Page 1

CentriVap Refrigerated

Centrifugal Concentrators

Models

73100 Series

Page 2

Copyright © 2018 Labconco Corporation. The information contained in this manual and the accompanying

Warranty

Labconco Corporation provides a warranty to the original buyer for the repair or replacement of parts and

reasonable labor as a result of normal and proper use of the equipment with compatible chemicals. Broken

glassware and maintenance items, such as filters, gaskets, light bulbs, finishes and lubrication are not

warranted. Excluded from warranty are products with improper installation, erratic electrical or utility supply,

unauthorized repair and products used with incompatible chemicals.

The warranty for CentriVap® Refrigerated Centrifugal Concentrators will expire one year from date of

installation or two years from date of shipment from Labconco, whichever is sooner. Warranty is nontransferable and only applies to the owner (organization) of record.

Buyer is exclusively responsible for the set-up, installation, verification, decontamination or calibration of

equipment. This limited warranty covers parts and labor, but not transportation and insurance charges. If the

failure is determined to be covered under this warranty, the dealer or Labconco Corporation will authorize

repair or replacement of all defective parts to restore the unit to operation. Repairs may be completed by 3rd

party service agents approved by Labconco Corporation. Labconco Corporation reserves the rights to limit this

warranty based on a service agent’s travel, working hours, the site’s entry restrictions and unobstructed access

to serviceable components of the product.

Under no circumstances shall Labconco Corporation be liable for indirect, consequential, or special damages

of any kind. This warranty is exclusive and in lieu of all other warranties whether oral, or implied.

products are copyrighted and all rights reserved by Labconco Corporation. Labconco Corporation reserves

the right to make periodic design changes without obligation to notify any person or entity of such change.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight carrier.

Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525

or 1-816-333-8811, between the hours of 7:30 a.m. and 5:30 p.m., Central Standard Time.

Part #7310605, Rev. G

ECO L447

Page 3

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION 1

Safety Symbols 2

CHAPTER 2: PREREQUISITES 3

Electrical Requirements 3

Location and Exhaust Requirements 4

Vacuum Pump Requirements 4

Vacuum Line Traps 5

Space Requirements 5

CHAPTER 3: GETTING STARTED 6

Unpacking Your CentriVap 7

CentriVap Components 7

Emergency Access Into the Chamber 8

Component Orientation & Hose Connections 9

Electrical Connection 10

Rotor Installation 10

Chemical Resistance of CentriVap Components 10

Solvent Safety Precautions 12

CHAPTER 4: USING YOUR CENTRIVAP 14

Planning 14

Glassware Selection 15

Loading Glassware into the CentriVap 15

Temperature Setting Guidelines 15

Time Setting Guidelines 15

CentriVap Controls 15

Operating the CentriVap Controls 16

Operating the CentriVap 17

Operational Note 18

Cycle Interruption 18

Safety Precautions 19

Page 4

CHAPTER 5: MAINTAINING YOUR CENTRIVAP 20

CHAPTER 6: ACCESSORIES FOR YOUR CENTRIVAP 22

Installing a Glass Lid 24

Installing a Vacuum Gauge 24

Installing a CentriZap Strobe Light 25

CHAPTER 7: TROUBLESHOOTING 26

APPENDIX A: CENTRIVAP COMPONENTS 29

APPENDIX B: CENTRIVAP DIMENSIONS 31

APPENDIX C: CENTRIVAP SPECIFICATIONS 32

Electrical Specifications 32

Environmental Conditions 33

Evaporation Rates 34

Page 5

1

Chapter 1:

Introduction

Congratulations on your purchase of a Labconco CentriVap Refrigerated

Concentrator. Models are available for operation on 115V or 230V.

The CentriVap Refrigerated Concentrator, when combined with the CentriVap

Cold Trap, uses centrifugal force and vacuum with or without heat to rapidly

evaporate and condense solvents from biological and analytical samples.

Centrifugation eliminates bumping and foaming as vacuum is applied and also

concentrates the solute in the bottom of the vial. This allows recovery of solutes

from sample volumes as small as a few microliters. The unique advantage of this

concentrator is that it may be cooled to -4°C to prevent damage to heat labile

samples. For faster evaporation, the concentrator is equipped with a 300 watt

heater to warm the chamber during processing. The concentrator may be placed

on a benchtop or other laboratory work surface.

The microprocessor, which controls the operation of the heater and the motor,

provides excellent regulation and reproducibility of protocols. The end of the run

can be signaled by a manually preset timer. Nine different protocols can be stored

in memory so exact test parameters can be easily repeated.

As the companion to the Concentrator, the CentriVap Cold Trap protects the

vacuum pump by trapping moisture, vapors and corrosive fumes as they evaporate

from the samples.

Product Service 1-800-522-7658

Page 6

Chapter 1: Introduction

2

Safety Symbols

Your Refrigerated CentriVap Concentrator was designed with safety in mind,

however conditions may exist that could be hazardous.

Throughout this manual potentially hazardous conditions are identified using the

following words and symbols.

It is important that you understand the warnings listed throughout this manual

before you operate the CentriVap Concentrator.

Product Service 1-800-522-7658

Page 7

3

Chapter 2:

Prerequisites

Before you install your CentriVap Refrigerated Concentrator, you need to prepare

your site for installation. You must be certain that the area is level and of solid

construction. In addition, a means to exhaust the vacuum pump must be provided.

An electrical source must be located near the installation site.

Carefully read this chapter to learn:

The electrical supply requirements.

The exhaust requirements.

The vacuum pump requirements.

Refer to Appendix C: CentriVap Refrigerated Concentrator Specifications for

complete electrical and environmental conditions, specifications and requirements.

Electrical Requirements

The CentriVap Refrigerated Concentrator requires a dedicated grounded electrical

outlet. This outlet requires a 20 Amp circuit breaker or fuse for models rated at 115V

(60 Hz). An 8 Amp circuit breaker or fuse is required for models rated at 230V

(50/60 Hz). 115V models are equipped with a 20 Amp NEMA 5-20P plug. 230V

models are available with either a NEMA 6-20P plug for use in the United States or a

PS1363 plug for use in the UK or a CHI-10P plug for use in China or a CEE7/7 plug

for use in the EU. If this does not match with the available receptacle, remove this

plug and replace it with an approved plug of the suitable style.

It is recommended that an emergency switch for disconnecting the mains in the

case of a malfunction is located remote from the CentriVap. It should be outside

the room in which the CentriVap is housed, or adjacent to the exit from that room.

Product Service 1-800-522-7658

Page 8

Chapter 2: Prerequisites

4

Location and Exhaust Requirements

The CentriVap Concentrator should be located on a surface that is stable, flat and level.

WARNING: The CentriVap System should be located within a fume hood if

hazardous or flammable solvents are used. Heating of materials could lead

to the liberation of hazardous gases. In all cases, regardless of the solvent

used, it is strongly recommended that the vacuum pump is vented in a fume

hood. An accessory secondary trap is available to minimize the exhausting of

solvents into the atmosphere. This does not, however, negate the need to

exhaust the vacuum pump into a fume hood. Failure to properly vent the

CentriVap will expose personnel to potentially harmful chemicals.

The CentriVap Refrigerated Concentrator has not been evaluated by an

approval agency for the use of biological, radio toxins or flammable liquids

or materials.

Vacuum Pump Requirements

A vacuum pump must be provided by the user. A vacuum pump with a free air

flow rate of 90 liters per minute and 2 x 10-4 mBar ultimate pressure is adequate

for aqueous samples. More volatile samples can be satisfactorily processed using

a diaphragm pump with a free airflow of 75 liters per minute and 2 mbar vacuum.

The inlet fitting on the vacuum pump must be suitable for 0.50 ID hose.

Vacuum pumps used with 115V models should be equipped with a 115V, 15 Amp

NEMA 5-15P plug. Vacuum pumps used with 230V models should be equipped

with a “reverse” IEC 320 plug. This will allow the vacuum pump to be plugged

into the receptacle on the back of the CentriVap.

IMPORTANT NOTE: To ensure that aggressive samples used in the

CentriVap Refrigerated Concentrator do not damage the vacuum pump, it is

recommended that all internal wetted parts are PTFE or PTFE coated.

Product Service 1-800-522-7658

Page 9

Chapter 2: Prerequisites

5

When selecting the vacuum pump it is very important to consider the

flammability of the solvent that will be used. If the solvents are flammable,

an explosion-proof vacuum pump or one suitable for the solvents to be

processed is recommended. See Chapter 3 Solvent Safety Precautions for

solvents suitable for use in the CentriVap.

Vacuum Line Traps

When using a mechanical pump that is not corrosion resistant, the CentriVap Cold

Trap or equivalent trap must be used in the vacuum line to prevent damage from

solvent vapors. When evaporating acids, it is advisable to include an acid

secondary trap in the vacuum line. This adds additional protection for the pump.

NOTE: Several components within the CentriVap Refrigerated

Concentrator are made from stainless steel or aluminum and can be

degraded if exposed to acids. Contact Labconco before evaporating acids.

A moisture trap, solvent trap and radioisotope trap are also available. Refer to

Chapter 6: Accessories for Your CentriVap for ordering information.

Space Requirements

Refer to Appendix C: CentriVap Refrigerated Concentrator Specifications for

dimensional drawings of the CentriVap.

No person or any hazardous material should be within 12 inches of the CentriVap

Concentrator while it is operating.

Product Service 1-800-522-7658

Page 10

6

Chapter 3:

Getting Started

Now that the site for your CentriVap is properly prepared, you are ready to

unpack, inspect, install, and test your CentriVap. Read this chapter to learn how

to:

Unpack and move your CentriVap.

Set up your CentriVap.

Connect the electrical supply source to your CentriVap.

Properly exhaust your CentriVap.

Safely use solvents with your CentriVap.

CAUTION: The CentriVap Refrigerated Concentrator weighs over 95 lbs.

(43 Kg). The carton allows for lifting with a mechanical lift truck or hand

truck. If you must lift the CentriVap manually, use at least two (2) persons

and follow safe lifting guidelines.

Product Service 1-800-522-7658

Page 11

Chapter 3: Getting Started

7

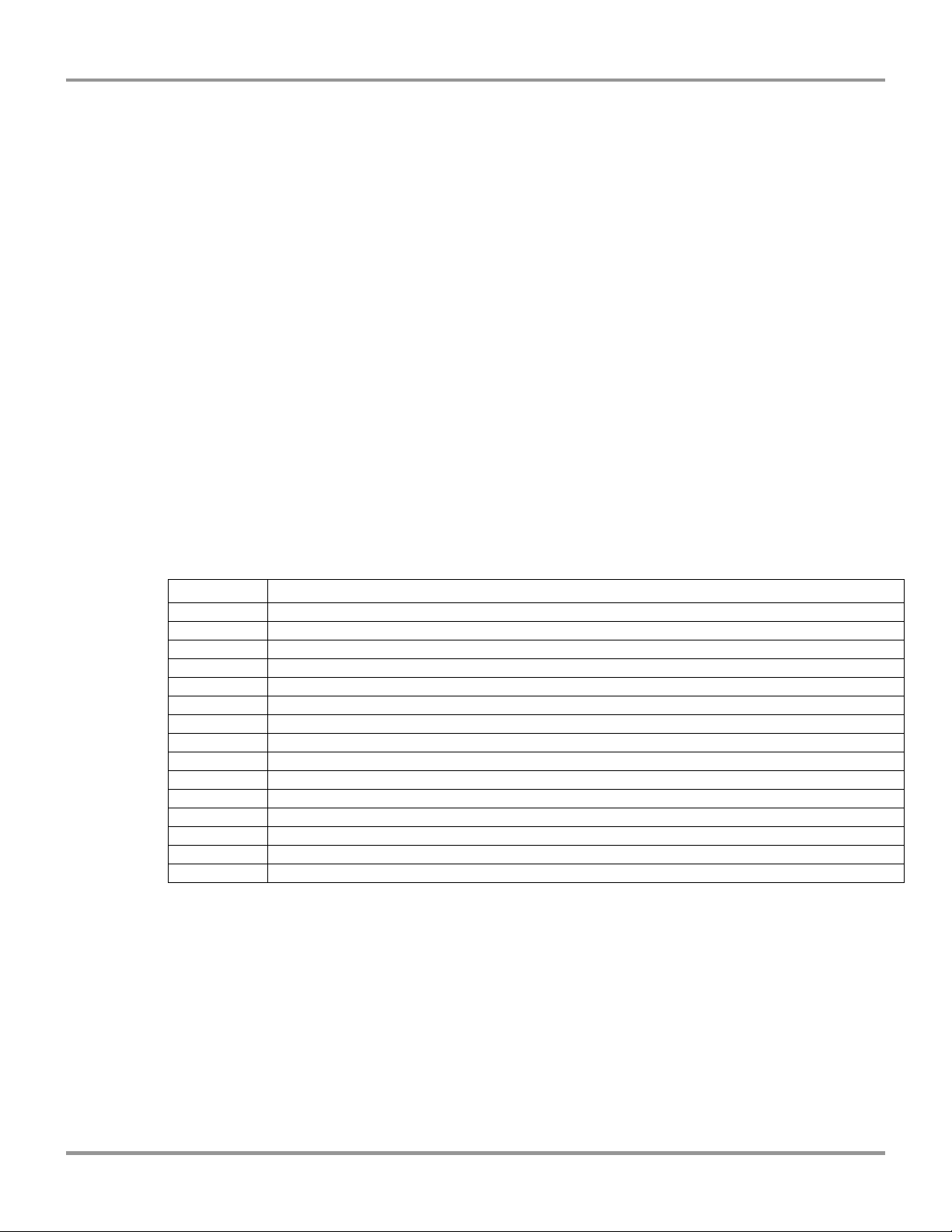

Catalog #

Product Description

7310020

CentriVap Refrigerated Concentrator – 115V/60Hz with Acrylic Lid – US

7310021

CentriVap Refrigerated Concentrator – 115V/60Hz with Glass Lid – US

7310022

CentriVap Refrigerated Concentrator – 115V/60Hz Acid Resistant – US

7310030

CentriVap Refrigerated Concentrator – 230V/50Hz with Acrylic Lid – EU

7310031

CentriVap Refrigerated Concentrator – 230V/50Hz with Glass Lid – EU

7310032

CentriVap Refrigerated Concentrator – 230V/50Hz Acid Resistant – EU

7310034

CentriVap Refrigerated Concentrator – 230V/50Hz Acid Resistant – UK

7310035

CentriVap Refrigerated Concentrator – 230V/50Hz with Acrylic Lid – UK

7310036

CentriVap Refrigerated Concentrator – 230V/50Hz with Glass Lid – UK

7310037

CentriVap Refrigerated Concentrator – 230V/50Hz with Acrylic Lid – China

7310038

CentriVap Refrigerated Concentrator – 230V/50Hz with Glass Lid – China

7310039

CentriVap Refrigerated Concentrator – 230V/50Hz Acid Resistant – China

7310040

CentriVap Refrigerated Concentrator – 230V/60Hz with Acrylic Lid – US

7310041

CentriVap Refrigerated Concentrator – 230V/60Hz with Glass Lid – US

7310042

CentriVap Refrigerated Concentrator – 230V/60Hz Acid Resistant – US

Unpacking Your CentriVap

Carefully unpack your CentriVap and inspect it for damage that may have

occurred in transit. If your CentriVap is damaged, notify the delivery carrier

immediately and retain the entire shipment intact for inspection by the carrier.

The United States Interstate Commerce Commission rules require that claims be

filed with the delivery carrier within fifteen (15) days of delivery.

Do not discard the carton or packing material for your CentriVap until you have

checked all of the components and installed and tested the CentriVap.

NOTE: Do not return goods without the prior authorization of Labconco.

Unauthorized returns will not be accepted. If your CentriVap was damaged

in transit, you must file a claim directly with the freight carrier. Labconco

Corporation and its dealers are not responsible for shipping damage.

CentriVap Components

As previously mentioned, the CentriVap System is available in 115V or 230V.

Locate the model of CentriVap you received in the following table. Verify that

the components listed are present.

Product Service 1-800-522-7658

Page 12

Chapter 3: Getting Started

8

Part #

Component Description

7310605

User’s Manual

1336400

1332700

1332600

1338000

1336100

Power Cord – 115V – US

or

Power Cord – 230V – China

or

Power Cord – 230V – UK

or

Power Cord – 230V – US

or

Power Cord – 230V – EU

7828606

Tubing

1488800

Clamp (2)

7397601

7396206

Coupling Insert

or

Coupling Inert – Acid Resistant

Plus the following:

If you do not receive one or more of the components listed for your CentriVap,

contact Labconco Corporation immediately for further instructions.

Emergency Access into the Chamber

The CentriVap is designed to prevent access to the chamber in the event of a

power disruption. If it is necessary to open the lid when there is no electrical

power connected to the CentriVap, insert a small screwdriver or similar

instrument into the small round hole on the left side of the case behind the control

panel. This will unlock the lid latch mechanism. While holding the screwdriver

in place, raise the lid with the other hand.

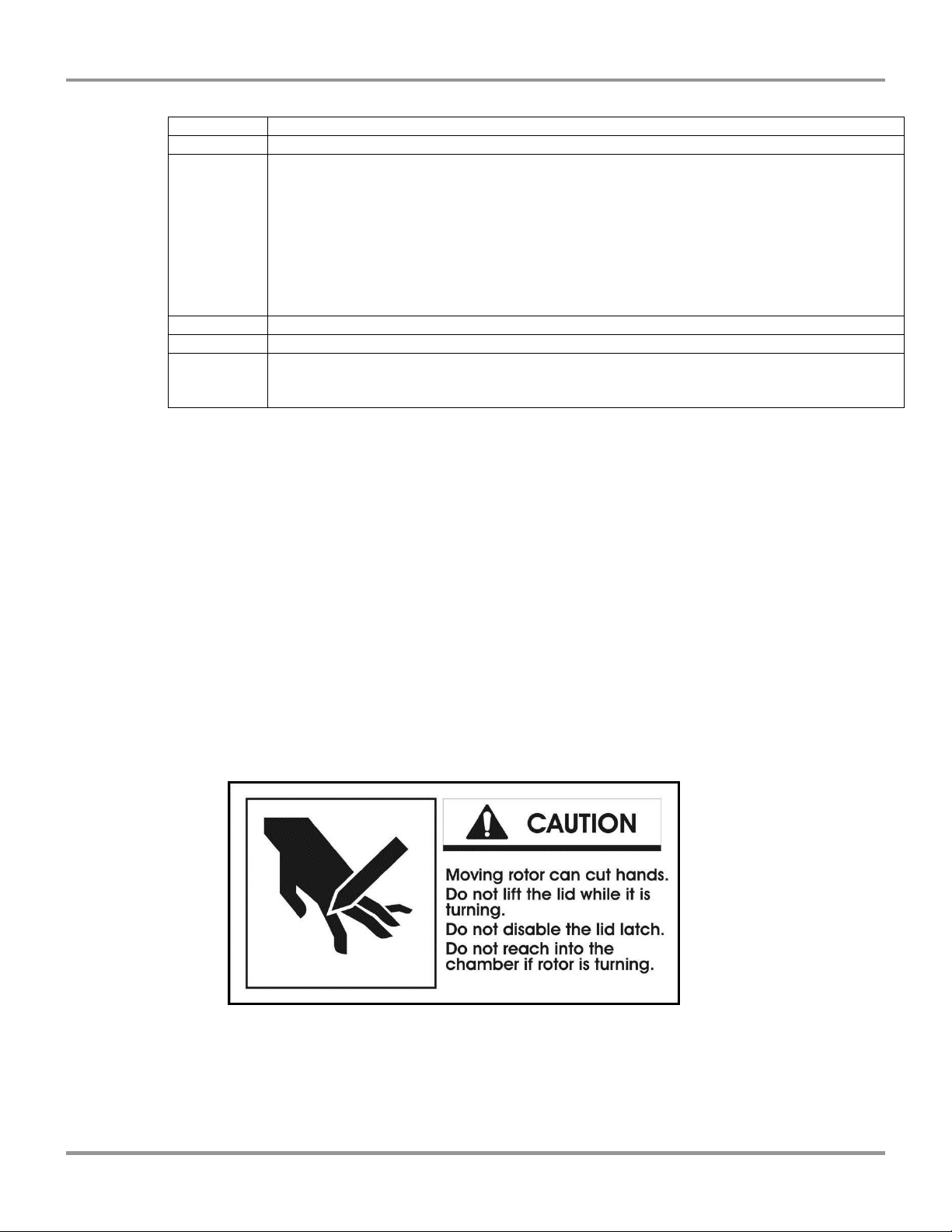

CAUTION: Never attempt to defeat the latch or open the lid while the

CentriVap is running. Personnel injury can result from moving parts and

chemicals.

Product Service 1-800-522-7658

Page 13

Chapter 3: Getting Started

9

Component Orientation & Hose

Connections

The relative position of the

CentriVap, Cold Trap and

Vacuum Pump should be as

shown to optimize the air flows of

the refrigeration systems. There

must be at least 6 inches between

the Refrigerated CentriVap and

the Cold Trap. More space is

better. There must be at least 3

inches between the back of the

refrigerated CentriVap and the

adjacent wall surface. Restriction

of the airflow through the cabinet

during operation could adversely

affect performance.

After positioning the components, it is necessary to join the system together using

the hoses provided. Attach one hose to the tube that extends out the back of the

Concentrator. Attach the other end of this hose to one of the barb fittings on the

Cold Trap Cover. Secure the hoses with the clamps supplied. Attach another hose

to the remaining barb fitting on the Cold Trap Cover and clamp securely. If the

accessory Secondary Trap is not used, attach the other end of the hose to the inlet

port on the vacuum pump. If the accessory Secondary Trap is used, install the

Secondary Trap as explained in Chapter 6: Accessories for Your CentriVap. Then

attach the hose from the Cold Trap Cover to the “out” connector on the Secondary

Trap and clamp securely. Attach another hose from the remaining connector on the

Secondary Trap to the inlet port on the vacuum pump and clamp securely.

WARNING: It is recommended that the CentriVap be located inside a fume

hood or other laboratory ventilation device if hazardous solvents are used in

the CentriVap. If this is not possible, the vacuum pump should be located

inside a hood or should have a hose attached to the exhaust port and the other

end of the hose should be positioned inside the fume hood or ventilation device.

Product Service 1-800-522-7658

Page 14

Chapter 3: Getting Started

10

Electrical Connection

Plug the power cord into the receptacle on the back of the CentriVap Concentrator

and plug the other end into a suitable power receptacle. Plug the power cord into the

receptacle on the back of the CentriVap Cold Trap and plug the other end into a

suitable power receptacle. Plug the power cord from the vacuum pump into the

receptacle on the back of the Concentrator. If the vacuum pump has an off/on switch,

turn the switch ON. The vacuum pump will be controlled by the Concentrator.

Rotor Installation

Place the rotor onto the shaft of the Concentrator. Rotate the rotor slightly to

engage the drive pin in the shaft with the slots in the rotor hub. The top of the

shaft should be in line with the top of the rotor hub.

IMPORTANT NOTE: Do not use a rotor if it shows any signs of damage.

Failure of a spinning rotor could damage the CentriVap or cause samples to

be lost.

Chemical Resistance of CentriVap

Components

Your CentriVap Centrifugal Concentrator and Cold Trap are designed to be

chemical resistant to most compounds that are commonly used in concentration

processes. However, by necessity, the CentriVap is comprised of a number of

different materials, some of which may be attacked and degraded by corrosive

chemicals. The degree of degradation is obviously dependent on the concentration

and duration of exposure. Some major components of the CentriVap that are

susceptible to degradation are as follows:

Product Service 1-800-522-7658

Page 15

Chapter 3: Getting Started

11

Acids

Acids

Bases Solvents

Bases Solvents

COMPONENT MATERIAL

Acetic Acid 20%

Boric Acid

Formic Acid

Hydrobromic Acid 20%

Hydrochloric Acid 20%

Nitric Acid 20%

Sulfuric Acid 10%

Trifluoroacetic Acid (TFA)

Ammonium Hydroxide

Acetone

Acetonitrile

Chloroform

Dimethyl Formamide

Dimethyl Sulfoxide (DMSO)

Ethanol

Ethyl Acetate

Hexanes

Isoproponal

Methanol

Methylene Chloride

Methyl t-Butyl Ether (MTBE)

Toluene

Water

Standard

CentriVap

Lid Acrylic C D C D D D D C D D C D D

Bearings High Carbon Steel D D D D D D D D D D D

Lid Gasket EPDM D D D D D C C D

Rotor Shaft Stainless Steel D D D

Valve Stainless Steel D D D

O Rings Viton (Fluorocarbon) C C C D C

Fittings Polypropylene D C

Rotor Anodized Aluminum D D

Rotor Hub Acetal (Delrin) C C C D D D C D C

Tubing PVC D C D D D D D D D C D D D D

Acid Resistant

CentriVap

Chamber Teflon coated Aluminum

Lid Glass

Bearings Stainless Steel D D D

Lid Gasket EPDM D D D D D C C D

Rotor Shaft Hastelloy

Valve Teflon D

O Rings Viton (Fluorocarbon) C C C D C

Fittings Polypropylene D C

Rotor Teflon coated Aluminum

Rotor Hub Polypropylene D C

Tubing PVC D C D D D D D D D C D D D D

Cold Trap -50°C

Chamber Stainless Steel D D D

Lid Acrylic C D C D D D D C D D C D D

Cold Trap Gasket Neoprene D D C D D C D D D D D C D

Cold Trap -84°C

& -105°C

Chamber Stainless Steel D D D

Lid Stainless Steel D D D

Cold Trap Gasket Neoprene D D C D D C D D D D D C D

C- Moderate Degradation- Questionable use

D- Severe Degradation- Infrequent use recommended- immediate thorough cleaning required

Epoxy coated Aluminum

Chamber

CDC

D

Acid Resistant models have a number of enhancements to minimize chemical

attack on components. The lid is glass, the chamber and rotors are PTFE coated,

the rotor shaft is Hastelloy, bearing are stainless steel and the coupling insert is

polypropylene, and all wetted parts in the vacuum release valve are made from

PTFE. Even though parts in the Acid Resistant models are considerably more

resistant to corrosion, it is very important that the CentriVap is immediately

cleaned and neutralized.

If a rotary vane vacuum pump is used, frequent oil changes are required.

Most compounds used in the CentriVap will degrade the oil if allowed to

enter to pump.

Product Service 1-800-522-7658

Page 16

Chapter 3: Getting Started

12

Diaphragm vacuum pumps sold by Labconco have wetted parts either made

from PTFE or protected by PTFE coatings and are suitable for nearly all

procedures.

When using compounds in the CentriVap that are hostile to the materials of

construction, it is imperative that the equipment is appropriately maintained.

After each run, clean up all residues, spills and materials that might have

splashed in the chamber.

Drain the Cold Trap immediately after the collected ice is melted to prevent

corrosive liquids from residing in the trap. Flush out the trap with water after

draining.

DO NOT chip ice off the Cold Trap walls as damage may occur.

DO NOT start a rotary vane pump when the Cold Trap contains any liquid.

The liquid will be drawn into the pump and will contaminate the vacuum

pump oil.

If the compounds used attack acrylic, consider using the optional glass

chamber lid. See Chapter 6: Accessories for Your CentriVap.

If the compounds used attack stainless steel, consider using the optional

Glass Trap insert in the Cold Trap. See Chapter 6: Accessories for Your

CentriVap.

When using a rotary vane vacuum pump the oil in the pump should be

checked often. It must be changed if it is cloudy, shows particles or is

discolored. The useful life of vacuum pump oil can be extended if the

vacuum pump is operated for an extended period of time after the CentriVap

run is over. This allows contaminants to be purged from the hot oil. This

must be done with the inlet to the pump blocked off to prevent air from free

flowing through the pump. Close the lid and press the RUN button. If the

pump is operated at an elevated vacuum level, oil will be expelled from the

pump and damage will occur.

If optional secondary traps are used, monitor their condition often and

replace them when they are saturated. A new acid trap is off-white and

changes color to purple when used up. A new moisture trap is blue and

changes color to pink when used up. The solvent trap molecular sieve does

not change color when saturated so extra care must be taken to determine

when a replacement cartridge should be installed.

Solvent Safety Precautions

CAUTION: The CentriVap is not classified as “explosion proof.” It has

been designed with safety as a primary consideration and should be used in a

prudent manner using “good laboratory practices.” It has been designed

for use with compounds as described in the United States National Electrical

Code Class I, Group D. The heater may be programmed to run as hot as

100°C, however, the heater element may normally run at 110°C. A thermal

fuse limits the heater to a maximum temperature of 141°C. It is important

Product Service 1-800-522-7658

Page 17

Chapter 3: Getting Started

13

that the solvents used are compatible with these temperatures. Do not

evaporate solvents that have an autoignition temperature below 180°C. Do

not evaporate solvents that are classified as Group A, B, or C by the

National Electrical Code. Evaporate only non-flammable or Group D

solvents with autoignition temperatures 180°C or above. Use of other

compounds could cause an explosion.

CAUTION: Solvents used in the CentriVap may be flammable or hazardous.

Use extreme caution and keep sources of ignition away from the solvents.

When using flammable or hazardous solvents, both the CentriVap and the

vacuum pump should be operated inside a fume hood.

If a sample is spilled in the chamber it must immediately be cleaned up.

Hazardous materials, such as strong acids or bases, radioactive substances

and volatile organics, must be handled carefully and promptly cleaned up if

spilled.

Do not store flammable or hazardous solvents within 12 inches (300 mm) of

the CentriVap.

IMPORTANT NOTE: The disposal of substances used in connection with

this equipment may be governed by various Federal, State or local

regulations. All users of this equipment are urged to become familiar with

any regulations that apply in the user’s area concerning the dumping of

waste materials in or upon water, land or air and to comply with such

regulations.

Product Service 1-800-522-7658

Page 18

14

Chapter 4:

Using Your CentriVap

Refrigerated Concentrator

After your CentriVap has been installed as detailed in Chapter 3: Getting Started,

you are ready to begin using your CentriVap. Read this chapter to learn how to:

Set operating parameters.

Operate the controls.

Properly select and position glassware inside your CentriVap.

Understand the display.

Interrupt a cycle after it has begun.

NOTE: See Appendix C: CentriVap Refrigerated Concentrator

Specifications for electrical requirements.

NOTE: Do not store or stack supplies or equipment on top of the CentriVap.

Planning

Thoroughly understand procedures and the equipment operation prior to

beginning work. The unique performance of the CentriVap is dependent upon the

proper balance of heat, vacuum and centrifugal force. If the proper balance is not

established, it is possible to damage or lose a portion of the sample. Therefore, if

you are unfamiliar with the CentriVap or are attempting a new protocol, it may be

helpful to make a trial run that is void of the sample you are attempting to

concentrate.

Product Service 1-800-522-7658

Page 19

Chapter 4: Using Your CentriVap Refrigerated Concentrator

15

Glassware Selection

Normally, sample tubes should be filled no more than approximately half full.

Select the size of the sample tube so it is compatible with the rotor and the desired

sample size. Tubes should not be excessively loose in the rotor. Rotors are

available with holes for various size tubes. Refer to Chapter 6: Accessories for

Your CentriVap for available rotor sizes.

Loading Glassware into the CentriVap

Smooth operation of the CentriVap is dependent upon proper balance of the

machine. Therefore, if less than a full load of samples is run, it is important to

load samples into the CentriVap in a fairly symmetrical manner distributing the

weight of the samples evenly in the sample rotor.

Temperature Setting Guidelines

The evaporation rate achieved by the CentriVap is dependent upon a variety of

factors. These include the nature of the solvent, the temperature and the pressure

in the vacuum system.

As a general guideline, to speed the evaporation process, the CentriVap

temperature should be set as high as possible as long as the temperature will not

damage the sample or cause the sample to bump.

Time Setting Guidelines

The Refrigerated CentriVap allows two different temperatures to be programmed

for user specified periods of time. If sequential temperatures are not desired, set

Time at 2 to “0”. When both programmed times expire, the rotor will stop, the

heater and refrigeration systems shut off, the vacuum pump stops and vacuum is

purged from the chamber. An alarm sounds until any control button is pressed.

CentriVap Controls

The control panel for the CentriVap is shown below with a description about its

function.

Product Service 1-800-522-7658

Page 20

Chapter 4: Using Your CentriVap Refrigerated Concentrator

16

1. Display – The liquid crystal display (LCD) shows set point parameters and

actual measured conditions.

2. Program Buttons – Used to initiate the start of a run with the use of just one

button.

3. Run/Stop Button – Press this to start or stop a run.

4. Preheat/Cool Button – Used to turn on the heater or refrigeration system to

heat or cool the chamber prior to loading samples.

5. Increase Button – When pressed, the last selected set point will increase.

6. Decrease Button – When pressed, the last selected set point will decrease.

7. Set Point Select Button – To select a parameter to change, press the select

button. Arrows on the display will point to the parameter that may be altered.

Operating the CentriVap Controls

Preheat/Cool:

To preheat or precool the chamber, press the “PREHEAT/COOL” button. The

display will show:

SP: XXX ACT: XXX

Press the increase or decrease button until the desired set point (SP) is displayed.

The actual chamber temperature, (ACT) is displayed to the right. When power is

being supplied to the heaters, a bar under the actual temperature will illuminate.

The chamber will continue to maintain the set point temperature until either the

“PREHEAT/COOL” button is pressed again or the “RUN” button is pressed.

Select existing program:

Operating parameters can be stored in memory so protocols can be repeated.

Nine programs can be stored. To select a program, press the set point “SELECT”

button until arrows point to the program number indicating that this set point can

be run or altered. To change the program number, press the increase or decrease

button until the desired program number is displayed. When the program number

is changed, all its set points change also to indicate the last entered parameters for

that program.

Store frequently run protocols in program 1, 2, or 3. Then, by pressing “PROG

1,” “PROG 2” or “PROG 3,” the stored program will be initiated without having

to press any other button. Pressing just the one button starts the rotor, the heater,

refrigeration system, the timers and the vacuum pump.

Change “Temperature” Set Points:

To change the “Temperature” set point, press the set point “SELECT” button until

arrows point to the “Temperature” set point, which can be changed from -4°C up

to 99°C by pressing the increase or decrease buttons. The set point is 100°C if the

display shows “HI.” The last entered set point is stored in memory.

Product Service 1-800-522-7658

Page 21

Chapter 4: Using Your CentriVap Refrigerated Concentrator

17

Change “Run Time” set points:

To change the time set points, press the set point “SELECT” button until arrows

point to the “Time at 1” or “Time at 2” set point which can be changed from 1 to

999 minutes by pressing the increase or decrease buttons. If it is desired to have

the CentriVap run continuously without alarming at the end of a time period,

press the increase button until the “Time” display says “ON.” The last entered set

point is stored in memory.

If during a run the “STOP” button is pressed, the timers remember the time at

which stop occurred. If “RUN” is then pressed, the timers continue to count

down from the time at which they were stopped. If running program 1, program 2

or program 3, pressing “PROG 1,” “PROG 2” or “PROG 3” resets the timers to

the original set point time and the CentriVap starts a new run.

To reset the timers to the original set point time when running programs other

than program 1, program 2 or program 3, press the start button and hold it for five

seconds. The display will indicate that the timer is reset.

Operating the CentriVap

CAUTION: To avoid injury; Do not operate the CentriVap if the lid is

scratched, nicked or shows signs of damage. A damaged lid could fail under

vacuum.

While the CentriVap Concentrator is operating, do not lean on the lid, do not

stand near it longer than necessary and do not place hazardous materials

within 12 inches.

1. Press the Cold Trap “ON” switch. The top amber indicator will illuminate.

Additional indicators will illuminate, as the Cold Trap gets colder. A green

indicator will illuminate when the Cold Trap reaches operating temperature.

2. Press the CentriVap “ON” switch.

3. Select a program or set the set point parameters.

4. Preheat/precool the chamber if desired.

5. Place samples in vials. Normally the vials should be no more than half full.

Place vials in a rotor.

Product Service 1-800-522-7658

Page 22

Chapter 4: Using Your CentriVap Refrigerated Concentrator

18

6. Load the rotor with samples into the chamber.

7. Close the lid. A safety switch prevents the CentriVap from starting when the

lid is open.

8. Press “RUN.” If the display was showing set point parameters, it will change

to show actual parameters. Press “RUN” again. The “S” (STOP) in the

display changes to “R” (RUN). The program on the display alternately

displays “R” or the number of the program that is running. If you intend to

run program 1, 2 or 3, simply press “PROG 1,” “PROG 2” or “PROG 3” to

start the CentriVap. A latch will activate to lock the lid closed, the rotor will

start, the vacuum break valve will close and the vacuum pump will start after

the rotor reaches operating speed.

9. Set point parameters can be altered at any time during a run by first selecting

the parameter using the set point “SELECT” button and then pressing the

“INCREASE” or “DECREASE” switch.

10. If the time set point is used, at the end of the set time an alarm sounds. All

functions cease.

11. Press “STOP” to terminate operation if the CentriVap has not already stopped

itself.

12. When the evaporation is complete, allow the rotor to stop moving, lift the lid

and remove the samples.

Operational Note

When the CentriVap power switch is turned ON, the CentriVap returns to the

same mode (“RUN” or “STOP”) that it was in when the power switch was turned

OFF. If the CentriVap was in the “RUN” mode when the power switch was

turned OFF, when the power switch is turned ON, the CentriVap attempts to

return to the programmed set points and continue the run.

Cycle Interruption

At any time during a run, the cycle may be stopped by pressing the “STOP”

button. This shuts off all operating functions. After the rotor stops, the lid may

be opened. If it is necessary to re-start the CentriVap, close the lid and press

“RUN.” The CentriVap resumes operation at the same set point parameters and

the timer continues to count down from the time at which the CentriVap was

stopped.

Product Service 1-800-522-7658

Page 23

Chapter 4: Using Your CentriVap Refrigerated Concentrator

19

Safety Precautions

Special precautions must be observed if the materials used in the CentriVap

Concentrator are known to be hazardous, toxic, radioactive, or contaminated with

pathogenic micro organisms. These actions should include but are not limited to

the following:

Refer to the World Health Organization Laboratory Biosafety Manual,

paying special attention to information about centrifuges and the handling

of hazardous materials.

Operate or vent the CentriVap Concentrator inside a suitable fume hood or

ventilation device. Load rotors in a ventilation device.

Periodically inspect all parts of the CentriVap Concentrator including the

lid, gasket, chamber, plumbing components and rotors.

Product Service 1-800-522-7658

Page 24

20

Chapter 5:

Maintaining Your CentriVap

Refrigerated Concentrator

Under normal operation, the CentriVap requires little maintenance. The

following maintenance schedule is recommended. Before servicing the

CentriVap Refrigerated Concentrator, disconnect electrical power. Special

precautions must be observed if materials used in the CentriVap Concentrator are

known to be hazardous, toxic, radioactive or contaminated with pathogenic micro

organisms. Before servicing, the CentriVap Concentrator must be suitably

decontaminated. Wear appropriate eyewear, gloves and other safety apparel.

As needed:

Before using any cleaning or decontamination method except those recommended

by the manufacturer, users should check with the manufacturer that the proposed

method will not damage equipment.

1. Clean up all spills; remove liquids from the chamber. Clean or decontaminate

all surfaces using agents suitable for the substance spilled.

2. Clean lid and gasket using soft cloth, sponge or chamois and a mild, non-

abrasive soap or detergent.

3. Check oil level of the vacuum pump, if applicable. It should be between MIN

and MAX. If the oil level is less than an inch (25.4 mm) above MIN, add oil

to proper level.

4. If oil shows cloudiness, particles or discoloration, drain the pump and replace

with fresh oil.

5. Utilization of acids requires immediate cleaning and neutralization after a run

or physical damage to the collection chamber will result.

6. Check the Cold Trap for condensed or frozen solvents and dispose of

appropriately. Completely empty the trap before the next run. The Cold Trap

cover is removed by first lifting and rotating the two retainers that secure the

lid in place. If solvents are frozen in the glass trap, run it under cold water

immediately after operating.

NOTE: IF THE ICE HAS MELTED, THE GLASS TRAP INSERT MUST

BE EMPTIED BEFORE THE COLD TRAP IS STARTED AGAIN.

Product Service 1-800-522-7658

Page 25

Chapter 5: Maintaining Your CentriVap Refrigerated Concentrator

21

7. If the Glass Trap is used, check to see that the ethanol in the stainless steel

trap is free of ice or water. Drain the ethanol and replace it with fresh ethanol.

8. If the media in the cartridge in the optional clear canister has changed color,

discard and replace the insert with a new insert. For the radiochemical trap

insert, no indicator exists; therefore, it should be discarded after each use. In

radioactive applications, the system should be monitored with a Geiger

counter.

9. Check rotors for loose or missing parts. Tighten or replace as required. Do

not use defective rotors.

10. Inspect the chamber to insure that there are no cracks or structural damage.

Call Labconco if defects exist.

11. Check continuity of the protective earth between the ground terminal on the

power inlet and a bare metal housing panel. Contact Labconco if there is no

continuity.

12. Repair any defects to the surface where the CentriVap is installed.

Monthly:

1. The rubber components on the CentriVap may eventually deteriorate and

require replacement. The effective life of rubber parts depends upon both

their usage and the surrounding environment. Check all hoses and gaskets

and replace any that show signs of hardening, permanent set or deterioration.

2. Using a soft cloth, sponge or chamois and a mild, non-abrasive soap or

detergent, clean the glass lid.

3. Using a soft cloth, sponge, or chamois and a mild, non-abrasive soap or

detergent, clean the exterior surfaces of the unit. Liquid spray cleaners and

polishes may be used on the exterior surfaces. Do not use solvents to remove

stains from the exterior surfaces as they may damage the finish.

Annually:

1. Every 12 months, or more often, if the Refrigerated CentriVap or Cold Trap is

operated in a dusty environment, the refrigeration system condenser should be

cleaned. Using a vacuum cleaner with brush attachment, clean the condenser

to ensure proper airflow for peak performance. Disconnect power before

removing covers.

Product Service 1-800-522-7658

Page 26

22

Chapter 6:

Accessories for Your CentriVap

The configuration of your CentriVap can be changed to accommodate your needs.

If the solvents used in the CentriVap degrade the acrylic lid, it may be replaced

with an optional glass lid to gain added chemical resistance. To observe the

samples while they are processing, an optional CentriZap Strobe light may be

installed. Read this chapter to learn how to:

Install a glass lid

Install a vacuum gauge.

Install a CentriZap™ strobe light.

Product Service 1-800-522-7658

Page 27

Chapter 6: Accessories for Your CentriVap

23

PART #

DESCRIPTION

7462900

7462901*

Rotor (DNA)

Holds (72) 0.5 ml microcentrifuge tubes

and

(60) 1.5 ml microcentrifuge tubes or

(60) 2.0 ml microcentrifuge tubes

7450700

7450701*

Rotor (1.5 ml)

Holds (132) 1.5 ml microcentrifuge tubes or

(132) 2.0 ml microcentrifuge tubes

7455000

7455001*

Rotor (15 ml)

Holds (44) 12 x 55 mm tubes or

(36) 12 x 75 mm tubes or

(36) 12 x 95 mm tubes or

(36) 13 x 75 mm tubes or

(36) 13 x 100 mm tubes

and

(24) 16 x 100 mm tubes or

(18) 16 x 120 mm conical tubes or

(18) 17 x 95 mm tubes or

(18) 17 x 100 mm centrifuge tubes or

(18) 17 x 120 mm tubes

7455100

7455101*

Rotor (12-13 mm)

Holds (40) 1.5 ml microcentrifuge tubes or

(40) 2.0 ml microcentrifuge tubes

and

(16) 12 x 55 mm tubes or

(100) 12 x 75 mm tubes or

(64) 12 x 95 mm tubes or

(100) 13 x 75 mm tubes or

(64) 13 x 100 mm tubes

7455200

7455201*

Rotor (50 ml)

Holds (32) 1.5 ml microcentrifuge tubes or

(32) 2.0 ml microcentrifuge tubes

and

(12) 28 x 115 mm conical tubes or

(12) 28 x 135 mm conical tubes or

(12) 28 x 140 mm conical tubes

7461900

7461901*

Rotor (96 well plate)

Holds (4) Standard 96 well plates or

(2) Deep well 96 well plates

7460900

Clear Canister – Accommodater inserts listed below:

7814800 Acid Trap Insert

7814900 Moisture Trap Insert

7815000 Radiochemical Trap Insert

7815200 Solvent Trap Insert

7995600 Ammonia Trap Insert

7397605

Glass Trap for Cold Trap

The following accessories are available for the CentriVap Concentrator and Cold

Trap System.

*PTFE Coated

Product Service 1-800-522-7658

Page 28

Chapter 6: Accessories for Your CentriVap

24

1467700

Vacuum Pump – 195 liters/minute capacity with gas ballast. Ultimate pressure 1.3 x 10-4

mBar. 115 VAC, 60 Hz, single phase, 7.8 amp.

1472100

Vacuum Pump – 117 liters/minute pumping capacity with gas ballast. Ultimate pressure 1.3

x 10-4 mBar. 115 VAC, 60 Hz, single phase, 4.6 amp.

7739402

Vacuum Pump – 117 liters/minute. Same as 1472100 except 220/208-230 VAC, 50/60 Hz,

single phase, 2.4 amp operation.

7739403

Vacuum Pump – 195 liters/minute. Same as 1467700 except 220/208-230 VAC, 50/60 Hz,

single phase, 4.0 amp operation.

1473400

Pump Exhaust Filter – Disposable filter that removes visible oil mist and odor from vacuum

pump exhaust. Fits vacuum pumps 1467700, 1472100, 7739402 and 7739403

1473200

Replacement Element, Oil Mist, Pump Exhaust Filter – Fits pump exhaust filter 1473400.

1473300

Replacement Element, Odor, Pump Exhaust Filter, package of 5 – Fits pump exhaust filter

1473400 or vacuum pumps 1472100, 1467700, 7739402 and 7739403.

1988000

Vacuum Pump Oil, 1 Liter – A molecularly distilled hydrocarbon oil low vapor pressure.

For vacuum pumps 1467700, 1472100, 7739402 and 7739403.

7393000

Vacuum Pump – 75 liters/minute @ 50Hz, 82 liters/minute @ 60Hz

Ultimate pressure < 2 mBar, 115V, 50/60 Hz, 3.5 Amp

7393001

Vacuum Pump – 75 liters/minute @ 50Hz, 82 liters/minute @ 60Hz

Ultimate pressure < 2 mBar, 230V, 50/60 Hz, 2.0 Amp

7539902

Vacuum Pump – 200 liters/minute @ 60Hz, 183 liters/minute @ 50Hz

Ultimate vacuum < 1x10-3 mBar, 230V, 50/60 Hz

7584000

Vacuum Pump – 110 liters/minute @ 60Hz, 96 liters/minute @ 50Hz

Ultimate vacuum < 2x10-3 mBar, 115V, 50/60 Hz

7584002

Vacuum Pump – 110 liters/minute @ 60Hz, 96 liters/minute @ 50Hz

Ultimate vacuum < 2x10-3 mBar, 230V, 50/60 Hz

7456600

Glass Lid for Concentrator – Direct replacement for standard equipment acrylic lid. For use

with chemicals that could craze acrylic.

7464300

CentriZap Strobe Light – For observing samples while the rotor is spinning.

Installing a Glass Lid

Turn off the CentriVap. Pull outward on the hinge pin knob. Lift and remove the

old lid. To install the new lid, reverse the process.

Installing a Vacuum Gauge

A user-supplied vacuum gauge may be attached to the CentriVap to monitor the

vacuum level. Attach the vacuum gauge to the barb end of the Quick Disconnect

Coupling fitting that was supplied with the CentriVap using a length of suitable

rubber hose. The Quick Disconnect Coupling fitting can then be pushed into the

mating connector on the left side of the CentriVap located towards the rear. The

Quick Disconnect Coupling fitting can be removed from the mating connector by

pressing on the tab on the connector and then pulling out the insert fitting. Always

remove the Quick Disconnect Coupling from the CentriVap when a vacuum

gauge is not attached to it.

Product Service 1-800-522-7658

Page 29

Chapter 6: Accessories for Your CentriVap

25

*Velcro is a registered trademark of Velcro Industries B.V.

Installing a CentriZap™ Strobe Light

An accessory strobe light is available to enable you to see the samples as they are

rotating in the rotor. Attach the holder to the right hand side of the CentriVap

Concentrator using the screws provided. Plug the connector on the strobe light

harness into the receptacle on the back of the CentriVap marked “STROBE

OUTLET.” Peel the protective backing off the enclosed Velcro® and attach it to

the back of the Concentrator. Secure the power supply box on the harness to the

Velcro. Place the light in the holder.

To use the strobe light while the CentriVap is operating, remove the light from its

holder, press the trigger and shine the light on the samples in the rotor.

Product Service 1-800-522-7658

Page 30

26

DISPLAY ERROR CODE

CAUSE

CORRECTIVE ACTION

Heat Sensor

Sensor failure

Replace sensor assembly.

Connection failure

Repair connection.

Close Lid

Lid open

Close lid.

Latch Fail

Solenoid failure

Check component.

Switch or sensor failure

Check connections.

Mem Fail P1

Memory failure

Push program button #1.

New memory IC chip

Push program button #1.

Bad memory IC chip

Call Labconco – Replace IC chip or control PCB.

MOTOR ERROR

Defective motor

Replace motor.

Hall effect sensor failure

Replace sensor.

Wire failure

Replace wire.

Chapter 7:

Troubleshooting

Refer to the following if your CentriVap fails to operate properly. If the

suggested corrective actions do not solve your problem, contact Labconco for

additional assistance. The following failure codes may appear on the display

when problems are sensed by the internal self check system.

CAUTION: Disconnect power before servicing the CentriVap.

Product Service 1-800-522-7658

Page 31

27

Chapter 7: Troubleshooting

Product Service 1-800-522-7658

Page 32

Chapter 7: Troubleshooting

28

PROBLEM

CAUSE

CORRECTIVE ACTION

Unit will not operate

Unit not connected to electrical

power

Connect unit to proper electrical receptacle.

Circuit breaker blown

Correct electrical problem and reset circuit

breaker by pressing button.

Lid open

Close lid.

Excessive vibration

Sample tubes not located

symmetrically in rotor

Reposition sample tubes.

Sample odor in lab

Vent hose exhausting into lab

area

Redirect hose to fume hood.

Evaporation rate is reduced

Heater inoperable

Contact Labconco.

Vacuum pump failure

Check pump.

Obstruction in hose

Remove obstruction or replace hose.

Lack of adequate vacuum

See below.

No vacuum/poor vacuum

Pump not on

Turn on pump.

Control valve open

Check control valve.

Leaks in lines or connectors or

gasket

Locate and repair.

Foreign material on lid gasket

Clean gasket and lid.

Pump is not functioning properly

Check pump by locating vacuum gauge closer to

pump and close off rest of system. Check pump

oil for cloudiness or particles and change.

If pump is faulty, seek authorized service or

replace pump.

Cold Trap or Concentrator

gasket is not sealing properly

Check gasket for cleanliness. Adjust gasket as

needed.

Cold Trap lid not seated

Hold lid down until vacuum is initiated.

Ice formed on Cold Trap lid

sealing surface

Defrost and wipe dry.

Secondary Trap Canister not

fitted properly

Tighten all connections to and from the

Secondary Trap Canister.

Secondary Trap Insert is spent

Replace with new insert.

New Secondary Trap has

moisture in it

Run vacuum pump for 24 hours to remove

moisture.

Other corrective actions for potential problems are as follows:

Product Service 1-800-522-7658

Page 33

Chapter 7: Troubleshooting

29

PROBLEM

CAUSE

CORRECTIVE ACTION

Frequent oil change needed in

pump

Secondary Trap insert is spent

Change insert often.

Cold Trap is not emptied after

each run and dried

Empty the traps (glass or stainless steel) after

each run and replace.

Vacuum too strong for chemical

Use a Secondary Trap insert and diaphragm

pump.

Unit starts and shuts off

Latch optical sensor improperly

calibrated

Unplug power cord. Wait 10 seconds. Plug in

power cord.

Product Service 1-800-522-7658

Page 34

30

Item

Quantity

Part No.

Description

1 1 7310601

Motor w/Capacitor

2 1 7546700

Valve, Vacuum Break (115V)

2A 1 7446701

Valve, Vacuum Break (230V)

2B 1 7396308

Valve, Vacuum Break Acid Resistant

3 1 7453500

Heater (115V)

3A 1 7453501

Heater (230V)

4 1 1647106

O-Ring, Outer

5 1 1647105

O-Ring, Inner

6 1 7975902

Fuse, High Temp Limiter

7 1 7456000

Harness, Temp & Speed Sensor

8 1 7441002

Printed Circuit Board

9 1 1289200

Relay Vacuum Pump (115V)

9A 1 1289100

Relay Vacuum Pump (230V)

10 1 7826000

Switch, Latch

11 1 7478700

Solenoid, Latch

12 1 7403701

Display

13 1 7310602

Label/Switch Pad

14 1 7452600

Gasket, Lid

15 1 7456600

Lid, Glass

15A

1

7452500

Lid, Acrylic

16

42.2 inch

7451700

Extrusion

17 2 7452200

Hinge, Bracket Assembly

18 1 1289320

Circuit Breaker (115V)

18A

2

1289310

Circuit Breaker (230V)

19 1 7953800

Motor Fan 115V

19A

1

7953801

Motor Fan 230V

20 1 7437700

Compressor 115V 60Hz

20A

1

7437701

Compressor 230V 50Hz

20B

1

7437702

Compressor 230V 60Hz

21 1 1289200

Relay Refrigeration 115V and 230V

Not Shown

1

1336400

Power Cord (115V) – US

Not Shown

1

1332700

Power Cord (230V) – China

Not Shown

1

1332600

Power Cord (230V) –UK

Not Shown

1

1338000

Power Cord (230V) – US

Not Shown

1

1336100

Power Cord (230V) – EU

Appendix A:

CentriVap Refrigerated

Concentrator Components

The following pages list components that are available for your CentriVap. The

parts shown are the most common replacement parts. If other parts are required,

contact Product Service.

Product Service 1-800-522-7658

Page 35

Appendix A: CentriVap Refrigerated Concentrator Components

31

Product Service 1-800-522-7658

Page 36

Appendix A: CentriVap Components

32

Product Service 1-800-522-7658

Page 37

33

Appendix B:

CentriVap Refrigerated

Concentrator Dimensions

Product Service 1-800-522-7658

Page 38

34

Appendix C:

CentriVap Refrigerated

Concentrator Specifications

This Appendix contains technical information about the CentriVap including

specifications, environmental operating conditions, and evaporation rates.

Electrical Specifications

Nominal amperage for 115V CentriVap Concentrator (model 7310020

series) (excluding vacuum pump): 3.1 amps (with vacuum pump) 12.00A

max.

Nominal amperage for 230V CentriVap Concentrator (model 7310030 &

7310040 series) (excluding vacuum pump): 1.6 amps (with vacuum pump)

6.0 amps max.

Heater Power: 300 watts

Phase: Single

Rotor Speed: Up to 1,725 RPM

CAUTION: Do not use the CentriVap in a manner not specified by the

manufacturer. The electrical protection properties of the CentriVap may

be impaired if the CentriVap is used in appropriately.

Product Service 1-800-522-7658

Page 39

Appendix B: CentriVap Dimensions

35

Environmental Conditions

Indoor use only.

Maximum altitude: 6562 feet (2000 meters).

Ambient temperature range: 41° to 104°F (5° to 40°C).

Maximum relative humidity: 80% for temperatures up to 88°F (31°C),

decreasing linearly to 50% relative humidity at 104°F (40°C).

Main supply voltage fluctuations not to exceed ±10% of the nominal

voltage.

Transient overvoltages according to Installation Categories II

(Overvoltage Categories per IEC 1010). Temporary voltage spikes on the

AC input line that may be as high as 1500V for 115V models and 2500V

for 230V models are allowed.

Used in an environment of Pollution degrees 2 (i.e., where normally only

non-conductive atmospheres are present). Occasionally, however, a

temporary conductivity caused by condensation must be expected, in

accordance with IEC 664.

Product Service 1-800-522-7658

Page 40

Appendix B: CentriVap Dimensions

36

Tube

Size (ml)

Number

of Samples

Sample

Size (ml)

Heater

Temp (C)

Vacuum

Pump

Time to

Dry (min)

Cold

Trap

Rate

Overall (ml/min)

Methylene

Chloride

bp 40

50

12

25

45

Diaphragm

80

no

3.75

15

18

10

45

Diaphragm

45

no

4.00

Toluene

bp 111

50

12

25

45

Diaphragm

204

no

1.47

50

12

25

100

Diaphragm

96

no

3.13

15

18

10

45

Diaphragm

119

no

1.51

15

18

10

100

Diaphragm

42

no

4.29

Acetonitrile

bp 82

50

12

25

45

Diaphragm

184

no

1.63

50

12

25

100

Diaphragm

81

no

3.70

15

18

10

45

Diaphragm

106

no

1.70

15

18

10

100

Diaphragm

52

no

3.46

1.5

132 1 45

Diaphragm

55

no

2.40

1.5

90 1 45

Diaphragm

47

no

1.92

1.5

132 1 60

Diaphragm

37

no

3.57

1.5

132 1 75

Diaphragm

33

no

5.74

1.5

132 1 100

Diaphragm

21

no

6.29

Methanol

bp 65

50

12

25

45

Diaphragm

233

no

1.29

15

18

10

45

Diaphragm

141

no

1.28

1.5

132 1 35

Diaphragm

88

no

1.50

1.5

132 1 45

Diaphragm

64

no

2.06

1.5

132 1 60

Diaphragm

50

no

2.64

1.5

90 1 75

Diaphragm

38

no

2.37

1.5

132 1 75

Diaphragm

39

no

3.38

1.5

132 1 100

Diaphragm

25

no

5.28

Water

bp 100

50

12

25

45

Diaphragm

1397

no

0.21

50

12

25

100

Diaphragm

445

no

0.67

15

18

10

45

Diaphragm

841

no

0.19

1.5

132 1 45

Diaphragm

427

no

0.30

1.5

132 1 60

Diaphragm

303

no

0.44

1.5

132 1 75

Diaphragm

196

no

0.67

1.5

132 1 100

Diaphragm

117

no

1.13

50

12

25

45

Rotary vane

1002

yes

0.30

50

12

25

100

Rotary vane

424

yes

0.70

15

18

10

45

Rotary vane

565

yes

0.32

15

18

10

60

Rotary vane

456

yes

0.39

1.5

132 1 45

Rotary vane

299

yes

0.44

1.5

132 1 75

Rotary vane

207

yes

0.64

1.5

132 1 100

Rotary vane

131

yes

1.01

1.5

132 1 25

Rotary vane

627

yes

0.21

1.5

132 1 15

Rotary vane

794

yes

0.17

1.5

132 1 5

Rotary vane

1160

yes

0.11

1.5

132 1 -4

Rotary vane

1485

yes

0.09

Ethanol

1.5

132 1 100

Rotary vane

34

yes

3.88

1.5

132 1 75

Rotary vane

45

yes

2.93

1.5

132 1 60

Rotary vane

55

yes

2.40

1.5

132 1 45

Rotary vane

70

yes

1.89

1.5

132 1 25

Rotary vane

95

yes

1.39

1.5

132 1 15

Rotary vane

120

yes

1.10

1.5

132 1 5

Rotary vane

160

yes

0.83

1.5

132 1 -4

Rotary vane

190

yes

0.70

Vacuum Pumps:

Chamber preheated prior to each run to run temp.

Diaphragm – Rated at 12 mbar ultimate vacuum and 34 L/min displacement

Rotary vane – Rated at 2.0 x 10-3 mbar ultimate vacuum and 195 L/min displacement

Evaporation Rates

Product Service 1-800-522-7658

Loading...

Loading...