Operators Manual

CoaLAB 6000

For in-vitro diagnostic use only!

Order

Bedienungsanleitung CoaLAB 6000 Best. Nr.: 30.000.1615 German Version

Operators Manual CoaLAB 6000 Order No.: 30.000.1616 English Version

Revision History

Version Manual

Date

(mm/dd/yy)

Software-Version - Release -

Analyser

1.0 10/29/99 1.0 Final release Version

1.2 02/20/01 1.02a Software update

1.3 07/17/01 1.02d Software update/corrections

1.4 05/07/02 1.03 Software update/corrections

1.5 08/12/02 1.03 Corrections

1.6 02/06/03 1.04 Software update/corrections

1.7 08/21/03 1.04 IVD update

1.8 11/26/04 1.04 Updates/Corrections

Copyright of Software

All software by LABiTec LAbor BioMedical Technologies GmbH (in the following LABiTec-Software) is the

intellectual property of the LABiTec LAbor BioMedical Technologies GmbH. Intellectual property rights shall

remain with LABiTec LAbor BioMedical Technologies GmbH. You are entitled to use LABiTec-Software and

the printed accompanying material at a place of work that cannot be transferred. Any violation of property

rights or copyright or trademark or using conditions may be subject to legal action. LABiTec reserves the

rights to modify the software, documentation as well as this operator manual without prior written notice.

Your Distributor:

(Please do not hesitate to contact your local distributor if you have any questions or problems.)

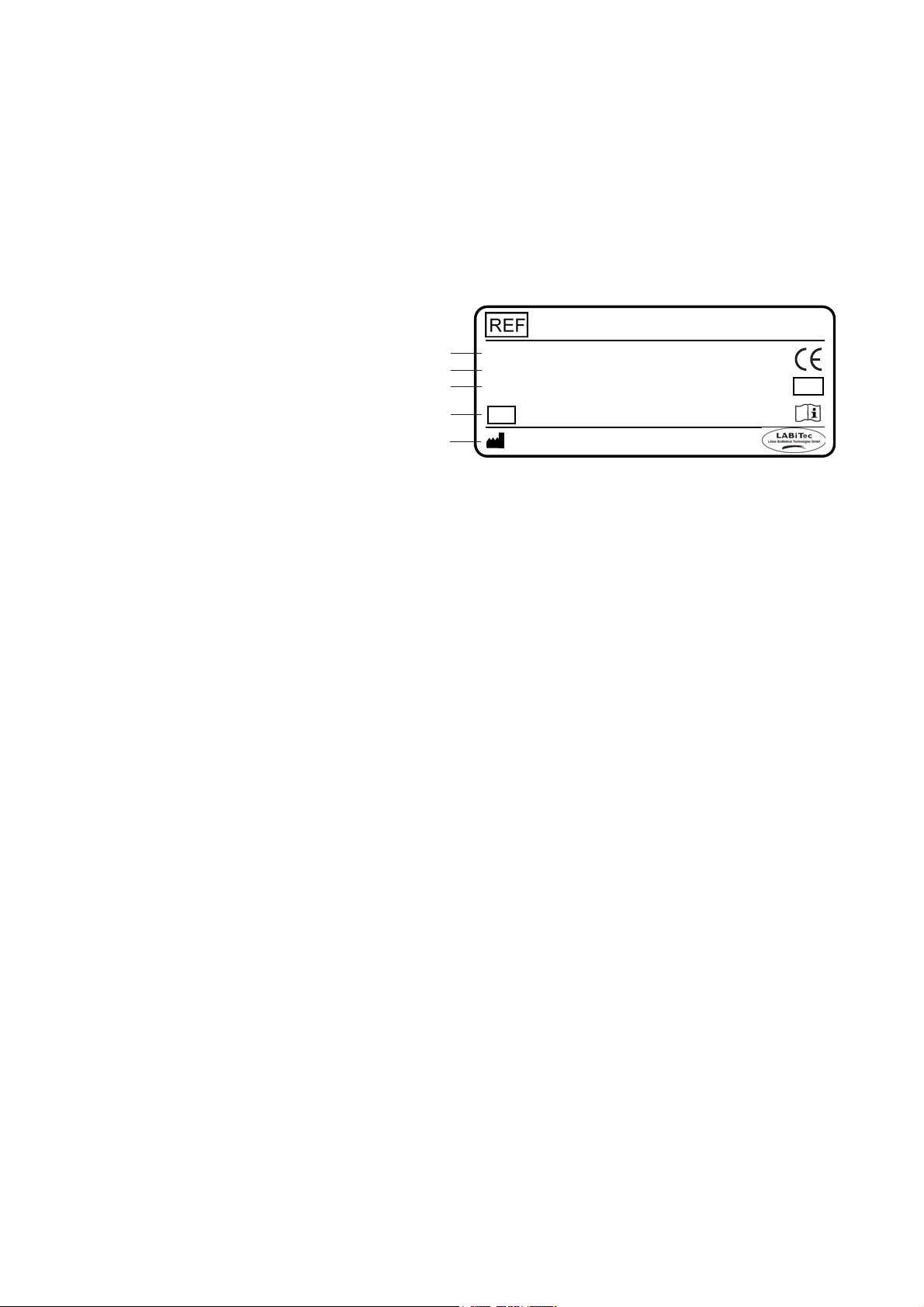

CoaLAB 6000

The name and serial number of your system can be found on the plate located on the back of the instrument.

Legend:

1 Type

2 Product Identification

3 Input

- Voltage (V)

- Power consumption (VA)

- Frequency (Hz)

- Fuses

1

2

3

4

4 Serial Number coded*

5 IVD Manufacturer

5

* Serial number code:

e.g. C 28 2 0501

C Productions month

28 Production date

2 Production year

0501 consecutive instrument number

Please enter the following information:

Serial number: ____________________________

Type: CoaLAB 6000

P-ID: D6-99.0000

Input: 230-240V~150VA, 47/63Hz, Fuse: 4AT/250V

110-120V~150VA, 47/63Hz, Fuse: 4AT/125V

SN

90.000.0300

C 28 2 0501

LABiTec GmbH

22926 Ahrensburg, Germany

Made in Germany

IVD

Contents

Table of contents

1 INTRODUCTION................................................................. 3

1.1 Definitions..............................................................................4

1.2 Description of the system ....................................................5

1.3 Measuring principle ..............................................................9

1.4 Software Overview ................................................................ 9

2 HAZARD AND PRECAUTION.......................................... 11

3 WARRANTY ..................................................................... 15

4 SERVICE .......................................................................... 16

5 INSTALLATION ................................................................ 17

5.1 Unpacking and installation of the system ........................17

5.1.1 How to prepare the installation area .........................................17

5.1.2 Check Contents.........................................................................17

5.1.3 Unpacking the system...............................................................18

5.1.4 Assembly of the system ............................................................19

5.1.4.1 Mount the diluter syringe and tubes.......................................19

5.1.4.2 Connect the Liquid System Containers .................................21

5.1.4.3 Connect the Barcode Scanner (Optional)..............................22

5.1.4.4 Connect a HOST or Personal Computer to the System........22

5.1.4.5 Insert and change printer paper.............................................23

5.1.4.6 Mount the cuvette waste box.................................................24

5.2 Instrument control Card (ICC)............................................ 25

5.3 Language Setup ..................................................................25

6 OPERATION ..................................................................... 26

6.1 Routine Operation <1 ROUTINE MENU>...........................26

6.1.1 Switch ON the system...............................................................27

6.1.2 Rinsing with distilled water ........................................................27

6.1.3 Disinfection of waste tubing (Terralin), change of FW-Filter.....28

6.1.4 Rinsing with Washing Solution..................................................31

6.1.5 Loading and unloading reagents...............................................32

6.1.6 Delete joblist, delete samples ...................................................34

6.1.7 Enter a new joblist.....................................................................35

6.1.8 Handle the joblist.......................................................................37

6.1.9 Print of a joblist..........................................................................37

6.1.10 Start measuring, load cuvette bars ...........................................38

6.1.11 Interrupt a current run (User interrupt)......................................41

6.1.12 Print results, send results to HOST...........................................42

6.1.13 Refill liquids, clean containers...................................................43

6.1.14 Empty and clean the waste water container .............................44

6.2 Enter Test Parameter .......................................................... 45

6.2.1 Enter Reagent Specific Parameters..........................................45

6.2.1.1 Enter a reference curve (PT, for example) ............................45

CoaLAB 6000 – Operators Manual 1.8 Page 1

Contents

6.2.1.2 Enter ISI value .......................................................................47

6.2.1.3 Enter RATIO (APTT for example)..........................................49

6.2.1.4 Enter normal ranges (for example PT) ..................................50

6.2.2 Enter Method Parameter...........................................................52

6.2.2.1 Enter single or double determinations ...................................52

6.2.2.2 Enter PT Test Parameter.......................................................54

6.2.2.3 Enter APTT Test Parameter ..................................................58

6.2.2.4 Enter Fibrinogen Test Parameter ..........................................63

6.2.2.5 Print of Test Parameters (Fibrinogen for example) ...............67

6.2.3 Read ChipCARD to load a new test (Read test).......................69

6.2.4 Save Tests on a ChipCARD......................................................71

6.2.5 Print of Test Parameters (Print test)..........................................73

6.2.6 Delete Test ................................................................................74

6.3 STAT Management..............................................................75

6.4 General Setting (SETUP MENU)......................................... 81

6.4.1 Define Primary Tubes ...............................................................82

6.4.2 Define STAT positions in the sample rotor ...............................83

6.4.3 Date and Time...........................................................................84

6.4.4 Printer Setup .............................................................................85

6.4.5 Beeper Setup ............................................................................86

6.4.6 Set PIN Code ............................................................................87

6.4.7 Language ..................................................................................88

6.4.8 Print of Setup Parameters.........................................................89

6.5 Removing cuvette bars from the system..........................90

6.6 Switch OFF the system....................................................... 90

7 FAILURES ........................................................................ 92

7.1 Status Messages ................................................................. 93

7.2 Application Errors...............................................................94

7.3 Non-Fatal Errors..................................................................95

7.4 Fatal Errors.......................................................................... 96

7.5 Change fuses.......................................................................97

8 ANNEX.............................................................................. 99

8.1 Maintenance and Hygiene .................................................. 99

8.1.1 Cleaning and Disinfection of housing and waste box .............100

8.1.2 How to dispose of used disposables.......................................100

8.1.3 How to dispose the used system ............................................100

8.2 Protocol of Maintenance Check....................................... 101

8.3 Safety Specifications........................................................ 101

8.4 Technical Data................................................................... 101

8.5 Accessories and Consumables ....................................... 104

8.6 Mathematics ......................................................................106

8.7 Adaptation of coagulation reagents................................106

8.8 Packing of the system, preparation of transport ........... 107

CoaLAB 6000 – Operators Manual 1.8 Page 2

Introduction

1 Introduction

The instrument type CoaLAB 6000 (in the following titled as

analyzer/system) is a compact and automatic blood coagulation analyzer for

routine and STAT samples in the clinical laboratory.

For in-vitro diagnostic use only!

The system can perform 3 clotting tests such as PT / aPTT and Fibrinogen

simultaneously. It can perform additional tests such as Thrombin Time,

when the ChipCARD is used to replace any of the 3 standard tests. The

system can work in batch mode (individual test handling) or in randomaccess mode simultaneous test handling). In both cases the analyzer will

manage the results automatically.

The analyzer has 6 digital measuring channels based on the

turbodensitometric FIBRINTIMER

To avoid sedimentation a Teflon stirrer (2 stirrers are included) can be

added to the reagent. The reagent positions are always at room

temperature.

TM

measuring principle.

Purpose of this instruction manual

The instruction manual describes the system and is directed to all users of

the system.

This instruction manual gives all information necessary for the installation,

operation, maintenance, storing, packing, and transport of the system.

Service information is handled separately.

Careful observation of all information, especially of hazards and precautions

will ensure the correct and safe operation of the analyzer.

Therefore it is absolutely necessary to read the instruction manual

completely.

This instruction manual was prepared with greatest care. Should you have

any questions please refer to your distributor or to the manufacturer.

Validity of this instruction manual

All information in this instruction manual refers to this system:

For all requests please indicate type and serial number of your system

which can be found on the type plate on the back of the instrument or under

‘identification’ of this manual.

CoaLAB 6000 – Operators Manual 1.8 Page 3

Introduction

1.1 Definitions

Analyzer/System/ Instrument

Manufacturer

User

Personnel

In this manual the following terms are used:

This is the CoaLAB 6000.

The manufacturer according to IVD directive 98/79/EC is the

company/dealer who distributes the system within the respective country.

User is the current operator of the instrument.

Personnel are all people authorised to work with the system and meeting

the specifications required by the manufacturer for the operation of the

system.

Skilled personnel

All people who are especially qualified and authorised to handle specific

matters in connection with the instrument.

Life phases

All phases of the system from end of manufacture to disposal of the

instrument.

In this instruction manual all phases of the system will be mentioned.

QUALIFICATION OF PERSONNEL

The different life phases of the system require different qualifications of the personnel. The minimum

requirements for qualification are described at the beginning of each chapter or at the proper place in this

manual.

CoaLAB 6000 – Operators Manual 1.8 Page 4

Introduction

130-3-12-13

TSG

weiss

blau

nc.

gr-n

schwarz

rot

rot

schwarz

gr-n

nc.

blau

weiss

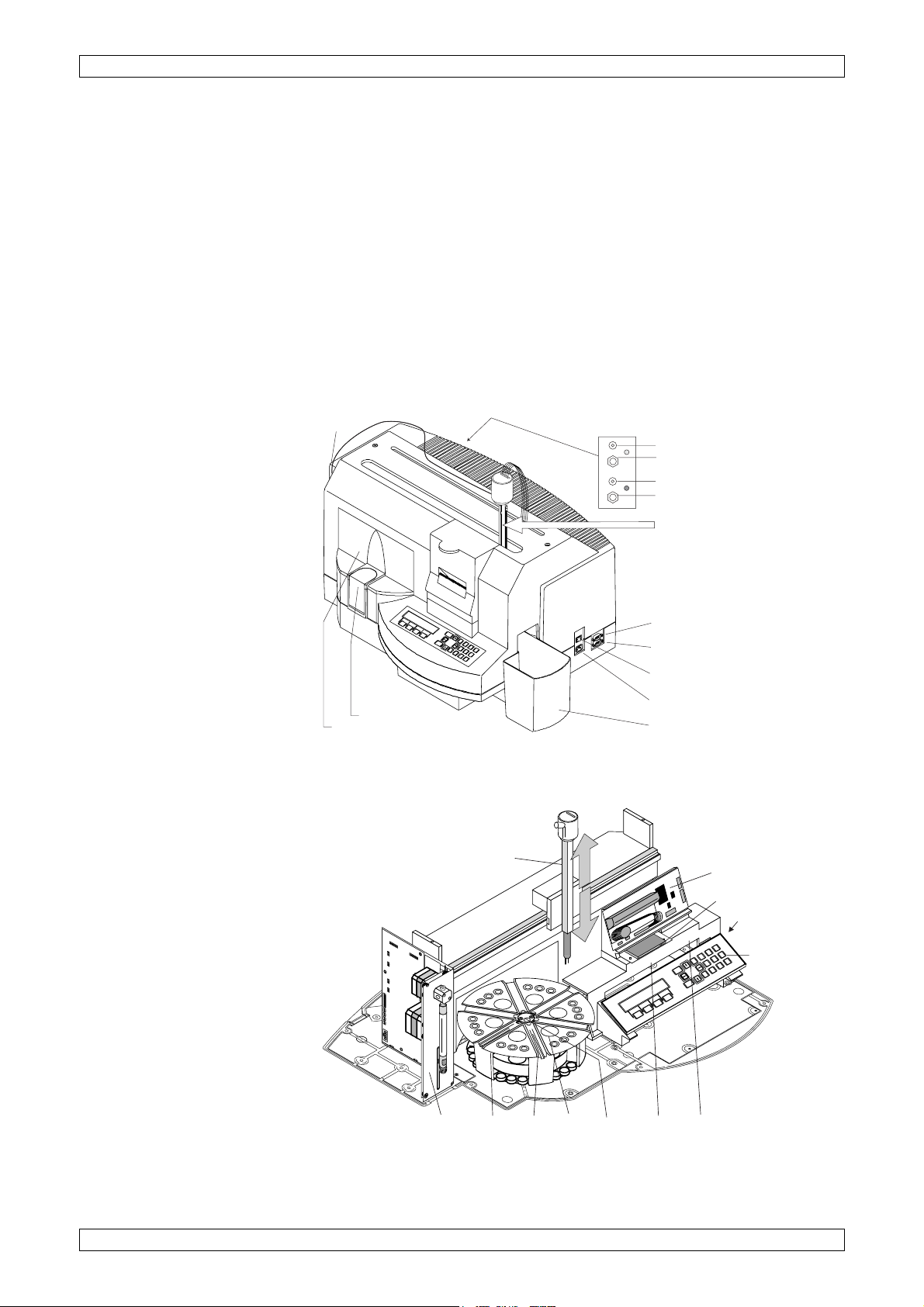

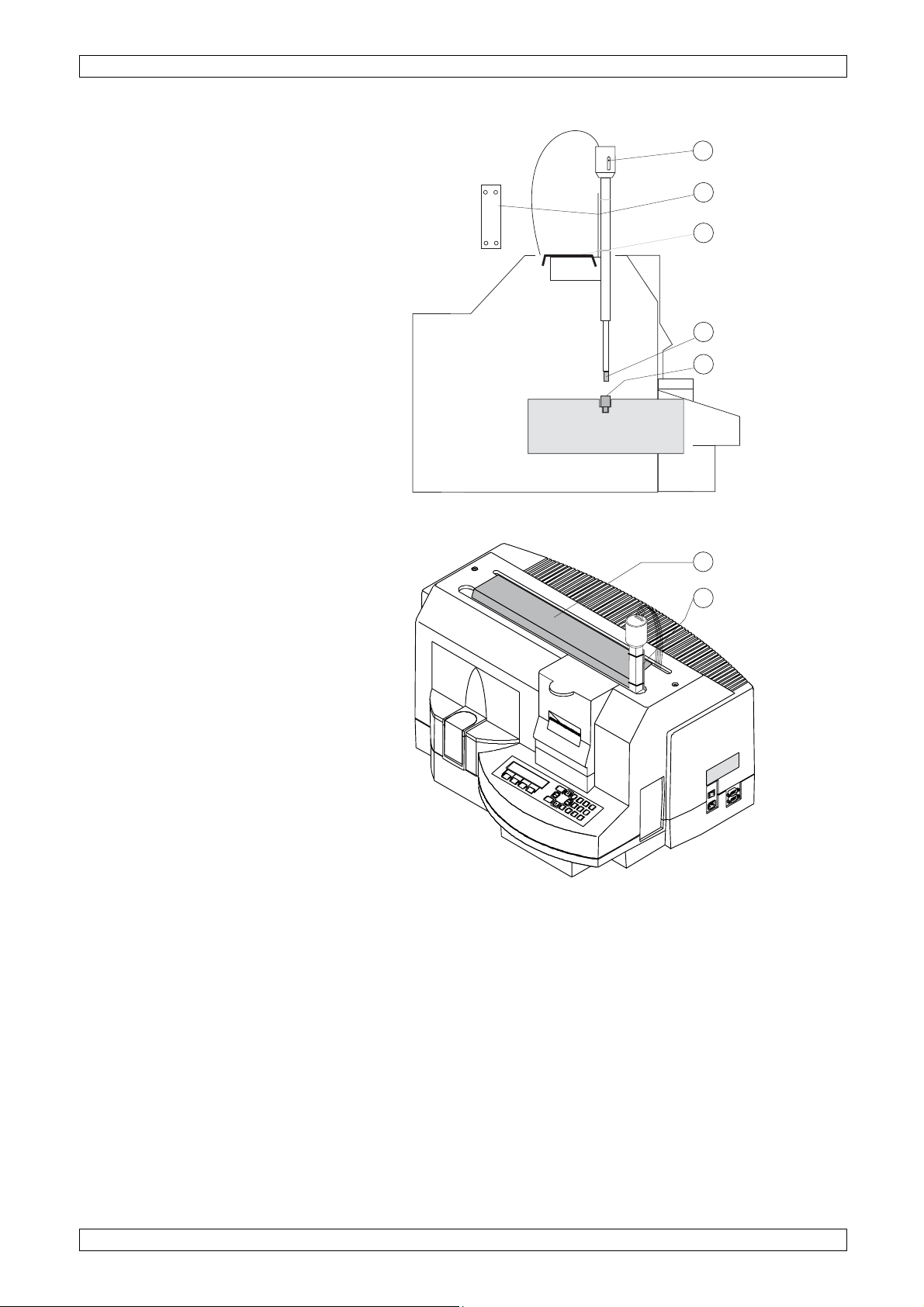

1.2 Description of the system

The System

No additional equipment is necessary to operate the instrument. The

integrated module and system software controls the system and manages

all data. The system can be connected to a host computer for the

management of results. All measured results, reagent and test-specific data

can be printed on the internal thermal printer.

The system will be loaded with samples, reagents, and cuvette bars. The

samples in primary tubes (Becton Dickinson Vacutainer, Sarstedt

Monovette or specially designed sample cups) are loaded into the sample

rotor. At any time STAT samples can be loaded for priority handling. The

system can either work sample-orientated or test-selective.

Dilutor

Big loading lid

Printer

ChipCARD

F1

F2

F3

ESC

F4

Key pad

ENTER

7

8

4

0

9

5

1

6

2

3

Small loading lid

Figure 1 System Connections

1

rot

blau

schwarz

gr-n

gr-n

schwarz

rot

blau

schwarz

rot

gr-n

nc.

blau

weiss

1111

schwarz

rot

gr-n

nc.

blau

weiss

a3a2

TSG

130-3-12-13

50%

6a 6b 6c7

Figure 2 Modules

8

Connection of containers for

system liquids

Sensor connection

Dist. water (green)

Sensor connection

Waste water (red)

Pipettor with steel tubing and level

sensor with tubing connected to

dilutor

Barcode scanner

RS 232 interface

Power supply ON/OFF

Main plug

Cuvette waste box

2

3

4

9

8

7

ESC

0

R

E

T

N

E

F4F3F2F1

456

2

1

5

3

910

CoaLAB 6000 – Operators Manual 1.8 Page 5

Introduction

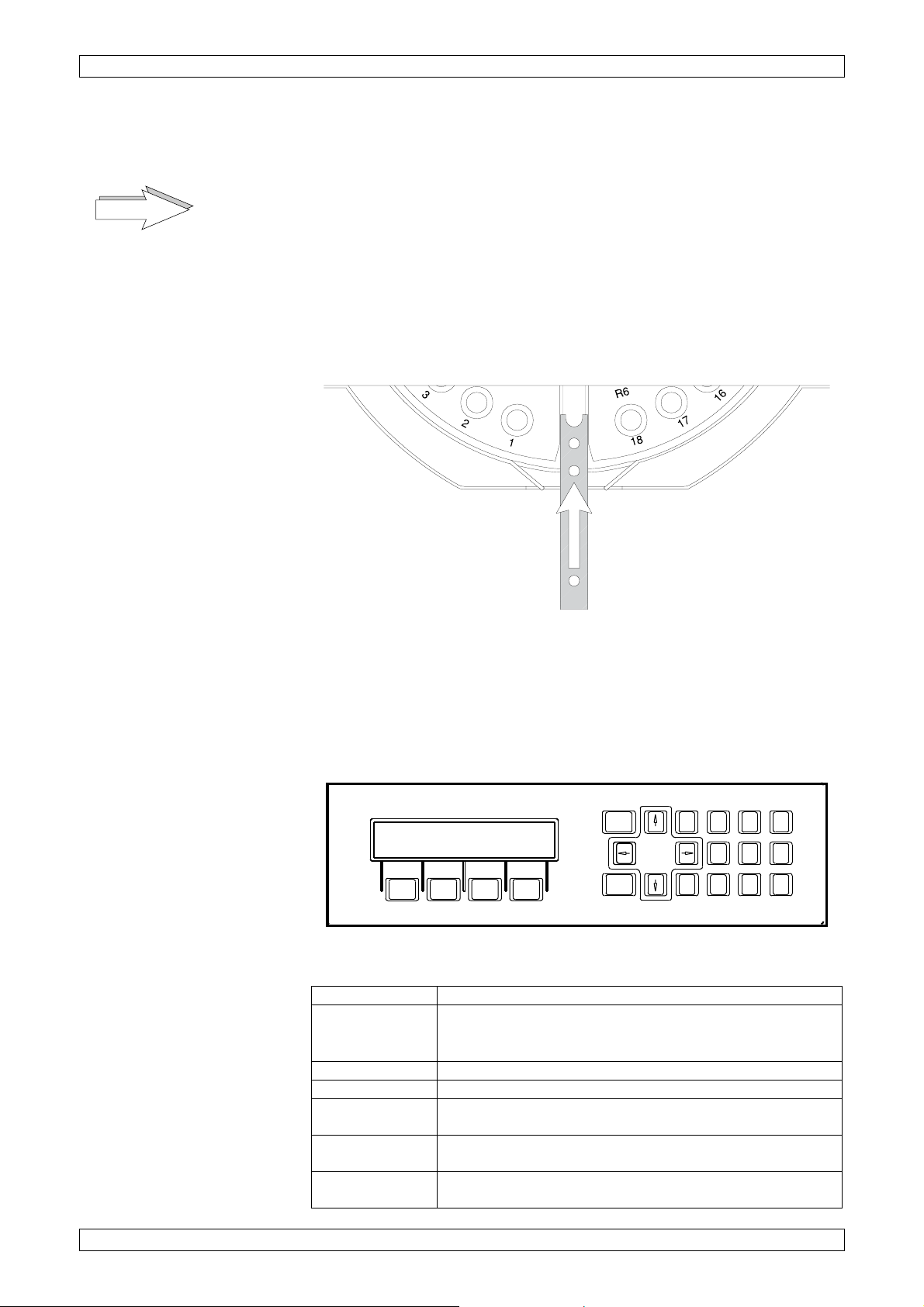

R5

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

R6

R1

R2

R3

R4

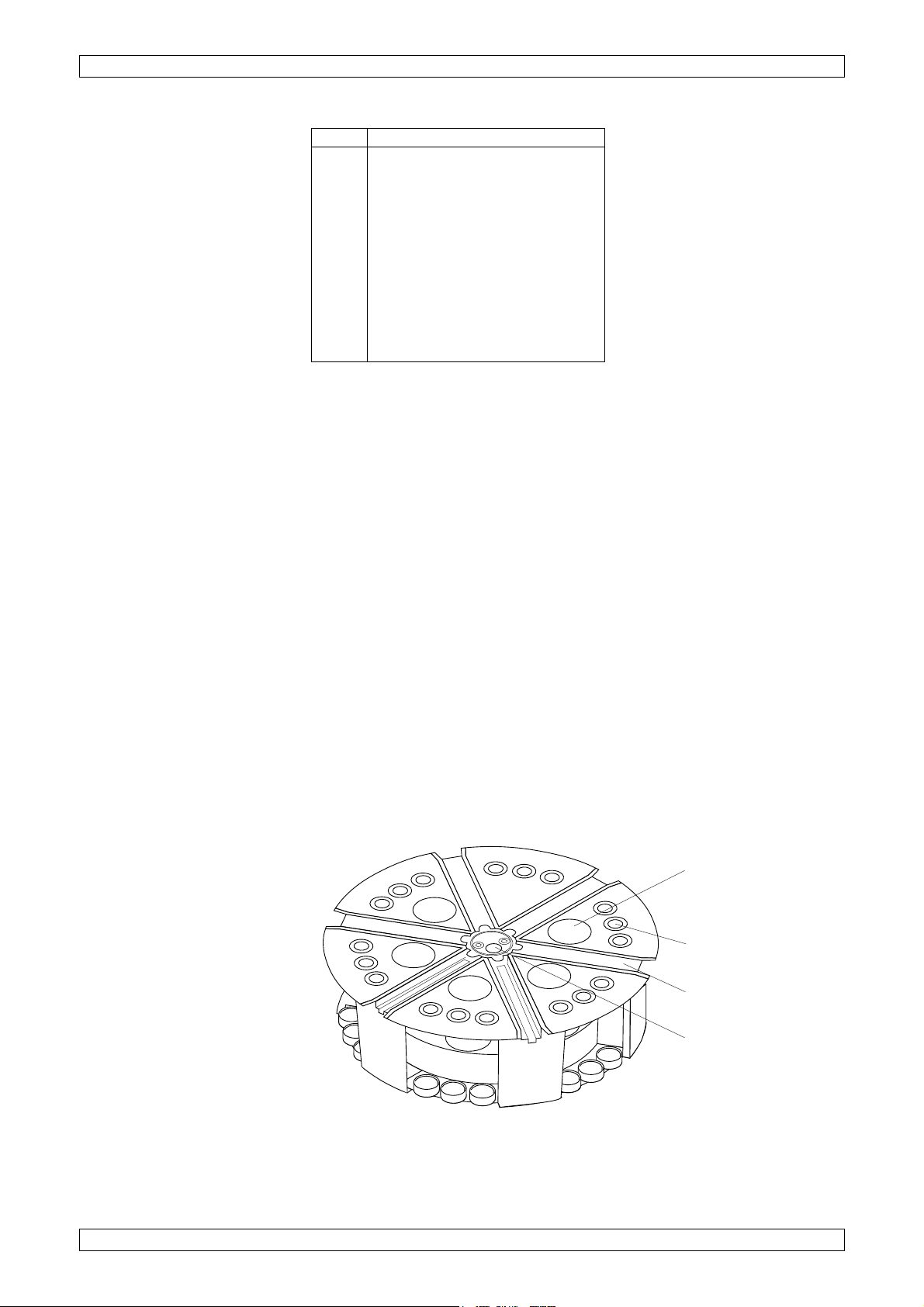

Reagent positions:

10 ml Adapter (white)*

4 ml Adapter (blue)*

* test specific

Sample positions:

1 - 18 for patient plasmas

Cuvette positions:

6 rials for cuvette bars

Rinsing station:

central station to rinse and

wash the pipettor steel tubing

and the level sensor

The sample rotor

Item Description

1. 37C temp. pipettor

2. Thermal printer

3. ChipCARD reader

4. Cuvette waste box

5. Keyboard

6a. Sample rotor

6b. Cuvette rail

6c. Reagent position

7. Dilutor

8. Washing position for pipettor

9. Incubation cell

10. Measuring cells (6 parallel)

The combined sample and reagent rotor consists of:

- 6 positions for the cuvette bars (6 cuvettes per bar).

- 6 numbered positions (R1 - R6) for the reagent vials.

Two different vials can be used:

- 4 ml plastic vial with blue adapter ring

- 10 ml plastic vial with white adapter ring

- 1 reagent stirrer position on which all 6 reagent positions can be stirred

just prior to sampling.

- 18 numbered sample positions

- rinsing station

Primary tubes

The following primary tubes can be selected in the Setup Menu under

< 1 Primary Tubes >:

- Sample cup

- 4.5 ml Beckton Dickinson Vacutainer (the short Vacutainer only)

- 3.0 ml Sarstedt Monovette

For further information refer to section 6.4.1 Define Primary Tubes.

CoaLAB 6000 – Operators Manual 1.8 Page 6

Figure 3 Sample rotor with positions

Introduction

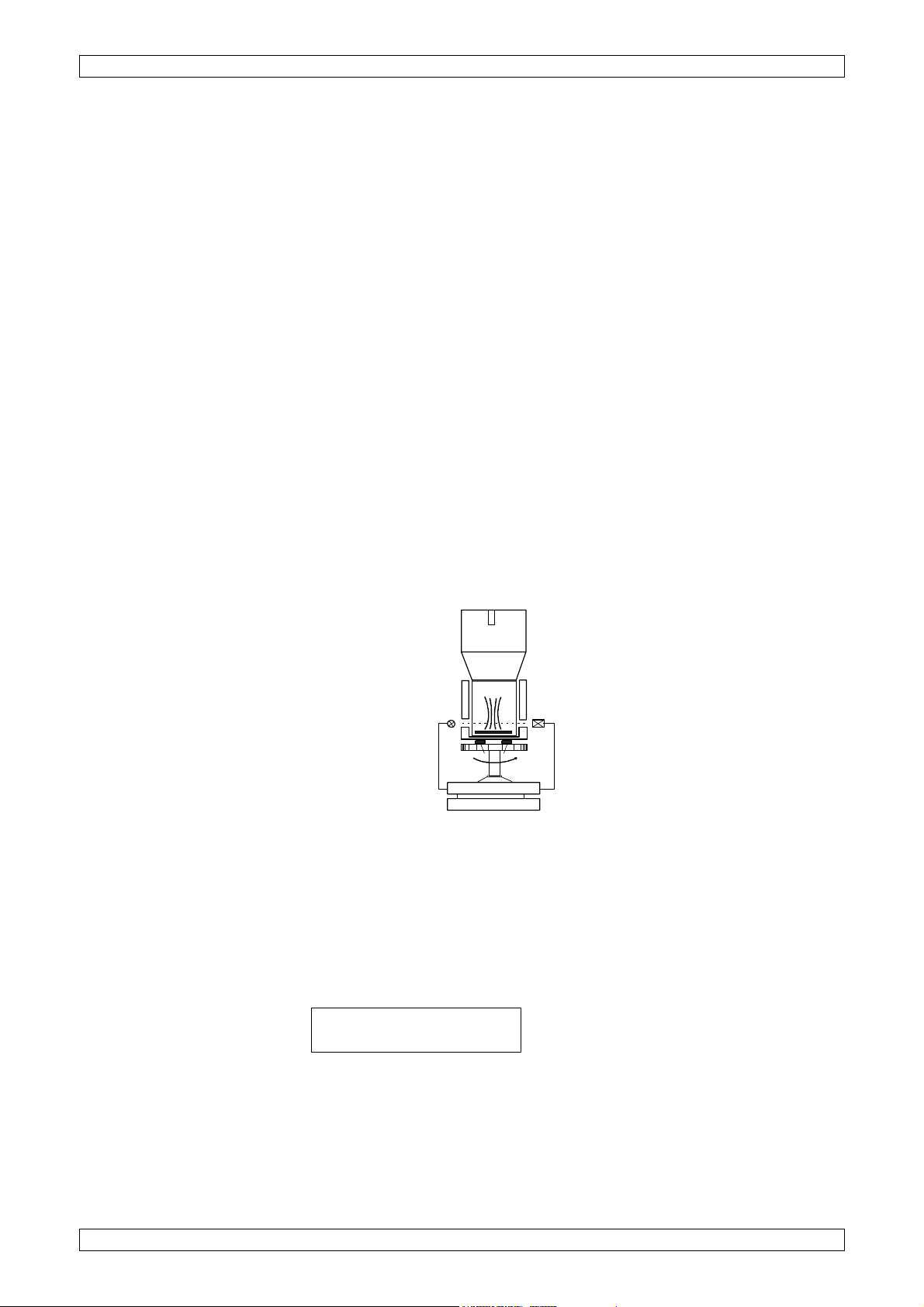

The cuvette bar

The cuvette bar has 6 wells. Up to 6 bars (36 cuvettes) can be loaded onto

the sample rotor.

To ensure correct loading, the cuvette bar is designed so that it can only be

NOTE

inserted one way (with semi-round opening inserted first), see picture.

Remove metal foil before using the cuvette bar.

Each well of the bar contains a 1 x 3 mm stir bar. These stir bars are

necessary to obtain accurate measurements.

Ensure that only the original cuvette bars and stir bars provided by the

manufacturer are being use to operate the system otherwise the warranty

may become null and void.

Figure 4 Bar with loading direction

The keyboard

The keys are used for direct control of the system and lead you through the

operating software. The display informs you of the current operation mode

of the system.

ESC

7

8

9

456

1

2

F4F3F2F1

ENTER

0

3

Figure 5 The keyboard

Keys Meaning

Arrow Keys Function key to scroll through the menu

• The right arrow-key sets the decimal point.

• The left arrow-key deletes single characters.

ESC-key Function key to quit or confirm a certain menu point.

ENTER-key Function key to confirm and save menu information.

Number-keys Function keys to enter digits and enter or select special

menu points.

Function keys

(F1-F4)

Delete-key

(blank)

Function keys to select certain operation steps which

are displayed directly above.

Function key to delete Pat. ID or Lot-No completely or to

be used as line feed key.

CoaLAB 6000 – Operators Manual 1.8 Page 7

Introduction

RS232

Barcode

1 Fuses

2 Power switch

3 Mains connection

4 Barcode plug

5 Barcode socket

6 Interface RS232

Mains connection fuses and power

switch

The main connection fuses and power switch of the system are combined

and integrated into the right side of the instrument. There is also a socket

for a barcode scanner (optional) and for a connection to a host computer

(optional) via an RS 232 C interface. The connections are marked

accordingly.

Figure 6 Power filter with mains plug

The system is delivered without power supply cable. The cable must

NOTE

meet the local regulations. (e.g. IEC 320, VDE, CSA-C22.2, No. 21 and

No. 49).

The cable has to be designed with NYLHY. The recommended length

is 1.5 m, and the minimum cross section 3x 0.75 mm2. A cold device

plug is used at the system’s end.

Use only fuses recommended by the manufacturer. Observe the

instructions on the name plate located on the back side of the system.

The analyzer is set to 230V by the manufacturer, change fuses

(supplied in accessories) in power filter, if analyzer will be operated in

115V. See chapter 7.5 on changing fuses.

CoaLAB 6000 – Operators Manual 1.8 Page 8

Introduction

L

r

1.3 Measuring principle

The system operates according to the opto-mechanical measuring principle:

It is well suited for lipemic and icteric samples as well as reagents with

kaolin.

A light beam passes through the cuvette containing the test plasma onto a

photo-detector. Any change in intensity of the transmitted light, that is light

increase or decrease, is converted into an electric signal.

The period from adding the start reagent until clot formation is measured. It

can be converted into the appropriate units then (%, Ratio, INR, mg/dl, g/l).

Once the start reagent has been added the measuring channel is

repeatedly adjusted, that means the lamp intensity automatically adjusts to

the turbidity of the test sample. In this process the turbidity of the sample

plasma and the reagent are levelled out.

A stir bar in each cuvette provides homogeneity of the reagent-plasma

medium during the measuring process. At the same time a small whirl

emerges through the stir bar movement which assures that even the

smallest fibrin clot is formed in front of the photo-detector.

This stirring action combined with the optical measurement, constitute the

basic features of the patented „turbodensitometric measuring principle“.

Figure 7 Measuring principle

Test cuvette

amp

Stirrer - Motor

ELECTRONIC

DISPLAY

Detecto

perm. magnet

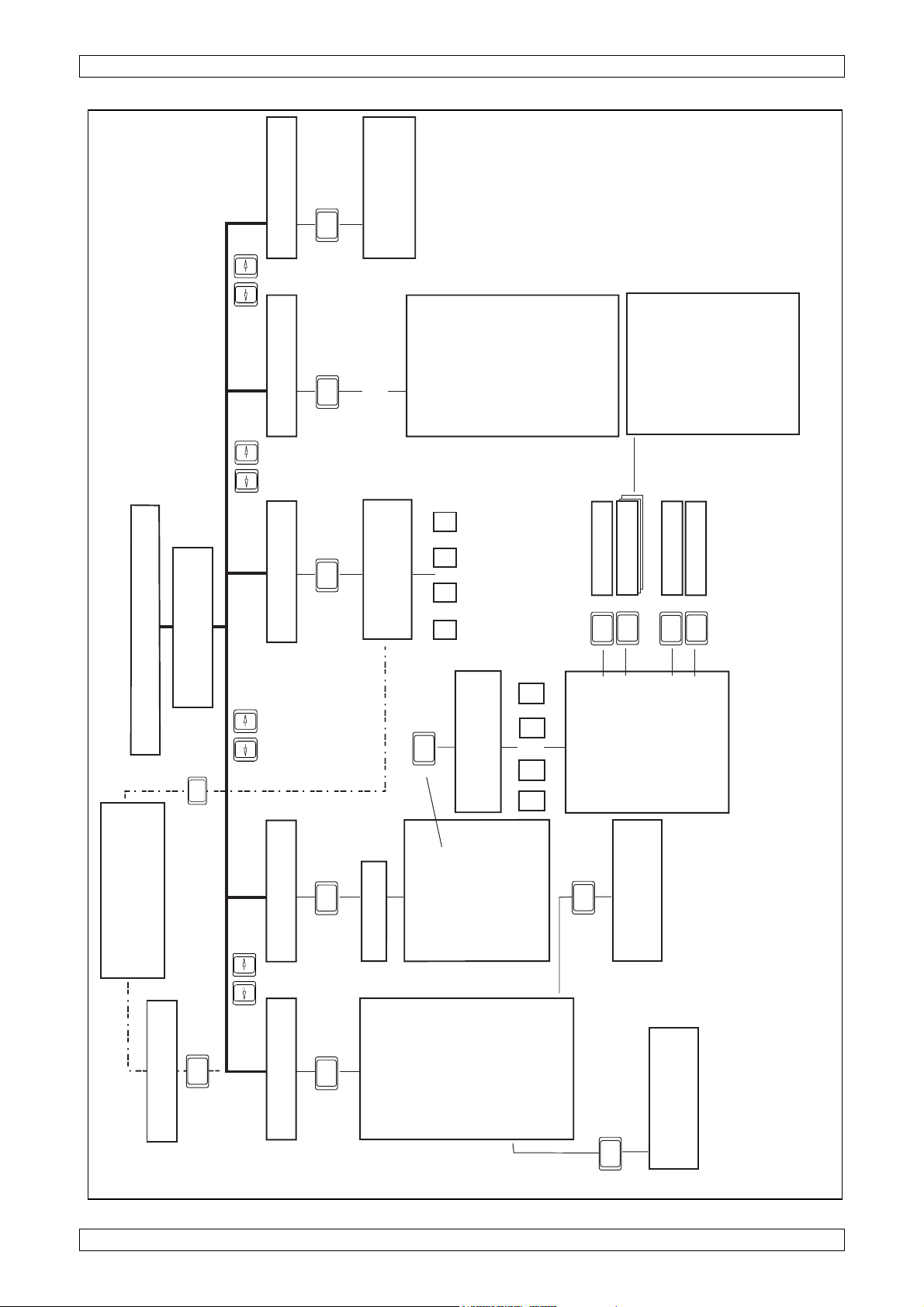

1.4 Software Overview

The software overview makes it easier to find the different functions desired.

After the instrument has been switched on, it will initialize and automatically

display the MAIN MENU.

MAIN MENU

< ROUTINE MENU >

By pressing the

• Arrow-keys right/left you can select a menu.

• ENTER-key opens a menu or selects a function.

• ESC-key steps back a level in the menu.

CoaLAB 6000 – Operators Manual 1.8 Page 9

Introduction

Initialising

MAIN MENU:

Analyzer Power ON

F4

user interrupt (ESC)

Yes No Stop STAT

Esc

< 5 Start measure >

Enter

< 5 UTILITY MENU >

Enter

< 4 SETUP MENU >

Enter

< 3 STAT MANAGEM. >

Enter

< 2 TEST MENU >

Enter

< 1 ROUTINE MENU >

UTILITY MENU:

< 1 Init Instrument >

PIN

SETUP MENU:

< 1 Primary Tube >

< 2 No of STAT pos >

STAT Measurement

Edit Ins Prnt Start

F1 F2 F3 F4

Enter

Select test:

PT aPTT FBG END

PIN

TEST MENU:

< 1 Modify test >

< 2 Read test >

ROUTINE MENU:

< 1 Erase joblist >

< 2 Insert sample >

< 3 Edit joblist >

< 4 Print j oblist >

< 3 Date / Time >

< 4 Printer setup >

< 5 Beeper Setup >

< 6 Modify PIN >

< 7 Language >

< 8 Print Setup >

Enter

Enter

F1 F2 F3 F4

PARAMETER

< 1 Replication > sngl / DBLE

< 2 Measurement > < Parameter >

Enter

< 3 Print test >

< 4 Erase test >

< 5 Write test >

< 5 Start measure >

< 6 Result managem. >

< 7 Load reagents >

< 8 Maintenance >

Maintenance

Enter

< 1 Sample volume >

< 2 Diluent >

< 3 Reagent 1 >

< 7 Incub. time >

< 8 Start reagent / Vol ume

/ Lot . No. / Bottle type >

< 9 max meas time >

Enter

Enter

< 3 Normal range >

< 4 1st Conversion > Reference curve /..

< 5 2nd Conversion > Ratio / INR

< 6 Print test >

wash FLUSH remov

Result Management

send disp. PRINT

CoaLAB 6000 – Operators Manual 1.8 Page 10

Hazard and Precaution

2 Hazard and Precaution

This section contains the safety regulations that must be observed by all

users of the system, to ensure safe and economic operation.

Importance of safety regulations

All safety instructions in this instruction manual must be observed to avoid

damage to persons, property and the environment.

All local safety and environmental regulations and guidelines must also be

observed.

Disregarding of safety regulations

Disregarding these safety regulations or technical specifications may result

in accidents with personnel or equipment, or environmental damages.

Hazards and Precautions

The system has been delivered by the manufacturer in a technically

flawless condition. In order to keep this condition the user must follow

the following safety regulations of this manual.

The system must be operated by skilled personnel only.

NOTE

Note introduces rules to be observed.

Warning signals

ATTENTION!

WARNING!

Two different warning signals with different meanings are used in this

section.

Potential danger may cause minor injury or equipment damage, if no

precautions are taken.

Potential danger may cause severe injury or death if no precautions are

taken.

CoaLAB 6000 – Operators Manual 1.8 Page 11

Hazard and Precaution

Electrical safety:

WARNING!

Ensure that the operating voltage is set correctly before the instrument is

connected to the main power supply.

Use only grounded sockets and extension cords when connecting the

instrument to a power supply. Never disconnect grounding contacts.

Never disconnect the grounding contacts intentionally.

There is the risk of an electrical shock if

- The protective conductor is interrupted within or outside the device

- The grounded contact has been disconnected from the line.

Never remove protective guards or secured components, since you

could expose electrically live parts. Even after the instrument has been

switched off, some parts may contain voltage due to electrical charge.

All current carrying parts are sources of danger for an electrical shock.

Never use the instrument on a moist surfaces (floor, worktable or

countertop), or place containers of liquids on top of the instrument. Liquids

spilled into the instrument may cause an electrical shock.

Switch off the instrument and disconnect it from all power sources

before performing maintenance or repair work. Perform only the

maintenance/repair work described in this manual; unauthorized work on

the instrument may cancel the warranty, and require expensive service

work.

All work which requires the instrument to be opened under voltage must

only be carried out by a technician who is familiar with the risks related

thereto.

Use only replacement fuses of the stated type and with the stated

minimum current;

- Never use ‘repaired’ fuses.

- Never short-circuit the fuse holder.

Fire and Explosion hazards:

WARNING!

Do not place the instrument near explosive mixtures of flammable

gases, such as oxygen or hydrogen; electrical sparks could cause fire or

explosions.

Mechanical Safety (system in

operation)

WARNING!

CoaLAB 6000 – Operators Manual 1.8 Page 12

Never remove housing parts while the instrument is on; moving parts

such as the fan or motor drives may cause injury.

Always close the sample rotor-loading inlet during operation, to avoid

contact with moving parts. The probe will not stop when the loading inlet

is open.

Ensure that the pipettor does not stop over the sample rotor or the

measuring block when the instrument is switched off.

Hazard and Precaution

- Use the protection cap for the pipettor if the system will not be operated

for a long time, to avoid damage and contamination.

- Do not open covers during a run, to avoid damaging the pipettor.

If safe operation of the instrument is not possible switch the

instrument off and secure it against use if:

- The instrument is damaged

- The instrument does not work properly

- The instrument has been stored / transported under adverse conditions

- The instrument has experienced severe temperature fluctuations

Samples, Reagents

WARNING!

Follow the instructions on the directional inserts for the correct use of

reagents.

Avoid skin contact with samples and/or test reagents, as well as those

instrument parts that touch samples and/or test reagents. All instrument

parts are potentially infectious, and reagents might irritate mucous

membranes and the skin. All liquid and waste containers which carry

sample and/or test reagents are marked with a biohazard symbol.

If sample material is spilled onto the instrument, wipe it off immediately and

decontaminate the affected surfaces.

Ensure that no foam or air bubbles are on the surface of reagents and

sample material prior to loading the system: their presence could influence

the measured results and the level detection of the needle. Ensure reagents

are used at room temperature only.

Before using sample cups and reagent vials make sure to remove all

covers/lids beforehand. Do not use organic solvents unless explicitly

authorized by the manufacturer, as their use may result in damage to

the cuvette bars, primary tubes, and waste water tubes.

Waste Liquids:

WARNING!

Dispose of waste liquids must be in compliance with applicable

regulations.

Accuracy and Precision of

Results:

WARNING!

CoaLAB 6000 – Operators Manual 1.8 Page 13

Measure control samples and ensure the instrument is operating

properly to obtain accurate results.

Inaccurate results may lead to a false diagnosis and endanger the patient.

Hazard and Precaution

User Qualification:

WARNING!

Barcode Scanner:

ATTENTION:

CAUTION

LASER LIGHT

DO NOT STARE INTO BEAM

670nm LASER DIODE

1.0 MILLIWATT MAX

CLASS II LASER PRODUCT

VORSICHT

LASERSTRAHLUNG, NICHT IN DEN LICHTSTRAHL BLICKEN,

SICHTBARE LASERSTRAHLUNG, LASERKLASSE 2

The system should be operated by trained personnel only.

Be careful when using the barcode scanner laser light.

- Avoid direct eye contact with the laser beam.

- Follow the manufacturer’s instructions.

- Ensure the scanner was tested and authorized for use by the

manufacturer.

Acoustic Signals

A beeper confirms all key strokes on the system keyboard. Thus, the user

can recognise, for example, the end of a run, possible failures during

operation, or the access to STAT mode without looking at the display.

CoaLAB 6000 – Operators Manual 1.8 Page 14

Warranty

3 Warranty

The representatives or authorised dealers warrant that the system does not

have any material or manufacturing damages after installation if the

instruction manual has been observed.

The warranty does not apply for damages which are caused

- By accidents, negligence, or non-observation of the instruction manual,

- By using inadmissible reagents or disposables, or

- By operating the instrument in an environment contradicting the

specifications of this instruction manual.

Repair and service work must be carried out by technicians who have been

authorised.

CoaLAB 6000 – Operators Manual 1.8 Page 15

Service

4 Service

The representatives or authorised dealers guarantee to carry out repair

work during the official working hours from Monday to Friday with the

exception of public holidays.

If you need service outside of that time contact our parent company or our

authorised dealer.

CoaLAB 6000 – Operators Manual 1.8 Page 16

Installation

5 Installation

This section describes how to unpack, install and prepare the instrument for

use.

Safety regulations

We assume that you have read chapter 2 Hazard and Precaution carefully.

5.1 Unpacking and installation

of the system

5.1.1 How to prepare the

installation area

Select a stable and level area for installation.

NOTE

Ensure the power cable will reach the outlet without

cords.

Ensure there is enough light for proper operation, but no direct sunlight.

Do not put the analyzer on a shelf or on a roll-desk. Protect from

direct sun light, significant temperature changes, humidity, and

Ensure there will be a cleared space of at least 12 inches (30 cm) to the

voltage variations.

sides and rear of the system, to allow easy access and air circuation.

Ensure the space above the system will be clear of equipment, supplies and

shelves.

using any extension

5.1.2 Check Contents

NOTE

The instrument weighs about 35 pounds (17 kg), and can be carried or

moved by one person. For the safety of the instrument and yourself,

however, you should move the instrument using a rolling cart of have

someone assist you.

Do not damage any packaging material, and keep them for possible

later use, including the transport protection devices. Store them

away from heat and humidity.

• Place box on the floor

• Remove all small parts from the box first, and ensure all accessories

and disposables listed in section 8.5 have been received.

CoaLAB 6000 – Operators Manual 1.8 Page 17

Installation

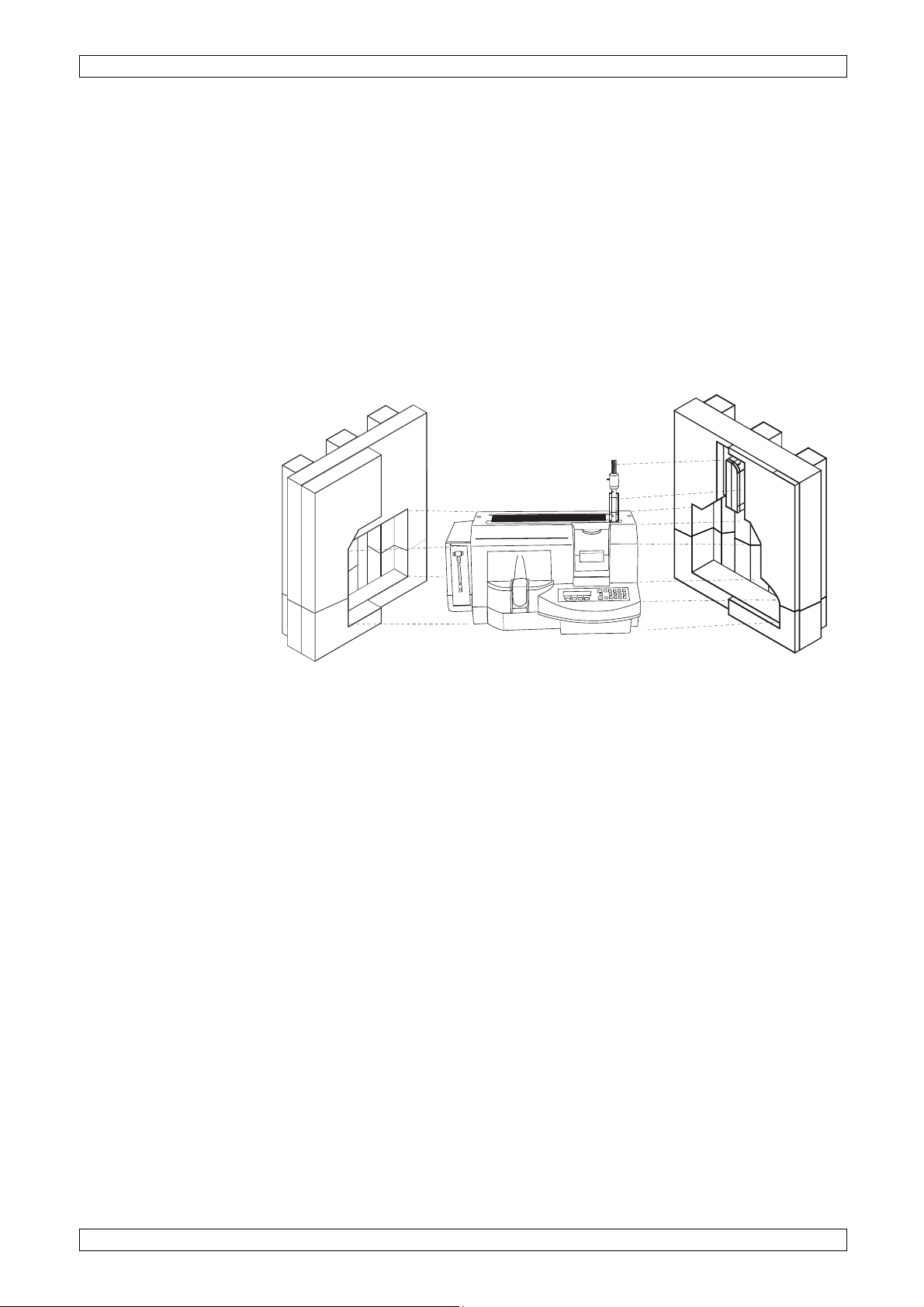

5.1.3 Unpacking the system

• Lift the system from the box (with assistant), and place on the installation

area.

• Remove the left (1) and right (2) foam inserts and set aside (See figure 8).

Pay attention to the pipettor!

Be careful not to damage the pipettor, flat cable, steel tubing or level sensor;

any damaged or defective parts must be replaced by a service technician

before operating.

• Place the system in the correct position on the table.

• Remove all tapes and transport protection devices (see figure 9).

1

2

1

2

Figure 8 The system with foam inserts

Transport protection devices are:

See figure 9.

1. Box insert: protects the pipettor from moving in X-direction.

2. Plastic plate with cable ties: protects the pipettor from moving in Z-

direction.

3. Red plastic screw on the steel tubing (top): protects from contamination.

4. Plastic protection cap on the steel tubing (bottom): protects from

contamination.

5. Empty cuvette rack between sample rotor and measuring block.

CoaLAB 6000 – Operators Manual 1.8 Page 18

Installation

2

t

P

c

. Transport protection of

he pipettor:

lastic with

able ties

3

2

1

4

5

System

sectional view

ROTOR

1. Transport protection of

pipettor with carton

1

2

F1

F2

F3

ESC

F4

ENTER

7

8

4

0

9

5

1

6

2

3

Figure 9 The system with transport protection devices

5.1.4 Assembly of the system

Before connecting the instrument to the main power supply, complete all

instructions in this section.

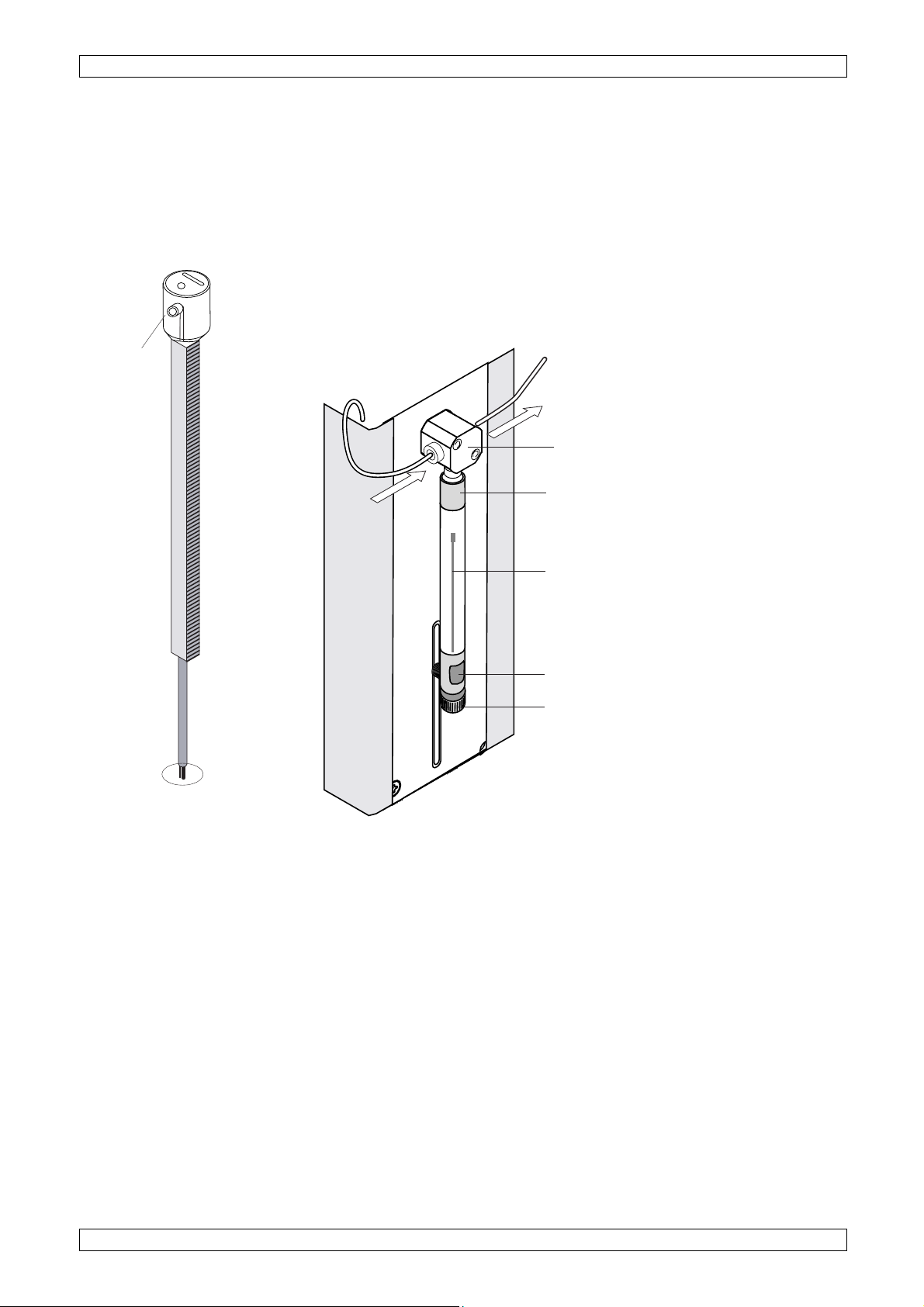

5.1.4.1 Mount the diluter

syringe and tubes

Mount the 250 µl dilutor syringe to the dilutor of the system according, see

figure 10. When properly mounted, the syringe should not be wedged, and

must be watertight.

CoaLAB 6000 – Operators Manual 1.8 Page 19

Installation

S

• Press the syringe piston completely into the dilutor syringe.

• Open the locking screw.

• Push the syringe holder at the dilutor downward.

• Place the opening of the syringe piston onto the syringe holder of the

dilutor.

• Screw the top of the syringe onto the adapter of the dilutor valve.

• Tighten the locking screw.

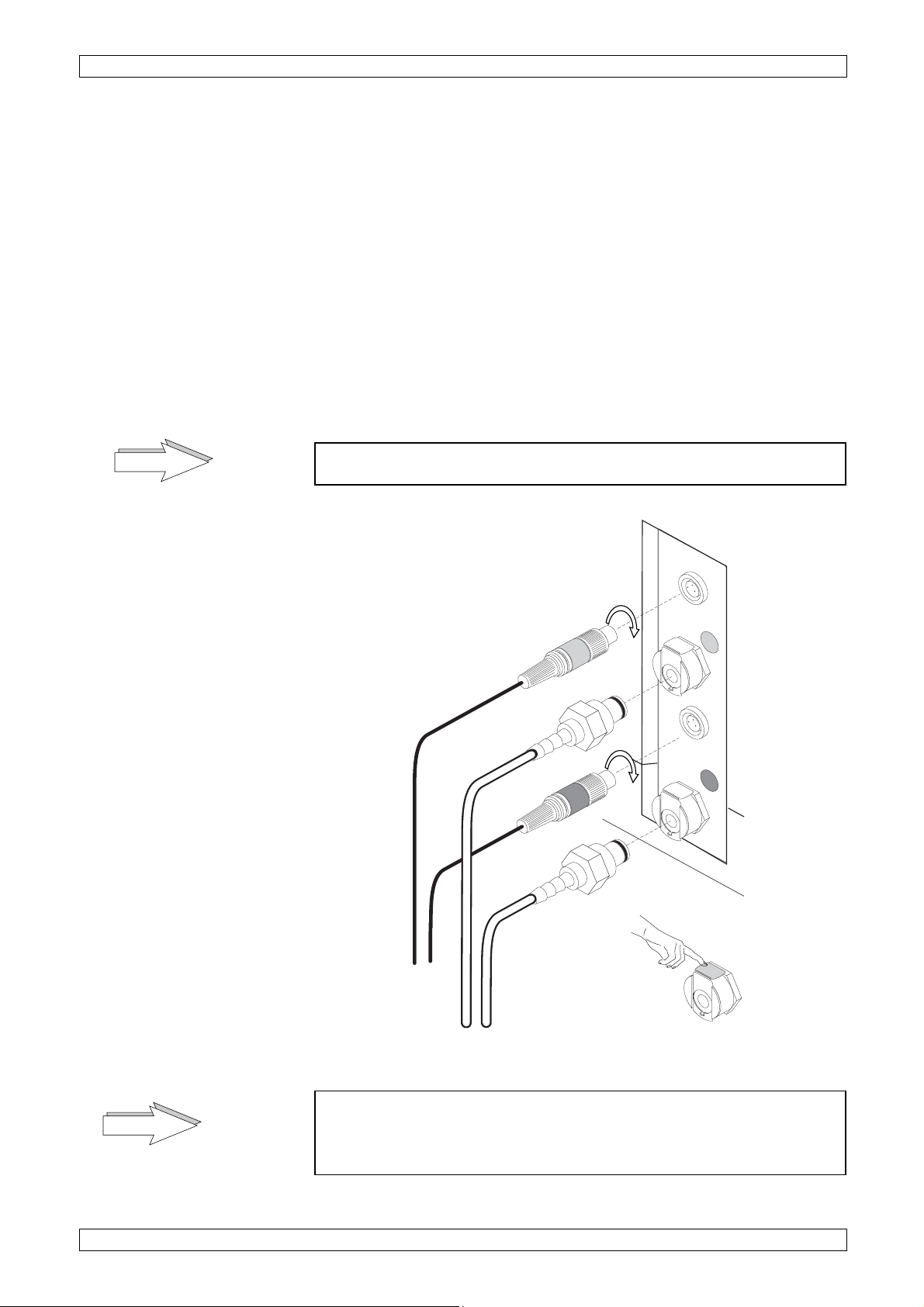

• Connect all tubing’s to the dilutor valve.

teel tubing

pipettor

Dist. water to

Dilutor valve

Top of syringe

Pipettor

Dist. water

Syringe piston

Syringe holder

Locking screw

Steel tubing

point and

level sensor

Figure 10 Diluter and syringe

Attach the tubes

The liquid system requires tubing between the diluter and pipettor. Connect

the tube as follows:

• Take the tubing out of its plastic accessory bag.

• Remove the red plastic screw at the steel tubing of the pipettor.

• Screw the tubing (white screw) onto the diluter valve until hand-tight.

• Run the other end of the tubing through the tubing guides on the back of

the instrument.

• Screw the end into the top of the arm (black screw). Make sure it fits

properly and watertight.

• Review the entire tube path to ensure the tubes will be neither bent nor

squeezed during instrument operation.

CoaLAB 6000 – Operators Manual 1.8 Page 20

Installation

5.1.4.2 Connect the Liquid

System Containers

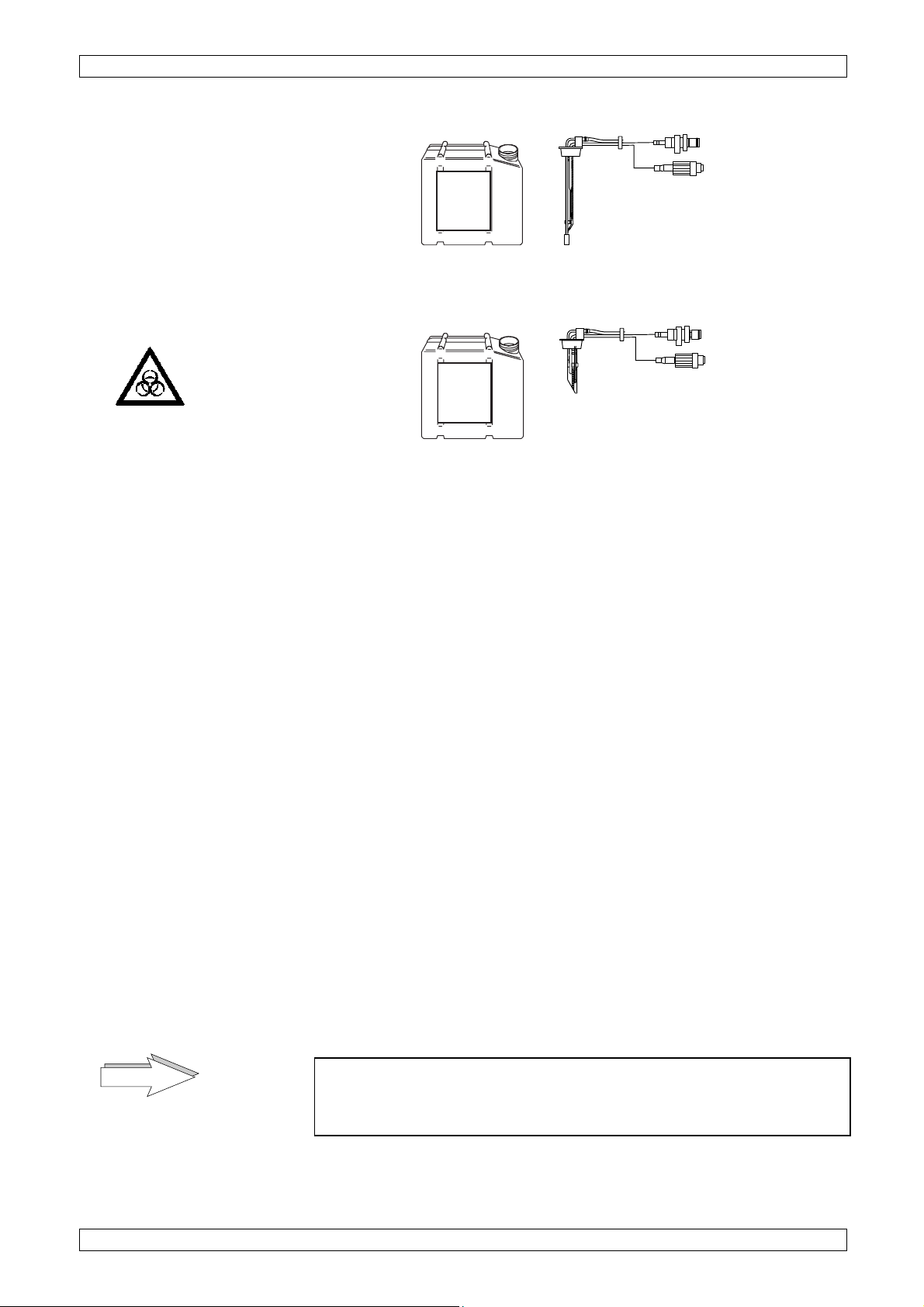

• Place the distilled water container (with the green label) and the empty

waste water container (with the red label) to the left rear of the system. Fill

the distilled water container with at least 1 Liter of distilled water.

• Place the colour-coded sensors into the appropriate containers (green for

dist. water, red for waste water). Ensure there are no air bubbles in the

tubing of the distilled water container, or in the container itself.

• Plug the green and red colour-coded couplings into their matching sockets

on the back of the system (see figure 11). A „click“ indicates the proper

seating of the connectors.

The system will only function if the distilled and waste water tubes have

been connected properly to the system.

NOTE

The system is switched OFF.

The couplings are color-coded:

Red for

waste water

Green for

dist water

Green

Red

Figure 11 Connect the level sensor tubes to the system

< NOTE >

Decoupling of the tube adapter

Press on the metal shield to

release the tube adapter.

The distilled water container must have at least 1 Liter of distilled

NOTE

water. The waste water container should be emptied every day. Be

careful not to have air bubbles in the distilled water container as well

as in the tube.

CoaLAB 6000 – Operators Manual 1.8 Page 21

Installation

Container

Figure 12 Container for distilled water. Container and tubes are

Figure 13 Container for waste water. Container and tubes are coded

dist

water

coded with green.

waste

water

with red.

5.1.4.3 Connect the Barcode

Scanner (Optional)

5.1.4.4 Connect a HOST or

Personal Computer to

the System

NOTE

• Connect the optional barcode scanner to the system. Use the

recommended type only.

• Connect the barcode scanner data cable to the upper socket (marked

barcode) on the system (see figure 6).

• Plug the power supply into the socket next to it.

The system has an additional interface port (RS 232 C).The RS 232

interface is a uni-directional interface which allows the transfer of patient ID

and results to a connected HOST or PC. Due to many different used

HOST/LIS PC systems the interface protocol may vary, please ask your

distributor or the manufacturer for further information on transfer of data’s.

• Before switching on the computer, the PC must have been connected to

the external periphery instruments. Use the data cable recommended by

manufacturer or dealer only. Then connect the PC to the power supply.

Do not switch the computer on yet!

Now connect the data cable to the lower socket (marked RS 232) on the

right side of the system and to the interface port of your computer.

Before switching on the analyzer and before each re-initialisation,

pay attention that all cuvettes and vials have been removed from the

rotor and the measuring block.

• Now connect the system to the power supply. The ON/OFF switch is on

the right side of the instrument.

CoaLAB 6000 – Operators Manual 1.8 Page 22

Installation

• After complete installation the instrument and, possibly, the computer can

be switched on and off accordingly.

See figure 6 Power ON/OFF, Power filter.

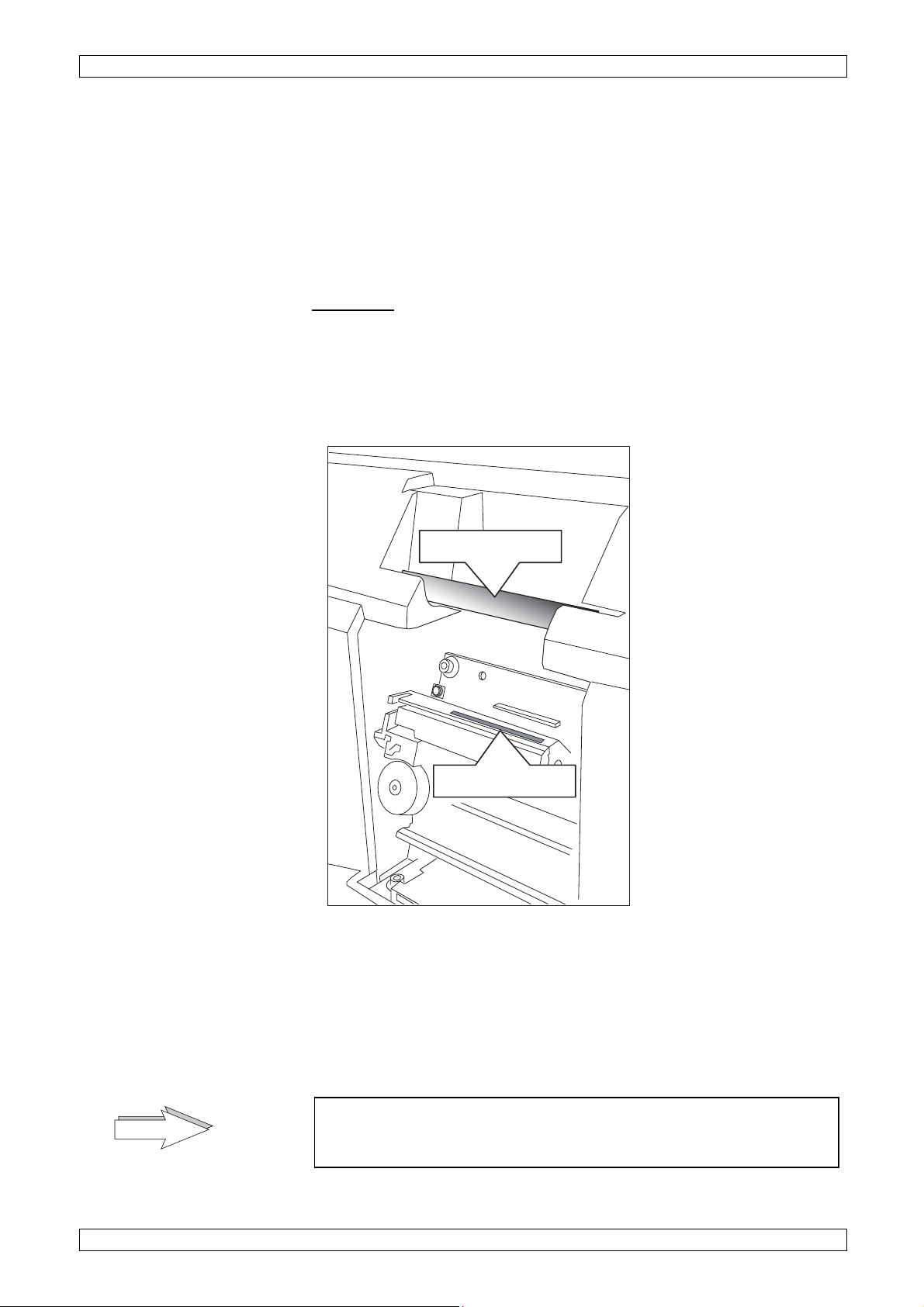

5.1.4.5 Insert and change

printer paper

After switching on the system you can now insert the printer paper (see

accessories). The printer paper can be inserted only when the system is

switched on

.

• Lift the printer cover above the keyboard and remove the previous paper

roll holder, if necessary.

• Place the new paper roll with the paper roll holder into the correct position.

The unrolling paper must run towards the inside of the printer

Paper roll axis

paper insert slot

Figure 14 Printer housing

• Guide the paper - with a clear-cut end- into the paper slot of the printer.

Once the paper has been captured it will be advanced automatically.

• Guide the paper through the slot of the printer cover and re-install the

cover.

Use manufacturer’s printer paper only. Otherwise, the warranty

NOTE

may become void. Over time the text will fade. It is recommended

that all printouts be copied for storage purposes.

CoaLAB 6000 – Operators Manual 1.8 Page 23

Installation

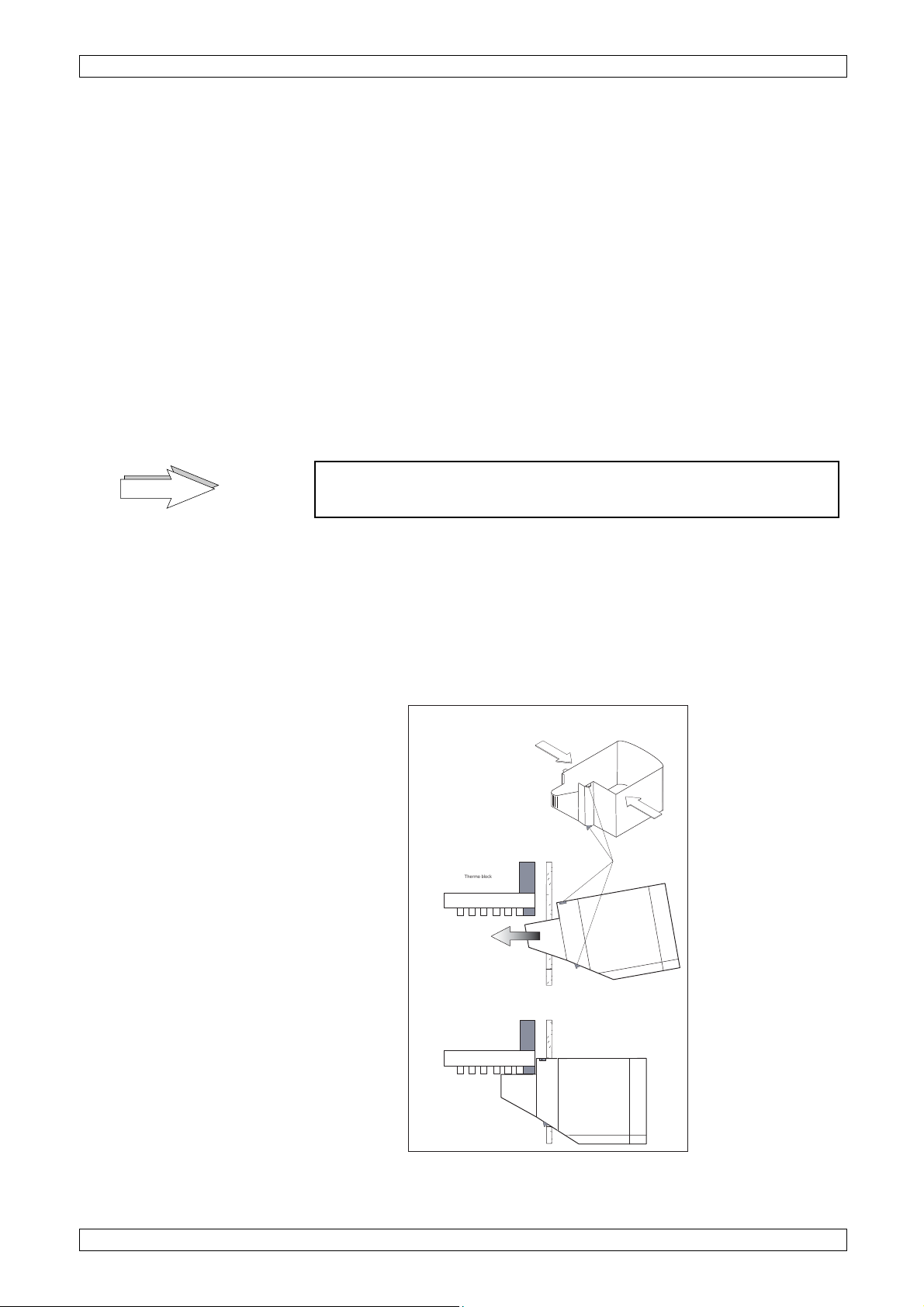

5.1.4.6 Mount the cuvette waste

box

The cuvette waste box must be attached before using the instrument. The

cuvette bars which are automatically ejected from the measuring unit will be

collected.

Be careful that plasma as well as reagents can flow out from the cuvette

bars.

Therefore it is necessary to clean the box in regular intervals.

Mounting the waste box

See figure 15 next page

• Take the waste box out of the accessory box.

• As shown in the figure, press the box gently.

• Guide the waste box, gently pressed and slightly tipped, into the housing

space so that the locking devices on the inside prevent the box from

slipping.

Use caution, as the cuvette bars that are collected in the waste box,

NOTE

may leak plasma and reagents.

If mounted properly the nose of the waste box will be placed under the

measuring block and will collect used cuvette bars. It is recommended to

clean the waste box weekly using a 10% bleach solution.

Demounting the waste box

• Remove the box by pressing it gently and slightly tipping it.

• Dispose of the cuvette bars in compliance with biohazard regulations. •

Mount waste box

1. Press box gently

see arrows

2. Tip box slightly while

inserting it

Thermo block 37˚C

Movement direction

of the cuvette rack --->>>

waste box fixpoints

3. Bring box into proper

position as shown in

the sectional

view.

Figure 15 mounting the cuvette waste box

CoaLAB 6000 – Operators Manual 1.8 Page 24

Installation

5.2 Instrument control Card

(ICC)

The manufacturer recommends to fill in the Instrument Control Card (see

attachment) of each system after its initial installation and to return it to the

manufacturer within four weeks. With this Instrument Control Card the

manufacturer will register your system. The customer confirms proper

receipt, functioning and completeness of the delivered system.

The Instrument Control Card is the basis for any warranty claims.

NOTE

Possible claims can only be called for if the Instrument Control Card

had been returned to the manufacturer after the initial installation of

the system.

The document is enclosed.

5.3 Language Setup

The analyzer is pre-set to the English language.

If you want to change the language follow section 6.4.7 Language.

CoaLAB 6000 – Operators Manual 1.8 Page 25

Operation

6 Operation

Training

Safety precautions

6.1 Routine Operation

<1 ROUTINE MENU>

This section describes how to routinely operate the system as well as

information on quality control of coagulation measurements. Furthermore

you will find hints to possible failures and troubleshooting.

Onsite training courses are offered for this instrument. For additional

information contact your distributor.

Thoroughly review the Hazard and Precautions section of this manual

before proceeding.

The system will be ready for coagulation analysis after initial set-up has

been completed, see section 6.4 General Setting (SETUP MENU). The

following descriptions explain the ROUTINE MENU and give an insight into

safe coagulation analysis.

In the ROUTINE MENU you can select between three different methods.

You can use nearly all well-known PT / aPTT and Fibrinogen reagents on

the system. Please note that due to the large variety of coagulation

reagents on today’s markets only a certain number of reagents have been

checked and adjusted to the system. See section 8.7 Adaptation of

coagulation reagents for further information.

Preparing routine operation

white

blue

- The instrument is connected to the power supply.

- The distilled water container is filled with water (without bubbles) and

connected to the system.

- The waste water container is empty and connected to the system.

- The waste box is cleared of cuvette bars.

- All tubes have been properly connected, and are neither squeezed nor

bent.

- Sufficient printer paper has been inserted.

- The liquid system is filled and without bubbles.

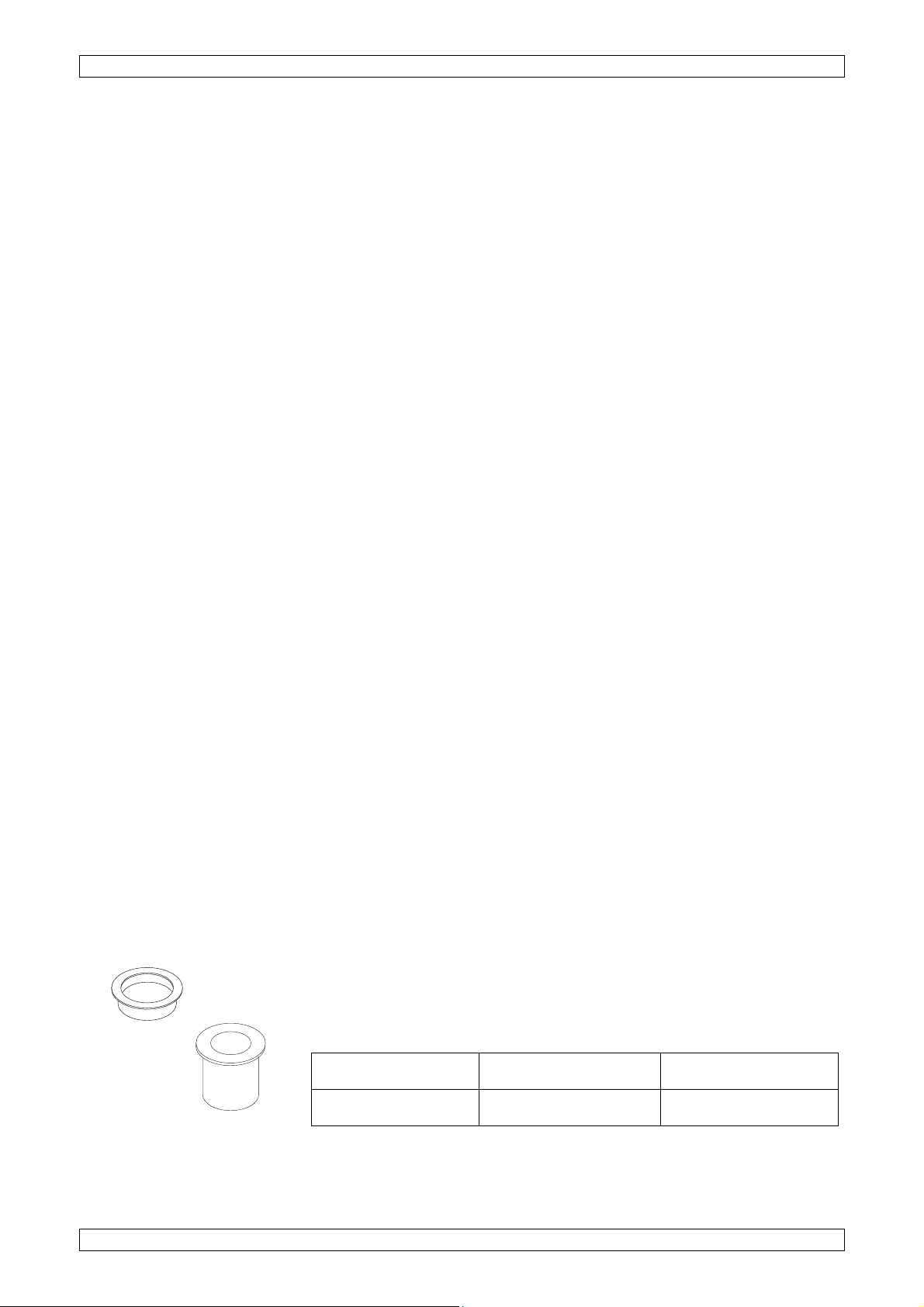

Reagents for the tests will be reconstituted according to the package insert

and will be filled into the reagent vials. The delivered reagent vials have the

following dead volumes:

10 ml reagent vial

(white adapter)

4 ml reagent vial

(blue adapter)

without stir bar

with stir bar

without stir bar

with stir bar

dead volume: 1.5 ml

dead volume: 2.0 ml

dead volume: 0.5 ml

dead volume: 0.8 ml

CoaLAB 6000 – Operators Manual 1.8 Page 26

Operation

6.1.1 Switch ON the system

The instrument must be free of cuvette bars, sample and reagent

NOTE

vials.

• Switch the instrument on by setting the power switch to the position I =

ON.

The display shows the instrument name and checks all internal modules

automatically (the pipettor moves to the washing station).

Diverse displays ...

User dialogue display

of the system

Then all system modules will be initialised.

The following data will be printed:

C2820501 V1.04 04/22/02

07.05.2002 08:55

Ser. No. / SW-Version / Release

Date / Time

The instrument is ready for operation.

• Use the arrow keys (</>) to select <1 ROUTINE MENU> in the MAIN

MENU.

MAIN MENU:

< 1 ROUTINE MENU >

• Press the ENTER-key to confirm.

The following display appears:

MAIN MENU:

< 1 Erase joblist >

6.1.2 Rinsing with distilled

water

For transport protection reasons the system has been delivered in dry

condition, without any liquids. Before measuring with the system it is

necessary to perform a rinsing process and fill all system modules with

liquid (pumps, dilutor and tubing’s). This procedure also removes any air

bubbles from the tubing system and the dilutor tubing. You can now check

whether all tube and screw connections have been installed properly.

Should you notice any leaking, tighten the connections to the point that they

are watertight.

• Use the arrow keys (</>) to select < 8 Maintenance > in the ROUTINE

MENU.

ROUTINE MENU:

< 8 Maintenance >

• Press ENTER to confirm and rinse the pipetting system of the system.

CoaLAB 6000 – Operators Manual 1.8 Page 27

Operation

The following display appears:

Maintenance

wash FLUSH remov

F1 F2 F3 F4

= accompanying function keys

• Press function key F2.

The instrument will rinse the system with distilled water. After the initial

installation this procedure should be repeated until all tubes are filled with

liquid completely.

By Pressing F4 = remov cuvette bars will be ejected into the waste box.

During rinsing the following display appears:

Maintenance

Maintenance

wash FLUSH remov

• Leave the menu after rinsing by pressing ESC.

The following display appears:

ROUTINE MENU:

< 8 Maintenance >

Pressing ESC will take you back to the MAIN MENU.

After this procedure the instrument pipetting system has been rinsed with

distilled water. The manufacturer recommends repeating this procedure

after the initial installation several times to secure that no air bubbles are in

the pipetting tube and that no liquids containing thrombin, for example, will

remain in the liquid system (if system has already been used). Check the

system for leakage’s again and re-mount, if necessary, all connections and

tubes before repeating the rinsing cycle.

6.1.3 Disinfection of waste tubing

(Terralin), change of FW-Filter

It is necessary to disinfect and clean the liquid system, tubing’s at regular

intervals, see section 8.1 Maintenance and Hygiene to avoid reagent or

sample residues, possibly causing inaccurate results or improper functioning

of the analyzer. Therefore, regular disinfection and cleaning cycles must be

run to guarantee proper functioning of the system.

Follow the instructions for disinfection of the system tubing’s:

Clean the distilled water container

and change filter

1. Remove the Distilled Water Sensor (green mark) from the Distilled

Water Container.

2. Remove the white fresh water filter

from the end of the Distilled Water

Sensor and replace it with a new fresh water filter.

CoaLAB 6000 – Operators Manual 1.8 Page 28

Operation

3. Empty the Distilled Water Container and clean the inside using a 70%

alcohol solution.

4. Rinse the Distilled Water Container thoroughly with distilled water to

remove any traces of the alcohol solution.

5. Refill the Distilled Water Container and return the Distilled Water

Sensor to the container.

Disinfection of Wash Station and Waste

tubing with Cleaning Solution

6. Make a working solution of Cleaning Solution. Fill 2 Liters of distilled

water into the Cleaning Solution Container (white label) and add 20

ml of concentrated Cleaning Solution. Swirl gently.

7. Place the Waste Water Container carrying the Waste Level Sensor

(red label, sensor) beside or behind the analyzer on the same height

level. The container may not be

placed underneath the analyzer. Make

sure the waste tubing (red marked) and the electrical plug of the waste

tubing are correctly connected to the fluid panel of the back side of the

analyzer.

NOTE

Do not disconnect any of the level sensor tubing’s (red/green) and

electrical plugs at the fluid panel at the back side of the analyzer.

8. Take out 4ml of the diluted working Cleaning Solution from the

Cleaning Container using a standard commercial pipette, e.g.

Eppendorf.

9. Guide the pipette over the Wash Station, located in the center of the

reagent and sample rotor.

Make sure that neither the steel needle nor the level sensor of the

NOTE

probe will be damaged or bent during this operation. The system may

not be in operation, moving.

10. Dispense the diluted Cleaning Solution out of the pipette into the wash

station. Repeat this process until you have added 4ml into the Wash

Station. Leave the working Cleaning Solution in the Wash Station for

at least 2 min.

Make sure the Cleaning Solution inside the Wash Station remains on

NOTE

the same level. It may not disappear inside the Wash Station. In this

event place the Waste Water Container on a higher level, meaning

above the height of the wash station of the analyzer and repeat adding

the Cleaning Solution into the Wash Station. Further make certain not

to overflow the wash station to avoid any liquid flowing into the

sample/reagent rotor.

Flush after cleaning

After the disinfection/cleaning cycle with Cleaning Solution it is

absolutely necessary to rinse the liquid system with distilled water to

ensure that no Cleaning Solution may remain in the liquid system at

all.

CoaLAB 6000 – Operators Manual 1.8 Page 29

Operation

NOTE

NOTE

Follow the instructions to rinse the system with distilled water:

11. Make sure the Distilled Water Sensor is equipped with a NEW fresh

water filter and the Distilled Water Sensor is placed correctly in the

Distilled Water Container.

12. Run flush cycles with distilled water described as follows:

• Use the arrow keys (</>) to select <5 UTILITY MENU> in the MAIN

MENU.

MAIN MENU

< 5 UTILITY MENU >

• Press ENTER to confirm.

The following display appears:

UTILITY MENU

<1 Init Instrument>

• Press ENTER to confirm the message.

The following display appears:

Init Instrument

Init ... (ESC=Stop)

The motors and the diluter will be initialised. During this phase the cuvette

racks in the measuring block will be moved one position to the right and will

be ejected from the measuring block.

The following display appears:

Init Instrument

Flush... (ESC=Stop)

Then the liquid system will be initialised. Liquids are pumped into the

tubing’s. Press ESC if you want to finish initialisation.

This flush process should run a minimum 5-8 minutes or until no foam

residues of Cleaning Solution will remain in the liquid system, waste

tubing (red marked). Check if waste water runs through the waste

tubing into the Waste Water Container and no foam remains in the

waste tubing.

The manufacturer recommends repeating this procedure at least twice

a month. Once a year it is recommended to renew all liquid containing

parts of the system. Ask your local dealer

available maintenance/service kits.

or the manufacturer for

CoaLAB 6000 – Operators Manual 1.8 Page 30

Operation

6.1.4 Rinsing with Washing

Solution

In the ROUTINE MENU you can choose to clean the pipetting system of the

instrument with an extra Washing Solution. This is especially recommended

after the use of reagents containing thrombin, such as Fibrinogen. The

system disposes of an automatically wash cycle if Thrombin containing

reagents, e.g. Fibrinogen are being used. Once the reagents are

introduced, see section 6.1.5 and are requested to run in a joblist, section

6.1.7 the system automatically washes the system with washing solution

after the use of such thrombin containing reagents.

NOTE

This intensive washing cycle must be run daily after routine work in

order to avoid any residues of previous measurements.

Follow the instructions to wash the system:

• Use the arrow keys (</>) to select < 8 Maintenance > in the ROUTINE

MENU.

ROUTINE MENU

< 8 Maintenance >

• Press ENTER to confirm.

The following display appears:

Maintenance

WASH flush remov

F1 F2 F3 F4

• Press F1= WASH and follow the instructions of the display.

The following display appears:

1: washer:

LOAD 3.0ml skip

F1 F2 F3 F4

If no washing solution has been loaded the following display appears. Put

the white adapter ring into reagent position 1: = R1 extended automatically

and put the 10 ml reagent vial filled with min. 3 ml Washing Solution into the

reagent position. Confirm either with F1= Load or with ENTER.

Maintenance

To cancel this procedure press F4= skip. After having confirmed with F1 or

ENTER the analyzer will start an automatic wash cycle to clean the tubing’s

(consumption per wash cycle ca. 110 µl).

The next display appears:

Maintenance

WASH flush remov

• Press ESC to leave the menu.

CoaLAB 6000 – Operators Manual 1.8 Page 31

Operation

6.1.5 Loading and unloading

reagents

NOTE

The following display appears:

ROUTINE MENU

< 8 Maintenance >

The system has now been cleaned with Washing Solution. If necessary, this

procedure can be repeated. Press ESC to get back to the upper menu level.

Before entering a joblist it is possible to load and later unload reagents for

daily routine. Observe the following preconditions:

- All reagents must be reconstituted according to the package insert.

- The system is preset to the supplied reagent vial types. To avoid

inaccurate level detection you should use the reagent vials with the

adapter rings only. Make sure that only predefined reagent vial types (4 ml

or 10 ml) are positioned in the sample or reagent rotor. For definition of

reagent vial types see section 6.2.2 Enter Method Parameter for definition

of reagent vial types.

10 ml reagent vial

(white adapter)

4 ml reagent vial

(blue adapter)

without stir bar

with stir bar

without stir bar

with stir bar

dead volume: 1.5 ml

dead volume: 2.0 ml

dead volume: 0.5 ml

dead volume: 0.8 ml

The dead volumes mentioned above have been considered when the

volume is asked for.

Loading PT, aPTT and Fibrinogen reagent is described in the following

example.

Remember to use the provided adapter rings (4 ml vial = blue ring;

10ml vial = white ring). Always position the reagent vials with the

adapter rings into the correct reagent position in the sample rotor and

make sure to use predefined reagent vial types only to avoid

inaccurate level detection.

The system has an automatic reagent stir position in order to avoid

sedimentation’s. If reagents are stirred, Teflon stir bars must be put

into the reagent vials. To select reagent vial types, see section 6.2.2

Enter Method Parameter.

• Use the arrow keys (</>) to select <7 Load reagents> in ROUTINE

MENU.

ROUTINE MENU

< 7 Load reagents >

• Press ENTER to confirm.

The following display appears:

1: washer:

LOAD unload

F1 F4

CoaLAB 6000 – Operators Manual 1.8 Page 32

Operation

The reagent position for the Washing Solution will be extended

automatically. Should you have loaded Washing Solution already, the above

display appears.

• Press F1 to confirm loading.

By pressing F4 ‘remove’ you inform the system that you have

removed reagent and/or washing solution from the sample rotor.

NOTE

‘Remove’ will always be displayed if you have loaded the sample rotor

with reagents and/or washing solution beforehand. Once the sample

rotor has been loaded with reagents and/or washing solution ‘remove’

will be displayed to ‘unload’ the sample rotor.

If ‘skip’ is displayed instead of ‘remove’ you can press F4 to skip over

loading with reagent and/or Washing Solution. Remember however,

that the analyzer cannot run measurements or start cleaning cycles if

reagents and/or Washing Solution have not been loaded. This

message will always be displayed when no reagents and/or Washing

Solution have been loaded to the sample rotor.

The following display appears:

2: Buffer: 9999992

LOAD skip

The sample rotor position will be extended automatically. Load the sample

rotor with Buffer in position 2: = R2 and confirm with F1.

If you want to skip over this position and not load Buffer press F4.

The following display appears:

3: FBG 8888

LOAD skip

The sample rotor position will be extended automatically. Load the sample

rotor with Fibrinogen reagent in position 3: = R3 and confirm with F1.

If you want to skip over this position and not load Fibrinogen press F4.

The following display appears:

4: CaCl2 88888

LOAD skip

The sample rotor position will be extended automatically. Load the sample

rotor with Calcium Chloride in position 4: = R4 and confirm with F1.

If you want to skip over this position and not load Calcium Chloride press

F4.

The following display appears:

5: aPTT 99999995

LOAD skip

CoaLAB 6000 – Operators Manual 1.8 Page 33

Operation

The sample rotor position will be extended automatically. Load the sample

rotor with aPTT reagent in position 5: = R5 and confirm with F1.

If you want to skip over this position and not load aPTT reagent press F4.

The following display appears:

6: PT 88888

LOAD skip

The sample rotor position will be extended automatically. Load the sample

rotor with PT reagent in position 6: = R6 and confirm with F1.

If you want to skip over this position and not load PT reagent press F4.

After all reagents have been positioned on the sample rotor the following

display appears.

ROUTINE MENU

< 7 Load reagents >

• Press ESC to get back into the MAIN MENU.

6.1.6 Delete joblist, delete

samples

If you want to delete a joblist from the memory follow the instructions:

• Use the arrow keys (</>) to select <1 Erase joblist > in the ROUTINE

MENU.

The following display appears:

ROUTINE MENU

< 1 Erase joblist >

Press ENTER to confirm.

The following display appears:

Really erase joblist?

YES no

If you want to delete the joblist confirm with F1 = YES. If you do not want to

delete it, press F2 = NO. Confirm with F1.

The following display appears:

Remove samples 1-9

and close cover

• Remove primary tubes 1 to 9 from the sample positions extended

automatically and confirm with ENTER.

If more than 9 primary tubes are in the sample rotor the following message

appears:

Remove samples 10and close cover

CoaLAB 6000 – Operators Manual 1.8 Page 34

Operation

• Remove the remaining primary tubes 10 - 18 and confirm with ENTER.

The following display appears:

ROUTINE MENU

< 1 Erase joblist >

• Press ESC to get back into the MAIN MENU.

6.1.7 Enter a new joblist

Before entering a joblist you must define whether single or double

determinations shall be made, see section 6.2.2.1

The following examples show how a joblist is to be entered:

Example 1:

01 = Sample 1 S-ID: 30001 = consecutive no. PT and APTT =

test to be measured

Example 2:

02 = Sample 2 S-ID: 30002 = consecutive no PT, APTT, FBG =

test to be measured

Example 3:

03 = Sample 3

S-ID: 123 = individual no PT =

test to be measured

Example 1:

• Use the arrow keys (</>) to select < 2 Insert sample > in the ROUTINE

MENU.

ROUTINE MENU

< 2 Insert sample >

• Press ENTER to confirm.

The following display appears:

01 S-ID: 30001

pt aptt fbg all

F1 F2 F3 F4

The sample rotor will automatically advance to the position to be loaded

with sample 1 (01 S-ID:). Load the sample rotor with the first primary tube

and select the tests with keys F1-F4. In this case the tests pt=F1 and

aptt=F2 have been selected.

The following display appears:

01 S-ID: 30001

pt APTT fbg all

After the tests have been selected they will appear in capital letters.

• Press ENTER to confirm.

CoaLAB 6000 – Operators Manual 1.8 Page 35

Operation

Example 2

Example 3

NOTE

The following display appears:

02 S-ID: 30002

pt aptt fbg all

The sample rotor will automatically advance to the position to be loaded

with sample 2 (02 S-ID:). Load the sample rotor with the second primary

tube and select the tests with keys F1-F4. In this case the tests pt, aptt and

fbg have been selected, i.e. all = F4.

• Press ENTER to confirm.

The following display appears:

03 S-ID: 123

pt aptt fbg all

The sample rotor will automatically advance to the position to be loaded

with sample 3 (03 S-ID:). Load the sample rotor with the third primary tube

and select the tests with keys F1-F4. In this case the test pt=F1 has been

selected. If you want to change the patient ID press the left arrow key (<)

until the patient ID is no longer displayed. You can now enter the individual

ID, here 123.

• Press ENTER to confirm.

The following display appears:

04 S-ID: 30003

pt aptt fbg all

The sample rotor will extend automatically the position to be loaded with

sample 4 (04 S-ID:). Repeat this procedure to insert more patient ID´s.

Press ESC to leave this Menu.

The analyzer offers two possibilities to enter patient ID’s. If no ID is entered

the system will automatically assign consecutive numbers.

1.) Enter the patient ID manually.

Using the number keys (0-9), enter the

patient ID up to 10 digits.

2) Enter the patient ID by using the barcode scanner.

Press the button on

the barcode scanner and direct the scanner window to the barcode

label of the primary tube. Continue pressing the button until a beep

confirms entry of ID.

A large number of barcodes can be used. If the system does not

accept a certain barcode contact the manufacturer or enter the patient

ID manually.

Press ESC to leave the Menu.

CoaLAB 6000 – Operators Manual 1.8 Page 36

Operation

The following display appears:

ROUTINE MENU

< 2 Insert sample >

The sample rotor has a maximum of 18 sample positions of which 15 can

be used for routine work. Up to 3 positions can be used for STAT

measurements. To load the sample positions repeat the procedures as

described in this chapter.

Press ESC to get back to the MAIN MENU.

6.1.8 Handle the joblist

After entering the joblist into the memory, entries may be reviewed for

accuracy or modification.

• Use the arrow keys (</>) to select <3 Edit joblist> in the ROUTINE MENU.

ROUTINE MENU

< 3 Edit joblist >

• Press ENTER to confirm.

The following display appears:

01 S-ID: 30001

PT APTT fbg all

The desired test of each sample is displayed in capital letters. All other tests

will be displayed in lowercase. By pressing the function keys F1-F4, tests

may be selected or deselected or further tests can be added.

With the up and down arrow keys you can select the next sample.

• Press ESC to leave this menu point.

The following display appears:

ROUTINE MENU

< 3 Edit joblist >

• Press ESC to get back to the MAIN MENU.

6.1.9 Print of a joblist

The description how to print a joblist follows in this section. The printed

joblist will provide an overview of the patient samples and methods.

• Use the arrow keys (</>) to select <4 Print joblist> in the ROUTINE

MENU.

ROUTINE MENU

< 4 Print joblist >

• Press ENTER to confirm.

CoaLAB 6000 – Operators Manual 1.8 Page 37

Operation

NOTE

The following display appears:

printing joblist

The joblist will be printed on the internal printer. After printing this function

will re-appear.

ROUTINE MENU

< 4 Print joblist >

• Press ESC to get back to the MAIN MENU.

Example of printed joblist.

C2820501 V1.04 04/22/02

07.05.2002 08:44

ROUTINE Joblist:

T1 = PT PT

T2 = APTT APTT

T3 = FBG Fibrinogen

No Sample-ID T1 T2 T3

1: 30001 x x

2: 30002 x x x

3: 123 x

------------------------------------------

Have the joblist printed after entry. Thus you can control whether it

contains all selected entries. See chapter 6.1.8 Handle the joblist if

you want to modify anything.

- Test name (short form)

- selected tests

6.1.10 Start measuring, load

cuvette bars

After printing the joblist start measurement. Follow the instructions in this

section to run measurements.

• Use the arrow keys (</>) to select <5 Start measure> in the ROUTINE

MENU.

ROUTINE MENU

< 5 Start measure >

• Press ENTER to confirm.

The following display appears:

Select test:

PT aPTT FBG all

CoaLAB 6000 – Operators Manual 1.8 Page 38

Operation

With the function keys F1-F3 below the display a single test will be run.

With the function key F4 = all, all three tests will be run automatically

(RANDOM ACCESS).

Example: PT = F1

The following display appears:

Prepare measure

The following display appears:

INFO

check waste box

The message ‘check waste box’ is displayed for a short moment every time

you enter a new joblist. Empty the waste box if used cuvette bars are still in.

The following message will be displayed:

Insert cuvette-bar

and close cover

The system will calculate according to the joblist how many cuvette bars are

needed. The sample rotor automatically advances to the next position for a

cuvette bar. Place the cuvette bar properly into its position.

This procedure will be repeated until all bars for the measurements have

been positioned.

• Press ENTER to confirm.

If no reagents are loaded the sample rotor will automatically advance to the

reagent position. Place the adapter ring and the predefined reagent vial of

the selected test (here PT) into it. See section, 6.2.2 Enter Method

Parameter.

The display will show the reagent volume necessary for the tests.

6: PT 123456789

LOAD 2.4ml skip

The displayed figure already considers the necessary dead volume of the

reagent vial.

Dead volumes:

10 ml reagent vial

(white adapter)

4 ml reagent vial

(blue adapter)

without stir bar

with stir bar

without stir bar

with stir bar

dead volume: 1.5 ml

dead volume: 2.0 ml

dead volume: 0.5 ml

dead volume: 0.8 ml

Having positioned the reagent vial with adapter into the sample rotor you

can confirm this in two ways:

F1 (load) or =

ENTER

The reagent has been loaded and the entry is

confirmed.

CoaLAB 6000 – Operators Manual 1.8 Page 39

Operation

F4 (skip) =

The reagent has not been loaded, the entry was not

confirmed.

• In this case press F1 or ENTER to confirm.

Remember that the supplied reagent vials consider sufficient dead

volume when calculating the reagent volume. Therefore the reagent

NOTE

volumes are larger than what is actually needed for the tests. Always

use the adapter rings and the pre-defined reagent vials as the volume

calculation of the reagent will be influenced negatively otherwise.

The instrument will check the reagents for sufficient volume. If reagents are

missing or the volume is insufficient the following display will appear:

For example:

6: PT 123456789

only x.xml of x.xml

Load the missing or insufficient reagent in position R6. Remember the

necessary dead volume.

• Press ENTER to confirm end of loading.

If you do not want to load the missing reagents press ESC. The analyzer

will measure as many samples as possible with the available reagents.

Samples not measured will be identified with a note on the printout.

By pressing ESC and thus refuse to load the missing reagents, not all

measurements will be worked off your joblist. The system will do all

NOTE

measurements possible with the reagent volume. Follow the steps in

this section to work off the remaining measurements.

The following display appears:

Pipettor M-Block

37.4 38.4

The message Pipettor / M-Block indicates the temperature of the measuring

block and the pipettor. This message will be displayed until the correct

temperature has been reached.

The following display appears:

4 PT Samples <

No Results available

The system will start measurements. The number (e.g. 4 PT samples) of

measurements for each method will be displayed. The results will

automatically be printed on the internal printer.

The display will show ‘no results available’.

The rotating symbol (<) in the upper right hand corner of the display means

that the instrument is measuring presently.

CoaLAB 6000 – Operators Manual 1.8 Page 40

Operation

At the completion of all tests a short beep will be heard and the following

message appears on the display:

STATE

Normal Termination

All cuvette bars that were not completely used will remain in the measuring

block, and be used in the next testing cycle.

Example of a printed result:

C2820501 V1.04 04/22/02

07.05.2002 08:44

Analyzer Mode : Batch

Research Mode : Off

Test PT 07.05.2002 10:30

No Sample-ID Result Cuv.

1: 123 online 01a

PT time1 15.4 sec

PT INR 1.74

PT conc 43.5 %

---------------------------------------------

Finished 07.05.2002 10:45

State: Normal Termination

6.1.11 Interrupt a current run

(User interrupt)

Follow the instructions in this section to interrupt a current run. The system

is measuring as described in section 6.1.10 Start measuring, load cuvette

bars.

The following display appears:

X PT Samples

03 123 --.--

• Press ESC to interrupt the run.

There may be a slight delay, before interruption of the current run is

confirmed on the display.

The following display appears:

User interrupt (ESC)

Yes no stop stat

F1 F2 F3 F4

Select the method of interruption by using the function keys F1-F4:

CoaLAB 6000 – Operators Manual 1.8 Page 41

Operation

Function

Instruction Meaning

key

F1 Yes The run will only be interrupted after all cuvette

bars in the measuring block have been

completed, and results are available. The

cuvette bars remaining in the sample rotor will

be used later.

F2 or No The run will not be interrupted.

F3 Stop The current run is interrupted immediately. The

cuvette bars in the incubation and measuring

position will not be used. The joblist will remain

active.

F4 Stat Places the instrument in STAT management

mode, see section 6.3 STAT Management.

Cuvette bars in the measuring block will be first

completed.

• Press F4 to get into the STAT measurement and follow the instructions as

indicated in section 6.3 STAT Management.

STAT Measurement

Edit Ins Prnt Start

• Press ENTER to run the selected tests.

6.1.12 Print results, send results

to HOST

This section describes how to print results or send to a HOST computer.

The system has an internal thermal printer to print all results, test and setup

parameters, and error messages. Moreover, results can be sent to a

connected HOST computer.

Use the RS 232C interface port to connect the HOST computer to the

NOTE

analyzer. The port is on the right side of the system below the socket

for the optional barcode scanner. The port is marked RS 232. For

further instructions, see section 5.1.4.4.

• Use the arrow keys (</>) to select <6 Result managem.> in the ROUTINE

MENU.

ROUTINE MENU

< 6 Result managem. >

• Press ENTER to confirm.

The following display appears:

Result managem.

send list PRINT

F1 F2 F3

Use F1 = send to send results to a HOST. To list the results in the display

press F2 = list. Use the arrow keys (</>) to select between the patients.

Use F3 = print to print the results on the internal printer.

CoaLAB 6000 – Operators Manual 1.8 Page 42

Operation

By pressing F1 = send the following message will appear on the display for

a short moment. The results and patient ID´s will be sent to the HOST

computer.

sending results

By pressing F2 = list the results of each patient and test will be displayed

accordingly. Using the arrow keys (</>) will display different patient results

per test. Using the arrow keys up/down will display different test results per

patient.

123 PT

1 result

After pressing F3 = print the following message will appear on the display