Kuppersbusch JZT-GWS3811.0ED-CN, JZT-KG7500.0E-CN, JZT-GKS3820.0ED-CN Instructions For Use And Installation

Page 1

COD. 04080DP - 29.08.2017 Rev. 0

BEDIENUNGSANWEISUNG

mit Montageanweinsungen

INSTRUCTIONS FOR USE

and installation

Lesen sie unbedingt die Gebrauchsanleitung

und den Montageplan vor Aufstellung,

Installation sowie Inbetriebnahme.

Please read the users and installation

instructions carefully before installation

of the appliance and before starting to use it.

Service und Kundendienst

Telefon: 0209 - 401 631

Email: kundendienst@kueppersbusch.de

JZT-GWS3811.0ED-CN

JZT-GKS3820.0ED-CN

JZT-KG7500.0E-CN

Page 2

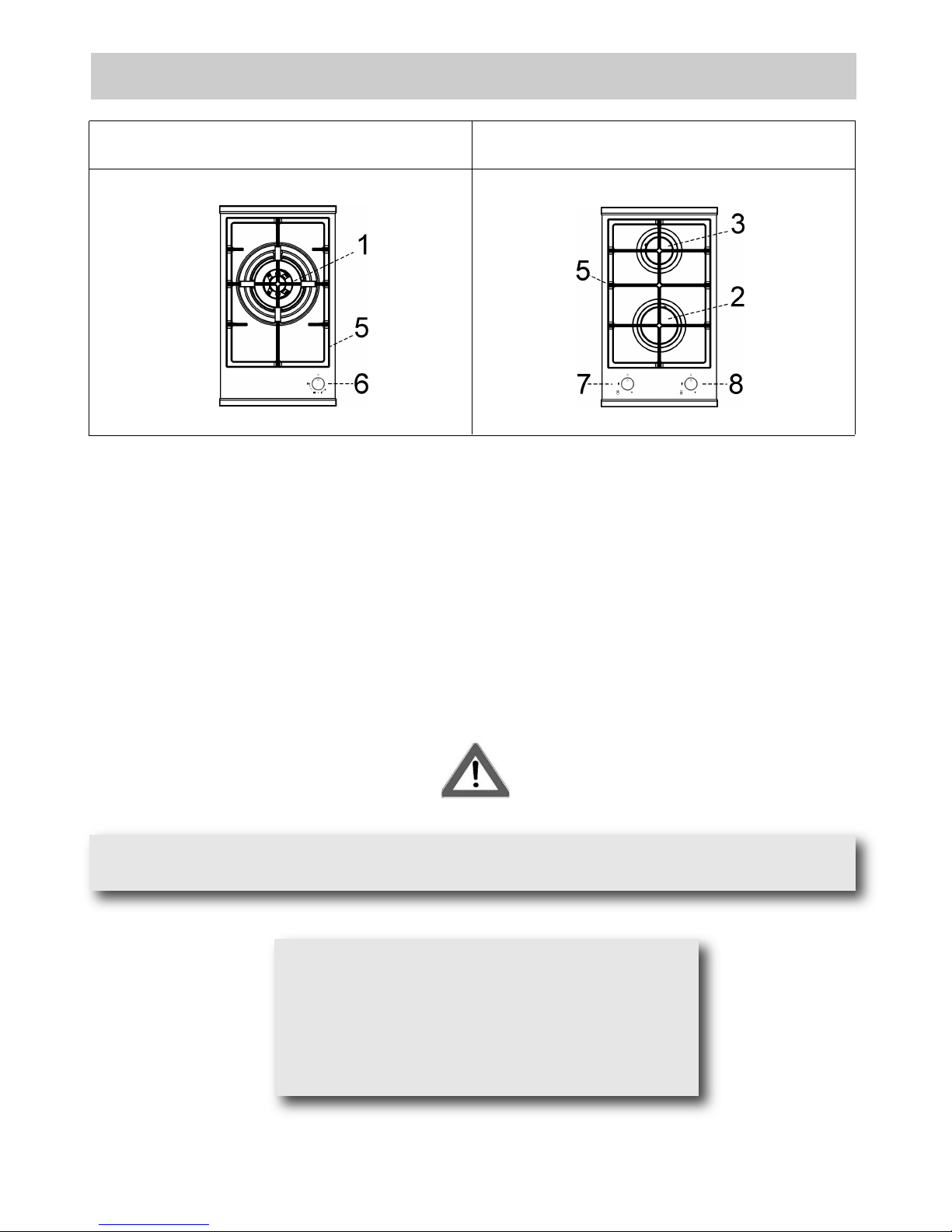

DESCRIPTION OF HOBS

2

1 “DUAL” burner 5600 W

2 Fast burner 3500 W

3 Semi Rapid burner 2000 W

5 Grids

6 Burner no.1 control knob

7 Burner no.2 control knob

8 Burner no.3 control knob

MODEL: JZT-GWS3811.0ED-CN

MODEL: JZT-GKS3820.0ED-CN

CAUTION:

In case of hotplate glass breakage:

●shut immediately off all burners and any electrical

heating element and isolate the appliance from

the power supply;

●do not touch the appliance surface;

●do not use the appliance.

This cook top was designed to be used exclusively as a cooking appliance: any other use (such

as heating rooms) is to be considered improper and dangerous.

Page 3

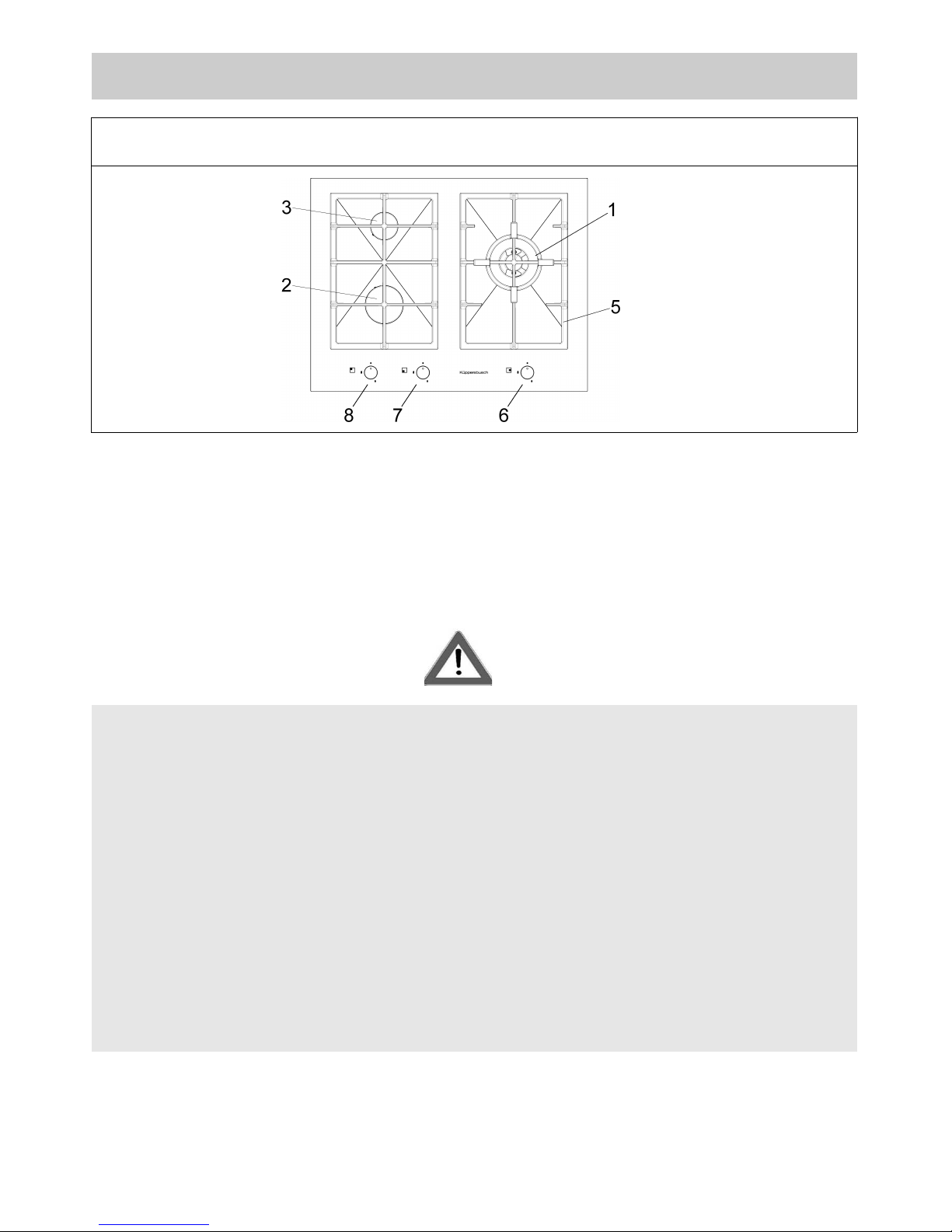

USE

3

1 “DUAL” burner 5000 W

2 Fast burner 3800 W

3 Semi Rapid burner 1750W

5 Grids

6 Burner no.1 control knob

7 Burner no.2 control knob

8 Burner no.3 control knob

MODEL: JZT-KG7500.0E-CN

WARNING:

Children less than 8 years of age shall be kept away unless

continuously supervised.

This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children

without supervision.

Page 4

4

USE

1) TRADITIONAL BURNERS

On the surface of the hob, there is a serigraphic

figure above each knob, indicating the burner to

which the knob refers. After turning on the gas at

the main or opening the valve on the gas bottle,

light the burners as indicated below:

- Manual ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

place a lighted match near the burner.

- Automatic electric ignition

Press the knob corresponding to the burner to use

and turn it clockwise to the “Maximum” position

(big flame fig. 1) pressing the knob right down.

- Lighting burners fitted with a safety cut-off

device

For burners fitted with a safety cut-off device, turn

the knob corresponding to the burner to use anticlockwise to the “Maximum” position (big flame

fig. 1) until it stops and then press the kn ob.

Continue pressing the knob for about 10 seconds

after the burner has been lit.

Should the flames accidentally go out, turn the

burner control knob off and wait at least 1 min befor

attempting to light it again.

How to use the burners

To obtain maximum performance with minimum gas

consumption, remember the following:

- use suitable pans for each burner (see the table

below and fig. 2).

- When boiling point is reached, turn the knob to the

“Minimum” position (small flame fig. 1).

- Always use pans with lids.

“DUAL” burner:

separate regulation of the inner and outer rings (in

practical terms, a dual burner controlled by a single

knob), offering very flexible use thanks to the

possibility to light either the inner flame only or the

whole burner (inner and outer flame at the same

time).

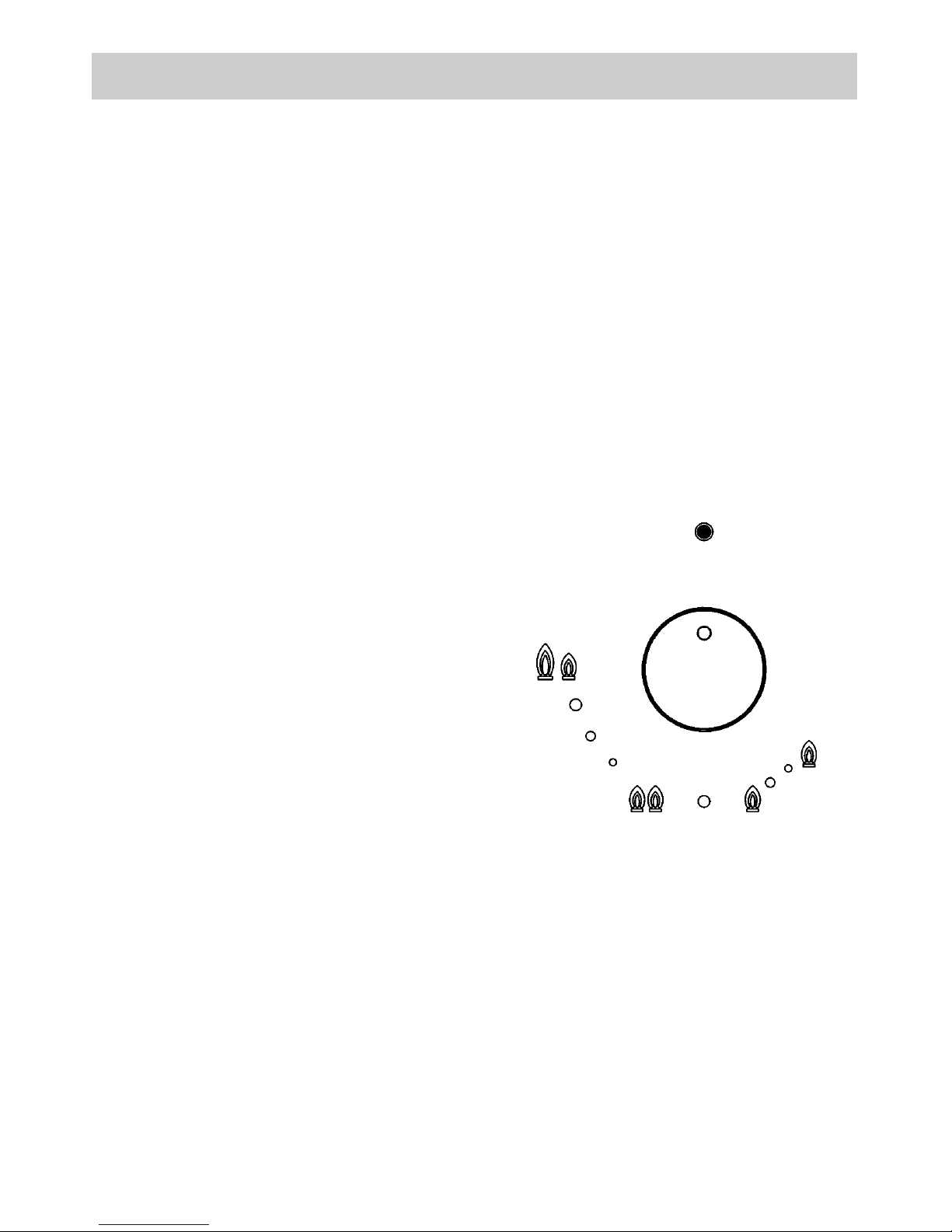

LIGHTING AND USING THE “DUAL” BURNER

Stand the pan on the burner before lighting.

Despite being controlled by a single knob, the

“DUAL” burner can be used in two different ways.

A) - Using the complete burner:

starting from the off position ● You must first press

the knob, simultaneously turning it anti-clockwise,

until the indicator points to the maximum delivery

position obtaining the maximum flow capacity of

both flames.

When the flames are lit, keep the knob pressed for

a few seconds, until the device automatically keeps

the burner lit.

It is now possible to regulate the intensity of the

flame by turning the knob anti-clockwise (from the

maximum flow capacity position of the inner and

outer flames to the maximum flow capacity of the

inner flame and the minimum of the outer flame.

To turn off the burner, turn the knob clockwise,

realigning the indicator with the ● off symbol.

B) - Using the inner flame only:

after lighting the burner and regulating the inner

flame to maximum flow capacity and the outer

flame to minimum flow capacity as described

above, turn the knob anti-clockwise until it clicks

once. The inner flame is now at maximum flow

capacity while the outer flame is turned off.

Continue turning anti-clockwise to regulate the inner

flame to the minimum flow capacity.

Turning off:

to turn off the burner, turn the knob clockwise,

realigning the indicator with the ● off symbol.

Once the “DUAL” burner is operating in either of the

two modes described, it is possible to swap from

one mode to the other by simply pressing and

turning the knob to the position required:

Position off

Max out

Max in

Min out

Max in

Max in

Min in

Page 5

5

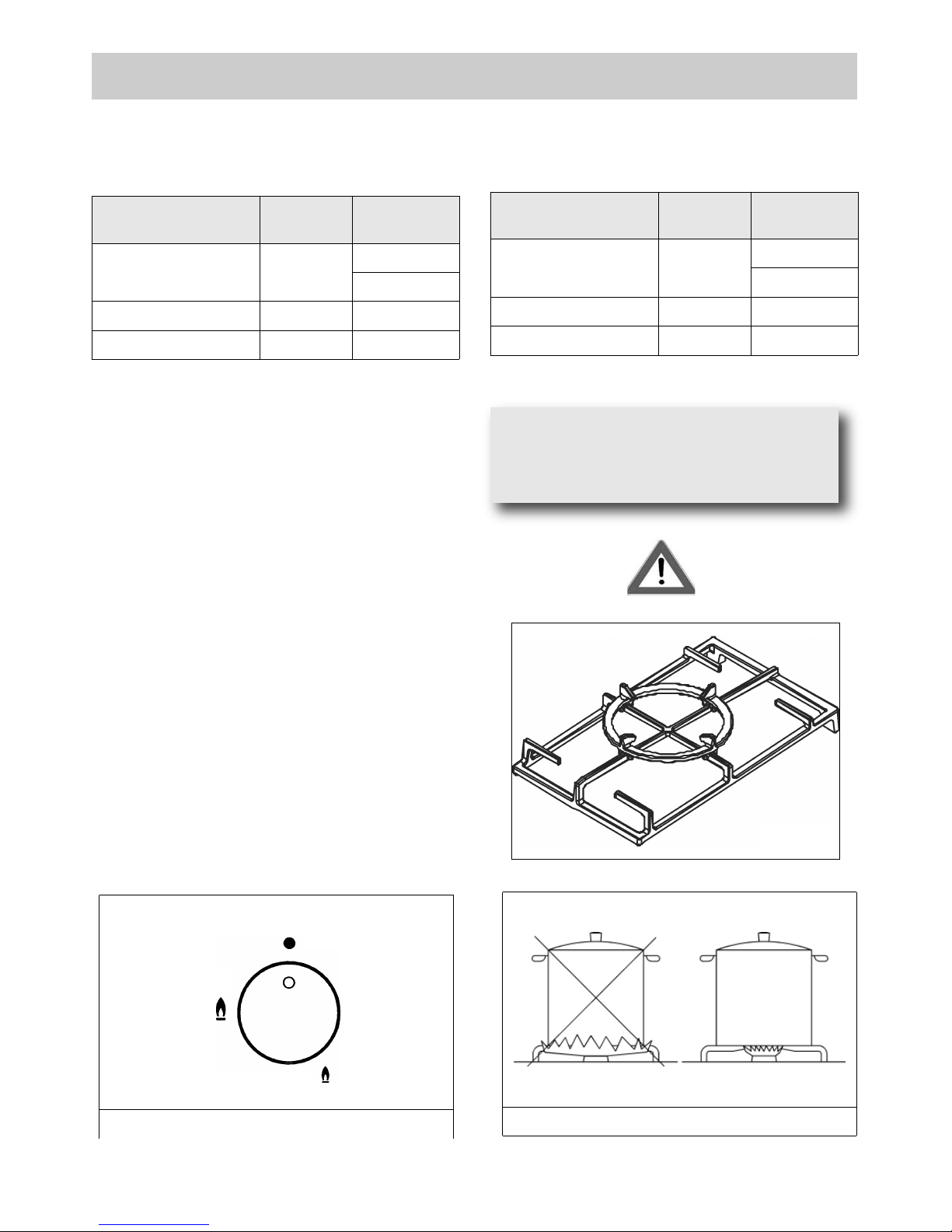

FIG. 2

USE

MODEL: JZT-GWS3811.0ED-CN

MODEL: JZT-GKS3820.0ED-CN

WARNINGS:

- burners fitted with safety cut-off devices can

only be lit when the knob is in the “Maximum”

position (big flame fig. 1).

- In the absence of electricity, the burners can

be lit with matches.

- Never leave the appliance unattended while

the burne rs ar e i n us e an d en sure t hat

children are kept at a safe distance. Make sure

that pan handles are correctly positioned and

supervise the cooking of foods in oil and fat,

as these are highly flammable.

- Do n o t use spr a y s near the appliance

during use.

- Do not drag pans across the glass hob as this

may scratch the surface.

- Do not use the hob as a work surface.

- Do not place pans with an unstable or deformed

bottom on the burner, as these may tip or spill

their contents, causing accidents.

- The pans must not extend beyond the edge of

the hob.

MODEL: JZT-KG7500.0E-CN

Burners

Power

(W)

Ø

Pan

(cm)

Complete DUAL

Central DUAL

5600

800

22 ÷ 27

8 ÷ 16

Fast

3500

20 ÷ 22

Semi Rapid

2000

10 ÷ 14

To use the WOK pan support on ultra rapid

gas burner only.

Put it on the ultra rapid pan support and

make sure of the stability (see fig. A).

FIG. 1

Position off

Position Max

Position Minimum

FIG.A

Burners

Power

(W)

Ø

Pan

(cm)

Complete DUAL

Central DUAL

5000

800

22 ÷ 27

8 ÷ 16

Fast

3800

20 ÷ 22

Semi Rapid

1750

10 ÷ 14

Page 6

6

USE

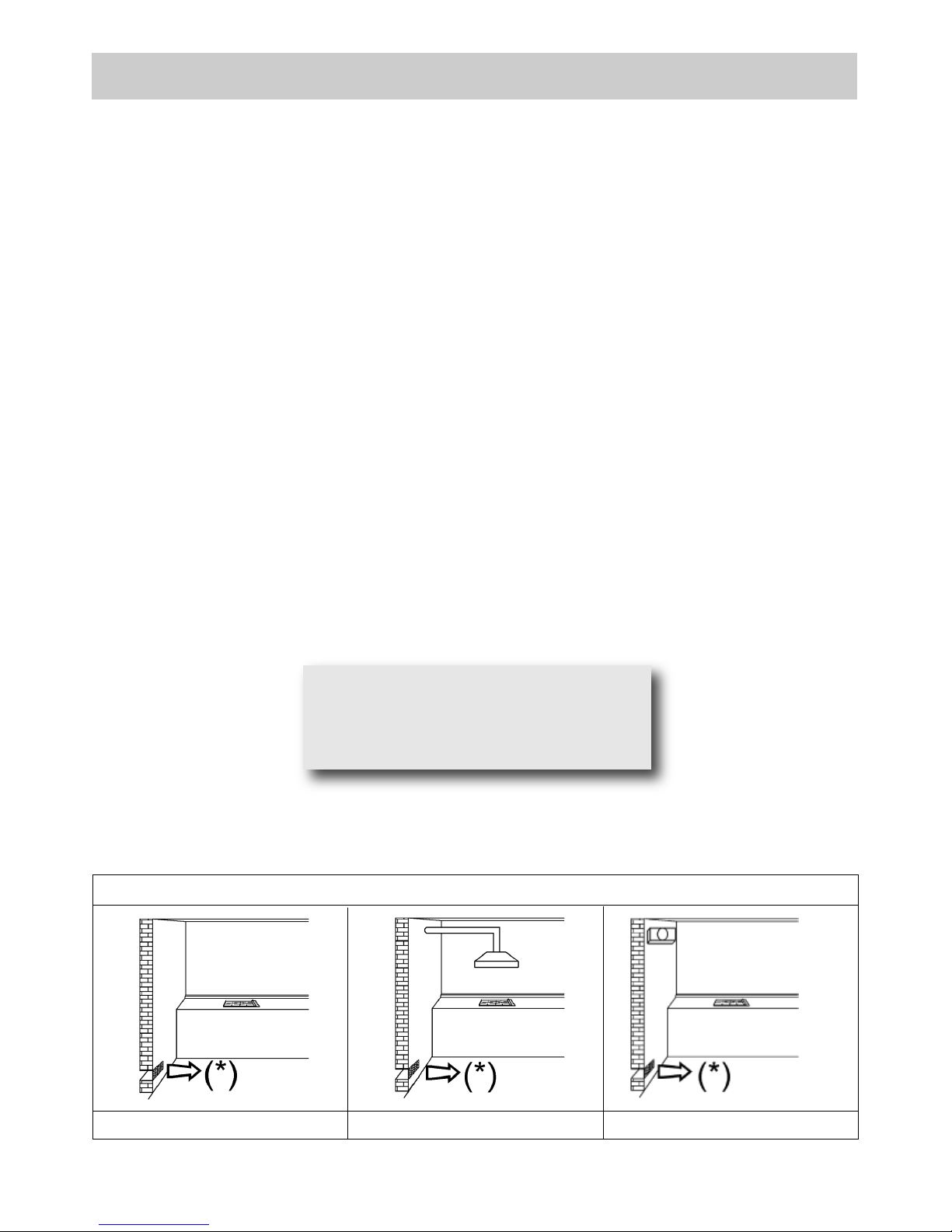

FIG. 3 FIG. 4 FIG. 5

(*) AIR INLET: SEE INSTALLATION CHAPTER (PARAGRAPHS 5 AND 6)

Warning:

during operation the work surfaces of the

cooking area become very hot:

keep children away!

WARNINGS:

use of a gas cooking appliance produces heat and moisture in the room in which it is installed. The

room must therefore be well ventilated by keeping the natural air vents clear (fig. 3) and by

activating the mechanical aeration device (suction hood or electric fan fig. 4 and fig. 5).

Intensive and lengthy use of the appliance may require additional ventilation. This can be achieved

by opening a window or by increasing the power of the mechanical exhausting system if installed.

Do not attempt to change the technical characteristics of the product because it can be dangerous.

- If you should not to use this appliance any more (or replace an old model), before disposing of it,

make it inoperative in conformity with current law on the protection of health and the prevention of

environmental pollution by making its dangerous parts harmless, especially for children who

might play on an abandoned appliance.

- Do not touch the appliance with wet or damp hands or feet.

- Do not use the appliance barefoot.

- The manufacturer will not be liable for any damage resulting from improper, incorrect or

unreasonable use.

- During, and immediately after operation, some parts of the cook top are very hot: avoid touching

them.

- After using the cook top, make sure that the knob is in the closed position and close the main tap

of the gas supply or gas cylinder.

- If the gas taps are not operating correctly, call the Service Department.

Page 7

7

CLEANING

IMPORTANT:

always disconnect the appliance from the gas

and electricity mains before carrying out any

cleaning operation

2) GAS HOB

Periodically wash the hot plate, the enamelled stell

pan support, the enamelled burner caps “A”, “B”

and “C” and the burner heads "T" (see fig. 6 and 7)

with lukewarm soapy water. They should also be

cleaned plugs "AC" and flame detection "TC" (see

fig.6). Clean them gently with a small nylon brush

as shown (see fig. 8) and allow to dry fully. Do not

wash in the dishwasher. It is very important to clean

the surface soon after every use, when the surface

is still tepid.

Do not allow vinegar, coffee, milk, salted water,

lemon or tomato juice from remaining in contact

with the enamelled surfaces for long periods of

time.

Do not clean using abrasive metal scourers, powder

abrasives or corrosive sprays.

WARNINGS:

when reassembling the components, observe

the following recommendations:

- check that the holes in the burner heads “T”

(fig. 6) are not blocked by foreign bodies.

- Ensure that the enamelled covers “A”, “B”

and “C” (fig. 6 and 7) are correctly positioned

on the burner head. The covers are correctly

posit ion ed o n the head wh en they a re

perfectly stable.

- If the opening and closing of any valve is

awkward, do not force it but request urgent

interve ntion by the tec hnical assistance

service.

- Do not place pans with an unstable or deformed

bottom on the burner, as these may tip or spill

their contents, causing accidents.

- The pan sup por t must be placed i n the

appropriate centering p ins verif ying the

perfect stability.

- Do not use jets of steam to cle an the

appliance.

- To prevent difficulties with lighting, regularly

clean the ignition elements (ceramic and

electrode) and safety cut-off devices (fig.8).

IMPORTANT:

when removing the burners to clean them, ensure

that a ll parts are correct ly pos itioned bef ore

relighting them.

FIG. 8

FIG. 7

FIG. 6

Page 8

8

INSTALLATION

FIG. 9

FIG. 10

MEASUREMENTS TO OBSERVE (in mm)

A B C D E F

1 - 2 BURNER 282 482 59 59 100 min. 70 min.

3 BURNER (70) 600 500 50 50 150 min. 70 min.

TECHNIC AL INFORM ATI ON FOR

THE INS TA L LER

Insta lla tion, adjus tments of contr ols a nd

maintenance must only be carried out by a

qualified engineer.

The appliance must be correctly installed in

confo rmi ty with curre nt law and th e

manufacturer's instructions.

Incorrect installation may cause damage to

persons, animals or property for which the

Manuf act urer shall not be considered

responsible.

During the life of the system, the automatic

safety or regulating devices on the appliance

may only be modified by the manufacturer or by

his duly authorized dealer.

3) INSTALLING THE COOKTOP

Check that the appliance is in a good condition after

having removed the outer packaging and internal

wrappings from around the various loose parts. In

case of doubt, do not use the appliance and contact

qualified personnel.

Never leave the p ackaging mater ial s

(cardboard, bags, polystyrene foam, nails, etc.)

withi n child ren’s reac h since they coul d

become potential sources of danger.

The measurements of the opening made in the top

of the modular cabinet and into which the cooktop

will be installed are indicated in either fig. 9.

Always comply with the measurements given for

the hole into which the appliance will be recessed

(see fig. 9 and 10).

The prospective walls (left or right) that exceed the

working table in height must be at a minimum

distance from the cutting as mentionned both in the

columns “E” of the scheme.

The appli ance b elongs to class 3 an d is

there for e subjec t t o all the p rov isions

established by the provisions governing such

appliances.

IMPORTANT!

A p erfect installati on, adjustment o r

transformation of the cook top to use

oth er gas es req uires a QUA LIFI ED

INSTALLER: a failure to follow this rule

will void the warranty.

Page 9

9

4) FITTING THE HOB

The hob is equipped with a special seal to avoid

any infiltration of liquid into the unit. To apply this

seal correctly, please follow the instructions given

below carefully:

- remove all the mobile parts of the hob.

- Cut the seal into 4 strips of the lengths suitable to

fit it along the 4 sides of the glass.

- Turn the hob upside down and place the adhesive

side of the seal “E” (fig. 11) correctly under the

edge of the hob so that the outer edge of the seal

perfectly matches the outer perimeter edge of the

glass. The ends of the strips must match without

overlapping.

- Stick the seal to the glass evenly and securely,

using your fingers to press it into place.

- Position the hob in the hole in the unit and fasten it in

place using the appropriate screws “F” of the

fastening hooks “G” (see fig. 12-12/A).

- In order to avoid accidental contact with the

surface of the box of the overheated hob during

use, it is necessary to install a wooden divider at a

minim um distan ce of 70 mm fro m the to p,

fastening it in place with screws (fig. 9).

- To fasten this product to the supporting structure,

we advise you not to use mechanical or electrical

screwdrivers and to exercise moderate pressure

by hand on the fastening hooks.

INSTALLATION

FIG. 11

FIG. 12/A

FIG. 11/A

FIG. 12

Caution: Do not allow the glass (A)

lay directly on the work top. it is the

bottomshelf (B) that has to be in

tou ch wit h t he wor k t op (se e

fig. 11/A).

Page 10

10

INSTALLATION

IM P ORTANT I NS TALL ATIO N

SP E CI F ICATIO N S

The installer should note that the

appliance that side walls should be no

higher than the hot plate itself.

Furthermore, the rear wall, the surfaces

surrounding and adjacent to the appliance

must be able to withstand an temperature of 90 °C.

The adhesive used to stick the plastic laminate to

the cabinet must be able to withstand a temperature

of not less than 150 °C otherwise the laminate could

come unstuck.

The appliance must be installed in compliance with

the provisions in force.

This appliance is not connected to a device able to

dispose of the combustion fumes. It must therefore

be connected in compliance with the above

mentioned installation standards. Particular care

should be paid to the following provisions

governing ventilation and aeration.

5) ROOM VENTILATION

It is essential to ensure that the room in which the

appliance is installed is permanently ventilated in

or der to allo w the applian ce itself to operate

correctly. the necessary amount of air is that

required for regular gas combustion and ventilation

of the relative room, the volume of which must not

be less than 20 m3. Air must naturally flow through

permanent openings in the walls of the room in

question. These openings must vent the fumes

outdoors and their section must be at least 100 cm

2

(see fig. 3). Construction of the openings must

ensure that the openings themselves may never be

blocked. Indirect ventilation by air drawn from an

adjacent room is also permitted, in strict compliance

with the provisions in force.

CAUTION: if the burners of the cooking top are

without safety thermocouple, the ventilation

outlet must have a minimum 200 cm² section.

6) LOCATION AND AERATION

Gas cooking appliances must always dispose of their

combustion fumes through hoods. These must be

connected to flues, chimneys or straight outside. If it

is not possible to install a hood, an electric fan can be

installed on a window or on a wall facing outside (see

fig. 4). This must be activated at the same time as the

appliance (see fig. 5), so long as the specifications in the

provisions in force are strictly complied with.

7) GAS CONNECTION

Before connecting the appliance, check that the

values on the data label affixed to the underside of

the hot plate correspond to those of the gas and

electricity mains in the home.

A label on the appliance indicates the regulating

conditions: type of gas and working pressure. Gas

connection must comply with the pertinent

standards and provisions in force.

When gas is supplied through ducts, the appliance

must be connected to the gas supply system:

● with a rigid steel pipe. The joints of this pipe must

consist of threaded fittings conforming to the

standards.

● With copper pipe. The joints of this pipe must consist

of unions with mechanical seals.

● With seamless flexible stainless steel pipe. The length

of this pipe must be 2 meters at most and the seals

must comply with the standards.

When the gas is supplied by a bottle, the appliance

must be fuelled by a pressure governor conforming to

the provisions in force and must be connected:

● with a copper pipe. The joints of this pipe must consist

of unions with mechanical seals.

● With seamless flexible stainless steel pipe. The length

of this pipe must be 2 meters at most and the seals

must comply with the standards. It is advisable to

apply the special adapter to the flexible pipe. This is

easily available from the shops and facilitates

connection with the hose nipple of the pressure

governor on the bottle.

● With rubber hose pipe in compliance with standards.

The diameter of this hose pipe must be 8 mm and its

length must be no less than 400 mm and no more

than 1500 mm. It must be firmly fixed to the hose

nipple by means of the safety clamp specified by

standards.

WARNINGS:

remember that th e ga s inlet union on th e

appliance is a 1/2" gas parallel male type in

compliance with EN 10226 standards.

Installation of stainless steel pipe and rubber

hose pipe must ensure that it is never able to

touch mobile parts of the built-in cabinet (eg.

dra wers ). Further more , i t m ust not pas s

through compartments that could be used for

storage purposes.

When using a rubber hose pipe, it is essential

to comply with the following instructions:

- no part of the pipe must be able to touch

parts the temperature of 90 °C.

- The pipe must not be pu lle d or t wisted,

throttled or tughtly bent.

- It must not come into contact with sharp

edges or corners.

- It must be easy to inspect the entire pipe

length in order to check its state of wear.

- The pipe must be replaced within the date

stamped on the pipe itself.

- The appliance complies with the provisions

of the following CEE Directives:

CE 2009/142 regarding gas safety

Page 11

11

INSTALLATION

8) ELECTRICAL CONNECTION

The electrical connections of the appliance

must be carried out in compliance with the

provisions and standards in force.

Before connecting the appliance, check that:

- The voltage matches the value shown on the

specification plate and the section of the wires of

the electrical system can support the load, which

is also indicated on the specification plate.

- The electrical capacity of the mains supply and

current sockets suit the maximum power rating of

the appliance (consult the data label applied to the

underside of the cooktop).

- The socket or system has an efficient earth

connection in compliance with the provisions and

standards in force. The manufacturer declines all

responsibility for failing to comply with these

provisions.

When the applianc e is connect ed to the

electricity main by a socket:

- Fit a standard plug suited to the load indicated on

the data label to the cable.

- Fit the wires following figure 13, taking care of

respecting the following correspondences:

letter L (live) = brown wire;

letter N (neutral) = blue wire;

earth symbol = green - yellow wire.

- The power supply cable must be positioned so that

no part of it is able to reach an temperature

of 90 °C.

- Never use reductions, adapters of shunts for

connection since these could create false contacts

and lead to dangerous overheating.

When the appliance is connected straight to the

electricity main:

- Install an omnipolar circuit-breaker between the

appliance and the electricity main. This circuitbreaker should be sized according to the load

rating of the appliance and possess a minimum 3

mm gap between its contacts.

- Reme mber t hat the ea rth wi re must not be

interrupted by the circuit-breaker.

- The electrical connection may also be protected by

a high sensitivity differential circuit- breaker.

You are strongly advised to fix the relative yellowgreen earth wire to an efficient earthing system.

Before performing any service on the electrical

part of the appliance, it must absolutely be

disconnected from the electrical network.

WARNINGS:

all our products are conform with the

European Norms and relative amendments.

The product is therefore conform with the

requirements of the European Directivesin

force relating to:

- compatibility electromagnetic (EMC);

- electrical security (LVD);

- re strictio n of use of cert ain haza rdous

substances (RoHS);

- EcoDesign (ERP).

IMPORTANT!

The appliance must be installed

follo wing the ma nufactur er's

instructions. The manufacturer

will not be liable for injury to

persons or animals or property damage

caused by an incorrect installation.

If the in stal lation req uire s

mod ific ations t o t he home 's

electrical system or if the socket is

incompatible with the appliance's

plu g, ha ve ch anges or repl acem ents

perfor med b y profes sio nal ly-qualified

person. In particular, this person must also

make sure that the section of the wires of

the sock et is suitabl e for the p ower

absorbed by the appliance.

FIG. 13

Page 12

12

REGULATION

Before performing any regulation, disconnect

the electricity supply to the appliance.

After carrying out a ny regu lation o r preregul ati on o perations, an y seals mus t be

replaced by the technician.

The regulation of primary air to our burners is

not necessary.

9) VALVES

Regulation of the “Minimum”:

- Remove knob “M” (fig. 14 and 14/A) of the tap,

which is simply pressed on to its rod. The by-pass

for minimal rate regulation can be: beside the tap

(fig. 14) or inside the shaft. In any case, to access

to regulation, it can be done trought the insertion

of a small screwdriver ‘’D’’ beside the tap (fig. 14)

or in the hole ‘’C’’ inside the shaft of the tap

(fig 14/A). Turn the throttle screw to the right or left

un til the burner flame has bee n adequately

regulated to the “Reduced rate” position.

The flame should not be too low: the lowest small

flame should be continuous and steady. Reassemble the several components.

It is understood that th e aforem entioned

regulation must only be carried out with burners

which use G20, while for burners which use G30

the screw must be blocked completely.

In the case of a “DUAL” burner, the regulation

screw situated inside the post of the valve regulates

the central flame, while the screw next to the valve

regulates the outer flame.

The operations described above can be carried out

easily, whatever the position of the hob or however

it is fastened to the unit.

THE B URNERS D O NOT RE QUI RE ANY

REGULATION OF THE PRIMARY AIR.

FIG. 14/A

TAPS LUBRIFICATION

Should a tap being blocked, do not

force and ask for Technical

Assistance.

WARNING:

To adjust the minimum “DUAL” burner first

remove the bushing “E” (fig. 14).

In the case of a “DU AL” burner, the

regulation screw situated inside the post of

the valve regulates the central flame, while

the screw next to the valve regulates the

outer flame.

FIG. 14

Page 13

13

TRANSFORMERS

10) REPLACING NOZZLES

The burners can be adapted to suited different

types of gas by fitting the nozzles that correspond to

the gas used. To do this, it is necessary to remove

the burner heads and use a straight key “B”, to

unscrew the nozzle “A” (see fig. 15-15/A) and

replace it with a nozzle corresponding to the gas

used.

We advise you to block the nozzle tightly.

After making these replacements, the technician

must regulate the burners as described in

parag rap h 9, seal any re gulation or preregul ati on or gan s and apply t he la be

l

corresponding to the new gas regulation carried

out on the appliance in place of that previously

applied. This label is contained in the spare

nozzle bag.

For the ease of the fitter, we have prepared a table

indicating the flow capacities, the heat capacities of

the burners, the diameter of the nozzles and the

working pressure for the various types of gas.

ARRANGEMENT OF THE BURNERS

TABLE

BURNERS

TYPE

OF GAS

WORKING

PRESSURE

mbar

HEAT

CAPACITY

NOZZLE

DIAMETER

1/100 mm

HEAT

CAPACITY (W)

No.

DENOMINATION

g/h l/h Min. Max.

1

DUAL total

external

NATURAL (12T)

20

1269

2 x 125 A + 71 A

3500 5600

DUAL

central

NATURAL (12T)

20

204

71 A

300 800

2

FAST

NATURAL (12T)

20 793

150 H3

800 3500

3

SEMI RAPID

NATURAL (12T)

20

397

105 Y

550 2000

Page 14

14

TRANSFORMERS

BURNERS

TYPE

OF GAS

WORKING

PRESSURE

mbar

HEAT

CAPACITY

NOZZLE

DIAMETER

1/100 mm

HEAT

CAPACITY (W)

No.

DENOMINATION

g/h l/h Min. Max.

1

DUAL TOTAL

external

NATURAL (12T)

20

1269

2 x 115 A + 71 A

3500 5000

DUAL

central

NATURAL (12T)

20

204

71 A

300 800

2

FAST

NATURAL (12T)

20 793

148 A

800 3800

3

SEMI RAPID

NATURAL (12T)

20

397

103 A

550 1750

FIG. 15

FIG. 15/A

Page 15

15

In case of failure or cut in the cable, please move away from

the cable and do not touch it. Moreover the device must be

unplugged and not switched on. Call the nearest authorized

service center to fix the problem.

MAINTENANCE

POWER CABLE TYPES AND SECTIONS

FIG. 16

TYPE OF HOB TYPE OF POWER

CABLE

MONOPHASE

CAUTION!!!

When replacing the power cable, the fitter must keep the earth conductor “B” longer than the phase

conductor (fig. 16) and must also observe the warnings indicated in paragraph 8.

Gas hob H05 RR-F Section 3 x 0.75 mm

2

WARNING:

MAINTENANCE MUST ONLY BE PERFORMED

BY AUTHORISED PERSONS.

Page 16

16

1 BURNER

“DUAL”

NATURAL (12T) = 20 mbar

Σ Qn Natural Gas = 5.6 kW

Voltage = 220 - 240 V ~

Frequency = 50 Hz

2 BURNERS

NATURAL (12T) = 20 mbar

Σ Qn Natural Gas = 5.50 kW

Voltage = 220 - 240 V ~

Frequency = 50 Hz

3 BURNERS

NATURAL (12T) = 20 mbar

Σ Qn Natural Gas = 10.55 kW

Voltage = 220 - 240 V ~

Frequency = 50 Hz

TECHNICAL DATA PRINTED ON THE LABEL

Page 17

17

TECHNICAL DATA OF THE

APPLIANCE GAS REGULATION

This hob gas is adjusted to operate on natural (12T) gas at 20

mbar.

Page 18

18

TECHNICAL ASSISTANCE AND SPARES

Before leaving the factory, this appliance was tested and regulated by specially qualified experts in order to

guarantee the best operating results.

The original spare parts can be found only in our Technical Assistance Centres and authorised shops.

Every repair or regulation operation which should become subsequently necessary must be carried out with

the utmost care and attention by qualified personnel.

This is why we recommend that you always contact the Dealer who sold the appliance or our nearest

Assistance Centre, specifying the brand, the model, the serial number and the type of problem affecting your

appliance. The pertinent data is stamped on the label applied to the underside of the appliance and on the

label applied to the packing box.

This information enables the technical assistance department to acquire the appropriate spare parts and

consequently guarantee prompt and targeted intervention. We recommend that you write this data in the

spaces below and keep it to hand at all times:

BRAND: ........................................................................

MODEL: ........................................................................

SERIES: ........................................................................

Keep the Warranty Certificate or the sheet of technical

data with the Instructions Handbook during the

appliance life. It contains important technical data.

This appliance is marked according to the European directive 2002/96/EC on

Waste Electrical and Electronic Equipment (WEEE).

This guideline is the frame of a European-wide validity of return and recycling on

Waste Electrical and Electronic Equipment.

Page 19

19

Küppersbusch Hausgeräte GmbH

Postfach 10 01 32, D-45801 Gelsenkirchen,

Küppersbuschstraße 16, D-45883 Gelsenkirchen

Telefon: (0209) 401-0, Telefax: (0209) 401-303

www.kueppersbusch.de

Teka Austria GmbH

Eitnergasse 13, A-1230 Wien

Telefon: (01) 86680-15, Telefax: (01) 86680-50

www.kueppersbusch.at

K04-0615/01

JZT-GWS3811.0ED-CN

K06-***

JZT-GKS3820.0ED-CN

K06-***

Loading...

Loading...