Page 1

La Cornue 1908

“Broche Flamberge”

Rotisserie

By La Cornue

Installation

GUIDE

C HÂTEAU L INE

Page 2

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

11

Dear Customer,

Thank you for choosing a La Cornue product. We hope that you will derive tremendous enjoyment

from cooking delicious meals with it.

The aim of this document is to make you familiar with the potential provided by a professional

quality product designed for individuals, and to facilitate its maintenance.

Above all, a La Cornue product is manufactured using noble and pure materials. The choices made

for some components, such as brass for the burners and cast-iron for the gas simmering plate, are the

result of criteria of technicality and professional performance, which are not attainable with other

materials or protective treatments. We are very much attached to the authenticity of our products and

we are convinced that you will appreciate them even more as you use them.

In order to make sure that you will be satisf ied with your product for a long time, we recommend that

you follow the advice given in the "User's Instructions" section of this document.

Thank you for choosing us,

Kind regards,

Xavier Dupuy

President

La Broche Flamberge

Page 3

Page

WARNINGS ........................................................................................................ 3

C

OMPLIANCE WITH E

UROPEAN DIRECTIVES ............................................................ 4

L

A BROCHE FLAMBERGE ..................................................................................... 5

D

ESCRIPTION ...................................................................................................... 6

1. General ............................................................................................... 6

2. Dimensions ......................................................................................... 7

B

EFORE DELIVERY .............................................................................................. 8

1. Safety .................................................................................................. 8

2. Electrical supply ................................................................................. 9

3. Gas supply .......................................................................................... 9

C

ONNECTIONS

.................................................................................................. 10

1. Electrical connections ....................................................................... 10

2. Gas connection ................................................................................. 11

I

GNITION

- ADJUSTMENT .................................................................................... 12

1. Tests .................................................................................................. 12

2. Adjustment ....................................................................................... 13

3. Injector replacement ........................................................................ 14

F

UNCTIONING ................................................................................................... 16

1. Ignition - Broche Flamberge gas ...................................................... 16

2. Ignition - Broche Flamberge electric ................................................ 16

3. Operation on the rods ...................................................................... 16

4. Positioning of the rods ..................................................................... 16

5. How to use the various rods ............................................................. 16

6. Cooking ............................................................................................ 17

7. Cleaning ........................................................................................... 17

8. Important ......................................................................................... 17

WARRANTY ...................................................................................................... 18

CONTENTS

LA CORNUE - Installation Guide - Broche Flamberge - Europe GB

June 2007 - Anna K.

Page 4

WARNINGS

This appliance must be installed by a qualified professional in accordance with the current regulations in the country where the appliance is installed and must only be used in

a well ventilated area. Read the manuals before installing and using this appliance.

Before installing the appliance, ensure that the local gas supply conditions (gas type and

pressure) and the adjustment of the appliance are compatible.

The adjustment conditions for this appliance are indicated on the label at the back of the

hob and on the test certificate.

This appliance is not intended to be connected to a ventilation system or a ventilation

shaft for combustion products. It must be installed and connected in accordance with current regulations. Particular care shall be taken concerning ventilation arrangements.

Furthermore, we advise you to connect your Flamberge to a natural ventilation

shaft (separate chimney) to evacuate the hot air correctly.

The Flamberge must never be connected to a motorized hood.

The use of a gas cooking appliance results in the production of heat and moisture in the

room where it is installed. Ensure that this room is well ventilated: keep the natural ventilation apertures open or install a mechanical ventilation device.

Prolonged or intensive use of the appliance may call for additional ventilation, e.g. by

opening a window, or for more effective ventilation, by increasing the power of the

mechanical ventilation system, if there is one.

This appliance can only be installed in an alcove made of non-combustible

material (e.g.: a brick alcove).

The accessible parts are hot when in use: ensure that all combustible materials are at least

2m away from the appliance (in front, above and at the sides). It is forbidden to place the

appliance under a hood made of wood or other combustible material.

The parts that are protected by the manufacturer must not be manipulated by the installer or the user.

WARNING

The accessible parts are hot when in use: keep young children at a safe distance.

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

33

Page 5

All of our appliances comply with the following European Directives:

- Directive 90/396/EEC "GAS APPLIANCES"

- Directive 2006/95/EC "LOW VOLTAGE"

- Directive 89/336/EEC "ELECTROMAGNETIC COMPATIBILITY"

- Directive 2002/96/EEC "WEEE - WASTE FROM ELECTRICAL AND ELECTRONIC

EQUIPMENT"

- Directive 2002/95/EEC "RoHS - RESTRICTIONS ON HAZARDOUS SUBSTANCES"

The European Parliament’s 2002/96/EC Directive on waste from electrical and electronic

equipment (WEEE) requires that used household appliances are not disposed of in unsorted municipal landfills and must be collected separately to optimise recovery and recycling of the materials they contain and thus reduce their impact on human health and

the environment. Consumers should contact their local authorities or their dealer with

regard to the procedure to be followed for the collection of their old appliance. Please

comply with local regulations for disposal of the packaging material. The packaging can

thus be recycled.

This “crossed-out bin” logo found on all products means that the equipment cannot be disposed of with other waste, that it is the object of a

selective collection with a view to recovery, reuse or recycling.

WASTE FROM ELECTRICAL AND ELECTRONIC EQUIPMENT

COMPLIANCE WITH EUROPEAN DIRECTIVES

Compliance with European Directives

COMPLIANCE WITH EUROPEAN DIRECTIVES

44

Page 6

"ON DEVIENT CUISINIER

, MAIS ON NAIT ROTISSEUR"

"C

OOKING CAN BE LEARNED, BUT ROTISSERIE COOKING IS AN INNATE SKILL"

This dictum, scrupulously believed by the Chaîne de Rôtisseurs (guild of rotisserie cooks),

demonstrates all the difficulties and subtleties of cooking on a spit.

Certain absolute principles of this type of ancestral cooking mode must be respected in

order to achieve outstanding results

.

"L

"L

A

A

B

B

ROCHE

ROCHE

F

F

LAMBERGE

LAMBERGE

"

"

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

55

LA BROCHE FLAMBERGE

Description

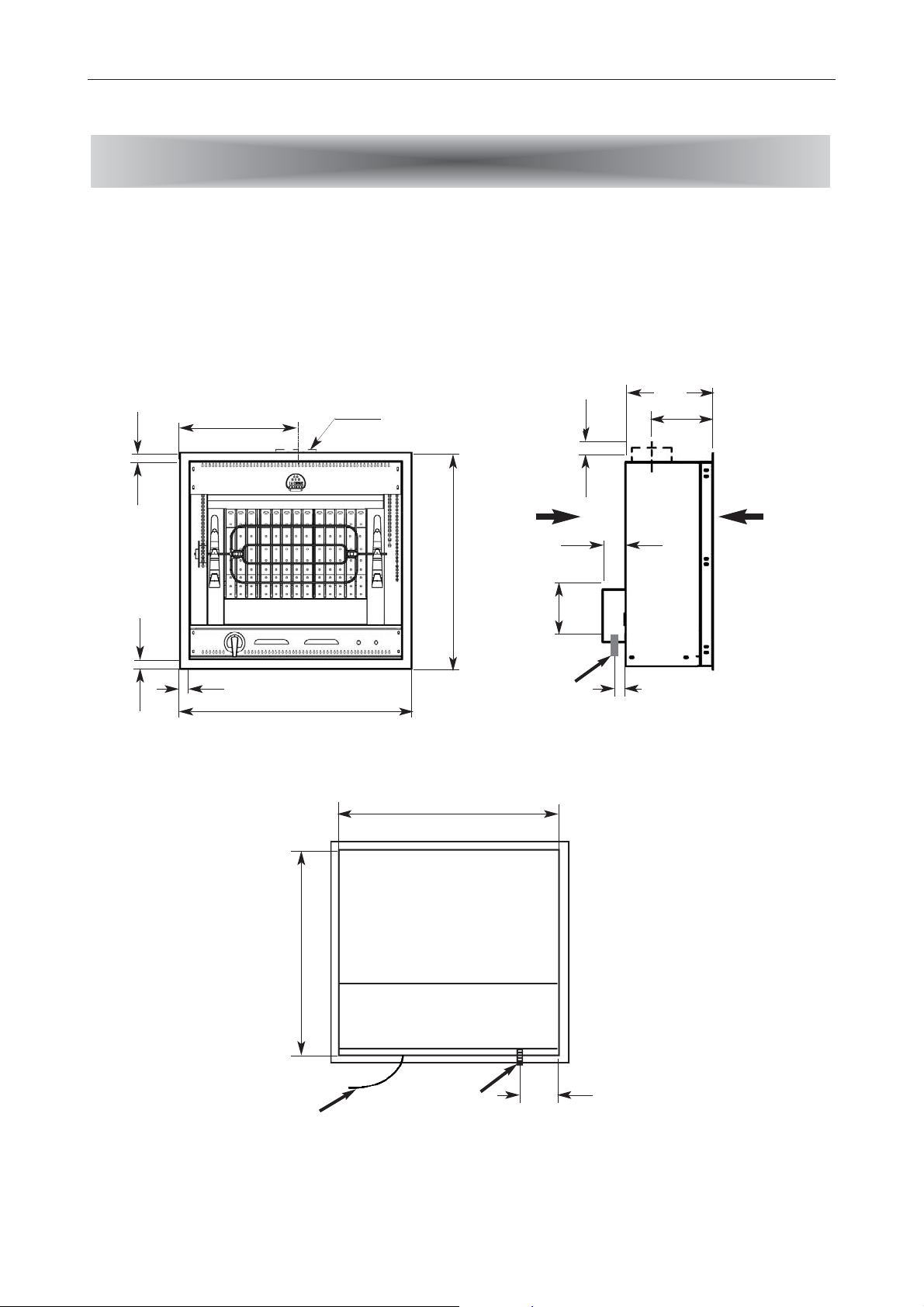

755

200

30

50

30

30

805

715

750

~ 35

~ 160

100

310

205

402,5

FF

139

Gas inlet

G 1/2 (15/21)

for BFG

Gas inlet

G 1/2 (15/21)

for BFG

Electrical cable

230 V a.c. (BFG or BFE)

400 V a.c. 3 N (BFE)

All dimensions are

given in mm

Side B

Side B

Side A

Side A

Page 7

The "Broche Flamberge" is a rotisserie fr

om the "La Cornue"

line, designed for non-combustible built-in installation. It

consists mainly of a heating source (gas burner or electric element) and an electrical motor for the rotisserie. It is delivered

with the following accessories:

— 1 sauce tray

— 2 flat rods,

— 1 English-style rod

— 1 sauce spoon,

— 1 fork,

The "Broche Flamberge" comes out in 2 models:

— Electrical model, ref. BFE- - 00E00 ;

— Gas model, ref. BFG- -00E00, for use with either natural

or butane / propane gas at the following supply pressures:

- Natural gas G 20 / G 25 - 20 / 25 mbar

- butane/propane gas G30 / G31 - 28-30/37/50 mbar

The following table outlines the nominal electrical power and gas input ratings of the

models BFE and BFG Broche Flamberge.

General

DESCRIPTION

66

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

DESCRIPTION

Volume Flow

Rate

Mass Flow Rate

MMooddeell BBFFEE-- --0000EE0000

4 660 W

—

MMooddeell BBFFGG-- --0000EE0000

60 W

12 000 W

1,27 m3/hour

1,48 m3/hour

0,93 kg/hour

0,946 kg/hour

Electrical power

Heat Flow

Flat rod

English-style rod

Natural gas (G20 - 20 mbar)

Natural gas (G25 - 20 mbar)

Propane gas (G31)

Butane gas (G30 - 50 mbar)

1. GENERAL

Page 8

Broche Flamberge

— Height: 715 mm

— Width: 750 mm

— Depth: 310 mm for electrical model

410 mm for gas model

— Weight: 60 kg

Built-in Opening

— Height: 725 mm

— Width: 760 mm

— Depth: 420 mm minimum

Frame

— Height: 755 mm

— Width: 805 mm

DESCRIPTION

Dimensions

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

77

Housing enclosure

Natural discharge

diameter 139 mm

Broche Flamberge

Fresh air inlets

(for BFG)

2. DIMENSIONS

Page 9

In order to be able to install your appliance as soon as it is delivered, you must check that

the layout of your kitchen and your gas and electricity supplies are adapted.

1.1. Ventilation

The “La Broche Flamberge” spit is not intended to be connected to a ventilation shaft or

ventilation system for combustion products leading to the outside. It is therefore vital that

the room where the spit is to be installed has excellent ventilation, i.e. to the outside

- for hot air, vapour and burnt gases – and a fresh air inlet.

Do not use an air recycling system.

A flow rate of at least 4 cubic metres per hour of fresh air per KW of gas heat power is

necessary to guarantee an adequate combustion air supply.

The external evacuation system must consist of fixed aerators, flipping glass panes,

vapour extractors or extractor hoods. We advise you to adopt one of the latter two

solutions.

Recommended power: 500 m3/h minimum or 10 to 15 times the volume of air in the

room per hour.

"La Cornue" can supply models of customized hoods in materials matching your cooker or

extractors that can be integrated into a hood manufactured by the user.

Fresh air inlet: to be efficient, this must be located either directly at the back and front

of the alcove (see diagrams 5 and 7), or at the back or front of the alcove and in a radius

of 2 to 3 metres at ground level.

1.2. Fitting the spit

The “La Broche Flamberge” spit is intended for installation in an alcove made of bricks,

tiles or other non-combustible material. This alcove must have the following

dimensions: Height: 725 - 730 mm

Width: 760 - 770 mm

Depth: 420 mm minimum

A frame fits over the edge of the alcove.

The “La Broche Flamberge” spit must be attached to the frame on the front by 4 screws.

The position of these screws is established by the installer according to the appearance or

the arrangement of the wall covering.

Safety

BEFORE DELIVERY

88

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

BEFORE DELIVERY

1. SAFETY

Page 10

The accessible parts are hot when in use: ensure that all combustible material is at least 2

m away from the appliance (in front, above and at the sides). It is forbidden to place

the spit under a hood made of wood or other combustible material.

The appliance must be well ventilated, with several fresh air inlets, and hot air outlets on

the front and rear of the appliance.

Furthermore, we advise you to connect your Flamberge to a natural ventilation shaft

(separate chimney) to evacuate the hot air correctly. The Flamberge must never be

connected to a motorized hood.

The “La Broche Flamberge” spit is delivered with a 139 mm diameter connection collar.

Leave a minimum of 100 mm between the wall and the rear of the Flamberge.

As an option, the “La Broche Flamberge” spit can be supplied in a “ready to use” version

with an enamelled or stainless steel surround. Ventilation requirements for this version

are identical to the fitted version.

The “ready to use” “La Broche Flamberge” spit can only be installed on or against non-

combustible surfaces.

Voltage: 230 volts in single-phase, for the BFG- -00E00 model

230 volts in single-phase of 400 volts in 3-phase + neutral,

for the BFE- -00E00 model

Safety: the electrical supply must be grounded and must be equipped with a

protective circuit breaker compatible with the appliance’s power rating. In

high-risk regions, an additional protection against natural electrical phenomena

(lightning) must be used.

Power: for the BFE- -00E00 (electric) model, you should check that the power of your

electrical installation is adequate, given the other electrical appliances already

installed. The table on page 10 indicates the power and current required by the

“La Broche Flamberge” electric spit.

Plug connection is not recommended in view of the power of the BFE- -00E00

(electric) model. The connection will be made using a flexible cable directly connected to

the circuit breaker outlet via a junction box. Space must be left for a continuity box, with

terminal bar - preferably of the anti-shearing type – located on the right behind the “la

Broche Flamberge” spit.

The gas must be supplied via a rigid metallic pipe, terminated by an easily accessible

manual shut-off valve, installed on the supply side of the connection.

BEFORE DELIVERY

Electrical supply

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

99

2. ELECTRICAL

SUPPLY

3. GAS SUPPLY

Page 11

This valve must be installed bearing in mind that the gas inlet is located on the rear lefthand side of the appliance.

When all of the work has been carried out on your gas supply network, perform a

functional test before connecting the “La Broche Flamberge” spit. This will ensure

that no metallic burrs can enter the appliance’s gas supply pipe and thus obstruct the

burners.

This paragraph does not concern the BFG- -00E00 gas-only model, for which there are no particular

electrical connection requirements, the only connections being those of the 60 W motor.

The “La Broche Flamberge” spit is delivered ready equipped with a flexible cable

consisting of 3 (230 V, single-phase) or 5 (400 V, 3-phase) conductors, 1.50 m in length,

ready for connection to a single-phase or 3-phase + neutral supply, according to the

indications on the order form.

•All electricity supply circuits must be disconnected before accessing

the connection terminal boxes.

If the “La Broche Flamberge” spit is connected to a different type of power supply at a

later date, the wiring must be modified accordingly, as per the following settings:

- Unscrew the cover at the rear of the appliance to access the connector block to

which the heating elements are connected.

- For a 230 V Single-phase supply (1 phase + neutral + ground), shunt the Ph1, Ph2

and Ph3 studs, and then connect the cable conductors as follows:

- the neutral on N,

- the phase on Ph1,

- the ground on T (yellow/green).

Electrical connection

CONNECTIONS

1100

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

CONNECTIONS

MMooddeell

44 666600

2200 22,,55 33GG22,,55 1100 11,,55 55GG11,,55

BBFFEE-- --0000EE0000

Total Power

in Watts

Current

in Ampères

Nominal

cable sec-

tion

in mm

2

Cable refe-

rence

HH0077 RRNN--FF

Current

in Ampères

Nominal

cable sec-

tion

in mm

2

Cable refe-

rence

HH0077 RRNN--FF

Power and current for electrical model BFE -- 00E00

( * phase 1 and 2 - heating element 2300 W each ; phase 3 - motor 60 W )

230 V a.c. Power supply

(1 Ph + N + T)

400 V a.c. 3N Power supply

(3 Ph + N + T) *

1. ELECTRICAL CONNECTION

Page 12

- For a 400 V 3-phase supply (3 phases + neutral + ground):

- connect the neutral to N

- the other three connection cable conductors to studs Ph1, Ph2 and Ph3, (phases),

- the ground on T (yellow/green).

REMINDER: the appliance should be connected to the main power supply via terminal

blocks (preferably of the anti-shearing type) and not by means of simple plugs.

Insert the cable below the hot air outlets at the back of the “La Broche Flamberge”

spit, never in front of them.

This chapter only concerns the BFG- -00E00 “La Broche Flamberge” gas spit.

Your “La Broche Flamberge” spit is delivered with equipment adapted to the type of gas

supply specified when ordering (natural gas, butane or propane), and according to the

country where the spit is to be installed. In most cases, only the injector needs to be

changed if a different type of gas is used. However, it may be necessary to adjust the “bypass” screw and the pilot light.

See page 14 for the table summarising the injectors to be used for each type of gas, the

country of installation and injector replacement instructions.

If no particular instructions are specified in the order, the appliance is equipped

with injectors for natural gas G20 (pressure: 20 mbar).

The type of gas for which the appliance is equipped is indicated on a label at the

rear of the appliance, near the gas supply pipe.

Connection to the previously installed shut-off valve must be made using a rigid

metallic tube installation, whatever type of gas is used.

The “La Broche Flamberge” spit is connected to the gas supply using a G ½ thread

male threaded coupling (previous reference: 15/21).

If a sealing compound has to be used, we recommend using LOCTITE 542.

If it is impossible to connect the spit using a metallic tube, only certified flexible

hoses with mechanical coupling may be used.

CONNECTIONS

Gas connection

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

1111

2. GAS CONNECTION

230 V single-phase 400 V 3-phase

T = Ground

N = Neutral

Ph1 = Phase 1

Ph2 = Phase 2

Ph3 = Phase 3

Page 13

The hose must not pass behind, in front of or close to a hot air outlet. It must not be

crushed or kinked.

Recommended hose: Approved TUBOGAZ hose

It is forbidden to connect our gas appliances with flexible hoses mounted on hose

tailpieces.

For appliances operating with BUTANE / PROPANE gas, use two cylinders with an

automatic reversing switch or an outdoor tank, and a standard regulator adapted to

the total flow rate for your model and the gas pressure.

We advise you to use a 2 kg/h minimum regulator.

As a general rule, an additional safety margin corresponding to 20 – 30% of the

appliance’s maximum flow rate must be respected.

To guarantee constant pressure from the gas supply, the regulator should not be

placed more than 2 m from the appliance.

Each appliance must have its own regulator.

This chapter only concerns the “La Broche Flamberge” gas spit. For the electric models, only 15 to 20

minutes preheating is required before installing the meat to be roasted.

The “La Broche Flamberge” gas spit is fitted with a shut-off tap with thermocouple and

pilot light: if the pilot light should accidentally go out, the gas supply is automatically shut

off after a few seconds.

To ignite the spit proceed as follows:

— push the control lever and turn it to the left to the "star" position, whilst at the

same time holding a large lighted match to the pilot light located on the left-hand side

above the gas burners.

— hold the lever down for another 20 seconds or more to activate the safety mechanism.

— release the lever: the pilot light remains lighted and the safety mechanism is then

operational.

If the pilot light goes out, repeat the procedure, holding the lever down slightly longer. When

the system is new, the safety mechanism takes longer to activate than normal.

— to ignite the burners, press the lever and turn it to “high flame”. The flame can then be

adjusted to the required strength.

— to switch off the flame, set the lever to “0”.

15 to 20 minutes preheating is required before installing the meat to be roasted.

Tests

IGNITION

1122

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

IGNITION - ADJUSTMENTS

1. TESTS

Page 14

All adjustments are made before leaving the factory to ensure an optimal setting.

However, after changing an injector for use with a different type of gas supply, the “low”

flame and pilot light settings should be adjusted.

All settings and injector replacements should be carried out by a qualified

professional.

After any intervention on the gas circuit (adjustments, injector replacements,

etc) the system should be checked for tightness, according to current standards.

2.1. Adjusting the “low” flame setting

Only the burner “low flame” setting can be modified by the following procedure:

1. Remove the control lever by unscrewing the screw (a)

which holds it in place.

2. Remove the lower plate by unscrewing the screws (b)

blocking it.

3. Re-install the control lever; light the burner and turn the

lever to the "low flame" position.

4. Remove the control lever again and using a screwdriver,

turn the slotted screw (A) located on the body of the tap (B)

to the left to increase the gas flow or to the right to

reduce it.

Re-install the lever to switch off the burner.

Comment: the flame height must not be more than a third of the height of the hearth.

5. Re-install the lower plate and the control lever, tightening the appropriate screws.

IGNITION

Adjustments

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

1133

a b

2. A

DJUSTMENTS

A

B

Page 15

Warning: Make sure that there is enough room between the lever and the lower plate to

allow the lever to be pressed down before turning when lighting the burner.

2.2. Adjusting the pilot light

The “La Broche Flamberge” spit is fitted with a pilot light which is adjusted before

leaving the factory to ensure an optimal setting.

The pilot light should be adjusted after changing an

injector for use with a different type of gas supply from

that initially installed.

Adjustment procedure:

1. Unscrew the plug (A) with a N° 11 spanner.

2. To adjust the length of the flame, tighten or loosen the

screw inside the body of the pilot light using a

screwdriver.

WARNING: the flame must remain long enough to heat

the thermocouple.

3. Adjust the flame combustion using the air inlet ring

(B).

The burner injector reference differs according to the type of gas and country of

installation.

The following table indicates which injectors should be used following a change in the gas

supply or a house move.

Injectors

IGNITION

1144

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

AT, CH, DK, ES, FI, GB,

GR, IE, IT, PT, SE

NATURAL

II

NNJJEECCTTOORRSS

Country

Gas

Category

Gas type

G20 20

LU

260

G20 / G25

2E

G25 25

NL2L

Pressure

(mbar)

20 / 25

BE, FR2E+

G20 20

2H

170

G20 20 DE

20

DE

2ELL

G25

BE, CH, ES, FR, GB, GR,

IE, IT, PT

G30 / G31

28-30 / 37

DK, FI, NL, NO, SE

30

3+

BUTANE PROPANE

170

BUTANE -

PROPANE

G30

3B/P

150

PP

RRIIMMAARRYY AAIIRR

AADDJJUUSSTTMMEENNTT

((mmmm))

+ 1

++ 11

++ 11

-- 11

AT, CH, DE, LU

G30

50

3B/P

3. INJECTOR

REPLACEMENT

B

A

Page 16

The injectors are always replaced in the following sequence:

1. To access the injector, remove the rear cover from the “La Broche Flamberge” spit by

unscrewing the retaining screws.

2. Screw the adjusting cone (A) and insert it into the mixing tube (B) in order to free

sufficient space to unscrew the injector.

3. Unscrew the injector (C) using a N° 17 spanner.

4. Insert the injector corresponding to the new gas supply and screw it in.

5. Ignite the burner and adjust the air inlet by screwing or unscrewing the adjusting cone

(A) until you obtain a slightly blue flame showing no separation: separation of the flame

indicates that there is too much air.

6. Then block the adjusting cone with the lockwasher (D).

IGNITION

Injectors

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

1155

KKeeyy::

AT: Austria

BE: Belgium

CH: Switzerland

DE: Germany

DK: Denmark

ES: Spain

FI: Finland

FR: France

GB: Great Britain

GR: Greece

IE: Ireland

IT: Italy

LU: Luxemburg

NL: Netherlands

NO: Norway

PT: Portugal

SE: Sweden

+ 1

B D A C

- 1

**

Page 17

Cock with thermocouple and pilot:

- To light the pilot, turn the control knob 1/6 of a turn, press it and keep down a few

seconds to heat the thermocouple.

- When the pilot is on, turn the knob to the "HIGH" position.

Your Broche Flamberge electric has 2 selector switches. On position "1" the corresponding

heating elements are lighted. On position "0" the elements are switched OFF.

To light the Broche Flamberge electric you have to operate both left and right switch. The left one

is lighting the left heating elements and the right switch the right heating elements.

On each side an indicator light is showing wether the elements are working (red light if selector

switch put on position "1").

Lift the switch on the right-hand side of the rotisserie to start driving the motor.

Your motor is protected by a fuse 1 Amp situated near the switch controlling the motor.

For the horizontal rods, engage the corresponding chain at the desidered height into the wheel, and

rest the tip of the rod on the matching hook. On the drive wheel side, the rod should rest only on the

chain. It is recommended to center the roasts on the rod.

All types of meat that can be put on a spit, such as chicken, turkey, duck, hare, etc… should be

supported by square or flat rods. Secure the meat with the forks supplied to that end.

For red meat, or sides that are difficult to balance on the rod, use the English-style rod.

5. HOW TO USE THE VARIOUS RODS

4. POSITIONING OF THE RODS

3. O

PERATION OF THE RODS

2. IGNITION - BROCHE FLAMBERGE ELECTRIC

Ignition

FUNCTIONING

1166

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

FUNCTIONING

1. IGNITION - BROCHE FLAMBERGE GAS

Page 18

White meat, such as poultry, veal, pork, can be placed in the rotisserie without preheating it.

For red meat, such as joints of beef or lamb, it is recommended to preheat the rotisserie for about

15 - 20 minutes, before placing the roast. This will ensure that the outside of the meat will be properly

sealed.

Leave the rotisserie on the "HIGH" position for 10 minutes, then reduce the temperature by

placing the knob on the "LOW" position (gas model only).

Oil regularly the whole gears (gearwheels, chains, …) as well as the rods (every 3 months

approximately).

It is recommended not to touch the bunches of ceramic fibers, as this may damage them.

Pay attention not to touch the gears during functioning.

8. IMPORTANT

7. CLEANING

6. COOKING

FUNCTIONING

Cooking

IInnssttaallllaattiioonn GGuuiiddee ""BBrroocchhee FFllaammbbeerrggee""

1177

Page 19

WARRANTY (3 YEARS)

Following receipt of full payment for our

goods, our appliances are guaranteed three

years from the invoice date against any

structural faults and any material defects. The

warranty excludes improper use of the

appliance or a non-compliant installation.

Intervention and travel costs will be billed in

this event.

If our goods were to dysfunction, the buyer

then has to contact us once he has ensured

that it is not due to a non-compliant

installation or abnormal use in order to

decide with us how the appliance should be

repaired. The appliance should be cleaned

and clean prior to any intervention.

Any complaints with regard to the state, the

presentation or the non-compliance of our

goods should be addressed to our

headquarters by recommended letter with

acknowledgement of receipt within a

maximum of eight days following delivery.

The application of the warranty will be

subject to LA CORNUE SAS receiving a

certificate stating that the material has been

installed by a professional in accordance with

the current technical and safety standards.

Under this warranty, the seller shall replace at

no cost the parts recognized as faulty by its

technical department. This warranty covers

all labour costs with the exception of travel

expenses.

The warranty period specified above shall not

be extended if faulty parts need to be

replaced.

This warranty shall cease to apply:

- If the operational defect is the result of an

unauthorized intervention on the appliance;

- If the faulty operation is due to normal wear

and tear of the appliance or from negligence

or insufficient maintenance by the buyer;

- If the faulty operation is due to force

majeure.

LA CORNUE SAS shall not be held legally

responsible in these three cases.

The seller’s guarantee and his responsibility

for products shall be limited to repairs to any

defects as stipulated in the above conditions.

As expressly agreed between the contracting

parties, the seller’s responsibility in the event

of an operational fault shall be limited to the

above provisions, especially with regard to

concealed defects as well as material and

immaterial damage.

In all cases, the buyer may not suspend

payment if he lodges a complaint about the

quality of the goods.

The goods are always transported at the

buyer’s or his representative’s own risks. It is

therefore their responsibility to check them

upon arrival and, if necessary, to lodge a

complaint with the haulier. After having

expressed specific established reservations on

the delivery slip upon receipt, the buyer must

confirm them by recommended letter to the

haulier within two days of receipt (Article

105 of the Commercial Code).

We cannot in any event honour this warranty

if these requirements are not met.

1188

After- Sales Department:

- Covered by the warranty:

tel: +33 (0)1.34.48.36.15 fax: +33 (0)1.34.48.52.31

- Not covered by the warranty (appliance older than three years):

tel: +33 (0)1.47.37.56.00 fax: +33 (0)1.47.39.10.49

Page 20

La Cornue 1908

Ateliers La Cornue

14, rue du Bois du Pont - Z.I. les Béthunes

95310 Saint-Ouen l'Aumône - FRANCE

Adresse postale : La Cornue SAS - B.P. 99006

95070 Cergy Pontoise Cedex - FRANCE

Tél. : + 33 (0)1 34 48 36 36 - Fax : + 33 (0)1 34 64 32 65

E-mail : a.table@la-cornue.com

www.la-cornue.com

Loading...

Loading...