BEDIENUNGSANWEISUNG

mit Montageanweisungen

Instructions for use and installation instructions

Instructions d’ utilisation et avis de montage

Gebruiksaanwijzing en montagehandleiding

KEH 650.0

07 22 53 G41

For your information

Please read the information in this leaflet carefully. It contains important instructions for the safety, installation, use and maintenance of your appliance.

The appliance is only intended for the preparation of food in the home.

Please keep the operating instructions in a safe place.

The appliance belongs to appliance category 3.

If any changes are made to the appliance and its connection, this will

impair the appliance’s safety and proper functioning in all other countries.

Conditions of guarantee

The conditions of guarantee applicable for this product are those published

by our representative in the relevant country.

Details regarding these terms of guarantee may be obtained from the dealer

from whom the appliance was purchased. The sales receipt must be

produced when making claims under guarantee.

Contents

Your cooker at a glance . . . . . . . . . . . . . . . . . . . . . . . 22

Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

for connection and functions

for the gas hob

for the oven

Before first use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Disposing of the packaging and the old appliance

Initial cleaning

Setting the time

Using the rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setting the burners

Notes on the right types of saucepan

The oven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Selecting the heating mode and temperature

Switch symbols and heating modes

Shelf levels

Slide-in accessories

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting the time

Minute minder

Switching the oven off automatically

Switching the oven off and on automatically

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Roasting

Baking

Thawing

Baking pizza

Preserving

Grilling

backmobil (special accessory no. 600) . . . . . . . . . . . . . . . . 29

Cleaning and caring . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rings

Regenerating the ökotherm

®

backmobil

Oven

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Nameplate

Installation instructions for fitter . . . . . . . . . . . . . . . . . . 31

Planning the supply lines

Installing the cooker into your fitted kitchen

Installing the glass ceramic gas hob

Installation into the hob

Checking the supply lines

Checking the ring burners

Factory setting / conversion possibilities . . . . . . . . . . . . . . . 35

Table of permissible types of gas and pressures

Table of injector sets

Conversion injector sets

Table of heat input

Gross calorific values according to EN 437

Resetting the ring burners

Final assembly

KEH 650.0 21

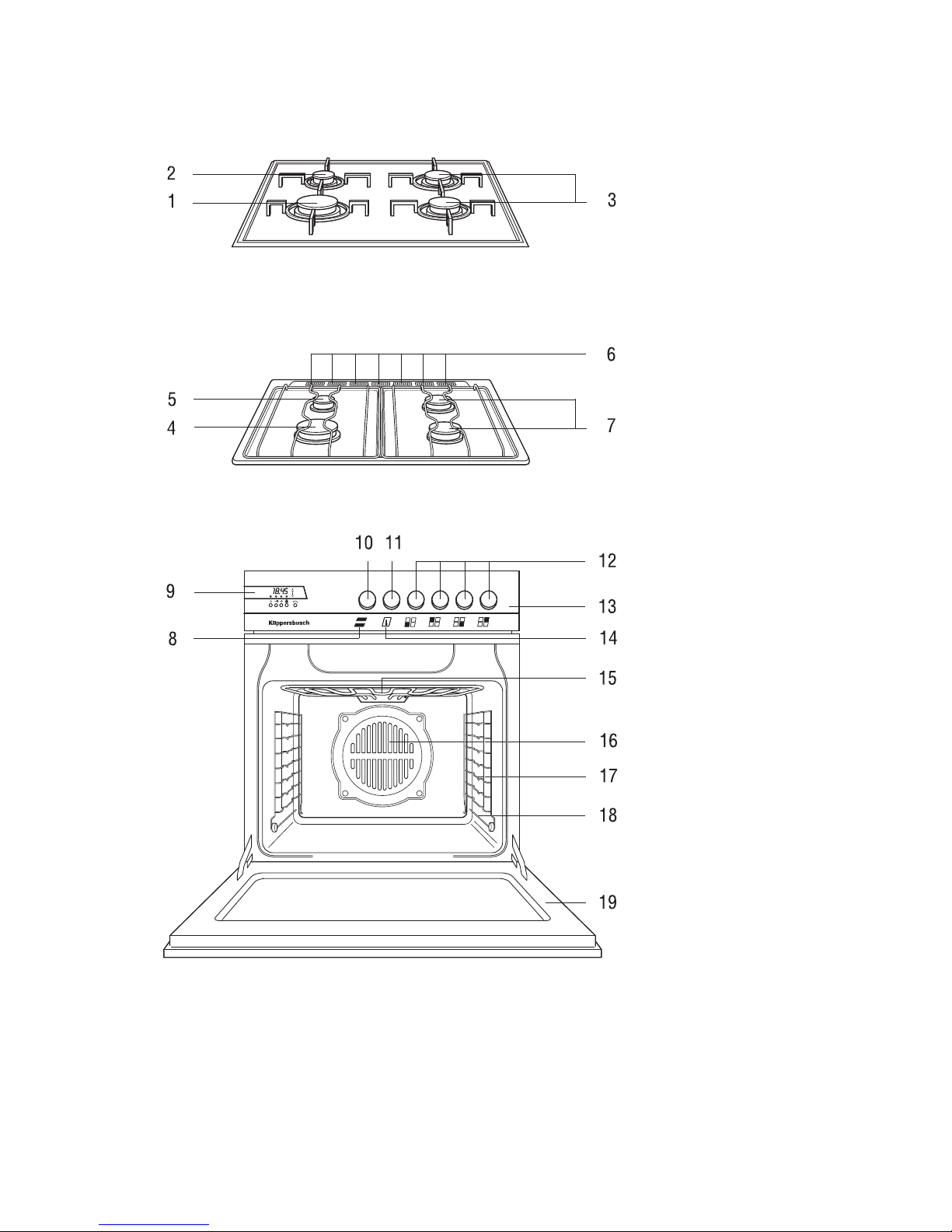

Your cooker at a glance

1 High speed ring

2 Simmering ring

3 Standard ring

4 High speed ring

5 Simmering ring

6 Ventilation slits

7 Standard ring

8 Oven function indicator

9Timer

10 Oven function switch

11 Oven temperature switch

12 Hob controls

13 Control panel

14 Heating indicator

15 Fold-down grill (top heat/grill)

16 Hot air fan

17 Side grids

18 Frame

19 Oven door

Available accessories:

Grilling rack with lifter acc.-no. 125

Pizza slab acc.-no. 126

Ring for small pots acc. no. 160

Roasting grid acc.-no. 440

Roasting tray acc.-no. 441

Infrared grill acc.-no. 540

Baking tray, enamel acc.-no. 541

Drip pan acc.-no. 543

backmobil

acc.-no. 600

22 KEH 650.0

Safety instructions

for connection and functions

Before the appliance is installed, it must be checked whether the local

supply conditions (type of gas and gas pressure) and the settings of the

appliance correspond. All settings for the appliance are stated in this

user guide. This appliance should not be connected to a pipe for extracting

combustion products. It must be fitted and connected in accordance with

the applicable conditions of installation. Particular attention should be

paid to suitable ventilation measures. The use of a gas cooker causes

heat and humidity to build up in the room where the cooker is installed. For this reason it should always be ensured that the kitchen is

well ventilated; keep the ventilation slits open or provide for a mechanical ventilation facility (e.g. a cooker hood). If the appliance is subject to

particularly intensive use or use over a long period of time, it might be

necessary to provide for additional ventilation, e.g. by opening a window or operating a cooker hood at a high power level.

Küppersbusch cookers are made according to the applicable safety

regulations. Only Küpperbusch ovens may be connected to Küpperbusch hobs.

The appliance should only be connected to the gas mains by a qualified

gas fitter. The same applies for all adjustments and conversions. Attention

must be paid to the statutory regulations at all times. It is also

necessary to observe the instructions of the relevant gas board for

connecting up the appliance.

The cooker should only be installed in a well ventilated area.

Do not use the cooker for heating rooms.

If problems occur during operation the gas supply should be turned off

immediately.

The appliance should only be serviced and repaired by a qualified

technician in accordance with the applicable safety regulations. When

repair jobs are being carried out on any equipment running on gas, it is

always important to turn off the gas supply. Work carried out incorrectly

places your safety at risk.

If the cooker is run on liquefied petroleum gas (propane/ butane) it is vital to

ensure that all joints between the gas bottle and the cooker are secure and tight.

External flexible supply hoses should not be wedged into tight positions

or laid cross hot surfaces.

The surfaces of the oven, oven door and hob are very hot when in

operation. Always keep children away!

Connection leads of electrical appliances should not be placed on the

hot hob or be allowed to become jammed in the hot oven door.

Do not lift the appliance by the handle of the oven door.

We recommend that you have the appliance serviced at regular intervals.

WARNING! This appliance must be earthed!

for the oven

When repairs are being carried out or oven light bulbs are being

replaced, the cooker must be disconnected from the mains (switch off

the fuse).

Never store any objects in your oven which could cause a hazard if the

oven is unintentionally switched on.

Take special care when working with a hot oven. Use a dish cloth, oven

gloves or similar.

The oven door must close well. In the event of damage to the door

sealing, hinges, sealing surfaces or to the glass pane, do not use your

cooker until it has been repaired and checked by a qualified and

authorised installer.

Caution! When opening and closing the oven door, do not reach into the

hinge. Risk of injury!

Always close the oven door completely when food is being cooked in

the oven.

Keep at least 5 cm away from the grill and top heat.

for the hob

Cooker hoods above the hob must be fitted at a minimum distance of 650 mm.

The rings should not be ignited unless you are cooking something.

Always ensure that the plug-on rings and burner tops are in the correct

position.

Attention: The electronic automatic spark ignition will not work if there is

a power failure! In such cases please use matches.

Overheated fats and oils may spontaneously ignite. Food cooked in fat or

oil, e.g. chipped potatoes, should only be cooked under supervision.

Never extinguish ignited fats and oils with water! Put the lid on the pan,

switch off the ring and remove the pan from the hot hob.

Pressure cookers should be constantly supervised until the correct

pressure has been reached. First turn the burners of the rings up to

maximum flame and then (following the instructions of the manufacturer

of the pressure cooker) turn the heat down in good time.

The ventilation slits in the hob should not be covered over.

Food which is placed in the oven to be heated later may have gone off

by that time.

High surface temperatures may occur during the regeneration of the

ököthermâ catalyst. Keep children away.

If the oven temperature deviates too much from the preset value, have

the temperature controller repaired.

If the cooling fan (cross-flow fan) fails, switch the oven off and call the

customer service.

Before first use

Disposing of the packaging and the old appliance

Dispose of the transport packaging in such a way that is not harmful to the

environment.

If the appliance is purchased in Germany the dealer who sold you the appliance will dispose of the transport packaging for you. Recycling the packaging saves raw materials and reduces the amount of waste disposed

appliances still contain useful materials. Dispose of your old appliance at a

collection point for recycling useful materials.

Before disposing of your old appliance ensure that it cannot be used any

longer. This will prevent misuse.

Initial cleaning

Remove foreign objects and the packaging.

Before preparing meals for the first time clean the inside of the oven and all

accessories thoroughly.

Clean the glass ceramic hob, baking sheets, drip pan, gridiron, core temperature probe etc. with a damp cloth and a little washing-up liquid

Heating up the oven: Shut the oven door. Heat up the oven by switching

on the top and bottom heat at maximum temperature for 60 minutes.

Air the kitchen well while you are doing this.

KEH 650.0 23

Setting the time

If the timer flashes, this means that the time has not been set. Proceed as

follows:

hold and

pressed set the time.

Using the rings

Take note of the safety instructions on page 23!

Switching the cooking zones on and off

Each cooking zone has its own regulator, which can be pushed down.

The symbols on the control panel indicate which regulator operates which

cooking zone.

The cooking zone burners are ignited by an electric spark.

They can also be lit with matches or something similar (e. g. in the event of

power failure).

Igniting the cooking zone burners:

- Release the depressed cooking zone

regulator by pressing down.

- Turn the regulator anti-clockwise to

the high position and press in

halfway, until a resistance can be

felt. The flame has been ignited.

- Keep the cooking zone regulator

down for another 5-10 seconds and

press in firmly once more, before releasing. The flame is now burning.

If at any time the flame does not light successfully, allow about two seconds and repeat the procedure. Press the control knob in slightly longer

and possibly a little bit more firmly.

Adjusting the setting:

The maximum and minimum settings are marked on the cooking zone regulators. The flame can be regulated directly.

- Bring to the boil at a high setting if

possible and continue simmering at

a low setting.

Switching off the cooking zone burners:

- Turn the cooking zone regulator clockwise to zero setting.

All cooking zone burners are protected thermoelectrically. If at any time the

flame is extinguished unintentionally (e. g. due to pans boiling over or due

to a strong draught), the gas supply switches off automatically.

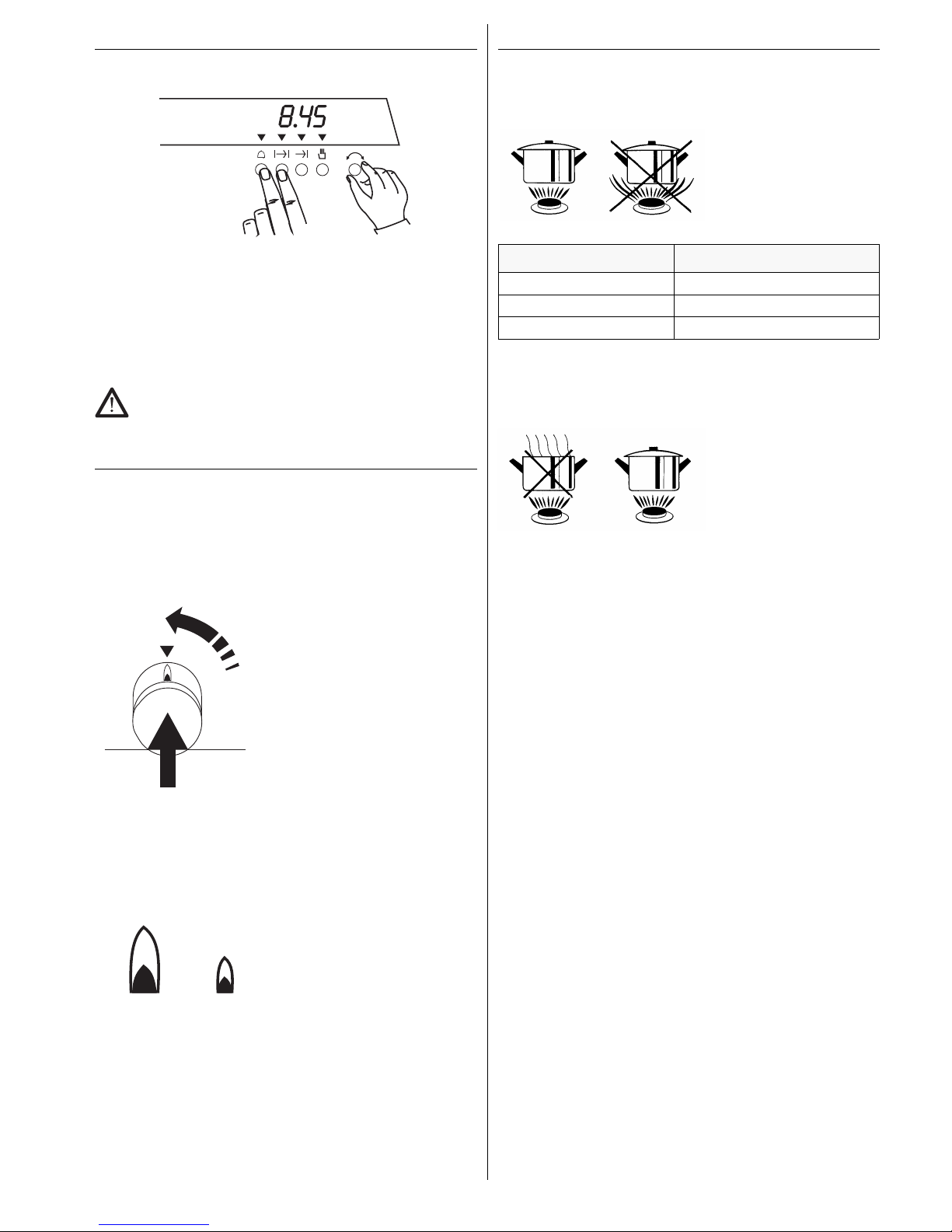

Notes on the right types of saucepan

Using the right types of saucepan will help you to save energy and cut

down on cooking times.

Make sure that the diameter of the saucepan base fits the ring.

Place the saucepan onto the

ring so that the two fit correctly.

The flame should completely

cover the area at the bottom of

the saucepan, but should not

burn round it at the sides.

Ring Diameter of saucepan base

High-speed ring (2.8 kW) 240 - 260 mm

Standard ring (1.9 kW) 200 - 220 mm

Simmering ring* (1.1 kW) approx. 160 mm

*Small pots can also be used using the small pot ring only on the highspeed ring (acc. No. 160).

Always make sure that the lid is on the saucepan.

The food will only boil over if the

flame is set too high. With a

little practice you will learn to

set the flame to just the right

heat so that the food will not

boil over, even when the lid is

on the saucepan.

24 KEH 650.0

The oven

Please note the safety instructions on page 23!

The oven becomes very hot when in use. If the oven temperature exceeds

95°C the cooling fan will switch on, even if the oven has been switched off.

The oven offers you eight operation modes.

Selecting the operation mode and the temperature

Selecting the operation mode:

Turn the oven selection switch (the

switch on the left) to the right.

Setting the temperature:

Turn the temperature selection switch

(the 2nd switch from the left) to the right.

The heating up indicator on the operation fascia will light up while the appliance is heating up and will go out as soon as the set temperature has

been reached.

The controls are of the pop-out type and can be countersunk in every setting. They pop out at a slight press of the finger. No settings can be made

while the controls are countersunk. If the oven selection switch is countersunk the oven lighting will switch off.

Symbols and operation modes

0

OFF

! Oven lighting

# Hot air convection Roasting, baking and cooking on several le-

vels.

# Cold air convection without temperature setting, for gently tha-

wing and cooling food.

$

Top heat/bottom heat Preheating,

Baking sponges and moist cakes.

- Bottom heat Prebaking very moist cake, preserving.

. Top heat Browning

*

Grilling Grilling small portions. Position the pieces of

meat at the centre of the roasting rack.

+

Large-area grill For grilling larger portions such as steak,

fish and sausages, but also for browning

toast dishes and gratins.

0 Intensive hot air

convection

For baking large flat cakes with a dry topping, such as a crumble topping, for intensive roasting of large joints and large birds

such as goose or turkey.

Pizza mode For baking bread, pizza and moist cakes,

also for preserving

The oven offers five heating modes.

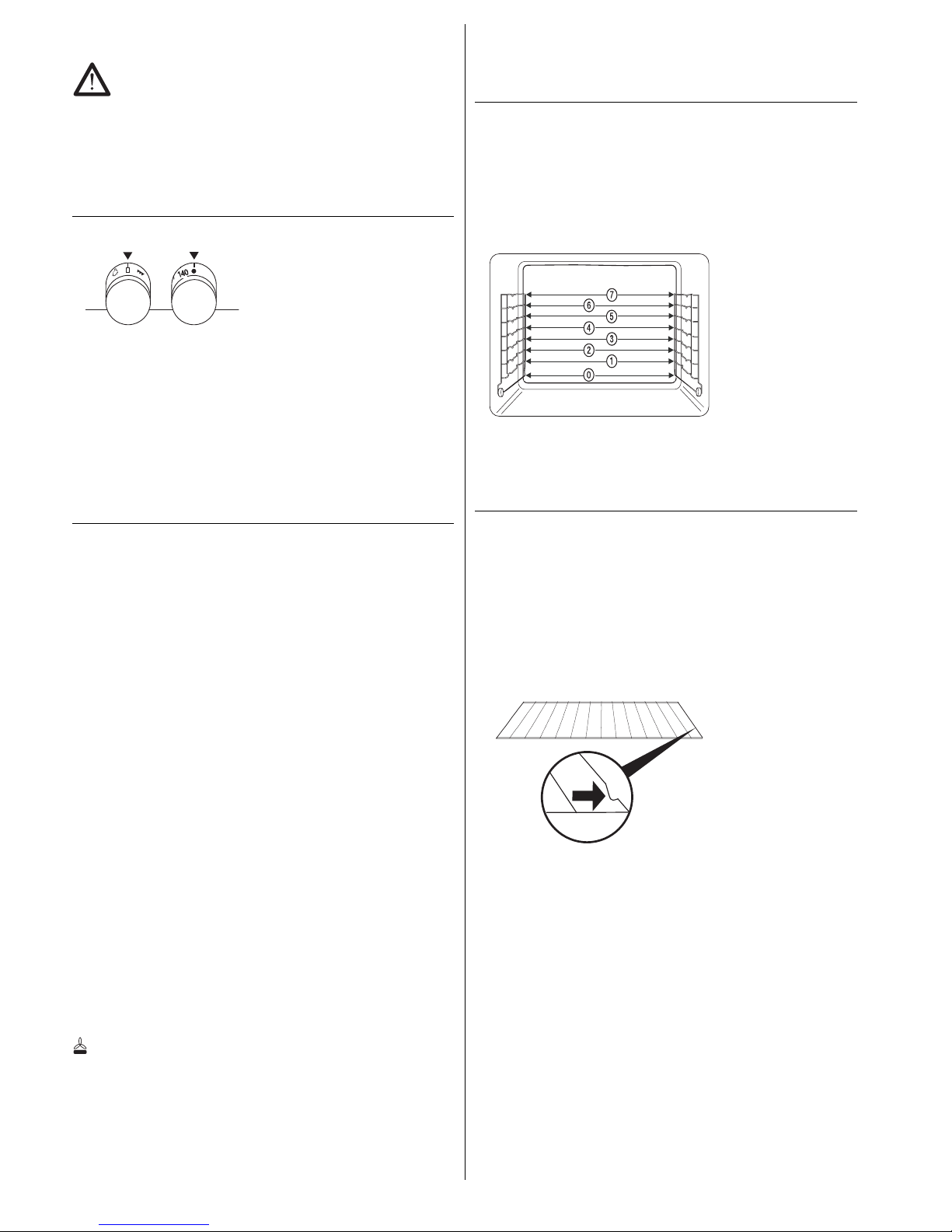

Shelf levels

The oven has grids on both sides each with 8 shelf levels. They form the levels 0 to 7.

The level heights are counted from the bottom upwards (see diagram).

For example, the drip tray when roasting, baking tray with a pizza or the

grid with the pizza stone can be inserted in level 0.

The grid and/or baking trays can be inserted into levels 1 to 7 depending

on the food being cooked.

Instructions on which shelf to use can be found in the baking and roasting

table.

Slide-in accessories

Do not cover the bottom of the oven with aluminium foil!

Baking sheets:

When removing the baking sheet lift it slightly.

When the baking sheet is slid back into the oven the slanted edge must

face the oven door.

Push the fat pan and baking tray with the two slots right into the rear of

the oven.

Gridirons:

Please make sure that the lock-in position of the gridirons

always faces the front (towards you).

KEH 650.0 25

Timer

The timer allows you to control the cooking time for all heating modes. The

selected heating modes can be switched off automatically via the timer. The

timer can also be used as a reminder (minute minder).

Display: 1clock

with function button:

minute minder time/ cooking time/

end of cooking time

2 automatic display

Selecting: 4 minute minder

7 oven cooking time

8 end of oven cooking time

Setting: c minute minder time / cooking time /

end of cooking time

f A mode selection switch

f B oven temperature control

Setting the time

Hold 4 7 pressed and

set the time with c .

Minute minder

The minute minder will not switch the oven off. It only serves as a reminder.

Hold 4

pressed,

c set the time.

Release 4 .

The set time will immediately begin to

count down. When the set time has

elapsed a signal will sound.

Press 4 to switch off the signal.

Switching the oven off automatically

When the set cooking time has come to an end the operation functions

selected via f A and f B are automatically switched off.

Press 7 and set the required cooking

time with c .

Release 7..

Automatic operation will begin; “AUTO”

will light up in the display.

f A Select heating mode,

f B Set the temperature.

At the end of the cooking time

At the end of the cooking time a signal will sound and “AUTO” will blink.

Set f A and

f

B to “0”.

Press the n button to return the oven to normal operation. The signal will

stop.

Switching the oven off and on automatically

The functions selected via f A and f B will automatically switch on at

the selected starting time and switch off at the set time.

Hold 7 pressed and set the cooking

time with c .

Release 7 .

Hold 8 pressed and set the time when

the oven is to switch off with c .

Release 8 .

f

A Select heating mode,

f B Set the temperature.

At the end of the cooking time

At the end of the cooking time a signal will sound and “AUTO” will blink.

Set

f

A and

f

B to “0”.

Press the n button to return the oven to normal operation.

The signal will stop.

Checking the settings Press 7 – to display the remaining

cooking time.

Press 8 – to display the end of the

cooking time.

Switching off the automatic ahead of time, cancelling the settings

Press 7 and set to 00.00 with c .

Press n , to reset the appliance to normal function.

26 KEH 650.0

Applications

Roasting

Use the drip pan and the roasting rack.

The roasting time depends on the type of meat you are roasting and on the

thickness of the joint. To measure the joint, lift it slightly as it collapses

slightly under its own weight. The roasting time for meat with a layer of fat

can be as much as twice as long as usual.

Be absolutely certain to observe the notes on the rack levels!

0

Intensive hot air convection

Place drip pan into frame and roasting rack on 1st rack level from bottom.

#

Hot air convection

Place drip pan on 1st rack level from bottom and roasting rack on 2nd rack

level from bottom.

$

Top heat and bottom heat

Place the drip pan on the 1st rack level from the bottom and the roasting

rack on the 2nd rack level from the bottom.

Roasting in a pan (oven)

Select 0 Intensive hot air convection at a temperature of 180 to 200 °C.

You can use any type of pan (enamel-coated steel, cast iron or glass) which

does not have plastic handles.

We recommend the following procedure:

-

Rinse out the pan with water or grease it lightly

-

After preparing the meat (adding spices), place it into the pan. Put

the lid on the pan and place the pan onto the rack in the cold oven.

-

Select Intensive hot air convection and set the temperature to between 180 and 200 °C.

-

At the end of the roasting time prepare the gravy in the usual way.

Recommended temperatures for roasting

Dish Hot air

convection

Intensive

hot air

Cooking

time

Always turn the

joint

Temperature in °C

per cm of the

thickness of the

joint in mins

Joint of beef 160 18

Roast beef (English

style)

180 180-200 8-10

Fillet 180

180-200

8

Veal 160 160-180 12

Roas pork 160 160-180 12-15

Smoked loin of pork 160 160-180 8

Shoulder of pork

160

160-180 12-15

Roast pork with

crackling

160

160-180

12-15

Game 160 15

Wild boar

160

15

Fillet of game 180 180-200 8-10

Mutton 150-160 15

Duck 160 160-180 12

Goose 160

160-180

12

Chicken* 160 160-180 8

Turkey 160 160-180 12

Fish 160 8

* Whole chicken: 45 - 60 min

Thawing

with # Hot air convection

Remove the frozen food from the packing, place it in a dish and insert into

the oven with the rack on the 3rd rack level from the bottom. Set the tem-

perature to 150 °C

Baking

# Hot air convection

No need to preheat the oven - Baking is possible on several levels simultaneously.

Rack levels:

One baking tray 3rd rack level from the bottom

Two baking trays 3rd and 6th rack levels

Three baking trays 1st, 4th and 7th rack levels

Four baking trays 1st, 3rd, 5th and 7th rack levels

If you are baking several cakes in baking tins, about 5 to 10 minutes additional baking time will be needed for each baking tray.

Remove the baking trays individually, depending on how well

browned the cakes are.

Bake using hot air convection at a temperature of 160 °C, if there are no

instructions for baking by hot air convection in your recipe.

Important:

When cakes with a moist fruit topping are being baked, the development of

humidity is particularly high. You should bake no more than two cakes at

the same time.

$

Top heat/bottom heat

Preheating the oven - baking on one level.

Preheat the oven by intensive hot air convection and when the temperature

has been reached, set the oven back to Top heat/bottom heat.

Baking tins made of black metal and aluminium are particularly suitable.

0

Intensive hot air convection

No need to preheat the oven - baking on one level.

Only for large flat cakes with a dry topping, such as a crumble topping.

Pizza mode

Baking on one level

-

for moist cakes

-

for pizza: preheat the oven with a baking tray or a pizza slab (accessory)

-

for bread

Baking pizza

Set the operation mode selection

switch (the switch on the left) to

Pizza level.

Using the oven temperature regulator

(second switch from the left) set the

temperature to 250 °C.

Preheat the oven to 250 °C.

Example

Basic recipe for pizza

375 g of flour, 20 g of yeast, 1/8. l of lukewarm water,

3 tablespoons of oil, salt

Make a yeast dough out of the specified ingredients. Allow the dough to

rise for approx. 30 minutes until it has doubled in size. Then knead the

dough for a few minutes and allow it to prove for another 15 minutes.

Divide the dough into 2 or 3 pieces, roll out to a circle, form an edge and

add any topping you like, but do this quickly so that the dough does not become wet.

- Place the baking tray into the frame.

- Place the pizza onto the baking tray.

- Preheat the oven at Pizza level to a temperature of 250 °C.

- Bake for approx. 8 - 12 minutes and at a temperature of 250 °C.

KEH 650.0 27

Recommended temperatures for baking

The recommended temperatures for the best operation modes have been highlighted.

Type of cake

or biscuit

# Hot air convection

$

Top heat /

Bottom heat

0 Intensive hot air

convection

Pizza level

Baking time

Rack level Temperature

in °C

Rack level Temperature

in °C

Rack level Temperature

in °C

in mins.

Cake mixture

Large cake 3

150-160

1 170-180 50-65

Tin cake 3

150-160

1 170-190 50-70

Madeira cake 3

150-160

1 160-180 60-70

Gateaux and flans 3

150-160

1 170-180 40-60

Flan bases 3

170-180

2 180-200 20-30

Fine fruit flans 3 150-160 1 170-180 3

150-160

45-60

Small biscuits 3 150 2

170-180

15- 30

Large flat cakes:

With a dry topping 3 150-160 2 180 -190 3

0 150-160

25-35

With a moist topping 3 160-170 2 170-180 3

160-170

35-50

Kneaded dough

Flan bases 3 170-180 2

180-200

25-35

Cheese cake 3 150 1 160-170 3

140-150

70-90

Small biscuits 3 150 2

180-190

15- 35

Large flat cakes:

With dry topping 3 180 2 180-190 3

0 150-160

25-35

With moist topping 3 170 2 170-180 3

160-170

30-50

Leavened dough

Large cake 3

150-160

1 175-180 40-65

Ring cake 3

150-160

2 175-180 40-50

Small biscuits 3

140-150

2 180-200 15-30

Large flat cakes :

With dry topping 3 150 -16 0 2 180-190 3

0 150-160

25-35

With moist topping 3 160-170 2 170-180 3

160-170

30-50

Sponge cake

Gateaux and flans 3 150-160 2

175-180

30-40

Rolls 3 170-180 2

180-200

12- 25

Biscuits made with white of egg

Meringue 3

80-90

2 100-120 80-120

Cinnamon stars 3

100-120

2 120-140 20-40

Macaroons 3

100-120

2 120-140 20-50

Puff pastry

Puff pasty 3

170-180

2 190-210 15-30

Puff pastry made with

leavened dough

3

170-180

2 190-210 30-40

Puff pastry made with curd

cheese

3

160-180

2 180-200 30-40

Choux pastry 3

170-180

2 190-210 30-40

Pastry made with curd

cheese and oil

3

150-160

2 170-180 30-40

Honey cake 3

140-150

2 170-180 20-35

Bread and pizza

Leaven and bread made

with yeast:

Preheat: 230 °C

10 mins. at 230 °C

2 180 2/3 160 50-65

Bread made with

yeast/white bread

22003 180 30-50

Pretzels,

Preheat: 10 mins. at 230 °C

1 200 2 220 15-20

Pizza,

Preheat to 250 °C

0 250 8-12

28 KEH 650.0

Preserving

Select Pizza mode.

Only use fresh food and prepare according to the usual recipes. Prepare no

more than 6 preserving jars with a capacity of 1-1.5 litres at one time.

Only use jars of the same height which are suitable for preserving and

which have the same contents. The jars should not touch.

Fruit

-

Place the drip pan on the 1st rack level from the bottom and fill

about 1 litre of water into the drip pan.

-

Select Pizza mode and set to a temperature of 180 °C and observe

preserving process. After 20 to 40 minutes, the liquid in the jars will

start to bubble, usually in the jar on the front right first.

-

Then switch off the oven and keep the jars in the closed oven for

another 30 mins (approx. 15 minutes if preserving very sensitive fruit

such as strawberries).

Meat and vegetables

-

Prepare the preserving jars. Place the drip pan into the oven and set

the temperature as described above.

-

When the liquid starts to bubble, turn the oven down to 150 °C and

continue to heat for a further 30 to 60 minutes.

-

Then switch off the oven and keep the jars in the closed oven for

another 30 minutes.

Food to be

preserved

Heating time

(Further heating)

Residual heat

in mins.

Cauliflower

60-80 30

Beans

60-80 30

Peas

80-90 30

Cucumbers

Switch off 30

Carrots

60-80 30

Mushrooms

60-80 30

Brussels sprouts

60-70 30

Asparagus

80-90 30

Tomatoes

Switch off 30

Caution! During the cooking process a lot of moisture develops in the oven

interior owing to the evaporation of water. This moisture emerges through

the ventilator openings and as a result the control panel may become hot.

Grilling

Set the operation mode

*

Grill for grilling small portions or +

for large-

area grilling.

-

Preheat the oven for 5 to 10 minutes.

-

Place the food to be grilled in the oven.

-

Grill the food for the times specified in the table below.

-

Place the drip pan with the roasting tray (optional accessory) onto the

3rd or 4th rack level from the bottom. Place the roasting rack on the

rack level specified in the table.

Always close the oven door when grilling.

The backmobil

®

The oven can be fitted with a backmobilâ (special accessory No. 600).

The backmobil

®

makes it easier for you to use the oven.

For successful roasting or baking it is important to select the correct shelf

level for baking sheets and gridirons. The backmobil enables you to correctly position the baking sheets and gridirons even before you put them into

the oven.

Caution! The backmobil

®

and the lock can be very hot. Use oven cloths,

oven gloves, pan holders etc.

Gliding the backmobil

®

out of the oven: Press down the lever.

Sliding the backmobil

®

into the oven: Slide in slowly until it locks int

Dish Rack

level

Grill Large-area grill

1st side

in mins.

2nd side

in mins.

1st side

in mins.

2nd side

in mins.

Pork chops

Escalope

6 8-10 6-8 10-15 8-10

Fillet of pork 6 10-12 8-10 14-16 10-12

Sausages 6 8-10 6-8 15-20 10-15

Shashlik 6 7-8 5-6 18-20 8-10

Rissoles 6 8-10 6-8 10-15 10-12

Beef steak 7 6-7 5-6 10-11 9-10

Slices of liver 7 3-4 2-3 7-8 6-7

Escalope of

veal

6 5-7 4-5 9-11 8-9

Veal steak 6 6-8 4-6 10-12 8-10

Mutton chops 6 8-10 6-8 12-14 10-12

Lamb chops 6 8-10 6-8 12-14 10-12

Half a chicken

3 10-12 5-7 14-16 9-11

Fillet of fish 7 6-7 4-5 10-11 8-9

Trout 4 4-7 3-6 8-11 7-10

Toast 5 2-3 2-3 6-7 6-7

Toasted

sandwiches

4 6-8 10-12

KEH 650.0 29

Cleaning and caring

Make sure that the appliance and the fascia have cooled down

completely before cleaning!

Usually it is sufficient to clean the oven with a damp cloth and a little

washing-up liquid each time you use it. Wipe dry afterwards.

Do not use any abrasive or aggressive cleaning or scouring agents such as steel wool,

soap-impregnated steel wool, metal or plastic sponges or similar agents with an abrasive surface.

Do not use any cleaning agents with a bleaching effect or containing chlorine.

Remove any deposits of calcium or any spots of grease, starch or

egg-white as soon as possible. If this is neglected, corrosion can

develop under these deposits in stainless steel appliances due to

the lack of oxygen.

When cleaning stainless steel appliances please

use the usual cleaning agents for stainless

steel. Please take general note of the instructions of the respective manufacturers and try out

products on small surfaces first, before spreading the cleaning agent over the entire surface.

Clean the glass ceramic hob after every use.

It is best to first wipe encrusted and spilled food with a damp cloth first.

Then remove with a glass scraper. Remove sugar and melted plastic immediately while the cooking zone is hot.

Apply a care agent to the glass ceramic hob once a week. This forms a

protective film and also facilitates daily cleaning. Please observe the relevant instructions of the manufacturers of cleaning and care agents.

Rings

Clean the glass ceramic surface or the

hob with commercially available cleaning

agents, the burner tops and the plug-on

rings with hot soapy water. Soak areas

which are more difficult to clean and

places where food has boiled over and

become stuck first before cleaning.

Make sure that the intermediate rings

and burner tops are replaced correctly.

Turn the burner tops until they catch.

Regenerating ökotherm

Heat the empty oven by intensiv hot air convection at maximum temperature

for 60 mins.

backmobil

(special accessory no. 600)

Extending the backmobil

®

Press down the lever at the bottom of

the backmobil

®

frame, extend the back-

mobil

®

until it has gone beyond the

catch and lift it diagonally upwards.

Taking the backmobil® apart

Remove the holder rods of the slot-in

gratings first from the front and then

from the back holes on the frame of

the backmobil. The slot-in gratings can

then be removed.

Assembling the backmobil

®

Insert the holder rods of the slot-in gratings back into the holes on the frame

of the backmobil

®

and proceed in the

reverse sequence to the sequence

used when taking the backmobil

®

apart. Push the lever into place.

Oven

From time to time the oven needs to be cleaned thoroughly.

Removing the oven door

Open the oven door as wide as it will

go.

Fold up the clamps on the door hinges.

Take hold of the oven door on the both

sides and close it slowly. When the

oven door is about half-closed, the hinges will fall out of the catches. The

oven door can now be removed.

Loosen the screw to fold down the grill.

Removing the side-grating

Loosen the screws.

Remove the slot-in grating.

To fold down heating element (top

heat/grill)

Loosen the screws and fold down the

heating element.

Fold up the heating element again and

fasten with a screw.

Reassembling the oven door

Take hold of the oven door on both sides and push the hinges into the relevant holes on the oven.

Very slowly open the oven door.

Fold down the clamps at the door hinges. Close the oven door.

30 KEH 650.0

Troubleshooting

Repairs should only be carried out by a qualified technician!

Problem Cause Remedy

Rings will not ignite. Power failure. Check power supply.

Food remains or

cleaning agent between

the spark ignition and

the burner.

Release carefully and clean.

Spark ignition defective. Call Customer Service.

Light with matches in the

meantime.

The flame of the

burners suddenly

changes.

The plug-on rings or

burner tops are not

mounted correctly.

Mount plug-on rings or

burner tops so that they

catch.

The cooking ring

control knob suddenly

needs to be held

down longer until the

flame ignites.

Temperature sensor

bent.

Carefully bend the

temperature sensor back

into the correct position.

Plug-on rings or tops of

burners are skew.

Plug-on rings or tops of

burners until they click into

the right position.

It is not possible to

switch off the oven.

Defective electronic

component.

Switch off fuse.

Oven does not heat

up.

Fuse defective. Check or replace fuse.

Oven temperature

control or function

switch has not been

switched on.

Set oven temperature

control or function switch

as required.

Oven light no longer

works.

Light bulb defective. Call Customer Service to

replace the light bulb.

Glass of oven door is

broken.

Switch off the appliance,

Call Customer Service.

Strong smells from

oven in spite of

ökotherm

catalyst.

ökotherm

catalyst

must be regenerated.

Preheat empty oven to

maximum temperature with

hot air convection.

Strong smell of

vinegar when

preparing food.

Sour dough,

yeast dough,

dishes with alcohol.

Unavoidable odours.

Oven door will not

shut.

Door or door sealing

dirty.

Clean door and sealing

using only warm soapy

water and a damp cloth.

Fruit juice or spots of

egg-white on

enamelled parts.

Moist cake or meat

juices.

Harmless change to the

enamel, no remedy.

Nameplate

is located on the right-hand side strip and is visible when the oven door is

open. Please note the following information for when you contact Customer

Service:

F-number

Model designation oven

Model designation hob

Installation instructions

Attention!

The appliance category approved for connection can differ from region

to region. If in doubt, ask your local gas board which appliance category

you should use.

Check whether the details on the nameplate correspond to the type of

gas in your area. If not, the hob must be converted to run on the right

type of gas/gas quality!

The appliance should not be connected up or put into operation by

anyone except a qualified gas fitter in accordance with the applicable

regulations.

Küppersbusch built-in ovens should not be installed by anyone except an

authorised fitter and should only be connected up to the corresponding

Küppersbusch built-in hobs.

It is important to adhere to the statutory regulations and installation rules

issued by the local gas board and the local electricity board.

When connecting the appliance or when replacing the oven lamp,

disconnect the appliance from the electricity mains.

It must not be possible to touch the insulated parts of built-in ovens.

The appliance should be protected by a line-protecting cutout, fuses or

contactors with an opening width of at least 3 mm.

The earthing cable must be so long that when the strain relief fails, it is

not subjected to strain until after the live wires of the connection cable.

Planning the supply lines

Threaded appliance joint: R 1/2 “ 150/R 7

Take the following into account when planning the supply lines:

Gas connection with flexible gas safety hose

The joint must be provided with a stop cock and must be accessible.

It is recommended to have a safety gas outlet in the right-hand cabinet.

A flexible gas safety hose, 800 mm in length (as per DIN 3383) is screwed

directly onto the connection points of the hob and screwed on tightly so

that no gas escapes.

If connecting from the left-hand cabinet it is necessary to have a flexible

gas safety hose. Length: max. 1.50 m!

Gas connection to immobile fitting

The joint must be provided with a stop cock and be accessible.

Electrical connection

For the power supply to the oven and the electric automatic spark ignition a

230-240 shockproof socket is required.

The appliance is supplied with a connection cable.

KEH 650.0 31

Installing the cooker into your fitted kitchen

To protect adjacent surfaces (parts of kitchen furniture) against overheating,

the cooker is an appliance of type Y. The plastic surfaces or veneer

(150 °C) must be protected by a heatproof film. This film prevents the

surfaces from becoming deformed or peeling away, especially on the short

sides of the kitchen furniture.

Standard distances in accordance with DIN 68901

Minimum distances

between the gas rings and cooker

hoods: 650 mm or according to manufacturer’s instructions.

The back panel and one side of the appliance can be fitted against cupboards or walls of any height. The furniture on the other side of the appliance, however, must be flush with the appliance.

It is essential that the appliance is

installed so that it is level.

Preparing the built-in cupboard

In the upper area of the side wall of the cupboard cut out an opening

measuring 100 x 100 mm for the supply lines.

Important: Remopve the back wall of the cupboard and the crossbar

between the side walls, if applicable!

Cutting out the openings in the worktop

The appliance comes supplied with a template for marking out the opening

in the worktop.

Important: Do not mark out the opening in the worktop unless the worktop is already properly fitted.

Place the template against

the front edge of the cabinet.

Mark out the opening for

the cooker in the worktop

and cut out.

Remove transport securing devices.

- The plastic clips used to secure the burner covers during transport are to

be removed from all four burners.

- The burner covers and intermediate rings are to be removed from all four

burners.

- The two front burners are screwed onto housing sheets to secure them

in-transit. Undo the screws.

- The two rear burners are screwed to sheet angles to secure them in-transit. Undo the screws.

- The fume grating and the screws are to be used for the installation of a

hob (stainless steel, enamel). The grating is not needed for the installation of a glass ceramic hob.

Preparing the gas connection

Check that the details on the nameplate (s. p. 31) are the same as the type

of gas used in your area. If there are any discrepancies, the hob will have

to be converted for the corresponding type or quality of gas (s. p. 35).

Connect the flexible gas safety

hose to the connection points of

the hob and screw on tightly so

that no gas can escape.

Sliding the appliance into place

Slide the oven a small way into

the space intended for it in the

cabinet.

Pull the supply lines through the

opening in the side wall. Now slide the oven all the way into its

space. Ensure that the supply lines are not wedged in!

Make absolutely certain that the

hose does not touch any parts of

the appliance which become hot

during cooking!

Fastening in the appliance

Open the oven door.

Using the screws provided and

slanting them outwards, fasten

the appliance to the cabinet.

32 KEH 650.0

Readjusting the retractable handles!

After the appliance has been connected and fitted the handles must be

checked to see whether they work in different positions.

If, on account of connecting to the gas supply or fitting into the kitchen

units, the handles no longer work perfectly, the following steps should be taken:

- remove both middle handles

- loosen the screws next to the valve shaft, which are visible through the

handle opening

- using a screwdriver to raise or lower the valve shafts through the handle

opening, align the handle shaft with the centre of the hole and then retighten the screws using a second screwdriver

- replace the handles and check again.

Installing the glass ceramic gas hob

The parts are not assembled when delivered.

Assembly is easy, quick and simple owing to the clip method.

- Hammer the clips into the worktop recess at the intervals specified in the

drawing. No height alignment is necessary owing to the horizontal stop.

Should the worktop recess have been made slightly too large, it is possible to increase the spring tension of the clips by screwing them.

- Insert the glass ceramic hob.

Installing the burners

- Raise the burner with the tool

provided and move it into position.

- Screw on the holding sheet

for the burner.

- Assemble the burner.

- Place the burner cover and attachment carefully in the correct position. Turn the cover

to bring into position.

Installation into the hob

- Attach the fume grating previously removed from the transport securing

feature on the rear of the worktop recess with the screws 4.2 x 16 mm.

- Insert the support frame and fasten with screws 4.2 x 16 mm.

- Position the hob loosely.

- Raise the burner with the tool provided, position and screw on with three

screws 4.2 x 16 mm and washers in the holes with the thread collar visible.

- Then align the hob and fasten to the appliance with screws 4.2 x 32 mm

and washers through the remaining free hole at each burner location.

- Assemble the burner.

- Place the burner cover and attachment carefully in the correct position. Turn the cover

to bring into position.

Checking the supply lines

Power supply

Check the installation of the connection cable. It must not be

tightly wedged in,

pass across the cooker,

be located at a ventilation channel.

Gas supply

Check that all joints are tight and secure.

The hoses must be installed in such a way that they are at a safe

distance from hot surfaces.

The hoses must not be tightly wedged in!

Checking the ring burners

Ignite the burner and test the stability of the flame.

The flame should be steady.

34 KEH 650.0

Factory setting / conversion possibilities

This appliance can be converted to run on other types of gas.

Adjustment and conversion work should only be carried out by a

qualified gas fitter! The applicable rules and regulations should be

observed. Disconnect the appliance from the power supply so that

it is completely free of voltage.

The type of gas and the gas supply pressure must correspond to the

gas setting specified on the appliance.

The factory setting is indicated on an information plate or on

the appliance nameplate.

Table of permissible types of gas and pressures

Table of injector sets

Any subsequent conversions to different types of gas must be

permanently marked on the nameplate of the appliance.

Use only the special injectors which can be ordered from Customer Service.

Country

(ISO country

codes)

Natural gas

H,E

(G 20)

Natural gas LL

(G 25)

Natural gas L

(G 25)

Pressure couple

natural gas

(G 20/25)

Propane

(G 31)

Pressure couple

(Butane/propane)

(G 30/31)

Butane

(Butane/propane)

(G 30)

Category

mbar mbar mbar mbar mbar mbar mbar

Germany (DE) 20 20 50 II

2ELL3B/P

Denmark (DK)

Finland (F)

Sweden (SE)

Iceland (IS)

Norway (NO)

20 28-30 II

2H3B/P

Netherlands (NL) 25

28

50

28-30

II

2L3P

II

2L3B/P

France (FR)

Belgium (BE)

20/25 28-30/37 II

2E+3+

United Kingdom (GB)

Spain (ES)

Italy (IT)

Portugal (PT)

Ireland (IE)

Greece (GR)

20 28-30/37 II

2H3+

Austria (AT) 20 50 II

2H3B/P

Luxembourg (LU) 20 28-30/37 I2E, I

3+

Type of gas,

pressure of gas

High speed ring Standard ring Simmering ring

Main injektor Low flame injektor Main injektor Low flame injektor Main injektor Low flame injektor

Natural gas H, E, E+

G 20 (20/25 mbar)

1255693477241

Natural gas LL

G 25 (20 mbar)

145 62 117 52 79 47

Natural gas L

G 25 (25 mbar)

118 61 104 49 78 44

Liquefied gas butane/propane

G 30(50 mbar)

73 34 62 26 49 23

Liquefied gas butane/propane

G 30 (28-30/37 mbar

81 39 70 26 53 24

Liquefied gas propane

G 31 (50 mbar)

79 36 67 30 51 26

KEH 650.0 35

Conversion injector sets

Table of heat input

Total nominal heat input = 7.7 kW

Connected load of the appliance = 555 g/h

Gross calorific values according to EN 437

The HSB calorific value can be obtained from the relevant gas supply company upon installation.

The flow rate is calculated as follows:

flow rate l/min =

heat input kW x 1000

gross calorific value kWh/m

3

x 60

Resetting the ring burners

Main injectors

If the ring burners are set to run on a different type or quality of gas the

main injector must be replaced.

-

Remove the burner cap.

-

Through the mixing pipe of the burner mount the socket wrench onto

the injector and unscrew the injector using a screwdriver.

-

Place the new injector into the socket wrench and screw it in as far

as it will go.

Low flame injectors

After you have removed the control knobs (for the rings and the oven) and

removed the operation fascia (see below) the low flame injectors can be

adjusted or reset. If you are using natural gas and liquefied petroleum gas

the low flame injectors must be changed. Screw in the injectors as far as

they will go (see Injector Sets table).

- Disconnect the appliance from

the power supply (disconnect

the mains plug).

- Remove the control knobs (for

rings and oven).

- Open the oven door.

Caution: The operation fascia remains connected to the appliance due

to the electrical wiring. It must therefore be handled with care!

- Unscrew the four screws at

the left and right side below

the operating fascia and the

two screws behind the operating fascia.

Lift off the operating fascia,

slightly pull it towards the

front at the lower edge and

carefully remove it towards

the bottom.

- Undo screws,

replace low-setting injectors,

tighten screws.

Final assembly

On completion of the conversion and setting work, final assembly can be

performed.

- Mount control panel.

- Insert the control knobs.

Ring Natural gas

20 mbar

25 mbar

Butane/propane

Input

kW

Input

kW

Gas rate

g/h

Simmering

ring

large 1.1 1.1 79

small 0.3 0.3 22

Standard ring large 1.9 1.9 137

small 0.38 0.38 27

High-speed

ring

large 2.8 2.8 202

small 0.56 0.56 40

Gross calorific

values

Calorific value H

s

15 °C

MJ/m3 kWh/m

3

MJ/kg kWh/kg

Natural gas H (G 20) 37,78 10.5

Natural gas L (G 25) 32,49 9.03

Butane (G 30) 49,47 13.75

Propane (G 31) 50,37 14.00

Type of gas,

pressure of gas

Injector sets

Natural gas H, E , E+

G 20 (20/25 mbar)

Natural gas LL

G 25 (20 mbar)

Acc. no. 219

Natural gas L

G 25 (25 mbar)

Liquefied gas butane/propane

G 30 (50 mbar)

Acc. no. 211

Liquefied gas butane/propane

G 30 (28-30/37 mbar)

Acc. no. 218

socket wrench

main injector

36 KEH 650.0

Loading...

Loading...