Laarsen Associates Lite 2 LG User Manual

Installation and Operation Data

FOR YOUR SAFETY - This product must be installed and serviced by a professional service technician, qualified in pool heater installation. Improper installation and/or operation could create carbon monoxide gas in flue gases which

could cause serious injury, property damage, or death. Improper installation

and/or operation will void the warranty.

Installation and

Operation Manual

Laars Lite 2

™

Pool and Spa Heater

Models LG and LD

Natural Gas or LP Gas

NOTE: LD LP Gas For

Outdoor Use Only

WARNING: If these instructions are not followed exactly, a fire or explosion

may result, causing property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity

of this or any other appliance.

H0235900-

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency,

or the gas supplier.

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction...................................................1

1B. Description ...................................................2

1C. Warranty....................................................... 2

1D. Technical Assistance....................................2

SECTION 2.

Installation Instructions

2A. General Information ..................................... 2

2B. Field Assembly.............................................2

2C. Site Location ................................................ 3

2C-1. Installation Information ................................. 3

2C-2. Outdoor Installation ......................................4

2C-3. Flooring - Typical Installation ....................... 4

2C-4. Indoor and Outdoor Shelter Installation........ 4

2D. Combustion and Ventilation Air Supply........ 5

2E. Gas Supply and Piping.................................5

2E-1. General Instructions ..................................... 5

2E-2. Special Precautions for Propane Gas .......... 6

2F. Electrical Wiring ........................................... 6

2F-1. General Information (LD Only) ..................... 6

2F-2. Auxiliary Time Clock Wiring......................... 8

2F-3. Remote Operation (Model LD Only)............. 9

2G. Water Flow System ...................................... 9

2G-1. Flange Installation ........................................ 9

2G-2. Reversible Water Connections................... 10

2G-3. Valve Installation ........................................ 12

2G-4. Chlorinators, Ozone Generators, and

Sanitizing Chemicals..................................12

2G4a Water Chemistry ........................................ 13

2G-5. Pressure Relief Valve................................. 13

2G-6. Adjusting the Pressure Switch....................13

2G-7. Automatic Flow Control Valve....................14

2G-8. Temperature Rise....................................... 14

2G-9. Adjusting the Manual Bypass Valve ........... 15

SECTION 3.

Operating Instructions

3A. General Information ................................... 16

3B. Lighting and Shutdown Procedures............ 16

3B-1. Model LD (Direct Ignition) .......................... 16

3B-2. Model LG (Standing Pilot) .......................... 16

3C. Setting the Temperature Control ................ 16

3D. Seasonal Care ............................................ 19

3D-1. Spring and Fall Operation .......................... 19

3D-2. Winterizing .................................................19

3D-3. Spring Startup ............................................ 19

3E. Water Chemistry ........................................ 20

3F. Spa/Hot Tub Safety Rules .......................... 20

3G. Swimming Pool Energy Saving Tips .......... 20

3H. Periodic Inspection ..................................... 21

3H-1. Owner Inspection........................................ 21

3H-2. Professional Inspection .............................. 21

SECTION 4.

Parts List for Laars Lite 2 Heater

4A. General Information .................................. 21

4B. Parts List ................................................... 21

Model LG & LD Pool and Spa Heater

Page 1

SECTION 1.

General Information

1A. Introduction

This manual provides installation and operation

instructions for the Laars Lite 2, Model LG and LD

pool and spa heaters. Read these installation and

operation instructions completely before proceeding

with the installation. Consult the Waterpik Laars

factory, or local factory representative, with any

questions regarding this equipment. Experience has

shown that most operating problems are caused by

improper installation.

The Laars Lite 2 heater is design certified by

International Approval Services (formerly American

Gas Association and Canadian Gas Association) as

complying with the latest edition of the Standard for

(920 cm)

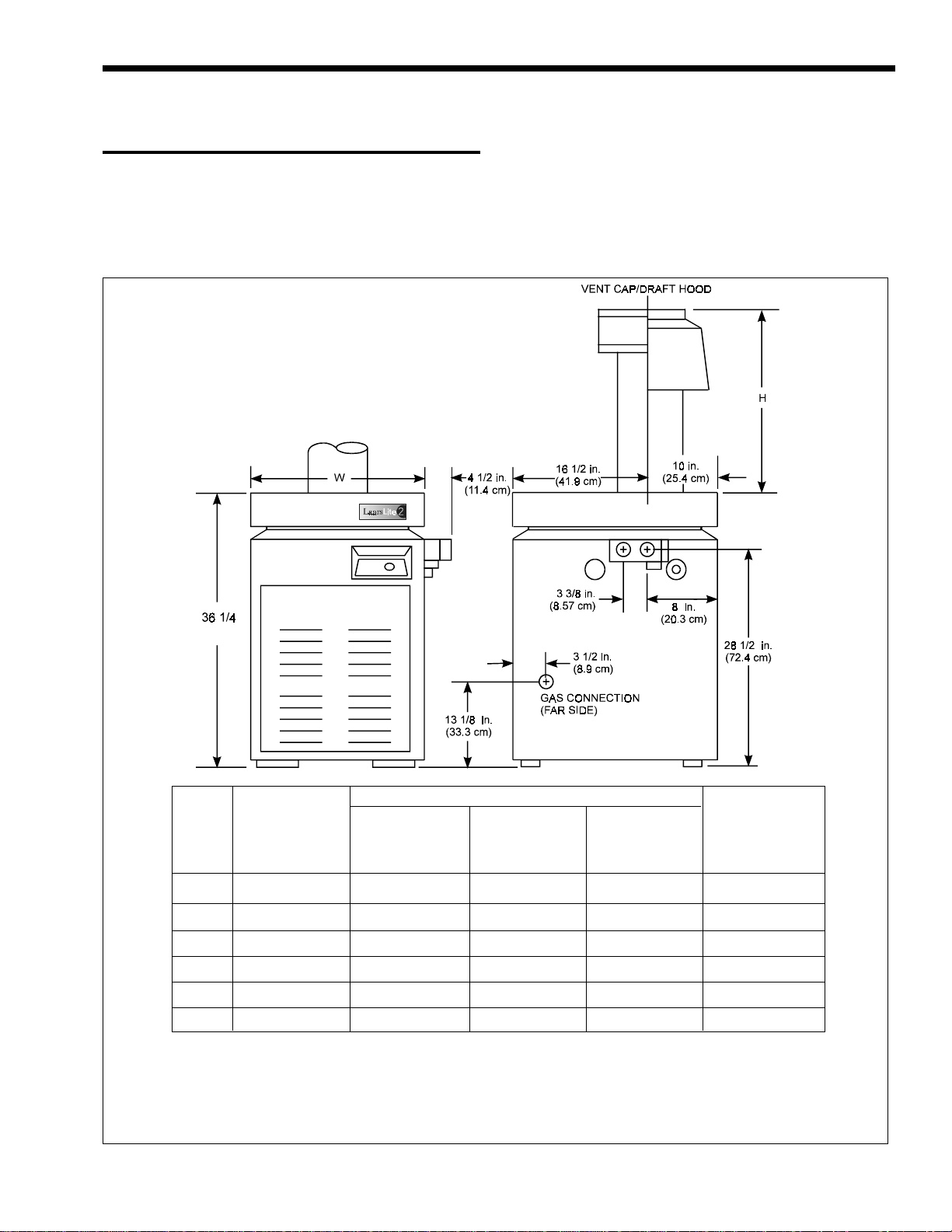

Venting Dimensions

Model Heater U.S. Indoor or Firing Rate / Hr.

Size Width

in (cm) in (cm) in (cm) in (cm) BTU (kcal)

125 15 (38) 5 (12.7) 9 1/8 (23) 16 1/4 (41.3) 125 (31.5)

175 18 (45.7) 6 (15.2) 9 3/4 (24) 24 1/8 (61.3) 17 5 (44.1)

250 22 1/2 (57.2) 7 (17.8) 10 (26) 25 1/4 (64.1) 250 (63)

325 26 3/4 (67.9) 8 (20.3) 10 5/8 (27) 26 1/2 (67.3) 325 (81.9)

400 31 3/4 (80.6) 9 (22.9) 13 1/4 (34) 27 1/2 (69.9) 40 0 (101)

Notes:

1. In Canada, derate BTU/Hr input and output 10 percent for altitudes of 2,000 to 4,500 feet (609 to 1372 m) above sea

level. No derating necessary up to altitude of 2,000 feet (609 m). In United States derate input 4 percent for each 1,000

feet (305 m) above sea level, starting at 2,000 feet (609m).

2. The Laars Lite 2 is constructed for 75 psi working pressure.

3. Ratings shown are for both natural and propane gas.

Vent U.S. Outdoor

Diameter Dim "H"

CAN Outdoor (1,000's)

Shelter Dim "H"

Figure 1. General Configuration.

Page 2

WATERPIK TECHNOLOGIES INC.

Gas-Fired Pool Heaters, ANSI Z21.56, and in Canada

with CAN1-4.7-M85.

Certain sections of this manual are specific to

either United States or Canadian installations, and are

labeled as such.

1B. Description

The Laars Lite 2 LD heater gets electrical power

from an external 120VAC or 240VAC source and

provides a dual thermostat Flex-Temp control system

for pool/spa combinations or preheat convenience. The

Laars Lite 2 LD heater also meets the California, New

York, Hawaii, and Oregon state energy requirements

for intermittent ignition gas appliances. The Laars Lite

2 LG heater is a self contained standing pilot unit and

requires no external power.

The Laars Lite 2 heater is specifically designed

for heating swimming pools and spas. Do not use it as

a general service water heater. There is a specially

designed model of Laars Lite 2 for heating salt water

pools. Consult your dealer for the appropriate

Waterpik Laars products for these applications.

1C. Warranty

The Laars Lite 2 heater is sold with a limited

factory warranty. Details are specified on the back

cover of this manual. A copy of the warranty and a

warranty registration card are included in the plastic

bag shipped with the heater. Fill out and return the

warranty registration card.

Make all warranty claims to an authorized

Waterpik Laars representative or directly to the

factory. Claims must include the heater serial number

and model (this information can be found on the rating

plate), installation date, and name of the installer.

Shipping costs are not included in the warranty coverage.

Damage caused by improper installation or

assembly, or to the heat exchanger by corrosive water,

is NOT covered by the Warranty. See Section 3D for

maintaining proper pool water chemistry.

NOTE: Keep this manual in a safe place for

future reference when inspecting or servicing the

heater.

1D. Technical Assistance

Consult Waterpik Laars or your local distributor

with any questions or problems involving the specifications, installation, and operation of your Waterpik

Laars equipment. An experienced technical support

staff is ready to assist in assuring the proper performance and application of Waterpik Laars products.

For technical support call (415) 382-8220 extension

260.

SECTION 2.

Installation Instructions

2A. General Information

Install the Laars Lite 2 heaters, vent caps and

drafthoods in accordance with the procedures in this

manual, local codes and ordinances, and in accordance

with the latest edition of the National Fuel Gas Code,

ANSI Z223.1. In Canada, the installation must be in

accordance with CAN1-B149.1 or .2 and local codes.

The authority having jurisdiction may require that the

installation conform to the Standard for Gas-Fired

Heaters, ANSI Z21.56. Any changes to the heater, gas

controls, gas orifices, wiring, draft diverter, or improper installation may void the warranty. If field

conditions require change to any of the above, consult

the factory.

All gas-fired products require correct installation

to assure safe operation. The requirements for pool

heaters include the following:

1. Field assembly (if required)

2. Appropriate site location (clearances) and

flooring

3. Sufficient combustion and ventilation air

4. Properly sized gas meter and piping

5. Proper electrical wiring (if required)

6. Adequate water flow

This manual provides the information needed to

meet these requirements. Review all application and

installation procedures completely before continuing

the installation.

2B. Field Assembly

The Laars Lite 2 heater is shipped from the

factory with the top assembly in the low-profile

configuration for outdoor installation in the U.S. In

Canada, an outdoor installation requires the addition of

a factory approved vent cap. The Laars Lite 2 heater is

design certified for indoor installation when equipped

with a drafthood, which must be installed without

modification.

The Laars Lite 2 heater is also certified for

installation in an outdoor shelter in Canada when

equipped with a drafthood. An outdoor shelter is an

enclosure not normally occupied which does not

communicate directly with occupied areas.

Check the rating plate on the heater or the Parts

List (Sec. 4) of this manual for the correct Waterpik

Laars drafthood or vent cap part number. See instructions supplied with the drafthood or vent cap for

installation and attachment. When the drafthood is

used, locate the heater so as to be in the same atmospheric pressure zone as the combustion air inlet to the

heater.

Model LG & LD Pool and Spa Heater

g

Notes:

1. An Underwriters' Laboratories listed vent cap is required to prevent downdraft and allow the heater to function properly

and safely.

2. Use approved roof jack.

Page 3

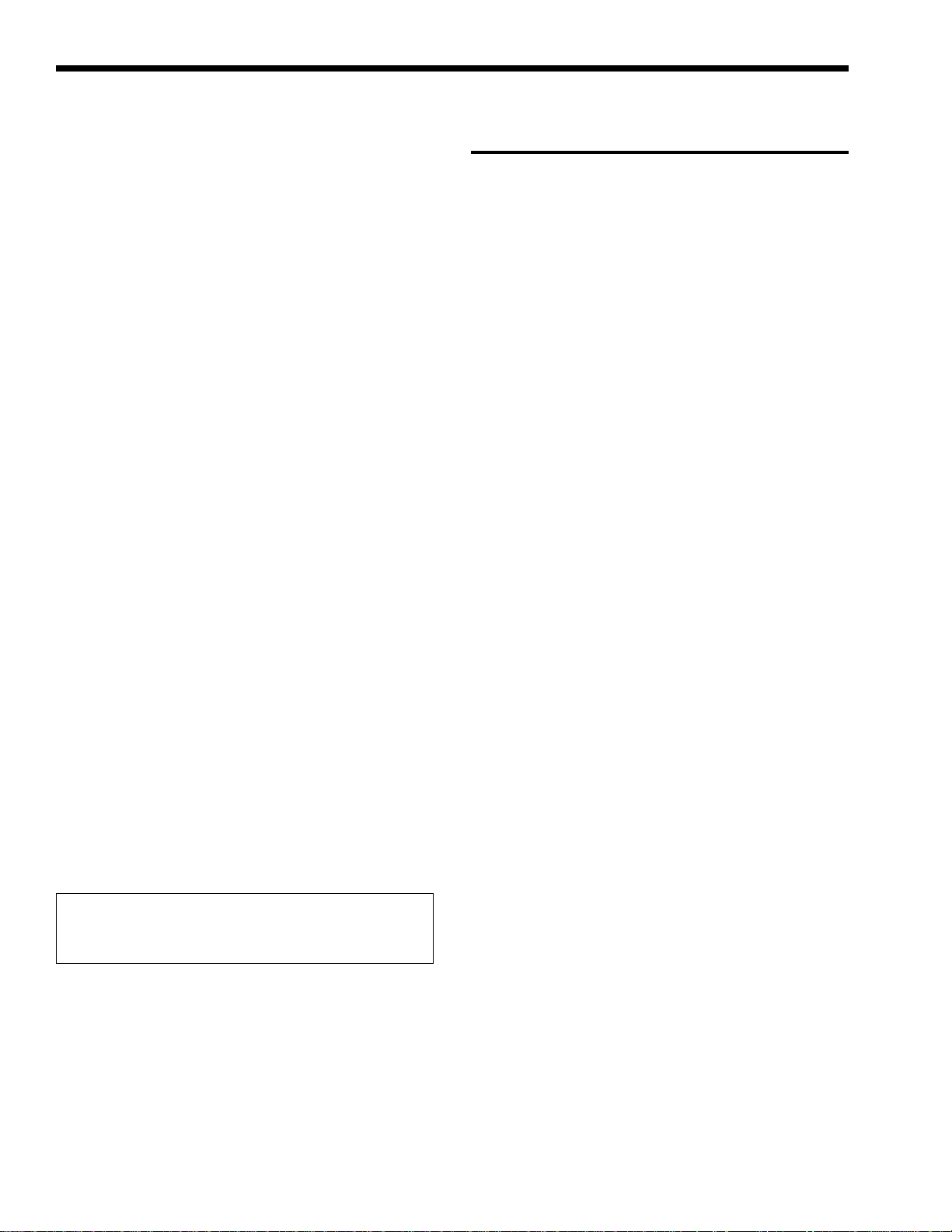

Figure 2. Indoor Installation Venting (USA), or Outdoor Shelter (Canada).

Table 1. Air Openings to Outside.

Required Net Free Open Area

for Combustion Air Openings

Direct from outside Duct from outside

Model in

125 32 (206) 64 (413)

175 44 (284) 88 (568)

250 63 (406) 126 (813)

325 82 (429) 164 (1058)

400 100 (645) 200 (1290)

Note: If using screens and/or louvers, compensate by adding 50%

additional area to each opening.

2

(cm2)in2(cm2)

2C. Site Location

Improper installation or maintenance can

cause nausea or asphyxiation from carbon

monoxide in flue gases which could result in

2C-1. Installation Information

Avoid placing the heater in locations where it can

cause damage by water or condensate leakage. If this is

When a drafthood is used, it must be connected to

a vent pipe which stops at least 2 feet (0.61 meters

[m]) above the highest point of the roof or other object

that is within 10 feet (3.05 m) from the vent termination. The vent pipe must have a listed vent cap which

not possible, provide a suitable drain pan to catch and

divert any leakage. The pan must not block natural

flow of air around the heater.

Locate the heater so the clearances from combus-

tible surfaces shown in Table 2 are met.

allows a full equivalent opening for flue products (see

Figure 2).

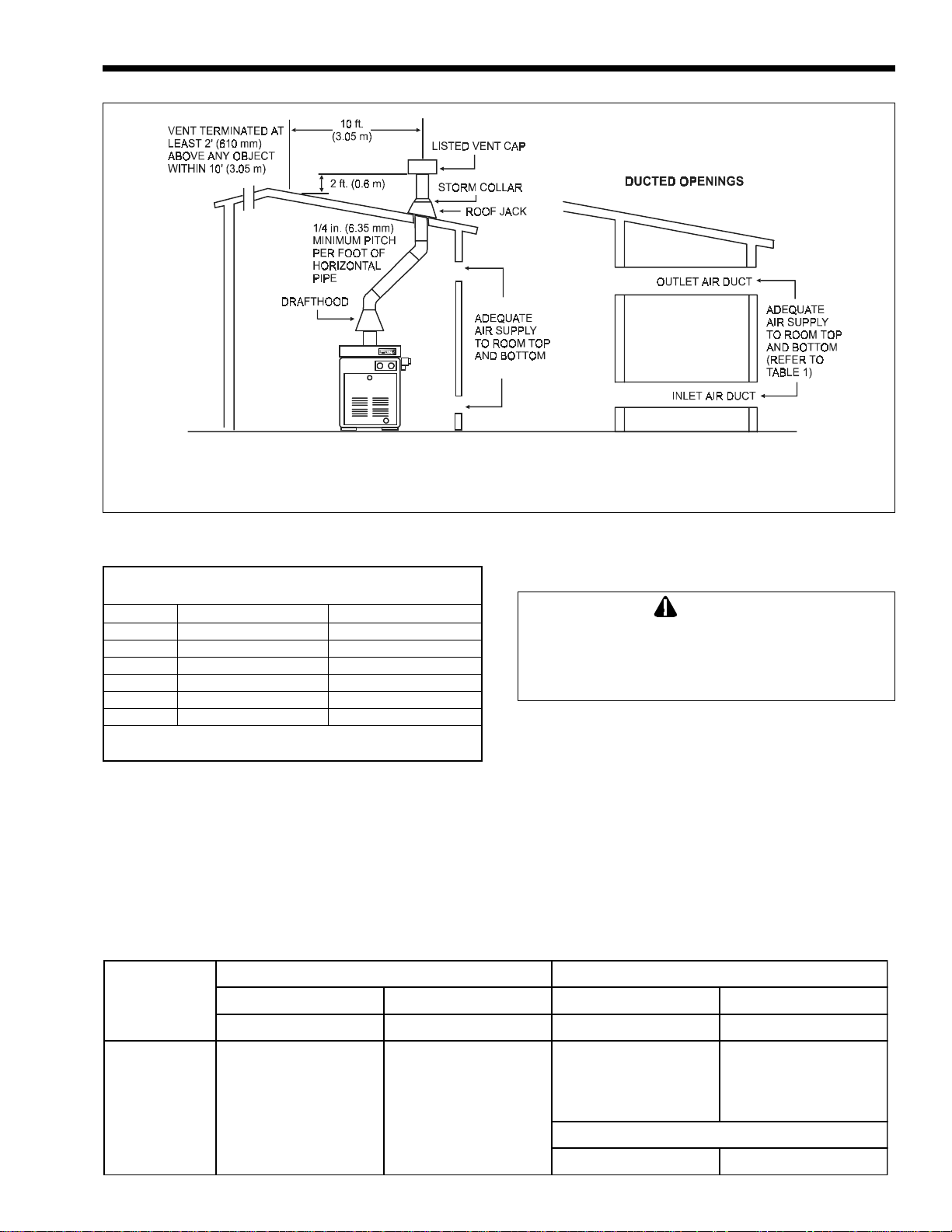

Table 2. Minimum Heater Clearances From Combustible Surfaces

Indoor (Outdoor Shelter) Installation Outdoors Installation

WARNING

severe injury, or death.

U.S. Canada U.S. Canada

Side of Heater

Blank 6 15.2 6 15.2 6 32 6 15.2

Rear 6 15.2 6 15.2 6 32 6 15.2

Pipin

Top 44 111.7 44 111.7 Open Unroofed Area

Front 18 45.7 36 91.4 18 45.7 36 91.4

inch cm inch cm inch cm inch cm

12 30.5 18 45.7 12 30.5 18 45.7

( )

()

()

()

()

()

()

()

()

()

()

()

( )

()

()

()

()

( )

()

()

()

()

Page 4

WATERPIK TECHNOLOGIES INC.

2C-2. Outdoor Installation

Laars Lite 2 heaters can be installed in the lowprofile, grate top configuration (U.S.A. only) as

received from the factory, or with an optional high

wind vent cap/stack. Canadian units require a factory

approved vent cap.

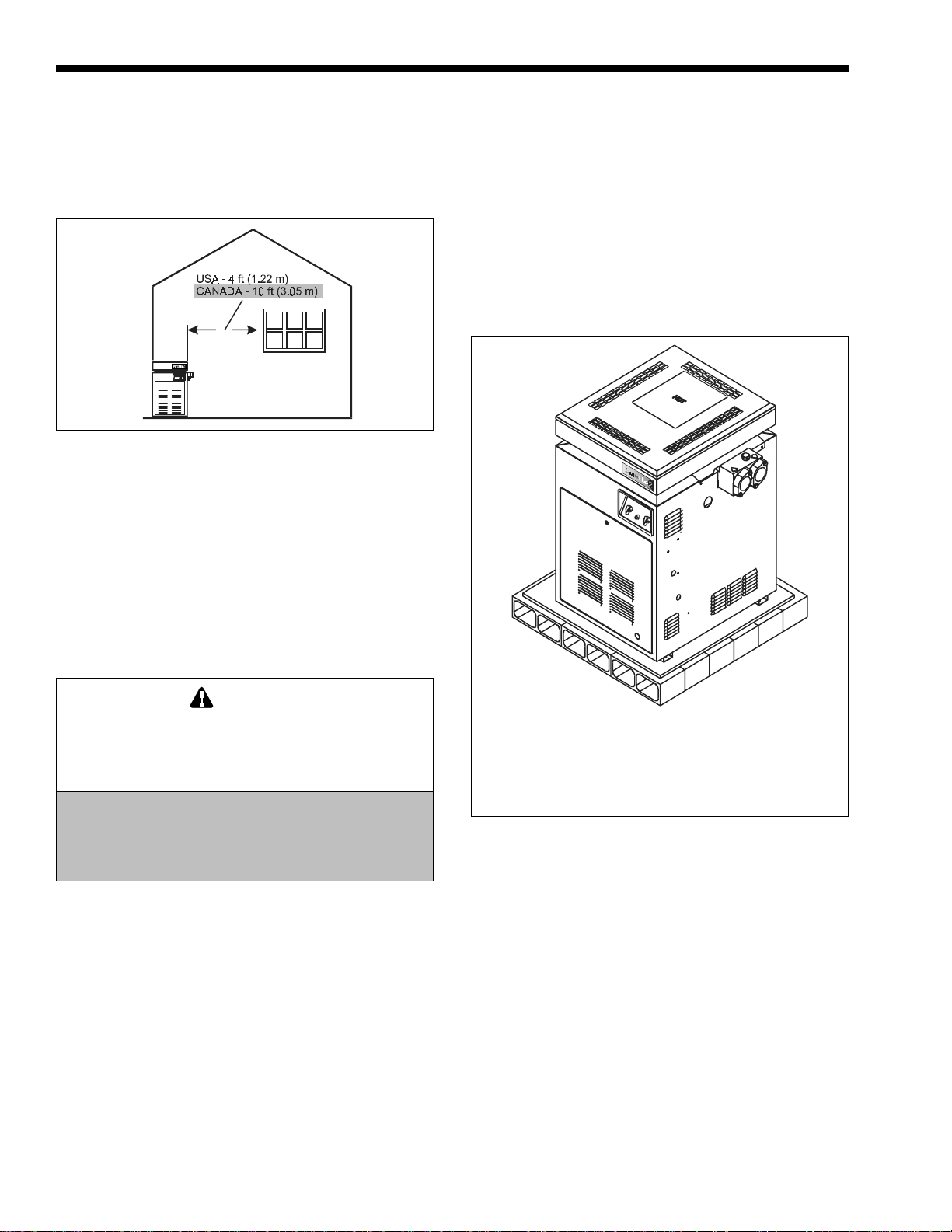

Figure 3. Outdoor Heater Installation.

Locate the heater in an open, unroofed area. Do

not install the heater under a deck. Do not locate the

heater below or adjacent to any doors, glass openings,

louvers, grills, etc., which connect in any way with an

inhabited area of a building, even though the access

might be through another structure (e.g., a garage or

utility room. In the United States there must be a

minimum of 4 feet (1.22 m) horizontally or vertically

between the heater and any door, glass opening, or

gravity inlet to a building. In Canada this distance

must be at least 10 feet (3.0 m) (see Figure 3).

feet (0.91 m) from vertical surfaces (e.g., nearby

buildings and walls). The addition of a vent cap may

be necessary.

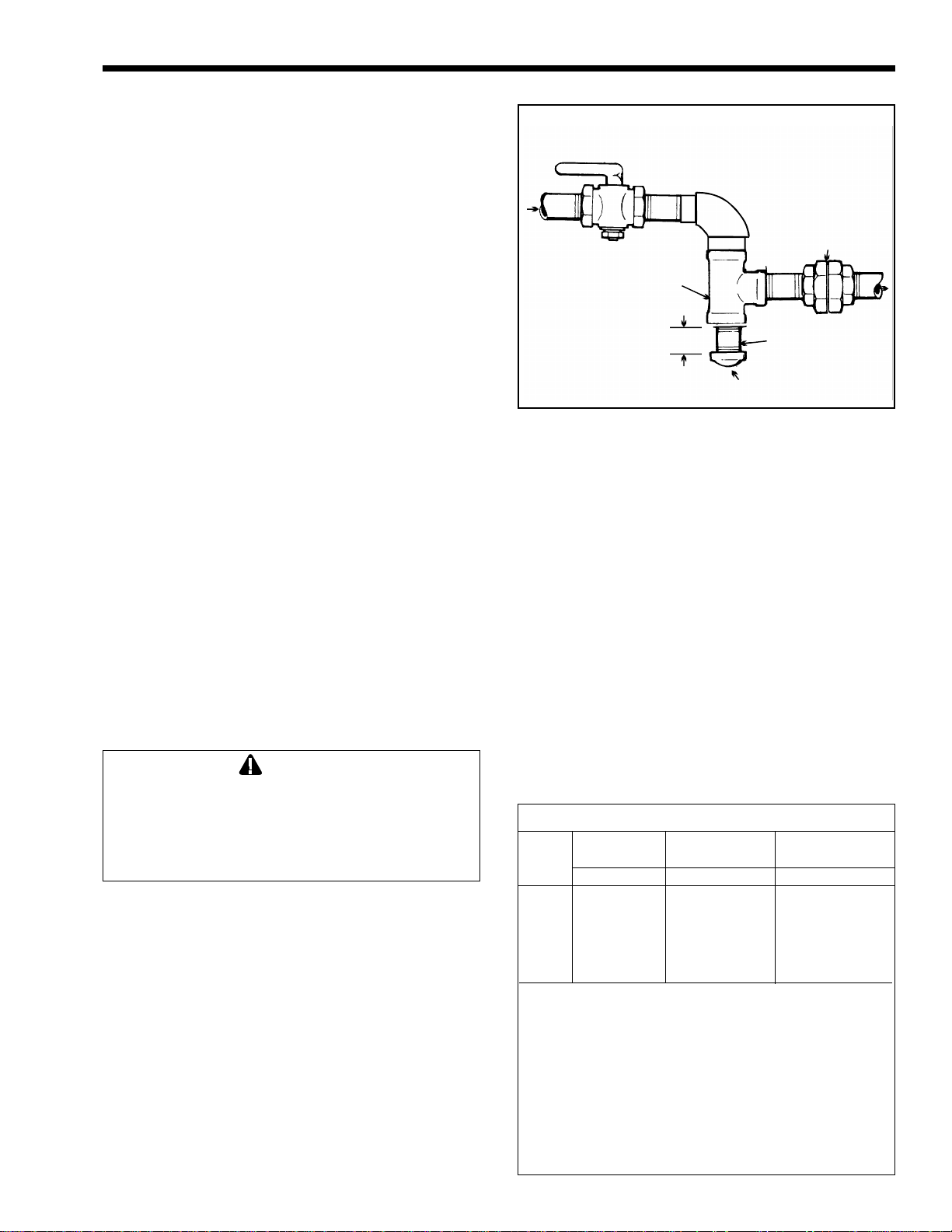

2C-3. Flooring - Typical Installation

Do not install the heater directly on a combus-

tible wood or carpet floor without placing a noncombustible platform between the floor and the heater. In

the United States, the National Fuel Gas Code allows a

heater to be placed on a combustible surface when

there is a platform under the heater made of hollow

masonry no less than 4 inches (102 millimeters [mm])

WARNING

United States

Do not install the heater with the top of the

vent assembly within 4 feet (1.22 m) of any

opening into a building.

Canada

Do not install the heater with the top of the

vent assembly within 10 feet (3.05 m) of any

opening into a building.

If the heater is installed under an overhang, there

must be a minimum clearance of 5 feet (1.5 m) above

the top of the heater and the structure should not

overhang the heater more than 12 inches (0.30m). The

area under the overhang must be open on three sides.

This prevents combustion gases from being diverted

into living areas through doors, windows, or gravity

inlets.

If the heater is installed close to a structure,

protect it from rain water runoff with rain gutters on

the roof or other measures. Do not locate the heater

near sprinkler systems that could spray water on it.

Avoid locations where wind deflection off nearby

structures might cause downdraft conditions. Where

downdraft conditions exist, locate the heater at least 3

Notes:

1. Blocks must provide solid base and be braced so they

cannot slip out of place.

2. Air openings in blocks must be arranged to provide

unrestricted opening through entire width or length of

base.

Figure 4. Non-Combustible Platform.

thick, covered with sheet metal at least 24 gauge thick

and extending beyond the full width and depth of the

heater by at least 6 inches (76.2 mm) in all directions.

The masonry must be laid with ends unsealed, and

joints matched to provide free circulation of air from

side to side through the masonry (see Figure 4). If the

heater is installed in a carpeted alcove, the entire floor

of the alcove must be covered by a noncombustible

panel. You can obtain a noncombustible base from

Waterpik Laars, see the Parts List (Sec. 4) of this

manual.

2C-4. Indoor and Outdoor Shelter

Installations

All indoor installations and outdoor shelter

installations (Canada) require the addition of a factory

approved drafthood. The drafthood must be installed

Model LG & LD Pool and Spa Heater

without modification and in accordance with all local,

state, provincial and national codes.

Proper ventilation of exhaust and combustion air

are essential for the safe operation of the heater.

2D. Combustion and Ventilation Air

Supply

All indoor installations must have openings to

outside air for combustion, ventilation, and dilution of

flue gases from inside the building (see Figure 2 and

Table 1). Waterpik Laars does not recommend indoor

installations that do not provide combustion air from

outside the building.

All outdoor shelter installations (Canada only)

must have uninterrupted openings to outside air for

combustion and ventilation. The installation must be in

accordance with the latest edition of CAN/CGA B149.

Waterpik Laars does not recommend outdoor shelter

installations that depend on internal air for combustion.

Combustion air should be ducted to the heater from

outside the structure.

If the heater is installed in a residential garage, or

where flammable vapors will be present, the

burners must be 18 inches (457 mm) above the garage

floor. Refer to the latest edition of the National Fuel

Gas Code for more information. In Canada, refer to the

latest edition of the Gas Installation Code, CAN/CGA

B149.

2E. Gas Supply and Piping

2E-1. General Instructions

Review the following general instructions before

continuing the installation.

WARNING

Do not convert this heater from natural gas to

propane gas, or propane to natural. Field

conversion could create carbon monoxide gas

which can cause property damage, serious

injury, or death.

1. Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1 and all

local codes. In Canada, the installation must be in

accordance with CAN- B149.1 or .2 and all local

codes that apply.

2. Check the rating plate to make sure the heater is

fitted for the type of gas being used. Waterpik

Laars heaters, as shipped from the factory, are

certified to operate at an altitude of 0 to 3000 feet

(0 to 915 m) for natural gas and 0 to 5000 feet (0

to 1525 m) for propane gas in the United States.

Or if so ordered, at higher altitudes. For higher

altitudes, the heater manifold is marked with a

tag or sticker indicating one of the following high

altitude operation codes:

Page 5

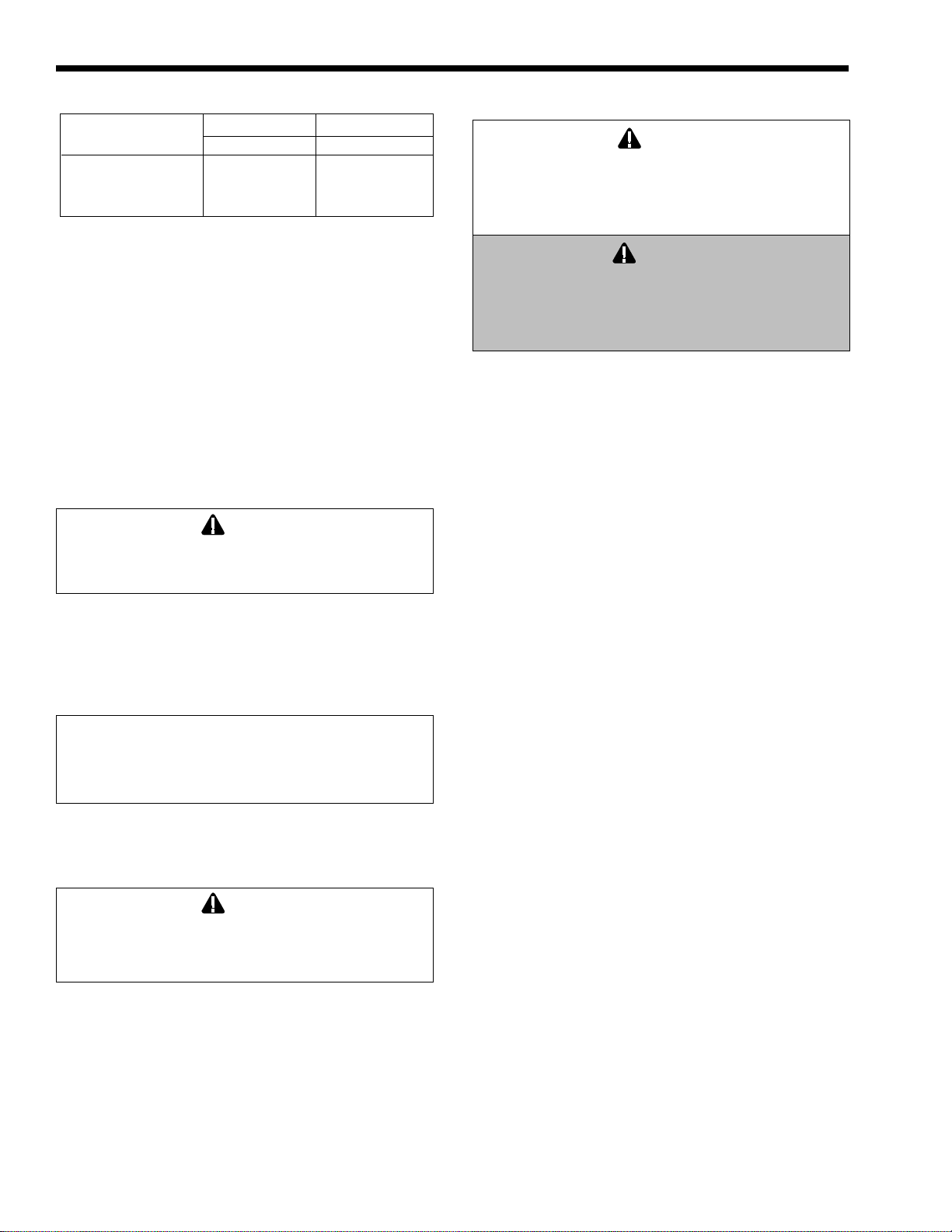

Manual Shutoff

Valve

Gas Supply

Inlet

T-Fitting

3" Min.

(76 mm)

Cap

Figure 5. The proper design for a sediment trap / drip

leg.

Nipple

Union

To

Equipment

Inlet

a. High altitude (H) - 3,000 to 6,000 feet (915 to

1,830 m) for natural gas and 5000 to 10,000

feet (1525 to 3050 m ) for propane gas.

b. High altitude (J) - 6,000 to 10,000 feet (1830

to 3,050 m)

3. In Canada, the heater rating plate is marked for

specific altitude requirements: lo altitude is 0 to

2,000 feet (0 to 610 m) and high altitude (H) is

2,000 to 4,500 feet (610 to 1,370 m) above sea

level for natural gas and 0 to 4500 feet (0 to 1370

m) for propane gas.

4. Use the figures in Table 3 to size the gas inlet

piping from the gas meter to the heater. Check all

local codes for compliance before installing the

heater.

Table 3. Natural Gas Pipe Size Requirements

Distance from Gas Meter

0-50 feet 50-100 feet 100-200 feet

Heater (0-15 m) (15-30 m) (30-60 m)

Size in. (mm) in. (mm) in. (mm)

125 3/4 (19) 1 (25.4) 1 (25.4)

175 1 (25.4) 1 (25.4) 1-1/4 (31.75)

250 1 (25.4) 1-1/4 (31.75) 1-1/4 (31.75)

325 1-1/4(31.75) 1-1/4 (31.75) 1-1/2 (38)

400 1-1/4(31.75) 1-1/2 (38) 1-1/2 (38)

Notes:

1. These numbers are for natural gas (0.65 Sp. Gr.) and are

based on 1/2 inch (13 mm) water column pressure drop.

Check supply pressure with a manometer, and local code

requirements for variations. For liquefied petroleum gas,

reduce pipe diameter one size, but maintain a 3/4 inch

(13 mm) minimum diameter.

2. Check supply pressure and local code requirements

before proceeding with work.

3. Pipe fittings must be considered when determining gas

pipe sizing.

Page 6

WATERPIK TECHNOLOGIES INC.

Table 4. Gas Supply Pressure Requirements

Supply Pressure Natural Gas Propane Gas

Water Column in. (mm) in. (mm)

Minimum 5.5 (140) 10.0 (254)

Maximum 10.0 (254) 14.0 (356)

5. Install a sediment trap (drip leg) ahead of the gas

controls (see Figure 5). Fit the trap with a

threaded cap which can be removed for cleaning.

6. Install a manual gas shutoff valve for service and

safety. Do not use a restrictive gas cock. DO

NOT USE FLEXIBLE GAS PIPING.

7. Disconnect the heater and its individual shutoff

valve from the gas supply system during pressure

testing of the system at pressures higher than 1/2

pounds per square inch (psi) (3.45 kilopascals

[kPa]). If the test pressure is equal to or less than

1/2 psi (3.45 kPa), close the manual shutoff valve

on the heater during the piping pressure test.

Caution

Permanent damage to the gas valve will occur

if the following procedures are not followed.

8. If the gas supply pressure is less than required,

check for undersized pipe between the meter and

the heater, a restrictive fitting, or an undersized

gas meter. Gas supply pressures to the heater are

listed in Table 4.

NOTE: The maximum inlet gas pressure must

not exceed the specified value. The minimum value

listed is for the purpose of input adjustment. Refer to

Table 4.

9. Before operating the heater, test the complete gas

supply system and all connections for leaks using

a soap solution. Do not use an open flame.

2F. Electrical Wiring

Caution

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Verify proper operation after servicing.

Attention

Au moment de l'entretien des commandes,

étiquetez tous les fils avant de les débrancher.

Des erreurs de câblage peuvent entraîner un

fonctionnement inadéquat et dangereux.

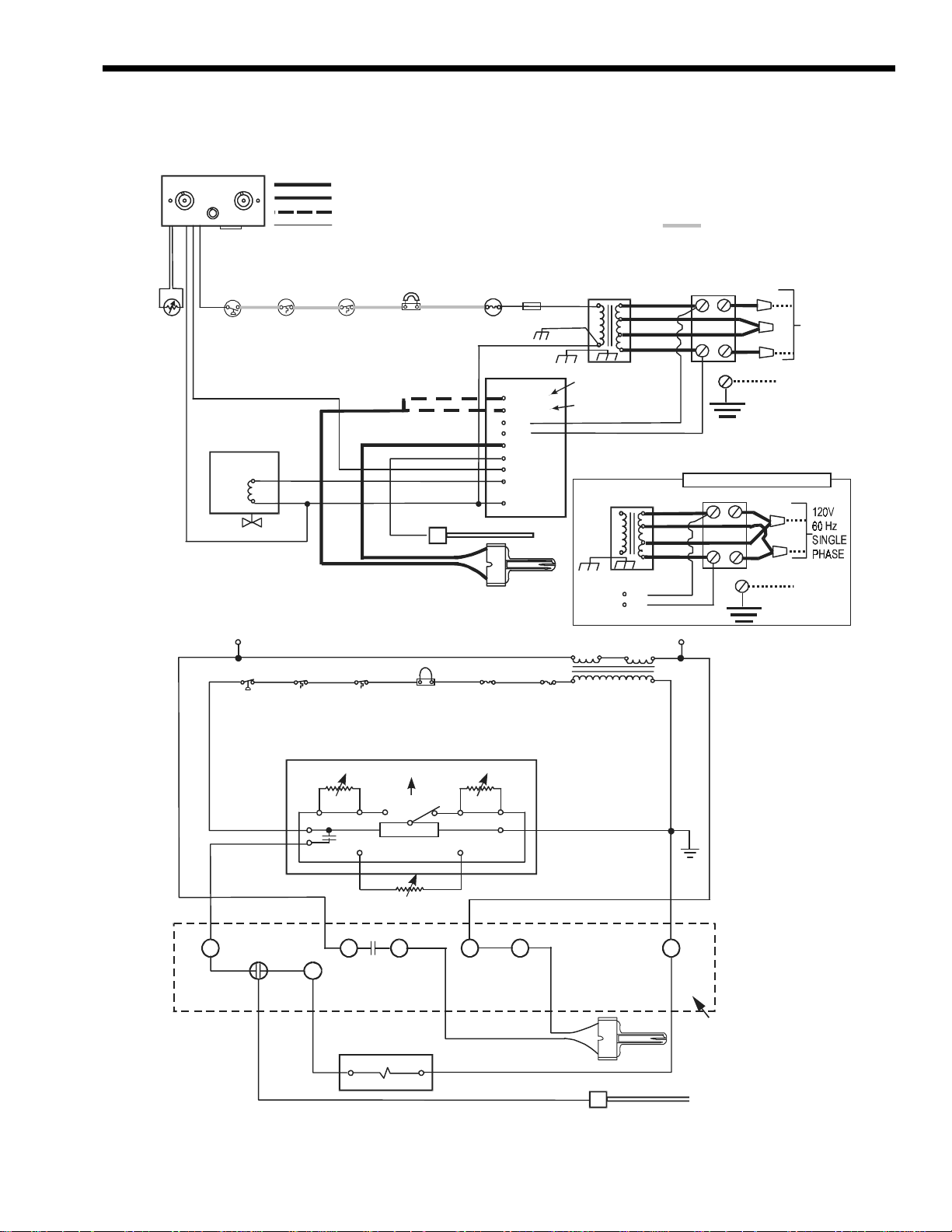

2F-1. General Information (LD Only)

Wiring connections must be made exactly as

shown in the wiring diagram found on the inside of the

heater (see Figures 6 and 7 for typical examples) . The

heater must include a definite means of grounding.

There is a bonding lug on the right side of the heater,

where a bond wire must be attached.

The heater comes factory-wired intended for

use with 240 Volt, 60 Hz AC field electrical supply.

To use 120 Volt, 60 Hz AC requires rewiring of the

heater. This should be done by a certified electrician

only, as with all wiring. To wire the heater for 120

Volt, 60 Hz AC, follow the alternate 120V wiring

method depicted in Figure 6. Additionally, the ignition

control module must be rewired. The wire from the

terminal marked IGN/240 must be removed from that

terminal and placed on the terminal marked IGN/120.

Electrical wiring must be in accordance with the

latest edition of the National Electric Code (NEC),

ANSI/National Fire Protection Association (NFPA)

70, unless local code requirements indicate otherwise.

To wire the Laars Lite 2 model LD heater to a

120V or 240V /60 Hertz (Hz) electrical source:

1. Remove the screw located to the lower right side

of the transformer and open the hinged cover of

the wiring enclosure.

Caution

Some leak test solutions (including soap and

water) may cause corrosion or stress cracking.

Rinse the piping with water after testing.

2E-2. Special Precautions for Propane

Gas

Liquefied petroleum (LP) gas is heavier than air.

Therefore, do not install pool heaters using LP gas in

pits or locations where gas might collect. Locate

heaters a safe distance from LP gas storage and filling

equipment. Consult local codes and fire protection

authorities about specific installation restrictions.

2. Connect the wires from the power source to the

leads on the right side of the heater in the space

behind the ignition control (see Figure 8). Be sure

to follow the wiring diagram on page 7 to configure the transformer for the correct input voltage.

3. Attach the ground wire to the green ground screw

located on the back panel of the wiring enclosure.

4. Close the cover of the wiring enclosure and

replace the screw to hold it in place.

5. Connect a bonding wire (8 ga copper) to the

bonding lug on the right side of the heater.

NOTE: No external junction box is required.

Model LG & LD Pool and Spa Heater

MODEL LD WIRING DIAGRAM

OFF

SPA

POOL

REMOTE

CONNECTOR

BK

WWW W

WATER

TEMP

SENSOR

PRES SURE

SWITCH

Y/BK

HONEYWELL

GAS VALVE

MV1

MV2

Y

a) Connection Diagram

L1

LIMIT

HSI IGNITION WIRE

FACTORY WIRED - 120 V/240 V

FIELD WIRED - 120V /240V

FACTORY WIRED - 24 V

LIMIT

BR

Y

FIREM AN

SWITCH

CONNECTION

W

W

W

W

IF ORIGIN AL WIRE SU PP L I ED W ITH HE ATE R

MUST BE REPLACED, APPLIANCE W IRING

MATERIAL RATED AT 105 C SH ALL B E USE D.

WIRIN G SH OWN A S S HALL U SE

APPLIANCE W IRING MATERIAL RATED AT 200 C.

FUSIBLE

LINK

FLAME SE N SE R O D

IGN /120

IGN /240

(LI)

(L2)

IGN

FS

TH

VALVE

GND

IGN ITE R

ELEC.

FUSE

NOTE:

TRANSFORMER

120-240 V

R

G/Y

Y

WIRE TO IGN /1 2 0

FOR 120 VOLTS

WIRE TO IGN /2 4 0

FOR 240 VOLTS

BK

W/R

W/BK

R

IGNITION CONTROL

(FE NWA L )

0533

TRANSFO RMER

120-240V / 24 V

(L1)

(L2)

ONLY 12 0 V

240V CONNECTION

SHOWN

60 HZ

O

G

G

BK

R

ALTERNATE 120 V WIRING

BK

W/R

W/BK

R

BK

L2

G

R

BK

240V

60 H z

SINGLE

R

PHASE

ATT ACH

GROUND

WIRE

HERE

BK

R

AT TACH

GROUND

WIRE

HERE

Page 7

O

TH

PRESSURE

SW ITCH

BK

BK/Y

W

FS

W

O

150 F

HI-LIMIT

SWITCH

SPA SET POINT

VA LVE

BR

O

135 F

HI-LIMIT

SWITCH

FIREMAN

SW ITCH

CONNECTOR

POOL SET POINT

OFF

CIRCUIT

SEN

WATER TEMPERATURE

SENSO R

L2 IGN

H/W G AS VALVE

MV1 MV2

FUSIBLE

LINK

SEN

L1 IGN 120

W

Y

R

ELECTR ICAL

FUSE

1-25 AM P

W

or

IGN 2 4 0

IGN IT O R

FLAME SENSO R

TRANSFO RMER

24 V

GND

Y

GND

W

IGN IT IO N

CONTROL

Black

BK -

White

W-

Brown

BR -

Yello w

Y-

Red

R-

Orange

O-

Yellow & Black

Y/BK -

Wh ite & Black

W/BK -

White & Red

W/R -

Green & Yellow

G/Y -

b) Schematic Diagram

Figure 6. LD Connection/Schematic Wiring Diagram.

H0236300-

Loading...

Loading...