Page 1

INSTRUCTION MANUAL

Laboratory Equipment Pty Ltd

email: sales@labec.com.au

Ph: 02 9560 2 811 • Fax: 02 9560 61 3 1

www.labec.com.au

2014

Page 2

OPERATION MANUAL

H2G-0

HOMOGENIZER

PLEASE READ THE MANUAL CAREFULLY BEFORE USE.

Page 3

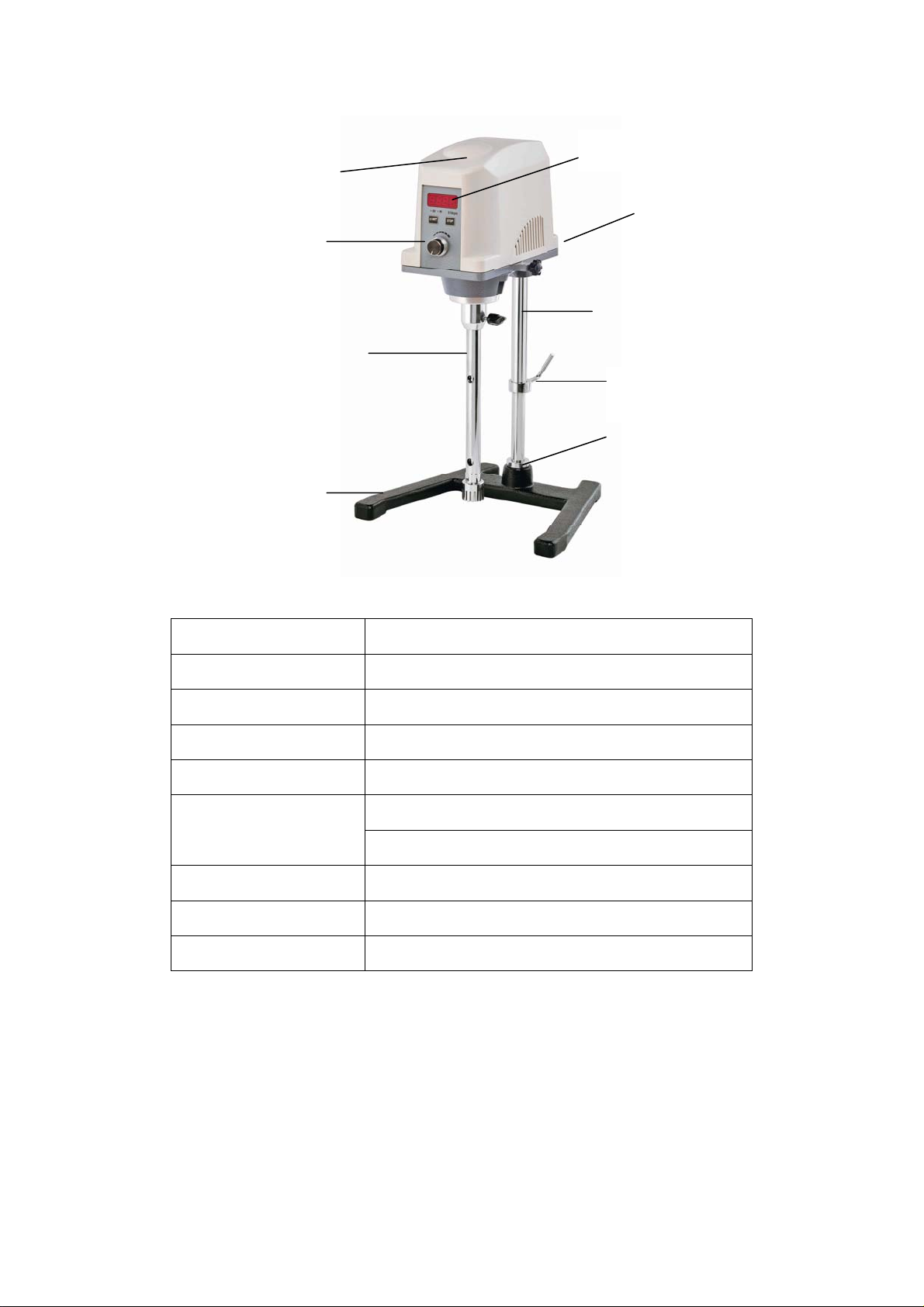

I. OUTLINE

MOTOR

SPEED ADJUSTER

HOMOGENIZER HEAD

UNIT

STAND BASE

SPEED DISPLAY

POWER SWITCH

(ON THE BACKSIDE

OF THE BODY)

POLE

HIGH-LOW ADJUSTER

RING FOR HIGHT

FIXING PURPOSE

II. SPECIFICATION

MODEL H2G-

POWER AC110V / 220V , 50 / 60Hz

CONSUMPTION 250W

SPEED (rpm) 20,000

ELECTRONIC

SAFTY DEVICE

COATING MEDICINE-RESISTING

SIZE (WxDxH mm) 310x270x690 mm

WEIGHT (kg) 10 kgs

ELECTRONIC BUFFERING ACCELERATED

OVER-HEAT PROTECTING SYSTEM

FUSE

1

Page 4

III. OPERATION INSTRUCTION

1. It should keep at least 1 cm of the distance between the tip of the

stirring shaft and the inside bottom of the vessel. Don’t let the

homogenizer head touch to the bottom of the vessel.

2. Rotate the speed adjuster knob toward the left end; then plug in the

power cord and switch the machine on.

3. Press “START” button and adjust to the desired speed; press “STOP”

button to stop the stirring.

4. For avoid idle running, the flowing speed of the liquid should be

available to the stirring speed of the machine.

5. After a long time use, if the motor temperature over 75 degree C, the

over-heat protection device will start and stop the motor running.

When the temperature come down (about 30 mins later), the machine

can re-start to run. If the situation repeats to happen, User should

reduce the loading on the machine. Don’t overload the machine;

otherwise its motor will be damaged possibly.

6. Using the homogenizer heads alternately is available. Just need

release the fixing screw under the homogenizer head, the

homogenizer head can be taken off easily.

7. The homogenizer head is available to be dismantled, so users can

clean it after the operation.

2

Page 5

IV. CAUTION

1. Avoid using this machine with other instruments in one and same

power supply.

2.

Serious or often overloaded use should be possible to cause the

fast carbon brush consumption as well as the motor damage.

3.

It’s necessary to turn to a low speed for 1~2 hours at least after

changing a new carbon brush, otherwise the motor will be damaged

possibly.

4.

The speed has to match material’s viscosity to avoid head at

empty rotation.

5. After cleaning or changing the homogenizer head, please fix and

screw it tightly.

6. The bad fluid sample is not suitable to be operated by this

instrument

7. The homogenizer head should be fixed at the correct position

carefully, any missing will make the head deformed and jammed

inside.

V. SELF-INSPECTION

When the machine is out of order, please check following possible facts:

1. Fuse burned out or not。

2. Carbon brushes at the both sides of the motor are used out or with the

contact improperly.

3. If carbon brushes are used out, please replace the new ones.

If User did the above self-inspections but still couldn’t delete the failure,

please contact with the distributor for help.

3

Page 6

VI. APPLICATION OF HEADS

Model

K-7S To homogenize or mix on cell tissue in micro volume.

K-12S

K-20S

K-30

Applicable range

1. To disperse plant or animal tissue.

2. To treat suspensions and emulsions.

3. Homogenizing and mixing.

4. Extraction function.

1. To disperse plant or animal tissue.

2. To treat suspensions and emulsions.

3. Homogenizing and mixing.

4. Extraction function.

1. To disperse organic and inorganic matters.

2. Homogenizing and mixing.

3. Extraction function.

VII. SPECIFICATION OF HEADS

Model

K- 7S 6.3 0.3~10 φ7 x 130

K-12S 11.3 2~250 φ12 x 170

K-20S 20.1 20~2000 φ20 x 200

K-30 29.9 100~3000 φ30 x 250

Circumference Speed

Capacity (ml) Size (mm)

(m/s)

4

Page 7

VIII. ASSEMBLING & DISMANTLING K-7S, 12S, 20S

AND K-30

STEPS FOR ASSEMBLING K-7S

(* REVERSE THE STEPS FOR DISMANTLING)

1. Follow the diagram to put all the parts orderly

into the connect pipe.

4

1 3 5

Each part name:

(1) Bolt (2) Inner shaft of connect pipe

(3) Pad (4) Connect pipe (5) Pipe

(6) Turning cutter

2. Follow the diagram to insert the tools into the

connect pipe.

2 6

3. Follow the diagram to turn the tools toward

their correct directions for fixing the whole

assembly. (For dismantling purpose, it should

follow the same steps but in reverse.)

5

Page 8

STEPS FOR ASSEMBLING K-12S

(* REVERSE THE STEPS FOR DISMANTLING)

1. Follow the diagram to put all the parts orderly

into the connect pipe.

6

1

3 2 4 5 7

Each part name:

(1) Bearing (2) E-typed washer (3) Bolt

(4) Inner shaft of connect pipe (5) Pipe

(6) Connect pipe (7) Turning cutter

2. Follow the diagram to insert the tools into the

connect pipe.

3. Follow the diagram to turn the tools toward

their correct directions for fixing the whole

assembly. (For dismantling purpose, it should

follow the same steps but in reverse.)

6

Page 9

STEPS FOR ASSEMBLING K-20S

(* REVERSE THE STEPS FOR DISMANTLING)

1. Follow the diagram to put all the parts orderly

into the connect pipe.

765

1 3 2 4 8

Each part name:

(1) Bearing (2) E-typed washer (3) Bolt

(4) Inner shaft of connect pipe (5) Connect pipe

(6) Pipe (7) Fixed cutter (8) Turning cutter

2. Follow the diagram to insert the tools into the

connect pipe.

3. Follow the diagram to turn the tools toward their

correct directions for fixing the whole assembly.

(For dismantling purpose, it should follow the same

steps but in reverse.)

7

Page 10

STEPS FOR ASSEMBLING K-30

(* REVERSE THE STEPS FOR DISMANTLING)

1. Follow the diagram to put all the parts orderly

1 3 2 4 8 9 10

into the connect pipe.

5 6 7

Each part name:

(1) Bearing (2) E-typed washer (3) Bolt

(4) Inner shaft of connect pipe (5) Connect pipe

(6) Pipe (7) Fixed cutter (8) Inner pipe

(9) Outer pipe (10) Turning cutter

2. Follow the diagram to insert the tools into the

connect pipe.

3. Follow the diagram to turn the tools toward their

correct directions for fixing the whole assembly.

(For dismantling purpose, it should follow the same

steps but in reverse.)

8

Page 11

IX. ERROR MESSAGES

Signal Status Description Repairing

Err-1

COOL 1. Motor stops running

1. Motor can not drive 1. Bad carbon brush touch

2. Motor stops during

running

3. Sensor can not detect

well

suddenly for an

over-heat happening.

OL 1. The pre-set RPM

can not be reached.

2. Wire matched badly.

3. The controller is out of order.

1. Bad carbon brush touch

2. Wire matched badly.

3. The controller is out of order.

1. Sensor is out of order

2. Wire matched badly.

3. The controller is out of order.

1. Temp. switch skips away.

2. Wire matched badly.

1. Over-loaded

1. Check the carbon brush.

2. Check the wiring.

3. Replace a new controller.

1. Check the carbon brush or

replace a new one.

2. Check the wiring.

3. Replace a new controller.

1. Check the speed sensor or

replace a new one.

2. Check wiring.

3. Replace a new controller.

1. Check if overloaded to the

motor.

2. Check temp. switch or

replace a new one.

3. Check wiring.

1. Check if over loaded.

z If all the function keys are failed during the error messages

happen, please turn off the machine then to turn it on again.

z Before rebooting the machine, please be sure no any danger

there.

9

Page 12

X. CIRCUIT DIAGRAM

MOTOR

AC IN

Power switch

1

SPEED SENSOR

VR

Power P. C.

Control

1

1

1

TEMP SW

Control board

GND

FUSE

DISPLAY

Loading...

Loading...