Page 1

C

HHAAPPTTEERR

C

1

1

I

NNTTRROODDUUCCTTIIOON

I

Congratulations on your purchase of a Labconco

Glassware Washer. Labconco manufactures two types

of Glassware Washers, the SteamScrubber® and the

FlaskScrubber®. Each of these washers is available in a

Mobile, Undercounter, and Freestanding model. Each

washer model is available in 115V or 230V, and with or

without a window in the door.

Your Labconco Glassware Washer is designed and

manufactured to thoroughly clean your laboratory

glassware and accessories. Using the soft-touch control

panel, you can select pre-programmed wash cycles or

program customized wash cycles to facilitate your

individual requirements.

The Glassware Washer Liquid Crystal Display (LCD)

identifies the cycle selected and details about the cycle.

Models with a window and light in the door allow you

to visually monitor the operation of your washer.

Option switches for steaming and using purified water

for the final rinses allow you to choose the best

conditions for cleaning your glassware.

N

Product Service 1-800-522-7658

1

Page 2

Chapter 1: Introduction

About This Manual

This manual is designed to help you learn how to

install, use, and maintain your Glassware Washer.

Instructions for performing routine maintenance and

making minor modifications to your washer are also

included.

Chapter 1: Introduction provides a brief overview of

the Glassware Washer, explains the organization of the

manual, and defines the typographical conventions used

in the manual.

Chapter 2: Prerequisites explains what you need to do

to prepare your site before you install your Glassware

Washer. Hot water, purified water, electrical, and

drainage requirements are discussed.

Chapter 3: Getting Started contains the information

you need to properly unpack, inspect, install, and test

your Glassware Washer.

Chapter 4: Using Your Washer discusses the basic

operation of your washer. Information on how to

arrange the racks inside your washer, properly position

the glassware, fill the detergent dispenser, and select an

operating cycle is included.

Chapter 5: Maintaining Your Washer explains how to

perform routine maintenance on your Glassware

Washer. Information on how to safely clean the

interior of your washer, maintain the water fill valve,

clean the overflow dome, and replace the light bulb is

included.

Chapter 6: Modifying Your Washer describes how to

disconnect the purified water pump, how to install pipet

inserts in a FlaskScrubber, and how to install an

optional top rack in a FlaskScrubber.

2

Product Service 1-800-522-7658

Page 3

Chapter 7: Troubleshooting contains a table of

problems you may encounter while using your

Glassware Washer, including the probable causes of the

problems, and suggested corrective actions.

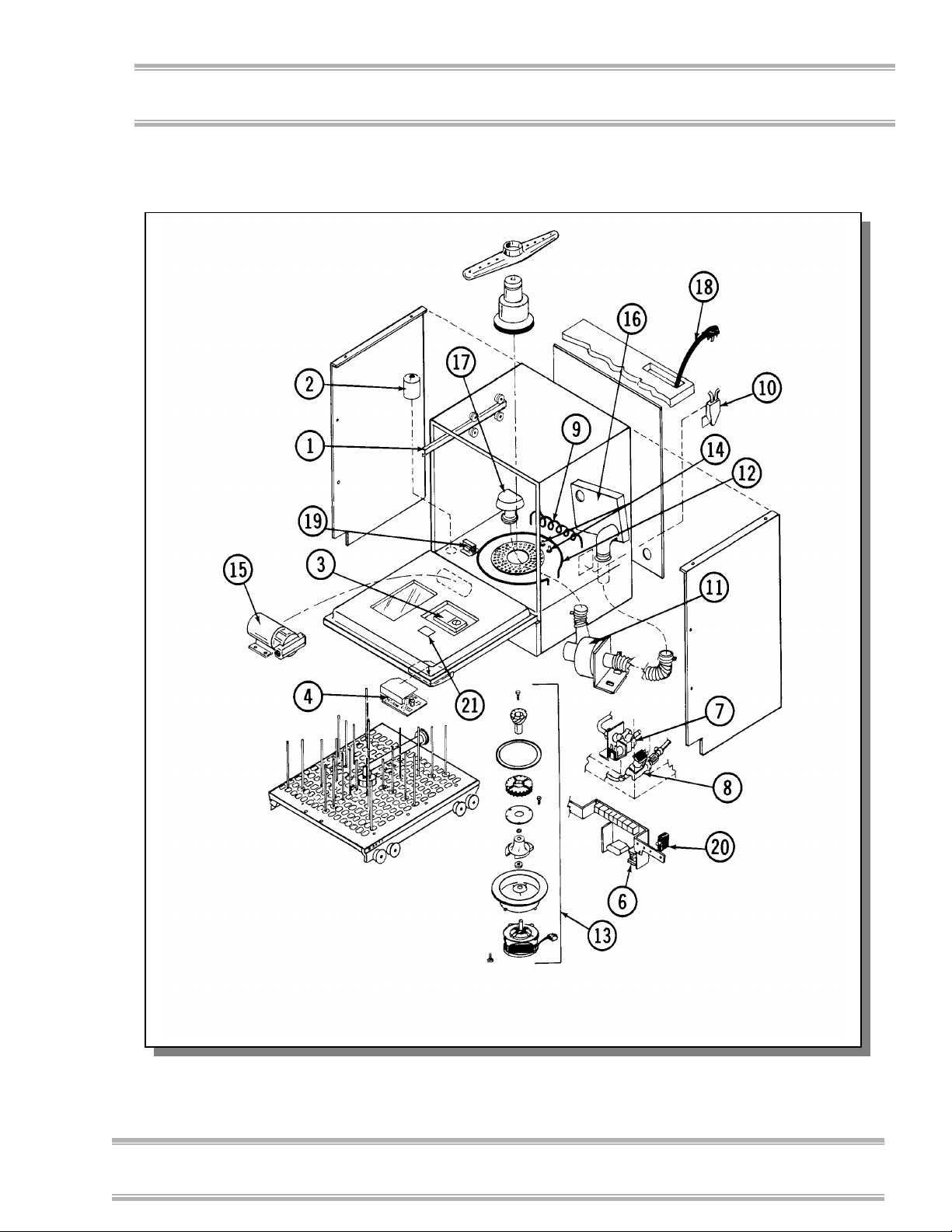

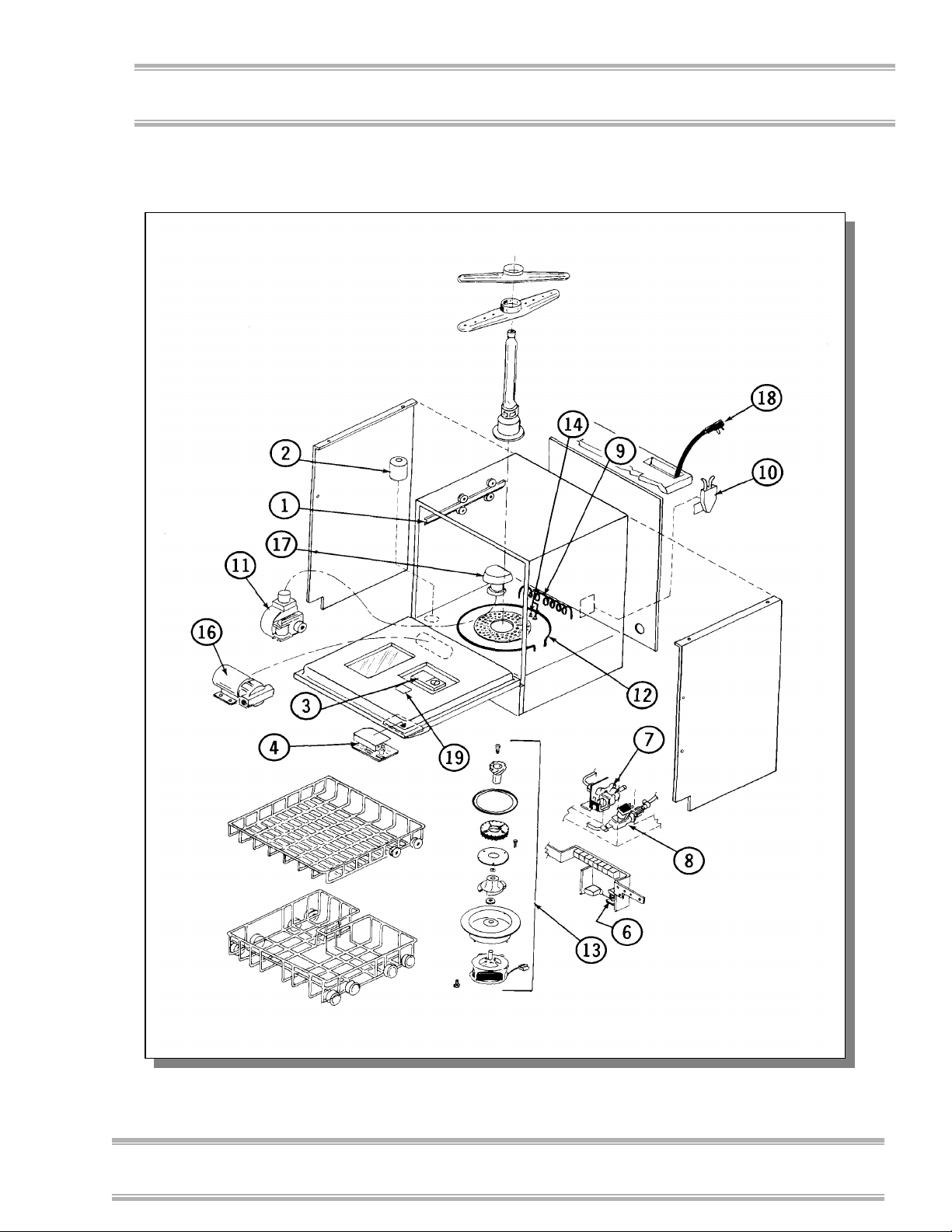

Appendix A: FlaskScrubber and SteamScrubber

Components contains labeled diagrams of all of the

components of the Glassware Washers.

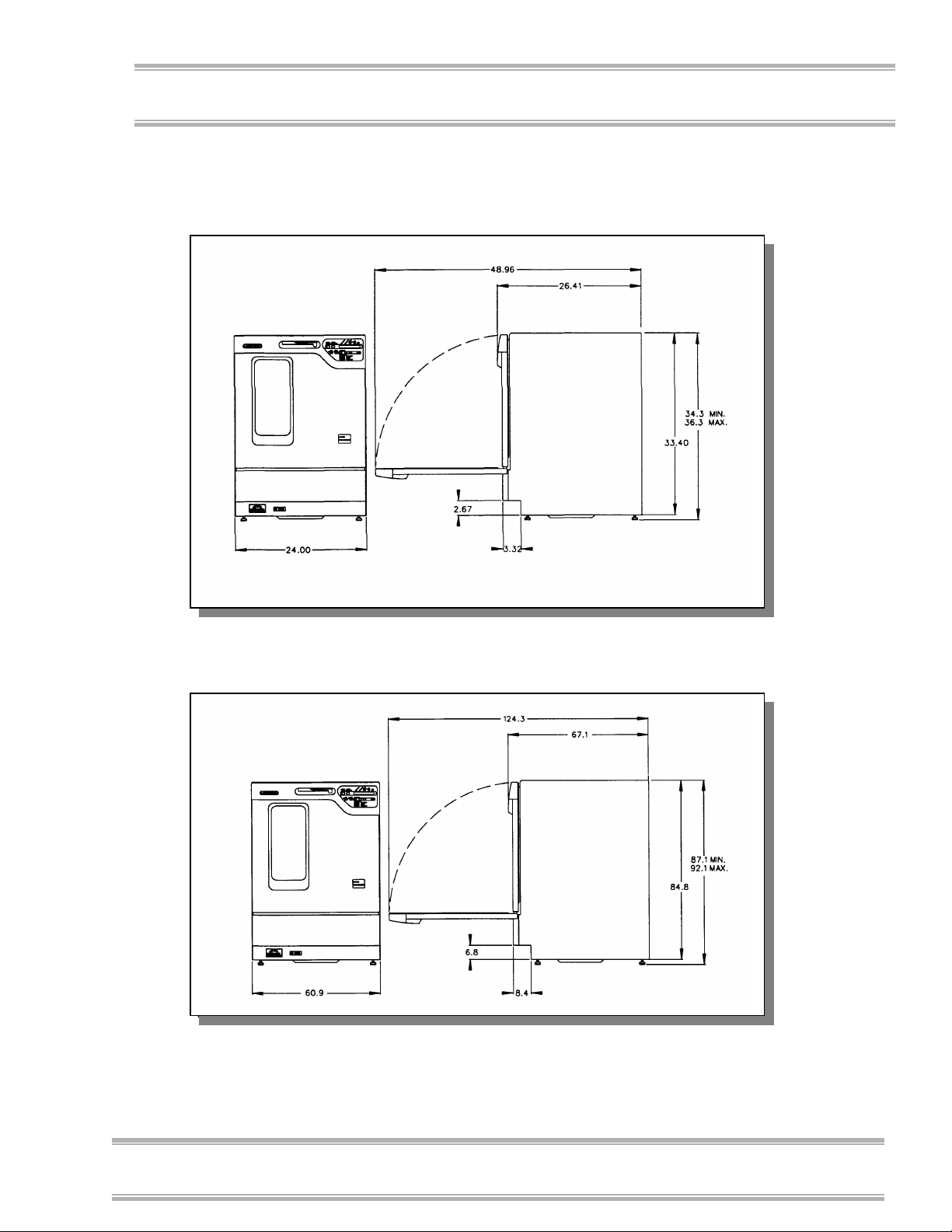

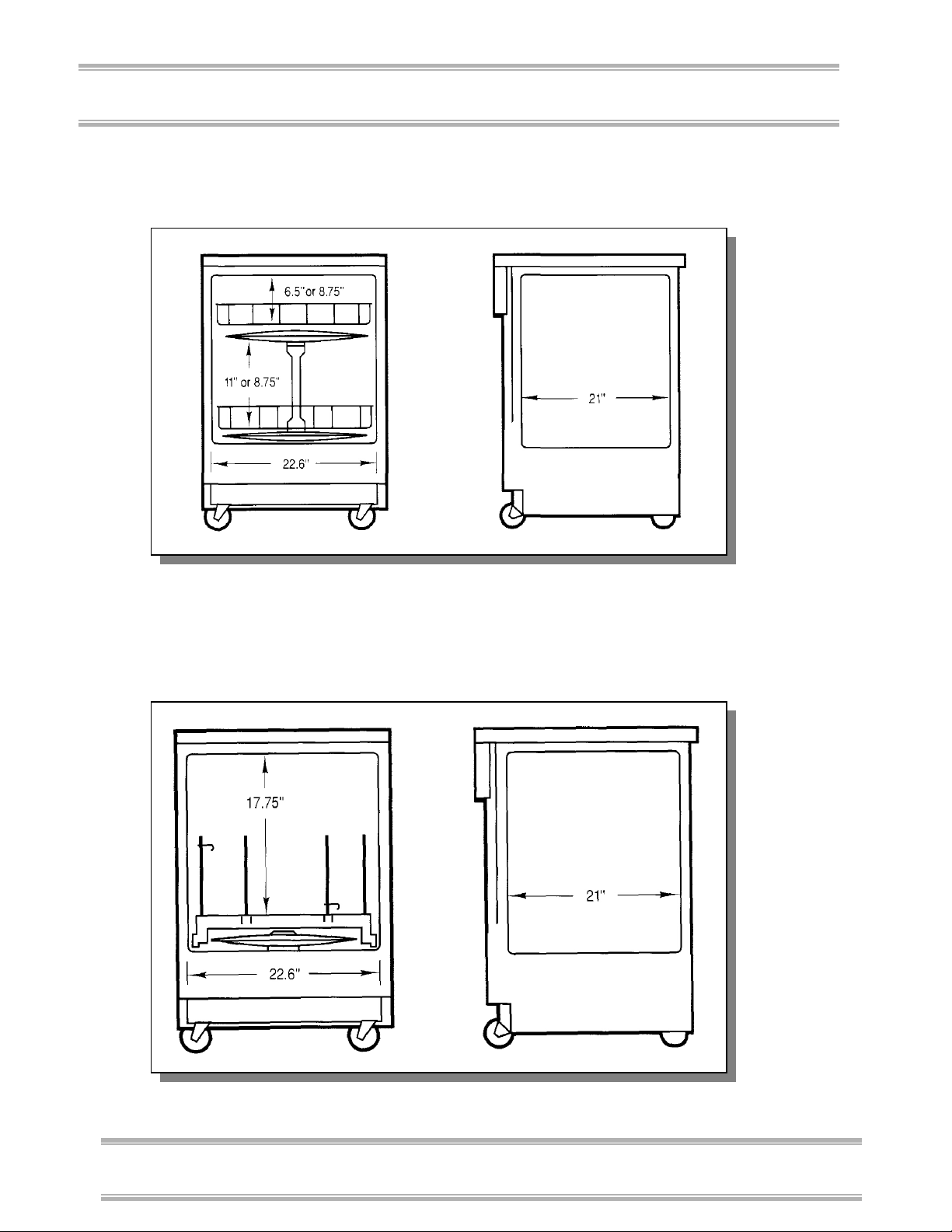

Appendix B: Glassware Washer Dimensions contains

comprehensive diagrams showing all of the dimensions

for the Freestanding, Mobile, and Undercounter models

of the Glassware Washers.

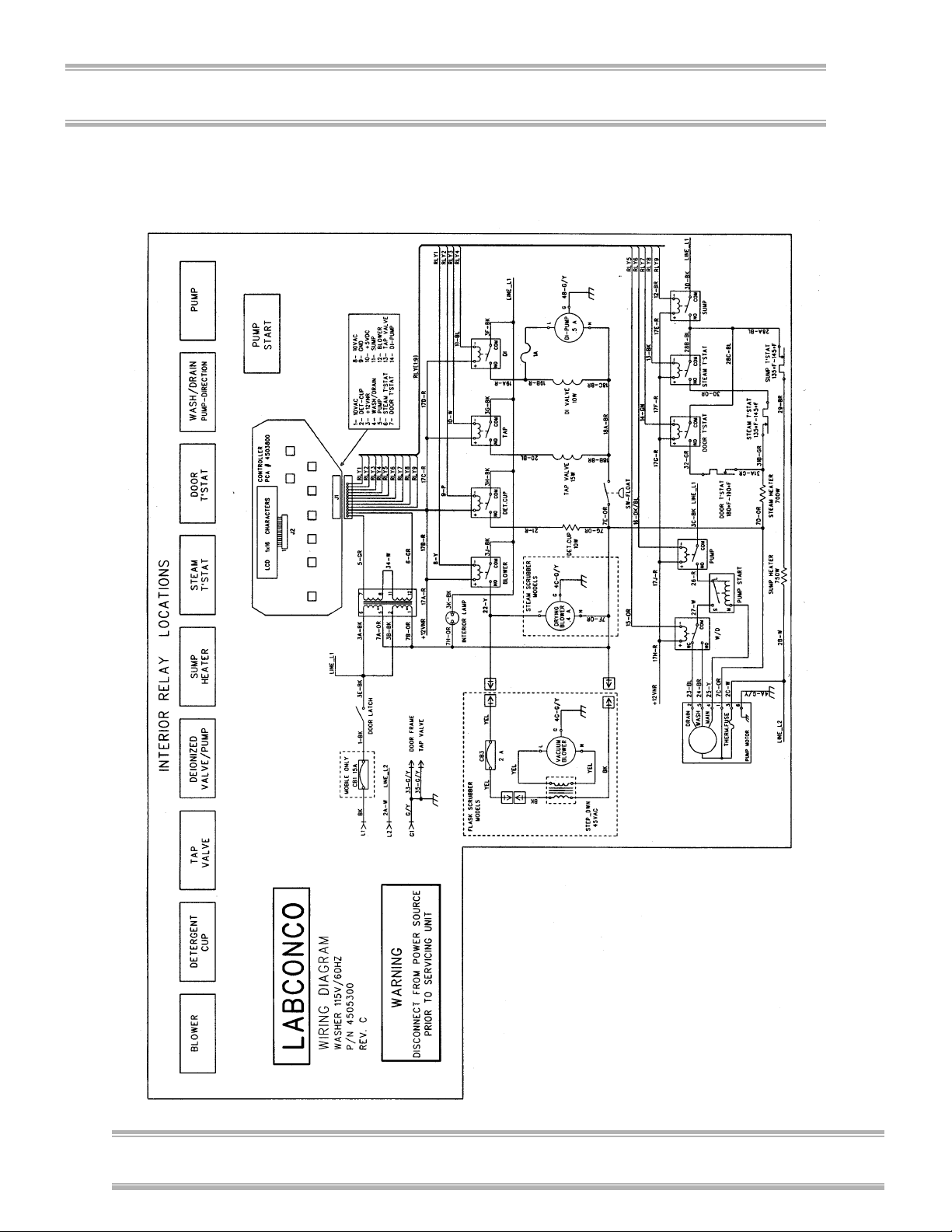

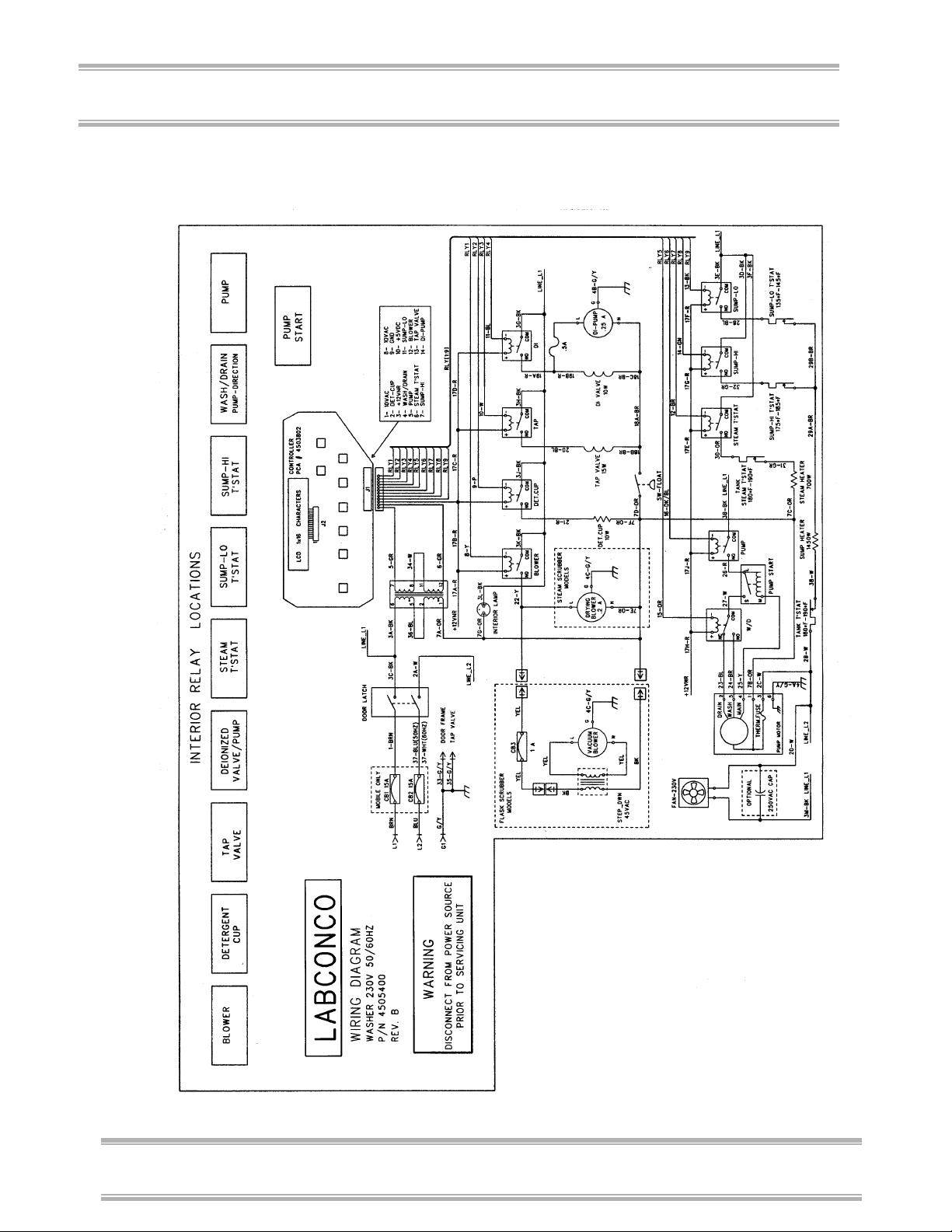

Appendix C: Glassware Washer Specifications contains

the program times and water consumption requirements

for the Glassware Washers. Wiring diagrams for both

the 115V and 230V washers are also included.

Chapter 1: Introduction

Appendix D: Glassware Washer Accessories lists the

part numbers and descriptions of all of the accessories

available for your Glassware Washer.

Typographical Conventions

Recognizing the following typographical conventions

will help you understand and use this manual:

• Book, chapter, and section titles are shown in

italic type (e.g., Chapter 3: Getting Started).

• Steps required to perform a task are presented in

a numbered format.

• Comments located in the margins provide

suggestions, reminders, and references.

• Critical information is presented in boldface

type in paragraphs that are preceded by the

exclamation icon. Failure to comply with the

information following an exclamation icon may

result in injury to the user or permanent damage

to your Glassware Washer.

!!!!

Product Service 1-800-522-7658

3

Page 4

Chapter 1: Introduction

☞

☞☞

☞

M

M

F

F

U

U

• Important information is presented in

capitalized type in paragraphs that are preceded

by the pointer icon. It is imperative that the

information contained in these paragraphs be

thoroughly read and understood by the user.

• Information that is specific to a particular model

of Glassware Washer is preceded by a letter

icon. The F icon indicates the text is specific to

the Freestanding washer model. The M icon

indicates the text is specific to the Mobile

washer model. The U icon indicates the text is

specific to the Undercounter washer model.

Your Next Step

If your Glassware Washer needs to be installed,

proceed to Chapter 2: Prerequisites to ensure your

installation site meets all of the requirements. Then, go

to Chapter 3: Getting Started for instructions on how to

install your Glassware Washer and make all of the

necessary connections.

For information on the operational characteristics of

your Glassware Washer, go to Chapter 4: Using Your

Washer.

If your Glassware Washer is installed and you need to

perform routine maintenance on the washer, proceed to

Chapter 5: Maintaining Your Washer.

For information on making modifications to the

configuration of your washer, go to Chapter 6:

Modifying Your Washer.

Refer to Chapter 7: Troubleshooting if you are

experiencing problems with your Glassware Washer.

4

Product Service 1-800-522-7658

Page 5

C

HHAAPPTTEERR

C

2

2

P

RREERREEQQUUIISSIITTEES

P

Before you install your Glassware Washer, you need to

prepare your site for installation. Carefully examine the

location where you intend to install your Glassware

Washer. You must be certain that the area is level and of

solid construction. In addition, a hot water source, a drain,

a purified water source (if applicable), and an electrical

source must be located near the installation site.

Carefully read this chapter to learn:

• the hot water source requirements for your

installation site.

• the purified water source requirements for your

installation site.

• the electrical supply requirements for your

installation site.

• the drainage requirements for your installation

site.

S

Product Service 1-800-522-7658

5

Page 6

Chapter 2: Prerequisites

Chapter 2: Prerequisites

Refer to Appendix C: Glassware Washer Specifications for

complete Glassware Washer electrical and environmental

conditions, specifications and requirements.

Hot Water Requirements

An existing hot water supply may be used as the hot water

source for your Glassware Washer. However, the washer

requires the inlet water temperature to be greater than

120°F (49°C) to fully activate powdered detergents and

raise the glassware temperatures to achieve fast and

complete drying. For ultimate washer performance, a hot

water inlet temperature setting of 150°F (66°C) is

recommended.

Water pressure must be between 20 – 120 psi (138 - 827

kPa) at the washer and provide a minimum of 1.25 gallons

(4.7 liters) per minute flow rate.

Pressurization is not

required for the purified

water source.

A shut-off valve should be installed in the water supply

line plumbed to the washer. The hot water inlet valve on

the Glassware Washer is equipped with a female 3/8 NPT

fitting.

Purified Water Requirements

If you intend to use purified water for the final rinse cycle,

a purified water supply is required. The washer can be

connected to an in-house, pressurized, purified water tap; a

water purification system; or a purified water container.

The purified water system must be provided with supply

piping of sufficient size to permit at least 1.25 gallons (4.7

liters) per minute of flow (½" internal diameter (ID)

minimum pipe is recommended). The purified water inlet

valve on your washer is equipped with a plastic hose barb

connection to accommodate ¾" (2 cm) ID flexible plastic

or rubber hose. Use a spring or band hose clamp to secure

the hose to the hose barb connection. The hose barb

connection may be removed from the valve to expose a

male ¾" - 11-1/2 NH hose coupling. A rigid plastic, tin-

6

Product Service 1-800-522-7658

Page 7

lined, or stainless steel tubing and fitting can be connected

M

to the washer fitting.

All connections on the purified water

system must be airtight so that the

!!!!

If the purified water is stored in a carboy, at least 5 gallons

(18.9 liters) must be available for each wash cycle. If all 5

gallons are not available at the start of a wash cycle, but

instead are produced concurrently with the wash cycle, the

production rate must permit at least 1.25 gallons (4.7

liters) per minute to be delivered to the washer. In

addition, all 5 gallons (18.9 liters) must be made available

over a 5-minute period.

washer pump is not allowed to pull air

instead of water.

Chapter 2: Prerequisites

Electrical Requirements

If your Glassware Washer is an Undercounter or

Freestanding model, it should be hard-wired directly into a

junction box using conduit. A 20 Amp circuit breaker or

fuse is required for models rated at 115V (60 Hz) or 230V

(50/60 Hz).

If your Glassware Washer is a Mobile model, a dedicated

electrical outlet is required. A 20 Amp circuit breaker or

fuse is required for models rated at 115V (60 Hz) or 230V

(50/60 Hz). 115V models are equipped with a 20 Amp

NEMA 5-20P plug. 230V models are equipped with a 15

Amp NEMA 6-15P plug. It may be necessary to remove

the plug and install a different plug to match the available

receptacle.

U

U

F

F

Product Service 1-800-522-7658

7

Page 8

Chapter 2: Prerequisites

M

M

☞

☞☞

☞

Chapter 2: Prerequisites

Drain Requirements

U

U

U

U

F

F

F

F

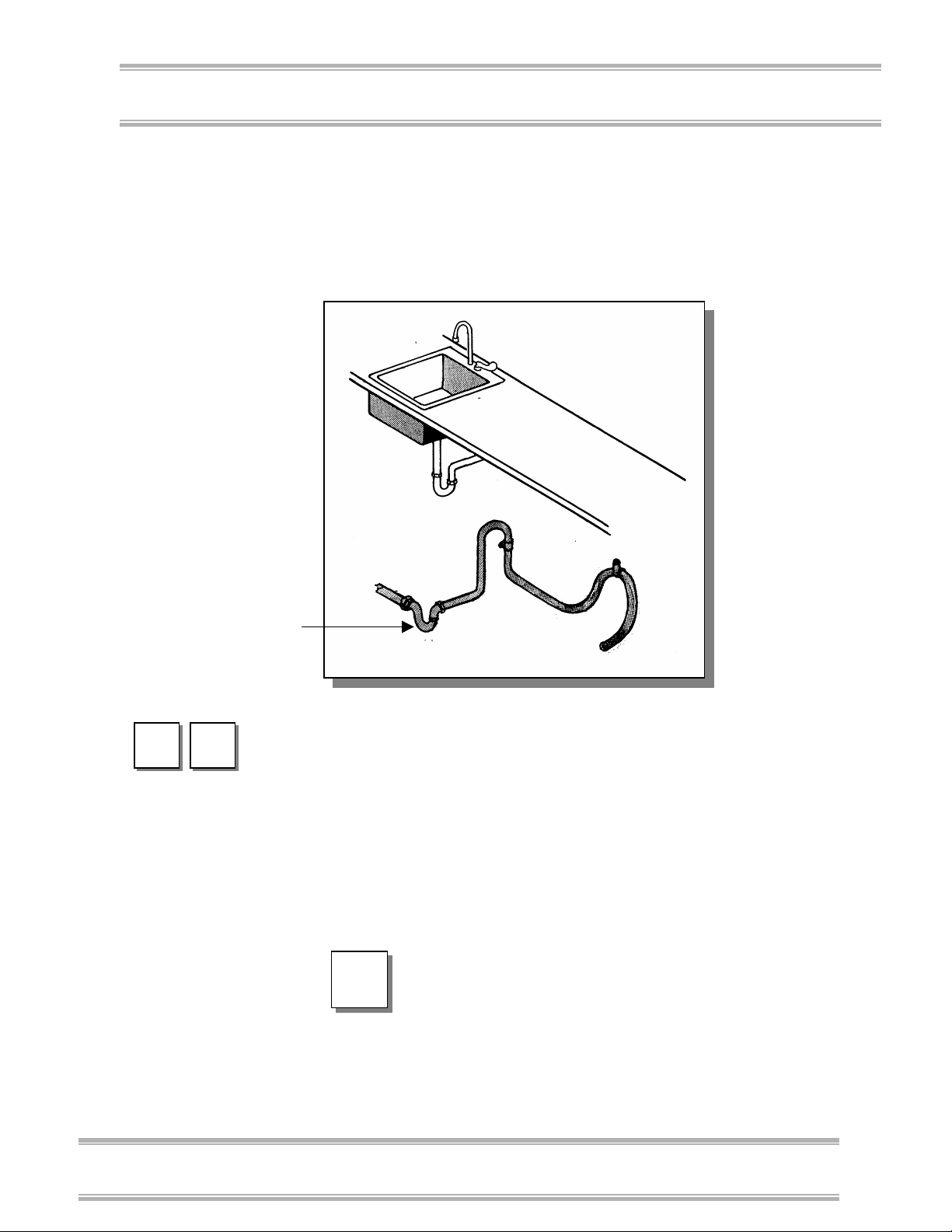

The Glassware Washer drain hose connects to a fitting on

the rear side of the pump/motor assembly. The drain hose

is installed at the factory prior to shipment. The hose

provides a flexible coupling to the building drain piping

and can be secured with a spring or band hose clamp. (A

band hose clamp is provided with the washer.)

Tubing or pipe, ½" (1.3 cm) ID or larger, should be

provided for the building drain. The use of an air gap is

strongly recommended to prevent siphoning of wastewater

into the washer.

DO NOT REDUCE THE SIZE OF THE

DRAIN PLUMBING.

Mobile models drain into a sink through a hose assembly

that attaches to the faucet.

8

Product Service 1-800-522-7658

Page 9

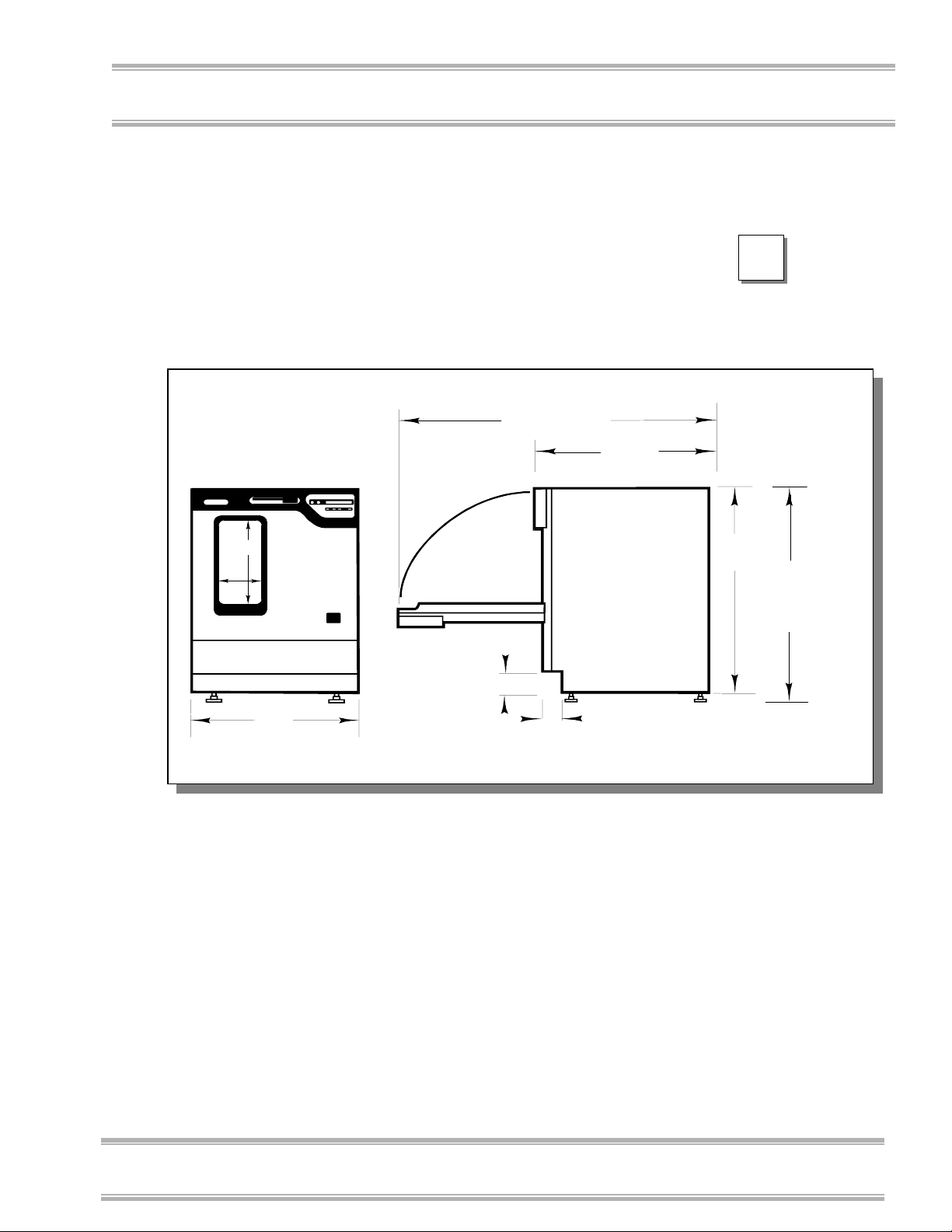

Space Requirements

If your Glassware Washer is an Undercounter model, you

must ensure the undercounter opening is the proper size to

accommodate the washer. The dimensions for the

Undercounter washer are shown below in Figure 2-2.

49.0"

124.3 cm

26.4"

67.1 cm

Chapter 2: Prerequisites

U

U

Figure 2-2

13.8''

6.3''

2.7"

6.8 cm

24.0"

60.9 cm

3.3" 8.4 cm

Your Next Step

After you have determined that the location for your

Glassware Washer accommodates the installation and

operational requirements of your washer, you are ready to

unpack and install your washer. Proceed to Chapter 3:

Getting Started.

33.4"

84.8 cm

34.3"

87.1 cm

36.3"

92.1 cm

MIN.

MAX

Product Service 1-800-522-7658

9

Page 10

Chapter 2: Prerequisites

Chapter 2: Prerequisites

10

Product Service 1-800-522-7658

Page 11

C

HHAAPPTTEERR

C

3

3

G

EETTTTIINNGG

G

Now that the site for your Glassware Washer is properly

prepared, you are ready to unpack, inspect, install, and test

your washer. Read this chapter to learn how to:

• unpack and move your washer.

• set up your washer.

• connect the hot water and purified water sources

for your washer.

• connect the electrical supply source to your

washer.

• properly drain your washer.

• perform set-up diagnostics on your washer.

Depending upon which model of washer you are

installing, you may need common plumbing and electrical

installation tools in addition to a 9/16" wrench, a flat-blade

screwdriver, a phillips screwdriver, and a carpenter level

to complete the instructions in this chapter.

S

S

TTAARRTTEED

D

The Glassware Washer weighs over 70

lbs. (33 Kg). The carton allows for lifting

!!!!

Product Service 1-800-522-7658

with a mechanical lift truck or hand

truck. If you must lift the washer

manually, use at least two (2) persons

and follow safe-lifting guidelines.

11

Page 12

Chapter 3: Getting Started

y

☞

☞☞

☞

☞

☞☞

☞

☞

☞☞

☞

Chapter 2: Prerequisites

Unpacking Your Glassware

Washer

The United States

Interstate Commerce

Commission rules

require that claims be

filed with the delivery

carrier within fifteen (15)

da

s of delivery.

Carefully unpack your Glassware Washer and inspect the

washer for damage that may have occurred in transit. If

your washer is damaged, notify the delivery carrier

immediately and retain the entire shipment intact for

inspection by the carrier.

DO NOT RETURN GOODS WITHOUT

THE PRIOR AUTHORIZATION OF

LABCONCO. UNAUTHORIZED

RETURNS WILL NOT BE ACCEPTED.

IF YOUR WASHER WAS DAMAGED IN

TRANSIT, YOU MUST FILE A CLAIM

DIRECTLY WITH THE FREIGHT

CARRIER. LABCONCO

CORPORATION AND ITS DEALERS

ARE NOT RESPONSIBLE FOR

SHIPPING DAMAGES.

BE CERTAIN TO REMOVE ALL

PACKAGING MATERIALS,

DETERGENT SAMPLES AND ANY

MATERIALS THAT ARE NOT AN

INTEGRAL COMPONENT OF THE

GLASSWARE WASHER FROM THE

INSIDE OF THE WASHER PRIOR TO

INSTALLING THE WASHER.

12

Do not discard the carton or packing material for your

washer until you have checked all of the components and

installed and tested the washer.

Do not remove the washer from its shipping skid until it is

ready to be placed into its final location. Move the washer

by placing a flat, low dolly under the shipping skid.

Product Service 1-800-522-7658

Page 13

Chapter 3: Getting Started

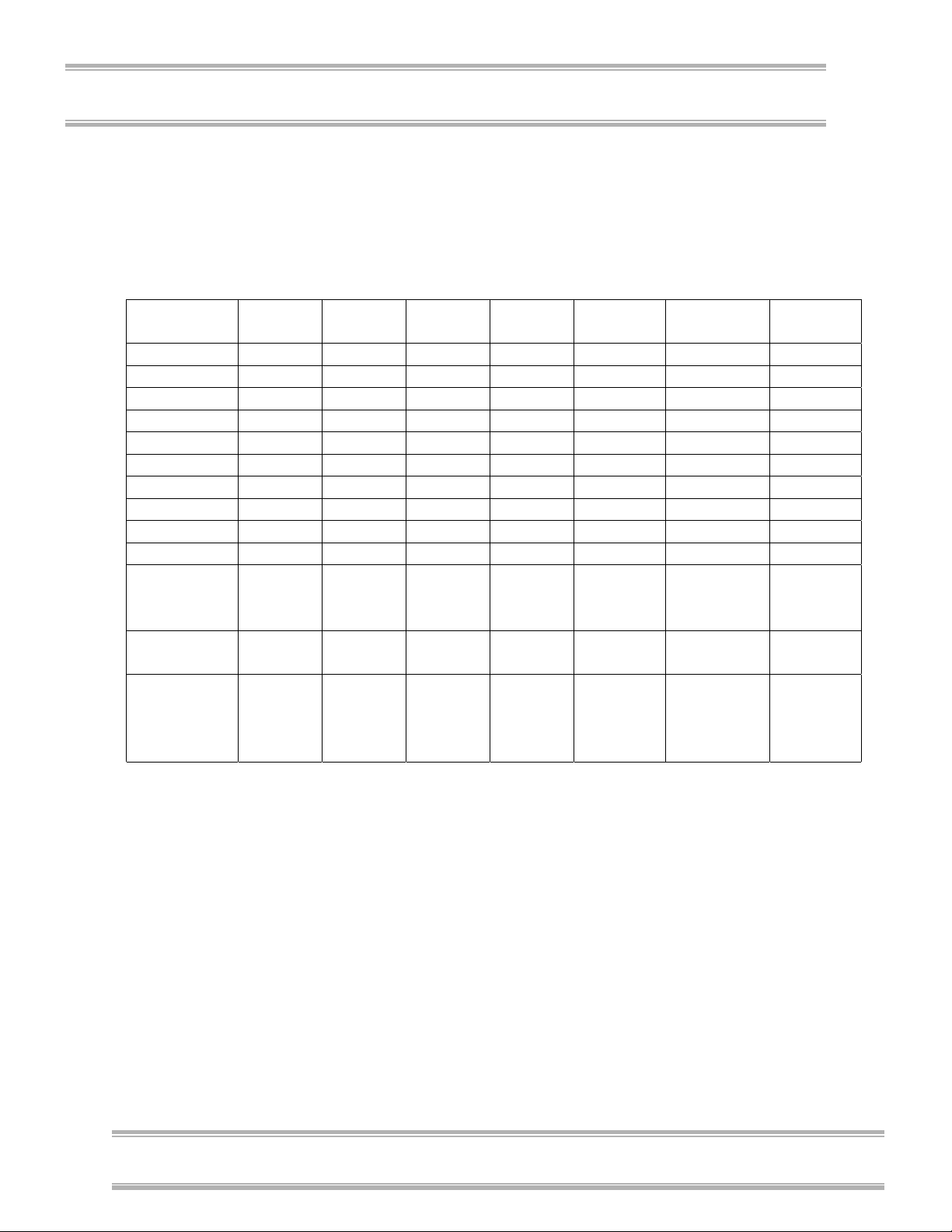

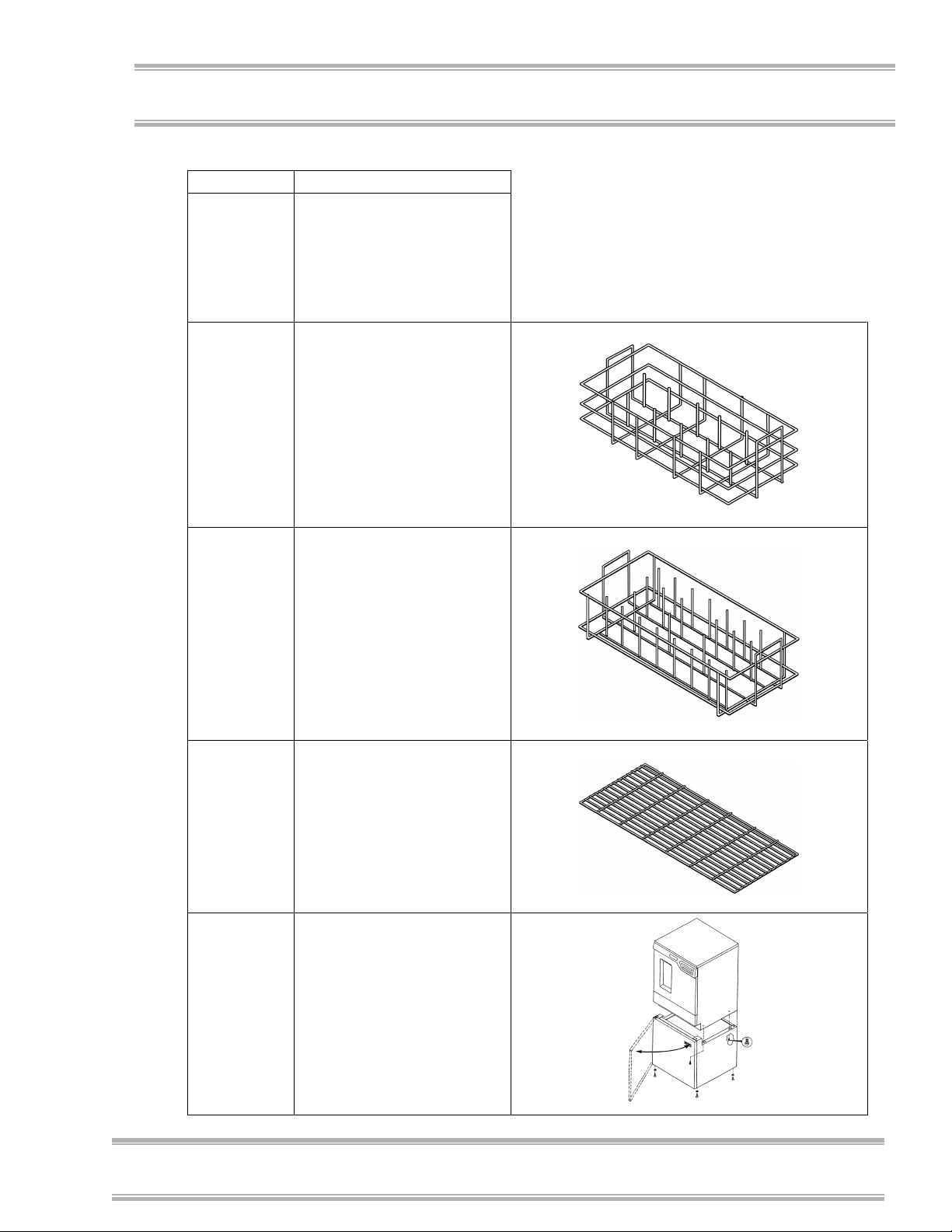

Washer Components

As previously mentioned, Labconco manufactures two

types of Glassware Washers, the SteamScrubber and the

FlaskScrubber. Each of these washers is available in a

Mobile, Undercounter, and Freestanding model. Each

washer model is available in 115V or 230V, and with or

without a window.

The different washer models require different assembly

components. Locate the model of washer you received in

the following group of tables. Verify that the components

listed are present and undamaged.

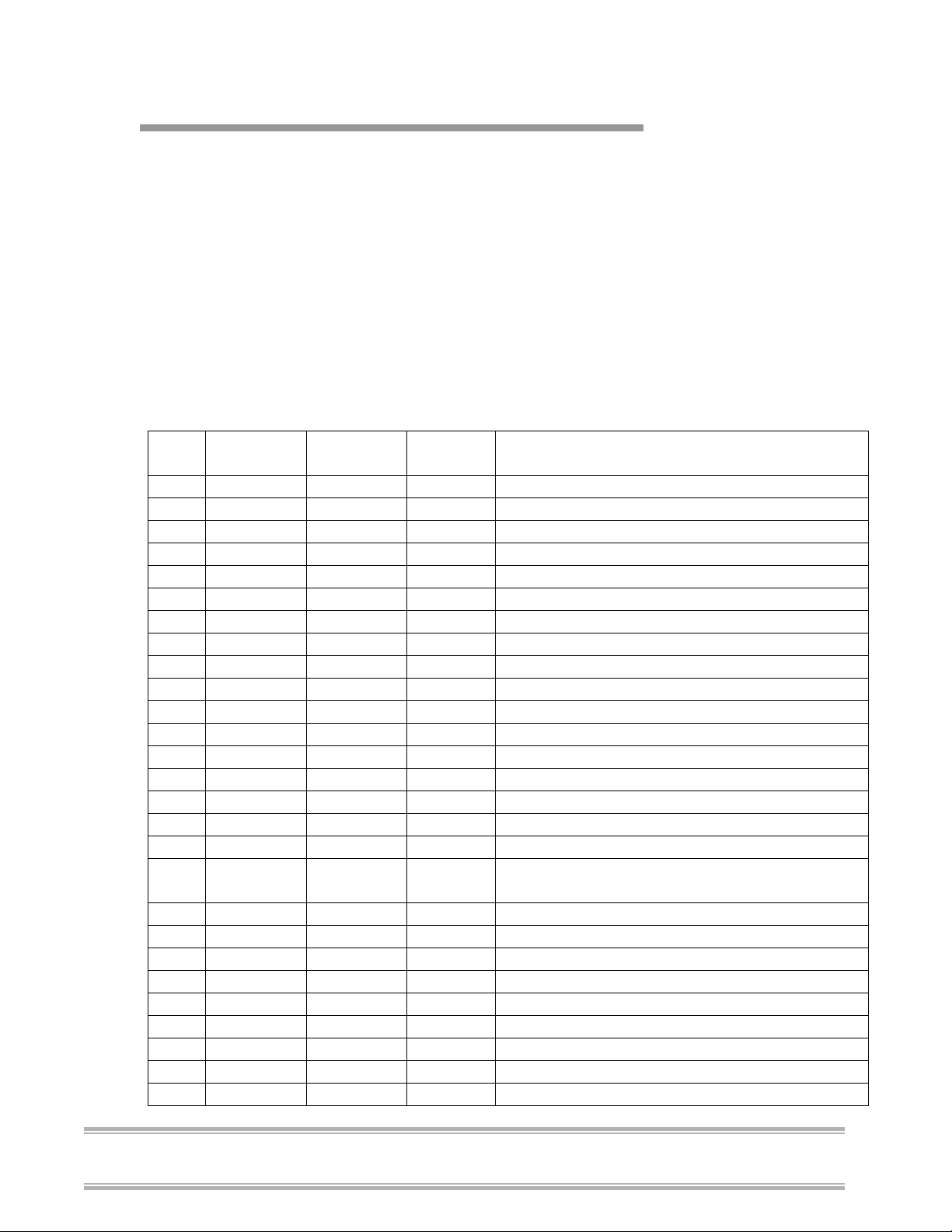

Catalog # Washer Description

44000-00 SteamScrubber Mobile – 115 V

44000-01 SteamScrubber Mobile – 230 V

44000-10 SteamScrubber Mobile – 115 V with window

44000-11 SteamScrubber Mobile – 230 V with window

Plus the Following:

Part # Component Description

44882-01 Four (4) Casters

45036-00 User Manual

44222-00 Three (3) ounces of LabSolutions Detergent (with MSDS)

44056-00 One (1) Aerator Adapter

44057-00 One (1) Adapter Fitting

SteamScrubber

Mobile Models

Catalog # Washer Description

44003-00 SteamScrubber Undercounter – 115 V

44003-01 SteamScrubber Undercounter – 230 V

44003-10 SteamScrubber Undercounter – 115 V with window

44003-11 SteamScrubber Undercounter – 230 V with window

Plus the Following:

Part # Component Description

18798-01 Four (4) Leveling Feet

45036-00 User Manual

44629-00 Two (2) Screws

14888-00 One (1) Clamp

44222-00 Three (3) ounces LabSolutions Detergent (with MSDS)

Catalog # Washer Description

44004-00 SteamScrubber Freestanding – 115 V

44004-01 SteamScrubber Freestanding – 230 V

44004-10 SteamScrubber Freestanding – 115 V with window

44004-11 SteamScrubber Freestanding – 230 V with window

Product Service 1-800-522-7658

SteamScrubber

Undercounter

Models

SteamScrubber

Freestanding

Models

13

Page 14

Chapter 3: Getting Started

Chapter 2: Prerequisites

Plus the Following:

Part # Component Description

18798-01 Four (4) Leveling Feet

45036-00 User Manual

44680-00 One (1) Hole Plug

14888-00 One (1) Clamp

44222-00 Three (3) ounces LabSolutions Detergent (with MSDS)

FlaskScrubber

Mobile Models

FlaskScrubber

Undercounter

Models

Catalog # Washer Description

44200-00 FlaskScrubber Mobile – 115 V

44200-01 FlaskScrubber Mobile – 230 V

44200-10 FlaskScrubber Mobile – 115 V with window

44200-11 FlaskScrubber Mobile – 230 V with window

Plus the Following:

Part # Component Description

44882-01 Four (4) Casters

45036-00 User Manual

44222-00 Three (3) ounces LabSolutions Detergent (with MSDS)

44056-00 One (1) Aerator Adapter

44057-00 One (1) Adapter Fitting

Catalog # Washer Description

44203-00 FlaskScrubber Undercounter – 115 V

44203-01 FlaskScrubber Undercounter – 230 V

44203-10 FlaskScrubber Undercounter – 115 V with window

44203-11 FlaskScrubber Undercounter – 230 V with window

Plus the Following:

Part # Component Description

18798-01 Four (4) Leveling Feet

45036-00 User Manual

44629-00 Two (2) Screws

14888-00 One (1) Clamp

44222-00 Three (3) ounces LabSolutions Detergent (with MSDS)

FlaskScrubber

Freestanding

Models

14

Catalog # Washer Description

44204-00 FlaskScrubber Freestanding – 115 V

44204-01 FlaskScrubber Freestanding – 230 V

44204-10 FlaskScrubber Freestanding – 115 V with window

44204-11 FlaskScrubber Freestanding – 230 V with window

Plus the Following:

Part # Component Description

18798-01 Four (4) Leveling Feet

45036-00 User Manual

44680-00 One (1) Hole Plug

14888-00 One (1) Clamp

44222-00 Three (3) ounces LabSolutions Detergent (with MSDS)

Product Service 1-800-522-7658

Page 15

If you did not receive one or more of the components

M

M

listed for your washer, or if any of the components are

damaged, contact Labconco Corporation immediately for

further instructions.

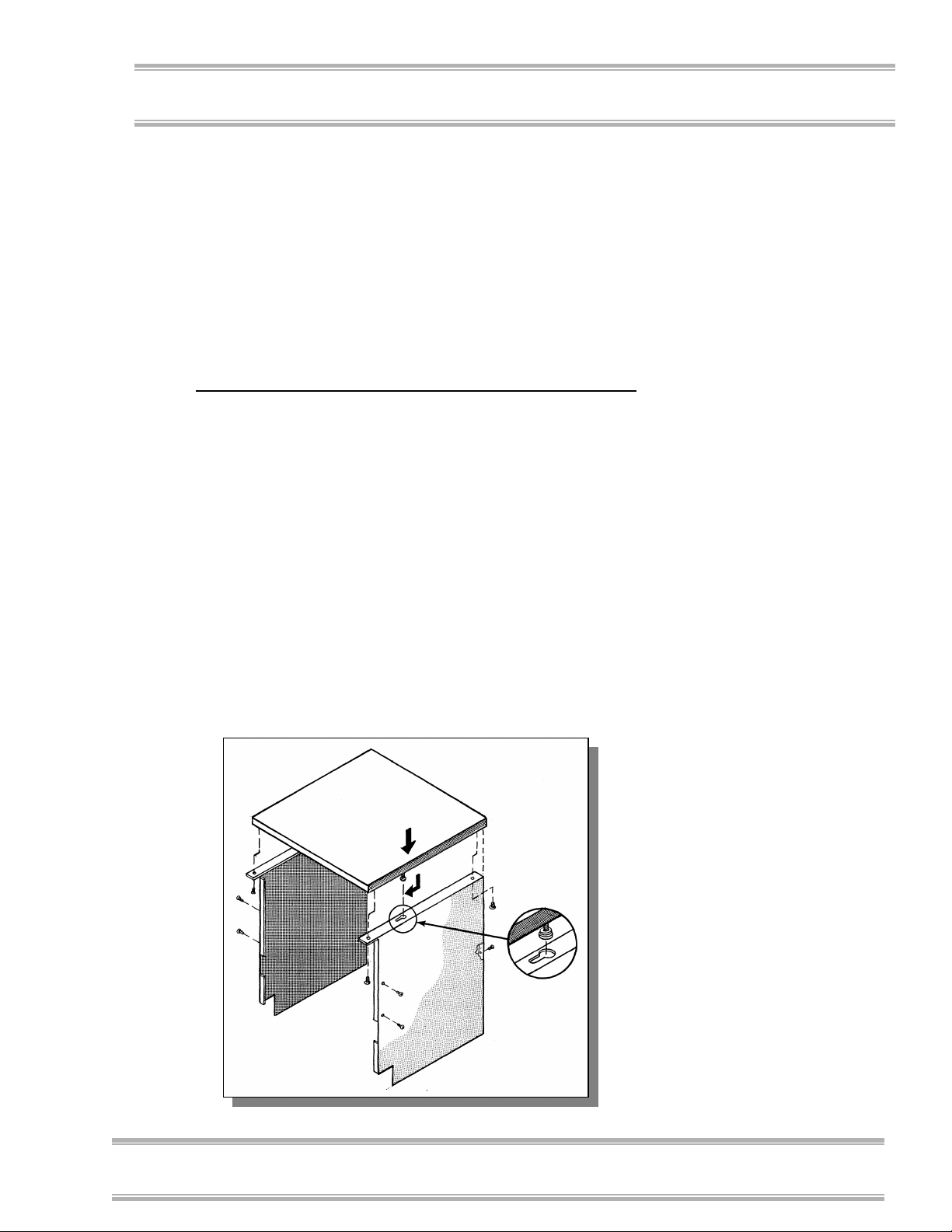

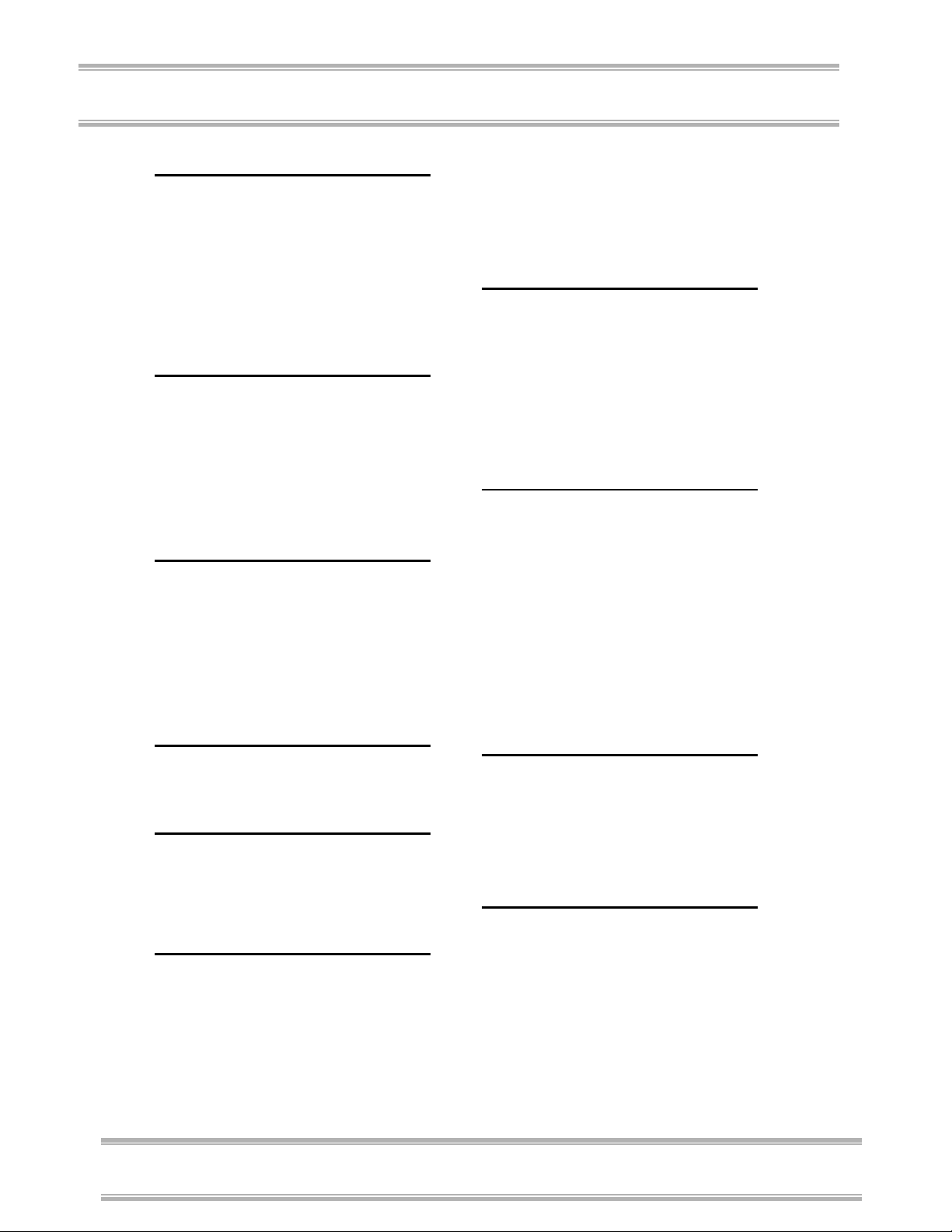

Removing the Shipping Skid

Chapter 3: Getting Started

After you verify the washer components, move your

washer to the location where you want to install it. Then,

follow the steps listed below to remove the shipping skid

from your washer.

To remove the shipping skid:

1. Make certain any loose items inside the washer have

been removed.

2. Gently place the washer on its back, positioning the

washer on the shipping carton or other cushioning

material.

3. Remove the four screws fastening the skid to the

washer.

Setting Up Your Washer

After you remove the skid from your washer, you must

install either casters or leveling feet on the bottom of the

washer. If you have an Undercounter or Freestanding

model, then you must level the washer and center the

washer door. If you have an Undercounter model, you

must also attach the washer to the countertop or

worksurface.

Move the washer by

placing a flat, low dolly

under the shipping skid.

Retain the shipping skid

until you test the various

features of the washer.

Installing the Casters or Leveling

Feet

If you have the Mobile model of the SteamScrubber or

FlaskScrubber washer, the washer must sit on a level floor.

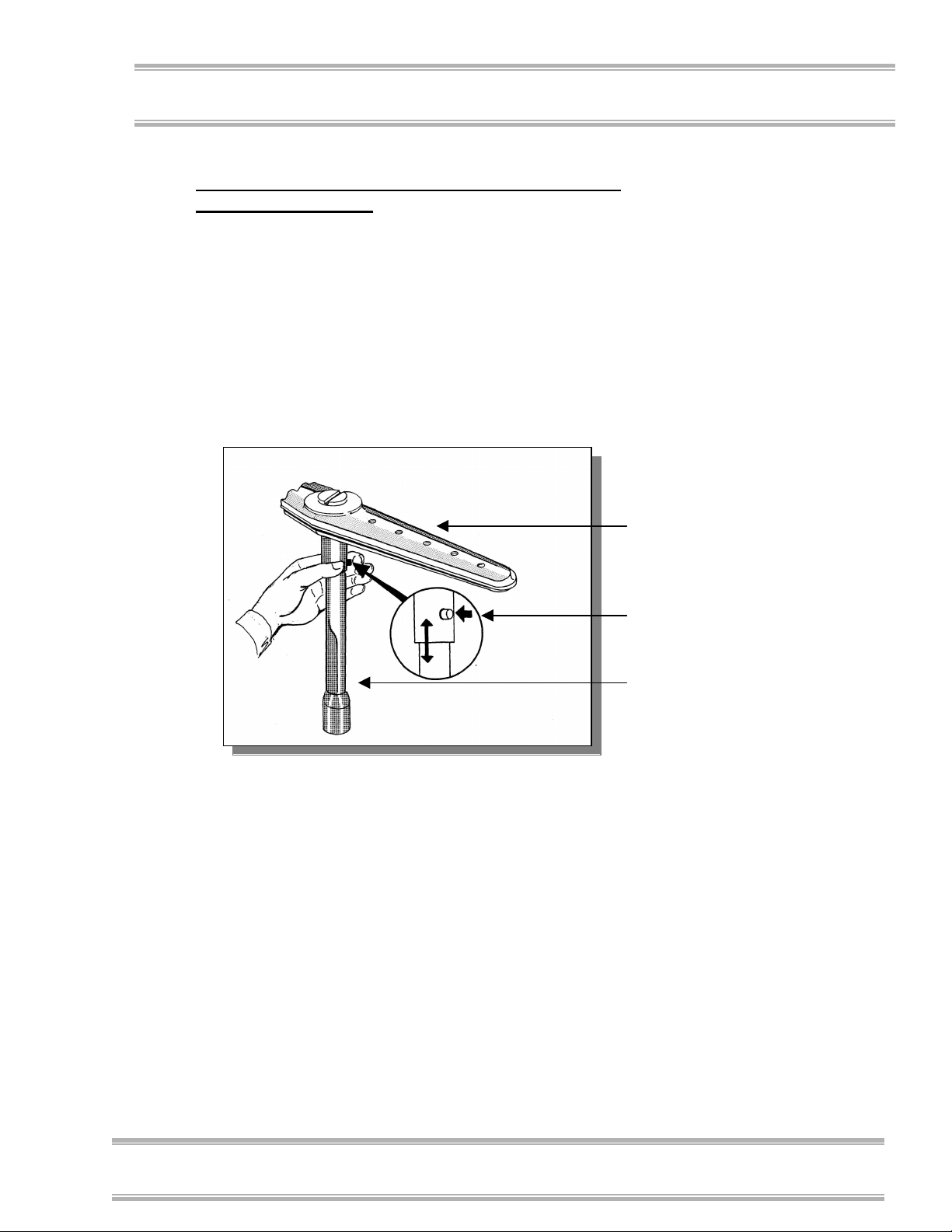

Refer to Figure 3-1 and follow the steps below to install

the casters on your washer.

Product Service 1-800-522-7658

15

Page 16

Chapter 3: Getting Started

Chapter 2: Prerequisites

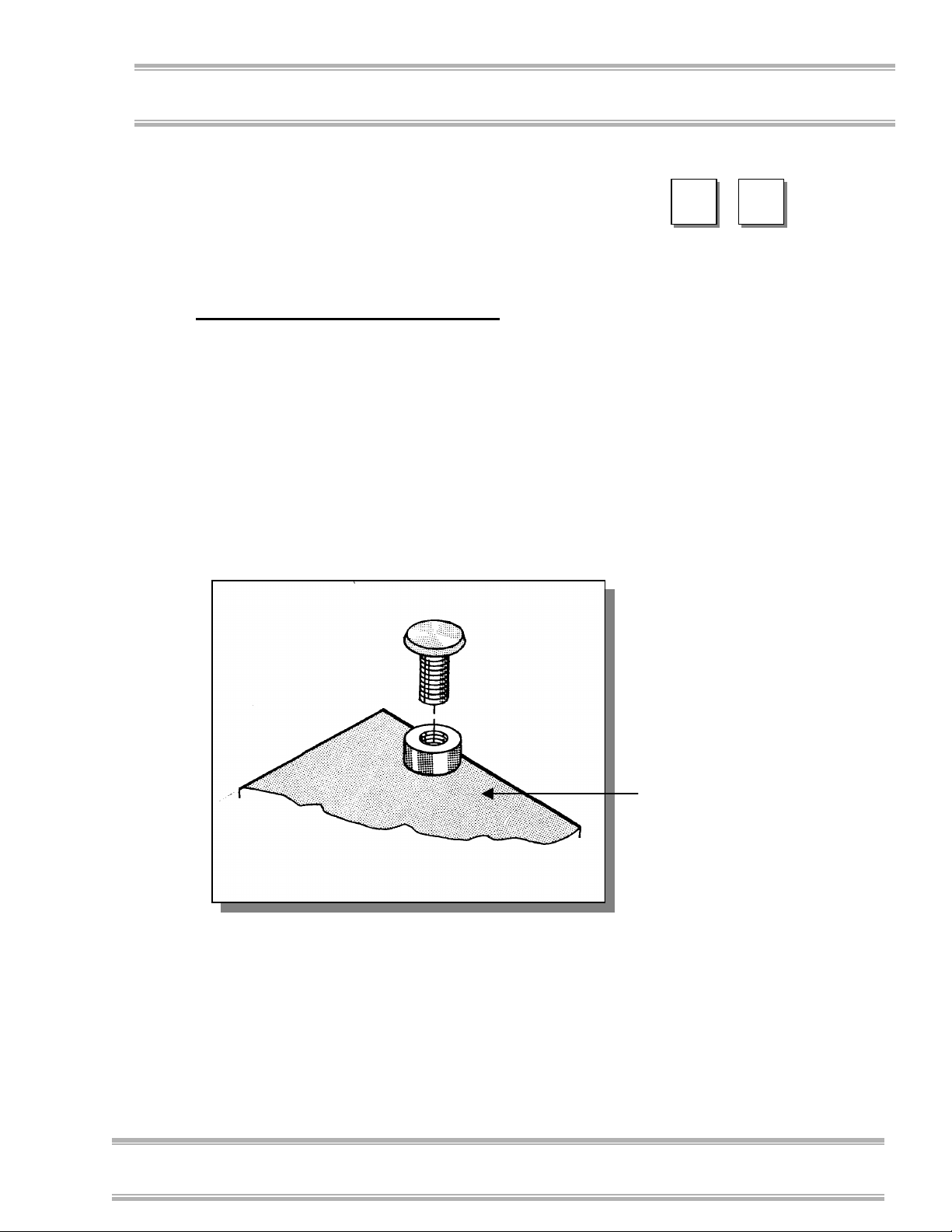

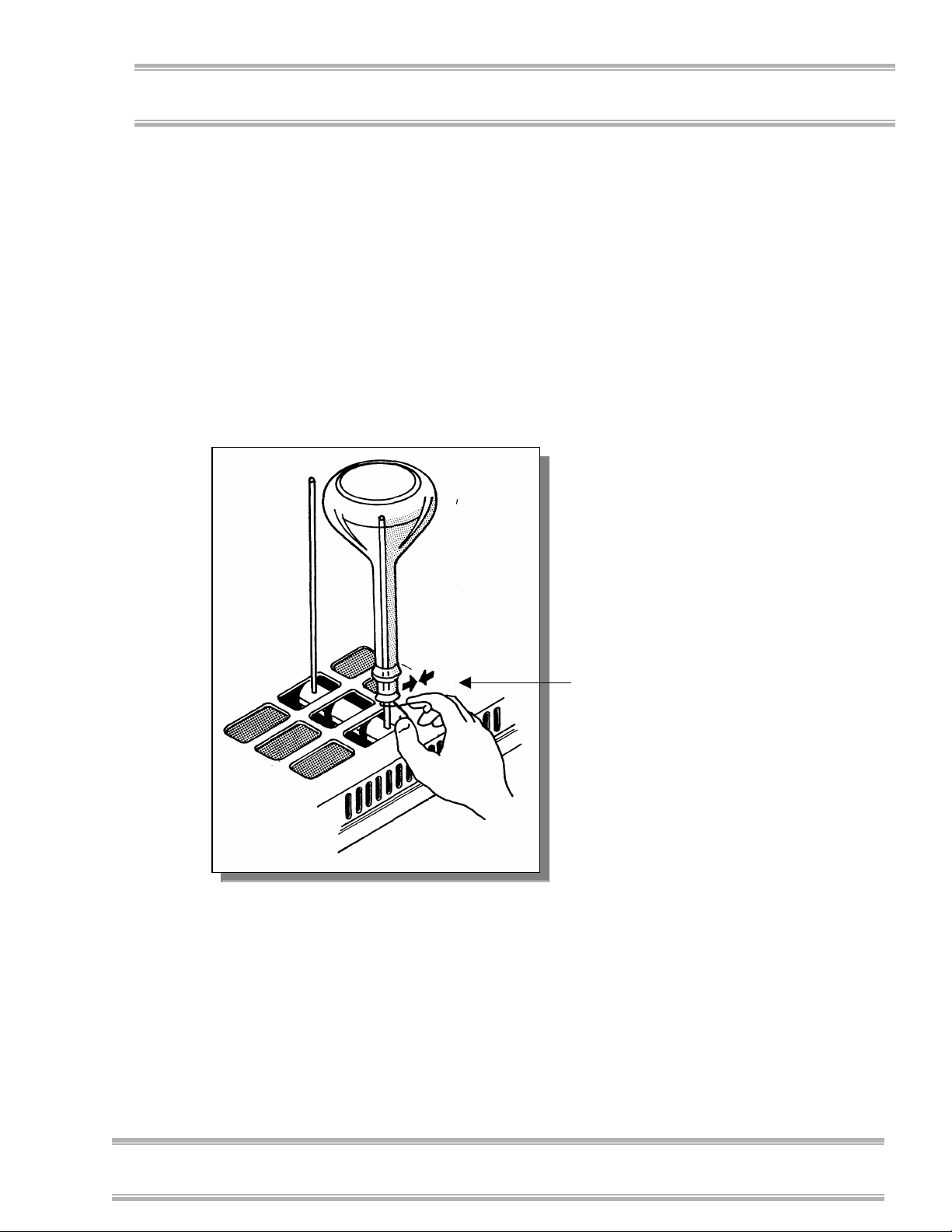

To install the washer casters:

1. Locate the holes on the bottom of the washer where

2. Thread the four casters into these holes until the

3. Carefully move the washer into an upright position.

the four skid-fastening screws were previously

attached.

casters fit tightly.

Be careful to distribute the weight evenly on the

casters when setting the washer upright.

Figure 3-1

16

Bottom of

washer

Product Service 1-800-522-7658

Page 17

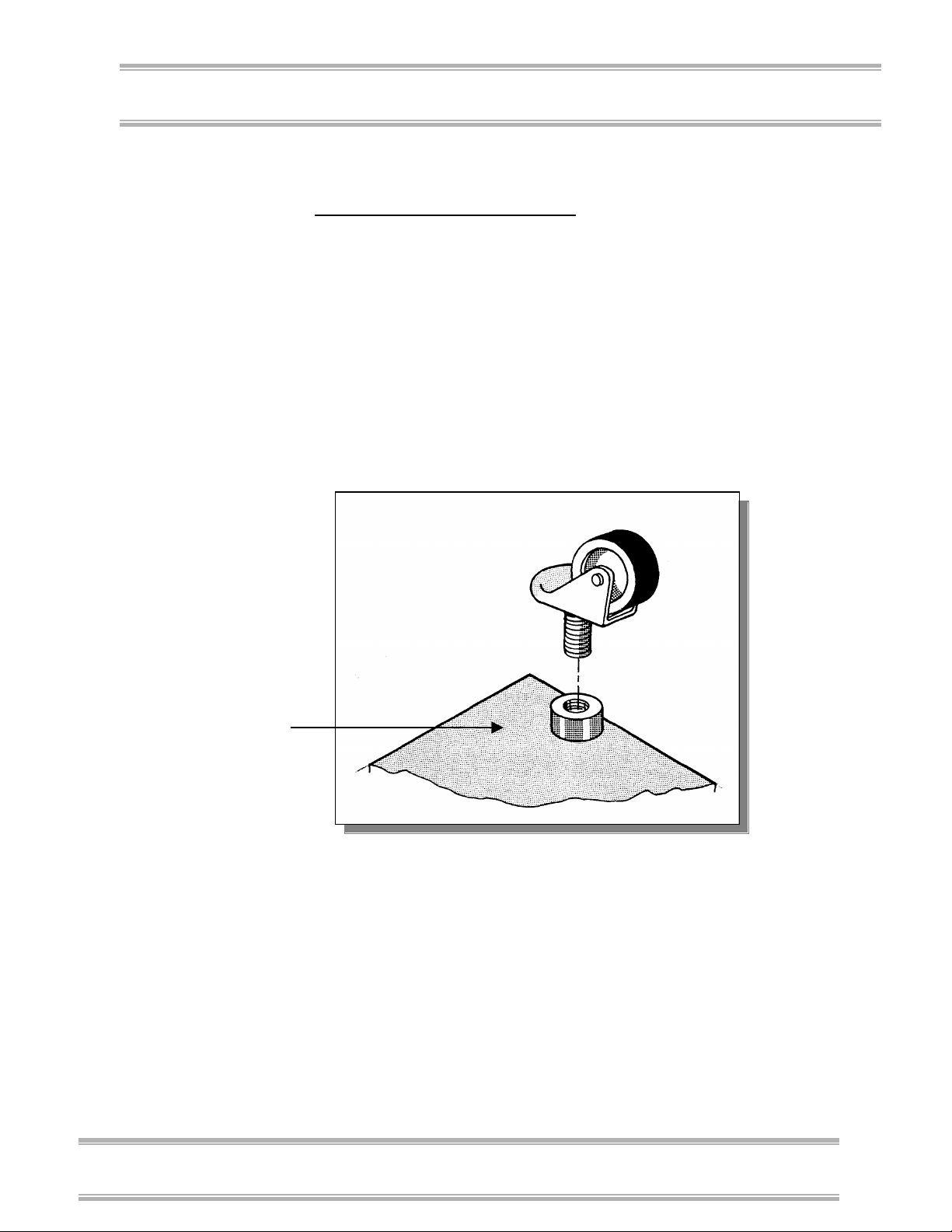

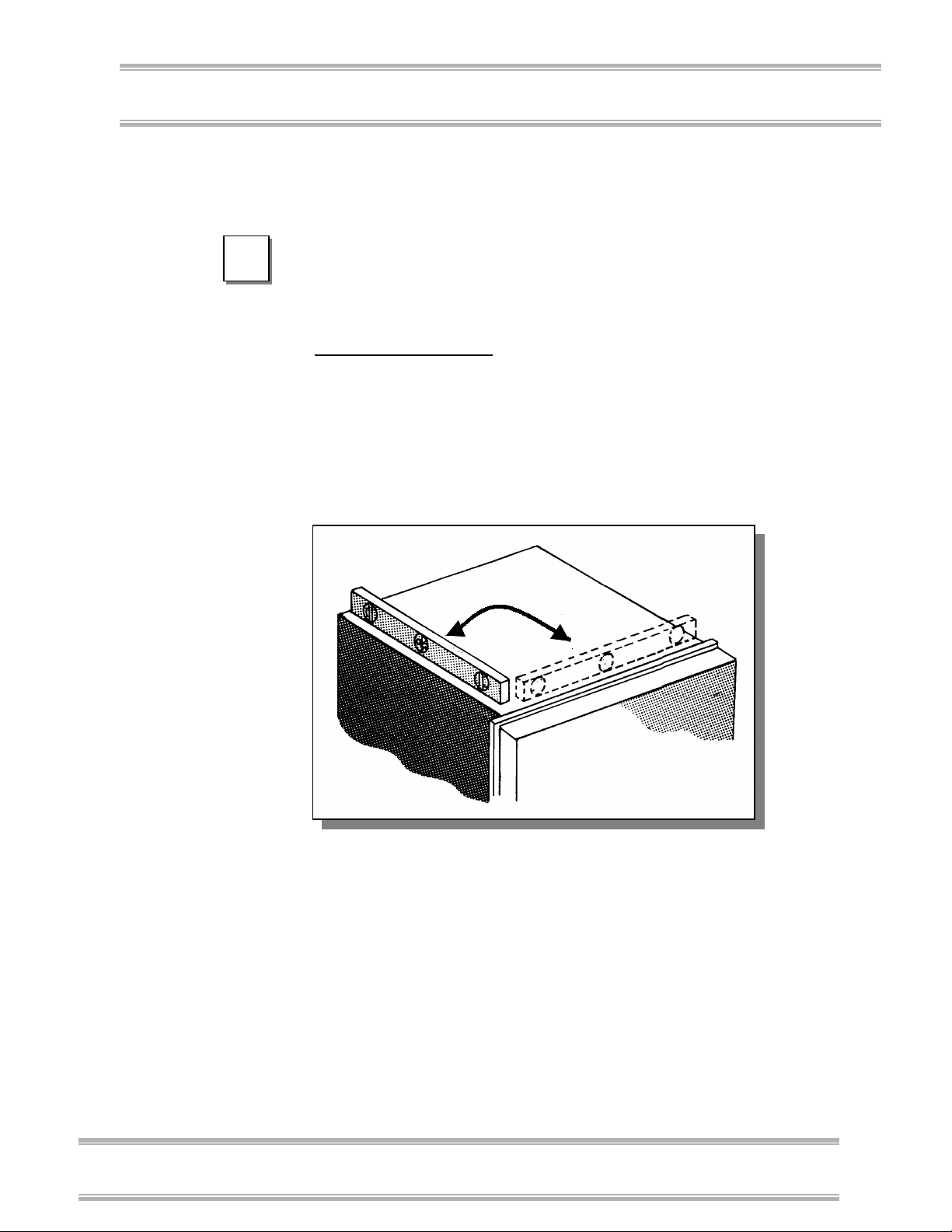

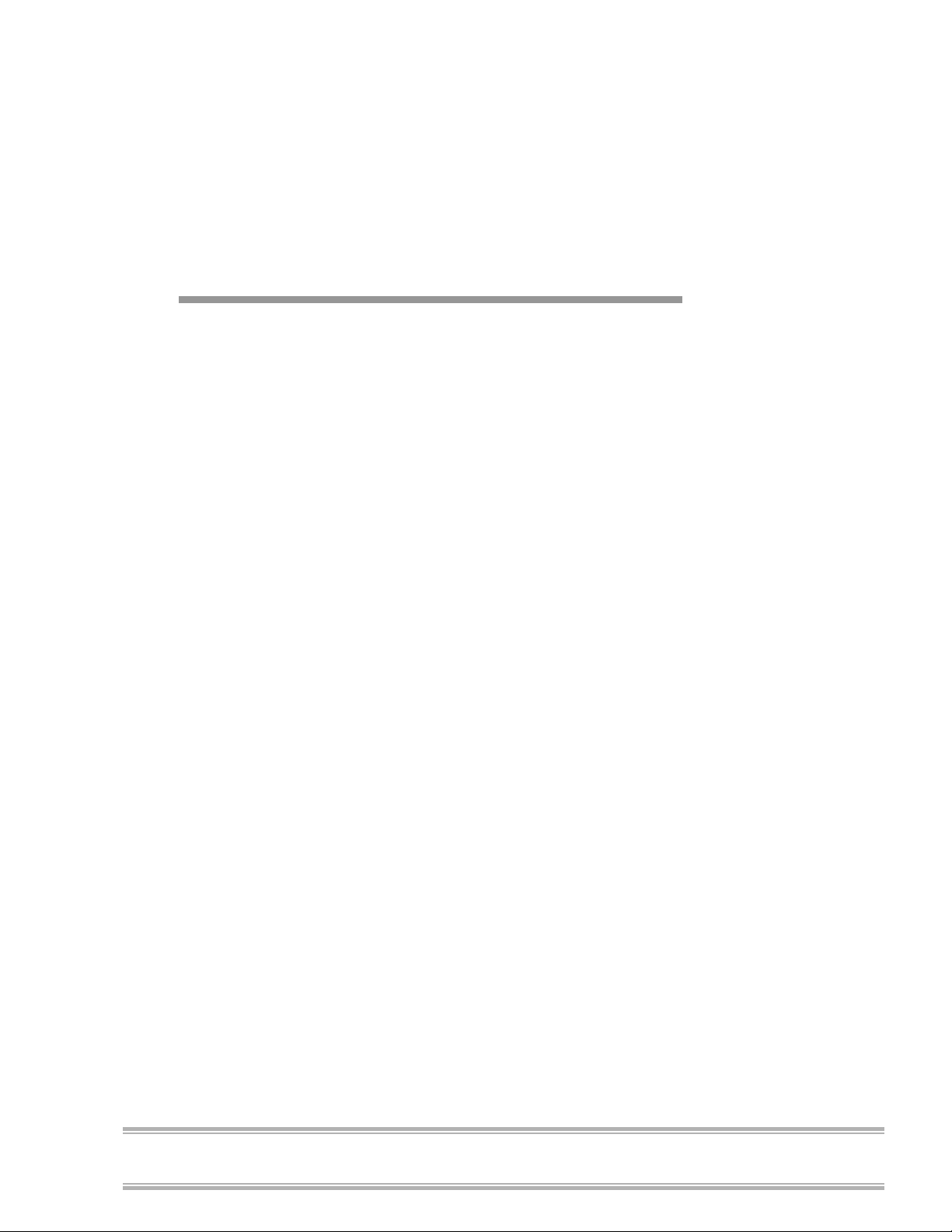

If you have the Undercounter or Freestanding model of the

SteamScrubber or FlaskScrubber washer, refer to Figure

3-2 and follow the steps detailed below to install the

leveling feet on your washer.

To install the washer leveling feet:

1. Locate the holes on the bottom of the washer where

the four skid-fastening screws were previously

attached.

2. Thread the four leveling feet into the holes.

3. Carefully move the washer into an upright position.

Be careful to distribute the weight evenly on the

leveling feet when setting the washer upright.

Chapter 3: Getting Started

U

U

F

F

Figure 3-2

Bottom of washer

Product Service 1-800-522-7658

17

Page 18

Chapter 3: Getting Started

Chapter 2: Prerequisites

Leveling the Washer

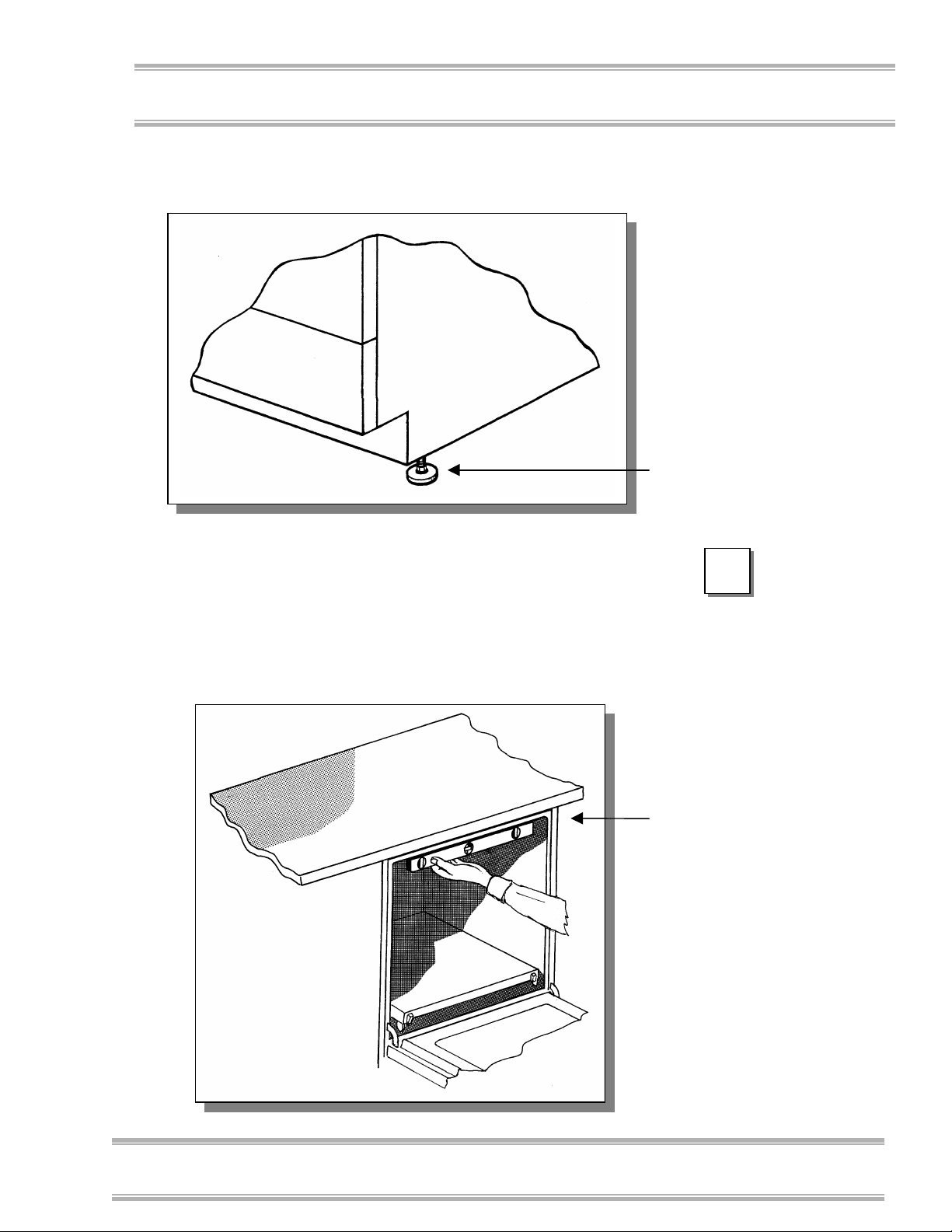

If you have the Freestanding model of the SteamScrubber

F

F

or FlaskScrubber Glassware Washer, after you have

installed the leveling feet, you must level the washer by

adjusting the leveling feet.

To level the washer:

1. Position the washer in its final installation site.

2. Place a carpenter level on the washer in the positions

shown in Figure 3-3.

Figure 3-3

Position the level

in both directions

to ensure the

washer is level

front-to-back and

side-to-side.

3. Turn the four leveling feet, as needed, to level the

washer. A leveling foot is illustrated in Figure 3-4.

18

Product Service 1-800-522-7658

Page 19

Figure 3-4

Chapter 3: Getting Started

Turn the leveling

foot clockwise to

lower the washer and

counterclockwise to

raise the washer.

Leveling foot

If you have the Undercounter model washer, you may

level it side-to-side by placing a short level on the inside

top edge of the door. Refer to Figure 3-5 for the

placement of the level on the washer.

Figure 3-5

U

U

Position the level

as shown to level

the Undercounter

model washer from

side-to-side

.

Product Service 1-800-522-7658

19

Page 20

Chapter 3: Getting Started

Chapter 2: Prerequisites

Centering the Washer Door

When the washer is level, check the operation of the

washer door for alignment with the washer tank. If the

door is not centered in the opening, you must center the

door by adjusting the corresponding leveling foot. (For

example, if the door hits the right side of the tank, raise the

right front corner of the washer. If the door hits the left

side of the tank, raise the left front corner of the washer.)

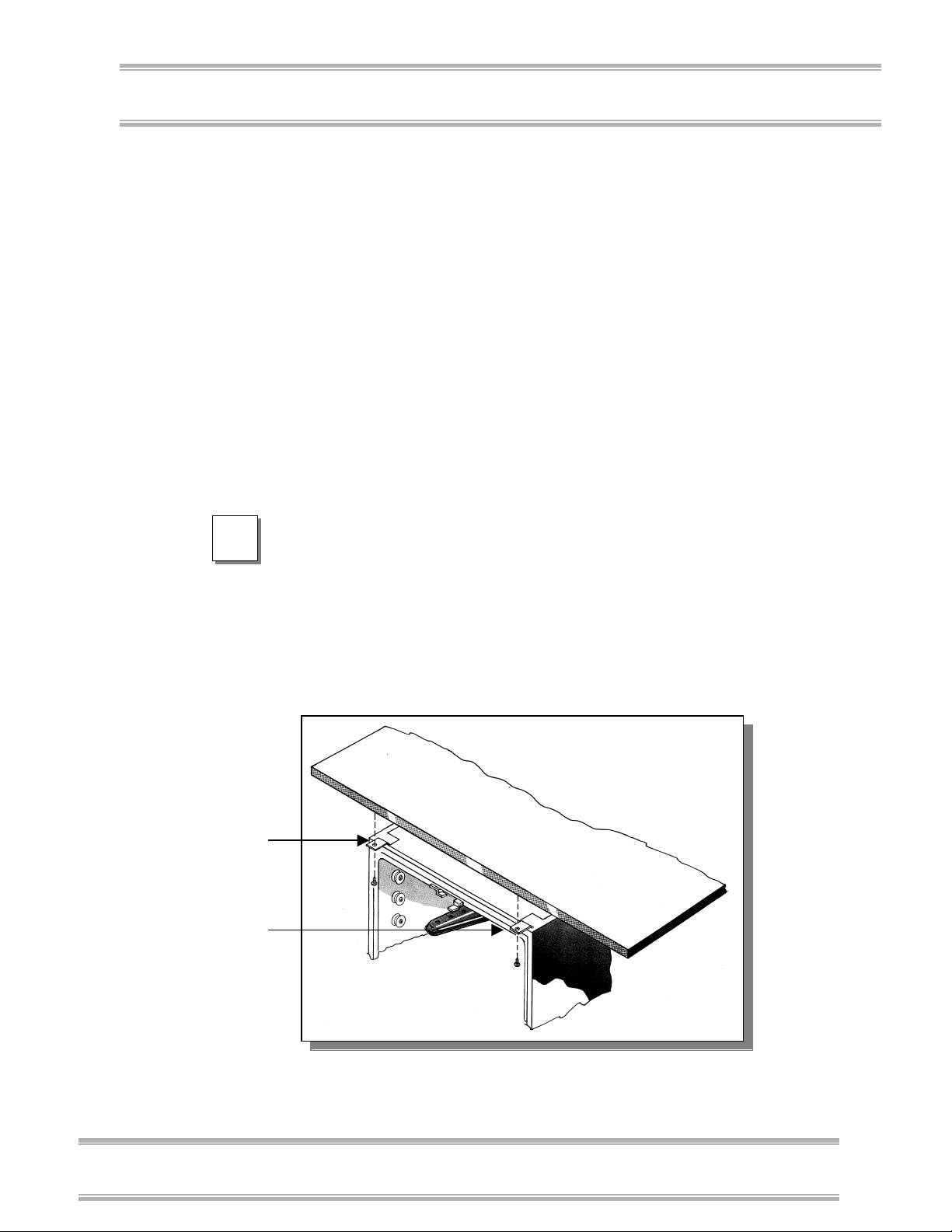

Attaching the Washer to the

Countertop

U

U

Insert the

screws through

the holes in the

clips in the

front corners of

the washer and

secure the

screws to the

countertop.

If you have an Undercounter Glassware Washer, two

screws have been provided to attach the front of the

washer to the underside of the countertop or worksurface.

After the washer is leveled in its final position and the

washer door is properly centered, install the two screws as

shown in Figure 3-6 to stabilize the unit and prevent it

from moving.

Figure 3-6

20

Product Service 1-800-522-7658

Page 21

Connecting the Water

Supplies

A hot water supply must be attached to your Glassware

Washer. If you need purified water for the final rinse

cycle, then you must also connect a purified water source

to your washer.

Chapter 3: Getting Started

Connecting the Hot Water

To prevent valve clogging, flush all of the hot water lines

for your hot water supply source prior to connecting the

washer to the water lines. The water supply valve to

which the hot water supply must be connected is located in

the lower right front corner of the washer. The lower

panel of the washer must be removed to access the valve.

To remove the panel, refer to Figure 3-7 and the

instructions below.

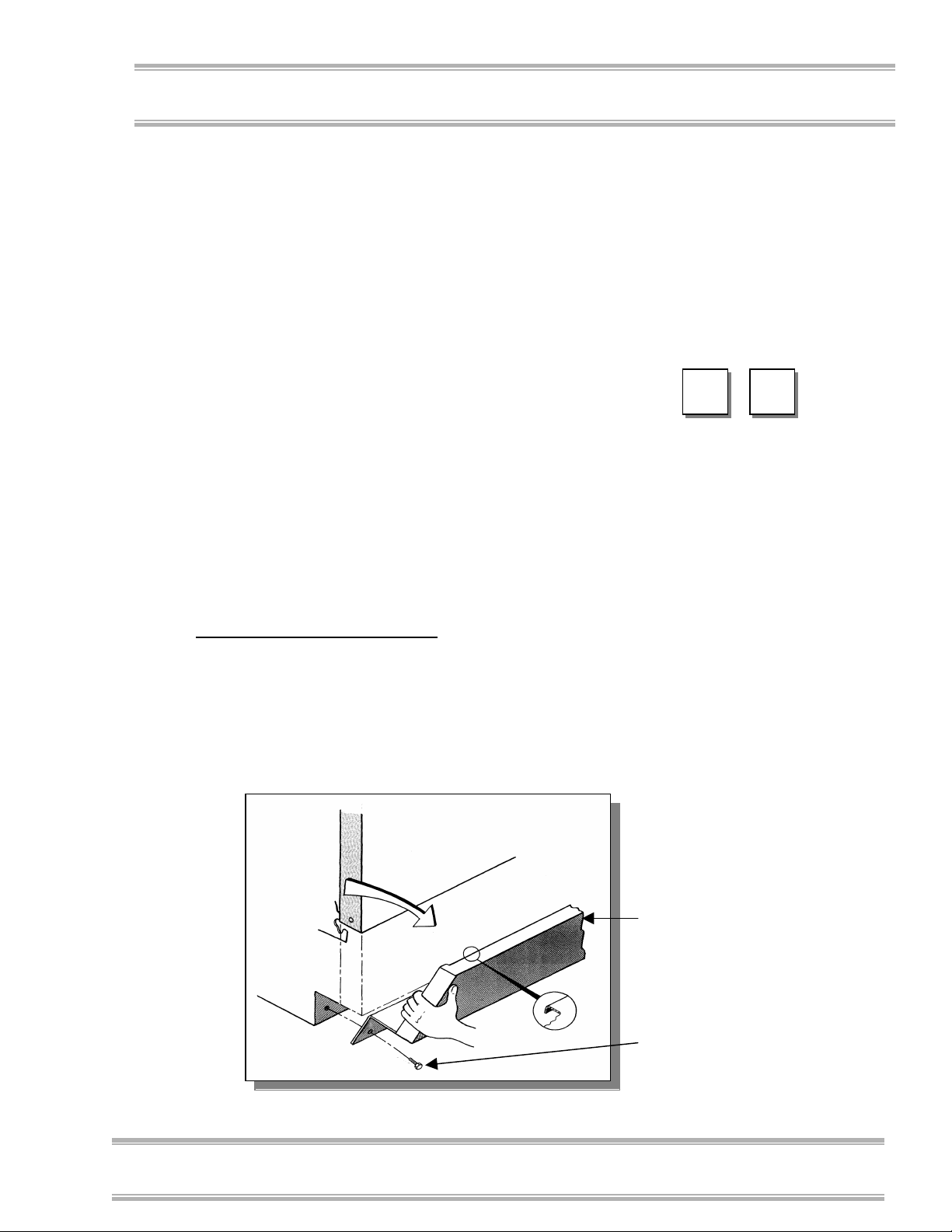

To remove the lower panel:

1. Remove the two screws at the bottom of the lower

panel of your washer.

2. Remove the panel by lifting slightly and pulling out.

Figure 3-7

U

U

Before continuing with

this section, be certain

your hot water source

meets the requirements

discussed in Hot Water

Requirements in

Chapter 2:

Prerequisites.

F

F

Product Service 1-800-522-7658

Lift the panel slightly

before pulling out to

disengage the panel

“lip.”

Screw

21

Page 22

Chapter 3: Getting Started

☞

☞☞

☞

Chapter 2: Prerequisites

After you remove the lower panel, you are ready to

connect the hot water source. Refer to Figure 3-8 and

follow the instructions below to connect the hot water.

To connect the hot water supply:

1. Be certain the hot water supply piping has been

2. Make the necessary plumbing connections to properly

YOU MUST PROVIDE THE PLUMBING

FITTINGS AND COMPONENTS

NEEDED TO CONNECT THE HOT

WATER SUPPLY SOURCE. THE

WASHER HOT WATER SUPPLY

VALVE IS EQUIPPED WITH A 3/8"

FEMALE NPT FITTING. 3/8" TUBING

OR LARGER IS RECOMMENDED FOR

THE SUPPLY PLUMBING.

thoroughly flushed prior to connecting it to the washer.

Debris in the piping can clog the washer valve.

connect the hot water supply to the washer.

Customer-

supplied

plumbing

Washer hot

water valve

Figure 3-8

22

Product Service 1-800-522-7658

Page 23

Chapter 3: Getting Started

P

☞

☞☞

☞

Connecting the Purified Water

Supply

To prevent valve and pump clogging, flush all of the water

lines for your purified water supply source prior to

connecting the washer to the water lines. The water

supply valve to which the purified water supply must be

connected is located in the lower right front corner of the

washer. The lower panel of the washer must be removed

to access the valve. Refer to Figure 3-9 and follow the

instructions below to connect the purified water source.

THE PURIFIED WATER INLET VALVE

IS EQUIPPED WITH A PLASTIC HOSE

BARB CONNECTION TO ACCOMMODATE ¾" (2 CM) ID FLEXIBLE

PLASTIC OR RUBBER HOSE. THE

HOSE CONNECTION MAY BE

REMOVED FROM THE VALVE TO

EXPOSE A MALE 3/4" - 11-1/2 NH

HOSE COUPLING. RIGID PLASTIC,

TIN-LINED, OR STAINLESS STEEL

TUBING AND FITTINGS MAY BE

CONNECTED TO THE WASHER

FITTING.

Before continuing with this

section, be certain your

purified water source meets

the requirements discussed

in Purified Water

Requirements in Chapter 2:

rerequisites.

Product Service 1-800-522-7658

Figure 3-9

Customersupplied

plumbing

Hose barb

connector

supplied with

washer

Purified

water

valve

23

Page 24

Chapter 3: Getting Started

☞

☞☞

☞

M

M

Chapter 2: Prerequisites

If the washer is a Mobile model and is moved to various

locations, and if purified water is used, provisions must be

made to use a flexible hose from a source of housepurified water. If a carboy is used, place the carboy on a

carboy cart and move it with the washer. Be careful not to

let the hose kink or become damaged.

To connect the purified water supply:

AT LEAST 1.25 GALLONS (4.7 LITERS)

PER MINUTE OF PURIFIED WATER

FLOW IS REQUIRED. AT LEAST 5

GALLONS OF PURIFIED WATER

MUST BE AVAILABLE FOR EACH

WASH CYCLE. A ½" ID PIPE IS THE

MINIMUM RECOMMENDED.

If you do not use

purified water during

the washer cycle, you

may want to disconnect the purified

water pump. Refer

to the section,

Disconnecting the

Purified Water Pump

in Chapter 6:

Modifying Your

Washer.

1. Make certain the purified water supply piping has been

thoroughly flushed prior to connecting it to the washer.

2. Remove the two screws at the bottom of the lower

panel of your washer, as shown in Figure 3-7.

3. Remove the panel by lifting slightly and pulling out.

4. Make the necessary plumbing connections to properly

connect the purified water supply to the washer.

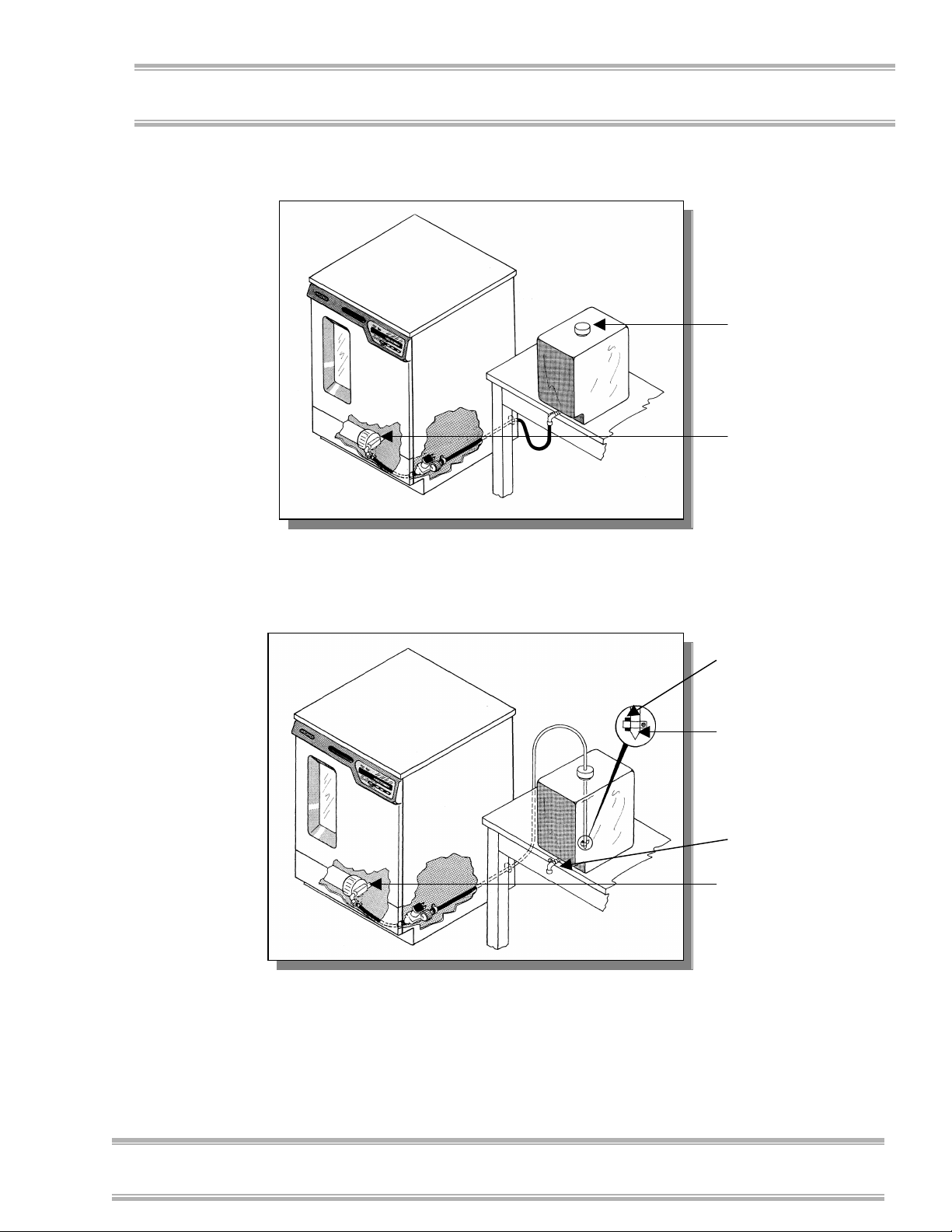

NOTE: If the purified water source is a carboy, complete

steps 5 and 6.

5. Connect the purified water source through either the

top or the bottom of the carboy, as illustrated in

Figures 3-10 and 3-11. If the purified water supply

feeds directly from the carboy top, make certain the

hose is submerged under the water line. Attach a

weight to the end of the tubing, as shown in Figure 311, to keep it from floating on top of the water and

possibly allowing air into the system.

6. Make certain the top of the carboy is vented to permit

proper flow from the carboy to the washer.

24

Product Service 1-800-522-7658

Page 25

Figure 3-10

Chapter 3: Getting Started

Open for vent

Purified water pump

Example of a Bottom Feed Connection

Figure 3-11

Example of a Top Feed Connection

Clamp weight to hose

to keep it submerged.

Cut hose into a V

configuration for

siphoning.

Spigot

Purified water pump

Product Service 1-800-522-7658

25

Page 26

Chapter 3: Getting Started

☞

☞☞

☞

M

M

Chapter 2: Prerequisites

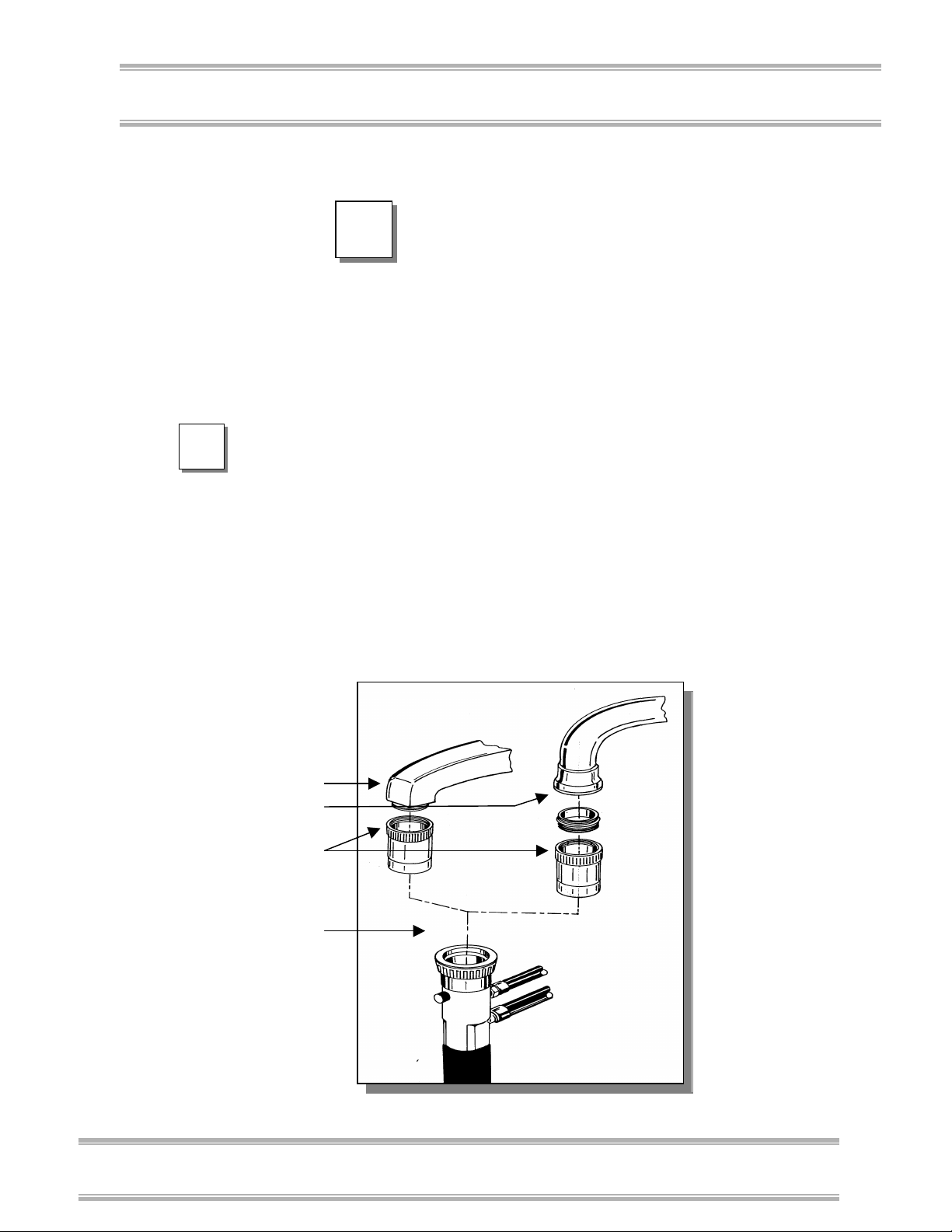

Installing Faucet Adapters

If you purchased a Mobile Glassware Washer, you need to

install a faucet adapter to provide a quick disconnect highpressure coupling between the faucet and the hose-end

fill/drain connector on your washer. Examples of two

faucet adapter configurations are shown in Figure 3-12.

MAKE CERTAIN THAT ALL OF THE

CONNECTIONS ON THE PURIFIED

WATER SYSTEM ARE AIR TIGHT.

THE PUMP MUST NOT PULL AIR

INSTEAD OF WATER. MAKE

CERTAIN THE SUPPLY HOSE IS NOT

CRIMPED.

External

faucet thread

Internal

faucet thread

Aerator adapters

Hose-end

coupling

Figure 3-12

26

Product Service 1-800-522-7658

Page 27

An aerator adapter and a standard-size adapter fitting are

☞

☞☞

☞

provided with your Mobile washer. If the adapter fitting

provided does not allow for a tight connection to your

faucet, a variety of internally and externally threaded

fittings are available at your local hardware store. Use

caution when installing the fittings to prevent stripping the

threads.

Attaching the Hose-End

Coupling

After you have installed the faucet adapter, the hose-end

coupling of your washer (shown in Figure 3-12) attaches

and seals to the aerator adapter by pushing the parts

together. The hose-end coupling must be snapped into

place BEFORE turning on the hot water faucet. Turn the

hot water on SLOWLY until the faucet is completely

open.

Chapter 3: Getting Started

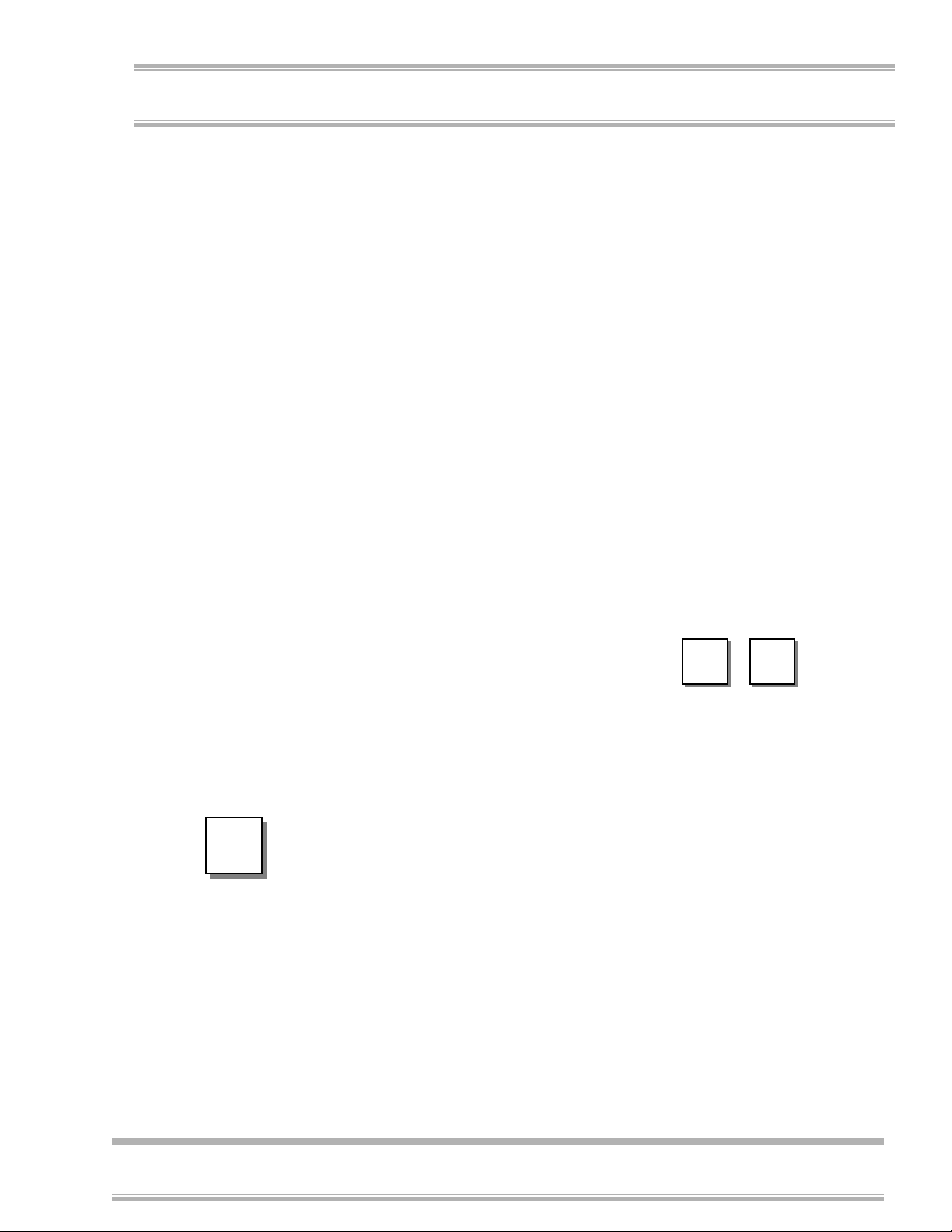

Connecting the Drain Hose

Before continuing with this section, be certain that your

drain meets the requirements detailed in Drain

Requirements in Chapter 2: Prerequisites. The washer

drain hose is connected to a fitting on the rear side of the

pump/motor assembly.

BE CERTAIN YOU CONFORM TO ALL

LOCAL PLUMBING CODES WHEN

YOU ROUTE AND CONNECT THE

DRAIN.

The drain hose is installed at the factory. The hose

provides a flexible coupling to the drain piping and can be

secured with a spring or band hose clamp. (A band hose

clamp is provided with your washer.)

U

U

F

F

Product Service 1-800-522-7658

27

Page 28

Chapter 3: Getting Started

☞

☞☞

☞

The use of an air

gap is strongly

recommended for

all installations to

prevent the siphoning of waste water

into the washer.

Chapter 2: Prerequisites

Tubing or pipe ½" (1.3 cm) ID should be used for the

drain.

The drain piping can be routed to either a sink or a floor

drain. If you route the drain piping to a sink drain without

using an air gap, the highest point of the drain pipe must

be above the sink drain, as shown in Figure 3-13.

DO NOT ROUTE THE DRAIN TO AN

ELEVATION LESS THAN 15" (38 cm)

OR MORE THAN 30" (76 cm) ABOVE

THE PUMP DISCHARGE. DO NOT

REDUCE THE SIZE OF THE DRAIN

PLUMBING.

If an air gap is

not used, the

drain line must be

elevated above

the water level of

the sink.

Figure 3-13

28

Product Service 1-800-522-7658

Page 29

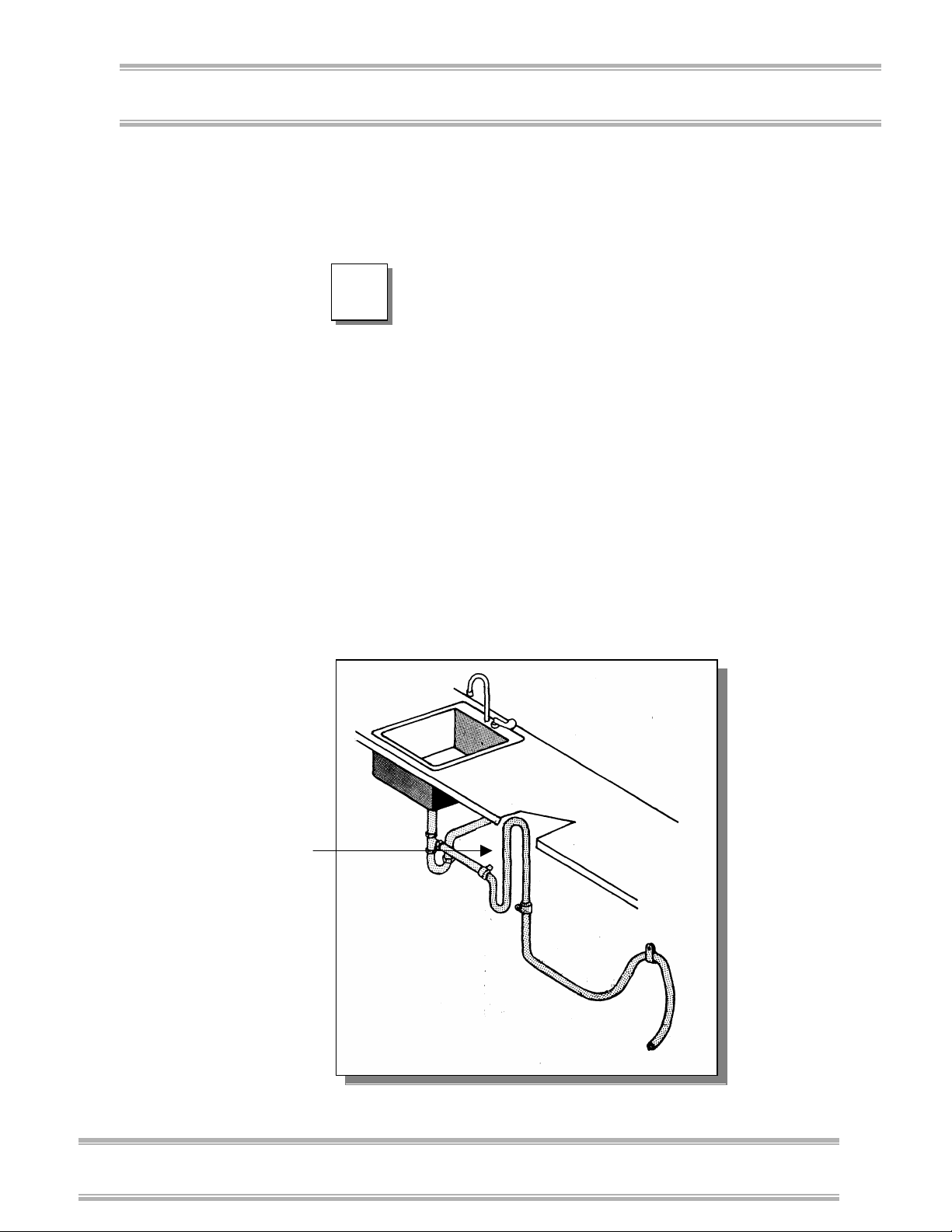

If you route the drain piping to a sink drain and use an air

gap, refer to Figure 3-14 for the placement of the air gap.

Figure 3-14

Chapter 3: Getting Started

Air gap

Drain line

Product Service 1-800-522-7658

29

Page 30

Chapter 3: Getting Started

☞

☞☞

☞

Chapter 2: Prerequisites

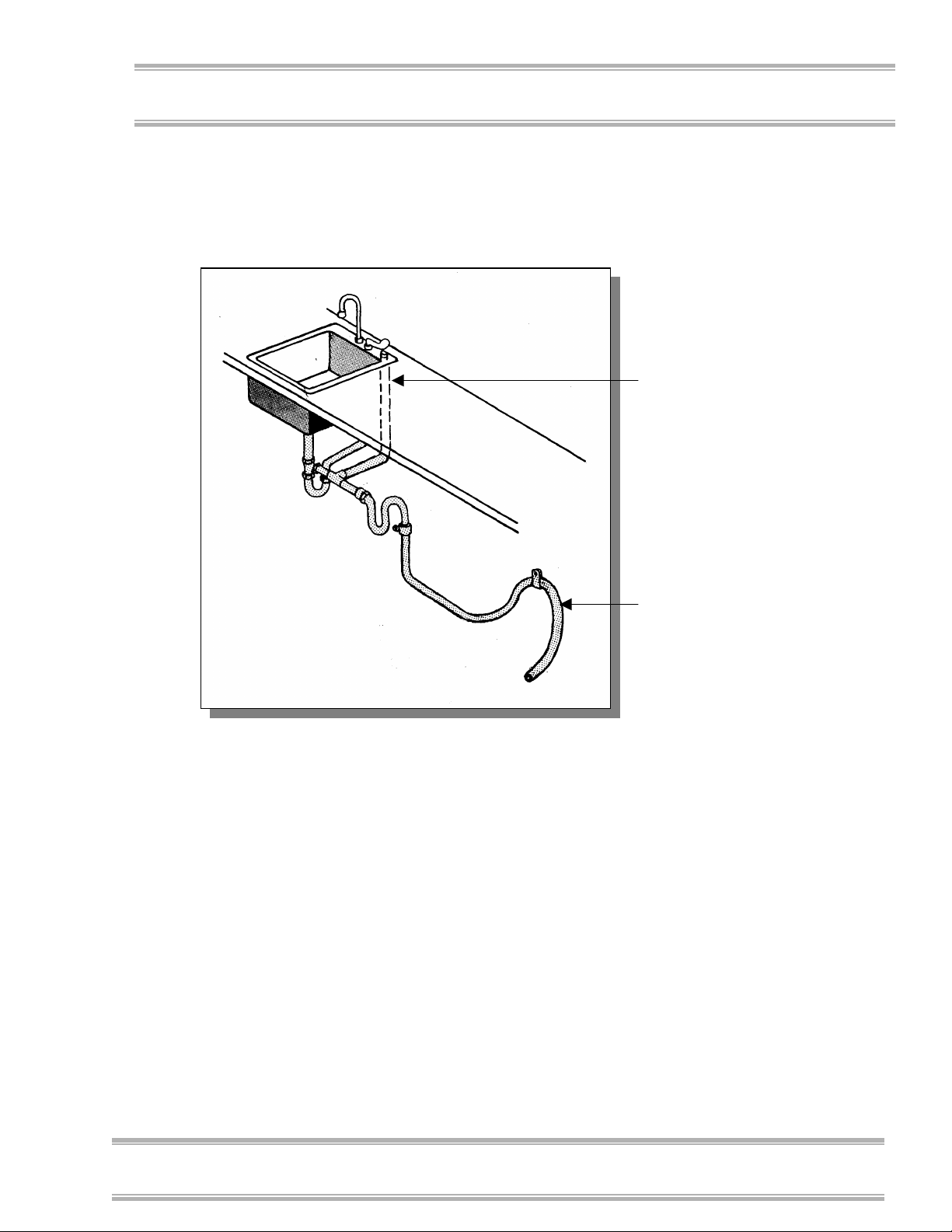

If you route the drain piping to a floor drain, refer to

Figure 3-15 for placement of the drain tubing and trap.

Figure 3-15

U

U

Drain trap

F

F

Connecting the Power Supply

Before continuing with this section, be certain your power

supply meets the requirements specified in Electrical

Requirements in Chapter 2: Prerequisites

and Freestanding Washers should be hard-wired directly

into a junction box. Refer to Figure 3-16 and follow the

steps below to connect your washer to the appropriate

power source.

BE CERTAIN THAT YOU CHECK AND

CONFORM TO ALL LOCAL

ELECTRICAL CODES. DO NOT

DISTURB ANY INTERNAL WIRING IN

THE WASHER.

.

Undercounter

30

Product Service 1-800-522-7658

Page 31

THE SUPPLY CIRCUIT MUST CONSIST

☞

☞☞

☞

☞

☞☞

☞

OF NUMBER 12 AWG 3-WIRE CABLE

OR HEAVIER. WASHERS MUST BE

CONNECTED TO A SERVICE WITH A

20 AMP CIRCUIT BREAKER OR FUSE.

To connect the electrical supply:

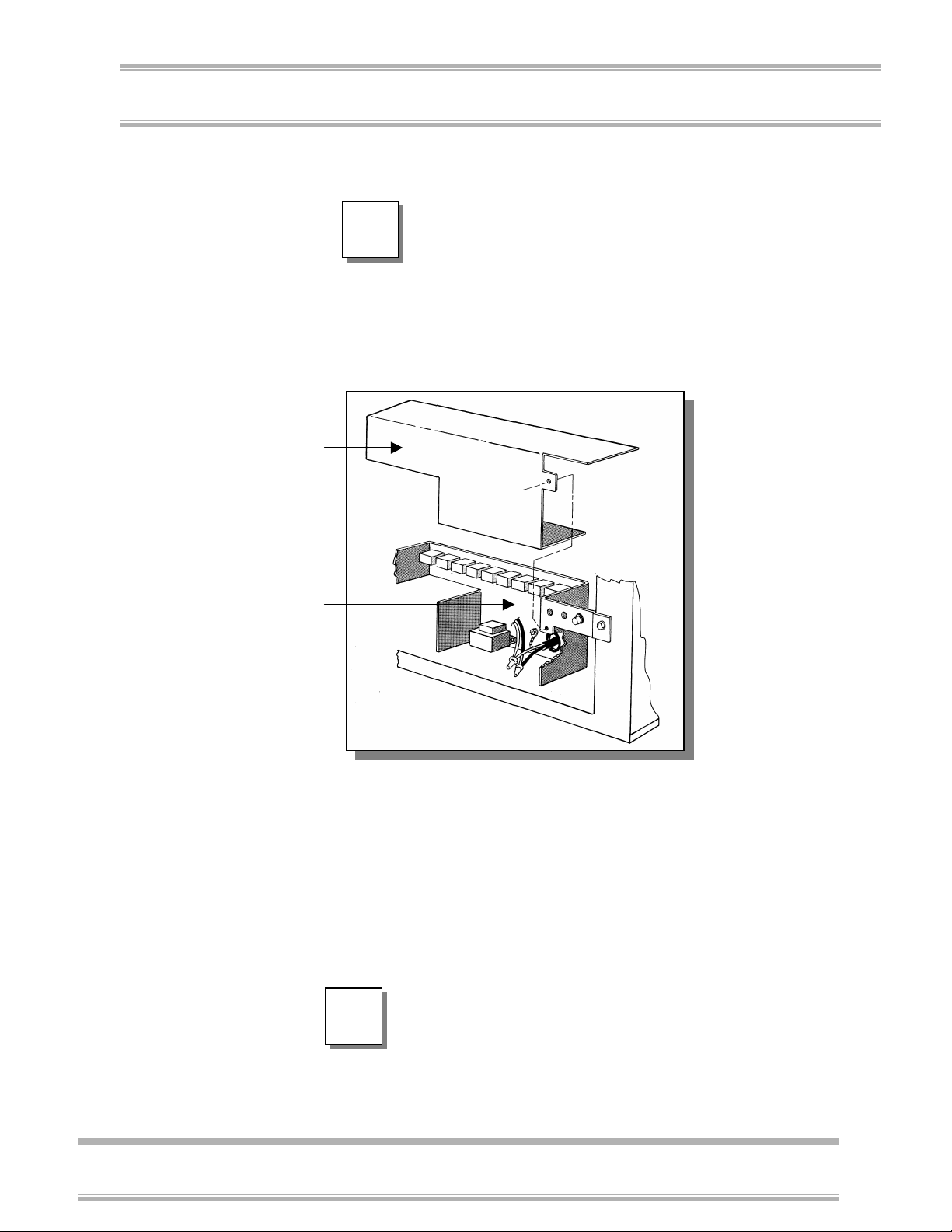

1. Remove the lower panel on the washer by removing

the two screws located at the bottom of the panel, as

shown previously in Figure 3-7.

2. Lift the panel slightly and pull outward.

3. Remove the cover over the electrical junction box,

shown in Figure 3-16, by removing the two screws.

4. On 115V models, connect the customer-supplied

power wires to the black and white wires, using wire

nuts. On 230V models, attach customer-supplied

power wires to the brown and blue wires, using wire

nuts.

5. Connect the customer-supplied ground wire to the

green screw.

Chapter 3: Getting Started

CUSTOMER-SUPPLIED WIRES MUST

BE CLAMPED TO THE HOLE WHERE

THEY PASS THROUGH THE REAR OF

THE JUNCTION BOX, IF PRESCRIBED

BY LOCAL CODES. IF IT IS

NECESSARY TO USE A BUSHING

WITH AN INTEGRAL CLAMP AT THE

INLET TO THE JUNCTION BOX,

REMOVE THE PLASTIC BUSHING

SUPPLIED WITH THE WASHER

BEFORE INSTALLING THE NEW

BUSHING.

6. Replace the cover on the electrical junction box.

7. Replace the lower panel on the washer.

Product Service 1-800-522-7658

31

Page 32

Chapter 3: Getting Started

☞

☞☞

☞

Electrical junction

box cover

Chapter 2: Prerequisites

BEFORE TURNING ON THE WASHER,

MAKE CERTAIN THE WATER IS

TURNED ON AND NO PACKING

MATERIAL REMAINS INSIDE THE

WASHER.

Figure 3-16

Electrical

junction box

Testing Your Washer

Now that you have made the required water and electrical

connections to your washer, you need to test the operation

of the washer. A series of diagnostic steps are provided in

this section.

If the washer is interrupted in the middle

of the diagnostic steps, wait 4 to 5

!!!!

seconds before opening the washer door

to prevent hot water from splashing out.

The hot water and steam from the

washer may cause scalding.

32

Product Service 1-800-522-7658

Page 33

Connecting the Hose-End

M

M

Coupling

If you purchased a Mobile Glassware Washer, the first

action you must take is to connect the hose-end coupling

to the hot water faucet. Snap the hose-end coupling onto

the aerator adapter on the faucet by pushing the parts

together, as shown previously in Figure 3-12. After the

hose-end coupling is attached to the faucet, slowly turn on

the hot water faucet.

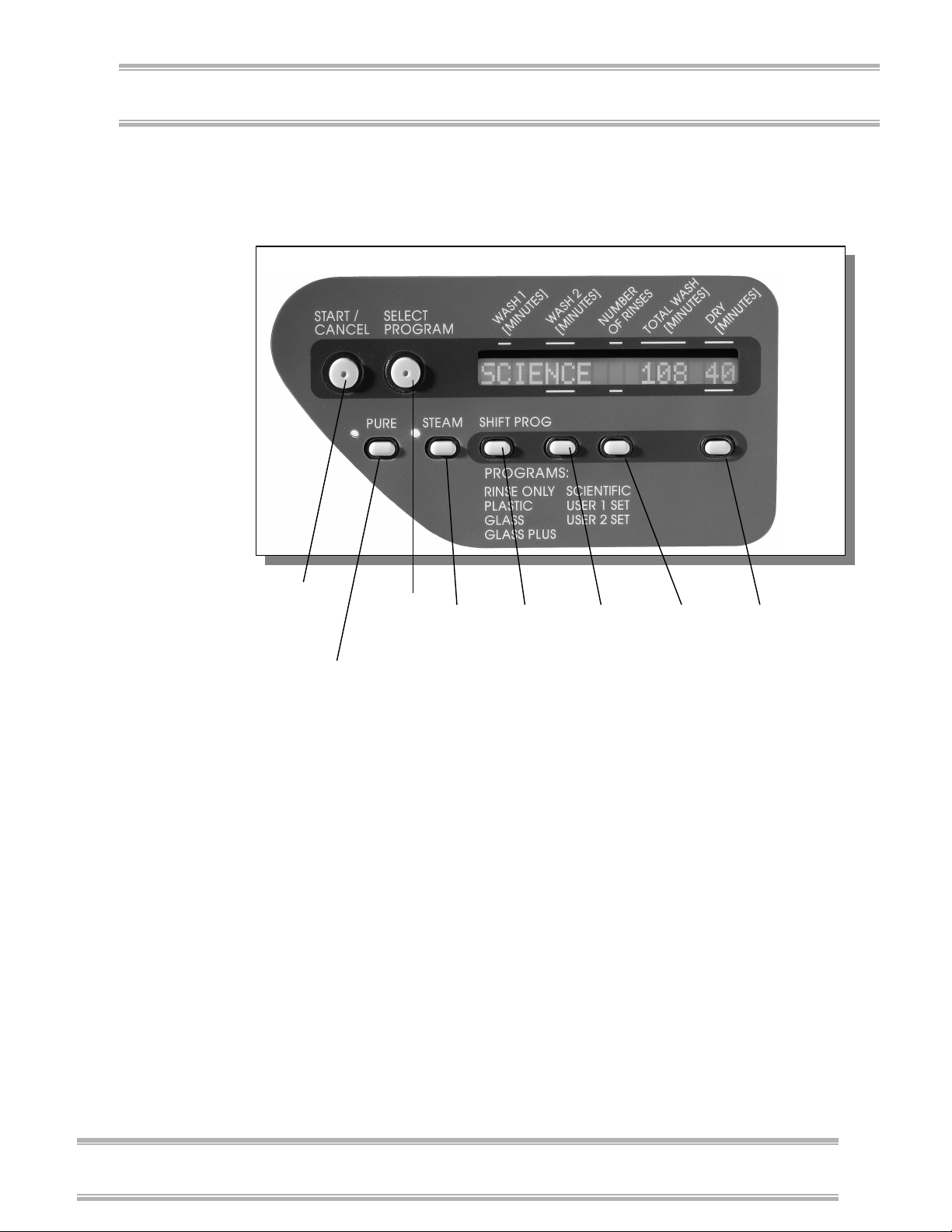

Running the Diagnostics

To ensure your washer is operating properly, it is

recommended that you perform the diagnostics procedure

detailed below, which should take approximately 10

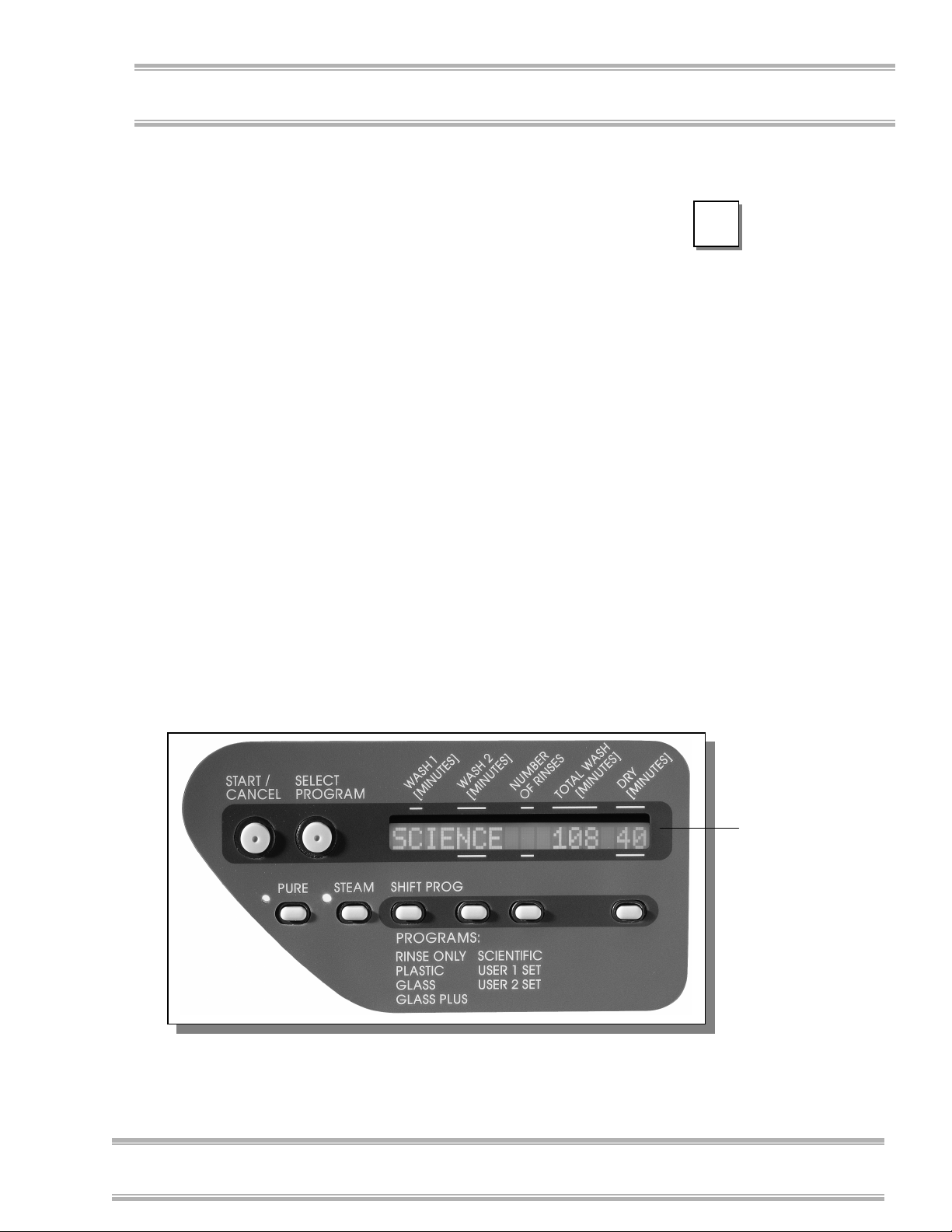

minutes to complete. Refer to Figure 3-17 to familiarize

yourself with the control panel before you begin the

procedure.

Chapter 3: Getting Started

Figure 3-17

The Scientific

wash cycle is

selected. The

wash will run a

total of 108

minutes, with a

40 minute

drying time.

Product Service 1-800-522-7658

33

Page 34

Chapter 3: Getting Started

☞

☞☞

☞

Chapter 2: Prerequisites

To run the diagnostics test:

1. Locate the control panel on the front of your washer.

2. Press and hold the bottom right button and close the

3. The display window should read: PRESS SELECT:

4. Press the Select Program button.

5. The display window should read: FILL VIA TAP.

6. Press the Select Program button.

7. The display window should read: FILL VIA DE-ION.

8. Press the Select Program button.

9. The display window should read: PUMP - ON:

10. Press the Select Program button.

11. The display window should read: PAUSE. All washer

12. Press the Select Program button.

13. The display window should read: PUMP - ON:

14. Press the Select Program button.

15. The display window should read: DETERGENT CUP.

16. Press the Select Program button.

BEFORE OPERATING THE WASHER

WITH THE PURIFIED WATER OPTION

SELECTED, CHECK THE PURIFIED

WATER SUPPLY FOR AMPLE

QUANTITY.

handle of your washer by sliding the door latch knob

to the right.

TST.

Tap water should be heard entering the washer. Allow

tap water to enter for approximately one minute.

De-ionized (DI) water enters the washer and the DI

pump should be heard. After approximately one

minute the float switch should turn off the flow of DI

water.

WASH. The wash cycle should activate.

functions should be off.

DRAIN. The water drains from the washer. Allow all

the water in the washer to drain. You can tell when

this occurs when the sound of the pump changes.

Within a minute, you should hear the detergent cup lid

open.

34

Product Service 1-800-522-7658

Page 35

17. If you have a 115V model, the display window should

M

M

read: HEAT STEAM DOOR, and the steam heater

activates. If you have a 230V model, the display

window should read: HEAT - SUMP: HIGH and the

sump heater activates.

18. Press the Select Program button.

19. If you have a 115V model, the display window should

read: HEAT - STEAM: SUMP and the steam heater

activates. If you have a 230V model, the display

window should read: HEAT STEAM and the steam

heater activates.

20. Press the Select Program button.

21. If you have a 115V model, the display window should

read: HEAT – SUMP and the sump heater activates. If

you have a 230V model, the display window should

read: HEAT – SUMP: LOW and the sump heater

activates.

22. Press the Select Program button.

23. The display window should read: BLOWER ON. The

washer blower should be heard.

24. Press the Select Program button.

25. The display window should read: DONE. Open the

door latch to turn off the electronics, or select a wash

cycle and use the washer.

Chapter 3: Getting Started

Disconnecting the Hose-End

Coupling

If you purchased a Mobile Glassware Washer, you can

choose to disconnect the hose-end coupling from the hot

water faucet after the diagnostics procedure is completed.

Refer to Figure 3-18 and the instructions below to

disconnect the hose-end coupling.

Product Service 1-800-522-7658

35

Page 36

Chapter 3: Getting Started

Plastic release ring

Chapter 2: Prerequisites

To disconnect the hose-end coupling:

1. Turn off the hot water faucet.

2. Push the pressure relief button on the hose-end

3. Pull down on the plastic release ring on the hose-end

coupling to relieve the water pressure.

coupling to disconnect it from the faucet.

Figure 3-18

Fill hose

Pressure relief button

Your Next Step

The installation and setup of your Glassware Washer is

now complete. To learn how to load and operate your

washer, proceed to Chapter 4: Using Your Washer. To

make a modification to the configuration of your washer,

proceed to Chapter 6: Modifying your Washer. To

perform additional diagnostics on your washer, proceed to

Chapter 7: Troubleshooting. To learn about the

maintenance requirements for your washer, proceed to

Chapter 5: Maintaining your Washer.

Drain hose

36

Product Service 1-800-522-7658

Page 37

C

HHAAPPTTEERR

C

4

4

U

SSIINNGG

U

After your washer has passed the basic diagnostics test

detailed in Chapter 3: Getting Started, you are ready to

begin using your washer. Read this chapter to learn how

to:

• arrange the racks inside your washer to meet your

specific needs.

• properly position glassware inside your washer.

• fill the detergent and neutralizing acid dispensers.

• interrupt a wash cycle after it has begun.

• select an operating cycle.

!!!!

Y

OOUURR

Y

Do not use the Glassware Washer in a

manner not specified by the

manufacturer. The electrical protection

properties of the washer may be

impaired if the washer is used

inappropriately.

W

W

AASSHHEER

R

Arranging the Washer Racks

The FlaskScrubber and SteamScrubber are equipped with

different rack configurations to accommodate the various

types of laboratory glassware. In addition to the standard

configuration of the Glassware Washers, many optional

racks and inserts are available to customize your washer to

Product Service 1-800-522-7658

37

Page 38

Chapter 4: Using Your Washer

Chapter 2: Prerequisites

best suit your needs. For a complete list of available rack

accessories, refer to Appendix D: Glassware Washer

Accessories.

If you purchased a SteamScrubber, proceed to the

following section, The SteamScrubber Racks. If you

purchased a FlaskScrubber, proceed to the section, The

FlaskScrubber Racks, later in this chapter.

The SteamScrubber Racks

The SteamScrubber is equipped with two racks (a top rack

and a bottom rack), and two 10-pin inserts. The top rack

of the SteamScrubber Glassware Washer is designed to

accommodate beakers and other wide-mouth laboratory

glassware. The top rack is not recommended for narrownecked glassware.

The bottom rack of the SteamScrubber Glassware Washer

is designed to accommodate flasks, beakers, culture-tubes,

graduated cylinders, Erlenmeyer flasks, petri dishes, watch

glasses, BOD bottles, and a variety of other laboratory

glassware. In addition to the two 10-pin inserts that are

provided with your washer, there are a variety of other

inserts that are available to accommodate the various types

of glassware, as detailed in Appendix D.

Lowering the Top Washer Arm

and Top Rack

The top rack of your SteamScrubber may be lowered to

accommodate taller glassware. Perform the steps listed

below to lower the washer arm and the top rack. Refer to

Figure 4-1 for help in lowering the washer arm. Figure 42 illustrates how to remove the rail bumpers. Refer to

Figure 4-2 for help in lowering the top rack rails.

38

Product Service 1-800-522-7658

Page 39

Chapter 4: Using Your Washer

To lower the top washer arm and the top rack of

the SteamScrubber:

1. Open the washer door by sliding the latch knob to the

left. Pull the door toward you and down.

2. Depress the button on the right side of the upper wash

arm tower, as illustrated in Figure 4-1.

3. Lower the upper portion of the tower and the wash arm

by gently pushing down.

Figure 4-1

Wash arm

4. Secure the wash arm by clicking the wash arm into the

upper hole in the wash arm support tube.

5. Remove the rubber bumper at the front of each side

rail, as shown in Figure 4-2.

Depress the button and

gently push down to

lower the wash arm.

Wash arm tower

Product Service 1-800-522-7658

39

Page 40

Chapter 4: Using Your Washer

Remove the rail

by twisting out

and down.

You must remove

the rubber bumper

from the front of

the rail before the

rack can be

removed.

Chapter 2: Prerequisites

Figure 4-2

6. Pull the upper rack forward and lift the front until the

wheels disengage from the track.

7. With a twisting motion, remove the rails from the

rollers on each side of the tank, as shown above in

Figure 4-2.

8. Reposition the rails on the lower set of rollers and with

a twisting motion insert them in the rollers.

9. Place the rack rollers in the rails.

10. Replace the rubber bumpers.

40

Product Service 1-800-522-7658

Page 41

Chapter 4: Using Your Washer

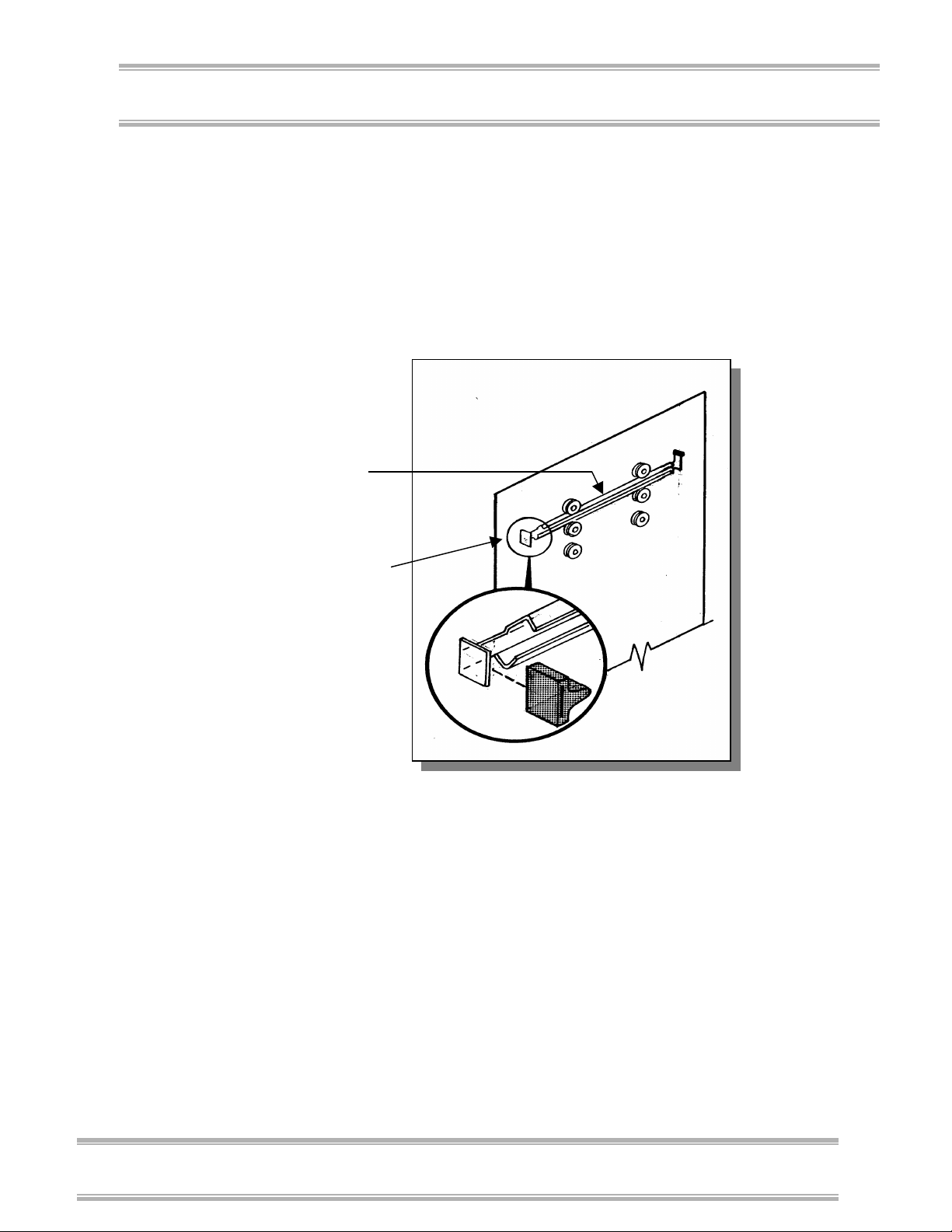

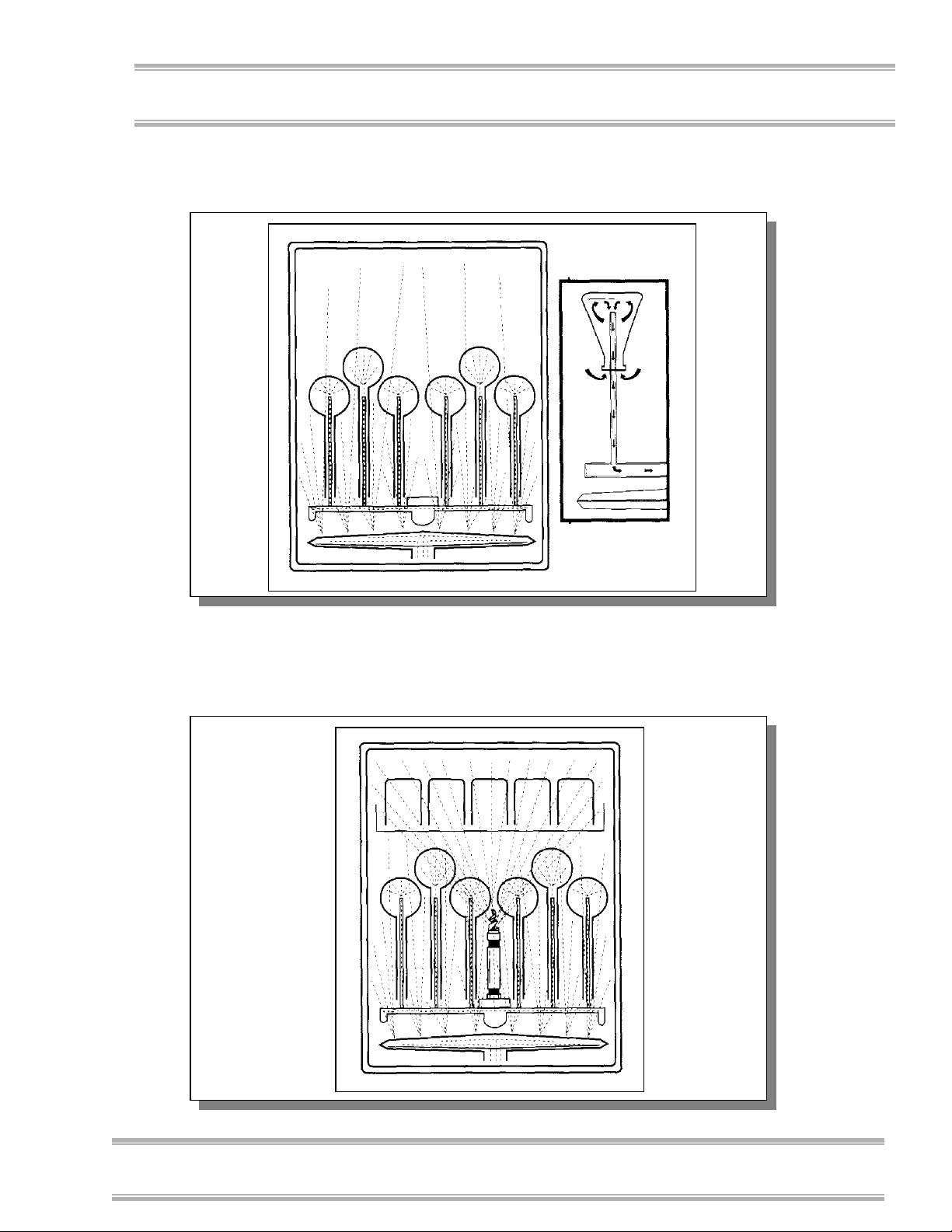

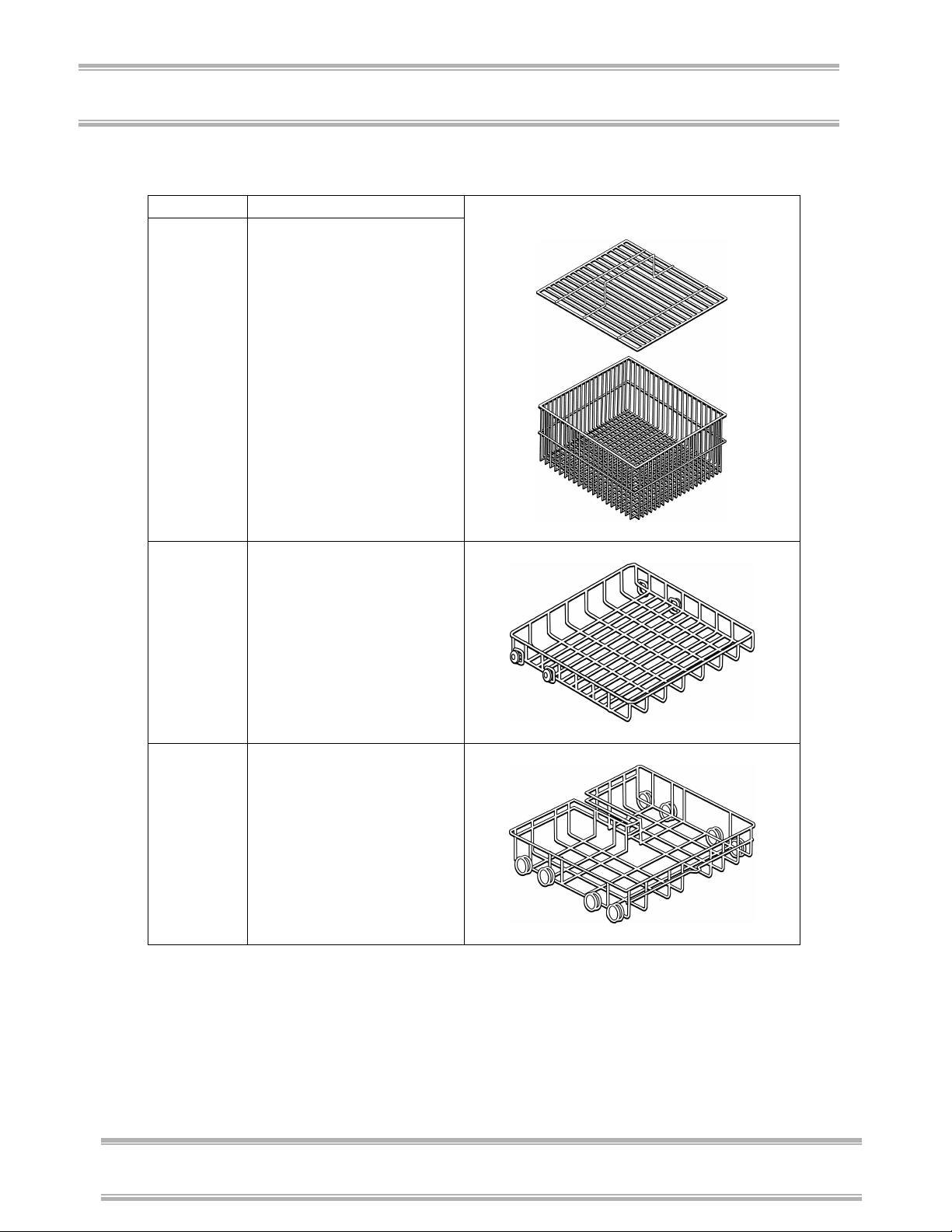

The FlaskScrubber Racks

The FlaskScrubber Glassware Washer is equipped with a

spindle rack, four glassware holders, and a multi-pin

insert. The FlaskScrubber spindle rack is designed for

narrow-necked glassware such as volumetric flasks,

Erlenmeyer flasks, graduated cylinders, Kjeldahl flasks,

test tubes, and digestion tubes.

Two sizes of spindles are provided with the washer:

twenty-four 1/4" OD and ten 1/8" OD spindles. Twenty of

the spindles are factory installed: fourteen 1/4" OD

spindles and six 1/8" OD spindles. The front fourteen

positions on the spindle rack are threaded with nylon

plugs. You can remove the plugs to accommodate the

remaining spindles, if needed.

The glassware holders and multi-pin insert that are

included with your Glassware Washer allow for the

positioning and washing of beakers and other wide-mouth

glassware. The multi-pin insert may be positioned over

spindles. The spindles can be removed with a 9/64" hex

wrench. Figure 4-3 illustrates the placement of the multipin insert.

Product Service 1-800-522-7658

41

Page 42

Chapter 4: Using Your Washer

☞

☞☞

☞

The multi-pin insert

can be placed over

spindles. The multi-

pin insert accom-

modates a variety of

glassware types

and sizes.

To remove a spindle,

insert a hex wrench

into the slot on the top

of the spindle and turn

clockwise. After

removing the spindle,

thread a nylon plug

into the resulting hole.

Chapter 2: Prerequisites

Figure 4-3

42

An optional, adjustable top rack is available for the

FlaskScrubber, to expand the washer’s capacity to

accommodate many types of glassware, particularly

beakers. The rack includes two 24-pin inserts.

IF THE MULTI-PIN INSERT IS

INSTALLED ON THE BOTTOM RACK

AND THE OPTIONAL UPPER RACK IS

USED, DO NOT HEAVILY LOAD THE

MULTI-PIN INSERT WITH WIDE

MOUTH GLASSWARE. THIS MAY

RESTRICT WATER FLOW FROM THE

LOWER DISTRIBUTION ARM TO THE

GLASSWARE IN THE UPPER RACK.

Product Service 1-800-522-7658

Page 43

Loading Glassware into the

FlaskScrubber

To load glassware onto a spindle, place the glassware on

the spindle and adjust the position by raising or lowering

the spring clip, as shown in Figure 4-4. The outlet of the

spindle should be as close to the center of the flask as

possible. Do not allow the glassware to rest on the end of

the spindle.

Figure 4-4

Chapter 4: Using Your Washer

Squeeze the spring clip

together and raise or

lower the clip to position

the glassware properly.

Product Service 1-800-522-7658

43

Page 44

Chapter 4: Using Your Washer

Chapter 2: Prerequisites

Two large and two small glassware holders are supplied

with each FlaskScrubber. These holders enable you to

place wide-mouth glassware onto the FlaskScrubber

spindles. To position glassware in a glassware holder and

install the holder on a spindle, refer to Figure 4-5 and

follow the instructions below.

To use a glassware holder:

1. Press the glassware into the holder; the clamps should

spring out and grip the glassware.

2. Loosen the set screw in the hub, as shown in Figure 4-

5, and raise or lower the holder to position the spindle

near the center of the glassware. Do not allow the

glassware to rest on top of the spindle.

3. Re-tighten the set screw.

Press the glassware

into the glassware

holder. Then, turn

the set screw

counterclockwise to

loosen the glassware

holder hub. Position

the glassware holder

so that the spindle is

near the center of the

glassware. Turn the

set screw clockwise

to tighten the glass-

ware holder in place.

Figure 4-5

44

Product Service 1-800-522-7658

Page 45

Chapter 4: Using Your Washer

Glassware should be loaded so that it does not touch each

other during a wash cycle. The washer has been designed

for quiet operation. To prevent noise and glass breakage,

be certain that the glassware does not touch.

Place heavily soiled items toward the center of the racks.

Place lightly soiled items in the corners.

The Detergent Dispenser

Your Glassware Washer is equipped with a detergent

dispenser that contains a main wash cavity and a

neutralizing solution port, as shown in Figure 4-6. In

addition, the washer door has a depression where detergent

may be added for use during the first wash of the cycle.

Figure 4-6

Neutralizing acid

dispenser cover

Main wash cavity

Neutralizing

solution port

Neutralizing solution

dial

Product Service 1-800-522-7658

45

Page 46

Chapter 4: Using Your Washer

Chapter 2: Prerequisites

The detergent dispenser opens during the second wash

cycle, except when the Plastic cycle is selected, which has

only one wash cycle. If your glassware is heavily soiled,

you may want to add detergent to the pre-wash cavity.

Refer to the table below to determine which cavities to fill,

based on the selected wash choice. You may use either the

pre-wash cavity stamped in the washer door or the one on

the lid of the detergent cup.

Wash Cycle Fill Pre-wash Cavity Fill Main Cavity

Rinse Only NO NO

Plastic NO YES

Glass OPTIONAL YES

Glass Plus OPTIONAL YES

Scientific OPTIONAL YES

User 1 OPTIONAL YES

User 2 OPTIONAL YES

To achieve the best

results with your

Glassware Washer, use

Labconco’s LabSolutions Detergent.

Store detergent in a

cool, dry place.

Immediately replace

the detergent container lid after

dispensing. If lumps

develop due to

exposure to moisture,

discard the detergent

according to local

regulations.

Do not use combustible solvents in the

Glassware Washer. If soiled glassware

!!!!

contains flammable compounds, rinse the

glassware thoroughly prior to placing the

glassware into the washer. Heaters in

the washer are very hot and could cause

a fire.

Non-foaming powder or liquid detergent formulated for

labware washers, in conjunction with adequate hot water,

is vital for obtaining clean glassware. If the water is soft,

less detergent may be needed. Too much detergent with

softened water may cause etching of the glassware. This

appears as a permanent cloudy film on the glassware.

Fill the main detergent cavity three-fourths full if the water

hardness grains per gallon (GPG) for your water measures

0 – 4 GPG (soft water). Fill the detergent cavity

completely if your water measures 4 GPG or higher

(medium to hard water). If you use the pre-wash cavity

stamped in the washer door, fill it completely.

46

Product Service 1-800-522-7658

Page 47

To open the detergent dispenser, gently

!!!!

slide the white tab sideways. If the tab is

pulled upward or perpendicular to the

door, it will break.

Filling the Neutralizing Acid

Dispenser

If it is necessary to neutralize the alkalinity of the

detergent, a mild or weak acid may be placed in the

detergent cup neutralizing dispenser from which it will be

dispensed during the first rinse. If pure water rinse is

selected, the last two rinses will be made with pure water.

To avoid dispensing neutralizing acid during a pure rinse,

more than two rinses should be selected. The dispenser

holds approximately 170 ml and should be checked and

replenished as needed. To fill the neutralizing acid

dispenser, refer to Figure 4-6 and follow the instructions

below.

Chapter 4: Using Your Washer

To fill the neutralizing acid dispenser:

1. Twist and pull up on the cap to remove the round cover

on the neutralizing solution port.

2. Fill the cavity with either 1M citric acid or 10%

phosphoric acid until the level of the liquid rises and is

visible in the port.

3. Set the dial to read 4 ml.

4. Replace the cover.

Selecting an Operating Cycle

The microprocessor control on your Glassware Washer

allows you to select one of four factory preset wash cycles,

to custom program two additional cycles, or to run a rinseonly cycle. The control panel is shown in Figure 4-7.

Product Service 1-800-522-7658

47

Page 48

Chapter 4: Using Your Washer

Chapter 2: Prerequisites

Figure 4-7

Press to

start wash

cycle.

Press to

rinse with

pure water.

Press

to

select

the

wash

cycle.

Press to

activate

the

steam

function.

Press to

display

details

about the

selected

wash cycle.

Press to

change

the

length of

Wash 2

cycle.

Programming and Starting a

Wash Cycle

Refer to Appendix C: Glassware Washer Specifications for

complete details on the various factory-set programs and

the options available for customizing cycles. After you

have decided which washer cycle you need to use, follow

the instructions below to start your washer.

Washers built for use on 230V have the capability to wash

glassware at a temperature of 180°F (82°C). They also are

able to operate at the lower temperature of 140°F (60°C)

which is the standard temperature of the 115V models.

Selecting a high-heat operation is achieved by selecting an

appropriate program.

Press to

change

the

number

of

rinses.

Press to

change

the

drying

time.

48

Product Service 1-800-522-7658

Page 49

Chapter 4: Using Your Washer

☞

☞☞

☞

On 230V models, the Glass Plus, Scientific, and User 2 Set

programs operate at the higher temperature. When one of

these programs is selected, the display window indicates

the program chosen, as well as the term, “HI HEAT.”

When the Rinse Only, Plastic, Glass, or User 1 Set

program is selected, the display window indicates the

program chosen, as well as the term, “LOW HEAT.”

USE CARE WHEN SELECTING HIGHHEAT PROGRAMS IF PLASTIC WARE

IS BEING WASHED.

To start a wash cycle:

1. Close the washer door and energize the electronic

control by sliding the door latch knob from the left to

the right position to lock the latch.

2. Press the Select Program button until the desired

program is shown on the display. To observe the

details of the program, press the Shift Prog button.

The display will then show the Wash 1 time, the Wash

2 time, the number of rinses, the total wash time, and

the drying time.

3. If you need to alter the Wash 2 time, the number of

rinses, or the drying time, press the appropriate button

directly below the displayed parameter until the

desired information is displayed.

4. If a pure water rinse is needed, press the corresponding

button. If the purified water is feeding from a nonpressurized system, make certain there is adequate

water in the reservoir (a minimum of 5 gallons or 18.9

liters).

If steam operation is needed, press the corresponding

button. In this mode, the Glassware Washer will refill

with fresh water after the completion of Wash 1. Both

the sump and steam heaters will operate for 10 minutes

to produce hot vapor to penetrate and soften dried

residue, allowing detergent and hot water to work

effectively.

5. On Mobile washers, turn the hot water on.

6. Press the Start button to begin the wash cycle.

Product Service 1-800-522-7658

49

Page 50

Chapter 4: Using Your Washer

Chapter 2: Prerequisites

7. Press the Shift Program button if you want the display

to indicate details about what mode the washer is in

and the time remaining.

Interrupting a Wash Cycle

To temporarily pause a wash cycle, simply unlatch the

washer door. After the door is unlatched, wait 4 to 5

seconds before opening the door to prevent water from

splashing out of the washer.

To resume the wash cycle, close and re-latch the washer

door. The washer will pause to equalize temperatures and

then the cycle will resume at the point it was interrupted.

The wash cycle can be terminated at any time by pressing

the Start/Cancel button.

50

Product Service 1-800-522-7658

Page 51

☞

☞☞

☞

C

HHAAPPTTEERR

C

M

AAIINNTTAAIINNIINNG

M

5

5

G

Y

Y

OOUUR

R

W

W

Under normal operation, your Glassware Washer will

require little routine maintenance to keep it functioning

properly. Read this chapter to learn how to:

Maintaining the Stainless

Steel Interior

The interior of your Glassware Washer is stainless steel.

AASSHHEER

• safely clean the stainless steel interior

• maintain the water fill valve

• clean the overflow dome

• remove the top and side panels of your washer

• clean the filter screen

R

NEVER USE METAL SCOURING PADS

ON THE STAINLESS STEEL INTERIOR.

METAL SCOURING PADS CAN

SCRATCH OR LEAVE METAL CHIPS

THAT WILL RUST.

Product Service 1-800-522-7658

51

Page 52

Chapter 5: Maintaining Your Washer

Chapter 2: Prerequisites

To maintain the appearance and quality of the stainless

steel interior, perform the following tasks as needed:

• Wipe the outer edges on the inside door panel to

remove particles and residue that occur during

loading.

• Use a sponge sprinkled with non-abrasive stainless

steel cleaner to gently wipe the washer tank and

door to remove surface discoloration caused by

exposure to halogenated compounds or steel parts.

In some cases, the finish may be slightly dulled by

this action.

If your water has a high mineral content, film or spots may

develop on the washer interior. If the procedures listed

above do not eliminate the film or spots, you may need to

follow the steps below to run your washer through a

special cycle.

To remove film or spots from the washer interior:

1. Remove all glassware from the washer.

2. Choose the Glass Program, Steam OFF, Pure Rinse

OFF, and set the drying time to zero.

3. After the first fill is complete, open the washer and

carefully pour one cup of bleach into the bottom of the

tank.

4. Close the washer door and allow the unit to wash and

drain (approximately six minutes).

5. When the washer fills the second time, open the

washer and add two cups of 4 – 8% acetic acid (or

white vinegar) to the bottom of the tank.

6. Close the washer door and allow the unit to wash and

drain without further interruption.

52

Product Service 1-800-522-7658

Page 53

Maintaining the Air Gap

Chapter 5: Maintaining Your Washer

If you employed an air gap during the installation of your

washer, you need to clean the air gap at least once a

month. The air gap is not part of the washer; therefore, it

is not covered by the washer warranty. The air gap

protects the washer against water backing up in the event

of a clogged drain.

Most types of air gaps are easy to clean. Simply follow

the manufacturer’s directions for maintaining your air gap.

Maintaining the Water Fill

Valve

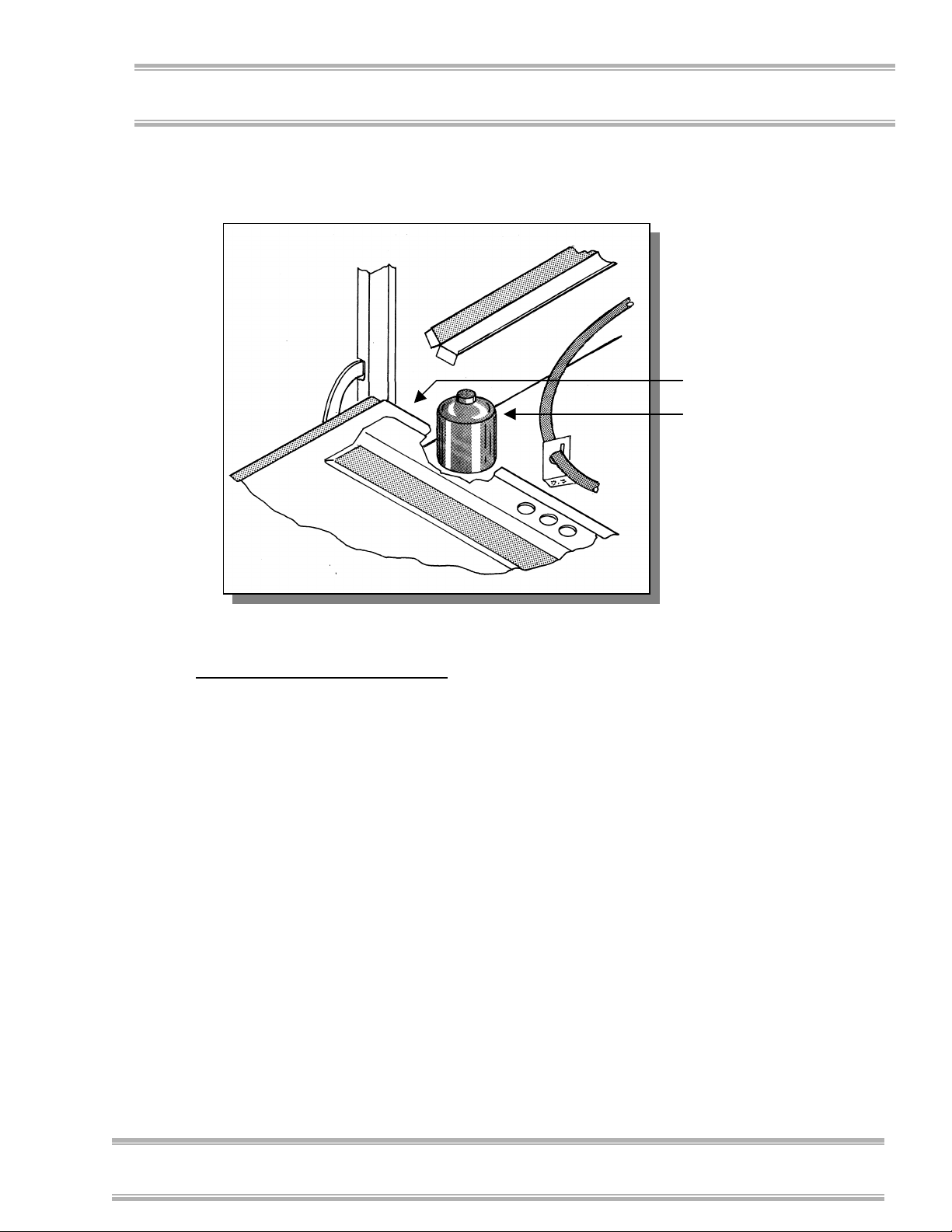

The filter screen of the water fill valve, illustrated in

Figure 5-1 below, may require periodic cleaning to remove

trapped particles. A low water fill occurs if the blockage

is not removed.

Figure 5-1

Check the air gap for

build-up any time your

washer is not draining

well.

Hot water supply

Screen

O-ring

Water fill valve

Product Service 1-800-522-7658

53

Page 54

Chapter 5: Maintaining Your Washer

Chapter 2: Prerequisites

To clean the water fill valve:

Refer to Figure 3-7

in Chapter 3: Getting

Started for an

illustration showing

how to remove the

lower panel of your

washer.

1. Turn off the water and electricity to the washer.

Unplug the Mobile model; turn off the circuit breaker

that services the Undercounter or Freestanding model.

2. Remove the two screws at the bottom of the lower

panel of your washer.

3. Remove the panel by lifting slightly and pulling out.

4. Place a pan under the fill valve.

5. Remove the four screws from the valve plate and

separate the valve from the inlet connection.

6. Drain the water into the pan.

7. Remove the valve filter screen and clean it under

running water.

8. Replace the screen and reassemble the valve

connection. Be certain the O-ring gasket, identified in

Figure 5-1, is positioned in the groove in the fill valve

body.

9. Tighten all screws; replace the lower panel, restore

electrical power to the washer, and turn on the water.

10. Check for leaks and adjust as needed. Replace the

lower panel.

54

Maintaining the Overflow

Dome

The overflow dome is located inside the washer in the

front left corner, as illustrated in Figure 5-2. The dome

may require periodic cleaning to remove residue from

inside the dome.

Product Service 1-800-522-7658

Page 55

Figure 5-2

Chapter 5: Maintaining Your Washer

Front left corner of

washer

Gray overflow dome

To clean the overflow dome:

1. Turn off electrical power to the Glassware Washer.

2. Remove the two screws at the bottom of the lower

panel of your washer.

3. Remove the panel by lifting slightly and pulling out.

4. Locate the gray dome in the front left corner of the

washer.

5. Remove the nut from the bottom of the dome stem by

holding the dome with one hand and loosening the nut

with the other.

6. Lift the dome off and clean it with warm soapy water.

7. Clean the spot inside the washer where the dome was

positioned.

8. Replace the dome and tighten the nut until the plastic

stem is flush with the surface of the nut.

9. Replace the lower panel.

Figure 3-7 in

Chapter 3: Getting

Started illustrates

how to remove the

lower panel of your

washer.

Product Service 1-800-522-7658

55

Page 56

Chapter 5: Maintaining Your Washer

Chapter 2: Prerequisites

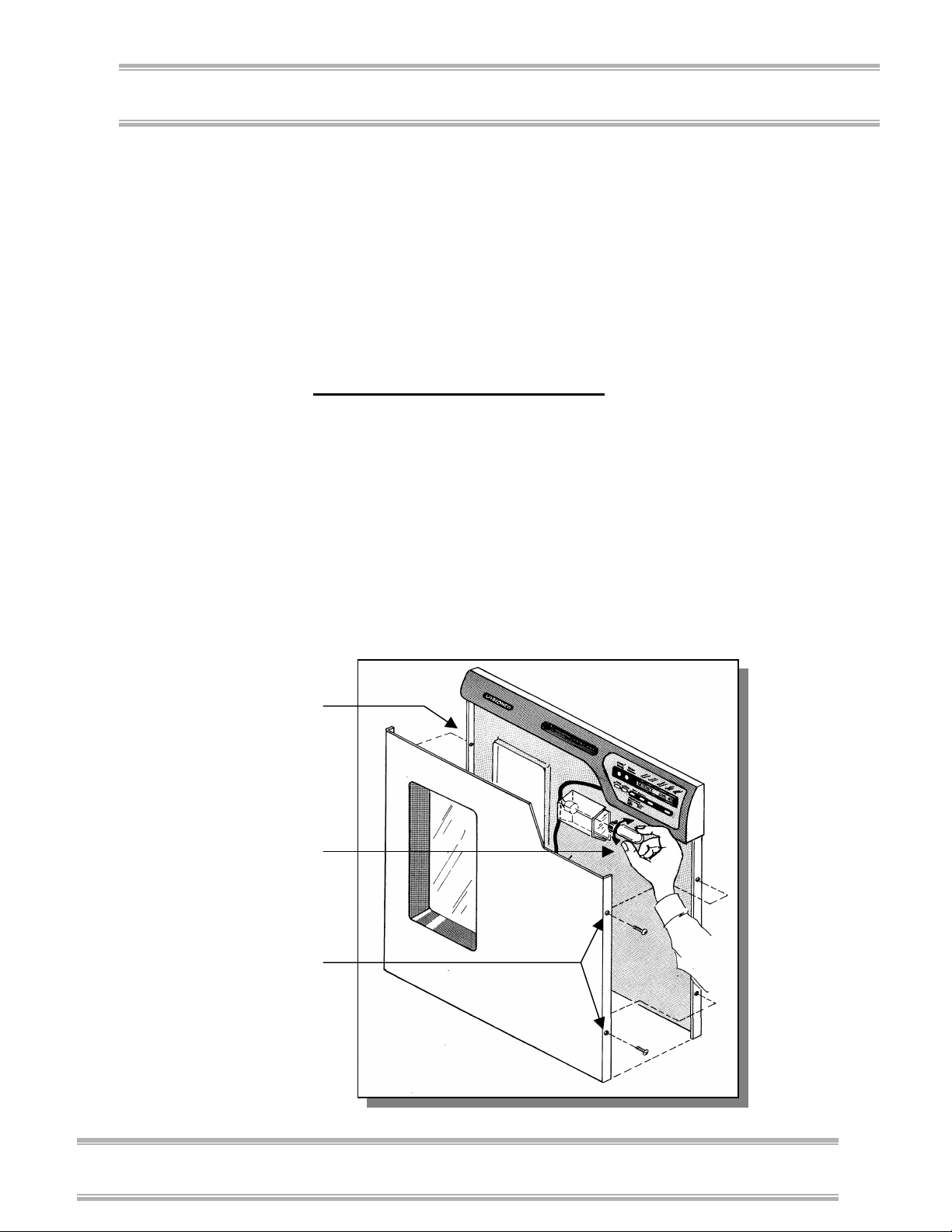

Replacing the Washer Light

Bulb

If your Glassware Washer is equipped with a window, you

will need to periodically replace the 25-watt washer light

bulb. Refer to Figure 5-3 and follow the instructions

below to replace the washer light bulb.

To replace the washer light bulb:

1. Turn off electrical power to the Glassware Washer.

2. Remove the outer door panel by removing the two

screws located on each side of the washer, identified in

Figure 5-3.

3. Remove the bulb by pressing in on the bulb and

rotating the bulb counterclockwise.

4. Insert the new bulb and rotate clockwise into place, as

shown in Figure 5-3.

5. Replace the outer door panel.

Washer screw

Press in new bulb

and rotate clockwise.

Washer screws

Figure 5-3

56

Product Service 1-800-522-7658

Page 57

Chapter 5: Maintaining Your Washer

Removing the Washer Top,

Back, and Side Panels

There may be times when you need to remove the washer

top, back, and side panels to clean, maintain, or repair your

washer. Refer to Figure 5-4 and follow the instructions

below to remove the top, back, and side panels of your

washer.

To remove the washer top, back, and side panels:

1. Turn off electrical power to the Glassware Washer.

2. Remove all of the screws from the back panel of the

washer and remove the back panel.

3. Remove the two screws in the front of the washer that

attach the washer top to the sides.

4. Remove the two screws in the back of the washer that

attach the washer top to the sides.

5. Slide the washer top toward the rear. Lift the washer

top and remove.

6. Remove the two screws from each side of the washer

at the front edge.

7. Remove one screw at the rear of the washer.

8. Remove the side panels.

Figure 5-4

Remove four

screws that attach

the top to the sides.

Then, slide the

washer top toward

the rear of the

washer and lift to

remove.

Product Service 1-800-522-7658

57

Page 58

Chapter 5: Maintaining Your Washer

Chapter 2: Prerequisites

Cleaning the Sump Filter

Screen

If debris accumulates on the filter screen that is located in

the washer sump, you can remove and clean the screen.

To clean the sump filter screen, refer to Figure 5-5 and

follow the instructions below.

To clean the sump filter screen:

Refer to Figure 4-1 in

Chapter 4: Using Your

Washer for an illustration

of the SteamScrubber

wash arm and tower.

Lower wash arm

1. Open the washer door and remove the bottom rack.

2. If you have a SteamScrubber, remove the upper wash

arm. Depress the button on the wash arm tower and

lift the upper portion of the tower to remove the wash

arm. If you have a FlaskScubber, remove the plastic

clamp and rubber diaphragm from the wash tower, as

illustrated in Figure 5-5.

3. Lift and rotate the lower wash arm.

4. Remove the screw and clip at the rear of the filter

screen.

5. Carefully lift the screen, using care not to drop debris

into the pump.

Figure 5-5

Rubber diaphragm

Plastic clamp

58

Filter screen screw and clip

Product Service 1-800-522-7658

Page 59

C

HHAAPPTTEERR

C

M

OODDIIFFYYIINNG

M

6

6

G

Y

Y

OOUUR

R

W

W

The configuration of your washer may need to be changed

to accommodate your needs. For example, you may want

to disconnect the purified water pump, install pipet inserts,

or install an optional top rack. Read this chapter to learn

how to:

Disconnecting the Purified

Water Pump

If you have no need for the purified water pump on your

washer, you may choose to disconnect it. Refer to Figure

6-1 and follow the steps detailed below to disconnect the

purified water pump.

AASSHHEER

• disconnect the purified water pump from your

washer

• install pipet inserts in a FlaskScrubber washer

• install an upper rack in a FlaskScrubber washer

R

Product Service 1-800-522-7658

59

Page 60

Chapter 6: Modifying Your Washer

M

M

Chapter 2: Prerequisites

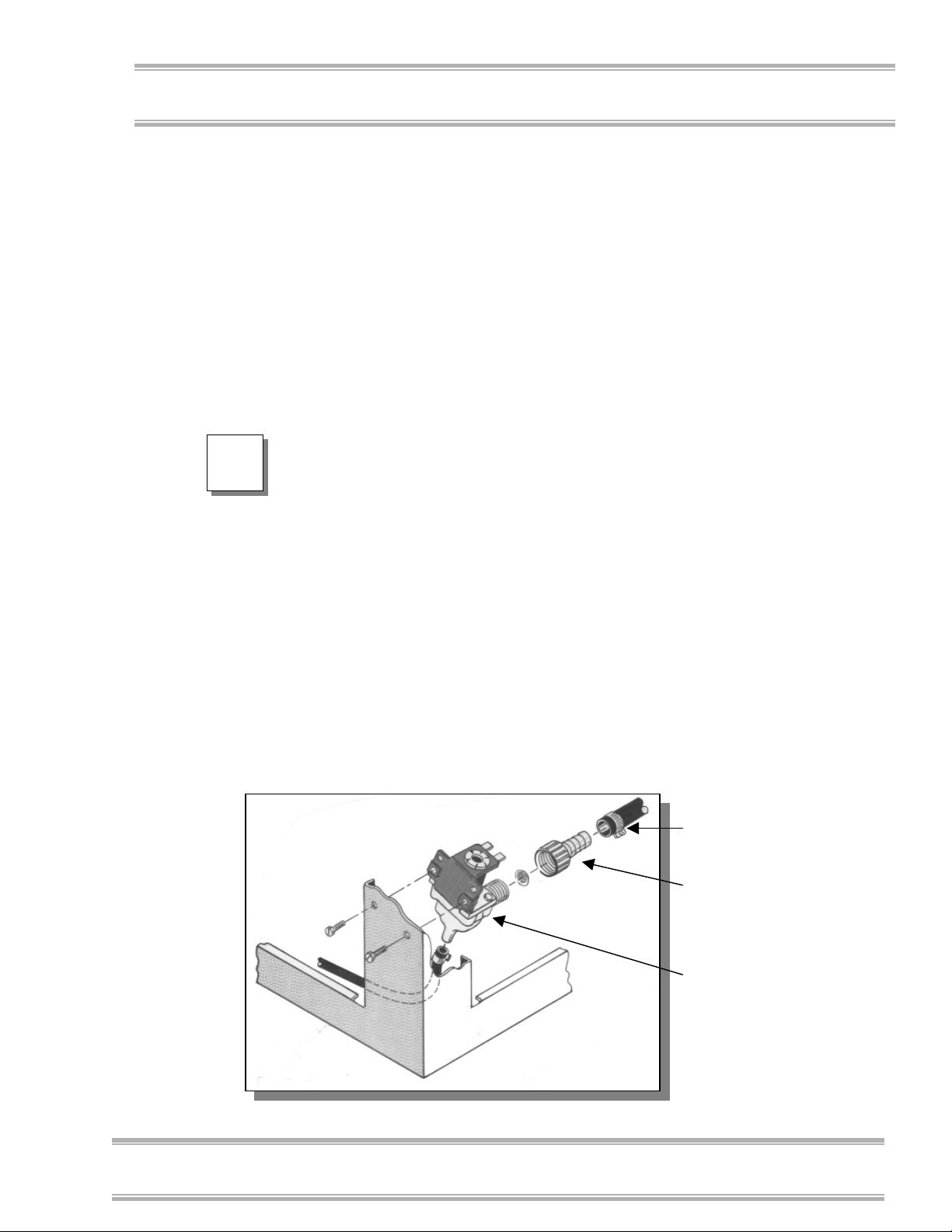

To disconnect the purified water pump:

Refer to Figure 3-7

in Chapter 3:

Getting Started for

help in removing

the lower panel.

F

F

Purified

water pump

1. Disconnect the washer from its electrical source.

2. Remove the two screws at the bottom of the lower

panel of your washer.

3. Remove the panel by lifting slightly and pulling out.

4. If you have the Freestanding or Mobile model of the

Glassware Washer, remove the left side panel. Refer

to Figure 5-4 in Chapter 5: Maintaining Your Washer.

5. Remove the fuse from the fuse holder located on the

end of the purified water pump, as shown in Figure

6-1.

6. Replace the side and lower panels.

Figure 6-1

Remove the fuse

from the fuse

holder located on

the end of the

purified water

pump.

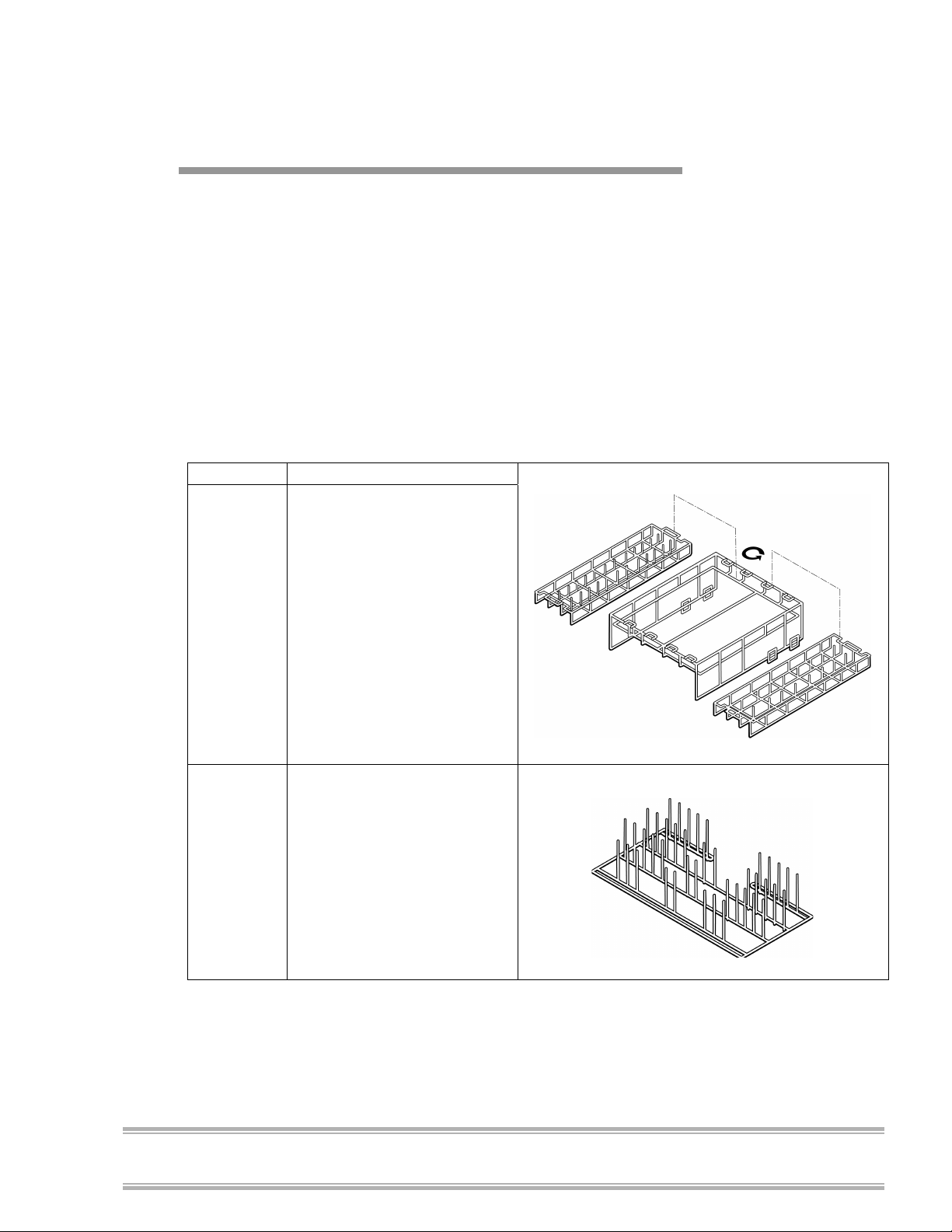

FlaskScrubber Options

If you purchased a FlaskScrubber Glassware Washer,

you can modify the configuration of your washer to better

suit your needs, if desired. Two pipet inserts and an

optional top rack are available. The pipet inserts are easily

installed in place of one or more spindles in the washer

and are designed to accommodate 1 ml to 50 ml pipets.

60

Product Service 1-800-522-7658

Page 61

Chapter 6: Modifying Your Washer

Installing Pipet Inserts in a

FlaskScrubber

Two sizes of pipet inserts are available. The 8-place pipet

insert, shown in Figure 6-2 accommodates 1 ml to 10 ml

pipets. Multiple pipet inserts may be installed, if desired.

Refer to Figure 6-2 and follow the instructions below to

install an 8-place pipet insert.

To install an 8-place pipet insert:

1. Insert a 9/64" hex wrench into the top of any ¼"

spindle and turn counterclockwise to remove the

spindle. Small spindles may be removed by hand.

2. In the position previously occupied by the spindle,

thread into place the short spindle you received with

the pipet insert.

3. Push the pipet insert over the short spindle.

Figure 6-2

Pipet holder

Loosen set screw to slide

pipet holder to various

positions; tighten to secure

in place.

8-place pipet insert

Short spindle provided

with pipet insert.

Spindle rack

Product Service 1-800-522-7658

61

Page 62

Chapter 6: Modifying Your Washer

Chapter 2: Prerequisites

The 14-place pipet insert, shown in Figure 6-3,

accommodates 1 ml to 50 ml pipets. Two of these inserts

may be installed, if desired. Refer to Figure 6-3 and

follow the instructions below to install a 14-place pipet

insert.

To install a 14-place pipet insert:

1. Use a 9/64" hex wrench to remove the three spindles

on either the right side or left side of the spindle rack.

2. Replace the center spindle with one of the plastic plugs

that you received with your washer.

3. Replace the front and back spindles with the two short

spindles that you received with the pipet insert.

4. With the support facing the center of the spindle rack,

slide the pipet insert over the spindles until it

completely seats.

14-place pipet

insert

Short spindles

supplied with

pipet insert.

Spindle rack

Figure 6-3

62

Product Service 1-800-522-7658

Page 63

Chapter 6: Modifying Your Washer

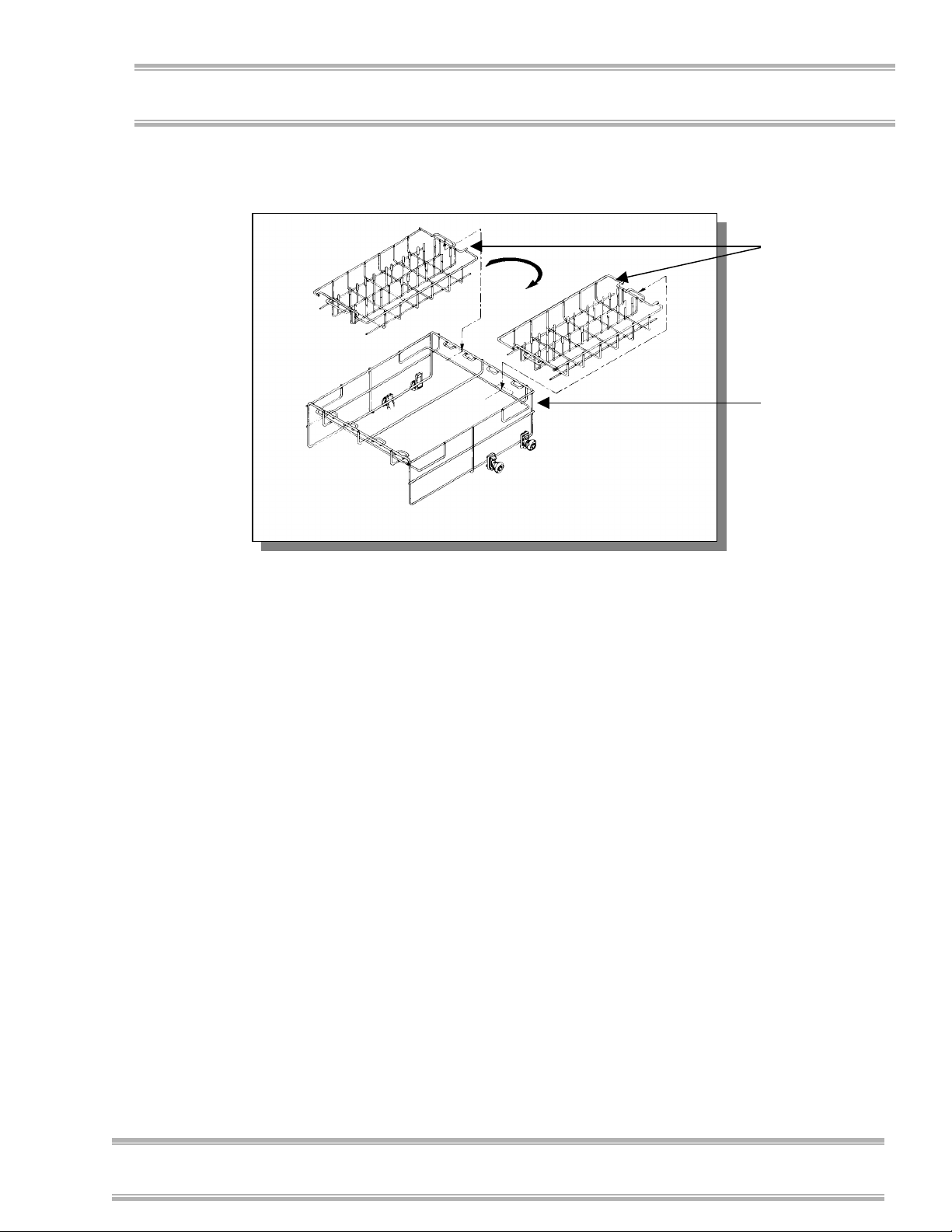

Installing the Optional,

Adjustable-Height Top Rack

An optional top rack, shown in Figure 6-6, is available to

increase the capacity of the FlaskScrubber to handle many

types of labware, particularly beakers. To install the

optional top rack, refer to Figures 6-4 and 6-5 and follow

the instructions below.

To install the optional upper rack:

1. Remove all of the parts from the carton. See Appendix

D for a list of parts shipped.

2. Use a 5/16" hex wrench to remove the black plug in

the center of the spindle rack.

3. If the rack is to be located in the upper position, thread

in the longer hub-adapter assembly that you received

with the rack. If the rack is to be located in the lower

position, thread in the shorter hub-adapter. Remove

the nozzle from the longer hub-adapter assembly and

thread it into the shorter hub-adapter. Figure 6-4

illustrates the hub adapter installed in the spindle rack.

Figure 6-4

Nozzle

Hub adapter

Remove black plug

to accommodate hub

adapter.

Spindle rack

Product Service 1-800-522-7658

63

Page 64

Chapter 6: Modifying Your Washer

Chapter 2: Prerequisites

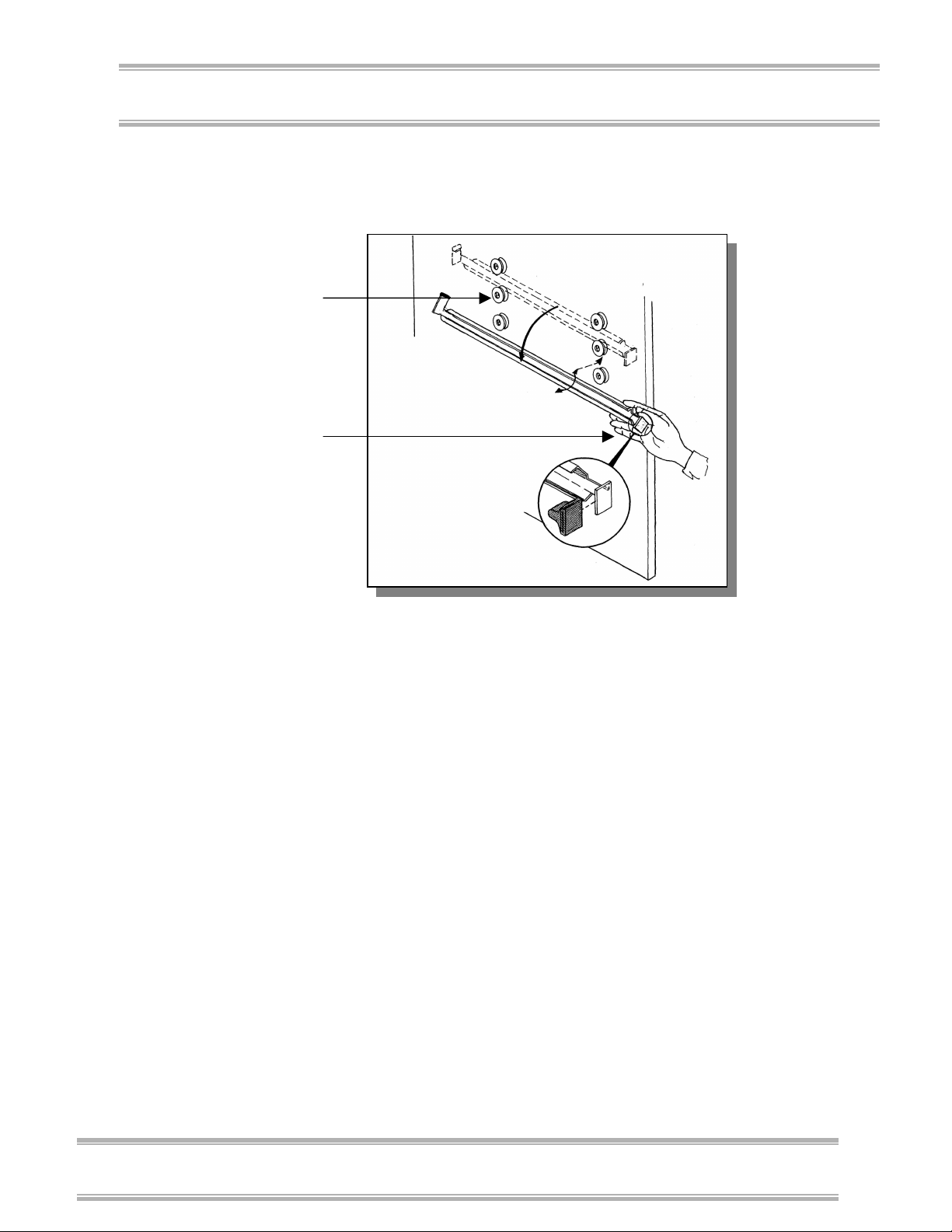

Install the rails with

the slots on the bottom.

Tilt and position the top

of the rail between the

factory-installed rollers

bottom of the rail into

Install a rubber bumper on