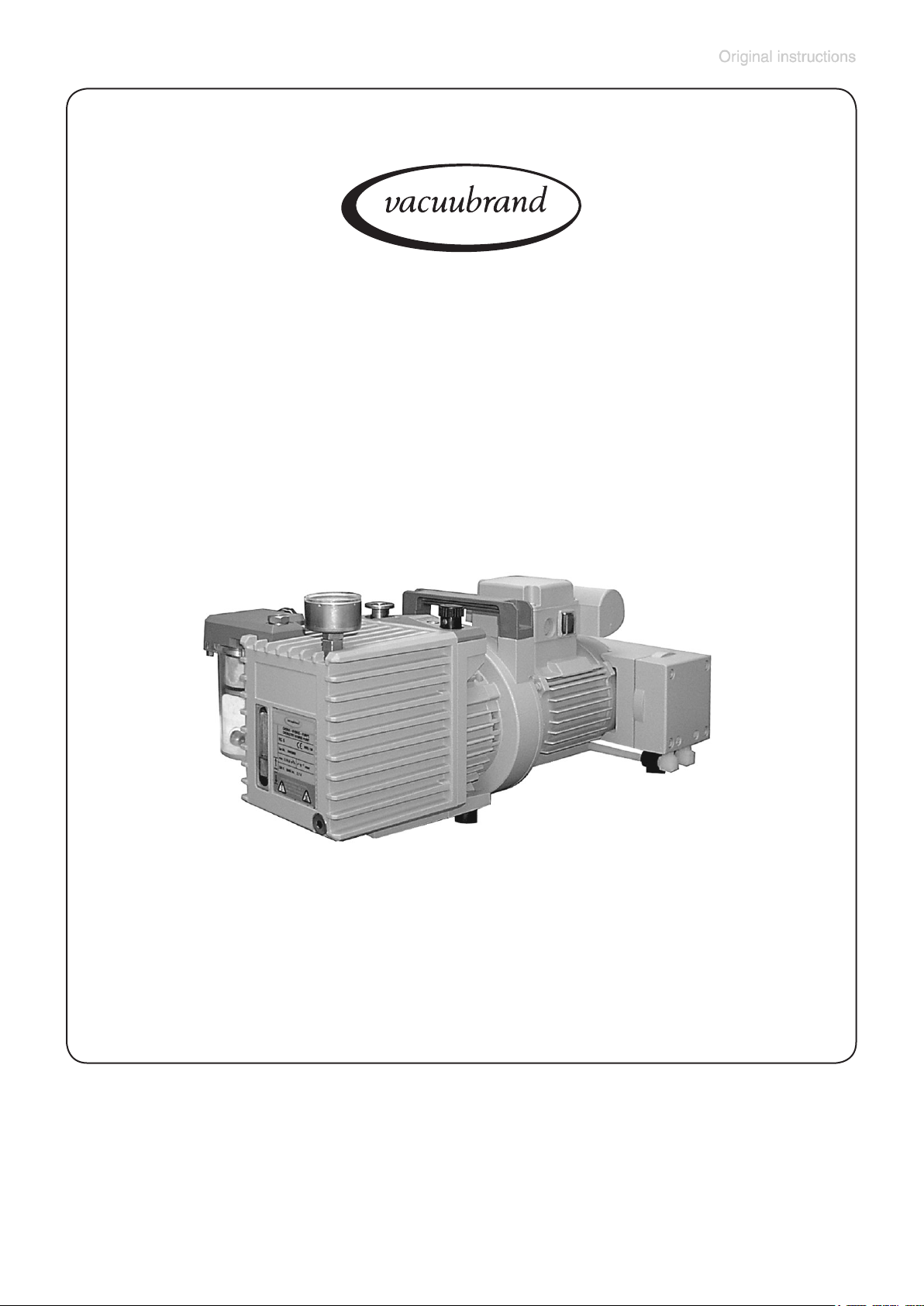

Page 1

page 1 of 56

Technology for Vacuum Systems

Instructions for use

RC 6

Chemistry-HYBRID-pump

Page 2

page 2 of 56

Dear customer,

Your VACUUBRAND pumps are designed to provide you with many years

of trouble-free service with optimal performance. Through our long experience in design, construction and operation of vacuum pumps, combined

with the latest developments in material and manufacturing technology,

we have accumulated a wealth of application and safety insights that we

want to share with you.

Please read these instructions for use before the initial operation of your

pump.

Our quality maxim is the ”zero fault principle”:

Every pump, before leaving our factory, is tested intensively, including an

endurance run of 60 hours. Any faults, even those which occur rarely, are

identied and can be eliminated immediately.

After completion of the endurance run, every pump is tested, and must

achieve specications before shipment.

We are committed to providing our customers only pumps that meet this

high quality standard.

While our pumps cannot eliminate all of your work, we design, manufacture and test them to ensure that they will be an effective and trouble-free

tool to assist you in that work.

Yours,

VACUUBRAND GMBH + CO KG

After sales service:

Contact your local dealer or call +49 9342 808-5500.

Trademark index:

VACUU•LAN

®

(US-Reg.No 3,704,401), VACUU•BUS®, VACUU•CONTROLTM,

chemistry-HYBRIDTM, Peltronic®, TURBO•MODETM, VARIO® (US-Reg.No

3,833,788), VARIO-SPTM, VACUUBRAND® (US-Reg.No 3,733,388) and also

the shown company logos are trademarks of VACUUBRAND GMBH +

CO KG in Germany and/or other countries.

Page 3

page 3 of 56

Contents

Safety information! ............................................................. 4

Important information! ......................................................................... 4

General information ............................................................................. 6

Intended use........................................................................................ 6

Setting up and installing the equipment .............................................. 7

Ambient conditions ............................................................................ 10

Operating conditions ..........................................................................11

Safety during operation ..................................................................... 12

Maintenance and repair..................................................................... 15

Technical data ................................................................... 18

Gas inlet temperatures ..................................................................... 19

Wetted parts ..................................................................................... 20

Abbreviations .................................................................................... 20

Pump parts ....................................................................................... 20

Use and operation ............................................................ 22

Installing a pump in a vacuum system .............................................. 22

During operation ................................................................................ 25

Important notes regarding the use of gas ballast .............................. 28

Operating the pump with condensate in the catchpots ..................... 29

Pumping chemically aggressive or toxic gases and vapors .............. 30

Shutdown .......................................................................................... 31

Oil change ......................................................................... 32

Oil change procedure ........................................................................ 33

Notes on choosing the appropriate oil for the application ................. 34

Accessories ...................................................................... 36

Troubleshooting ............................................................... 38

Replacing diaphragms and valves.................................. 41

Cleaning and inspecting the diaphragm pump heads ...................... 43

Replacing the diaphragm ................................................................. 45

Assembling the pump heads ............................................................ 47

Assembling the connecting hose ...................................................... 48

Checking the operability of the diaphragm pump ............................. 48

Replacing the lter element in the oil mist lter ................................ 49

Inspecting the safety pop valve ........................................................ 49

Notes on return to the factory ......................................... 50

Warranty ............................................................................ 53

Health and safety clearance form ................................... 54

EC Declaration of Conformity of the Machinery ............... 55

Page 4

page 4 of 56

Safety information!

Important information!

+ Keep this manual complete and accessible to per-

sonnel at all times!

+ Read this manual carefully before installing or op-

erating the equipment. Observe the instructions

contained in this manual.

+ Do not modify the equipment without authorization.

NOTICE

This manual is an integral part of the equipment described therein. It describes the safe and proper use

of the vacuum pump.

Make operating personnel aware of dangers arising

from the pump and the pumped substances.

VACUUBRAND disclaims any liability for inappropriate use of these pumps and for damage from failure

to follow instructions contained in this manual.

This manual is only to be used and distributed in its complete and original form. It is strictly the users’ responsibility

to check carefully the validity of this manual with respect

to his product.

Manual-no.: 997829 / 09/18/2012

The following signal word panels and safety

symbols are used throughout this manual:

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury and death.

Page 5

page 5 of 56

➨ DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

+ WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

• CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to per-

sonal injury.

Caution! Hot surface!

Disconnect equipment from AC power.

Formatting used in this manual:

Note: The signal word panels in all sections of this manual always refer

to all paragraphs of the same format (➨ / + / • / plain text) following each

signal word panel.

The document ”Safety information for vacuum equipment” is

part of this manual! Read the ”Safety information for vacuum

equipment” and observe the instructions contained therein!

Page 6

page 6 of 56

General information

NOTICE

Remove all packing material from the packing box. Remove the product from its packing-box and retain all packaging until the equipment is inspected and tested. Remove the protective caps from the inlet and outlet ports

and retain for future use. Inspect the equipment promptly

and carefully.

If the equipment is damaged, notify the supplier and the

carrier in writing within three days. Retain all packing material for inspection. State the item number of the product

together with the order number and the supplier’s invoice

number. Failure to check and give notice of damage will

void any and all warranty claims for those deciencies.

Replace the protective caps, if the equipment is not used

immediately. Store the equipment in dry and non-corrosive

conditions (see also “Technical data”, pg. 18).

+ Do not use any damaged equipment.

• Check the pump‘s oil level.

• The pump is delivered without oil lling. Fill with oil

before operating the pump, see section “Oil change”,

pg. 32.

• Aging of the oil (as indicated by darker color compared

to new oil, strange odor of the oil, particles in the oil, or

contamination) necessitates an oil change.

• Use the handle when moving the pump.

Intended use

+ Do not use the pump or any system parts on humans

or animals.

+ Prevent any part of the human body from coming into

contact with vacuum.

+ Ensure that the individual components are only con-

nected, combined and operated according to their de-

Page 7

page 7 of 56

sign and as indicated in the instructions for use.

+ Comply with all notes on correct vacuum and electri-

cal connections; see section “Use and operation”, pg.

22.

+ Do not use the pump to generate pressure.

+ The pumps are designed for ambient temperatures

during operation between +54°F and +104°F (+12°C

and +40°C). Periodically check maximum temperatures if installing the pump in a cabinet or a housing.

Make sure ventilation is adequate to maintain recommended operating temperature. Install an external automatic ventilation system if necessary. If pumping hot

NOTICE

process gases, make sure that the maximum permitted

gas inlet temperature is not exceeded. The maximum

permitted gas inlet temperature depends on several

parameters like inlet pressure and ambient temperature (see “Technical data”, pg. 18).

+ Do not aspirate particles and dust.

+ Do not pump liquids.

• Ensure that the pump is chemically resistant to the

pumped substances prior to operation.

Use the equipment only as intended, that is, for generation of vacuum in vessels designed for that purpose. Any

other use will automatically invalidate all warranty and liability claims. Remain aware of safety and risks.

Setting up and installing the equipment

➨ Equipment must be connected only to a suitable elec-

trical supply and a suitable ground point. As such,

the plug must be plugged into an outlet that is properly

grounded. Failure to connect the motor to ground may

result in deadly electrical shock.

The supply cable may be tted with a molded Euro-

Page 8

page 8 of 56

pean IEC plug or a plug suitable for your local electrical

supply. The cable contains wires color coded as follows: green or green and yellow: ground; blue or white:

neutral; brown or black: hot.

+ Due to the high compression ratio, the pump may gen-

erate overpressure at the outlet. Check pressure compatibility with system components (e.g., exhaust pipeline or exhaust valve) at the outlet.

+ Do not permit any uncontrolled pressurizing. Make

sure that the exhaust tubing cannot become blocked. If

there is an exhaust isolation valve, make sure that you

cannot operate the equipment with the valve closed to

avoid a risk of bursting!

+ Always provide a free and pressureless exhaust outlet

to avoid damage to the pump and a risk of bursting.

+ Keep the electrical power cord away from heated sur-

faces.

• Provide a rm, level platform for the equipment. Check

that the system which you are going to evacuate is

mechanically stable. Check that all ttings are secure.

Ensure a stable position of the pump without any mechanical contact other than the pump feet.

• Comply with maximum permissible pressures at in-

let and outlet and with maximum permissible pres-

sure differences between inlet and outlet. See section

“Technical data”, pg. 18. Do not operate the pump

with overpressure at the inlet.

• Avoid overpressure of more than 17.5 psi absolute (1.2

bar absolute) in the event that gas or inert gas is connected to the pump, to the gas ballast or to a venting

valve.

• Note: Flexible elements will shrink when evacuated.

• Connect hoses gas tight at inlet and outlet of the pump.

• Ensure that no foreign objects can be drawn into the

pump.

Page 9

page 9 of 56

• Check the power source and the pump’s rating plate

to be sure that the power source and the equipment

match in voltage, phase, and frequency.

• Use only oil of the recommended type. Other oils or operating uids may cause damage of the pump or dan-

ger.

Use special oils (see “Oil change”, pg. 32) for the

rotary vane pump, if, e.g.,

- acid vapors are pumped.

- extremely high aging stability is required.

- oxygen or other strong oxidizing agents are pumped.

NOTICE

• Take adequate precautions when handling pump uids,

lubricants, and solvents. Use appropriate protective

clothing, safety goggles and protective gloves to avoid

excessive contact with the skin and possible skin irritations (including dermatitis). Do not inhale or swallow!

Ensure that the pump location is well ventilated and

that possible toxic effects of certain vapors are avoided.

Maintain adequate levels of hygiene and cleanliness.

• Comply with all relevant statutory requirements and

regulations concerning the handling, storage and disposal of oil.

Note: Do not allow oils to enter the drainage system

or other bodies of water. Spillage can cause accidents

(slip hazard)!

Keep a minimum distance of 8 in (20 cm) between the

cooling fan and surrounding items (e.g., housing, walls,

etc.). Check fan regularly for dust/dirt. Clean fan guard if

necessary to avoid a reduction of ventilation.

The On/Off switch is located at the side of the terminal

box.

Use only hoses at the inlet and outlet of the pump with

an inner diameter at least as large as the diameter of the

pump’s connections (to avoid overpressure at the outlet,

Page 10

page 10 of 56

and reduction of pumping speed at the inlet).

Allow the equipment to equilibrate to ambient temperature

if you bring it from cold environment into a room prior to

operation. Notice if there is water condensation on cold

surfaces.

Comply with all applicable and relevant safety require-

ments (regulations and guidelines). Implement the required actions and adopt suitable safety measures.

Ambient conditions

➨ Do not reach for this product if it has fallen into liquid.

There is a risk of deadly electrical shock. Unplug the

system immediately.

+ Do not use this product in an area where it can fall or

be pulled into water or other liquids.

+ Pay attention to the permissible maximum ambient

and gas inlet temperatures (see”Technical data”, pg.

18).

• Adopt suitable measures in case of differences from

recommended conditions, e.g., using the equipment

outdoors, installation in altitudes of more than 6500 ft

(2000 m) above mean sea level, conductive pollution or

external condensation on the pump.

NOTICE

• Do not operate this product near ames.

To the best of our knowledge the equipment is in compliance with the requirements of the applicable EC-directives and harmonized standards (see ”Declaration of Conformity”) with regard to design, type and model. Directive

EN 61010-1 gives in detail the conditions under which the

equipment can be operated safely (see also IP degree of

protection, “Technical data”, pg. 18).

Page 11

page 11 of 56

Operating conditions

➨ These pumps are not approved for operation in po-

tentially explosive atmospheres. Do not operate the

pumps in potentially explosive atmospheres.

➨ These pumps are not approved for the pumping of po-

tentially explosive atmospheres. Do not pump poten-

tially explosive atmospheres.

➨ The pumps are not suitable to pump any of the sub-

stances listed below.

Do not pump:

- unstable substances

- substances which react explosively under impact

(mechanical stress) without air

- substances which react explosively when being ex-

posed to elevated temperatures without air,

- self inammable substances,

- substances which are inammable without air

- explosive substances.

➨ The pumps are not approved for operation below

ground. Do not operate the pump below ground.

+ The pumps are not suitable for pumping dust.

Do not pump dust.

• Do not pump substances which may form deposits in-

side the pump. The pumps are not suitable for pumping

substances which may form deposits inside the pump.

Deposits and condensate in the pump may lead to increased temperatures even to the point of exceeding

the maximum permitted temperatures. Deposits may

cause seizing of the pump unit.

• Check the inlet and outlet of the pump and its oil condition, if there is a danger of forming deposits inside the

pump, e.g., in the pump unit of the rotary vane pump or

in the pump chamber of the diaphragm pump. Inspect

the pump regularly and clean if necessary.

Page 12

page 12 of 56

• Install a cold trap in front of the pump if pumping aggressive or corrosive gases or vapors.

• Consider interactions and chemical reactions of

the pumped media. Ensure that the materials of the

pump’s wetted parts are compatible with the pumped

substances, see section “Technical data”, pg. 18.

When changing the substances pumped, we recom-

mend purging the pump with air or inert gas prior to

changing the pumped media. Purging the pump will

pump out residues and it will reduce the possibility of

reactions of the pumped substances with each other

and with the pump’s materials.

Safety during operation

➨ Adopt suitable measures to prevent the release of dan-

gerous, toxic, explosive, corrosive, noxious or polluting

uids, vapors and gases. To prevent any emission of

such substances from the pump outlet, install an appropriate collecting and disposal system and take protective action for pump and environment.

➨ You must take suitable precautions to prevent any for-

mation of explosive mixtures in the expansion chamber, in the oil reservoir, in the pump chamber of the diaphragm pump, or at the outlet of the pump. In case, e.g.,

of a diaphragm failure, mechanically generated sparks,

hot surfaces or static electricity may ignite these mixtures. Use inert gas for gas ballast or venting, if necessary.

➨ Drain appropriately or otherwise remove any potential-

ly explosive mixtures at the outlet of the pump, or dilute

them with inert gas to non-explosive concentrations.

➨ Never operate this pump if it has a damaged cord or

plug.

Page 13

page 13 of 56

+ If the pump is not working properly, has been dropped

or has fallen into water, contact your pump service provider.

+ Prevent any part of the human body from coming into

contact with vacuum.

+ Never aspirate liquids or dust into the pump.

+ Make sure that the exhaust tubing cannot become

blocked. Do not exceed an pressure of 16 psi (1.1 bar)

in the exhaust tubing.

+ Comply with applicable regulations when disposing of

chemicals. Take into consideration that chemicals may

be contaminated. Take adequate precautions to protect people from the effects of dangerous substances

(chemicals, oil mist, thermal decomposition products of

uoroelastomers). Use appropriate protective clothing

and safety goggles.

+ Even if the pumped medium is only air or a pure gas,

the discharge from rotary vane pumps will contain small

quantities of oil vapor and petroleum fractions. These

substances are particularly contaminating in closed

spaces or in case of insufcient ventilation.

The discharge from the pump invariably contains the

pumped gases or vapors! Connect a hose to the pump

outlet to dispose of the exhaust gases.

Prevent any dangerous reactions with oil or oil vapors

and the formation of impermissible or dangerous emissions.

+ Use only original manufacturer’s spare parts and

accessories. Otherwise the safety and performance of

the equipment, as well as the electromagnetic compatibility of the equipment might be reduced.

The CE mark may be voided if not using original manu-

facturer’s spare parts.

+ Failure of the pump (e.g., due to power interruption),

failure of connected components or of parts of the supply, or a change of parameters must not be allowed to

Page 14

page 14 of 56

lead to a dangerous situation under any circumstances.

In case of a leak in the manifold or at the shaft seal of

the rotary vane pump, or in case of a diaphragm crack

of the diaphragm pump, pumped substances might be

released into the environment or into the pump housing

or motor.

Especially comply with notes on use and operation and

maintenance.

+ The residual leak rate of the equipment might render

possible an exchange of gas, albeit extremely slight,

between the environment and the vacuum system.

Adopt suitable measures to prevent contamination of

the pumped substances or the environment.

• Ensure that no parts of your clothing, hair or ngers

can be caught or drawn in at the inlet of the pump. Nev-

er insert ngers or drop any other object into the inlet or

outlet.

• Pumping at high inlet pressure may lead to overpressure at the gas ballast valve. Pumped gases or condensate might be expelled if the valve is open. If an

inert gas supply is connected to the gas ballast, ensure

that its inlet pipeline is not contaminated.

• Check oil level of the rotary vane pump (through sight

glass) every time before starting the pump.

• Check the pump’s oil level and the condition of the oil

on a regular basis.

• Pay attention to the safety symbol ”hot surfaces” on

the equipment. Hot parts may cause burns if touched.

Adopt suitable measures to prevent any danger arising

from hot surfaces or electric sparks. Ensure that hot

surfaces of the pump do not cause burns. Provide a

suitable contact guard if necessary.

• A power failure or switching off the pump may cause

accidental ventilation of the pump or the vacuum sys-

Page 15

page 15 of 56

tem, if the manual gas ballast valve of the rotary vane

pump is open. If this constitutes a potential source of

danger, take appropriate safety measures, e.g., install

a solenoid operated gas ballast valve.

NOTICE

Do not start the pump if the pressure difference between

inlet and outlet exceeds 16 psi (1.1 bar) at maximum.

Prevent the backpressure of gases and the backow of

condensates at the outlet.

Important notes on working with condensable vapors:

Allow the pump to attain its operating temperature before

pumping condensable vapors. Keep the vapor inlet pressure below the permitted maximum (see ”Technical data”,

pg. 18).

Open the gas ballast valve in case of pumping signicant

amounts of vapor.

Provide appropriate protective measures to allow for the

possibility of failure and malfunction. The protective measures must also allow for the requirements of the respective application.

In case of overload, the motor is shut down by a self-hold

thermal cutout in the winding.

Note: Only manual reset is possible. Switch off the pump

and disconnect from the power source. Identify and elimi-

nate the cause of failure. Wait approx. ve minutes before

restarting the pump.

Avoid high heat supply (e.g., due to hot process gases).

See “Technical data”, pg. 18, for maximum permitted

gas and ambient temperatures.

Maintenance and repair

NOTICE

In order to comply with laws (occupational, health and

safety regulations, safety at work law and regulations for

Page 16

page 16 of 56

environmental protection) vacuum pumps, components

and measuring instruments can only be returned when

certain procedures (see section “Notes on return to the

factory”, pg. 50) are followed.

Take advantage of our service seminars, which put special

focus on the maintenance and repair of vacuum pumps.

For details and for the online ”Instructions for repair” manual see www.vacuubrand.com.

Under conditions of normal wear, the lifetime of the diaphragms and valves is > 10000 operating hours. Bearings

have a typical durability of 40000 h. Motor capacitors have a

typical durability in the range of 10000 to 40000 h depending

strongly on operation conditions, including ambient temperature, humidity or load.

➨ Ensure that the pump cannot be operated acciden-

tally. Never operate the pump if covers or other

parts of the pump are disassembled.

➨ Switch off the pump. Disconnect the electrical pow-

er cord and wait two minutes before starting mainte-

nance to allow the capacitors to discharge.

➨ Note: The pump may be contaminated with process

chemicals, which have been pumped during operation.

Ensure that the pump is completely decontaminated

before maintenance commences. Avoid the release of

pollutants.

+ Take adequate precautions to protect people from the

effects (e.g., in case of inhalation or skin contact) of

dangerous substances if contamination has occurred.

Use appropriate protective clothing, safety goggles and

protective gloves.

+ Wear parts have to be replaced regularly.

+ Never operate a defective or damaged pump.

Page 17

page 17 of 56

+ Check every motor capacitor regularly by measuring

its capacity and estimating its time in operation. Replace old capacitors early enough to prevent a failure in

operation. If an old motor capacitor fails, the capacitor

may get hot. It may even melt or emit a ame, which

could be dangerous for persons and equipment in

the vicinity. The capacitors have to be replaced by an

electrician.

+ Vent the pump before starting maintenance. Isolate the

pump and other components from the vacuum system.

Allow sufcient cooling of the pump. Drain condensate,

if applicable.

NOTICE

Ensure that maintenance is done only by suitably trained

and supervised technicians. Ensure that the maintenance

technician is familiar with the safety procedures which relate to the products processed by the pumping system.

Page 18

page 18 of 56

Technical data

Type RC 6

Maximum pumping speed

50/60 Hz (ISO 21360)

Ultimate partial pressure

without gas ballast

a.)

Ultimate total pressure

without gas ballast

b.)

Ultimate total pressure

with gas ballast

Water vapor tolerance

c.)

Oil capacity min./max.

Total pressure in oil reservoir

Oil temperature

e.)

(under typical

operating conditions)

d.)

cfm

(m3/h)

Torr

(mbar)

Torr

(mbar)

Torr

(mbar)

Torr

(mbar)

quarts

(ml)

Torr

(mbar)

°F

(°C)

3.5 / 4.1

(5.9 / 6.9)

-4

3*10

(4*10-4)

1.5*10

-3

(2*10-3)

0.75*10

-2

(1*10-2)

>>30

(>>40)

0.36 / 0.56

(340 / 530)

13.5

(18)

140

(60)

Recommended oil VACUUBRAND B-oil

Maximum permissible inlet / outlet

pressure (absolute)

Maximum permissible pressure

difference between inlet and outlet

Maximum permissible pressure

(absolute) at gas ballast valve

Permissible ambient temperature

storage / operation

psi

(bar)

psi

(bar)

psi

(bar)

°F

(°C)

16

(1.1)

16

(1.1)

17.5

(1.2)

14 to 140 / 54 to 104

(-10 to +60 / +12 to +40)

Permissible relative atmospheric

moisture during operation

% 30 to 85

(no condensation)

Rated motor power

hp

(kW)

0.5

(0.37)

No-load speed 50/60 Hz rpm 1500 / 1800

Maximum permissible range of

supply voltage

Attention: Observe specications

100-120 V~ +5%/-10% 50/60 Hz

230 V~ ±10% 50/60 Hz

of rating plate!

Motor protection

self-hold thermal cutout,

manual reset

Page 19

page 19 of 56

Type RC 6

Rated current during operation

100-120 V~ 50/60 Hz

230 V~ 50/60 Hz

f.)

at:

A

A

5.7 / 5.1

2.7 / 2.6

Degree of protection IEC 529 IP 40

A-weighted emission sound

pressure level

(uncertainty K

g.)

: 3 dB(A))

pA

dB(A) 50

Inlet small ange KF DN 16

Outlet

Dimensions L x W x H approx.

Weight with oil lling approx.

a.) Partial pressure of permanent gases measured at pump inlet.

b.) The total pressure is higher than the partial pressure because the former includes the vapor

pressure of the pump oil and other condensable vapors (e.g., water); the condition of the oil

(cleanliness, content of hydrocarbons with higher partial pressures) is crucial for this value.

c.) The maximum inlet pressure for water vapor, or rather the maximum inlet pressure for vapor,

cannot be specied in accordance with ISO 21360-2 because it cannot be determined for the

HYBRID pump in accordance with this standard. Because the diaphragm pump reduces the

pressure in the oil-sealed part of the RC 6, however, the water vapor tolerance is considerably

higher than that of a conventional oil-sealed rotary-vane pump.

d.) With inlet sealed and without gas ballast.

e.) Oil temperature and pressure in the oil reservoir are the relevant parameters for maximum

vapor inlet pressure and chemical resistance.

f.) During the start-up period of the pump (rst 6 minutes after switching-on), the current draw

may be elevated to twice the nominal current draw during normal running conditions.

g.) Measurement according to EN ISO 2151:2004 and EN ISO 3744:1995 at 230V/50Hz and

ultimate vacuum with exhaust tube at outlet.

(mm)

lbs.

(kg)

hose nozzle for tubing I.D. 3/8”

(hose nozzle DN 10 mm)

in

20.1 x 12.0 x 9.1

(510 x 305 x 230)

53.4

(24.2)

Gas inlet temperatures

Operating condition Inlet pressure

Continuous operation

Continuous operation

Short-time

(< 5 minutes)

> 75 Torr (100 mbar)

(high gas load)

< 75 Torr (100 mbar)

(low gas load)

< 75 Torr (100 mbar)

(low gas load)

We reserve the right for technical modication without prior notice!

Permitted range of gas

temperatures at inlet

➨ 50 °F to 104 °F

(+10°C to +40°C)

➨ 32 °F to 140 °F

(0°C to +60°C)

➨ 14 °F to 176 °F

(-10°C to +80°C)

Page 20

page 20 of 56

Wetted parts

Components Wetted materials

Metal parts

Plastic materials

aluminum alloy, stainless steel, grey cast iron, steel

(partly plasma nitrated), nickel-plated, zinc-plated

epoxy resin, FFKM, FPM, NBR, PBT, PEEK, PFA,

PPS glass-ber reinforced, PTFE, PVC

The pump RC 6 doesn’t contain any nonferrous heavy metal.

Abbreviations

FFKM: Peruoro elastomer

FPM: Fluoroelastomer

NBR: Nitrile butadiene rubber

PBT: Polybutylene terephthalate

PEEK: Polyether ether ketone

PFA: Peruoroalkoxy

PPS: Polyphenylene sulde

PTFE: Polytetrauoroethylene

PVC: Polyvinyl chloride

Pump parts

Position Component

1 Inlet

2 Outlet

3 Manual gas ballast valve

4 ON/OFF switch

5 Power connection

6 Handle

7 Rating plate with min. / max. mark for oil level

8 Oil inlet

9 Oil outlet

10 Sight glass for oil level

11 Manometer for oil reservoir pressure control

12 Oil mist lter

Page 21

page 21 of 56

RC 6

12

10

11

1

6

5

8

7

3

4

9

2

We reserve the right for technical modication without prior notice!

Page 22

page 22 of 56

Use and operation

Method of operation:

The RC 6 is a four-stage vacuum pump consisting of an oil-sealed, twostage rotary vane pump with a series-connected two-stage diaphragm

pump. The two units are mounted on a common shaft and are connected

directly to the drive motor. The dry-running compressor-type diaphragm

pump evacuates the headspace of the oil reservoir of the rotary vane

pump, thus considerably increasing the latter’s maximum vapor inlet

pressure and chemical resistance.

With the gas ballast valve closed, the rotary vane pump shuts off vacuum

tight. This, in turn, prolongs the intervals between oil changes and improves corrosion resistance. The oil system incorporates an oil pump;

this forced-lubrication system ensures an adequate supply of oil to the

pump unit even at high inlet pressures. A mechanical retaining valve in

the oil system prevents oil suck-back into the vacuum system.

The oil mist lter of the rotary vane pump removes 99 % of the oil mist. If

an exhaust waste vapor condenser is tted (available on request), the va-

pors handled by the pump can be condensed to a large extent and either

be recycled or disposed of in accordance with regulations.

Installing a pump in a vacuum system

➨ If dangerous or polluting uids, oil mist, or toxic or nox-

ious gases could be released at the outlet, install an

appropriate system (e.g., oil mist separator, see “Accessories”, pg. 36) to catch and dispose of those uids or gases.

+ Connect a gas-tight exhaust line at the pump outlet if

necessary. Always vent exhaust gases appropriately

(e.g., into a fume hood). If needed, install an exhaust

waste vapor condenser (see ”Accessories”, pg. 36).

+ Never block the gas outlet. The exhaust line must al-

Page 23

page 23 of 56

ways be free of obstructions (no back pressure) to ensure an unimpeded discharge of gas. The cross-section of the outlet tubing must be at least the size of the

pump’s exhaust connection.

+ Failure to connect the inlet and outlet lines correctly

will cause overpressure and risk of bursting! The outlet

(hose nozzle) is marked ”EX”.

+ Particles and dust must not be aspirated. If necessary,

you must install appropriate lters. You must ensure

their suitability concerning gas ow, chemical resis-

tance and resistance to clogging prior to use.

+ Make sure ventilation is adequate, especially if the pump

is installed in an enclosure, or if the ambient temperature

is elevated. Provide external ventilation, if necessary.

• Reduce the transmission of vibration. Prevent mechanical load due to rigid pipelines. Insert elastic hoses or

exible elements as couplings between the pump and

rigid pipes.

Note: Flexible elements will compress or atten when

evacuated if not designed for use under vacuum.

• Hose connections at the pump inlet must always be

gas tight.

• Install a cold trap in front of the pump, if pumping aggressive or corrosive gases or vapors.

• A power failure may cause accidental ventilation of the

pump or the vacuum system, if the manual gas ballast

valve is open. If this constitutes a potential source of

danger, take appropriate safety measures, e.g., install

a solenoid operated gas ballast valve (see “Accessories”, pg. 36).

• The pump is supplied dry (i.e., without oil lling) in order

to ensure that oil cannot make its way from the rotary

vane pump into the housing of the oil mist lter. A can

containing 0.5 liter (0.53 quarts) of rotary-pump oil is

supplied with the pump. Before starting the pump for

Page 24

page 24 of 56

the rst time, remove the manometer and its adapter

(open end wrench width 17 mm) and pour in the oil as

described below.

Note: Because new oil contains gas, a considerable

degree of foaming can occur during operation with new

oil, and oil could penetrate the oil separator.

- Pour only approx. 350 ml (0.37 quarts) of oil into the

pump (bringing oil level to ”min.” mark, approx.).

- Reinstall the manometer (carefully re-seating the O-

ring) and with inlet line closed, operate the pump for

approx. 5-10 minutes.

- Add approx. 100 ml (0.11 quarts) of oil. As a rule, it

is not necessary to use all of the oil supplied. Do not

overll!

NOTICE

• Check the power source and the pump’s rating plate

to be sure that the power source and the equipment

match in voltage, phase, and frequency.

Keep a distance of minimum 8 in (20 cm) between fan and

adjacent equipment or casework.

Use connecting hoses with large diameter and keep them

as short as possible to avoid ow losses. Locate the pump

as closely as possible to the application. Use only hoses

at the inlet and outlet of the pump with an inner diameter

at least as large as the diameter of the pump’s connections.

Always install outlet tubing descending from the pump to

avoid backow of condensate towards the pump.

Use a suitable valve (see”Accessories”, pg. 36) to isolate the pump from the vacuum application. This is to allow

the pump to warm up before pumping condensable vapors

and to clean the pump after use before it is switched off.

When assembling, ensure vacuum-tightness. After assembly, check the whole system for leaks.

Secure hose connections at the pump appropriately, e.g.,

Page 25

page 25 of 56

with hose clamps, to protect against accidental detachment.

Note: The pump must only be operated in a horizontal

position. When transporting a pump containing oil, take

great care not to tilt the pump to an angle that would allow

oil to make its way into the lter element.

During operation

➨ Vent and dispose of potentially dangerous gases or

vapors at the outlet of the pump appropriately.

+ Due to the high compression ratio, the pump might gen-

erate overpressure at the outlet. Check pressure compatibility with system components (e.g., exhaust tubing

or exhaust valve) at the outlet. Ensure that the pump

outlet is neither blocked nor restricted.

+ Maximum ambient temperature: 104 °F (40 °C)

Check the maximum temperatures, if installing the

pump in a cabinet or a housing. Make sure ventilation

is adequate, especially if the ambient temperature is

elevated.

• If the pump is installed at an altitude of more than 6500

ft (2000 m) above mean sea level, check compatibility

with applicable safety requirements, and adopt suitable

measures. There is a risk of the motor overheating due

to insufcient cooling.

• Check compatibility with the maximally permitted

pressures at inlet and outlet and the maximum pressure difference between inlet and outlet ports.

• Check the oil level of the rotary vane pump every time

before starting the pump, however at least once a week.

Check the oil level more frequently if high amounts of

gas or vapor are pumped.

Page 26

page 26 of 56

• If pumping aggressive, corrosive or otherwise dangerous gases and vapors, take appropriate measures to

protect personnel, pump, and environment. Use appropriate equipment such as cold trap, separator, oil sepa-

rator, full ow oil lter, shut-off valve, or exhaust waste

vapor condenser (see “Accessories”, pg. 36) as well

as special oil.

NOTICE

The ambient temperature should be at least 54°F (12

°C). Otherwise the pump may not start because of the

high oil viscosity at low temperature.

Pumping down can be started at any pressure at the inlet

below atmospheric pressure.

Do not start the pump if the pressure at the outlet port

exceeds 16.0 psi (1.1 bar) absolute.

Continuous operation is possible at any pressure below

atmospheric pressure.

Oil consumption will increase at inlet pressures above 75

Torr (100 mbar). Check oil level more frequently.

Prevent internal condensation, transfer of liquids or dust.

The pump unit as well as the diaphragms and valves will

be damaged if liquids are pumped in signicant amounts.

Check the pump regularly for external soiling and deposits. Clean the pump if necessary to avoid an increase of

the pump’s operating temperature.

In case of overload, the motor is shut down by a self-hold

thermal circuit breaker in the winding.

Note: Only a manual reset is possible. Switch off the

pump and disconnect the electrical power cord. Identify

and eliminate the cause of failure. Wait approximately ve

minutes before restarting the pump.

Avoid high heat supply (e.g., due to hot process gases).

See “Technical data”, pg. 18, for maximum permitted

gas and ambient temperatures.

Page 27

page 27 of 56

A warm up period (approximately 30 min.) is required to

ensure that the rated ultimate vacuum and pumping speed

as well as the full vapor pumping rate and chemical resistance of the pump are attained. To warm up the pump

effectively before connecting to the vacuum application,

install a shut-off valve (see ”Accessories”, pg. 36).

The attainable ultimate vacuum is limited by the properties

of the vacuum vessel (leak-tightness, cleanliness and degassing of the inner surfaces), degassing of substances

used and the condition of the pump oil (cleanliness, content of hydrocarbons with higher partial pressures).

Use the manometer monitoring the pressure in the oil

reservoir of the HYBRID pump to check the operability of

the diaphragm pump. If during the process the pressure

inside the oil reservoir should rise signicantly (manometer needle clearly in the red zone), it is necessary to take

appropriate measures to reduce the inlet pressure.

For the HYBRID principle to work it is necessary to

prevent the pumped vapors from condensing inside

the oil reservoir. Therefore the pressure inside the

oil reservoir has to be lower than the vapor pressure

of the pumped media at the oil’s temperature (140°F

(60°C)). If necessary, the volume of pumped vapors

has to be reduced or a cold trap has to be installed.

If no improvement is achieved even with the vacuum

chamber being absolutely leak tight, this points to a potential failure of the diaphragm pump, e.g., a diaphragm

crack. A more accurate check of the pressure inside the oil

reservoir is possible with a more precise manometer, e.g.,

a DVR 2 digital vacuum gauge. If a pressure higher than

19 Torr (25 mbar) is measured with inlet port and gas ballast valve closed, check the diaphragm pump and replace

the diaphragms if necessary.

Any drop in the diaphragm pump’s pumping speed produces a pressure increase in the oil reservoir. Although

this does not have a direct effect on the pumping speed

and on the ultimate vacuum attainable by the HYBRID

pump, it does have a considerable effect on the aging of

the oil and the HYBRID pump’s chemical resistance.

Page 28

page 28 of 56

All bearings are encapsulated and are lled with long-life

lubricant. Under normal operating conditions, the drive

system is maintenance free. The valves and diaphragms

are wear parts. Aging of the oil of the rotary vane pump

necessitates oil changes.

Important notes regarding the use of gas ballast

Gas ballast is a continuous purge to keep the pump’s interior as clean as possible and to reduce the possibility of

condensation inside the pump.

NOTICE

➨ Air and pumped media might react inside the pump or

at the outlet of the pump and form hazardous or explosive mixtures, when you use air rather than inert gas

for the gas ballast. This constitutes a risk of signicant

damage to equipment and/or facilities, a risk of personal injury or even loss of life.

+ Make sure that air/gas intake through the gas ballast

valve can never lead to hazardous, explosive or otherwise dangerous mixtures. If in doubt, use inert gas.

To reduce condensation in the pump, do not pump vapor

before the pump has reached its operating temperature.

Open the gas ballast valve when pumping condensable

vapors.

gas ballast

(open)

For condensable vapors (water vapor, sol-

vents, etc.):

- Let the pump run with gas ballast to reduce

condensation of pumped substances (water

vapor, solvents, ....) in the pump or to de-

contaminate the pump oil from volatile substances.

- With gas ballast valve open, the ultimate vacuum will

be reduced.

Page 29

page 29 of 56

- Use inert gas for gas ballast to avoid the formation of

explosive mixtures.

- To open and to close the gas ballast valve turn the gas

ballast valve cap. The manual gas ballast valve is open

if the arrow on the gas ballast cap is pointing towards

the inlet of the pump respectively towards the labelling

”Gasballast”.

- Close the manual gas ballast valve by turning the cap

180°.

Operate the pump without gas ballast only in case of

a clean system or when there are no condensable vapors.

NOTICE

Do not pump vapors until the pump has reached its operating temperature. Install an in-line valve in the inlet line

and open it only approx. 30 minutes after the pump has

been started.

Check the maximum vapor inlet pressure. The pump can

operate continuously at any pressure lower than the maximum specied inlet pressure for vapor. Avoid sudden vapor surges when evacuating commences (large inner surfaces, large-volume vacuum vessel).

Use a ow-control valve in the inlet line and open the valve

gradually.

Operating the pump with condensate in the catchpots

NOTICE

Observe the condensate levels in the catchpots of the sep-

arator at the inlet and of the oil mist lter. The condensate

level in an optional separator at the inlet must always be

kept below the bottom of the separator tube. The conden-

sate level in the oil mist lter must always be kept below

the bottom edge of the lter.

Drain condensate in time. To drain condensate, switch off

and vent the pump. Then open drain screw of the catchpot. Condensate of the inlet catchpot (see ”Accessories”,

Page 30

page 30 of 56

pg. 36) in particular must not be drained while pump is

operating.

In case of a clogged lter, oil mist might be visible in the

oil lter housing, or the lter might be discolored or exhibit

deposits on the inside. If the lter element is clogged, disassemble the oil mist lter and replace the lter element.

Under certain circumstances, clogged lter elements can

be cleaned using suitable solvents. However, it is safer to

use a new lter element (see section ”Replacing the lter

element in the oil mist lter”, pg. 49).

Do not reuse separated oil if it is contaminated or discolored.

+ Important: Comply with regulations when disposing

of solvents/condensates. Recycle if possible; purify if

contaminated.

Pumping chemically aggressive or toxic gases and vapors

➨ Avoid explosive conditions when compressing explo-

sible and ammable substances/mixtures. In such instances, use inert gas for gas ballast.

Attention: The gas ballast of the diaphragm pump is

permanently connected to the system.

+ Implement special protective measures to protect per-

NOTICE

sonnel, pump, and environment.

• Install a cold trap (see ”Accessories”, pg. 36), if the

thermodynamic conditions of the application are such

that vapors could condense in the rotary vane pump.

Wait until the pump has reached its operating tempera-

ture before connecting it to the vacuum system.

Before switching off, allow the pump to run for a few min-

utes, initially with the rotary vane pump‘s gas ballast valve

Page 31

page 31 of 56

open and then with the gas ballast valve closed, after the

pump has been isolated from the vacuum application.

Prevent internal condensation, transfer of liquids or dust.

The pump requires regular inspection and maintenance.

Shutdown

NOTICE

Has the pump been exposed to condensate?

- Allow the pump to continue to run for a few minutes

with the rotary vane pump’s gas ballast valve open before switching off.

Long-term:

- Separate the pump from the application.

- Drain condensates (catchpots of the separator at the

inlet and of the oil mist lter).

- Flush the pump with dry nitrogen.

- Carry out oil change (see “Oil change”, pg. 32).

- Fill the pump completely with new oil (to above the

”max.” mark!).

Attention: Before restarting the pump, drain oil to the

maximum oil level (”max.” mark)!

- Close the manual gas ballast valve.

- Close inlet and outlet ports (e.g., with transport caps or

blind anges).

- Store the pump under dry conditions.

- Carry out oil change and maintenance prior to use if the

pump has been stored for longer than one year.

Note: When transporting a pump containing oil, take great

care not to tilt the pump to an angle that would allow oil to

make its way into the lter element. Drain oil if necessary.

Page 32

Oil change

➨ Never operate the pump if parts of the pump are dis-

assembled. Ensure that the pump cannot be operated

accidentally.

➨ Before starting maintenance, isolate the pump from its

application and disconnect the electrical power cord.

➨ Note: The pump or the pump oil might be contami-

nated with dangerous or corrosive process chemicals

that have been pumped during operation. Adopt suitable decontamination measures if necessary. Take adequate precautions to protect people from the effects of

page 32 of 56

dangerous substances if contamination has occurred.

Ensure that the maintenance technician is familiar with

the safety procedures which relate to the products processed by the pumping system.

+ Use appropriate protective clothing, safety goggles and

protective gloves. Avoid inhalation and skin contact.

• Take adequate precautions when handling pump uids, lubricants, and solvents. Use appropriate protective

clothing, safety goggles and protective gloves to avoid

excessive contact with the skin and possible skin irritations (including dermatitis).

Comply with all relevant statutory requirements and

regulations concerning the handling, storage and disposal of oil.

NOTICE

Aging of the oil (as indicated by darker color compared to

new oil, strange odor of the oil, particles in the oil, or contamination) necessitates an oil change.

Depending on the application (especially if corrosive gases or vapors have been pumped) it may be appropriate to

check the oil frequently and to carry out an oil change, if

necessary.

Page 33

page 33 of 56

Under normal operating conditions:

- Check oil level every time before starting the pump.

- Carry out an oil change once aging of the oil is indicated by darker color compared to new oil.

- Carry out oil changes at least once a year.

- Dispose of the used oil, which may be contaminated,

according to all applicable regulations.

If the oil contains small quantities of water/solvent:

+ The oil can be cleaned to a certain extent by operating

the pump for 1 - 2 hours with the inlet line sealed and

the gas ballast valve open.

Oil change procedure

(8)

(10)

(1)

+ Carry out the oil change only after the pump has reached

its normal operating temperature.

➨ Switch off the pump and isolate it from its application.

Ventilate the pump to atmospheric pressure. Disconnect the electrical power cord. To vent the oil reservoir,

remove the manometer with its adapter carefully (open

end wrench width 17 mm). Pay attention to the O-ring!

Do not turn the manometer itself as leaks might be

caused!

+ Choose a suitable pad; oil may drip. Use a suitable

container to catch the oil.

➨ Place a suitable container below the oil outlet

(9).

➨ Remove the oil drain plug (9) below the rat-

ing plate, paying attention to the O-ring.

➨ Tilt the pump slightly and catch the oil in a

(9)

suitable container.

+ Dispose of the used oil according to regula-

tions.

➨ Screw in oil drain plug (9) with O-ring.

➨ Screw in manometer with O-ring.

➨ To ush the pump, pour in fresh oil (approx. 0.05 quarts

(50 ml)) through the pump inlet (1) (remove separator if

necessary).

Page 34

page 34 of 56

➨ Operate the pump briey. Drain ushing oil and repeat

ushing procedure, if necessary, until all contaminations are ushed out.

➨ Remove the manometer (see above). Add fresh oil (at

rst approx. 0.37 quarts (350 ml) only) through the oil

inlet port for the oil level to reach the ”min.” mark (10).

➨ Close the oil inlet port (8). Operate the pump with

closed inlet for approx. 5-10 minutes.

➨ Top off the oil (add approx. 0.11 quarts (100 ml)). As a

rule, it is not necessary to use the maximum quantity of

oil. Do not overll!

➨ Screw in manometer with O-ring.

Note: The oil degasses and foams at low pressures. This

is a welcome condition which helps to protect the pump

against corrosion and to prolong the working life of the oil.

The quantity, condition and quality of the pump oil have a

decisive effect on the pump’s performance and dependability.

Important: It may not be possible to reach the specied

ultimate vacuum if an oil other than VACUUBRAND B-oil

is used. Similarly, failure to use the recommended oil may

impair cold-start performance and pump lubrication!

Notes on choosing the appropriate oil for the application

The standard oil for VACUUBRAND rotary vane pumps is the B-oil. This

is a mineral oil, which is used for the rst lling of the pump.

The advantages of the B-oil are: Flat viscosity curve, low vapor pressure,

good chemical resistance, extended stability when pumping oxidants,

acid or basic vapors compared to conventional mineral oils, and good

skin compatibility.

Certain pumped media may attack the conventional oil in the pump. Special oils can be used preventively. It is at the users’ responsibility to check

if the materials of the wetted parts are resistant against the pumped substances. This is also mandatory if special oils are used.

Page 35

page 35 of 56

Special oils:

Rotary vane pump oil K8

The rotary vane pump oil K8 is a special oil designed for pumping acid

vapors. The oil is very hygroscopic and has a limited capacity for acids.

With decreasing pH, the anticorrosive effect decreases as well, and it is

necessary to change the oil at appropriate intervals. When the pump will

stand still for prolonged periods (i.e., for several days), the oil must be

drained and the pump must be lled with mineral oil.

Synthetic oil (peruoropolyether oil, e.g., Fomblin®*)

Synthetic oils have an excellent chemical resistance and are certied

for pumping pure oxygen. Therefore these oils are excellent for handling

strong oxidants, e.g., halogens, nitrogen oxides, etc.

Attention: As peruoropolyether oils mixed with mineral oils result in an

emulsion, pumps used with these oils must be absolutely free of any

residues of mineral oils. To accomplish this, you must completely disassemble and diligently clean the pump unit.

* reg. trade mark Montedison

Attention if using special oils: Due to a different viscosity / density com-

pared to the standard oil, pumps lled with special oil may not achieve

the specied ultimate pressure, or the pumps may not start reliably at

temperatures below 54°F (12°C).

VACUUBRAND B-oil

1 liter (1.06 qt) ...............................................................................................687010

5 liter (5.3 qt) .................................................................................................687011

20 liter (5.3 gal)..............................................................................................687012

200 liter (52.8 gal)..........................................................................................687013

Rotary vane pump oil K8

1 liter (1.06 qt) ...............................................................................................687100

5 liter (5.3 qt) .................................................................................................687101

20 liter (5.3 gal)..............................................................................................687102

Peruoropolyether oil

500 ml (0.53 qt) .............................................................................................687600

Page 36

Accessories

page 36 of 56

Glass cold trap GKF 1000i ...........................667056

at the inlet

Protection of the pump against aggressive substances, protection of the recipient against oil molecules.

Separator AK R at the inlet ............................ 698006

Protection of the pump against damaging liquid and

solid substances, protection of the vacuum chamber

against back ow of pump oil.

Retrot kit

Chemistry pumping unit PC 8 .....................699949

Pump base with pre-mounted exhaust waste vapor

condenser and collecting ask.

Shut-off valve

Ball valve VKE 16, KF DN 16 .........................675004

Buttery valve

VS 16C ...........................................................665007

Page 37

page 37 of 56

Hose nipple, aluminum, for hoses DN 19.....................................................662531

Vacuum hose (rubber, DN 20)......................................................................686005

PTFE vacuum hose (antistatic) with stainless steel small anges. The inner side of

the PTFE hose is smooth for increased chemical resistance, reduced deposits and

high conductance

KF DN 16, 500 mm (19.7”) ............................................................................686030

KF DN 16, 1000 mm (39.4”) ..........................................................................686031

KF DN 25, 500 mm (19.7”) ............................................................................686032

KF DN 25, 1000 mm (39.4”) ..........................................................................686033

Vacuum gauge DCP 3000 with gauge head VSP 3000 (Pirani),

2

7.5*10

Torr - 1*10-3 Torr (1*103 mbar - 1*10-3 mbar) .....................................683190

100-230V 50/60 Hz

Maintenance kit RC 6 .................................................................................649990

(rotary vane pump and diaphragm pump)

➨ A service manual with exploded view drawings, spare parts list and

directions for repair is available on request.

+ The service manual is intended for trained service people only.

Page 38

page 38 of 56

Troubleshooting

Fault Possible cause Remedy

❑

Pump does not

start.

➨

Electrical power cord

not plugged in, electrical supply failure?

➨

Supply voltage does

not correspond with

the pump (see rating

plate)?

➨

Start-up control defective?

➨

Oil temperature below

54°F (12°C)?

➨

Pump unit of rotary

vane pump contaminated?

➨

Motor thermally overloaded?

✔

Plug in power cord.

Check fuse.

✔

Connect pump to a suitable supply voltage.

✔

Contact local distributor.

✔

Operate the pump in suitable ambient conditions.

✔

Perform maintenance or

clean the pump unit.

✔

Allow motor to cool down

(< 50°C (122°F)), identify and eliminate cause

of failure. Manual reset

is necessary. Switch off

pump or unplug. Provide

sufcient ventilation.

❑

Pump does not

achieve its ultimate

vacuum or usual

pumping speed.

➨

Overpressure in outlet

line?

➨

Oil mist lter clogged

(lter element in con-

tact with oil) or over-

lled?

➨

Pump seized?

➨

Measuring procedure

or vacuum gauge not

suitable for the application?

➨

Inlet blocked?

➨

Centring ring at small

ange connection not

correctly positioned?

✔

Remove blockage in line,

open valve.

✔

Drain oil, replace lter

element if necessary.

✔

See below.

✔

Choose a suitable measuring procedure or vacuum gauge.

✔

Open inlet. Ensure that

the inlet line does not become blocked.

✔

Check small ange connections.

➨

Long, narrow vacuum

line?

✔

Use lines with larger diameter, length as short as

possible.

Page 39

page 39 of 56

Fault Possible cause Remedy

❑

Pump does not

achieve its ultimate

vacuum or usual

pumping speed.

➨

Leak in the pipeline or

vacuum system?

➨

Long, narrow vacuum

line?

➨

Not enough oil?

➨

Wrong type of oil?

➨

Oil contaminated (also

with solvents)?

➨

Outgassing substances

or vapor generated in

the process?

✔

Check pump directly connect vacuum gauge

directly at pump inlet then check connection,

pipeline and vacuum

system if necessary.

✔

Use lines with larger diameter, length as short as

possible.

✔

Top up oil to correct level.

✔

Change oil and ush with

oil (see ”Oil change”).

✔

Change oil and ush with

oil (see ”Oil change”).

✔

Check process parameters.

❑

Pump too noisy or

strange noise.

➨

Pump has not yet

reached its operating

temperature?

➨

None of the above

mentioned causes?

➨

Too much oil?

➨

Motor thermally overloaded?

➨

Diaphragm damaged?

➨

Pump seized?

➨

Overpressure in outlet

line?

➨

None of the above

mentioned causes?

✔

Allow the pump to reach

its operating temperature.

✔

Contact local distributor.

✔

Lower oil level to mark

”max.”.

✔

Allow motor to cool down

(< 50°C (122°F)), identify

and eliminate cause of

failure. Provide sufcient

ventilation.

✔

Replace diaphragm.

✔

See below.

✔

Remove blockage in line,

open valve.

✔

Contact local distributor.

❑

Oil in the inlet line.

➨

Back diffusion (small

amount of oil, oil lm)?

➨

Back streaming (large

amount of oil)?

✔

Install a sorption trap or a

separator, if necessary.

✔

Contact local distributor.

Page 40

page 40 of 56

Fault Possible cause Remedy

❑

Oil leakage.

❑

High oil consumption.

❑

Fast aging of the

oil.

➨

Oil spilled?

➨

Other cause?

➨

High inlet pressure?

➨

Operation with gas ballast?

➨

Oil level too high?

➨

Pumping aggressive

gases?

➨

Condensation in the

pump?

➨

Oil mist lter defective?

✔

Absorb the oil and dispose of according to regulations.

✔

Contact local distributor.

✔

Normal. Top off oil whenever necessary. Install oil

mist lter at outlet.

✔

Top off oil whenever nec-

essary. Install oil mist lter

at outlet.

✔

Lower oil level to mark

”max.”.

✔

Use suitable oil.

✔

Use separator or cold

trap.

✔

Replace lter. Check

safety pop valve.

❑

Pump seized.

➨

Diaphragm pump does

not reach its pumping

speed?

➨

Ambient temperature

too high ( > 104 °F

(40°C))?

➨

None of the above

mentioned causes?

✔

Perform maintenance of

diaphragm pump.

✔

Provide sufcient ventilation.

✔

Contact local distributor.

Page 41

page 41 of 56

Replacing diaphragms and valves

+ Please read section ”Replacing diaphragms and valves” com-

pletely before starting maintenance.

The pictures may show other versions of pumps. This does not change

the method of replacing diaphragms and valves.

➨ Never operate the pump if covers or other parts of

the pump are disassembled.

➨ Before starting maintenance, disconnect the electri-

cal power cord. Wait two minutes after isolating the

equipment from AC power to allow the capacitors to

discharge.

➨ Ensure that the pump cannot be operated accidentally.

➨ Note: The pump might be contaminated with the pro-

cess chemicals that have been pumped during operation. Ensure that the pump is decontaminated before

maintenance.

➨ Avoid the release of pollutants.

+ Never operate a defective or damaged pump.

+ Take adequate precautions to protect people from the

effects (e.g., in case of inhalation or skin contact) of

dangerous substances that may have contaminated

the pump and may be released upon disassembly. Ensure that the maintenance technician is familiar with

the safety procedures which relate to the products processed by the pumping system.

Use appropriate protective clothing, safety goggles and

protective gloves.

+ Check every motor capacitor regularly by measuring its

capacity and estimating its service life. Replace old capacitors early enough to prevent a failure. The capacitors must be replaced by a trained electrician.

+ Allow sufcient cooling of the pump before starting

maintenance. Drain condensate, if applicable.

+ Vent the pump and isolate it from the vacuum sys-

tem before you start maintenance.

Page 42

page 42 of 56

NOTICE

Ensure that maintenance is done only by suitably

trained and supervised technicians.

The valves and diaphragms as well as the motor capacitors are wear parts. At the latest if the pressure inside the

oil reservoir should rise signicantly (manometer needle

clearly in the red zone), or in case of increased noise level,

the pump interior, the diaphragms and the valves must be

cleaned and the diaphragms and valves must be checked

for cracks or other damage.

All bearings are encapsulated and are lled with long-life

lubricant. Under normal operating conditions, the drive

system is maintenance free.

The operability of the diaphragm pump can be checked as

well by measuring the pressure in the oil reservoir:

➨ Unscrew the manometer with its adapter (open end

wrench width 17 mm). Remove the hose nozzle from

the distributor plate (outlet) and install at the oil inlet.

Make sure the O-ring is seated correctly.

➨ Using a suitable vacuum gauge (e.g., DVR 2) and mak-

ing sure that it is correctly calibrated, measure the pressure in the oil reservoir. When the pump operates with

the inlet line closed, the measured pressure in the oil

reservoir should be less than 25 mbar (19 Torr) (with

gas ballast valve of rotary vane pump closed).

➨ Remove the hose nozzle from oil inlet. Reinstall it in the

distributor plate and reassemble the manometer with

O-ring.

In demanding circumstances, it may be efcient to

check and clean the pump heads on a regular basis. In

normal use, the lifetime of the diaphragms and valves

is more than 10,000 operating hours.

- Prevent internal condensation, transfer of liquids or

dust. The diaphragms and valves will be damaged if

liquid is pumped in signicant amount.

- Carry out maintenance frequently if the pump is exposed to corrosive media or in case of deposits.

- Regular maintenance will improve the lifetime of the

pump and also protect both users and the environment.

Page 43

page 43 of 56

Diaphragm ....................................................................................................639786

Valve .............................................................................................................638440

Vacuum gauge DVR 2..................................................................................682902

Diaphragm key (width 66 mm) ....................................................................636554

Tools required (metric):

- Phillips screw driver size 2

- Open-ended wrench 14/17 mm

- 5 mm wide Allen key

- Diaphragm key width 66 mm

Cleaning and inspecting the diaphragm pump heads

➨ Drain the catch pot of the oil mist lter before beginning maintenance

to prevent leaking of condensate!

➨ Drain oil (see ” Oil change”) to prevent oil from making its way into the

lter element. Rell pump with oil before restarting the pump!

➨ For maintenance, lay the pump on its side with the pump head to be

maintained at the top. Support the pump appropriately.

Attention: Prevent any damage to the oil mist lter or to the manome-

ter. Do not use the oil mist lter to prop up the pump.

➨ Loosen the union nuts of the hose connec-

tions at the pump head with an open-ended

wrench (17 mm).

A

➨ Remove the cover plate. Use a Phillips screw

driver size 2 to loosen both screws (A). Pay

attention to lock washers.

Page 44

page 44 of 56

View of the disassembled pump head parts

6

7

8

9

1

2

3

4

5

1: Housing

2: Connecting rod

3: Washer

4: Diaphragm support disc

5: Diaphragm

6: Diaphragm clamping disc

with square head screw

➨ Turn the ttings with an open-ended wrench

7: Head cover

8: Valve

9: Housing cover with

housing cover insert

(14 mm) to detach the hoses from the pump

heads (1/4 of a turn at maximum).

+ Do not remove the elbow ttings from the

pump heads; during reassembly a leak may

result.

Page 45

page 45 of 56

➨ Disassemble the housing cover to check the

diaphragm and the valves.

➨ Unscrew four Allen screws with a 5 mm wide

Allen key. Remove the housing cover with

housing cover insert together with the head

cover and the valves (head cover with valves

will remain within the housing cover).

+ Never remove parts by using a pointed or sharp-edged tool (e.g., screw

driver). We recommend to use a rubber mallet or compressed air (to

be blown carefully into port).

➨ Remove the head cover carefully from the housing cover. Note the

position and orientation of the valves and remove them.

+ Replace valves if necessary.

+ Check diaphragm for damage and replace if necessary.

+ Use petroleum ether or industrial solvent to remove deposits. Do not

inhale vapors.

Replacing the diaphragm

➨ Lift diaphragm carefully sidewise.

+ Never use a pointed or sharp-edged tool to

lift the diaphragm.

➨ Use the diaphragm key to grip the diaphragm

support disc below the diaphragm.

➨ Unscrew diaphragm support disc with dia-

phragm and diaphragm clamping disc.

+ If the old diaphragm is difcult to separate from the diaphragm support

disc, immerse assembly in naphtha or petroleum ether. Do not inhale

vapors!

➨ Check for washers between the diaphragm support disc and the con-

necting rod. Do not mix the washers from the different pump heads,

since these are set at the factory to ensure proper pump performance.

Make sure that the original number is reassembled at the individual

pump head.

Page 46

page 46 of 56

+ Too few washers: The pump will not attain vacuum specication. Too

many washers: Diaphragm clamping disc will hit head cover, causing

noisy operation and possibly causing the pump to seize up.

➨ Position new diaphragm between diaphragm

clamping disc with square head screw and

diaphragm support disc.

+ Note: Position diaphragm with pale side

towards diaphragm clamping disc (facing

pump chamber).

+ Make sure that the square head screw of the diaphragm clamping disc

is correctly seated in the guide hole of the diaphragm support disc.

➨ Lift the diaphragm at the side. Place the diaphragm carefully together

with diaphragm clamping disc and diaphragm support disc in the diaphragm key.

+ Avoid damage of the diaphragm: Do not excessively bend or crease

the diaphragm.

+ Assemble the original number of washers

between diaphragm support disc and connecting rod.

➨ Screw diaphragm clamping disc , diaphragm,

diaphragm support disc, and washers to connecting rod.

➨ Optimum torque for the diaphragm support disc: 4.4 ft.lbf (6 Nm), it is

recommended to use a torque wrench. Attach torque wrench to diaphragm key (hexagonal bolt 6 mm wide).

Note: Never use the diaphragm key with any additional tools like tongs

or Allen keys without appropriate torque limitation.

Page 47

page 47 of 56

Assembling the pump heads

➨ Bring the diaphragm into a position, in which

it is in contact with the housing and centered

with respect to the bore.

➨ Place the head cover over the diaphragm. Check for its correct orien-

tation by aligning it beforehand with the housing cover which has to be

put over it later on.

+ Pay attention that the diaphragm stays positioned centrally so that it

will become clamped uniformly between housing and head cover.

A

B

➨ Place the valves at their respective positions

on the head cover.

+ Make sure that the valves are correctly seat-

ed. See gure for the correct position of the

valves: Valves at the outlet with round centered opening (A) under valve; valves at the

inlet with kidney-shaped opening (B) beside

valve.

➨ Place the housing cover with housing cover insert onto the head cover.

➨ By turning the eccentric bushing, bring the connecting rod into the up-

per turning point position (max. stroke of the rod).

➨ Loosely screw in the Allen head screws at

the head cover diagonally at rst slightly with

a 5 mm wide Allen key, then tighten.

+ Recommended torque: 8.9 ft.lbf (12 Nm).

Page 48

page 48 of 56

Assembling the connecting hose

➨ Slip the hoses onto the hose connectors by

turning the ttings with an open-ended 14

mm wrench.

➨ Tighten the union nuts of the hose connec-

tions at the pump heads with an open-ended

17 mm wrench.

+ Tighten union nuts rst by hand and then

tighten one full turn using the open ended

wrench.

Replace diaphragm and valves of the opposite side of the

pump in the same way.

➨ Assemble the cover plate. Pay attention to lock washers. Put the pump

in normal operating position.

+ Attention: Make sure that the pump is lled with oil before switching it

on, rell oil if necessary (see ”Oil change”, pg. 32)!

Checking the operability of the diaphragm pump

Check the operability of the diaphragm pump by measuring the pressure

in the oil reservoir:

➨ Unscrew the manometer with its adapter (open end wrench width 17

mm). Remove the hose nozzle from the distributor plate (outlet) and

install at the oil inlet. Make sure the O-ring is seated correctly.