Page 1

Fume Adsorbers

Models

115V 230V

3955200 Organic 30" 3955220 Organic 30"

3955400 Organic 60" 3955420 Organic 60"

3955201 Formaldehyde 30" 3955221 Formaldehyde 30"

3955401 Formaldehyde 60" 3955421 Formaldehyde 60"

3955202 Ammonia 30" 3955222 Ammonia 30"

3955402 Ammonia 60" 3955422 Ammonia 60"

To receive important product updates,

complete your product registration card

online at register.labconco.com

Labconco Corporation

HOME PAGE www.labconco.com

Please read the User’s Manual before operating the equipment.

User’s Manual

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

Page 2

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas

of defective material and workmanship, provided such defect results from normal and proper use of

the equipment. Glassware is not warranted from breakage when dropped or mishandled.

The warranty for a Labconco Fume Adsorber will expire one year from date of installation or two

years from date of shipment from Labconco, whichever is sooner.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If

the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will repair

or replace all defective parts to restore the unit to operation. Under no circumstances shall

Labconco Corporation be liable for indirect, consequential, or special damages of any kind. This

statement may be altered by a specific published amendment. No individual has authorization to

alter the provisions of this warranty policy or its amendments. Lamps and filters are not covered by

this warranty. Damage due to corrosion or accidental breakage is not covered.

Copyright © 2005, 2007, 2014 Labconco Corporation. All rights reserved.

The information contained in this manual and the accompanying products are copyrighted and all rights

reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic design

changes without obligation to notify any person or entity of such change.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight carrier.

Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525

or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Part #6960400, Rev. E

ECO J105

Page 3

ORIGINAL INSTRUCTIONS

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION 1

About This Manual 2

Typographical Conventions 3

CHAPTER 2: PREREQUISITES 5

Support Requirements 5

Location and Air Current Requirements 6

Electrical Requirements 6

Space Requirements 6

CHAPTER 3: GETTING STARTED 7

Unpacking Your Enclosure 7

Installing the Enclosure on a Supporting Structure 8

Installation of Carbon Filters 8

Connect the Electrical Supply Source to the Enclosure 9

Validating the Fume Adsorber Face Velocity 9

CHAPTER 4: PERFORMANCE FEATURES AND SAFETY

PRECAUTIONS 10

Performance Features 10

Safety Precautions 11

CHAPTER 5: APPROPRIATE APPLICATIONS FOR YOUR

ENCLOSURE 14

Routine Daily Work Procedures 14

Suitable Applications 15

Appropriate Chemicals for Carbon Filters 15

Definition of Terms 16

Hazardous Misapplications for Carbon Filters with

Volatile Chemicals 17

Chemical Carcinogen Use with Carbon Filters 17

Prohibited Acid Use 17

CHAPTER 6: MAINTAINING YOUR ENCLOSURE 18

Routine Maintenance Schedule 18

Determination of When to Replace Carbon Filters and

How to Replace 19

Calculating Carbon Filter Life 21

CHAPTER 7: TROUBLESHOOTING 23

Page 4

APPENDIX A: ENCLOSURE COMPONENTS

AND REPLACEMENT PARTS 25

APPENDIX B: DIMENSIONS 28

APPENDIX C: FUME ADSORBER SPECIFICATIONS 29

APPENDIX D: QUICK CHART FOR THE FUME ADSORBER 30

APPENDIX E: REFERENCES 31

DECLARATION OF CONFORMITY 33

Page 5

1

CHAPTER 1

INTRODUCTION

Congratulations on your purchase of a Labconco Fume Adsorber. Your enclosure

uses carbon filtration to provide personnel protection of annoying solvents,

formaldehyde or ammonia vapors generated by histology and pathology

operations.

When properly installed and operated, these enclosures will effectively contain low

concentrations of noxious fumes and chemicals. Each enclosure uses carbon

filtration and is only intended for chemical use with a time weighted exposure limit

(TWA) of 100 ppm or greater (Reference the NIOSH Pocket Guide,

www.cdc.gov/niosh/npg/npg.html). The carbon filters are available with three

different carbons for adsorbing organic vapors, formaldehyde or ammonia and

amines.

Please acquaint yourself with this manual and keep it handy for future reference to

review all the Fume Adsorber’s features. If you are unfamiliar with how Fume

Adsorbers operate, please review Chapter 4: Performance Features and Safety

Precautions before you begin working in the enclosure. Even if you are an

experienced user, please review Chapter 5: Using Your Fume Adsorber, which

describes the features so that you can use the enclosure efficiently.

Product Service 1-800-522-7658

Page 6

Chapter 1: Introduction

2

Width

Fume Adsorber

Model No’s.

Filter

Blower

Application

Exhaust

30"

3955200 (115V)

3955220 (230V)

Carbon Filter*

Organic Vapor

Built-In Integral

Motorized Impeller

When ducting to the outside is

not feasible, the filters keep

low level concentrations below

OSHA recommended time

weighted averages, restoring

clean air to the laboratory.

To the room

60"

3955400 (115V)

3955420 (230V)

Width

Fume Adsorber

Model No’s.

Filter

Blower

Application

Exhaust

30"

3955201 (115V)

3955221 (230V)

Carbon Filter*,

Formaldehyde

Built-In Integral

Motorized Impeller

When ducting to the outside is

not feasible, the filters keep

low level concentrations below

OSHA recommended time

weighted averages, restoring

clean air to the laboratory.

To the room

60"

3955401 (115V)

3955421 (230V)

Width

Fume Adsorber

Model No’s.

Filter

Blower

Application

Exhaust

30"

3955202 (115V)

3955222 (230V)

Carbon Filter*,

Ammonia

Built-In Integral

Motorized Impeller

When ducting to the outside is

not feasible, the filters keep low

level concentrations below

OSHA recommended time

weighted averages, restoring

clean air to the laboratory.

To the room

60"

3955402 (115V)

3955422 (230V)

!

!

Note: Formaldehyde filters can adsorb up to 30% organic vapors.

Note: Ammonia filters can adsorb up to 30% organic vapors.

* It is recommended that a Labconco product specialist review the chemical

application to determine if it is suitable. Consult Chapter 5 and Chapter 6.

Acids must not be used in Fume Adsorbers.

About This Manual

This manual is designed to help you learn how to install, use, and maintain your

enclosure. Instructions for installing accessory carbon filters on your filtered

enclosure are also included. Your Fume Adsorber ships with either one or two

organic vapor carbon filters depending on the model width.

If the unit is not operated as specified in this manual it may

impair the protection provided by the unit.

Si l'unité n'est pas utilisée comme spécifié dans ce manuel il

peut diminuer la protection fournie par l'unité.

Product Service 1-800-522-7658

Page 7

Chapter 1: Introduction

3

Chapter 1: Introduction provides a brief overview of the enclosure, explains the

organization of the manual, and defines the typographical conventions used in the

manual.

Chapter 2: Prerequisites explains what you need to do to prepare your site before

you install the enclosure. Electrical and service requirements are discussed.

Chapter 3: Getting Started contains the information you need to properly unpack,

inspect, install, and certify the enclosure.

Chapter 4: Performance Features and Safety Precautions explains how the

enclosure operates and the appropriate precautions you should take when using it.

Chapter 5: Appropriate Applications for Your Enclosure discusses the basic

operation of how to prepare, use and shut down your enclosure.

Chapter 6: Maintaining Your Enclosure explains how to perform routine

maintenance on the enclosure.

Chapter 7: Troubleshooting contains a table of problems you may encounter while

using the enclosure including the probable causes of the problems and suggested

corrective actions.

Appendix A: Components and Replacement Parts contains labeled diagrams of all

of the components of the enclosures.

Appendix B: Dimensions contains comprehensive diagrams showing all of the

dimensions for the enclosures.

Appendix C: Specifications contains the electrical requirements for enclosures.

Wiring diagrams are also included.

Appendix D: Quick Chart provides an airflow table and test data for the

enclosures.

Appendix E: References lists the various resources available that address

laboratory ventilation.

Typographical Conventions

Recognizing the following typographical conventions will help you understand and

use this manual:

Book, chapter, and section titles are shown in italic type (e.g., Chapter 3:

Getting Started).

Steps required to perform a task are presented in a numbered format.

Comments located in the margins provide suggestions, reminders, and

references.

Product Service 1-800-522-7658

Page 8

Chapter 1: Introduction

4

!

!

Critical information is presented in boldface type in paragraphs that are

preceded by the exclamation icon. Failure to comply with the information

following an exclamation icon may result in injury to the user or permanent

damage to the enclosure.

Critical information is presented in boldface type in paragraphs that are

preceded by the wrench icon. Only a trained certifier or contractor should

perform these operations. Failure to comply with the information following a

wrench icon may result in injury to the user or permanent damage to your

enclosure.

Important information is presented in capitalized type in paragraphs that are

preceded by the pointer icon. It is imperative that the information contained in

these paragraphs be thoroughly read and understood by the user.

CAUTION – See Manual. When this symbol is on the unit it indicates a

caution that is detailed in this manual.

ATTENTION - Voir manuel. Lorsque ce symbole est sur l'unité, il indique une

mise en garde qui est indiqué dans ce manuel.

Product Service 1-800-522-7658

Page 9

5

CHAPTER 2

PREREQUISITES

Before you install the Fume Adsorber, prepare your site for installation. A source

of electrical power should be located near the installation site to power the

enclosure. Additionally, the enclosure should be strategically placed in the lab to

provide efficient workflow.

Carefully read this chapter to learn the requirements for your installation site:

The support requirements.

The location and air current requirements.

The electrical power requirements.

The space requirements.

Refer to Appendix B: Dimensions for complete enclosure dimensions.

Refer to Appendix C: Specifications for complete enclosure electrical and

environmental conditions, specifications and requirements.

Support Requirements

At a minimum, the supporting structure usually consists of a work surface in the

laboratory. See Chapter 3 for setting up installation.

Product Service 1-800-522-7658

Page 10

Chapter 2: Prerequisites

6

!

Location and Air Current Requirements

The Fume Adsorbers have been designed to contain hazardous fumes by negating

typical cross drafts and turbulence within the opening. As precautionary safety

measure and a higher level of quality management, it is recommended that the

Fume Adsorber be placed in an area to avoid:

High traffic areas where walking might cause an air disturbance or be a

nuisance.

Overhead or wall HVAC diffusers, fans, radiators or other lab equipment

producing air currents.

Next to doorways or windows that may be opened.

Do not position the unit so that it is difficult to operate the main

disconnect device.

Ne placez pas l'appareil de sorte qu'il est difficile de faire

fonctionner le dispositif principal de déconnexion.

Electrical Requirements

Standard duplex electrical receptacles should be nearby for connecting the Fume

Adsorber. See the nameplate on the rear of the enclosure for rated electrical

service.

Space Requirements

The dimensions for the different Fume Adsorber models are shown in Appendix B:

Dimensions.

Product Service 1-800-522-7658

Page 11

7

The United

States

Interstate

Commerce

Commission

rules require

that claims be

filed with the

delivery carrier

within fifteen

(15) days of

delivery.

CHAPTER 3

GETTING STARTED

Now that the site for your Fume Adsorber is properly prepared, you are ready to

unpack, inspect and install the enclosure. Read this chapter to learn how to:

Unpack and move the enclosure.

Set up the enclosure with the proper supporting structure.

Installation of carbon filter(s). (Fume Adsorbers ship with organic vapor

filter(s).

Connect the electrical supply.

Validate the enclosure face velocity.

Unpacking the Enclosure

Carefully remove the shrink-wrap and carton on the unit and inspect it for damage

that may have occurred in transit. If damaged, notify the delivery carrier

immediately and retain the entire shipment intact for inspection by the carrier.

DO NOT RETURN GOODS WITHOUT THE PRIOR

AUTHORIZATION OF LABCONCO. UNAUTHORIZED

RETURNS WILL NOT BE ACCEPTED.

IF ENCLOSURE WAS DAMAGED IN TRANSIT, YOU MUST

FILE A CLAIM DIRECTLY WITH THE FREIGHT CARRIER.

LABCONCO CORPORATION AND ITS DEALERS ARE NOT

RESPONSIBLE FOR SHIPPING DAMAGE.

Do not discard the packing material until you have checked all of the components

and tested the enclosure. We recommend that you do not remove the enclosure

from its shipping container until it is ready to be placed in its final location.

Product Service 1-800-522-7658

Page 12

Chapter 3: Getting Started

8

Filter Type

Appropriate Use

Organic Vapor

Activated Carbon

6961300

6.0 lbs.

Adsorbs organic compounds designated by NIOSH

guidelines as acceptable for use with chemical

cartridge-type respirators. Concentrations in the

enclosure’s work area must not exceed the IDLH for

the chemical and the exhaust from the enclosure must

be monitored not to exceed the TWA.

Formaldehyde

(Formalin)

6961301

7.5 lbs.

Formaldehyde requires the use of an impregnated

carbon. Concentrations in the enclosure’s work area

must not exceed the IDLH for the chemical and the

exhaust from the enclosure must not exceed the TWA.

Ammonia and

Amines

6961302

8.7 lbs.

Treats ammonia, low molecular weight amines and

other bases designated by NIOSH as acceptable for use

with ammonia cartridge type respirators. Requires the

use of an impregnated carbon. Concentrations in the

enclosure’s work area must not exceed the IDLH for

the chemical and the exhaust from the enclosure must

not exceed the TWA.

!

Installing the Enclosure on a Supporting

Structure

Use caution when lifting or moving the enclosure.

When installing the enclosure onto a chemical-resistant work surface or benchtop,

ensure that the structure can safely support the weight of the enclosure. The 30"

wide Fume Adsorber weighs 62 lbs, and the 60" wide Fume Adsorber-2 weighs

125 lbs. The work surface should be at least as wide as the enclosure to properly

support it.

Installation of Carbon Filters

For carbon filter installation, first remove the four (or eight) Phillips screws on the

perforated baffle located inside the enclosure. Slowly remove the perforated baffle.

See the following list of available carbon filters below. All carbon filters are

installed with the gasket side on the downstream exhaust side. The carbon filters

are installed behind the upper and lower filter clamps and are removed by Phillips

screws. Install the correct carbon filter for the application. In choosing the correct

filter for your application call Labconco for assistance. See Figures A-1, A-2 and

A-3 in Appendix A and Figure 4-2 in Chapter 4 for installation diagrams.

Important: Carbon filters do not provide any particulate protection,

but provide odor control for low level concentrations below OSHA

recommended time weighted averages.

Product Service 1-800-522-7658

Page 13

9

!

115V

Maximum

is 2 amps.

230V

is 1 amp.

!

circuit load

Maximum

circuit load

Chapter 3: Getting Started

Connecting the Electrical Supply Source

to the Enclosure

115V Models

Simply connect the 115V power cord supplied to the IEC electrical supply plug on

the back of the enclosure.

230V Models

The same procedure applies for the 230V except it is shipped without a plug.

Install the appropriate plug for your electrical specifications per local codes.

Do not use any detachable power cord that is not adequately rated

for the unit.

Ne pas utliser un fil électrique amovible qui n’est pas du tension

nominale de l’appareil.

Validating the Fume Adsorber Face

Velocity

To determine the actual face velocity at the sash opening, airflow velocity readings

are taken. The “average face velocity” is achieved by taking readings in two rows

across the enclosure with the readings 6" from the ends and evenly spaced every

12". The average velocity across the opening of the enclosure is 35 fpm and should

be validated. Do not use the enclosure with an average velocity of less than 25

fpm. Consult your safety officer.

NOTE: Face velocity profiles and smoke testing should be

performed at least monthly.

Product Service 1-800-522-7658

Page 14

10

Figure 4-1

Performance Features

3

2

4

CHAPTER 4 PERFORMANCE

FEATURES AND SAFETY

PRECAUTIONS

Performance Features

The Fume Adsorbers are designed to meet the needs of the laboratory scientist and

provide containment of light emissions of solvents, formaldehyde and ammonia

vapors. Annoying vapors, such as xylene and toluene fumes used in cover slipping

operations are efficiently adsorbed by the Fume Adsorber carbon filter(s). The

Fume Adsorber uses a carbon filter to collect low concentrations and exhaust

filtered air back into the room.

Product Service 1-800-522-7658

Page 15

Chapter 4: Performance Features & Safety Precautions

11

Figure 4-2

Performance Features, Exploded View

2 5 3

1

1. Built-In Motorized Impeller Provides up to 35 fpm average face velocity.

Airflow capacity is 100 CFM on the 30" wide unit and 200 CFM on the 60"

wide unit.

2. Perforated Baffle provides uniform removal of noxious fumes. Remove

this baffle to access the carbon filter.

3. Blower Switch provides convenient ON/OFF control.

4. Hood Canopy maximizes the work area and visibility.

5. Carbon Filter is designed to remove small amounts of fumes and

chemicals. (See Chapter 6 for carbon types and estimated filter life.)

Safety Precautions

1. Although the enclosure has been engineered to maintain optimum operator

safety, caution should always be used while working inside the enclosure.

Prior to using, check to make sure that the exhaust blower is operating and

air is entering the enclosure at its specified face velocity.

2. Use good housekeeping in the enclosure at all times. Clean spills

immediately. Periodically clean the enclosure interior with mild soap and

water.

3. Do not store containers or supplies against the rear baffle, as this will affect

airflow. Blocking large portions of the rear baffle will change the airflow

pattern in the enclosure causing turbulence.

Product Service 1-800-522-7658

Page 16

Chapter 4: Performance Features and Safety Precautions

12

4. Always work with your hands as far back into the enclosure as possible.

5. Do not work in this enclosure without the exhaust system running.

6. General acid use, as well as perchloric acid use in this enclosure is prohibited.

7. High-level radioisotope materials are prohibited in this enclosure. Consult

your Safety Officer.

8. Avoid cross drafts and limit traffic in front of the enclosure. Air

disturbances created may draw chemical vapors out of the enclosure.

9. The use of safety goggles, protective clothing, gloves and any other personal

protective equipment recommended by your safety officer should be used.

10. Care must be taken to ensure that the concentration of gases or vapors do

not reach flammable or explosive limits. Use of an open flame must be

avoided in the enclosure.

11. Applications that generate gases or vapors from toxic chemicals must be

evaluated carefully so that buildup to levels above the TWA of the

chemical does not occur. Do not work with chemicals having a TWA

below 100 ppm.

12. Ensure that the enclosure is connected to electrical service in accordance

with local and national electrical codes. Failure to do so may create a fire

or electrical hazard. Do not remove or service any electrical components

without first disconnecting the enclosure from electrical service.

13. Dispose of carbon filters as hazardous waste. The user is responsible for

recording the chemicals adsorbed or treated by the filters and disposing properly.

14. Ensure only trained operators use the enclosure. New users should review

the User’s Manual and become familiar with the operation of the enclosure.

15. If the enclosure is to be used in a confined space, make sure the space is

well ventilated and the concentration of chemical vapors cannot accumulate

greater than the TWA.

16. Only chemicals that can be safely adsorbed and treated with specific

carbon-based filters are appropriate for use in this enclosure. Contact

Labconco for chemical assessment.

17. The warning properties (i.e., odor, taste) of the volatile organic compounds

or other material being used in the enclosure must be adequate to provide

an early indication that the carbon filters may be saturated or inadequate.

Contact Labconco for help with chemical assessment.

18. Use the smallest possible quantity of chemical(s) within the enclosure and

never exceed the amount that can be effectively adsorbed by the carbon

filters before breakthrough. Consult Chapter 6 for filter life estimates.

19. Leave the blower on for at least one minute after work in the enclosure has

been completed.

20. If a chemical is spilled on the work surface, DO NOT switch off the

blower until all traces have been removed.

Product Service 1-800-522-7658

Page 17

Chapter 4: Performance Features & Safety Precautions

13

21. Tag the enclosure with appropriate warning if filters have been removed for

service.

22. If the blower fails during use, processes should cease and the area should

be vacated and ventilated.

23. Always refer to the NIOSH Pocket Guide to Chemical Hazards to

understand the chemical’s properties and health risks. (See Chapter 5). For

additional help with filter and chemical selection contact Labconco at 1800-821-5525 or 1-816-333-8811.

Product Service 1-800-522-7658

Page 18

14

CHAPTER 5

APPROPRIATE APPLICATIONS

FOR YOUR ENCLOSURE

Now that the installation of your enclosure is completed, you are ready to use your

Fume Adsorber. Read this chapter to learn about:

1. Routine Daily Work Procedures.

2. Suitable Applications.

3. Appropriate Chemicals for Carbon Filters.

4. Definition of Terms.

5. Hazardous Misapplications for Carbon Filters.

6. Chemical Carcinogen use with Carbon Filters.

7. Prohibited Acid Use.

Start-up

Turn on exhaust system blower with the ON/OFF switch.

Check the baffle air slots for obstructions.

Wear a long sleeved lab coat and rubber gloves. Use protective eyewear.

Wear a protective mask if appropriate. Consult your Safety Officer for

additional personal protective equipment recommendations.

Load only the materials required for the procedure. Do not overload the

enclosure.

Work Techniques

Keep all materials inside the enclosure and perform all contaminated

operations as far to the rear of the work area as possible.

Avoid using techniques or procedures that disrupt the airflow patterns of

the enclosure.

Final Purging

Upon completion of work, the enclosure should be allowed to operate for

two to three minutes undisturbed, to purge airborne contaminants from the

work area before shutting off the blower.

Product Service 1-800-522-7658

Page 19

Chapter 5: Appropriate Applications for Your Enclosure

15

!

Shutdown

Turn off the exhaust system blower with the ON/OFF switch.

Suitable Applications

NIOSH (National Institute for Occupational Safety and Health, USA) has

established guidelines for chemical cartridge and HEPA filtered respirators.

Suitable applications for the carbon filtered enclosures are based on guidelines

below. As with respirators, chemical contaminants are adsorbed or treated by

carbon.

Release of low concentrations of vapors effectively adsorbed or treated in

carbon based filters. Recommended for use with chemicals with a TWA of

100 or greater unless chemical can be filtered with the use of an

impregnated specialized filter; impregnated filters such as formaldehyde,

formalin, ammonia, and amines are examples of specialized filters.

Treatment of low-level carcinogens or suspected carcinogens. (See Chemical

Carcinogens in Chapter 5)

Procedures that may have traditionally been done on the open bench (low

levels only).

Odoriferous chemicals that are an unpleasant nuisance.

Other applications, not fitting the above guidelines, would be better suited with the

exhaust ducted to the outside by using some other containment enclosure offered

by Labconco.

REFERENCES TO NIOSH OR OSHA GUIDELINES AND

REGULATIONS APPLY TO ANY WORK PLACE UNDER THE

JURISDICTION OF THE U.S. DEPARTMENT OF LABOR.

OTHER COUNTRIES OUTSIDE THE U.S. HAVE

ESTABLISHED STANDARDS, WHICH MAY DIFFER

SLIGHTLY FROM THOSE USED AS GUIDELINES FOR THIS

PRODUCT. IT IS THE USER’S RESPONSIBILITY TO

BECOME AWARE OF LOCAL REGULATIONS GOVERNING

THE SAFE USE AND DISPOSAL OF CHEMICALS AND

CARBON FILTERS. KNOWLEDGE OF ESTABLISHED SAFE

EXPOSURE LEVELS IS IMPERATIVE TO THE PROPER USE

OF CARBON FILTERED ENCLOSURES.

Appropriate Chemicals for Carbon Filters

Below is a general set of rules to determine appropriateness of chemical usage.

Selected organic chemicals considered to be occupational

carcinogens by NIOSH can only be used in the filtered

enclosure with carbon filters under rigid restrictions. See

separate discussion on next page on carcinogens for special

instructions.

Product Service 1-800-522-7658

Page 20

Chapter 5: Appropriate Applications for Your Enclosure

16

Organics must have time weighted exposure limits (TWA) of 100 PPM or greater.

Chemicals must have a detectable odor at concentrations below the TWA for the

chemical.

Chemicals must be designated by NIOSH guidelines as acceptable for use with

chemical cartridge-type respirators (the exception is formaldehyde and

ammonia/amines, which used impregnated carbon). Chemicals not listed by

NIOSH in the Pocket Guide must be approved by Labconco Product Specialist (or

Engineering).

Inlet concentration must never exceed the IDLH (Immediately Dangerous to Life

and Health) concentrations.

Chemicals having a recommendation by NIOSH of at least “Escape GMFOV”

(Gas Mask Full-Face Respirator).

When evaporating a mixture of chemicals, the chemical having the lowest TWA

will be used to determine if the mixture meets the guidelines.

Call a Labconco Product Specialist at 1-800-821-5525 for assistance in

determining chemical appropriateness.

Definition of Terms

NIOSH – National Institute for Occupational Safety and Health/Mine Safety and

Health Administration. (U.S.A.)

TWA – Recommended Exposure Limits expressed as a Time Weighted Average.

The exposure limit for that chemical for up to a 10-hour workday, 40 hours a

week. Expressed in units of parts per million or milligrams per cubic meter.

Odor Threshold – The value in parts per million or milligrams per cubic meter for

which one might expect to smell a chemical’s presence in the air. This value is very

subjective and detection will vary with the sensitivity of one’s nose. The period of

time until the odor threshold is reached in the exhaust stream can be estimated from

Labconco’s exclusive chemical assessment program. Contact Labconco on

estimates for carbon filter life for specific applications. See Chapter 6.

Saturation Level or Time – There is a limit to the amount of chemical that can be

adsorbed by activated carbon or neutralized by chemically-treated carbon. Once

the capacity of the carbon is reached, it is considered to be saturated and will

adsorb (or neutralize) no further material; the outlet concentration of the chemical

will equal the inlet concentration from that point until the filter is replaced. (Note

that the capacity of activated carbon is not a constant, but varies with the inlet

concentration). Labconco Product Specialists can determine the estimated

saturation time for a particular chemical.

Product Service 1-800-522-7658

Page 21

Chapter 5: Appropriate Applications for Your Enclosure

17

!

Carbon

IDLH (Immediately Dangerous to Life and Health). An atmosphere that poses

an immediate hazard to life or produces immediate irreversible health effects.

IDLH concentrations should not be approached in the enclosure.

Hazardous Misapplications for Carbon

Filters with Volatile Chemicals

There is one scenario where the accessory carbon filter misapplication would be a

part of a hazardous condition. If the user continues to operate the enclosure with

any of the following conditions present a potentially hazardous condition will exist:

1. The inlet concentration of vapors is greater than the TWA.

2. The carbon filter becomes saturated.

3. The ventilation of the room is insufficient to dilute the exhaust of the

enclosure to below the TWA for the chemical.

When the inlet concentration is greater than the TWA, extra measures must be

taken to monitor the filter and number of room air exchanges.

Chemical Carcinogen Use with Carbon

Filters

Selected carcinogens can only be used with carbon filters in the Fume Adsorber

under strict guidance from your Safety Officer.

The use of a vented fume hood or ventilated enclosure with

ducting to the outside is always the preferred method when

working with carcinogens.

Prohibited Acid Use

The Fume Adsorber with integral blower motorized impeller cannot be exposed to

acids. Where applications require the use of acids, a vented fume hood or vented

enclosure should be used with a remote blower and ducted to the outside. Consult

Labconco for other small enclosures used with a remote blower suitable for acid

work. No exceptions are permitted, as the impeller life span will be limited with

acid use. Consult Labconco for other enclosures suitable for acid work.

Product Service 1-800-522-7658

Page 22

18

CHAPTER 6

MAINTAINING YOUR

ENCLOSURE

Monitoring airflow and changing the carbon filters (if equipped) is the primary

maintenance required.

Review this chapter on maintenance for the following:

1. Routine Maintenance.

2. Determination of when to replace carbon filters and how to replace.

3. Calculating carbon filter life.

Routine Maintenance Schedule

Weekly

Wipe down the interior and exterior surfaces of the enclosure with a mild

soap, depending upon the usage of the unit, and allow to dry.

Operate the exhaust system, noting the airflow velocity through the

enclosure using a source of visible smoke.

Monthly (or more often as required)

Determine the actual face velocity through the sash opening of the

enclosure where the average reading should be at the specified velocity of

35±10 fpm. (Use calibrated thermal anemometer or other approved

apparatus).

While the enclosure is filled with the contaminant, test filter condition on

carbon filters using the appropriate gas detector tube at intervals of 20% of

the total estimated time. There is a 5/16" diameter hole on the upper right

side for inserting the detector tube. The exception to the 20%

Product Service 1-800-522-7658

Page 23

Chapter 6: Maintaining Your Enclosure

19

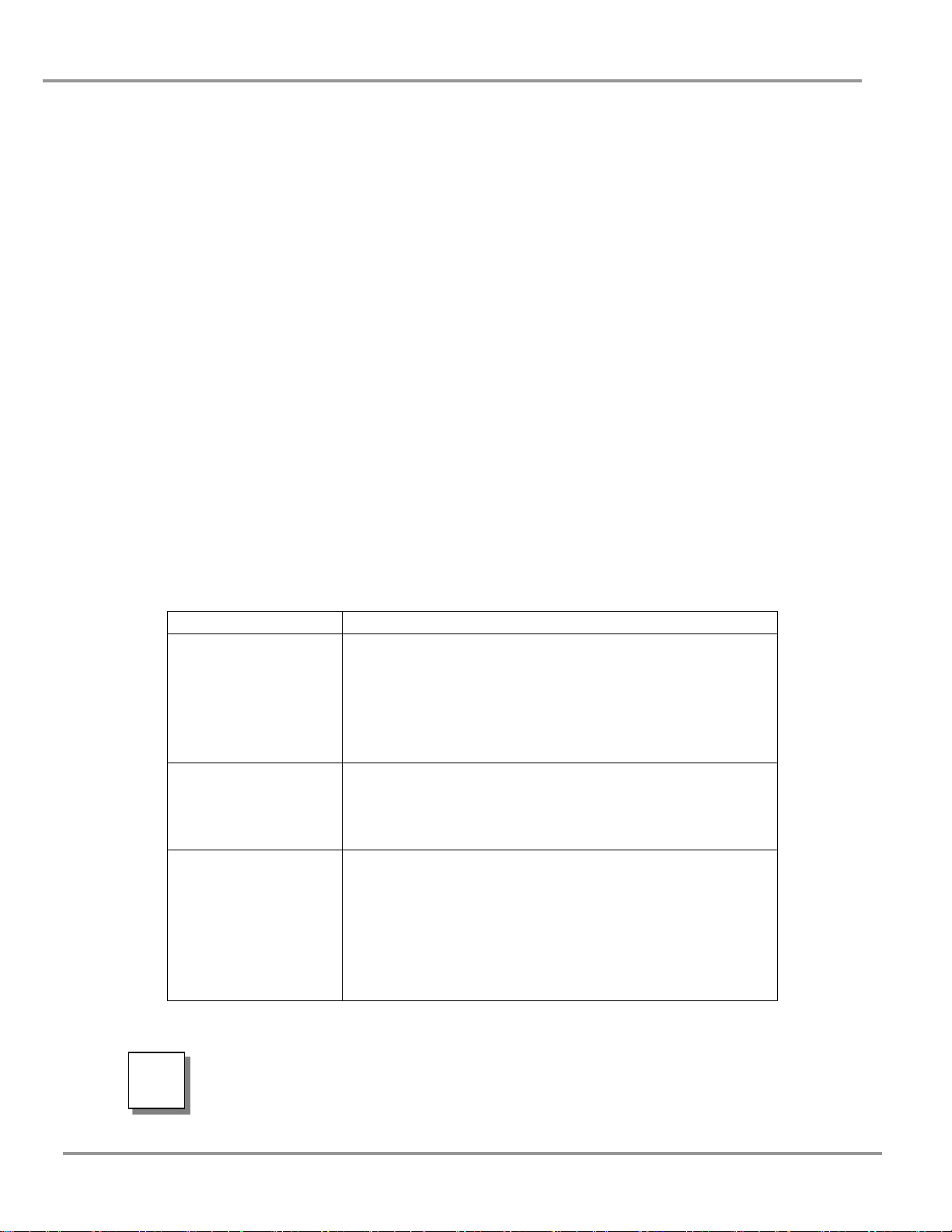

Catalog #

Filter

Size

Pounds of

Carbon

Carbon Type

For use with

Adsorption

weight

Adsorption

Volume

6961300

9x26x1.38

6.0

Organic

Vapor

Organic

Vapors

Varies, see

chemical

chart

Varies, see

chemical guide and

chapter 6

6961301

9x26x1.38

7.5

Impregnated

Formasorb

Formaldehyde

10%, 0.75lbs

851 ml of 37%

Formalin

6961302

9x26x1.38

8.8

Impregnated

Ammonasorb

Ammonia and

Amines

10%, 0.88lbs

800 ml of 37%

Formalin

recommendation is formaldehyde or any carcinogen or suspected

carcinogen. These hazardous chemicals must be checked at least every 10%

of the total estimated time. Gas detector tubes for the specific chemicals

that are being used in the enclosure can be obtained from your laboratory

supply dealer.

Replace carbon filters when chemical breakthrough is indicated by odor,

time, detector tube, or for some chemicals, analytical instrumentation. See

“Replacing Carbon Filters” section of this manual in Chapter 6.

Determination of When to Replace

Carbon Filters and How to Replace

Carbon filter(s) MUST be replaced when any one of the following two conditions

are met:

1. The filtered enclosure outlet (exhaust) concentration approaches the inlet

concentration, indicating filter saturation.

2. The odor in the work area becomes intolerable or the concentration of the

chemical in the work area is greater than the TWA.

There are four means of determining when its time to change the carbon filters (not

shown in the order of preference).

Odor - A person’s sensitivity to odor, tolerance of odor and their comfort level

under odoriferous conditions vary with the individual. While odor is an indicator

that chemicals are passing through the carbon filter, several points need to be

understood:

Odor within the room is not necessarily an indication of saturation or

hazardous exposure concentrations.

Odor can be used as a prompt to sample the chemical concentration on the exit

side of the carbon filter.

Organic chemicals approved for use in the filtered enclosure have odors that

are detectable before reaching the time weighted exposure limits.

Product Service 1-800-522-7658

Page 24

Chapter 6: Maintaining Your Enclosure

20

!

Detection Tubes - Color change indicators can be used to measure the

concentration of the chemical at the exit side of the carbon filter or in the outlet

exhaust. A kit including syringe pump and flexible tubing can be purchased as an

accessory from Labconco (Catalog # 6924900). Labconco Customer Service

Representatives are supplied with detector tube catalog numbers, as well as

telephone numbers to direct you to where to purchase these items.

For Organic, Formaldehyde and Ammonia, chemical specific detector tubes should

be purchased when installing fresh filters. Each kit contains instructions on how

many strokes of the syringe are required to obtain the stated sensitivity. The

sampling syringe is connected to the filtered enclosure exhaust. There is a 5/16"

diameter hole on the upper right side for inserting the detector tube. Connect the

syringe to the detector tube while the system is running and pull the air through the

tube with the syringe. Each stroke of the syringe represents a 100-ml sample and

corresponds to the number of strokes necessary to give the indicated color changes.

Due to the wide variety of organics and varying TWA’s, it is recommended that

specific detector tubes be purchased directly from Sensidyne, Draeger or your

laboratory supply dealer. Alternate detector pumps can also be purchased from

your laboratory supply dealers. The vast majority of detector tubes available start

measuring at the TWA. When a user observes a color change in the tube, they

should replace the filter immediately. If no detector tube for your specific

chemical is available, other means of detection must be used.

Time - For applications that have very consistent inlet concentrations and

operating time, “Time” can be used to anticipate saturation or TWA levels based

on prior experience. However, this does not replace the need for sampling.

Consult Labconco technical specialist for an estimate of carbon filter life based on

chemical usage. Detector tubes, or analytical instrumentation should always be

used to determine concentrations in the carbon filter. It is recommended that the

carbon filters be checked with detector tubes or other means at intervals of 20% of

the total estimated filter life. The exception to the 20% recommendation is

formaldehyde and any carcinogen or suspected carcinogen. These more hazardous

chemicals must be checked at least every 10% of the total estimated time.

Analytical Instrumentation - This is the most accurate means of measuring

concentrations of any chemical. It is the method of choice when no detector tubes

are available or the tubes are not sensitive enough to measure at the TWA

concentration for the chemical. This method is also to be used to determine

saturation when the chemical concentration is below the measurement range of

detector tubes.

Carbon Filter Replacement Procedure – See Figure(s) A-2 and A-3 in Appendix

A for Carbon Filter Replacement.

Do NOT contact blower wheel while still in motion.

NE PAS être en contact avec la roué du ventilateur tant qu’il est

en marche.

Product Service 1-800-522-7658

Page 25

Chapter 6: Maintaining Your Enclosure

21

= 4.4 weeks before filter saturation

= .17 ml/min

1. The carbon filter(s) are replaced by first removing the rear perforated

baffle.

2. Remove the upper support bracket for the filter. Then loosen the lower

support bracket.

3. Carefully remove the carbon filter. For 60" wide units there are two carbon

filter(s)

4. Replace the new carbon filter(s) with the gasket on the downstream side

facing the blower. Replace the filter support brackets and tighten.

5. Replace the perforated baffle; replace and tighten the screws.

Calculating Carbon Filter Life

Labconco developed a modeling program to estimate the filter life for typical

carbon filters. Since filter life is dependent on the chemical used, the airflow, filter

size, and the dwell time, refer to the Chemical Guide for the Paramount® Filtered

Enclosure. The estimated life for carbon filters for the Fume Adsorbers with

integral impeller is conservatively calculated at 10% of the published values for

the Paramount in the Chemical Guide. Consult with a Labconco Technical

Specialist for further information on filter life. For example, if you use p-Xylene

in your process and evaporate approximately 100 ml per week during 2 hours of

use per day then follow these steps to calculate the concentration in parts per

million (ppm).

Steps for Calculating PPM and Filter Life

1. Determine the amount of the proposed chemical lost to evaporation over a

given amount of time. For example, if you use p-Xylene and lose

approximately 100 ml per week during 2 hours of use per day.

2. Convert the amount lost into ml/min. For this example:

100 ml X 1 week X 10 hours = 100 ml lost

week 10 hours use 600 minutes 600 minutes

3. Convert ml/min to PPM by multiplying ml/min by the conversion factor

found in the second to the last column on the right of the Paramount

Chemical Guide. For p-Xylene .17 x 25 = 4.2 PPM.

4. Find the PPM value on the chart that comes closest to the value you just

calculated in step #3. In this example, round up to 5 PPM, which is close to

the calculated 4.2. We may approximate the filter life to be around 437 hours

of actual use, but use 10% of this for the Fume Adsorber filter or 44 hours.

5. Insert the estimated filter life to determine how long filters will last.

44 hours filter life

10 hours per week use

6. This value is for one organic vapor filter. So, 4.4 weeks is approximately

one month before filter saturation.

Product Service 1-800-522-7658

Page 26

Chapter 6: Maintaining Your Enclosure

22

Number of

Filters

Filter Size

Pounds of

Formasorb

Carbon

Adsorbed weight of

Formaldehyde

Adsorption Volume of

Formalin

1

26x9x1.38

7.50

0.75 lbs./340 g

851 ml

Number of

Filters

Filter Size

Pounds of

Ammonasorb

II Carbon

Adsorbed weight of

Ammonia

Adsorbed Volume of

50% Ammonia Solution

1

26x9x1.38

8.75

.88 lbs./ 400 g

800 ml

Formaldehyde only

For formaldehyde, use 10% of the impregnated carbon weight. Formalin is 37%

formaldehyde by weight. The density of formalin is 1.08 g/ml. These values are

for one filter.

Ammonia only

For ammonia, use 10% of the impregnated carbon weight. Assume use of a 50%

solution of ammonia for these calculations. These values are for one filter.

Product Service 1-800-522-7658

Page 27

23

PROBLEM

CAUSE

CORRECTIVE ACTION

Contaminants outside

of enclosure.

Improper user

techniques for the

enclosure.

See Chapter 3 and Chapter 4 sections in

the manual. (Ref. Appendix D).

Restriction of the

baffle air slots or

blockage of the

exhaust outlet.

Remove obstruction to ensure that all

air slots and the exhaust outlet are

unobstructed.

External factors are

disrupting the

enclosure airflow

patterns or acting as a

source of

contamination.

See “Location Requirements” Chapter

2, “Certifying the Enclosure” Chapter

3, and “Safety Precautions” Chapter 4

sections of this manual. (Ref. Appendix

D).

Enclosure has

improper face

velocity.

Have the enclosure’s exhaust system

checked. Check carbon filters for

loading. Enclosure should have an

average face velocity of 35 fpm.

Filtered exhausted.

Change and replace the carbon filter.

CHAPTER 7

TROUBLESHOOTING

Refer to the following table if your Fume Adsorber fails to operate properly. If the

suggested corrective actions do not solve your problem, contact Labconco for

additional assistance.

Product Service 1-800-522-7658

Page 28

Chapter 7: Troubleshooting

24

PROBLEM

CAUSE

CORRECTIVE ACTION

Blower won’t

operate.

Unit not plugged

into outlet.

Plug the enclosure into appropriate

electrical service.

Circuit breaker(s)

or Ground Fault

Interrupter.

Reset circuit breaker.

Blower wiring is

disconnected.

Inspect blower wiring and re-connect.

Blower switch is

defective.

Replace switch.

Motorized impeller

or blower is

defective.

Replace motorized impeller or blower.

Product Service 1-800-522-7658

Page 29

25

Item

Qty.

Part Number

Description

1A 1 6961000

Canopy Hood, Plastic 30"

1B 1 6961001

Canopy Hood, Plastic 60"

2A 1 6961500

Baffle, 30" Perforated

2B 1 6961501

Baffle, 60" Perforated

2C

4 or 8

1887808

Screw, Machine #10-24 x .50 PH Phil

3

2 or 4

6962500

Bracket, Filter Clamp

4

4 or 8

1896810

Screw, Machine #10-24 x .62 Phil PH/W

5A

1 or 2

6962000

Motorized, Impeller, 115V

5B

1 or 2

6962001

Motorized, Impeller, 230V

6A 1 1307000

Switch, Rocker-DPST

6B 1 6962600

Wire Harness 115/230V

7A 1 1327205

Circuit Breaker 2 Amp (115V)

7B 2 1327206

Circuit Breaker 1 Amp (115V)

8A 1 1334500

Power Cord, 115V

8B 1 1334100

Power Cord, 230V

9A

1 or 2

6961300

Filter, Disposable Organic Vapor

9B

1 or 2

6961301

Filter, Disposable Formaldehyde

9C

1 or 2

6961302

Filter, Disposable Ammonia

APPENDIX A

ENCLOSURE COMPONENTS

AND REPLACEMENT PARTS

The components that are available for your Fume Adsorber are listed. The parts

shown are the most commonly requested. If other parts are required, please

contact Product Service.

Product Service 1-800-522-7658

Page 30

Appendix A: Enclosure Components & Replacement Parts

26

Figure A-2

30" Wide Exploded View

Figure A-1

Replacement Parts Isometric

6

2

1

4

3

4

9

7, 8 Not Shown

6

2

4

3

5

Product Service 1-800-522-7658

Page 31

Appendix A: Enclosure Components & Replacement Parts

27

Figure A-3

60" Wide Exploded View

4

3

9

6

7, 8 Not Shown

5

5 3 9

Product Service 1-800-522-7658

Page 32

28

APPENDIX B

DIMENSIONS

See the following dimensions below for all Fume Adsorbers.

Figure B-1

Dimensions for 30" & 60" Wide Fume Adsorber

(Dimensions are in inches)

Product Service 1-800-522-7658

Page 33

29

APPENDIX C

FUME ADSORBER

SPECIFICATIONS

This Appendix contains technical information about all the Fume Adsorber

enclosures including electrical specifications and environmental operating

conditions.

Electrical Specifications

2 Amps, 115V, 50/60 Hz

1 Amp, 230V, 50/60 Hz

Environmental Conditions

Indoor use only.

Maximum altitude: 6562 feet (2000 meters).

Ambient temperature range: 41° to 104°F (5° to 40°C).

Maximum relative humidity: 80% for temperatures up to 88°F (31°C),

decreasing linearly to 50% relative humidity at 104°F (40°C).

Main supply voltage fluctuations not to exceed ±10% of the nominal

voltage.

Transient over-voltages according to Installation Categories II (Over-

voltage Categories per IEC 1010). Temporary voltage spikes on the AC

input line that may be as high as 1500V for 115V models and 2500V for

230V models are allowed.

Used in an environment of Pollution degrees 2 (i.e., where normally only

non-conductive atmospheres are present). Occasionally, however, a

temporary conductivity caused by condensation must be expected, in

accordance with IEC 664.

Product Service 1-800-522-7658

Page 34

30

Model Size

30"

60"

Height from Work Surface (inches)

13.50

13.50

Total Open Area with Bypass (sq. ft.)

2.75

5.55

Exhaust Airflow Volume at 35 fpm (CFM)

100

200

*Motor Horsepower (HP)

0.05

0.10

APPENDIX D

QUICK CHART FOR THE FUME

ADSORBERS

To determine the actual face velocity at the sash opening, airflow velocity readings

will need to be taken across the opening. The “average face velocity” is achieved

by taking readings in two rows across the enclosure with the readings 6" from the

ends and evenly spaced every 12"; the first row is 3" down from the upper plastic

hood canopy and the second row is 3" up from the work surface.

Product Service 1-800-522-7658

Page 35

31

APPENDIX E

REFERENCES

Many excellent reference texts and booklets are currently available. The following

is a brief listing:

Applicable Standards

UL 61010-1 Standard for Safety Electrical Equipment for Measurement, Control

and Laboratory Use; Part 1: General Requirements

Specifies the general safety requirements for electrical equipment.

Based on International Electrotechincal Commission (IEC) Publication

61010-1 with differences noted for U.S. use.

Tests for protection against electrical shock, mechanical hazards, spread of

fire, radiation, liberated gases, explosions and implosion.

Tests for resistance to shock, vibration, impact, heat, moisture and liquids.

Underwriters Laboratories Inc.

333 Pfingsten Road

Northbrook, IL 60062

(847) 272-8800

www.ul.com

NIOSH Pocket Guide to Chemical Hazards

NIOSH Publications

Mail Stop C-12

4676 Columbia Parkway

Cincinnati, OH 45226-1998

Fax (513) 533-8573

Product Service 1-800-522-7658

Page 36

Appendix C: Fume Adsorber Specifications

32

General References

American Conference of Governmental Industrial Hygienists. Industrial Ventilation, A

Manual of Recommended Practice, Cincinnati, OH

Department of Labor, Occupational Safety and Health Administration, 29 CFR Part 1910,

Occupational Exposures to Hazardous Chemicals in Laboratories, Final Rule. Vol. 55,

No. 21. Washington D.C.:1990

NIH Guidelines for the Laboratory Use of Chemical Carcinogens. NIH Publication No.

81-2385.

Product Service 1-800-522-7658

Page 37

33

Product Service 1-800-522-7658

Loading...

Loading...