Labconco Labconco-4028931_rev_c_users_manual_cell_logic+_b2_l3 Nellcor Pediatric SpO2 Sensor Instructions For Use

LABCONCO CORPORATION

8811 Prospect Avenue

Kansas City, MO 64132

(800) 821-5525 I +1 (816) 333-8811

labconco.com

Please read user’s manual before

operating equipment

Original Instructions

User’s Manual

Cell Logic+® Type B2 Biosafety Cabinets

Register this product

Cell Logic+® Type B2 Biosafety Cabinets

2019—Present

32348xxx1 33348xxx1 34348xxx1

32368xxx1 33368xxx1 34368xxx1

2

Copyright © 2019 Labconco Corporation. The information contained in this manual and the accompanying products are copyrighted and all rights reserved by

Labconco Corporation. Labconco Corporation reserves the right to make periodic design changes without obligation to notify any person or entity of such change.

Warranty

Labconco Corporation provides a warranty to the original buyer for the repair or replacement of parts and reasonable labor as a result of normal and proper use of

the equipment with compatible chemicals. Broken glassware and maintenance items, such as filters, gaskets, light bulbs, finishes and lubrication are not

warranted. Excluded from warranty are products with improper installation, erratic electrical or utility supply, unauthorized repair and products used with

incompatible chemicals.

Purifier® Cell Logic®+ Biological Safety Cabinets carry a five-year warranty from date of installation or six years from date of shipment from Labconco, whichever is

sooner. Warranty is non-transferable and only applies to the owner (organization) of record.

Buyer is exclusively responsible for the set-up, installation, verification, decontamination or calibration of equipment. This limited warranty covers parts and labor,

but not transportation and insurance charges. If the failure is determined to be covered under this warranty, the dealer or Labconco Corporation will authorize

repair or replacement of all defective parts to restore the unit to operation. Repairs may be completed by 3rd party service agents approved by Labconco

Corporation. Labconco Corporation reserves the rights to limit this warranty based on a service agent’s travel, working hours, the site’s entry restrictions and

unobstructed access to serviceable components of the product.

Under no circumstances shall Labconco Corporation be liable for indirect, consequential, or special damages of any kind. This warranty is exclusive and in lieu of

all other warranties whether oral, or implied.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be accepted. If your shipment was damaged in transit, you must

file a claim directly with the freight carrier. Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by various federal, state, or local regulations. All users of

this equipment are required to become familiar with any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water, land,

or air and to comply with such regulations. Labconco Corporation is held harmless with respect to user’s compliance with such regulations.

For additional questions or support:

Labconco Customer Care +1 (816) 333-8811

Labconco Technical Support (800) 821-5525

Hours 7:30 a.m.-5:30 p.m. CST

Part #4028931 Rev. C

ECO M575

3

Table of Contents

1: INTRODUCTION 9

About This Manual 9

Contents Included 9

2: BEFORE YOU INSTALL 10

Location Requirements 10

Clearance Requirements 11

Electrical Requirements 11

Service Line Requirements 11

Exhaust Requirements 12

Air-Tight Damper 14

User-Supplied Microscope Requirements – Scope-ReadyTM Package Only 14

User-Supplied Circulator Requirements – Temp-ZoneTM Package Only 15

3: SAFETY PRECAUTIONS 16

Typographical Conventions 16

General Safety Precautions 18

Safety Precautions for this Product 20

4: INSTALLATION 22

Unpacking 22

Electrical Connection 27

Service Line Connection 28

Drain Valve Installation (Optional) 29

Exhaust Connection 30

4

Microscope Installation (optional) 31

Circulator Installation (optional) 33

Figure 4-9 34

Certification 35

5: PERFORMANCE FEATURES 36

Laminar Airflow 36

Directional Airflow 37

Cabinet Air Intake (Front Grille) 37

HEPA Filters 38

ULPA Filters 38

Motor/Blower 39

Airflow Sensor 39

UV Lamp (optional) 40

Scope-ReadyTM Package (optional) 40

Pure-Vu™ Seal 40

Stand-StillTM Isolation Platform 41

Temp-ZoneTM Package (optional) 41

6: MYLOGICTM OPERATING SYSTEM 42

Home Screen 42

Display Sleep Mode 43

Keypad 43

Main Menu 44

Configuration Submenu 45

45

Audible Tones 45

Selecting a Language 45

Setting the Clock 46

Setting Automatic Operation Options (SmartStartTM) 47

5

Navigating the Settings Submenu 48

Selecting the Units of Measure 48

Activating the Security Lock 48

Setting the USB Output Rate 48

UV Parameters 49

The Tools Submenu 49

Timer Operation 50

Interval Timer Operation 50

Stopwatch Timer Operation 50

Airflow Alert 51

Resetting the Airflow Alert System 51

Alarms 52

Power Loss Alarm 52

Sash Height Alarm 52

Blower Failure Alarm 52

Exhaust Airflow Check 53

Running Exhaust Alarm 53

7: USING YOUR CELL LOGIC+ TYPE B2 54

Feature Overview 54

System Reset Switch 55

Keypad 56

Sash Operation 57

Blower Operation 57

Light Operation 57

Outlet Operation 57

Vacu-PassTM Cord & Cable Pass Thru (optional) 58

Working in the Cabinet 59

Planning 59

Cabinet Start-up 59

Wipe Down 59

Loading Materials and Equipment 60

Work Techniques 60

Final Purging 60

Unloading Materials and Equipment 60

Wipe Down 60

Shutdown 61

6

8: MAINTAINING YOUR CELL LOGIC+ TYPE B2 62

Maintenance Safety Precautions 62

Recommended Maintenance Schedule 63

Service Operations 64

Resetting a Circuit Breaker 64

Dished Work Surface Removal 65

Front Grille Removal 65

Front Panel Removal 66

Changing the LED Lamps 67

Changing the Optional UV Lamp 69

Storage 70

9: ACCESSORIES 71

Telescoping Base Stands 71

Manual or Electric Hydraulic Lift Base Stands 71

IV Bar 72

Stand-StillTM Isolation Platform 72

Pure-VUTM Seals 72

10: TROUBLESHOOTING 73

Blower and Lights not working 73

Blower only will not start 74

Lights only will not illuminate 75

UV Light will not illuminate 76

Airflow Alert activating 77

Filter Life Gauge not at 100% when new 78

Contamination in the work area 79

Exhaust Alarm activates 60 seconds after turning the blower on 80

APPENDIX A: PARTS LIST 81

7

APPENDIX B: DIMENSIONS 83

APPENDIX C: SPECIFICATIONS 84

Power Data 84

Motor Specifications 84

Environmental Conditions 85

APPENDIX D: QUICK CHART REFERENCE 86

APPENDIX E: INSTALLATION GUIDE:

PURE-VUTM SEALS AND STAND-STILLTM

ISOLATION PLATFORMS 87

PURE-VU TEMPLATE 94

8

1: Introduction

Congratulations on the purchase of a Cell Logic+® Type B2 biosafety cabinet. The

biosafety cabinet is designed to protect you, the product and the laboratory environment

from biohazardous aerosols. It is the result of years of experience in manufacturing

laboratory equipment, and users like you suggested many of its features to us.

This biosafety cabinet offers many unique features. To take full advantage of them,

please acquaint yourself with this manual and keep it handy for future reference.

About This Manual

This manual is written for the installer and user of this product. For detailed service,

certification, or technical information, please utilize the Technical Manual located on the

website labconco.com.

This manual contains important operation and safety information. When you see a

symbol, such as the INFO symbol to the left, pay close attention to the information

provided. Before installing or operating this product, you must read Section 3: Safety

Precautions.

Contents Included

The following items are packaged with the product.

User’s manual thumb drive

Drain valve assembly and fasteners

Power cord

Vacu-PassTM accessory plug (if option package ordered)

The location of these items and additional details are found in Section 4: Installation.

9

Preferred

location

Air register blocked

or redirected

Alternate

location

Room

Door

Figure 2-1

2: Before You Install

Before you install the product, the site should be prepared for installation. Examine the

location where you intend to install it. You must be certain that the area is level and of

solid construction. In addition, a dedicated source of electrical power must be located

within 10 feet (3 m) of the installation site.

Location Requirements

A biosafety cabinet should be located away from areas of high foot traffic, doors, fans,

ventilation registers or vents, chemical fume hoods or other air-handling devices. Any

of these may interfere with the airflow patterns in and around the product, and

subsequently diminish product and/or personnel protection. All windows in the room

should remain closed. Figure 2-1 shows the preferred and alternate locations for this

product.

10

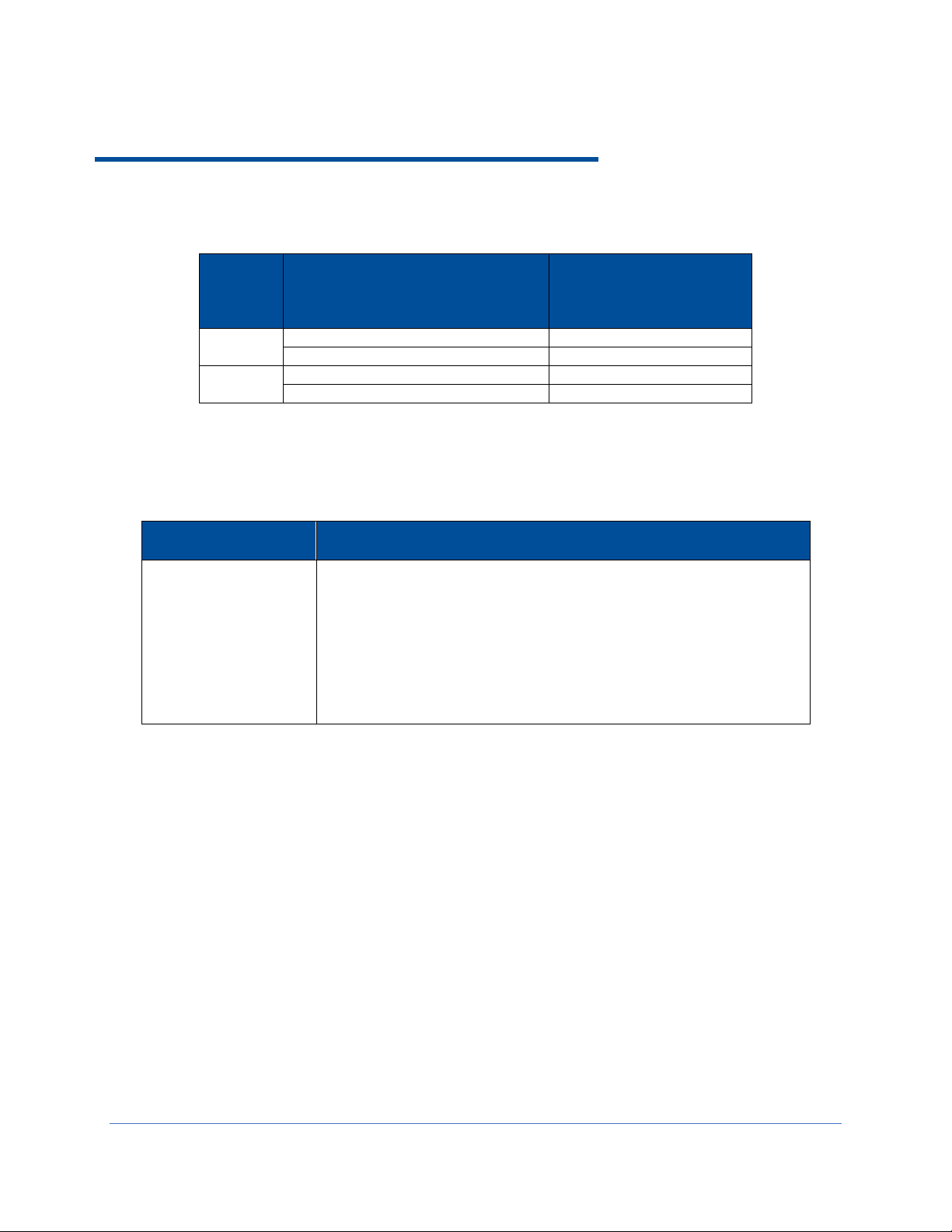

Clearance Requirements

Catalog Number

Typical Operating

Current (Amps)

Electrical Circuit Requirements1

3x349xx01

3 A

115 V, 60 Hz, 12 A

1 Phase

3x349xx21

3 A

100 V, 50/60 Hz, 12 A

1 Phase

3x349xx-11, 31, 41, 51, 61, 71

1.5 A

230 V, 50/60 Hz, 6 A

1 Phase

3x369xx01

5 A

115 V, 60 Hz, 12 A

1 Phase

3x369xx21

5 A

100 V, 50/60 Hz, 12 A

1 Phase

3x369xx-11, 31, 41, 51, 61, 71

2.5 A

230 V, 50/60 Hz, 6 A

1 Phase

1 Electrical Requirements, ‘V’ = VAC (Voltage with alternating current), ‘A’ = Amperes

A minimum clearance of at least 6 inches (150 mm) is suggested on the top and both

sides of the product for service.

See Appendix B: Dimensions for overall product dimensions.

Electrical Requirements

The product models have the following electrical requirements.

A dedicated outlet with an appropriate circuit breaker should be located as close as

possible to the product, but no greater than 10 feet (3 m). Consult your local electrical

codes for properly rated circuit breakers. For safe operation the dedicated outlet must

provide a protective earthing ground connection to the product.

On 100V and 115V models, both internal electrical outlets are protected by a ground

fault interrupter circuit (GFIC). Labconco does NOT recommend connecting the

product’s power cord into a GFIC outlet. GFIC outlets can nuisance trip, resulting in

complete removal of power to the product. Such a scenario would result in complete

loss of product and/or personnel protection.

Service Line Requirements

All utility service lines should be ¼ inch O.D., brass, copper, or stainless steel, and

equipped with an easily accessible shut-off valve. The service valves are rated for

operation at 40 PSI (275 kPa). If the service line pressure exceeds this, it must be

equipped with a pressure regulator to reduce the line pressure.

Note: The use of flammable gases or solvents should be avoided in the biosafety

cabinet. Open flame in the cabinet will disrupt the laminar airflow in the cabinet and may

damage the HEPA filters. Flammable gases or solvents may reach explosive

concentrations in the cabinet or ductwork. If you feel that the procedure requires the use

of an open flame or flammable materials, contact your institution’s safety office.

11

Note: The use of air or gases under high pressure should be avoided as they may

Figure 2-2

Examine the location to ensure that it

accommodates the cabinet’s exhaust duct. The

area directly above the cabinet’s exhaust port

should be clear of structural elements, water and

utility lines, or other fixed obstructions. There

should be enough clearance to accommodate a

10-inch diameter duct. See Figure 2-2.

Figure 2-3

Avoid cabinet locations that require an elbow

directly above the cabinet’s exhaust connection

or an excessive number of elbows in the exhaust

system. There should be a straight length 10

duct diameters long between the cabinet

connection and any elbow, and between

subsequent elbows. See Figure 2-3.

seriously disrupt the airflow patterns in the cabinet.

Exhaust Requirements

This product must be connected to a remote (building) exhaust system.

Note: Only connect the biosafety cabinet to a suitable exhaust system that is dedicated

to the biosafety cabinet, or dedicated to exhausting laboratory ventilation equipment.

Do NOT connect the biosafety cabinet to the building’s general HVAC system for room

exhaust.

12

The exhaust system must be capable of moving the following volumes of exhaust air at

Cell Logic+

Type B2 Model

Airflow Volume

Concurrent

Balance Value

Recommended

Duct Vacuum

ft3/min

m3/hr

ft3/min

m3/hr

WC1

Pa

4-foot, 8" Sash

723

1228

852

1448

1.8

450

6-foot, 8" Sash

1083

1840

1265

2149

2.2

550

Table 2-1

the negative pressures listed. The Airflow Volumes are the values recorded via direct

measurement using a flow hood at the front opening of the cabinet. The Concurrent

Balance Values are measured in the exhaust duct via traverse methodology, and will

always be higher due to differences in volume measurement methodologies.

NOTE: The Concurrent Balance Values (CBV) is established by NSF during listing

testing. The static pressure listed is measured at the biosafety cabinet’s connection to

the exhaust system. The values published include 0.7 inches H2O of filter loading from

the biosafety cabinet’s original pressure. In order to obtain maximum exhaust HEPA

filter loading, the system should be capable of generating a static pressure 1.3 inches

higher than the Recommended Duct Vacuum pressure listed in Table 2-1.

1: WC = Inches of Water Column, typically expressed in units of inches H2O.

NOTE: The facility’s remote blower cannot run at its nominal flow rate with the sash

completely closed. If the sash must be closed completely to utilize the internal UV Light

(optional), then the facility’s remote blower must be shut off or its flow rate reduced by

90% or more for proper operation of the biosafety cabinet. The Cell Logic+ biosafety

cabinet has an optional EN/Dry Contact Board that contains dry relay contacts which

can be configured to signal the facility’s remote blower to turn on and turn off (or reduce

speed). For further information, contact Labconco’s Product Service Department or

refer to the Logic+ Technical Manual. A remote electrical switch to control the facility’s

remote blower can also be installed near the biosafety cabinet for manual control of the

remote blower.

13

Air-Tight Damper

AIR-TIGHT DAMPER

DUCT COLLAR

BUILDING EXHAUST DUCT

(NOT INCLUDED)

AIRFLOW

ADJUSTMENT

HANDLE

EXHAUST HOUSING

Figure 2-4

Visual appearance of biosafety cabinet and exhaust connection may vary by model.

The exhaust housing on a Type B2 biosafety cabinet is sealed to the top of the

biosafety cabinet. All of the biosafety cabinet’s airflow is exhausted through the exhaust

housing by the facility’s remote blower. The Cell Logic+ Type B2 biosafety cabinet

includes an air-tight damper as an integral part of the exhaust housing. See Figure 2-4.

The air-tight damper allows for fine adjustment of the exhaust air volume provided, in

order to correctly set the necessary exhaust airflow for each biosafety cabinet. It also

allows the biosafety cabinet to be sealed off from the building exhaust system, should it

become necessary to do so.

User-Supplied Microscope Requirements – Scope-ReadyTM Package Only

If installing a microscope, locate the Stand-Still™ Isolation Platform in a separate box

shipped with the cabinet. The Stand-Still Isolation Platform supports the microscope on

top of the stainless steel work surface to eliminate up to 94% of vibrations and to

promote safe airflow. If using a stereoscope with a forward extending base, the

extended Stand-Still XL Isolation Platform should be ordered from Section 9:

Accessories. Figures from Appendix E should be used to assist your set-up.

14

On models with the Scope-Ready package, the Cell Logic+ Biosafety Cabinet includes

a clear, disposable Pure-Vu™ Seal that can be altered to accommodate most

microscope’s eyepieces. Utilize the Punch Kit (Catalog Number 4027801), supplied

with your cabinet, to cut the two eyepiece holes at approximately 2.75" (69.9 mm)

spacing to match the height of your scope. As a convenience, pre-cut Pure-Vu

eyepiece seals can be ordered from Section 9: Accessories. The pre-cut accessory

Pure-Vu Seals are based off the nominal height from the base of the microscope to

eyepiece centerline and can save time modifying the seal shipped with the Cell Logic+.

If using a stereoscope with a forward extending base, one of the Pure-Vu XL Seals

should be ordered from Section 9: Accessories. Figures from Appendix E should be

used to assist your set-up for all Pure-Vu Seals.

User-Supplied Circulator Requirements – Temp-ZoneTM Package Only

The Temp Zone™ features a temperature controlled area on the work surface where

heated or chilled samples may be transferred and kept at optimum temperature. A

user-supplied circulator that continually delivers heated or chilled water at a minimum

flow rate of 0.5 GPM (1.9 LPM) with typical volume of 6 liters is required and may be

obtained from your laboratory supply dealer.

Quick connection fittings are included on the left side of the cabinet and are sized for

3/8" diameter polyethylene tubing. As a convenience, the following items are included

with the Temp-Zone package:

20 Feet (6 meters) of 3/8" (9.5 mm) outer diameter tubing

Insulation for 3/8” outer diameter tubing

Quick-connect fittings (3/8 tube x 1/8 NPT, 3/8 tube x 1/4 NPT, 3/8 tube x 3/8

NPT)

The above items will allow for connection to a water circulator. The water circulator can

be located underneath the work surface of the cabinet or next to the cabinet on the

floor.

15

3: Safety Precautions

Before unpacking, installing, operating, maintaining, or servicing this equipment, read

the following safety warnings and precautions.

Avant le déballage, l’installation, le fonctionnement, l’entretien ou la maintenance de cet

équipement, lire les avertissements de sécurité et les précautions d’emploi.

CAUTION – See Manual. When this symbol is on the equipment, it indicates a

caution that is detailed in this manual.

MISE EN GARDE – Voir le manuel. Lorsque ce symbole est apposé sur

l’équipement, il renvoie à une mise en garde détaillée dans ce manuel.

Typographical Conventions

DANGER – An imminently hazardous situation which, if not avoided, will result in

death or serious injury.

DANGER – Situation dangereuse imminente qui, si elle n’est pas évitée, peut

entraîner la mort ou des blessures graves.

CAUTION – Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or damage to property.

MISE EN GARDE – Signale une situation potentiellement dangereuse qui, si elle

n’est pas évitée, peut provoquer des blessures mineures à modérées ou des

dommages matériels.

NOTE – Advice or suggestions to help the process.

REMARQUE – Conseils ou suggestions pour le déroulement du processus.

16

BURN RISK (HIGH TEMPERATURE) – Air or components that will be very hot.

Take care not to touch these defined areas. Failure to avoid these areas may

result in moderate to severe injury.

RISQUE DE BRÛLURE (TEMPÉRATURE ÉLEVÉE) – Air ambiant ou

composant devenant très chaud. Veiller à ne pas toucher ces zones délimitées.

L’absence de précaution pour éviter ces zones peut entraîner des blessures

modérées, voire graves.

EXTREME COLD (LOW TEMPERATURE) – Air or components that will be very

COLD. Take care not to touch these defined areas. Failure to avoid these areas

may result in moderate to severe injury.

FROID INTENSE (TEMPÉRATURE BASSE) – Air ambiant ou composant

devenant très froid. Veiller à ne pas toucher ces zones délimitées. L’absence de

précaution pour éviter ces zones peut entraîner des blessures modérées voire

graves.

PINCH POINT – Areas or components that can pinch or cut. Take care not to

touch these defined areas.

POINT DE PINCEMENT – Zones ou composants présentant un risque de

pincement ou de coupure. Veiller à ne pas toucher ces zones délimitées.

MOVING PARTS – Areas or components that contain moving parts. Take care

not to touch these defined areas.

PIÈCES MOBILES – Zones ou composants contenant des pièces mobiles.

Veiller à ne pas toucher ces zones délimitées.

RISK OF ELECTRICAL SHOCK – The specified procedure or area poses a risk

of electrical shock. ALWAYS disconnect main power cord or electrical supply

before proceeding.

RISQUE DE CHOC ÉLECTRIQUE – La procédure ou la zone spécifiée présente

un risque de choc électrique. TOUJOURS débrancher le cordon d’alimentation

secteur ou l’alimentation électrique avant toute intervention.

FLAMMABLE / NO SOLVENTS – Do not place flammable liquids or solvents in

this product.

INFLAMMABLE / PAS DE SOLVANTS – Ne placez aucun liquid inflammable

dans cette produit.

17

LIFTING HAZARD – Do not lift or move this equipment without assistance.

DANGER DE LEVAGE – Ne pas soulever ou déplacer cet équipement sans

assistance.

MAGNETIC FIELD IN USE – Magnets or magnetic field present.

CHAMP MAGNETIQUE UTILISE – Présence d'aimants ou de champ

magnétique.

DO NOT TOUCH – Components or areas indicated are sensitive and will suffer

damage if touched. Take care not to touch these defined components or areas.

Failure to avoid these areas will result in damage to the product.

NE PAS TOUCHER – Les composants ou les zones indiquées sont sensibles et

subiront des dégâts s’ils sont touchés. Veiller à ne pas toucher ces composants

ou zones délimité(e)s. L’absence de précaution pour éviter ces zones

endommagera le produit.

TOOL REQUIRED – Tool required to access specified area.

OUTIL NÉCESSAIRE – Outil nécessaire pour accéder à la zone spécifiée.

General Safety Precautions

Follow all the safety precautions described in this section.

Before removing any panels which require a tool for removal, ALWAYS

disconnect the main power cord or electrical supply. Failure to remove all

electrical power before proceeding will result in moderate to serious injury, death,

or damage to property.

Avant le retrait d’un panneau nécessitant l’utilisation d’un outil, TOUJOURS

débrancher le cordon d’alimentation secteur ou l’alimentation électrique. Le non-

respect de la consigne consistant à couper complètement l’alimentation

électrique avant toute intervention peut entraîner des blessures graves, la mort

ou des dommages matériels.

18

Never contact moving parts with your person. Failure to avoid moving parts will

result in moderate to serious injury, death, or damage to property.

Ne jamais toucher les parties mobiles. Le non-respect de la consigne consistant

à éviter les pièces mobiles peut entraîner des blessures graves, la mort ou des

dommages matériels.

Never misuse this product. Never disable, override, or otherwise bypass safety

guards, panels, switches, sensors or alarms. Doing so will result in moderate to

serious injury, death, or damage to this product or property.

Ne jamais utiliser ce produit à mauvais escient. Ne jamais désactiver, annuler ou

contourner les capots, panneaux, interrupteurs, capteurs ou alarmes de sécurité.

Ceci entraînerait des blessures graves, la mort ou des dommages matériels à ce

produit ou à d’autres biens.

If the unit is not operated as specified in this manual it may impair the protection

provided by the unit.

Si l'unité n'est pas utilisée comme spécifié dans ce manuel il peut diminuer la

protection fournie par l'unité.

Do not position the unit so that it is difficult to operate the main disconnect

device.

Ne placez pas l'appareil de sorte qu'il est difficile de faire fonctionner le dispositif

principal de déconnexion.

Do not lift or move this equipment without assistance.

Ne pas soulever ou déplacer cet équipement sans assistance.

19

Safety Precautions for this Product

Electrical outlets in the cabinet are restricted to 5 amps (100-115v) or 3 amps

(230v) maximum current.

Prises électriques dans l'armoire sont limitées à 5 (100-115v) o 3 (230v) courant

maximum ampères.

Do not use any detachable power cord that is not adequately rated for the unit.

Ne pas utliser un fil électrique amovible qui n’est pas du tension nominale de

l’appareil.

The biosafety cabinet should be certified by a certification technician before its

initial use. The cabinet should be recertified whenever it is relocated, serviced or

at least annually thereafter. Filter integrity and airflow performance should be

verified before using the cabinet.

Some internal components of the biosafety cabinet may become contaminated

during operation of the unit. Only experienced personnel competent in

decontamination procedures should decontaminate the cabinet before servicing

these components. If you have any questions regarding certification agencies, or

need assistance in locating one, contact Labconco’s Product Service Department

at 800-821-5525 or 816-333-8811.

DO NOT load more than 50 lbs. (23 Kg) in the work area. Exceeding this limit

may damage the work surface and its supports. Excessive weight in the cabinet

may increase the risk of it overturning, or failure of hydraulic lift stands, resulting

in the cabinet and stand overturning. If your application requires loading more

than 50 lbs., contact Labconco’s Product Service Department at 800-821-5525 or

816-333-8811 for assistance.

Avoid the use of flammable gases or solvents in the biosafety cabinet. Care must

be taken to ensure against the concentration of flammable or explosive gases or

vapors. An open flame should NOT be used in the biosafety cabinet. Open

flames will disrupt airflow patterns, burn the HEPA filter and/or damage the filter’s

adhesive. Gases under high pressure should not be used in the biosafety

cabinet, as they may disrupt its airflow patterns.

HEPA filters only remove particulate matter. Operations generating volatile toxic

chemicals or radionuclides must be evaluated carefully.

20

The media of HEPA filters is fragile and should not be touched. Avoid puncturing

either HEPA filter during installation or normal operation. If you suspect that a

HEPA filter has been damaged, DO NOT use the cabinet; contact a local

certification agency or Labconco at 800-821-5525 or 816-333-8811 for recertification information.

The HEPA filters in the biosafety cabinet will gradually accumulate airborne

particulate matter from the room and from work performed in the cabinet. The

rate of accumulation will depend upon the cleanliness of the room air, operating

time and the nature of work being done in the cabinet. The Filter Gauge

accurately displays the amount of filter life remaining.

Proper operation of the cabinet depends largely upon its location and the

operator’s work habits. Consult Section 4: Installation and Section 7: Using Your

Cell Logic+ Type B2 for further details.

Avoid direct exposure of plastic or coated materials to ultraviolet (UV) radiation.

Never bypass the UV safety interlock that only allows the UV light to work when

the sash is closed. When surface disinfecting the biosafety cabinet:

o Avoid splashing the disinfecting solution on skin or clothing.

o Ensure adequate ventilation.

o Carefully follow the disinfectant’s safety instructions.

o Always dispose of disinfecting solutions in accordance with local and national

laws.

o DO NOT allow disinfectants with high concentrations of free chlorine to

contact the stainless steel components of the biosafety cabinet for a long

period of time. Free chlorine will corrode stainless steel after extended

contact.

Biosafety cabinets should be decontaminated for any of the following reasons:

o Before maintenance work requiring entry into contaminated areas.

o Before HEPA filter changes.

o Before performing certification tests requiring entry into contaminated areas.

o Before relocating the cabinet.

o Before changing research programs.

o After the gross spill of biohazardous material or toxic chemicals.

21

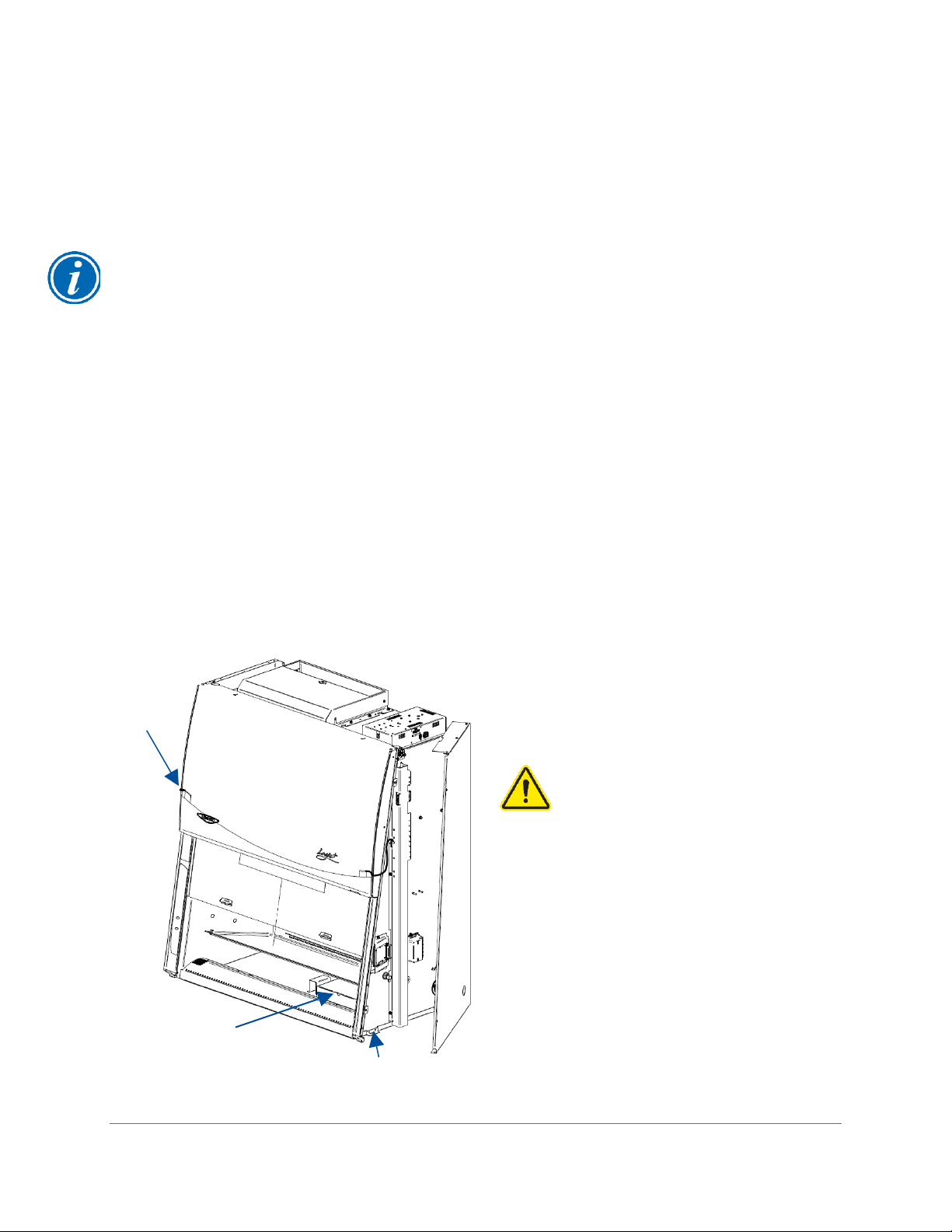

A quick reference Installation Guide is located on the front sash glass (see Figure 4-2)

4: Installation

With the installation site properly prepared, you are ready to unpack and install the

equipment. This section covers how to:

Unpack and move the product

Install the product

Connect electrical service

Connect service utilities

Connect to an exhaust system (optional)

Arrange certification for the product

Install the microscope (optional with Scope-Ready package only)

Install the circulator (optional with the Temp-Zone package only)

Unpacking

The following tools are required to unpack the equipment:

Box knife

#2 Phillips screwdriver

Two ½” wrenches

Pliers

Carpenter’s level

The following safety precautions must be followed by all personnel unpacking the

equipment.

Wear safety glasses and gloves

No loose fitting clothes

Wear close-toed shoes

Follow safe-lifting practices (do NOT attempt to lift this product without

specialized lifting equipment certified to lift up to 1000 lbs.)

22

Step 1

Yellow String (to

Left End Pins)

Shipping Bolts (2 per end)

Parts Box

(ref Fig. 3-2)

Figure 4-1

The side panels must be

removed to access the

fasteners that secure the

biosafety cabinet to the pallet.

DO NOT attempt to lift the

biosafety cabinet by the

side panels; damage will

occur.

Visual appearance of

biosafety cabinet and

exhaust connection

may vary by model.

Carefully remove the outer carton and inspect the product for damage that may have

occurred in transit. If the product is damaged, take pictures of the product and the outer

packaging, and notify the delivery carrier immediately. Retain the entire shipment,

including outer packaging, intact for inspection by the carrier.

Note: United States Interstate Commerce Commission rules require that claims be filed

with the delivery carrier within fifteen (15) days of delivery.

Do not return goods without the prior authorization of Labconco. Unauthorized returns

will not be accepted.

If the product was damaged in transit, you must file a claim directly with the freight

carrier. Labconco Corporation and its dealers are not responsible for shipping damages.

Do not discard the carton or packing material for the product until all of the components

have been checked, installed and tested.

The product is secured to the pallet in two places on each side. To access the nuts and

bolts holding the product to the pallet, remove the side panels by removing and keeping

the two Phillips screws on both panels. Swing the front of each panel away from the

cabinet, and lift it straight up to remove the panel from the cabinet. See Figure 4-1.

23

Step 2 – Installation on an Existing Work Surface

Move the cabinet, attached to its pallet, by using a floor jack, or a furniture dolly

underneath the unit. DO NOT move the cabinet by tilting it onto a hand truck.

When lifting the cabinet DO NOT lift the cabinet in the middle front area of the hull.

Lifting here may bend or distort the bottom of the cabinet, causing damage to the unit.

Note: The cabinet is very top heavy. Use caution when lifting or moving it.

When installing the cabinet onto an existing work surface or benchtop, ensure that the

structure can safely support the combined weight of the cabinet and any related

equipment. The work surface should be at least as wide as the cabinet and 31 inches

(787 mm) deep to properly support the unit. A hole or notch may be cut in the

supporting surface in the right front corner to accommodate the optional drain valve.

Step 2 – Installation on a Labconco Base Stand

Move the cabinet, attached to its pallet, by using a floor jack, or a furniture dolly

underneath the unit. DO NOT move the cabinet by tilting it onto a hand truck.

When lifting the cabinet DO NOT lift the cabinet in the middle front area of the hull.

Lifting here may bend or distort the bottom of the cabinet, causing damage to the unit.

Note: The cabinet is very top heavy. Use caution when lifting or moving it.

Labconco offers accessory base stands in a variety of configurations to suit your

particular needs. If assembly of the base stand is required, the assembly instructions

are packaged with the base stand.

Using a mechanical lift, raise the cabinet.

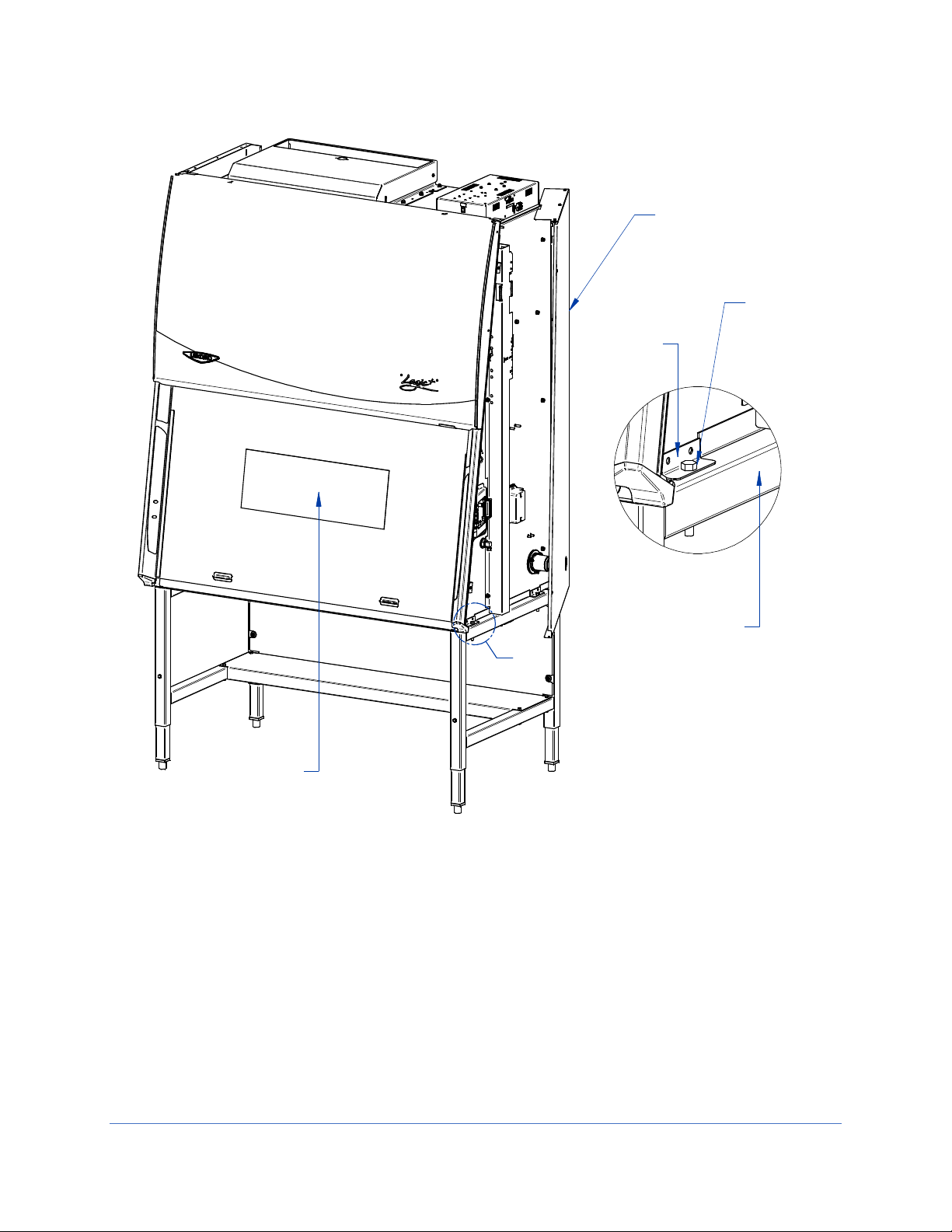

Before setting the cabinet onto the stand, using the four attachment bolts supplied with

the stand, align the mounting tab holes on the cabinet with the four holes on the stand’s

top rail. Drop each bolt through the mounting tab hole and into each hole on the stand’s

top rail. Carefully lower the cabinet onto the stand. See Figure 4-2.

After the cabinet is in place, remove each attachment bolt, and flip it over to install it up

through the stand’s top rail, and add the associated washers and nut. Tighten each

bolt.

24

A

DETAIL A

Attachment

bolts

(Supplied

with stand)

Stand rail

Side panel

Mounting

tab

Installation

Instructions

Figure 4-2

Visual appearance of

biosafety cabinet and

exhaust connection

may vary by model.

25

Step 3

Same on opposite end

Clevis Pin

Support

Pin

Yellow

String

Yellow String (to

Left End Pins)

Parts Box

Figure 4-3

Visual appearance of

biosafety cabinet and

exhaust connection

may vary by model.

The front sash will not slide open yet. The sash counterweights are pinned for

shipment. The Side Panels must still be removed or hinged open for this step. Locate

the Support Pin and Clevis Pin on each sash counterweight. See Figure 4-3. For

convenience a yellow tag and string are provided. Locate each yellow tag on the front

of the product, and follow the yellow string to each Clevis Pin. Remove the Clevis Pin

(also referred to as a Cotter Pin), then pull the Support Pin toward the rear of the

product until it is free. You will hear the counterweight drop a short distance when the

Support Pin is removed. Discard the Tags, String, and Pins.

Replace or close each Side Panel and secure the panels with two screws per panel.

Raise the front sash. Lift the front edge of the stainless steel work surface, locate and

retrieve the Parts Box. See Figure 4-3. The following items are located inside this box.

User’s manual thumb drive

Drain valve assembly and fasteners

Power cord

Vacu-PassTM accessory plug (if option package ordered)

26

Electrical Connection

IEC Connector

Knockout

Figure 4-4

The product’s power cord is located in the Parts Box removed in the final step of

Unpacking (previous section). Connect the IEC end of the power cord to the IEC

connector located on the rear side of the top electrical box. See Figure 4-4. Connect the

plug end of the power cord into an appropriately rated outlet (see Electrical

Requirements in Section 2: Before You Install).

A knockout is also provided in the electrical box to allow for direct wiring of the product.

Do NOT attempt to connect power via the knockout or otherwise directly wire the

product without consulting your local codes and regulations, and it is highly

recommended to utilize a licensed electrician to make this wiring connection. The

wiring must meet the minimum gauge requirement for the current specified in Section 2:

Before You Install listed under Electrical Requirements, and must be a dedicated wiring

run to a circuit breaker appropriately rated for this product’s electrical requirements.

27

Service Line Connection

Petcock valve

(pre-installed)

Coupling

(pre-installed)

90 degree fitting

(included)

Figure 4-5

Service fixtures are not pre-installed on all models. If your model does not include a

service fixture, this step may be skipped. A service fixture can be field installed at any

time, the service fixture kit will contain instructions for installing the fixture. Follow the

instructions below to make the plumbing connection to the service fixture.

Note: Some models have a solenoid valve connected to the service valve on the right

side, rear position. The solenoid prevents gas from flowing to the service valve when

the cabinet’s blower is off, or there is a loss of electrical power. It is the only service

valve position that can be fitted with a solenoid valve. Connect the gas service to the

solenoid valve.

The incoming service line(s) should be connected to the tube compression fitting(s) on

the outside of the liner wall as shown in Figure 4-5. Open the side panel, then:

1. Ensure that the tubing is ¼ inch O.D., soft metal, and that the end has been

completely deburred.

2. Route the tubing from the rear of the cabinet, ensuring that it will line up with the slot

in the back of the side panel. The slot is located from 8 ¾ to 11 ¼ inches (222 to 288

mm) from the bottom of the cabinet.

Note: Make sure that the tube routing will not contact any electrical wires. DO NOT

loop service line tubing within the side panels of the cabinet.

3. Make sure that the nut on the 90 degree tube fitting is loose, but do not remove it.

Make sure the tube ferrule is in the fitting.

4. Push the tube into the fitting until it is properly seated. The tube will go

approximately ¾ inch (19 mm) into the fitting.

5. Tighten the tube fitting nut hand tight and then, using a 7/16-inch wrench, tighten it

at least ¾ turn more.

6. Close the service valve in the cabinet and then slowly open the shutoff valve on the

service valve. Test all fittings for leakage. Tighten the tube nut slightly if needed.

28

Drain Valve Installation (Optional)

Screws (3)

Drain flange

Cabinet bottom

Drain valve

Nuts (3)

Figure 4-7

A drain valve assembly is provided in the Parts Box. The drain allows for removal of

large amounts of liquid trapped in the area underneath the work surface. The

installation of the drain valve is not required. If not installing the drain valve, this section

may be skipped.

Note: The work surface is heavy. Use caution when handling it.

1. Lift and remove the work surface by lifting on the knobs at the front of the work

surface. Locate the cover sealed over the drain mounting holes.

2. Using a putty knife, remove and discard the stainless steel cover that is sealed over

the drain mounting holes. Scrape out remaining sealant around the holes.

NOTE: The drain valve assembly attaches to the underside of the cabinet bottom.

3. Apply a light coating of silicone sealant (not provided) to the mounting surface of the

drain flange. Attach the drain flange under the bottom of the cabinet as shown in

Figure 4-7. Wipe off any excess sealant from the cabinet bottom. Ensure that the

center drain hole is unobstructed.

4. Secure the drain assembly with the hardware provided. Tighten all hardware.

5. Make sure the drain valve is in the closed position.

6. Reinstall the work surface.

7. Allow the silicone sealant to cure for at least eight hours before exposing it to liquid.

29

Exhaust Connection

The Cell Logic+ Type B2 biosafety cabinets are “total exhaust biosafety cabinets”,

meaning all of their HEPA filtered exhaust air must be exhausted out of the laboratory.

WARNING: Type B2 Total Exhaust Biosafety Cabinets are designed to be

connected to an appropriate exhaust system. Without verified inflow velocity, the

cabinet may NOT contain hazardous particulate or gasses. Do not attempt to

operate the biosafety cabinet when it is not connected to an appropriate exhaust

system that has been inspected by a qualified certifier.

WARNING: Type B2 Biosafety Cabinets rely on external blowers (usually on the

roof of a building) to exhaust 100% of the air entering the cabinet. If the building

exhaust blower fails or is mistakenly turned OFF, the cabinet will become

pressurized, resulting in airflow from the work area into the laboratory. It is

imperative that the following be considered in a risk assessment:

Justify the type of work is appropriate for a Type B2 biosafety cabinet.

Exhaust system must be reliable, maintained, frequently inspected and

preferably redundant.

Exhaust termination must be distant from other building air intake systems

to prevent the reintrainment of volatile chemicals into the facility.

NOTE: The facility’s remote blower cannot run at its nominal flow rate with the sash

completely closed. If the sash must be closed completely to utilize the internal UV Light

(optional), then the facility’s remote blower must be shut off or its flow rate reduced by

90% or more for proper operation of the biosafety cabinet. The Cell Logic+ biosafety

cabinet has an optional EN/Dry Contact Board that contains dry relay contacts which

can be configured to signal the facility’s remote blower to turn on and turn off (or reduce

speed) as the biosafety cabinet’s operational needs require. For further information,

contact Labconco’s Product Service Department or refer to the Cell Logic+ Technical

Manual. A remote electrical switch to control the facility’s remote blower can also be

installed near the biosafety cabinet for manual control of the remote blower.

WARNING: THE EXHAUST CONNECTION IS A SEALED EXHAUST SYSTEM FROM

THE TOP OF THE CABINET TO THE REMOTE BLOWER. THE EXHAUST SYSTEM

CONTROL SHOULD BE DEDICATED TO A SINGLE BIOSAFETY CABINET. THE

CABINET IS EQUIPPED WITH AN EXHAUST AIRFLOW ALARM, SUCH THAT AN

ALARM SOUNDS, AND THE CABINET BLOWER SHUTS OFF IN THE EVENT OF

INSUFFICIENT EXHAUST AIRFLOW.

If your research involves the use of toxic compounds or volatile materials, contact your

facility’s safety officer or Labconco to ensure that your Cell Logic+ and its exhaust

system are compatible with the materials you will be working with.

30

Microscope Installation (optional)

In order to successfully install a user-supplied microscope in a Cell Logic+ biosafety

cabinet with Scope-Ready package, please follow the steps below and refer to Figure 48 as well as Appendix E.

Note: The work surface is heavy. Use caution when handling it.

1. Before installing a microscope, locate the Stand-Still Isolation Platform that is

packaged in a separate carton underneath the work surface. Note: Stereoscopes

will typically require the Stand-Still XL Isolation Platform; more information can be

found at labconco.com.

2. Install the Stand Still Isolation Platform so that the leading edge is in line with the

work surface leading edge. See Appendix E for typical pictures of proper set-up

of the Stand-Still Isolation Platform.

3. With the sash in the up position, place a user-supplied microscope inside and on

top of the Stand-Still Isolation Platform. Remove the microscope eyepieces.

4. The Cell Logic+ biosafety cabinet with Scope-Ready Package includes one Pure-

Vu Seal that requires 0.5" (12.7 mm) diameter holes spaced approximately 2.75"

(69.9 mm) apart and located from the base of the microscope to the centerline of

the eyepiece. The eyepiece holes can be cut with the 0.5" (12.7 mm) diameter

hole Punch Kit (Catalog Number 4027801) supplied with your cabinet.

For your convenience, pre-cut accessory Pure-Vu Seals can be found at

labconco.com, and may be an easier installation.

5. If punching the 0.5" (12.7 mm) diameter holes, with the microscope eyepieces

removed line up the centerline of the eyepiece base with the seal. Then mark

the centerline of each eyepiece hole spaced at approximately 2.75" (69.9 mm).

6. Remove the 14 screws (#6-32 x 0.25") that retain the Pure-Vu Seal.

7. Either reinstall one of the pre-cut accessory Pure-Vu Seals from Section 9 or

punch the holes in the blank seal supplied and then re-install the seal. For your

convenience, see Appendix E for installation of pleated Pure-Vu XL Seals used

with stereoscopes requiring frequent eyepiece height adjustment of +/- 2.0" (51

mm).

8. After the seal is re-installed, then move the microscope forward to carefully

stretch the Pure-Vu Seal over both of the microscope eyepiece bases.

9. Finally, re-install the microscope eyepieces.

10. The Pure-Vu Seal should now provide an optimum seal for safe airflow and

ergonomic visibility.

31

Figure 4-8

32

Circulator Installation (optional)

In order to successfully install a user-supplied circulator on a Cell Logic+ biosafety

cabinet with Temp-Zone package please follow the steps below and refer to Figure 4-9:

Note: The work surface is heavy and two Easy-Clean™ Prop Rods are provided to

pivot and support the Temp-Zone work area and the work surface.

1. The Temp-Zone work area has supply and return lines for the user-supplied

circulator. Refer to Figure 4-9 and locate the two quick connect elbows on the

left side of the cabinet behind the left side panel.

2. Find a suitable place next to the cabinet or underneath the cabinet to place the

circulator. Accessory shelves for small circulators are available from

labconco.com. Larger circulators should be placed on the floor.

3. Pivot the work surface up and use the Easy-Clean Prop Rods to support the work

surface. Then locate the tubing, insulation, and quick connect fittings shipped

with your Cell Logic+. The tubing is 3/8" OD (9.5 mm) and tube inserts must be

placed inside the tubing to properly support the tubing inside the quick connect

fitting. 20 feet (6.1 meters) of tubing length is provided for your convenience.

Note: The tube inserts prevent the tubing from collapsing at connection points

and must be used.

4. Plan, route and cut the tubing from the two elbows on the left side of the cabinet

to the circulator.

5. Locate the quick connect fittings (3/8" tube x 1/8 NPT, 3/8" tube x 1/4 NPT, and

3/8" tube x 3/8 NPT) and install the appropriate fittings to the user-supplied

circulator with appropriate pipe sealant or PTFE tape.

6. Place tube inserts in all ends of the cut-to-size tubing.

7. Cut and install the insulation around the cut tubing lengths.

8. Insert cut tubing lengths into the elbows on the cabinet and then install both

tubing lengths into the circulator to complete the water circulator loop.

9. Read and follow the circulator instructions before operating. The circulator

should have a minimum flow rate of 0.5 GPM (1.9 LPM). In all cases, the

temperature of the circulator will not equal the temperature of samples on the

Temp-Zone. Factors such as the sample vessels, sample sizes, aluminum tube

racks, and length of tubing connecting the circulator to the Temp-Zone can

influence the sample temperature. Circulator settings to hold heated incubator

sample temperatures may require 0.3-2.0°C higher temperatures than the

desired sample temperature. Furthermore, circulator settings to maintain chilled

refrigerated samples may require 0.3-3.0°C colder temperatures than the desired

sample temperature. Experimentation is necessary to achieve proper sample

temperatures.

10. For chilled applications, the Temp-Zone work area comes with a drain line

installed that can be routed to the cabinet’s drain valve, if desired. This TempZone drain line installation is optional for chilled applications should excessive

33

condensation occur under the work surface. Simply snap in the supplied press-fit

Quick-Connect

Elbow Fitting

Circulator

(User-

Supplied)

Circulator Tubing

and Insulation

Temp-Zone

Optional

Drain Line

Drain Valve

Press-fit

Elbow

Prop

Rod

Figure 4-9

elbow to the drain valve shown in Figure 4-9. Follow the diagram to finish the

installation.

34

Certification

*These tests are user comfort related tests and may be

omitted at the user’s or certifier’s discretion.

Prior to use, a qualified certifier should certify a biosafety cabinet. Under normal

operating conditions, the cabinet should be recertified at least annually and when

relocated or serviced. The certifier should perform the following tests, as recommended

in NSF/ANSI Standard Number 49 in effect when the cabinet was manufactured:

Downflow Velocity Profile Test

Inflow Velocity Test

Airflow Smoke Patterns

HEPA Filter Leak Test

Optional Canopy Alarm Test and Operation

Vibration Test *

Noise Level Test *

Lighting Intensity Test *

If you have any questions regarding certification agencies or help locating one, contact

Labconco’s Product Service Department at (800) 821-5525 or +1 816-333-8811.

Detailed information for product certification is located in the Logic+ Technical Manual.

35

Figure 5-1

Laminar

downflow of air

5: Performance Features

The Cell Logic+ Type B2 biosafety cabinet protects items placed on the work surface,

the personnel working with material inside the cabinet, and the lab environment, when

operated to manufacturer’s specifications and proper aseptic techniques are employed.

This protection is provided through the use of laminar airflow, HEPA filtration, careful

cabinet construction, and Constant Airflow ProfileTM (CAP) ECM motors. Each of the

key performance features are detailed in this section.

Laminar Airflow

Laminar airflow is defined as the movement of a body of air in a single direction, with a

uniform velocity. In practice, the laminar downflow of air in the cabinet captures any

aerosol generated in the work area of the cabinet, and directs it to the HEPA filters. In

order to be true laminar downflow, a number of individual downflow velocity test points,

commonly referred to as the Downflow Velocity Profile, must be +/- 16 feet per minute

(0.08 m/s) of the average of all the test points.

36

Directional Airflow

Figure 5-2

Front Grille

Directional airflow also plays a key role in cabinet performance. Air is drawn into the

front of the cabinet at the front grille. This “curtain” of air makes it more difficult for

aerosols to escape out of the cabinet’s work area and into the laboratory environment.

This airflow is often calculated and referred to as the Inflow Volume or Average Inflow

Velocity. This is illustrated in Figure 5-2.

Cabinet Air Intake (Front Grille)

The location, size, and pattern of the grille openings in the work area affect cabinet

containment and performance. The front grille’s airfoil profile, and air intake openings

play an important role in establishing Directional Airflow, as described previously. See

Figure 5-2.

Note: Do not block or obstruct the grille openings of the biosafety cabinet.

37

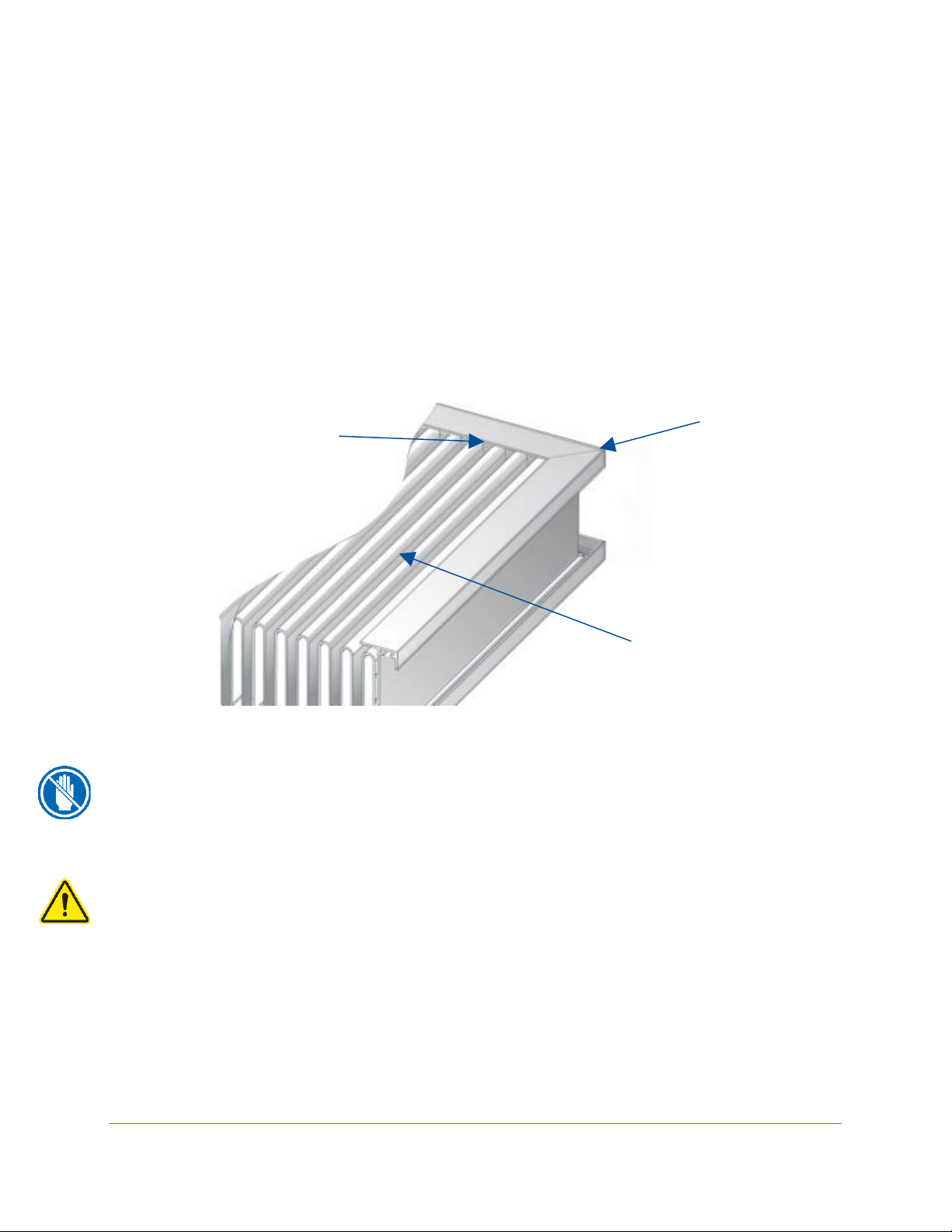

HEPA Filters

Filter frame

Filter media pack

Polyurethane seal

between media pack

and filter frame

Figure 5-3

HEPA filters are disposable, dry-type particulate filters. The filter material or media is

typically made of borosilicate microfibers formed into a thin sheet, in a process similar to

the production of paper. This sheet is folded, or pleated to increase its surface area.

The pleats are typically held in place by beads of glue that add rigidity to the media

pack. The pack is then set into a frame, and sealed as shown in Figure 5-3.

The HEPA filter manufacturer establishes the efficiency of the filter by challenging it with

an aerosol of known particle size. The number of particles that penetrate the filter are

quantified, and this establishes the efficiency of the filter. The HEPA filters used in the

biosafety cabinet are at least 99.99% efficient in removing particles 0.3 micron.

Note: HEPA filter media is very fragile. DO NOT touch the media. If you think the

media of a HEPA filter is damaged, DO NOT USE THE CABINET. Have the HEPA filter

integrity tested by a certifier before using the cabinet.

Note: HEPA Filters are only effective against particulate material. Gases and vapors will

pass through the filter.

ULPA Filters

Optional ULPA filters may be used to replace the standard HEPA filters in this product.

ULPA filters have the same properties as described above except they are rated at least

99.999% efficient in removing particles 0.1-0.2 or 0.2-0.3 micron in size.

38

Motor/Blower

Figure 5-4

The motor/blower assembly pulls room air into the top of the cabinet, sends that air

through the supply HEPA filter, and over the internal work area. This air is referred to

as the laminar downflow previously detailed. The downflow air and the inflow are then

removed from the cabinet via the exhaust HEPA filter by the facility’s remote blower.

The airflow patterns within the cabinet are shown in Figure 5-4. The motor in the cabinet

is an electronically commutated motor (ECM). The ECM is a brushless DC motor that

includes its own power supply to convert the incoming alternating current to direct

current, as well as its own microprocessor to control and measure the motor’s

operation. The motor utilizes Labconco’s exclusive Constant Airflow Profile

program to deliver a consistent volume of air, throughout the life of the cabinet.

TM

(CAP)

Airflow Sensor

An airflow sensor, located above the Exhaust HEPA filter, constantly monitors the flow

of exhaust air out of the cabinet. If the exhaust falls below a safe level, the control

board turns off the cabinet blower, and sounds an audible and visual alarm. This

prevents the escape of hazardous material from the front of the cabinet, in the event of

an exhaust system failure. The airflow sensor reading is shown on the display as Inflow

in feet per minute (FPM) or meters per second (M/S).

39

UV Lamp (optional)

The optional UV lamp generates a primary wavelength of light of 254nm. A secondary

emission is in the visible (blue) wavelength, resulting in the characteristic blue color

while operating. UV light at this wavelength is biocidal, primarily by creating thymine

dimers in DNA. These dimers prevent the correct transcription of the DNA into RNA,

resulting in cellular death or viral inactivation. In order to be effective, the UV light must

directly strike the nucleic acid, and its effectiveness can be diminished or negated by

dissolved proteins or metals, or by other UV-opaque substances protecting the target

nucleic acid.

Because of its limitations, UV light should be used as an adjunct to good surface

disinfection practices. In order to achieve optimum performance from the UV lamp, it

should be replaced after 6,000 hours of operation or less, and the exterior surface of the

lamp should be kept clean and free of dust.

Note: The product records the number of hours of operation of the UV light. You can

program in the number of hours (in 100-hour increments) it will operate before a

replacement message is displayed.

Note: UV irradiation is absorbed by the tempered safety glass of the sash. Independent

research has shown that the level of UV irradiation on the outside of the cabinet’s sash

is equal to background radiation levels.

Note: The UV sensitivity of a target organism varies, depending on the UV output of the

lamp, the genus and species of the organism, the medium the agent is suspended in,

etc. Contact the Health and Safety Officer at your facility for UV light use and

recommendations.

Scope-ReadyTM Package (optional)

Models with the Scope-Ready package option allow a user-supplied microscope to be

integrated into the safety cabinet. On these models, two features work together to

assure containment and reduced vibration:

Pure-Vu™ Seal

The Pure-Vu Seal includes a 7 inch wide x 10.5 inch (267 mm) high sash cutout that

accommodates most microscopes’ eyepieces. The clear, disposable eyepiece seal

prevents contaminants from escaping while providing ergonomic visibility into the

cabinet. The removable seal attaches tightly to an aerodynamic, epoxy-coated steel

collar. The unique teardrop shape of the aerodynamic collar design keeps

contaminants contained with the microscope in place. The Pure-Vu Seal conforms to

both ASHRAE 110 and NSF 49 testing criteria.

40

Stand-StillTM Isolation Platform

The Stand-Still Isolation Platform supports the microscope on the cabinet’s work surface

and removes up to 94% of vertical and horizontal vibrations. ASHRAE 110 and NSF 49

testing confirms this unique elevated, aerodynamic base ensures safe airflow.

Constructed of seamless Type 304 stainless steel, the isolation platform is non-porous,

easy to clean, and autoclavable. Important Note: Always remove the rubber isolation

feet prior to autoclaving. The 12 inch (305 mm) wide x 18.75 inch (476 mm) deep

platform accommodates most microscopes. See Section 9: Accessories for ordering an

extended Stand-Still XL Isolation Platform for use with microscope bases that extend

over the front of the lower work surface.

Temp-ZoneTM Package (optional)

Models with the Temp-Zone package option include a temperature-controlled area 10.5

inch (267 mm) wide x 12 inch (305 mm) deep. Note: the temperature-controlled are is 7

inch (178 mm) wide x 12 inch (305 mm) deep on 3 foot models. Samples heated in an

incubator or chilled in a refrigerator may be transferred to the Temp-Zone and kept at

optimum temperature. Quick connection fittings on the left side of the cabinet attach to

a user-supplied circulator that continually delivers heated or chilled water through

channels located underneath the Temp-Zone area of the work surace. Uniform

temperature distribution is maintained on the Temp-Zone area of the work surface.

41

Figure 6-1

Filter Life

Remaining

Current Time

Light Status

Airflow Sensor Current

Reading

Outlet Power Status

Blower Status

Filter Life Bar

Light Status = UV Light ON

UV Countdown Timer (minutes)

6: MyLogicTM Operating System

The Cell Logic+ Type B2 biosafety cabinet features the MyLogic operating system,

which provides clear status information on the LCD display and user control with the

keypad (Figures 6-1 & 6-3). Read this section along with Section 7: Using Your Cell

Logic+ Type B2 to fully understand the features and controls of this product.

Home Screen

The Home Screen will display the following information (Figure 6-1).

When the glass sash is closed, the light icon may change as follows if the optional UV

Light is installed:

42

Display Sleep Mode

Figure 6-2

Figure 6-3

[BLOWER]

[LIGHT]

[OUTLET]

[UV LIGHT]

[TIMER]

[OK/MUTE]

[MENU]

[UP]

[DOWN]

The LCD display will enter sleep mode when the blower is off (Figure 6-2). If the blower

is not turned on, and no keys are pressed on the keypad, after 5 minutes the screen will

automatically turn off to relax the LCD display, which extends its life. When the display

transitions from sleep mode to off, the screen will appear black. Any key press will

wake the screen and return to the Home Screen.

Keypad

The Keypad button functions are explained in detail in Section 7: Using Your Cell Logic+

Type B2, under the subsection Keypad. A summary description is provided here with

Figure 6-3.

43

Settings

Main Menu

[MENU]

Figure 6-4

Configuration

Tools

Figure 6-5

Keypad button presses are shown as [BLUE WITH BRACKETS]. Menu screen

selections are shown as green italics.

To access the Main Menu from the Home Screen, press [MENU] on the keypad. See

Figure 6-4. The display will change to the Main Menu. To return to the Home Screen,

press [MENU].

The Main Menu displays three submenu options, as shown in Figure 6-5. To select from

the various submenu options, press the [UP] or [DOWN] buttons until the selected

option is highlighted. Press [OK/MUTE] to accept that option, or press [MENU] to return

to the Home Screen.

44

Configuration Submenu

CABINET START

TONE

Audible Tone

Language

Clock

SmartStart

English

French

German

Chinese

Spanish

Italian

Portuguese

Japanese

Figure 6-6

Figure 6-7

Figure 6-8

Keypad button presses are shown as [BLUE WITH BRACKETS]. Menu screen

selections are shown as green italics.

This submenu allows you to set preferences for

audible tones, set the language, set the clock, and

configure how the unit operates when the sash is

opened or closed (SmartStartTM).

Audible Tones

When enabled, an audible tone will sound during

cabinet power up. This also enables or disables

audible tones from the keypad (any button press).

Audible tones associated with alarms cannot be

muted.

Selecting a Language

[UP] and [DOWN] will move among the selectable

language options. When the desired language is

highlighted, press [OK/MUTE]. Language options:

45

Setting the Clock

3 : 15

[OK/MUTE]

Figure 6-9

Figure 6-10

Select either 12 Hour (AM/PM) format or 24 Hour

format.

The selected field (Hours or Minutes) flashes, set the

current time using [UP] and [DOWN]. Hours will

flash first, once correct, use [OK/MUTE] to switch to

Minutes. Holding [UP] and [DOWN] in the Minutes

field will fast scroll.

Note: AM or PM will not show if 24 Hour format

selected.

46

Setting Automatic Operation Options (SmartStartTM)

OPEN SASH:

BLOWER

OPEN SASH:

CLOSE SASH:

Whether the UV Light is initiated from the [UV

Light] button on the keypad, or automatically

initiated upon closing of the sash, this screen

controls the time the UV lamp will remain on.

Select the length of time desired, press

[OK/Mute].

Figure 6-11

Figure 6-12

Figure 6-13

Figure 6-14

Continuous On

The cabinet allows configuration to activate functions automatically when the sash is

opened or closed. The following screens will display sequentially with [OK/Mute].

The first screen provides the option of activating the

blower; if you want the cabinet blower to start every

time you raise the sash, select Blower On, and then

[OK/Mute]. If Blower Off is selected, the blower

must be manually started from the keypad. When

START

[OK/Mute] is pressed, the next configuration screen

will appear.

If you want the cabinet lights to turn on every time

the sash is opened, select Light On, and then

[OK/Mute]. If Light Off is selected, the lights must

be manually illuminated from the keypad. When

[OK/Mute] is pressed, the next configuration screen

LIGHT ON

will appear if the cabinet is configured for a UV lamp.

If your Cabinet is configured for a UV light, you will

see Fig. 6-13 and 6-14. If you want the UV lamp to

turn on every time the sash is closed, select

UV Light On, and press [OK/Mute]. If UV Light Off is

selected, the UV light will not turn on when the sash

UV LIGHT ON

is closed. When [OK/Mute] is pressed, the final

configuration screen will appear.

47

Navigating the Settings Submenu

METRIC (M/S)

IMPERIAL (FT/MIN)

PASSWORD

1 / SECOND

OUTPUT DATA

1 / 10 SECONDS

1 / 30 SECONDS

1 / 60 SECONDS

Units of Measure

System Lock

Data Output

UV Parameters

Figure 6-15

Figure 6-16

Figure 6-17

Figure 6-18

Keypad button presses are shown as [BLUE WITH BRACKETS]. Menu screen

selections are shown as green italics.

This submenu allows you to select: Units of

Measure, System Lock, Data Output, or UV

Parameters.

Selecting the Units of Measure

If your cabinet is equipped with an airflow sensor,

the units of measure can be set for FT/MIN (feet per

minute) or M/S (meters per second). Select the

appropriate units of measure, then [OK/Mute].

Activating the Security Lock

The Security Lock “locks” the keypad to prevent

unauthorized use of the cabinet. To enable / disable

select Protected / Unprotected, then [OK/MUTE].

When enabled, the keypad is locked immediately

after the blower is turned off. The security lock is

deactivated by holding [DOWN] for three seconds. If

blower is not turned on within 5 minutes of unlocking,

the keypad will relock. The feature remains enabled

until it is disabled in this screen.

Setting the USB Output Rate

This menu option selects the rate that cabinet status

data is exported out of the mini USB port on the side

of the top electrical box. Data can output at a rate of

once per second, once per 10 seconds, once per 30

seconds, or once per 60 seconds. Make the

appropriate selection, then [OK/MUTE].

48

RUNTIME

2139 H

REMAINING

3861 H

6000 H

SET LIFETIME

Reset

Lifetime

Figure 6-19

Figure 6-20

UV Parameters

For models equipped with the optional UV light, the cabinet has an integral UV light

maintenance system. It allows you to monitor how many hours the lamp has been on, to

reset the UV lamp hourmeter, and to define how many hours you want the UV lamp to

operate before receiving a reminder to replace it.

This screen displays the hours of UV lamp operation

(Runtime), and how many hours remain (Remaining)

until you receive a warning to replace the lamp. To

reset the Runtime hourmeter to zero (after replacing

the UV lamp), select Reset, then [OK/MUTE]. The

hour text will begin to flash, if you entered this

condition by mistake, press [MENU]. If you want to

reset the hourmeter, hold [OK/MUTE] for 3 seconds.

To change the desired UV lamp lifetime, select

Lifetime as seen in Fig. 6-19, then [OK/MUTE]. The

screen shown in Fig. 6-20 will display. To change the

UV lamp lifetime (number of operating hours before

receiving a warning), change the Hour field accordingly

using [UP] or [DOWN], then [OK/MUTE].

For most UV lamps, the output of UV light decreases at a constant rate. Typically, after

6,000 hours of operation the lamp’s output intensity will reduce to 80% of when it was

new. This option allows you to set operational life of the UV lamp, in 100 hour

increments. 6,000 hours is the default.

The Tools Submenu

This submenu is reserved for use by certifiers, during certification or service

procedures. CAUTION! - Entering this submenu will disable some alarms and

functionality so that diagnostic and certification procedures can be performed.

Additional details on the Tools Submenu are found in the Logic+ Technical Manual.

49

Timer Operation

Stopwatch

Interval

Figure 6-21

The timer allows activation of an interval (countdown) or elapsed (stopwatch) timer. The

timers cannot be operated simultaneously.

To access the Timer Menu, press [Timer] anytime during normal operation (from the

Home Screen). The Timer Menu is displayed (Figure 6-21). Select Interval or Stopwatch

Timer, then [OK/MUTE].

Interval Timer Operation

1. The interval timer defaults to 05:00 (minutes:seconds).

2. Press [UP] or [DOWN] to increase or decrease the timer interval.

3. When the proper interval is selected, press [OK/Mute] to start the timer.

4. When the timer reaches 00:00, an audible alarm will sound.

5. Press [OK/Mute] to pause the timer. Press [OK/Mute] while paused, and the

timer will reset to the previously selected interval.

6. Press [Menu] to clear the interval timer and return to the main timer menu.

Stopwatch Timer Operation

1. The stopwatch timer defaults to 00:00.

2. Press [OK/Mute] to start the timer.

3. Press [OK/Mute] again to pause the timer. Press [OK/Mute] while paused, and

the timer will reset to 00:00.

4. Press [Menu] to return to the main timer menu.

50

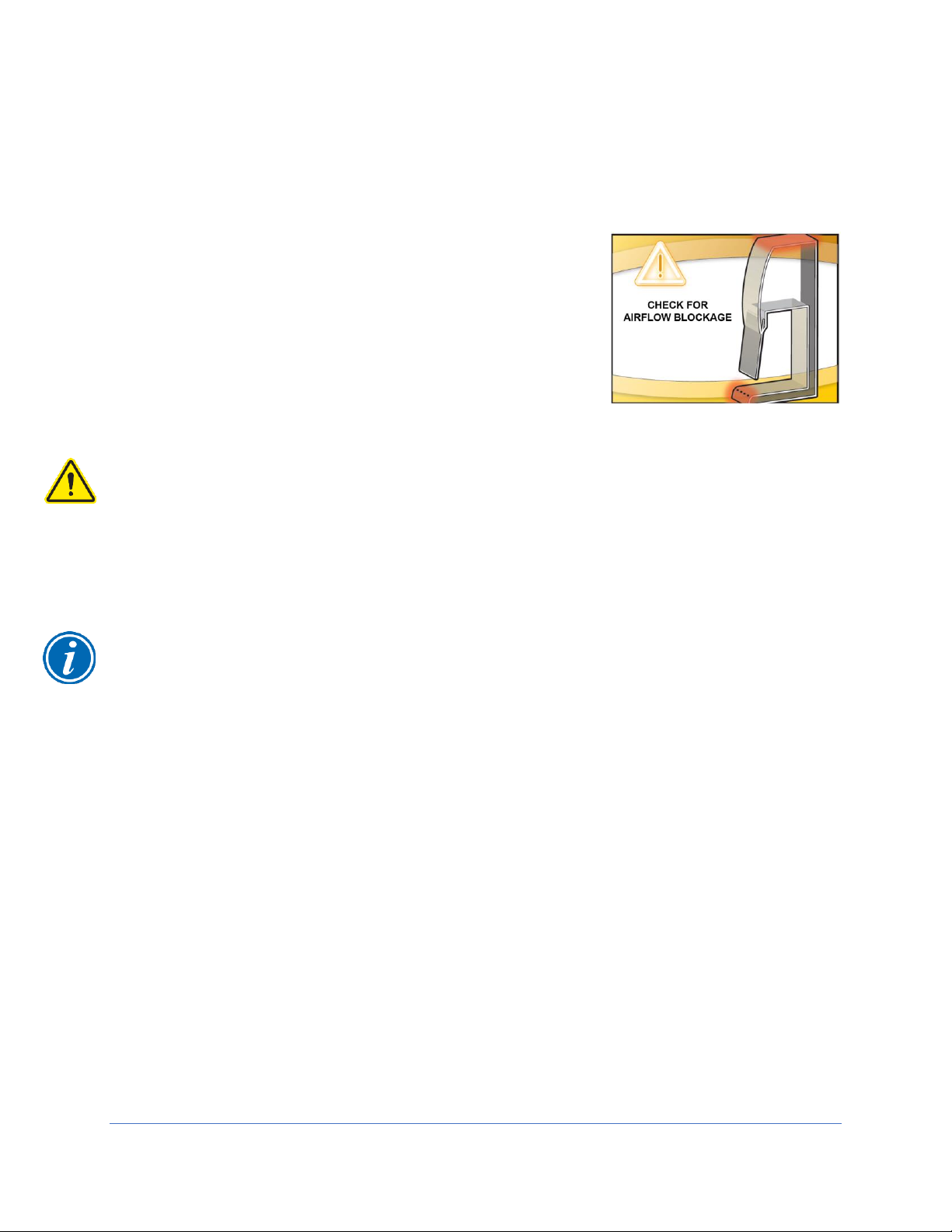

Airflow Alert

Figure 6-22

While the blower is on, any sudden disruption to the airflow within the cabinet will trigger

an Airflow Alert. When an Airflow Alert activates, the display will automatically change

(Figure 6-22), and the audible alert tone will sound.

The most common causes of an Airflow Alert are:

Blockage of the inlet grilles

Removal of the work surface or grille during

operation

Look to identify the cause of the airflow disruption, and

remove the blockage or return the work surface to its

proper position.

When a blockage of the airflow occurs, the cabinet’s blower automatically increases its

speed to maintain constant volume airflow. This is a protective feature; however, if the

disruption is significant (for example blocking the entire front grille) it will not guarantee

product or personnel protection remains during the significant blockage event.

Resetting the Airflow Alert System

The Airflow Alert automatically dismisses once the motor speed has stabilized.

Note: Once the blockage or disruption has been resolved, the Airflow Alert may

reactivate while the blower returns to correct operating speed. It will dismiss

automatically once the blower reaches correct operating speed.

51

Alarms

BLOWER FAILURE

Figure 6-23

Figure 6-24

Figure 6-25

BLOWER FAILURE

DETECTED

Any alarm that activates requires the user’s immediate attention, and some form of

actionable response to clear the alarm.

Power Loss Alarm

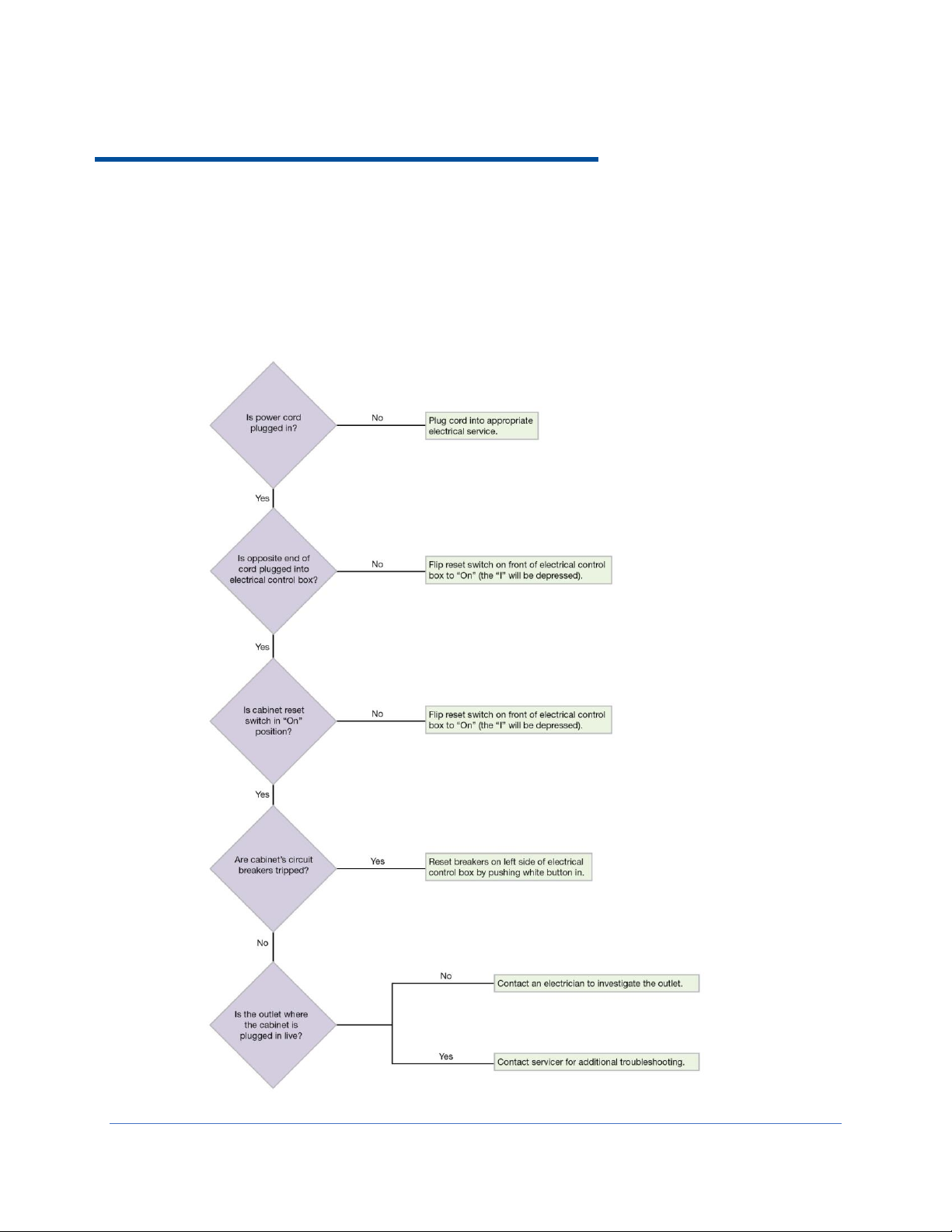

The cabinet has lost power. See Figure 6-23

Press [OK] on the keypad to acknowledge that

a power loss occurred.

Note: This alarm will activate any time power is

cycled, including turning the System Reset

Switch (see Figure 7-2) off and back on.

Sash Height Alarm

The sash is not at the proper operating height.

Return sash to proper working height.

Blower Failure Alarm

The blower motor has failed, or the motor and

display circuit board are not communicating

properly. Press [BLOWER] on the keypad to

clear the alarm.

DO NOT USE THE CABINET UNTIL THE PROBLEM HAS BEEN CORRECTED.

DETECTED

CONTACT

CERTIFIER

52

EXHAUST FAILURE

Figure 6-26

EXHAUST FAILURE

Figure 6-27

Exhaust Airflow Check

When [BLOWER] is pressed to turn on the cabinet’s

internal blower, If there is insufficient exhaust system

airflow for a proper startup, this alarm will be

displayed for 60 seconds to allow the exhaust

system to begin operation. If there is insufficient

airflow after 60 seconds, the Running Exhaust Alarm

DETECTED

CONTACT CERTIFIER TO

CHECK EXHAUST

AIRFLOW

will be activated.

Running Exhaust Alarm

When the cabinet’s internal blower has successfully

started, and the building exhaust airflow drops below

the minimum safe level, this alarm will be displayed.

Once this alarm activates, the cabinet’s blower will

automatically turn off. This is a safety feature to

DETECTED

CONTACT CERTIFIER TO

CHECK EXHAUST

AIRFLOW

reduce the amount of potentially contaminated work

air that escapes the cabinet into the laboratory.

Press [BLOWER] on the keypad to clear the alarm.

DO NOT USE THE CABINET UNTIL THE PROBLEM HAS BEEN CORRECTED.

53

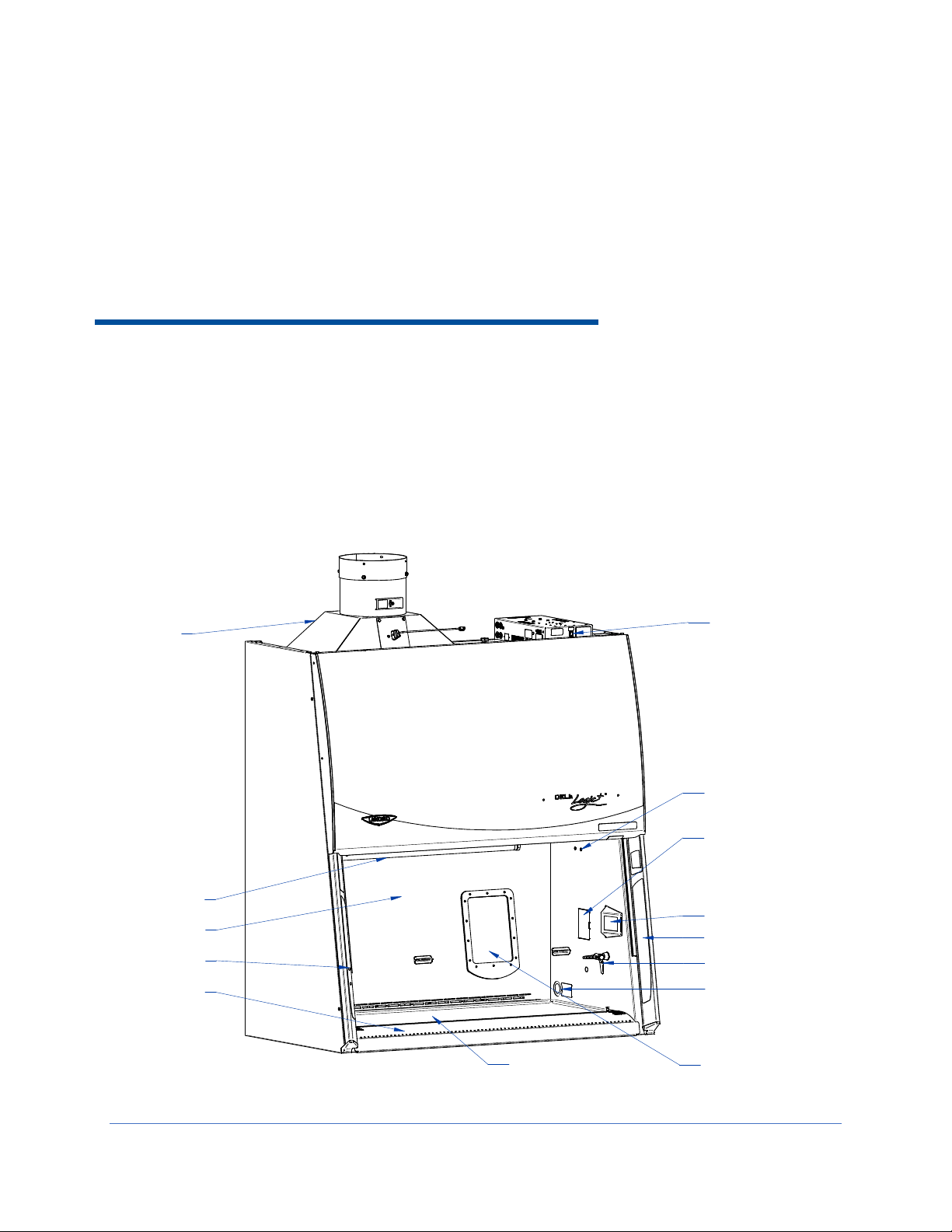

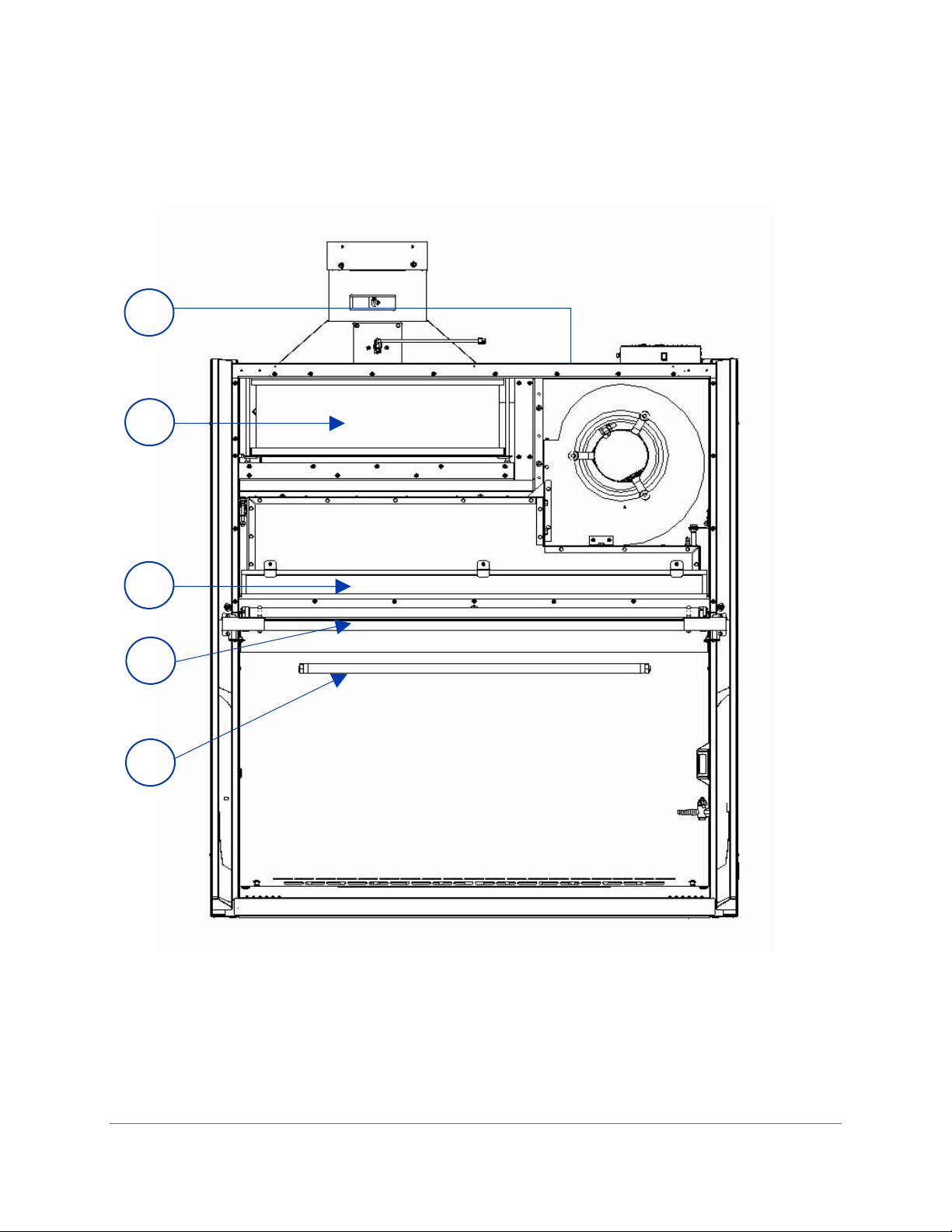

Exhaust Housing

Reset Switch

(optional) UV Lamp

Sash Position Label

Glass Sash

Dished Work Surface

Vacu-Pass (optional)

Service Fixture (optional)

LCD Display

Keypad

GFIC outlet, RH

Attachment Point

Optional IV Bar

Front Grille

Pure-Vu Seal

Figure 7-1

7: Using Your Cell Logic+ Type B2

This section details the functional features and proper techniques for safely and

efficiently using the Cell Logic+ Type B2 biosafety cabinet.

Feature Overview

Figure 7-1 illustrates key features and components of the product.

54

System Reset Switch

Power Reset Switch

Figure 7-2

The system reset switch removes power from the control board and microprocessor. It

is located on the front side of the electrical box on the top, right side of the product. See

Figure 7-2. This switch will NOT remove all electrical power from the product. For

service operations, always disconnect the main electrical connection prior to removing

service panels.

55

Keypad

Figure 7-3

The keypad of the cabinet is shown in Figure 7-3. Take a moment to familiarize yourself

with the buttons, their locations and functions. Also familiarize yourself with the display

located on the right side wall. The display will report system functions, such as filter

capacity, timer displays, alarm or error messages, as well as icons that illuminate when

cabinet functions such as the light and blower are operational.

[BLOWER] – Starts or stops the cabinet blower. When the

blower is in automatic (SmartStart) mode, opening the sash from

from the closed position turns the blower on automatically. The

Pressing the blower button at any time overrides the

automatic operation.

[LIGHT] – Turns the LED lamps on or off. Closing the sash

automatically turns the lights off. When the lights are in

automatic (SmartStart) mode, raising the sash turns the lights on

automatically. Pressing the light button at any time overrides the

automatic operation.

[OUTLETS] – Turns on/off electrical outlets in the work area.

[UV LIGHT] – Turns on/off the UV lamp (when installed).

When the UV lamp is in automatic mode, closing the sash turns