Labconco Labconco-3849920-rev-e-technical-manual Logic+ and Cell Logic+ A2 | B2 Biosafety Cabinets Axiom C1 Biosafety Cabinets PuriCare Procedure Stations Technical Manual

Logic+® and Cell Logic+® A2 | B2 Biosafety Cabinets

Axiom® C1 Biosafety Cabinets

PuriCare® Procedure Stations

Register this product

LABCONCO CORPORATION

8811 Prospect Avenue

Kansas City, MO 64132

(800) 821-5525 I +1 (816) 333-8811

labconco.com

Please read user’s manual before

operating equipment

Original Instructions

Technical Manual

2

Logic+® Type A2 Biosafety Cabinets

30231xxx1 30241xxx1 30251xxx1 30261xxx1

30238xxx1 30248xxx1 30258xxx1 30268xxx1

30242xxx1 30252xxx1 30262xxx1

PuriCare® Procedure Stations

31241xxx1 31261xxx1 31242xxx1 31252xxx1 31262xxx1

Logic+® Type B2 Biosafety Cabinets

30348xxx1 30368xxx1

Cell Logic+® Type A2 Biosafety Cabinets

32239xxx1 33239xxx1 34239xxx1

32249xxx1 33249xxx1 34249xxx1

32259xxx1 33259xxx1 34259xxx1

32269xxx1 33269xxx1 34269xxx1

Cell Logic+® Type B2 Biosafety Cabinets

32348xxx1 33348xxx1 34348xxx1

32368xxx1 33368xxx1 34368xxx1

Axiom® Type C1 Biosafety Cabinets

30441xxx1 30448xxx1 30461xxx1 30468xxx1

3

Copyright © 2021 Labconco Corporation. The information contained in this manual and the accompanying products are copyrighted and all rights reserved by

Labconco Corporation. Labconco Corporation reserves the right to make periodic design changes without obligation to notify any person or entity of such change.

Warranty

Labconco Corporation provides a warranty to the original buyer for the repair or replacement of parts and reasonable labor as a result of normal and proper use of

the equipment with compatible chemicals. Broken glassware and maintenance items, such as filters, gaskets, light bulbs, finishes and lubrication are not

warranted. Excluded from warranty are products with improper installation, erratic electrical or utility supply, unauthorized repair, use with incompatible chemicals,

or non-factory modifications to the original product.

Purifier® Logic®+ and AxiomTM Biological Safety Cabinets and PuriCare® Procedure Stations carry a five-year warranty from date of installation or six years from

date of shipment from Labconco, whichever is sooner. Warranty is non-transferable and only applies to the owner (organization) of record.

Buyer is exclusively responsible for the set-up, installation, verification, decontamination or calibration of equipment. This limited warranty covers parts and labor,

but not transportation and insurance charges. If the failure is determined to be covered under this warranty, the dealer or Labconco Corporation will authorize

repair or replacement of all defective parts to restore the unit to operation. Repairs may be completed by 3rd party service agents approved by Labconco

Corporation. Labconco Corporation reserves the rights to limit this warranty based on a service agent’s travel, working hours, the site’s entry restrictions and

unobstructed access to serviceable components of the product.

Under no circumstances shall Labconco Corporation be liable for indirect, consequential, or special damages of any kind. This warranty is exclusive and in lieu of

all other warranties whether oral, or implied.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be accepted. If your shipment was damaged in transit, you must

file a claim directly with the freight carrier. Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by various federal, state, or local regulations. All users of

this equipment are required to become familiar with any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water, land,

or air and to comply with such regulations. Labconco Corporation is held harmless with respect to user’s compliance with such regulations.

For additional questions or support:

Labconco Customer Care +1 (816) 333-8811

Labconco Technical Support (800) 821-5525

Hours 7:30 a.m.-5:30 p.m. CST

Part #3849920 Rev. E

ECO M149

4

Table of Contents

1: INTRODUCTION 11

Contacting Labconco 11

About This Manual 12

Theory of Operation 12

Type A2 12

Type B2 13

Type C1 – A mode 13

Type C1 – B mode 14

2: SAFETY PRECAUTIONS 15

Typographical Conventions 15

General Safety Precautions 17

Safety Precautions for this Product 19

3: CATALOG NUMBER CONFIGURATOR 21

4: SERIAL TAG 22

Serial Tag Location 22

Serial Tag Information 23

Primary Serial Tag 23

Secondary Serial Tag 23

5: FACTORY TEST REPORT 24

Test Report Location 24

Test Report Information 25

6: ADDITIONAL PRODUCT INFORMATION 26

Data Plate Location 26

5

Data Plate Information 27

7: EXHAUST SYSTEM CONNECTIONS 28

Exhaust Connection Best Practices 28

Air-Tight Damper 30

Exhaust System Requirements 31

Type A2 Models 31

Cell Logic+ Type A2 Models 32

Type B2 Models 32

Type C1 Models 33

8: CONFIGURATION 34

Current Configuration 34

Change Configuration 36

9: CALIBRATION 40

Certifier Password 40

Adjusting Blower Speed 41

Adjusting the Internal Air Damper 43

Setting the Filter Life Gauge 45

Type A2 (8-inch through 10-inch sash) and Type B2 45

Type A2 (12-inch sash) and Type C1 46

Airflow Sensor Calibration 47

Type A2 and Type C1 47

Type B2 48

Zero Point Calibration 50

Vacuum Start Switch Calibration (Type C1 only) 51

10: CERTIFICATION 53

Certifier Password 53

Type A2 HEPA Filter Leak Test Preparation 53

Theoretical Upstream Concentration 54

Upstream Concentration Sampling 54

6

Type A2 Supply HEPA Filter Leak Test 56

Acceptance Criteria 57

Type A2 Exhaust HEPA Filter Leak Test 58

Acceptance Criteria 59

Type B2 Supply HEPA Filter Leak Test Preparation 60

Theoretical Upstream Concentration 60

Upstream Concentration Sampling 60

Type B2 Supply HEPA Filter Leak Test 62

Acceptance Criteria 63

Type B2 Exhaust HEPA Filter Leak Test Preparation 64

Theoretical Upstream Concentration 64

Type B2 Exhaust HEPA Filter Leak Test 65

Acceptance Criteria 65

Type C1 Supply HEPA Filter Leak Test Preparation 66

Theoretical Upstream Concentration 66

Upstream Concentration Sampling 66

Type C1 Supply HEPA Filter Leak Test 68

Acceptance Criteria 69

Type C1 Exhaust HEPA Filter Leak Test Preparation 70

Theoretical Upstream Concentration 70

Type C1 Exhaust HEPA Filter Leak Test 72

Acceptance Criteria 73

Downflow Velocity 74

Acceptance Criteria 75

Inflow Velocity 76

Primary Method 76

Acceptance Criteria 78

Secondary Method 79

Acceptance Criteria 83

Work Area Air Cleanliness Test (optional) 84

Acceptance Criteria 84

Lighting Test (optional) 85

Acceptance Criteria 85

Noise Test (optional) 86

Acceptance Criteria 86

Vibration Test (optional) 86

Acceptance Criteria 86

7

UV Light Intensity Test (optional) 87

Acceptance Criteria 87

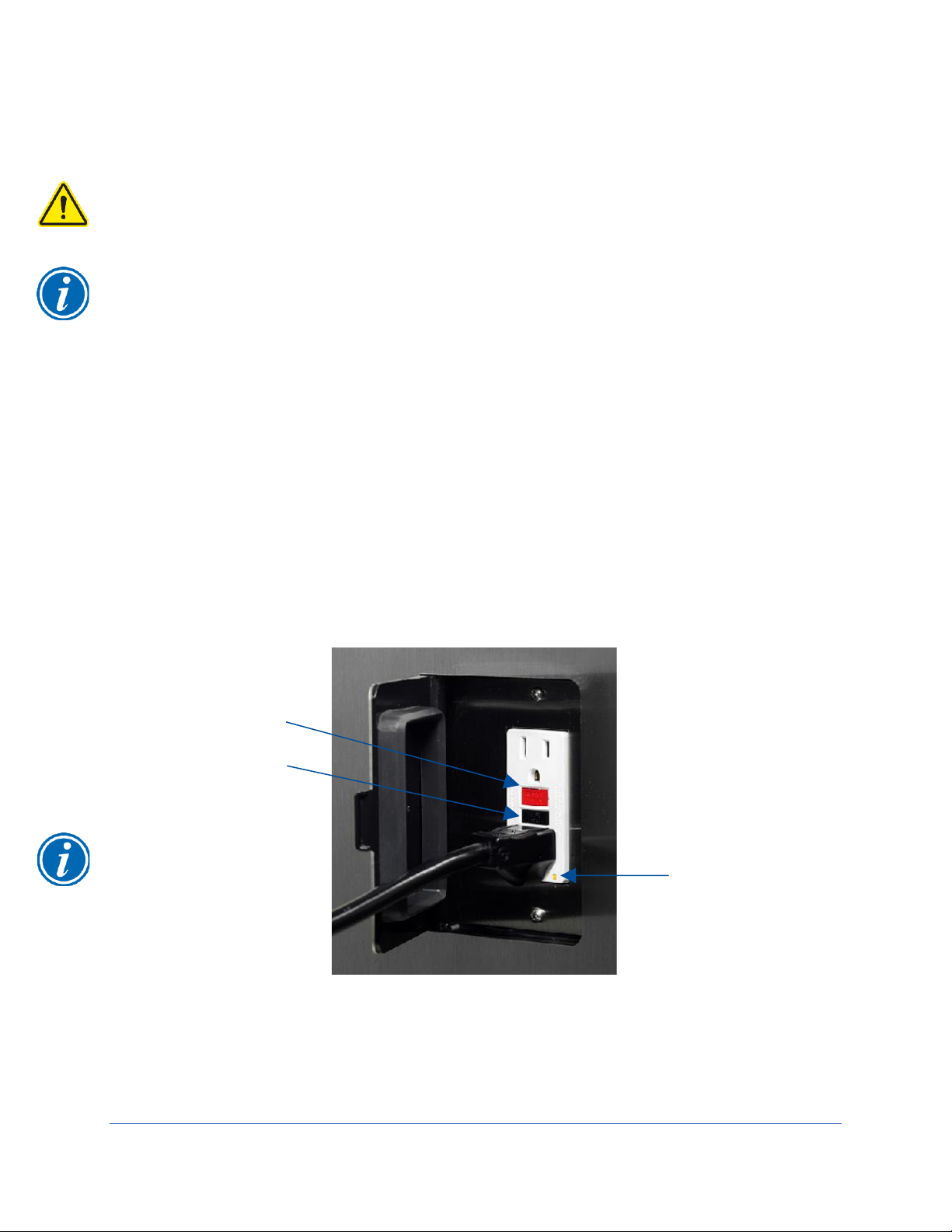

Ground Fault Circuit Interrupter (GFCI) Test 88

Acceptance Criteria 88

11: QUICKCHARTS 89

QuickChart – Type A2 3-ft & 4-ft 90

QuickChart – Type A2 5-ft & 6-ft 91

Type A2 Footnotes 92

QuickChart – Type B2 93

Type B2 Footnotes 94

QuickChart – Type C1 95

Type C1 Footnotes 96

12: ADVANCED SERVICE PROCEDURES 97

Tools 97

Required 97

Optional 97

Removal of External Dress Panels 98

Dress Panel 98

Side Panels 99

Front Sash 100

Sash Level Adjustment 100

Sash Sensor Adjustment or Replacement 101

HEPA Filter Replacement 104

Type A2 (8, 9, 10-inch sash) 104

Type A2 (12-inch sash) 107

Type B2 110

Type C1 114

Blower/Motor Replacement 117

Type A2 (8, 9, 10-inch sash) & B2 117

Type A2 (12-inch sash) & C1 Supply Blower/Motor 121

Type A2 (12-inch sash) & C1 Exhaust Blower/Motor 124

Changing the LED Lamps 129

LED Lamp Socket Cap Replacement 131

Changing the Optional UV Lamp 132

8

UV Lamp Socket Replacement 133

Type B2 Prefilter Replacement 134

Air-Tight Damper Adjustment 135

Preparing the Biosafety Cabinet for Gaseous Sterilization 136

Service Fixture Installation & Service Connection 137

13: ELECTRICAL COMPONENTS 140

Electronics Module 140

Electronic Module Components 141

Resetting a Circuit Breaker 142

Power Supply Board 143

Display Board 144

Speaker 145

Blower Motor 146

Wiring Diagrams 148

100-115V 148

208-240V 149

14: TROUBLESHOOTING 150

Blower and Lights not working 150

Blower only will not start 151

Lights only will not illuminate 152

UV Light will not illuminate 153

Airflow Alert activating 154

Filter Life Gauge not at 100% when new 155

Contamination in the work area 156

15: DIAGNOSTICS 157

Sash Sensors 157

Keypad 158

9

Airflow Sensor (optional) 159

Canopy (optional) 160

16: BMS DATA OUTPUT CONNECTION 161

Connection Type 161

Data Output Format 162

Data Output Rate 162

Data Output String Definition 163

Data Output Software Requirements 164

17: VENTUSTM CANOPY CONNECTION KIT 165

Kit Catalog Numbers 166

Installation Procedure 166

Exhaust Damper Installation Procedure 167

Canopy Switch Wiring Connection 168

Calibrate for Operation 169

18: AIRFLOW SENSOR KIT 171

Installation – Type A2 without Ventus Canopy 171

Installation – Type A2 with Ventus Canopy 173

Connection to Electronics Module 175

Configuration (new install only) 176

Calibration 178

19: UV LAMP KIT 181

Kit Catalog Numbers 181

Installation 181

Configuration 183

10

20: IV BAR KIT 185

Kit Catalog Numbers 185

Installation 185

21: PREFILTER KIT 187

Kit Catalog Numbers (Type A2 and B2 only) 187

Installation 187

Attach Prefilter(s) to Towel Catch – G4 Paper 188

Attach Prefilter(s) to Towel Catch – Aluminum Washable 189

22: EN ALARM/RELAY CONTACT KIT 190

Installation 190

Example 1 – Blower Relay Contact (Single Phase AC) 194

Example 2 – Blower Relay Contact (Three Phase AC) 195

23: PARTS LIST 196

Type A2 Consumables 196

Type B2 Consumables 197

Type C1 Consumables 198

Advanced Service Components 199

11

1: Introduction

This text is designed for biosafety cabinet certifiers and servicers. Labconco has

compiled this information to use in the certification or servicing of our Logic+, Cell

Logic+ and Axiom biosafety cabinets, and Puricare procedure stations.

As always, we at Labconco want to assist you in a better understanding of our products

and their operation; if you have any questions, or need additional information, please

contact us.

Thank you for all your support in the past, and in the future.

Contacting Labconco

LABCONCO Corporation

8811 Prospect Avenue

Kansas City, MO 64132

USA

Our hours of operation are from 7:30 am - 5:30 pm CST, Monday through Friday,

except national holidays

We can be reached at the following numbers:

1 (800) 821-5525 +1 (816) 333-8811

Should you require technical assistance, service parts, or have general questions

regarding the product, please direct them to our Product Service Department, so that

your call can be properly routed and answered.

12

About This Manual

This manual contains technical information for all types and models of Labconco

biosafety cabinets and procedure stations. Type A2 biosafety cabinets with a 12 inch

sash operating height, and C1 biosafety cabinets utilize two internal blowers, and Type

A2 and B2 biosafety cabinets with sash operating heights of 8, 9, or 10 inch utilize one

internal blower. Where information is applicable only to Type A2 12 inch or Type C1

models, a color-coded bar is provided to alert model-specific information. Below are

examples of this color-coded bar.

Theory of Operation

This section offers a brief overview of the operation of Type A2, B2, and C1 biosafety

cabinets.

Type A2

All Logic+ Type A2 biosafety

cabinets meet the airflow

requirements of ANSI/NSF Standard

49. Approximately 55-60% of the air

in the cabinet is filtered and

recirculated, while 40-45% is filtered

and exhausted. All Type A2 Logic+

biosafety cabinets feature

intrinsically safe designs, jacketing

contaminated positive pressure

areas with negative pressure zones.

Figure 1-1

Type A2 12

-inch

and C1

51

CURRENT / AVG = 1103 / 1104

NEW FILTER / MAX = 994 / 1450

REV. D

EXHAUST

Type

C1

RECIRCULATE (A MODE)

EXHAUST (B MODE)

13

Type B2

Type C1 – A mode

Figure 1-2

All Logic+ Type B2 biosafety

cabinets meet the airflow

requirements of ANSI/NSF Standard

49. All of the air in the cabinet is

filtered and none is recirculated. All

Type B2 Logic+ biosafety cabinets

feature intrinsically safe designs,

with all contaminated areas under

negative pressure.

Figure 1-3

All Logic+ Type C1 biosafety

cabinets meet the airflow

requirements of ANSI/NSF Standard

49. Approximately 55-60% of the air

in the cabinet is filtered and

recirculated, while 40-45% is filtered

and exhausted back to the lab. All

Type C1 Logic+ biosafety cabinets

feature intrinsically safe designs,

jacketing contaminated positive

pressure areas with negative

pressure zones.

14

Type C1 – B mode

Figure 1-4

All Logic+ Type C1 biosafety

cabinets meet the airflow

requirements of ANSI/NSF Standard

49. The Chem-ZoneTM (center work

surface) air is filtered and exhausted

via a remote building exhaust

system, while the inflow and outer

work surface air is filtered and

recirculated. All Type C1 Logic+

biosafety cabinets feature

intrinsically safe designs, jacketing

contaminated positive pressure

areas with negative pressure zones.

15

2: Safety Precautions

Before unpacking, installing, operating, maintaining, or servicing this equipment, read

the following safety warnings and precautions.

Avant le déballage, l’installation, le fonctionnement, l’entretien ou la maintenance de cet

équipement, lire les avertissements de sécurité et les précautions d’emploi.

CAUTION – See Manual. When this symbol is on the equipment, it indicates a

caution that is detailed in this manual.

MISE EN GARDE – Voir le manuel. Lorsque ce symbole est apposé sur

l’équipement, il renvoie à une mise en garde détaillée dans ce manuel.

Typographical Conventions

DANGER – An imminently hazardous situation which, if not avoided, will result in

death or serious injury.

DANGER – Situation dangereuse imminente qui, si elle n’est pas évitée, peut

entraîner la mort ou des blessures graves.

CAUTION – Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or damage to property.

MISE EN GARDE – Signale une situation potentiellement dangereuse qui, si elle

n’est pas évitée, peut provoquer des blessures mineures à modérées ou des

dommages matériels.

NOTE – Advice or suggestions to help the process.

REMARQUE – Conseils ou suggestions pour le déroulement du processus.

16

BURN RISK (HIGH TEMPERATURE) – Air or components that will be very hot.

Take care not to touch these defined areas. Failure to avoid these areas may

result in moderate to severe injury.

RISQUE DE BRÛLURE (TEMPÉRATURE ÉLEVÉE) – Air ambiant ou

composant devenant très chaud. Veiller à ne pas toucher ces zones délimitées.

L’absence de précaution pour éviter ces zones peut entraîner des blessures

modérées, voire graves.

EXTREME COLD (LOW TEMPERATURE) – Air or components that will be very

COLD. Take care not to touch these defined areas. Failure to avoid these areas

may result in moderate to severe injury.

FROID INTENSE (TEMPÉRATURE BASSE) – Air ambiant ou composant

devenant très froid. Veiller à ne pas toucher ces zones délimitées. L’absence de

précaution pour éviter ces zones peut entraîner des blessures modérées voire

graves.

PINCH POINT – Areas or components that can pinch or cut. Take care not to

touch these defined areas.

POINT DE PINCEMENT – Zones ou composants présentant un risque de

pincement ou de coupure. Veiller à ne pas toucher ces zones délimitées.

MOVING PARTS – Areas or components that contain moving parts. Take care

not to touch these defined areas.

PIÈCES MOBILES – Zones ou composants contenant des pièces mobiles.

Veiller à ne pas toucher ces zones délimitées.

RISK OF ELECTRICAL SHOCK – The specified procedure or area poses a risk

of electrical shock. ALWAYS disconnect main power cord or electrical supply

before proceeding.

RISQUE DE CHOC ÉLECTRIQUE – La procédure ou la zone spécifiée présente

un risque de choc électrique. TOUJOURS débrancher le cordon d’alimentation

secteur ou l’alimentation électrique avant toute intervention.

FLAMMABLE / NO SOLVENTS – Do not place flammable liquids or solvents in

this product.

INFLAMMABLE / PAS DE SOLVANTS – Ne placez aucun liquid inflammable

dans cette produit.

17

LIFTING HAZARD – Do not lift or move this equipment without assistance.

DANGER DE LEVAGE – Ne pas soulever ou déplacer cet équipement sans

assistance.

MAGNETIC FIELD IN USE – Magnets or magnetic field present.

CHAMP MAGNETIQUE UTILISE – Présence d'aimants ou de champ

magnétique.

DO NOT TOUCH – Components or areas indicated are sensitive and will suffer

damage if touched. Take care not to touch these defined components or areas.

Failure to avoid these areas will result in damage to the product.

NE PAS TOUCHER – Les composants ou les zones indiquées sont sensibles et

subiront des dégâts s’ils sont touchés. Veiller à ne pas toucher ces composants

ou zones délimité(e)s. L’absence de précaution pour éviter ces zones

endommagera le produit.

TOOL REQUIRED – Tool required to access specified area.

OUTIL NÉCESSAIRE – Outil nécessaire pour accéder à la zone spécifiée.

General Safety Precautions

Follow all the safety precautions described in this section.

Before removing any panels which require a tool for removal, ALWAYS

disconnect the main power cord or electrical supply. Failure to remove all

electrical power before proceeding will result in moderate to serious injury, death,

or damage to property.

Avant le retrait d’un panneau nécessitant l’utilisation d’un outil, TOUJOURS

débrancher le cordon d’alimentation secteur ou l’alimentation électrique. Le non-

respect de la consigne consistant à couper complètement l’alimentation

électrique avant toute intervention peut entraîner des blessures graves, la mort

ou des dommages matériels.

18

Never contact moving parts with your person. Failure to avoid moving parts will

result in moderate to serious injury, death, or damage to property.

Ne jamais toucher les parties mobiles. Le non-respect de la consigne consistant

à éviter les pièces mobiles peut entraîner des blessures graves, la mort ou des

dommages matériels.

Never misuse this product. Never disable, override, or otherwise bypass safety

guards, panels, switches, sensors or alarms. Doing so will result in moderate to

serious injury, death, or damage to this product or property.

Ne jamais utiliser ce produit à mauvais escient. Ne jamais désactiver, annuler ou

contourner les capots, panneaux, interrupteurs, capteurs ou alarmes de sécurité.

Ceci entraînerait des blessures graves, la mort ou des dommages matériels à ce

produit ou à d’autres biens.

If the unit is not operated as specified in this manual it may impair the protection

provided by the unit.

Si l'unité n'est pas utilisée comme spécifié dans ce manuel il peut diminuer la

protection fournie par l'unité.

Do not position the unit so that it is difficult to operate the main disconnect

device.

Ne placez pas l'appareil de sorte qu'il est difficile de faire fonctionner le dispositif

principal de déconnexion.

Do not lift or move this equipment without assistance.

Ne pas soulever ou déplacer cet équipement sans assistance.

19

Safety Precautions for this Product

Electrical outlets in the cabinet are restricted to 5 amps (100-115v) or 3 amps

(230v) maximum current.

Prises électriques dans l'armoire sont limitées à 5 (100-115v) o 3 (230v) courant

maximum ampères.

Do not use any detachable power cord that is not adequately rated for the unit.

Ne pas utliser un fil électrique amovible qui n’est pas du tension nominale de

l’appareil.

The biosafety cabinet should be certified by a certification technician before its

initial use. The cabinet should be recertified whenever it is relocated, serviced or

at least annually thereafter. Filter integrity and airflow performance should be

verified before using the cabinet.

Some internal components of the biosafety cabinet may become contaminated

during operation of the unit. Only experienced personnel competent in

decontamination procedures should decontaminate the cabinet before servicing

these components. If you have any questions regarding certification agencies, or

need assistance in locating one, contact Labconco’s Product Service Department

at 800-821-5525 or 816-333-8811.

DO NOT load more than 150 lbs. (68 kg) in the work area. Exceeding this limit

may damage the work surface and its supports. Excessive weight in the cabinet

may increase the risk of it overturning, or failure of hydraulic lift stands, resulting

in the cabinet and stand overturning. If your application requires loading more

than 150 lbs. (68 kg), contact Labconco’s Product Service Department at 800821-5525 or 816-333-8811 for assistance.

Avoid the use of flammable gases or solvents in the biosafety cabinet. Care must

be taken to ensure against the concentration of flammable or explosive gases or

vapors. An open flame should NOT be used in the biosafety cabinet. Open

flames will disrupt airflow patterns, burn the HEPA filter and/or damage the filter’s

adhesive. Gases under high pressure should not be used in the biosafety

cabinet, as they may disrupt its airflow patterns.

HEPA filters only remove particulate matter. Operations generating volatile toxic

chemicals or radionuclides must be evaluated carefully.

20

The media of HEPA filters is fragile and should not be touched. Avoid puncturing

either HEPA filter during installation or normal operation. If you suspect that a

HEPA filter has been damaged, DO NOT use the cabinet; contact a local

certification agency or Labconco at 800-821-5525 or 816-333-8811 for recertification information.

The HEPA filters in the biosafety cabinet will gradually accumulate airborne

particulate matter from the room and from work performed in the cabinet. The

rate of accumulation will depend upon the cleanliness of the room air, operating

time and the nature of work being done in the cabinet. The Filter Gauge

accurately displays the amount of filter life remaining.

Proper operation of the cabinet depends largely upon its location and the

operator’s work habits.

Avoid direct exposure of plastic or coated materials to ultraviolet (UV) radiation.

Never bypass the UV safety interlock that only allows the UV light to work when

the sash is closed. When surface disinfecting the biosafety cabinet:

o Avoid splashing the disinfecting solution on skin or clothing.

o Ensure adequate ventilation.

o Carefully follow the disinfectant’s safety instructions.

o Always dispose of disinfecting solutions in accordance with local and national

laws.

o DO NOT allow disinfectants with high concentrations of free chlorine to

contact the stainless steel components of the biosafety cabinet for a long

period of time. Free chlorine will corrode stainless steel after extended

contact.

Biosafety cabinets should be decontaminated for any of the following reasons:

o Before maintenance work requiring entry into contaminated areas.

o Before HEPA filter changes.

o Before performing certification tests requiring entry into contaminated areas.

o Before relocating the cabinet.

o Before changing research programs.

o After the gross spill of biohazardous material or toxic chemicals.

21

3: Catalog Number Configurator

Logic+ and Axiom biosafety cabinets and Puricare procedure stations utilize catalog

numbers (also referred to as model numbers) where each digit of the catalog number

provides key information about the model. Use the configurator below to identify

specifics about your product.

30248xxx1

Product Group

3=Laminar Flow Products

Product Family

0= Logic+

1= PuriCare

2-4= Cell Logic+

Cabinet Type

2= Type A2

3= Type B2

4= Type C1

Cabinet Width

3= 3-foot Wide

4= 4-foot Wide

5= 5-foot Wide

6= 6-foot Wide

Sash Height

1= 10” sash opening

2= 12” sash opening

8= 8” sash opening

9= 9” sash opening

22

4: Serial Tag

If you need to contact Labconco regarding this product, it is required you provide the

serial number. The serial number provides all product details, including the revision

level under which the product was constructed. It is the single, most important piece of

information when assistance is requested.

Serial Tag Location

See Figure 4-1 for the location of the primary and secondary serial tags.

Dress Panel

Primary

Serial Tag

Secondary

Serial Tag

Data Plate

Dress Panel

Screw

Dress Panel

Screw

Factory

Test

Report

Wiring

Diagram

Behind

Dress

Panel

Figure 4-1

23

Serial Tag Information

The following information is located on the Serial Tags:

Primary Serial Tag

Serial Number

Catalog (Model) Number

Revision

Electrical Requirements

o Voltage

o Frequency

o Amperage

o Phase

Secondary Serial Tag

Serial Number

Catalog (Model) Number

Figure 4-2

Figure 4-3

24

5: Factory Test Report

The factory test report is a valuable reference for the product’s airflows and blower

setting(s), as well as information about the HEPA filters, and accessories that may be

factory installed.

Test Report Location

The test report is located on the blower/plenum cover, which is behind the front dress

panel. See Figure 5-1. The Dress Panel Screws must be removed and the Dress Panel

lifted off to reach the test report.

Dress Panel

Primary

Serial Tag

Secondary

Serial Tag

Data Plate

Dress Panel

Screw

Dress Panel

Screw

Factory

Test

Report

Wiring

Diagram

Behind

Dress

Panel

Figure 5-1

25

Test Report Information

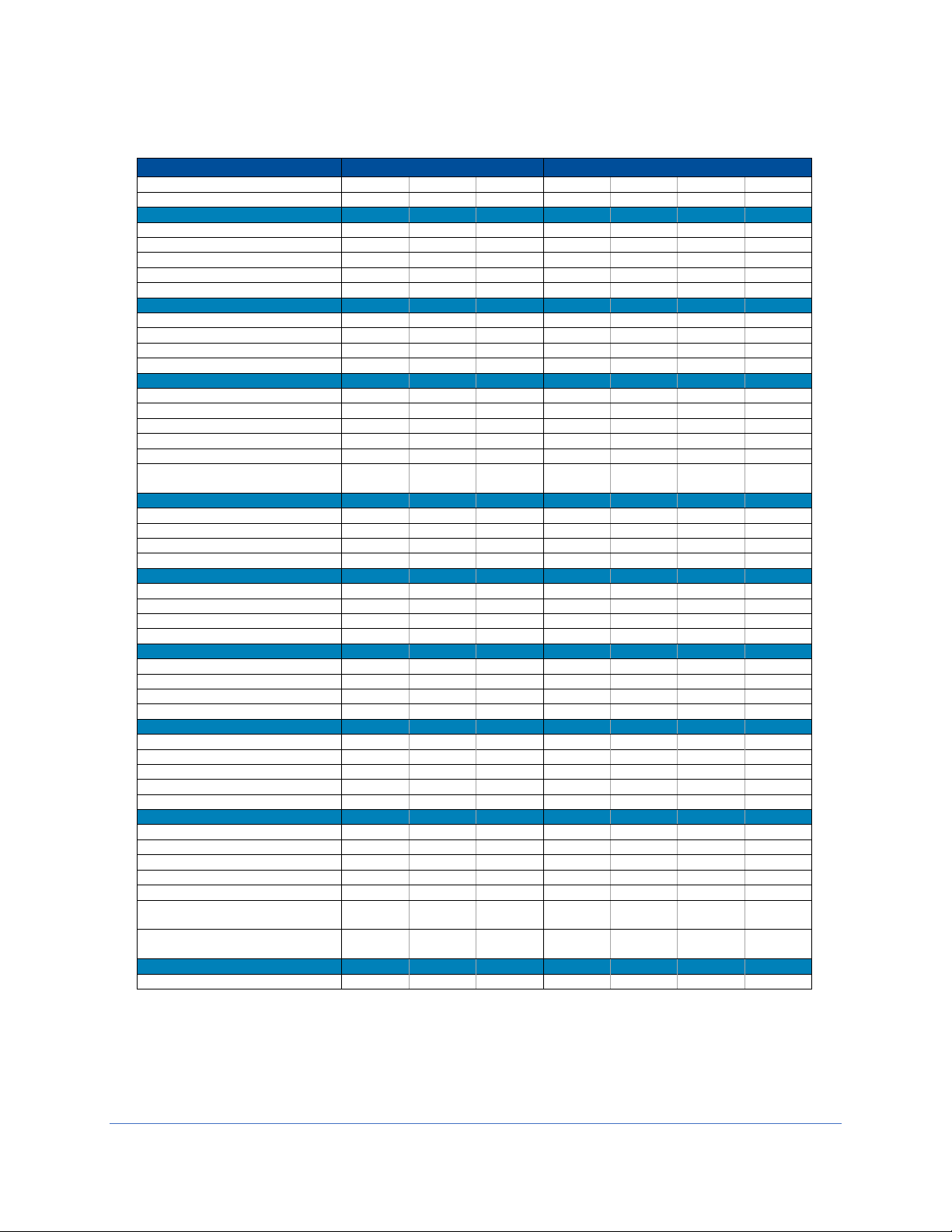

See Figure 5-2 for a typical test report. Review this carefully to identify where on the

report specific information is located. Important information is highlighted below.

Note: The test report shown is an A2-12inch model with two internal blowers. A2-12inch and C1 model

reports list two blower speeds (supply and exhaust blower). All other models report one blower speed.

Figure 5-2

Catalog

Number

Serial

Number

Blower

Speed(s)

Inflow

(Avg.

Velocity)

Downflow

(Avg. Velocity)

26

6: Additional Product Information

All NSF-Listed biosafety cabinets are required by NSF49 regulations to display a Data

Plate on the front of the product in a readily visible location.

Data Plate Location

See Figure 6-1 for the Data Plate location.

Dress Panel

Primary

Serial Tag

Secondary

Serial Tag

Data Plate

Dress Panel

Screw

Dress Panel

Screw

Factory

Test

Report

Wiring

Diagram

Behind

Dress

Panel

Figure 6-1

27

Data Plate Information

The Data Plate provides the following important information for certifier use during onsite certifications:

Nominal Airflows (Inflow and Downflow)

Downflow Grid Test Point Locations

Introduction Location for Test Aerosol

Secondary Inflow Methodology

NSF49 standard revision under which the biosafety cabinet is listed

Figure 6-2 shows a Type A2, 4-feet width Data Plate as an example to identify where

the required information is located on the Data Plate. All Labconco Data Plates are in

the same format.

Figure 6-2

28

7: Exhaust System Connections

Not all models of biosafety cabinets are connected to a remote or building exhaust

system. Type A2 models may recirculate their exhaust back to the laboratory, or

remove their exhaust air from the lab via a VentusTM Canopy (also referred to as a

Thimble Connection) connected to a remote (building) exhaust system. Type B2

models must always be connected to an exhaust system. Type C1 models may operate

in A-mode where the exhaust is recirculated to the laboratory, or B-mode when

connected to a remote exhaust system.

This section provides recommended best practices when connecting a biosafety cabinet

to a remote exhaust system to avoid operational problems with the cabinet. In addition,

the specific exhaust volumes and vacuum pressures required to properly operate each

cabinet model are listed by cabinet width and sash operating height.

If a biosafety cabinet is being altered from recirculating operation to ducted (exhausted)

operation in the field, it must be recertified by a qualified certifier before being used.

Exhaust Connection Best Practices

Note: Only connect the biosafety cabinet to a suitable exhaust system that is dedicated

to the biosafety cabinet, or dedicated to exhausting laboratory ventilation equipment.

Do NOT connect the biosafety cabinet to the building’s general HVAC system for room

exhaust.

Figure 7-1

Examine the location to ensure that it

accommodates the cabinet’s exhaust duct. The

area directly above the cabinet’s exhaust port

should be clear of structural elements, water and

utility lines, or other fixed obstructions. There

should be enough clearance to accommodate a

10-inch diameter duct. See Figure 7-1.

29

Avoid cabinet locations that require an elbow

directly above the cabinet’s exhaust connection

or an excessive number of elbows in the exhaust

system. There should be a straight length 10

duct diameters long between the cabinet

connection and any elbow, and between

subsequent elbows. See Figure 7-2.

Figure 7-3

The Inlet Relief Valve located on the top of the

cabinet is designed to draw a maximum of 100

CFM (170 m3/hr).

Attempting to draw additional room air through

the valve (room air exhaust), can result in

unstable cabinet operation. See Figure 7-3.

Figure 7-4

If additional room exhaust needs to be drawn

through the exhaust system, install an additional

duct and balancing damper downstream of the

cabinet’s damper. This will allow for proper

balancing of the system. See Figure 7-4.

Figure 7-2

This information applies to Canopy-Exhausted Type A2 and C1 (in B-Mode) only

30

Air-Tight Damper

On canopy-exhausted Type A2 and C1 (operating in B-mode) models, Labconco highly

recommends installing an air-tight damper above each biosafety cabinet when

connected to a building exhaust system. The air-tight damper allows for fine adjustment

of the exhaust air volume provided, in order to correctly set the necessary exhaust

airflow for each biosafety cabinet. It also allows the biosafety cabinet to be sealed off

from the building exhaust system, should it become necessary to do so.

Note: Type B2 models must always be connected to a remote exhaust system. Type B2

models have an air-tight damper built into the biosafety cabinet’s exhaust housing.

AIR-TIGHT DAMPER

DUCT COLLAR

BUILDING EXHAUST DUCT

(NOT INCLUDED)

AIRFLOW

ADJUSTMENT

HANDLE

BIOSAFETY CABINET

DUCT STUB

Figure 7-5

Visual appearance of biosafety cabinet and exhaust connection may vary by model.

31

Exhaust System Requirements

The exhaust system must be capable of moving the following volumes of exhaust air at

the negative pressures listed. The Airflow Volumes are the values recorded via direct

measurement using a flow hood at the front opening of the cabinet. The Concurrent

Balance Values are measured in the exhaust duct via traverse methodology, and will

always be higher due to differences in volume measurement methodologies.

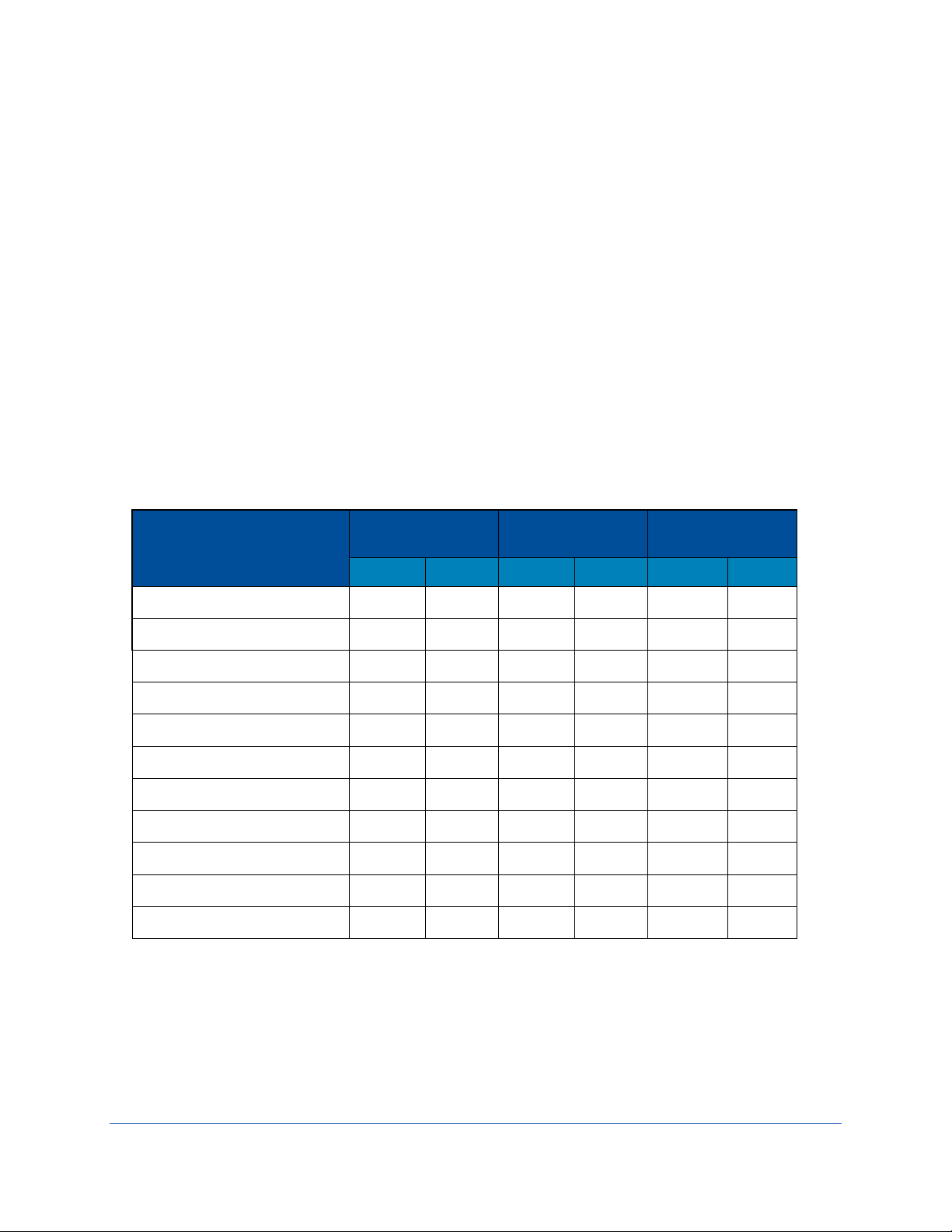

For Type A2 models with Ventus Canopy Connections, see Table 7-1.

For Cell Logic+ Type A2 models with Ventus Canopy Connections, see Table 7-2

For Type B2 models, see Table 7-3.

For Type C1 models operating in B-mode, see Table 7-4.

Type A2 Models

1: Unlike Type B biosafety cabinets, the recommended vacuum will remain constant

throughout the life of the exhaust HEPA filter. Duct vacuums below 0.05 inches H2O

(12 Pa) or above 0.5 inches H2O (125 Pa) may result in erratic operation and throw an

alarm condition from the product.

2: WC = Inches of Water Column, typically expressed in units of inches H2O.

Logic+ Type A2 Model

Airflow Volume

Concurrent

Balance Value

Recommended

Duct Vacuum1

ft3/min

m3/hr

ft3/min

m3/hr

WC2

Pa

3-foot, 8" Sash

263

447

289

491

0.15

38

3-foot, 10" Sash

316

537

348

591

0.15

38

4-foot, 8" Sash

333

566

366

622

0.15

38

4-foot, 10" Sash

404

687

444

754

0.15

38

4-foot, 12" Sash

474

805

521

885

0.15

38

5-foot, 8" Sash

403

685

443

753

0.15

38

5-foot, 10" Sash

491

834

540

917

0.15

38

5-foot, 12" Sash

580

985

638

1084

0.15

38

6-foot, 8" Sash

473

804

520

883

0.15

38

6-foot, 10" Sash

579

984

637

1082

0.15

38

6-foot, 12" Sash

686

1166

755

1283

0.15

38

Table 7-1

32

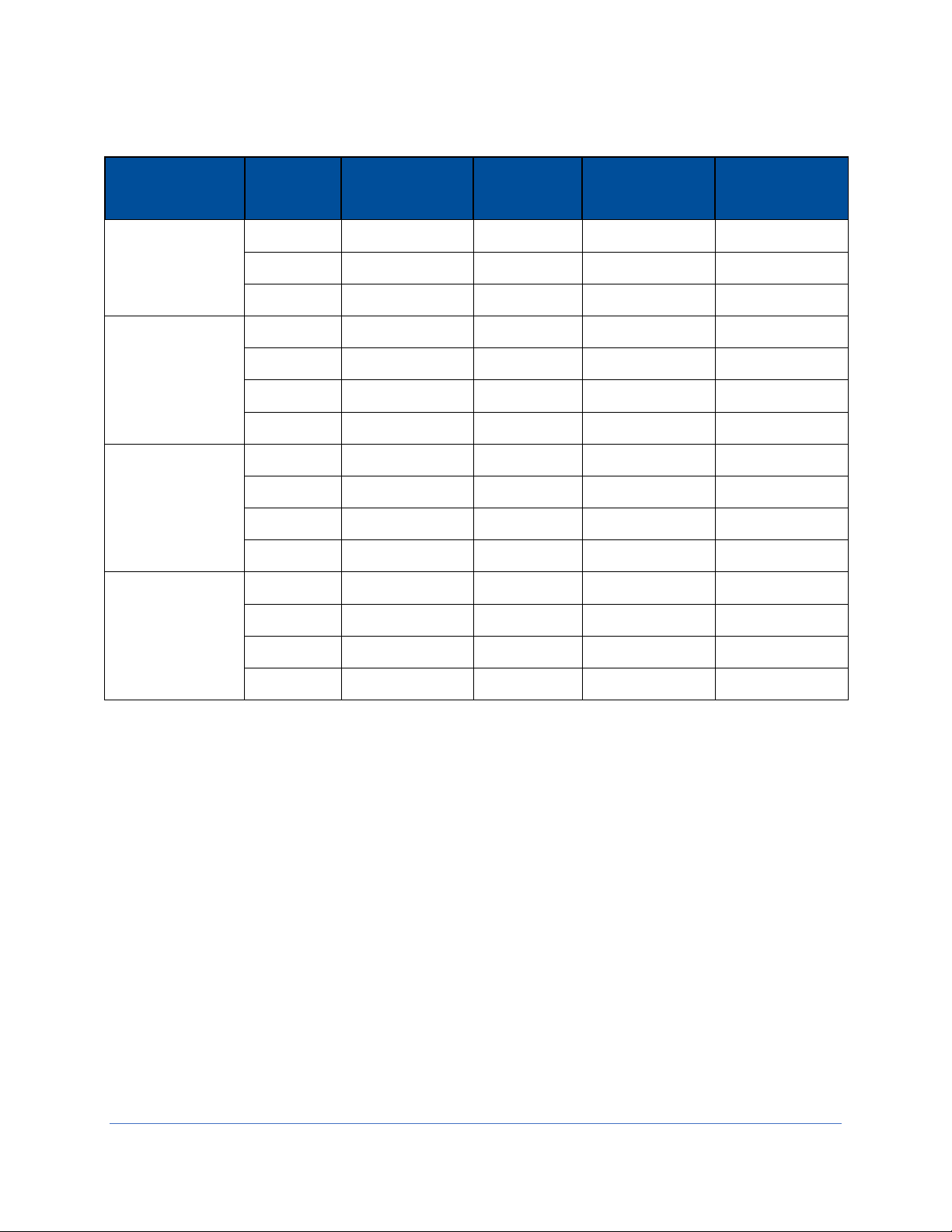

Cell Logic+ Type A2 Models

1: Unlike Type B biosafety cabinets, the recommended vacuum will remain constant

throughout the life of the exhaust HEPA filter. Duct vacuums below 0.05 inches H2O

(12 Pa) or above 0.5 inches H2O (125 Pa) may result in erratic operation and throw an

alarm condition from the product.

2: WC = Inches of Water Column, typically expressed in units of inches H2O.

Type B2 Models

1: WC = Inches of Water Column, typically expressed in units of inches H2O.

Logic+ Type B2 Model

Airflow Volume

Concurrent

Balance Value

Recommended

Duct Vacuum

ft3/min

m3/hr

ft3/min

m3/hr

WC1

Pa

4-foot, 8" Sash

723

1228

852

1448

1.8

450

6-foot, 8" Sash

1083

1840

1265

2149

2.2

550

Table 7-3

Logic+ Type A2 Model

Airflow Volume

Concurrent

Balance Value

Recommended

Duct Vacuum1

ft3/min

m3/hr

ft3/min

m3/hr

WC2

Pa

3-foot, 9" Sash

290

492

319

541

0.15

38

4-foot, 9" Sash

369

627

405

688

0.15

38

5-foot, 9" Sash

447

760

492

835

0.15

38

6-foot, 9" Sash

526

894

579

983

0.15

38

Table 7-2

33

Type C1 Models

1: Unlike Type B biosafety cabinets, the recommended vacuum will remain constant

throughout the life of the exhaust HEPA filter. Duct vacuums below 0.05 inches H2O

(12 Pa) or above 0.5 inches H2O (125 Pa) may result in erratic operation and throw an

alarm condition from the product.

2: WC = Inches of Water Column, typically expressed in units of inches H2O.

Axiom Type C1 Model

Airflow Volume

Concurrent

Balance Value

Recommended

Duct Vacuum1

ft3/min

m3/hr

ft3/min

m3/hr

WC2

Pa

4-foot, 8" Sash

323

549

387

658

0.30

75

4-foot, 10" Sash

400

680

480

816

0.30

75

6-foot, 8" Sash

463

787

556

945

0.30

75

6-foot, 10" Sash

570

968

684

1162

0.30

75

Table 7-4

34

8: Configuration

This section provides instructions to access and understand the current configuration of

the biosafety cabinet, and make changes to the configuration.

Keypad button presses are shown as [BLUE WITH BRACKETS]. Menu screen

selections are shown as green italics.

Current Configuration

It is important to understand the current configuration of the biosafety cabinet for many

reasons, some of which include:

Verify model and type

Verify accessories installed

Troubleshooting

The Info Screen provides information on the current configuration of the biosafety

cabinets, and details the current blower speed(s). The Info Screen is not password

protected. To access this screen, follow these steps:

1. From the Main Menu, press [MENU], using [UP] or [DOWN] select the Tools

icon. Press [OK/MUTE].

[MENU]

Tools

35

2. The Info icon should be highlighted, if not select Info, press [OK/MUTE].

*Option(s) not installed are shown with a strikethrough. To activate options (after field

installation), see Change Configuration later in Section 8. To change the blower

speed(s), see Section 9: Calibration and Certification.

Type A2 12

-inch

and C1

Info

AFS

UV LIGHT

CANOPY

C1 - A MODE

REV. D

10 INCH

[OK/MUTE]

58

CURRENT / AVG = 1217 / 1219

NEW FILTER / MAX = 1074 / 1800

REV. D

SUPPLY

51

CURRENT / AVG = 1103 / 1104

NEW FILTER / MAX = 994 / 1800

REV. D

EXHAUST

[UP] [DOWN]

[UP] [DOWN]

Type

Sash

Height

Option(s)

Installed *

Software

Version

Blower

PWM

Only shown on two

blower models

(A2 12-inch and C1)

Instantaneous Blower RPM /

Time dampened average Blower RPM

Blower RPM with new HEPA filters /

Maximum Blower RPM

This screen only shown

on two blower models

(A2 12-inch and C1)

36

Change Configuration

Changes to the biosafety cabinet configuration can be made in the field. This typically

occurs after an accessory is field installed, or the user requests a change to the sash

height (between 8 and 10 inches) on a Type C1 only.

Never change the following configuration parameters:

Cabinet Type – if the cabinet type is changed, it can result in incorrect operation

of the biosafety cabinet, and the biosafety cabinet may not protect the product,

personnel, or environment.

Sash Height – On Type A2 and B2 cabinets, never change the sash height.

The following instructions detail all screens in the Configuration menu, which is

password protected. The password is [LIGHT] [UV LIGHT] [TIMER] [TIMER]

[OK/MUTE].

1. From the Main Menu, press [MENU], using [UP] or [DOWN] select the Tools

icon. Press [OK/MUTE].

2. Use [UP] or [DOWN] to select the Password icon, press [OK/MUTE].

[MENU]

Tools

Password

[OK/MUTE]

WARNING !

RESTRICTED AREA

FOR TECHNICIAN

USE ONLY

37

3. From the Warning Screen, press [OK/MUTE] to acknowledge the warning that

the following screens are restricted.

4. On the Password Screen, enter the password: [LIGHT] [UV LIGHT] [TIMER]

[TIMER] [OK/MUTE].

5. Configuration should be highlighted, if not, select it, press [OK/MUTE]. The first

screen will display the biosafety cabinet type. Do NOT change this selection,

press [OK/MUTE].

Type

C1

CONFIGURATION

CALIBRATION

PASSWORD

* * * * *

Password

Entered

TYPE A2

TYPE B2

TYPE C1

[OK/MUTE]

RECIRCULATE (A MODE)

EXHAUST (B MODE)

AIRFLOW SENSOR

AIRFLOW SENSOR

[OK/MUTE]

This screen only shown

on Type C1 models

If changing between A-

Mode and B-Mode on a

Type C1, do so here

Type B2 models must have an

Airflow Sensor, so this screen is

not shown on a Type B2

38

6. On a Type A2 or C1 only, if field installing, or removing the Airflow Sensor,

change the selection accordingly, press [OK/MUTE].

7. On all biosafety cabinet types, if field installing, or removing the UV Light, change

the selection accordingly (screen shown above), press [OK/MUTE].

8. On Type A2 models only, if field installing, or removing the Canopy connection,

change the selection accordingly, press [OK/MUTE].

Note: When a Type C is selected previously, the Canopy Screen will not appear, but

the software will default the selection correctly based on whether A-mode (No Canopy)

or B-mode (Canopy) was previously selected.

9. The Sash Height selection will display next, and should NOT be changed, unless

the model is a C1, and the user has decided to switch between 8-inch and 10inch sash operation. Press [OK/MUTE].

If the biosafety cabinet is a Type A2 or B2, this is the final screen selection. If a C1,

proceed to step #10.

AIRFLOW SENSOR

AIRFLOW SENSOR

[OK/MUTE]

UV LIGHT

UV LIGHT

CANOPY

CANOPY

SASH HEIGHT

8 INCH

[OK/MUTE]

39

10. If a Type C1 model, and B-Mode operation was selected previously, the Active

Protection Screen will appear. This allows the selection of the time for which the

Type C1 will continue to operate (while sounding an alarm) when a remote

(building) exhaust failure occurs. This allows the user time to secure critical work

and exit before the cabinet shuts off. Set in 10 second increments up to 5

minutes (300 seconds). Use [UP] or [DOWN] to select the Active Protection

time. Press [OK/MUTE].

C1

B MODE

ACTIVE PROTECTION

10 SECONDS

40

9: Calibration

This section provides instructions to access and understand the procedures to calibrate

the biosafety cabinet. Use this section in conjunction with Section 10: Certification when

performing initial or annual certification.

Never enter the password-protected area, or change settings of the biosafety cabinet if

you are not a trained and qualified certifier or technician. Changing parameters in the

password-protected area may impair the product’s performance and result in loss of

protection and/or harm or death to personnel in the laboratory.

Certifier Password

The certifier password is: [LIGHT] [UV LIGHT] [TIMER] [TIMER] [OK/MUTE].

Use this password for all normal calibration and certification activities.

If installing or replacing an Airflow Sensor, the sensor will need a zero point calibration.

In order to access the zero-point calibration screen, a different password is required.

This password is: [LIGHT] [UV LIGHT] [TIMER] [OUTLET] [OK/MUTE].

41

Adjusting Blower Speed

During initial or annual certification of the biosafety cabinet, the blower speed may need

to be adjusted. Blower speed must only be adjusted by a trained, qualified certifier. To

adjust the blower speed, following these instructions.

1. From the Main Menu, press [MENU], using [UP] or [DOWN] select the Tools

icon. Press [OK/MUTE].

2. Use [UP] or [DOWN] to select the Password icon, press [OK/MUTE].

3. From the Warning Screen, press [OK/MUTE] to acknowledge the warning that

the following screens are restricted.

[MENU]

Tools

Password

[OK/MUTE]

WARNING !

RESTRICTED AREA

FOR TECHNICIAN

USE ONLY

42

4. On the Password Screen, enter the password: is [LIGHT] [UV LIGHT] [TIMER]

[TIMER] [OK/MUTE]. If also installing a new airflow sensor, see Certifier

Password earlier in this section to enter the correct password to allow for zero-

point calibration of the airflow sensor.

5. Use [UP] or [DOWN] to select Calibration. Press [OK/MUTE].

Note: The sash must be at operating height when pressing [OK/MUTE]. Access will

not be granted if the sash is closed.

Use [UP] or [DOWN] to adjust the blower speed. Each single press of [UP] or

[DOWN] increments the PWM signal sent to the blower by 0.5. It may take two

presses of the button to see the displayed PWM value change; however the

blower speed will adjust with each button press.

When the Instantaneous Blower rpm is within 15 rpm of the Average Blower rpm,

the blower speed has stabilized, and [OK/MUTE] can be pressed to move to the

next screen.

CONFIGURATION

CALIBRATION

PASSWORD

* * * * *

Password

Entered

58

CURRENT RPM = 1217

AVERAGE RPM = 1219

‘OK’ TO CONTINUE

SUPPLY

Blower

PWM

Only shown on two

blower models

(A2 12-inch and C1)

Instantaneous

Blower RPM

‘OK’ displayed

when blower

speed stabilizes

43

Adjusting the Internal Air Damper

On Type A2 8-inch through 10-inch sash heights and all Type B2 (single blower)

models, during the certification of the biosafety cabinet, it may be necessary to adjust

the split of air between downflow and exhaust. This is an important part of balancing

the biosafety cabinet and hitting the specified average downflow and inflow values

specified for each model and size cabinet.

Note: On Type A2 12-inch sash height and Type C1 (dual blower) models, there is no

internal air damper. One blower is dedicated to the supply (downflow) air, and one to

exhaust (inflow) air. On these models, the blower speed of each will be set

electronically. See the previous section Adjusting Blower Speed, and note the text

“Supply” displayed on Step #5. After setting the supply blower speed, the screens will

advance to the exhaust blower speed adjustment.

To adjust the internal damper, follow these instructions:

1. Remove the front Dress Panel (reference Figure 5-1 and 9-1) by removing the

two (2) Dress Panel Screws, pulling the bottom of the Dress Panel away from the

cabinet, and the lifting up on the Dress Panel.

CAUTION: The Dress Panel is large and heavy, especially on models 5-feet in width

and larger. Use two (2) persons to safely lift and remove the Dress Panel.

Figure 9-1

Dress Panel

Screws

44

2. Locate the exhaust damper adjustment bolt (reference Figure 9-2). The

adjustment bolt is in the center of a flexible, orange cup seal. Use a 7/16-inch nut

driver or socket and ratchet to turn the bolt. The bolt has 16 turns from fully open

to fully closed. The adjustment decal shows the number of turns from fully closed

that balanced the biosafety cabinet correctly at the factory. The adjustment bolt

and adjustment decal are shown in Figure 9-2.

Figure 9-2

Turning Counterclockwise:

Decreases Inflow (Exhaust)

Increases Downflow

Adjustment

Decal

Adjustment

Bolt

Turning Clockwise:

Increases Inflow (Exhaust)

Decreases Downflow

45

Setting the Filter Life Gauge

During initial or annual certification of the biosafety cabinet, and after the HEPA filters

are changed, the Filter Life Gauge may need to be reset. There are three options to

choose from when resetting the Filter Life Gauge. Below are the three options, and an

explanation on which to select.

1. New Filter – Select this option when the HEPA filters are new. This occurs

during initial certification of a new biosafety cabinet, or after new HEPA filters are

installed and the biosafety cabinet’s Inflow and Downflow have been verified by a

trained and qualified certifier.

2. Same Filter – Select this option when passing through this screen in the

Calibration submenu to reach the sensor calibrations, or when the blower

speed(s) have been adjusted slightly (but the HEPA filters have not been

replaced) during an annual certification.

3. Set Filter Life – This option is seldom selected. It may be used to set the Filter

Life Gauge to a specific percentage, for example, after the display circuit board is

replaced, and the settings from the previous display board need to be

programmed into the new display board.

To access the Filter Life Gauge screen(s), follow the steps in Adjusting the Blower

Speed previously shown in this section, until on the Blower Speed screen. Then follow

these instructions:

Type A2 (8-inch through 10-inch sash) and Type B2

1. On the Blower Speed screen, press [OK/MUTE].

2. Use [UP] or [DOWN] to select one of the three Filter Life options displayed,

press [OK/MUTE].

58

CURRENT RPM = 1217

AVERAGE RPM = 1219

‘OK’ TO CONTINUE

‘OK’ displayed when blower speed stabilizes

NEW FILTER

SAME FILTER

SET FILTER LIFE

[OK/MUTE]

46

Type A2 (12-inch sash) and Type C1

1. On the Supply Blower Speed screen, press [OK/MUTE].

2. Use [UP] or [DOWN] to select one of the three Filter Life options displayed,

press [OK/MUTE].

3. On the Exhaust Blower Speed screen, press [OK/MUTE].

4. Use [UP] or [DOWN] to select one of the three Filter Life options displayed,

press [OK/MUTE].

Note: On dual blower models, each filter has a separate Life Gauge for percentage of

filter remaining. The lower of the two Filter Life percentages is displayed on the Home

Screen.

58

CURRENT RPM = 1217

AVERAGE RPM = 1219

‘OK’ TO CONTINUE

‘OK’ displayed when blower speed stabilizes

NEW FILTER

SAME FILTER

SET FILTER LIFE

[OK/MUTE]

SUPPLY

SUPPLY

51

CURRENT RPM = 1193

AVERAGE RPM = 1075

‘OK’ TO CONTINUE

‘OK’ displayed when blower speed stabilizes

NEW FILTER

SAME FILTER

SET FILTER LIFE

[OK/MUTE]

EXHAUST

EXHAUST

47

Airflow Sensor Calibration

All Type B2 biosafety cabinets have an airflow sensor to sense the exhaust air pulled

from the cabinet by the remote (building) exhaust system. Type A2 and C1 biosafety

cabinets may have an airflow sensor as an optional accessory.

Unless installing or replacing the airflow sensor, the zero point should be correctly set

from the factory (see Zero Point Calibration later in this section). Once proper airflows

have been set by a trained and qualified certifier, the nominal set point should be

calibrated after setting the Filter Life Gauge in the Calibration menu. For a Type B2

biosafety cabinet, both the nominal and alarm set point will be calibrated.

Type A2 and Type C1

Note: If installing an airflow sensor on an A2 or C1 biosafety cabinet in the field, which

did not previously have this accessory installed, first enable the Airflow Sensor in

Configuration, as described in Change Configuration in Section 8: Configuration.

To access the Airflow Sensor Calibration screen(s), follow the steps in Adjusting the

Blower Speed and Setting the Filter Life Gauge previously shown in this section, until on

the Filter Life Selection screen. Then follow these instructions:

1. On the Filter Life Selection screen, press [OK/MUTE].

2. Using the average inflow velocity measured during airflow certification, use [UP]

or [DOWN] to adjust the Nominal Inflow Value to match this measured velocity.

The Nominal Inflow Value will flash, and it will be displayed in feet per minute

(FPM) or meters per second (M/S) based on the desired units selected in the

Settings submenu. Once set, press [OK/MUTE].

NEW FILTER

SAME FILTER

SET FILTER LIFE

[OK/MUTE]

INFLOW = 105 FPM

INFLOW

CALIBRATION

‘OK’ TO CONTINUE

Nominal

Inflow

Value

48

3. Using the average downflow velocity measured during airflow certification, use

[UP] or [DOWN] to adjust the Nominal Downflow Value to match this measured

velocity. The Nominal Downflow Value will flash, and it will be displayed in feet

per minute (FPM) or meters per second (M/S) based on the desired units

selected in the Settings submenu. Once set, press [OK/MUTE].

Note: Type C1 models with an airflow sensor will only display Inflow on the Home Screen.

Type B2

To access the Airflow Sensor Calibration screen(s), follow the steps in Adjusting the

Blower Speed and Setting the Filter Life Gauge previously shown in this section, until on

the Filter Life Selection screen. Then follow these instructions:

1. On the Filter Life Selection screen, press [OK/MUTE].

2. Using the average inflow velocity measured during airflow certification, use [UP]

or [DOWN] to adjust the Nominal Inflow Value to match this measured velocity.

The Nominal Inflow Value will flash, and it will be displayed in feet per minute

(FPM) or meters per second (M/S) based on the desired units selected in the

Settings submenu. Once set, press [OK/MUTE].

DOWNFLOW = 56 FPM

DOWNFLOW

CALIBRATION

‘OK’ TO CONTINUE

NEW FILTER

SAME FILTER

SET FILTER LIFE

[OK/MUTE]

INFLOW = 105 FPM

INFLOW

CALIBRATION

‘OK’ TO CONTINUE

Nominal

Inflow

Value

[OK/MUTE]

A2

C1

Returns to Main Menu

Proceeds to Vacuum Start

Switch Calibration

Nominal

Downflow

Value

49

3. The nominal set point for Inflow has been set in the previous step. Now the

alarm set point must be established. The screen below is displayed. While on

this screen, reduce the remote or building exhaust system until the TOTAL

volume of air drawn by the remote exhaust system is reduced to 90% of nominal.

For a B2 biosafety cabinet, the remote exhaust system pulls both the downflow

air volume AND inflow air volume from the cabinet and exhausts it.

4. Once the total exhaust airflow has been reduced to 90% of nominal, look at the

Current Sensor Value. It should be at least 4 or 5 points less than the Nominal

Sensor Value. These values are not velocity or flow values, they are the raw

digital output values from the airflow sensor. To avoid nuisance alarms in

operation, these two values should be at least 4 or 5 points apart. Press

[OK/MUTE].

5. Restore the remote exhaust system to nominal airflow. Press [OK/MUTE].

REDUCE EXHAUST FLOW

TO 90%, PRESS OK

AIR SENSOR: 219

ZERO / NOMINAL: 95 / 220

Logic+ Type B2 Model

Inflow @ 90%

Alarm Set Point

ft3/min

m3/hr

4-foot, 8" Sash

216

367

6-foot, 8" Sash

322

547

Note: To set alarm point airflow, if unable to

measure airflow in the exhaust duct above the

biosafety cabinet, slowly close the Air-Tight

Damper until the Inflow into the cabinet equals

the values in Table 9-1.

Table 9-1

Nominal

Sensor

Value

Current

Sensor

Value

RESTORE EXHAUST FLOW

TO 100%, PRESS OK

AIR SENSOR: 219

ZERO / NOMINAL: 95 / 220

50

Zero Point Calibration

If a new airflow sensor is being calibrated (field installation or replacement), a zero point

calibration will be performed. To gain access to the Zero Point Calibration screens, a

different password must be entered on the Password Screen. This password is:

[LIGHT] [UV LIGHT] [TIMER] [OUTLET] [OK/MUTE]

Upon entering this password successfully, select Calibration on the first screen shown.

Press [OK/MUTE]. Follow these instructions:

1. Before entering the Blower Speed screen(s), the Zero Point Warning screen is

shown (below). The biosafety cabinet’s internal blower(s) will automatically shut

off. If the biosafety cabinet is connected to a remote exhaust system, stop all

exhaust airflow before proceeding. Once all airflow is removed, press

[OK/MUTE].

2. The biosafety cabinet will display Wait for approximately 15 seconds while it

samples the airflow sensor readings. When complete, the screen below is

shown. At this time, if the biosafety cabinet is connected to a remote exhaust

system, restart the remote exhaust now. Press [OK/MUTE].

3. Zero point calibration is now complete. The follow screens will proceed through

setting the blower speed(s) as would normally be done if the standard password

had been entered.

AFS ZERO POINT

INTERNAL BLOWER WILL

SHUT OFF NOW. IF

CONNECTED TO EXHAUST

SYSTEM, STOP ALL

EXHAUST AIR FOR PROPER

ZERO POINT CALIBRATION

‘OK’ ONCE EXHAUST AIR REMOVED

[OK/MUTE]

AFS ZERO POINT

WAIT

IF CABINET CONNECTED TO

EXHAUST SYSTEM,

RESTART EXHAUST

SYSTEM NOW

‘OK’ WHEN EXHAUST AIR ON

AFS ZERO POINT

51

Vacuum Start Switch Calibration (Type C1 only)

A Type C1 biosafety cabinet operating in B-mode must sense sufficient remote exhaust

volume before starting the internal blowers. This is accomplished with the Vacuum

Start Switch (VSS) located in the exhaust housing of the biosafety cabinet. After setting

the Filter Life Gauge, or calibrating the Airflow Sensor (if present), a Type C1 biosafety

cabinet will ask if the VSS needs to be calibrated.

The VSS is factory calibrated, and should not need recalibration. If the biosafety

cabinet fails to start its internal blowers on demand, and an Exhaust Failure Alarm is

displayed after the Exhaust Airflow Check fails, the VSS may need to be recalibrated if it

has been determined the remote exhaust system is pulling the correct airflow volume.

To reach the VSS calibration screen, access the Calibration submenu as described in

Adjusting the Blower Speed earlier in this section. Pass through the Blower Speed,

Filter Life, and (if present) Airflow Sensor Calibration screens using [OK/MUTE].

If not recalibrating the VSS, select No on the screen below and press [OK/MUTE]. To

recalibrate the VSS, select Yes on the screen below and press [OK/MUTE]. Follow

these instructions:

1. Identify the VSS and Inlet Relief Valve atop the cabinet, see Figure 9-3. The Inlet

Relief Valve is a clear flap; the VSS is a black cube with clear hose protruding.

Figure 9-3

VSS

INLET RELIEF

VALVE

AIRFLOW

ADJUSTMENT

HANDLE

DUCT COLLAR ON

BIOSAFETY CABINET

AIR-TIGHT DAMPER

DUCT COLLAR ON

AIR-TIGHT DAMPER

EXHAUST DUCT

(NOT SUPPLIED)

52

1. After selecting Yes on the screen to the left below and pressing [OK/MUTE],

watch the Inlet Relief Valve and slowly reduce the remote exhaust system flow

until the Inlet Relief Valve begins to flutter, but is not completely closed. Hold the

remote exhaust system flow at this point. The state of the Inlet Relief Valve can

be seen on the display screen. The Inlet Relief Valve should still be Open. In

this state, press [OK/MUTE].

2. When the screen below is shown, the biosafety cabinet’s internal blowers will

shut off. Using a small, flat blade screwdriver, if the VSS status shown is Open,

adjust the VSS set screw slowly clockwise until the VSS status changes to

Closed. See Figure 9-4 for reference. Then slowly turn the set screw

counterclockwise until the status changes to Open. Because the screen is not

readily visible when adjusting the set screw, the biosafety cabinet will play an

audible alarm tone whenever the VSS status is Closed. Stop turning the set

screw counterclockwise when this tone stops. The VSS Calibration is complete.

3. Restore the remote exhaust system to nominal airflow. Press [OK/MUTE].

YES NO

CALIBRATE VACUUM

START SWITCH?

INLET VALVE: OPEN

REDUCE EXHAUST UNTIL

INLET VALVE ALMOST CLOSED

‘OK’ TO CONTINUE

[OK/MUTE]

SWITCH: OPEN

ADJUST VSS SCREW SLOWLY

UNTIL SWITCH OPENS

‘OK’ TO CONTINUE

Figure 9-4

SET SCREW

INLET RELIEF

VALVE

VSS

53

10: Certification

This section provides instructions to certify the biosafety cabinet. Use this section in

conjunction with Section 9: Calibration when performing initial or annual certification.

Never enter the password-protected area, or change settings of the biosafety cabinet if

you are not a trained and qualified certifier or technician. Changing parameters in the

password-protected area may impair the product’s performance and result in loss of

protection and/or harm or death to personnel in the laboratory.

Certifier Password

The certifier password is: [LIGHT] [UV LIGHT] [TIMER] [TIMER] [OK/MUTE].

Use this password for all normal calibration and certification activities.

If installing or replacing an Airflow Sensor, the sensor will need a zero point calibration.

In order to access the zero-point calibration screen, a different password is required.

This password is: [LIGHT] [UV LIGHT] [TIMER] [OUTLET] [OK/MUTE].

Type A2 HEPA Filter Leak Test Preparation

All biosafety cabinet models were tested to the HEPA Filter Leak Test as described in

the current NSF/ANSI Standard 49. This section describes the methods, specifications,

and Pass/Fail criteria to challenge each HEPA filter in the biosafety cabinet.

You never know what a biosafety cabinet has been exposed to, so it is always

recommended to surface decontaminate any components prior to working inside the

biosafety cabinet and/or removing components from the biosafety cabinet.

1. Remove the work surface by lifting the handles on either end. Pull the work

surface straight out of the biosafety cabinet.

2. Turn the blower(s) of the biosafety cabinet on.

3. Place the aerosol generator in the left, rear corner of the biosafety cabinet’s drip

pan, see Figure 10-2. Ensure that the generator is level, and the oil level is

within 1/8 inch (3 mm) of the level line.

54

4. If the model has a pre-filter installed on the towel catch, remove it for testing.

5. If the aerosol generator requires pressurized air, connect the air line. Turn on the

appropriate number of Laskin nozzles for the model under test based on Table

10-1 to ensure they are each working properly.

6. Verify the generator’s air pressure is 23 psi.

7. Turn on the photometer and allow it to operate for a minimum of 5 minutes.

Leave the valve in the “CLEAR” setting.

Theoretical Upstream Concentration

If the biosafety cabinet has been used with biohazards, toxic chemicals, or

radioisotopes, the Upstream Sample Tube cannot be used (Figure 10-1). Testing at

Labconco has shown the actual concentration varies from the theoretical value. Table

10-1 shows the actual vs. calculated concentrations for Type A2 models. Establish the

100% and 0% concentration levels for the photometer using the actual values provided

in Table 10-1 for the model being tested.

Upstream Concentration Sampling

If the biosafety cabinet has NOT been used with biohazards, toxic chemicals, or

radioisotopes, the Upstream Sample Tube can be used (Figure 10-1).

You never know what a biosafety cabinet has been exposed to, so it is always

recommended to surface decontaminate any components prior to working inside the

biosafety cabinet and/or removing components from the biosafety cabinet.

1. Locate the Upstream Sample Tube on the right side, protruding from the rear

baffle. See Figure 10-1. On some models this tube is clear.

2. Pull the Upstream Sample Tube forward. Do not remove the cap yet.

3. When prompted by the photometer, turn on the appropriate number of Laskin

nozzles on the aerosol generator, uncap the Upstream Sampling Tube and

sample the upstream concentration to establish the 100% concentration level.

4. Establish the 0% concentration level according to your photometer’s instructions.

Figure 10-1

Figure 10-2

55

Type A2

Cabinet Width

Sash

Height

(inches)

Air

Displacement

(CFM)

Laskin

Nozzles

Required

Calculated

Concentration

(ug/L)1

Actual

Concentration

(ug/L)2

3-foot

8

550

1

25

14

9

570

1

24

12

10

600

1

23

12

4-foot

8

725

2

37

21

9

760

2

36

18

10

800

2

34

18

12

900

3

30

15

5-foot

8

900

2

30

17

9

950

2

28

14

10

1000

2

27

14

12

1130

3

24

13

6-foot

8

1100

2

25

17

9

1140

2

24

15

10

1200

2

23

15

12

1350

3

20

10

1. The calculated concentration was established using the formula:

Concentration (ug/l) = (# Laskin nozzles @ 23 PSIG x 13,500) / Volume of air displaced

2. Based on Mineral oil

Table 10-1

56

Type A2 Supply HEPA Filter Leak Test

During this test the supply HEPA filter will be challenged and scanned to check for

leaks. This section describes how to access and test the supply HEPA filter on a Type

A2 biosafety cabinet. The aerosol generator and photometer should be prepared at this

point as described in the preparation steps listed in the previous section.

1. Raise the glass sash as high as it will go.

2. Using a 7/16 inch nut driver or socket and ratchet, remove the two acorn nuts

along the front of the diffuser. See Figure 10-3. Note: Dress Panel and LED

lamps removed for clarity.

3. Lower the front edge of the diffuser until it clears the bottom of the sash, then pull

the diffuser straight out of the biosafety cabinet. See Figure 10-4.

4. The supply HEPA filter is now ready to be scanned. Set the photometer sampling

valve to “DOWNSTREAM”. Ensure proper vacuum at the sampling nozzle.

Figure 10-3

Acorn Nuts (2)

Note: The diffuser acorn nuts

are secured to the studs with a

removable thread locking

compound to prevent them from

vibrating loose during shipment.

There may be some resistance

the first time the nuts are

removed; this is normal. No

additional thread locking

compound need be applied to

these acorn nuts unless the unit

is being prepared for shipment.

Figure 10-4

Diffuser

HEPA Filter

57

5. Open the correct number of Laskin Nozzles on the aerosol generator (refer to

Table 10-1).

6. Scan the downstream side of the supply HEPA filter by passing the sampling

nozzle in slightly overlapping strokes over the entire surface of the filter. The

sampling nozzle must be no more than 1 inch from the surface of the filter media.

Scan at a traverse rate of not more than 2 inches per second.

7. Scan the entire periphery of the supply HEPA filter, including the gasket between

the filter frame and the biosafety cabinet structure.

Note: When scanning the front edge of the supply HEPA filter, photometer operation

may become erratic due to the aspiration of room air into the front of the work area.

This problem can be minimized or eliminated by placing the edge of a sheet of rigid

plastic or metal just outside the edge of the HEPA filter when scanning the front edge.

See Figure 10-5 as reference.

Acceptance Criteria

Aerosol penetration shall not exceed 0.01%.

Reinstall the diffuser, ensuring the two holes in the back of the diffuser frame engage

the posts on the rear wall of the cabinet. See Figure 10-6 for reference.

Figure 10-5

Figure 10-6

Diffuser Pins

engaged

correctly

58

Type A2 Exhaust HEPA Filter Leak Test

During this test the exhaust HEPA filter will be challenged and scanned to check for

leaks. This section describes how to access and test the exhaust HEPA filter on a Type

A2 biosafety cabinet. The aerosol generator and photometer should be prepared at this

point as described in the preparation steps listed in the previous section.

Before starting, examine the clearance between the top of the biosafety cabinet and the

ceiling or any overhead obstructions. If there is 18 inches (46 cm) or more of overhead

clearance, follow the procedure below to hinge the exhaust cover open. If there is not

enough clearance, remove the exhaust cover altogether.

1. Loosen the two (2) Phillips screws on the front sides of the exhaust filter cover,

see Figure 10-7. Tilt the cover back to access the downstream side of the filter.

The exhaust HEPA filter media is now exposed. Never touch the media, it is easily

damaged.

2. The exhaust HEPA filter is now ready to be scanned. Set the photometer

sampling valve to “DOWNSTREAM”. Ensure proper vacuum at the sampling

nozzle.

3. Open the correct number of Laskin Nozzles on the aerosol generator (refer to

Table 10-1).

4. Scan the downstream side of the exhaust HEPA filter by passing the sampling

nozzle in slightly overlapping strokes over the entire surface of the filter. The

sampling nozzle must be no more than 1 inch from the surface of the filter media.

Scan at a traverse rate of not more than 2 inches per second.

5. Scan the entire periphery of the exhaust HEPA filter, including the gasket

between the filter frame and the biosafety cabinet structure.

Figure 10-7

Loosen these screws

If removing the cover,

remove these screws

59

Note: When scanning the edges of the exhaust HEPA filter, photometer operation may

become erratic due to the aspiration of room air into the exhaust air stream. This

problem can be minimized or eliminated by placing the edge of a sheet of rigid plastic or

metal just outside the edge of the HEPA filter when scanning the filter edges. See

Figure 10-8 as reference.

Acceptance Criteria

Aerosol penetration shall not exceed 0.01%.

Replace and secure the exhaust cover and its screws.

Figure 10-8

60

Type B2 Supply HEPA Filter Leak Test Preparation

All biosafety cabinet models were tested to the HEPA Filter Leak Test as described in

the current NSF/ANSI Standard 49. This section describes the methods, specifications,

and Pass/Fail criteria to challenge the supply HEPA filter in the biosafety cabinet.

You never know what a biosafety cabinet has been exposed to, so it is always

recommended to surface decontaminate any components prior to working inside the

biosafety cabinet and/or removing components from the biosafety cabinet.

1. Remove the work surface by lifting the handles on either end. Pull the work

surface straight out of the biosafety cabinet.

2. Turn the blower of the biosafety cabinet on.

3. Check the oil level of the aerosol generator is within 1/8 inch (3 mm) of the level

line.

4. If the aerosol generator requires pressurized air, connect the air line.

5. Verify the generator’s air pressure is 23 psi.

6. Turn on the photometer and allow it to operate for a minimum of 5 minutes.

Leave the valve in the “CLEAR” setting.

Theoretical Upstream Concentration

If you do not wish to connect the Upstream Sampling Tube to the photometer to

establish the actual 100% concentration value, the theoretical value will need to be used

instead. Testing at Labconco has shown the actual concentration varies from the

theoretical value. Table 10-2 shows the actual vs. calculated concentrations for Type B2

models. Establish the 100% and 0% concentration levels for the photometer using the

actual values provided in Table 10-2 for the model being tested.

Upstream Concentration Sampling

You never know what a biosafety cabinet has been exposed to, so it is always

recommended to surface decontaminate any components prior to working inside the

biosafety cabinet and/or removing components from the biosafety cabinet.

1. Locate the Upstream Sample Tube on the right side, protruding from the rear

baffle. See Figure 10-9. On some models this tube is clear.

2. Pull the Upstream Sample Tube forward. Do not remove the cap yet.

3. Place the aerosol generator on top of the biosafety cabinet, see Figure 10-10.

4. Remove the inlet pre-filter (Figure 10-10).

5. When prompted by the photometer, turn on the appropriate number of Laskin

nozzles on the aerosol generator (see Table 10-2), uncap the Upstream

Sampling Tube and sample the upstream concentration to establish the 100%

concentration level.

6. Establish the 0% concentration level according to your photometer’s instructions.

61

Figure 10-9

Figure 10-10

Type B2

Cabinet Width

Sash

Height

(inches)

Supply Air

Displacement

(CFM)

Laskin

Nozzles

Required

Calculated

Concentration

(ug/L)1

Actual

Concentration

(ug/L)2

4-foot

8

445

1

30

15

6-foot

8

665

1

20

12

1. The calculated concentration was established using the formula:

Concentration (ug/l) = (# Laskin nozzles @ 23 PSIG x 13,500) / Volume of air displaced

2. Based on Mineral oil

Table 10-2

Pre-Filter

Thumbnuts (2)

Place aerosol

generator here

62

Type B2 Supply HEPA Filter Leak Test

During this test the supply HEPA filter will be challenged and scanned to check for

leaks. This section describes how to access and test the supply HEPA filter on a Type

B2 biosafety cabinet. The aerosol generator and photometer should be prepared at this

point as described in the preparation steps listed in the previous section.

1. Raise the glass sash as high as it will go.

2. Using a 7/16 inch nut driver or socket and ratchet, remove the two acorn nuts

along the front of the diffuser. See Figure 10-11. Note: Dress Panel and LED

lamps removed for clarity.

3. Lower the front edge of the diffuser until it clears the bottom of the sash, then pull

the diffuser straight out of the biosafety cabinet. See Figure 10-12.