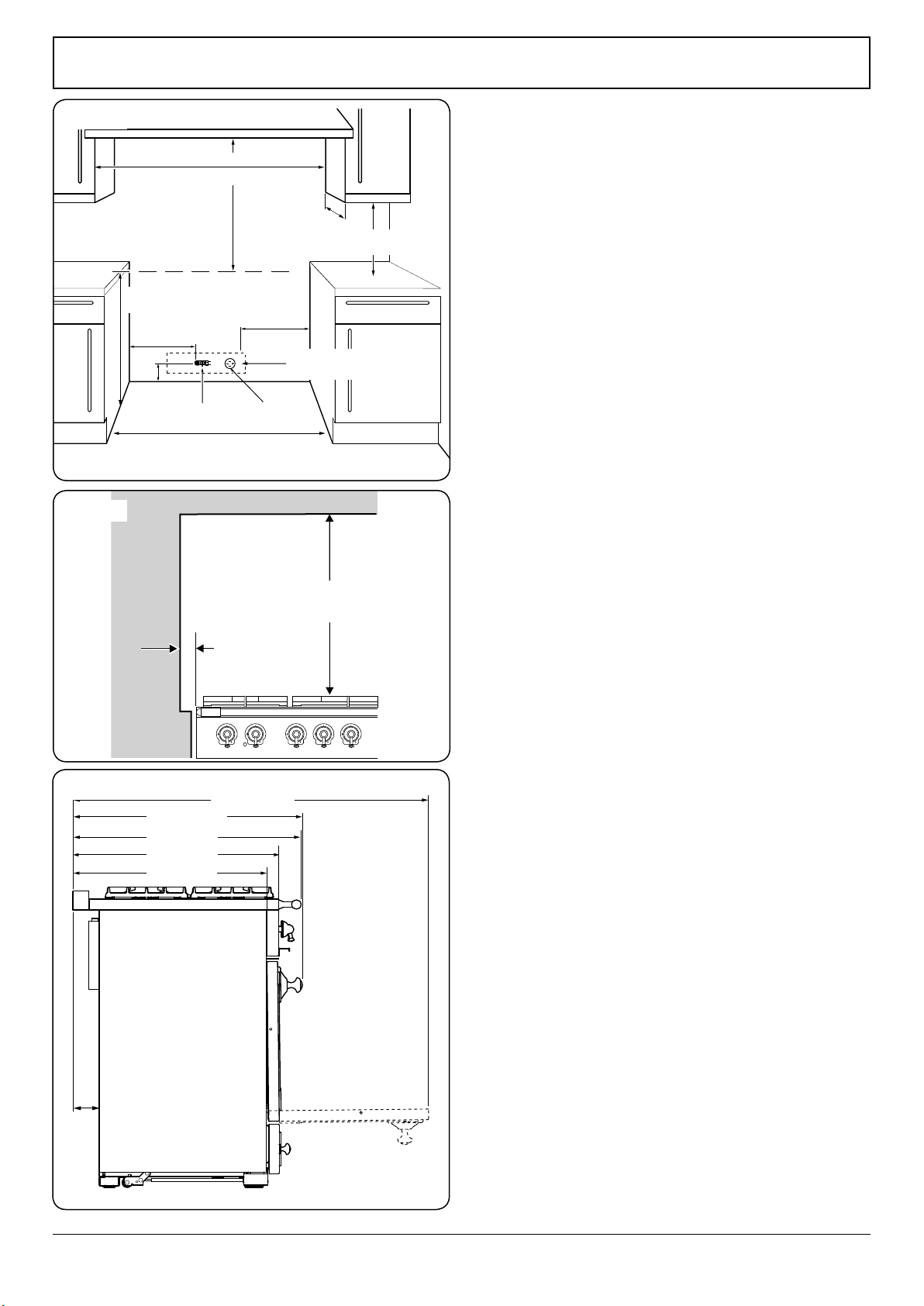

ArtNo.280-0001 36” wide oven dimensions

Min 35½” (90 cm) - 36“ (91 cm)

Min 31½” (80 cm)

between the top of the cooktop

and a horizontal combustible surface

Maximum 13”

(33 cm)

Min 35½” (90 cm) - 36“ (91 cm)

recommended to allow for moving the range.

For Canada, min 36/” (92.5 cm)

For electrical and

gas supply zone

Min 35 ⁄” (91 cm)

Max 36 /” (93.7 cm)

For Canada, min 36/” (92.5 cm)

6” (15.2 cm)

16” (40.6 cm)

16” (40.6 cm)

Gas shut-o

valve

Electrical

outlet

Minimum 18”

(46 cm)

Check the appliance is electrically safe and gas sound when you have nished.

Fig. 9.1

Min 35½” (90 cm) - 36“ (91 cm)

For Canada, min 36⁄

Min 31½” (80 cm) between the top

of the cooktop and a horizontal

combustible surface

Min 35⁄” (91 cm)

Max 36⁄” (93.7 cm)

Gas shut-o

valve

Min 35½” (90 cm) - 36“ (91 cm) recommended to

allow for moving the range.

For Canada, min 363/8” (92.5 cm)

Fig. 9.2

” (92.5 cm)

Maximum 13”

16” (40.6 cm)

Electrical

outlet

(33 cm)

Minimum

18” (46 cm)

For electrical and gas

supply zone

Positioning the range

Fig. 9.1 and Fig. 9.2 show the minimum recommended

distances and clearances from the range to nearby surfaces.

You must provide adequate clearances between the range

and adjacent combustible surfaces. These dimensions must

be met for safe use of your range.

The location of the electrical outlet and pipe opening (see

Gas Pipe and Electric Outlet Locations) may be adjusted to

meet specic requirements.

A gap of at least 3” (7.5cm) should be left between each

side of the range ABOVE the cooktop level and any adjacent

vertical surface.

The cooktop surround should be level with, or above, any

adjacent work surface.

For non-combustible surfaces (such as unpainted metal or

ceramic tiles) the gap each side can be reduced from 3” to 1”

(2.5 cm).

A minimum space of 31½” (80 cm) is required between the

top of the cooktop and a horizontal combustible surface. The

maximum depth for cabinets installed above cooktops is 13’’

(33 cm).

Fig. 9.3

3” (7.5cm)

minimum

31½” (80cm)

minimum

The depth of the range is 28⁄’’ (72 cm) overall (Fig. 9.3).

Any range hood should be installed in accordance with the

hood manufacturer’s instructions.

*Any splashback must be tted in accordance with the

manufacturers instructions. Allowance should be made for

*

the additional height of the ue trim, which is tted to the

cooker hob.

For safety reasons curtains MUST NOT be sited

n

immediately behind the range.

We recommend a gap of 35½” (90 cm) – 36” (91 cm (for

Canada 36⁄” (92.5cm) between units to allow for moving the

range.

If a ush t is required (USA only), install the range up to the

unit at one side then install the unit the other side.

DO NOT box the range in – it must be possible to move the

range in and out for cleaning and servicing.

3⁄” (8.5cm) without side

extension tted

ArtNo.281-0015 - Albertine SC - dimensions

Open oven door

shown dotted

24

Page 31

INSTALLATION

Check the appliance is electrically safe and gas sound when you have nished.

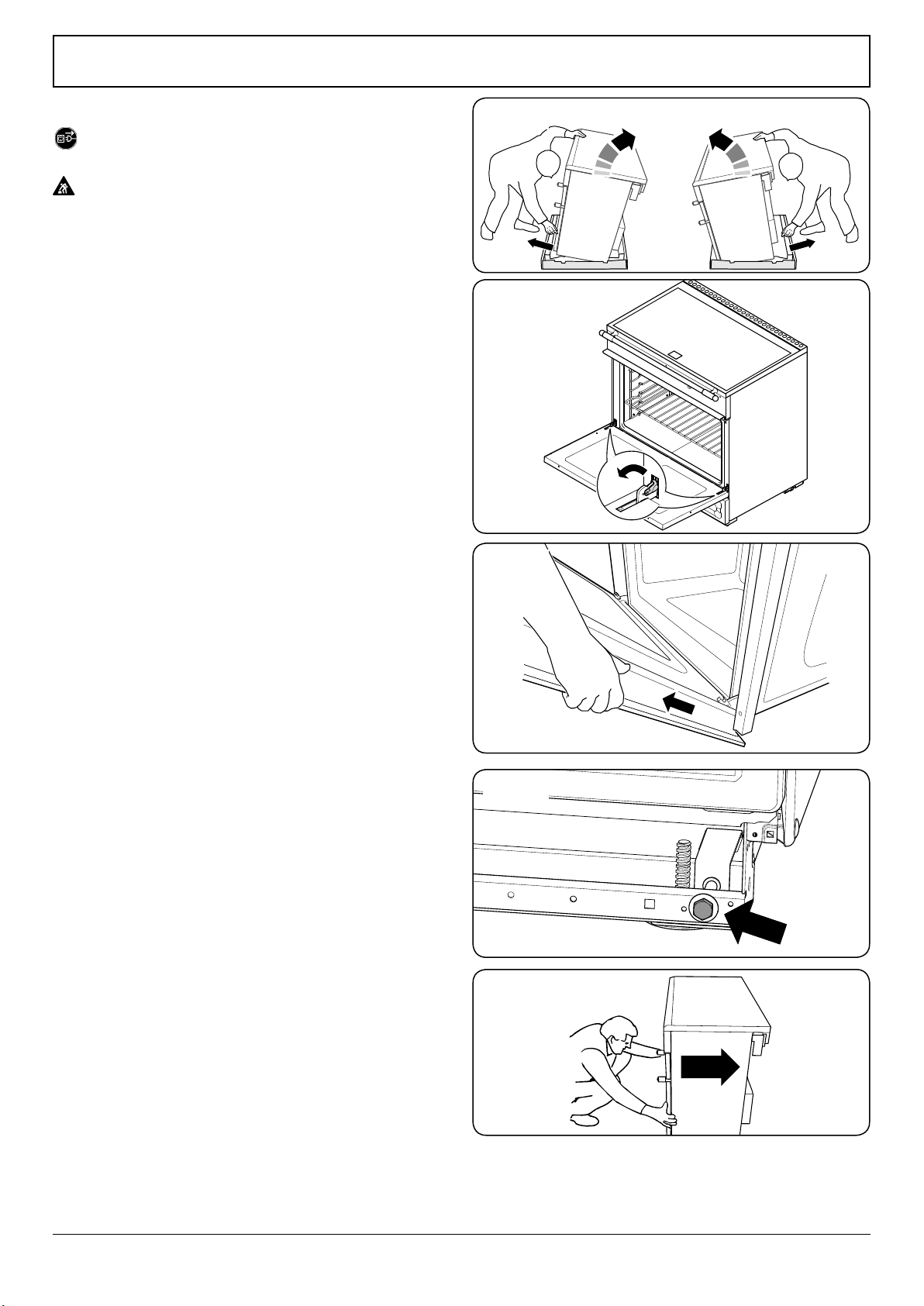

Moving the range

On no account try and move the range while it is

plugged into the electricity supply.

This appliance is heavy. Ensure you have the correct

facilities to complete the move. To nd the weight of

the appliance refer to the “Technical data”.

We recommend two people maneuver the range. Make sure

that the oor covering is rmly attached, or removed to

prevent it being disturbed when moving the range around.

To help you, there are two levelling rollers at the back, and

two screw-down leveling feet at the front.

Remove the polystyrene base pack. From the front, tilt the

range backwards and remove the front half of the polystyrene

base Fig. 9.4.

Repeat from the back and remove the rear half of the

polystyrene base.

Removing the door

Remove the oven door as follows: open the door fully. Swivel

the locking ‘U’ clips forward to the locking position (Fig. 9.5).

To remove the oven door, grip the sides of the door, lift

upwards and then slide the door forwards (Fig. 9.6) and

remove.

Fig. 9.4

Fig. 9.5

Fig. 9.6

Lowering the two rear rollers

To adjust the height of the rear of the range, rst t a 13 mm

spanner or socket wrench onto the hexagonal adjusting

nut (Fig. 9.7). Rotate the nut – clockwise to raise – counterclockwise to lower.

Make 10 complete (360°) turns clockwise. Make sure you

lower BOTH REAR ROLLERS.

Unfold the rear edge of the cardboard base tray. Get a good

grip on the top of the oven cavity panel as you move the

oven. Carefully push the range backwards o the cardboard

base. Remove the base tray.

Position the range close to its nal position, leaving just

enough space to get behind it (Fig. 9.8).

IMPORTANT: Remove all tape and packaging. Make sure

the burner heads are properly seated and level. Take the

accessory pack out of the oven. Check to be sure that no

range parts have come loose during shipping.

Fig. 9.7

Fig. 9.8

25

Page 32

INSTALLATION

ArtNo.280-0029 - Flue Grill

ArtNo.280-0030 - Fixing Flue Grill

ArtNo.280-0031 - Flue Extension Fixing

Alternative positions

for anti-tip device

Check the appliance is electrically safe and gas sound when you have nished.

Fig. 9.9

Fig. 9.10 Fig. 9.11

Fig. 9.12

Alternative positions for

anti-tip device

Installing the flue grille

The ue grille is packed separately (Fig. 9.9).

The larger of the holes along the sides are for screwdriver

access and should face to the rear. Use the screws and nuts

supplied to hold the grille in place (Fig. 9.10).

Clip the exible extensions of the oven ues to the ue grille

using the clips provided inside the ue grille (Fig. 9.11).

Leveling

It is recommended that you use a spirit level on a shelf in one

of the ovens to check the level.

Place the range in its intended position, taking care not to

twist it within the gap between the kitchen units as damage

may occur to the range or the units.

The front feet and rear rollers can be adjusted to level the

range. To adjust the height of the rear of the range turn the

adjusting nuts at the front bottom corners of the range.

Anti-tip device

NOTE: The range must be set to the correct height and

leveled before the anti-tip bracket is installed.

Anti-tip bracket

Stability bracket

Anti-Tip bracket

01⁄8" (3 mm) min

ArtNo.070-0014 - Stability bracket - Wall fitting

3 mm min

Typical oor mounting

Typical oor mounting

Range

Range

Cooker

Fig. 9.13

Floor

Floor

Fitting the anti-tip device

1. A range using a exible gas connector must be secured

with a suitable anti-tip device.

2. A suitable anti-tip device is supplied and shown in

Fig. 9.12.

3. When tting the anti-tip bracket (Fig. 9.12 and

Fig. 9.13), adjust the bracket to give the smallest

practicable clearance between the bracket and the

engagement slot in the rear of the range.

4. Fit the bracket so that it engages as far as possible over

the chassis of the range.

DO NOT operate the range before the appliance is

n

in its installed position and the anti-tip devices are

engaged.

If the appliance is moved ensure that the anti-tip

n

devices are re-engaged and the range has been

returned to its original installed position.

DO NOT step, lean or swing on the range doors

n

or drawer as this could tip the range and result in

serious injury or death.

Wall fixing

Where oor xing is impractical and provided that the outer

anti-tip bracket can be attached to a solid wall, the anti-tip

device may be attached to a wall (Fig. 9.14). Make sure to use

suitable screws and xings.

26

Page 33

INSTALLATION

ArtNo.280-0070 - Side extension A

ArtNo.281-0004 - 90SC

- Fitting the side panel

ArtNo.281-0005 - Albertine SC

- Side panel in place

Check the appliance is electrically safe and gas sound when you have nished.

Side panel extension kit

Two side extension panels are supplied with the range. These

can be installed where the side of the range is exposed. The

extension installation must be performed by a qualied gas

installer, preferably during installation of the appliance (Fig.

9.15).

Kit Contents:

• Side panel extension 2

• M5 screw 4

• M5 nut 4

• Large washer 4

• Shakeproof washer 4

Procedure

1. Place a screw and washer in the top hole in the rear

edge of the range side panel. Add a shakeproof washer

and start the nut on the screw threads so that the screw

is loosely held in place. Repeat with the other hole (Fig.

9.16).

2. Slide the side extension in from the side behind the

washers (Fig. 9.17).

Fig. 9.14

Fig. 9.15

Outer anti-

Outer stability

Outer anti-tip

bracket

bracket

bracket

1/8” (3mm) min

Wall

Wall

3 mm min

Range

Range

Cooker

Floor

Floor

3. Tighten the top and bottom screws to hold the side

extension in place.

Reposition the range making sure the anti-tip device is reengaged properly when the range is replaced. Failure to take

this precaution could result in tipping of the range and cause

injury.

NOTE: Check that the extension panel does not foul the

mains lead or gas connection when the cooker is pushed

back Reconnect the electricity supply.

Fig. 9.16

Fig. 9.17

ArtNo.280-0071 - Side extension B

27

Page 34

Check the appliance is electrically safe and gas sound when you have nished.

9¾” (24.7 cm)

from the side of the range

6” (15.2 cm)

from the oor with the range at its lowest setting

10

1

/

4

“

(26 cm)

6

4

/

5

“

(17.4 cm)

11. Gas connection

INSTALLATION

Area accessible through drawer

Area accessible through drawer

6”

6”

Gas shut-o valve

Gas shut o valve

10”

Gas inlet

Gas inlet

Fig. 11.1

9 ¾”

Side of range

Side of range

Fig. 11.2

Installation of this range must conform with local codes or, in

the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1-latest edition.

In Canada

The range must be installed in accordance with the current

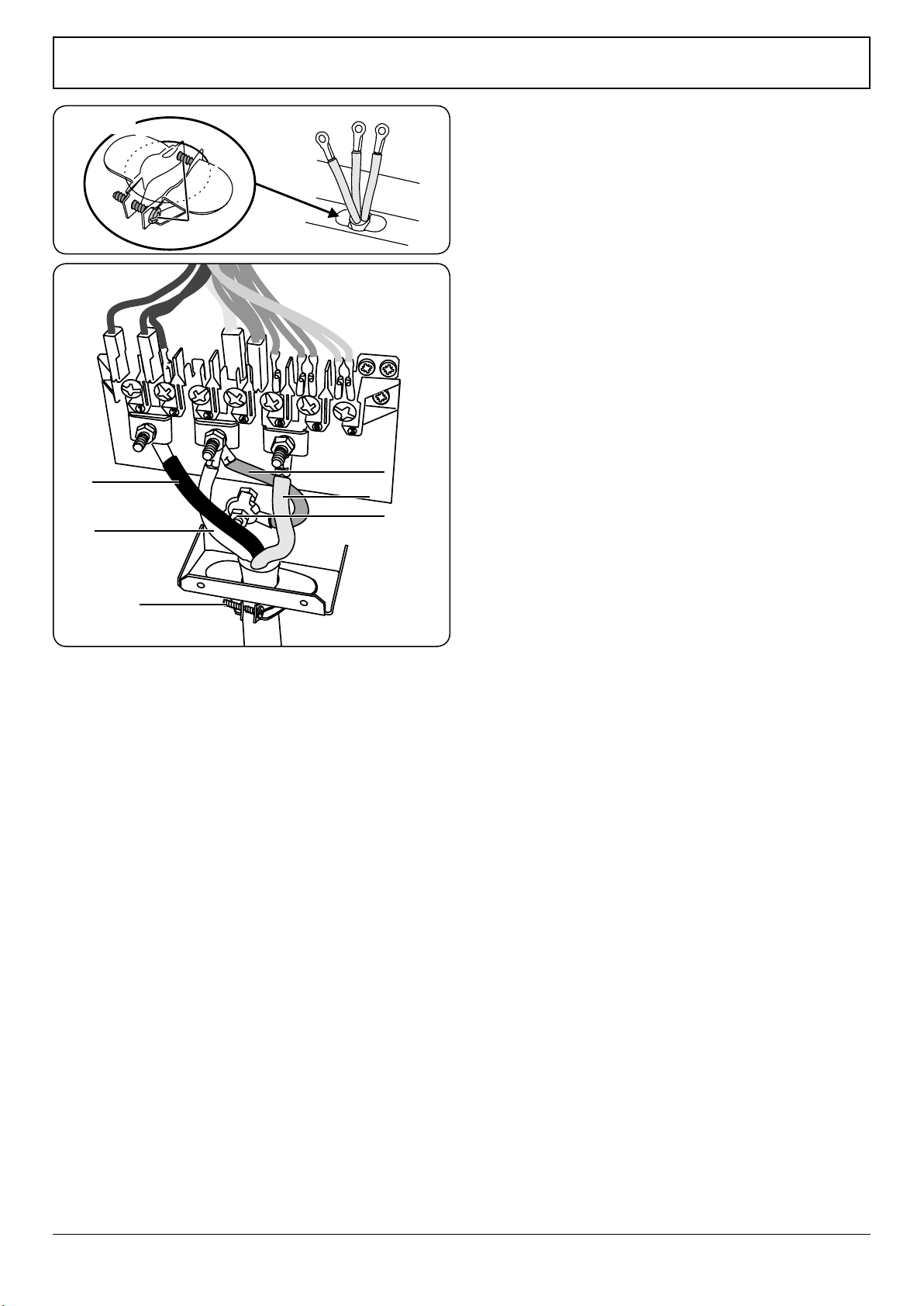

CGA Standard CAN/CGA-B149 – Installation Codes for Gas