Page 1

®

®

rreeeeZZoonne

QQuuiicckkGGuuiiddeettooIInnssttaallllaattiioonn

iisstteemmii ddii lliiooffiilliizzzzaazziioonnee FFrreeeeZZoonne

GGuuiiddaarraappiiddaaaallllʹʹiinnssttaallllaazziioonnee

yyssttèèmmeess ddee llyyoopphhiilliissaattiioonn FFrreeeeZZoonne

GGuuiiddeeddʹʹiinnssttaallllaattiioonnrraappiiddee

rreeeeZZoonne

KKuurrzzaannlleeiittuunnggzzuurrIInnssttaalll

iisstteemmaass ddee ddeesshhiiddrraattaacciióónn ppoorr ccoonnggeellaacciióónn

rreeeeZZoonne

e

FFrreeeezzee DDrryy SSyysstteemms

s

®

®

e

GGeeffrriieerrttrroocckknnuunnggssaannllaaggeen

l

aattiioonn

®

®

e

e

®

®

e

®

®

n

GGuuííaaddeeiinnssttaallaacciióónnrrááppiiddaa

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Labconco Installation Guide 7389910, Rev. B, ECO G900

Page 2

FFrreeeeZZoonne

e

®

®

FFrreeeezzee DDrryy SSyysstteem

mss

QQuuiicckk GGuuiiddee ttoo IInnssttaallllaattiioonn

Note: This Quick Guide to Installation may not provide all the information for

your installation. Refer to the User’s Manual for details and precautions. Do not

discard packaging until you have identified all parts that were shipped and the

freeze dryer operates properly.

PPrreeppaarraattiioonns

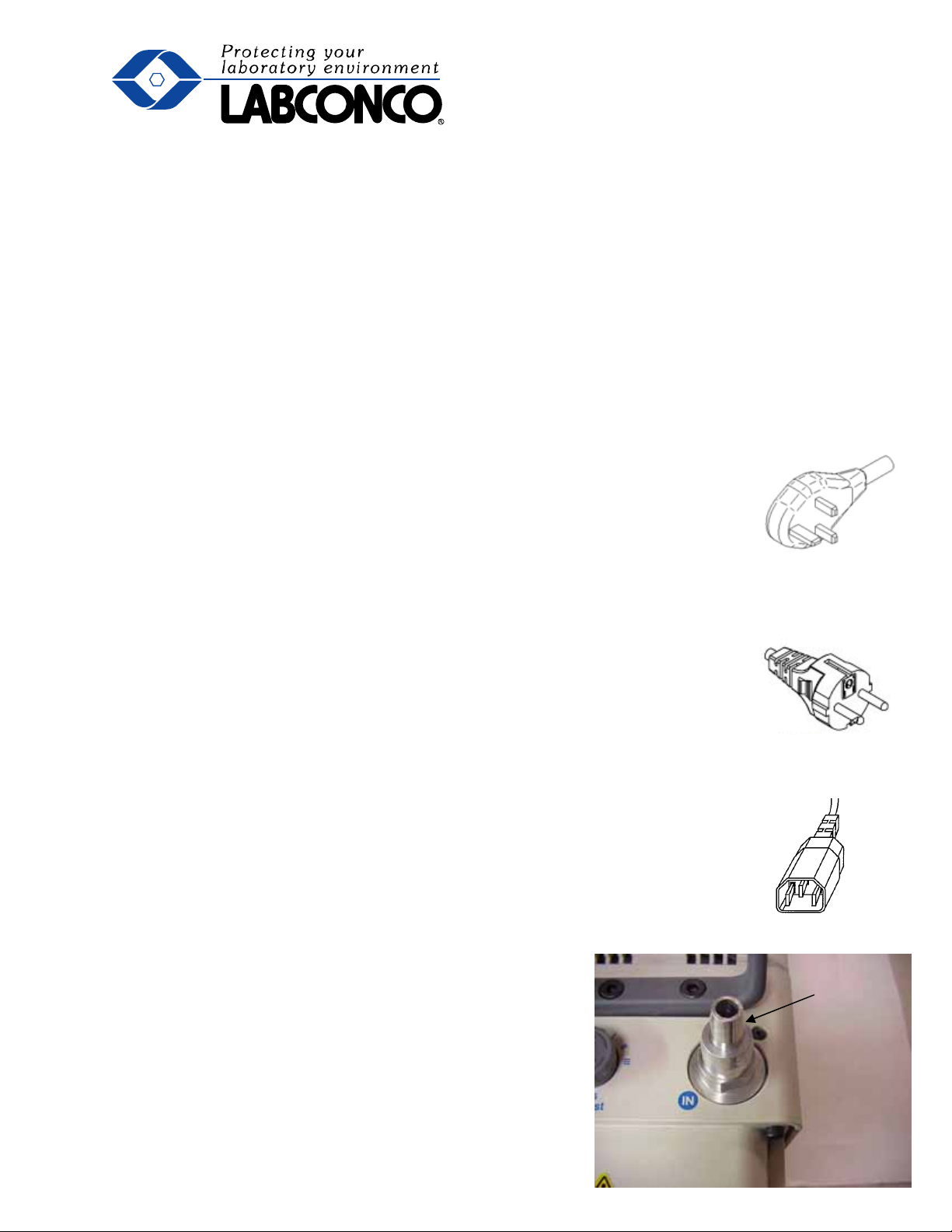

Step 1. Proper Electrical Supply

• 230V models

o 15-Amp dedicated single phase circuit. Additional

o Frequency must agree with the serial tag rating.

s

appliances on the same circuit may cause the current to

exceed the rating of the circuit breaker or fuse.

Improper frequency will damage the compressor.

UK plug

EU plug

Step 2. Rotary Vane Vacuum Pump Requirements

• 1 Liter, 2.5 Liter, 4.5 Liter models

o 88 liters per minute minimum displacement

o .002 mBar ultimate vacuum

• 6 Liter, 12 Liter, 18 Liter models

o 98 liters per minute minimum displacement

(144 liters per minute recommended)

o .002 mBar ultimate vacuum

• Plug Requirements on vacuum pump power cord

o 230V models- reverse IEC plug

• Hose barb connection to fit .75-inch inside diameter hose

Reverse IEC plug

Page 1 of 5

Page 3

IInnssttaallllaattiioon

n

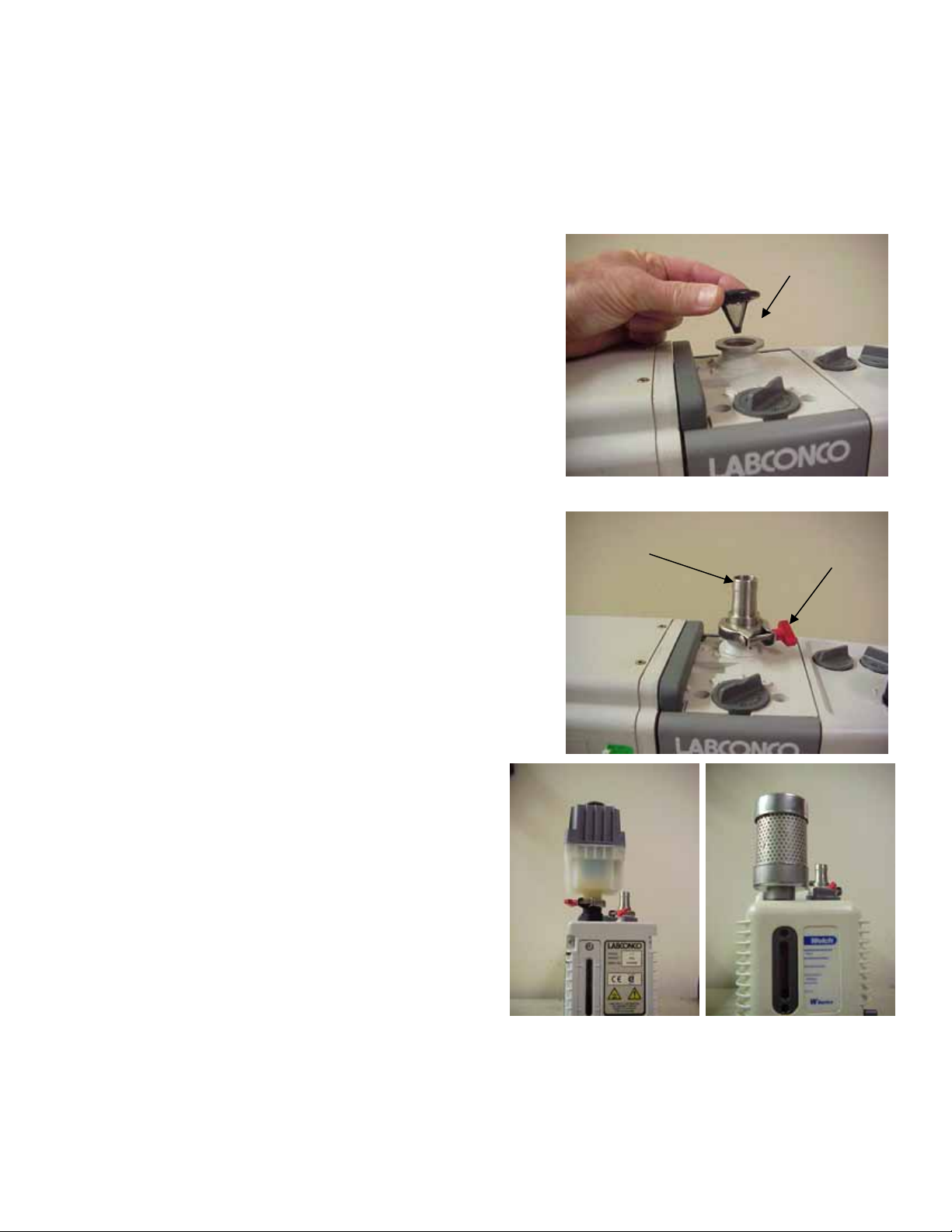

Step 3. Vacuum Pump Set Up

• Remove protective caps from inlet and outlet

Inlet Hose

Barb

ports.

• Some vacuum pumps have inlet fittings that

screw into the inlet port. Make sure the O-ring

is on the sealing surface. Insert fitting into the

pump housing and tighten securely.

• Some vacuum pumps have inlet fittings that

Inlet Fitting

clamp to the pump. Place the centering ring

with filter screen on the inlet fitting.

• Place the hose barb fitting on top of the

centering ring.

Hose Barb

Clamp

• Secure the fitting with the clamp.

• Attach the exhaust filter to the exhaust port.

Some pumps have filters that screw in.

Others require that a centering ring is

placed on the fitting and then a clamp

secures it similar to the inlet fitting.

• NOTE: Rotary vane vacuum pumps

must have an exhaust filter to prevent

oil mist from exiting the pump and

depleting the oil supply.

Page 2 of 5

Page 4

• Fill the pump with oil so the level is between the lines on the sight gauge on the end of

the pump housing.

• Verify that the vacuum pump voltage setting agrees with the Freeze Dryer voltage

shown on the serial number label. Reconfigure if necessary. See pump instructions.

• Turn the vacuum pump power switch ON.

• Set the gas

ballast to

closed or

minimum

position.

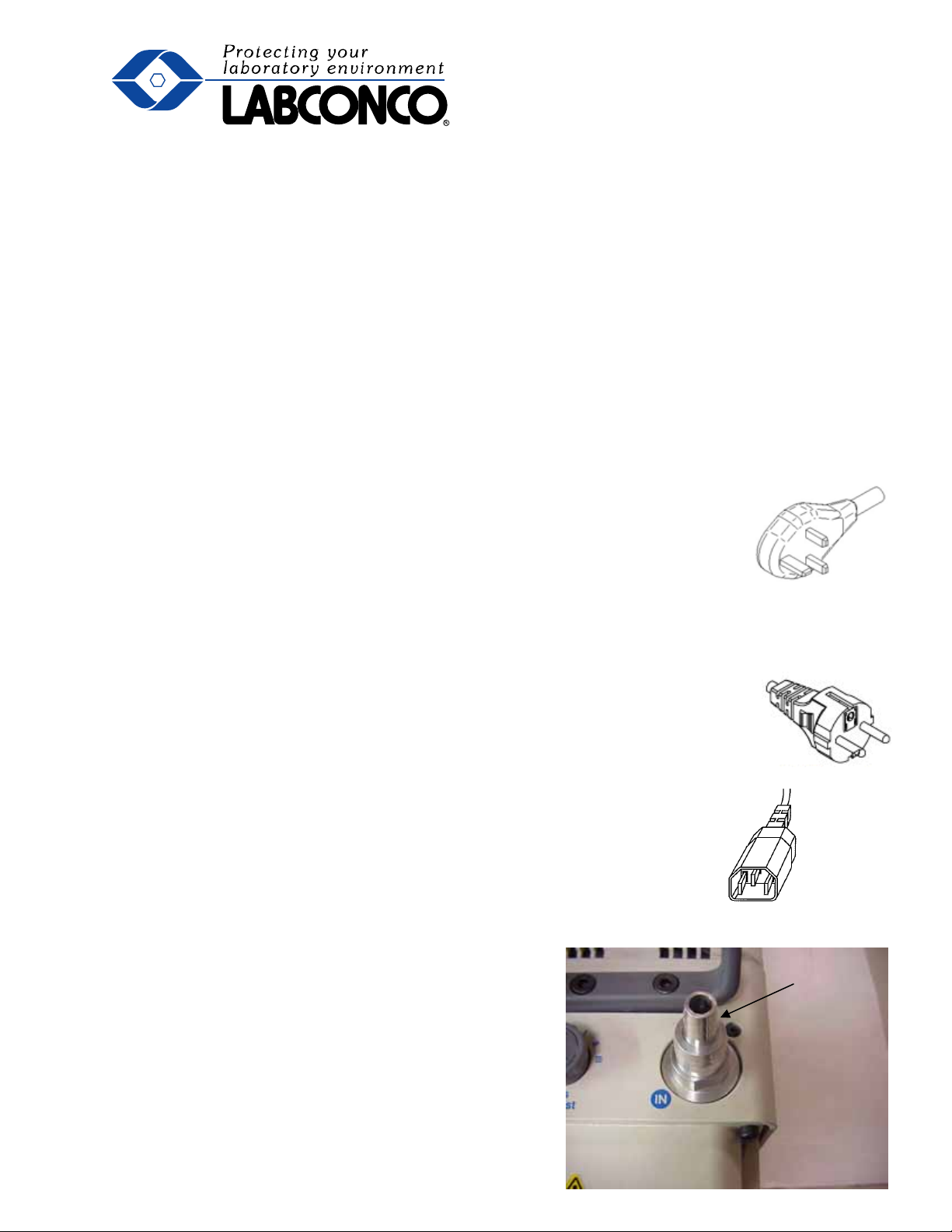

Step 4. Vacuum Pump Connections

• Benchtop models

o Position the vacuum pump within 2 feet

of the .75-inch diameter port on the

back of the cabinet.

o Attach one end of the vacuum hose to

the port on the Freeze Dryer and the

other end to the inlet port of the

vacuum pump. Clamp both ends

securely.

o Connect the vacuum pump power cord

into the receptacle on the back of the

Freeze Dryer.

• Console models

o CAUTION - Make sure that power to

the Freeze Dryer is disconnected.

o Remove the front lower panel from the

Freeze Dryer by inserting a screw

driver into the slot below the center of

the front panel. Pivot the screwdriver

handle downward while pulling the

bottom of the panel outward.

Pull

Push down

Page 3 of 5

Page 5

o Place the vacuum pump inside the

cabinet.

o Connect the vacuum hose to the inlet

fitting of the vacuum pump. Clamp

securely.

o Reinstall the front panel by positioning the top edge

under the control panel and pushing the bottom

inward.

o CAUTION - Make sure that power to the

Freeze Dryer is disconnected before

Upper Back

Panel

removing the lower back panel. Do NOT

remove the upper back panel.

o Plug the vacuum pump power cord into the

receptacle in the junction box marked

Vacuum Pump.

o Replace the rear panel.

Vacuum Pump

Receptacle

Chamber Lid

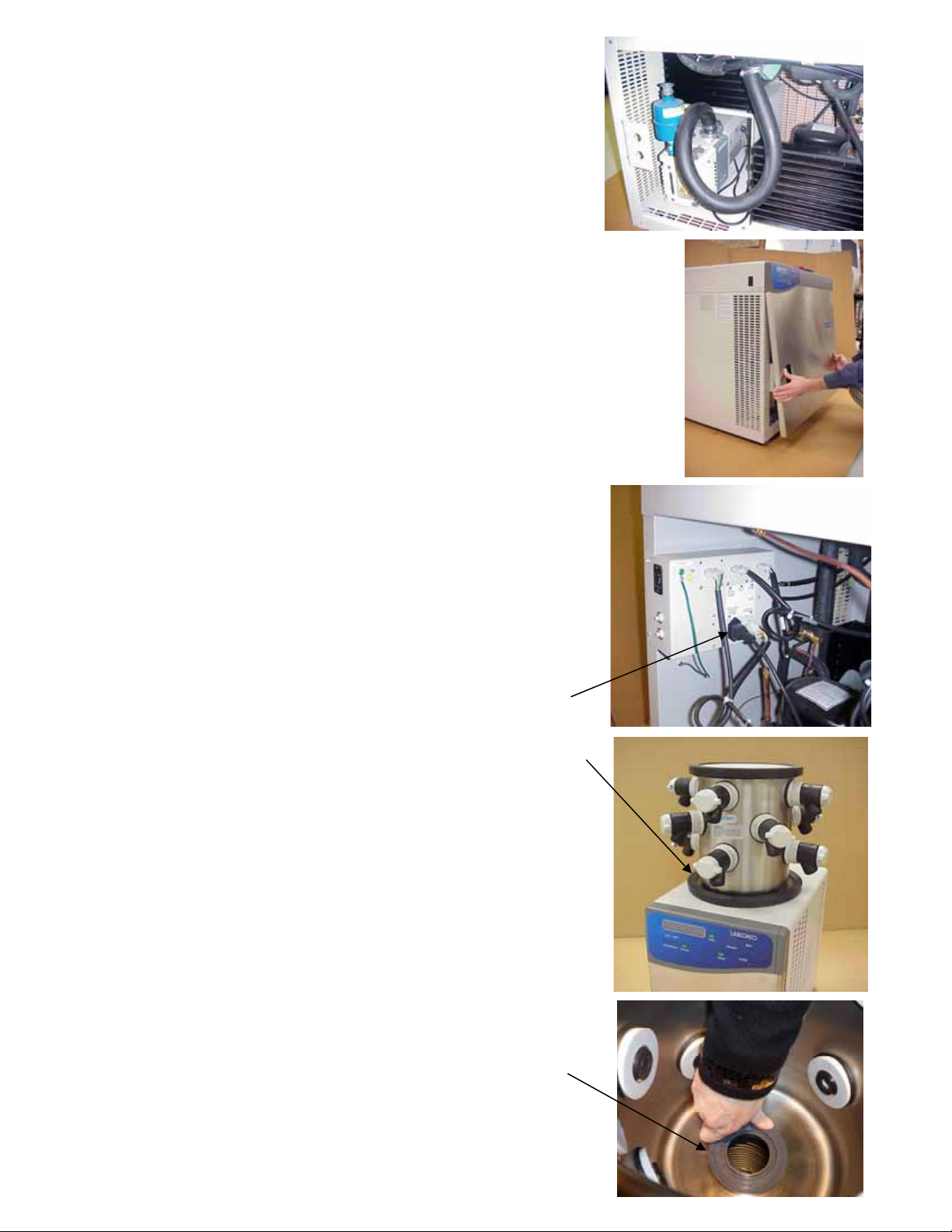

Step 5. Installing a Chamber or Manifold (except

4.5L models which have chamber already attached)

• 1L and 2.5L Models

o Place the collector chamber lid on top of the

chamber.

o Center the flat rubber gasket on the hole in the

center of the chamber lid.

o Place the chamber or manifold over the gasket.

o If installing chamber, insert plastic fitting

(7386901) through hole in the chamber and

through hole in the gasket.

Page 4 of 5

(7386901)

Page 6

• 6L, 12L and 18L Model Chambers

o Place the flat rubber gasket over the inlet port.

o Place the chamber over the gasket.

o Reaching into the chamber, set the stainless

steel ring over the port opening. Slide the lock pin

through the holes in the port and rotate over

center (stainless steel chamber only).

Stainless Ring

• 6L, 12L and 18L Manifolds- see instructions

supplied with Manifolds.

Lock Pin

TTeessttiinngg oorr SSttaarrtt UUp

p

Step 6. Testing the System

• Connect the power cord into the receptacle on the back of the Freeze Dryer and insert

the other end into a suitable wall receptacle.

• Turn the power switch ON.

• Vacuum check

o Make sure the lid is on the collector and either a manifold

or chamber is in place.

o Close all manifold valves.

o Set the vacuum level for .002 mBar (except 1L models

without vacuum control).

o Press the Vacuum button.

o Vacuum should reach .133 mBar or less within 15

minutes.

• Refrigeration (leave the vacuum pump running)

o Press the Refrigeration button.

o Collector temperature should reach operating temperature

(-50°C or -84°C depending on the model) within 40

minutes.

• If the Freeze Dryer fails to perform as expected, consult the User’s Manual for

troubleshooting information or call Labconco.

Labconco Corporation * 8811 Prospect Ave * Kansas City, MO 64132-2696 Web: www.labconco.com

800-821-5525 * 816-333-8811 * Fax 816-822-3785 * E-mail: Labconco@labconco.com

Page 5 of 5

Page 7

SSiisstteem

mii ddii lliiooffiilliizzzzaazziioonnee

FFrreeeeZZoonne

e

®

®

GGuuiiddaa rraappiiddaa aallll''iinnssttaallllaazziioonnee

Nota bene. Questa guida rapida può non offrire tutte le informazioni necessarie

per l'installazione. Fare riferimento

al manuale operativo in merito ai particolari

ed alle precauzioni. Non smaltire l'imballaggio prima di identificare tutti i pezzi

spediti e verificare il buon funzionamento del liofilizzatore.

AApppprroonnttaammeenntto

Passo 1. Alimentazione elettrica

• Modelli da 230 V, 50 Hz

o Circuito monofase dedicato da 15 A. L'alimentazione di

ulteriori dispositivi tramite lo stesso circuito può far sì che

la corrente superi il valore nominale dell'interruttore

automatico o del fusibile.

o La presa accetta una spina europea o del Regno Unito,

come illustrata.

o La frequenza deve corrispondere a quella indicata

sull'etichetta del numero di serie e dei valori nominali.

Una frequenza errata può danneggiare il compressore.

o

Spina Regno

Unito

Spina UE

Passo 2. Requisiti della pompa a vuoto, rotativa a palette

• Modelli da 1 litro, 2,5 litri e 4,5 litri

o Portata minima di 88 litri al minuto (5,2 m3/h)

o Vuoto finale di 0,002 mbar

• Modelli da 6 litri, 12 litri e 18 litri

o Portata minima di 98 litri al minuto (5,9 m

(144 litri al minuto raccomandato)

o Vuoto finale di 0,002 mbar

• Requisiti di spina del cavo di alimentazione della pompa a vuoto

o Modelli da 230 V – spina IEC

• Connessione a portagomma per tubi a vuoto aventi un diametro

interno di 19 mm

IInnssttaallllaazziioonne

Passo 3. Impostazione della pompa a vuoto

• Rimuovere i tappi di protezione dall'ingresso e

dall'uscita.

e

Page 1 of 5

3

/h)

Spina IEC

Ingresso con

portagomma

Page 8

• Alcune pompe a vuoto sono dotate di raccordi

di ingresso filettati. Accertarsi che l'O-ring sia

ben posizionato sulla superficie di tenuta.

Inserire il raccordo nell'alloggiamento della

pompa e serrarlo saldamente.

• Altre pompe a vuoto sono dotate di raccordi di

ingresso a morsetto. Posizionare l'anello di

centraggio munito di filtro a retino nel raccordo

di ingresso.

• Posizionare il portagomma per tubi sopra

l'anello di centraggio.

• Fissare saldamente il raccordo con il

morsetto.

• Collegare il filtro all'uscita di scarico. Alcune

pompe sono dotate di filtri filettati. Altre

richiedono il posizionamento di un

anello di centraggio sul raccordo ed il

morsettaggio del filtro, ripetendo il

trattamento riservato al raccordo di

ingresso.

• NOTA BENE. Le pompe rotative a

palette devono essere munite di un

filtro di scarico per evitare l'emissione

di olio nebulizzato e la conseguente

deplezione della riserva di olio.

Portagomma per

tubi

Raccordo di

ingresso

Morsetto

Page 2 of 5

Page 9

• Riempire il serbatoio d'olio della pompa fino a raggiungere il livello di pieno tra le

tacche dell'indicatore a trasparenza posto sull'alloggiamento della pompa stessa.

• Verificare che l'impostazione della tensione della pompa a vuoto corrisponda a quella

riportata sull'etichetta del numero di serie del liofilizzatore. Riconfigurarla se

necessario. Vedere le istruzioni relative alla pompa.

• Far scattare l'interruttore di alimentazione della pompa a vuoto nella posizione ON.

• Impostare la

manopola della

zavorra gas

(GAS

BALLAST)

nella posizione

chiusa o

minima.

Passo 4. Connessioni della pompa a vuoto

• Modelli da banco

o Posizionare la pompa a vuoto a non

più di 610 mm di distanza dall'uscita da

19 mm di diametro, posta sul retro

dell'unità.

o Collegare una estremità del tubo a

vuoto all'uscita del liofilizzatore e l'altra

estremità all'ingresso della pompa a

vuoto. Morsettare saldamente

entrambe le estremità.

o Collegare la spina del cavo di

alimentazione della pompa a vuoto alla

presa sul retro del liofilizzatore.

• Modelli a consolle

o ATTENZIONE! Accertarsi che il

liofilizzatore non sia collegato alla rete

di alimentazione.

o Rimuovere il pannello anteriore

inferiore dal liofilizzatore inserendo un

cacciavite nella sfinestratura centrale

sotto il pannello stesso. Inclinare verso

il basso l'impugnatura del cacciavite e

tirare verso l'esterno il fondo del

pannello.

Tirare

Spingere verso il

basso

Page 3 of 5

Page 10

o Collocare la pompa a vuoto all'interno del

mobiletto.

o Collegare il tubo a vuoto al raccordo di

ingresso della pompa a vuoto. Morsettare

saldamente.

o Reinstallare il pannello anteriore, collocandone l'orlo

superiore sotto il pannello dei comandi e spingendone

il fondo verso l'interno.

o ATTENZIONE! Accertarsi che il liofilizzatore

non sia collegato alla rete di alimentazione

prima di rimuovere il pannello posteriore

Pannello

posteriore

superiore

inferiore. NON rimuovere il pannello

posteriore superiore.

o Inserire la spina del cavo di alimentazione

della pompa a vuoto nella presa

appositamente contrassegnata del quadro

elettrico.

o Rimontare il pannello posteriore.

Presa della pompa a vuoto

Coperchio della

camera

Passo 5. Installazione di una camera o rampa

(eccetto nel caso dei modelli da 4,5 L, dotati di

camera precollegata)

• Modelli da 1 L e 2,5 L

o Porre il coperchio della camera del collettore

sulla parte superiore della camera stessa.

o Centrare la guarnizione piatta in gomma

attorno al foro al centro del coperchio della

camera.

o Collocare la camera o rampa sulla

guarnizione.

Page 4 of 5

(7386901)

Page 11

• Modelli con camera da 6 L, 12 L e 18 L

o Porre la guarnizione piatta in gomma

sull'ingresso.

o Posizionare la camera sulla guarnizione.

o Infilando la mano nella camera, appoggiare

l'anello in acciaio inossidabile sull'apertura

dell'ingresso. Far scorrere il perno di bloccaggio

attraverso i fori dell'ingresso e farlo ruotare sul

centro (per le sole camere in acciaio

inossidabile).

Perno di

bloccaggio

Anello in acciaio

inossidabile

• Rampe da 6 L, 12 L e 18 L - Vedere le istruzioni fornite assieme alle rampe.

CCoollllaauuddoo oo aavvvviiaammeenntto

o

Passo 6. Prova del sistema

• Inserire una spina del cavo di alimentazione nella presa posta sul retro del liofilizzatore

e l'altra in una presa a muro idonea.

• Far scattare l'interruttore di alimentazione nella posizione ON.

• Verifica dell'aspirazione

o Accertarsi che il collettore sia munito di coperchio e che

sia stata installata una camera o una rampa.

o Chiudere tutte le valvole della rampa.

o Impostare il livello di aspirazione su 0,002 mbar (ad

eccezione dei modelli da 1 L privi di comando del vuoto).

o Premere il pulsante VACUUM.

o Il vuoto dovrebbe raggiungere 0,133 mbar o un valore

inferiore entro 15 minuti.

• Refrigerazione (lasciare in funzione la pompa a vuoto)

o Premere il pulsante REFRIGERATION.

o La temperatura del collettore dovrebbe raggiungere il

valore di esercizio (-50°C o -84°C a seconda del modello)

entro 40 minuti.

• Se il liofilizzatore non consegue i risultati previsti, consultare il relativo manuale

operativo per individuare i possibili guasti o rivolgersi a Labconco.

• Lo schema completo dei pezzi è presentato nell'appendice A del manuale.

Labconco Corporation * 8811 Prospect Ave * Kansas City, MO 64132-2696 Web: www.labconco.com

800-821-5525 * 816-333-8811 * Fax 816-822-3785 * E-mail: Labconco@labconco.com

Page 5 of 5

Page 12

SSyyssttèèm

meess ddee llyyoopphhiilliissaattiioonn

®

®

e

FFrreeeeZZoonne

GGuuiiddee dd''iinnssttaallllaattiioonn rraappiiddee

Remarque : Ce guide d'installation rapide peut ne pas fournir toutes les informations

nécessaires à votre installation. Veuillez vous reporter au manuel de l'utilisateur pour les

détails et les précautions. Ne jetez pas l'emballage tant que vous n'avez pas identifié toutes

les pièces qui ont été expédiées et vérifié que le lyophilisateur fonctionne correctement.

PPrrééppaarraattiioon

Etape 1. Alimentation électrique correcte

• Modèles de 230 V, 50 Hz

n

o Circuit monophasé dédié de 15 ampères. Si d'autres

appareils électriques sont connectés au même circuit, le

courant pourrait dépasser la valeur nominale du

disjoncteur ou du fusible.

o Le réceptacle doit accepter une prise européenne ou

anglaise comme indiqué.

o La fréquence doit être conforme à la valeur nominale de

l'étiquette du numéro de série. Une mauvaise fréquence

endommagera le compresseur.

Prise anglaise

Etape 2. Spécification de la pompe à vide à palettes

• Modèles de 1 litre, 2,5 litres et 4,5 litres

o Cylindrée minimum de 88 litres/minute (5,2 m3/heure)

o Pression de vide limite de 0,002 mbar

• Modèles de 6 litres, 12 litres, 18 litres

o Cylindrée minimum de 98 litres/minute (5,9 m

(144 litres/minute recommandé)

o Pression de vide limite de 0,002 mbar

• Spécification de la prise du câble d'alimentation de la pompe à vide

o Modèles de 230 V - prise IEC mâle

• Raccord cannelé de tuyau, adapté au tuyau à vide d'un

diamètre intérieur de 19 mm (0,75 pouce)

IInnssttaallllaattiioon

Etape 3. Configuration de la pompe à vide

• Retirer les capuchons de protection des orifices

d'admission et de sortie.

n

3

/heure)

Prise

européenne

Prise IEC mâle

Raccord

cannelé

d'arrivée

Page 1 of 5

Page 13

• Certaines pompes à vide ont des raccords

d'admission qui se vissent dans l'orifice

d'admission. S'assurer que le joint torique est

placé sur la surface d'étanchéité. Introduire le

raccord dans le boîtier de la pompe et serrer

bien.

• Certaines pompes ont des raccords

d'admission qui sont attachés à la pompe

avec une bride. Placer l'anneau de centrage

avec le tamis sur le raccord d'admission.

• Placer le raccord cannelé du tuyau au-dessus

de l'anneau de centrage.

• Attacher le raccord avec la bride.

• Attacher le filtre d'échappement à l'orifice

d'échappement. Certaines pompes ont des

filtres qui sont vissés. D'autres

nécessitent qu'un anneau de centrage

soit placé sur le raccord, puis que le

raccord soit attaché avec une bride,

comme le raccord d'admission.

• REMARQUE : Les pompes à vide à

palettes doivent avoir un filtre

d'échappement pour empêcher le

nuage d'huile de sortir de la pompe et

de réduire le volume d'huile

d'alimentation.

Raccord

d'admission

Raccord cannelé

Bride

Page 2 of 5

Page 14

• Remplir la pompe avec de l'huile de façon que le niveau soit entre les traits sur la jauge

visuelle à l'extrémité du boîtier de la pompe.

• Vérifier que le réglage de la tension de la pompe à vide correspond à la tension du

lyophilisateur indiquée sur l'étiquette du numéro de série. Reconfigurer si nécessaire.

Voir les instructions de la pompe.

• Mettre l'interrupteur de la pompe à vide sur Marche (ON).

• Régler la

soupape de

lest (gas

ballast) sur la

position fermée

ou la position

minimale.

Etape 4. Connexions de la pompe à vide

• Modèles de banc

o Placer la pompe à vide à moins de 610

mm (24 pouces) de l'orifice de 19 mm

(0,75 pouce) de diamètre à l'arrière du

coffret.

o Attacher une extrémité du tuyau à vide

à l'orifice du lyophilisateur et l'autre

extrémité à l'orifice d'admission de la

pompe à vide. Attacher les deux

extrémités de façon sécurisée.

o Connecter le câble d'alimentation de la

pompe à vide au réceptacle à l'arrière

du lyophilisateur.

• Modèles de console

o PRECAUTION - S'assurer que

l'alimentation du lyophilisateur est

déconnectée.

o Retirer le panneau avant inférieur du

lyophilisateur en introduisant un

tournevis dans le logement sous le

centre du panneau avant. Pivoter la

poignée du tournevis vers le bas tout

en tirant le bas du panneau vers

l'extérieur.

Tirer

Pousser vers le

bas

Page 3 of 5

Page 15

o Placer la pompe à vide à l'intérieur du

coffret.

o Connecter le tuyau à vide au raccord

d'admission de la pompe à vide. Le serrer

de façon sécurisée.

o Remettre en place le panneau avant en plaçant le

bord supérieur sous le panneau de commande et en

poussant le bas vers l'intérieur.

o PRECAUTION - S'assurer que

l'alimentation du lyophilisateur est

Panneau arrière

supérieur

déconnectée avant de retirer le panneau

arrière inférieur. Ne PAS retirer le

panneau arrière supérieur.

o Brancher le câble d'alimentation de la

pompe à vide dans le réceptacle de la

boîte de jonction marqué Pompe à vide

(Vacuum Pump).

o Remettre en place le

panneau arrière.

Réceptacle

pompe à vide

Couvercle de

chambre

Etape 5. Installation d'une chambre ou d'un

distributeur (sauf pour les modèles de 4,5 l qui

ont déjà une chambre attachée)

• Modèles de 1 l et 2,5 l

o Placer le couvercle de la chambre de

collecteur au-dessus de la chambre.

o Centrer le joint plat en caoutchouc sur le

trou au centre du couvercle de la chambre.

o Placer la chambre ou le distributeur sur le

joint.

o Pour installer la chambre, insérez le raccord

plastique (7386901) à travers

l’orifice de la chambre et à

travers l’orifice du joint.

Page 4 of 5

(7386901)

Page 16

• Chambre des modèles de 6 l, 12 l et 18 l

o Placer le joint plat en caoutchouc sur l'orifice

d'admission.

o Placer la chambre sur le joint.

o A l'intérieur de la chambre, placer l'anneau en

acier inoxydable sur l'ouverture de l'orifice.

Glisser la goupille de verrouillage à travers les

trous de l'orifice et la tourner au-dessus du centre

(chambre en acier inoxydable seulement).

• Distributeurs de 6 l, 12 l et 18 l - voir les

instructions fournies avec le distributeur.

Goupille de

verrouillage

Anneau en acier

inoxydable

EEssssaaii oouu mmiissee eenn mmaarrcchhe

e

Etape 6. Essai du système

• Connecter le câble d'alimentation au réceptacle à l'arrière du lyophilisateur et introduire

l'autre extrémité dans une prise murale appropriée.

• Mettre l'interrupteur d'alimentation sur Marche (ON).

• Vérification du vide

o S'assurer que le couvercle est placé sur le collecteur et

qu'un distributeur ou une chambre est en place.

o Fermer toutes les soupapes du distributeur.

o Régler le niveau de vide à 0,002 mbar (sauf pour les

modèles de 1 l sans commande de vide).

o Appuyer sur le bouton de vide (Vacuum).

o Le vide devrait atteindre 0,133 mbar ou moins en 15

minutes.

• Réfrigération (laisser la pompe à vide en marche)

o Appuyer sur le bouton de réfrigération.

o La température du collecteur devrait atteindre la

température de marche (-50°C ou -84°C selon le modèle)

en 40 minutes.

• Si le lyophilisateur ne fonctionne pas de la façon anticipée, consulter le manuel de

l'utilisateur pour des informations de dépannage ou contacter Labconco.

• Un diagramme complet des pièces se trouve dans l'annexe A du manuel.

Labconco Corporation * 8811 Prospect Ave * Kansas City, MO 64132-2696 Web: www.labconco.com

800-821-5525 * 816-333-8811 * Fax 816-822-3785 * E-mail: Labconco@labconco.com

Page 5 of 5

Page 17

FFrreeeeZZoonne

e

®®

GGeeffrriieerrttrroocckknnuunnggssaannllaaggeen

n

KKuurrzzaannlleeiittuunngg zzuurr IInnssttaallllaattiioonn

Hinweis: Diese Kurzanleitung enthält möglicherweise nicht alle Informationen für Ihre

Installation. Details und Vorsichtshinweise sind im Bedienerhandbuch enthalten.

Entsorgen Sie die Verpackung erst, wenn Sie alle gelieferten Teile identifiziert haben

und die Gefriertrocknungsanlage einwandfrei funktioniert.

VVoorrbbeerreeiittuunnggeen

Schritt 1. Richtige Stromversorgung

• 230 V, 50 Hz Modelle

o 15 A dedizierter Einphasenkreis. Weitere Geräte am

gleichen Kreis können zu einer Überlastung der

Sicherung führen.

o Die Buchse muss den gezeigten EU- oder GB-Stecker

aufnehmen.

o Die Frequenz muss mit dem zulässigen Wert auf dem

Typenschild übereinstimmen. Eine falsche Frequenz führt

zu Schäden am Kompressor.

n

Stecker für

GB

Schritt 2. Voraussetzungen für Drehschieberpumpen

• 1 Liter, 2,5 Liter, 4,5 Liter Modelle

o 88 Liter pro Minute (5,2 m3 pro Stunde)

Mindestverdrängung

o 0,002 mBar Höchstvakuum

• 6 Liter, 12 Liter, 18 Liter Modelle

o 98 Liter pro Minute (5,9 m

Verdrängung (144 Liter pro Minute empfohlen)

o 0,002 mBar Höchstvakuum

• Steckeranforderungen am Netzkabel der Vakuumpumpe

o 230 V Modelle - IEC-Umkehrstecker

• Schlauchwiderhaken-Anschluss muss an Vakuumschlauch mit

19 mm (0,75 Zoll) Innendurchmesser passen.

IInnssttaallllaattiioon

Schritt 3. Einrichten der Vakuumpumpe

• Die Schutzkappen von der Eingangs- und

Ausgangsöffnung entfernen.

n

3

pro Stunde) mindest-

Stecker für

EU

IEC-Umkehrstecker

Schlauchwiderhaken

am Eingang

Page 1 of 5

Page 18

ur

• Manche Vakuumpumpen haben

Eingangsarmaturen, die in die Eingangsöffnung geschraubt werden. Darauf achten,

dass der O-Ring auf der Dichtfläche aufliegt.

Die Armatur in das Pumpengehäuse

einpassen und fest sichern.

• Manche Vakuumpumpen haben

Eingangsarmaturen, die an der Pumpe

festgeklemmt werden. Den Zentrierring mit

Filtersieb auf die Eingangsarmatur legen.

• Die Schlauchwiderhaken-Armatur auf den

Zentrierring platzieren.

• Die Armatur mit der Klemme sichern.

• Den Ausgangsfilter am Ausgangsport

anbringen. Manche Pumpen verfügen über

Filter zum Einschrauben. Andere setzen

voraus, dass ein Zentrierring auf die

Armatur gelegt wird; eine Klemme

sichert ihn dann an der

Eingangsarmatur.

• HINWEIS:

Drehschiebervakuumpumpen brauchen

einen Ausgangsfilter, damit kein

Öldunst aus der Pumpe austritt und der

Ölvorrat verbraucht wird.

Schlauchwiderhaken

Eingangsarmat

Klemme

Page 2 of 5

Page 19

• Die Pumpe bis auf eine Höhe zwischen den beiden Linien auf dem Sichtglas am Ende

des Pumpengehäuses mit Öl füllen.

• Prüfen, dass die Spannungseinstellung an der Vakuumpumpe mit der

Spannungsangabe auf dem Typenschild des Gefriertrockners übereinstimmt. Ggf. neu

konfigurieren. Siehe die Pumpenanleitungen.

• Den Netzschalter an der Vakuumpumpe auf EIN stellen.

• Den Gasballast

auf

„Geschlossen“

oder „Minimum“

stellen.

Schritt 4. Anschlüsse der Vakuumpumpe

• Werkbank-Modelle

o Die Vakuumpumpe innerhalb von

610 mm (24 Zoll) vom Port mit einem

19 mm (0,75 Zoll) Durchmesser auf der

Schrankrückseite positionieren.

o Ein Ende des Vakuumschlauchs am

Port des Gefriertrockners und das

andere Ende am Eingangsport der

Vakuumpumpe anbringen. Beide

Enden sicher festklemmen.

o Das Netzkabel der Vakuumpumpe an

der Buchse auf der Rückseite des

Gefriertrockners anschließen.

• Konsolenmodelle

o VORSICHT - Sicherstellen, dass der

Strom zum Gefriertrockner getrennt ist.

o Die vordere Platte unten am

Gefriertrockner durch Einführen eines

Schraubenziehers in den Schlitz in der

Mitte unter der Frontplatte lösen. Den

Schraubendrehergriff nach unten

biegen, und die Platte unten nach

außen ziehen.

Ziehen

Nach unten

drücken

Page 3 of 5

Page 20

o Die Vakuumpumpe in den Schrank setzen.

o Den Vakuumschlauch an der

Eingangsarmatur der Vakuumpumpe

anschließen. Festklemmen.

o Die Frontplatte wieder einbauen. Dazu den oberen

Rand unter die Bedientafel positionieren und den

unteren Rand nach innen drücken.

o VORSICHT - Vor dem Entfernen der

Rückwand sicherstellen, dass der

Obere

Rückwand

Gefriertrockner vom Strom getrennt ist. Die

obere Rückwand NICHT ENTFERNEN.

o Das Netzkabel der Vakuumpumpe in die

Buchse am Schaltkasten mit der Markierung

„Vakuumpumpe“ anschließen.

o Die Rückwand wieder einbauen.

Buchse der

Vakuumpumpe

Kammerdeckel

Schritt 5. Einbau einer Kammer oder eines

Verteilers (außer 4,5 l Modelle, an denen bereits

eine Kammer befestigt ist.)

• 1 l und 2,5 l Modelle

o Den Deckel der Kollektorkammer auf die

Kammer setzen.

o Die flache Gummidichtung auf dem Loch in

der Mitte des Kammerdeckels zentrieren.

o Die Kammer oder den Verteiler auf die

Dichtung setzen.

(7386901)

Page 4 of 5

Page 21

• Kammern für die Modelle 6 l, 12 l und 18 l

o Die Gummidichtung auf den Eingangsport legen.

o Die Kammer auf die Dichtung setzen.

o In die Kammer greifen, um den Edelstahlring

über der Port-Öffnung anzubringen. Den

Sperrstift durch die Löcher am Port schieben und

über die Mitte drehen (nur Edelstahlkammern).

Edelstahlring

6 l, 12 l und 18 l Verteiler - siehe die

Anleitungen, die den Verteilern beiliegen.

Sperrstift

TTeesstteenn ooddeerr SSttaarrtteen

n

Schritt 6. Das System testen

• Das Netzkabel an der Buchse hinten am Gefriertrockner anschließen und das andere

Ende in eine geeignete Wandsteckdose stecken.

• Den Netzschalter auf EIN stellen.

• Vakuumprüfung

o Sicherstellen, dass der Deckel auf dem Kollektor sitzt und

entweder ein Verteiler oder eine Kammer angebracht

sind.

o Alle Verteilerventile schießen.

o Den Vakuumwert für 0,002 mBar (außer bei 1l Modellen

ohne Vakuumsteuerung) einstellen.

o Die Taste „Vakuum“ drücken.

o Das Vakuum sollte innerhalb von 15 Minuten 0,133 mBar

oder weniger erreichen.

• Kühlung (Vakuumpumpe laufen lassen)

o Die Taste „Kühlung“ drücken.

o Die Kollektortemperatur sollte innerhalb von 40 Minuten

Betriebstemperatur erreichen (-50 °C oder -84 °C je nach

Modell)

• Falls der Gefriertrockner nicht wie erwartet funktioniert, im Kapitel „Fehlersuche“ im

Benutzerhandbuch nachschlagen oder Labconco anrufen.

• In Anhang A des Handbuchs befindet sich ein komplettes Teilediagramm.

Labconco Corporation * 8811 Prospect Ave * Kansas City, MO 64132-2696 Web: www.labconco.com

800-821-5525 * 816-333-8811 * Fax 816-822-3785 * E-mail: Labconco@labconco.com

Page 5 of 5

Page 22

SSiisstteemmaass ddee ddeesshhiiddrraattaacciióónn ppoorr ccoonnggeellaacciióónn FFrreeeeZZoonne

e

®

®

GGuuííaa ddee iinnssttaallaacciióónn rrááppiiddaa

Nota: Esta Guía de instalación rápida puede que no contenga toda la información

necesaria para la instalación. Consulte el Manual del Usuario para obtener detalles y

precauciones. No deseche el material de embalaje hasta que haya identificado todas

las partes enviadas y confirmado que el deshidratador por congelación funciona

correctamente.

PPrreeppaarraacciioonnees

Paso 1. Suministro de alimentación eléctrica apropiado

• Modelos de 230 V, 50 Hz

o Circuito monofásico especialmente asignado de 15-Amp.

o El receptáculo debe aceptar enchufe europeo o británico,

o La frecuencia debe ser compatible con la capacidad

s

Conectar más artefactos en el mismo circuito puede

causar que la corriente exceda la capacidad nominal del

interruptor o fusible.

tal como se muestra.

nominal indicada en la etiqueta de serie. Una frecuencia

incorrecta dañará el compresor.

Enchufe para el

Reino Unido

Paso 2. Requisitos para la bomba de vacío de aspas rotatorias

• Modelos de 1 litro, 2.5 litros, 4.5 litros

o Desplazamiento mínimo de 88 litros por minuto (5,2 m3

por hora)

o Vacío final de 0,002 mBar

• Modelos de 6 litros, 12 litros, 18 litros

o Desplazamiento mínimo de 98 litros por minuto

(5,9 m3 por hora) (144 litros por minuto recomendada)

o Vacío final de 0,002 mBar

• Requisitos de enchufe para el cordón eléctrico de la bomba de

vacío

o Modelos de 230 V – enchufe IEC inverso

• Conexión de espiga de la manguera para caber

en la manguera de vacío de 19 mm (0.75 pulg.)

de diámetro interior.

IInnssttaallaacciióón

n

Paso 3. Instalación de la bomba de vacío

• Quite las tapas protectoras de los puertos de

entrada y salida.

Enchufe para la

Unión Europea

Enchufe IEC inverso

Espiga de la

manguera de

entrada

Página 1 de 5

Page 23

• Algunas bombas de vacío tienen accesorios

de entrada que se entornillan dentro del

puerto de entrada. Asegúrese de que el anillo

tórico esté en la superficie de sellado. Inserte

el accesorio dentro de la carcasa de la bomba

y apriete de manera segura.

• Algunas bombas de vacío tiene accesorios de

entrada que se sujetan a la bomba. Coloque

el anillo centrador con la malla en el accesorio

de entrada.

• Coloque el accesorio de espiga de la

manguera encima del anillo centrador.

• Asegure el accesorio con la abrazadera.

• Acople el filtro de escape al puerto de escape.

Algunas bombas tienen filtros que se atornillan.

Otras requieren que se coloque un

anillo centrador en el accesorio y luego

la abrazadera lo asegura de manera

parecida al accesorio de entrada.

• NOTA: Las bombas de vacío de aspas

rotatorias deben tener un filtro de

escape para evitar que el rocío de

aceite salga de la bomba y se agote de

esa manera el suministro de aceite.

Espiga de la

manguera

Accesorio de

entrada

Abrazadera

Página 2 de 5

Page 24

• Llene la bomba con aceite de manera que el nivel esté entre las líneas del indicador de

nivel ubicado al extremo de la carcasa de la bomba.

• Verifique que el voltaje de la bomba de vacío esté conforme con el voltaje del

deshidratador por congelación que aparece en la etiqueta de número de serie. Vea las

instrucciones de la bomba.

• Coloque el interruptor de potencia de la bomba en posición de encendido (ON).

• Coloque el

lastre de gas

en la posición

de cerrado o

mínimo.

Paso 4. Conexiones de la bomba de vacío

• Modelos de mesa

o Ubique la bomba de vacío a 610 mm

(24 pulgadas) del puerto de 19 mm

(0.75 pulgadas) de diámetro ubicado

en la parte posterior del gabinete.

o Conecte un extremo de la manguera

de vacío al puerto del deshidratador

por congelación y el otro extremo al

puerto de entrada de la bomba de

vacío. Asegure firmemente ambos

extremos con abrazaderas.

o Conecte el cordón eléctrico de la

bomba de vacío al receptáculo ubicado en la parte

posterior del deshidratador por congelación.

• Modelos de consola

o PRECAUCIÓN – Asegúrese de que el

suministro eléctrico al deshidratador

por congelación esté desconectado.

o Extraiga el panel inferior frontal del

deshidratador por congelación,

insertando un destornillador en la

ranura situada debajo del centro del

Jale

panel frontal. Presione el mango del

destornillador hacia abajo mientras jala

la parte inferior del panel hacia fuera.

Empuje hacia

abajo

Página 3 de 5

Page 25

o Coloque la bomba en dentro del gabinete.

o Conecte la bomba de vacío al accesorio de

entrada de la bomba de vacío. Asegure

firmemente con abrazadera.

o Vuelva a instalar el panel frontal colocando el borde

superior debajo del panel de control y empujando la

parte inferior hacia adentro.

o PRECAUCIÓN – Asegúrese de que el

suministro eléctrico al deshidratador por

Panel posterior

superior

congelación esté desconectado antes de

extraer el panel posterior inferior. NO retire

el panel posterior superior.

o Enchufe el cordón eléctrico de la bomba

de vacío dentro del receptáculo de la caja

de empalmes etiquetado "Vacuum Pump”

(bomba de vacío).

o Vuelva a colocar el panel posterior.

Receptáculo

de la bomba

de vacío

Tapa de la cámara

Paso 5. Instalación de la cámara o distribuidor

(excepto en modelos de 4.5 litros que ya tienen

la cámara instalada)

• Modelos de 1 litro y 2.5 litros

o Coloque la tapa de la cámara recolectora

encima de la cámara.

o Centre la empaquetadura de caucho plana

en el agujero ubicado en el centro de la

tapa de la cámara.

o Coloque la cámara o distribuidor sobre la

empaquetadura.

o Para instalar la cámara, inserte el conector

de plàstico (7386901) a través del orificio

de la cámara y a través del orificio del

empaque.

(7386901)

Página 4 de 5

Page 26

• Cámara para modelos de 6 litros, 12 litros, y 18 litros

o Coloque la empaquetadura de caucho plana

sobre el puerto de entrada.

o Coloque la cámara sobre la empaquetadura.

o Ingresando dentro de la cámara, coloque el anillo

de acero inoxidable sobre la abertura del puerto.

Deslice el pin de sujeción a través de los

agujeros en el puerto y rote sobre el centro (para

cámaras de acero inoxidable solamente)

Pin de

sujeción

Anillo de acero

inoxidable

• Para los distribuidores para modelos de 6 litros, 12 litros y 18 litros, vea las

instrucciones que vienen con los distribuidores.

PPrruueebbaa oo aarrrraannqquue

e

Paso 6. Prueba del sistema

• Conecte el cordón eléctrico al receptáculo ubicado en la parte posterior del

deshidratador por congelación e inserte el otro extremo dentro de un tomacorriente

apropiado.

• Coloque el interruptor de potencia en la posición de encendido (ON)

• Revisión del vacío

o Asegúrese de que la tapa esté encima del colector y que el distribuidor o la

cámara estén en su lugar.

o Cierre todas las válvulas del distribuidor.

o Fije el nivel de vacío en 0,002 mBar (excepto los modelos de 1 litro que no

tienen control de vacío).

o Presione el botón “Vacuum” (vacío).

o El vacío debe llegar a 0,133 mBar o menos antes de que transcurran 15

minutos.

• Refrigeración (deje la bomba de vacío funcionando)

o Presione el botón “Refrigeration” (refrigeración).

o La temperatura del colector debe llegar a la temperatura de operación (-50° C o

-84° C dependiendo del modelo) en 40 minutos o menos.

• Si el deshidratador por congelación no funciona según lo esperado, consulte el Manual

del usuario para obtener información sobre la resolución de problemas o llame a

Labconco.

• El diagrama completo de partes se encuentra en el Apéndice A del Manual.

Labconco Corporation * 8811 Prospect Ave * Kansas City, MO 64132-2696 Web: www.labconco.com

800-821-5525 * 816-333-8811 * Fax 816-822-3785 * E-mail: Labconco@labconco.com

Página 5 de 5

Loading...

Loading...