Page 1

INSTRUCTION MANUAL

Laboratory Equipment Pty Ltd

email: sales@labec.com.au

Ph: 02 9560 2 811 • Fax: 02 9560 61 3 1

www.labec.com.au

2014

Page 2

Operation Manual for

TIT-5

Automatic Potential Titrator

PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATION

Page 3

ADVICE:

Read this instruction in detail before operating the meter.

The meter should be re-tested by metrological department when it is used over one year. And

the meter can't be used until it is up to standard.

The warranty of quality for all electrode is one year. The electrode should be changed in time

after warranty no matter whether it is used, since the performance of it will be influenced.

2

Page 4

CONTENT

I. General

II. Main Specifications and Performance

III. Construction of the meter

IV. Operation

1. Installation of the meter

2. Functions of the meter

3. Mode of titration

4. Switching on the meter

5. Feeding solution

6. Cleaning

7. Titration

7.1 Pre-titration

7.2 Preset end point titration

7.3 Mode titration

7.4 Blank titration

7.5 Manual titration

8. Settlement of titration data

8.1 Present data settlement

8.1.1 Store titration data

8.1.2 Mode of production

8.1.3 Concentration of sample

8.1.4 End point set or amendment

8.1.5 Print

8.1.6 About

8.2 View and print stored data

9. Mode

10. Setting up of parameter

10.1 Setting stirring speed

10.2 Setting time

10.3 Setting printer

10.4 Setting burette

11. Calibration of electrode

12. PH measurement

13. Calibration of burette coefficient

V. Maintenance and Service of the Meter

VI. The Complete Sets of the Meter

VII. Appendix

3

Page 5

I. GENERAL

Model TIT-5 Automatic Potential Titrator is a high precision laboratory analyzer, which is

mainly used in chemical analysis of college, scientific research departments, petroleum chemical

industry, pharmacy, medicine inspection and metallurgy.

FEATURES OF THE METER:

With panel technology: Control unit, volume titration unit and pH/mV measuring unit can form

Potential Titrator; Control unit, volume titration unit and dead-stop titration measurement unit

can form dead-stop titrator; Control unit, volume titration unit and conductivity measurement

unit can form conductivity titrator. User can also change volume titration unit to coulomb

titration unit to form coulomb titrator. The control unit is PC instead of the meter.

With touch LCD, titrating curve chart, one step derivative and graphing contrast analysis are

instantly displayed on the meter. Titration mode can be compiled and amended.

With comfortable operating interface, with English display, menu, graph, quick key etc.

operating method. The meter has the function of protection from electricity cutting off. The

stored data and parameter will be kept even if unusual electricity cutting off happens.

Different electrodes are fitted with the meter to make pH measurement, acid and alkali titration,

oxidation-reduction titration, complex titration and non-water titration. The meter can generate

special titration modes with the functions of pre-titration, preset end point titration, blank

titration and manual titration. The operation range of the meter becomes larger.

With PWM technology, the software adjusts speed in stirring system. Applying the material of

perchloric acid-proof, the titration system can make non-water titration.

The meter can be connected with (Model TP-16, TP-24 or TP-40) serial printers to print

measuring data, titration curve and calculating results.

The meter controlled by computer is able to instantly display titration curve chart, one step and

two steps derivative and graphing contrast analysis. Titration mode can be compiled and

amended. The results of the measurement can also be counted up.

II. MAIN SPECIFICATIONS AND PERFORMANCE

1. Measuring range: pH: (0.00~14.00)pH;

mV: (-1999.0~1999.0)mV;

temperature: (-5.0~105.0)℃;

2. Resolution: pH: 0.01pH;

mV: 0.1mV;

temperature: 0.1℃.

3. Electronic unit accuracy: pH: ±0.01pH ±1 bit

mV: ±0.03% (FS)

temperature: ±0.3℃

sensitivity of controlling titration: ±2mV

4. Burette volume accuracy: 10ml burette: ±0.025 ml;

20ml burette: ±0.035ml.

5. Dripping or feeding rate of burette: 55±10s (burette FS)

4

Page 6

6. Repeatability of titration analysis: 0.2%

7. Electronic unit repeatability: ≤0.2mV

8. Electronic unit stability: ±0.3mV ±1 bit/3h

9. Normal operating conditions:

ambient temperature: (5.0~35.0) ℃

relative humidity: ≤80%

power supply: (220±22)V, frequency: (50±1)Hz;

Without disturbing by electron magnetic field except terrestrial magnetic field.

10. Outside dimensions (mm): 360×300×300 (l×w×h)

11. Weight (kg): about 10.

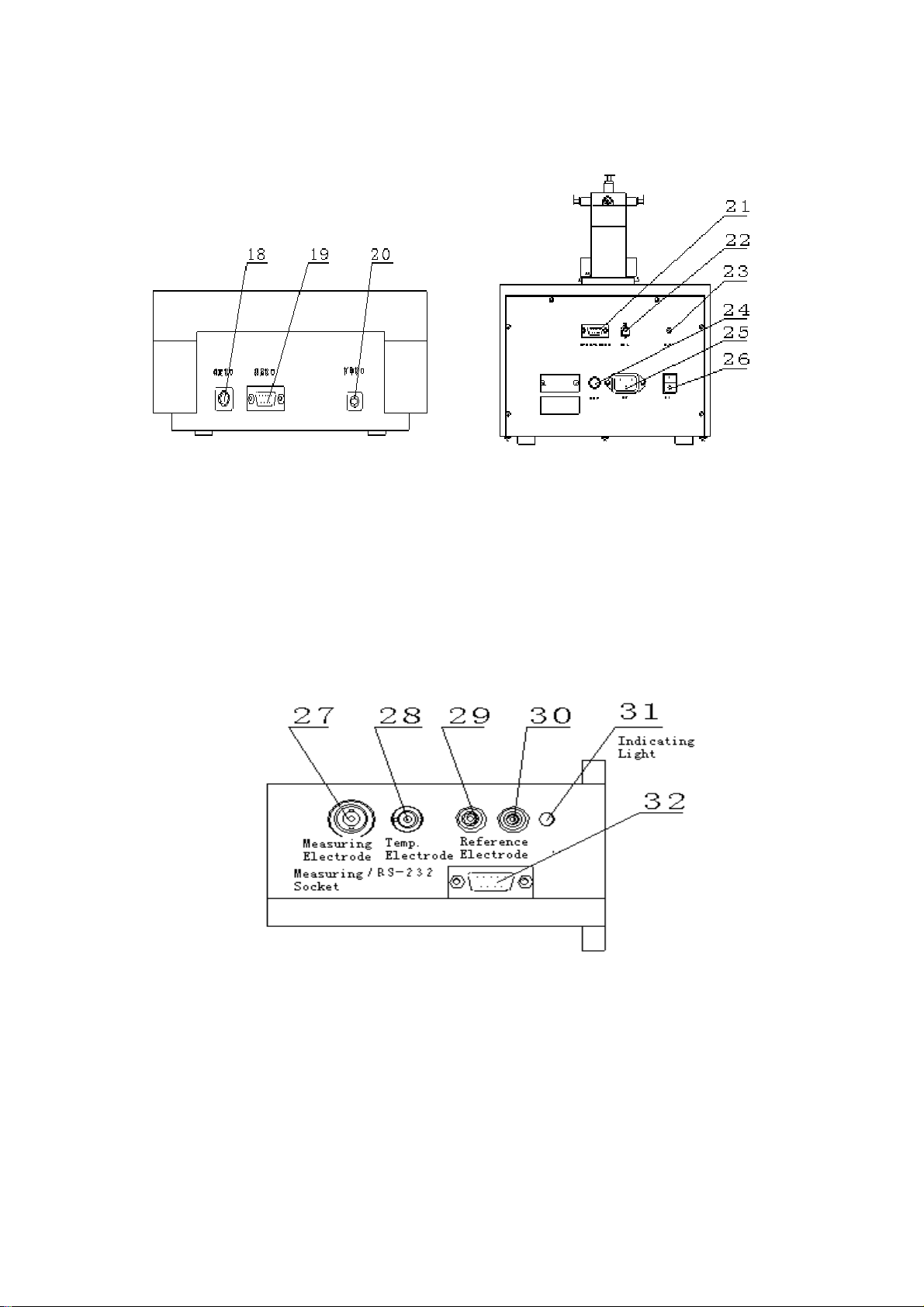

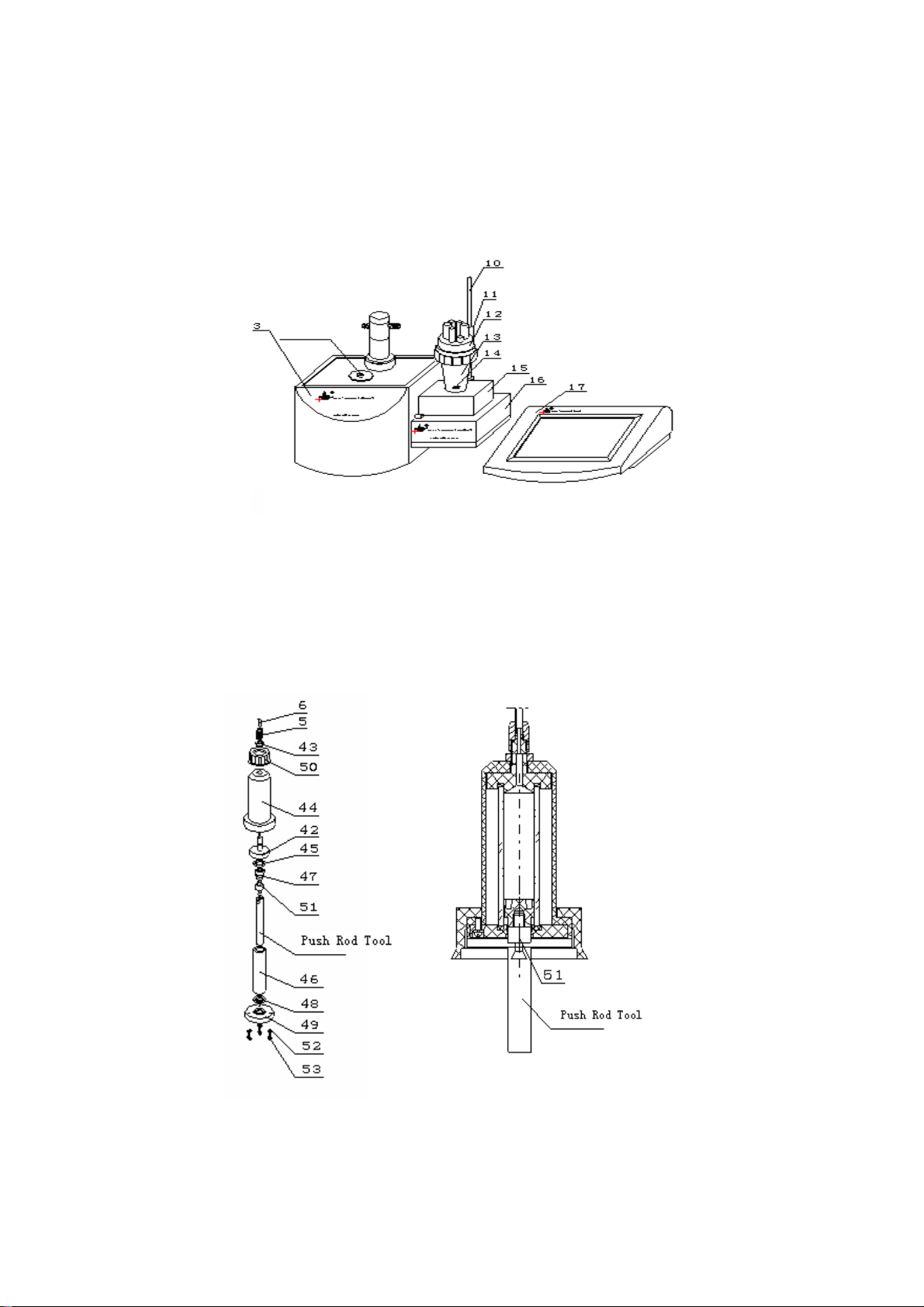

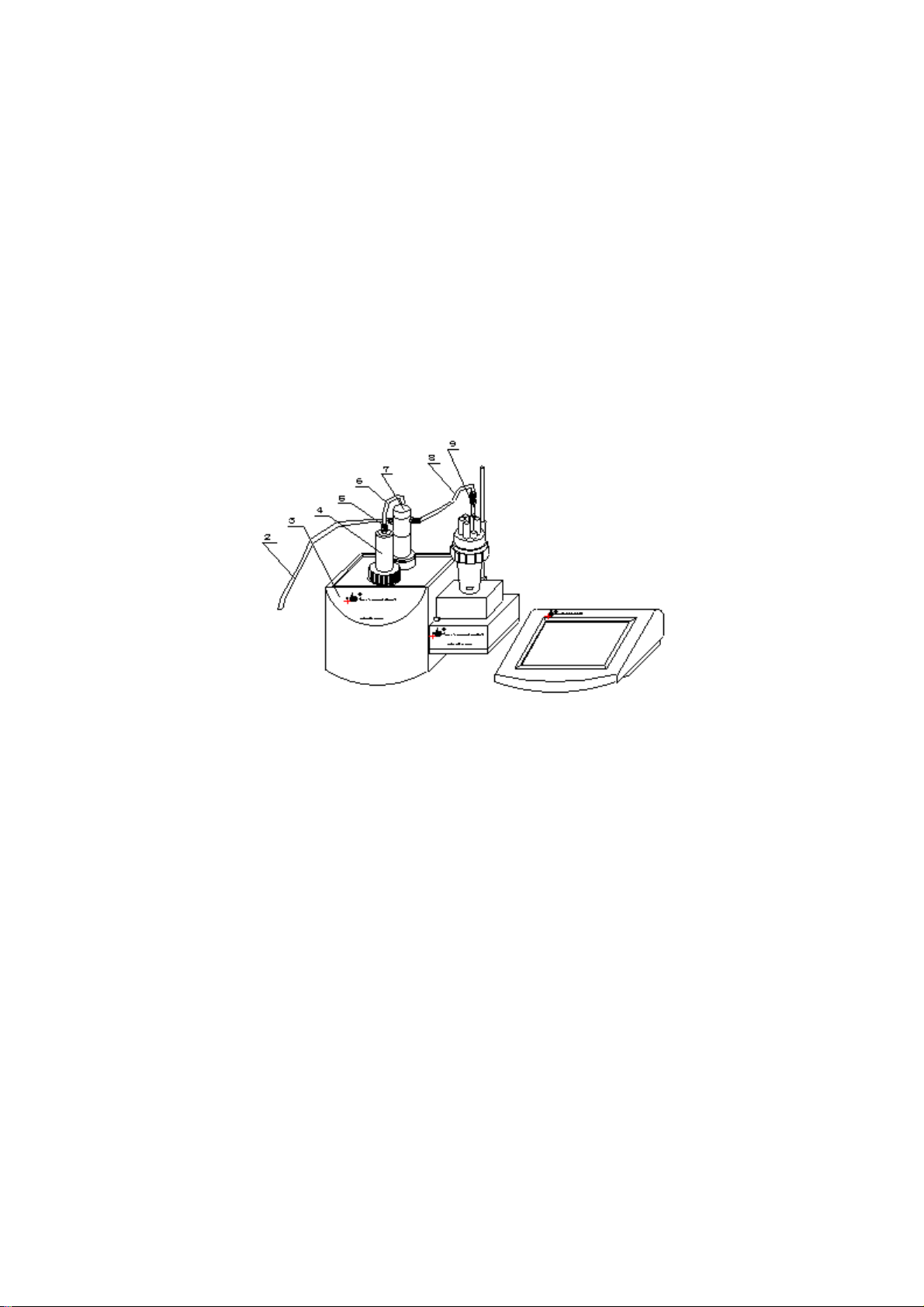

III. CONSTRUCTION

1. Front panel of the meter

Diag.1

(1) Solution bottle (2) feeding tube (3) volume titration unit (4) burette (5) joint nut

(6) feeding tube (7) turning valve (8) feeding tube (9)dripping tube

(10) electrode pole (11) screw (12) beaker supporter (13) beaker

(14) stirring drop (15) stirrer (16) potential measuring unit (17) control unit

As shown in diag.1, three parts constitute the meter: control unit (17), volume titration unit (3) and

potential measuring unit (16). Computer (must be installed TIT-5 automatic titrator control software)

can be replace control unit to control titration.

5

Page 7

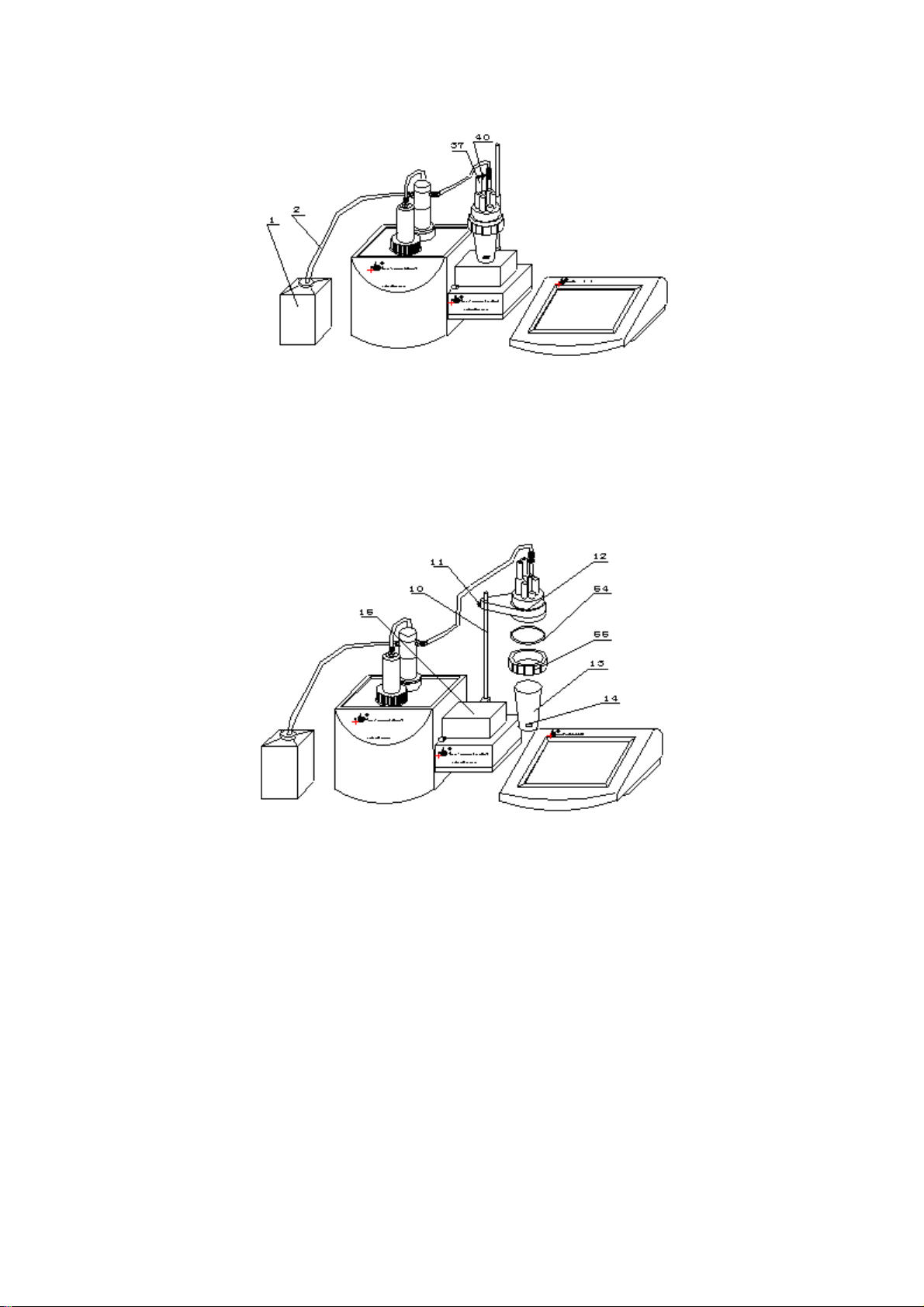

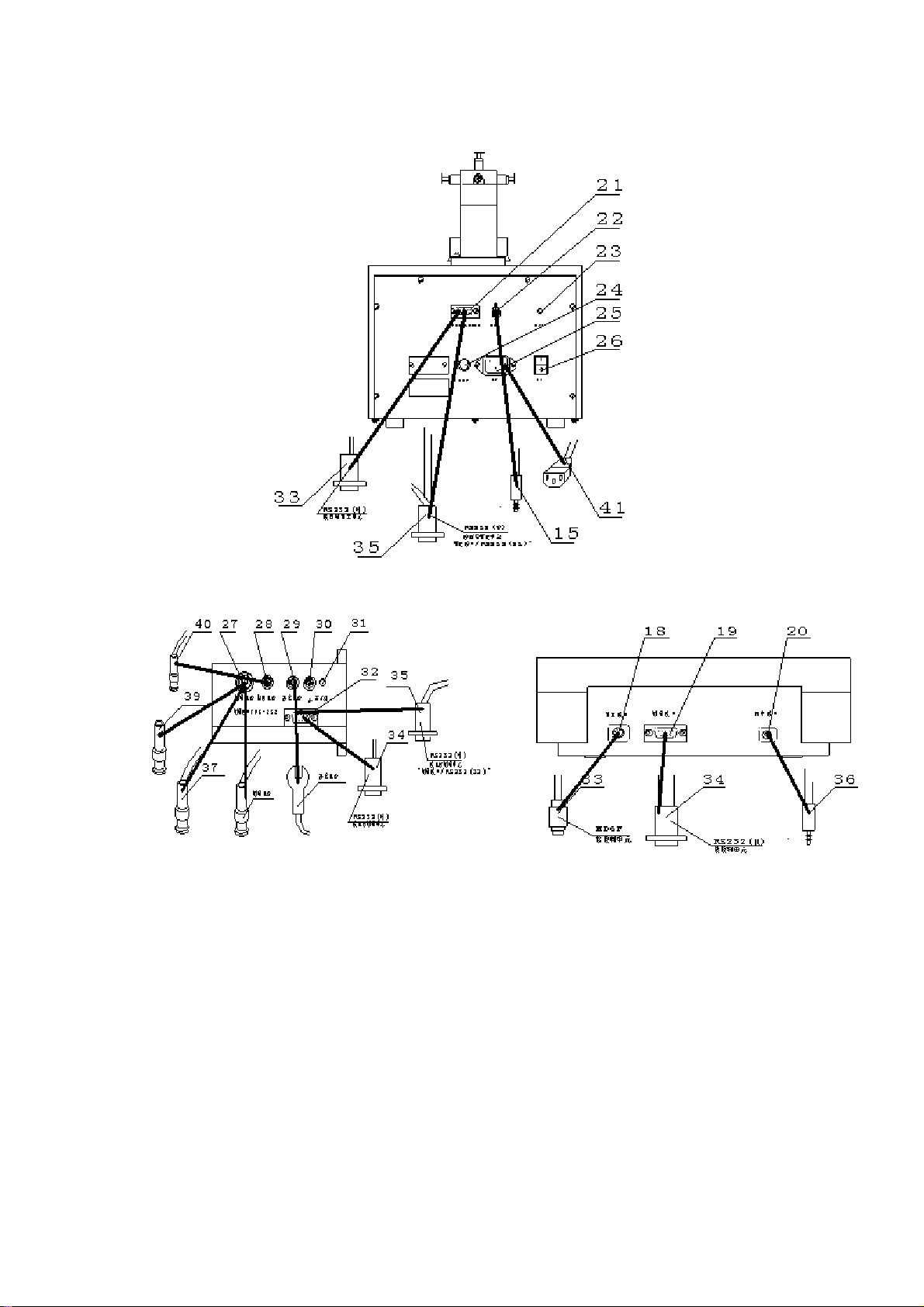

2.Rear panel of the meter

a. Rear panel of control unit b. Rear panel of volume unit

Diag.2 Diag.3

(18) titration socket (19) measuring socket (20) printing socket

(21) titration socket/RS232 (22) stirrer socket (23) indicating light

(24) fuse socket (25) power socket (26) switch

c. Rear panel of potential measuring unit

Diag.4

(27) measuring electrode socket (28) temperature sensor socket (29) reference electrode pole

(30) grounding socket (31) indicating light

(32) measuring socket/RS232: connect control unit ‘titration socket (18) to volume unit ‘titration

socket/RS232’ (21); connect control unit ‘measuring socket’ (19) to potential measuring unit

‘measuring socket/RS232’ (32).

6

Page 8

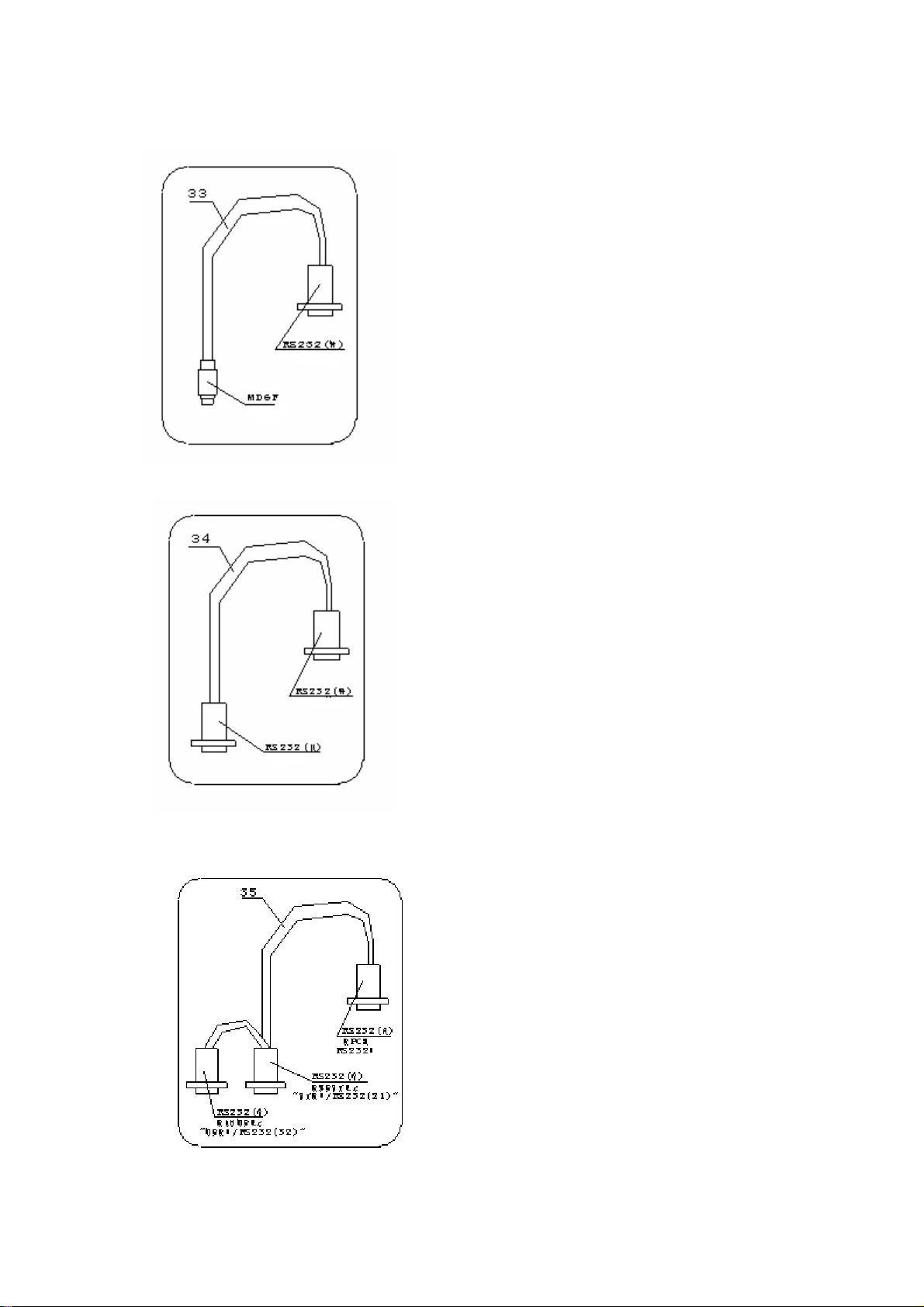

3.Fittings of the meter

(33)Control unit →volume titration unit special

connecting li

ne.

Diag.5

(34) Control unit potential measuring unit special

connecting line

Diag.6

(35) Computer →

TIT-5 automatic titrator

special connecting line

Diag.7

7

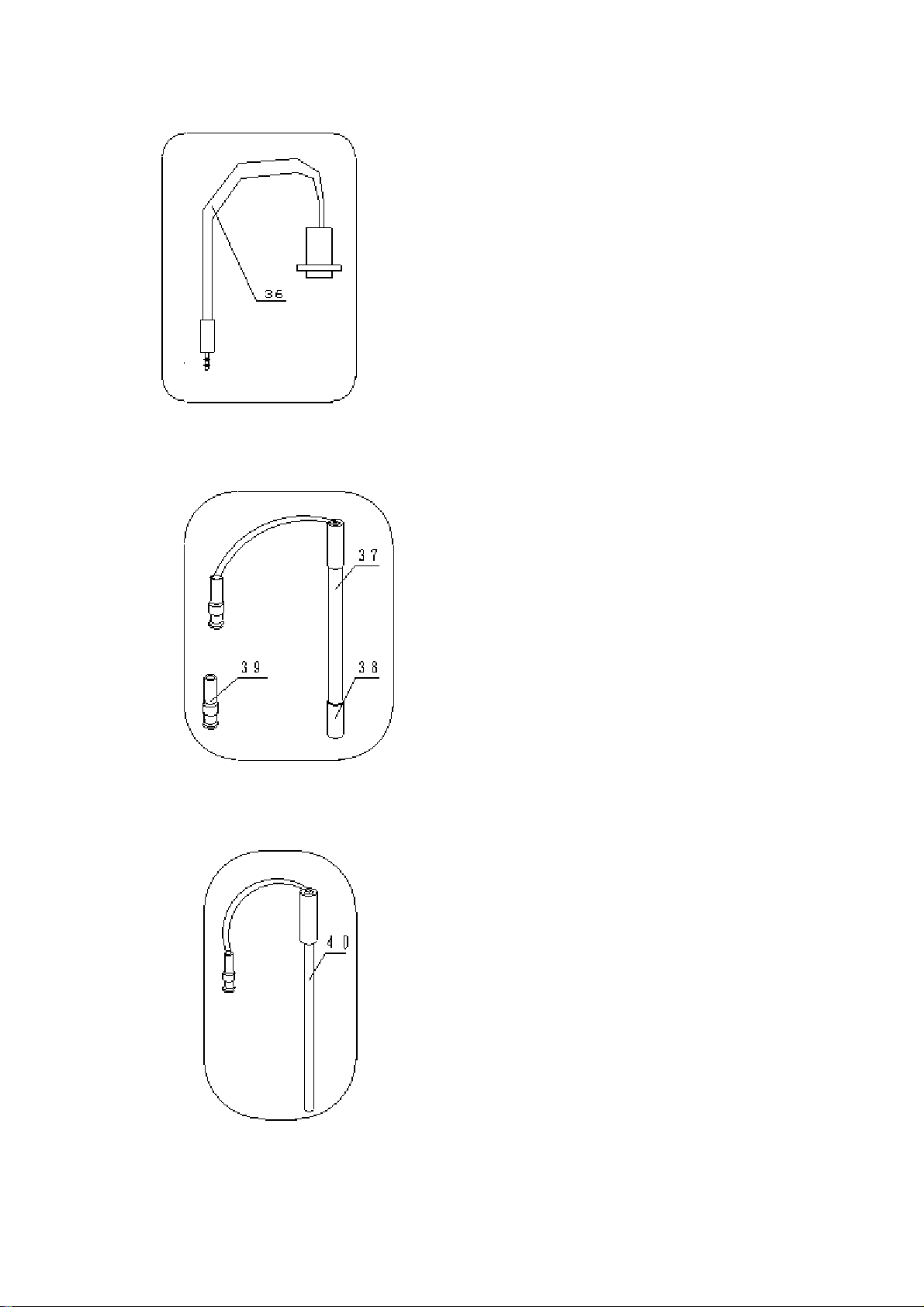

Page 9

Diag.8

Diag.9

Diag.10

(36)

(40) T

TP-40 printer sp

ecial connecting line

(37) E-201-C-9 pH com

(38) Electrode sleeve

(39) Q9 short circuit plug

-818-B-6 tem

perature sensor

bination electrode

8

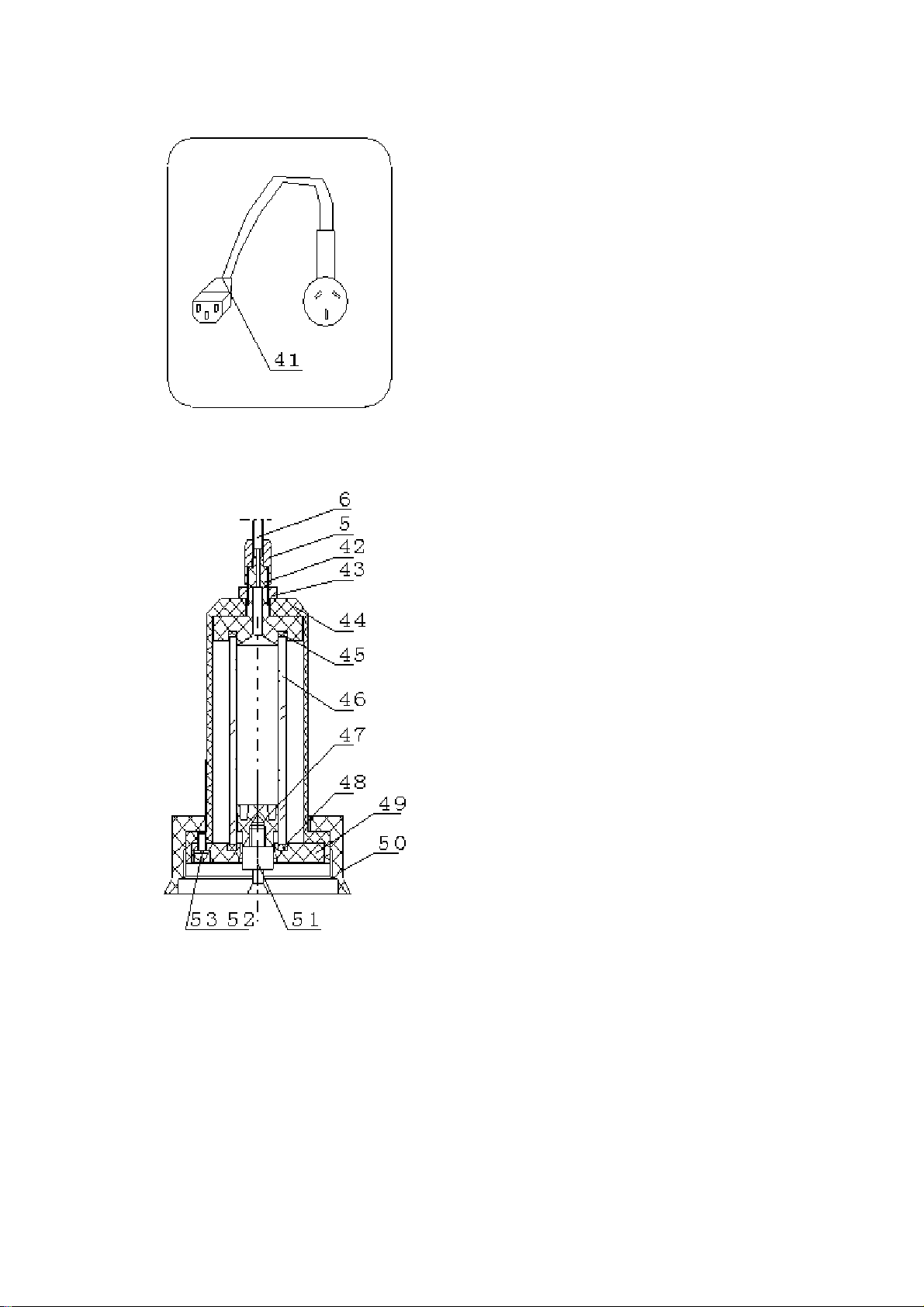

Page 10

(41) Universal power line

Diag.11

(42) Top sealing cap

(43) Small nut

(44) Protecting cover

(45) Top sealing ring

(46) Burette

(47) Piston

(48) Bottom sealing ring

(49) Bottom sealing cap

(50) Big nut

(51) Piston pole

(52) Spring washer (3 pieces)

(53) Screw M3×8 (3 pieces)

Diag.12

9

Page 11

IV. OPERATION

1. Installation and Connection

1.1 Installation of the meter

Diag.13

a. Put volume titration unit(3) and control unit on table, put stirrer on potential measuring unit(16)

according to mentioned Diag13 and insert electrode pole(10); install beaker supporter (12) and

beaker(13) respectively, put stirring drop(14) into beaker(13), then tighten stirrer(15) and

beaker(13) with screws(25).

Diag14

b. Before titration, burette must be cleaned especially when you are going to do titration of different

concentrations or different solutions. Installation of burette (4) is shown on left side as diag14,

take out push rod tool from spare parts, connect it to the piston pole (51), shown as below

10

Page 12

diagram14, then according to diagram 14, firstly take off 3 pieces of screws (M3×8) (53), 3

pieces of spring washers (52), then take off bottom sealing cap (49), bottom sealing cap (48),

burette (46) and piston (47) respectively, clean the burette with distilled water repeatedly, then

absorb water drops on the burette (46) with distilled paper.

Install burette according to diagram 14, firstly install the piston (47) into burette from the top with

push rod tool, then install the burette (46) and piston (47) into protection cover (44), the top of

burette (46) should be tightly closed to the top sealing ring (45) but please be careful not to break

the burette (46), then install the bottom sealing ring (48) and the bottom sealing cap (49) properly.

At last, tighten the burette with 3 pcs of M3×8 screws (53) , 3 pcs of spring washers(52). Please

note that when tighten with screws (53), you must tighten it evenly to prevent burette from

leaking probably that may influence titration accuracy. Pull the piston (47) to the lowest point

with push rod (see diagram 14)

Diag.15

c.Install the burette (4) on volume titration unit (3), please note: the piston pole on the burette

should be inserted into the groove of the push rod, then tighten the screws (50) on the burette

(4); insert dripping tube (9) according to diagram 15; then connect the feeding tube (2) (the

longest one), the feeding tube (6) (the shortest one), feeding tube (8) by tightening joint nut (4).

Note: Turn the joint nut (4) tightly to prevent from leaking.

11

Page 13

Diag.16

d. Insert T-818-B-6 temperature sensor (40), take off sleeve (38) on E-201-C-9 combination

electrode (37), then insert E-201-C-9 combination electrode (37), put feeding tube (2) into the

bottom of solution bottle (1) all according to diagram 16.

Diag.17

e. While the meter is doing titration, if you need to change solution, the beaker should be taken

apart and assembled. Shown as diagram 17, loosen the screws (11) first, raise the whole

beaker system higher and turn to the position according to diagram 17, then turn the screws

(11) tight, hold the beaker (13) with hand, loosen the big nut (55), take out beaker (13), pour

solution out of the beaker (13), wash it for several times. Take notice: stirring drop (14)

must be cleaned as well. Fill the beaker (13) with measured solution. Take notice: stirring

drop (14) must be put at the bottom of the beaker (13). Install the beaker (13) to the

position, tighten the big nut (55) and loosen the screws (11), move the beaker system down

to make the beaker (13) touch the surface of the stirrer (15). The beaker should be put in the

middle of the stirrer (15). Finally turn screws (11) tight.

12

Page 14

1.2 Connection of the meter

Diag.18 Rear panel of volume titration unit

.19

Diag

Diag.19 Rear panel of potential measurement unit Diag.20 Rear panel of control unit

a. Use control unit → volume titration unit special connecting line(33) to connect ‘titration

socket’ (18) under control unit and ‘Titration Socket/RS232’ (21) under volume titration unit.

b. Insert the joint of Stirrer (15) in the socket of ‘Stirrer’ under volume titration unit. Use TP-40

printer special connecting line to connect printer to ‘Printing Socket’ (20) under control unit.

Inset universal power line (41) into power socket of control unit. Screw down the fuse cover

off the fuse socket, put the fuseΦ5×20 (1A) from spare parts in the fuse socket, then tighten

the screw of the cover (fuse is already put in when the meter is ex-factory).

c. Use control unit → potential measuring unit special connecting line (34) to connect

‘Measuring Socket’ (19) under control unit with ‘Measuring Socket/RS232’ under potential

measuring unit.

13

Page 15

d. If the meter links up with computer, use computer → TIT-5 Automatic potential Titrator

special connection line (35) to connect hole style socket with RS232 socket on computer.

Separately connect the needle style socket to ‘Titration Socket/RS232’ (21) under volume

titration unit and ‘Measuring socket/Rs232’ (32) under potential measuring unit.

e. Insert T-818-B-6 temperature sensor (40) joint into ‘Temperature Sensor socket’ (28) under

pH/mV measuring unit. Insert E-201-C-9 pH combination electrode (37) into ‘measuring

electrode socket’ (27) under potential measuring unit. When measuring electrode and

reference electrode is used, please insert measuring electrode into ‘Measuring electrode

socket’ (27) under potential measuring unit and insert reference electrode into ‘reference

electrode pole’ (29) under potential measuring unit. Now the meter is ready to use.

2. Functions of the meter

The main titration modes of the meter contain pre-titration, preset end point titration, mode

titration and manual titration. Different electrodes can be fitted with the meter to make different

titration, such as: acid and alkali titration, oxidation-reduction titration, complex titration,

non-water titration and permanent pH measuring etc. The above titrations are generated into

special titration modes. The meter can be controlled by computer. Titration curve, titration curves

of one step and two steps derivative are instantly displayed on computer.

3. Mode of Titration

Pre-titration: pre-titration is one of the main titration modes of the meter, many modes titration

are generated from pre-titration mode. The meter is able to find titration end point through

pre-titration mode, thus special titration mode is generated.

NOTE: The end point jump parameter of pre-titration mode is classified into: large, middle,

small, the default value of this parameter is set "middle". If it has reaction to low end point

jump, the users must set this parameter to "small" (see 6.7 setup of pre-titration parameter in

detail.)

Preset end point titration: If users know the titration end point value of pH or potential, preset

end point titration function is available. Input end point number, end point pH or potential

value and pre-controlled point value (pre-controlled point is transferring point from high speed

titration to low speed titration), you can begin titration.

Mode titration: The meter provides two kinds of special mode titration.

a. HCl NaON (0.1 mol/L)

The rest mode titration is to be

b. K2Cr2O7 Fe2 (0.1 mol/L)

generated with pre-titration by users. Users will get titration

parameter after pre-titration, press "Mode" button, store this parameter in the meter, special

titration mode is thus generated. Titration can be done later only if this mode is down loaded

(see 8.12 "Generation of mode" for detail)

Manual Titration: Set added volume to make manual titration. This titration mode will help

users find titration end point.

Blank Titration: This mode is suitable for the titration which demands less titrant (below 1m1).

In this mode, every time the meter adds 0.02 ml of volume (users can amend this parameter),

users can also set pre-added volume parameter so as to make titration speed higher. Thus the

meter will automatically search for titration end point to generate special titration mode

14

Page 16

4. Switch on the Meter

K

Use can connect TIT-5 volume titration panel, mV/pH measuring panel and control panel

together to form the automatic potential titrator, following call meter in short. After mentioned

panels connecting properly, switch on the meter, it can be used now.

When meter is switched on, it starts self-checking and then displays ‘TIT-5’ automatic potential

titrator’. After a while, the meter starts to check connected titration panel and measuring panel.

When checking finished, the checking result shown as follows:

If the connection is wrong or connecting line of the meter or the meter itself, meter will reminder

user automatically. Shown as follows. Following is the diag.22 in case the connection of

measuring panel fails. At this time, user should cut off the power, check the connecting line

carefully, if the connection is correct, then the problem maybe from the meter itself., please

contact with our company for help. Of course, user can press ‘Enter’ button to continue, but meter

will limit some operations automatically, which cause user not able to use all functions.

When the meter finished self-checking, it enters into measuring status automatically. Shown as

follows is the starting status and all functions of the meter starts from here.

Diag.23 For starting status mV

Diag.21 For checking result

Diag.22 Connection of measuring panel fail

View Titrate Mode Set Calibrate

Titration panel READY +

System checking finished

Present meter is:

Measuring panel … mV/pH

Titration panel …… volume titration

System warning

Connection of measuring panel fail

Enter

100.1mV

25.0℃

Titrate

Clean

Feed

10/21

15

Page 17

The meter shows menu on the top of screen which including ‘View’ (if there is titration data or

stored data), ‘Titrate’, ‘Mode’, ‘Set’, ‘Calibrate’ etc In the middle shows measuring result such as

current potential value (or PH value) and temperature value. On the right side is the press button

in common use including ‘Titrate’, ‘Clean’, ‘Feed’ and at the bottom, it displays the status of

titration panel, stirrer chart, electrode slope chart and system time. User can enter the

corresponding function panel by pressing menu, press button or the chart.

In case the connection of titration panel or measuring panel fails, user can press ‘Enter’ button

continue the operation, the current potential area displays as ’88.888’ and the status of titration

panel displays ‘Off Line’.

The meter has following functions: Feeding solution, Cleaning, Titration (including pre-titration,

preset end point titration, mode titration, blank titration and manual titration). It can calibrate

electrode slope, select burette, set burette coefficient, set stirrer speed, set system time, select

printer etc It displays titration curve dynamically in the process of titration. When titration

finished, user can view and stored titration data. And the meter can also generate user’s own

mode according to user’s requirement. The meter provides two sets of system mode and allow

user to view mode, delete mode, edit mode, hereafter we will introduce all these functions.

5. Feeding Solution

In the starting status, press ‘Feed’ bottom, titration panel starts to feed solution. The meter

displays as follows:

View Titrate Mode Set Calibrate

Feeding solution

Feeding solution ……

End

Titrate

Clean

Feed

Titration panel DOWN

Diag.24 Feeding solution of titration panel

When feeding finished, meter will be back to starting status automatically. In the process of

feeding, if user can terminate feeding by pressing ‘End’ button, titration panel stop feeding and

meter remind user to Enter, shown as follows:

View Titrate Mode Set Calibrate

Feeding solution

Terminate feed

Enter

ing?

Exit

End

Titrate

Clean

Feed

Titration panel PAUSE

Diag25.Pause in process of feeding solution in titration panel

16

Page 18

At this time user can press ‘Exit’ to continue feeding or press ‘Enter’ to terminate feeding, meter

returns to starting status automatically.

6. Cleaning

In starting status, press ‘Clean’ button, meter displays as follows:

User can set cleaning times at mostly 10 times. When setting finished, press ‘Start cleaning’ button

to start, shown as follows:

When cleaning is finished, meter returns back to starting status automatically and the same user can

terminate it in the process of cleaning at any time.

7. Titration

The meter provides 5 kind of titration modes: pre-titration, preset end point titration, mode

titration, manual titration and blank titration. In starting status, press ‘Titrate’ button or press

‘Titrate’ in menu, meter shows all titration modes, user can select needed titration mode for

View Titrate Mode Set Calibrate

Cleaning

Number of cleani

Titration panel READY

Diag.26 Set number of cl

View Titrate Mode Set Calibrate

Cleaning

Number of cleaning times …… 05

Number

Titration panel Down

Diag.27 Cleaning in titration panel

01 time of cleaning

05

ng times

Titrate

Clean

Start cleaning

eaning times in titration panel

End

Feed

Titrate

Clean

Feed

17

Page 19

corresponding titration, shown as follows:

View Titrate Mode Set Calibrate

Titration

Pre-titration

Preset end point titration

Mode titration

Blank titration

Manual titration

Enter

Exit

Titrate

Clean

Feed

Titration mode READY

Diag.28 Titration mode selection

7.1 Pre-titration mode

Pre-titration mode is one of the main titration modes, many mode titration generate from

pre-titration mode. Meter can find titration end automatically through pre-titration then

generate special titration mode. When user is not familiar with some of titration or not clear

with the actual titration end, he can use pre-titration mode. In starting status, press ‘Titrate’

button, meter displays all titration modes, user select ‘Pre-titration’ then press ‘End’ button or

select ‘pre-titration’ again, meter enters into pre-titration, shown as follows:

Pre-titration/parameter setting

MV titration pH titration

Balance potential switch: on

Value: 1mV

MV/pH Titration Jump Value Set

EP1 end point

Jump value: large middle small

Value: 100

Balance time switch: on

Value: 10s

Minimal volume: 0.02mL

End volume: 40mL

Start titration Stirring Resume set

Diag.29 Parame

ter setting for pre-titration mode

Before pre-titration mode, user needs to set some parameters for pre-titration mode. The parameter

including: mV/pH titration parameter, minimal volume parameter, balance potential parameter,

balance time parameter, end point jump value parameter and end volume parameter. This part of

parameter controls pre-titration mode of the meter, amending of it will influence the result of

pre-titration. In the most situations, it is unnecessary for users to amend this part of parameter; the

titration demand will be satisfied.

18

Page 20

7.1.1 mV/pH Titration Parameter

mV/pH titration parameter is used to indicate the titration is mV titration or pH titration.

When user select mV titration, the current titration is mV titration, all displayed parameter are

according to mV and vice versa.

7.1.2 Balance Potential Parameter

The process of pre-titration mode is: Firstly meter will add certain amount of titrant, when

adding finish, meter sampling the potential value, then calculate the amount to add for next

time according to potential changing value between before adding and after adding. Adding

again, sampling, calculating and repeat like this till titration finished. After titrant added,

meter will sampling the potential after adding and calculate the amount to add for next time,

so the potential sampling is very important. The meter allow user to set potential balance

range which is also called potential changing range. When titration started, the meter will

judge, sampling current potential, if the change of current potential satisfy the balance

potential set by user, this potential is valuable, otherwise the meter will keep on waiting till

the potential is satisfied. Of cause, meter allows user to switch off the judgment of balance

potential.

7.1.3 Balance Time Parameter

Same as balance potential parameter, balance time parameter is also used to control the

potential sampling after adding titrant. When potential varies big and cannot satisfy the

balance condition, it is necessary to use time parameter to limit, otherwise the meter will

always wait for the balance of potential. The meter allows user to set balance time i.e. if

potential cannot balance, the meter can still continue titration when set balance time is up. So

if potential satisfy balance potential condition first, balance time condition will be invalid;

when user switch off balance potential parameter, the meter will take balance time parameter

as valuable (user is not able to switch off Balance Time Parameter and Balance Potential

Parameter as the same time); vice versa.

7.1.4 Minimal Volume Parameter

User is allowed to set minimal adding volume, usually is 0.02mL

7.1.5 End Point Jump Value Parameter

End point jump value is the final basis for meter to judge the end point, it is divided into three

grades: large, middle and small, user only need to select large/middle/small and no need to set

specific jump value. If user observes that end point jump of titration is somewhat low or noise

is too large, with the result that titration end point is difficult to find, we suggest that user

reset this part of parameter (set end point jump to "small" if end point jump is low, and set

end point jump to "middle" or "large" if noise is large).

In order to satisfy the requirement of multi-end point titration, the meter allows five end

points at most in any titration. There are five independent controlled values corresponding to

five end points. The controlled value can be set to be large or small independently. It is

impossible that various titration to have the united mode or method. In consideration of

demand of general users, we divide end point jump into three grades that is large end point

19

Page 21

jump, middle end point jump and small end point jump. Middle end point jump can satisfy

general titration demand, it's unnecessary for the users to know the concrete end point jump

value or to make the concrete set, if by any chance the meter can't satisfy the titration demand,

please reset corresponding end point jump value, therefore, generally speaking, that'll do if

users select end point as large, middle and small.

After user know something about needed titration, he can select end point jump value in

st

correspondence to a certain end point, e.g. set end point jump corresponding to the 1

nd

point to "large", the end point jump of 2

st

Select “1

large. Press “1

you have set 2

end point” and then select "large" means you have set 1st end point jump value to

st

end point” again, the meter displays “2nd end point”, select “small” means

nd

end point jump value to small.

end point to "small", the operation is as follows:

end

If user hopes to know end point jump value corresponding to every end point, then he can

press “number end point” in sequence, the meter will display in sequence the end point value

in correspondence to each corresponding end point. If user wants to amend the value, select

jump value directly and enter new jump value.

NOTE: 1. Pre-titration end point jump value controls pre-titration directly, amendment of end point

jump value will influence directly the next titration. Please pay attention before revising.

2. Generally, it is no need for user to amend the jump value

7.1.6 End Volume Parameter

While pre-titration, if a titration end point is found, the meter will automatically search for the

next end point, in the meantime, titration does not stop, Press "Stop" button or according to

end volume setup value, titration will stop. End volume default is 40ml, user can reset it

according to actual requirement. When adding volume reaches to user’s set end volume,

meter will stop titration automatically.

If user needs to amend some parameter, please select a certain parameter and meter will jump

out a key-in window, input necessary corresponding data is fine.

Reminder: All these parameter control the whole titration directly and any amendment of

parameter will influence the final titration results. So please understand all these parameter

before amendment.

The meter has the function to resume the original parameter (ex-factory parameter), when

user find set parameter is incorrect or is not able to finish some titration, he can press

“Resume set” to resume.

For easy use, user can set speed of stirrer here, when user selects pH titration, he can calibrate

electrode slope directly (press “Calibrate” button, then press “Enter”)

When all parameter setting finished, press “Start Titration” button to start pre-titration.

20

Page 22

nnnnn

End

Pre-titration>Titration panel READY 00:04:18

30 Display in titration

Diag.

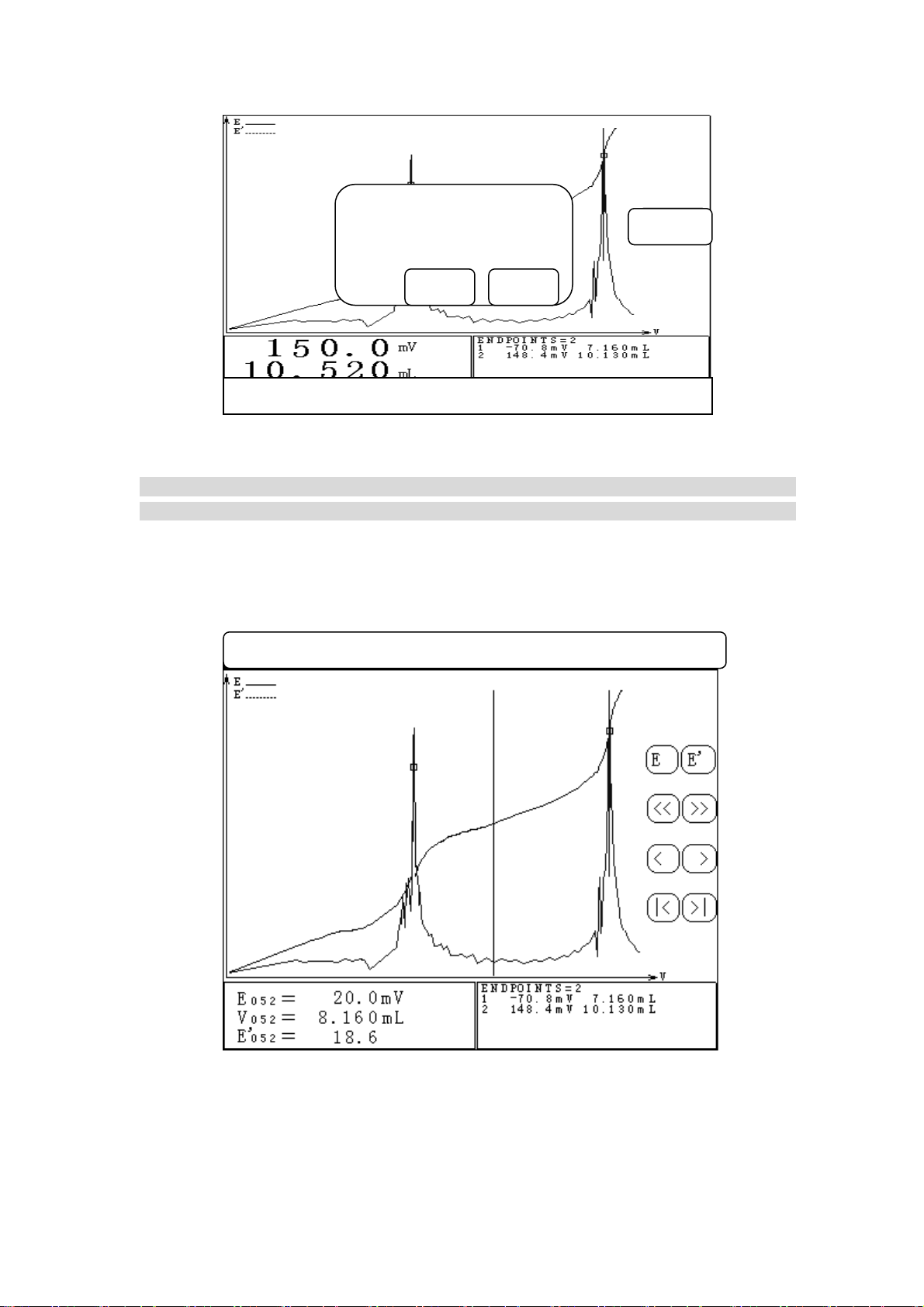

When titration started, the meter will display as following diag.30 On the bottom of left corner is

current potential (or pH) value and current volume of titration. On the bottom of right corner is end

point area that displays the end point figure and end point value. On the bottom is the name of

current titration, status of titration panel and actual titration time. On the top left is titration curve,

actual line is titration volume curve corresponding to potential, false line is titration volume curve

corresponding to one time differential.

When titration starts, meter will switch on the stirrer automatically and stir for 10s with set stirring

speed. At the same titration panel starts feeding solution, after feeding finished, meter can start

titration actually. Meter will control the whole process of titration according to pre-titration mode

and no need to interfere. Automatic adding, automatic judgment, automatic sampling, automatic

judge end point, displaying dynamic state of titration curve and titration data while adding will be

done by meter. Meter will chirp for three times to remind user when finds end point. Meter will not

stop when it finds one end point, it will go on titration to find next end point. If user consider all end

points are found, he can press ‘End’ button to terminate titration and meter will display ‘end

titration’ to reconfirm whether user really want to end titration. User can terminate or go on titration

according to actual need. If meter finds have adding over set ending volume (max volume), it will

remind user whether to continue and user can select end titration or go on titration according to

actual need. Press ‘End’ button to end titration, press ‘ Exit’ button to continue. Display as follows:

21

Page 23

Ending volume for your

setting adding is o

ver!

End titration?

Enter Exit

End

Pre-titration>Titration panel PAUSE 00:04:18

Diag.31 Display for titration of end volume

NOTE: If the meter finds that 5 pcs end points have been found, it will stop titration directly no

matter whether the titration has other end points or not.

When titration finished, meter will switch off the stirrer automatically and control the feeding of

solution till end, then meter enters into viewing status, the display of whole titration curve and end

point results as follows:

Store Mode Concentration End point Print About

Diag.32 Displ

ayed current titration data when titration finished.

Menu includes: ‘Store’, ‘Mode’ (if there is end point), ‘Concentration’ (if there is end point), ‘End

point’, ‘Print’, ‘About’ and ‘Switch off’ buttons. In the middle is titration curve that user can view

the titration data. On the bottom of left corner is the titration data corresponding to indicating line

22

Page 24

including potential, volume and differential, etc. On the bottom of right corner is end point area that

displays number of end point and corresponding end point value.

From here user is allowed to store titration curve, print titration result, print titration data, print

titration curve, view titration parameter and time, set or cancel end point. If titration has end point,

user is also allowed to generate special panel and calculate the concentration value of sample.

(please see ‘Settling of titration data’ for detailed operation.)

Before next titration, current titration data will be stored. User can press ‘View’ button in menu

under starting status, select ‘View current data’ and then press ’Enter’ button to enter again.

NOTE: While making pre-titration, please pay attention to the following:

1. When making low jump titration, the user must select jump "large, middle, small" to "small",

otherwise, the meter won't be able to find titration end point.

2. While making pre-titration, when the meter has found titration end point, the user should press

‘Stop’ button to stop titration, because the meter won't stop titration automatically even if it has

found titration end point.

3. Before pH titration, please calibrate the electrode first (see "electrode calibration" chapter).

7.2 If titration end point value is known, user can arrange titration with Preset End Point Titration

Mode. User only need to input number of end point, end point value (pH or potential value)

and pre-control point value (pre-control point is the transferring point from high speed

titration to low speed titration), then can start titration. At starting status, press ‘Titration’

button, select ‘Preset end point titration’ to enter into ‘Preset end point titration mode’,

displayed as follows:

Preset end point titration/Parameter Setting

MV titration pH titration

MV/pH titration

End point number 1

Switch of pre-control value off

Value:

Pre-control set

First end point

Pre-control point: 500mV

End point: 300.0mV

Time delay: 10s

stirring Resume set

Start titration

iag.33 Preset end po

D

int titration mode, parameter setting

Before Preset end point titration mode, user needs to set some parameter. Preset end point titration

mode has following parameter: mV/pH titration parameter, end point number parameter, pre-control

point parameter corresponding to each end point, end point parameter, time delay parameter,

pre-control switch and value parameter.

23

Page 25

7.2.1 mV/Ph Parameter

mV/pH titration parameter is used to indicate current titration is mV or pH titration. When user

selects mV titration, current titration is mV titration and all display are according to mV. Vice

versa.

7.2.2 End Point Number Parameter

End point number parameter indicates the total number in current preset end point titration.

Maximum is 5.

7.2.3 Pre-control Point Parameter

Pre pre-control point parameter tells user titration end point is coming and the meter need to

slow down the adding speed. The setting of this value will directly influence the correction of

final result and actual titration time. If pre-control point is set close to end point, when it

reached pre-control point, the result will be incorrect caused by the speed of titration too fast. If

pre-control point is set far from end point, the total titration time will be increased. Also

pre-control point should be set before end point, otherwise the pre-control point will be invalid.

The principle for setting pre-control point is: to the reaction of large jump, pre-control point

should be set far from end point potential (usually more than 100mV from end point potential).

And to the reaction of small jump, pre-control point could be set close to end point to quicken

the speed of titration.

NOTE: 1. When setting several end point parameters, the direction of end point potential of several

end points and pre-controlled point potential should be same, and it should be in right order,

otherwise the meter won't display "Start" on the bottom right corner of screen, as the result that

titration is unable to be made, e.g. the user has selected preset end point titration of two end points,

set the 1st end point potential to "200mV", the 1st pre-controlled point to "100mV", the second end

point to "-100mV", the second pre-controlled point to "0mV", that is mistaken setup.

2. If pre-controlled point is set in opposite direction, the meter will display "pre-controlled point is

set by mistake", e.g. potential is "100mV" when titration starts, while end point is set to "500mV",

pre-controlled point is set to "600mV", then the pre-controlled point is set by mistake, but it will do

if pre-controlled point is set to "50mV", the meter will enter slow titration when it starts working.

7.2.4 End Point Parameter

End point parameter is the known titration end point and just need to input

7.2.5 Time Delay Parameter

Time delay parameter means the delay time after titration reached set end point. Generally,

there will be potential wave near end point and set a certain time delay will let you get more

correct result. When meter judge the titration reached set end point, it will control titration

panel and let it pause, at this time, delay time starts. If potential returns back to set end point

before delay time finished, meter will go on titration till titration pass the end point and delay

time finished.

24

Page 26

7.2.6 Pre-control Value Switch and Value Parameter

Pre-control value parameter is set for controlling titration time, it will influence the titration

speed and analysis time of preset end point titration directly. Generally it is no need for user to

set it but only need to tacit admit the system setting. If user finds titration is too slow and

analysis time is too long, titration is too fast or does not enter into slowest status when it closes

to end point, you can switch on pre-control value switch and reset the amount of pre-control

value (when pre-control value is switched off, meter use tacit parameter). Set pre-control value

large, titration speed fast, vice versa. The adjust range of pre-control value is 30 – 90%.

After setting all above parameter correctly, press ‘Start titration’ button to start Preset End

Point Titration. Also when set above parameter, user can set stirrer speed or calibrating

electrode slope.

7.3 Mode of Titration

Mode titration is for a particular titration and its end point is known; or it is a special mode

generated by user when you are satisfy with the result after pre-titration for convenience of next

reusing. Meter provides two specific mode of titration:

a. HC1 → NaOH (0.1mol/L)

B. K

2Cr2O7

→ Fe2+ (0.1mol/L)

The rest mode of titration is to be generated with pre-titration by users. Users will get titration

parameter after pre-titration, press ‘Mode’ button in menu, select ‘Generation of mode’ and then

store this parameter in the meter to generate user’s own titration mode. Titration can be done

later only if this mode is down loaded (see 8.1.2 ‘Generation of mode’ in detail). In starting

status, press ‘Titration’ button, select ‘Mode of Titration’ to enter into ‘Mode of Titration Mode’.

Displayed as follows:

Saves Delete Titration Stir Calibration

Select Mode 01/02

01 HC1 →

NaOH(0.1)

02 K2Cr207 →

Fe2+(0.1)

PgDn PgUp

Mode HC1 → NaOH (0.1)

pH titr

Number of end point: 1

2003/06/15 00:00:00

First end point Sample volume

10.0mL

End point: 7.00Ph

Time delay: 10s Titrant

Concentration

End point switch: ON 0.1000

Diag.34 Mode titration select mode

ation

25

Page 27

In Diag.34, on left side is current stored assemble mode figure and current mode symbol, on the

right is relative parameter corresponding to the mode under cursor. Including Name of Mode, mV

or pH Titration, Number of End Point, Mode Storing Time, Sample Volume, Titrant

Concentration, End Point Value corresponding to Each End Point, Time Delay and End Point

Switch (Detailed instruction and amendment of Mode Parameter are in chapter ‘View Mode’).

On the top of Diag.34 is pressing button area. User can select proper mode on his own need. Press

‘Titration’ button, meter display ‘Start Mode Titration?’, press ‘Enter’ button to start mode titration.

7.3.1 mV/pH Titration Parameter

When mode is generated, the parameter is confirmed too, use is not able to amend. Diag.34

is pH titration.

7.3.2 End Point Number Parameter

When mode is generated, the end point number is confirmed too, use is not able to amend.

Diag.34 is one end point

7.3.3 Stored Time Parameter

This parameter only indicate current mode generation or the time when store.

7.3.4 Mode Title Parameter

This parameter is set for users better memory and management mode. User can edit this

parameter.

7.3.5 End Point Parameter

This end point parameter is also the actual end point value for this time titration. User is

allowed to amend this parameter, but the amendment of end point value will change the final

titration result directly, user should pay attention to this before amendment.

7.3.6 Time Delay Parameter

This Parameter means the delay time after the titration reaches the end point. User is allowed to

amend this parameter. Also the amendment of delay time may change the final titration result.

User should pay attention to this before amendment.

7.3.7 End Point Switch Parameter

Normally, when mode is generated, end point switches are all set as ‘ON’ which means this

end point is valid. If in multi-end point titration, user finds a certain end point is unnecessary

or user need to screen a certain end point with some other reason, you can set the switch of

certain end point to ‘OFF’, then in the process of titration, meter will jump over this end point

but will not ignore all the other end point.

7.3.8 Sample Volume Parameter

When mode is generated, the parameter is usually set to BLANK and user should input this

parameter when calculating concentration value (see 8.1.3 ‘Sample Concentration).

26

Page 28

7.3.9 Titrant Concentration Parameter

When mode is generated, the parameter is usually set to BLANK and user should input this

parameter when calculating concentration value (see 8.1.3 ‘Sample Concentration).

7.4 Blank Titration Mode

This mode is suitable for the titration that demands less titrant (below 1ml). In this mode, every

time the meter adds 0.02 ml of volume (users can amend this parameter), users can also set pre-

added volume parameter so as to make titration speed higher. Thus the meter will automatically

search for titration end point to generate special titration mode. When the volume is small in

titration, user can select blank titration. In starting status, press ‘Titration’ button, select ‘Blank

Titration’ to enter into blank titration mode, displayed as follows:

Blank Titration/Parameter setting

MV Titration pH Titration

MV/pH Titration Jump Value Set

First end point 100

Balance Potential Switch ON

Value: 0.2mV

Balance Time Switch: ON

Value: 10s

Pre-adding Volume: 0.5mL

Each Adding: 0.02mL

Ending Volume: 5mL

Start Titration Stirring Resume set

Diag.3

5 Parameter Setting in Blank Titration Mode

Blank titration mode includes: mV/pH Titration Parameter, Balance Potential Switch and Value

Parameter, Balance Time Switch and Value Parameter, End Point Jump Value Parameter,

Pre-adding Volume Parameter, Each Adding Volume Parameter, End Volume Parameter.

7.4.1mV/pH Titration Parameter

The same as mV/pH Titration Parameter in Pre-Titration Mode.

7.4.2 Balance Potential Switch and Value Parameter

The same as Balance Potential Switch and Value Parameter in Pre-Titration Mode.

7.4.3 Balance Time Switch and Value Parameter

The same as Balance Time Switch and Value Parameter in Pre-Titration Mode.

27

Page 29

7.4.4 End Point Jump Value Parameter

The same as End Point Jump Value Parameter in Pre-Titration Mode.

7.4.5 Pre-adding Volume Parameter

The same as Pre-adding Volume Parameter in Pre-Titration Mode.

7.4.6 Each Adding Volume Parameter

Blank titration mode is to add pre-adding volume first. When first adding finished, add the

same volume each time in sequence. The adding volume every time is the adding volume

after pre-adding volume.

7.4.7 End Volume Parameter

The same as Titration Mode End Volume Parameter

When all above setting finished, press ‘Start Titration’ button to start blank titration.

7.5 Manual Titration Mode

It can be used to add titrant manually and to make titration manually. This titration mode will

help user to find titration end point. In starting status, press ‘Titration’ button, select ‘Manual

Titration’ to enter into manual titration mode. Displayed as follows:

Manual Titration/Parameter setting

MV/pH Titration Jump Value Set

MV Titration pH Titration

Pre-adding: 10mL

Jump Value: Large Middle Small

Value: 100

First end point

Next Adding: 0.2mL

End volume: 40mL

Resume Set

Stirring

Start Titration

Diag.36 Parameter Setting in Manual Titration Mode

All the same, Manual Titration Mode has following parameter: mV/pH Titration Parameter,

Pre-adding Volume Parameter , Next Adding Volume Parameter ,End Point Jump Parameter,

End Volume Parameter.

7.5.1 mV Titration Parameter

The same as mV/pH Titration Parameter in Pre-Titration Mode

7.5.2 Pre-adding Volume Parameter

The same as Pre-adding Volume Parameter in Blank Titration Mode.

28

Page 30

7.5.3 Next Adding Volume Parameter

Next adding volume parameter is next adding volume after adding volume this time, this

volume can be reset after anyone adding.

7.5.4 End Volume Parameter.

The same as End Volume Parameter in Pre-Titration

When all the above setting finished, press ‘Start Titration’ button to enter into Manual

Titration. After pre-adding volume, the meter will wait for user’s next operation. User can

press ‘Add’ button to add titrant of set volume, or to press ‘Set Adding Volume’ button to set

new volume, press ‘End’ to stop titration.

Add

0.130mL

End

Set Adding

Vo l u m e

Manual Titration>Titration Panel READY 00:14:08

Diag.37 Manual T

itration

8. Handling of Titration Data (including Viewing, Storing, Printing and Generating Mode)

The meter provides two viewing method:

a. Allow user to view the titration data again after titration.

b. User could view stored titration data

Note: a. In the process of the titration, if user stops titration soon which cause the titration data of

actual record is less (less than 3), user is not able to view current titration data, if user did not store

titration data, he also cannot view the stored data.

b. After each titration, previous titration data will lose automatically and user is not able to view

previous titration data

29

Page 31

In starting status, press ‘View’ button in menu, select viewing method you need, press ‘Enter’ button

to view relative titration data. Displayed as follows

Diag.38 Display when select viewing method

View Titration Mode Set Calibrate

View

View current data

View stored data

Enter

Exit

Titration

Clean

Feed

Titration panel READY + K 10/21

8.1 Handling of Current Data

When titration finished, meter will save current titration data, user can view the titration data

again

Store Mode Concentration End point Print About

Diag.39 Display of viewing current data

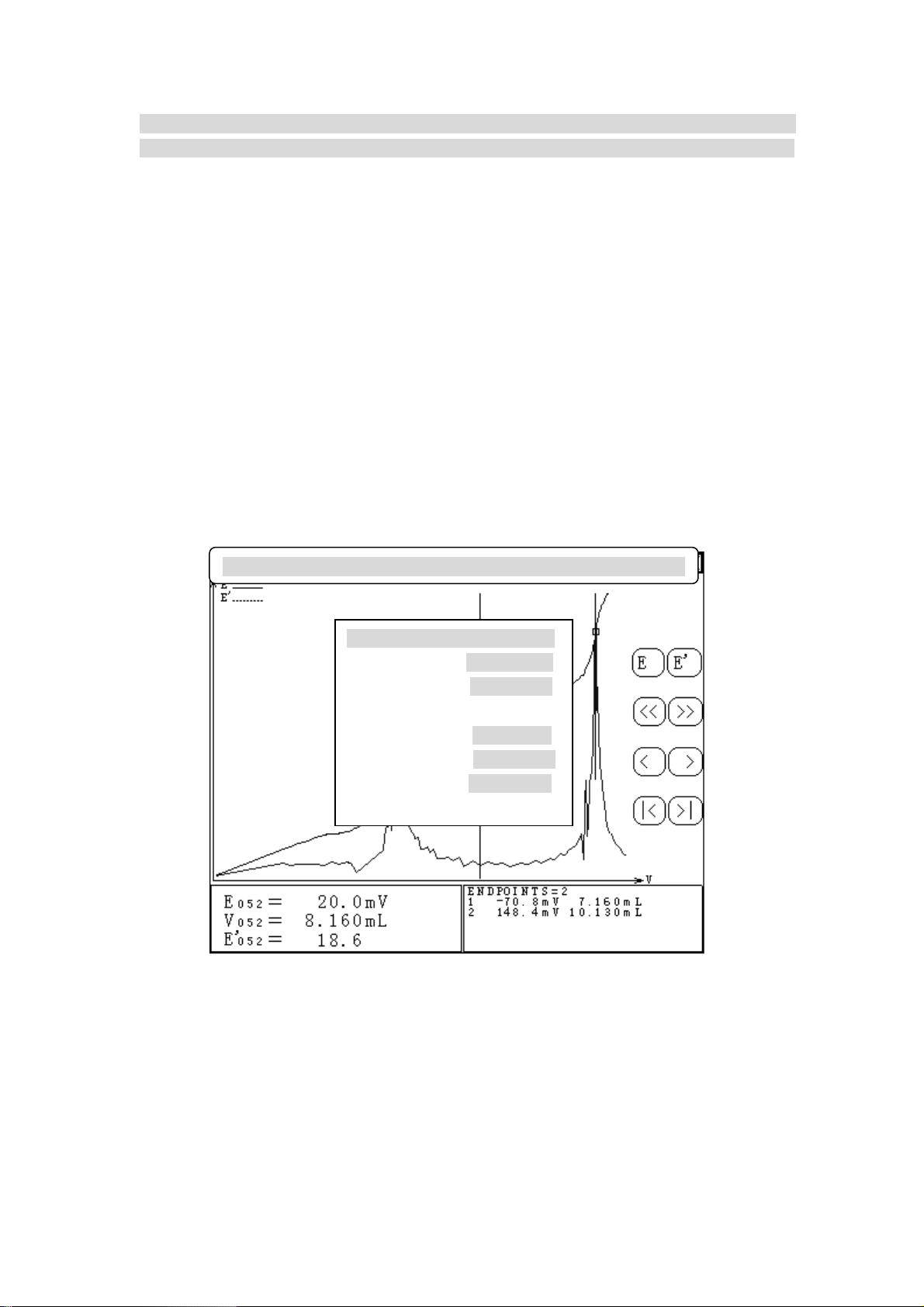

One the top is menu including ‘Store’, ‘Mode’ (if there is end point), ‘Concentration’ (if there is

end point), ‘End Point’, ‘Print’, ‘About’ and ‘Close button’. In the middle is titration curve area,

user could view and handle titration data. Perpendicular line is indicating line, user could move it to

a certain position and view or hand the titration data at this position. Moving could be done by

pressing ‘﹤’, ‘﹥’, ‘1﹤’, ‘﹥1’.

30

Page 32

In which:

‘﹤’ is moving left,

‘﹥’ is moving right,

‘1﹤’ is moving leftmost,

‘﹥1’ is moving rightmost.

User could also move the indicating line to a certain position directly by pressing the position in

curve display area. In which:

‘﹤﹤’ is reduce button, the graph will be reduced by pressing this button,

‘﹥﹥’ is enlarge button, the graph will be enlarged by pressing this button (get the indicating

line as central).

The real curve is potential-volume curve. Virtual curve is one time differential-volume curve.

‘E’ is the transferring witch to switch on/off of potential-volume curve.

“E’”is the transferring witch to switch on/off of one time differential-volume curve.

The small square on curve is end point position. On the bottom of left corner is the titration data

corresponding to indicating line, including potential, volume and differential. On the bottom of right

corner is end point area, displaying end point number and corresponding end point value.

From here, user is allowed to store titration curve, print titration result, print titration data, print

titration curve, view titration parameter and titration time. User is also allowed to set end point,

delete end point. If titration has end point, user is also allowed to generate special mode and

calculate concentration value of sample.

8.1.1 Store Titration Data

When titration is finished, user can store titration curve in order to use it for analysing and

observation. In viewing status, press ‘Store’ button in menu, select ‘Store Titration Data’ and

then press ‘Enter’ button, meter will display ‘Store Titration Data?’ you can press ‘Enter’ to

store current titration data, press ‘Exit’ to quit and return to viewing status. Please note: Meter

can only store titration curve once, after storing, meter will delete previous titration curve

automatically.

Store Mode Concentration End point Print About

Store Titration Data?

Enter Exit

Diag.40 Displ

31

ay Storing Titration Curve

Page 33

8.1.2 Mode of Generation

After pre-titration, if necessary, user could generate titration mode. There are two ways:

One is in viewing status, press ‘Mode’ button in menu, select ‘Mode of Generation’ and press

‘Enter’.

The second is in starting status, when meter has not made next titration, press ‘Mode’ button,

select ‘Mode of Generation’ and then press ‘Enter’ button. Meter will display ‘Titration Data

Generating Mode?’ press ‘Enter’ to arrange mode of generation.

Store Mode Concentration End point Print About

Titration Data Generating Mode?

Enter Exit

Diag.41 Generating Mode in viewing status

When meter enters into mode of generating, user needs to input the title of mode, displaying as

follows:

View Titration Mode Set Calibrate

Input the Title Mode

Enter

Diag.42 Display when input mode’s title

32

Page 34

For the title of mode, user is allowed to key-in some necessary description so that user can

remember the name of the mode in next input and amendment. User could key-in 20 figures mostly.

One the top of the screen is title column. In the square down the title column is word symbol chart.

There is a curser in the chart to indicate the position of input symbol. Press ‘﹤’ or ‘﹥’ to move

curser or press title frame directly, meter will calculate automatically and move curser to relative

position. User could press letter in the chart directly to key-in the title.

When input finished, press ‘Enter’ button, meter will generate mode through input title and titration

data and display ‘Mode in Store…’ When storing finished, user could use this mode to make

titration in future mode of titration.

Note: If titration finished and the titration has end point, meter will add ‘Mode’ in menu

automatically otherwise meter will not display mode menu. The same, ‘Concentration’ in menu also

has this limitation.

8.1.3 Concentration of Sample

Concentration value of sample is calculated as follows:

*

VC

EPS

C

V

0

In which: C is concentration value of sample

C

V

V

is concentration of titrant

s

is titrant volume consumed corresponding to end point

EP

is sample volume

0

In viewing status, press ‘Concentration’ in menu, select ‘Concentration of Sample’ and press ‘Enter’

button to calculate the concentration of sample. Displaying as follows:

Store Mode Concentration End point Print About

Concentration of Sample

Sample Concentration

Volume of Titrant

33

Diag.43 Display of calculation of sample concentration

Page 35

If user doesn’t input concentration of titrant and sample volume (Concentration of titrant and sample

volume are all ‘BLAND’), then Concentration of Sample in ‘Concentration’ column will display as

‘BLANK’, otherwise meter will automatically calculate concentration value of sample according to

the sample volume in current end point. Display as diag.43.

From here, user could reset sample volume, concentration value of titrant. User could input new

sample volume or concentration value of titrant by selecting sample volume or concentration of

titrant. Press ‘Exit’ button in concentration of sample window to quit from calculating of sample

concentration and return to viewing status

8.1.4 Set or Amend End Point

8.1.4.1 Set End Point

User is allowed to set a certain titration data as end point depends on his own judgment and

get titration mode according to it. The way is: User considers a certain position on curve is

end point, he could move indicating line to this position, press ‘End Point’ button, select ‘Set

End Point’ and finally press ‘Enter’.

8.1.4.2 Delete End Point

User is allowed to delete a certain end point depends on his own judgment. The way is: User

needs to delete a certain end point, he could move indicating line to this position, press ‘End

Point’ button, select ‘Delete End Point’ and finally press ‘Enter’.

8.1.5 Print

When titration finished, If user needs to print out the titration result, titration data, titration

curve, he could press ‘View’ button and then press ‘Print’ button. Display as follows:

Select the content needed to print, switch on the printer and print out the relevant content.

Store Mode Concentration End point Print About

Print

Print Titration Result

Print Titration Data

Print Titration Curve

Enter Exit

Diag.44 Print selection

34

Page 36

Note: Before printing, user must set the type of printer, parameter of communication baud ratio and

connect printer correctly. (see ‘Set Print’ chapter)

8.1.5.1 Print Titration Result

Meter will print out the name of current titration, titration time, titration parameter and

titration result.

8.1.5.2 Print Titration Data

Meter will print out all titration data

8.1.5.3 Print Titration Curve

Meter will print out titration curve according to titration curve graph.

8.1.6 About

When titration finished, meter will save some parameter used in current titration automatically,

including current titration name, total titration time, type of burette used, burette coefficient

and electrode slope. User could press ‘About’ button in menu and then press ‘Enter’ to view the

titration parameter. Displayed as follows:

Store Mode Concentration End point Print About

Titration Parameter

Titration Mode: Pre-titration

Titration Time: 00:05:56

Burette: 10mL

Burette coefficient:100.00%

Electrode slope: 100.0%

Diag. 45 Titration Parameter Display

8.2 View and Print Stored Data

In starting status, press ‘View’ in menu, select ‘View Stored Data’ and press ‘Enter’ to view the

stored titration data, displayed as follows. In view stored data, user is only allowed to print

stored titration data and view the parameter in titration.

35

Page 37

Print About

Diag. 46 Display for Viewing Stored Data

The same as the ‘Print’ function in viewing current titration data, user is allowed to select ‘Print

Titration Result’, ‘Print Titration Data’ or ‘Print Titration Curve’, press ‘Print’ button in menu and

select needed operation and print them out.

The same as the ‘About’ function in viewing current titration data, user is allowed to view titration

name, titration time, burette, burette coefficient and electrode slope of current titration.

9. Mode

Meter provides two modes function: one is generate mode function, the other is view and edit

mode parameter function. In starting status, press ‘Mode’ button in menu and select generation

mode or viewing mode

View Titrate Mode Set Calibrate

Mode

Generation of Mode

Viewing Mode

Enter

Exit

Titrate

Clean

Feed

Titration Panel READY + K 10/21

Diag. 47 Function of Mode

36

Page 38

9.1 Generation of Mode

When titration finished, if necessary, user could generate titration mode, please see chapter

8.1.2 Generation of Mode for details.

9.2 Viewing Mode

User could view and amend relative parameter by viewing the mode generated by himself or the

system mode provided by meter. In starting status, press ‘View’ in menu, select ‘Viewing Mode’

and press ‘Enter’ to view the mode. Displayed as follows:

Save as Delete Titrate Stir Calibrate

Select Mode 01/02

01 HC1 ---﹥

NaOH(0.1)

02 K2Cr207 ---﹥

Fe2+(0.1)

PgDn PgUp

Mode HC1 → NaOH (0.1)

pH Titration

Number of end point: 1

2003/06/15 00:00:00

First End Point Sample Volume

10.0mL

End Point: 7.00pH

Time Delay: 10s Concentration

of Titrant

End Point Switch: ON 0.1000

Diag. 48 Display for Viewing Mode

On the left side is total number of mode and current selected mode, in mentioned diag.48, there are

total two modes and currently user selects No. 1 mode. On the bottom, there are ‘PgUp’ and ‘PgDn’,

user could turn over the page to display the mode.

On the right side is the relative parameter corresponding to selected mode, including Name of

Mode, mV/pH Titration, Number of End Point, Storing Time, End Point Value corresponding

to Each End Point, Time Delay, End Point Switch and Sample Volume, Concentration of

Titrant.

In current page, user could select mode directly, otherwise user could press ‘PgUp’ and ‘PgDn’,

button to display the other modes.

Please refer to chapter 7.3 Mode of Titration for the meaning of each mode parameter. User could

select and amend the parameter depends on actual need.

Note: User could not amend the system mode parameter provided by meter.

In viewing status, user is allowed to save as (copy), delete the mode, of course user is also allowed

to make mode titration. So in viewing mode, user is allowed to set stirring speed, calibrate electrode

slope.

37

Page 39

9.2.1 The Mode’s Save As

For the research or some other purpose, the mode can be copied and generate another mode.

In viewing mode, press ‘Save As’ button, the meter displays ‘Save As Current Mode’?

Displayed as following Diag.49, press ‘Enter’ button, amend or key-in new name of the mode,

meter will automatically copy current mode.

Save as Delete Titrate Stir Calibrate

Select Mode 01/02

03 HC1 ---﹥

NaOH(0.1)

04 K2Cr207 ---﹥

Fe2+(0.1)

Save as Current Mode?

PgDn PgUp

Mode HC1 → NaOH (0.1)

Ph titration

Number of end point: 1

2003/06/15 00:00:00

First end point sample volume

Exit Enter

10.0mL

End point: 7.00pH

Concentration

Time delay: 10s of Titrant

Diag.49 The mode’ save as

.2.2 Delete of M

9

ode

If user finds a certain mode useless, you could select deleting of this mode. In viewing mode,

pressing ‘Delete’ button, the meter will display ‘Delete Current Mode’?, press ‘Enter’ button

to delete this mode. Displayed as follows:

Save as Delete Titrate Stir Calibrate

Select Mode 01/02

05 HC1 ---﹥

06 K2Cr207 ---﹥

Delete Current Mode?

NaOH 0.1) (

Fe2+(0.1)

Mode HC1 → NaOH (0.1)

PH titration

Number of end point: 1

2003/06/15 00:00:00

Exit Enter

sample volume

10.0mL

End point: 7.00pH

PgDn PgUp

Time delay: 10s Concentration

of Titrant

End point switch: ON 0.1000

Diag.50 Delete of Mode

Diag.50 Delete of Mode

38

Page 40

9.2.3 Mode Titration

User could select suitable mode according to your own need, press ‘Titration’ button, the

meter will display ‘Start Mode Titration?’ press ‘Enter’ button to start mode titration

Save as Delete Titrate Stir Calibrate

Select Mode 01/02

07 HC1 ---﹥

Start Mode Titration?

NaOH(0.1)

08 K2Cr207 ---﹥

Fe2+(0.1)

PgDn PgUp

Mode HC1 → NaOH (0.1)

Ph titration

Number of end point: 1

2003/06/15 00:00:00

First end point sample volume

Exit Enter

10.0mL

End point: 7.00pH

Time delay: 10s Concentration

of Titrant

End point switch: ON 0.1000

Diag. 51

Start Mode T

itration

9.2.4 Set Stirring Speed

Press ‘Stir’ button, meter displays ‘Set Stirring Speed?’ , user could set the speed of stirrer,

please see chapter 10.1 Set Speed of Stirrer for details.

9.2.5 Calibrate Electrode Slope

Press ‘Calibrate’ button, meter displays ‘Calibrate Electrode Slope?’, user could re-calibrate

the electrode slope, please see chapter 11 Electrode Calibration.

10. Set System Parameter of the Meter

The system parameter of meter includes: Speed of Stirrer, System Time, Type of Printer,

Burette and Burette Coefficient.

Note: user must set correctly the burette, burette coefficient, type of printer, system date and time,

etc

Note:The meter has the function of protection from electricity cutting off. The stored data and

parameter will be kept even if the meter is switched off or unusual electricity cutting off happens.

In order to operate the meter correctly, for the first time, user must check whether the set parameter

accords with operating condition. If not, new parameter must be set. In ordinary operation, if user

finds some mistaken of operating condition, date or time, please set relevant parameter again.

In starting status, press ‘Set’ button in menu, select relative item to set the corresponding parameter.

39

Page 41

When setting finished, meter will return to starting status. See following Diag.52 for setting of each

parameter.

View Titrate Mode Set Calibrate

Set

Stirring Speed

System Time

Printer

Burette

Enter

Exit

Titrate

Clean

Feed

Titration Panel READY + K 10/21

Diag.52 Set Parameter of the meter

10.1 Set Speed of Stirring

In starting status, press ‘Set’ button in menu, select ‘Stirring Speed’ and press ‘Enter’ button to

set the stirring speed of stirrer.

View Titrate Mode Set Calibrate

Set Stirring Speed

Stirring Sp

…………………………………………………

eed : 40

Stop

Titrate

Clean

Feed

Titration Panel READY + K 10/21

Diag. 53 Set stirring speed in starting status

In setting window, ‘Start’ (or ‘Stop’) button is used to start (or close) stirrer, sliding bar and

displayed stirring speed is in corresponding to the actual speed value of current stirrer, user could

press sliding bar directly or press ‘﹤’, ‘﹥’ to set the speed of stirrer. When setting finished, press

‘Close’ button on top right corner to return to starting status.

40

Page 42

10.2 Set System Time

In starting status, press ‘Set’ button in menu, select ‘System Time’ and press ‘Enter’ to set date,

time of the meter.

View Titrate Mode Set Calibrate

Set System Time

2003/10/29

09:22:58

Titrate

2003

10

29

Clean

09

22

58

Feed

Titration Panel READY + K 10/21

Diag. 54 Display of System Time

In D

iag.54 , t

op left corner in Set System Time window displays current time and date of the meter

and six buttons on the bottom of left corner are in corresponding to year, month, day, hour, minute

and second. If user needs to amend month, you could press ‘Month’ button, meter will display

month and stop counting time, beside the button, there are ‘Input’ and ‘set’ button, display as

follows:

View Titrate Mode Set Calibrate

Set System Time

2003/10/29

09:22:58

2003

11

22 09

29

Set

58

Input

Titrate

Clean

Feed

Titration Panel READY + K 10/21

Diag. 55 Set System Time

Press ‘Month’ button could increase the month, or user could press ‘Input’ button to key-in the

month directly. When input finished, press ‘Set’ is all right. User could set the other time according

to the same procedure.

41

Page 43

10.3 Set Printer

RS-232 interface is taken as output of the meter. Therefore, user must purchase serial printer to

print titration result, titration data, titration curve etc. It is allowed to select ‘Model TP-16,

TP-24 or TP-40 serial printers (to print respectively 16 alphabets, 24 alphabets, 40 alphabets

each line). Since the width of printers is different, the printing form of the printers is obviously

different. We suggest Model TP-40 serial printer be available.

Note : The Baud rate of serial printers are 9600bps, N, 8, 1. The way of shake hands is K4=ON

View Titrate Mode Set Calibrate

Set current printer

Tp-16s Printer

Tp-24s Printer

Tp-40s Printer

Enter

Exit

itrate

T

Clean

Feed

Titration Panel READY + K 10/21

Diag.56 Set Printer Type

User could jus

t select the pri

nter connected with the meter. When selection finished, press ‘Enter’ to

return to the starting status.

10.4 Set Burette

Two kinds of burettes are provided with the meter, 10ml and 20ml burette. The burette must be

set corresponding to the operating burette, otherwise, the meter will not make titration

correctly.

In starting status, press ‘Set’ Button in menu, select ‘Burette’ and press ‘Enter’ to set burette

type and coefficient. Each burette is marked with burette coefficient. User must set correctly

otherwise it will influence the titration result directly.

View Titrate Mode Set Calibrate

Set Burette

Burette : 10ml burette

Burette Coefficient: 100.00%

Enter Exit

Titrate

Clean

Feed

Titration Panel READY + K 10/21

Diag. 57 Set burette and burette coefficient

42

Page 44

Set burette or set burette coefficient is simple, user just need to select ‘10ml burette’ or ’20ml

burette. After selecting burette, select burette coefficient, user only needs to key-in the burette

coefficient marked on burette. When setting finished, press ‘Enter’ to return to starting status.

11. Electrode Calibration

Before pH titration begins, electrode slope can be calibrated. If users needs to make two-point

calibration, two kinds of standard buffer solutions must be prepared beforehand, if user needs to

make one-point calibration, then one kind of standard buffer solution is enough. Preparation of

standard buffer solution is shown in Appendix.

11.1 One-Point Calibration

One point calibration means the electrode system is calibrated with only one kind of pH

standard buffer solution to calibrate automatically the Eo of the meter. The meter will take

percentage slope of pH combination electrode as 100%. This method can be used to simplify

the operation if precise measurement is not required. The procedure of operation is as follows:

a. Insert pH combination electrode and temperature electrode into measuring electrode sockets,

clean the electrode with distilled water and put it in pH standard solution B (any one of the three

pH standard buffer solutions).

b. In starting status, press ‘Calibrate’ button, displayed as follows:

Press ‘Enter’ button, me

displays the current measured pH value and temperature. Displayed as Diag.59:

View Titrate Mode Set Calibrate

Calibrate

Calibrate electrode slope

Titration Panel READY + K 10/21

Diag. 58 Calibration in menu

ter will enter into one-point calibration working status. At this time, meter

View Titrate Mode Set Calibrate

Calibration/one-point calibration

7.00 pH

25.0 ℃

Titration Panel READY + K 10/21

Diag. 59 One –point Calibration in starting status

Enter Exit

Enter

Exit

Titrate

Clean

Feed

Titrate

Clean

Feed

43

Page 45

c. When pH value stable, press ‘Enter’ Button, the meter displays percentage slope. Now one-point

calibration has finished. Displayed as follows:

View Titrate Mode Set Calibrate

Calibration/one-point calibration

Ca e librate electrode slop

Calibration finished!

Electrode sl

ope: 100.0%

Enter Exit

Titrate

Enter Clean

Feed

Titration Panel READY + K 10/21

Diag. 60 One-point calibration finished slope in starting status

Press ‘Enter’, meter will ask user

if you want to make two-point calibration, displayed as follows:

press ‘Enter’ to make two-point calibration, press ‘Exit’ to stop calibration and meter returns to

starting status. User could stop calibration at anytime by press ‘Exit’ button.

View Titrate Mode Set Calibrate

Calibration/one-point calibration

Two-point calibration?

Calibrate electrode slope

Titrate

Enter Exit Clean

Enter Exit

Feed

Titration Panel READY + K 10/21

Diag.61 Display of whether making two-point calibration

11.2 Two-Point Calibration

Two-point calibration ensures pH measurement precise, which means the electrode system is

calibrated with two standard solutions to obtain actual percentage slope and Eo value of pH

combination electrode. The operation procedure is as follows:

a. When one-point calibration finished, the meter will ask you if you want to make two-point

calibration, press ‘Enter’ to enter into two-point calibration working status. Take out the electrode,

clean it with distilled water then, put it in pH standard buffer solution C. Meter displays current

pH value and temperature value.

44

Page 46

hen displ

b. W

calibrated electrode slope value, this means two-point calibration finished. Now calibration also

finished. Press ‘Enter’ button to quit from calibration panel. In the process of calibration, user

could stop calibration at any time by pressing ‘Exit’ button

12. pH Measurement

In the starting state, if the meter displays the potential value and temperature value, user can

press potential and temperature displaying area, the meter will turn to pH measuring status.

Press again, meter will return to potential displaying status. Displayed as diag.63

Diag. 63 PH displaying in starting status

13. Calibration of

In the starting state, clean burette for several times, fill the burette with distilled water (there

can't be bubbles in the burette). Set the burette and set the burette coefficient as 100%. Take a

clean weighing bottle, first weigh the empty bottle with the balance of 1/10000, put dripping

tube into the weighing bottle, press "Titration" button to enter into titration mode, move cursor

onto "Manual Titration", then press "Enter" to enter into manual titration mode. Please select

View Titrate Mode Set Calibrate

Calibration/Two-point calibration

9.18 pH

25.0

Titration Panel READY + K 10/21

Diag.62 Two-point Calibration in starting status

ayed pH value stable, press ‘Enter’ button, meter displays ‘Calibration finished!’ and

View Titrate Mode Set Calibrate

℃

Enter Exit

Titrate

Clean

Feed

Titrate

1.00 pH

Clean

25.0 ℃

Titration Panel READY + K 10/21

Burette Coefficient

Feed

45

Page 47

mV manual titration when titrate the parameter by manual, if the burette is 10ml, set pre-added

volume to "10ml"; if the burette is 20 ml, set pre-added volume to "20 ml" (ensures that end

volume is larger than pre-added volume), refer to diag.64

Manual Titration/Parameter setting

mV/pH Titration

MV Titration pH Titration

Pre-adding volume: 10mL

Jump value: Large Middle Small

Val u e : 100

Jump Value Set

First end poin

t

Next adding: 0.2mL

Ending volume: 40mL

Resume Set Stir Start Titration

Diag.64 Parameter setting in Manual Titration

When setting finished, pres

s ‘Start Titration’ button, meter will push the burette full of distilled

water into the weighing bottle, then weigh it with balance. Calculate the burette coefficient

according to following formula:

gg

12

f

*Vd

×100%

0

In which: f= burette coefficient

g

= weight of empty weighing bottle

1

= weight of weighing bottle for adding solution

g

2

d= density of water

= volume of burette full scale

V

0

V. MAINTENANCE AND SERVICE OF THE METER

1. Maintenance

Keep the sockets of the meter clean and dry, keep them away from acidity, alkaline, salt

solution, and also keep them damp-proof to ensure insulation and high input impedance

performance of the meter. When the meter is not working, insert Q9 short circuit plug into the

socket of measuring electrode to prevent it from dust and steam. On the occasion that is with

higher humidity, dry the plug of the electrode with clean gauze first.

Often clean the whole burette with distilled water, especially the titrant which produces

sediment or crystal (eg. AgNO

When using perchloric acid Acetic acid as the titrant, keep the ambient temperature ≥16℃,

otherwise it will produce crystal, and damage the valve.

2.Settle the common trouble: See Table 1

), clean the burette in time after it is used.

3

46

Page 48

VI. THE COMPLETE SETS OF THE METER

1. Model TIT-5 Automatic Potentiometer 1 set

2. Model TIT-5 Automatic Potentiometer volume titration and measuring unit 1

3. Model T-818-B-6 Temperature Sensor 1

4. Model E-201-C-9 pH Combination Electrode 1

5. Accessories, see Packing List 1

VII.APPENDIX

1. pH standard buffer solution A (pH 4.00, 25℃)

Weigh 10.12g of KHC

1L of de-ion water.

2. pH standard buffer solution B (pH 6.86, 25℃)

Weigh 3.388g of KH

2PO4

3. pH standard buffer solution C (pH 9.18, 25℃)

Weigh 3.80g of Na

2B4O7

dissolve it in 1L of de-ion water.

Table 1

Symptom Trouble cause Settlement

No display

that has been dried under 110℃~130℃ for 2~3 hours, dissolve it in

8H4O4

and 3.533g of Na2HPO4 respectively, dissolve it in 1L of de-ion water.

, H2O which was put in the desiccator with saturated NaBr for two days,

a. power is off

b. fuse is damaged

c. bad connection between

control unit and volume

titration unit

a. check the power

b. change the fuse of same