Laarsen Associates IW, PW, VW User Manual

Installation and Operation Instructions Document 2040D

Installation and Operation

Instructions for

Mighty Therm

Volume Water Heaters

Models VW, PW and IW

Sizes 500-1825

These instructions are to be stored in the pocket provided on the boiler.

FOR YOUR SAFETY : This product must be installed and serviced by a professional service technician,

qualified in hot water heater installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0105000D

Page 2

LAARS HEATING SYSTEMS

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction................................................... 3

1B. Heater Identification .....................................3

1C. Flow Requirements ...................................... 4

1D. Water Chemistry...........................................4

SECTION 2.

Installation

2A. Heater Placement......................................... 4

2B. Installation of Indoor Heaters .......................4

2B-1. Combustion Air Supply................................. 6

2B-2. Venting .........................................................6

2C. Installation of Outdoor Heaters.....................7

2D. Gas Supply and Piping................................. 7

2E. Electrical Wiring............................................ 8

2F. Water Piping of System ................................ 8

2G. Water Expansion .......................................... 9

2H. Pump Performance and Installation ...........10

2I. Water Pressure .......................................... 16

2J. Tank Installation .........................................16

2K. Two-Temperature System .......................... 16

SECTION 3.

Operation

3A. Controls - General ......................................16

3B. Initial Start-Up............................................. 17

3C . To Start Up System .................................... 18

3D. To Turn Off Heater ....................................... 19

3E. To Shut Down System ................................ 19

SECTION 4.

Maintenance

...................................................................19

SECTION 5.

Troubleshooting and Analysis of

Service Problems

...................................................................20

SECTION 6.

Parts Descriptions and Order Numbers

...................................................................22

SECTION 7.

Outdoor Parts Descriptions and

Order Numbers

...................................................................30

SECTION 8.

Optional Parts Descriptions and

Order Numbers

...................................................................32

Mighty Therm Volume Water Heater

Page 3

SECTION 1.

General Information

1A. Introduction

This manual provides information for the

installation and operation of Laars volume water

heaters. It is strongly recommended that all application

and installation procedures be reviewed completely

before proceeding with the installation. Consult the

Laars factory, or local factory representative, with any

problems or questions regarding this equipment.

Experience has shown that most problems are caused

by improper installation.

Some accessory items are shipped in separate

packages. Verify receipt of all packages listed on the

package slip. Inspect everything for possible damage

upon delivery, and inform the carrier of any shortages

or impairments. Any such claims should be filed with

the carrier. The carrier, not the shipper, is responsible

for shortages and damage to the shipment whether

visible or concealed.

WARNING

All volume water heaters must be installed in

accordance with the procedures outlined in this

manual. The warranty does not apply to

heaters not installed or operated in accordance

with these procedures. Consult local building

and safety codes before proceeding with work.

The installation must conform to the

requirements of the authority having jurisdiction

or, in the absence of such requirements, to the

latest edition of the National Fuel Gas Code;

ANS1 Z223.1, National Electrical Code ANSI/

NFPA 70 and/or in Canada CAN1-B149

requirement.

When required by the authority having

jurisdiction, the installation must conform to

American Society of Mechanical Engineers

safety codes for controls and safety devices for

automatically fired heaters No. CSD-1, and in

Canada CGA 3.3. Any modification to the water

heater, its gas controls, gas orifices, wiring or

draft diverter may void the Laars warranty. If

field conditions require such modifications,

consult factory.

1B. Heater Identification

Consult rating plate on the heater. The following

example simplifies the heater identification.

1 2 3456

PW 1670 I N 09 C

1. Basic heater model.*

2. Input rate X 1000 BTU/hr.

3. Indoor (I) or Outdoor (E) installation.

4. Gas type: Natural (N) or Propane (P).

5. Ignition system: I.I.D. (09) or continuous pilot

(16).**

6. Firing rate: On/Off (C), 2-stage (K), 4-stage (L).

*

Model VW water heaters for use with separate

storage tank. There must be a field installed pump to

circulate water between the heater and the storage

tank.

*

Model PW water heaters are basically the same

as the VW series except that the PW heaters come

with integrally mount pumps.

*

Model IW water heaters are tankless

instantaneous heaters, complete with mount pump for

use in applications having a suitable diversity in heater

load.

**

Special Options: I.I.D. (04) 115 volts.

Laars commercial water heaters are available in

two models: an indoor version and an outdoor version.

Both are available from the factory (see Figure 1).

295/

8

Pump

12¼

(311)

Gas

Conn.

A

Front

Top

B

Pump

(PH Models)

19

Gas

(483)

Inlet

12

(305)

Figure 1. Boiler Configuration.

A

Front

10¼

(260)

V

30¾

(781)

58

(1473)

17

(432)

7¾

(197)

(752)

Out In

(197)

28¼

(718)

Side

Out In

41¾

(1060)

Side

17¾

14

(356)

C

(102)

Rear

4

29

(737)

61

(1549)

Page 4

LAARS HEATING SYSTEMS

1C. Flow Requirements

For proper operation, all low volume hot water

heaters must have continuous flow through the heat

exchanger when firing. The system pump must be

capable of developing sufficient pressure to overcome

the resistance of the heater plus the entire circulating

system at the designed flow rate.

1D. Water Chemistry

Laars equipment is designed for use in a wide

variety of water conditions. The water velocity

maintained in the heat exchanger tubes is kept high

enough to prevent scaling from hard water and low

enough to avoid corrosion from soft water. Ninetyfive percent of the urban areas in the country have

water that is compatible with this equipment, but in

some areas a water supply will contain a large quantity

of scaling chemicals or the water may be extremely

soft and corrosive. In rare situations the water will

contain both scaling chemicals and corrosive

chemicals such as calcium or sodium chloride. These

conditions may be the result of a nearby well or

pumping station and the particular condition may not

be characteristic of the entire city water system.

If an installer observes damage from these

conditions to any water handling equipment in the

area, a factory representative should be contacted

immediately for assistance in minimizing maintenance

costs. If erosion is present, the pump impeller can be

replaced to reduce water velocity. If scaling conditions

are bad, tube cleaning maintenance schedules can be

established to prevent tube burn-out and cracking.

Neglecting the problem could mean serious damage to

the heater and water system.

Scaling can be recognized as a layer deposited

on the inner walls of the tube which reduces the inner

diameter of the tube. Scale can be any color or texture;

smooth or rough, granular or amorphous. Signs of

erosion are generally pitting, cavitation, ridges and

“islands” on the inner walls of the tubes. Since this

condition results from extremely soft water sources, or

as a result of a water softening program, the internal

copper surfaces will be extremely shiny. Other

chemicals, such as chlorine or chlorides in the water,

will cause dark surfaces of erosion.

In areas where the water supply is extremely

corrosive, it is advisable to order the heater with

cupro-nickel tubes in the exchanger.

Damage From Scaling, Corrosion, or Erosion

is Not Covered by the Warranty.

SECTION 2.

Installation

2A. Heater Placement

The heater must be placed to provide specific

clearances on all sides for maintenance and inspection.

There must also be minimum distances maintained

from combustible surfaces. These clearances also

apply to non-combustible materials because the heater

requires air circulation for proper operation.

Heater should be mounted on a level surface. An

integral combustible flooring base is provided as

standard equipment on

can be installed on a combustible floor with a special

base assembly which is available from the factory, or

with a base that complies with local code

requirements. See rating plate for part number of the

base assembly.

Do not install a heater on carpeting.

Under the National Fuel Gas Code, ANSI

Z223.1, it is permissible to place the heater on floors

other than non-combustible when the installation

complies with the American Insurance Code. Figures

2, 3, 4 and 5 show common installation on

combustible flooring.

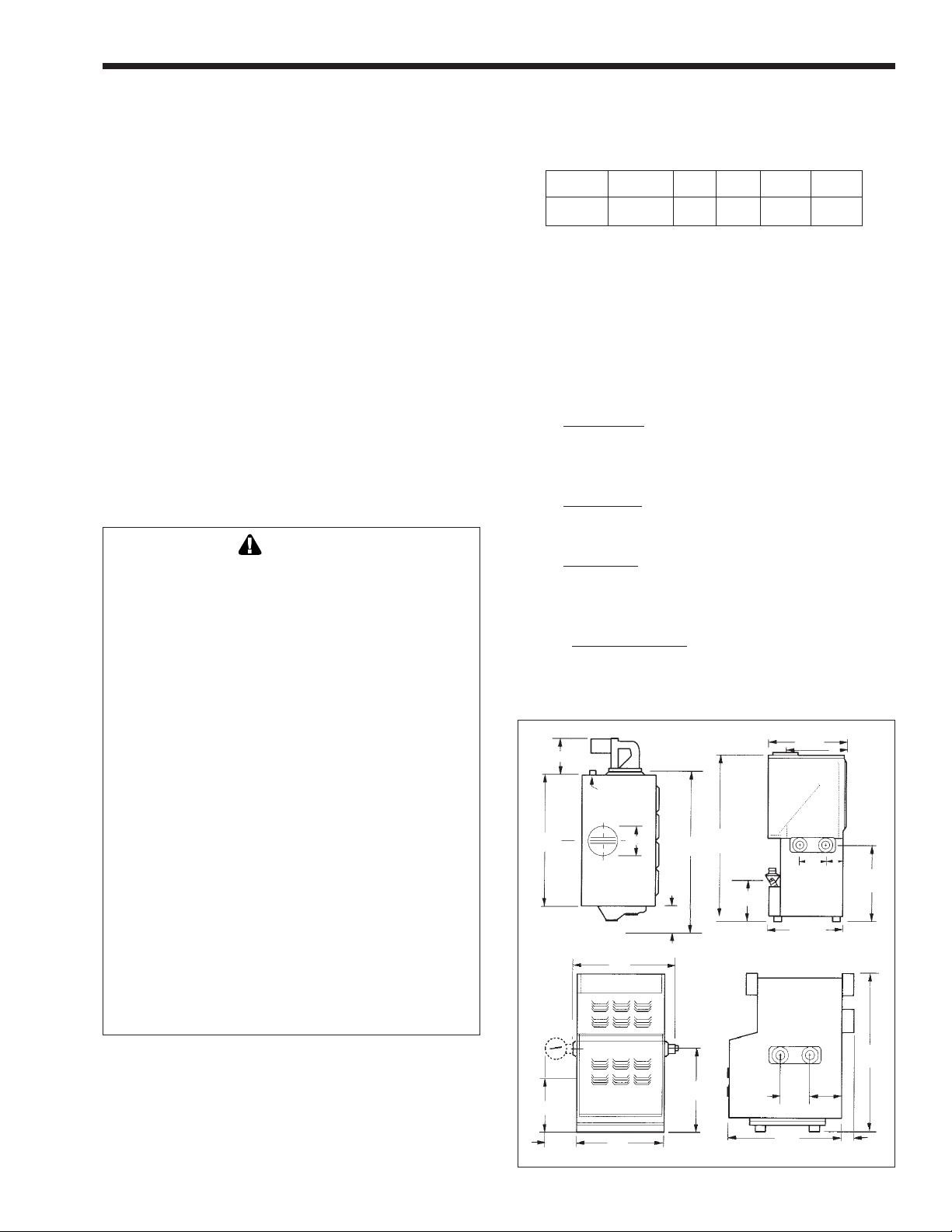

2B. Installation of Indoor Heaters

1. Locate the water heater to provide adequate

clearance for inspection and service on all sides

(see Table I). We recommend minimums of 24"

from front (for proper access to and service of

controls) and 18" at water connection end. For

alcove installation (see Figure 6).

2. Install the heater on a waterproof floor with an

adequate floor drain and a 6" minimum curb on

all four sides to protect the building if heater

repairs are required. The manufacturer will not

be held liable for any water damage in

connection with this heater.

Clearance Indoor Outdoor

From (inches) (inches)

Top 30 unobstruct

Water Conn. Side 12 24

Opposite Side 6 24

Front Alcove Unobstruct

Rear 8 24

Vent Pipe* 6 —

Hot Water Pipes Per Code Per Code

*1" when using type B V ent (refer to Manufacturer's

Instructions

Table 1. Minimum Boiler Clearances

From Combustible Surfaces.

outdoor models. Indoor models

Mighty Therm Volume Water Heater

0

0

0

0

0

0

0

0

0

0

0

0

0

12345678901234567890

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

12345678901234567890

Figure 2. Typical Heater Installation with Base for

Combustible Floors, Example A.

Page 5

Figure 3. Typical Heater Installation with Base for

Combustible Floors, Example B.

Figure 5. Installation on Concrete Blocks or Tile.

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

CLOSET INSTALLATION

(UNACCEPTABLE)

A closet is any 4 sided enclosure

which is less than 16

volume of all the gas fired appliances

within the enclosure.

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

2345678901234567890

Water

Heater

times the total

*

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

Water

Heater

ROOM INSTALLATION

(ACCEPTABLE)

A room is any enclosure which is at

least 16

times greater than the total

*

volume of all the gas fired appliances

within the enclosure.

ALCOVE INSTALLATION

(ACCEPTABLE)

An alcove suitable for the installation

of a water heater is a restricted section

of a room not separated from the

room by a door or partition and which

meets the minimum clearances for

the specific model water heater listed

below.

Figure 4. Typical Heater Installation with Base for

Combustible Floors, Example C.

When the ceiling height exceeds 8 feet, you are only allowed to

*

consider 8 feet when calculating the total volume of the enclosure.

Figure 6. Alcove Installation.

Page 6

LAARS HEATING SYSTEMS

2B-1. Combustion Air Supply

1. The heater location must provide sufficient air

supply for proper combustion and ventilation of

the surrounding area as outlined in the latest

edition of ANSI standard Z223.1, and any local

codes that may be applicable. Inadequate

combustion air supply may result in incomplete

combustion, sooting of the heat exchanger, and

unsafe operation of the heater.

2. In general, these requirements specify that small

heater rooms should be provided with two

permanent air supply openings communicating

directly through the wall to outside air; one

within 12 inches of the ceiling, and the other

within 12 inches of the floor. Each opening

should have a minimum free area of one square

inch per 4,000 BTUH input of the total input

rating of all appliances in the enclosed area. See

Table 2 for recommended air supply for each

model. An improperly ventilated equipment

room can get excessively hot and cause

accelerated deterioration of controls and

electrical components.

IMPORTANT: In beauty shops, barber shops,

cleaning establishments and self-service laundries

with dry cleaning equipment, it is important that the

water heater be installed in a location where

Heater Each Opening*

Model (Square Inches)

combustion and ventilation air is received from a

source outside the building. Please refer to the most

recent edition of the National Fuel Gas Code, ANSI

Z223.1, or in Canada, CGA requirements.

3. (a) In the United States: Exhaust Fans or Vents:

Any equipment which exhausts air from the

heater room can deplete the combustion air

supply or reverse the natural draft action of the

venting system. This could cause flue products to

accumulate in the heater room. Additional air

must be supplied to compensate for such exhaust.

The information in Table 2 is not applicable in

installations where exhaust fans or blowers of

any type are used. Such installations must be

designed by qualified engineers.

(b) In Canada: Follow Canadian standard,

CANI-B149or local codes.

4. If a blower or fan is used to supply air to the

heater room, the installer should make sure it

does not create drafts which could cause

nuisance shutdowns of the pilot. If a blower is

necessary to provide adequate combustion air to

the heater, a suitable switch or equivalent must

be wired into the heater control circuit to prevent

the heater from firing unless the blower is

operating.

5. The heater must be completely isolated and

protected from any source of corrosive chemical

fumes such as trichlorethylene, perchlorethylene,

chlorine, etc.

500 125

600 150

715 179

850 213

1010 253

1200 300

1430 358

1670 418

1825 457

*Net Free Area in Square Inches

Area indicated is for one of two openings; one at

floor level and one at the ceiling, so the total net

free area could be double the figures indicated.

For special conditions refer to the latest edition of

ANSI Z223.1.

Consult factory if not communicating directly

through the walls with the outdoors.

Note: Check with louver manufacturers for net

free area of louvers. Correct for screen

resistance to the net free area if a screen is

installed. Check all local codes applicable to

combustion air.

Table 2. Minimum Recommended

Air Supply to Boiler.

2B-2. Venting

1. Laars heaters have built-in draft diverters for

natural draft operation and must not be

connected to any portion of a mechanical draft

system under positive pressure. The flue outlet

must be connected to a clear, unobstructed vent

of adequate capacity ending above the highest

point of the building with an approved vent cap.

The venting system should be installed according

to the latest edition of ANSI Z223.1 and/or, in

Canada, CAN1-B149 requirement and any local

codes having jurisdiction.

IMPORTANT NOTE: Do not use sheet metal

screws at the snap lock joints of Type B gas vents.

2. Do not weld or fasten the vent pipe to the heater

draft hood. The weight of the stack must not rest

on the heater.

The draft hood and heater top must

be easily removable for normal heater service

and inspection.

3. Avoid using long horizontal runs of the vent

pipe, and too many 90° elbows, reductions or

restrictions. Horizontal runs should have at least

a 1/4" rise per foot in the direction of flow. A

vent connector should be supported for the

design and weight of the material used to

Mighty Therm Volume Water Heater

maintain clearances and prevent physical damage

and separation of joints.

4. Avoid ending heater vents near air conditioning

or air supply fans. The fans can pick up exhaust

flue products from the heater and return them

inside the building, creating a possible health

hazard. A minimum of 4 feet horizontal distance

must be maintained from electrical meters, gas

meters, and relief equipment.

5. Always use double-wall or insulated vent pipe

(Type B or equivalent). In cold weather,

uninsulated outside vents can chill the rising flue

products, blocking the natural draft action of the

venting system. This can create a health hazard

by spilling flue products into the heater room.

6. Avoid oversize vent piping or extremely long

runs of the pipe which may cause excessive

cooling and condensation. Rule of Thumb: The

total length of the vent, including the connector

and any offset, should not exceed 15 feet for

every inch of vent diameter. Longer total lengths

shown in venting tables are based on maximum

capacity, not condensation factors.

7. When the installation of a draft fan is necessary

in connecting a venting system to a Laars heater,

the installation should be engineered by

competent personnel following good engineering

practices. The draft fan supplier should be

consulted for correct size. The installation should

be in accordance with the latest edition of ANSI

Z223.1 and/or, in Canada, CAN1-B149

requirement and any local codes having

jurisdiction. When a draft fan is installed, a

suitable draft switch must be wired into the

heater control circuit at terminal designated

“Field Interlock” to prevent firing of the heater

unless a positive draft has been established.

Page 7

Figure 7. Incorrect Outdoor Installation.

the danger of freezing exists unless proper

precautions are taken for freeze protection.

2D. Gas Supply and Piping

Review the following instructions before

proceeding with the installation.

1. Verify that the heater is fitted for the proper type

of gas by checking the rating plate. Laars heaters

are normally equipped to operate below a 2000

foot altitude. Heaters equipped to operate at

higher altitudes have appropriate stickers or tags

attached.

2. Use the figures in Table 3 to provide adequate

gas piping from the gas meter to the heater.

3. A trap (drip leg) must be provided ahead of the

gas controls (see Figure 8 ). A manual gas

shutoff valve must also be provided for service

convenience and safety. Check the local codes.

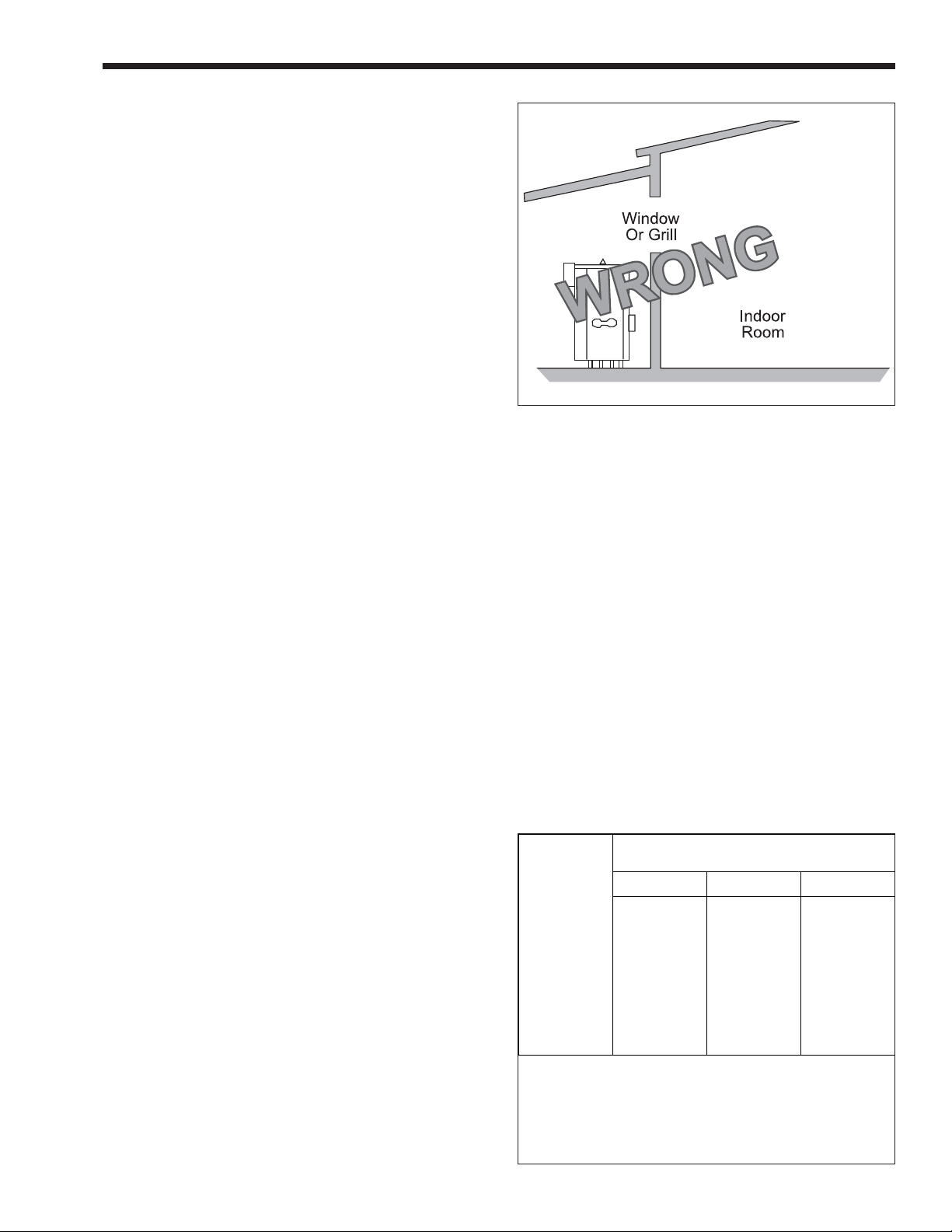

2C. Installation of Outdoor Heaters

1. Locate the heater to provide the minimum

clearances as listed in Table 1, “Placement of

Heater”.

2. Do not place the heater in an enclosure or wall

recess. Avoid locations where wind deflection

off structures might cause down draft. When

such wind conditions are possible, place the

heater at least three (3) feet from the structures.

3. Never install the heater under any kind of roof

overhang. Do not place the heater below or

adjacent to any doors, windows, louvers, grills,

etc. which connect in any way with an inhabited

area of a building. This includes other structures

such as garages or utility rooms (see Figure 7).

4. Although these models are AGA and CGA

designed certified for outdoor installations, such

installations are not recommended in areas where

Distance from G as Meter

or Last Stage Regulator

Size 0-100' 100-200' 200-300'

500

600

715

850

1010

1200

1430

1670

1825

Note: These figures are for Natural Gas (.65 Sp. Gr.), and are

based on 1/2" water column pressure drop. Check supply

pressure with a manometer, and local code requirements for

variations. For LPG, reduce pipe diameter one size, but maintain

a 1" minimum diameter. A normal number of Tees and elbows

have been taken into allowance.

1-1/2"

1-1/2"

2"

2"

2"

2-1/2"

2-1/2"

2-1/2"

2-1/2"

Table 3. Gas Piping Sizes.

2"

2"

2"

2-1/2"

2-1/2"

3"

3"

3"

3"

2"

2-1/2"

2-1/2"

2-1/2"

3"

3"

3"

3"

3-1/2"

Page 8

Figure 8. T-Fitting Sediment Trap Installation.

4. The boiler and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig. The boiler must

be isolated from the gas supply piping system by

closing its individual manual gas shutoff valve

during any pressure testing of the gas supply

piping system at test pressures equal to or less

than 1/2 psig.

5. Provide gas supply pressure to the heater as

follows:

LAARS HEATING SYSTEMS

Caution

Since some leak test solutions (including soap

and water) may cause corrosion or stress

cracking, the piping must be rinsed with water

after testing, unless it has been determined

that the leak test solution is noncorrosive.

2E. Electrical Wiring

WARNING

The heater must be electrically grounded in

accordance with the most recent edition of the

National Electrical Code, ANSI/NPA 70. In

Canada, all electrical wiring to the heater

should be in accordance with the Canadian

Electrical Code, CSA C22.1 Part 1. Do not rely

on the gas or water piping to ground the metal

parts of the heater. Oftentimes, plastic pipe or

dielectric unions isolate the heater electrically.

Service and maintenance personnel who work

on or around the heater may be standing on

wet floors and could be electrocuted by an

underground heater.

Natural Gas LPG

Min. (inches

water column)

Max. (inches

water column)

Per Rating Plate

9 14

Note: The heater and all other gas appliances

sharing the heater gas supply line must be firing at

maximum capacity to properly measure the inlet

supply pressure. Low gas pressure could be an

indication of an undersized gas meter and/or

obstructed gas supply line.

6. The correct burner manifold gas pressure is

stamped on the rating plate. The regulator is

preset at the factory and normally requires no

further adjustment.

7. The gas manifold and control assembly was

tested and conform to the safe lighting and other

performance criteria specified in the latest

editions of ANSI Z21.13 and CGA 3.3 Low

Pressure Boiler Standard.

8. Before operating the boiler, the complete gas

supply system and all connections must be tested

for leaks using a soap solution. Do not use raw

flame.

1. Check heater wiring and pump for correct

voltage, frequency and phase. If the pump circuit

is other than 115V, check to see that the heater is

provided with an appropriate transformer.

2. Wire the heater and pump exactly as shown in

the wiring diagram supplied with the heater.

3. The pump and heater must be electrically

interlocked so the heater cannot come on unless

the pump is running.

4. All field installed electrical safety devices and all

field installed devices (draft switches, relays,

timers, outdoor temperature reset devices, etc.)

can be connected to the heater wiring at points

shown in the wiring diagram designated “Field

Interlock”.

2F. Water Piping of System

1. Be sure to provide valves at the inlet and outlet

of the boiler so it can be readily isolated for

service. A butterfly or similar type of valve is

recommended.

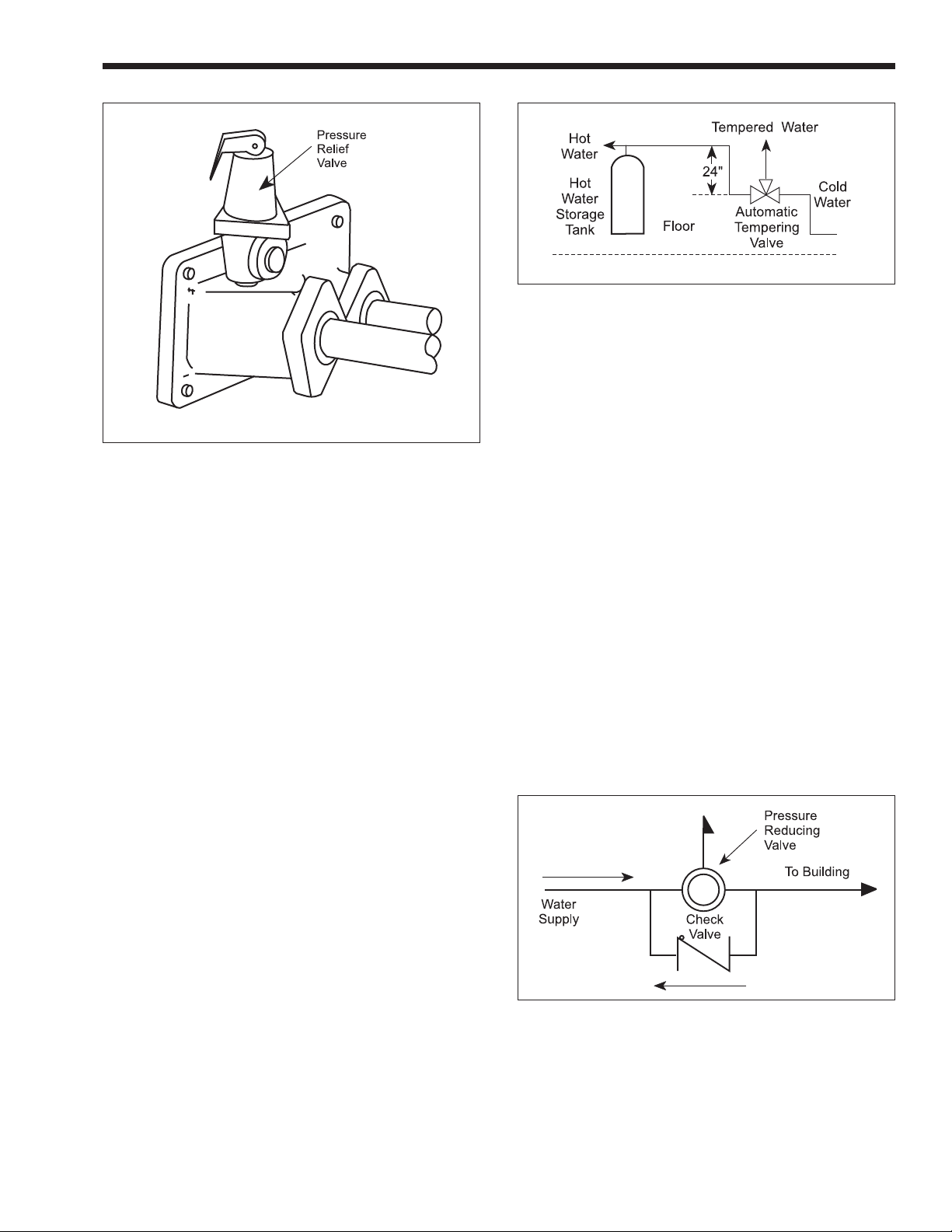

2. The pressure relief valve installed in the tapped

opening provided in the outlet header (see

Figure 9), must be piped, but not fastened, to a

drain or floor sink. The drain pipe must be the

same size as the valve outlet and must pitch

downward from the valve.

Mighty Therm Volume Water Heater

Figure 9. Pressure Relief Valve Location.

Special attention must be given to relief valve

settings in installations where the heater is

located on the ground floor of a tall building.

The static pressure of the system is elevated and

could cause the relief valve to leak. Where no

special setting of the relief valve is ordered, the

factory will furnish a 125 psi setting. Never

reduce the relief valve openings.

3. Pressure relief valve lever must be tripped at

least once a year to insure that waterways are

clean. When manually operating lever, water will

discharge through drain line. Precautions must be

taken to avoid contact with hot water and water

damage.

4. The weight of all water and gas piping should be

supported by suitable hangers or floor stands.

5. Check piping diagrams with local applicable

plumbing, heating and building safety codes.

6. All two-temperature systems using temperature

valves must have forced recirculation in the low

temperature building loop.

7. A check valve installed at the hot water inlet to

the tempering valve will prevent cold water from

being drawn in reverse through the tempering

valve into the hot water.

8. When installing a tempering valve, place at

bottom of antithermosyphon loop at least 24"

high to prevent excessive hot water from

entering mixed water supply. Bring the cold

water supply up from the floor to the valve (see

Figure 10).

Page 9

Figure 10. Tempering Valve Installation.

2G. Water Expansion

When cold water is heated the water expands. If

no water is being used during the heat-up period the

expanded water will normally back up into the city

mains.

A water pressure reducing valve installed in the

incoming cold water line may act as a check valve and

prevent the expanded water from moving backward.

This will cause pressure to rise in the heater, which

will be relieved by the pressure relief valve.

If the relief valve pops frequently a mineral

deposit may build up on the valve seat, causing it to

leak.

The following suggestions may solve the problem:

1. Install a properly sized expansion tank.

2. Replace the installed water pressure reducing valve

with a suitable valve having a back flow port. These

valves have a back flow port which allows water

to flow backwards when the pressure in the system

exceeds the pressure in the mains.

3. Install a check valve around the pressure reducing

valve to permit reverse flow. This will allow

the expanded water to back flow into the mains.

4. Install an auxiliary small relief valve set at 25 psi

less than the main relief valve. The valve must be

piped to a drain and may require occasional

cleaning. It will bleed off the expanded water

and protect the main pressure relief valve from

becoming fouled.

Page 10

LAARS HEATING SYSTEMS

2H. Pump Performance and Installation

1. The factory provided pump on PW heaters and

the recommended field provided pump for

model VW heaters are sized to provide proper

circulation through the heater and heater-totank circulation loop (see Figures 11 and 12). If

the heater-to-tank circulating loop does not

contain more than 6 elbows or 30 feet of

pipe, use pipe fittings in the loop no smaller

than the following:

Model Pipe Size

500 through 850 2"

1010 through 1825 2-1/2"

If the heater-to-tank circulating loop contains

more than 6 elbows or 30 feet of pipe, use pipe

or fittings in the loop no smaller than the

following:

Model Pipe Size

500 through 850 2-1/2"

1010 through 1825 3"

To assure free circulation, do not use globe

valves, side outlet tee connections or other

restrictive fittings in heater-to-tank loop.

2. The Model IW heater is designed for use in a

system without a hot water storage tank. The hot

water supply line to usage point must have a

return leg to the heater (see Figure 13, 14 and

15). A built-in circulating pump and internal heat

exchanger bypass maintains the heater in a

standby condition. It also maintains the

temperature at the controller setting of the water

in the entire building circulating loop whether or

not there is any use of hot water.

Minimum

Reservoir Equivalent Pipe

Model IW Gallons* Size and Length

500 through 850 ...............6.3 ................. 1 1/4" x 100 ft.

1010 through 1220 .........10.2................. 1 1/2" x 100 ft.

1430 through 1670 .........17.0....................... 2" x 100 ft.

1825................................27.0................. 2 1/2" x 100 ft.

* The gallons shown are the calculated volumes of the pipes.

4. Model VW, PW and IW heaters are not suitable

for heating swimming pools or any other

application where temperature of the water

flowing through the heater remains below the

dew point (110°F).

In applications requiring the rapid use of

measured volumes of water, the recovery of the

heater between the time intervals of use must

equal the volume used. See the recovery table in

the current Document 2045 (Submittal Data).

5. Pump Sizing: A suitable pump must be fieldprovided for circulation of water between Model

VW heaters and the storage tank. This pump

must be sized to avoid excessive temperature rise

and to provide correct flow for water hardness

conditions. Specifications in Table 4 include

allowance for 30 feet of piping and normal

fittings between heater and tank.

6. Install pump in a cool location. When pump is

installed where it is subjected to excessive heat,

the life of the pump will be shortened. Heat will

embrittle motor insulation and dry out bearing

lubricants. If the pump motor is equipped with

thermal protection, excessive heat may trip the

thermal switch and shut down the pump

intermittently. This could result in rapid scaling

of the heater.

A separate circulating pump is required for

circulation of water in the building loop. The

control system provides variable heat inputs to

match periods of higher or lower water

consumption.

3. The Model IW heater requires a minimum of

circulating hot water in the building circulation

loop. To prevent excessive temperature

fluctuations in the delivered water, the whole

building system, including the return loop, must

have the equivalent volume of pipe shown

below:

IMPORTANT: Check oil level in pump before

starting. Oil pump every three (3) months. Fill bearing

assembly to lower level of overflow vent. Add five (5)

or six (6) drops of oil to front and rear of motor. Use

20W non-detergent oil. Pumps located in excessively

hot or dusty locations should be oiled once a month.

Self lubricating pumps do not require oiling.

7. The pump should be accessible for lubrication,

inspection and service.

8. If pump is designed for floor mounting, install

securely on concrete block or pad at least six (6)

inches above floor level. This will prevent

flooding of motor when floor is washed. Be sure

that floor mounted pumps are not suspended

from piping and that piping is plumbed to avoid

strain on the pump casing.

Loading...

Loading...