Labconco Labconco-6544100_rev_f_rapidstill_ii_user_manual RapidStill II Models 6520000 User's Manual

RapidStill™ II

Models

6520000

Copyright © 2017 Labconco Corporation. The information contained in this manual and the

Warranty

Labconco Corporation provides a warranty to the original buyer for the repair or replacement of parts and

reasonable labor as a result of normal and proper use of the equipment with compatible chemicals. Broken

glassware and maintenance items, such as filters, gaskets, light bulbs, finishes and lubrication are not

warranted. Excluded from warranty are products with improper installation, erratic electrical or utility

supply, unauthorized repair and products used with incompatible chemicals.

The warranty for the Rapid Still II will expire one year from date of installation or two years from date of

shipment from Labconco, whichever is sooner. Warranty is non-transferable and only applies to the owner

(organization) of record.

Buyer is exclusively responsible for the set-up, installation, verification, decontamination or calibration of

equipment. This limited warranty covers parts and labor, but not transportation and insurance charges. If the

failure is determined to be covered under this warranty, the dealer or Labconco Corporation will authorize

repair or replacement of all defective parts to restore the unit to operation. Repairs may be completed by 3rd

party service agents approved by Labconco Corporation. Labconco Corporation reserves the rights to limit

this warranty based on a service agent’s travel, working hours, the site’s entry restrictions and unobstructed

access to serviceable components of the product.

Under no circumstances shall Labconco Corporation be liable for indirect, consequential, or special damages

of any kind. This warranty is exclusive and in lieu of all other warranties whether oral, or implied.

accompanying products are copyrighted and all rights reserved by Labconco Corporation. Labconco

Corporation reserves the right to make periodic design changes without obligation to notify any

person or entity of such change.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight

carrier. Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the

delivery carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed

by various federal, state, or local regulations. All users of this equipment are required to become

familiar with any regulations that apply in the user’s area concerning the dumping of waste materials

in or upon water, land, or air and to comply with such regulations. Labconco Corporation is held

harmless with respect to user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-8215525 or 1-816-333-8811, between the hours of 7:30 a.m. and 5:30 p.m., Central Standard Time.

Part #6544100, Rev. F

ECO L123

T

T

AABBLLEE

O

O

FF

C

C

OONNTTEENNTTSS

CHAPTER 1: INTRODUCTION 1

Components Shipped 1

General Description 2

Performance 2

Component Identification 3

CHAPTER 2: INSTALLATION 8

Location 8

Electrical Connection 8

Water Connection 8

Drain Connection 9

NaOH Pump Connection 9

Optional Water Inlet Kit 10

Rear View of Standard RapidStill II 11

Rear View w/Optional Water Inlet Kit Installed 12

CHAPTER 3: NORMAL OPERATION 13

Standard Operation Procedure 13

Safety Precautions 14

CHAPTER 4: ROUTINE MAINTENANCE 16

CHAPTER 5: SERVICING THE RAPIDSTILL II 18

Fuse Replacement 18

Removing the Boiler 18

Heating Element Replacement 19

Condenser Extension Replacement 19

Timer Replacement 20

NaOH System Service 20

CHAPTER 6: TROUBLESHOOTING 22

CHAPTER 7: REPLACEMENT PARTS 24

APPENDIX A: DIMENSIONS 26

APPENDIX B: SPECIFICATIONS 27

APPENDIX C: WIRING DIAGRAM 28

APPENDIX D: REFERENCES 29

1

CChhaapptteerr 11::

IInnttrroodduuccttiioonn

Part Number

Description

6520000

RapidStill II

6544100

User’s Manual

Installation Kit (Contains hoses and fittings)

!

Thank you for displaying confidence in us by selecting a Labconco RapidStill II.

Our design engineers, assemblers and inspectors have utilized their skills and

years of experience to ensure that the Labconco RapidStill II meets our high

standards of quality and performance.

This manual should be read carefully by all the end users in

order to become familiar with the operation of the RapidStill II.

Recommendations are made within the manual to help you

obtain maximum performance and life from your product.

We have included sections on initial set up, operation, and

maintenance to provide you with all the tools necessary to

achieve maximum performance. If you have questions or

concerns, do not hesitate to call us at 1-800-821-5525 for

assistance.

WARNING: The disposal of substances used in connection with

this equipment may be governed by various federal, state or

local regulations. All users of this equipment are urged to

become familiar with any regulations that apply in the user’s

area concerning the dumping of waste materials in or upon

water, land or air and to comply with such regulations.

Components Shipped

Carefully check the contents of the carton for damage that might have occurred in

transit. Do not discard the carton or packaging material until all components have

been checked against the following component list and the equipment has been

installed and tested.

As shipped, the carton should contain the following:

Product Service 1-800-522-7658

Chapter 1: Introduction

2

General Description

The Labconco RapidStill II is designed specifically for the determination of

macro concentrations of nitrogen. The RapidStill II performs rapid steam

distillation from sulfuric acid digest prepared from nitrogen-bearing materials

such as food products, feeds, grains, soils, plant tissue, wastewater effluent,

organic wastes, etc. Sample digestions are accomplished using Labconco’s Rapid

Digestor systems, described in the Accessories section of this manual.

Figure 1

Performance

The RapidStill II produces steam by heating a 1 liter flask (boiler) with a 1200

watt heating element. Activation of the heater, the addition of water to the boiler,

and the addition of NaOH to the sample are all controlled by switches on the front

control panel of the unit. An electric timer on the control panel allows the

distillation time to be set from 0 to 15 minutes. Typical distillation times range

from 5 to 10 minutes.

Product Service 1-800-522-7658

Chapter 1: Introduction

3

Component Identification

Component Identification (Figure 2)

(1) Boiler Water Switch. This momentary contact switch fills the boiler

with water. It is interlocked to prevent its operation during the heating

of the boiler. Water should never be added to the boiler when it is hot

and low on water (less than ¼ full) or dry. Allow the boiler to cool

before adding water.

(2) Boiler Heater Switch. The boiler heater switch activates the boiler

heating element. The Boiler Heater should never be turned on when

the boiler is dry or low on water.

(3) NaOH Addition Switch. This momentary contact switch activates the

NaOH pump to pump caustic from a user-supplied vessel into the

digestion tube. The switch is interlocked to operate only when the

boiler heater is on. At the end of every day, the NaOH pump lines

must be rinsed with purified water.

(4) Digestion Tube Clamping Device. The clamping device quickly and

securely locates the digestion tube against the connection stopper.

(5) Safety Door. The safety door surrounds the digestion tube and is

designed to protect the operator. The door should always be in the

closed position during operation of the RapidStill II.

(6) NaOH Delivery Tube. This tube is used to dispense the user-supplied

caustic directly into the digestion tube.

(7) Connection Stopper. The stopper located on the bottom of the

distribution head seals the digestion tube to the head. The connection

stopper should be inspected and cleaned after every operating session

of the unit.

(8) Distribution Head. This distribution head acts as a junction for the

steam and NaOH delivery tubes. The central part of the distribution

head acts as a trap by preventing the NaOH from entering the

receiving flask.

(9) Steam Inlet Tube. The steam inlet tube is PTFE and dispenses steam

directly into the digestion tube.

(10) Condenser Extension. The condenser extension is a replaceable

glassware fitting that connects the condenser and distribution head.

(11) Condenser. The RapidStill II is equipped with a combined Allihn and

spiral condenser for efficient recovery of the distillate.

Product Service 1-800-522-7658

Chapter 1: Introduction

4

(12) Ventilation Valve. The ventilation valve prevents the distillate from

being aspirated back into the condenser after the distillation is

completed. If the valve sticks closed, remove it and wash out any

material accumulated inside the valve.

(13) Safety Screen. The plastic safety screen is designed to protect the

operator. The screen should always be in the closed position during

operation of the RapidStill II.

(14) Boiler Viewing Slot. Looking through this slot the operator can easily

inspect the water level in the boiler. Low and high water level marks

are on the boiler flask to ease the inspection and addition operations.

(15) Distillate Outlet Tube. This tube carries distillate from the condenser

to the solution in the receiving flask. The bulb of the tube must be

totally immersed in the receiving solution.

(16) Distillation Timer Switch. The infinitely adjustable 0-15 minute

timer controls the dispensing of steam into the digestion tube. It is

interlocked to function only when the boiler heater is on. As an

additional safety measure, NaOH cannot be dispensed into the

digestion tube when the timer is in operation.

(17) Spillage Tray. The spillage tray is designed to collect spilled reagents

and overflow. The tray is removable and may be cleaned with

ordinary soap and water.

Product Service 1-800-522-7658

Chapter 1: Introduction

5

Figure 2

Product Service 1-800-522-7658

Chapter 1: Introduction

6

Component Identification (Figure 3)

(18) Heater Cup Assembly. The heater cup assembly consists of the heater

cup to support the boiler, and the heating element itself.

(19) Boiler. The 1 liter boiler contains the boiling water that is the source

of steam for the distillation.

(20) Water Fill Valve. The valve dispenses water into the boiler when it is

energized. The inlet of the valve is equipped with a filter screen, to

prevent fouling with particulate matter.

(21) Plastic Check Valves. These valves function as vacuum breaks,

preventing negative pressurization of the system after it is shut off.

(22) Steam Control Valve. The steam control valve directs steam from the

boiler to the drain pipe during standby, or the steam delivery tube

during distillation. The valve is controlled by the timer switch.

(23) Drain Pipe. The drain pipe acts as a condenser for the steam not used

in the distillation and as a drain for the condenser cooling water. DO

NOT restrict the discharge from the drain pipe or its hose. The

RapidStill II may be damaged by high water pressure.

(24) Flow Restrictor. The flow restrictor prevents the cooling water flow

rate from exceeding 1.0 gallon per minute. This minimizes water

usage and prevents damage to the unit.

(25) NaOH Pump. The peristaltic pump dispenses a user-supplied caustic

solution from its container directly into the digestion tube. The pump

inlet and outlet are equipped with quick connects to reduce the

possibility of spillage during maintenance. The pump must be rinsed

with purified water at the end of every work day to prevent damage to

the pump or its fittings.

(26) Water Inlet Fitting. The water inlet fitting is a push-on style fitting

designed to connect tot the feed water line supplied in the installation

kit.

(27) Electrical Connector. The electrical connector mates with the power

cord supplied in the installation kit.

(28) Fuse. The 15 amp fuse protects the RapidStill II from an electrical

overload. Replace this fuse with the appropriate replacement part.

NEVER attempt to install a fuse with a higher amperage rating.

Product Service 1-800-522-7658

Chapter 1: Introduction

7

Figure 3

Product Service 1-800-522-7658

8

CChhaapptteerr 22::

IInnssttaallllaattiioonn

Location

The RapidStill II should be located on a level work surface, adjacent to

appropriate electrical, water and drain connections.

Electrical Connection

The electrical outlet should be rated for 115 VAC, 60 Hz, 15 Amps, and dedicated

to the RapidStill II.

Water Connection

The feed water should be municipal drinking water grade and of sufficient quality

to prevent or minimize scaling of the boiler. The feed water should have a

minimum supply volume of 1 gallon (3.8 liters) per minute, at 10 PSI.

Using the supplied braided water line, connect the tube to the water inlet fitting on

the rear of the RapidStill II as shown in Figure 3. To connect or disconnect the

fittings, follow the instructions in Figure 4, below. If your feed water promotes

excessive scaling of the boiler, or has high NH3 levels, you may wish to install the

Optional Water Inlet Kit, part #6544200.

Product Service 1-800-522-7658

Chapter 2: Installation

9

Figure 4

Drain Connection

Using the supplied molded drain hose, connect and clamp the hose to the drain

outlet located at the bottom of the drain pipe. The drain hose should be routed to

an appropriate drain system, rated for a minimum capacity of 2 gallons (7.6 liters)

per minute. The RapidStill II’s drain pipe is designed for gravity drainage. The

drain hose and all connections must be below the level of the drain pipe outlet.

The drain hose connection to the drain system must meet all applicable local

standards for drain connections. DO NOT restrict the drain hose or its

connections. Restrictions of the drain line may produce a pressure buildup

in the RapidStill II, resulting in damage to the unit and water leakage.

NaOH Pump Connection

Using either the silicone tubing supplied in the installation kit, or another

acceptable type of tubing, connect the NaOH pump inlet quick connector to the

tubing. Connect the connector to the pump inlet by pressing it straight in until the

connector ‘clicks’ and locks in place. The connector can be removed by

depressing the metal button on the body of the connector and pulling the

connector straight out. Place the other end of the tubing into the user-supplied

caustic container. Provisions should be made for the easy removal of the tube

from the caustic container, and its placement into a container of purified water for

rinsing of the system at the end of each work session.

Product Service 1-800-522-7658

Chapter 2: Installation

10

Optional Water Inlet Kit

With the purchase and installation of the Optional Water Inlet Kit, part #6544200,

two separate water supplies may be used to feed the RapidStill II; ordinary tap

water may be used to supply the condenser while purified water is fed to the

boiler.

To function properly, the purified water source must be capable of delivering 1

gallon (3.8 liters) per minute at a minimum of 5 PSI. The purified water supply

pressure should not exceed 20 PSI.

The kit is installed as follows:

(1) Unplug the RapidStill II and disconnect the feed water and drain lines,

so the unit can be turned around.

(2) Turn the unit around and locate the water inlet fitting as shown in

Figure 5.

(3) Locate the optional water inlet hole just above the water inlet fitting,

as shown in Figure 5.

(4) Install the supplied bulkhead union in a manner similar to the water

inlet fitting below it. DO NOT overtighten the nut on the bulkhead

union; it may damage the fitting.

(5) Remove the flow restrictor assembly from the T-shaped fitting.

Discard the short length of rigid plastic tubing that runs from the outlet

of the flow restrictor to the T-shaped fitting.

(6) Disconnect the condenser inlet fitting from the T-shaped fitting, as

shown in Figure 5.

(7) Plug the flow restrictor outlet into the condenser inlet fitting, as shown

in Figure 6.

(8) Install the braided tube assembly supplied with the kit from the

bulkhead union installed in Step #4 to the T-shaped fitting.

(9) Install the supplied plug into the open port of the T-shaped fitting.

(10) When completed, the installation should appear as shown in Figure 6.

The upper bulkhead fitting (that was just installed) supplies the boiler

with water and may be connected to a purified water source. The

lower bulkhead fitting (the original fitting) will now supply only the

condenser with cooling water and should remain connected to an

appropriate supply of feed water (tap water).

Product Service 1-800-522-7658

11

Rear View of Standard RapidStill II

Chapter 2: Installation

Figure 5

Product Service 1-800-522-7658

Chapter 2: Installation

12

Rear View of RapidStill II with Optional Water Inlet Kit Installed

Figure 6

Product Service 1-800-522-7658

13

CChhaapptteerr 33::

NNoorrm

maall OOppeerraattiioonn

Standard Operating Procedure

(1) Turn on the cooling water, allowing it to flow through the

condenser. The flow rate will be regulated to 1 gallon per minute

(3.8 liters per minute).

(2) Depress the ‘Boiler Water’ switch. Looking through the Boiler

viewing slot, fill the boiler approximately 2/3 full, or to the top

line of the flask. If the boiler fills too slowly, slightly increase the

flow rate of the cooling water supply. If the Optional Water Inlet

Kit is installed and the boiler fills too slowly, increase the pressure

or flow rate of the purified water supply. When the proper water

level is obtained, release the switch.

(3) Turn the ‘Boiler Heater’ switch to the ‘ON’ position. After

approximately 10 minutes, or when the water in the boiler is at a

steady boil, the unit is ready for operation.

(4) Place the digestion tube with a digested sample in the RapidStill

II, giving the tube a slight twist to assure a complete seal.

(5) Place a receiver flask under the Distillate Outlet Tube. Make sure

that the outlet tube is fully submerged.

(6) Add NaOH solution to the digestions tube by depressing the

‘NaOH Addition’ switch. For each 5 ml of concentrated sulfuric

acid used in the digestion process, add approximately 15 ml of

50% NaOH solution to make the distillation solution strongly

alkaline. Use the graduated decal on the front panel of the

RapidStill II as an approximate gauge of the volume in the

digestion tube.

(7) Turn the distillation Time switch to the desired time setting. Be

sure to allow enough time for the distillation solution to reach

boiling.

Product Service 1-800-522-7658

Chapter 3: Normal Operation

14

(8) When the distillation is completed, the unit will return to a

standby position, with the boiler heater still in operation.

(9) Remove the digestion tube, using appropriate heat and chemically

resistant gloves.

(10) If there are to be additional distillations and the boiler water level

is low, turn the ‘Boiler Heater’ switch off and depress the ‘Boiler

Water’ switch on. Allow the boiler to refill with water, release the

‘Boiler Water’ switch and turn the ‘Boiler Heater’ switch on.

When the water in the boiler resumes boiling, the RapidStill II is

ready for another distillation.

(11) Titrate the distillate in the receiving flask. If the temperature of

the solution exceeds 120°F (50°C), check the flow rate of the

condenser cooling water.

Safety Precautions

The disposal of substances used in connection with this equipment may be

governed by various federal, state or local regulations. All users of this

equipment are urged to become familiar with any regulations that apply in the

user’s area concerning the dumping of waste materials in or upon water, land

or air and to comply with such regulations.

The RapidStill II should not be operated in damp conditions or those suspect

of an explosion and should be situated to allow adequate room and

ventilation during its normal usage.

The RapidStill II employs the following: electrical devices, heating element,

hot water, steam, pressurized water and steam lines. Care should be taken

when installing, operating, or servicing the unit.

Ensure that the RapidStill II is connected to electrical service in accordance

to local and national electrical codes. Failure to do so may create a fire or

electrical hazard.

The RapidStill II is designed to be connected to a cold, potable water supply

purified by municipal water treatment facilities. The installation of the

optional water inlet kit allows for the use of purified water to supply the

boiler. Never connect the RapidStill II to non-potable, unprocessed surface

or well water systems. The use of inadequate water supplies may damage the

unit.

Always wear appropriate eye protection, protective gloves and clothing when

using the RapidStill II.

Product Service 1-800-522-7658

Chapter 3: Normal Operation

15

Never operate the RapidStill II without the Safety Screen and Safety Door in

their proper position.

Never turn on the boiler heater when the boiler flask is dry or low on water.

Do not let the boiler run dry. Do not attempt to refill the boiler when it is dry

or low on water and hot. Failure to ensure proper water level in the boiler, or

attempting to fill it when hot may result in the breakage of the boiler flask

and/or damage to the heating element.

At the end of the day, rinse the caustic delivery system with purified water.

Remove any accumulated spillage or deposits from the surfaces of the unit to

prevent corrosion or damage.

Product Service 1-800-522-7658

16

CChhaapptteerr 44::

RRoouuttiinnee MMaaiinntteennaannccee

Under normal operation, your RapidStill II will require little routine maintenance.

The following maintenance schedule is recommended:

After Every Day

(1) Rinse the caustic pump, its delivery system and the distribution head as

follows:

(a) Install a clean empty digestion tube in place. Remove the caustic

supply tubing from the caustic vessel and place it in a vessel of

purified water.

(b) Turn on the cooling water and fill the boiler as described in

Chapter 3: Normal Operation.

(c) Turn on the boiler heater.

(d) Depress ‘NaOH Addition’ switch and hold it on until all of the

caustic has been purged out of the system and into the distillation

tube.

(e) Remove the digestion tube and dispose of the liquid appropriately.

(f) Replace the digestion tube and fill it approximately half full by

depressing the ‘NaOH Addition’ switch.

(g) When the water in the boiler is at a rolling boil, turn the distillation

timer to approximately 10 minutes.

(h) At the end of the distillation cycle, turn the boiler heater and the

cooling water off. Remove the digestion tube wearing appropriate

heat and chemically resistant gloves. Dispose of the liquid

appropriately.

(2) Clean the exterior surfaces of the RapidStill II using a soft cloth and a

solution of mild soap and water to remove any spilled chemicals or

deposits.

Product Service 1-800-522-7658

Chapter 4: Routine Maintenance

17

!

Weekly

(1) Examine the boiler for any build-up of deposits. Accumulate deposits

in the boiler may be removed by dilute solution of hydrochloric acid, or

by using commercially available descaling solutions that are compatible

with glass.

USE APPROPRIATE PROTECTIVE SAFETY

EQUIPMENT WHEN HANDLING CLEANING

SOLUTIONS. ALWAYS FOLLOW THE CLEANING

SOLUTION INSTRUCTIONS REGARDING THEIR

USE, SAFETY PRECAUTIONS TO BE FOLLOWED,

AND DISPOSAL.

For instructions on how to remove the boiler, refer to ‘Removing the

Boiler’ in Chapter 5: Servicing the RapidStill II.

(2) Examine all plumbing and steam lines, ensuring that the tubing is

intact. Examine all tubing connections. Examine the connection

stopper for deterioration or cracking.

Product Service 1-800-522-7658

18

CChhaapptteerr 55::

SSeerrvviicciinngg tthhee RRaappiidd SSttiillll IIII

Fuse Replacement

(1) Unplug the unit from electrical service.

(2) Using a small screwdriver or coin, turn the slotted fuse holder ¼ turn

counterclockwise.

(3) Pull the fuse and holder straight out. Remove the fuse from its holder

by pulling the fuse straight out.

Replace the fuse with a proper replacement part only. DO NOT

attempt to replace the fuse with one of a higher amperage rating.

(4) To reinstall the fuse, reverse the above steps.

Removing the Boiler

(1) Unplug the RapidStill II from electrical service.

(2) Turn the unit around to gain access to the boiler flask.

(3) Remove the head of the boiler by pulling it straight up. If the head is

stuck onto the boiler, apply water to the joint to loosen it.

(4) Pull the ring that secures the boiler straight up until it clears the neck of

the boiler flask. The boiler can now be removed.

(5) To reinstall the boiler, reverse the above steps.

Product Service 1-800-522-7658

Chapter 5: Servicing the RapidStill II

19

Heating Element Replacement

(1) Unplug the RapidStill II.

(2) Remove the boiler as described previously.

(3) Remove the perforated screen surrounding the heating element by

removing the three screws that secure it.

(4) Disconnect the two heating element wires from the wiring harness by

pulling the electrical connectors straight apart. Remove the ground

wire from the bottom of the heater cup by pulling the wire straight

down.

(5) Remove the four nuts and lockwashers that secure the heating element

cup and its platform to the frame of the RapidStill II.

(6) Pull the heating element cup and its platform straight away from the

frame.

(7) Remove the heating element cup from its platform by removing the

three screws on the underside of the cup.

(8) Remove the heating element from the cup by removing the two heating

element bulkhead nuts located on the bottom of the cup. Pull the

element and its wires straight out of the cup.

(9) Install the new element by reversing the above steps.

Condenser Extension Replacement

(1) Rotate the safety screen assembly up until it is fully open.

(2) Loosen the knurled nut that secures the condenser extension to the

distribution head. Remove the plastic clamp that connects the

extension to the condenser.

(3) While supporting the condenser, use a Phillips screwdriver to remove

the screws that secure the condenser bracket straps to the condenser

bracket.

(4) Rotating the condenser out of the way, pull the extension straight out of

the distribution head.

Product Service 1-800-522-7658

Chapter 5: Servicing the RapidStill II

20

(5) Remove the knurled nut and its sealing ring from the old extension

tube, and install it on the new tube, noting the correct orientation of the

nut and washer.

(6) Install the new extension tube, orienting the drip point of the tube to the

bottom. Reverse steps 1-4 to complete the installation.

Timer Replacement

(1) Unplug the RapidStill II from electrical service.

(2) Remove the four screws that secure the front panel on the base of the

unit and pull the panel straight out.

(3) Using an allen wrench, loosen the two set screws that secure the timer

knob on its shaft. Pull the knob straight off.

(4) Disconnect the electrical connections on the timer, noting the terminals’

orientation.

(5) Using the proper wrench, loosen the hex nut that secures the timer to

the front panel and pull the timer out of the panel.

(6) Install the new timer by reversing the above steps.

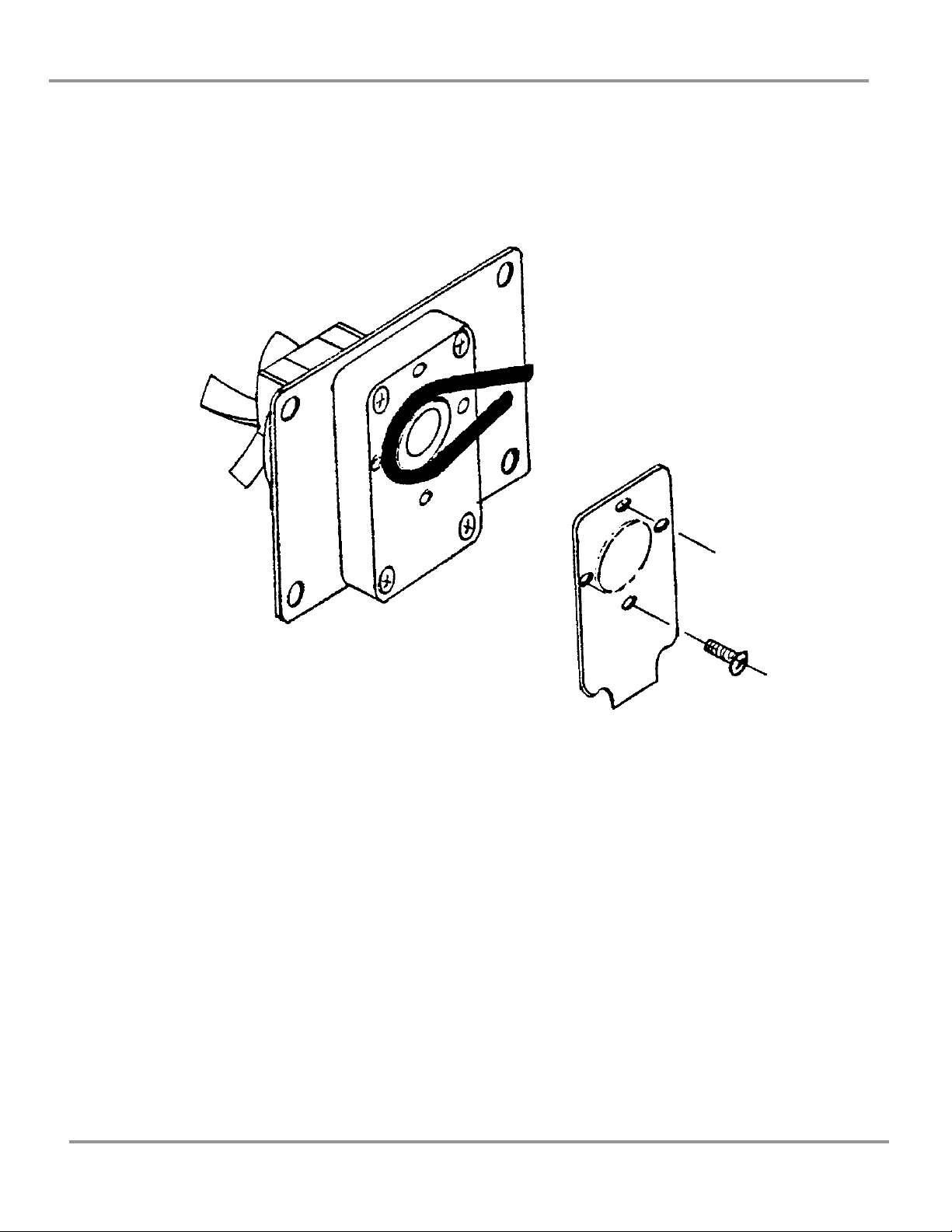

NaOH System Service

The tubing in the NaOH delivery system should not require replacement if

properly rinsed after each work session. To replace the peristaltic pump tube,

proceed as follows:

(1) If possible, purge the NaOH delivery system and peristaltic pump with

purified water, as described in Chapter 4: Routine Maintenance.

(2) Unplug the RapidStill II from electrical service.

(3) Turn the unit around to gain access to the peristaltic pump.

(4) Remove the four small Phillips screws as shown in Figure 7.

(5) Remove the pump cover, exposing the pump tube.

(6) Pull the pump tube straight out of the pump housing.

Product Service 1-800-522-7658

Chapter 5: Servicing the RapidStill II

21

(7) Thoroughly rinse the tube and remove the pump fittings and clamps.

Retain the fittings and clamps for use on the new tube.

(8) Install the new tube by reversing the above steps.

Product Service 1-800-522-7658

Figure 7

22

CChhaapptteerr 66::

TTrroouubblleesshhoooottiinngg

PROBLEM

CAUSES

CORRECTIVE ACTION

Unit will not operate

at all

Tripped circuit breaker

Check facility’s circuit breaker

Blown fuse

Replace fuse

Power cord not plugged

in

Plug in cord

Boiler doesn’t fill

‘Boiler Heater’ switch

is on

Turn off boiler heater before

filling

Cooling water off or

flow rate insufficient

Check flow rate of condenser

cooling water

Water fill valve plugged

or defective

Clean inlet screen of filter;

replace valve

‘Boiler Water’ switch

defective

Replace switch

Heating element

doesn’t work

Heating element is

defective

Replace heating element

‘Boiler Heater’ switch

is defective

Replace switch

Product Service 1-800-522-7658

Chapter 6: Troubleshooting

23

PROBLEM

CAUSES

CORRECTIVE ACTION

NaOH pump runs,

but doesn’t pump

NaOH tube is kinked or

restricted

Check all lines for kinks or

blockage

Peristaltic pump tube

damaged

Replace peristaltic pump tube

Peristaltic pump is

damaged

Replace peristaltic pump

Water is noisy when

flowing through the

unit

Excessive water flow

rate

Reduce the water flow rate

slightly

Steam drains

erratically; steam

valve is noisy during

standby

Drain hose is kinked or

elevated above the drain

pipe

Drain hose must flow

unrestricted to a drain below

the drain pipe

Boiling flask breaks

Flask has gone dry

Do not let flask go dry

Water added when

boiler is dry or low on

water and hot

Do not add water to the boiler

when it is hot and dry, or low

on water

Recoveries are low

Seal is leaking

Clean/replace the seal

Receiving tube is not

completely submerged

The receiving tube must be

completely submerged in the

receiving vessel

Not collecting enough

distillate

Increase distillation time

Recoveries are too

high

Excessive NH3 in feed

water

Connect to a different water

source; install Optional Water

Inlet Kit #6544200 and feed

purified water to the boiler

Product Service 1-800-522-7658

24

CChhaapptteerr 77::

RReeppllaacceem

meenntt PPaarrttss

ITEM

QTY.

PART NO.

DESCRIPTION

1

1

6539400

Heating Element

2

1

6523000

Boiling Flask, 1000 M/L

3

1

6541600

Boiler Head

4

1

6543500

Balance Tee

5

2

1359400

Plastic Check Valve

6

1

1363500

Steam Control Valve

7

1

4411500

Water Fill Valve

8

1

1624000

Tubing, Silicone, 1/2 x 5/16 inch (ordered by the foot)

9

1

1624100

Tubing, Silicone, 9/32 x 5/32 inch (ordered by the foot)

10

1

6538800

Flow Restrictor Assembly

11

1

6544800

Peristaltic Pump Tube

12

1

1344400

Fuse, 15 Amp

Figure 8

Product Service 1-800-522-7658

Chapter 7: Replacement Parts

25

ITEM

QTY.

PART NO.

DESCRIPTION

13

2

1302300

Switch, Momentary Contact

14

1

1302200

Switch DPDT

15

1

6522900

Connection Stopper

16

2

6520600

Cap/Gasket (GL-18)

17

1

6520700

Dispensing Tube – NaOH

18

1

6520300

Distribution Head

19

1

6521200

Cap/Gasket (GL-32)

20

1

6543600

Condenser Extension

21

1

6541000

Condenser

22

1

6521300

Ventilation Valve

23

1

2128801

Distillation Outlet Tube

24

1

6543400

Timer Assembly

Figure 9

Product Service 1-800-522-7658

26

AAppppeennddiixx AA::

DDiim

meennssiioonnss

Figure 10

Product Service 1-800-522-7658

27

AAppppeennddiixx BB::

SSppeecciiffiiccaattiioonnss

Electrical Requirements:

115 VAC, 15 Amps,

60 Hz, single phase

Heating Element:

1200 Watt, 115 VAC

Boiler Capacity:

1 liter total volume,

750 ml operating volume

Condenser Flow Rate:

1 gallon per minute (3.8 liters per minute)

Timer:

0-15 minutes, infinitely adjustable

Product Service 1-800-522-7658

28

AAppppeennddiixx CC::

W

Wiirriinngg DDiiaaggrraa

m

m

Figure 11

Product Service 1-800-522-7658

29

AAppppeennddiixx DD::

RReeffeerreenncceess

Rapid Kjeldahl Methodology for the Determination of Nitrogen in Paper

Products. 1993. Labconco Corporation, Kansas City, MO.

Rapid Kjeldahl Methodology for the Determination of Total Kjeldahl Nitrogen

in Water. 1993. Labconco Corporation, Kansas City, MO.

Methodology for the Determination of Alcohol in a Mixture by Direct

Distillation. 1993. Labconco Corporation, Kansas City, MO.

Methodology for the Determination of Ammonia in Water by Direct

Distillation. 1993. Labconco Corporation, Kansas City, MO.

Rapid Kjeldahl Methodology for the Determination of Nitrogen in Meat

Products. 1993. Labconco Corporation, Kansas City, MO.

Rapid Kjeldahl Methodology for the Determination of Nitrogen in Feeds,

Foods, Grains, Cereals, and Grasses. 1993. Labconco Corporation, Kansas

City, MO.

Rapid Kjeldahl Methodology for the Determination of Protein Content in

Milk. 1993. Labconco Corporation, Kansas City, MO.

Product Service 1-800-522-7658

Loading...

Loading...