Page 1

User’s Manual

Purifier®Vertical Clean Benches

Models

3970200, 3970201, 3970203, 3970204, 3970220, 3970221,

3970223, 3970224, 3970300, 3970301, 3970303, 3970304,

3970320, 3970321, 3970323, 3970324, 3970400, 3970401,

3970403, 3970404, 3970420, 3970421, 3970423, 3970424

To receive important product updates,

complete your product registration card

online at register.labconco.com

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Please read the User’s Manual before operating the equipment.

Page 2

Copyright © 2004, 2007 Labconco Corporation. All rights reserved.

The information contained in this manual and the accompanying products are copyrighted and all rights

reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic design

changes without obligation to notify any person or entity of such change.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas

of defective material and workmanship, provided such defect results from normal and proper use of

the equipment.

The warranty for all Labconco products will expire one year from date of installation or two years

from date of shipment from Labconco, whichever is sooner, except the following;

• Purifier® Delta® Series Biological Safety Cabinets and PuriCare® Lab Animal Research

Stations carry a three-year warranty from date of installation or four years from date of

shipment from Labconco, whichever is sooner.

• SteamScrubber® & FlaskScrubber® Glassware Washers carry a two-year warranty from

date of installation or three years from date of shipment from Labconco, whichever is

sooner.

• Blood Drawing Chairs carry a ten year warranty.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mi shan dl ed.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If

the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will repair

or replace all defective parts to restore the unit to operation. Under no circumstances shall

Labconco Corporation be liable for indirect, consequential, or special damages of any kind. This

statement may be altered by a specific published amendment. No individual has authorization to

alter the provisions of this warranty policy or its amendments. Lamps and filters are not covered by

this warranty. Damage due to corrosion or accidental breakage is not covered.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized return s will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight carrier.

Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525

or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Part #3938100, Rev. C

ECO E161

Page 3

T

AABBLLEE

T

CHAPTER 1: INTRODUCTION 1

ISO Class 5 Definition 2

About This Manual 2

Typographical Conventions 3

CHAPTER 2: PREREQUISITES 5

Support, Vibration & Movement Requirements 6

Location and Air Current Requirements 6

Airflow Specifications 6

Electrical Requirements 7

Space Requirements 7

CHAPTER 3: GETTING STARTED 8

Unpacking the Clean Bench 9

Installing Vertical Clean Bench on a Supporting

Structure and Work Surface 9

Verifying HEPA Filter Integrity 12

Connecting the Electrical Supply Source to the Vertical Clean

Bench 12

Setting the Downflow Velocity with Speed Control Adjustment 13

Validating the Vertical Clean Bench 13

Sealing the Vertical Clean Bench to the Work Surface 14

CHAPTER 4: PERFORMANCE FEATURES AND

Components 16

Safety Precautions 20

CHAPTER 5: APPROPRIATE APPLICATIONS FOR YOUR

Routine Daily Work Procedures 23

Suitable Applications 24

HEPA Filter Applications, Suitability & Guidelines 25

CHAPTER 6 MAINTAINING YOUR VERTICAL CLEAN

Routine Maintenance Schedule 27

When to Replace HEPA Filters 27

How to Install a New HEPA Filter 28

HEPA Filter Leak Test 30

O

O

SAFETY PRECAUTIONS 15

VERTICAL CLEAN BENCH 23

BENCH 26

FF

C

C

OONNTTEENNTTSS

Page 4

Setting the Downflow Velocity with the Speed Control Adjustment 32

Calibrate and Operate the Airflow Monitor 32

Initial Certification 36

Re-Certification 36

Fluorescent Light Replacement 36

UV Light Replacement (If equipped) 37

Motorized Impeller Replacement 37

Speed Control Replacement 39

CHAPTER 7 ACCESSORIZING & MODIFYING YOUR

VERTICAL CLEAN BENCH 40

CHAPTER 8 TROUBLESHOOTING & SERVICER

OPERATING LOG 44

APPENDIX A: VERTICAL CLEAN BENCH COMPONENTS

AND REPLACEMENT PARTS 48

APPENDIX B: DIMENSIONS 53

APPENDIX C: VERTICAL CLEAN BENCH SPECIFICATIONS 55

APPENDIX D: REFERENCES 60

DECLARATION OF CONFORMITY 61

Page 5

C

HHAAPPTTEERR

C

I

NNTTRROODDUUCCTTIIOONN

I

Congratulations on your purchase of a Labconco Purifier®

Vertical Clean Bench. Your enclosure provides product

protection. It is the result of Labconco’s more than 30 years

experience in manufacturing filtered enclosures.

These enclosures will effectively provide product protection from

airborne particulate matter. During operation, room air is drawn

through the prefilter on top, forced through the blower and then

through the HEPA filter and diffuser. The clean air in the work

area in the enclosure meets or exceeds ISO Standard Class 5

conditions defined per ISO Standard 14644-1 and Class 100

conditions as defined by Federal Standard 209E. The enclosure is

set to deliver nominal downward airflow of 40-55 feet per minute.

Each enclosure uses a single HEPA filter, which is rated at least

99.99% efficient for 0.3-micron particles. The Purifier enclosures

offer many unique features to enhance performance. To take full

advantage of them, please acquaint yourself with this manual and

keep it handy for future reference. If you are unfamiliar with how

filtered Vertical Clean Benches operate, please review Chapter 4:

Performance Features and Safety Precautions before you begin

working. Even if you are an experienced user, please review

Chapter 5: Using Your Vertical Clean Bench, which describes the

enclosure features.

1

1

Product Service 1-800-522-7658

1

Page 6

Chapter 1: Introduction

Table 1-1 Selected airborne particulate cleanliness classes for cleanrooms and clean zones.

classification

number (N)

ISO Class 1 10 2

ISO Class 2 100 24 10 4

ISO Class 5 Definition

Airborne particulate cleanliness inside any clean bench or

enclosure is designated by ISO Class 5, which is equivalent to

3520 particles 0.5 µm or larger per cubic meter of air per ISO

Standard 14644-1. ISO Class 5 cleanliness is illustrated in the

table to follow and is equivalent to Class 100 air conditions as

defined by Federal Standard 209E. Class 100 is equal to 100

particles 0.5 µm or larger per cubic foot of air.

ISO

Maximum concentration limits (particles/m3 of air) for particles equal to and

larger than the considered sizes shown below (concentration limits are

calculated in accordance with 3.2 of Standard 14644-1)

0.1 µm 0.2 µm 0.3 µm 0.5 µm 1 µm 5 µm

ISO Class 3 1 000 237 102 35 8

ISO Class 4 10 000 2 370 1 020 352 83

ISO Class 5 100 000 23 700 10 200 3 520 832 29

ISO Class 6 1 000 000 237 000 102 000 35 200 8 320 293

ISO Class 7 352 000 83 200 2 930

ISO Class 8 3 520 000 832 000 29 300

ISO Class 9 35 200 000 8 320 000 293 000

Table 1-1 ISO Classification Number (N)

About This Manual

This manual is designed to help you learn how to install, use, and

maintain your Clean Bench.

Chapter 1: Introduction provides a brief overview of the Clean

Bench, explains the organization of the manual, and defines the

typographical conventions used in the manual.

Chapter 2: Prerequisites explains what you need to do to prepare

your site before you install the Clean Bench. Electrical and service

requirements are discussed.

Chapter 3: Getting Started contains the information you need to

properly unpack, inspect, install, and certify the Clean Bench.

2

Product Service 1-800-522-7658

Page 7

Chapter 1: Introduction

Chapter 4: Performance Features and Safety Precautions explains

how the Purifier Vertical Clean Bench operates and the appropriate

precautions you should take when using it.

Chapter 5: Appropriate Applications for your Vertical Clean

Bench discusses the basic operation of how to prepare, use and

shut down your Clean Bench.

Chapter 6: Maintaining Your Vertical Clean Bench explains how

to perform routine maintenance on the Clean Bench.

Chapter 7: Accessorizing Your Vertical Clean Bench explains

acceptable modifications to the Clean Bench or how to add

accessories.

Chapter 8: Troubleshooting contains a table of problems you may

encounter while using the Clean Bench including probable causes

and suggested corrective actions.

Appendix A: Components and Replacement Parts contains labeled

diagrams of all of the components of the Clean Benches.

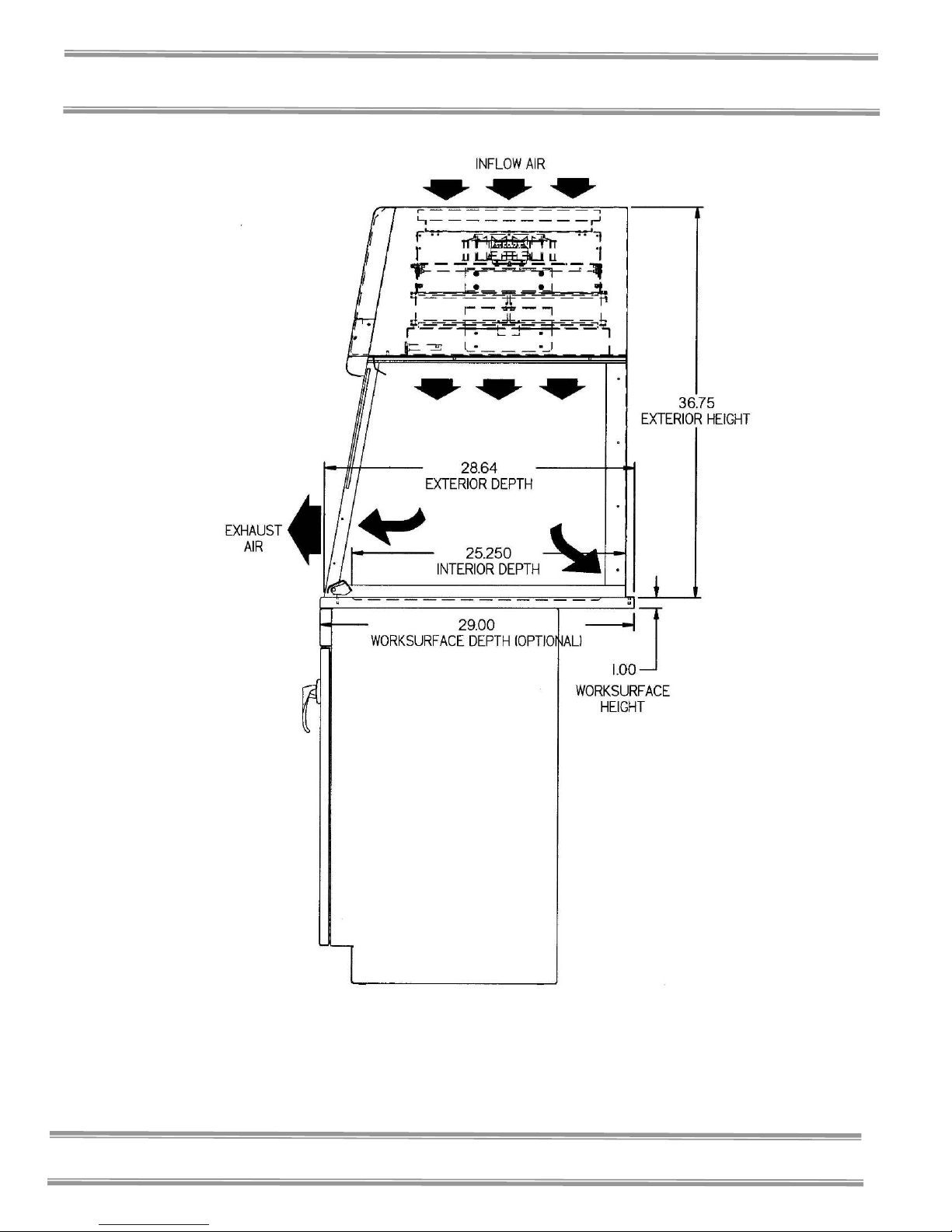

Appendix B: Dimensions contains comprehensive diagrams

showing all of the dimensions for the Clean Benches.

Appendix C: Vertical Clean Bench Specifications contains the

electrical requirements for clean benches. Wiring diagrams are

also included.

Appendix D: References lists the various resources available that

address clean rooms and Clean Benches.

Typographical Conventions

Recognizing the following typographical conventions will help

you understand and use this manual:

• Book, chapter, and section titles are shown in italic type (e.g.,

Chapter 3: Getting Started).

• Steps required to perform a task are presented in a numbered

format.

• Comments located in the margins provide suggestions,

reminders, and references.

• Critical information is presented in boldface type in paragraphs

that are preceded by the exclamation icon. Failure to comply

Product Service 1-800-522-7658

!

3

Page 8

Chapter 1: Introduction

)

2'

3'

4'

with the information following an exclamation icon may result

in injury to the user or permanent damage to the enclosure.

• Critical information is presented in boldface type in paragraphs

that are preceded by the wrench icon. Only a trained certifier

or contractor should only perform these operations. Failure to

comply with the information following a wrench icon may

result in injury to the user or permanent damage to your Clean

Bench.

• Important information is presented in capitalized type in

paragraphs that are preceded by the pointer icon. It is

imperative that the information contained in these paragraphs

be thoroughly read and understood by the user.

• A number icon precedes information that is specific to a

particular model of enclosure. The 2' icon indicates the text is

specific to the 2-foot wide model. The 3' icon indicates the text

is specific to the 3-foot model, etc.

4

Product Service 1-800-522-7658

Page 9

C

HHAAPPTTEERR

C

P

RREERREEQQUUIISSIITTEESS

P

Before you install the Vertical Clean Bench, you need to prepare

your site for installation. You must be certain that the area is level

and of solid construction. In addition, a dedicated source of

electrical power should be located near the installation site to

power the Clean Bench, and other apparatus. Additionally, the

enclosure should be strategically placed in the lab to provide

efficient workflow.

Carefully read this chapter to learn the requirements for your

installation site:

• The support, vibration and movement requirements.

• The location and air current requirements.

• The exhaust and blower requirements.

• The electrical power requirements.

• The space requirements.

Refer to Appendix B: Dimensions for complete Vertical Clean

Bench dimensions.

Refer to Appendix C: Vertical Clean Bench Specifications for

complete Vertical Clean Bench electrical and environmental

conditions, specifications and requirements.

2

2

Product Service 1-800-522-7658

5

Page 10

Chapter 2: Prerequisites

Support, Vibration and Movement

Requirements

At a minimum, the supporting structure usually consists of a base

cabinet or base stand and chemically-resistant work surface.

Location and Air Current

Requirements

Purifier Vertical Clean Benches have been designed to provide

particulate-free clean air meeting Class 5 conditions by negating

typical cross drafts and turbulence within the opening. However,

as a precautionary safety measure and a higher level of quality

management, it is recommended that the clean bench be placed in

an area away from:

• High traffic areas where walking might cause an air

disturbance or be a nuisance.

• Overhead or wall HVAC diffusers, fans, radiators or other lab

equipment producing air currents.

• Doorways or windows that may be opened.

Airflow Specifications

Purifier Vertical Clean Benches use an integral motorized impeller

to draw room air from the top and through the enclosure. This

room air is then pushed down through the HEPA filter. The

enclosure is factory set to deliver 40-55 fpm downflow velocity

measured 6" below the upper diffuser. The Class 5 HEPA-filtered

air flows across the work area and exits out the front of the

enclosure.

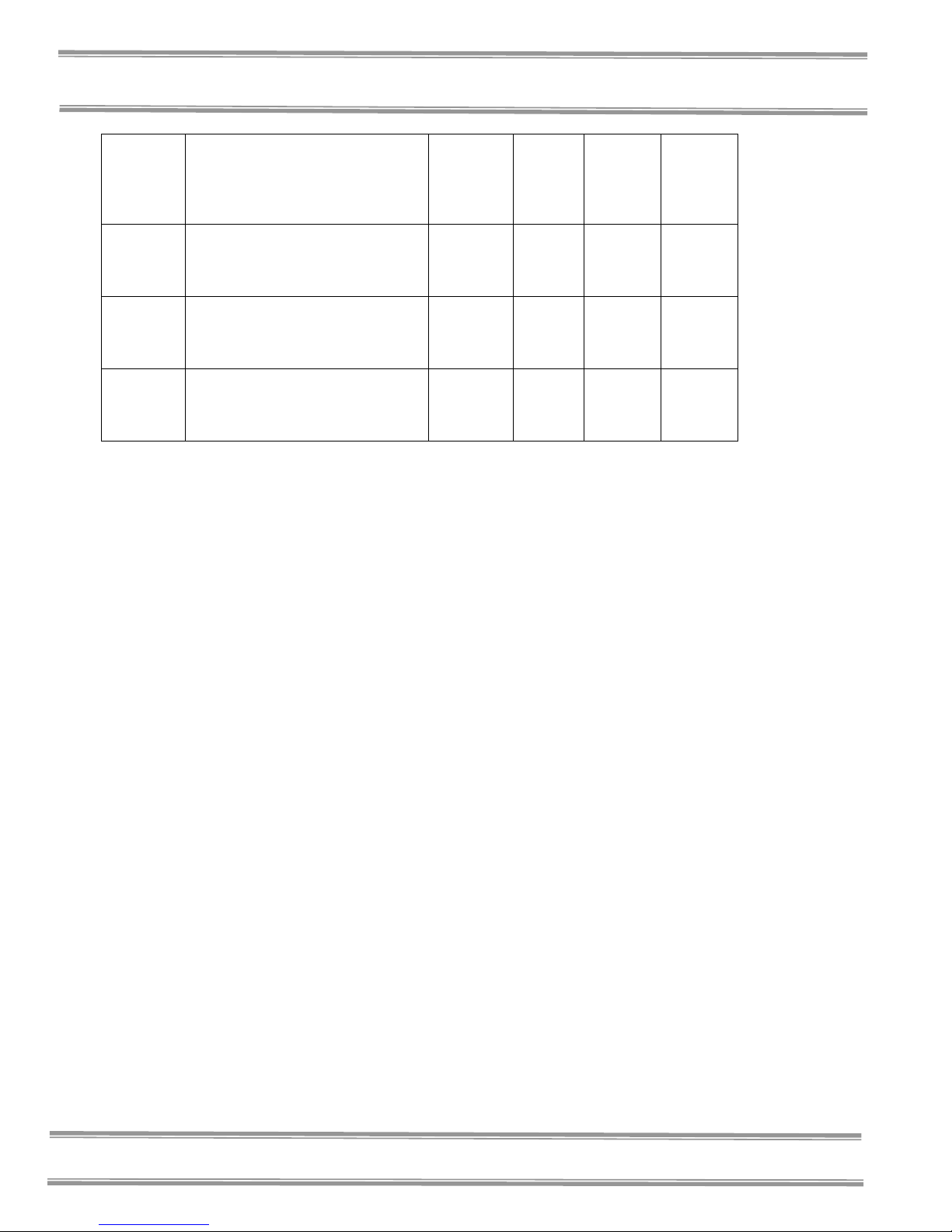

Data for the outflow exhaust volume, downflow velocities and outflow face velocities are listed for each Vertical Clean Bench model

below.

6

Product Service 1-800-522-7658

Page 11

Enclosure

Width Model Description

2'

3'

4'

2' Vertical Clean Bench

3' Vertical Clean Bench

4' Vertical Clean Bench

Electrical Requirements

Downflow

Velocity

(fpm)

30

40

50

60

30

40

50

60

30

40

50

60

Out-

Flow

Exhaust

Volume

(CFM)

120

165

210

250

180

250

310

370

240

330

420

500

Chapter 2: Prerequisites

Average

Outflow

Noise

Pressure

db(A)

53-57

58-60

60-61

62-63

58-60

60-62

62-66

66-70

58-62

60-64

62-66

66-70

Face

Velocity

(fpm)

85

115

145

170

85

115

145

170

85

115

145

170

Standard duplex electrical receptacles should be nearby for

connecting the Vertical Clean Bench, or other equipment. The

enclosures include iris pass-throughs to allow electrical cords

through the back of the enclosure without leaving a large hole.

Space Requirements

The dimensions for all the different models are shown in Appendix

B: Dimensions.

Product Service 1-800-522-7658

7

Page 12

C

HHAAPPTTEERR

C

G

EETTTTIINNGG

G

Now that the site for your Vertical Clean Bench is properly

prepared, you are ready to unpack, inspect, install, and validate

your Clean Bench. Read this chapter to learn how to:

• Unpack and move the Clean Bench.

• Set up the enclosure with the proper supporting structure

and work surface.

• Verify HEPA filters integrity.

• Connect the electrical supply.

• Set the downflow velocity with the speed control

adjustment.

• Validate enclosure airflow.

• Seal the enclosure to the work surface.

Depending upon which model you are installing, you may need

common mechanical and electrical installation tools in addition to

wrenches, ratchets, sockets, a nut driver set, a flat-blade

screwdriver, a Phillips screwdriver, and a carpenter level to

complete the instructions in the chapter.

Each Clean Bench model weighs between 125 to

195 lbs. each (55 to 85 kg). The shipping

!

container allows for lifting with a mechanical lift

truck or floor jack. If you must lift the enclosure

manually, follow safe-lifting guidelines. Do not

lift by the lower air foil.

S

3

3

TTAARRTTEEDD

S

8

Product Service 1-800-522-7658

Page 13

Chapter 3: Getting Started

Unpacking the Clean Bench

Carefully remove the shrink-wrap or carton on the Clean Bench

and inspect it for damage that may have occurred in transit. If

damaged, notify the delivery carrier immediately and retain the

entire shipment intact for inspection by the carrier.

DO NOT RETURN GOODS WITHOUT THE

PRIOR AUTHORIZATION OF LABCONCO.

)

)

Do not discard the packing material until you have checked all of

the components and tested the Clean Bench.

We recommend that you do not remove the Clean Bench from its

shipping container until it is ready to be placed into its final

location. Move the Clean Bench by placing a flat, low dolly under

the shipping skid, or by using a floor jack.

!

UNAUTHORIZED RETURNS WILL NOT BE

ACCEPTED.

IF CLEAN BENCH WAS DAMAGED IN

TRANSIT, YOU MUST FILE A CLAIM

DIRECTLY WITH THE FREIGHT CARRIER.

LABCONCO CORPORATION AND ITS

DEALERS ARE NOT RESPONSIBLE FOR

SHIPPING DAMAGES.

Do not move the Clean Bench by tilting it onto a

hand truck.

The United States

Interstate Commerce

Commission rules

require that claims be

filed with the delivery

carrier within fifteen (15)

days of delivery.

Installing the Vertical Clean

Bench on a Supporting Structure

and Work Surface

Use caution when lifting or moving the Clean Bench.

When installing the Clean Bench onto a chemical-resistant work

surface or benchtop, ensure that the structure can safely support the

combined weight of the Clean Bench and any related equipment.

Product Service 1-800-522-7658

9

Page 14

Chapter 3: Getting Started

The work surface should be at least as wide and deep as the

enclosure to properly support it. The front of the Clean Bench

should be aligned within 0.30" (8 mm) of the front of the work

surface. Mounting holes are provided in the Labconco accessory

work surfaces to secure the Clean Bench.

Work Surface Specifications

The work surface should be smooth, rigid and durable, such as a

chemical-resistant epoxy resin. The surface should be non-porous

and resistant to the materials used in conjunction with the Purifier

Vertical Clean Bench. The work surface should also contain a

dished recessed area for containing primary spills.

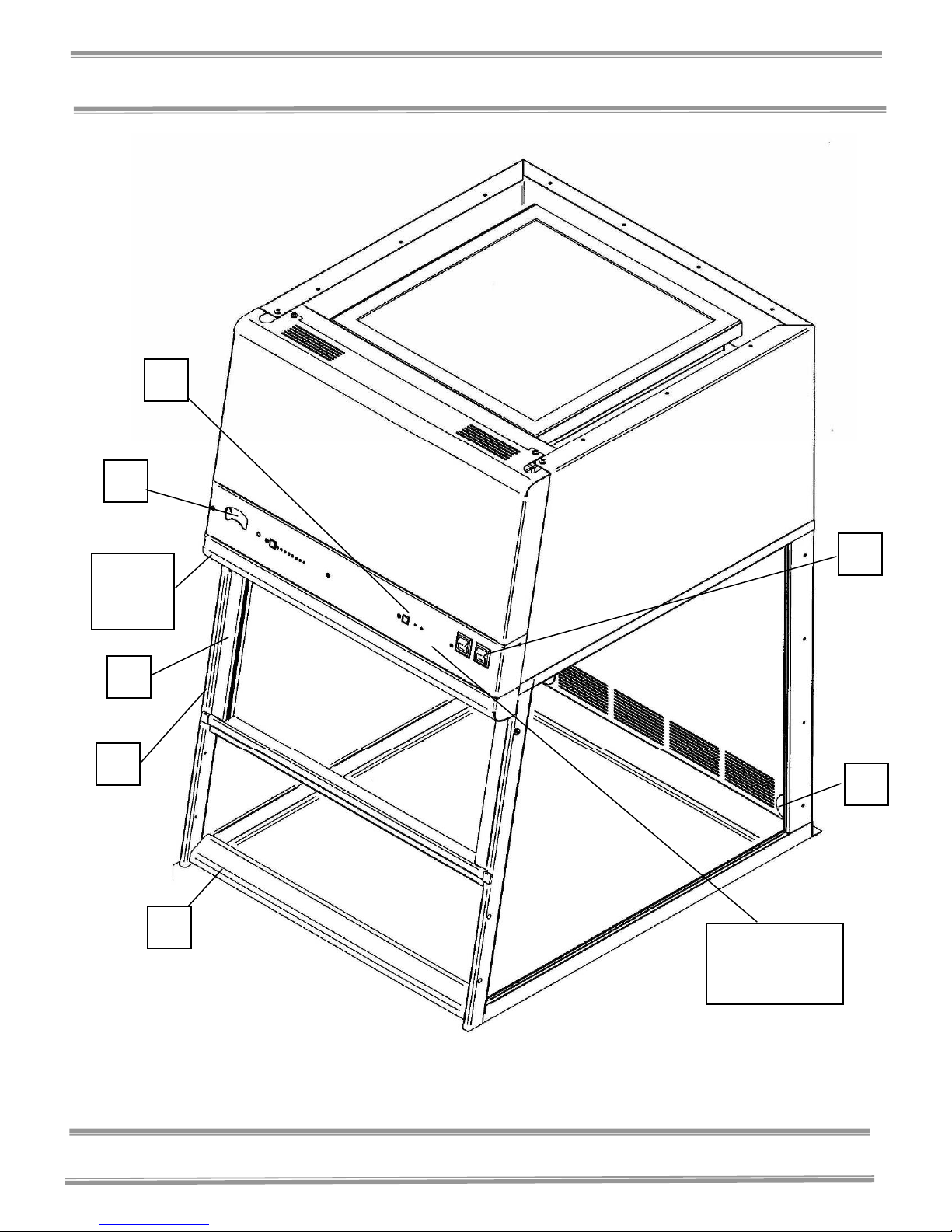

Vertical Clean Bench Work Surface

1. Level the base cabinet or stand and the work surface. See

Figure 3-1.

2. Position the work surface in its intended location and with

the front of the work surface towards you. (Rear mounting

holes are located close to the rear edge.)

3. Secure the work surface to the base cabinet or stand with a

structural adhesive or silicone sealant.

4. Insert the supplied mounting screws in the four holes.

Allow a minimum of 1/8" clearance under the head of the

screw for positioning the Clean Bench.

5. Place the Clean Bench on the work surface and slide the

rear flange and front air foil flanges under the mounting

screw heads.

6. Tighten the four screws to complete the installation.

10

Product Service 1-800-522-7658

Page 15

Chapter 3: Getting Started

Figure 3-1

Vertical Clean Bench Installation

Product Service 1-800-522-7658

11

Page 16

Chapter 3: Getting Started

Verifying HEPA Filter Integrity

The HEPA filter is shipped installed with the gasket on the

downstream side. The HEPA filter is leak checked at Labconco.

A second leak check is recommended before using the enclosure

and at least annually thereafter. Consult your Safety Officer and

Chapter 6 for the HEPA Filter Leak Test. See Figure 4-2 for

HEPA filter location, HEPA filter gasket, and filter clamp bolts.

All seams downstream of the HEPA filter are jacketed by positive

pressure. This intrinsically safe design ensures Class 5 conditions

inside the Vertical Clean Bench.

HEPA Filter Appropriate Use

Filter Size

2'

3'

4'

Part No.

3707900

3707901

3707902

HEPA filters are high-efficiency particulate

air filters having a particulate removable

efficiency of 99.99% for particles with a

diameter of 0.3 micron.

Connecting the Electrical Supply

Source to the Vertical Clean

Bench

115V Models

Simply connect the 115V power cord supplied to the IEC electrical

supply plug on the back of the Clean Bench. If using at 50 Hz

operations, blower performance maximum airflow will be reduced

by 17%.

230V Models

The 230V is shipped without a plug. Install the appropriate plug

for your electrical specifications per local codes.

12

Product Service 1-800-522-7658

Page 17

Chapter 3: Getting Started

Setting the Downflow Velocity

with the Speed Control

Adjustment

Adjustment of the speed control gives the correct downflow

velocity and is located behind the front panel. The downflow

velocity should be from 30-65 fpm for Class 100 (ISO class 5)

conditions. ISO Class 5 clean air conditions are maximized at a

setting within this range. The Vertical Clean Bench is factory set

at 40-55 fpm downflow velocity. (Consult your Safety Officer for

airflow recommendations for your application). Working at the

downflow velocity appropriate for the application will give the

quietest operation. Downflow velocity measurements are made

using an anemometer. An electric anemometer can be obtained

from your laboratory supply dealer. Downflow velocity

measurements should be taken 6" below the interior upper diffuser.

Using a small Phillips screwdriver, adjust the speed control to give

the required downflow velocity. See Figures 6-1 and 6-2 in

Chapter 6 to locate the speed control. The downflow velocity is

increased by turning the speed control counterclockwise and

clockwise to decrease downflow velocity.

2'

3'

Validating the Vertical Clean

Bench

To determine the actual downflow velocity, airflow velocity

readings are taken. This should be done 6" down from the top of

the interior upper diffuser. The “average downflow velocity” is

achieved by averaging the readings in the downflow test grid for

each model:

The downflow test grid consists of 9 test points, 3 points in 3 rows.

The back row of the grid is 6" from the rear of the work area. The

middle and front rows are 6.57" apart from the back to the front.

The first and last column of the downflow grid are spaced 6" in

from each sidewall with a center column spaced 5.32" away from

the first and last column.

The downflow test grid consists of 12 test points, 4 points in 3

rows. The back row of the 6" from the rear of the work area. The

middle and front rows are 6.57" apart from the back to the front.

The first and last column of the downflow grid are spaced 6" in

from each sidewall with two columns spaced 7.54" away from the

first and last column.

Product Service 1-800-522-7658

13

Page 18

Chapter 3: Getting Started

4'

The downflow test grid consists of 15 test points, 5 points in 3

rows. The back row of the grid is 6" from the rear of the work area.

The middle and front rows are 6.57" apart from the back to the

front. The first and last column of the downflow grid are spaced 6"

in from each sidewall with three columns spaced 8.66" away from

the first and last column.

Refer to the exhaust specifications table in Chapter 2 for proper

airflow volumes and downflow velocities for your particular

model. A certified technician should complete validation.

The Purifier Vertical Clean Benches have been tested at Labconco

before shipment and provide ISO Class 5 clean air conditions

inside the enclosure. Labconco also performed extensive

performance testing to validate the clean benches for product

protection under ISO Class 5 conditions. For copies of these

validation reports, contact Labconco Customer Service.

Sealing the Vertical Clean Bench

to the Work Surface

When the Vertical Clean Bench has been set in place and wired, it

may be sealed at the work surface to prevent materials from

collecting under the walls. A bead of silicone sealant is

recommended to seal the Vertical Clean Bench to the work

surface.

14

Product Service 1-800-522-7658

Page 19

C

HHAAPPTTEERR

C

P

EERRFFOORRMMAANNCCE

P

F

EEAATTUURREESS

F

P

RREECCAAUUTTIIOONNSS

P

The Purifier Vertical Clean Bench is designed to provide

product protection only from airborne particulate matter.

During operation, room air is drawn from the top and filtered

by the HEPA filter providing Class 5 conditions inside the

enclosure. The Purifier Vertical Clean Bench delivers Class 5

air conditions when operating at downflow velocities of 30 to

65 feet per minute. The HEPA filter is jacketed by negative

pressure preventing contaminated air inside the enclosure and

ensuring Class 5 air conditions inside the enclosure.

4

4

A

A

E

NNDD

S

AAFFEETTYY

S

The Purifier Vertical Clean Bench HEPA filter is located

behind the front panel. Users are encouraged to routinely

check airflow to satisfy Class 5 air conditions inside the

enclosure or purchase a model with an airflow monitor. For

additional surface decontamination inside the enclosure, users

are encouraged to use the model with the internal UV light and

UV sash closure.

Product Service 1-800-522-7658

15

Page 20

Chapter 4: Performance Features and Safety Precautions

6

10

9

Located

Behind

4

2

1

Figure 4-1

12

5

8

Located Behind

Control Panel

16

Product Service 1-800-522-7658

Page 21

19

6

Airflow

Switch with

Adjustment

Screw

15

Optional

UV light

(Not

Shown)

4

1

13

Chapter 4: Performance Features and Safety Precautions

Figure 4-2

Vertical Clean Bench Airflow Diagram

17

Figure 4-2

Vertical Clean Bench Airflow Diagram

7

11

18

Product Service 1-800-522-7658

17

Page 22

Chapter 4: Performance Features and Safety Precautions

16

Figure 4-3

Optional UV Sash Closure

18

Product Service 1-800-522-7658

Page 23

Chapter 4: Performance Features and Safety Precautions

1. Aerodynamic Lower Air Foil allows air to sweep the

work surface and promote ISO Class 5 air conditions inside

the enclosure. See Figure 4-1.

2. Ergonomic Slope of 10 degrees provides maximum

visibility and comfort, reduces glare, thereby minimizing

operator fatigue. See Figure 4-1.

3. Internal Depth of 25" provides necessary depth to work

inside the enclosure. See Figure 4-1.

4. Safety Glass Sash with Spring-Loaded Latch has a

wiping seal and features a spring-loaded latch to secure

sash open for loading and cleaning. The sash must be

down for normal operation. See Figure 4-1.

5. Utility Ports with Iris allows electrical cords and data

cords to pass through the back of enclosure without leaving

a large hole. The enclosure ships with solid plugs. Iris

plugs are included with the User’s Manual. See Figure 4-1

and 4-2.

6. Optional Guardian™ Airflow Monitor continuously

monitors airflow. An audio/visual alarm alerts the user to

low airflow conditions. The Guardian™ Airflow Monitor

is an available option on all Vertical Clean Bench models.

See Figure 4-1 and 4-2.

7. Inherently Safe Impeller has a negative pressure plenum

that surrounds the positive pressure impeller so that if a

leak should occur, the unfiltered air is captured and

refiltered. See Figure 4-2.

8. Speed Control regulates the speed of the motorized

impeller and is used by the certifier to validate and adjust

the downflow velocity. Located behind the front panel.

See Figure 4-2.

9. Fluorescent Lamp is located above the work area, out of

contact with the clean air. A safety glass window beneath

the lamp distributes the light evenly across the work

surface. See Figure 4-1.

10. Filter Pressure Gauge indicates the pressure across the

HEPA filter to help predict HEPA filter loading. See

Figure 4-1.

Product Service 1-800-522-7658

19

Page 24

Chapter 4: Performance Features and Safety Precautions

11. Filter Clamping Bolt evenly seals the HEPA filter to the

frame of the enclosure. See Figure 4-1 and 4-2.

12. Control Panel. The control panel, which is located above

the sash, contains the filter pressure gauge, control switches

and electronics. See Figure 4-1.

13. HEPA (High Efficiency Particulate Air) Filter is rated to

remove 99.99% of all particles 0.3 micron in size. See

Figure 4-2.

14. Lamp Ballast (Not Shown) for the fluorescent lamp is

located behind the control panel.

15. UV (Ultraviolet) Lamp (Not Shown), found only on some

Clean Bench models, allows the operator to surface

disinfect the work area of the enclosure when it is not in

use. The UV light rays will not penetrate the plane of the

sash and lower air foil.

16. UV Sash Closure (Optional) provides added safety to

prevent access inside the enclosure. See Figure 4-3.

17. Accessory Work Surface is dished and contoured to fit the

dimensions of the Clean Bench to contain spills.

18. Upper Diffuser Screen provides protection for the HEPA

Filter and promotes even distribution of downflow air. See

Figure 4-2.

19. Prefilter (roughing) enhances the life of the HEPA filter

by trapping large particles. It should be replaced quarterly.

Safety Precautions

1. Although the Clean Bench has been engineered to maintain

Class 5 air conditions, caution should always be used while

working. Prior to using the Clean Bench, check to make

sure that the blower is operating and periodically ensure

that air is flowing through the enclosure at its specified

downflow velocity of 30 to 65 fpm. The use of an airflow

monitor is recommended to alert the user to a problem with

airflow.

20

Product Service 1-800-522-7658

Page 25

Chapter 4: Performance Features and Safety Precautions

2. Use good housekeeping in the Clean Bench at all times.

Clean up spills immediately. Periodically clean Clean

Bench interior.

3. Do not overload the work surface with apparatus or work

material.

4. The Purifier Vertical Clean Bench should never be used

with biohazardous materials, toxins, acids, or radionuclides.

Air from the work area is dispersed directly into the

laboratory from the Clean Bench. A qualified Safety

Officer must carefully assess any risk associated with the

use of the Purifier Vertical Clean Bench.

5. Always work with your hands as far back into the Clean

Bench as possible. Keep all materials and apparatus inside

the lower air foil of the enclosure.

6. Do not work in this Clean Bench without the blower

running.

7. Perchloric acid use in this Clean Bench is prohibited.

8. Radioactive materials are prohibited in this Clean Bench.

Consult your Safety Officer.

9. Avoid cross drafts and limit traffic in front of the Clean

Bench. Air disturbances created may disturb Class 5

conditions.

10. A qualified certification technician should test the Clean

Bench before it is initially used. The Clean Bench should

be validated annually and whenever it is relocated.

11. The sash must remain in the down position while using the

Clean Bench.

12. The HEPA filter provides Class 5 clean air conditions and

only provides product protection inside the Clean Bench.

Do not use the Clean Bench for personnel protection.

13. Never use flammable gases or solvents in the Clean Bench.

Use of an open flame must be avoided in the Clean Bench.

Open flames may disrupt the airflow patterns in the Clean

Bench, burn the HEPA filter and damage the filter’s

adhesive. Gases under high pressure should not be used in

the enclosure as they may disrupt the airflow patterns of the

Clean Bench.

14. HEPA filters are only effective for entrapment of

particulate matter.

Product Service 1-800-522-7658

21

Page 26

Chapter 4: Performance Features and Safety Precautions

15. The surface of the HEPA filter is fragile and should not be

touched. Care must be taken to avoid puncturing the

HEPA filter during maintenance. If you suspect that a

HEPA filter has been damaged DO NOT use the Clean

Bench; contact a local certification agency or Labconco.

16. The HEPA filter in the enclosure will gradually accumulate

airborne particulate matter from the room. The rate of

accumulation will depend upon the cleanliness of the room

air, and the amount of time the Clean Bench is operating.

With normal usage, the HEPA filters will last two to five

years before requiring replacement.

17. Avoid direct exposure to ultraviolet (UV) radiation;

NEVER work in the enclosure when the UV light is on.

18. Ensure that the Clean Bench is connected to an electrical

service in accordance with local and national electrical

codes. Failure to do so may create a fire or electrical

hazard. Do not remove or service any electrical

components without first disconnecting the filtered

enclosure from electrical service.

19. Increase the downflow velocity by adjusting the speed

control of the motorized impeller or change the HEPA filter

when the downflow velocity falls below acceptable limits

established by your Safety Officer.

20. Ensure only trained operators use the Clean Bench. New

users should review the User’s Manual and become

familiar with the operation of the Clean Bench.

21. Proper operation of the Clean Bench depends largely upon

the enclosure location and the operator’s work habits. The

enclosure should be located away from traffic patterns,

doors, fans, ventilation registers, fume hoods, and any other

air-handling device that could disrupt its airflow patterns.

Consult Chapter 2: Prerequisites and Chapter 3: Getting

Started sections of this manual for further details.

22

Product Service 1-800-522-7658

Page 27

C

HHAAPPTTEERR

C

A

PPPPRROOPPRRIIAATTE

A

A

PPPPLLIICCAATTIIOONNSS FFOORR YYOOUURR

A

V

EERRTTIICCAAL

V

B

EENNCCHH

B

Now that the installation of your Vertical Clean Bench is

completed, you are ready to use it. Read this chapter to learn

about:

1. Routine Daily Work Procedures.

2. Suitable Applications.

3. Appropriate HEPA Filter Applications, Suitability and

Guidelines.

L

5

5

C

C

E

LLEEAAN

N

Routine Daily Work Procedures

Planning

• Arrange for minimal disruptions, such as room traffic or

entry into the room while the Clean Bench is in use.

Start-up

Product Service 1-800-522-7658

• Turn on blower and light. Turn off the UV light, if

equipped.

• Only raise the sash for loading and cleaning.

• Allow the Clean Bench blower to operate unobstructed for

1 minute.

23

Page 28

Chapter 5: Appropriate Applications For Your Vertical Clean Bench

• Wear a long sleeved lab coat, rubber gloves and protective

eyewear. Wear a protective mask if appropriate. Consult

your Safety Officer for additional personal protective

equipment recommendations.

• Wipe down interior surfaces with a mild household

detergent or disinfectant. DO NOT use abrasive cleaners,

bleach or solvents.

Loading Materials and Equipment

• Load only the materials required for the procedure. Do not

overload the Clean Bench.

• Do not obstruct the upper air diffuser screen.

• Large objects should not be placed close together.

• After loading, wait one minute to purge airborne

contaminants from the work area.

Work Techniques

• Keep all materials inside the lower air foil, and perform all

operations as far to the rear of the work area as possible.

• Segregate all clean and contaminated materials in the work

area.

Final Purging

• Upon completion of work, the Clean Bench should be

allowed to operate for two to three minutes undisturbed, to

purge airborne contaminants from the work area before

shutting down the blower.

• If equipped, turn on the UV light to decontaminate the

work area as determined by your Safety Officer.

Unloading Materials and Equipment

• All open trays, weigh vessels or containers should be

covered before being removed from the Clean Bench.

Suitable Applications

Suitable applications for the Purifier Vertical Clean Benches are

based on guidelines established by the Institute for Environmental

Sciences. Particulates are filtered by the HEPA filter before air is

returned to the room. Biohazardous materials or other hazardous

solids cannot be used with the Purifier Vertical Clean Bench, as air

is directed over the work surface and out of the enclosure. The

Purifier Vertical Clean Bench only provides product protection

and offers no personnel protection whatsoever.

24

Product Service 1-800-522-7658

Page 29

Chapter 5: Appropriate Applications For Your Vertical Clean Bench

Listed below are suitable applications for HEPA filters.

HEPA Filter Applications,

Suitability and Guidelines

• Procedures traditionally performed on an open bench where a

clean Class 5 air environment is now required.

• The HEPA filtered enclosure provides product protection from

particulate matter. Because air from the Clean Bench enters

from the room during operation, this enclosure should only be

used for operations requiring sample protection from

environmental contamination.

• HEPA filters are only effective for entrapment of particulate

matter. The surface of the HEPA filter is fragile and should

not be touched. Care must be taken to avoid puncturing the

HEPA filter during installation. If you suspect that a HEPA

filter has been damaged, DO NOT use the enclosure. See

Chapter 6 for Replacing the HEPA Filter.

• The HEPA filter will gradually accumulate airborne

particulate matter from the room. The rate of accumulation

will depend upon the cleanliness of the room air, and the

amount of time the enclosure is operating. With normal

usage, the HEPA filters will last two to five years before

requiring replacement.

Product Service 1-800-522-7658

25

Page 30

C

HHAAPPTTEERR

C

M

V

B

Monitoring airflow and changing the filters are the primary

maintenance required. Certification and recertification is also

reviewed in Chapter 6.

Review this chapter on maintenance for the following:

1. Routine Maintenance.

2. Determination of when to replace the HEPA filters.

3. How to install a new HEPA filter.

4. HEPA filter leak test.

5. Speed control adjustment and setting the downflow velocity.

6. Operating and calibrating the airflow monitors.

7. Initial certification.

8. Re-certification.

9. Fluorescent light replacement.

10. UV light replacement, if applicable.

11. Motorized impeller replacement.

12. Speed control replacement.

AAIINNTTAAIINNIINNG

M

EERRTTIICCAAL

V

EENNCCH

B

H

L

6

6

C

C

Y

G

Y

LLEEAAN

OOUURR

N

26

Product Service 1-800-522-7658

Page 31

Chapter 6: Maintaining Your Vertical Clean Bench

Routine Maintenance Schedule

Weekly

Monthly (or more often as required)

Annually

• Wipe down the interior surfaces of the enclosure with a

disinfectant or cleaner, depending upon the usage of the

unit and allow to dry.

• Using a damp cloth, clean the exterior surfaces of the

enclosure, particularly the front and top to remove any

accumulated dust.

• Operate the exhaust system, noting the airflow velocity out

the front of the enclosure using a source of visible smoke.

Airflow monitors are recommended for constant

monitoring.

• Determine the actual downflow velocity 6" below the upper

diffuser of the enclosure where the average reading should

be at the specified velocity. (Use calibrated thermal

anemometer or other approved apparatus). Airflow alarms

are recommended for constant monitoring.

• All weekly activities.

• Check downflow velocity. Increase speed control or

change HEPA filter when downflow velocity of the

enclosure drops below the recommended speed for your

facility or if the airflow alarm monitor alerts you. Airflow

monitors are recommended.

• Replace UV lamps if equipped.

• Have the enclosure validated by a qualified certification

technician. See Certification and Recertification to follow

in Chapter 6.

• All monthly activities.

• Change prefilter.

HEPA

When to Replace HEPA Filters

The HEPA filter in the Purifier Vertical Clean Bench gradually

accumulates airborne particulate matter from the room. The rate of

accumulation will depend upon the cleanliness of the room air, and

the amount of operational time the enclosure is operating. In

typical

Product Service 1-800-522-7658

27

Page 32

Chapter 6: Maintaining Your Vertical Clean Bench

installations and usage, the HEPA filters will last two to five years

before requiring replacement. Replace HEPA filters when

downflow velocity drops below the recommended 30-65 fpm

velocity and the speed control is adjusted to full speed. Replace

HEPA filter if it fails the HEPA Filter Leak Test in Chapter 6.

How to Install a New HEPA Filter

NOTE: Only a qualified certifier should service the HEPA filter.

After the HEPA filter is replaced, the enclosure MUST be

certified. See Figure 6-1.

1. Unplug the enclosure and remove the prefilter located on

top.

2. Remove the front panel by loosening the two screws that

secure it.

3. Using a 9/16" deep socket, loosen the filter clamp bolts

located on top. Refer to Figure 6-1.

4. With the clamp bolts loosened, the HEPA filter-clamping

frame should be clear of filter. Carefully pull the filter

straight out of the enclosure and discard properly.

5. Cover the surface of the new HEPA filter gasket with a

light coating of silicone grease, if desired.

6. Install the new HEPA filter by pushing it straight into the

Vertical Clean Bench, ensuring that it is correctly oriented

with the gasket facing down on the exhaust side of the

enclosure.

CAUTION: The filter clamp bolts should only be tightened

enough to ensure a proper seal at maximum tightness. The

filter gasket should be compressed 50% or less.

7. Tighten the clamp bolts uniformly until the filter gasket is

properly compressed against the frame. Inspect the seal

thoroughly before proceeding.

8. Reinstall the front panel and prefilter.

9. Plug the Vertical Clean Bench in and have it checked for

leaks and downflow velocity.

28

Product Service 1-800-522-7658

Page 33

HEPA Filter

Gasket Side

Down as

Shown

Gasket

Chapter 6: Maintaining Your Vertical Clean Bench

HEPA Filter

Sealing

Surface

Front Panel

Figure 6-1

HEPA Filter Changing Diagram & Filter Leak Test Diagram

Prefilter

Filter Clamp

Bolt

Speed Control

Adjustment Screw

Product Service 1-800-522-7658

29

Page 34

Chapter 6: Maintaining Your Vertical Clean Bench

HEPA

HEPA Filter Leak Test

Purpose

After installing the new HEPA filter, the HEPA filter should be

leak checked. This test is performed to determine the integrity of

the HEPA filter, the filter housing, and the filter seal. Leak testing

must be done by a qualified technician with calibrated equipment.

Remove the upper perforated diffuser located inside the enclosure

by using a Phillips screwdriver to unfasten the screws. (See Figure

6-1). The filter passes the leak test at .01% or better. Reference

Leak Testing and Photometer scanning from the Institute of

Environmental Services (IES-RP-CC001.3)

Apparatus

1. An aerosol photometer ATI model 2D, 2E, 2G or

equivalent. Air Techniques Hamilton Associates Inc., 11403

Cron Ridge Dr., Owings Mills, MD 21117

2. One aerosol generator of the Laskin nozzle(s) type. An

aerosol of mineral oil or suitable liquid shall be created by

flowing air through it. The compressed air supplied to the

generator should be adjusted to a pressure of 10± 1 psig. during

operation. Air Techniques Inc. Model TDA-4A or equal. One

nozzle at 10 psig is (67.5 cfm x 100ug/l)/(Vol. of air), For the

2' at 55 fpm or 230 cfm, one nozzle @10 psig is 6750/230 cfm

= 30 ug/l. For the 3' at 55 fpm or 340 cfm, one nozzle @ 10

psig is 20 ug/l. For the 4' at 55 fpm or 460 cfm, one nozzle at

10 psig is 15 ug/l.

3. Mineral oil (Catalog #1491400).

4. Sampling Nozzle, Rectangular 1/2" x 3-1/4", Air Techniques,

Inc.

Procedure

For the ATI 2G Photometer

1. Turn on the photometer and allow it to operate for a minimum

of 5 minutes. Leave the valve in the “CLEAR” setting.

2. Press the “ENTER” keypad. Press the “REF” keypad.

3. The display will display “P1” for approximately 1 second, and

then display a numerical value.

30

Product Service 1-800-522-7658

Page 35

Chapter 6: Maintaining Your Vertical Clean Bench

4. Using the “^” or “ν” keypads, respectively, increase or

decrease the numerical value until it equals 30 (2'), 20 (3'). 15

(4') for the Purifier Vertical Clean Bench enclosure at 55 fpm

downflow velocity.

5. Press the “ENTER” Keypad. The photometer will scan for 15

seconds, and then the “0” keypad will flash. Press the “Enter”

keypad. The unit will scan for 5 seconds, the display will read

“0000,” and the unit will sound a confirming tone.

6. Set the valve to “DOWNSTREAM.” Place the palm of your

hand over the sampling port of the pistol. There should be a

strong vacuum at this port. If the vacuum is weak, contact Air

Techniques Hamilton Associates.

7. Turn the enclosure on and let it operate for a minimum of 5

minutes.

8. If necessary, adjust the speed control of the enclosure to

maintain the following downflow airflows at 55 fpm; 2'

(230cfm), 3' (340 cfm), 4' (460 cfm.)

9. Position the aerosol generator discharge in the intake of the

prefilter on top of the enclosure.

10. Start the aerosol generator (Pressure to be 10 +/- 1 PSIG).

Ensure that one Laskin nozzle is in the “open” position.

11. Allow the generator to operate for a minimum of 15 seconds.

Scan the downstream exhaust side of the HEPA filter by

passing the sampling nozzle of the gun in slightly overlapping

strokes over the entire surface the filter, with the sampling port

not more than 1 inch from the surface of the filter media. Scan

the entire periphery of the filter and the gasket between the

filter frame and the enclosure frame. Scanning shall be done at

a traverse rate of not more than 2 inches per second.

Acceptance

Aerosol penetration shall not exceed 0.01 percent measured by the

photometer.

Product Service 1-800-522-7658

31

Page 36

Chapter 6: Maintaining Your Vertical Clean Bench

Setting the Downflow Velocity

with the Speed Control

Adjustment

1. Remove the front panel by loosening the (2) Phillips screws

on top that secure the front panel.

2. The speed control is located on the electrical subassembly

located behind the switched control panel and below the

front panel. See Figure 6-1.

3. Adjust the speed control with a small Phillips screwdriver

by turning the screw counterclockwise to increase blower

speed or clockwise to decrease the blower speed. The

speed control is very sensitive, so proceed with caution.

4. Measure the downflow velocity per the averaging

technique outlined in Chapter 3 and adjust the speed

control slowly for the desired speed. Allow the speed to

stabilize and re-measure the downflow velocity to confirm.

5. Replace the front panel and tighten the screws.

Options

Calibrate and Operate the Airflow

Monitor

Optional Guardian Airflow Monitor

Refer to Figure 6-2 for operation and calibration.

Labconco Airflow Monitor / Airflow Switch Operation

The Guardian Airflow Monitor consists of a circuit board and an

airflow switch. This switch indicates airflow as safe or low. It

does not provide an actual velocity, but a small setscrew in the

back of the sensor can adjust the airflow level that it classifies as

“good/safe” or “low/alert.”

The circuit board provides power to the sensor and also contains a

“safe (green)” and “alert (red)” airflow LED indicators, as well as

a “SILENCE ALARM” button to quiet the audio alarm. When

first powered up, the Printed Circuit Board (PCB) will light both

red and green LED indicators and sound the alarm to indicate it is

working. After 5 seconds, the air monitor will indicate either good

or bad airflow based on what the connected airflow switch detects.

For low airflow, the unit will wait for 10 seconds after low

indications before it sounds both the audio alarm and the red

“alert” LED indicator. If

32

Product Service 1-800-522-7658

Page 37

Chapter 6: Maintaining Your Vertical Clean Bench

the “SILENCE ALARM” button is pressed, the audio alarm will

be silenced, but the red “alert” LED will remain on. The alarm is

silenced indefinitely unless an airflow change is detected. If safe

airflow is later detected for 10 seconds, the green “safe” LED will

be lit and the “alert” (red) LED will be shut off. At any time the

airflow is safe/good, one can press the SILENCE ALARM test

button and the audio alarm and the red LED will turn on as long as

this button is held down. The PCB has also a two-pin connector

for use as an external output with isolated relay contacts that close

when the red/alert LED is lit (low airflow). These relay contacts

are not affected by the “SILENCE ALARM” button.

The PCB is mounted behind the front panel using standoffs and an

appropriate label is used to highlight the “SILENCE ALARM”

button with clear areas for the red and green LED’s.

By special order, the PCB can be prepared as a factory special with

an additional connector for the following external inputs, and

having the following possible functions:

• External Alarm allows an external signal to sound the alarm

from the building airflow system of a failed condition.

• Alarm Disable allows an external signal to prevent a “low”

airflow alarm from occurring.

• Night Setback allows an external signal to prevent a “low”

airflow alarm from occurring (not any different from Alarm

Disable above other than the terminology.)

• Contact Labconco for ordering information on this special

PCB.

Calibration

1. Ensure the flow switch and alarm circuit board are installed

and operational.

2. Allow the enclosure to operate for at least two minutes.

3. If factory installed, the monitor will alarm at 30±10 fpm

downflow velocity with the average outflow velocity set at

85±10 fpm.

4. To change the factory setting, set the downflow velocity to

the desired alarm condition using the speed control

adjustment procedure outlined in Chapter 6. Once the

alarm condition is set, use a small screwdriver to turn the

adjustment screw on the airflow switch counterclockwise

(facing the screw) until the “low” airflow red LED lights

and the audible flow alarm sounds.

5. Adjust the downflow velocity to the nominal operating

point required. The green “safe” LED should light.

Product Service 1-800-522-7658

33

Page 38

Chapter 6: Maintaining Your Vertical Clean Bench

6. Over time the HEPA filter will load and eventually slow

the downflow velocity. Once the alarm condition is met,

simply increase the speed control as outlined in Chapter 6

or replace the HEPA filter if the speed control is

maximized.

7. The table below lists typical alarm conditions based on

normal operating conditions. Typical alarm conditions are

set at downflow velocities of 10 to 30 feet per minute

below the normal operating conditions due to supply air

and exhaust air fluctuations, as well as room air cross

drafts. Consult your Safety Officer or Laboratory Manager

for proper operating speeds.

Enclosure Operating

Downflow Speed

55 ± 10 fpm 25-35 fpm

45 ± 10 fpm 25-35 fpm

Alarm Condition Set Point

Speed

34

Product Service 1-800-522-7658

Page 39

Light

Reflector

Chapter 6: Maintaining Your Vertical Clean Bench

Speed Control

Airflow Monitor LED

Circuit Board

Airflow Switch

with Adjustment

Control Panel

Green “Safe” LED

Silence Alarm Button

with Test/Reset

Red “Alert” LED with

Audible Alarm

Figure 6-2

Guardian Airflow Monitor with Airflow Switch

Product Service 1-800-522-7658

35

Page 40

Chapter 6: Maintaining Your Vertical Clean Bench

Initial Certification

The Purifier Vertical Clean Bench has been certified at the factory

for an average downflow velocity of 40-55 fpm along with the

HEPA Filter Leak Test. The Purifier Vertical Clean Bench should

be certified for the proper downflow velocity required by your

Safety Officer. It is also a conservative recommendation to

perform the HEPA Filter Leak Test again should there be any

damage caused during transport.

Re-Certification

Under normal operating conditions, the Purifier Vertical Clean

Bench should be recertified at least annually. The certifier should

perform the minimum following tests:

• Downflow Velocity Test

• HEPA Filter Leak Test

In addition, the following tests should also be performed at the

user’s discretion:

• Measure of Line Voltage and Current

• Smoke Test to determine proper airflow patterns

• Lighting Intensity Test (when appropriate)

• Noise Level Test (when appropriate)

• Vibration Test (when appropriate)

Fluorescent Light Replacement

1. Disconnect the power.

2. Locate the small light reflector located under the control

3. Remove the light reflector by removing two Phillips screws

4. Rotate and remove the old fluorescent lamp.

5. Reinstall the new fluorescent lamp and light reflector in

6. Power the unit up and try the new fluorescent lamp.

36

panel.

on the bottom of the light reflector.

reverse order.

Product Service 1-800-522-7658

Page 41

Chapter 6: Maintaining Your Vertical Clean Bench

UV Light Replacement (if

equipped)

1. Disconnect the power.

2. Locate the UV lamp located inside the enclosure.

3. Rotate and remove the old UV lamp.

4. Reinstall the new UV lamp.

5. Power the unit up and try the new UV lamp.

Motorized Impeller Replacement

The motorized impeller must be replaced as a complete unit.

When the motorized impeller is replaced, the capacitor should also

be replaced. See Appendix A for Replacement Parts Diagram. See

Figure 6-3 for an isometric view of the motorized impeller plenum

assembly. The HEPA filter rests below the motorized impeller

assembly.

1. Unplug the enclosure from the electrical outlet.

2. Remove HEPA filter per the HEPA filter removal procedure

outlined earlier in this chapter.

3. Consult the wiring diagram in Appendix C of the manual and

disconnect all the wires of the motorized impeller. Be sure to

connect wires on the new motor in the same way the old motor

was wired. The 3' and 4' enclosures have two motorized

impellers.

4. Remove four screws in each motorized impeller.

WARNING: High-speed blower. Never operate

!

5. Replace each capacitor with a new one of equal voltage and

capacity.

6. Reassemble each new motorized impeller by reversing the

assembly steps.

7. Perform a HEPA filter leak check.

impeller with housing off.

Product Service 1-800-522-7658

37

Page 42

Chapter 6: Maintaining Your Vertical Clean Bench

p

p

r

p

Mounting Screws

2' Model

for Motorized

Im

elle

HEPA Filter

Motorized

Im

eller

Wire Access

Hole

Impeller

Mounting

Bracket

Hardware

Front Panel

Capacitor

Mounted here on

Electrical

Subassembly

Located behind

the Control

Panel

38

Wire Access

Holes

Motorized

Im

ellers

3' or 4' Models

Figure 6-3

Motorized Impeller Replacement

Product Service 1-800-522-7658

Page 43

Chapter 6: Maintaining Your Vertical Clean Bench

Speed Control Replacement

1. Remove the bracket that the speed control is attached to. See

Figures 6-1, and 6-2.

2. Remove the two screws holding the speed control using a

Phillips screwdriver. Refer to Appendix A for Replacement

Parts Diagram.

3. Disconnect all wires leading to the speed control. Connect

wires on new speed control in the same position as the old

speed control.

4. Reassemble to the system in the same position and with the

same screws that were removed earlier.

Product Service 1-800-522-7658

39

Page 44

C

HHAAPPTTEERR

C

A

CCCCEESSSSOORRIIZZIINNGG AANND

A

M

V

B

There are several ways to accessorize and modify the Vertical

Clean Bench for your individual requirements. These include the

addition of accessory work surfaces, airflow monitors, filters, and

storage cabinets or stands.

OODDIIFFYYIINNG

M

EERRTTIICCAAL

V

EENNCCH

B

1. Work Surfaces

An optional dished work surface is available to attach to the

Vertical Clean Bench.

Dished work surfaces are contoured to fit the dimensions of

the filtered enclosures to contain spills. Epoxy is chemical

resistant. See Figure 3-1 for installation.

Catalog # Description Dimensions (W x D x H)

3909900 Black, 2-foot wide 24" x 29" x 1"

3909901 Black, 3-foot wide 36" x 29" x 1"

3909902 Black, 4-foot wide 48" x 29" x 1"

3909903 Gray, 2-foot wide 24" x 29" x 1"

3909904 Gray, 3-foot wide 36" x 29" x 1"

3909905 Gray, 4-foot wide 48" x 29" x 1"

H

L

7

7

G

Y

C

C

Y

OOUUR

LLEEAAN

R

N

D

40

Product Service 1-800-522-7658

Page 45

Chapter 7: Accessorizing and Modifying Your Vertical Clean Bench

2. Guardian™ Airflow Monitor

The Guardian Airflow Monitor allows you to continuously

monitor airflow through the Clean Bench. The Guardian

monitor can be placed on any Purifier Vertical Clean

Bench.

Description Order Part #’s Individual Parts Required

Guardian Airflow Monitor

115V or 230V

1 ea. 3811500 Airflow Monitor Printed Circuit Board

1 ea. 3910700 Airflow Sensor w/ Connector

2 ea.

2 ea.

1 ea. 3935501 Upper Diffuser w/ Air cutout 2'

1 ea. 3935503 Upper Diffuser w/ Air cutout 3'

1 ea. 3935505 Upper Diffuser w/ Air cutout 4'

1885405

1891808

#6-32 x .31” Phillips machine screw to

mount Airflow Monitor Circuit Board

#6-32 x .50” Phillips thread cutting screw to

mount Airflow Sensor

3. Accessory Filters

HEPA Filter

HEPA Filter is 99.99% efficient on particles 0.3 micron.

Width Catalog # Size

2' 3707900 18" x 18" x 3.31"

3' 3707901 30" x 18" x 3.31"

4' 3707902 42" x 18" x 3.31"

Prefilters (Roughing)

A roughing prefilter to extend HEPA filter life.

Filter Catalog # Qty.

2' 3935700 1

3' 3935701 1

4' 3935702 1

Product Service 1-800-522-7658

41

Page 46

Chapter 7: Accessorizing and Modifying Your Vertical Clean Bench

4. Storage Cabinets and Stands

Size/Description Dual Doors Right Hinge Left Hinge Dual Doors Right Hinge Left Hinge

48" 9902000 - - 9901000 - 36" 9902100 - - 9901100 - 30" 9902200 - - 9901200 - 24" - 9902300 9902400 - 9901300 9901500

18" - - - - 9901400 9901600

12" - - - - - 48" w/Self-Closing Doors 9903000 - - - - 36" w/Self-Closing Doors 9903100 - - - - 30" w/Self-Closing Doors 9903200 - - - - 24" w/Self-Closing Doors - 9903300 9903400 - - 24" ADA - 9906000 9906100 - 9905000 9905200

24" ADA w/Self-Closing

Doors

18" ADA - - - - 9905100 9905300

12" ADA - - - - - -

Size/Description Dual Doors Right Hinge Left Hinge Dual Doors Right Hinge Left Hinge

48" 9900000 - - - - 36" 9900100 - - - - 30" 9900200 - - - - 24" - 9900300 9900600 - - 18" - 9900400 9900700 - 9907000 9907100

12" - 9900500 9900800 - - 48" w/Self-Closing Doors - - - - - 36" w/Self-Closing Doors - - - - - 30" w/Self-Closing Doors - - - - - 24" w/Self-Closing Doors - - - - - 24" ADA - 9904000 9904300 - - 24" ADA w/Self-Closing

Doors

18" ADA - 9904100 9904400 - - 12" ADA - 9904200 9904500 - - -

- 9906200 9906300 - - -

- - - - - -

SOLVENT ACID

STANDARD BASE VACUUM PUMP

Base Stands

3747000 2' Telescoping Base Stand with Fixed Feet 24" w x 25.5" d x 27. 5" to 33.5" h

3746701 3' Telescoping Base Stand with Fixed Feet 36" w x 29.25" d x 27.5" to 33.5" h

3746702 4' Telescoping Base Stand with Fixed Feet 48" w x 29.25" d x 27.5" to 33.5" h

3747010 2' Telescoping Base Stand with 5" Casters 24" w x 25.5" d x 27. 5" to 33.5" h

3746711 3' Telescoping Base Stand with 5" Casters 36" w x 29.25" d x 27.5" to 33.5" h

3746712 4' Telescoping Base Stand with 5" Casters 48" w x 29.25" d x 27.5" to 33.5" h

42

Product Service 1-800-522-7658

Page 47

5. IV Bar Kits

For pharmacy applications, IV Bar Kits support intravenous

bottles and bags.

3721000 2' IV Bar Kit

3721001 3' IV Bar Kit

3721002 4' IV Bar Kit

Chapter 7: Accessorizing and Modifying Your Vertical Clean Bench

Product Service 1-800-522-7658

43

Page 48

C

HHAAPPTTEERR

C

T

RROOUUBBLLEESSHHOOOOTTIINNGG AANNDD

T

S

EERRVVIICCEERR

S

L

OOGG

L

Refer to the following table if your Vertical Clean Bench fails to

operate properly. If the suggested corrective actions do not solve

your problem, contact Labconco for additional assistance.

PROBLEM CAUSE CORRECTIVE ACTION

Class 5 air conditions

are not present inside

the enclosure.

External factors are

Improper user

techniques for the

enclosure.

disrupting the

enclosure airflow

patterns.

Enclosure has

improper downflow

velocity.

8

8

O

O

PPEERRAATTIINNGG

See “Certifying the Enclosure” Chapter

3 and “Safety Precautions” Chapter 4

sections in the manual. (Ref. Appendix

D).

See “Location Requirements” Chapter

2, “Certifying the Enclosure” Chapter

3, and “Safety Precautions” Chapter 4

sections of this manual. (Ref. Appendix

D).

Have enclosure certified and check

exhaust system. Check HEPA filters for

loading. Adjust enclosure speed

control. Enclosure should have an

average downflow velocity of 30-65

fpm.

44

Product Service 1-800-522-7658

Page 49

Chapter 8: Troubleshooting

PROBLEM CAUSE CORRECTIVE ACTION

Blower won’t

operate.

Circuit breaker(s)

Unit not plugged

into outlet.

Plug the enclosure into appropriate

electrical service.

Reset circuit breaker.

or ground fault

Interrupter.

Blower wiring is

Inspect blower wiring.

disconnected.

Blower switch is

Replace switch.

defective.

Motorized impeller

or blower is

Replace motorized impeller or blower.

See Chapter 6.

defective.

Poor internal Class

5 air conditions

HEPA filter

Enclosure sash not

closed.

Close sash.

Replace HEPA filter or increase speed.

clogged.

Blower and lights

won’t operate.

Circuit breaker(s)

Unit not plugged

into outlet.

Plug enclosure into appropriate

electrical service.

Reset or replace circuit breaker.

tripped.

Lights do not work. Lamp not installed

Inspect lamp installation.

properly.

Lamp wiring

Inspect lamp wiring.

disconnected.

Defective lamp. Replace lamp.

Light switch is

Replace light switch.

defective.

Defective electronic

Replace ballast.

ballast.

Airflow monitor

malfunction.

No power.

No lights.

No display.

Power cable to circuit board is

disconnected and needs to be

connected. Sensor cable needs to be

connected. Verify that all airflow

monitor interface cables are connected.

Check fuses on enclosure.

No audible alarm. Alarm has been temporarily silenced

using “SILENCE ALARM.”

Product Service 1-800-522-7658

45

Page 50

Chapter 8: Troubleshooting

PROBLEM CAUSE CORRECTIVE ACTION

Airflow Monitor

Malfunction

(Continued)

Constant audible

Continuous alarm. Check the downflow velocity of the

Monitor alarms; air

Audible disable

Wrong alarm set

point.

alarm.

way to airflow

monitor sensor is

blocked by insects,

dust or debris.

will not stay

operational.

Airflow monitor was not properly

adjusted. Repeat calibration steps

outlined in this manual in Chapter 6.

Check airflow and calibration of

airflow monitor. See Chapter 6.

enclosure as the airflow of the

system may have changed. If

incorrect, adjust the speed control to

increase downflow velocity. The

HEPA filter may have become

loaded. If downflow velocity is

correct, calibrate the airflow monitor

outlined in this manual in Chapter 6.

Lightly clean the airway with clean

air. Be careful not to touch sensitive

electrical components.

An alarm condition must be

continuously present before the

audible alarm can be silenced. If

flow conditions fluctuate near the

alarm set point, the airflow monitor

will automatically reset it. Action

should be taken to bring the

enclosure airflow into proper

operating parameters or adjust the

alarm set point lower.

46

Product Service 1-800-522-7658

Page 51

Chapter 8: Troubleshooting

Service Operating Record Log

Customer Name Model Number

Date Installed Serial Number

Unit Location

Date Comments

Product Service 1-800-522-7658

47

Page 52

A

PPPPEENNDDIIXX

A

V

EERRTTIICCAAL

V

B

EENNCCH

B

A

NND

A

P

AARRTTSS

P

The components that are available for your Vertical Clean Bench

are listed. The parts shown are the most commonly requested. If

other parts are required, please contact Product Service.

D

R

R

C

H

C

EEPPLLAACCEEMMEENNT

A

L

C

A

C

LLEEAAN

N

OOMMPPOONNEENNTTS

T

S

48

Product Service 1-800-522-7658

Page 53

Appendix A: Vertical Clean Bench Components and Replacement Parts

Item Qty. Part Number Description

1 1 3911000 Glass, Side

2A 1 3911900 Glass, Sash 2'

2B 1 3911901 Glass, Sash 3'

2C 1 3911902 Glass, Sash 4'

3A 1 3938900 Sash Assembly, 2'

3B 1 3938901 Sash Assembly, 3'

3C 1 3938902 Sash Assembly, 4'

4A 1 3905600 Lower Air Foil, 2'

4B 1 3905601 Lower Air Foil, 3'

4C 1 3905602 Lower Air Foil, 4'

5A 1 3907400 Bracket, Air Foil R.H.

5B 1 3907401 Bracket, Air Foil L.H.

6 2 1554500 Stop, Sash Bumper.

7A 1 6916500 Latch, Sash

7B 1 3906700 Bracket, Latch

7C 1 1927403 Spring, Compression Latch

7D 2 1893206 Screw, 8-32 x .38" Lg. Phillips Pan S.S. Type F

9A 2 1889316 Screw, 10-24 x 1.00 PH Phil S.S.

9B 2 1912108 Washer, Plastic .194 ID. x .380 OD

9C 2 7868402 Bushing, Spacer .31 x .63

10 1.9 Ft 6913700 Wiper, Sash Seal

11A 2 1936800 Bushing, Heyco closed 1.50 Dia.

11B 2 1934601 Bushing, Heyco w/ Flex Shutter 1.50 Dia.

12A 2 3940500 Hinge, outer

12B 2 3940501 Hinge, Inner

12C 4 1591606 Rubber Bumper

12D 2 3939600 2' and 4' Sash Closure Door

12E 2 3939601 3' Sash Closure Door

12F 2 3940700 Extension Bi-Fold Door 3'

12G 2 3940701 Extension, Bi-Fold Door 4'

13A 1 3907700 Reflector, Light 2'

13B 1 3907701 Reflector, Light 3'

13C 1 3907702 Reflector, Light 4'

13D 2 1889308 Screw, Mach. 10-24 x .50 PH Phillips

14A 1 3708300 Lamp, Fluorescent 2' Enclosure (F15T8-SP35)

14B 1 9721902 Lamp, Fluorescent 3' Enclosure (F17T8)

14C 1 9721901 Lamp, Fluorescent 4' Enclosure (F25T8)

15A 1 1270100 Lamp, UV 2' or 3' Enclosure (G15T8)

15B 1 1271300 Lamp, UV 4' enclosure (G30T8)

16A 1 3911700 Bracket, Right Reflector Support

16B 1 3911701 Bracket, Left Reflector Support

16C 4 1893108 Screw, #8 x 1/2 AB Hex Washer Head

Product Service 1-800-522-7658

49

Page 54

Appendix A: Vertical Clean Bench Components and Replacement Parts

Item Qty. Part Number Description

17A 1 3937900 Wiring Harness Main, 115V, 2'

17B 1 3937901 Wiring Harness Main, 230V, 2'

17C 1 3938000 Wiring Harness, 115V, 3' and 4'

17D 1 3938001 Wiring Harness, 230V, 3' and 4'

18A 1 3811500 Guardian Airflow Monitor Printed Circuit Board

18B 2 1885405 Screw Mach #6-32 x .31 PH Phil. S.S.

19 1 3936700 Label, Front Set

20A 1 3910700 Airflow Switch

20B 2 1891808 Screw, Thread Cutting #6-32 x .50 PH

22A 1 1307000 Switch, Rocker (2 position) - Blower

22B 1 1306300 Switch, Rocker (3 position) – UV Light Only

23A 1 3904800 Front Panel, 2'

23B 1 3904801 Front Panel, 3'

23C 1 3904802 Front Panel, 4'

23D 1 4472400 Screw, Thread cut 10-24 x .50 Type F PH Phillips

24A 1, 1 or 2 3934500 Impeller, Motorized 2', 3', or 4' Enclosure, 115V

24B 1, 1 or 2 3934501 Impeller, Motorized 2', 3', or 4' Enclosure, 230V

24C 2 3934600 Impeller, Motorized 4', 115V (older units prior to 7-1-05)

24D 2 3934601 Impeller, Motorized 4', 230V (older units prior to 7-1-05)

25A 1 1306900 Capacitor, 2', 115V 10 MFD

25B 1 or 2 1306900 Capacitor, 3' or 4', 115V 10 MFD

25C 2 1306600 Capacitor, 4', 115V 15 MFD (prior to 7-1-05)

25D 2 1306800 Capacitor, 2', 230V 4 MFD (effective 2MFD)

25E 2 or 4 1306800 Capacitor, 3' or 4', 230V 4 MFD (effective 2MFD)

25F 2 1306800 Capacitor, 4', 230V 4 MFD (prior to 7-1-05)

26A 1 1235400 Ballast, Fluorescent 2', 115V

26B 1 1235500 Ballast, Fluorescent 2', 230V

26C 1 1294000 Ballast, Fluorescent 3' or 4', 115V or 230V

27A 1 1235400 Ballast, UV 2' or 3', 115V

27B 1 1235500 Ballast, UV 2' or 3', 230V

27C 1 1233400 Ballast, UV 4', 115V

27D 1 1233600 Ballast, UV 4', 230V

28A 1 3922100 Speed Control, 115V

28B 1 3922101 Speed Control, 230V

29A 1 3935500 Upper Diffuser Screen 2' (Internal)

29B 1 3935502 Upper Diffuser Screen 3' (Internal)

29C 1 3935504 Upper Diffuser Screen 4' (Internal)

29D 1 3935501 Upper Diffuser w/ Air cutout 2'

29E 1 3935503 Upper Diffuser w/ Air cutout 3'

29F 1 3935505 Upper Diffuser w/ Air cutout 4'

50

Product Service 1-800-522-7658

Page 55

Appendix A: Vertical Clean Bench Components and Replacement Parts

Item Qty. Part Number Description

30 10 1893712 Screw, #10 x .75 PH Phil. Thd. Forming

31A 2 1881196 Capscrew, 3/8 –16 x 6.0 Lg. Hx. Hd.

31B 4 1911018 Washer, Flat 3/8

31C 2 1906925 Nut, Hex 3/8 Nylon Lock

32A 1 3707900 HEPA Filter (2') 18 x 18 x 3.32 w/ Gasket

32B 1 3707901 HEPA Filter (3') 30 x 18 x 3.32 w/ Gasket

32C 1 3707902 HEPA Filter (4') 42 x 18 x 3.32 w/ Gasket

35A 1 1333800 IEC Power Inlet, 115V

35B 1 1305800 Power Cord, 115V, Right Angle

35C 1 1305900 Power Cord, 230V, Right Angle

35D

36A

36B

1

1 - (115V)

2 - (230V)

1339200 Receptacle, RFI Inlet 230V

1327204 Circuit Breaker, 5 AMP

1327200 Circuit Breaker, 3 AMP

40A 1 1952500 Gauge, Pressure Mini Helic II

40B 1 3667400 Bracket, Gauge

40C 2 1905617 Nut, #10-24 KEPS

40D 2 1551700 Tubing, 3/16" ID x 5/16" OD, PBC 7.00" Lg.

40E

2, 1" Long

3788200 Snubber, Filter Pressure Gauge