Operating Instructions

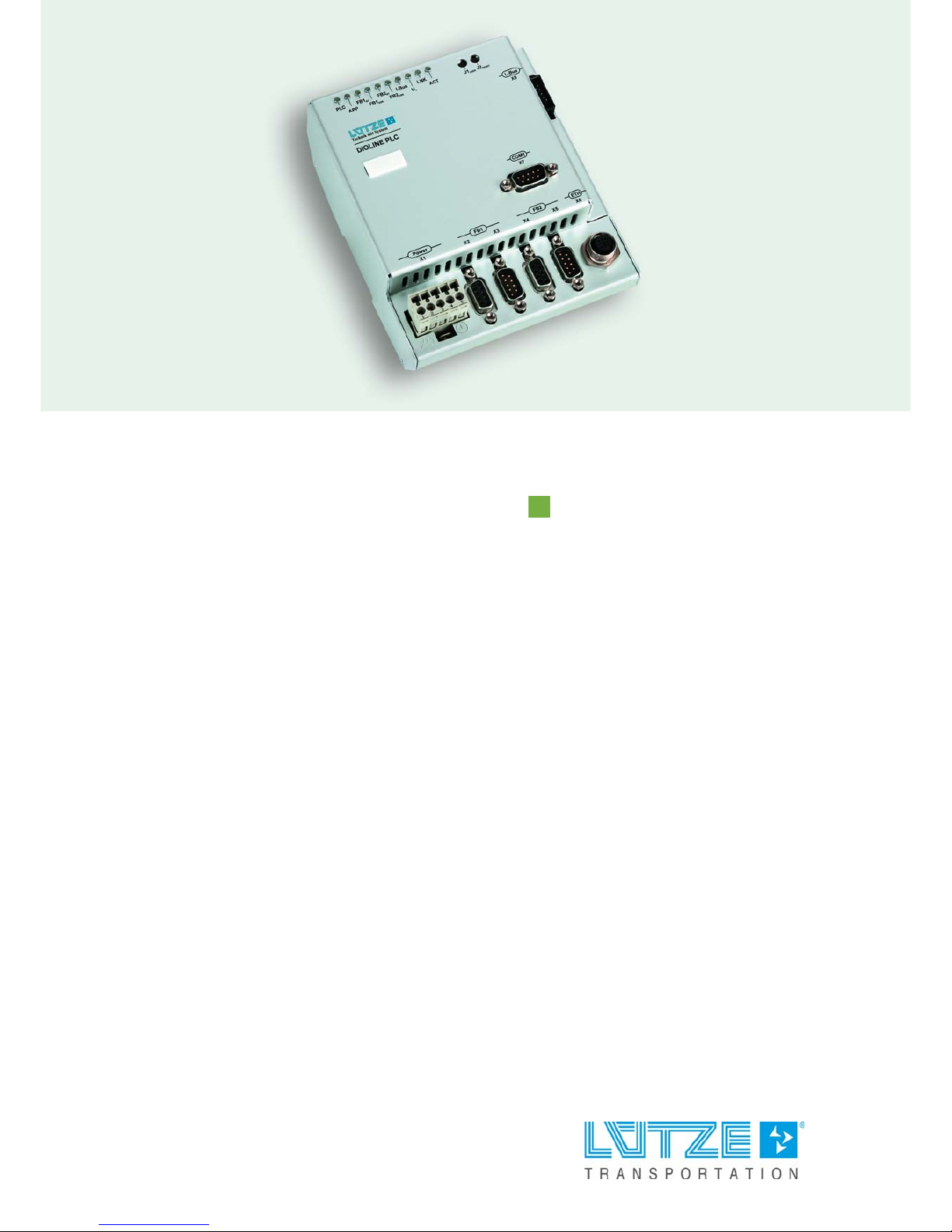

DIOLINE PLC

COS-COM, Part-No. 746032

Version 03

Lütze Transportation GmbH

Bruckwiesenstraße 17-19

D-71384 Weinstadt

Tel.: +49 (0) 7151 6053-545

Fax: +49 (0) 7151 6053-6545

Sales.Transportation@luetze.de

www.luetze-transportation.com

3

DIOLINE PLC ▪ Content

Content

1 Introduction .................................................................................................. 5

2 General Information ..................................................................................... 6

2.1 Symbol Description ................................................................................................................ 6

2.2 Copyright ................................................................................................................................ 6

2.3 Disclaim of Liability................................................................................................................. 6

2.4 Related Documents................................................................................................................ 7

3 Safety ............................................................................................................ 8

3.1 Content of the Manual ............................................................................................................ 8

3.2 Intended Use .......................................................................................................................... 8

3.3 Recipients............................................................................................................................... 8

3.4 Operating Employees............................................................................................................. 8

3.5 Responsibility of the Operator ................................................................................................ 9

3.6 Protective Clothing and Equipment ........................................................................................ 9

3.7 Labeling.................................................................................................................................. 9

3.8 Reconstruction and Modifications of the Product ................................................................. 10

3.9 Safety Arrangement ............................................................................................................. 10

3.10 Special Safety Messages ..................................................................................................... 10

4 Product Overview....................................................................................... 11

4.1 Product Description .............................................................................................................. 11

4.2 Hardware Options ................................................................................................................ 11

4.3 Software Options.................................................................................................................. 12

4.4 System Overview ................................................................................................................. 13

4.5 Field of Application ............................................................................................................... 14

5 Transport and Storing ............................................................................... 15

6 Scope of Delivery ....................................................................................... 16

7 Product Assembly...................................................................................... 17

7.1 LED Display.......................................................................................................................... 18

8 Technical Data............................................................................................ 20

9 Mounting ..................................................................................................... 23

9.1 Mounting Options ................................................................................................................. 23

10 Initial Operation – Hardware ..................................................................... 24

10.1 Power Supply ....................................................................................................................... 24

10.2 L-Bus – Interface .................................................................................................................. 25

10.3 Serial Interface ..................................................................................................................... 27

10.4 SD Card Slot ........................................................................................................................ 28

10.4.1 Changing the SD Card ......................................................................................................... 29

10.5 Ethernet Interface................................................................................................................. 30

10.6 Fieldbus 1 Interface – CANopen Master .............................................................................. 31

10.7 Fieldbus 2 Interface – CANopen Slave ................................................................................ 32

11 Initial Operation – Software....................................................................... 33

11.1 Installation ............................................................................................................................ 34

11.1.1 MULTIPROG ........................................................................................................................ 34

11.1.2 ProConOS OPC Server........................................................................................................ 35

11.1.3 Lütze Addons ....................................................................................................................... 36

11.2 IP Configuration.................................................................................................................... 37

11.2.1 PC IP Address...................................................................................................................... 37

11.2.2 Communication Check ......................................................................................................... 39

11.2.3 PLC IP Address.................................................................................................................... 40

4

DIOLINE PLC ▪ Content

11.2.4 Resetting the TCP/IP Address ............................................................................................. 41

11.3 Development Environment System – MULTIPROG............................................................. 42

11.3.1 Creating a MULTIPROG Project .......................................................................................... 42

11.3.2 Ressource Settings .............................................................................................................. 44

11.3.3 Function Blocks and Firmware Libraries .............................................................................. 46

11.3.4 ProConOS.INI ...................................................................................................................... 51

11.3.5 Variables .............................................................................................................................. 52

11.4 Configuration of the Fieldbusses and other Interfaces......................................................... 58

11.4.1 L-Bus Configuration.............................................................................................................. 58

11.4.2 SD Card Configuration ......................................................................................................... 64

11.4.3 PFD – Parallel Flash Disk .................................................................................................... 67

11.4.4 Real Time Clock Configuration............................................................................................. 73

11.4.5 CANopen Master Configuration ........................................................................................... 76

11.4.6 CANopen Slave Configuration .......................................................................................... 97

11.5 Compiling and Loading......................................................................................................... 99

11.5.1 Download of Configuration Files .......................................................................................... 99

11.5.2 Downloading a MULTIPROG Project ................................................................................. 100

11.5.3 Deleting the Flashdisk ........................................................................................................ 102

11.6 Visualization – ProVisIT ..................................................................................................... 103

12 Operation .................................................................................................. 104

12.1 Hardware Architecture........................................................................................................ 104

12.2 Software Architecture ......................................................................................................... 106

12.3 Memory Architecture (non volatile memory)....................................................................... 107

12.3.1 RAM Architecture (volatile memory)................................................................................... 108

12.3.2 Configuration of the PLC Memory Ranges......................................................................... 109

12.3.3 Monitoring the PLC tasks and CPU Capacity..................................................................... 112

12.3.4 L-Bus Performance ............................................................................................................ 115

13 Maintenance Software ............................................................................. 116

13.1 Update Firmware (ProConOs)............................................................................................ 116

13.1.1 Update via MULTIPROG.................................................................................................... 116

13.1.2 Updating the PLC via the SD Card..................................................................................... 118

14 Final Shutdown and Disposal ................................................................. 123

15 Service ...................................................................................................... 124

16 Error Treatment ........................................................................................ 125

16.1 Error Messages of the Function blocks .............................................................................. 125

16.1.1 L-BusInfo ............................................................................................................................ 125

16.1.2 MVBInfo, Sink and Source ................................................................................................. 125

16.1.3 CoRec and CoSend ........................................................................................................... 126

16.1.4 SetDateTime ...................................................................................................................... 127

16.1.5 FILE_OPEN........................................................................................................................ 127

16.1.6 FILE_READ........................................................................................................................ 127

16.1.7 FILE_WRITE ...................................................................................................................... 128

16.1.8 FILE_CLOSE...................................................................................................................... 128

17 Appendix ................................................................................................... 129

17.1 Content of the Firmware Libraries ...................................................................................... 129

17.1.1 MVB-IKS Firmware Library................................................................................................. 129

17.1.2 ProConOS Firmware Library .............................................................................................. 130

17.2 DIOLINE 20 Module Types ................................................................................................ 135

17.3 Autoexec.bat Commands ................................................................................................... 136

18 Revision of the Document....................................................................... 137

DIOLINE PLC ▪ Introduction

5

1 Introduction

This manual is part of the DIOLINE PLC. It contains important information about

the handling and safety. To avoid hazardous situations read the manual before

installing the product and using it.

Store the manual at a handy place. If selling, renting or in case of a divestiture

pass the manual to the authorize person.

DIOLINE PLC ▪ General Information

6

2 General Information

2.1 Symbol Description

The manual contains several safety messages. Each safety message contains a

defined signal word and a color. The color and the word are referring to an alert

level. There are 4 levels. The safety messages point out hazardous situations and

give information to avoid those.

2.2 Copyright

This manual is intended for the operator and his staff. It is forbidden to give the

content to a third party, to duplicate, exploit or impart it. The Lütze Transportation

GmbH has to allow it explicit in writing.

General data, text, images and drawings are copyrighted and are liable to the

industrial property right. Contravention can be prosecuting criminally. The named

brands and product names in this document are trademarks or registered

trademarks by titleholder.

2.3 Disclaim of Liability

The manual was written under consideration of the applied standards, regulations

and the current state of technology.

The content is verified of accuracy. Discrepancies are not excluded. For those

discrepancies we disclaim liability. Applicable changes and additional information

will be in the next version of the manual.

The Lütze Transportation GmbH does not assume liability for any damages and

accidents of following reasons:

▪ Nonobservance of the manual

▪ Untrained and unqualified employees

▪ Non conventional use

▪ Non approved reconstructions and functional modifications of the product

▪ Using non original or non admitted parts or equipment

▪ The real-time capability of the controller

Indicates a hazardous situation which, if not avoided will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided could result in death

or serious injury.

Indicates a hazardous situation which, if not avoided could result in minor

or moderate injury.

Is used to address practices not related to personal injury.

DIOLINE PLC ▪ General Information

7

2.4 Related Documents

The programming environment of the DIOLINE PLC is a product of the company

KW Software and Hilscher. The companies are responsible for the documentation

and the compliance of standards. This document contains short parts of the

software documentation. In particular cases apply to:

KW-Software GmbH

Lagesche Straße 32

32657 Lemgo

Tel. +49 52619373-0

Fax. +49 52619373-26

Hilscher Gesellschaft für Systemautomation mbH

Rhein Straße. 15

65795 Hattersheim

Tel. +49 61909907-0

Fax. +49 61909907-50

DIOLINE PLC ▪ Safety

8

3Safety

3.1 Content of the Manual

Read and follow the manual before using the product the first time.

This applies to every person which is getting in touch with the product. Trained

employees and experts especially qualified persons which had worked with

similar products before have to read and understand the manual.

3.2 Intended Use

The DIOLINE PLC is designed for the exclusive use in railway vehicles.

For:

▪ automation of simple vehicles

▪ as a subsystem controller or

▪ as a high capacity gateway for the realization of different vehicle specific bus

signals

Use the DIOLINE PLC just for the listed cases and just with external devices

recommended and allowed by Lütze Transportation GmbH.

3.3 Recipients

The operating manual adresses planers, project manager and programmers. It

also adresses the operating employees which are responsible for the initial

operation, the operating and for the maintenance of the products and systems.

Regarding the employees different qualification levels are differentiated.

3.4 Operating Employees

Trained Employees

The employee was trained by the employer on the task and possible hazardous

situations. The employee does not have any technical knowledge.

Experts

The employee has a technical education, knowledge and/or experience in the

required field. The employee is capable to do specific operations on and with the

product.

Electrically Qualified Persons

The employee has a technical education in the required field. The employee is

capable to do special operations on and with the product.

The different sections referringt to the qualification level of the operating

employees.

Risk of injury by deploying insufficient qualified operating employees.

Inappropriate use of not qualified or insufficient personal can cause property

damages and personal injuries. Tasks which apply special procedures should be

done by trained and qualified employees or experts, especially electrically

qualified persons.

DIOLINE PLC ▪ Safety

9

3.5 Responsibility of the Operator

The operator is obligate by the law of occupational safety, if the product is used

in a commercial field.

▪ The operator is responsible to train the employees and to inform himself about

the industrial safety regulation.

▪ The operator is responsible that safety-, environment protection regulations

and rules for accident prevention are observed.

▪ The operator has to run a risk assessment at the working environment/place

of installation to expose hazards and to alert those.

▪ The manual has to be stored near the product.

▪ The manual has to be obeyed.

▪ The product can just be run in a faultless technical condition.

3.6 Protective Clothing and Equipment

If working with or on the PLC special ESD clothing and equipment is mandatory.

Also follow the instructions and regulations of the employer.

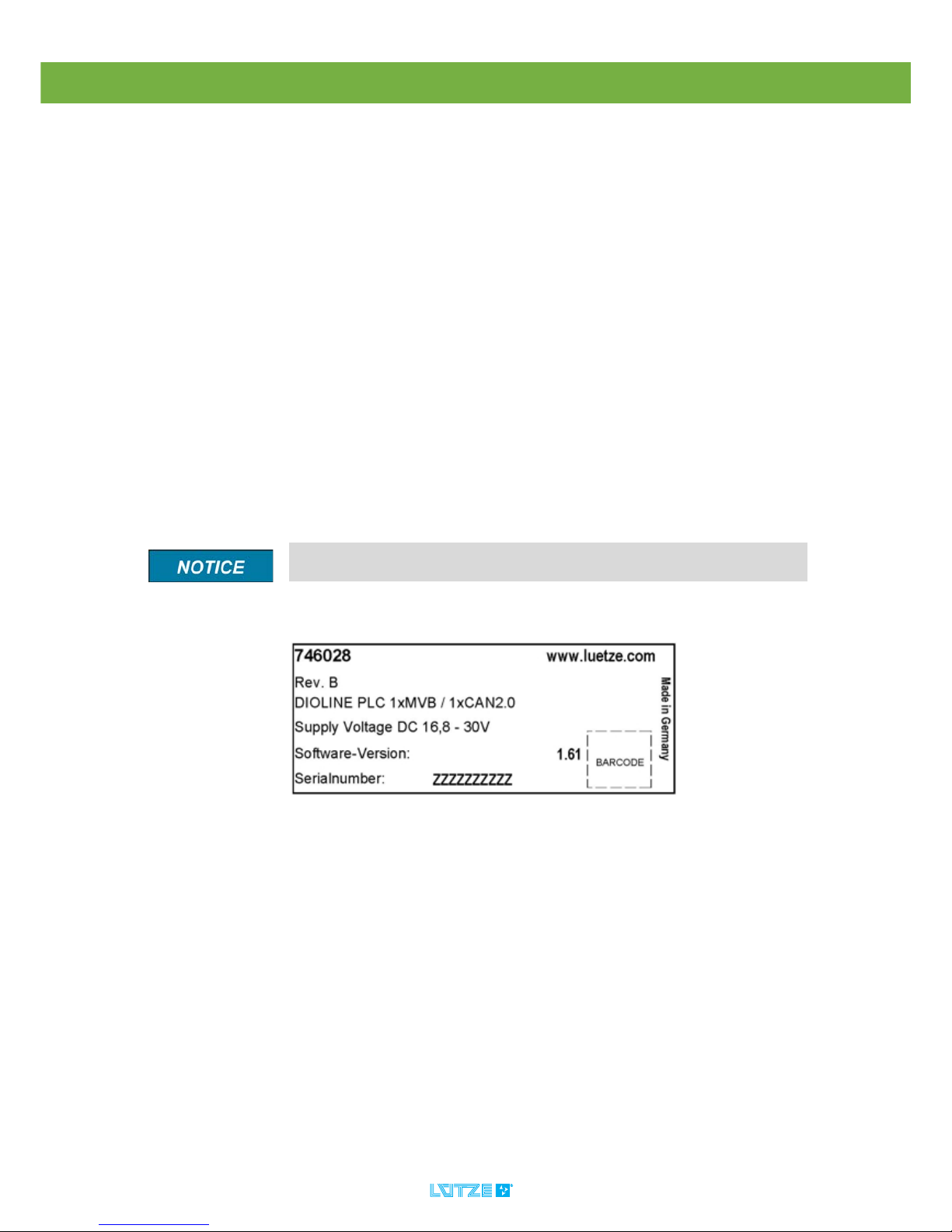

3.7 Labeling

On the product following label with following data can be found:

Fig. 1: Example Label

▪ Part-Number

▪ Hardware Revision

▪ Assembly Term

▪ Software-Version

▪ Serialnumber

Mind the original adhesive labels. Keep them readable.

DIOLINE PLC ▪ Safety

10

3.8 Reconstruction and Modifications of the Product

3.9 Safety Arrangement

3.10 Special Safety Messages

Reconstructions and modifications of the product can cause property

damages or personal injuries. Do not reconstruct or modify the product if the

manufacturer does not allow it explicit in writing.

Do not bypass protection equipment and safety arrangements. The product

can be damaged by overvoltage and electric shocks are possible.

Use a nominal operating voltage of 24 Volts. The lower (16.8 Volts) and upper

(30 Volts) threshold voltage is given in the technical data. A higher voltage can

cause electric shocks and damage the product.

Dismount all electronic modules and their connections from the frame if

you intend to do some welding. The product can be damaged by

compensating current.

DIOLINE PLC ▪ Product Overview

11

4Product Overview

4.1 Product Description

The DIOLINE PLC is a programmable compact controller in the automation

system DIOLINE20. The product is based on a high-performance

ARM = Microprocessor (Advanced Risk Machine). It is possible to connect

several I/O modules over the L-Bus interface. The L-Bus is a Lütze invention. The

product can provide up to 4 bus interfaces. The interfaces can be flexible

configured.

The DIOLINE PLC can be programmed and configured by the application

development system MULTIPROG from KW software. The programming can be

done in the established languages which are based on the IEC 61131 standard.

The software can handle multiuser projects over a network access.

There are several options regarding the interfaces and software.

4.2 Hardware Options

Option Item Number

DIOLINE PLC-COM-COM-LUE 746026

DIOLINE PLC-COM-CAN-LUE 746027

DIOLINE PLC-MVB-CAN-LUE 746028

DIOLINE PLC-COM-NFB-RS485-LUE 746029

DIOLINE PLC-COS-COM-LUE 746032

DIOLINE PLC-MVB-COM-LUE 746033

DIOLINE PLC-NFB-NFB-LUE 746034

DIOLINE PLC-MVB-CAN-RS485-LUE 746036

DIOLINE PLC-MVB-CAN-DI-LUE 746037

DIOLINE PLC-MVB-COM-DIO-LUE 746038

DIOLINE PLC-CAN-NFB-LUE 746039

DIOLINE PLC-MVB+-COM-LUE 746040

DIOLINE PLC-COS-CAN-LUE 746041

Legend:

CAN Controlled Area Network

MVB Multi Vehicle Bus (Slave) (EMD)

MVB+ Multi Vehicle Bus (Slave) (ESD+)

COM CANopen Master

COS CANopen Slave

DI Local Digital Inputs (24V)

DO Local Digital Outputs (24V)

DIOLINE PLC ▪ Product Overview

12

4.3 Software Options

RS485 Two Wire Serial Bus

RSBUS One Wire Serial Bus

NFB No Field Bus

Option Description Item Number

DR-PC-SW-KWS KW MULTIPROG Development

Suite+ V 4.8

▪ Multiprog development

environment

▪ IEC61131 Editor

▪ SYCON.NET CANopen fieldbus

configurator

▪ ProVisIT visualizing editor

▪ ProVisIT runtime license

746090

DR-PC2-SW-KWPD KW ProVisIT Development

enviroment

746091

DR-PC2-SW-KWM KW MULTIPROG Monitoring

Pro+ V 4.8

▪ MULTIPROG download and

debugging environment

746092

DR-PC2-SW-KWOPC ProConOS OPC Server 2.1 Desktop 746093

DR-PC2-SW-KWPR ProVisIT Runtime 746095

DR-PC2-SW-KWP KW MULTIPROG Development

Pro+ V 4.8

▪ Multiprog development

environment

▪ IEC61131 Editor

746096

DIOLINE PLC ▪ Product Overview

13

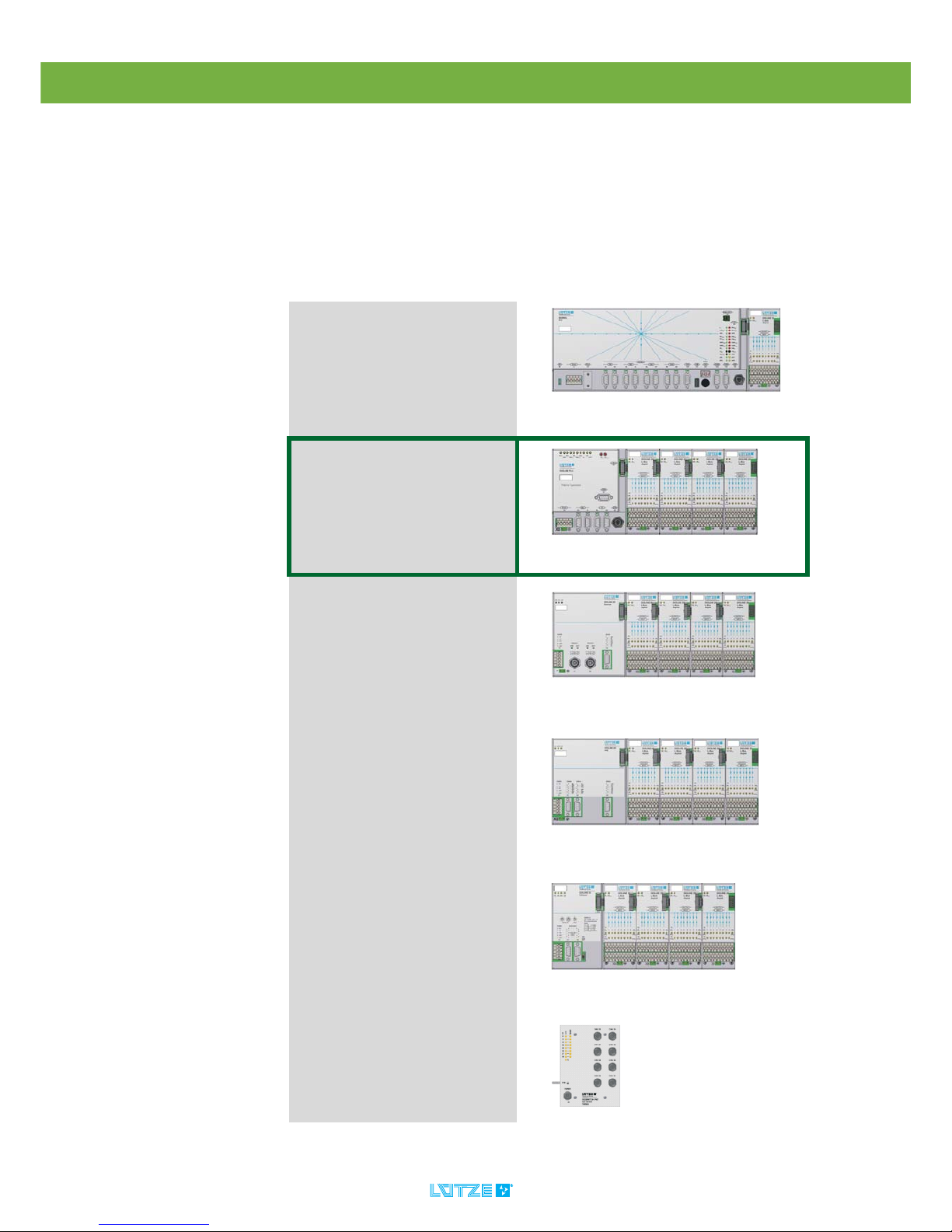

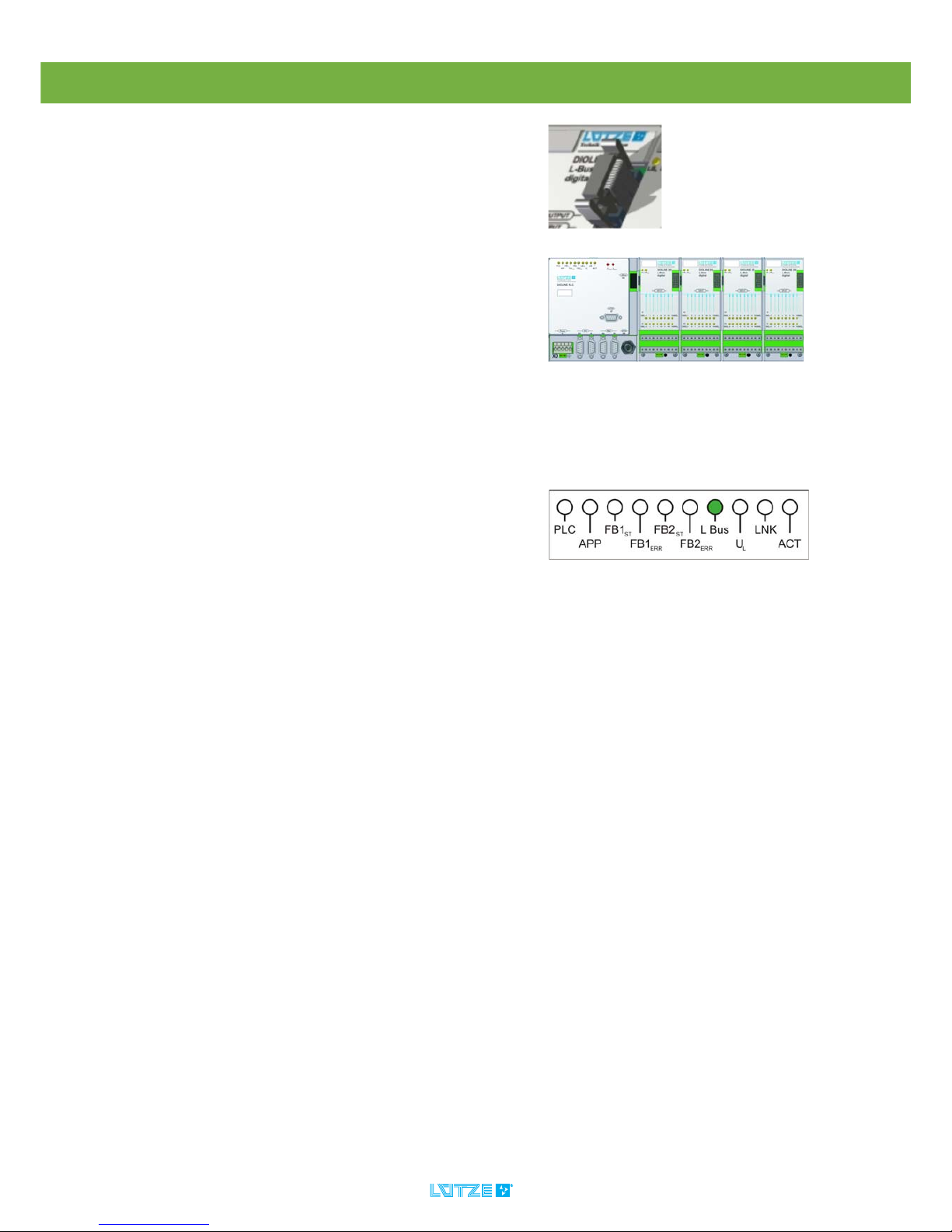

4.4 System Overview

The DIOLINE PLC can be integrated in the product line of the DIOLINE 20

automating system as follows.

The DIOLINE product line contains modular components. A unit consists of a

controller with an integrated CPU and an extension module. It is possible to

connect max. 10 local I/O extension modules on the controller. The extension

modules are connected over the L-Bus. The graphic shows the DIOLINE product

after their intelligence. The first module is the most intelligent one. The last one is

a module with the fewest intelligence.

DIORAIL PC 2

Vehicle Control Unit

DIOLINE PLC

Compact Control Unit

DIOLINE20

Buscoupler Ethernet IP Adapter

Remote I/O Modules

DIOLINE20

Buscoupler MVB Slave

Remote I/O Modules

DIOLINE20

Buscoupler CANopen Slave

Remote I/O Modules

DIOSWITCH

Unmanaged Ethernet Switch

DIOLINE PLC ▪ Product Overview

14

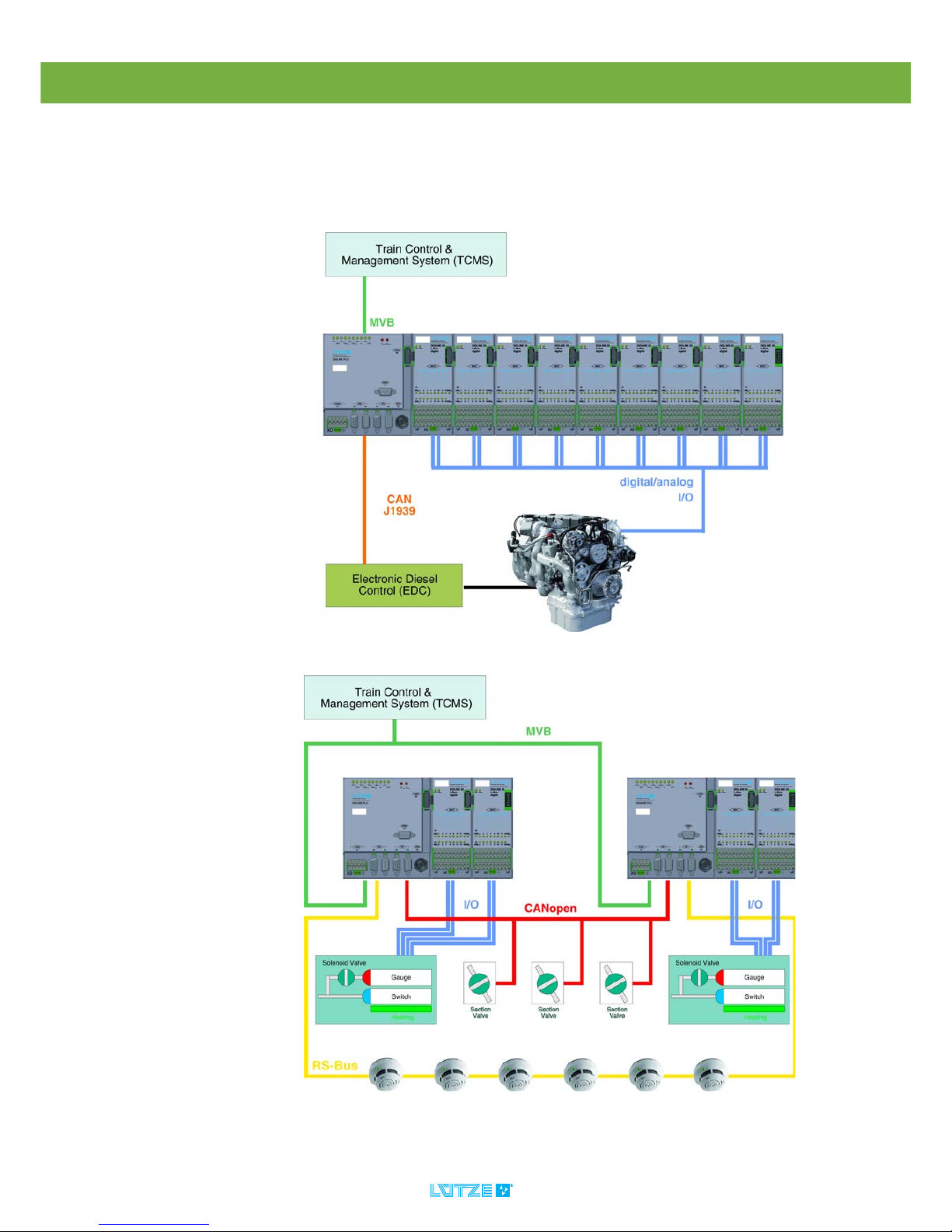

4.5 Field of Application

The DIOLINE PLC is designed for use in railway vehicles. It can be used for

automation of simple vehicles, as subsystems or for high-capacity gateways to

transfer vehicle specific bus signals. The graphic below shows possible

application areas in trains:

Fig. 2: Example Application 1: Powerpack Control Unit

Fig. 3: Example Application 2: Fire Protection Control Unit

DIOLINE PLC ▪ Transport and Storing

15

5 Transport and Storing

▪ Protect the product from humidity. Store the product in a dry room

between -40 and 85°C.

▪ Make sure that the PLC is safely packaged for transporting, that

possible crushes can be absorbed.

▪ Dust can destroy electronic components. The circuit board of the PLC is

coated. But try to store and transport it in a dust free environment to avoid

damages of the PLC.

DIOLINE PLC ▪ Scope of Delivery

16

6 Scope of Delivery

▪DIOLINE PLC

▪ Dummy connector for L-Bus interface

▪ Shielding Cover for SUB-D interface

▪ Instruction Leaflet

The software for the DIOLINE PLC can be downloaded in the internet. The

Link and the password will be send by e-mail.

DIOLINE PLC ▪ Product Assembly

17

7 Product Assembly

1 LED-Diagnosis Display

2 User and Reset Button

3 L-Bus Interface X8

4 RS 232 Interface X7

5 Ethernet Interface X6

6 Fieldbus 2 – CANopen Master Interface outgoing X5

7 Fieldbus 2 – CANopen Master Interface incoming X4

8 Fieldbus 1 – CANopen Slave outgoing X3

9 Fieldbus 1 – CANopen Slave incoming X2

10 Mounting Tab X0

11 Power Supply

DIOLINE PLC ▪ Product Assembly

18

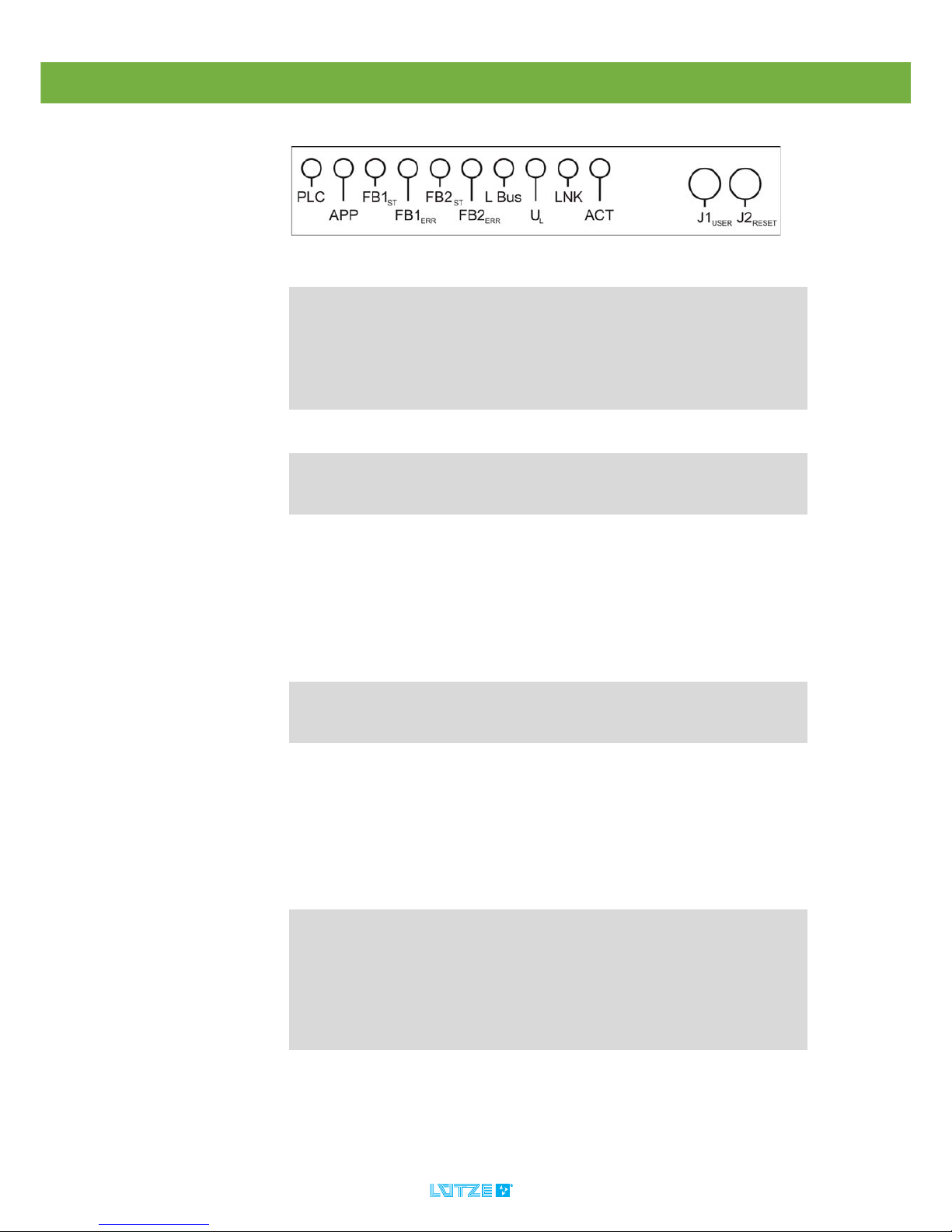

7.1 LED Display

LED Color State Description

PLC yellow 0.1s on/0.9s off

0.5s on/0.5s off

0.8s on/0.2s off

on

off

PLC is ready – no project

PLC is in STOP mode

PLC alert an error

PLC is in RUN mode

PLC is defect

APP green

red

on

on

User defined green

User defined red

FB1ST– CANopen green flashes one time

flashing

on

Stop mode.

Preoperational mode.

Operational mode.

FB1

ERR

– CANopen red off

flashes one time

flashes two

times

on

At least one error counter

of the CAN-Controller has

reached the warning limit.

An error control event or a

heartbeat event occured.

CAN-Controller is in the

mode: bus off

FB2ST– CANopen green flashes one time

flashing

on

Stop mode.

Preoperational mode.

Operational mode.

FB2

ERR

– CANopen red off

flashes one time

flashes two

times

on

At least one error counter

of the CAN-Controller has

reached the warning limit.

An error control event or a

heartbeat event occured.

CAN-Controller is in the

mode: bus off

L-Bus green

red

flashing

on

on

Initialization of L-Bus is

OK, waiting on PLC.

L-Bus in RUN modeconfiguration is OK

L-Bus error

UL green on

off

Power supply of the logic

is OK.

Power supply is defect.

DIOLINE PLC ▪ Product Assembly

19

LNK green on

off

Ethernet connection is OK.

No Ethernet connection.

ACT yellow flashing

off

Ethernet data transfer is

OK.

No Ethernet data transfer.

DIOLINE PLC ▪ Technical Data

20

8 Technical Data

Mechanics

Dimensions 123x141.5x64.1 mm (wxhxd)

Weight 0.550kg/piece

Housing Aluminum, anodized surface

Mounting Top Hat Rail TS 35 7.5 mm

Electrical Characteristics

Power Supply DC 24 V (voltage range 16.8-30 V)

Ripple Max. 10 %

Power Consumption 5 W + L-Bus Module Consumption

Protective Device Inverse-polarity protection, overvoltage protection

Potential Separation AC 500 V CAN and electronic

AC 500 V Ethernet and electronic

DIOLINE PLC ▪ Technical Data

21

Interfaces

▪ RS232

▪ Ethernet 100Base TX

▪ SD Card Slot

Fieldbus Interfaces ▪ L-BUS

▪ CANopen

Software

Operating System Real-Time Operating System rcX

Controller Software IECX 61131 Soft-PLC ProConOS KW Software

CPU

Processor ARM9-CPU NetX 500, 32 Bit

Monitoring External Watchdog voltage monitor of the control

software

Boot time Run up time state: “ready“ after switching on the

power supply <15s

Memory

Internal Serial Flash

Memory

4 MB Serial Flash Memory

Internal RAM 32 MB SDRAM

Internal FRAM 4 kB

Internal parallel Flash

Memory

2 MB

Diagnosis

Diagnosis Interface Ethernet 100BaseTX

Diagnosis LED 10 LED for visual device diagnosis

Switches/Key-Buttons 1 reset key button, 1 key button, evaluated in the

control software

Clock Real Time Clock RTC

Enviromental Condition

Operating Temperature -40°C to +70°C

Storage Temperature -40°C to +85°C

Relative Humidity 100% short time condensation allowed

DIOLINE PLC ▪ Technical Data

22

International Protection

Class (IP)

IP20

Standards

EN 50155 Electronic Equipment on Railway Vehicles

EN 5021-3-2 Electromagnetic Compability

EN 50124-1 Insulation Coordination

EN 61373 Vibration and Shock

DIOLINE PLC ▪ Mounting

23

9 Mounting

9.1 Mounting Options

The DIOLINE PLC can be mounted on a top-hat rail. Following mounting options

are possible:

Risk of injury by electric current. Persons can be injured by electric current

and the product can be damaged. De-energize the system before mounting.

Mount the product with a distance of 5 mm minimum to other products to

provide good air conditions.

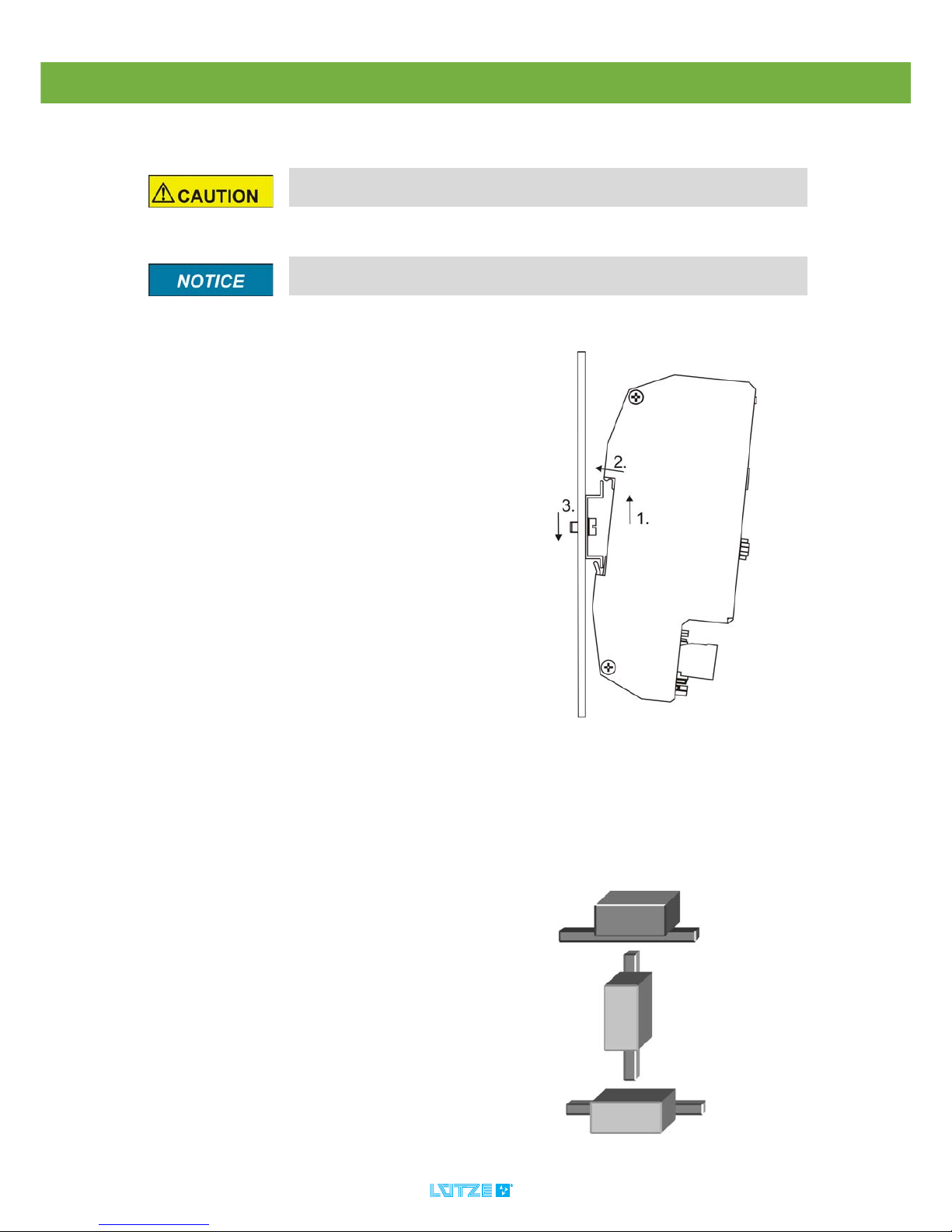

1. Hook the product into the lower part

of the top-hat rail.

2. Push the product a little bit up.

3. Push the product back that it

catches the top-hat rail.

▪horizontal

▪vertical

▪across

DIOLINE PLC ▪ Initial Operation – Hardware

24

10 Initial Operation – Hardware

10.1 Power Supply

The initial operation has to be done by expert employees.

Short circuits and electric shocks by wrong voltage application and wrong

wiring. Switch off the power of the whole system before wiring. Make sure that

the connectors are wired correctly before switching on the power. Use a direct

voltage of 24 V according to the train standard EN 50155.

Do not operate the product without the protective conductor. If the product

is defect, the housing can be energized and can cause electric shocks.

1. Switch off the power.

2. Connect the devices regarding the

pin assignment.

3. Switch on the power.

4. The device is booting.

The PLC LED is flashing yellow.

Fig. 1: Cage Clamp with Mounting Tab X1, X0

If the LED is not flashing or is permanently on the product might be defect.

For possible error solutions see chapter "Error Treatment" on page 125. If

problems are still occuring please contact Lütze Transportation GmbH.

Pin Signal Description

1 VCC 24 V

Supply Voltage

2VCC24 V

Supply Voltage

3 PE Protective Earth

40V0 V

Supply Voltage

5 0V 0 V

Supply Voltage

DIOLINE PLC ▪

25

10.2 L-Bus – Interface

The L-Bus interface is for connecting DIOLINE20 I/O modules. The L-Bus, also

called Lütze Bus, is a special Bus invented by company Lütze.

Switch off the power when connecting or disconnecting the I/O modules.

If not observe, the whole system can be damaged. Hot Plugging is not supported

by the system.

Connect max 10 I/O modules over the L-Bus interface. Mind the current

consumption of the single modules. In the appendix on Seite 135 you can find

a table with the according values. A total current of max 1 A is possible on the

L-Bus.

1. Switch off the power

2. Mind the pin assignment

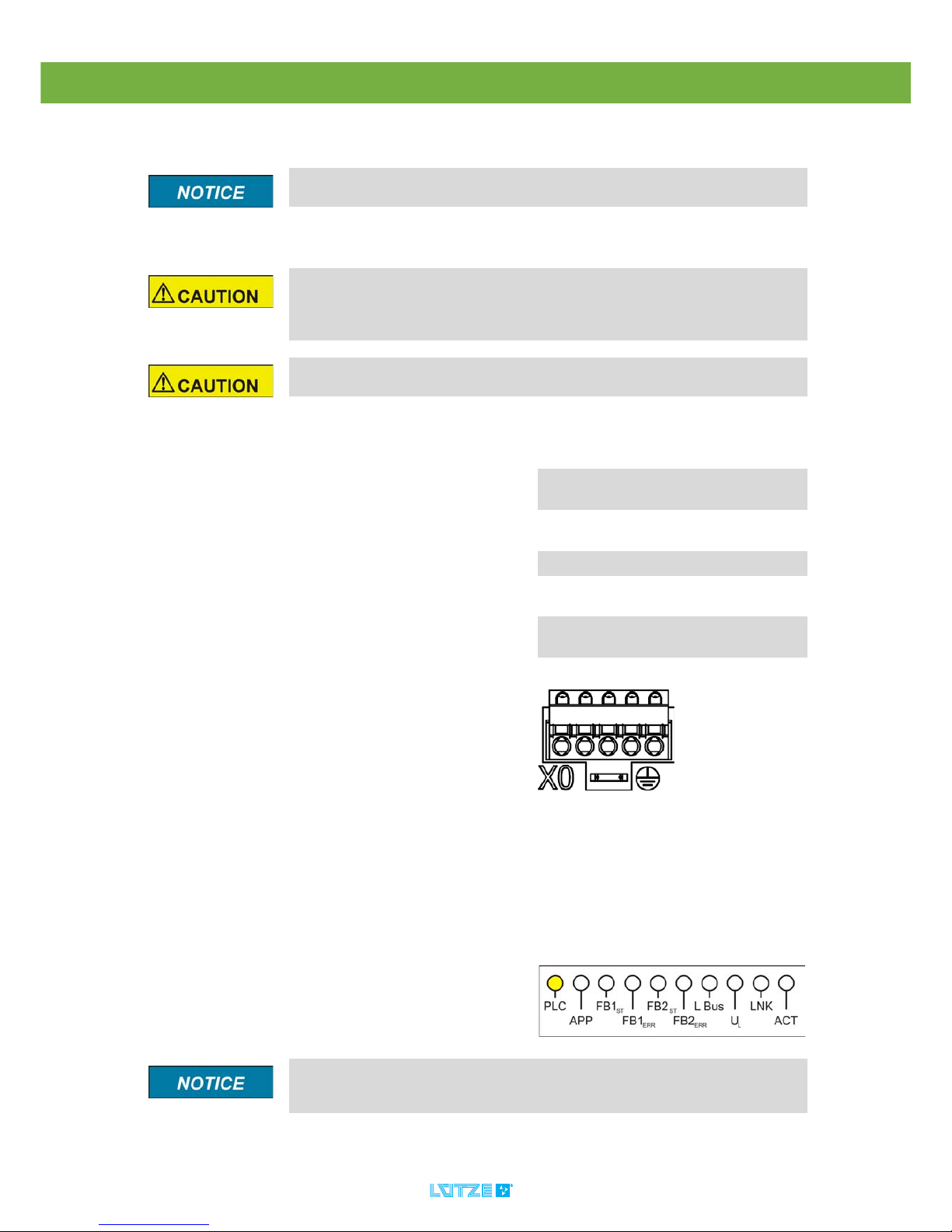

Fig. 2: L-Bus Master, X8

Pin Signal Description

1 24 V Supply Voltage

2 24 V Supply Voltage

3 GND 0 V Potential

4 /L_BUS_

RESET

Module Reset

5 BUS_END Identifier Bus End

6 OUT_OK Data Confirmation

7 SDIN Receiving Serial Data

8 SCK Clock

9 SDOUT Transmitting Serial

Data

10 GND 0 V Potential

It is not possible to change the pin assignment.

DIOLINE PLC ▪

26

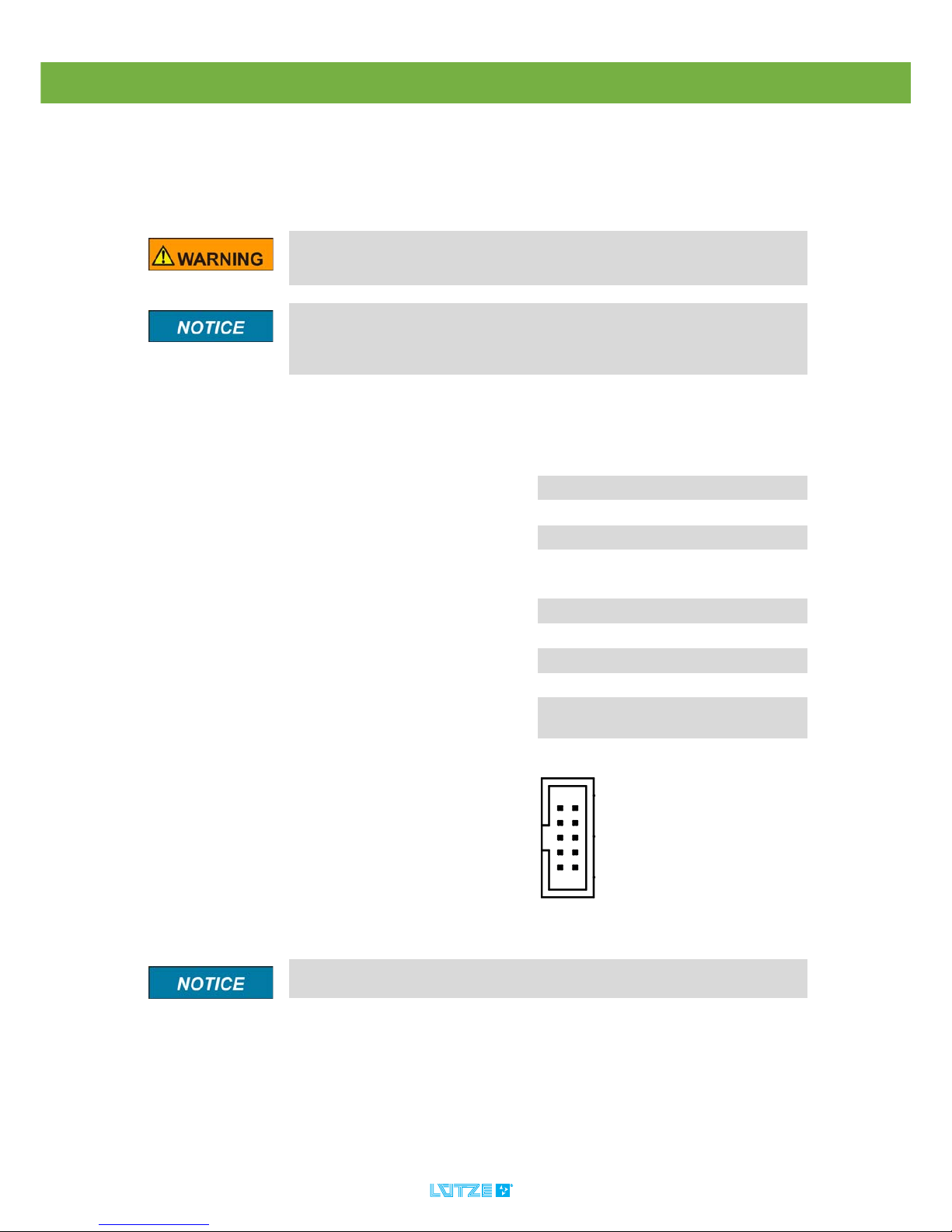

3. Connect the DIOLINE 20 I/O

Modules over the L-Bus interface.

4. Switch on the power.

5. The LB LED is green.

The device is ready.

Fig. 3: L-Bus connector

Fig. 4: PLC with connected I/O Modules

DIOLINE PLC ▪

27

10.3 Serial Interface

The serial interface can be programmed by MULTIPROG and should only be

used for diagnosis.

It is not possible to program or parameterize the PLC over the serial

interface RS232. The serial Interface can be programmed out of MULTIPROG.

The access to the serial interface is only possible by the user specific

applicationsoftware. We recommend to use the interface only for diagnosis.

1. Connect the PLC and the devices

with a suitable cable.

“Hot Plugging“ is possible.

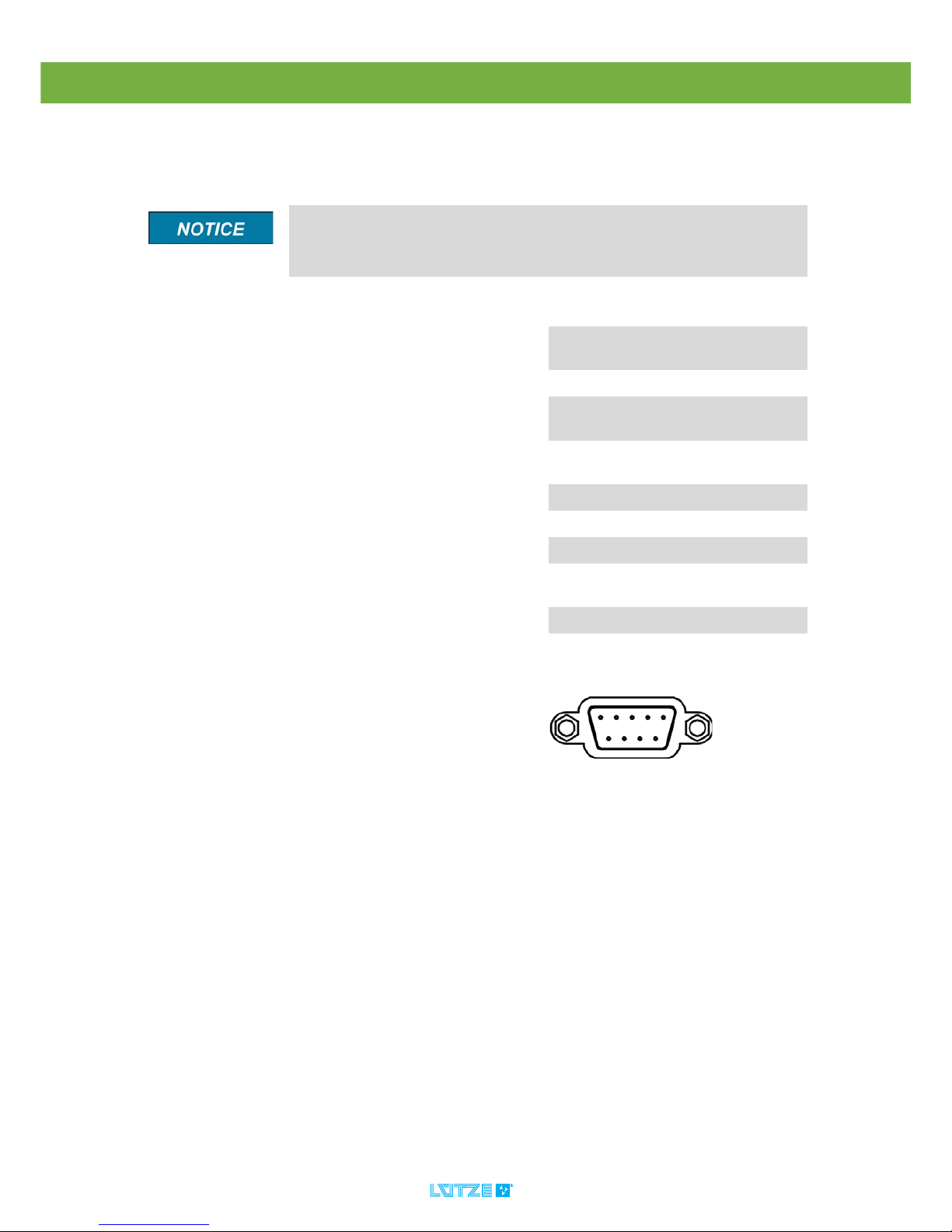

Fig. 5: Serial Interface SUB-D, X7

Pin Signal Description

Connector

Housing

PE Protective

Earth

1 NC Not connected

2 RXD Receiving

Data

3 TXD Transmitting

Data

4 NC Not connected

5 GND 0 V Potential

6 NC Not connected

7 RTS Request to

Send

8 CTS Clear to Send

9 NC Not connected

DIOLINE PLC ▪

28

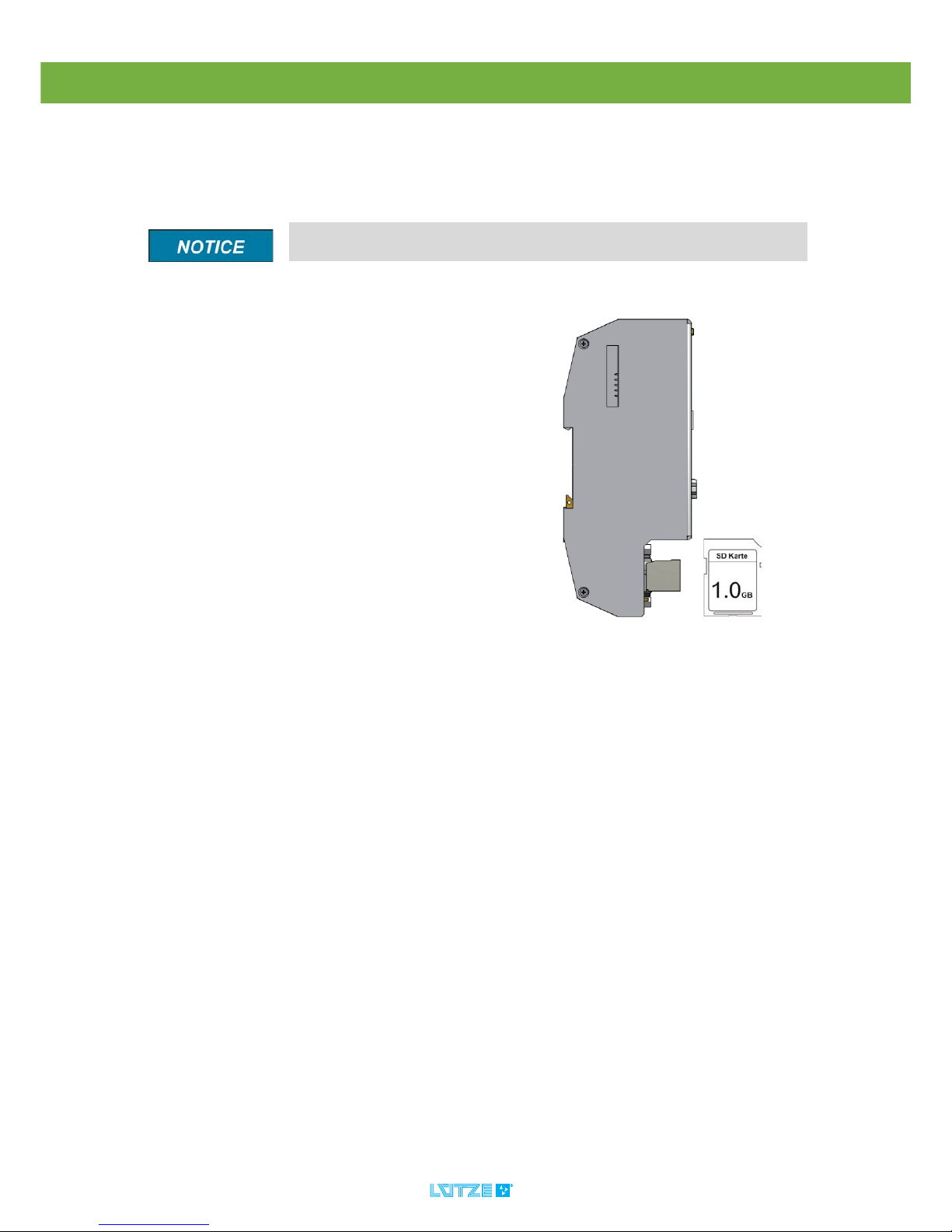

10.4 SD Card Slot

The PLC comes with a SD card slot. You can find the slot for the card on the left

side of the PLC housing. The slot is covered by a foil to protect the PLC from

incoming dust and other environmental influences.

If saving a high capacity of data on the SD card, there can be a delay in the

L-Bus communication.

▪ The delivered and recommended

SD card by Lütze has a 1 GB

memory. It is possible to use a SD

card with a maximum of 2 GB.

▪ The card can be used for saving

maintenance data.

DIOLINE PLC ▪

29

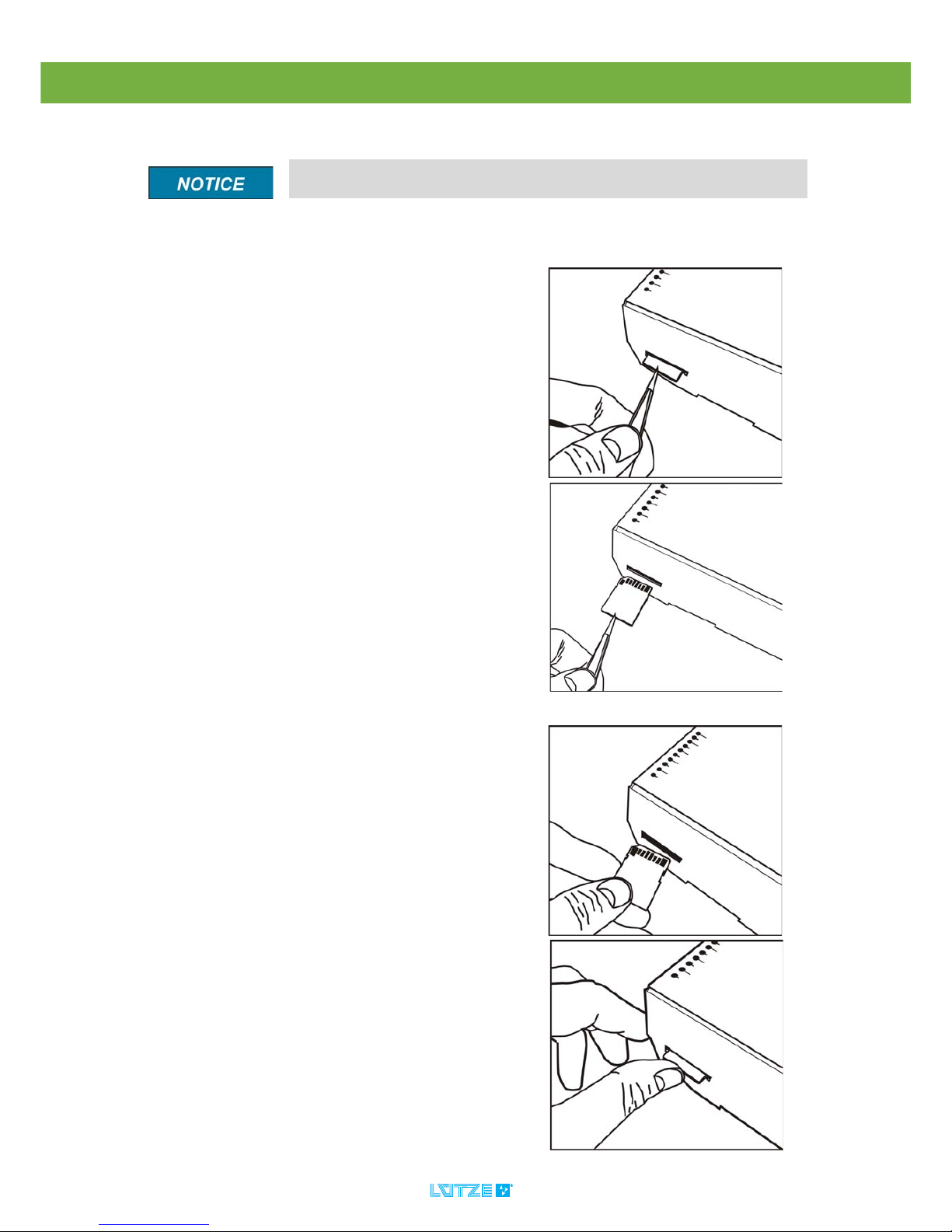

10.4.1 Changing the SD Card

To change the SD Card follow these steps:

If changing the SD Card to a new one, make sure that you are using a

special industrial card which is specified by Lütze.

1. Pull out the card by using tweezers.

See the pictures.

2. Put in the new card by pushing the

card in the slot as far as it will go.

DIOLINE PLC ▪

30

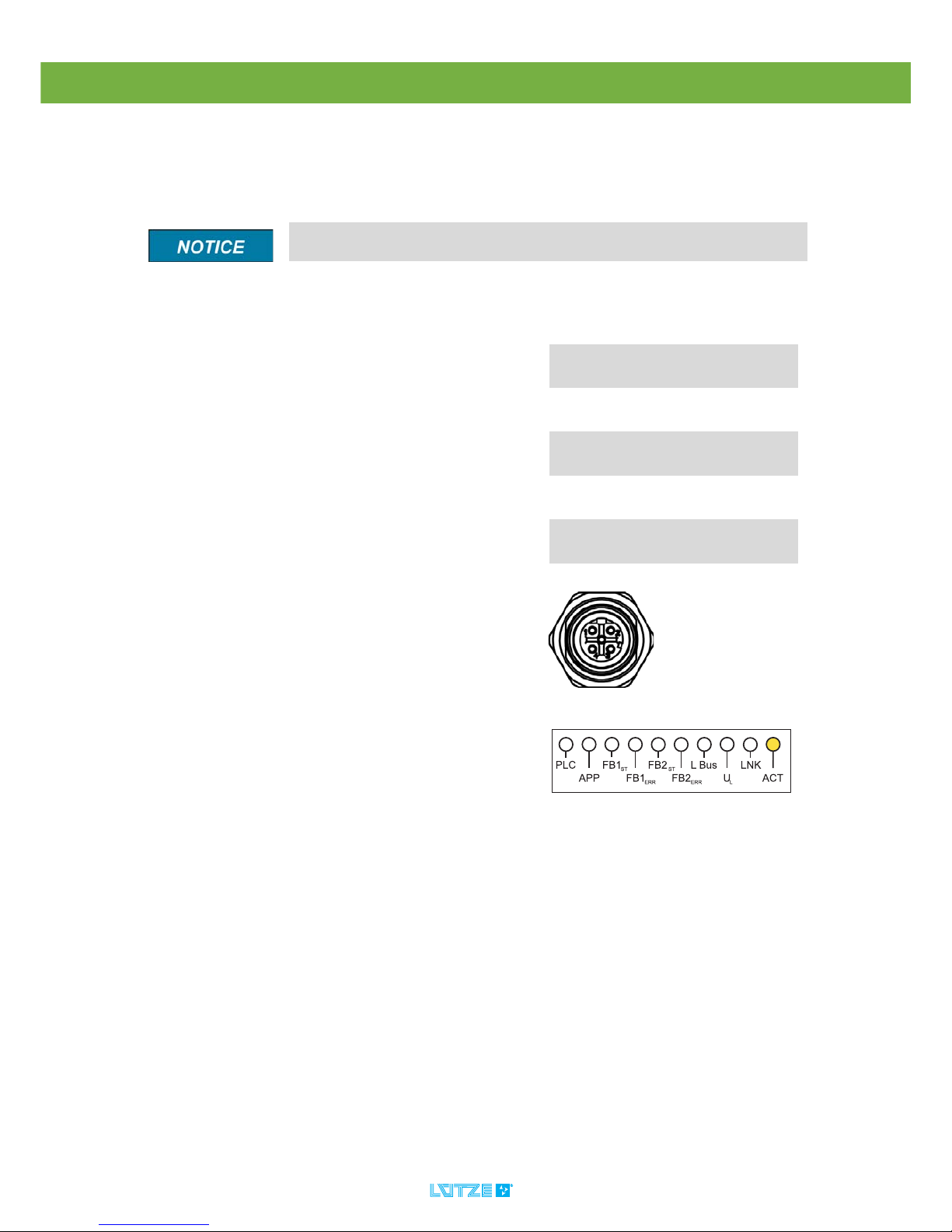

10.5 Ethernet Interface

The Ethernet interface is for the communication between PLC and PC. Over this

interface the PLC can be programmed, visualized, parameterized and debugged

in the application software.

The Ethernet interface is hot plugging compatible. There is no need to

switch of the power when connecting or disconnection the Ethernet interface.

1. Connect the PLC with the PC with a

suitable cable over the Ethernet

interface.

2. The Ethernet connection is active.

The ACT LED is on.

Fig. 6: Ethernet Interface M12, X6

Pin Signal Description

Connector

Housing

PE Protective

Earth

1 TXD+ Transmitting

Data

2 RXD+ Receiving

Data

3 TXD- Transmitting

Data

4 TXD- Receiving

Data

DIOLINE PLC ▪

31

10.6 Fieldbus 1 Interface – CANopen Master

1. Switch off the power.

2. Connect the PLC with the devices

over a suitable bus cable.

3. Switch on the power.

4. The FB

1st

LED is green, if all

devices are communicating .

Fig. 7: Fieldbus 1 Interface, Sub-D, 9 pole, X2,X3

If the FB1

ERR

LED is red, an error occurred, see chapter "LED Display" on

page 18.

Pin Signal Description

Connector

Housing

PE Protective

Earth

1 PE Not connected

2 CANL CAN-Signal

low

3 DGND CAN-Signal

ground

4 NC Not connected

5 NC Not connected

6 NC Not connected

7 CANH CAN-Signal

high

8 NC Not connected

9 NC Not connected

DIOLINE PLC ▪

32

10.7 Fieldbus 2 Interface – CANopen Slave

1. Switch off the power.

2. Connect the PLC with the devices

over a suitable bus cable.

3. Switch on the power.

4. The FB

2st

LED is green, if all

devices are communicating .

Fig. 8: Fieldbus 2 Interface, Sub-D, 9 pole, X4,X5

Pin Signal Description

Connector

Housing

PE Protective

Earth

1 PE Not connected

2 CANL CAN-Signal

low

3 DGND CAN-Signal

ground

4 NC Not connected

5 NC Not connected

6 NC Not connected

7 CANH CAN-Signal

high

8 NC Not connected

9 NC Not connected

If the FB2

ERR

LED is red, an error occurred, see chapter "LED Display" on

page 18.

DIOLINE PLC ▪ Initial Operation – Software

33

11 Initial Operation – Software

1. Download the software under the sent link. The software has to be requested

at Lütze.

2. Install the Software in the following order:

1.MULTIPROG

2.ProConOS Server

3.Lütze Addons

Install all software package into one and the same directory. Otherwise the

software package does not work right.

System Requirement

MULTIPROG Basic

Pro 4.8

MULTIPROG Suite/

Suite+ 4.8

Processor Pentium 500 MHz Pentium 1 GHz

RAM 64MB

(128MB recommended)

Hard Drive 250 MB disk space 350 MB disk space

Communication TCP/IP

Operating System Win 95/98/ME/NT 4.0

(>SP5), Win 2000 (SP2),

Win XP (SP1)

Wi n N T 4.0 (>SP 5 ) Win

2000 (SP2) Win XP

(SP1)

Internet Explorer 4.02 or newer version

DIOLINE PLC ▪ Initial Operation – Software

34

11.1 Installation

11.1.1 MULTIPROG

Before installing the software mind the system requirements. The

MULTIPROG software is an integrated development environment according to

the IEC 61131 standard. With the software you program your application

software and parameterize the PLC.

1. Open the setup file MULTIPROG

4.8 Development Suite.

The automatic installation assistant

starts.

2. Follow the steps of the installation

assistant. Click Next to confirm the

settings.

To cancel the installation, click Exit.

3. Click OK to complete the

installation.

4. After a successful installation,

restart the PC.

5. Start MULTIPROG.

6. Click the question mark in the

menu bar.

7. Choose Register….

Following window appears:

8. Type in the license key.

9. Click OK to confirm the key.

If not having any license key, please contact us. It is mandatory to purchase

a license key to use the full version of MULTIPROG.

DIOLINE PLC ▪ Initial Operation – Software

35

11.1.2 ProConOS OPC Server

The ProConOS OPC Server realizes the communication between PLC and OPC

Client. The client is the visualizing program ProVisIT. The data exchange is done

by TCP/IP.

If using the Multiprog Suite the ProVisIT visualization Software is installed

automatically.

1. Double click

ProConOs OPC-Server 2.1.

The automatic installation assistant

starts.

2. Follow the steps of the installation

assistant. Click Next to confirm your

settings. To cancel the installation,

click Exit.

3. Click OK to complete the

installation.

4. After a successful installation,

restart your PC.

5. Start the

ProConOs OPC-Server 2.1.

6. Click right on the symbol in the

windows task bar.

a) Choose Register.

Following window appears:

b) Type in the license key.

3. Click OK to confirm the key.

If not having any license key, please contact us. It is mandatory to purchase

a license key to use the full version of ProConOS Server.

DIOLINE PLC ▪ Initial Operation – Software

36

11.1.3 Lütze Addons

The addons contain functions for the programming system MULTIPROG. The

addons implementing necessary resources for embedding the PLC in the

integrated development environment.

1. Double click

setup Luetze_Addons_V4.0 .

2. The automatic installation assistent

starts.

3. Choose a language.

4. Follow the steps of the installation

assistant. Click Next to confirm your

settings.

To cancel the installation, click Exit.

5. Click Install to confirm the

installation.

DIOLINE PLC ▪ Initial Operation – Software

37

11.2 IP Configuration

To configure the IP address and subnet mask follow those steps:

11.2.1 PC IP Address

Mind choosing the same subnet for all communication devices by

configuring the subnet mask. Every communication node must have a

different IP address. The standard IP address for the PLC is 192.168.0.215 and

the standard subnet mask is 255.255.255.0.

The file TCPIP.CFG configures an individual PLC address. You can find

more information about this file in chapter on Seite 41.

1. Open the windows start menu.

2. Choose Network Connections.

Following window appears:

3. Open Network Connection by

double clicking.

4. Make a right click on

LAN- connection. Make sure

configuring the networkcard the

PLC is connected to.

5. Choose Properties.

DIOLINE PLC ▪ Initial Operation – Software

38

Following window appears:

6. Double click Internet protocol (TCP/

IP).

Do not use the PLC IP address.

7. Choose Using following

IP address.

8. Type in an IP address.

For example: 192.168.0.10

9. Type in a subnet mask:

255.255.255.0

10.Click OK to confirm the settings.

DIOLINE PLC ▪ Initial Operation – Software

39

11.2.2 Communication Check

To program and monitor the PLC with MULTIPROG make sure, that the

communication between PC and PLC is working. Proceed as follows:

1. Open Windows Start Menu > Run.

Following window appears:

2. Type in: cmd.

3. Click OK.

Following window appears:

4. Type in: ping 192.168.0.215

(standard address of the PLC) or

the PLC IP address according to the

changes.

5. Press enter.

▪ If you receive an answer:

the communication is working.

▪ If you do not receive an answer:

check the IP address and the

networks.

DIOLINE PLC ▪ Initial Operation – Software

40

11.2.3 PLC IP Address

To configure the IP address and subnet mask follow those steps:

Mind choosing the same subnet for all communication devices by

configuring the subnet mask. Every communication node must have a

different IP address. The standard IP address for the PLC is 192.168.0.215 and

the standard subnet mask is 255.255.255.0.

Before changing the IP Address the communication with the standard IP

address has to work.

Do not use the PC TCP/IP address. Just choose the same subnet.

Otherwise there will be no communication between PLC and PC. An example

file can be found in the download area, the link will be sent within an e-mail

request.

1. Open the TCPIP.CFG file.

The TCPIP.CFG is a default Lütze

standard file. It contains the following IP

configuration parameters as shown in

the picture.

2. Change the existing IP address by

the new one.

3. If needed set a new subnet mask.

4. Save the settings.

The DefaultGateway has to be in the network of the IP address.

To Download the configuration file see chapter see chapter "Download of

Configuration Files" on page 99.

To Reset the TCP/IP to the standard value 192.168.0.215 by the PLC

buttons see chapter "Resetting the TCP/IP Address" on page 41.

DIOLINE PLC ▪ Initial Operation – Software

41

11.2.4 Resetting the TCP/IP Address

The resetting of the TCP/IP is just possible during the start of the PLC.

The resetting of the TCP/IP is not possible if an SD card with the

autoexec.bat is inserted.

1. Switch on the PLC.

2. Press and hold the

J1USER button.

3. Still holding the J1USER button,

Press shortly the J2RESET button,

4. After pressing the J2RESET button

keep holding the J1USER button for

10 more seconds, until the PLC and

APP LED flashes 20 times with 10

Hz alternately.

5. Check the communication between

PC and PLC using the standard ip

192.168.0.215, see chapter

"Communication Check" on page

39.

DIOLINE PLC ▪ Initial Operation – Software

42

11.3 Development Environment System – MULTIPROG

11.3.1 Creating a MULTIPROG Project

To program the PLC, it is necessary to create a project with the MULTIPROG

software. To create a project use the project assistant.

1. Start the MULTIPROG software.

2. Click on in the tool bar or

choose File > New Project in the

menu bar.

Following window appears:

3. Double click following symbol:

Step 1- Project Assistant

1. Type in any project name. Following

characters are forbidden:

':-=;<>[]/?|*".

The name can have a length of 24

characters. But only 12 characters

can be read in the info dialog out of

the PLC.

In t he field Project Path a standard path

is entered. The Project Path should be

no longer than 171 characters.

If you want to change the path, follow

those steps:

a) Click

The window FOLDER appears:

b) Choose any path.

c) Click OK.

2. Click NEXT.

DIOLINE PLC ▪ Initial Operation – Software

43

Step 2 Project Assistant

1. Type in any name for the first

program organization Unit (POU) in

the field Name of POU.

2. Choose a language for the POU.

3. Click NEXT.

Step 3 Project Assistant

1. Choose any configuration name.

2. Choose the configuration type

ARM_L_33.

3. Click NEXT.

Step 4 Project Assistant

1. Type in any resource name.

2. Choose PCOS_ARM_IKS as

resource type.

3. Click NEXT.

Step 5 Project Assistant

1. Type in any task name.

2. Choose the task type CYCLIC

3. Click NEXT.

Step 6 Project Assistant

The settings are listed in the overview.

Click Finish to confirm the settings.

DIOLINE PLC ▪ Initial Operation – Software

44

11.3.2 Ressource Settings

In the resource settings you configure MULTIPROG specific parameters for the

communication between the PLC and PC.

1. Start MULTIPROG.

2. Click with the right mouse button on

Ressource:PROCONOS in the

Project tree window.

3. Choose Settings.

Following window appears:

4. Choose DLL under Port.

5. Choose:

▪ Array boundary check on PLC

Checks the access to not defined

array elements.

▪ Force Bool 8 for Boolean variables

Saves any boolean variables as a

byte without a defined storage

location.

▪ TCP/IP for DLL

The name for the dynamic library

DLL.

DIOLINE PLC ▪ Initial Operation – Software

45

Other options are:

▪ Stack check on PLC

If activated the stack will be checked

for overflows. A possibility of a

decreased operation speed can

occur. A higher security is provided.

▪ Generate bootproject during

compile

The MULTIPROG generated

Bootfile.pro is a inbetween code

which is translated to a machine

code on the PLC after the donload

procedure.

6. Under “parameter” type in the

standard IP as follows:

▪ ip 192.168.0.215 -TO2000

▪ -TO2000 defines the timeout

between the PLC and the Multiprog

sofware in ms. If the PLC does not

resp onse in this time on a reques t of

the PC an Timout Message will be

generated in the Message-Window

of Multiprog.

7. Choose Marked Variables under

PDD and OPC.

▪ PDD (Process Data Directory)

The operating system can directly

access those variables. For

example the variables are needed

for serial interface or symbolic

variables access.

▪ OPC (OLE for Process Control,

Object Linking for Embedding)

Needed for the visualization of

variables in ProVisIT.

8. Choose All POUs under Use

reserve.

Allows to change and upload the

MULTIPROG project during the

runtime. While changing a storage

reserve is used.

9. To confirm the settings click OK.

This file cannot be loaded on the PLC. Because after the download through

MULTIPROG the machine code is translated on the PLC a second time. To

download this file from the PLC see chapter "Maintenance Software" on page

116.

DIOLINE PLC ▪ Initial Operation – Software

46

11.3.3 Function Blocks and Firmware Libraries

Function blocks can be inserted from the firmware or user libraries in

MULTIPROG. There is also the option to program your own function blocks.

The fieldbusses and other interfaces are controlled and monitored in

MULTIPROG by function blocks from the firmware libraries which are coming with

the software package.

The table below shows the related firmware libraries of the fieldbusses and other

interfaces.

To load the firmware libraries and use the function blocks follows those steps:

For further information to program your own function blocks, read the KW

Software MULTIPROG manual.

Interface Firmware Library

CANopen CIFNetx

SD Card PROCONOS

L-Bus (analog and digital monitor) IKS

CAN2.0 IKSCAN20

COM IKSCOM

MVB MVB-IKS

Serial Interface PCOSCom

The function blocks of the firmware libraries may not be triggerd several

times before the operation process of the block is completed. The state of

those function blocks are written by the outputs Done and Error. Non

compliance can cause errors.

1. Open MULTIPROG.

2. Make a right click on Libraries.

3. Choose Insertion >Firmware

Library.

4. Choose any firmware library.

5. Click Include.

6. The library appears under the folder

library in the project tree menu.

DIOLINE PLC ▪ Initial Operation – Software

47

7. In the project tree menu double

click on the POU in which the

function block should be insert.

8. Click on the work sheet. A cross will

appear.

9. In the toolbar click .

On the right side the menu Edit

Wizard appears.

10.Choose under Groups the firmware

library.

The names of the function blocks

will appear in a list.

11.Double click on the function block

which should be insert.

12.Define the function block.

13.Click OK to confirm your settings.

DIOLINE PLC ▪ Initial Operation – Software

48

Adding the POU to the Task

1. Click right in the project tree window

on any task.

2. Choose Insert.

3. Click Program Instance.

The window Insert appears.

4. Define a name for the program

instance.

5. Choose the program type (POU).

User defined functions and function blocks cannot be selected.

6. Confirm your settings by clicking

OK.

DIOLINE PLC ▪ Initial Operation – Software

49

11.3.3.1 Hardware Watchdog – IKSMonitor Digital

The function block controls the hardware watch dog. At every execution a signal

is sent to the hardware watch dog. This signalizes the correct operation of the

PLC. The outputs are displaying the different supply voltages of the system.

Additional the controlling of the APP LED (Input L0 and L1) and a hardware reset

of the PLC can be done by this function block.

If the PLC is in the RUN mode the IKSMonitorDigital function block has to

be triggered every 2 seconds. Otherwise there will be a hardware reset. The

POU which includes this function block has to be inserted in the task with a lower

cycle time than 2 seconds.

If the function block is not included in the bootproject , a reset is done

every two seconds, after the boot process (Endless Loop). To avoid the start

up of this bootproject see chapter "Maintenance Software" on page 116.

Input Description Type

L0 Input L0 controls the green state of the APP

LED.

BOOL

L1 Input L0 controls the red state of the APP

LED.

BOOL

L2 Input L2 – NOT USED BOOL

Reset In case of an increasing slope the system is

reseted after 2 seconds.

BOOL

Output Description Type

Supply_5 Displays the value “TRUE” if the power

supply is in the thresholds of 4.75 V..5.25 V.

BOOL

Supply_3_3 Displays the value “TRUE” if the power

supply is in the thresholds of 3.15 V..3.45 V.

BOOL

Supply_1_5 Displays the value “TRUE” if the power

supply is in the thresholds of 1.4 V.. 1.6 V.

BOOL

ResetRequest Displays if there is a request for a restart. BOOL

DIOLINE PLC ▪ Initial Operation – Software

50

11.3.3.2 IKSMonitor Analog

Shows all measured voltage values by the controller and the version of the PLC

firmware and the MAC address of the ethernet interface.

Output Description Type

Supply_5 Displays the analog power supply of 5 V. REAL

Supply_3_3 Displays the analog power supply of 3.3 V. REAL

Supply_1_5 Displays the analog power supply of 1.5 V. REAL

Version Displays the PLC firmware version. STRING

MacAdr Displays the MAC address of the TCP/IP

stack.

STRING

DIOLINE PLC ▪ Initial Operation – Software

51

11.3.4 ProConOS.INI

The ProConOS.INI is an initialization file which contains application specific

settings for following parameters:

▪ CANopen Slave

▪CAN2.0

▪ Serial Interface 1 and 2

▪ Parallel Flashdisk

▪MVB

▪ Retain Data Storing

The specific settings for the ProConOS.INI can be found in the different

configuration chapters.

The file can be created with any text editor or an example file can be downloaded

in the download section.

The entries of the file are case sensitive.

If the file was deleted on the PLC, default values will be set.

To Load the file on the PLC, see chapter "Download of Configuration Files" on

page 99.

DIOLINE PLC ▪ Initial Operation – Software

52

11.3.5 Variables

The valid area of the variables is local or global. The variables are declared by the

location, type and the name.

Following types are supported by MULTIPROG:

Type Description Bit

length

Range

TIME Time length 32 +#4.294.976.295 ms till

+#4.294.976.295 s

STRING string with max. 80

characters

BOOL Boolean 1 0 or 1

BYTE Bit string 8 0x00 till 0xFFh

REAL Floating point

number

32 +/-1.18x10^-38 till +/-3.40x10^38

LREAL Long floating point

number

64 +/-1.798x10^+308till +7-

2.225x10^-308

WORD Bit string 16 0x0000h till 0xFFFFh

DWORD Bit string 32 0x00000000h till 0xFFFFFFFFh

INT Integer with

algebraic sign

16 -32768 till +32767

UINT Integer without

algebraic sign

16 0 till 65535

SINT 8 bit integer with

algebraic sign

8 -128 till 127

USINT 8 bit integer without

algebraic sign

8 0 till 255

DINT Double integer with

algebraic sign

32 -2.147.483.648 till 2.147.483.647

UDINT Double integer

without algebraic

sign

32 0 till 4.294.967.295

DIOLINE PLC ▪ Initial Operation – Software

53

11.3.5.1 Globale Variables

The global variables can be used in the whole project. The variable has to be

declared as VAR_GLOBAL in the global variable datasheet. In the single POUs,

where the variable is used, it has to be declared as VAR_EXTERNAL. To allocate

global variables proceed as follows:

1. Double click Global Variable of the

used ressource.

The variable sheet appears:

2. Make a right click in the cell

“Default”

(The name can be changed).

3. Choose Insert variable.

A new row appears.

4. Make a right click in any cell.

5. Choose Properties....

DIOLINE PLC ▪ Initial Operation – Software

54

Type in one of the expressions followed by an address like in the following

example:

▪ %IB 1

Adresses the first bit of the first byte.

%IX 1.1

The first number adresses the first byte. The second number addresses the

first bit of the first byte.

6. Set the properties:

▪ Name

Type in a unique name for the

variable.

▪ Type

Choo s e a t ype f or t he variables. The

different types are listed in the

chapter “Variables“.

▪ Usage

The usage will be automatically set

to VAR_GLOBAL.

▪ Initial Value

An initial value can be defined for

the variable which will be set at PLC

starup.

▪ Address

With the address it is possible to link

a memory address, which can be

used by a driver.

With this operation variables can be

mapped for the fieldbus

communication.

For the fieldbus address

configuration see chapter

"Configuration of the Fieldbusses

and other Interfaces" on page 58.

▪ Description

You can type in any notes you want.

To define the mapping between the

variable and the driver it is necessary to

choose one of the expressions:

%IX Input Bit

%IB Input Byte

%IW Input Word

%QX Output Bit

%QB Output Byte

%QW Output Word

%MX Memory Bit

%MB Memory Byte

%MW Memory Word

DIOLINE PLC ▪ Initial Operation – Software

55

▪ %IW 1

The first number adresses the first and second byte at the same time.

▪ Init

Type in a start value for the variable. Depending on the data type.

▪ Retain

The marked variables are defined with the memory cycle time in the

PROCONOS.INI or by triggering the WriteRetain function block. More

Information can be found in the chapter see chapter "Retain Variables" on

page 57“.

▪ PDD – Process Data Directory

The operating system can directly access those variables. For example the

variables are needed for serial interface or symbolic variables access.

▪ OPC – OLE for Process Control, Object Linking for Embedding

Needed for the visualization of variables in ProVisIT. Check the box if you want

to visualize this variable in ProVisIT.

Function block instances are used like local variables.

DIOLINE PLC ▪ Initial Operation – Software

56

11.3.5.2 Local Variables

Local Variables can just be declared in the POUs datasheets. To allocate local

variables proceed as follows:

1. Double click Global Variable of the

selected POU in the project tree.

2. The variable sheet appears:

Make the same settings as

described in chapter “Global

Variables”.

3. Different settings have to be made

under Usage.

▪ Usage

Choose between:

▪VAR – for a local variable

▪VAR_EXTERNAL – for a link to a

global variable. The parameters

name and type have to be the

same as set in the global

variable.

If defining variables in function blocks, additional options under Usage c an

be set. For more information read the MULTIPROG KW Software manual.

Do not use the option VAR_IN_OUT for variables in function blocks.

It can cause data inconsistency.

DIOLINE PLC ▪ Initial Operation – Software

57

11.3.5.3 Retain Variables

All variables which are marked with RETAIN can be stored in the FRAM.

The storing cycle time can be configured in the ProConOS.INI.

The function block WRITE_RETAIN can also be used to trigger the storing cycle

time through a MULTIPROG project. If using the function block set the interval in

the ProConOS.INI to 0.

Function Block

Insert the firmware library PROCONOS and insert the function block

WRITE_RETAIN if the saving time of the variables should be controlled by the

function block.

ProConOS.INI

[Retain]

Intervall=2000

Cyclic storage interval in ms.

(0=disabled)

Input Description Type

IN At a increasing slope all checked retain variables

will be written on the FRAM

BOOL

Output Description Type

DONE If the value TRUE is set, the data was written on

the FRAM.

BOOL

If using the FRAM variable at the same time as the function block set date time,

a delay of the tasks can occure.

DIOLINE PLC ▪ Initial Operation – Software

58

11.4 Configuration of the Fieldbusses and other Interfaces

11.4.1 L-Bus Configuration

To control the DIOLINE20 modules, which are connect via the L-Bus, it is

necessary to configure the driver of the L-Bus.

Th e L-Bus driver is byte organize d. Every L-Bus module has a predefined amount

of input and output bytes. The total configuration of the bus is the sum of all

module bytes. The bytes are counted from left to right. It starts with the first

module connected to the PLC to the last module in the L-Bus chain.

The second driver needs the parameter offset. The offset is the amount of bytes,

which are used before the first analog module byte. If problems occurring during

the L-Bus configuration contact us.

In the I/O configuration set up the drivers with input and output bytes. Out of that

configuration a start address is defined. Input- and output addresses can be

equal, like in the following example. From the start address the first byte of the LBus module chain is reachable.

11.4.1.1 L-Bus I/O Configuration

The following steps are describing the configuration of a 8 DI/8 DO module.

If working with analog modules the modules can be adressed by words.

The modules have to be physically on an even byte address, otherwise a new

start address has to be defined for the analog modules in a second driver

configuration.

If using the SD-Card and the L-Bus interface at the same time there might

be some delays in the data transfer of the L-Bus. The L-Bus and SD card

sharing the SPI interface.

1. Double click I/O_Configuration in

the project-tree window.

The window I/O_Configuration

appears.

Configuration INPUT

1. Click on the register INPUT,

2. Click Add to add an input driver.

DIOLINE PLC ▪ Initial Operation – Software

59

The window Adding I/O group appears:

3. Type in the name of the interface.

4. Choose the task of the L-Bus driver

in which it should be processed

5. Type in an unused start address.

6. Type in the length of input bytes

which are used by the L-Bus. The

length in this case is 1.

7. Choose under Board/I/O-Modul the

item IKS LBUS.

8. Click on Driver parameters.

The window driver information

appears.

9. Set the offset to 0, if using one

driver.

10.Confirm the settings by clicking OK.

11.Confirm the settings in the window

Add I/O Groups by clicking OK.

The driver should not run in the Default task. It can cause data inconsistency.

Do not press enter. The configuration will not be set.

DIOLINE PLC ▪ Initial Operation – Software

60

12.Confirm the settings in the window

Add I/O Groups by clicking OK.

Configuration OUTPUT

1. Click on the register OUTPUT,

2. Click Add to add an Output.

The window Adding I/O group appears:

3. Type in the name of the interface.

4. Choose the task of the L-Bus driver

in which it should be processed.

5. Type in an unused start address.

6. Type in the length of output bytes

which are used by the L-Bus. The

length in this case is 1.

7. Choose under Board/I/O-Modul the

item IKS LBUS.

8. Click Driver Parameters.

9. The window Driver Information

appears.

10.Set the offset to 0, if using one

driver.

11.Confirm the settings by clicking OK.

Do not press enter. The configuration will not be set.

To allocate the variables for the L-Bus bytes read chapter see chapter

"Globale Variables" on page 53.

The driver should not run in the Default task. It can cause data inconsistency.

DIOLINE PLC ▪ Initial Operation – Software

61

11.4.1.2 L-Bus Function Blocks

The embedding of following function blocks from the IKSL-Bus library is

necessary.

L-BusInfo

The function block displays the state of the L-Bus interface and is used for the

parameterization.

The function block has to be implemented in a POU which is executed in the task

of the L-Bus I/O driver.

In the case of data inconsistency the L-Bus data will still be transmitted to

the used task. To avoid wrong data values in the program the function block

L-Bus Info must be executed and checked for errors before using the L-Bus data.

Input Description Type

Restart An increasing slope restarts the

initialization process of the L-Bus chain.

BOOL

ClearMax At an increasing slope the Output

MaxCycleTime is resetted.

BOOL

ContinueOnTime If the input is TRUE the L-Bus will still

run at a time error.

BOOL

ContinueOnOccurence If the input is TRUE the L-Bus will still

run at a occurrence error.

BOOL

MinMeasureTime Defines the minimal time of the cycle.

The L-Bus is not served faster than the

pending time. The function can be

disabled by the value 0. The default

value is 20 ms.

TIME

Use the MinMeasureTime value to process the L-Bus as often as needed

and as unusual as possible. By using this value the total system load of the

PLC can be kept low.

FailureAcceptanceTime Defines the maximal cycle time. The

standard value is 500 ms.

TIME

MaxErrorOccurence Defines the amount of error cycles

without a correct one in between. The

input is set 5, because the L-Bus is just

allowed to lose 5 frames in a row till an

error is displayed or the L-Bus is

stopped.

INT

Output Description Type

LastCycleTime Displays the time of the last L-Bus

cycle.

TIME

MaxCycleTime Displays the max. cycle time. TIME

DIOLINE PLC ▪ Initial Operation – Software

62

L-Bus Device

The L-Bus device function block displays the state of the connected DIOLINE20

modules. You need to insert one function block for every device.

AverageCycleTime Displays the average time of the 10 last

cycles.

TIME

SlaveCount Displays the number of the connected

DIOLINE20 modules.

INT

Run Signalizes that the L-Bus is initialized

correct. The L-Bus is running.

BOOL

Stop Signalizes that the L-Bus is stopped. No

communication of the L-Bus.

BOOL

Init The Output is active during the

initialization process of the L-Bus.

BOOL

Error Displays an error number. For the error

numbers see chapter "L-Bus

Configuration" on page 58.

INT

CycleErrorCount Displays the number of incorrect cycles.

Every report fault increases the value

multiplied by 1000. Every correct report

decreases the value by 1.

UINT

WD_LBus Watch Dog of the L-Bus, signalizes if

the time of the L-Bus is exceeded.

BOOL

WD_PLC Watch dog of the PLC, signalizes if the

time of the PLC is exceeded.

BOOL

ComError Displays TRUE if the last L-Bus cycle

has a protocol error.

BOOL

TimeError Displays TRUE if the

FailureAcceptanceTime is exceeded.

BOOL

OccurenceError Displays TRUE if the value of

MaxErrorOccurence is exceeded.

BOOL

Version Displays the version of the L-Bus

software.

REAL

After a frame break of 130 ms the L-Bus modules will go in the status

failsafe. This is a L-Bus module characteristic and can not be influenced by the

PLC.

The stop mode does not reset the L-Bus moduls. After the failsafe time the

outputs of the modules will be adjusted to zero.

Input Description Type

SlaveNo Defines the number of the connected I/

O modules. The first connected module

to the PLC is counted 0. The number is

increasing with every module.

INT

DIOLINE PLC ▪ Initial Operation – Software

63

Output Description Type

Type Displays the type ID. For a ID list see

chapter "DIOLINE 20 Module Types" on

page 135.

INT

Error Displays an error number. For the

description of error number, see

chapter "Error Treatment" on page 125.

INT

InputLen Displays the length of the input bytes of

the module.

INT

OutputLen Displays the length of the output bytes

of the module.

INT

DIOLINE PLC ▪

64

11.4.2 SD Card Configuration

With the SD card it is possible to read and write data during the runtime. The data

format is FAT. The written files will be stored in the ASCII format.

11.4.2.1 SD Card Function Blocks

FileOpen

The function block opens an existing file or creates a new one.

FileRead

The function block reads data from a file.

Make sure that you are using a special industrial card which is specified

by Lütze.

If using the L-Bus interface and the SD-Card at the same time there might

be some delays in the data transfer of the L-Bus. The L-Bus and SD card

sharing the SPI interface.

Input Description Type

Execute Opens an existing file or creates a new one if a

increasing slope is pending

BOOL

Name Defines the name of the file.

Filename: 8 characters for the name and 3 for the

extension

STRING

Output Description Type

Done Is TRUE if the file are opened or created

successfully.

BOOL

Handle Displays a handle value (≠ 0) for the chosen file. UINT

Error Is TRUE if an error occurred, otherwise the output is

FALSE.

BOOL

ErrorID Displays an error number. For an explanation of the

error numbers see chapter "FILE_OPEN" on page

127.

UINT

Input Description Type

Execute At an increasing slope the data of the specified file

will be read.

BOOL

Handle The output handle from the function block. UINT

Buffer The received data are stored in the buffer. ANY

MaxLength Defines the number of the characters which have

to be read.

UDINT

DIOLINE PLC ▪

65

FileWrite

This function block writes data in a file.

FileClose

The function block closes an opened file.

Output Description Type

Done Is TRUE if the data could be read correctly,

otherwise the output will be FALSE.

BOOL

LengthRead Displays the number of the characters which were

read.

UDINT

Buffer The received data are stored in the buffer. ANY

Error Is TRUE if an error occurred, otherwise the output

is FALSE.

BOOL

ErrorID Displays an error number. For an explanation of

the error numbers see chapter "FILE_READ" on

page 127.

INT

Input Description Type

Execute At an increasing slope the data of the specified

file will be written.

BOOL

Handle The output handle from the function block.

FileOpen has to be used.

UINT

Buffer The written data are stored in the buffer. ANY

Length Defines the number of characters which has to

be written.

UDINT

Output Description Type

Done Is TRUE if the data could be written correctly,

otherwise the output will be FALSE.

BOOL

LengthWritten Displays the number of written characters. UDINT

Buffer The written data are stored in the buffer. ANY

Error Is TRUE if an error occurred, otherwise the output

will be FALSE.

BOOL

ErrorID Displays an error number. For an explanation of

the error numbers see chapter "FILE_WRITE" on

page 128.

UINT

Input Description Type

Execute At an increasing slope the specified open file will

be closed.

BOOL

Handle The output handle from the function block

FileOpen has to be used.

UINT

DIOLINE PLC ▪

66

Output Description Type

Done Is TRUE if the file could be closed correctly,

otherwise the output will be FALSE.

BOOL

Error Is TRUE if an error occurred, otherwise the output

will be FALSE.

BOOL

ErrorID Displays an error number. For an explanation of

the error numbers see chapter "FILE_CLOSE" on

page 128.

UINT

DIOLINE PLC ▪

67

11.4.3 PFD – Parallel Flash Disk

The Parallel Flash Disk saves diagnostic data, which are defined by the user. The

memory is permanent. It can save a defined amount of data.

ProConOs.INI

The PFD is organized in two superior

data sections.

The section size can be configured by

the user, the sum of the two sections

cannot be bigger than 2 MB (2048KB).

At the configuration, notice that the size

of one section must be divisible by 128

the sum must be an integer. The

minimum size of one section must be

256 kB. The sections are divided into

slots. The slot s are the a ctua l ent ries of

the PFD. The slot size can also be user

defined. The size has to be organized

in bytes. The amount of bytes has to be

divisible by 2, the sum must be an

integer. Additional to every slot a

header of 16 Bytes will be automatically

added.

The header contains the following data:

Byte Description

0 – 1 CRC Checksum

2 – 3 Res1

4 – 7 Internal Timestamp

8 – 9 Defect1

10 – 11 Defect2

12 – 15 ID Counter

Use the following formula to calculate

the usable amount of slots (entries):

[ParFlashSect@1]

Mode=Ring

SlotSize=1024

SctSize=256

[ParFlashSect@2]

Mode=Ring

SlotSize=2024

SctSize=512

Section1

Saving mode Ring or Once

Slot Size in Byte

Section Size in kByte

Section 2

Saving mode Ring or Once

Slot Size in Byte

Section Size in kByte

DIOLINE PLC ▪

68

11.4.3.1 Saving Modes

Ring Mode

The flash memory is physically organized by pages. Every page has a size of

128 kB. If deleting data the flash will always delete the minimal amount of one

page (128 kB).

If the memory is full and additional data want to be saved, in that mode the oldest

data will be deleted and the new data will be written. The slots which are stored

in this page will be lost.

Example:

▪ Section Size 1024 kB

▪ Slot Size 128 Byte

7281 Slots=(1024 kB)/(128 Byte+16 Byte)

One page contains:

Slots in one Page 910=(Page Size 128 kB)/(Slot Size 128 Byte+ Header 16 Byte )

Slots which are saved in every case: 7281 Slots - 910 Slots = 6371 Slots

In the worst case 12.5% of the section is empty.

Once Mode

The slot size and the section size has to be defined. In the memory data can be

written till the section is full. The section will signalized the end of memory.

The calculation of the slot number can also be done as for the Ring Mode. In the

once mode pages are not automatically deleted. If the section is full, the

application will signalize. The section can be deleted completely or described

from the beginning.

11.4.3.2 PFD Functional Blocks

The embedding of following function blocks from the PFD library is necessary.

PFDStatus

The function block displays the state of the two sections.

With this block it is also possible to delete data manually out of the application.

Input Description Type

ActErase1 At an increasing slope the memory of section

1 will be deleted.

BOOL

ActErase2 At an increasing slope the memory of section

2 will be deleted.

BOOL