Page 1

INSTRUCTION MANUAL

Laboratory Equipment Pty Ltd

email: sales@labec.com.au

Ph: 02 9560 2 811 • Fax: 02 9560 61 3 1

www.labec.com.au

2014

Page 2

INSTRUCTION MANUAL FOR

PL-600

Lab pH Meter

PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATION

Page 3

Content

1. Introduction 4

2.Technical Data 4

3. Accessories and installations

4. LCD icon 5

5. Operation key 7

6. Measurement 8

6.1 PH measurement 8

6.2 mV measurement 9

6.3 Measurement ending point status setting 10

7. PH sensor calibration 10

8. Information storage, back display, clear & communication 12

8.1 Measurement information manual storage 12

8.2 Measurement information back display 13

8.3 Clear measurement information 13

8.4 RS232 communication 14

9. Setting of function parameters 14

9.1 Sensor calibration information(P1) 14

9.2 Date & time setting (P2) 15

5

10. Self diagnostics information 15

11. Maintenance 16

12. Packing accessories 17

13. Warranty period

Appendix I PH linear error checking method 19

18

- 2 -

Page 4

1. Introduction

We thank you for having purchased PL-600 lab pH meter。

Before using the instrument, please note that the operation

instructions should be read carefully, which will help you to operate and

maintain the instrument, as well as to avoid trouble caused by unsuitable

operation and maintenance.

PL-600 pH meter employs leading edge technology with integrated

microprocessor, which is suitable for pH and mV measurement in water

solutions for institutes, industrial labs and production fields.

The information presented in this manual is subject to change without

notice as improvements are made.

2.Technical data

2.1 Instrument can be used under following condition:

a. Ambiciant temperature:5~35℃;

b. Relative humidity:≤85%;

c. Power supply:DC9V power adapter;

2.2 Main parameters

2.2.1 Measurement arrange

pH:0.00~14.00 pH

mV:±2000 mV

Temperature: -5.0~105.0℃

2.2.2 Resolution:0.01pH、1mV、0.1℃

2.2.3 Measurement precision:

pH:≤0.01 pH

mV:≤0.1% F.S

Temperature:≤0.5℃

2.2.4 Input current:≤10

2.2.5 Input impedance:≥10

-12

A

12

Ω

2.2.6 Stability:≤0.01pH/3 hrs

2.2.7 Temperature compensation range:0.0~100.0℃

2.2.8 Storage capacity for measurement data:64 sets;

- 3 -

Page 5

2.2.9 Content of storage:number of measurement value、measurement

④

⑤

value 、 temperature value 、 ATC or MTC

status、measurement date、measurement

time

2.2.10 pH buffer which are suitable for the instrument:

standard PH buffer:PH4.00、PH7.00、PH10.01

2.2.11 Communication port:RS232

2.2.12 Dimension of enclusre:200×160×65mm

2.2.13 Weight:0.65 kg

2.2.14 Power:≤5W

3. Installation of accessories

Install the arm of the electrode holder on the base.

Plug the pH combination electrode and DC9V power adaptor into

relative socket. As soon as you have connected the DC9V power adaptor

to AC220V(or AC110V), the instrument is in hold mode.

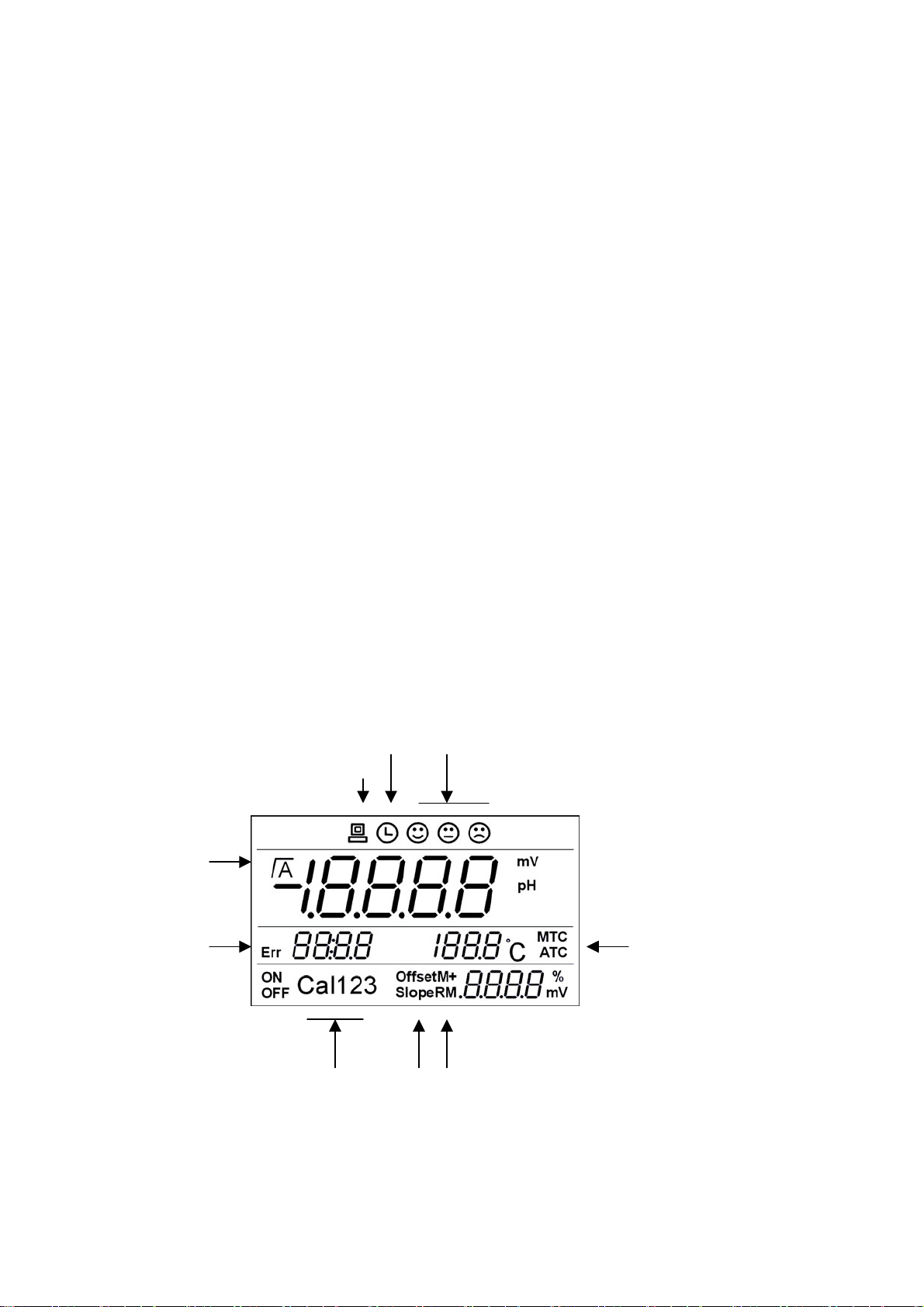

4. LCD icon

②

①

③

⑥

⑦ ⑧

⑨

- 4 -

Page 6

In above picture:

Icon ①:RS232 communication

strument has been connected with PC, When this icon displays, the in

the PS232 communication function is open automatically.

Icon ②:Timing storage of the measurement value

(only valid for type

640) When this icon displays, the measurement value timing storage

function is open, the instrument will store the measurement data according

to set intervals.

Icon ③:Sensor diagnostics

、 、

After pH sensor calibration, the instrument will display sensor

performance:

:sensor is in good performance;

Icon④:Measurement status icon

:sensor performance is so so;

:sensor is in bad performance, need to be changed

、 :

:when display this icon, the measurement value is in stable status,

but the instrument still goes on measurement.

:when display this icon,the measurement value is in stable

poising status, the value will be kept(auto ending point

function)

Icon ⑤:E n Err

Th gnostics function, when problems occurs

e instrument has self dia

rror ico

during operation, the instrument will display relative tips for error signal

and code, to remind you.

Icon ⑥:Temperature measurement

status icon

- 5 -

and pH temperature compensation

Page 7

MTC icon:the temperature displays is manual entered, pH manual

temperature compensation.

ATC icon:the temperat

tem

perature auto compensation.

Ic n Cal1、Cal2、Cal3:

on ⑦:PH sensor calibration ico

ure displays is actual measurement value, pH

Cal1 icon:first point pH calibration

Cal2 icon:second point pH calibrati

on

Cal3 icon:third point pH calibration

Icon

⑧:PH sensor performance icon

Offset icon:pH sensor zero point

icon

Slope icon:pH sensor slope icon

Icon

5. Opera

⑨:Measurement data storage, back display icon

icon:measurement data storage icon

icon:stored measurement data back display

tion key

The instrument

ON/O t, but the power

FF: Power key. When switch off the instrumen

has 6 operation keys,as follows:

adaptor has not plugged from the AC220V socket, the instrument is in hold

mode.

MOD

E: Function key. To be used to switch between measurement

functions(pH measurement function/mV measurement

function).Long key used to functional parameter setting

CAL:Ca

libration key. To be used to pH sensor calibration.

M+/∧ : Storage key、manual temperature setting key(

increase)、

.

functional parameter setting key.

After the measurement data

m

easurement information.

During pH measurement

unde

r MTC status, is used to setting the sample temperature manually.

getting stable, is used to store the

and calibration, when sample temperature is

(increase)。

- 6 -

Page 8

Under the functional parameter setting condition, is used to modify the

set

ting of the functional parameter.

R mperature setting key(decrease)、

M/∨ : Back display key、manual te

functional parameter setting key

Under measurement mode,

disp

lay stored measurement information;long key(press the key >1.5s)

short key(press the key <1.5s)to back

to clear all stored measurement information.

In pH measurement and calibration process,

tem r

pe ature is under MTC mode, to set the sample temperature

when the sample

manually(decrease)。

Under the functional p

set

ting of the functional parameter.

READ: Measurement key. This is a

arameter setting condition, is used to modify the

combination key. Press the key <

1.5s,the instrument in measurement mode.(short key)。Press

the key ≥1.5s,the instrument will set the auto ending point

function or cancel the action(long key).

6. Measu

6.1 pH measuremen

rement

t

Remarks:Befo

re first time using the pH sensor, the pH sensor

should be calibrated.

Under pH measurement mode, immerse the sensor into the sample

after rinsing with distilled water, shaking the vessel few minute, must press

“READ” key(short key),when the LCD display“

”auto ending function

icon, the instrument will block the

measurement value, the value could be

read. In left chart, the date is 1

st

March,

time is 8 o’clock 28 , the sample

ending function,measurement

temperat re is 25.0℃ , automatic

temperature c mp nsation ATC),auto

value 7.00pH,the electrode is in good

u

o e (

performance.

- 7 -

Page 9

Under pH measurement mode, immerse the sensor into the sample

after rinsing with distilled water, shaking the vessel few minutes, if the

instrument has not been set to auto ending function, LCD will display

“

”icon if the measurement is stable,

th measurement value could be read. In

e

left chart, the date is 1

st

March, time is 8

o’clock 28,the sample temperature is

25.0℃ , automatic temperature

s n a

function , measurement valu

compen atio ( ATC ), uto ending

e

7.00pH,the electrode is in good

performance.

Under pH

flash

es,to remind you the current pH temperature compensation mode, is

measurement mode, when press <READ>key, “MTC” icon

manual or automatic, as well as to confirm the sample temperature

displayed, then press < M+/∧>key、<RM/∨>key to modify the sample

temperature, then press, <READ>key to confirm the entered temperature

value and measure.

6.2 mV measurement

Under mV measuremen

t mode, immerse the sensor into the sample after

rinsing with distilled water, shaking the vessel few minute, must press

“READ” key(short key),when the LCD

display “

the in will block the

measurement valu the lue cou be

read. In left chart, the date is 1

”auto ending function icon,

strument

e, va ld

st

March,

time is 8 o’clock 28 , the sample

temperature is 25.0℃,automatic

temp ra ure compensation(ATC),auto

e t

ending function,measurement value 1818mV.

6.3 Set measurement ending point judgment sta

The instrument has 2 statuses of measurement

judg

ment(display“

”or “ ”icon),under the measurement mode, (PH

- 8 -

tus

ending point

Page 10

or mV measurement),press <READ> long key to change the status.

When the measurement is in balance status, “

instr enument will keep this value, the measurement is d; when the

measurement is in stable status, “

could be recorded, and the measurement is continuing, according to the

balance stability, to be sure if display “

” displays,the measurement

” or not.

”displays,the

value

7. pH sensor calibration

1 point calibration

Under the pH measurement mode,

pres

s<CAL>key,LCD displayed as left

chart,“Cal1”icon flashes,immerse the

electrode into the standard buffer after

rinsing with water, shake the vessel for

few minutes, wait for few seconds,

should be followed by the operat

press<CAL>key,the instrument wi

recognize which buffer solution is it,

display as well, wait the instrument ju

pH sensor response to ending point,

display as chart left, 1 point calibration

accomplished the display shows below,

“Cal2”flashes,the instrument reminds

you 1 point calibration is finished, do you

want to proceed 2 points calibration? If

only 1 point calibration needed, press

“READ”to exit calibration process, swit

to pH measurement mode. If the 2 points

calibration is needed, the next chapter

or.

ll

dge

is

ch

- 9 -

Page 11

Remarks:After 1 point calibration, only the zero potential of the

sensor is modified (Offset),the slope of the pH sensor is kept from last

calibration. Even to those electrodes which have good performances,

0.05pH measurement error could be reached during measurement.

2 points calibration

After 1 point calibration, LCD

disp hes),

lays as above chart (“Cal2”flas

immerse the electrode into standard

buffer solution, shaking the vessel for

minutes, wait for second, press“CA L”,

instrument will recognize which buffer

solution is it, display as well, wa

it the instrument judge pH sensor

response to ending point, the instrument displays as above chart,

calibration has been accomplished, automatically enter the pH

measurement mode, the display shows below, “Cal3”flashes,

the

instrument reminds you 1 point

calibration is finished, do you wa

proceed 3 points calibration? If only 2

point calibration needed, press “READ

to exit calibration process, switch to pH

measurement mode. If the 3 points

h rator.

calibration is needed, the next c

apter should be followed by the ope

few

the

2 points

nt to

”

Remarks: After 2 points calibration, the instrument will modify the

offset and slope of the electrode。PH measurement under this kind of

calibration status, the measurement precision is quite good.

3 points calibration

After 2 point calibration, LCD

disp hes),

lays as above chart (“Cal3”flas

immerse the electrode into third

standard buffer solution(e.g. PH9

.18

Buffer), shaking the vessel for few

- 10 -

Page 12

minutes, wait for second, press“CA L”, the instrument will recognize which

buffer solution is it, display as well, wait the instrument judge pH sensor

response to ending point, the instrument displays as above chart, 3

points

calibration has been accomplished, automatically enter the pH

measurement mode, the sensor performance icon after calibration is also

displayed.

After 3 pints calibration, the instrument has the best measurement

precision. Especially for broadly ranged pH measurement, the

measurement errors from unlinearity will also be modified.

During pH calibration, “MTC” icon on LCD displays,to remind you

current temperature compensation method, is manually(MTC),and

please confirm the temperature of current sample, press < M+/∧>、﹤RM/

∨>key to moodily the temperature of the sample, then press <CAL>key to

confirm the temperature imputed and start with pH sensor calibration.

8. Measurement information store, back display, clear and RS232

communication

8.1 Store measurement information manually

During PH or mV measurement, when the measurement value is

stable,(display “

”or “ ”icon), when the auto storage function of type

640 meter is set to “Off”,press< M+/∧>key,store the current measurement

value ( including measurement value number, measurement value,

temperature value ( ATC or MTC status )、 measurement date,

measurement time),LCD will display icon

, together with measurement

value store number in around 5 minutes, then back to last measurement

status.(display date on the position of storage number display).

8.2 Back display of measurement information

Under measurement status (PH or mV measurement),press< RM/∨

>short key,the instrument will back display of last stored measurement

data ( including measurement value number, measurement value,

temperature value ( ATC or MTC status )、 measurement date,

measurement time).

- 11 -

Page 13

In below chart, measurement value number is 88 , 7.00pH ,

measurement time 8:28(display measurement date and measurement

time alternatively), sample temperature

is 25.0℃(ATC).

Under the back display mode, the

instrument will pause operation of the

timing storage of the measurement

information.(Only valid for type 640).

8.3 Clear stored measurement information

When the instrument memory is full,

will not store the measurement

information; or the information stored is

not needed anymore, clear the memory

is needed. Under the measurement

mode(PH or mV measurement),press<

RM/∨>long key,LCD is displayed as left chart, icon

flashes,to

remind you clear the memory, if this operation is confirmed, then press<

RM/∨>short key to finish clearing of the memory; if this action is not

needed , press< READ>short key to abort, return to measurement mode.

Remarks:The measurement information cleared will not be recovered!

8.6 RS232 communication

After installed the communication software supplied by or company

on the PC, when connect PC and the instrument using the RS232

communication cable, LCD will display RS232 communication icon

,to

show that the instrument has been connected with PC.

When the LCD displays RS232 communication icon

,the manual

saving, auto saving, timing saving information (includes measurement

value number, measurement value, temperature value (ATC or MTC),

measurement time, measurement date) will be transferred through RS232

port to PC. Otherwise, the manual saving, auto saving, timing saving

information (includes measurement value number, measurement value,

- 12 -

Page 14

temperature value (ATC or MTC), measurement time, measurement date)

will be stored in memory of the instrument.

9. Functional parameter setting

Press <MODE> key longer than 1.5s, the instrument comes into

functional parameter setting mode. Under this mode, operator could check,

modify and set the relative information, parameter and function. Under this

mode, using <MODE>、<M+/∧>、<RM/∨> 3 short keys to set the procedure

parameter: <MODE> short key is used to cycle choosing functional

parameter setting items,<RM/∨> key、<M+/∧> key are used to modify the

process functional status and parameters. Press<MODE>long key to

protect procedure setting item parameters and end procedure parameter

setting status, back to formal status.

9.1 Electrode calibration information(P1)

Under this status, the operator could check the calibration information.

Press <MODE>long key to enter the program parameter setting status

“P1”,the LCD displays as left chart. Press< M+/∧>short key to display zero

potential of the pH sensor(Offset)mV value、Slope value alternatively.

Information displayed in left chart:the calibration date of PH sensor is 1

st

of March ( display calibration date and calibration time

alternatively);calibration method is 2 points calibration; temperature of the

solution is 25.0℃(ATC);PH sensor zero point (Offset)is 0.0mV.

9.2

Date and time setting(P2)

Factory setting of the instrument is

according to current Beijing date and

time. Press <RM/∨> key to choose the

number to set, press<M+/ ∧ >key to

modify the number. The instrument has

set to 24 hours. The left chart is 1

st

March, 2004, 8:28.

10. Self diagnostic information

- 13 -

Page 15

The instrument has self diagnostics function, during operation,

relative information will be reminded by the instrument, to solve problems

during usage:

Err1: Electrode potential ≥2000mV。Please check if the instrument has

been connected with the sensor, the electrode has been hanged in

air, or the electrode has damaged.

Err2: Electrode potential≤-2000mV。Please check if the instrument has

been connected with the sensor, the electrode has been hanged in

air, or the electrode has damaged.

Err3: pH value>15.00pH。Please check if the instrument has been

connected with the sensor, the electrode has been hanged in air, or

the electrode has damaged.

Err4: pH value<-1.00pH。Please check if the instrument has been

connected with the sensor, the electrode has been hanged in air, or

the electrode has damaged.

Err5: Memory is full, could not store measurement information. Please

record and store measured information and clear all information in

the memory

Err6: Electrode potential during calibration over ranged selected pH buffer

set. Please check if the instrument has been connected with the

electrode, the electrode has damaged, if pH buffer selection is

correct, then recalibrate the electrode.

Err7: pH electrode zero point potential over range. Zero point potential

Offset<-60mV,Offset>60mV. The instrument will not allow you to

operate. Please check if there is air bubbles in electrode head, if the

buffer selection is correct, the pH buffer is in good quality, then

recalibrate the electrode. If the error still occurs, please change the

electrode.

Err8: pH slope over range Slope<85%,Slope>105%。The instrument will

not allow you to operate. Please check if there is air bubbles in

electrode head, if the buffer selection is correct, the pH buffer is in

- 14 -

Page 16

good quality, then recalibrate the electrode. If the error still occurs,

please change the electrode and calibrate the electrode.

Err9:During 2 point/3point calibration, instrument judge 1point ( or 2 points)

which used buffer solution are same ( or the electrode has

damaged), the instrument will judge the reliable calibration

operation and modify the relative electrode parameter. If this

occurs, please recalibrate the pH electrode.

11. Maintenance of the instrument

The performance of the instrument, is not only rely on the self

construction of the instrument, but also on good maintenance. Especially

for pH meter, which high impedance is needed, and corrosive chemical

agents is sometimes contaminated, therefore, necessary maintenance is a

must

Please, only when the instrument is power off, the plug of the adaptor

could be removed.

Please keep the instrument away from directly sunshine, otherwise

the life time of the LCD will be shortened.

The pH value of the sample solution should be between the pH buffer

solutions you selected. If the temperature of the buffer solution during

calibration is same as the temperature of the sample, the highest

resolution will be reached by the instrument.

Temperature compensation function in the instrument is only

effected to compensate the sample temperature changes

according to pH sensor.

The electrode plug should always keep high cleaning and dry. In order

to protect the electrode from broken, please do not contact the head of the

electrode with hard materials, since it is very thin. Please refer to the

instruction manual of the electrode for the storage, cleaning and

maintenance of the electrode. .

Please do not contact the central part of the BNC electrode plug by

- 15 -

Page 17

hand or metal, the static electronic will destroy the electronic part of the

instrument and contaminate the input terminal of the electrode, decrease

the input impedance of the instrument.

Please do not use agent to clean the enclosure of the

instrument. The enclosure of the instrument is ABS engineering plastic

s.

11.Packing accessories

Operation manual, QC certificate are included in the package of the

instrument, as well as accessories below,

1. 1pcs of pH combination electrode;

2. pH 4、7, buffer solution 1 bottle each;

3. 1 set of electrode holder;

4. 1pcs of DC9V power supply;

13. Warranty period

The warranty period of electronic components is 2 years from the

date of purchase, under the condition of normal storage, operation and

transportation, improper working of the instrument due to quality problems,

the instrument will be repaired and the spare parts will be changed for

customers with supplying of the sales invoice and product inspection

certificate.

- 16 -

Page 18

Appendix 1 Checking method of pH linear error

Input 177.48mV(pH4.00 buffer solution electrode potential simulate

value)、-178.07mV(pH10.01 buffer solution electrode potential simulate

value) into the instrument,temperature compensation sent to 25℃,

operate according to 2 points calibration;after calibration the instrument

displays “

”signal.(if type 640 please set the buffer solution set to

b1)Check the linear error of the instrument according to following table.

mV

414.11 354.95 295.80 236.64 177.48 118.32 59.16 0

pH 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00

mV -414.11 -354.95 -295.80 -236.64 -177.48 -118.32 -59.16

pH 8.00 9.00 10.00 11.00 12.00 13.00 14.00

- 17 -

Loading...

Loading...