Page 1

Operators Manual

CoaDATA 501

For in-vitro diagnostic use only!

Page 2

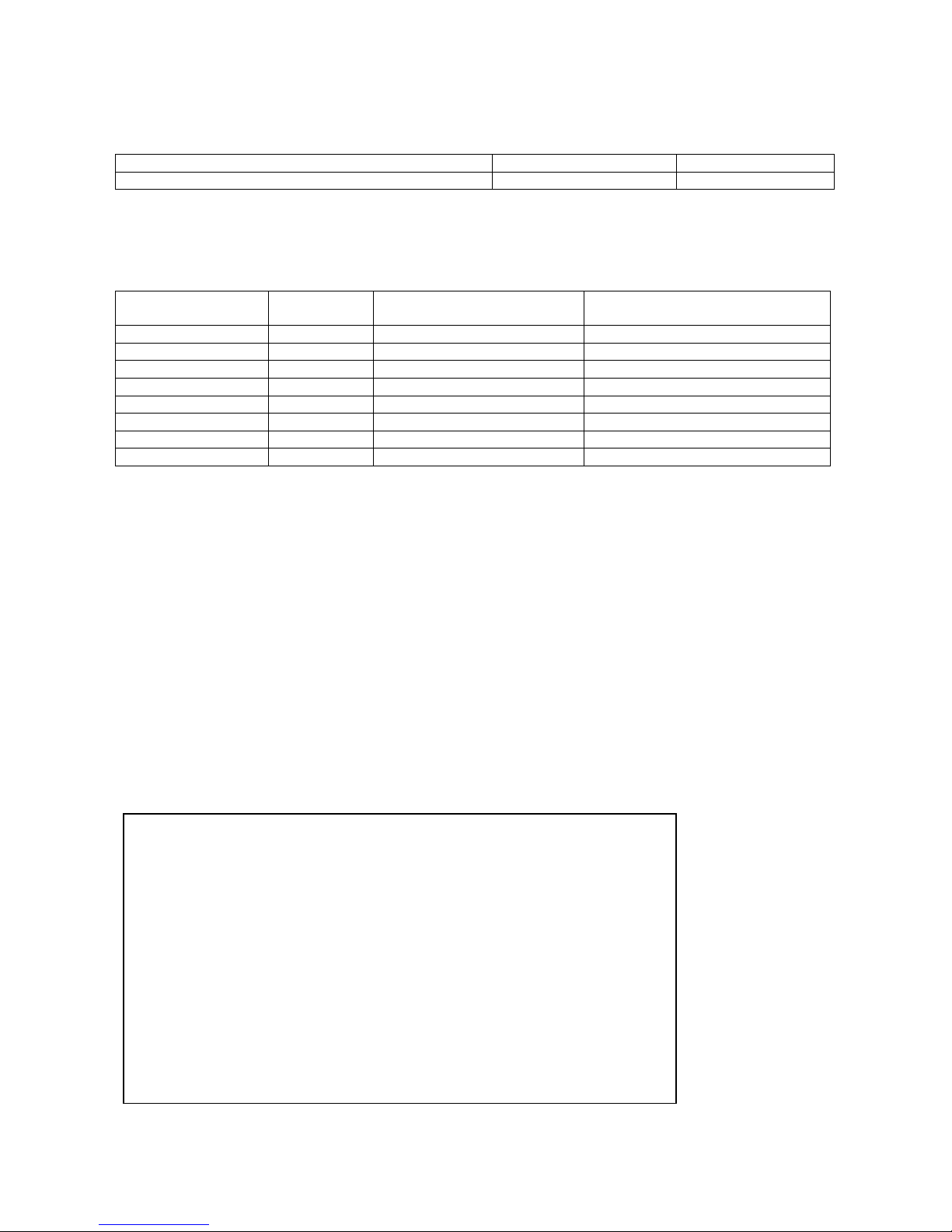

Order

Bedienungsanleitung CoaDATA 501 Order No.: 30.000.1613 German Version

Operators Manual CoaDATA 501 Order No.: 30.000.1614 English Version

Revision History

Version Manual

Date

(mm/dd/yy)

Changes

Software-Version

Print

1.0 June 2001 2.06 OM-CD501-2.PM6/PS

1.1 March 2003 2.06 OM-CD501a.p65

1.2 April 2003 2.10 OM-CD501b.p65

2.0 12/19/03 2.11 OM_CD501.doc

2.1 04/22/04 Corrections (2.11)

Copyright of Software

All software by LABiTec LAbor BioMedical Technologies GmbH (in the following LABiTec-Software) is the

intellectual property of the LABiTec LAbor BioMedical Technologies GmbH. Intellectual property rights shall

remain with LABiTec LAbor BioMedical Technologies GmbH. You are entitled to use LABiTec-Software and

the printed accompanying material at a place of work that cannot be transferred. Any violation of property

rights or copyright or trademark or using conditions may be subject to legal action. LABiTec reserves the

rights to modify the software, documentation as well as this operator manual without prior written notice.

Your Distributor:

(Please do not hesitate to contact your local distributor if you have any questions or problems.)

Page 3

Contents

CoaDATA 501 –Operators Manual 2.1 Page 1

Contents

1 INTRODUCTION .................................................................3

1.1 Application.................................................................................... 3

1.2 Instrument Description................................................................ 3

1.3 Installation .................................................................................... 6

1.3.1 Connect an external printer............................................... 6

1.4 Measuring Principle.....................................................................7

1.5 Reagents ....................................................................................... 8

2 OPERATION........................................................................ 9

2.1 Steps for Instrument Operation.................................................. 9

2.1.1 Turn on analyzer ............................................................... 9

2.1.2 STANDBY ......................................................................... 10

2.1.3 How to measure................................................................11

2.1.4 How to change methods ................................................... 13

2.1.5 How to change methods with a ChipCARD ...................... 15

2.2 Method Parameterization ............................................................ 16

2.2.1 PT-parameterization ......................................................... 16

2.2.2 aPTT - parameterization ................................................... 22

2.2.3 Fibrinogen 1 [g/l] - parameterization ................................. 25

2.2.4 Fibrinogen 2 [mg/dl] - parameterization ............................ 28

2.2.5 Thrombin time parameterization ....................................... 28

2.2.6 Intrinsic Factor parameterization....................................... 28

2.2.7 Extrinsic Factor – parameterization ..................................28

2.2.8 Utilities............................................................................... 29

2.2.8.1 Menu printer.............................................................. 29

2.2.8.2 Menu computer............................................................ 30

2.2.8.3 Menu beeper ................................................................ 30

2.2.8.4 Menu clock .................................................................. 30

2.2.8.5 Menu calibrate temp .............................................. 31

2.2.8.6 Menu secret number................................................. 32

2.2.8.7 Menu cuvette test ................................................... 32

2.3 Printer............................................................................................ 33

2.3.1 Sample print-outs PT and calibration................................ 34

2.4 Errors ............................................................................................ 37

2.4.1 Application errors .............................................................. 37

2.4.2 Error Messages................................................................. 38

2.4.3 Errors during operation ..................................................... 39

2.4.4 Warnings ........................................................................... 39

2.4.5 How to change fuses ........................................................ 39

3 SOFTWARE ........................................................................40

3.1 Software overview ....................................................................... 41

3.2 Flow Chart of different application methods ............................ 42

3.3 Method Parameters...................................................................... 43

4 SAFETY ISSUES................................................................. 44

4.1 Hazard and Precautions .............................................................. 44

4.2 Maintenance and Hygiene........................................................... 46

4.2.1 Disposal of analyzer.......................................................... 46

Page 4

Contents

CoaDATA 501 – Operators Manual 2.1 Page 2

5 APPENDIX .......................................................................... 47

5.1 Disposables .................................................................................. 47

5.2 Materials Supplied .......................................................................47

5.3 Technical Data.............................................................................. 48

5.4 Safety Specifications................................................................... 49

5.5 Mathematics .................................................................................50

5.6 Terminology.................................................................................. 52

Page 5

Introduction

CoaDATA 501 – Operators Manual 2.1 Page 3

1 Introduction

1.1 Application

The instrument type CoaDATA 501 (in the following titled as analyzer) as

described in this manual is an opto-mechanical coagulation analyzer which

applies the turbodensitometric measuring principle.

All routine coagulometric clotting tests such as Prothrombin time, activated

and partial Thromboplastin time, Fibrinogen, and single factor assays can

be performed with these types of instrument.

For in-vitro diagnostic use only!

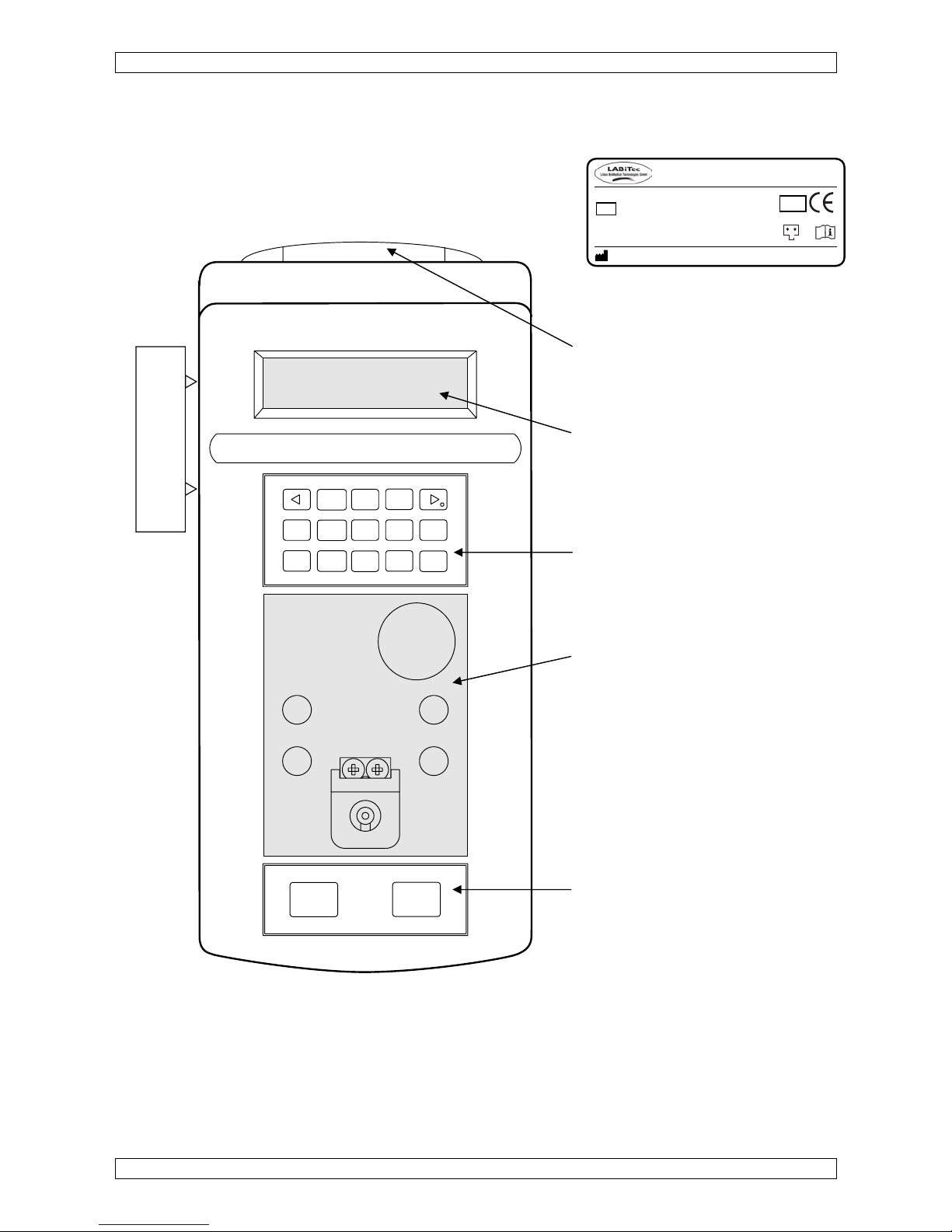

1.2 Instrument Description

The analyzer is constructed in modular units. A liquid crystal display with

one row and 8 characters has been integrated for visual communication.

The arrow keys <-- / --> allow the operator to select the next step in the

menu. The numbers are for the entry of method parameters.

The Enter key is used to confirm an entry or a selection. The parameter

memory is accessed with the Mode-key. Any procedure can be cancelled or

stopped with the Esc-key.

The measuring channel is integrated into the 37.4°C incubation block with 1

position for reagent bottle and 4 positions for cuvettes.

Immediately after the analyzer has been switched on, an adjustment

provides cuvette detection. According to the instructions on the display

cuvette in or cuvette out, place a cuvette into the measuring channel or

remove a cuvette from the measuring channel.

The next step during a run is always shown in the display.

A measurement is automatically started by adding the reagent to a sample

cuvette.

Results can be printed via on optional, external printer or can be read from

the display.

At the left side of the analyzer is the connector for the external power

adapter located. The external power adapter can be connected to the mains

with a voltage range from 100V - 240V, 47 - 63Hz.

Via the connection to the main voltage the analyzer is automatically

switched on or off.

For data output an RS 232 C 6-pin interface is also located on the left side

of the analyzer.

Page 6

Introduction

CoaDATA 501 – Operators Manual 2.1 Page 4

Analyzer

Name plate (underneath)

ChipCARD Reader

at front side

Display 1 line, 8 Characters

Power and printer plugs

leftward

Membrane keypad with keys:

0 - 9, Mode, Enter, ESC, <--, -->.

Incubation block 37°C:

- 4 positions for cuvettes

T = position for temp. adjustment

- 1 position for reagent bottle

- 1 measuring channel with light

protection caps designed for

Thrombi-Tips

Membrane keypad with keys:

Reset and Start.

Figure 1 Analyzer

Mode

Esc

0

123

456

789

Enter

Reset

Start

Power connector

Printer connector

T

Made in Germany

Type: CoaDATA 501

Input: 12

VDC~9.6VA Fuse: 0,8AT

: XXXXXX

IVD

SN

A 00 0 0000

P-ID CD500-96.0000

- +

Page 7

Introduction

CoaDATA 501 – Operators Manual 2.1 Page 5

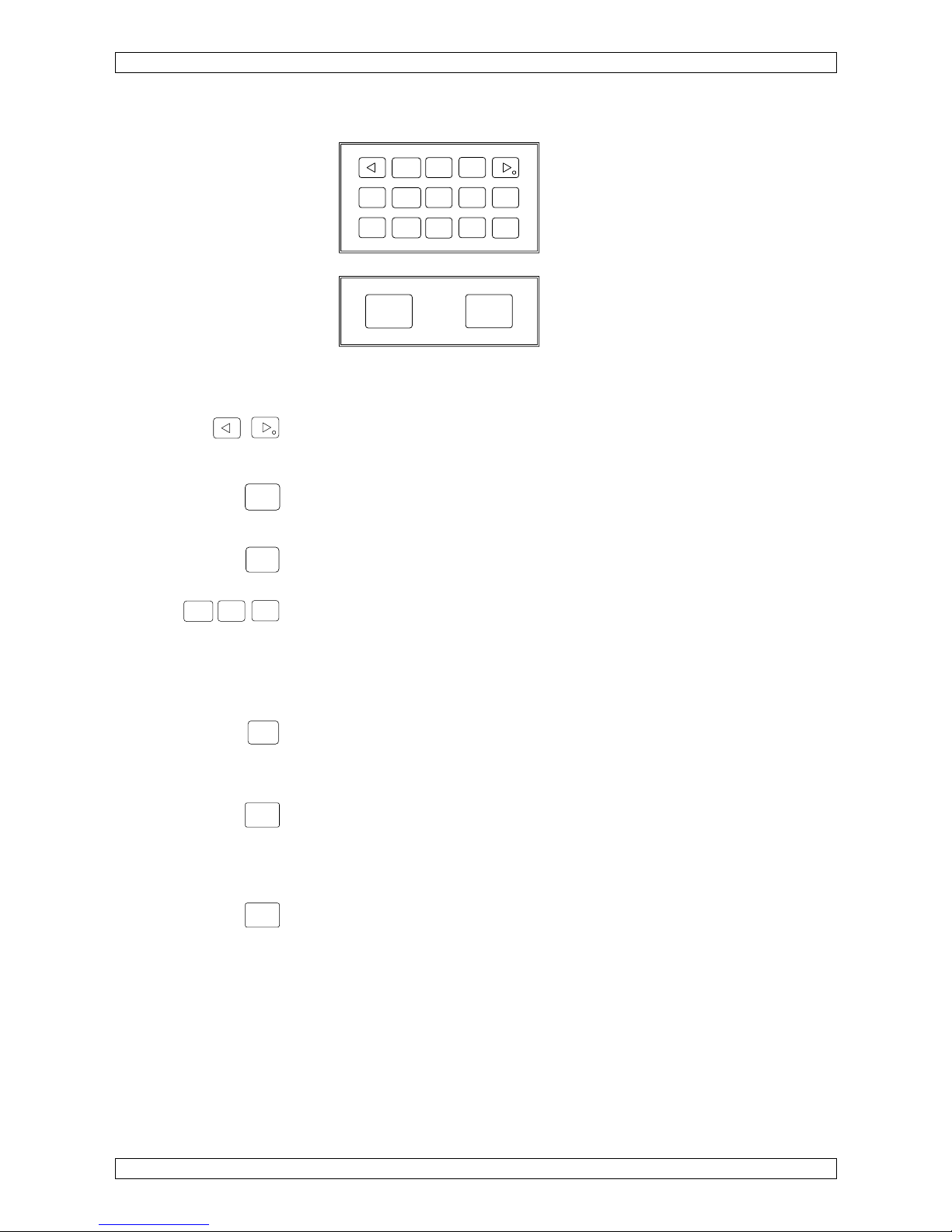

Description of keys

Figure 2 Membrane keypad

Arrow-key left, right

<- - select display to the left

-> - select display to the right, set decimal point

Esc-key

Switch from measuring to STANDBY

Exit a submenu

Enter-key

Confirm selection, advance printer paper

Number-keys

Enter parameters

0-key

A print-out of the respective parameters for the selected method is

generated by pressing 0 during measuring.

Mode-key

1. Calibration

2. Menu selection, analyzer settings, and method parameterization

3. Exit a menu and save entered or modified data.

Start-key: manual testing

- Start sample incubation timer

- Sample adjustment

- Manual test start

- Manual test stop

Reset-Key, reset testing,

Break of run, adjustment of sample

Mode

Esc

0

123

456

789

Enter

Reset

Start

Esc

Ente

r

123

Mode

Start

Reset

Page 8

Introduction

CoaDATA 501 – Operators Manual 2.1 Page 6

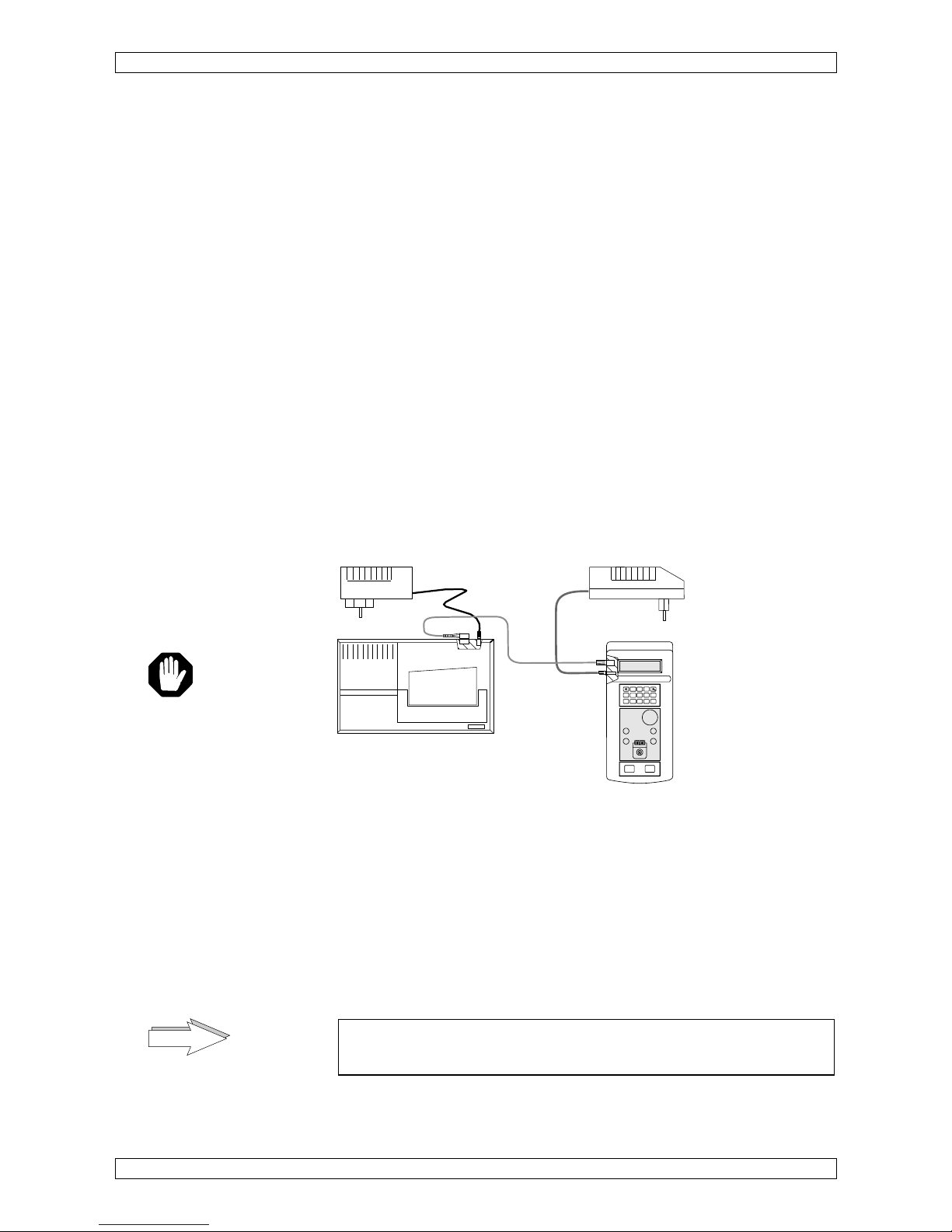

1.3 Installation

Remove the analyzer from its packaging and verify that the accessories kit

is complete. Please notify your distributor immediately in the event that the

shipment was incomplete. Refer also to Materials Supplied in chapter 5.2

Proceed as follows to install the analyzer:

• Prior to installation of the analyzer read the instructions under Hazard and

Precautions in chapter 4.1.

• Place the analyzer in a position that it is not exposed to excess humidity,

any explosive gases, or magnetic influences.

• Connect the power adapter between the analyzer and a power supply

(100V - 240V) free from interferences by large power users such as

elevators and centrifuges.

• Use only the included original AC power adapter.

• Use only original cuvettes and stir bars which will assure proper operation

of the instrument.

Switch on CoaDATA 501

• Connect the external power adapter with the analyzer

.

• Connect the external power adapter with the mains; automatically the

analyzer is switched on.

Figure 3 Analyzer connections

1.3.1 Connect an external printer

• Connect the data-cable between the analyzer and the printer. Ask your

dealer for recommended printer types.

• Connect the power adapter to the printer (see figure 3). The printer will be

set ON by connecting to the mains.

• Refer to chapter 2.2.8.1 for proper printer setting.

Never operate the printer without paper! Read the instructions

manual from the manufacturer of the printer for further details.

power supply

12 Volt, 0,8 Amp. 9,6VA

Printer

power supply

Mode

Esc

0

123

456

789

Enter

Reset

Start

D

ange

r!

NOTE

Page 9

Introduction

CoaDATA 501 – Operators Manual 2.1 Page 7

1.4 Measuring Principle

The analyzer operates according to the opto-mechanical measuring

principle. This measuring principle is especially suited for lipemic and/or

icteric colored samples as well as reagents with kaolin.

A light beam passes through the cuvette containing the test plasma onto a

photo detector. Any change in the intensity of the transmitted light, that is

light increase or decrease, is converted into an electric signal. Hence, even

the most unstable clot can be detected.

The period from adding the start reagent until clot formation is measured. It

then can be converted into the appropriate units (%, ratio, INR, mg/dl, g/l).

Once the start reagent has been added, the measuring channel is adjusted,

that is the lamp intensity automatically adjusts up or down depending on the

turbidity of the test sample. In this process the turbidity of the sample

plasma and the reagent are adjusted.

A mixer is located in the cuvette. During the measuring process the mixer

provides homogeneity of the reagent-plasma medium. At the same time a

small whirl emerges through the mixer movement which assures that even

the smallest fibrin clot is formed in front of the photo detector.

This stirring action combined with the optical measurement constitutes the

basic features of the patented "turbodensitometric measuring principle".

Figure 4 Measuring Principle

Test cuvette

Lamp

Detector

ELECTRONIC

DISPLAY

Stirrer - Motor

perm. magnet

Page 10

Introduction

CoaDATA 501 – Operators Manual 2.1 Page 8

1.5 Reagents

For proper coagulation analysis we recommend to use reagents, controls

and buffers from well known reagent manufacturers.

Contamination

With the application of different reagents, and here especially reagents

containing thrombin, there is a danger of reagent carry-over.

When adding reagents the light protection cap is exposed to

reagents and hence a point of contamination.

This point of contamination must be cleaned with a suitable thrombin in

activator and a cotton swab after each method change.

Useful hints:

Use the pipettor supplied with the respective pipette tips (Thrombi-Tips).

In General: The analyzer is equipped with light protection caps for

Thrombi-Tips.

To guarantee perfect functioning of the system it is absolutely

necessary to use only the variable Thrombi-Pette and original

Thrombi-Tips. Please understand that warranty shall not apply to

instruments which have problems due to the use of other types of

pipettes or tips.

Make sure no air bubbles are generated during the pipetting process.

Read the reagent packaging insert prior to use and follow the instructions.

Only use original cuvettes and stir bars from the manufacturer which

are subject to strict quality control measures. Please understand

that the use of non-original cuvettes or instruments problems

caused by the use of non-original cuvettes may lead to the warranty

obligation become null and void.

Perform analytical quality controls on a regular basis.

NOTE

NOTE

20-200µl

200

NOTE

Page 11

Operation

CoaDATA 501 – Operators Manual 2.1 Page 9

2 Operation

2.1 Steps for Instrument Operation

Communication with the analyzer is performed via the liquid crystal display.

We assume that you are familiar with the function of the individual keys as

described in chapter 1.2

2.1.1 Turn on analyzer

• Connect the analyzer power adapter to the mains, automatically it is

switched on.

The following text will appear in the display:

This sign <- informs of a floating text.

<- read param. .. analyzer name V X.xx (C)mm/dd/yy

LAbor GmbH

SELFTEST

Self test

ROM: ok

Testing of ROM

RAM: ok

Testing of RAM

WARM UP

Start of warning up

The changing display will show the

36.5oC

- actual temperature of the measuring block

14:26

- the remaining time of warm up phase.

The analyzer requires approximately 30 minutes to warm up the incubation

block to an operating temperature of 37.4°C (deg).

Use the warm-up phase to load the analyzer with cuvettes and reagents for

testing.

Each cuvette must be equipped with a stir bar.

• Comply with the instructions of the reagent manufacturer.

• Compare the method parameters with those stored in the analyzer.

• For your own safety follow instructions for hygiene.

As soon as the operating temperature has been reached, an adjustment for

automatic cuvette recognition will follow.

<- Remove cuv .. .ette, then press any key.

• Remove the existing cuvette from the measuring channel and close the

light protection caps.

• Press any key (e.g. Enter) for confirmation.

Page 12

Operation

CoaDATA 501 – Operators Manual 2.1 Page 10

<-auto blanking .. keep channels clear.

The measuring channel will be adjusted for automatic cuvette detection.

(Time requirement: approximately 10 seconds).

No cuvettes must be in the measuring channels when saving the

blank values. Otherwise a wrong value is saved which might lead

to evaluation problems. Protect against external light as this might

have an impact on the blank value as well.

The method used last e.g. PT is selected.

< 1 PT >

Printer

If the printer is set to AUTO in the menu UTILITIES the parameterization of

the selected method as well as the result of the first measurement is printed

as soon as the first measurement is completed.

Additional results will be printed automatically upon completion of a

measurement.

2.1.2 STANDBY

< 1 PT >

The selected method will be displayed.

• Press Enter to access the measuring mode.

• Press Esc to return to STANDBY.

A request for sample incubation will be displayed.

cuv in

If there is no action the next 10 minutes, automatically the display will

change to the STANDBY mode and show the actual temperature.

37.4°C

NOTE

Page 13

Operation

CoaDATA 501 – Operators Manual 2.1 Page 11

2.1.3 How to measure

One measuring channel is available for measuring.

The following description refers to a double determination of PT. The test

procedure varies depending on single or double determination. For

additional information please refer to chapter "3.2 Flow Chart of different

application methods".

Single/double determinations

The user can switch to single determination prior to or after a

measurement in the method menu <replication> (refer to chapter 2.2.1

PT-parameterization).

Sample incubation

Sample incubation is always performed in the measuring channel!

• Switch to measuring mode.

cuv in 1

• Open the light protection cap.

• Pipette 50 µl citrate plasma in a cuvette.

• Immediately place this cuvette into measuring channel.

• Close the light protection cap.

The analyzer automatically recognizes the cuvette and starts the timer for

sample incubation (timer count down). An acoustic signal indicates 5 sec

remaining incubation time.

incu 47

Timer count down

After sample incubation the measuring channel will be adjusted for sample.

(adjS = adjust Sample).

adj – S1

Sample adjustment

Once the sample has been adjusted the following display 100 ul alternately

GO – S1 appears:

100 ul

Request to add

GO – S1

add start reagent

• Aspirate 100 µl start reagent into the pipettor.

• Place the pipette vertically onto the light protection cap.

• The measurement is automatically started by pipetting the start reagent

into the sample cuvette.

1.2 s

current measurement in [sec]

An acoustic signal indicates the recognition of clotting in a measuring

channel and stops the timer.

t = 12.6 s

clot recognition in [sec]

Page 14

Operation

CoaDATA 501 – Operators Manual 2.1 Page 12

<-cuv out, then .. press „Reset“

• Open the light protection cap.

• Remove cuvette out of the measuring channel.

• Press Reset-key.

cuv in 2

• Pipette 50 µl citrate plasma in a cuvette.

• Immediately place this cuvette into measuring channel.

• Close the light protection cap.

The analyzer automatically recognizes the cuvette and starts the timer for

sample incubation (timer count down). An acoustic signal indicates 5 sec

remaining incubation time.

incu 52

Timer count down

After sample incubation the measuring channel will be adjusted for sample.

(adjS = adjust Sample).

adj – S2

Sample adjustment

Once the sample has been adjusted the following display 100 ul alternately

GO – S2 appears:

100 ul

Request to add

GO – S1

add start reagent

• Aspirate 100 µl start reagent into the pipettor.

• Place the pipette vertically onto the light protection cap.

• The measurement is automatically started by pipetting the start reagent

into the sample cuvette.

6.9 s

current measurement in [sec]

An acoustic signal indicates the recognition of clotting in a measuring

channel and stops the timer.

<- mean time =

..

12.2 s clot recognition in [sec]

Once the second measured value has been obtained, the mean from the

measured values will be determined and converted into %, ratio, and INR

via the entered calibration curve.

Page 15

Operation

CoaDATA 501 – Operators Manual 2.1 Page 13

The results will be displayed consecutively for duration of 5 sec. The printer

will automatically print the results. The last message cuv out then press

"Reset" will request the removal of the cuvettes from the measuring

channels.

<- mean time =

..

12.4s Display of mean value in [sec.]

% = 91.0

Display of activity in [%]

INR = 1.05

Display of INR

If ratio is selected under 2nd conversion, ratio will be displayed instead of

INR.

<-cuv out, then

.. press „Reset“

• Open the light protection cap.

• Remove cuvette from measuring channel and confirm by pressing Reset-

key (see chapter 3 Software).

The analyzer is now ready for additional measurements.

cuv in 1

Continue as described for additional measurements.

The timer can be started or stopped manually by pressing the

Start-key.

Refer to function keys in chapter 1.2

2.1.4 How to change methods

Methods can only be changed from STANDBY.

< 1 PT >

STANDBY

• Press Esc to switch to STANDBY.

• Press the right arrow; the next method aPTT is displayed as ready-to-

measure.

• Press the arrow-key --> (arrow-key <-- back); the following methods and

the UTILITIES Menu will be displayed:

< 1 PT >

< 2 aPTT >

< 3 Fib. 1 >

g/l

< 4 Fib. 2 >

mg/dl

< 5 Thrmb >

< 6 Intr. >

< 7 Extr. >

Can be overwritten by ChipCARD!

< UTILIT >

NOTE

Page 16

Operation

CoaDATA 501 – Operators Manual 2.1 Page 14

• Select the desired method (1-7).

• Press Enter to confirm the method selection.

The new method has been initialized. Incubation of the first samples can

begin.

cuv in 1

Continue as described for PT in chapter 2.1.3

Page 17

Operation

CoaDATA 501 – Operators Manual 2.1 Page 15

2.1.5 How to change methods with a ChipCARD

Unless a measurement is currently running, a ChipCARD can be inserted

into the adapter at any time for additional methods.

The method parameters will be loaded in memory 7 Extr. Factor. Once

another method is introduced, the method Extr. Factor will be overwritten

and can only be reloaded again using a ChipCARD for Extr. Factor.

The ChipCARD Reader can be accessed through a side opening

underneath the right membrane keypad.

The ChipCARD will be inserted into the ChipCARD reader with the contact

ahead and method description readable.

To load a method:

• Insert the ChipCARD with the selected method into the ChipCARD

Reader the method name and the lot-no. will be displayed automatically.

<-reading card

aPTT

Lot XXXXX

• Press Enter to confirm loading.

remove card

When remove card is displayed, remove the ChipCARD from the

ChipCARD Reader.

<-write param.

.. eter

When writing parameter to internal is displayed, the method parameters

will be stored in method memory 7.

Incubate next samples and continue as described above.

cuv in 1

UTILITIES

The menu Utilities is a group of menus in which instrument settings can be

performed after a "Secret no." (code number) has been entered.

The submenus are as follows: <printer>, <computer>, <beeper>, <clock>

<calibrate temp>, <secret number>, and <cuvette detect.>.

Refer to chapter 2.2.8 Utilities.

aPTT

Lot No.: 123456, Exper. Date 05/05

Insert ChipCARD

Reconstitute reagents according to

manufacturer information

TEST:

- pipette 50ul Plasma in cuvette

- add 50ul aPTT reagent

- 120s incubation time

- start with 50ul CaCl2

Page 18

Operation

CoaDATA 501 – Operators Manual 2.1 Page 16

2.2 Method Parameterization

2.2.1 PT-parameterization

Method parameters in the analyzer have been preset by the manufacturer.

Prior to performing clotting analysis you must update the method parameter

for the reagent used.

• Set analyzer to STANDBY mode

< 1 PT >

STANDBY

• Press Mode. The analyzer will request you to enter an up to 5 digit long

secret number (factory setting: 11111). For additional information refer to

chapter 2.2.8.6 Menu secret number.

<- secret no.:

..

_________

If the wrong number was entered STANDBY will be displayed. As soon as

the correct number has been entered, the following display will appear:

<1.conv>

Press the arrow key -> to display the following menus: <1. conversion>,

<2. conversion>, <replication>, <measurement> and <cuv remove

detec.>.

Overview PT parameterization:

<1.conversion>

<curve>

input of a 9-point calibration curve under or

<quick>

to enter the 100%-value and slope or

<none>

for no conversion

<2.conversion>

<INR>

input of the ISI-value for INR or

<ratio>

input of normal value for ratio calculation or

<none>

for no conversion

<replication>

select single or double determination

<single>

and the coefficient of variation

<double>

(CV 1-20%).

<measurement>

start reagent volume, reagent lot. no.

and sample incubation time.

<cuv remove detect.>

refer to chapter 3 Software

<ON>

activates the automatic cuvette detection

<OFF>

deactivates the automatic cuvette detection.

(default)

Page 19

Operation

CoaDATA 501 – Operators Manual 2.1 Page 17

Enter a calibration curve

1st conversion

curve

• Select 1. conversion and press Enter to confirm selection.

< curve >

A 9-point calibration curve can be entered with this menu.

Calibration curve points that are not to be used must have the entry 0.0 s.

For information of interpolation refer to chapter 5.5 Mathematics. The

system requires two points to be defined but we would recommend a

minimum of 3 points. You can exit the calibration curve menu with Esc if no

entry has been made. Once an entry has been made, all additional

calibration curve points must be retrieved and verified.

• Press Enter to type in the first calibration point. This point is defined as

point of greatest activity and shortest clotting time.

1.point

100.0 %

• Confirm the activity of 100.0 % by pressing Enter or overwrite the preset

entries by pressing the respective number keys. Confirm your entry with

Enter. The cursor switches to the time setting.

12.0 s

• Enter the clotting time for the respective activity of 100.0 %.

• Press Enter to confirm your entry.

The entry field for the next calibration curve point is displayed.

2.point

• Verify or update the second calibration curve point as described above.

• To enter additional calibration curve points follow the above instructions.

The following display appears once the last calibration curve point has been

confirmed:

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

Page 20

Operation

CoaDATA 501 – Operators Manual 2.1 Page 18

Quick

The curve for the PT calibration curve can be entered by typing in the 100

%-value and the factor for the slope of the calibration curve.

< quick >

• Press Enter to confirm selection.

<- 100 %

Example!

= 11.6 s

normal clotting time

factor = 54

Please use the value for factor as provided with the reagent package insert.

If you need to calculate the factor by yourself please refer to chapter 5.5.

If complete data has been entered for <curve> and <quick > the

calibration curve type selected last is active for con-versions in the

ready-to-measure mode. This is also valid for INR and ratio under

2nd conversion.

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

none

If < none > was selected no conversion will be performed.

2nd conversion

< 2.conv >

If a calibration curve has been entered in menu 1st conversion or if <none>

has been selected, the 2nd conversion can be used for INR or ratio.

INR

• Press Enter and the following display appears:

< INR >

• Press Enter to type in the ISI-value.

ISI= 1.05

ATTENTION:

If <none> was selected under 1st conversion the 100 % sec

value, e.g. 100 % = 12,6 sec. will be requested.

• Enter the ISI-value provided on the reagent package insert.

• Press Enter to confirm the entry.

NOTE

Page 21

Operation

CoaDATA 501 – Operators Manual 2.1 Page 19

<- select: ESC. .. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

ratio

< ratio >

• Press Enter to confirm the entry.

100% = 12.0 s

Input of normal time for the 100 % value

• Press Enter to confirm the entry.

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

none

If < none > was selected no conversion will be performed.

replication

In the menu "replication" you can select between "double" for double

determinations or "single" for single determinations by pressing the arrow

key.

< replic >

• Press Enter.

< double >

Selection of double determination

• Press Enter to confirm the selection

Only if double determination has been selected the following display for

entry of the coefficient of variation of the individual values will be displayed.

If this value is exceeded the message "mean error" will appear in the display

and print-out.

<-coef variatio n

= 10% possible entry range: 1% - 20%

• Enter the coefficient of variation

• Press Enter to confirm the entry.

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

Page 22

Operation

CoaDATA 501 – Operators Manual 2.1 Page 20

measurement

< measur >

• Press Enter

A display to type in the sample incubation time appears:

Incubation time

incubat.

= 60 s

• Enter the correct sample incubation time

• Press Enter to confirm the entry

A display which requests the entry of start reagent volume and lot number

appears.

Start reagent volume/

reagent lot number

<-Start Reagent

= 100 ul

• Enter the volume for the start reagent e.g. 100 µl

• Press Enter to confirm the entry

lot no.=

12345678

Example!

• Enter the reagent lot no.

• Press Enter to confirm the entry

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

cuvette remove detect.

< cuvdet >

• Press Enter-key to get the cuvette detection on the display.

< OFF >

Page 23

Operation

CoaDATA 501 – Operators Manual 2.1 Page 21

By selecting:

- <ON> Cuvette detection occurs as soon as a cuvette is placed in the

measuring channel or removed from the measuring channel.

- <OFF> Cuvette detection occurs only when a cuvette is placed into

the measuring channel. The removal of cuvettes must be

confirmed by pressing the Reset-key.

• Select the desired cuvette detection.

• Press Enter-key to confirm entry.

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

Page 24

Operation

CoaDATA 501 – Operators Manual 2.1 Page 22

2.2.2 aPTT - parameterization

• Change to STANDBY mode.

• Select method < 2 aPTT >

< 2 aPTT >

• Press Mode; and enter the secret no.

<- secret no.:

:_________

(Preset to 11111)

If you enter the wrong number STANDBY will appear.

The following dialog will appear as soon as the correct number has been

entered:

<2.conv>

The menus <2. conversion>, <replication>, <measurement> and <cuv

remove detec.> will be displayed by pressing the right arrow key.

Overview over aPTT parameterization

<2.conversion>

<ratio>

input of normal value for ratio calculation or

<none>

for no conversion

<replication>

select single or double determination

<single>

and the coefficient of variation

<double>

(CV 1-20%).

<measurement>

start reagent volume, reagent lot. no.

and sample incubation time.

<cuv remove detect.>

refer to chapter 3 Software

<ON>

activates the automatic cuvette detection

<OFF>

deactivates the automatic cuvette detection.

(default)

2nd conversion

<2.conv>

Selection Conversion

• Press Enter to confirm the selection.

ratio

< ratio >

• Press Enter to confirm the selection.

100% =

Example!

Page 25

Operation

CoaDATA 501 – Operators Manual 2.1 Page 23

27.5 s

Enter a normal value

• Press Enter to confirm the entry.

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

replication

< replic >

• Press Enter to confirm the selection.

< single >

or <double> for double determination

Only if double determination has been selected the following display for

entry of the coefficient of variation of the individual values will be displayed.

If this value is exceeded the message "mean error" will appear in the display

and print-out.

<- coef. variat

ion>

possible entry range

n = 5%

1% - 20%

• Enter the coefficient of variation

• Press Enter to confirm the entry

<- select: ESC.

.. = work ENTER= more parameters

• Press Enter to add additional parameter or Esc to access the

measuring mode.

measurement

< measur >

• Press Enter to confirm the selection.

<- incubat.

=120 s

• Enter the correct sample incubation time.

• Press Enter to confirm the selection.

A dialog will request the entry of start reagent volume and

reagent lot no.:

<-Start Reagent

Page 26

Operation

CoaDATA 501 – Operators Manual 2.1 Page 24

= 50 ul

• Enter the volume for start reagent.

lot. no. =

12345678

• Enter the reagent lot no.

• Press Enter to confirm the selection.

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

cuvette remove detection

< cuvdet >

• Press Enter-key to get the cuvette detection on the display.

< OFF >

By selecting:

- <ON> Cuvette detection occurs as soon as a cuvette is placed in the

measuring channel or removed from the measuring channel.

- <OFF> Cuvette detection occurs only when a cuvette is placed into

the measuring channel. The removal of cuvettes must be

confirmed by pressing the Reset-key.

• Select the desired cuvette detection.

• Press Enter-key to confirm entry.

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

Page 27

Operation

CoaDATA 501 – Operators Manual 2.1 Page 25

2.2.3 Fibrinogen 1 [g/l] - parameterization

• Select method < 3 Fib. 1 >

< 3 Fib. 1 >

Results will be calculated in [g/l]

• Press Mode; and enter the secret no.

<- secret no.:

: ______

(preset to: 11111)

If you enter the wrong number STANDBY will appear.

The following dialog will appear as soon as the correct number has been

entered:

< 1.conv >

The menus <1. conversion>, <replication>, <measurement> and <cuv

remove detec.> will be displayed by pressing the right arrow key.

Overview over Fibr. g/l parameterization

<1.conversion>

<curve>

input of a 9-point calibration curve under or

<none>

no conversion

<replication>

select single or double determination

<single>

and the coefficient of variation

<double>

(CV 1-20%).

<measurement>

start reagent volume, reagent lot. no.

and sample incubation time.

<cuv remove detect.>

refer to chapter 3 Software

<ON>

activates the automatic cuvette detection

<OFF>

deactivates the automatic cuvette detection.

(default)

• Press Enter to confirm the selection.

1st conversion

A 9-point calibration curve can be entered with this menu.

Calibration curve points that are not to be used must have the entry 0.0 s.

For information on interpolation refer to chapter 5.5 Mathematics. The

system requires two points to be defined but we would recommend a

minimum of 3 points. You can exit the calibration curve menu with Esc if no

entry has been made. Once an entry has been made, all additional

calibration curve points must be retrieved and verified.

< curve >

• Press Enter to enter the calibration curve.

1.point:

Definition as:

Page 28

Operation

CoaDATA 501 – Operators Manual 2.1 Page 26

5.28 g/l

Point of greatest concentration and

6.4 s

shortest clotting time!

• Enter the concentration and clotting time and confirm the entry with

Enter.

2.point:

2.53 g/l

11 s

• Enter the concentration and clotting time and confirm the entry with

Enter.

• Proceed as described to enter additional points on the calibration curve

The following display appears once the last calibration curve point has been

confirmed:

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

replication

< replic >

• Press Enter.

< double >

Selection of double determination

• Press Enter to confirm the selection

Only if double determination has been selected the following display for

entry of the coefficient of variation of the individual values will be displayed.

If this value is exceeded the message "mean error" will appear in the display

and print-out.

<- coef. variat

ion>

Possible entry:

n = 10%

1% - 20%

• Enter the coefficient of variation

• Press Enter to confirm the entry

Page 29

Operation

CoaDATA 501 – Operators Manual 2.1 Page 27

<- select: ESC. .. = work ENTER= more parameters

• Press Enter to add additional parameter or Esc to access the

measuring mode.

measurement

< measur >

• Press Enter to confirm the selection.

<- incubat.

= 60 s

• Enter the correct sample incubation time.

• Press Enter to confirm the selection.

A dialog will request the entry of start reagent volume and reagent lot no.:

<-Start Reagent

= 100 ul

• Enter the volume for start reagent.

lot. no. =

12345678

• Enter the reagent lot no.

• Press Enter to confirm the selection.

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters.

cuvette remove detection

< cuvdet >

• Press Enter-key to get the cuvette detection on the display.

< OFF >

By selecting:

- <ON> Cuvette detection occurs as soon as a cuvette is placed in the

measuring channel or removed from the measuring channel.

Page 30

Operation

CoaDATA 501 – Operators Manual 2.1 Page 28

- <OFF> Cuvette detection occurs only when a cuvette is placed into

the measuring channel. The removal of cuvettes must be

confirmed by pressing the Reset-key.

• Select the desired cuvette detection.

• Press Enter-key to confirm entry.

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or Enter to add or verify

additional parameters

2.2.4 Fibrinogen 2 [mg/dl] - parameterization

<4 Fib.2> same as described under 2.2.3 Fibrinogen g/l <3Fib. 1>.

2.2.5 Thrombin time parameterization

<5Thrmb> same as described under 2.2.2 aPTT, but without 2nd

conversion possibility.

2.2.6 Intrinsic Factor parameterization

Intr. Factors <6 Intr. > (Factor VIII, Factor IX, Factor XI, or Factor XII) can

be parameterized with this menu. >intrinsic factors< = endogenous

clotting factors.

The following menus can be accessed under method parameters:

<1.conversion>

<curve>

input of a 9-point calibration curve under or

<none>

no conversion

<replication>

select single or double determination

<single>

and the coefficient of variation

<double>

(CV 1-20%).

<measurement>

start reagent volume, reagent lot. no.

and sample incubation time.

<cuv remove detect.>

refer to chapter 3 Software

<ON>

activates the automatic cuvette detection

<OFF>

deactivates the automatic cuvette detection.

(default)

2.2.7 Extrinsic Factor – parameterization

<1.conversion>

<curve>

input of a 9-point calibration curve under or

<none>

no conversion

<replication>

select single or double determination

and the coefficient of variation

<measurement>

(CV 1-20%).

start reagent volume, reagent lot. no.

<cuv remove detect.>

and sample incubation time.

<ON>

<OFF>

refer to chapter 3 Software

activates the automatic cuvette detection

Page 31

Operation

CoaDATA 501 – Operators Manual 2.1 Page 29

2.2.8 Utilities

To enter the Utilities Menu:

• finish an actual measurement

• change to the Standby-Mode

• press the left arrow-key

< UTILIT >

• Press Mode to confirm selection.

The following menus can be accessed under Utilities provided the secret

number (11111) has been entered: <printer>, <computer>, <beeper>,

<clock>, <calibrate-temp>, <secret no>, <cuvette test>.

Menu overview Settings

< printer >

AUTO- MANUAL- parameter protocol - OFF

< computer >

OFF - ON

< beeper >

ON - OFF - CLICK

< clock >

date and time

< calibrate temp >

adjustment of temperature

< secret no >

enter personal secret number

< cuvette test >

test automatic cuvette detection

Use the left or right arrow-key to change the menu selection.

Each alteration in one of the menus is to be confirmed with the Enter- key.

The following display appears:

<- select: ESC.

.. = work ENTER= more parameters

• Press Esc to access the measuring mode or press Enter to access

additional menu items.

2.2.8.1 Menu printer

< printer >

• Press Enter to confirm selection.

A selection between <AUTO>, <MANUAL>, <Par Pro>, and OFF for the

optional printer EPSON P40 can be made from this menu.

A print-out includes:

Test results, method parameters, complete parameter list, and error

messages.

Page 32

Operation

CoaDATA 501 – Operators Manual 2.1 Page 30

If you select

- AUTO

The results will be printed out immediately after

they have been obtained.

- MANUAL

The results will be printed out after processing

results and pressing the Reset-key.

- OFF

The print function is switched off.

- Par Pro

All stored method parameters will be printed

out.

• Use the arrow keys to make a selection from the display.

• Press Enter to confirm a selection.

2.2.8.2 Menu computer

Change of the default parameters have only be done by the authorized

customer service of the distributor.

2.2.8.3 Menu beeper

< beeper >

• Press Enter to confirm selection.

The integrated beeper provides an acoustic signal

- during key strokes

- when an error occurs

- after sample incubation

- when clot recognition occurs

In this menu you can select between <ON>, <OFF>, and <CLICK>.

If you select:

- ON

The beeper will be activated. Each action will

be confirmed by the beeper.

- OFF

The beeper is deactivated.

- CLICK

Only key strokes will be confirmed.

• Use the arrow keys to make a selection in the display.

• Press Enter to confirm a selection.

2.2.8.4 Menu clock

< clock >

• Press Enter to confirm selection.

You can enter the current date and time with this menu. Once a selection

has been made the following dialog will appear:

18.05.99

Day, Month, Year

Page 33

Operation

CoaDATA 501 – Operators Manual 2.1 Page 31

The cursor (activated, highlighted field) is positioned on the field "day".

• Enter day, month, year and press enter after every input.

It is not necessary to enter a dot between the numbers.

Next the value of time will be displayed.

14:53:06

Hour, Minute, Second

• Enter the current hour, minute, and second and press Enter.

2.2.8.5 Menu calibrate temp

You can adjust the temperature of the incubation block with this menu. If

you have accessed the menu and you do not wish to adjust, press Esc to

exit the menu.

When does the temperature have to be readjusted? You must readjust

when the temperature of the incubation block deviates more than +/- 1°C

measured with a calibrated digital thermometer.

Position for adjustment:

The lower right cuvette position of the incubation block. Refer to chapter

1.2, figure 1, marked with "T". If you like to verify or adjust the temperature,

the cuvette at the position T must be filled with 400 µl bi-distilled water.

Measuring tools:

Digital multimeter with 4 1/2-digit display. For example Voltkraft M-4650B

and temperature measurement adapter for multimeter, e.g. Fluke 80T150U, output in °C.

To verify the temperature place the measuring sensor into position "T"

which is filled with bi-distilled water.

• Check the temperature after approx. 10 min.

If a temperature adjustment is necessary:

• Select <calib> and press Enter to confirm selection.

< calib >

The following display appears:

int 37.4

Example!

ext 37.4

• Wait until the temperature in the display has stabilized internally to 37.4

°C.

• Next enter the temperature displayed by the digital thermometer via the

numerical keypad. The entry will be displayed under extern.

• Press Enter to confirm the entry.

• Wait until the temperature has stabilized at 37.4 °C on the display intern.

Page 34

Operation

CoaDATA 501 – Operators Manual 2.1 Page 32

As soon as the temperature has stabilized at 37.4 °C on the display intern

the value must be compared with the value measured with the digital

multimeter. If the internal and external values are identical temperature

adjustment has been completed. Otherwise the procedure has to be

repeated.

• Press Esc. All values will be stored by the analyzer.

2.2.8.6 Menu secret number

< sec. no. >

• Press Enter to confirm selection.

In the menu <sec.no.> you are able to select a code number to restrict

access to the parameter menus.

A number in the range between 00001 and 65535 can be chosen.

Once a sec.no. has been selected the following display will appear:

<- enter new se .. cret no.

>11111<

(0=none)

You can overwrite the number preset by the manufacturer.

• Press Enter to save the new number. A print-out of secret number as well

as serial number follows (printer mode: AUTO).

----------------------------Analyzer name

ser. no. C1770711 Sample print-out!

secret no=xxxxx x= number

-----------------------------

If zero is entered and saved instead of a number the secret number will not

be queried when a parameter menu has been selected.

The entry must be completed with Enter if a secret number shorter 5 digit is

stored.

Without entering a secret number the customer can:

- perform tests

- change the test method

without use of the secret number.

Once you have entered the secret number, you can

- perform calibration of tests

- perform settings and controls under UTILITIES and all its submenus.

2.2.8.7 Menu cuvette test

< cuvet. >

• Press Enter to confirm selection.

Page 35

Operation

CoaDATA 501 – Operators Manual 2.1 Page 33

You can control the function of the automatic cuvette detection with this

menu.

CUV-TEST

cuv

If no cuvette is located in the measuring channel the display (-----) appears.

If a cuvette was placed in the measuring channel the display cuv appears.

The display will show the respective status once a cuvette is placed into or

removed from the analyzer.

• Press Enter to leave the menu.

2.3 Printer

It is possible to link an external printer (optional) to the analyzer, refer to

chapter 1.3.1 Connect an external printer. The connection to the printer

shall be done via the RS 232C interface of the analyzer. Ask your local

dealer for recommended printer models.

Page 36

Operation

CoaDATA 501 – Operators Manual 2.1 Page 34

2.3.1 Sample print-outs PT and calibration

General print-outs

Once a method has been selected the programmed calibration curve

parameters will be printed followed by the results. The print-out is automatic

as soon as a result has been obtained by the measuring channel.

Print-out of all parameters

A print-out of all programmed test parameters can be generated as

described in chapter 2.2.8 Utilities.

=======================

PARAMETER-PROTOCOL

( 980 Bytes)

1-channel

V X.xx, mm/dd/yy

math-vers V XX.xx

actual date & time:

02.12.99, 14:44:00

[dd.mm.yy, hh.mm.ss]

-- device-specific: --

ser.no. j582074

Serial number of analyzer

secret no. = 11111

ntc_soll = 509

------- global: -------

Global Parameter

Analyzer name

Dealer name

parameter-ID: F1890078

Printer AUTO

computer OFF

Header OFF

Beeper ON

cuv detection ON

method 1 PT

--- method store 1 ---

Stored method parameter

PT

for PT

cuv remove detection OFF

filter.no. = 0

mode SINGLE

incubat = 60 s

start-reagent:

Lot 1

reagent = 100 ul

1st convers INTERPOLAT:

2nd convers INR

ISI = 1.05

100.0 % 11.6 s

50.0 % 17.7 s

25.0 % 29.9 s

10.0 % 66.6 s

---- method store 2 ----

aPTT

Page 37

Operation

CoaDATA 501 – Operators Manual 2.1 Page 35

print-out of method parameters

If you press 0 when the analyzer is in the measuring mode, a parameter

print-out for the selected method is generated.

print-outs PT

PT Documentation

Example: Conversions via a 4-point calibration curve in % and INR.

--- method store 1 -- PT

actual date 02.12.99

cuv remove detection OFF

Automatic cuvette detection

mode DOUBLE

Double determination

coef.var = 5 %

Coefficient of variation

incubat = 60 s

Sample incubation time

start-reagent:

Lot 101xxx

Reagent lot no.

reagent = 100 ul

Reagent start volume

1st convers INTERPOLAT.

1. conversion, calib. curve / interpolation

2nd convers INR

2. conversion INR

ISI = 1.05

ISI-constant

100.0%= 11.6 s

Calibration curve points

50.0%= 17.7 s

25.0%= 29.9 s

10.0%= 66.6 s

----------------------results:

PT

Method

patient _____________

Patient name

02.12.99, 10:52:55

Date, Time

time 1 = 12.0 s

1st measured time

time 2 = 12.8 s

2nd measured time

Mean = 12.4 s

Mean of measured times

INR = 1.7

Conversion to INR

% = 88.4%

Conversion to PT %

Page 38

Operation

CoaDATA 501 – Operators Manual 2.1 Page 36

PT documentation

Example: Conversion via Factor calibration curve in % and INR.

--- method store 1 -- PT

actual date 02.12.99

cuv remove detection OFF

Automatic cuvette detection

mode DOUBLE

Double determination

coef.var = 5 %

Coefficient of variation

incubat = 60 s

Sample incubation time

start-reagent:

Lot 101xxx

Reagent lot no.

reagent = 100 ul

Reagent start volume

1st convers QUICK FACTOR

2nd convers INR

100% = 11.8s

factor = 52

ISI = 1.05

----------------------results:

PT

Method

patient _____________

Patient name

02.12.99, 12:58:38

Date, Time

time 1 = 11.7 s

1st measured time

time 2 = 12.1 s

2nd measured time

Mean = 11.9 s

Mean of measured times

INR = 1.01

Conversion to INR

quick = 98.1%

Conversion to PT %

Page 39

Operation

CoaDATA 501 – Operators Manual 2.1 Page 37

2.4 Errors

Errors can be generated by the user and/or the system itself. The analyzer

displays error messages and warnings in the display. If the printer has been

activated these messages will be printed.

2.4.1 Application errors

Application errors may cause error messages. Possible causes are:

- Air bubbles were created during pipetting

- Pipetting was performed directly into the measuring channel without

cuvette

- The wrong pipette tips were used

- The pipetted volume is incorrect (for variable Pipets)

- The pipetting process was too slow and the angle incorrect

- The temperature of the start reagent deviates from 37°C

- The reagent has been placed incorrectly

- The sample or control is too old

- No stir bar has been placed into the cuvette

- Reagents have been carried over (PT or Fibrinogen reagent)

- A reagent with the wrong lot number has been used

Should any of these errors occur and they are recognized in time, they must

be remedied immediately.

Certain of these errors can only be recognized when determining control

plasmas.

As a result we recommend running control plasma on a daily basis prior to

running routine determinations.

Cancel incubation / measurement:

By pressing the Reset-key, any process on the measuring channel can be

cancelled.

Page 40

Operation

CoaDATA 501 – Operators Manual 2.1 Page 38

2.4.2 Error Messages

Error message

(Display) Cause Remedy

BREAK timeout

the maximum measuring time has been

exceeded

possibly no clotting; optical test

for clots; repeat test.

BREAK dark

preparation for measurement is too turbid dilute plasma or mix reagent.

BREAK top lim

exceeded measuring range (too high)

possibly caused by air bubbles

repeat test

BREAK bot lim

exceeded measuring range (too low)

repeat test

BREAK motor

mixer motor error occurred contact technical service

BREAK noise

loud noise after sample adjustment check for air bubbles or other

particles.

BREAK drift

measured curve drifted after reagent has

been added

check sample for air bubbles

break

measurement cancelled with Reset caused by user!

break jump

Measuring break because of a measuring

value jump (no clotting)

repeat test and if necessary

contact technical Service.

break readjust

message is displayed if the light value is too

dark during the adjustment phase

Repeat test and dilute plasma if

necessary.

mg/dl <2.0

converted value is lower than the

parameterized minimum value.

check analytical steps and the

conversion parameter.

mg/dl <200.0

converted value is bigger than the

parameterized maximum value.

see above (mg/dl <2.0)

Err div0

Err log0

Err over

deviation through 0 during conversion

comp. of the logarithm from a negat. Value

computation overflow.

check conversion parameter,

if necessary, contact technical

Service

SYSTEM FAILURE:

EPROM: Sxxxx S9999

EPROM check sum error

xxxx=set value; yyyy=actual value

contact technical Service

SYSTEM FAILURE:

MPU-RAM: Sxxxx

MPU-RAM on address Sxxxx in error

contact technical Service

SYSTEM FAILURE:

ext. RAM: Sxxxx

external RAM on address Sxxxx in error contact technical Service

parameter-error!

press any key ...

check sum error for parameters in EEPROM

contact technical Service

ERROR/ERROR rekursiv

software error

contact technical Service

All errors will cancel the current measurement.

NOTE

Page 41

Operation

CoaDATA 501 – Operators Manual 2.1 Page 39

2.4.3 Errors during operation

Error Cause Remedy

Cannot start analyzer Main voltage failure? Fuse defect?

Is the power adapter accurate connected?

Check if main voltage available

and check power adapter

Analyzer fails during

operation

Main voltage failure? Fuse defect?

Is the power adapter accurately connected?

Prüfung ob Netzspannung vorhanden, Prüfung d. Sicherungen

Measuring cell polluted

with liquids

Additional pipetting of plasma or reagent

into the measuring cell without cuvette

Remove liquid with pipettor, clean

with appropriate absorbent cloth,

refer to chapter 4.2

2.4.4 Warnings

Warning Meaning

Cool down

This message will appear if the incubation block is too warm during a measuring

pause. No other measurements can be started during cool down.

TEM. WARN

If during a measurement the temperature of the incubation block deviates

significantly from the set value, the measurement is not cancelled. Instead this

warning appears in the display and is also printed out via the active printer.

mean error

Signals a wrong result after a double determination in relation to the coefficient.

max-time reached

- no more points

If a point of calibration curve meets the no more points maximum measured

time no additional points can be entered as they need to increase from point to

point. Input will be blocked when this message appears.

min-value reached

- no more points

or

max-value reached

- no more points

During the input of the calibration curve, the range of values (%, g/l, mg/dl) is

limited for each method due to manufacturer’s settings. In addition the points

must increase or decrease depending on the presetting. If the largest or smallest

permitted value for a point has been entered, no additional points can be

entered. Input will be blocked when this message appears.

2.4.5 How to change fuses

Fuses can not be changed in the external power adapter or inside the

analyzer. Contact your distributor if problems occur with the power adapter

or the instrument itself.

Page 42

Software

CoaDATA 501 – Operators Manual 2.1 Page 40

3 Software

The software for the analyzer is stored in a memory and will be activated as

soon as the analyzer is switched on. It controls the analyzer via start

functions for the analytic program.

Visual communication between the analyzer and the user is accomplished

via a liquid crystal display with one row and 8 characters.

The menu Utilities has been integrated into the method menu so that

system settings can be performed for the following menus <printer>,

<computer>, <beeper>, <clock>, <calibrate temp>, <secret number>, and

<cuvette test>.

The analyzer contains automatic cuvette detection. The following display

will appear after initialization:

<-auto blanking .. keep channels clear.

At this point the optical blank value will be determined and stored for the

measuring channel. No cuvettes may be located in the measuring channels

at this time!

Due to the optical change in the measuring channel, the analyzer

automatically recognizes whether a cuvette is placed in the measuring

channel or removed.

Storing of parameter

After a parameterization of an instrument or test-data, short information

"write parameter" will be shown on the display.

Page 43

Software

CoaDATA 501 – Operators Manual 2.1 Page 41

3.1 Software overview

Figure 7 Software Overview

Analyzer name

Power ON

Initialising

WARM UP

Remove cuvettes

then press any key

auto blanking

keep channels clear

< 1 PT >

Method parameter Test steps (double determ.) Method list

secret no.: cuv in 1 < 1 PT >

< 1. conv > incu 47 < 2 aPTT >

< 2. conv > adj – S1 < 3 Fib 1>

< replic > GO-S1 < 4 Fib 2>

< measure > 100 ul < 5 Thrmb>

< cuvdet > 1.2 s < 6 Intr.>

t= 12.6 s < 7 Extr.>

cuv out,* < UTILIT >

cuv in 2

Mode

incu 52 secret no.:

adj – S2 < print >

GO - S2 < comput >

100 ul < beeper >

6.9 s < clock >

mean time= < calib. >

% = 91.0 < sec.no >

INR = 1.05 < cuvet. >

cuv out, *

* then press “Reset”

Page 44

Software

CoaDATA 501 – Operators Manual 2.1 Page 42

3.2 Flow Chart of different application methods

Figure 8 Test procedure for single and double determination

Flow chart to set single or double determination at the analyzer.

Test steps for

double determination

Test steps for

single determination

cuv in 1 cuv in

incu 47 incu 47

adj – S1 adj – S

GO - S1 GO - S

100 ul 100 ul

1.2 s 1.2 s

t= 12.6 s time =…

cuv out,* = 12.6 s

cuv in 2 % = 91.0

incu 52 INR = 1.05

adj – S2 cuv out, *

GO - S2

100 ul

6.9 s

mean time=

% = 91.0

INR = 1.05

cuv out, *

* then press “Reset”

Page 45

Software

CoaDATA 501 – Operators Manual 2.1 Page 43

3.3 Method Parameters

The settings on the analyzer are set by the manufacturer. Before routine

tests can be performed, the user must change certain reagent specific

parameters such as lot number and calibration curve parameter.

The following parameter settings are manufacturer’s settings.

Program Version: V X.xx Release mm.dd.yy

Printer: AUTO

Computer: OFF (only for service purposes!)

Beeper: ON

Secret no.: 11111

Cuvette detection: OFF

Single determination: for all methods

Method Parameters

(factory settings)

Calibration curve P1 - P9

P1 P2 P3 P4 P5 P6 P7 P8 P9 Unit 100% ratio ISI Rea. Lot no.

1 PT Value 100 50 25 10 0,0 0,0 0,0 0,0 0,0 % 11,6 1 1.05 1

Time 11,6 17,7 29,9 66,6 0,0 0,0 0,0 0,0 0,0 sec

2 aPTT Value 0 0 0 0 0 0 0 0 0 27,5 0 1.05 -

time 0 0 0 0 0 0 0 0 0 sec

3 Fib.1 Value 8 4 2 1 0 0 0 0 0 g/l 0 0 0 2

Time 8,5 16,5 32 80 0 0 0 0 0 sec

4 Fib.2 Value 804 402 199 100 0 0 0 0 0 mg/dl 0 0 0 3

Time 8,5 16,5 32 80 0 0 0 0 0 sec

5 Thrmb Value 0 0 0 0 0 0 0 0 0 0 0 0 -

Time 0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 sec

6 Intr. Value 200 0,5 0 0 0,0 0,0 0,0 0,0 0,0 % 0 0 0 -

Time 5,0 150,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 sec

7 Extr. Value 200,0 0,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 % 0 0 0 -

Time 5,0 150,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 sec

method store

method name

max. 5 characters

incub [sec] (0=off)

start-reagent [µl]

1st conversion reference curve

(quick)

1st conversion unit

decimal place

2nd conversion (INR/RATIO)

min value (conc)

max value (conc)

time (lin / log / rezi)

value (lin / log / rezi)

1 PT 60 100 curve % 1 INR 5 150 lin rezi

2 aPTT 120 50 - 0 Ratio 0 0 lin lin

3 Fib.1 60 100 curve g/l 1 - 0,2 10,0 log log

4 Fib.2 60 100 curve mg/dl 0 - 20 1000 log log

5 Thrmb 60 100 - 1 - 0 0 lin lin

6 Intr. 120 50 curve % 1 - 0,5 200 log log

7 Extr. 60 100 curve % 1 - 0,5 200 log log

Page 46

Hazard and Precautions

CoaDATA 501 – Operators Manual 2.1 Page 44

4 Safety issues

4.1 Hazard and Precautions

The cautions and safety regulations in this instruction manual meet

international classifications:

Symbol warns of a risk of injury or of a risk to life (for example by electrical

shock).

Symbol warns of a risk of injury or of the instrument being severely

damaged.

Symbol introduces rules to be observed.

The following caution and safety regulations must be observed at all

times:

1. Electrical safety

Check that the operating voltage is set correctly before you connect the

device to the main power supply.

To connect the device to the power supply, use only sockets which are

grounded in order to keep the risk of an electrical shock as low as possible.

Use only grounded extension cables.

Never intentionally disconnect the grounding contacts.

There is the risk of electrical shock if

- the protective conductor is interrupted within or outside the device,

and/or

- the grounded contact has been disconnected from the line.

Never remove protective guards or secured components since you

could expose electrically live parts in this way.

Electrical connection contacts (plugs, sockets, etc.) can be electrically live.

Even after a device has been switched off, components (e.g.

capacitators) can be under voltage as the result of an electrical charge.

All current carrying parts are sources of danger for an electrical shock.

Surfaces (floors, work table) must not be moist when you are working with

any electrical device.

Carry out only the maintenance work and/or the replacement of parts

described in these operating instructions.

Caution!

NOTE

Danger!

D

ange

r!

Page 47

Hazard and Precautions

CoaDATA 501 – Operators Manual 2.1 Page 45

Unauthorized work on the device can lead to the guarantee obligation

becoming null and void with necessary expensive service work to correct it.

All work which requires the analyzer to be opened may only be carried

out by a technician who is familiar with the risks related thereto.

Use only replacement fuses of the stated type and with the stated nominal

current.

Never use fuses which have been "repaired".

Never short-circuit the fuse holder.

There is a Lithium battery type Li-Mn CR 2430 on board which must be

replaced by the distributor every 5 years.

2. Fire and explosion hazards

Do not place any flammable or hazardous explosive material in the

proximity of the analyzer.

Electrical sparks could cause fire or explosions.

3. Mechanical safety

(Analyzer is operating)

Never open screw-attached housing parts while the instrument is ON. There

is a risk of injury due to moving parts (fan, motor, drives).

Risk of infections

4. Samples

Avoid any direct contact with samples which are potentially infectious or

which may generate other risks to the human body.

If sample material is spilled onto the analyzer, wipe it off immediately and

decontaminate the surface. Refer to chapter 4.2.

5. Reagents

Observe the suggestions in the package inserts for a correct use of the

reagents.

6. Accuracy and precision

of the measured results

In order to ensure a flawless operation of the analyzer measure control

samples and watch the function of the instrument closely.

Faulty measurement results may result in an incorrect diagnosis or range

danger for patient.

Caution

!

Caution!

Caution!

Caution!

Page 48

Hazard and Precautions

CoaDATA 501 – Operators Manual 2.1 Page 46

7. Restrictions for samples

and reagents

For cuvettes no guarantee can be provided for any resistance against

organic solvents.

For this reason, do not use any organic solvents unless such solvents are

expressly indicated.

8. Operator qualification

The analyzer should only be operated by trained personnel. Ask you local

dealer or distributor for further information on the availability of user

trainings.

4.2 Maintenance and Hygiene

No organic acid based cleaning substances should be applied. Instead use

cleaner designed for cleaning and disinfecting laboratory instruments. Only

use a dampened cloth to clean the instrument. Never spray or pour cleaning

solution directly onto the instrument which may negatively impact the

analyzer's functions significantly.

Keep the instrument clean and do not spill liquids onto the analyzer. To

protect the instrument from dust, cover it with the supplied dust cover or

store instrument in a cabinet when not in use.

In case liquids were spilled onto the instrument, immediately absorb liquid

with an appropriate cloth.

If liquid has accidentically run or was pipetted into the measuring channel,

remove liquid with a pipette and clean the measuring channel with a lint-free

cloth.

Contact Technical Service if your control measurements do not produce the

expected results.

4.2.1 Disposal of analyzer

The following features should be observed when disposing of the analyzer:

- The top and bottom housing are made of polyurethane foam.

- Mechanical parts are mostly made of aluminium and precious metals.

- Electronic parts must be disposed off in accordance with the guidelines for

the disposal of electronic parts

- Make sure that the analyzer has been decontaminated before disposal.

Caution

!

Caution

!

Caution

!

Page 49

Appendix

CoaDATA 501 – Operators Manual 2.1 Page 47

5 Appendix

5.1 Disposables

Material Order number

Cuvettes

1 x Dispo-System micro 40.613.0002

500 cuvettes / stir bars 1,0 x 4,0 mm

1 x 500 cuvettes micro in plastic bag 40.612.0010

1 x 500 stir bars micro 1,0 x 4,0 mm 40.650.0021

in plastic vial

Thrombi-Tips

1 x Thrombi-Tips Racks, 16 x 144 Tips 40.673.0016

Manuals

Operators Manual CoaDATA 501 30.000.1613

(German Version)

Pipettes

Thrombi-Pette 20 - 200 µl 20.000.2712

Thrombi-Pette 20 µl 20.000.2713

Thrombi-Pette 50 µl 20.000.2714

Thrombi-Pette 100 µl 20.000.2715

Thrombi-Pette 200 µl 20.000.2716

5.2 Materials Supplied

Material

1 x CoaDATA 501

1 x 10 cuvettes + mixer, Dispo-System

2 x Plastic vials

1 x Power adapter 100V – 240 V (Europe) + 1 adapter

USA/Japan

1 x Operator Manual (English)

1 x Thrombi-Pette 20 - 200 µl adjustable (optional)

1 x 10 Thrombi-Tips (Only if Thrombi-Pette is supplied)

1 x Packaging

1 x Styropor inserts (set)

1x Analytical Protocol (copy)

20-200µl

200

Page 50

Appendix

CoaDATA 501 – Operators Manual 2.1 Page 48

5.3 Technical Data

Instrument type Analyzer for determination of plasmic clotting.

Application coagulometric tests such as PT, aPTT, TZ,

Fibrinogen, single factors FII - FXII

Restrictions only for traditional, coagulometric clotting tests (no

chromogenic substrates).

Operation manual

Measuring principle turbodensitometric; opto-mechanical with

automatic zero adjustment and magnetic stir bar

for homogenizing of the test suspension and

increased sensitivity.

Sensitivity PT > 10% of norm

Test throughput PT 30/h, aPTT 15/h, +/- 10 tests/h

Cuvette volume min. 150 µl, max. 300 µl (test suspension)

Calibration manual input of calibration points, method

dependent

Software loaded in memory

Programmed PT, in sec, %, Ratio, INR (combinations)

methods aPTT, in sec, and Ratio

Fibrinogen, in sec, g/l,

Fibrinogen in sec, mg/dl

Thrombin T., in sec

Intr. Factor, in %

Extr. Factor, in %

Light source LED, light emitting diode

Display 1 lines with 8 characters, liquid crystal

Display

Processor 80552 (single chip microcontroller)

Incubation block controlled at 37.4°C +/- 0.3°C

Measuring channels 1

Light protection caps: for Thrombi-Tips

optional for yellow tips by Eppendorf

Reagent vials for 1 position, diameter 23.0 mm

Cuvette positions 4

Disposables cuvettes, paper for thermal printer, tips

Measuring timer max. 600 sec

Interfaces RS 232 C

(optional printer) ChipCARD reader

Page 51

Appendix

CoaDATA 501 – Operators Manual 2.1 Page 49

Printer memory 10 KByte

Operating voltage 12 V DC

Power consumption 9.6 VA

Environmental temperature: +10° - 30°C

conditions relative humidity: less than 85 %,

no condensation

System time real time clock for time and date

Dimensions 9,7 x 21,2 x 5,2 cm (WxDxH)

Weight 0,6 kg

Warranty

Warranty is granted for a period of 12 months starting from the date of

delivery.

5.4 Safety Specifications

The instruments conform to the relevant European regulations.

The instruments described in this manual bear a CE mark which confirms

the compliance with the essential requirements of the following European

directives:

If the instrument's type plate bears an IVD symbol it complies with the

following directive: