Page 1

For Echo models: 520

550

555

Page 2

Echo Liquid Handler User Manual

Labcyte Part Number 001-5331 Rev 6

March 2013

Copyright © 2013 Labcyte Inc. All rights reserved.

The information contained in this manual is subject to change without notice.

Any unauthorized changes or modifications to the Echo® liquid handler will void its warranty. Contact Labcyte Inc. prior to

making any change or modification.

Labcyte and Echo are registered trademarks of Labcyte Inc.in the United States. Microsoft, Windows, Windows XP,

Windows 7, ActiveX, Excel, and Microsoft SQL Server are either registered trademarks or trademarks of Microsoft

Corporation in the United States and other countries. Intel and Intel Core 2 Duo, are trademarks or registered trademarks

of Intel Corporation or its subsidiaries in the United States and other countries. Alconox is a registered trademark of

Alconox, Inc.

All other registered or unregistered trademarks used herein are the exclusive property of their respective holders.

For research purposes only; not for use in diagnostics.

The Echo liquid handler is covered by one or more of the following patents:

6,416,164; 6,548,308; 6,603,118; 6,612,686; 6,642,061; 6,666,541; 6,707,038; 6,710,335; 6,746,104; 6,802,593;

6,808,934; 6,809,315; 6,849,423; 6,855,925; 6,869,551; 6,893,836; 6,893,115; 6,916,083; 6,932,097; 6,938,987;

6,938,995; 6,991,917; 7,070,260; 7,090,333; 7,354,141; 7,405,072; 7,717,544; 7,899,645; 7,900,505; 7,901,039;

8,107,319.

European Patent EP: 1337325; 1324823; 1337325; 1352112; 1366356; 1534526; 1585636.

Japan: 4189964; 4309131; 4434581; 4559218; 4624644; 4955901; 4990476

Additional patents pending in the United States and other countries.

ii Echo Liquid Handler User Manual

Page 3

Contents

Preface

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety warnings and precautions . . . . . . . . . . . . . . . . . . viii

Safety notation marks . . . . . . . . . . . . . . . . . . . . . viii

Electrical safety warnings . . . . . . . . . . . . . . . . . . . . . ix

Additional safety warnings . . . . . . . . . . . . . . . . . . . . x

Safety cautions . . . . . . . . . . . . . . . . . . . . . . . . . . x

Emergency Off switch (EMO). . . . . . . . . . . . . . . . . . . xii

Laser safety warnings . . . . . . . . . . . . . . . . . . . . . . . xii

Product labels . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Intellectual property label . . . . . . . . . . . . . . . . . . . . xiv

ETL label . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Laser safety labels. . . . . . . . . . . . . . . . . . . . . . . . xiv

Electrical hazard . . . . . . . . . . . . . . . . . . . . . . . . xiv

General warning label . . . . . . . . . . . . . . . . . . . . . xiv

Water system maintenance label . . . . . . . . . . . . . . . . . xv

WEEE label . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Emergency Off label . . . . . . . . . . . . . . . . . . . . . . . xv

Laser safety labels. . . . . . . . . . . . . . . . . . . . . . . . xvi

Product label . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Pinch point label . . . . . . . . . . . . . . . . . . . . . . . . xvi

High-voltage label . . . . . . . . . . . . . . . . . . . . . . . xvii

Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Who should read this manual? . . . . . . . . . . . . . . . . . xviii

What is in this manual?. . . . . . . . . . . . . . . . . . . . . xviii

Conventions used in this manual . . . . . . . . . . . . . . . . xix

Chapter 1 Introduction

1.1 Acoustic Droplet Ejection . . . . . . . . . . . . . . . . . . . . 1-2

1.1.1 How does the Echo system work? . . . . . . . . . . . . 1-2

1.1.2 Will the fluid splash or fall out? . . . . . . . . . . . . . 1-4

1.2 What are the Echo liquid handler features? . . . . . . . . . . . 1-5

1.2.1 “Touchless” fluid transfers . . . . . . . . . . . . . . . . 1-5

1.2.2 Reliability . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2.3 Ease of use. . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.2.4 System integration friendly. . . . . . . . . . . . . . . . 1-8

1.2.5 Low maintenance requirements . . . . . . . . . . . . . 1-9

1.2.6 Cost savings . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.2.7 High accuracy, precision, and speed . . . . . . . . . . . 1-10

1.2.8 Value-added quality control . . . . . . . . . . . . . . . 1-11

1.3 What types of liquid transfer are supported? . . . . . . . . . . 1-12

1.3.1 384-plate to 384-plate liquid transfer . . . . . . . . . . 1-13

1.3.2 384-plate to 96-plate liquid transfer . . . . . . . . . . . 1-14

1.3.3 384-plate to 1536-plate liquid transfer. . . . . . . . . . 1-15

1.3.4 1536-plate to 384-plate liquid transfer. . . . . . . . . . 1-16

Contents iii

Page 4

1.3.5 1536-plate to 1536-plate liquid transfer . . . . . . . . . 1-17

1.4 What system configurations are supported? . . . . . . . . . . 1-18

1.4.1 Manual operation . . . . . . . . . . . . . . . . . . . . 1-18

1.4.2 Echo applications . . . . . . . . . . . . . . . . . . . . 1-19

1.4.3 Modular workstation operation . . . . . . . . . . . . . 1-20

1.4.4 Small cell operation . . . . . . . . . . . . . . . . . . . 1-21

1.4.5 Fully automated operation . . . . . . . . . . . . . . . . 1-22

1.4.6 Multi-client considerations . . . . . . . . . . . . . . . . 1-23

Chapter 2 Installation and Relocation

2.1 Pre-installation requirements . . . . . . . . . . . . . . . . . . 2-2

2.1.1 Site requirements . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2 Additional components . . . . . . . . . . . . . . . . . 2-4

2.2 Installation overview . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3 Software installation . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.1 Install the software. . . . . . . . . . . . . . . . . . . . 2-7

2.3.2 Uninstall the Echo software . . . . . . . . . . . . . . . 2-9

2.3.3 Upgrade the Echo software . . . . . . . . . . . . . . . 2-9

2.4 Instrument Relocation . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.1 Prepare the Echo liquid handler for a move . . . . . . . 2-10

2.4.2 Reinstall the Echo liquid handler after a move . . . . . . 2-11

Chapter 3 System Description

3.1 System overview . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1 Front panel . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 Back panel . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2 Component description. . . . . . . . . . . . . . . . . . . . . 3-5

3.2.1 Process door . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.2 Source plate gripper stage . . . . . . . . . . . . . . . . 3-6

3.2.3 Source plate insert . . . . . . . . . . . . . . . . . . . . 3-6

3.2.4 Destination plate gripper stage. . . . . . . . . . . . . . 3-8

3.2.5 Status indicator lights . . . . . . . . . . . . . . . . . . 3-9

3.2.6 LCD screen. . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.2.7 Emergency Off switch . . . . . . . . . . . . . . . . . . 3-11

3.2.8 Anti-static bars. . . . . . . . . . . . . . . . . . . . . . 3-12

3.2.9 AC power and fuse compartment . . . . . . . . . . . . 3-14

3.2.10Coupling fluid bottle . . . . . . . . . . . . . . . . . . . 3-15

3.2.11Fluid chiller. . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.2.12Surge tank . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.2.13Fluidics panel . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.3.1 Physical . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.3.2 Mechanical . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.3.3 Environmental . . . . . . . . . . . . . . . . . . . . . . 3-19

iv Echo Liquid Handler User Manual

Page 5

3.3.4 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.3.5 Client PC. . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.3.6 Communications. . . . . . . . . . . . . . . . . . . . . 3-19

3.3.7 Fluid transfer. . . . . . . . . . . . . . . . . . . . . . . 3-20

3.3.8 Supported labware. . . . . . . . . . . . . . . . . . . . 3-22

3.3.9 Coupling fluid . . . . . . . . . . . . . . . . . . . . . . 3-23

Chapter 4 Manual Operation

4.1 Startup/Shutdown . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.1 Turn on Echo power . . . . . . . . . . . . . . . . . . . 4-2

4.1.2 Launch Echo software . . . . . . . . . . . . . . . . . . 4-4

4.1.3 Turn off Echo power . . . . . . . . . . . . . . . . . . . 4-5

4.2 Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.3 Create liquid transfer protocol . . . . . . . . . . . . . . . . . 4-10

4.3.1 Add new protocol . . . . . . . . . . . . . . . . . . . . 4-11

4.4 Run the liquid transfer protocol . . . . . . . . . . . . . . . . . 4-13

4.4.1 Prepare the microplates . . . . . . . . . . . . . . . . . 4-13

4.4.2 Start liquid transfer run . . . . . . . . . . . . . . . . . 4-14

Chapter 5 Echo Liquid Handler Software

5.1 Protocols window. . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.1 Create a protocol . . . . . . . . . . . . . . . . . . . . 5-4

5.1.2 Edit an existing protocol definition . . . . . . . . . . . . 5-16

5.1.3 Remove an existing protocol definition. . . . . . . . . . 5-17

5.1.4 Run a protocol . . . . . . . . . . . . . . . . . . . . . . 5-17

5.2 Labware window . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.2.1 Plate name convention. . . . . . . . . . . . . . . . . . 5-21

5.2.2 Plate specification editor . . . . . . . . . . . . . . . . . 5-23

5.3 Diagnostics window . . . . . . . . . . . . . . . . . . . . . . 5-28

5.3.1 Device control . . . . . . . . . . . . . . . . . . . . . . 5-29

5.3.2 Status indicators . . . . . . . . . . . . . . . . . . . . . 5-33

5.3.3 Diagnostic procedures . . . . . . . . . . . . . . . . . . 5-38

5.4 Calibration window. . . . . . . . . . . . . . . . . . . . . . . 5-44

5.4.1 Motion calibration . . . . . . . . . . . . . . . . . . . . 5-45

5.4.2 Power calibration . . . . . . . . . . . . . . . . . . . . 5-47

5.4.3 Transducer calibration . . . . . . . . . . . . . . . . . . 5-50

5.5 Advanced window . . . . . . . . . . . . . . . . . . . . . . . 5-53

5.5.1 Advanced liquid transfer controls . . . . . . . . . . . . 5-53

5.5.2 Advanced solvent concentration (DMSO only) . . . . . . 5-55

5.5.3 Advanced Echo control. . . . . . . . . . . . . . . . . . 5-57

5.6 Status window . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Chapter 6 Maintenance and Service

6.1 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . 6-2

Contents v

Page 6

6.1.1 Daily maintenance . . . . . . . . . . . . . . . . . . . . 6-2

6.1.2 Echo maintenance alerts . . . . . . . . . . . . . . . . . 6-3

6.1.3 Scheduled maintenance . . . . . . . . . . . . . . . . . 6-5

6.2 Maintenance procedures . . . . . . . . . . . . . . . . . . . . 6-7

6.2.1 Maintenance tools and materials. . . . . . . . . . . . . 6-7

6.2.2 Refill the coupling fluid bottle . . . . . . . . . . . . . . 6-8

6.2.3 Clean and refill the coupling fluid bottle . . . . . . . . . 6-10

6.2.4 Empty the coupling fluid bottle . . . . . . . . . . . . . 6-11

6.2.5 Replace the water filter . . . . . . . . . . . . . . . . . 6-15

6.2.6 Clean the anti-static bars. . . . . . . . . . . . . . . . . 6-16

6.2.7 Replace the AC power fuse . . . . . . . . . . . . . . . 6-18

6.3 Extended Non-Use and Storage. . . . . . . . . . . . . . . . . 6-19

6.3.1 Maintenance During Extended Non-Use . . . . . . . . . 6-19

6.3.2 Preparation for storage. . . . . . . . . . . . . . . . . . 6-20

Chapter 7 Contact Information and Troubleshooting

7.1 Contact information . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Setup problems. . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.3 Maintenance alerts . . . . . . . . . . . . . . . . . . . . . . . 7-3

Appendix A. Acoustic Droplet Ejection Technology

A.1 ADE history . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 ADE and the Echo liquid handler . . . . . . . . . . . . . . . . A-2

A.3 Source microplate survey . . . . . . . . . . . . . . . . . . . . A-3

A.4 Fluid transfer . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.4.1 Positioning the ADE elements . . . . . . . . . . . . . . A-4

A.4.2 Creating the acoustic pulse . . . . . . . . . . . . . . . A-4

A.4.3 Transferring the droplet . . . . . . . . . . . . . . . . . A-5

A.4.4 Examples of acoustic droplet ejection . . . . . . . . . . A-6

Appendix B. Barcode Locations

B.1 Short flange height microplates. . . . . . . . . . . . . . . . . B-2

B.2 Medium flange height microplates . . . . . . . . . . . . . . . B-2

Appendix C. Chiller Information

C.1 Shipping contents . . . . . . . . . . . . . . . . . . . . . . . C-2

C.2 Safety Warnings and Precautions . . . . . . . . . . . . . . . . C-2

C.3 Chiller Setup and Operation . . . . . . . . . . . . . . . . . . C-3

C.3.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.3.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . C-4

vi Echo Liquid Handler User Manual

Page 7

The preface to the Labcyte® Echo® liquid handler user manual contains

important information regarding the safe use of an Echo liquid handler and

how to use this manual. Read and understand the safety information

thoroughly before you begin operating the Echo liquid handler.

Intended audience

Safety warnings and precautions

Barcode scanner locations

Using this manual

The Labcyte Echo 520, 550 and 555 systems are referred to as the Echo

liquid handler throughout this manual. The information and illustrations

apply to all models unless specifically stated otherwise.

Intended audience

The Echo liquid handler is designed to be used by individuals who are

familiar with good laboratory practices (GLP)1 or similar laboratory safety

program.

CHAPTER 0PREFACE

Echo liquid handler operators must read this manual before using the Echo

liquid handler instrument.

Throughout this manual the word “you” or “user” refers to the Echo liquid

handler operator.

1 Good laboratory practice (GLP) for nonclinical laboratory studies, FDA regulation 21 CFR

Part 58.

Preface vii

Page 8

Safety warnings and precautions

The Echo liquid handler has been designed for safe operation.

The safety warnings and precautions in this section and throughout the

manual must be observed during installation, relocation, maintenance,

repair, and normal operation of an Echo liquid handler.

Failure to comply with these warnings and precautions, or with specific

cautions and warnings found elsewhere in this manual, violates the safety

standards of design, manufacture, and intended use of an Echo liquid

handler. This can result in hazardous exposure to laser light, high voltage,

or moving parts. Exposure to these hazards can cause severe injury.

Safety notation marks

This manual uses the following symbols in the left margin to draw your

attention to the specified type of information.

Symbol Meaning

Warning

Warnings alert all users to the following:

Potentially hazardous conditions

Actions that may result in personal injury or death

Caution

Cautions alert the user to actions that may result in the

following:

Damage to the equipment

Lost or corrupted data

Unrecoverable interruption of the operation being

performed

Note

Notes emphasize or expand upon the surrounding

information.

viii Echo Liquid Handler User Manual

Page 9

Electrical safety warnings

Always observe the following electrical safety warnings:

Warning: Plug the Echo liquid handler into a grounded circuit (Class 1)

capable of delivering at least:

15 A for a 100– 120 VAC~ power source.

10 A for a 200– 240 VAC~ power source.

If you are unable to insert an AC plug into your AC receptacle, contact an

electrician to correct the situation.

Warning: The Echo liquid handler operates with voltages and currents

that can be lethal. Pushing objects of any kind into the Echo liquid handler,

through slots or holes in its covers, may cause serious electrical shock or

may short out electrical circuits or parts. Do not spill any liquid inside or on

the Echo liquid handler.

Warning: The Echo liquid handler contains user-replaceable AC power

fuses. The fuse holder contains two fuses. Use only the specified

replacement fuses and the fuse replacement procedure found at “Replace

the AC power fuse” on page 6-18. If a fuse requires repeated replacement,

the Echo liquid handler could have an electrical problem. Do not use a

malfunctioning Echo liquid handler. Contact Labcyte Service and Support

(see “Contact information” on page 7-1).

Warning: Do not use AC power cords if the following conditions exist:

The power cords are frayed or damaged.

Other attached cords, cables, or receptacles are frayed or damaged.

Use of damaged power cords can cause an electrical shock hazard and

result in severe injury.

Warning: Do not connect (plug in) or disconnect (unplug) AC power cords

if the following conditions exist:

The Echo liquid handler, or attached equipment, has been exposed to

excessive moisture, or to liquids that have been spilled on it.

The Echo liquid handler, or any of its subassemblies or components,

has been dropped or damaged.

You suspect service or repair is required.

The Echo liquid handler is being cleaned, handled during a

maintenance procedure, or repaired—except as directed in the

applicable written procedure.

These conditions can cause an electrical shock hazard and result in severe

injury.

Preface ix

Page 10

Additional safety warnings

Warning: Do not try to gain access to the interior of the Echo liquid

handler. Do not remove the Echo liquid handler exterior covers. Exposure to

laser light, high voltage, or moving parts inside the Echo liquid handler can

cause severe injury.

Warning: Keep your hands, fingers, and clothing clear of the process door

and microplate assemblies, except when loading or unloading a plate. Be

aware of the possibility that either the source or the destination plate

gripper stages may move.

Warning: Use good laboratory practices and follow the manufacturer’s

precautions when working with chemicals. Labcyte is not responsible or

liable for any damages as a result of, or as a consequence of, the use of

hazardous chemicals.

Warning: The Echo liquid handler weighs approximately 128 kg (283 lbs).

Moving or lifting the Echo liquid handler incorrectly can cause severe injury.

Never attempt to move or lift the Echo liquid handler without using proper

equipment and proper safety techniques. Contact the safety coordinator at

your company for information.

Safety cautions

To protect the Echo liquid handler from damage, follow these precautions:

Caution: Always use the normal shutoff routine or the EMO (Emergency

Motion Off) button to turn off the Echo instrument. Turning off the

instrument by other methods (for example, unplugging the power cord),

can potentially result in damage to the electronics or corrupt the software.

Caution: Do not attempt to service or repair the internal Echo liquid

handler mechanisms yourself. The electrical, laser, and mechanical systems

must be maintained by Labcyte field engineers. If you have any questions

regarding what may be serviced by an Echo liquid handler user, please call

Labcyte (see “

Caution: Do not make modifications to the Echo liquid handler.

Caution: Use only replacement parts that are approved by Labcyte.

Caution: Use labware that is SBS-compliant

Contact information” on page 7-1).

2

or approved by Labcyte.

2 Society for Biomolecular Sciences. See “Supported labware” on page 3-22.

x Echo Liquid Handler User Manual

Page 11

Caution: Do not obstruct the air vents. Keep all air vents free of dirt or

dust.

Caution: Handle the Echo liquid handler coupling fluid and waste water

carefully. Avoid all spills.

Caution: Keep corrosive agents, or otherwise damaging material, away

from the Echo liquid handler and its attached devices.

Caution: Do not expose the Echo liquid handler to excessive moisture

(>80% relative humidity). Moisture, or condensation, can damage electrical

components.

Caution: Do not expose the Echo liquid handler to temperatures outside

of the storage range: 5°C–45°C (41°F–113°F). Temperatures outside of this

range can damage the instrument.

Caution: Do not run the Echo liquid handler without the chiller. Ensure

that the chiller is correctly connected to the Echo instrument and is running

at the recommended temperature. Incorrect coupling fluid temperature can

reduce the precision and accuracy of the fluid that is transferred. Extreme

fluid temperatures can potentially damage the acoustic transducer.

Caution: Do not allow the acoustic transducer to dry out. If the Echo

liquid handler is going to be shut down for longer than a week, start up

and run the pump once a week to keep the acoustic transducer wet. See

“Extended Non-Use and Storage” on page 6-19.

Caution: Do not run the pump if the chiller tubing is not connected.

Running the pump without the chiller tubing may damage other system

components.

Caution: Do not run the pump without the vacuum source connected and

active. Running the pump without vacuum can lead to flooding the system

or a system error.

Preface xi

Page 12

Emergency Off switch (EMO)

Laser apertures

The Echo liquid handler includes two Emergency Off

switches, also known as EMO (Emergency Motion Off)

switches. They are located on the front and rear of the unit

and are prominently labeled “EMERGENCY OFF.” See

“Emergency Off label,” on the next page for switch

location.

See “Emergency Off switch” on page 3-11 for a detailed explanation of

what the Emergency Off switch turns off, when to use it, how to use it, and

how to resume normal Echo liquid handler operation after using it.

Laser safety warnings

The Echo liquid handler is a Class I laser instrument that can house up to

three optional laser-based barcode scanners.

When operated as specified in this manual, the Echo liquid handler does

not expose the operator to laser light. Nevertheless, during a barcode scan,

the Class II diode lasers (with maximum power up to 1.0 mW at 650 nm)

can be visible from the interior of the unit. The barcode scanners are not

interlocked; therefore, if the Echo liquid handler is operated with the covers

off, the operator may be exposed to a Class II laser light hazard. Do not

operate the Echo liquid handler if its covers have been removed.

Figure 1 Barcode scanner locations

xii Echo Liquid Handler User Manual

Page 13

Product labels

You will find the following labels on the Echo liquid handler.

1. Intellectual property label

2. ETL label

3. Laser safety labels

4. Electrical hazard

5. General warning label

6. Water system maintenance label

7. WEEE label

8. Emergency Off label

9. Laser safety labels

10. Product label

11. Pinch point labels

12. High-voltage label

Figure 2 Echo liquid handler label locations (applies to all models).

Preface xiii

Page 14

Intellectual property label

The intellectual property label cites United States patents and other

applicable legal protection.

ETL label

The ETL label indicates conformance

to ETL SEMKO product safety

standards for the US and Canada.

Laser safety labels

One of two laser safety labels (this one is visible on

the instrument back cover).This warning indicates

that the Echo liquid handler optionally uses laserbased barcode scanners. The Echo liquid handler is considered a Class 1

laser light hazard under normal operating conditions (with instrument

covers on).

Electrical hazard

General warning label

xiv Echo Liquid Handler User Manual

The electrical hazard label warns of possible injury from

electrical cables, connections, and circuits inside the Echo

liquid handler.

The general warning label reminds users to take normal

safety precautions when operating and working around

an Echo liquid handler.

Page 15

Water system maintenance label

WEEE label

Waste Electrical and Electronic Equipment

(WEEE) directive

The WEEE label signifies that this instrument should

not be disposed of in the trash. Return it to the

manufacturer for recycle or ecological disposal.

The water system

maintenance label

is provided by

Labcyte to remind

the user to follow

recommended

maintenance

procedures. It also

emphasizes the use

of distilled water.

Emergency Off label

The Emergency Off label identifies the EMO (Emergency

M

otion Off) switch, which is used in an emergency to

shut down all mechanical activity in the Echo liquid

handler. There are two Emergency Off switches, one on

the front panel and one on the rear panel of the Echo

liquid handler.

Preface xv

Page 16

Laser safety labels

One of two laser safety labels

(this label is visible above the

opening when the front cover

is removed), This warning

indicates that the Echo liquid

handler optionally uses laserbased barcode scanners. The Echo liquid handler is considered a Class 1

laser light hazard under normal operating conditions (with instrument

covers on).

Product label

The Echo liquid handler product label (located inside, beside the pump),

contains Labcyte corporate identification, product identification, product

serial number, regulatory agency marks, origin of manufacture, date of

manufacture, input power specifications, and CE mark3.

Pinch point label

3 The CE mark indicates compliance with the EU (European Union) Directives.

xvi Echo Liquid Handler User Manual

The pinch point label warns of

possible injury if you do not keep your

hands or fingers clear of source plate

or destination microplate assemblies

when they are in motion.

Page 17

High-voltage label

The high-voltage label warns of

possible high-voltage injury from

electrical cables, connections, and

circuits inside the Echo liquid handler.

Preface xvii

Page 18

Using this manual

Who should read this manual?

The Echo liquid handler user manual supports several types of users

involved in liquid handling and liquid transfer.

The Preface contains safety information that should be read by

everyone.

Chapters 1, 3, 4, 5, and Appendix A and B should be read by

everyone.

Chapter 2 is of special interest to those involved in installing or

relocating an Echo liquid handler.

Chapter 6 should be read by everyone who is responsible for user-

level maintenance and interfacing with Labcyte service and support

personnel.

What is in this manual?

The Echo liquid handler user manual contains the following:

Chapter 1, “Introduction,” discusses the Echo liquid handler, its

several operating modes and applications, and how ADE (acoustic

droplet ejection) is performed.

Chapter 2, “Installation and Relocation,” covers pre-installation

requirements, software installation, and moving instructions.

Chapter 3, “System Description,” describes the system components,

controls, external connections, status indicators, and the LCD display.

Chapter 4, “Manual Operation,” takes the reader through the

performance of a sample fluid transfer protocol using the Echo liquid

handler software.

Chapter 5, “Echo Liquid Handler Software,” provides a thorough

description of software functions to: set up protocol and destination

plate definitions, run fluid transfer protocols, perform diagnostic and

calibration procedures, and set up advanced fluid transfer options.

Chapter 6, “Maintenance and Service,” covers maintenance

schedules and user-level preventive maintenance procedures.

Chapter 7, “Contact Information and Troubleshooting,“ provides

setup problems and signal alerts.

Appendix A, “Acoustic Droplet Ejection Technology,” describes

acoustic droplet ejection technology.

xviii Echo Liquid Handler User Manual

Page 19

Appendix B, “Barcode Locations,” specifies where a microplate

barcode label must be placed to be read by the Echo liquid handler.

Appendix C, “Chiller Information,”contains chiller descripton, setup

and operation, and troubleshooting.

Conventions used in this manual

Some of the text in this manual uses special formatting to help indicate

emphasis or keystrokes. The text conventions are as follows:

Convention Example Meaning

Small caps, bold Press the

Courier client.txt

client.old2.txt

Blue, underlined Software installation

Quotation

marks

See “Manage labware

definitions” on

page 5-31

NEXT button Indicates an on-screen button,

label, menu title, or menu item.

Indicates a display output, printed

output, keyboard input, or file

names.

Signifies a hyperlink to a topic.

Refers you to a topic elsewhere in

the manual. Usually includes a

hyperlink.

Preface xix

Page 20

xx Echo Liquid Handler User Manual

Page 21

CHAPTER 0INTRODUCTION

The Labcyte® Echo® 500 series includes the Echo

520, 550 and 555 liquid handlers.

Throughout this manual the descriptions,

illustrations, and procedures apply to all liquid

handlers unless the information is specifically

stated for one model.

C HAPTER

1

All models utilize ADE (acoustic droplet ejection)

technology patented by Labcyte Inc. Ultrasoundbased ADE precisely transfers nanoliter volumes of

liquids, including DMSO, buffers with or without

proteins or nucleic acids, surfactants, cell culture

media and serum between microplates.

The Echo 500 series also utilizes Dynamic

Fluid Analysis™, a patented Labcyte

process that enables the liquid handler toadjust transfer parameters on the

fly, without the need for user recalibration.

Excellent accuracy and precision in nanoliter volumes allow for direct

transfer of compounds, which reduces the need for intermediate plates and

multiple dilutions, and produces more accurate results in less time. The

Echo liquid handlers dispense as little as 2.5 nL without using pins, tips, or

washing.

Echo qualified source plates are specifically designed for the Echo liquid

handler to take advantage of acoustic transfer technology and improve

liquid transfer performance.

Nanoliter dispensing also makes an Echo liquid handler an excellent fit for

many challenging life science applications in drug discovery, genomics,

proteomics, and protein crystallography.

Figure 1.1 Echo 555 liquid handler

Introduction 1-1

Page 22

1.1 Acoustic Droplet Ejection

Loading source microplate

Acoustic droplet ejection (ADE) technology is the process of transferring

nanoliter volumes of liquid using acoustic energy. The Echo liquid handler

uses this technology to transfer fluid droplets from a source microplate to a

receiving surface.

The following is a simplified sequence of ADE events:

1. The Echo liquid handler creates an analog RF (radio frequency) wave.

2. The RF wave is amplified and transmitted to a focused acoustic

transducer, which transforms the RF wave into an acoustic pulse.

3. This acoustic pulse is transmitted into the fluid in the source

microplate well, causing the fluid to form a droplet that travels

upwards.

4. The droplet is captured by the receiving surface, which may be an

inverted destination microplate well or a flat substrate. Surface

tension of the fluid keeps it on the receiving surface.

For more information about Acoustic Droplet Ejection Technology, see

Appendix A

.

1.1.1 How does the Echo system work?

The Echo liquid handler uses the following basic steps to transfer liquid:

1. The robot (or operator) loads the

source microplate into the Echo

liquid handler. This step can also

be performed by a robot.

The Echo liquid handler retracts

the source microplate, then

surveys and measures the fluid

height in each well.

For aqueous solutions, the

reported value options will vary by fluid type. For more details, see

Diagnostic Survey” on page 5-39.

“

For DMSO-based solutions, the software reports DMSO/water

concentration (Echo 550 and Echo 555 only).

Note:

1-2 Echo Liquid Handler User Manual

Page 23

2. The operator loads the destination plate (can be microplate or slide

Loading destination plate

Plate being inverted Destination plate down

holder) that will receive the liquid into the Echo liquid handler.

Before retracting the destination plate, the Echo liquid handler inverts

the plate, with the open microplate wells or slide facing downward.

This step is required to receive droplets ejected UP from the source

microplate. See “

Will the fluid splash or fall out?” on page 1-4.

Figure 1.1 Inverting the destination plate

During the transfer process, the source microplate remains in a fixed

position; the destination plate is positioned just above the source

microplate and moves simultaneously with the acoustic transducer.

The acoustic transducer moves beneath the wells. At each well, the

acoustic transducer emits acoustic energy that ejects a specified

volume of liquid upwards to the receiving well or slide on the

destination plate.

Figure 1.2 Diagram of transferring fluid

After liquid transfer, the Echo liquid handler moves the filled

destination plate out of the instrument and inverts the plate again so

that it can be removed.

3. The operator removes the destination plate containing the transferred

compound.

Introduction 1-3

Page 24

1.1.2 Will the fluid splash or fall out?

The Echo liquid handler performs liquid transfer with an inverted

destination plate. Users might question whether all of the droplet remains

in the destination plate well after transfer. Will any of it splash out? Will the

repeated motions of the destination plate, or simply time passing, allow

any of the transferred liquid to fall or drain out of the destination plate

well?

Pre-loaded 1536-well destination microplates will not experience fluid loss

when they are inverted. Pre-loaded 384-well destination microplates

containing fluid with low surface tension may experience fluid loss when

inverted and should be tested. Pre-loaded 96-well destination microplates

may experience loss of fluid when inverted, depending on fluid type and

volume, and are not recommended for “wet” (pre-loaded) fluid transfers.

1-4 Echo Liquid Handler User Manual

Page 25

1.2 What are the Echo liquid handler features?

Echo liquid handlers are well suited to transferring low-nanoliter volumes of

aqueous and DMSO-based solutions for a wide variety of applications. Echo

liquid handler features that will be important to any organization include:

1.2.1 “Touchless” fluid transfers

Echo technology uses “touchless” fluid transfer.

Nothing physically touches the fluid in the wells or the interior walls

of the microplate. Droplets are ejected using an ultrasound wave

transmitted from below the source microplate. The ejected droplet is

directly transferred upward from the supply plate to the receiver.

No direct contact of the source fluid or the ejected droplet as it travels

to the destination plate, means no cross-contamination can occur.

“Touchless” fluid transfer provides the following benefits:

Improved reliability

Lower maintenance requirements

Lower transfer costs

Reduced waste

The following figure shows a single droplet ejected from a 384-well

microplate. Droplets are discrete and of consistent size without the creation

of spray or aerosol.

Figure 1.3 A single droplet ejection.

Introduction 1-5

Page 26

1.2.2 Reliability

The Echo liquid handler has been designed for heavy duty-cycles and

reliable operation. Compared to operating and maintaining existing liquid

handling equipment, Echo technology offers the customer a simpler,

trouble-free device.

Proactive control and monitoring of the systems reduce lost operational

time or material if an error occurs:

Multiple sensors monitor the coupling fluid system. One sensor

monitors the fluid level in the acoustic coupler catch basin. Another

sensor monitors for fluid at the low point of the bottom pan.

Compressed air and vacuum systems are monitored for correct supply

and operation.

Each of the moving mechanisms includes multiple sensors that define

home positions and absolute limits, reducing the possibility of

mechanical interference or misalignment.

When a problem is detected, the following actions occur:

The coupling fluid pump immediately turns off (depending on the

problem).

Front and rear panel fault lamps and LCD messages notify the

operator that a problem has occurred.

ActiveX

®

events notify remote systems that are connected to the

Echo liquid handler.

1-6 Echo Liquid Handler User Manual

Page 27

1.2.3 Ease of use

Select a protocol

Run the protocol

An Echo liquid handler is quickly ready for use.

Minimal operator training is required.

User calibration or recalibration are not required.

Preparation for liquid transfers requires little more than defining a

transfer protocol and selecting the source and destination plates

being used.

Protocols or destination plates can be quickly defined by the operator.

Liquid transfer requires only a few “clicks” by the operator, using the

software, which is included with each instrument.

The Echo liquid handler can be operated manually by a researcher or

as part of a fully automated drug discovery lab.

For example, Figure 1.4 demonstrates the simple, two-step process

required to run an existing fluid transfer protocol using the software

program.

Figure 1.4 Executing a transfer protocol in two steps.

Introduction 1-7

Page 28

1.2.4 System integration friendly

While manual mode (operator controlled via Labcyte software) and standalone mode (hand-loaded microplates) support all functionalities, the Echo

liquid handler excels in its ease of integration into automated systems.

The main body of the Echo liquid handler has a very small footprint:

53.9 cm wide and 68.3 cm deep (21.2 in x 26.9 in).

Facilities requirements (power, temperature, ventilation, compressed

air, vacuum, communications) are simple and straight forward.

Source and destination microplates are loaded onto stages presented

outside the instrument and placed in a fixed location for easy access

by a robotic arm (see the following figure).

Most barcode standards are supported. Barcodes can be located on

the short or long side of a microplate.

The control software supports manual operation “out of the box.”

device control, system monitoring, creation of destination plates and

protocol definitions, and protocol execution are available to the user.

Customers choosing to develop their own Echo software applications

are supported by a fully implemented ActiveX control library.

Figure 1.5 Access™ workstation loading a destination microplate.

See “What types of liquid transfer are supported?” on page 1-12 for more

information.

1-8 Echo Liquid Handler User Manual

Page 29

1.2.5 Low maintenance requirements

Echo instrument up-time is high, not only because it is reliable, but also

because very little maintenance is required.

Routine operator maintenance takes only minutes each week—

typically keeping the coupling fluid bottle clean and filled.

Field service maintenance is scheduled once every six months.

Echo technology means that there are no tips, no pins, and no

washing.

The acoustic transducer itself has no moving parts to wear out. It

simply converts RF (radio frequency) energy to ultrasound energy. The

mechanisms that move it into position are designed for a long and

serviceable life.

1.2.6 Cost savings

The Echo liquid handler reduces operating costs by:

Enabling the routine use of higher density, lower volume assays.

Moving to smaller assay volumes reduces the costs of compounds,

solvents, and reagents.

The use of higher density microplates. High density microplates

dramatically increase the number of assays that can be performed

with a limited amount of test compound used.

Minimizing the use of expendable supplies (for example, intermediate

microplates, tips, pins, and wash solutions).

Eliminating washing stations and their complex procedures and fluids.

Eliminating the requirement to calibrate reduces upkeep time or

delays in adopting new liquid handling procedures.

Introduction 1-9

Page 30

1.2.7 High accuracy, precision, and speed

High throughput capabilities are maintained without degrading fluid

transfer accuracy and precision.

Droplet-to-droplet volumetric precision exhibits a low CV (coefficient of

variation) for all fluid types tested to date. This is attributed to the

elimination of sample contact with the ejection mechanism. In addition,

dynamic real-time measurement of the fluid at multiple times during a run

allows the system to adjust automatically and instantaneously to changes in

fluid behavior.The use of a single, high-speed, serial mechanism reduces

sample-to-sample variability with the Echo liquid handler as compared to

tip-based and other instruments that use multiple mechanisms in parallel.

1-10 Echo Liquid Handler User Manual

Page 31

1.2.8 Value-added quality control

In addition to precise and accurate transfer of fluids, the Echo liquid

handler has an auditing function that can provide quality control of fluid

samples. The Echo liquid handler applies a low-energy sound pulse to the

fluid sample in each well, and the reflected signal is used to calculate the

following:

DMSO-based solutions: fill height and DMSO/water concentration.

Glycerol-based solutions: percentage of glycerol concentration

(up to 50%).

Protein crystallography fluids: impedance measurement in

megarayls (unit of acoustic impedance). In approximate values,

solutions at low megarayl values require less energy to transfer.

The data can then be uploaded to a LIMS (Laboratory Information

Management System) for post transfer processing and analysis.

For example, the following figure shows part of the plate survey of samples

in CP buffer. The plate survey was saved to CSV (comma separated values)

file format and opened in Microsoft® Excel®.

Figure 1.6 Example of aqueous fluid thickness data imported into a spreadsheet for analysis.

Introduction 1-11

Page 32

1.3 What types of liquid transfer are supported?

The Echo liquid handler supports a variety of simple to complex microplate

liquid transfer protocols. The bundled software program allows a user to

set up the following types of protocol transfers:

Table 1.1 Liquid transfer types

Source (Src)

Microplate

384-well 96-well

384-well 384-well standard (1 src plate to 1 dest plate)

384-well 1536-well

384-well 3456-well

1536-well 96-well

1536-well 384-well

1536-well 1536-well standard (1 src plate to 1 dest plate)

1 Destacking: transferring liquid from a single source (src) plate to several

destination (dest) plates

2 Stacking: transferring liquid from several source plates to a single destination

plate

Destination

(Dest)

Microplate

Transfer map type

(full or partial)

destacking

1

quadrant

(4 regions from 1 src plate

to 4 dest plates)

2

stacking

quadrant

(4 src plates to 4 regions

on 1 dest plate)

stacking quadrant

(9 src plates to 9 regions

on 1 dest plate)

destacking quadrant

(16 regions from 1 src plate

to 16 dest plates)

destacking quadrant

(4 regions from 1 src plate

to 4 dest plates)

destacking interleaved

(2x2, or every other

dest well)

stacking interleaved

(2x2, or every other

dest well)

stacking interleaved

(3x3, or every third dest

well)

destacking interleaved

(4x4, or every fourth

dest well)

destacking interleaved

(2x2, or every other

dest well)

Liquid transfer can be tailored to the user’s specific requirements.

Variables that are user selectable or definable include the following:

Source microplate type (from the list of qualified plates)

User-definable destination microplate or surface

Transfer type (for example, interleaved or quadrant 384-well to

96-well transfers)

Transfer volume

Number of copies (how many times the transfer protocol is executed)

Transfer map specifying exactly which wells, or regions of wells, will

be transferred

Predefined DMSO/water concentration maps

These fluid transfer attributes and choices are defined in Chapter 5.

1-12 Echo Liquid Handler User Manual

Page 33

Examples of these protocols are described later in this section.

A1 A1

A1 A1

Additional and more complex fluid transfer protocols can be defined with

the Echo Applications software packages (Echo Plate Reformat, Echo

Cherry Pick, Echo Dose-Response, and Echo Array Maker), as well as with

the extensive ActiveX control library defined in the Echo Software

Development Kit (Echo SDK). These protocols can specify virtually any

combination of transfers from source microplate wells to destination wells

and slides. Refer to the Echo Application manuals and Echo Integration

Guide for more information.

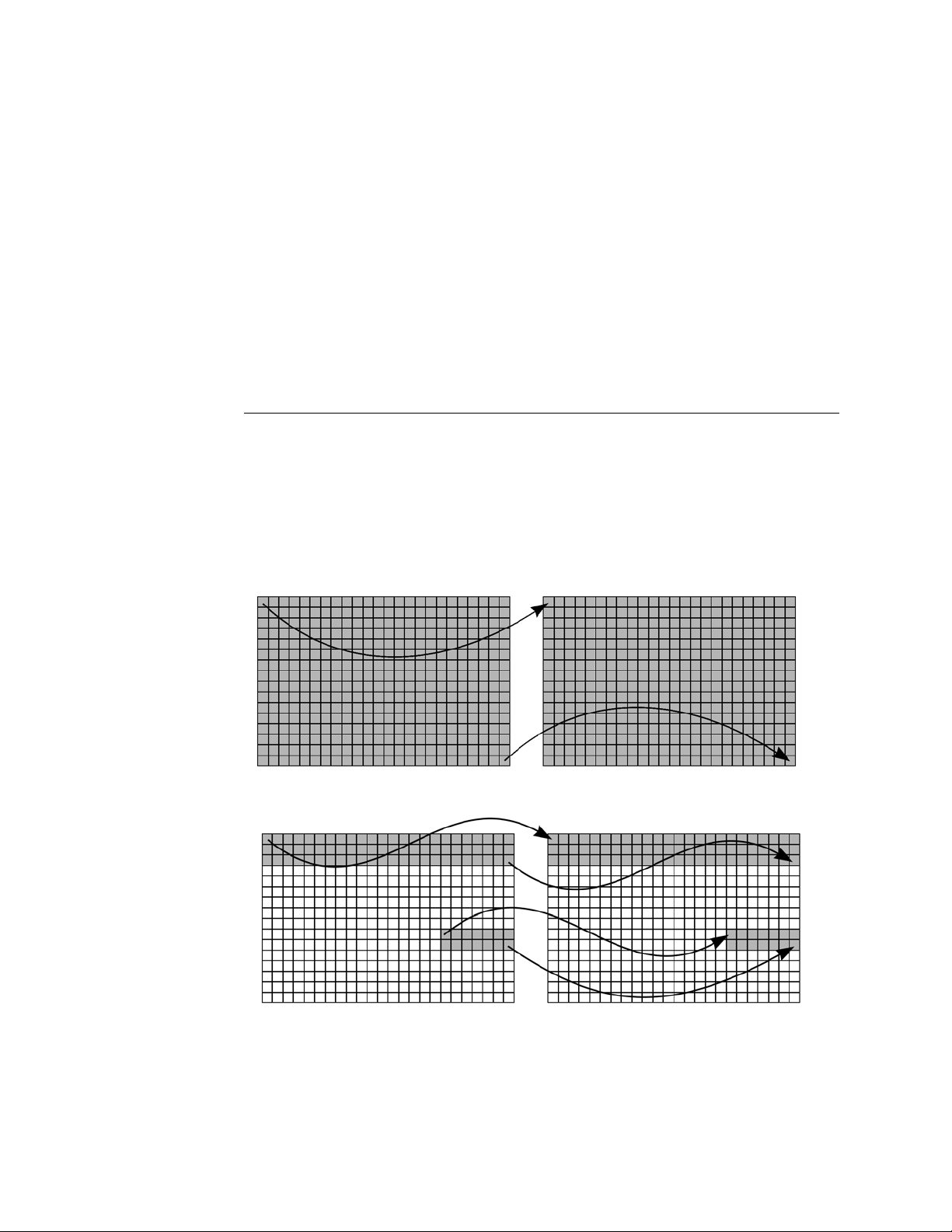

1.3.1 384-plate to 384-plate liquid transfer

Figure 1.7 and Figure 1.8 below illustrate simple fluid transfers between

two 384-well microplates. While Figure 1.7 shows a full-plate transfer,

Figure 1.8 shows a multi-region, partial plate transfer. Both transfer

protocols are easily defined by the operator using the Echo liquid handler

software.

Figure 1.7 384 to 384 full plate transfer

Figure 1.8 384 to 384 multi-region, partial plate transfer.

Introduction 1-13

Page 34

Figure 1.9 illustrates a more complex fluid transfer between two 384-well

microplates. Droplets are ejected from multiple source plate wells into the

same destination plate well (pooling). This transfer map and its transfer

protocol cannot be defined using the current software program, but it can

be defined using the Echo Applications software or with the Echo ActiveX

programming interface (refer to Echo Integration Guide).

Figure 1.9 384 to 384 multiple source plate wells pooled into one destination plate well transfer.

1.3.2 384-plate to 96-plate liquid transfer

Figure 1.10 illustrates a 384-well to 96-well quadrant fluid transfer.

Wells from a single 384-well plate can be transferred, or destacked, to four

96-well plates. Individual wells or all wells from each quadrant can be

transferred to the corresponding wells in the destination plate.

Figure 1.10 384 to 96 plate transfer.

1-14 Echo Liquid Handler User Manual

Page 35

1.3.3 384-plate to 1536-plate liquid transfer

Figure 1.11 illustrates a 384-well to 1536-well interleaved fluid transfer. An

interleaved transfer places, or stacks, all source A1 well transfers into a

single cluster on the destination plate. Figures 1.12 and 1.11 clearly show

these two schemes.

Each source microplate requires its own transfer map defining which wells

are to be transferred to the destination microplate. These transfer maps can

be unique for each of the source plates.

If the transfer maps consist of single- or multi-region transfers, the transfer

protocol can be easily defined using the software.

Complex transfer maps can be created using Echo Applications software or

ActiveX programming interface in the Echo Software Development Kit

(refer to the Echo Integration Guide).

Figure 1.11 384 to 1536 interleaved full plate transfer.

Introduction 1-15

Page 36

1.3.4 1536-plate to 384-plate liquid transfer

Figure 1.12 illustrates a 1536-well to 384-well quadrant fluid transfer.

Wells from a single 1536-well plate can be transferred, or destacked, to

four 384-well plates. Individual wells or all wells from each quadrant can be

transferred to the corresponding wells in the destination plate.

Figure 1.12 1536 to 384 quadrant full plate transfer

1-16 Echo Liquid Handler User Manual

Page 37

1.3.5 1536-plate to 1536-plate liquid transfer

Fluid transfers between two 1536-well microplates are exactly the same as

384-plate to 384-plate transfers, except for the well densities.

Note: Echo 555 only: High-throughput transfer of DMSO is available

for the 1536-well LDV plate (1536LDV_DMSO_HT). This special

calibration type uses the same 1536-well LDV plate that is used for

standard DMSO and aqueous transfer; however, the repetition rate for

droplet transfer is much faster. This calibration type is ideal for

preparing multiple screening plates and prewetted plates.

Note: For liquid transfer of very small volumes, or transfer that

requires precise droplet placement, use the 1536LDV_DMSO

calibration.

Introduction 1-17

Page 38

1.4 What system configurations are supported?

The Echo liquid handler can be used in a manual configuration or in several

levels of automated, system integrated configurations. This section explores

the following operating modes:

Manual mode

Software-driven mode

Modular workstation mode

Small cell mode

Fully automated mode

The server/client architecture allows multiple client computers/programs to

connect to an Echo liquid handler at the same time. Read “

considerations” on page 1-23 for a discussion of the advantages and

disadvantages of multiple-client operation.

Note: The software comes with a static IP address (192.168.1.1).

If this IP address is not available, or if you are installing more than one

Echo liquid handler on a network, use the Echo Admin Client (on the

Echo Server 2.4 disk) to change the IP address.

Multi-client

1.4.1 Manual operation

Manual operation leaves control of every step to the operator:

Defining new fluid transfer protocols or new destination microplates

Executing a fluid transfer protocol

Loading and unloading both source and destination microplates

Monitoring status

Figure 1.13 Manual operation.

Manual operation is also used when performing the following functions:

Defining new destination microplates

Defining new fluid transfer protocols

Performing periodic maintenance and calibration

For more information about manual operation, read Chapter 4.

1-18 Echo Liquid Handler User Manual

Page 39

1.4.2 Echo applications

Labcyte provides the following Echo Applications that extend beyond the

basic Echo software to enable the operator to easily create a variety of

more complex destination plates.Labcyte currently provides the following

software applications:

Echo Dose-Response: eliminates the tedious and error-prone steps

in manual serial dilution to produce assay-ready microplates for IC50,

EC50, and dose-response curves; includes creation of intermediate

plate for additional concentrations; generates customizable reports in

common data formats.

Echo Cherry Pick: transfers sample from any source well to any

destination well; uses customer-provided pick list to automate platemapping; generates customizable reports for tracking sample data.

Echo Plate Reformat: automates microplate replication, down-

stacking and up-stacking microplates; also provides custom plate

mapping for pooling, transposing or interleaving samples.

Echo Array Maker: automates sample transfer for specialized

microplates, such as protein crystallization; enables custom array

creation to SBS-compliant destination labware.

Echo Plate Audit: enables customers to collect information on

sample properties such as fluid height, fluid volume, and

composition; quickly assess sample quality across plates.

For customers requiring additional customization, Labcyte also provides

Echo application programming interfaces and code examples to integrate

the Echo system into their own laboratory automation system.

Contact your Labcyte representative for information on the Echo

applications listed above or on the Echo SDK (software development kit).

Introduction 1-19

Page 40

1.4.3 Modular workstation operation

Modular workstation operation differs from manual operation with the

addition of a robot to automate the loading and unloading of source and

destination plates. Typically, a custom program is written that controls and

synchronizes the Echo liquid handler and robot interactions.

An operator is still involved and performs the following functions:

Deliver master source microplates from the compound library.

Maintain a supply of empty destination microplates.

Select and execute the fluid transfer protocol.

Deliver the filled assay microplates to the next step in the process.

Monitor the status of the Echo liquid handler and the robot, possibly

with the assistance of a custom software program.

Figure 1.14 Modular workstation operation

1-20 Echo Liquid Handler User Manual

Page 41

1.4.4 Small cell operation

Small cell operation includes the automation of HTS processes other than

liquid transfer. Those processes might include several of the following:

Lidding and delidding

Microplate labeling

Microplate sealing

Incubation

Reaction detection

Temperature or humidity control

Reagent addition

Wash station (used with other instruments)

Small cell mode operation

Figure 1.15 Small cell mode operation

Introduction 1-21

Page 42

1.4.5 Fully automated operation

A more fully automated operation expands on the small cell concept and

may incorporate a larger range of processes and operations.

Figure 1.16 Full automated mode operation

Larger, fully automated

drug discovery labs might

include the following:

• A larger combination

of the processes and

stations listed in the

discussion of a small

cell mode operation.

See “Small cell

operation” on

page 1-21.

• One or more

supervisory

workstations.

• A conveyor system to

move microplates and

other material not only

between stations, but

into and out of the

lab.

• Multiple robots,

individually chosen

and programmed to

support a specific

function or machine.

• Multiple liquid

handlers.

Note: Echo Admin

Client allows the

operator to change

the IP address on the

client. This is included

with the Echo Server

2.4 disk.

1-22 Echo Liquid Handler User Manual

Page 43

1.4.6 Multi-client considerations

Larger research labs may have many computers, instruments, controllers,

and other devices interconnected on an Ethernet LAN (local area network).

Please review the following information and take appropriate measures to

avoid conflicts caused by multiple workstations controlling an Echo liquid

handler inappropriately.

The Echo liquid handler can be connected to a network or to more than

one workstation. This configuration allows one or more users to control the

Echo remotely, to download liquid transfer information directly to the

network, or to connect more than one Echo liquid handler to an automated

filling operation.

Figure 1.17 Multiple clients talking to an Echo liquid handler.

For example, a local workstation might be used to do the following:

Monitor instrument status.

Perform user maintenance.

Execute troubleshooting procedures.

At the same time, a central system may be used to control all of the day-today work flow involving the instruments in the lab. In relation to an Echo

liquid handler, it might be involved in the following:

Define fluid transfer protocols.

Define destination microplates.

Deliver source and destination microplates to the Echo liquid handler

via conveyor belt and robot.

Remove source and destination microplates.

Execute fluid transfer protocols.

Handle all of the data.

Introduction 1-23

Page 44

The Echo liquid handler is a client/server system. The “client” is the external

workstation that contains the user interface software to define plate and

protocol information. The “server” is the controller that runs the

instrument motors and sensors. Each subsystem is independent, with its

own system checks. This architecture allows the Echo liquid handler to be

commanded by multiple clients to run concurrent operations, yet ensure

that each operation is “safe” with respect to each other.

For example, one user might command the Echo liquid handler to do a

plate survey, then a liquid transfer protocol. During the source plate survey,

another user might command the Echo liquid handler to extend the source

plate. The plate survey that is in progress will continue to completion, then

extend the source plate. Thus, while the Echo liquid handler guarantees

"safe" operation, it cannot prevent the commands of one user interfering

with those of a second user.Therefore, it is the responsibility of the users to

coordinate their actions to ensure the proper fulfillment of a transfer

protocol.

Also, if more than one user creates, edits, or deletes fluid transfer protocol

definitions or destination microplate definitions, then there must be

communication between users to ensure that the definitions are consistent

with the protocols.

Users should be aware of the following considerations with the client/

server architecture.

An Echo liquid handler is not limited to a single client. One or more

clients can either monitor its status or command it to execute its

functions.

Uncoordinated clients could cause out-of-order execution that

interferes with other users' protocols. For example, client “A” could

delete or edit a protocol or destination microplate definition created

by client “B.” An edited protocol definition would only be detected if

the original definition was stored on client “B” and compared to the

definition in the database.

1-24 Echo Liquid Handler User Manual

Page 45

C HAPTER

2

CHAPTER 0INSTALLATION AND RELOCATION

Labcyte installs the Echo liquid handler and Echo software for the

customer. However, site preparation and additional software installation

are the customer’s responsibility.

This chapter covers pre-installation requirements, additional software

installation, and instrument relocation.

This chapter also provides a brief overview of the shipment contents and

installation steps performed by Labcyte field engineers.

Pre-installation requirements

Installation overview

Software installation

Instrument Relocation

Installation and Relocation 2-1

Page 46

2.1 Pre-installation requirements

5

9

c

m

(

2

3

.

2

i

n

)

9

9

c

m

(

3

9

i

n

)

118 cm (46.5 in)

Operating

Side clearance

Side clearance

2.5 cm (1 in)

2.5 cm (1 in)

30.5 cm (12 in)

Rear clearance

Top clearance

25.4 cm (10 in)

Envelope

7.6 cm (3 in)

Front clearance

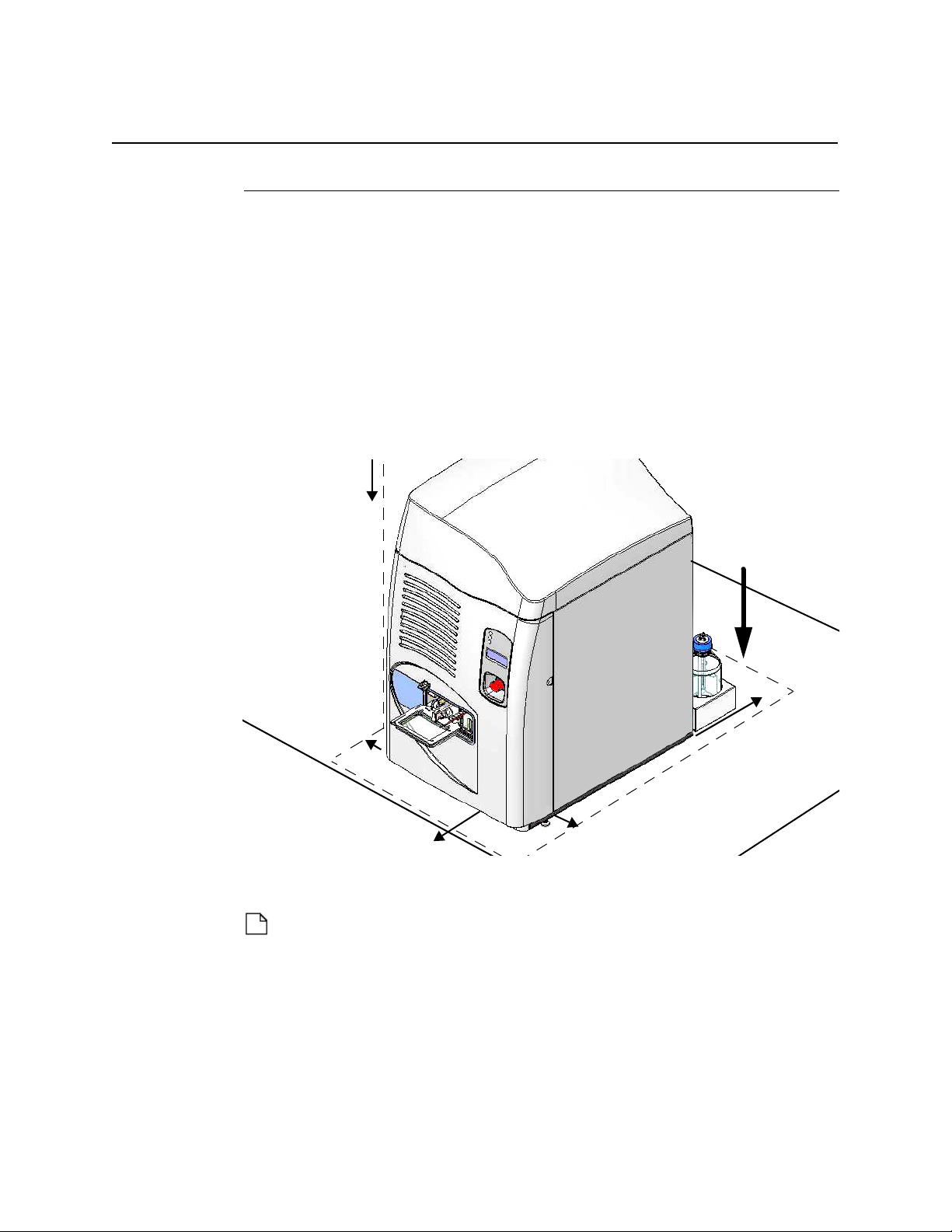

2.1.1 Site requirements

The following site requirements must be met before installation:

Operating environment of 19°–26°C (66°–79°F) and 10%–80%

relative humidity, non-condensing.

Sturdy, level, water-resistant bench top capable of supporting

128 kg (283 lbs) with sufficient bench space to accommodate the

Echo liquid handler in a minimum operating envelope as follows (see

Figure 2.1):

Operating space envelope: 59 cm (23.2 in) width x 99 cm (39 in)

depth x 118 cm (46.5 in) height

Figure 2.1 Instrument layout on bench top

2-2 Echo Liquid Handler User Manual

Top clearance: 25.4 cm (10 in) minimum above the instrument to

remove the top cover for servicing.

Note: Less height clearance (>2.5 in) is acceptable if there is

sufficient space to lift the top and slide it all the way forward. Talk to

your Labcyte field engineer.

Front clearance: sufficient clearance to load and unload microplates

by hand or by robot.

Side clearance: 2.5 cm (1 in) minimum on left and right sides.

Page 47

Rear clearance: 30.5 (12 in) minimum behind the instrument to

allow for cables, hoses, tubing, and maintenance access

Note: The coupling fluid bottle and caddy fit within the rear

clearance. If you position the bottle and caddy on the side of the

instrument, add at least 17.8 cm (7 in) to the side clearance.

The caddy must be placed within 16” of tubing run to the Echo.

Additional space for the client PC, coupling fluid chiller (if it is on the

bench), and microplates. Additional space would also be needed if

you use robotics.

AC power: The user must provide AC power matching one of the

two following power configurations:

115 VAC, 50/60 Hz, 10 A

230 VAC, 50/60 Hz, 5 A

Note: The power configuration is factory set and cannot be changed

onsite.

Compressed air source: Clean, dry air at 552 kPa (80 PSI) minimum,

1034 kPa (150 PSI) maximum. Consumption not to exceed 1cf/m @

150 PSI.

Labcyte provides the compressed air line and fitting with the Echo

liquid handler, but the customer must provide a source compatible

with 170 in ID/.250 in OD tubing.

Vacuum source: Vacuum returns the coupling fluid to the supply

bottle and dries source plates before they are unloaded. Customer

must provide a fitting that connects 3/8”ID, 5/8”OD tubing to either

house vacuum or vacuum pump. Vacuum source should have the

following specifications:

House vacuum:

Minimum vacuum at Echo connection: 200 Torr (266 mbar, 22 in Hg Vac)

Vacuum system capacity steady state: 15 L/min (0.9 m3/h, 0.53 cf/m)

3

Drying surge: 80 L/min for 10 sec, (4.8 m

/h, 2.8 cf/m),

33% max duty cycle.

Vacuum pump:

Minimum vacuum at Echo connection: 100 Torr (133 mbar, 26 in Hg Vac)

Pump flow rate: with 10 L surge tank: 40 L/min (2.4 m3/h, 1.4 cf/m)

without surge tank (not recommended): 80 L/min (4.8 m

3

/h, 2.8 cf/m)

Note: The 10 L surge tank comes standard with the Echo liquid

handler to ensure consistent vacuum.

Installation and Relocation 2-3

Page 48

2.1.2 Additional components

The following components are needed to work with the Echo liquid

handler:

Chiller for maintaining a constant fluid temperature. Included with

the Echo system. See “

information.

Distilled water for filling the chiller well, coupling fluid bottle, and

coupling fluid circuit.

Caution: Do not use de-ionized water, as it may corrode the fluidics

system.

Client PC (customer’s computer) running the Echo software to

monitor and control the Echo liquid handler. The PC should have an

Intel® Core™ 2 Duo processor or equivalent with Windows XP

Professional (SP3 or later); 1GB of RAM, minimum; 1 GB of available

disk storage; video resolution of 1280 x 1024; and a 10/100/1000

baseT Ethernet port.

Note: If you are integrating the Echo liquid handler into an

automated HTS (High Throughput Screening) system and need to

install the Client + Server software onto a workstation, it must

contain an Intel Core™ 2 Duo processor or better.

Chiller Information” on page C-1 for more

Network IP address: A static IP address must be allocated for the

Echo liquid handler. If you cannot use the preconfigured IP address

(192.168.1.1) in your network, or if you are installing more than one

Echo liquid handler, use the Echo Admin Client (included on the Echo

Server 2.4 disk) to change the IP address on the client PC.

2-4 Echo Liquid Handler User Manual

Page 49

2.2 Installation overview

Ethernet cable

Compressed air line

Vacuum line

Client PC

Chiller

Echo liquid handler

fluid lines

Chiller

Bench

Floor

(cross-over)

Surge tank

The Labcyte Echo liquid handler is installed by Labcyte field engineers. The

following is a brief overview of the hardware and software installation

steps they perform:

1. Unpack the Echo liquid handler and place it in the area that meets the

minimum operating space requirement.

2. Connect the Echo liquid handler to AC power, air pressure, vacuum

pressure, surge tank, coupling fluid bottle, and the coupling fluid chiller.

3. Fill the coupling fluid bottle and prime the coupling fluid circuit.

4. Perform a basic functional check of the Echo liquid handler.

5. Perform the Site Acceptance Test (SAT) process (optional).

6. Change the Echo IP address, if a different IP address is required by your

system administrator.

7. Install the Echo software onto the customer-supplied PC

(client workstation).

8. Connect the client PC to the Echo liquid handler and verify

communications.

Figure 2.2 Installed system

Installation and Relocation 2-5

Page 50

2.3 Software installation

Labcyte installs the Echo software onto the client PC that is connected to

the Echo liquid handler. If you need to install the software onto additional

computers, such as network PCs, use the instructions provided in this

section.

See “

Multi-client considerations” on page 1-23 for advantages and

disadvantages of connecting more than one workstation.

Note: If you are connecting the Echo liquid handler to a LAN via a

hub, switch, or router, use a standard ethernet cable. If you are

connecting the Echo liquid handler directly to a workstation, use the

included “cross-over” Ethernet cable.

During installation the Echo software will provide the following

installation types:

Client (Only): Installs the Echo software onto the client PC that is

connected to the Echo liquid handler (normal mode). The software

allows the operator to communicate with, control, and monitor an

Echo liquid handler through easy-to-use software screens (Graphical

User Interface). This option requires a host name or IP address of the

Echo server.

1

Client and Server:

Normal Mode installs the Echo client software onto the client PC

and the Echo server software onto the Echo controller. This

software is installed by Labcyte field engineers.

Stub Mode creates a virtual Echo instrument onto the client PC

that developers can use to develop and test custom software.

Note: Use this installation type only if you are writing your own

programs that will call the Echo ActiveX programming interface. Call

Labcyte Service and Support if you have any questions regarding this

installation type.

1 Ethernet cable that switches, or crosses over, receive and transmit wire pairs that enable

two devices to communicate with each other.

2-6 Echo Liquid Handler User Manual

Page 51

2.3.1 Install the software

The following procedure describes installation of Client (Only) software. For

information on installing Client + Server software, refer to the Labcyte Echo

Integration Guide.

To install Echo liquid handler software:

1. Insert the Echo liquid handler software installation CD into the CD drive.

The installation should automatically start.

If the installation does not start:

a. Go to My Computer and double-click the drive icon for the CD drive.

b. Look for setup.exe in the directory on the CD and double-click the

icon.

c. Select Install Client (Only)

2. Enter the Host Name or IP address that will be used by the Echo server.

The Echo liquid handler comes pre-configured with IP address

192.168.1.1 and a subnet mask of 255.255.0.0. If you cannot use this IP

address, run the Echo Admin Client on the Echo Server 2.4 disk to enter

a different IP address.

Figure 2.3 Entering host name

Installation and Relocation 2-7

Page 52

3. Click N

EXT and and then INSTALL to start the installation. Edit or verify

the previously entered information or selections by clicking the BACK

button.

Figure 2.4 Starting installation

A dialog window will report the installation’s activity and progress.

4. Click the FINISH button when the installation is done.

Note: Read the release notes for information about the version of

software being installed. The release notes are stored in the Labcyte

Echo liquid handler folder on your Windows Desktop for later viewing.

2-8 Echo Liquid Handler User Manual

Page 53

2.3.2 Uninstall the Echo software

If you need to uninstall the Echo software, use the following procedure:

1. Click the START button on the Windows Taskbar.

2. Point to SETTINGS and select CONTROL PANEL.

3. Double-click ADD OR REMOVE PROGRAMS.

4. Select Echo liquid handler and click REMOVE.

2.3.3 Upgrade the Echo software

Upgrading the software requires a new Echo software CD. Contact Labcyte

Service and Support for the most current version. See “Contact

information” on page 7-1.

Depending on your current software version, you may need to run a clean

installation. Check with Labcyte Service and Support to determine if your

software can be upgraded. If not, you will need to perform a new (or clean)

installation. Back up your existing liquid transfer and plate definition data.

1. Insert the new Echo liquid handler software CD on the client PC.

2. Follow the installation instructions. See “Install the software” on

page 2-7.

Installation and Relocation 2-9

Page 54

2.4 Instrument Relocation

Note: If you do not plan to set up the Echo liquid handler within two

weeks, refer to “

2.4.1 Prepare the Echo liquid handler for a move

Use the following procedure if the Echo liquid handler must be moved:

1. Determine if the move must involve Labcyte.

If the move requires transportation (truck, air, train) call Labcyte

Service and Support. Do not attempt to move the Echo liquid handler

yourself.

If the move can be easily accomplished using a moving dolly or cart,

the move can be performed without Labcyte involvement. If you have

any questions, contact Labcyte Service and Support See “

information” on page 7-1.

2. Finish any operation in progress.

3. Remove microplates and microplate inserts from the Echo liquid handler.

Extended Non-Use and Storage” on page 6-19.

Contact

4. Turn off the Echo liquid handler and the fluid chiller.

See “Turn off Echo power” on page 4-5 and “Chiller Setup and

Operation” on page C-3.

5. After the Echo liquid handler has been powered down, disconnect the

following lines from the back panel.

Chiller input and output tubing

Compressed air supply line

Vacuum supply line

Ethernet cable

AC power cable

Coupling fluid bottle, caddy, and cable

6. Use proper safety procedures to lift the Echo liquid handler gently onto a

moving dolly or cart of sufficient size and strength to support the unit.

j

Warning: The Echo liquid handler weighs approximately 128 kg

(283 lb.). Moving or lifting the Echo liquid handler incorrectly can cause

severe injury. Never attempt to move or lift the Echo liquid handler

without using proper equipment and trained personnel.

7. Move the Echo liquid handler and ancillary equipment and material

(bottles, tubing, microplates, source plate inserts, etc.) to the new

location, which should already be prepared and comply with all preinstallation requirements.

See “

Pre-installation requirements” on page 2-2.

2-10 Echo Liquid Handler User Manual

Page 55

2.4.2 Reinstall the Echo liquid handler after a

Fluid level sensor

move

After the move, use the following procedure to restore an Echo liquid

handler to normal operation.

1. Ensure that the new mounting surface is level.

2. Set up the Echo liquid handler, bottles, computer, and other ancillaries.

Remember to allow for minimum operating space around the Echo

liquid handler. See “Site requirements” on page 2-2.

3. Set up and start the chiller. See “Chiller Setup and Operation”in

Appendix C for instructions.

4. Set up the coupling fluid bottle. Ensure that the bottle cap is firmly

attached to ensure a tight vacuum seal. Place the filled coupling fluid

bottle in the caddy. The fluid level sensor (red LED) should be visible on

the side wall of the instrument to confirm that the bottle is positioned

correctly and is filled.

Figure 2.5 Fluid level sensor in bottle caddy

Note: Older systems hold the fluid bottle in a separate caddy with the

sensor showing through the hole on the top of the caddy. Also, some

older systems use a waste bottle.

Installation and Relocation 2-11

Page 56

5. Connect the air pressure and vacuum pressure supply lines to the fluidics

Coupler fluid bottle cap

(blue bottle cap)

From vacuum source

To coupler catch nozzle

(long, straight tube)

From catch basin

(J-tube)

From chiller (WATER OUT)

To chiller (

WATER IN)

panel. The connections are labeled for easy reference.

Figure 2.6 Bottle connections

Caution: Do not run the pump until the vacuum source is connected

and active. Running the pump without vacuum can lead to flooding

the system or a system error.

6. Connect the chiller. Attach the plastic tubing between the chiller and the

Echo liquid handler.

Figure 2.7 Tubing connections on the chiller

2-12 Echo Liquid Handler User Manual

Page 57

Caution: Do not run the pump until the chiller tubing is connected.

Fluidics panel

From chiller (Water In)

To chiller (Water Out)

Compressed air line (Air In)

Vacuum line (Vacuum)

Running the pump without the chiller tubing may damage other

system components.