Page 1

INSTRUCTION MANUAL

SHINVA 45 Litre

Page 2

Contents

Preface……………………………………………… …… ……… ……...1

Chapter 1 Overview……………………………… … … … …… … …....2

Chapter 2 Basic Introduction……………………… ………………...3

Chapter 3 Installation……………………………………………… ….6

Chapter 4 Preparation before Using………………………………10

Chapter 5 Operation……………………………………… …… … ….12

Chapter 6 Maintenance……………………………………… …… …13

Chapter 7 General Maintenance and Repairs……………………14

Page 3

1

Preface

1 Use of this Manual

The operation and maintenance manual is a part of the autoclave.

1) Instructions for equipment

2) How to assemble the machine correctly.

3) How to operate the machine correctly.

4) Daily maintenance of the machine.

5) Cautions about the safety matters.

2 Storage of the Manual

The manual must be kept properly with the equipment.

Explanation of warning marks

!!! Warning:

Notice user and operator: Avoid possible serious personal injury and equipment

damaged.

!! Be careful

Notice user and operator: Avoid possible slight personal injury and equipment damaged.

! Attention

Notice user and operator: The operation of the equipment will fail and sterilization will

not occur.

Please read and understand this manual before using the equipment.

It is very important!

Page 4

2

Chapter 1 Overview

1.1 Data and Marks for the Identification of the Equipment

Execution Standard:YZB/Shandong 0155-2008

The equipment passed CE certificate, ISO 9001 and ISO 13485 international quality

system certificate.

Technical parameters:

Designed pressure: 0.28MPa

Rated working temperature: 134

Model: TMQ.CV3250

Overall dimensions (mm): 835 x 600 x 515

Net weight: 85Kg

Power: 240V 50Hz 3.6KW

Rated working pressure: 0.22MPa

Water source: distilled water or pure

water

Volume: 45 litres

Diameter * depth (mm): φ317X580

Page 5

3

1.2 Attention

When the autoclave arrives, please open the package, check if the machine is damaged or

any parts are missing. During your check of the machine, please pay attention to the

packaging and keep the packaging materials. All autoclaves have been checked and

tested strictly before shipping.

The useful life of this equipment is 8 years.

Chapter 2 Basic Introduction

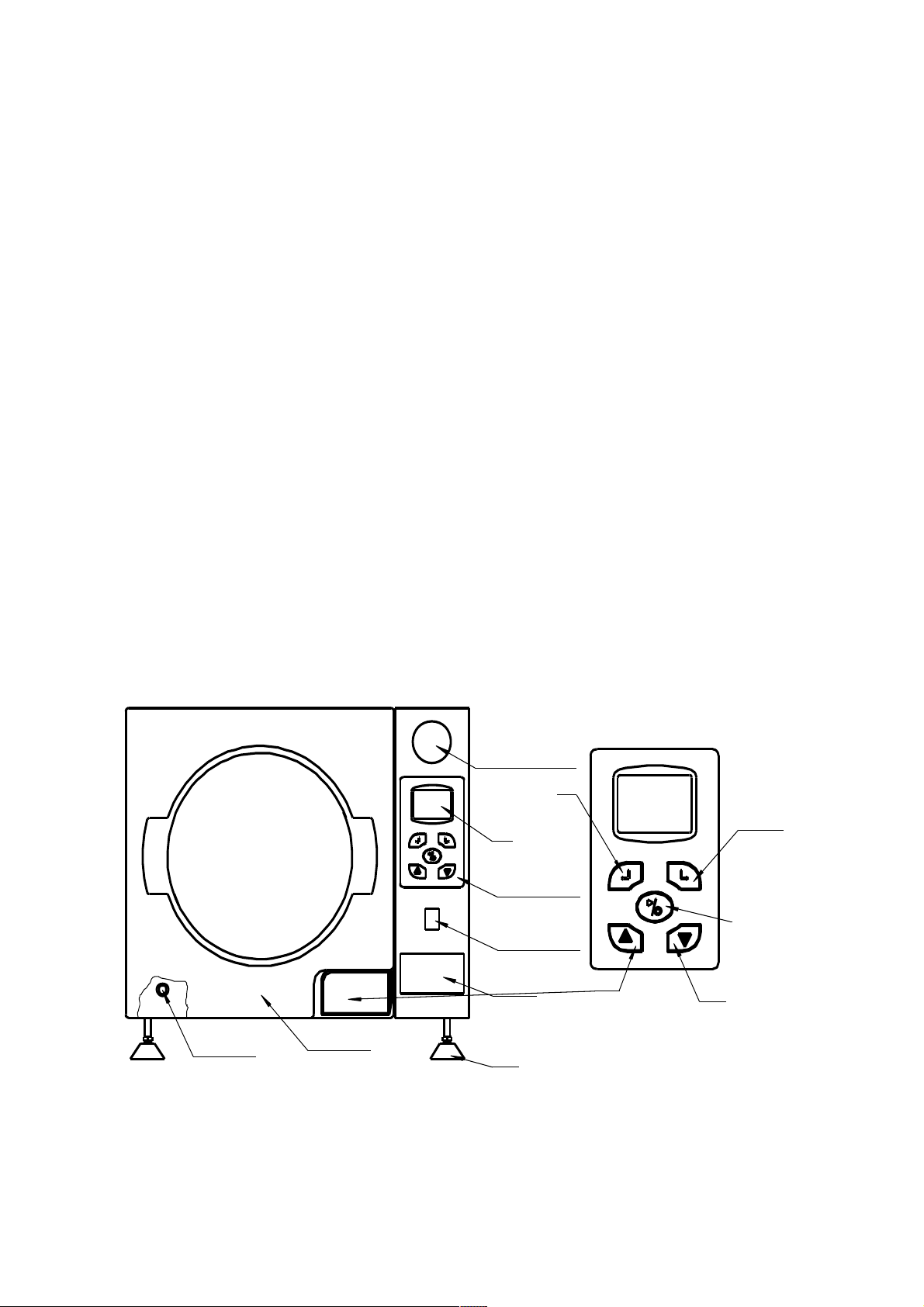

2.1 Overall and Key Pad

Instructions

p re ssu re m et er

L CD

co nt rol p an el

po we r s wi tc h

p rin te r

E sc

se t k e y

把手ad d

do wn

f oot

do or co v e r

wa te r p or t

Page 6

4

高水 位 H IGH LE VEL

L OW LEV EL

低水 位

w a te r l e v e l

2.2

Basic Features

! LCD display, touch key pad for easy operation.

! Independent steam generator device for heating quickly.

! Continuous pulse vacuum system together with air exhaust, thoroughly ensures

saturation of steam and efficient sterilization.

! The pulse vacuum system ensures dry products after sterilization.

2.3 Running: Environmental Requirements

1 Room temperature: 5—40。

2 Maximum relative humidity: 85%

3 The voltage fluctuation is ±10%

2.4 Safety Devices

! Auto protection device against over temperature:This system cuts off power

automatically if the designed temperature is surpassed

! Door safety interlock:The door cannot be opened until there is no pressure in the

chamber and power for heating cannot be switched on until the door is firmly

closed.

! The system will cut off the power when water not enough in steam generator.

Page 7

5

! Safety valve of auto release against overpressure:It opens when the designated

pressure is surpassed.

! Circuit safety device: AC loop short protection.

Chapter 3 Installation

3.1 Installation Procedures

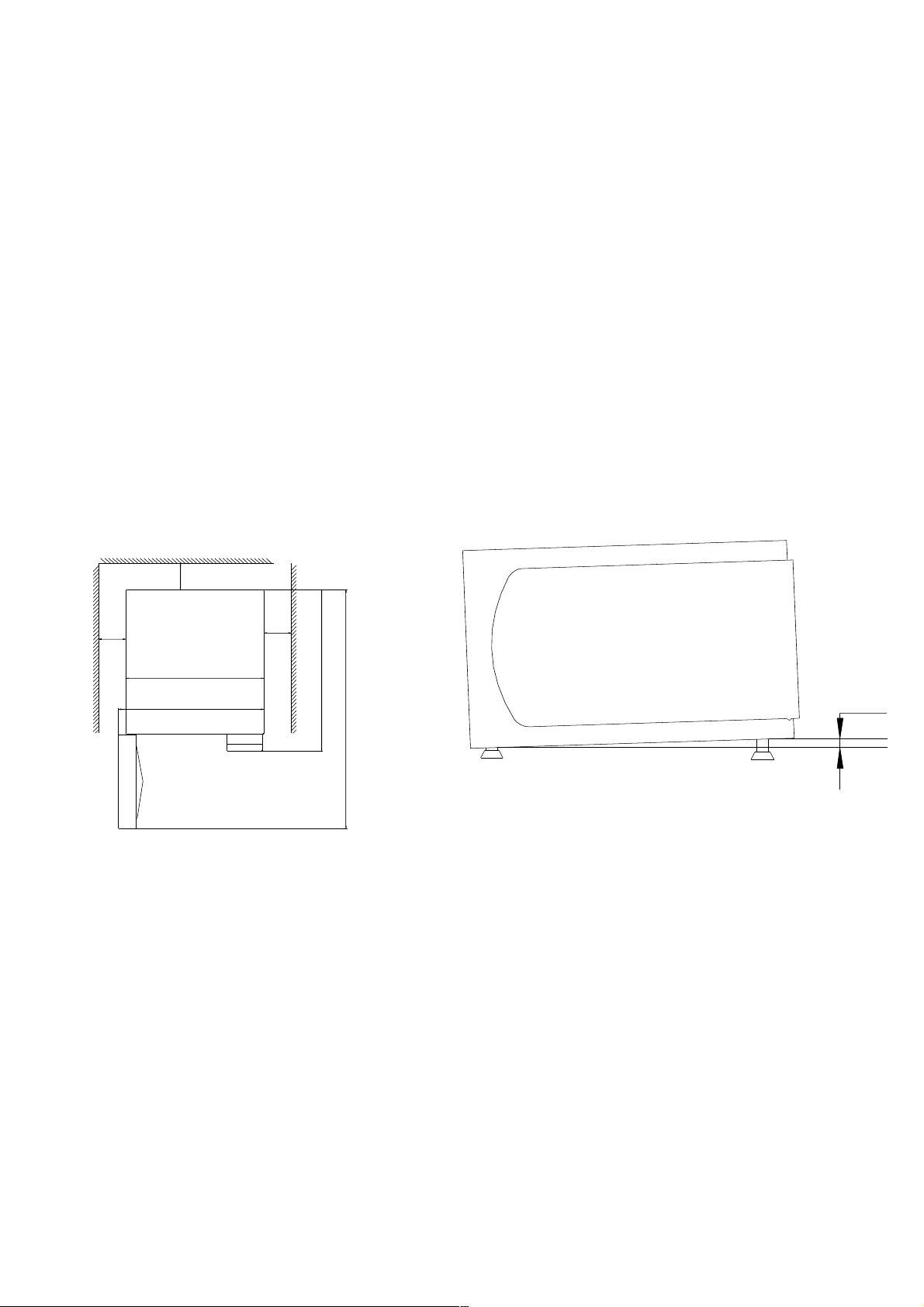

3.1.1 Placement of the Autoclave

Position the equipment on a level and firm surface in a room with good ventilation,

adjust the foot screws to make the equipment level. Allow at least 25cm ventilation space

on all sides of the equipment.

3.1.2 Water Preparation

Water quality:

! Conductivity less than 15µS/cm

! Bleacher content:≤2mg/l

! PH value is 5—7

! Hardness:≤0.02mmol/l

5 c m

2

5

c

m

2 5 c m

2 5 c m

5 8 0

6 2 0

8 2 8

1 2 0 0

Page 8

6

Pour distilled water into water tank. Do not exceed 4.6 litres the first time filling

tank.

3.1.3 Connection of Power

Connect power and turn air switch to ON position.

!

Caution:

Please check the plug is rated for current 15A

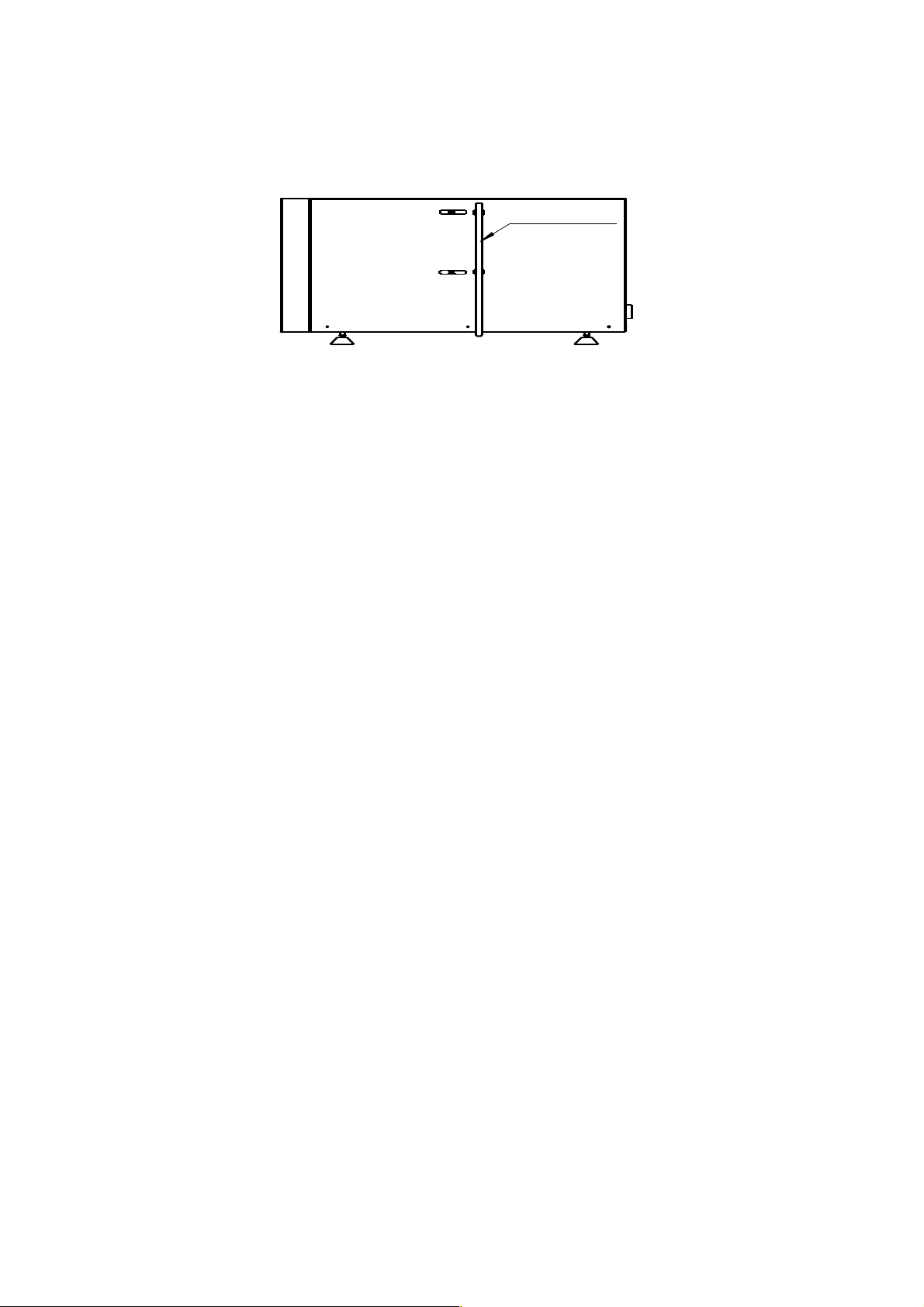

a ir filte rsa f e ty v a lv e

a ir sw itc h

p o w e rlin e

!!!

Caution:

1 Power supply must be grounded to earth.

2 Please attention safety when installing circuit.

3 Tag test the equipment annually.

Page 9

7

3.2 Debugging

3.2.1

Original Parameters Settings

TMQ.CV3250 table –top autoclave should display original parameters at first use. The

setting method is as follows:

1 Switch on power switch, and press “set”, the system entry picture is as follows:

Remark:P0-local atmospheric pressure, T0-local boiling point temperature

2 Set atmospheric pressure,original value is 101kPa,press“▲” key and “▼” key to

change the atmospheric pressure.

3 Press “Esc” key after set value completion.and system will return to original menu.

3.2.2

Opening the Door.

1 Quit original menu, the autoclave will self-test: balance pressure of inside and

outside. Close the door lock, LCD displays the following. This process need

several minutes

2 The screen display picture is as follows after the door lock is turned on, user can

open the door.

!!

Caution:

Please don’t open the door using force until it displays “Please open door”.

Original parameters

Atmospheric pressure:101kPa

Local boiling point:100℃

version:090000

Reminding:

Balancing pressure

XXXk P a XXX. X℃

Please wait

。。。

Reminding:

Door lock open

XXXk P a XXX. X℃

Please open the door

Page 10

8

3 The screen will display program parameters and picture as follows after the door is

opened

3.2.3

Vacuum Test

1 Press“▲” key or “▼” key until screen display 6# vacuum test program shows as

following,close the door and press “on/off” key and the vacuum test program will

start.

2 The buzzer alarming will remind user that the vacuum test program is finished, and

screen will display the following:

3

Leakage rate must be lower than 0.13KPa/min。

3.2.4

B&D Test

1 Press“▲”key or“▼” key until screen display 5#B&D test program picture shows as

following:

1#instrument door : open

Sterilization temperature :134. 0℃

Sterilization time: 4. 0 mi n u t e s

Dryness time: 2. 0 mi n u t e s

6#vacuum door : open

Test leakage rate

6#vacuum t est 20:00

Leakage r at e:

0. ***kPa/ Mi n

Please open the door

5#BDtest door : open

Sterilization temperature :134. 0℃

Sterilization time: 3. 5 mi n u t e s

Dryness time: 2. 0 mi n u t e s

Page 11

9

Put B&D test bag into autoclave and close the door, press “on/off ” key and program

will start.

2 Buzzer will sound after B&D test is finished.

3 Remove the tray and observe the B&D test bag.

!!

Caution:

Please use professional tongs and gloves with safety eyewear to remove the

tray in order to avoid injury.

Chapter 4 Preparation before Using

4.1 Preparation before Instrument Sterilization

The instruments must be cleaned before placing them into the chamber.

For example:Blood or other impurities.

Please refer to following methods:

1 Wash instruments immediately after use to dispose of any residue. It is

recommended that instruments should be washed with an ultrasonic cleaner, using

detergent solutions and distilled water.

2 After cleaning, rinse instruments again in order to ensure the instruments are free of

any residue.

3 Pay attention when arranging instruments on the tray:

Different instruments should be separated into different baskets, for example:

stainless steel instruments in one basket and carbon steel instruments are kept in another

basket. There must be a distance between the instruments. Sterile paper should be used

at the bottom of the basket if carbon steel instruments are to be treated, in order to prevent

the carbon steel from coming into direct contact with the stainless steel basket.

4 Place a sterilization indicator in each basket.

Page 12

10

5 Cuvette, glass bottles etc should be stood upside down vertically in order to allow

cold air exhaust and saturated steam goes inside.

4.2 Preparation for Rubber Tubing

Clean tubing and rinse with warm water. Ensure that both ends of the tubing are open,

without any sharp bends, twists or kinks.

4.3 Preparation for Dressings

Attention: Put dressing package into the tray vertically, avoid touching the inner wall of the

sterilizer.

Page 13

11

Chapter 5 Operation

5.1 Operation Process

1 Ensure there is enough water in the water tank and that the waste water tank is

empty.

To empty water from waste water tank, use water drain plug in the side of the water

tank and drain water.

If you want to drain water from water tank, the user can lay flat the drain tube.

2 Connect power and switch on, put articles into chamber when screen indicates

ready and then close the door.

3 Select correct program according to articles being sterlizied.

Press “▲” key,screen will in turn display 1#instrument, 2#instrument bag, 3#dressing,

4#rubber, 5#B&D test, 6# vacuum test program and related menu. As following:

Press “set” key, screen display mode shows as following:

Press“▲”key or“▼” key,select pre-heating mode,print mode or date and start to set.

For example, if you want to set the pre-heating mode, the background is clear after this

mode is selected, then press “set” key, the value will flicker and now user can press “▲”

or“▼” to adjust. Press “Esc” when setting is finished.

Program

Sterilization

temperature

Sterilization

time

Dryness time

1# instrument

134

4min

2min

2#instrument bag

134

4min

10min

3# dressing

134

6 min

15min

4# rubber

121

20 min

5min

5# B&D test

134

3.5 min

2 min

6#vacuum test

Test vacuum leakage rate of autoclave

Mode set

Pre-heating mode: Close

Print mode: Open

2008/11/19 09:20

Page 14

12

4、 After selecting desired program, press “start” key, when sterilization program is running,

the process are: preparation, pulse vacuum, pulse heating, pulse air exhaust, sterilization,

steam exhaust and pressure release, dryness, balance pressure, sterilization finished.

5、 In autoclave running, the user can observe the parameters information by screen, if the

autoclave is equipped with a printer, all process data can be record by it.

6、 The system will stop running and alarm will appear “surpassed temperature” or “lack of

water”. When these problems appear, please wait for the pressure to balance, buzzer to

sound and screen display “press Esc key”, and then open the door.

7、 When screen display shows “sterilization finished, please open the door” and the buzzer

sounds, the user can open the door and retrieve the articles.

8、 Close the door, turn off the power switch and disconnect power.

5.2 Quit while Autoclave is Running

User can not forcefully open the door when the autoclave is running, if there is a need stop the

program, please press “Esc” and wait for pressure to balance, buzzer to sound, and then press “Esc”

key again to open the door. Screen will go back to the menu picture.

Chapt er 6 Mai nt enanc e

The operations described in this chapter must be followed to keep the sterilizer in good

condition and to reduce breakdowns.

!!!

Caution

:

Before starting, ensure the electric cord is disconnected and there is no pressure in the

sterilizer.

Page 15

13

Daily

! Clean the door gasket with a soft cloth or a sponge.

! Clean the chamber, tray holder and trays with gauze with detergent and water.

Do not use steel wool or steel brush as this can damage the

chamber.

Periodical check:

! Once a week, empty the water tank, waste water tank and clean them with water.

! Once a month, inspect the safety valve.(refer 7.4)

! Once a year tighten the electrical connections and tag test. It should be done by an authorized

electrician.

! If the equipment is not used in a long time, please empty the water tank, waste water tank

and clean them. Close the door and disconnect power.

Chapt er 7 Ge ne r al Mai nt enance and Repai r

CAUTION:

Instructions in this chapter are provided to professionals. When problems occur, read the

instruction manual first, check and maintain the equipment following the instructions. The

maintenance methods have been described in this manual.

7.1 Troubleshooting

Symptom

Possible Cause

Correction

1 The power supply is

on, but the power

indication lamp does

not light

1.1 air switch disconnected

1.2 main power switch damaged

1.1 turn air switch to “ON”

position

testing door lock

2.1 door lock can not back

automatically

2.1 inspect electromagnetism

lock

3.1 door not closed correctly

3.2 door switch loose

3.1 close door again

3.2 adjust door switch

Warning!

Door open

Pressure: 0KPa

Page 16

14

Symptom

Possible Cause

Correction

4.1 too much water in waste water

tank

4.1 empty water from waste

water tank

5.1 safety valve does not open

5.1 open safety valve for 2

seconds and close it in B&D test

process, if will not open please

fit a new one.

6.1 short circuit in heating

controller

6.1 professional to inspect

circuit or fit a new controller

or drops slowly

7.1 high temperature in chamber

7.2 door gasket not sealing

correctly

7.3 air filter is blocked

7.4 steam exhaust pipe or water

drain pipe is blocked

7.1 open the door and try again

after half a hour

7.2 check door seal, may need a

new door gasket

7.3 detach filter and wash it

7.4 clean those pipes

pressure or temperature

not rising or rises slowly

8.1 controller of heater has short

circuit or is damaged

8.2 connection or safety valve

leakage

8.1 inspect and change damaged

parts

8.2 inspect and tighten

connector or safety valve

process, pressure or

temperature not

dropping or drops

slowly

9.1 filter of water drain is blocked

9.1 clean filter

process, pressure not

rising or rises slowly

10.1 air filter blocked

10.1 fit a new air filter

11.1 paper jammed or no paper

11.1 clear or fit new paper

Warni ng!

Ful l of was t e

wa t e r t a n k

XXXk P a XXX. X℃

Warning !

Higher pressure

Pressure : 0KPa

Warning !

Higher temperature

Pressure : 0KPa

Page 17

15

Symptom

Possible Cause

Correction

11.2 no printing ink

11.2 change new printing ink

7.2 How to Remove the Cover of Autoclave

!!!Make sure that the electrical cord is disconnected from the power supply and that there is no

pressure in the chamber.

Removal process:

1 Remove the screws on the side and back

2 Lift up the cover

7.3 How to Check the Safety Valve

In order to prevent the safety valve from blockage, every month under ordinary usage, it is necessary to allow the

steam pressure to escape through it.

1 Run 1# program

2 When pressure of chamber is 210Kpa, pull the ring of safety valve and open it 2 seconds

7.4 How to Replace the Safety Valve

Attention: This method should be used only by professionals.

Page 18

16

1 Remove the fastening screw of the safety valve with a screwdriver, take the valve from

base

2 Replace it with a qualified safety valve. (Ensure it opens at a pressure 0.25Mpa-0.26Mpa.)

7.5 Cleaning the Electromagnetic Valve.

1. Dismantle the sterilizer external cover and find broken electromagnetic valve.

2. Poke the pressing disc with screwdriver.

3. Take out the loop of valve.

4. Open the valve with spanner.

5. Clean the valve with water.

6. Restore the valve.

As following :

Page 19

17

7.2

Cleaning of the filter

Page 20

18

It is located inside and at the back of the autoclave; you can find filter cover at the bottom of

the autoclave.

1. Lift up the autoclave

2. Remove filter cover

3. Remove filter screen

4. Clean filter screen

5. Refit filter screen and cover

7.3 Door interlock system

It is a safety device that prevents the door being opened when there is pressure in the chamber.

Its function as following:

1. Right close the door, the program can start.

2. When the door was locked but electronic lock and can not open, the program can start

3. When pressure balance between inside and outside and the electronic lock get back, the

door can open

Cover of filter

Fi l t er screen

Page 21

19

in ch in g sw it ch

el ect r oni c l oc k

Loading...

Loading...