Instruction Manual for

Torbal AG and AGN Series Balances

101 Witmer Road, Suite 700 • Horsham, PA 19044 • Phone 1-800-521-0754 • Fax 215-442-9202

www.labrepco.com • sales@labrepco.com

Table of Contents

…….

…...

……………………….……….

…………………….

…………………………

………….

.………….

………………..

…….………………………………….………..

………….………………………………..

……………………….………………….………

…………………………….……….

………………………….………….

……………………………….………….

………………………………………………….

………………………………………………...

…………………………...

………………

……………………………………

SQC Process Control………………………………….……………………………...

………………………………………

8.2.

…………………………………..…..

8.3.

………………………………………………...

……………………………………………...

………………………………………………….

…………………………………………………

……………………………………………….………….

…………………………..

…………………………………………….…………

……......………………………….…………

…………………..………….

……………………………..………

………………………………………….

…………………………………………….

Calibration……………………………………………………………………….………

………………………….

…………………………………

Weighing…………………………………………………………………………………

……………………………………………

Cautionary Notes and Precautions…………………………………………………….

1.

Important Handling Cautions and Warnings……………………………..…………

1.1

Specifications………………………………………………...

2.

Keys, Display Indicators and Abbreviations……………………………

3.

Parts Descriptions…………………………………………………..

4.

Unpacking Balance and Getting Started…………………………………………...

5.

External Keyboard Connection (optional)………………………………………...

6.

7. Functions, Descriptions and Definitions…………………………………….

Main Menu…………..……………………..

8.

Mode Setup……………………………………

8.1.

8.1.1.

8.1.2.

8.1.3.

8.1.4.

8.1.5.

8.1.6.

8.1.7.

8.1.8.

8.1.9.

Weighing………………………….

Parts Counting…………………………………

Check Counting………..………………………

Percent Weighing……...………………….

Totalizing………………………….

Compounding………………………

Check Weighing…………………………………………

Animal and Dynamic Weighing………………….…………………..

Display Hold…………………………………….

8.1.10.

8.1.11.

Tare Setup……………………………………

.

Units of Measure……………...…………………...

Configurations…………………………...

8.3.1.

8.3.2.

8.3.3.

8.3.4.

8.3.5.

8.3.6.

8.3.7.

8.3.8.

8.3.9.

Auto-Zero………………………………………………………………………….. 32

Print……………………………………

8.3.2.1

8.3.2.2

GLP……..…………………..

Print Details……….…………..

Filter……………………….

Power Save and LCD Contrast…………………………...

RS232………………………..

USB Configuration….………………...

8.3.6.1

PC Connection via USB…………………..……...

Time and Date Adjustment…………………….

Reset and Default Restore………………...

Erasing the Database……………………

8.4.

8.4.1.

Using Functions and Modes………………………………..

9.

Auto Calibration Setting and Adjustment…………………

9.1.

9.1.1.

Taring……………………………………

3

4

5

7

8

10

12

13

14

14

15

16

18

19

21

22

23

25

27

28

30

31

32

33

33

34

34

35

36

36

37

38

39

39

40

41

42

42

42

- 1 -

9.1.2.

……………………………………………..

……………………………………..…….………….

………………………………………………………...…………..

.……

Counting Parts which Have Been Previously Stored in the Scale’s Database……

Manual………………………………………………………………….…………..

Check Counting……………………………………………………………………………

……………………..….

…………………………………………………….

………………………………………………………………

Percent Weighing for the First Time…………………………………………….

……….…………..

…………………………………………….……………

…………

………………………………..……………….………….

……………………………………….………….

………………………………………………………..

………………….…………..

………………….

………

…………………………………..…………………

………………………………….……………………………

9.2.

9.2.1.

Clearing a Tare………………………...

Parts Counting……………………

Automatic………

9.2.1.1

Counting Parts for the First time…………..………………………………

9.2.1.2

9.2.2.

9.3.

9.3.1.

9.4.

9.4.1.

Storing a Limit Set into the Scale’s Database……………...

Percent Weighing…...……………….

Automatic…………….

9.4.1.1

9.4.1.2

9.4.2.

Totalizing…………………………………………………………………….

9.5.

Compounding……………..

9.6.

Check Weighing……………………

9.7.

9.7.1.

Animal and Dynamic Weighing…...…………….……………………………………. 63

9.8.

Display Hold…………………..

9.9.

SQC Process Control……………………………………..

9.10.

9.10.1.

Using the Scale’s Alphabet for Data Entry………………………………………………… 67

10.

Connecting and Using a Barcode Scanner with the Scale’s Database……………………... 68

11.

Connecting the Scanner………………………………………………………………...68

11.1.

Assigning Barcodes to Samples or Limit Sets………………………..

11.2.

Recalling a Previously Stored Sample or a Limit Set from the Database………

11.3.

Technical Information……………………………………………………………………… 69

12.

Common Error and Troubleshoots…………………….……...……………………………. 70

13.

Maintenance…………………………..

14.

Accessories…………………

15.

Replacement Parts……………………………………………….…………………………. 72

16.

Limited Warranty…………….….…………………………………….…………………… 72

17.

Percent Weighing with Stored Reference Weights…………

Manual…………………..

Storing a Limit Set into the Scale’s Database…….…………………….…………. 62

Storing a Limit Set into the Scale’s Database…………………………..…….…… 66

43

44

44

44

46

48

49

52

52

52

52

55

56

57

59

61

64

65

68

68

71

71

- 2 -

Chapter 1: Cautionary Notes

The TORBAL Precision scale is a sensitive and a delicate instrument. Always handle your scale with care.

The correct location and proper environment makes an important contribution to the accuracy of the weighing

results of TORBAL precision scales.

The optimum location for your scale:

• Stable, vibration-free base as horizontal as possible

• Away from direct sunlight

• Not exposed to high temperature variations

• Away from direct drafts

• The best location is on a stable bench away from direct drafts, doors, windows, radiators and air

conditioner vents.

CAUTION:

WARNING:

• The scale is designed for indoor use only..

• Do not operate the scale in hazardous areas or conditions.

• Do not use the scale in locations subject to high humidity or dust levels.

• Do not connect cables in ways other than those mentioned in this manual.

• Be sure to set the scale on a firm, stable, horizontal surface.

• Never stand on or lean on this product. Equipment may fall or collapse,

causing breakage and possible injury.

• Before moving the product, unplug it and unplug all cables connected to it.

• When storing, transporting or returning the scale for service, always use the

original packaging.

• Never attempt to repair, disassemble or modify the scale yourself. Tampering

with the scale may result in injury and cause more damage to the equipment.

• Be sure to use the specified power source.

• Do not allow foreign matter to fall into the scale.

• If water or other liquid spills into the scale, do not continue to use it. Unplug

the power cord immediately and contact technical support.

- 3 -

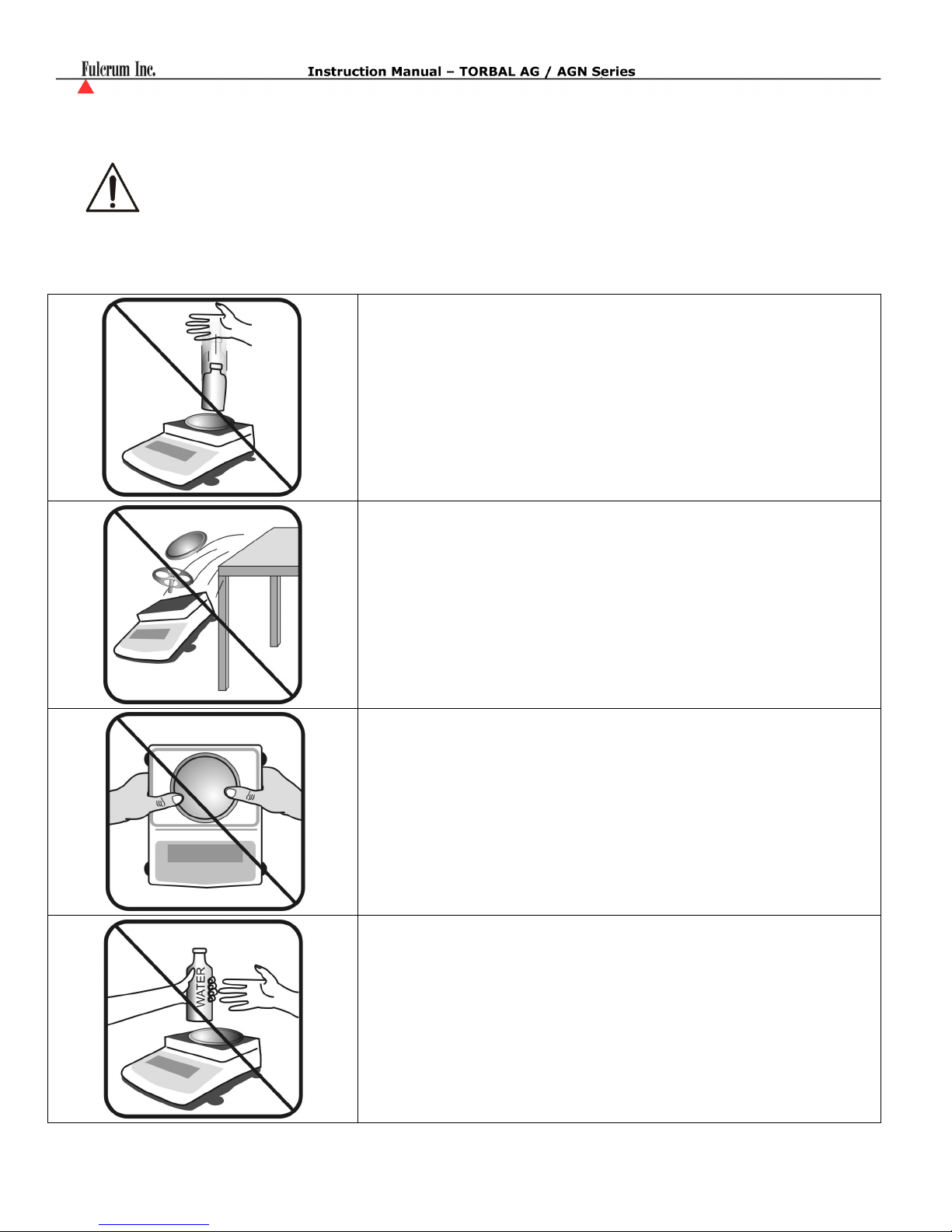

1.1. Important handling Cautions and Warnings

Always handle your scale with care. Damage caused by improper handling is

not covered under the scale’s warranty.

Never drop or throw any articles

onto the scale’s pan or onto any

other parts of the unit!

DO NOT let the scale fall or drop

from its tabletop surface!

When moving the scale do not

press or apply force onto the

scales pan!

DO NOT pass or handle liquids

directly over the scale to avoid

spillage and liquid damage!

- 4 -

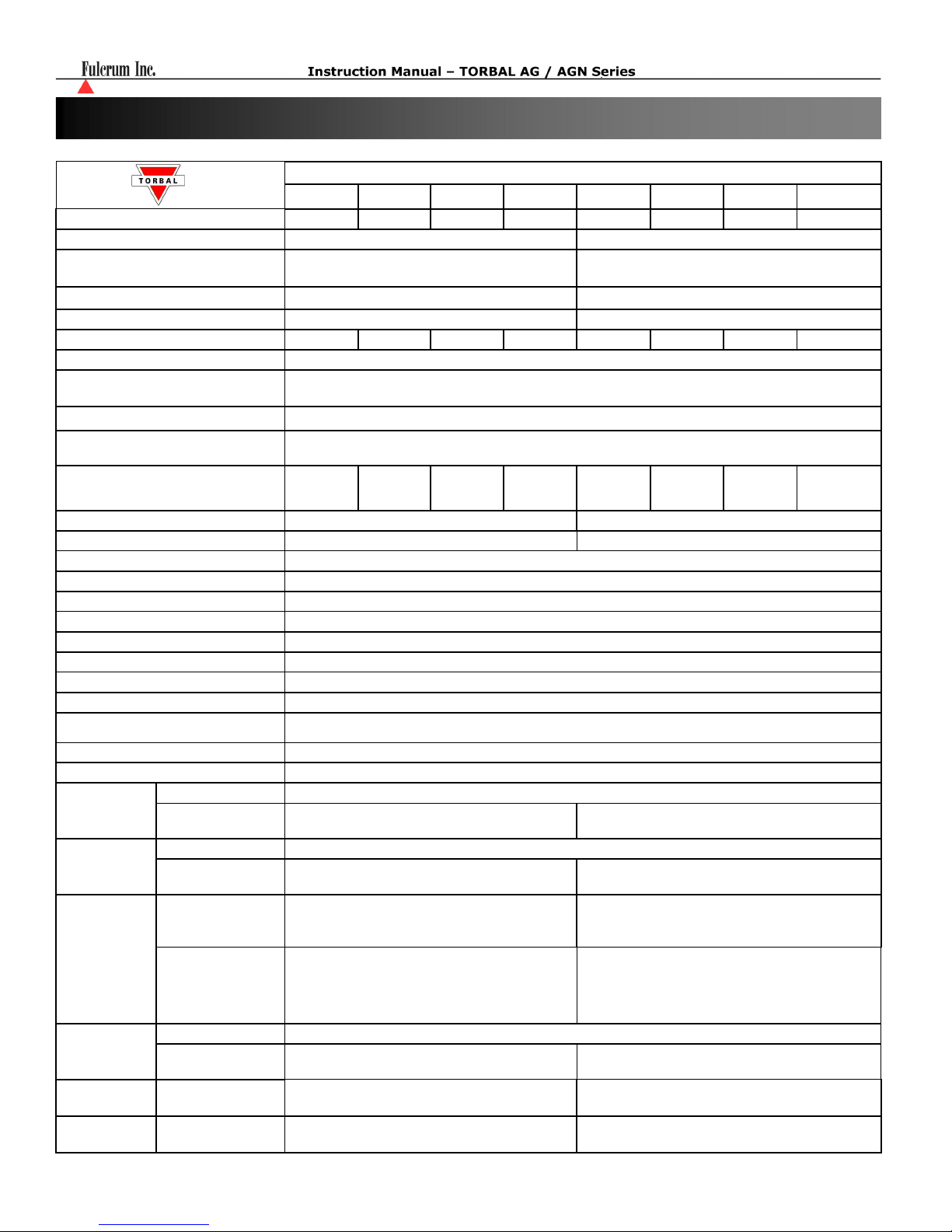

Chapter 2: Specifications

Capacity

Readability (d)

Repeatability (Standard

Divination)

Linearity

Stabilization time (typical)

Tare Range

Accuracy Class

Automatic Internal

Calibration

Time Configuration

Temperature

Configuration

Automatic Calibration

Adjustment Masses (g)

Pan Dimension

Draft Shield

Scale Dimension

Operating Temperature

PS2 Port

RS232 Port

USB

Power Supply

Display Type

Display Size

Application Modes

Weighing Units

Scale’s Net Weight (lb/kg)

Parts

Counting

Check

Counting

Percent

Weighing

Animal

Weighing

Totalizing

Display

Hold

Sample Size

Min Piece

Weigh

Sample Size

Min Piece

Weigh

Min

Reference

Weight

% Resolution

Displayed

(Reference

Weight)

Tiny Intervals

Modes (Min

Weight)

Modes (Min

Weight)

Modes (Min

Weight)

Model

AG100 AG200

100g 200g

Approx. 3 sec Approx. 3 sec

-100g -200g

20,50, 100

Weighing, Parts Counting, Animal Weighing, Check Weighing, Display Hold, Percent Weighing, Totalizing, Check

Manual, Auto (10mg), Semi-Auto (10mg) Manual, Auto (100mg), Semi-Auto (100mg)

Manual, Auto (10mg), Semi-Auto (10mg) Manual, Auto (100mg), Semi-Auto (100mg)

Manual, Auto (10mg), Semi-Auto (10mg) Manual, Auto (100mg), Semi-Auto (100mg)

50, 100,

200

Counting, Compounding, Statistics, SQC Quality Control, 512 KB Library Bank

Grams, Milligrams, Kilograms, Carats, Pounds, Newton, Grains, Ounces Troy, Pennyweight

0.1% (100mg to 7g), 0.01% (7g to 70g)

0.001% (>70g)

AG300 AG500 AG1000 AG2000 AG3000 AG4000

300g 500g 1000g 2000g 3000g 4000g

0.001g

0.001g

+/-0.002g

100, 200,

120 mm

Optional

30mg

30mg

100mg

-300 -500 -1000 -2000 -3000 -4000

I

YES

1h, 2,h, 3h, 4h, 5h, 6h

0.5°C, 1.0°C, 1.5°C, 2.0°C

300

Input: 120VAC 60Hz 15W Output: 12VDC 500mA

100, 200,

500

216 x 345 x 90 mm

1 through 100 or any

1 through 100 or any

3sec., 5sec., 10sec., 15sec.

200, 500,

1000

+15°C to +30°C

Standard

Bidirectional

Standard

Graphical LCD

30mm x 100mm

5kg/11lbs

500, 100,

0.1% (1g to 70g), 0.01% (70g to 700g)

0.01g

0.01g

+/-0.02g

1000,

2000

165 mm x 165 mm

Not Required

0.001% (>700g)

2000,

3000

300mg

300mg

1 g

1000, 2000,

4000

- 5 -

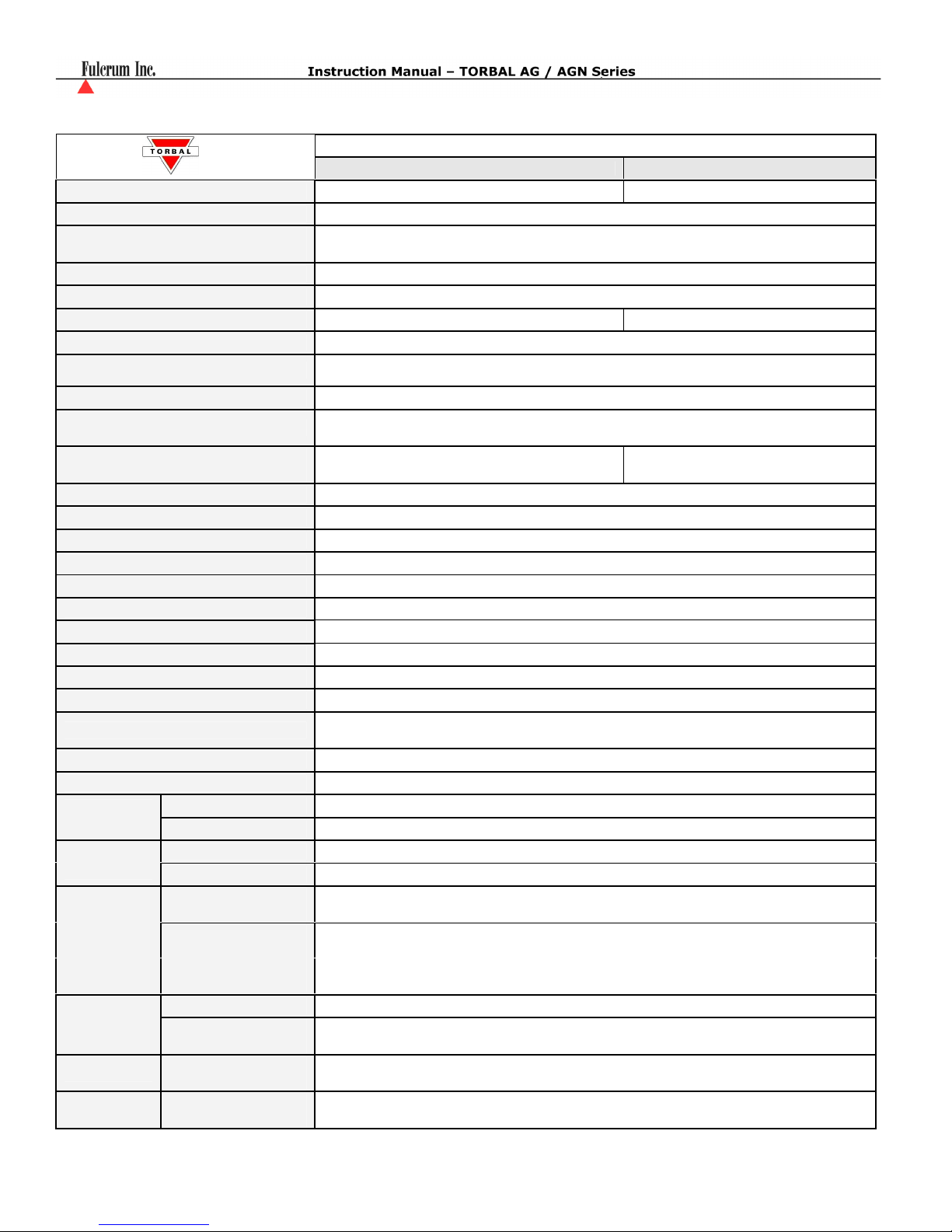

Capacity

Readability (d)

Repeatability (Standard

Divination)

Linearity

Stabilization time (typical)

Tare Range

Accuracy Class

Automatic Internal Calibration

Time Configuration

Temperature Configuration

Automatic Calibration

Adjustment Masses (g)

Pan Dimension

Draft Shield

Scale Dimension

Operating Temperature

PS2 Port

RS232 Port

USB

Power Supply

Display Type

Display Size

Application Modes

Weighing Units

Scale’s Net Weight (lb/kg)

Parts

Counting

Check

Counting

Sample Size

Min Piece Weigh

Sample Size

Min Piece Weigh

Min Reference

Weight

Percent

Weighing

% Resolution

Displayed

(Reference

Weight)

Animal

Weighing

Totalizing

Display

Hold

Tiny Intervals

Modes (Min

Weight)

Modes (Min

Weight)

Modes (Min

Weight)

Model

AGN100 AGN200

100g 200g

0.0001g

0.0001g

+/-0.0002g

Approx. 3 sec

-100g -200g

I

YES

1h, 2,h, 3h, 4h, 5h, 6h

0.5°C, 1.0°C, 1.5°C, 2.0°C

20,50, 100 50, 100, 200

120 mm

Optional

216 x 345 x 90 mm

+15°C to +30°C

Standard

Bidirectional

Standard

Input: 120VAC 60Hz 15W Output: 12VDC 500mA

Seven Segment LCD

30mm x 100mm

Weighing, Parts Counting, Animal Weighing, Check Weighing, Display Hold, Percent Weighing,

Totalizing, Check Counting, Compounding, Statistics, SQC Quality Control, 512 KB Library Bank

Grams, Milligrams, Kilograms, Carats, Pounds, Newton, Grains, Ounces Troy, Pennyweight

6kg/14lbs

1 through 100 or any

3e (30mg)

1 through 100 or any

3e (30mg)

1e (1mg)

0.1% (100mg to 7g), 0.01% (7g to 70g), 0.001% (>70g)

3sec., 5sec., 10sec., 15sec. or any

Manual, Auto 1e (1mg), Semi-Auto 1e (1mg)

Manual, Auto 1e (1mg), Semi-Auto 1e (1mg)

Manual, Auto 1e (1mg), Semi-Auto 1e (1mg)

- 6 -

Chapter 3: Keys, Display Indicators and Abbreviations

Key Primary Function

0

MENU

CLR

▲▼◄►

▼

F1

F2

F3

F4

F5

Display Indicator

Zero – used to zero the scale (Legal for Trade models only) N/A

Enter – used to accept and confirm commands N/A

Menu – used to access the main menu Number “9” key

Clear – used to clear and cancel operation N/A

Navigation Keys – used to navigate through the menus and functions N/A

Function Key – used access database and secondary function Number “0” key

Data Transfer – used to print data or transfer data to a PC via the RS232

Calibration Key - used to initialize internal calibration Number “8” key

Power On and Power Off -

Tare – used to tare the weighing pan N/A

communication port

Function Key Number “1” key

Function Key Number “2” key

Function Key Number “3” key

Function Key Number “4” key

Function Key Number “5” key

Description

Secondary

Function

Number “7” key

AUT

OFF

Diff.

SPL / SAPL

LOCK

PCS

CHKC

PERC

TOT

COMP

CHKW

ANL

HLD

SQC

Stability Indicator - The weighing result has stabilized and an accurate reading may be taken.

Zero - The scale is maintaining a “center of zero” condition. (Legal for Trade models only)

AZSM (Automatic Zero Setting Mechanism) is enabled. Always enabled in Legal for Trade models.

Power Off - The scale is turned OFF and in standby mode.

Difference

Sample or Samples

Display Locked

Parts Counting

Check Counting

Percent Weighing

Totalizing

Compounding

Check Weighing

Animal Weighing

Display Hold

SQC Process control

- 7 -

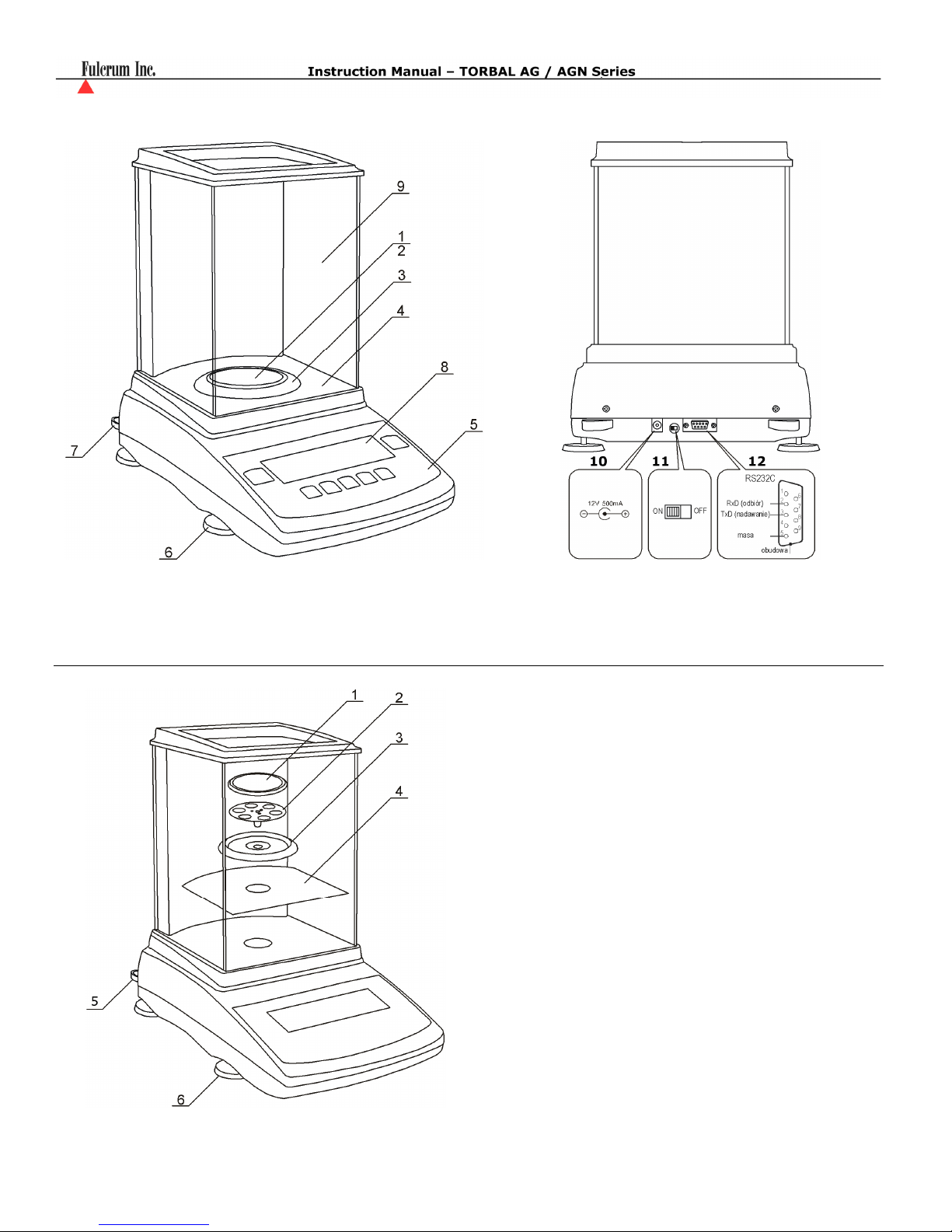

Chapter 4: Parts Description

AG Models:

Front View Rear View Side View

Pan Base Pan AC Adapter

RS232 Serial Port Service Switch Level Indicator AC Adapter Socket

- 8 -

AGN Models:

1 - Pan, 2 - Pan Base, 3 - Draft Ring, 4 - Weighing Chamber Base, 5 – Keypad, 6 - Adjustable Legs,

7 - Level Indicator, 8 - LCD Display, 9 - Weighing Chamber, 10 - AC Adapter Socket,

11 – Service Switch, 12 - RS232 Serial Port

1 - Pan, 2 - Pan Base, 3 - Draft Ring,

4 - Chamber Base, 5 - Level Indicator,

6 - Adjustable Legs

- 9 -

Chapter 5: Unpacking the Balance and Getting Started

1. Carefully remove the scale, pan, and all of its components out of the

packaging and place them on a stable base where the scale will not

be affected by any mechanical vibrations or air movements.

2. AG Modes: After removing the pan base and the pan from their packaging, carefully install the pan

base onto the scale by seating it on the pan support located in the middle of the scale. Once the pan

base has been installed, carefully place the pan on the base as shown below.

AGN Models:

After removing the chamber base (4), draft

ring (3), pan base (2), and the pan (1) from

their packaging, carefully install the chamber

base (4) on the case of the balance as shown

below. Once the chamber base is in place,

install the draft ring (3). Once components 4

and 3 are in place install the pan base onto the

scale by placing it on the pan support located

in the middle of the scale. Once the pan base

has been installed, carefully place the pan on

the base as shown.

- 10 -

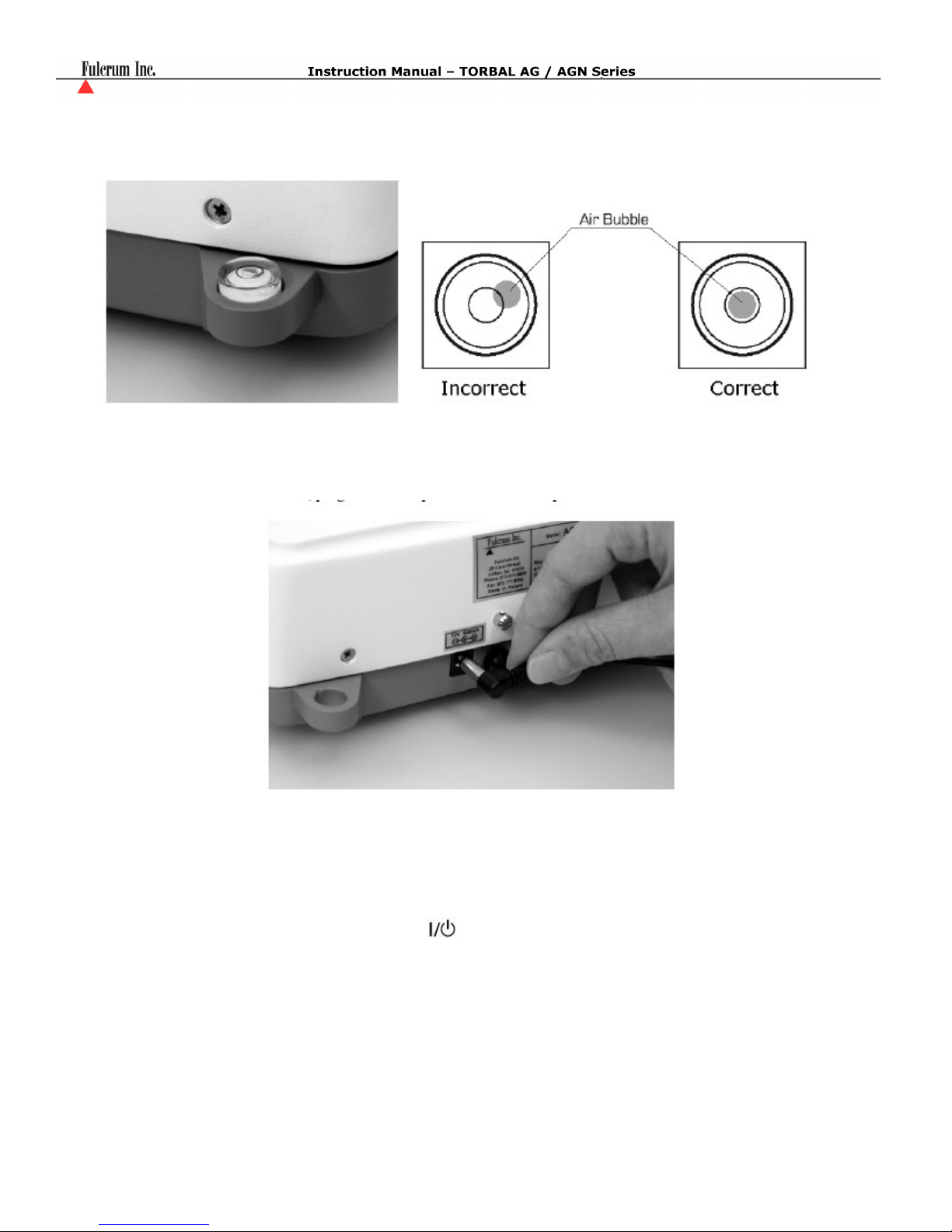

3. Once the pan has been installed, level the scale by adjusting the rear feet until the level indicator

shows the “air bubble” is in the center position of the sight glass. The level indicator is located in the

rear left side of the scale.

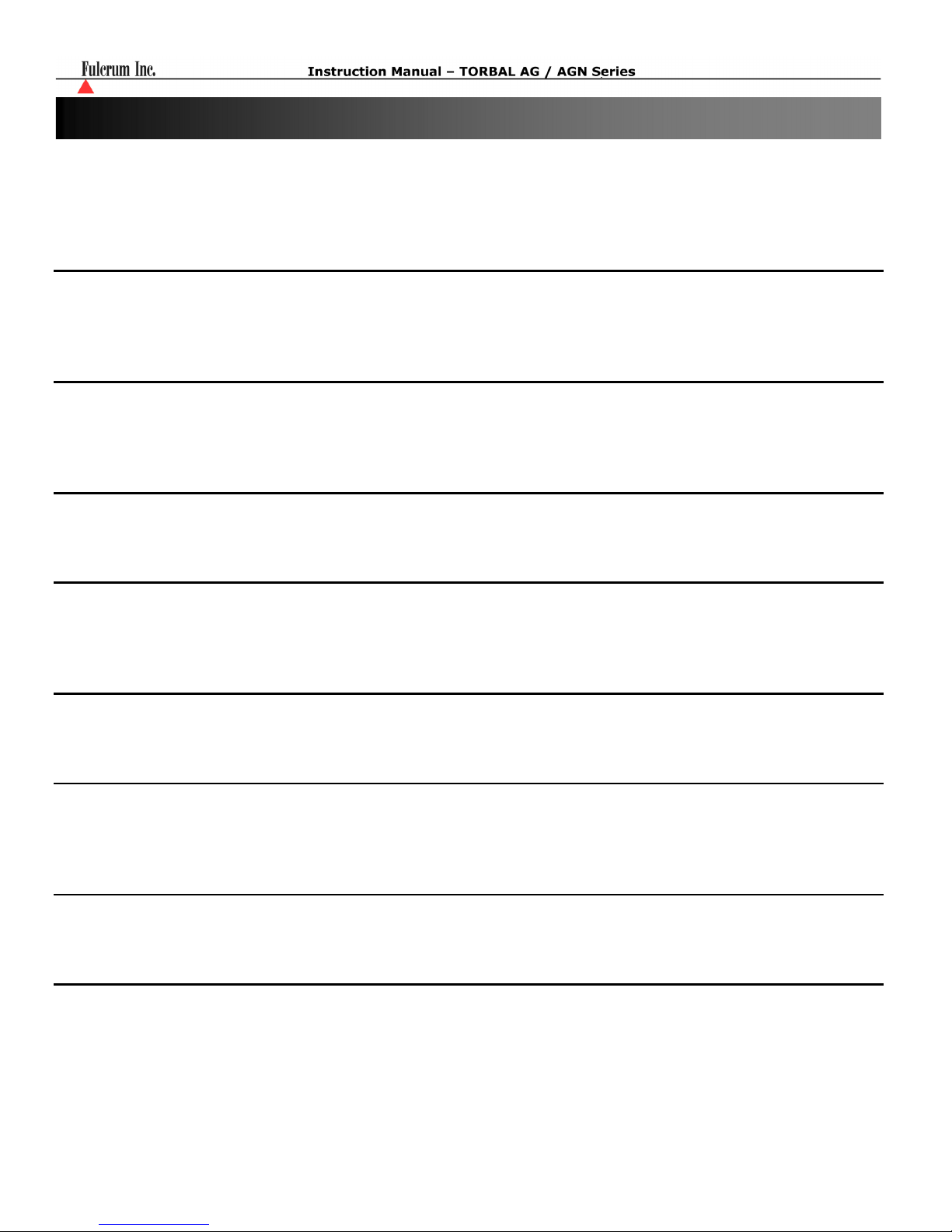

4. After leveling the scale, you may plug the AC adaptor to the AC adaptor socket located in the rear of

the scale.

5. When the AC adapter is plugged into the wall outlet, the scale will turn “ON” automatically, initialize

itself, perform automatic internal calibration and enter weighing mode.

6. To put the scale into standby mode, leave the AC adaptor plugged into both the scale and the wall

outlet and press the Power “OFF” button ( ). The “OFF” indicator will light up in the upper left

corner of the display signaling the scale is in standby mode.

- 11 -

Chapter 6: External Keyboard Connection (Optional)

Any PC external keyboard can be connected to the scale via the PS2. An external keyboard allows you to

input data quickly and easily. To connect a PC keyboard to the scale, follow the steps below.

1. Clear the pan and turn the scale off.

2. Locate the keyboard connection port at the rear of the scale, marked “keyboard.”

3. Insert the keyboard connector into the scale’s port.

4. Turn the scale on.

Note: Some keyboard keys remain disabled and do not work with the scale (i.e. function keys, Shift, Control

etc…). Do not use the number keypad located to the right of your keys. To key in numbers always use the

number keys in the upper row of the keyboard.

- 12 -

Chapter 7: Functions, Descriptions and Definitions

o Parts Counting is used to count parts or pieces of articles based on their average piece weight.

o Check Counting is used to verify whether a parts counting result falls within specified threshold

limits.

o Percent weighing is used to establish the relative weight of an unknown, compared to that of a stored

reference weight and expressed as a percent.

o Totalizing is used for summation of sequential weighing results of items or articles.

o Compounding is used for weighing and summing individual ingredients such as powers or liquids

during recipe making or mixing compounds.

o Check weighing is used to check whether a weight of an object falls within specified threshold limits.

o Animal and dynamic weighing is used to weigh animals or objects which are in motion while on the

pan.

o Display hold is used to lock and retain a weighing result on the display until cleared.

o Statistical quality control (SQC) is used to establish a trend analysis and statistical data of samples in

relation specified threshold limits.

- 13 -

Chapter 8: Main Menu

Main Menu is used to configure the scale and it’s weighing modes. Before entering the menu complete

and clear active functions by pressing the CLR key.

1. To enter the Main Menu press the MENU key. Once the MENU key is pressed the menu options will

be displayed.

8.1. Mode Setup

Torbal AG and AGN Scales can operate in ten application modes: Weighing, Parts Counting, Check

Counting, Percent Weighing, Totalizing, Compounding, Check Weighing, Animal Weighing, Display

Hold, and SQC Process Control. Before an application mode can be used it must be enabled and

configured. To use an application mode a quick key (Function keys F1 through F5) should be assigned

(recommended). Quick keys allow quick toggling between functions. By factory default the scale is in the

weighing mode. To enable other application modes follow the steps below.

1. From the Main Menu select “Mode Setup” and press the ENTER key. A list of available

applications and modes will be displayed.

- 14 -

8.1.1. Weighing

1. To configure the Weighing Function use the navigation keys to select “Weighing” in “Mode Setup”

and press ENTER. The status and available weighing options will be displayed. If the function is

currently in use the status will be set to “ON”.

2. To assign a “Quick Key” use the navigation keys to select “Quick Key” and press the ENTER key.

Use the navigation keys to select a desired quick key (F1 through F5). Once the desired key is selected

press the ENTER key to accept the selection.

If the key is not available (used by a different function) a warning message will be displayed

“Warning Quick Key Already In Use!” To override the key press ENTER. To abort and select a

different function key press the CLR key.

3. To exit the Weighing set up select “Exit” and press the ENTER key.

- 15 -

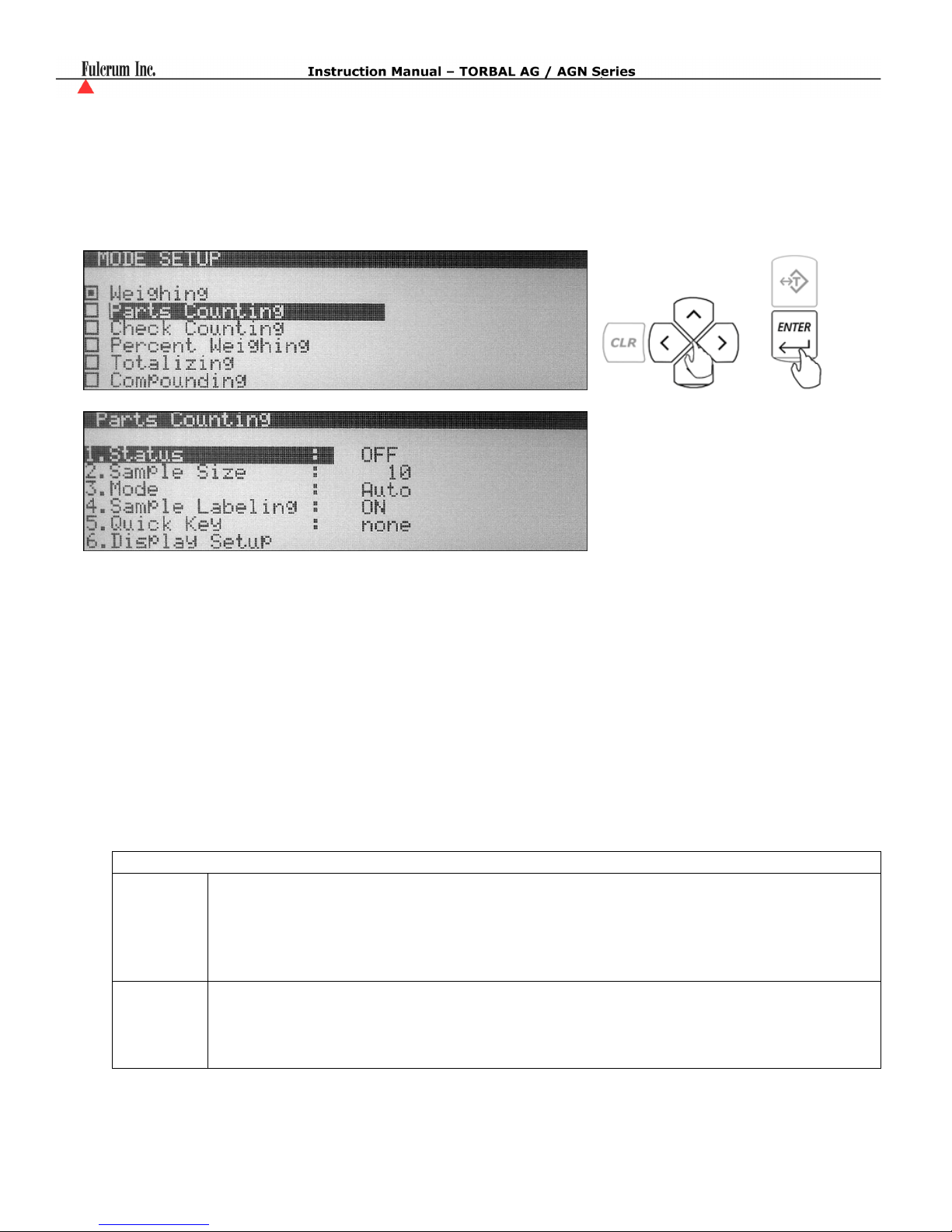

8.1.2. Parts Counting

1. To configure the Parts Counting Function use the navigation keys to select “Parts Counting” in

“Mode Setup” and press ENTER. The status and available parts counting options will be displayed. If

the function is currently in use the status will be set to “ON”.

2. To assign a default “Sample Size” that will be used in calculating the average piece weight use the

navigation keys to select “Sample Size” and press ENTER. To select a preset “Sample Size” use the

navigation keys to toggle until a desired sample size is displayed (1, 5, 10, 20, 50, 100, 200, 500). To

assign a custom “Sample Size” use the number keys on the scale’s keypad to key in a desired value.

Once the desired “Sample Size” is selected or entered, press the ENTER key to set and confirm the

selection.

3. To select an operating mode use the navigation keys to select “Mode” and press ENTER. By default

parts counting is set to “Auto” (Automatic). To operate parts counting in “Manual” use the navigation

keys to select “Manual” and press ENTER.

Parts Counting Operating Modes

When set to automatic the balance allows you to create a database of samples and

Automatic

average piece weights. Each sample can be labeled with a unique name or an alpha

numeric code and stored in the scale’s internal memory along with its average piece

weight. This eliminates the need for establishing a new average piece weight every time

a part is counted.

When using parts counting in manual, the database feature is disabled and samples size,

Manual

as well as, average piece weight is not stored in the scale’s memory. The sample size

must be manually counted and an average piece weight must be established every time

part counting is performed.

- 16 -

4. To enable sample labeling use the navigation keys to select “Sample Labeling” and press the ENTER

key. Use the navigation keys once again to enable or disable sample labeling. Once a desired selection

is made press the ENTER key.

“Sample Labeling” applies to the “Automatic Mode” only. It allows the user to assign a unique name

to a sample which is then stored in the scales database. When set to “OFF” the scale will not assign or

display names of the samples.

5. To assign a “Quick Key” use the navigation keys to select “Quick Key” and press the ENTER key.

Use the navigation keys to select a desired quick key (F1 through F5). Once the desired key is selected

press the ENTER key to accept the selection.

If the key is not available (used by a different function) a warning message will be displayed

“Warning Quick Key Already In Use!” To override the key press ENTER. To abort and select a

different function key press the CLR key.

6. To configure the scale’s display during parts counting use the navigation keys to select “Display

Setup” and press the ENTER key. To disable information from displaying during the function use the

navigation keys to highlight the desired selection and press the ENTER key to remove the check mark.

Once the check mark has been removed the information will not display while performing parts

counting.

7. To exit Parts Counting set up use the navigation keys to select “Exit” and press ENTER.

- 17 -

8.1.3. Check Counting

1. To configure the Check Counting Function, use the navigation keys to select “Check Counting” in

“Mode Setup” and press ENTER. The status and available Check Counting options will be displayed.

If the function is currently in use the status will be set to “ON”.

2. To assign a default “Sample Size” that will be used in calculating the average piece weight use the

navigation keys to select “Sample Size” and press ENTER. To select a preset “Sample Size” use the

navigation keys to toggle until a desired sample size is displayed (1, 5, 10, 20, 50, 100, 200, 500). To

assign a custom “Sample Size” use the number keys on the scale’s keypad to key in a desired value.

Once the desired “Sample Size” is selected or entered press, the ENTER key to set and confirm the

selection.

3. To enable Limit Set Labeling use the navigation keys to select “Limit Set Labeling” and press the

ENTER key. Use the navigation keys once again to enable or disable Limit Set labeling. Once a

desired selection is made press the ENTER key.

“Limit Set Labeling” allows the user to assign a unique name to a Limit Set which is then stored in the

scales database. When set to “OFF” the scale will not assign or display names of the Limit Set.

4. To assign a “Quick Key” use the navigation keys to select “Quick Key” and press the ENTER key.

Use the navigation keys to select a desired quick key (F1 through F5). Once the desired key is selected

press the ENTER key to accept the selection.

If the key is not available (used by a different function) a warning message will be displayed

“Warning Quick Key Already In Use!” To override the key press ENTER. To abort and select a

different function key press the CLR key.

- 18 -

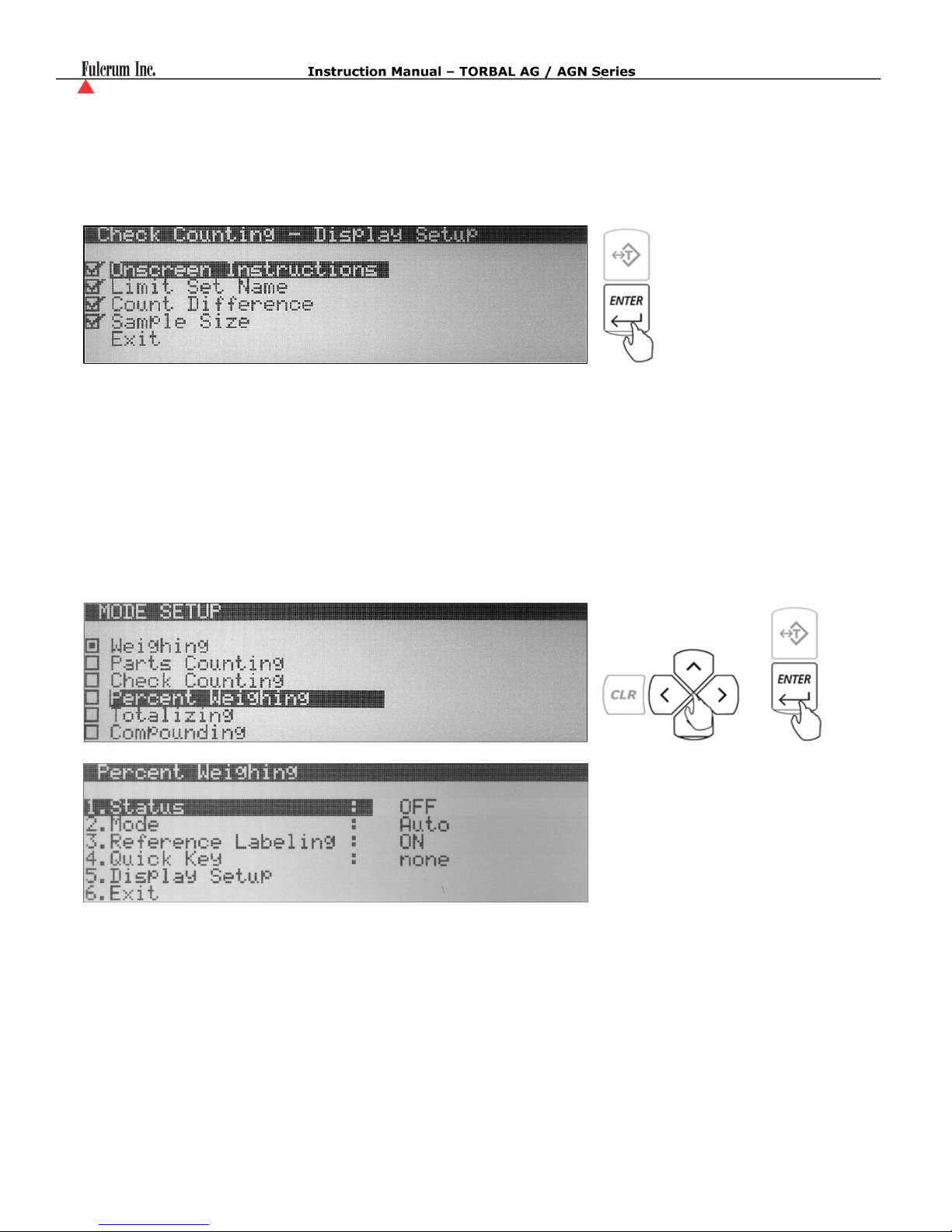

5. To configure the scale’s display during check counting use the navigation keys to select “Display

Setup” and press the ENTER key. To disable information from displaying during the function use the

navigation keys to highlight the desired selection and press the ENTER key to remove the check mark.

Once the check mark has been removed the information will not display while performing check

counting.

6. To exit Check Counting set up use the navigation keys to select “Exit” and press ENTER.

8.1.4. Percent Weighing

1. To configure the Percent Weighing Function, use the navigation keys to select “Percent Weighing” in

“Mode Setup” and press ENTER. The status and available Percent Weighing options will be

displayed. If the function is currently in use the status will be set to “ON”.

2. To select an operating mode use the navigation keys to select “Mode” and press ENTER. By default

Percent Weighing is set to “Auto” (Automatic). To operate Percent Weighing in manual use the

navigation keys to select “Manual” and press ENTER.

- 19 -

Percent Weighing Operating Modes

When set to automatic the balance allows you to create a database of reference weights.

Automatic

Each reference weight can be labeled with a unique name or an alpha numeric code and

stored in the scale’s internal memory along with its weight representing 100%. This

eliminates the need for establishing a new reference weights every time percent

weighing is performed.

When using Percent Weighing in manual the database feature is disabled and reference

Manual

weights are not stored in the scale’s memory. A reference weight equaling 100% must

be established every time Percent Weighing is performed.

3. To enable Reference Weight Labeling use the navigation keys to select “Reference Labeling” and

press the ENTER key. Use the navigation keys once again to enable or disable reference weight

labeling. Once a desired selection is made press the ENTER key.

“Reference Labeling” applies to the “Automatic Mode” only. It allows the user to assign a unique

name to a sample which is then stored in the scales database. When set to “OFF” the scale will not

assign or display names of the reference weights.

4. To assign a “Quick Key” use the navigation keys to select “Quick Key” and press the ENTER key.

Use the navigation keys to select a desired quick key (F1 through F5). Once the desired key is selected

press the ENTER key to accept the selection.

If the key is not available (used by a different function) a warning message will be displayed

“Warning Quick Key Already In Use!” To override the key press ENTER. To abort and select a

different function key press the CLR key.

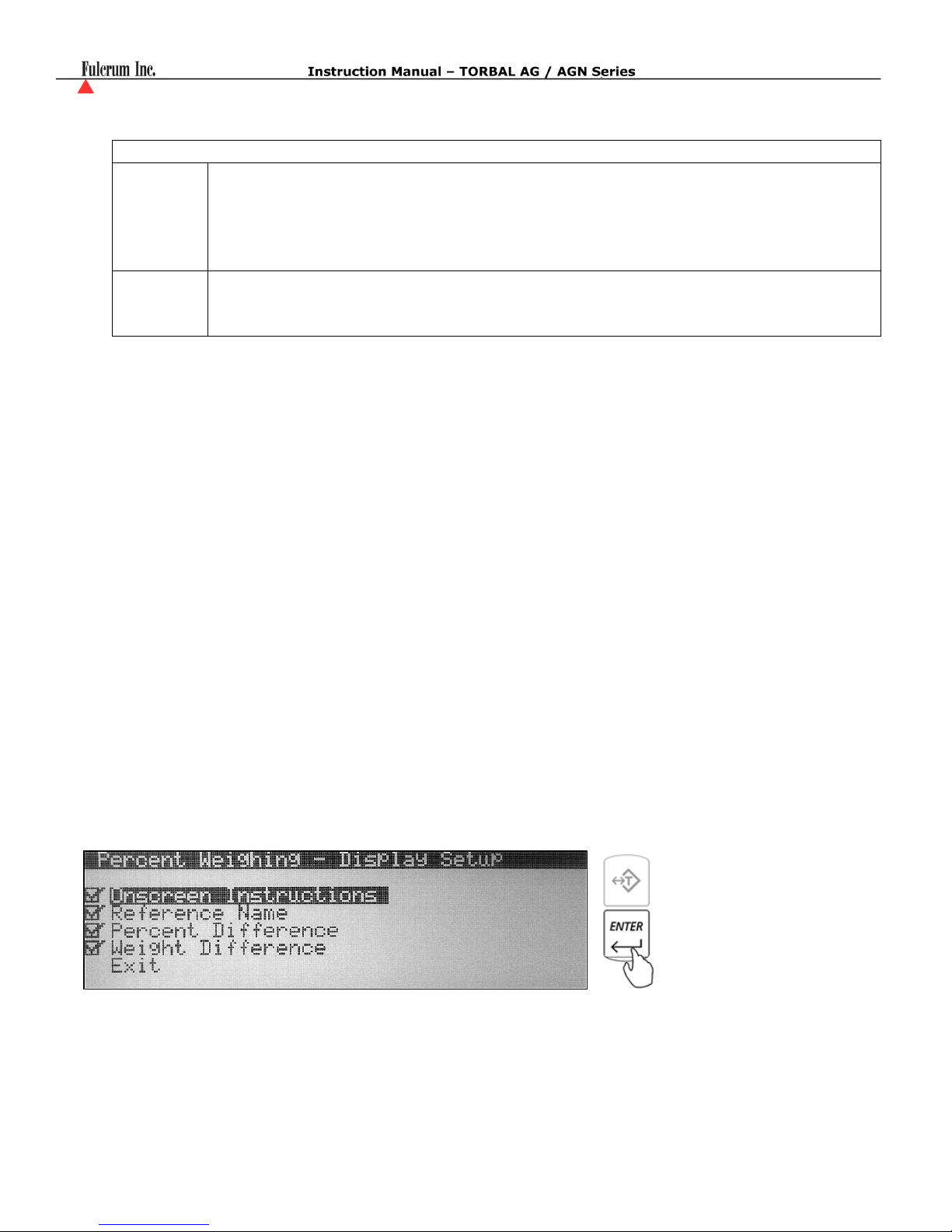

5. To configure the scale’s display during percent weighing use the navigation keys to select “Display

Setup” and press the ENTER key. To disable information from displaying during the function use the

navigation keys to highlight the desired selection and press the ENTER key to remove the check mark.

Once the check mark has been removed the information will not display while performing Percent

weighing.

6. To exit Percent Weighing set up use the navigation keys to select “Exit” and press ENTER.

- 20 -

8.1.5. Totalizing

1. To configure the Totalizing Function, use the navigation keys to select “Totalizing” in “Mode Setup”

and press ENTER. The status and available Totalizing options will be displayed. If the function is

currently in use the status will be set to “ON”.

2. To select an operating mode use the navigation keys to select “MODE” and press ENTER. By default

Totalizing is set to “Auto” (Automatic). To operate Totalizing in manual use the navigation keys to

select “Manual” and press ENTER.

Totalizing Operating Modes

Automatic Totalizing and Adding :

Automatic

When set to Automatic, the scale will automatically

add the first stable weight reading to the total.

Manual Totalizing and Adding : Manual When set to Manual each weigh has to be manually

added to the total by pressing a designated key.

3. To assign a “Quick Key” use the navigation keys to select “Quick Key” and press the ENTER key.

Use the navigation keys to select a desired quick key (F1 through F5). Once the desired key is selected

press the ENTER key to accept the selection.

If the key is not available (used by a different function) a warning message will be displayed

“Warning Quick Key Already In Use!” To override the key press ENTER. To abort and select a

different function key press the CLR key.

- 21 -

Loading...

Loading...