Page 1

CRUDE FIBER DIGESTION APPARATUS

Models 30001, 30002

(New Style)

INSTRUCTION MANUAL

Product designs are subject to change without notice

© 1997 Labconco Corporation

30023, Rev C / ECO 9302

Printed in U.S.A.

Page 2

TABLE OF CONTENTS

Preface...........................................................................................................................................................4

Introduction

Components Shipped.................................................................................................................. 5

General Description.................................................................................................................... 6

Component Identification........................................................................................................... 7

Installation

Location........................................................................................................................................... 8

Connections..................................................................................................................................... 8

Start-up - Check out ........................................................................................................................8

Dimensions...................................................................................................................................... 9

Normal Operation.......................................................................................................................... 10

Routine Maintenance..................................................................................................................... 11

Accessories.................................................................................................................................... 13

Wiring Diagram............................................................................................................................. 14

Warranty........................................................................................................................................ 15

Shipping Claims ............................................................................................................................ 16

Contacting Labconco..................................................................................................................... 17

3

Page 3

PREFACE

Thank you for displaying confidence in us by selecting a Labconco Crude Fiber

Digestion Apparatus. Our design engineers, assemblers and inspectors have utilized their skills

and years of experience to ensure that the new Labconco Crude Fiber Digestion Apparatus meets

our high standards of quality and performance.

IMPORTANT NOTICE

This manual should be read carefully by all the end users in order to become familiar with the

operation of the Crude Fiber Digestion Apparatus. Recommendations are made within the

manual to help you obtain maximum performance and life from your product.

We have included sections on initial set up, operation, maintenance and troubleshooting to

provide you with all the tools necessary to achieve maximum performance.

If you have questions or concerns, do not hesitate to call us at 1-800-821-5525 for assistance.

4

Page 4

INTRODUCTION

Components Shipped

Carefully check the contents of the carton for damage that might have occurred in transit.

Do not discard the carton or packing material until all components have been checked against the

following component list and the equipment has been installed and tested.

As shipped, the carton should contain the following:

Catalog # Description

30001 Crude Fiber Apparatus 115V, 50/60 Hz

or

30002 Crude Fiber Apparatus 230V, 50/60 Hz

19350 Crude Fiber Beakers - 600 ml (12)

5

Page 5

INTRODUCTION

General Description

The Labconco Crude Fiber Digestion apparatus is designed for single or multiple reflux

digestions of samples for crude fiber content according to methods prescribed by the Association

of Official Analytical Chemists (A.O.A.C.).

The following instructions outline the features, installations and maintenance of the

Crude Fiber Digestor Models 30001, 30002. This manual should be kept handy so that questions

of use or service can be answered.

6

Page 6

INTRODUCTION

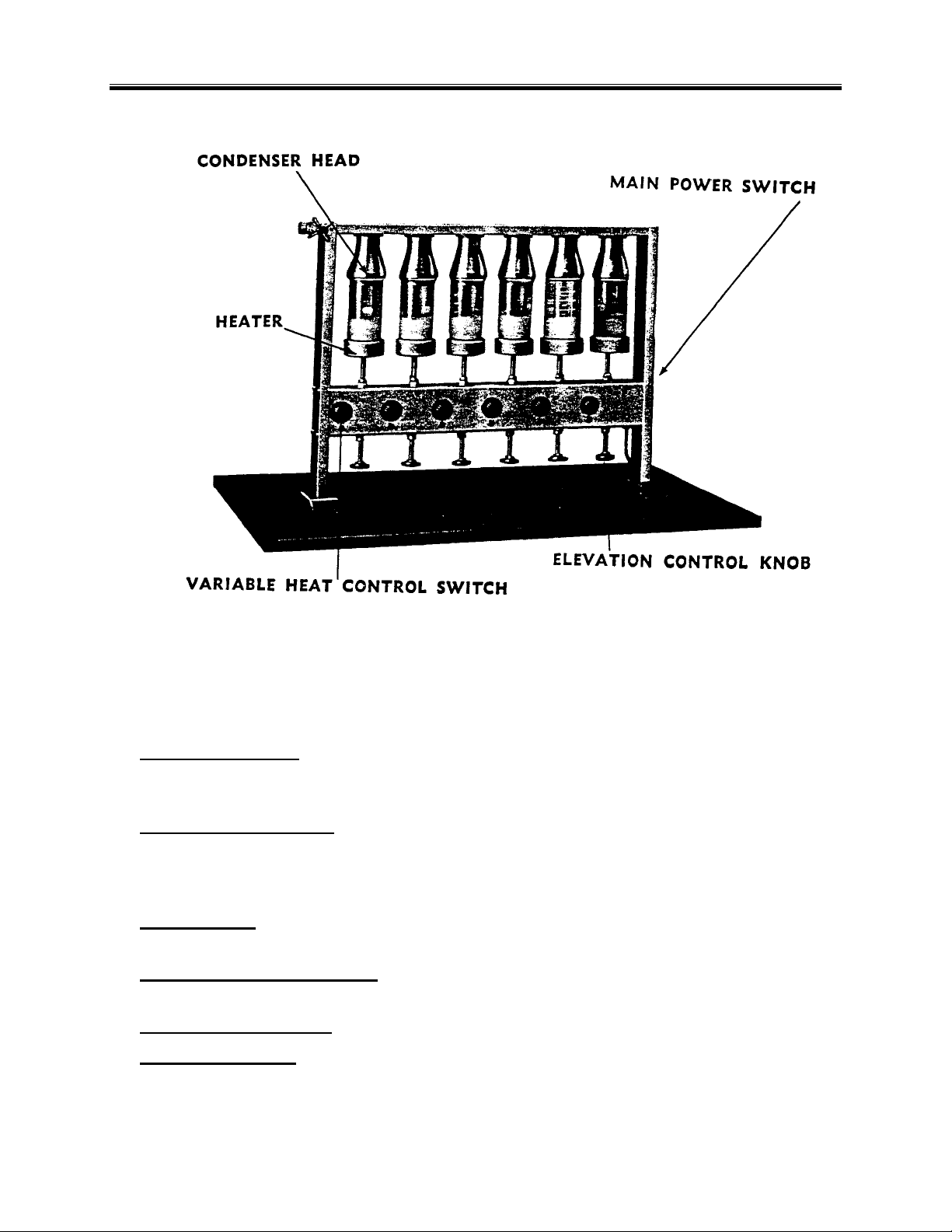

Figure 1

Detailed function of Components

1. Manifold Assembly. The hood features a molded, 6" diameter exhaust connection sized to

allow for a minimum of static pressure loss through the hood structure and one that still can

provide a good transport velocity through the exhaust system.

2. Condenser Head System

essential part of the digestion process. The vapors from the boiling digestion medium are

condensed on the condenser heads and returned to the medium continually washing the sides

of the beakers in the process.

3. Heater System. Each 350 watt adjustable spring loaded heater provides an even distribution

of heat through the use of coiled heater wires embedded in a ceramic material.

4. Variable Heat Control Switch. Provides variable input from 20-100% of capacity to each

heater.

5. Elevation Control Knob. Adjusts beakers positions.

. These cone shaped heads located above each heater provide an

6. Main Power Switch

control switches.

. Turn apparatus on and off without need of changing variable heat

7

Page 7

INSTALLATION

Installation

Model 30001, 115 Volt, 50/60 Hz. 18.3 amps, is complete except no power cord is

supplied on the unit. The customer must provide wiring to the main power switch in accordance

with local electrical codes. The unit is supplied with 12 - 600 ml beakers. The unit is also

equipped with individual infinite control switches with pilot lights for each heater and a main

ON/OFF switch. The condensers are Type 304 stainless steel. A 3/8" NPT valve is provided to

control water flow through condensers.

Model 30002, 6 unit, 230 Volt, 50/60 Hz, 9.11 amps, is complete except no power cord is

supplied on this unit. The customer must provide wiring to main power switch in accordance

with local electrical codes. The unit is supplied with 12 - 600 ml beakers. The unit is also

equipped with 12 each individual infinite control switches with pilot lights for each heater and a

main ON/OFF switch. The condensers are Type 304 stainless steel. A 3/8" NPT valve is

provided to control water flow through condensers.

Installation Instructions

Location

Choose a location in the laboratory which has a convenient electrical outlet of the voltage

required, a cold water supply of 3/8" NPT and drain facilities of at least 1/2" NPT.

Connections

Connect the 3/8" NPT water inlet valve, located on the upper left side of the unit to your

cold water supply. This valve regulates the flow of water through the condenser heads.

Connect the 3/8" NPT water outlet located on the upper right side of the unit to an open

drain area of at least 1/2" in size. An open drain connection will allow the operator to make a

visual check of water flow through the condenser head system.

After the proper electrical connections are made, the unit is now ready for routine

operation.

Start-Up and Check-Out

All the heater control switches should be turned on to insure proper performance.

8

Page 8

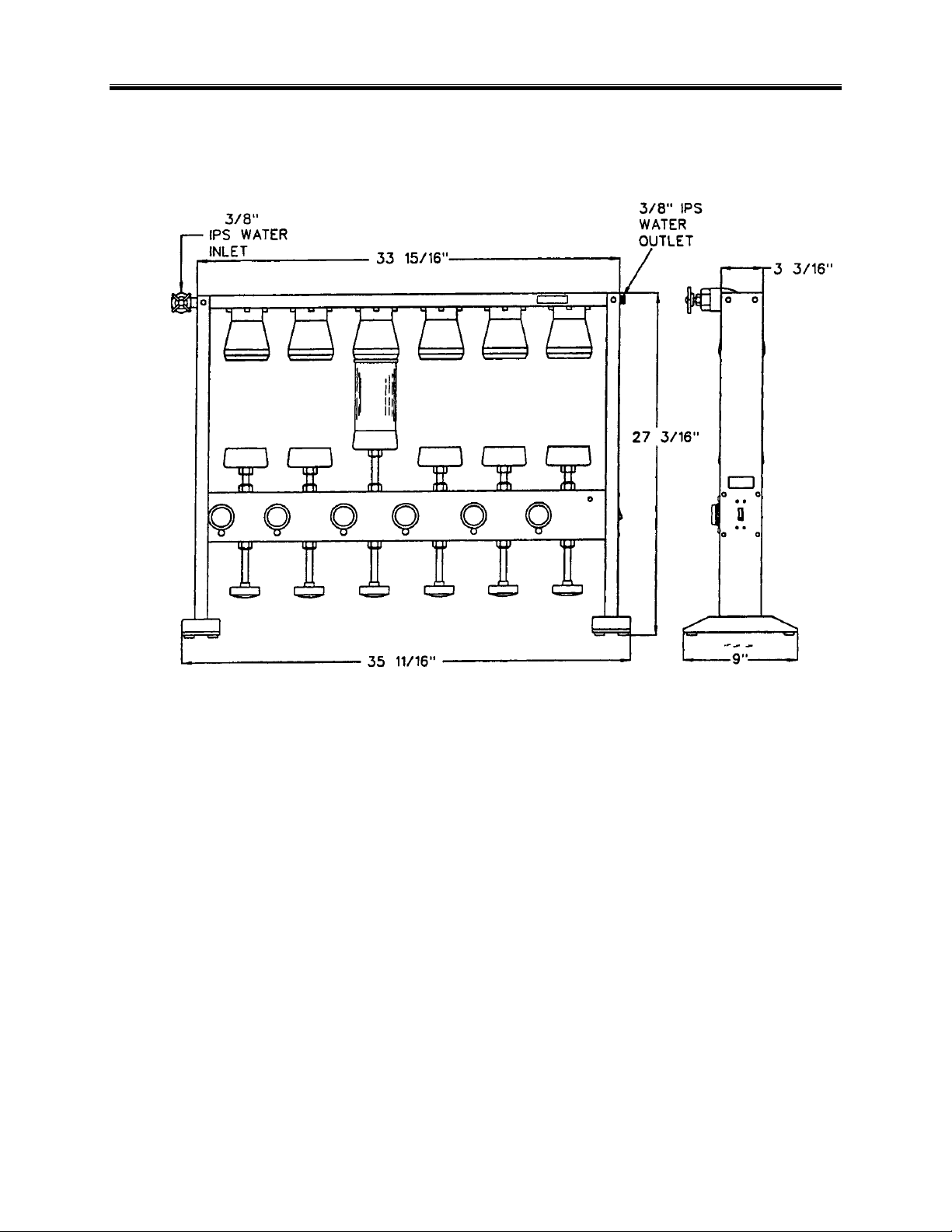

DIMENSIONS

Figure 2

9

Page 9

NORMAL OPERATION

Normal Operation

The following section provides a general outline of steps necessary to perform a routine

digestion on the Labconco Crude Fiber Digestor. Actual test methods, sample preparation,

solvent choices, etc., are determined by official methods of the A.O.A.C. and should be referred

to in all cases.

• Turn on cold water supply, check visual flow at the drain area. The heater and water

flow rates may be adjusted to vary the reflux rates according to the operator’s preference.

• Prepare samples per standard method for the product under examination

• Place required quantity of sample in the beaker.

• Place digestion medium of proper type and quantity into beaker.

• Place beaker on the heaters and while firmly holding knob turn 1/4 turn to the left, and

slowly let beaker rise to condenser head. DO NOT

position against condenser head.

• Turn the main power switch, located on the right side, to the “ON” position. Controls on

the panel independently regulate one 350 watt heater. The pilot lights indicate heater

“ON” cycle.

let go of knob until beaker is in

• Follow A.O.A.C. method and procedure for determination of fiber content

10

Page 10

ROUTINE MAINTENANCE

Maintenance

If problems develop with unit, contact the laboratory dealer from whom you purchased

the unit. He will be happy to assist you.

If satisfaction is not obtained, contact Labconco Corporation, 8811 Prospect, Kansas

City, Missouri 64132. Phone 1-800-821-5525, - Fax # 1-816-444-5353.

11

Page 11

REPLACEMENT PARTS

REPLACEMENT PARTS LIST

Models 30001, 30002

(New Style)

Part Number Description

13154 Infinite Control, 120 Volt, 15 Amp

13155 Infinite Control, 230 Volt, 15 Amp

13159 Toggle Switch, 120 Volt/ 230 Volt, 15 Amp

13516 Valve, needle, water

18702 Knob for infinite control

30031 Heating element, 115 Volt, 350 Watt

30032 Heating element, 230 Volt, 350 Watt

30043 Beaker, 600 ml, Package of 6

30135 No. 14AF – White heater harness wire, stranded, 15' length

30136 No. 14AF – Black heater harness wire, stranded, 15' length

30137 No. 12AF – White heater harness wire, stranded 15' length

30138 No. 18AF – Pilot light wire, stranded, 15' length

30139 No. 18 Heater lead wire, stranded nickel, glass braid, 15' length

30208 Condenser Assembly

30225 Condenser Gasket

12

Page 12

ACCESSORIES

ACCESSORY PARTS LIST

Part Number

55100 California Modified Buechner Funnel, complete. Consists of

55101 Upper section only (with screen), for #55100 above.

55201 Replacement screen only, for #55210 above

55202 Back-up plate only for #55210 below.

55210 Oklahoma State Filter, complete constructed of stainless steel, one

Description

standard polyethylene two-piece funnel with 200 mesh stainless

steel screen.

piece with threaded cap. 200 mesh screen with perforated back-up

plate.

13

Page 13

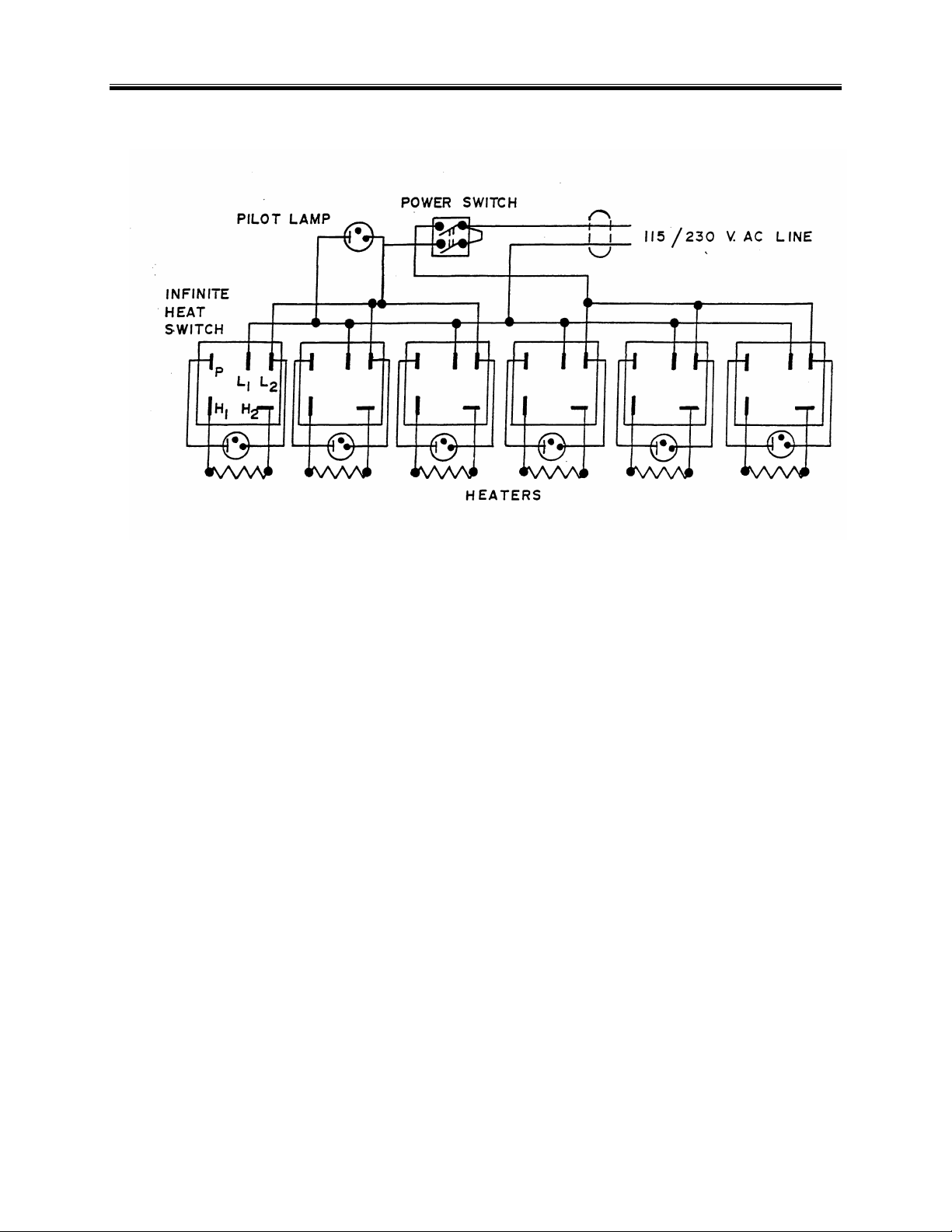

WIRING DIAGRAM

Figure 3

14

Page 14

WARRANTY

We are committed to providing our customers with quality equipment and service after

the sale. Part of this objective involves keeping you informed of changes and new product

additions. We therefore request that you take a moment to fill out the product registration

card so we may know your location as well as some of the reasons that prompted you to

purchase our products.

Labconco provides a warranty on all parts and factory workmanship. The warranty

includes areas of defective material and workmanship, provided such defect results from

normal and proper use of the equipment.

The warranty for all Labconco products will expire one year from date of installation or

two years from date of shipment from Labconco, whichever is sooner, except the following:

• Purifier® Delta® Series Biological Safety Cabinets carry a three-year warranty from

date of installation or four years from date of shipment from Labconco, whichever is

sooner.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance

charges. In the event of a warranty claim, contact Labconco Corporation or the dealer who

sold you the product. If the cause is determined to be a manufacturing fault, the dealer or

Labconco Corporation will repair or replace all defective parts to restore the unit to

operation. Under no circumstances shall Labconco Corporation be liable for indirect,

consequential, or special damages of any kind. This statement may be altered by a specific

published amendment. No individual has authorization to alter the provisions of this

warranty policy or its amendments. Lamps and filters are not covered by this warranty

WARNING: The disposal and/or emission of substances used in connection with this

equipment may be governed by various federal, state or local regulations. All users of this

equipment are urged to become familiar with any regulations that apply in the user’s area

concerning the dumping of waste materials in or upon water, land or air and to comply with

such regulations.

15

Page 15

SHIPPING CLAIMS

If a shipment is received in visibly damaged condition, be certain to make a notation on

the delivering carrier’s receipt and have his agent confirm the damage on your receipt.

Otherwise, the damage claim may be refused.

If concealed damage or pilferage is discovered, notify the carrier immediately and retain

the entire shipment intact for inspection. Interstate Commerce Commission rules requires that

the claim be filed with the carrier within 15 days after delivery.

NOTE: Do not return goods. Goods returned without prior authorization will not be

accepted. Labconco Corporation and its dealers are not responsible for shipping

damage. Claims must be filed directly with the freight carrier by the recipient. If

authorization has been received to return this product, by accepting this approval, the

user assumes all responsibility and liability for biological and chemical

decontamination and cleansing. Labconco reserves the right to refuse delivery of any

products, which do not appear to have been properly cleaned and/or decontaminated

prior to return.

16

Page 16

CONTACTING LABCONCO

If you have any questions that are not addressed in this manual, or if you need technical

assistance, please contact Labconco Sales Information Department at 800-821-5525, and Service

Information at 800-522-7658 or 816-333-8811, between the hours of 7:00 a.m., and 6:00 p.m.,

Central Standard Time.

You can visit Labconco through the Internet at:

http://www.labconco.com

or

email: labconco@labconco.com

17

Loading...

Loading...