Page 1

EKV 6800.1M

EKV 6800.1M

ISTRUZIONI DI USO E DI MONTAGGIO

USE AND ASSEMBLY INSTRUCTIONS INSTRUCTIONS DE MODE D'EMPLOI ET D'ENTRETIEN BEDIENUNGS-UND MONTAGEANLEITUNG

INSTRUCCIONES DE EMPLEO Y DE MONTAJE

Page 2

UK

Congratulations ,

upon the wise choice you have made by purchasing the EKV 6800.1M model.

Please read the information in this manual carefully before you operate the coffee machine.

Here you will find important indications regarding your safety and the care and maintenance of the appliance that will allow you satisfactory use over a

long term. Should any breakdown occur, first see the section entitled “Troubleshooting”. Often it is possible to repair small failures independently, thereby avoiding the costs of repairs.

This machine has been built in conformity with the directives EEC 89/392, EEC 89/336, EEC 73/23, EEC 89/109 and subsequent amendments.

The quality and reliability of this product are guaranteed by the fact that it has been built according to the UNI EN ISO 9001: 2000 COMPANY QUALITY SYSTEM.

With best wishes.

Küppersbusch

ENGLISH

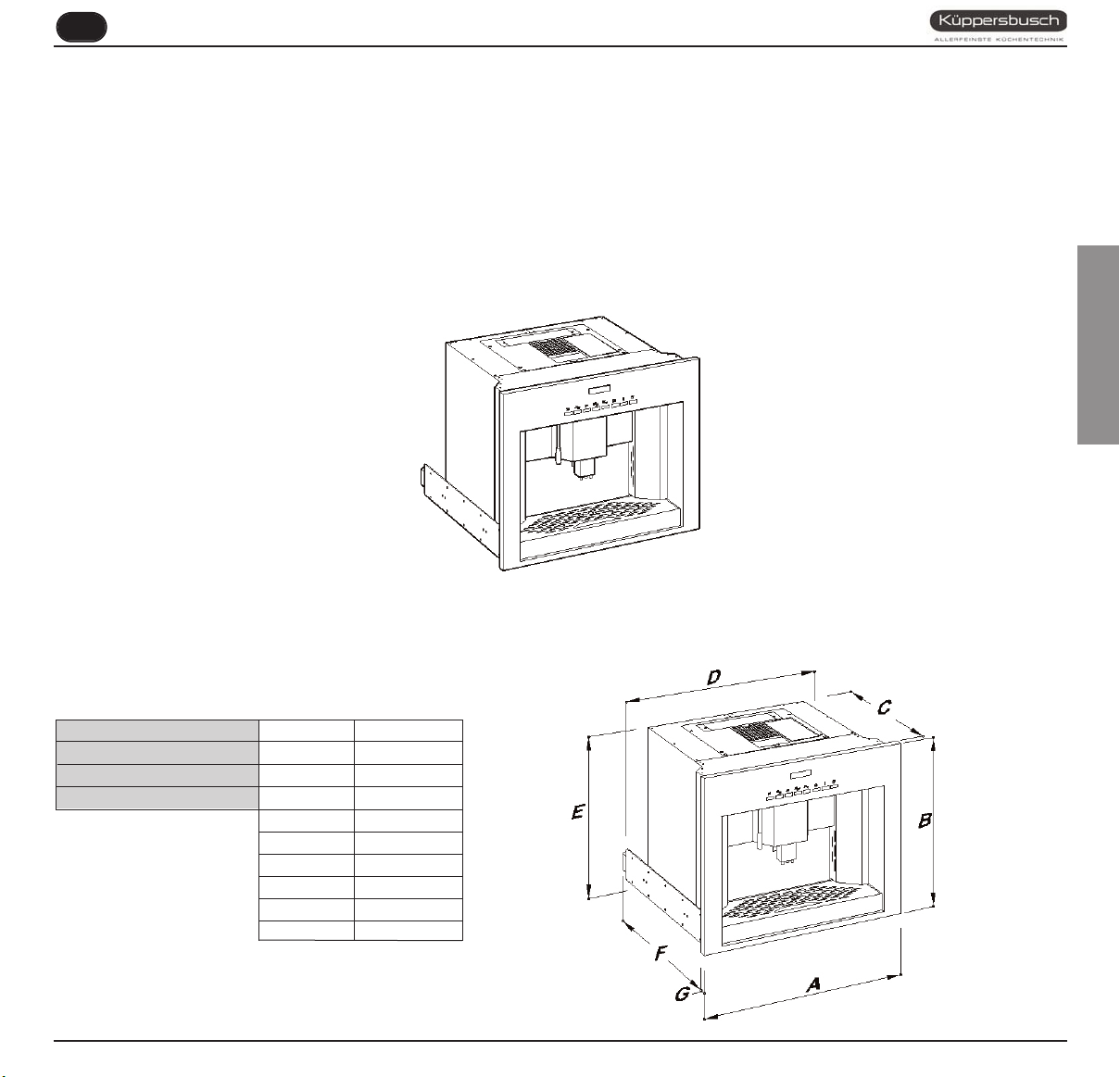

TECHNICAL CHARACTERISTICS

NET WEIGHT 52 Kg 114 Lb

GROS WEIGHT 63 Kg 139 Lb

POWER 1800 W 1800 W

A

DIMENSIONS A 596 mm

B 462 mm

C 442 mm

D 562 mm

E 445 mm

F 546,5 mmF21,52inc

G 20 mm

Rel. 00 - 2006

23,47 inc

B

18,1 9 inc

C

17,4 inc

D

22,13 inc

E

17,52 inc

E

0,08inc

EKV 6800.1M

35

Page 3

UK

1.

1.1

1.2

2.

3.

3.1

3.2

3.3

ENGLISH

4.

4.1

4.2

4.3

4.4

5.

5.1

5.2

5.3

5.4

5.5

5.6

INDEX

TECHNICAL CHARACTERISTICS . . . . .35

DESCRIPTION . . . . . . . . . . . . . . . . . . . .37

KEYBOARD DESCRIPTION (Standard configuration) . . .38

MICROBAR INTERNAL DESCRIPTION . . . . . . . . . . . . .38

SAFETY INSTRUCTIONS . . . . . . . . . . . .39

TRANSPORT AND HANDLING . . . . . . . .41

MACHINE IDENTIFICATION . . . . . . . . . . . . . . . . . . .41

TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

PRELIMINARY OPERATIONS . . . . . . . . .42

FILLING THE APPLIANCE . . . . . . . . . . . . . . . . . . . .42

MACHINE INSTALLATION

(VERSION FOR DIRECT CONNECTION) . . . . . . . . . .42

SWITCHING ON . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

SWITCHING OFF . . . . . . . . . . . . . . . . . . . . . . . . . . .44

ASSEMBLY INSTRUCTIONS FOR

QUALIFIED PERSONS . . . . . . . . . . . . . . .45

INSTRUCTIONS FOR BUILT-IN ASSEMBLY . . . . . . . .45

EKV 6800 .1M BUILT-IN UNIT DIMENSIONS . . . . . . .45

BUILT-IN INSTALLATION . . . . . . . . . . . . . . . . . . . . .45

NUMBER OF SPACER PLATES . . . . . . . . . . . . . . . . . .46

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.9

7.10

8.

8.1

8.2

8.3

8.4

8.5

9.

9.1

9.2

9.3

9.4

10.

10.1

10.2

10.3

10.4

11.

12.

HOW TO MAKE CAPPUCCINO . . . . . . . . . . . . . . . . .51

DISPENSING HOT WATER . . . . . . . . . . . . . . . . . . . . . .52

PROGRAMMING . . . . . . . . . . . . . . . . . . .53

LEGENDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

EXITING PROGRAMMING

PROGRAMMING CYCLE

USER MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

PROGRAMMING CYCLE

TECHNICIAN MODE . . . . . . . . . . . . . . . . . . . . . . . . . . .56

. . . . . . . . . . . . . . . . . . . . .54

SPECIAL MACHINE

SCALING FUNCTIONS . . . . . . . . . . . . . .60

RESETTING THE CLEANING FILTRE

LITRE COUNTER . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

RESETTING WASHING CYCLES . . . . . . . . . . . . . . . .60

RESETTING MACHINE PARAMETRES . . . . . . . . . . .60

HANDLING MANUAL COFFEE DELIVERY GROUP

’ . .60

CLEANING AND MAINTENANCE . . . . . .61

CLEANING THE OUTSIDE OF THE MACHINE . . . . . .61

CLEANING THE DELIVERY UNIT

AND THE MILK FOAMER . . . . . . . . . . . . . . . . . . . . . .62

REINSTATING AN INTERRUPTED

WASHING CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . .63

CLEANING THE MILK FOAMER . . . . . . . . . . . . . . . .63

STANDARD SETTING TABLE . . . . . . . .64

MACHINE FUNCTIONS MESSAGES . . . .65

6.

6.1

6.2

6.3

7.

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

36

ADJUSTMENTS TO BE MADE

BY A QUALIFIED TECHNICIAN ONLY . .48

GRINDING ADJUSTMENT . . . . . . . . . . . . . . . . . . . . .48

CAPPUCCINO MAKER AIR ADJUSTMENT

(foam amount and density . . . . . . . . . . . . . . . . . . . .48

MILK FLOW ADJUSTMENT

(Temperature adjustment) . . . . . . . . . . . . . . . . . . . .48

USE . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

STANDARD CONFIGURATION . . . . . . . . . . . . . . . . .49

SWITCHING ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

SWITCHING OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

HEIGHT-ADJUSTABLE COFFEE DISPENSER . . . . . . . .50

HOW TO MAKE COFFEE . . . . . . . . . . . . . . . . . . . . . .50

HOW TO MAKE 2 COFFEES . . . . . . . . . . . . . . . . . . .50

PREPARING DECAFFEINATED COFFEE IN POWDER 51

PREPARING LONG COFFEE . . . . . . . . . . . . . . . . . . . . .51

EKV 6800.1M

13.

MACHINE BLOCK

ALARM MESSAGES . . . . . . . . . . . . . . . .67

Page 4

UK

1.

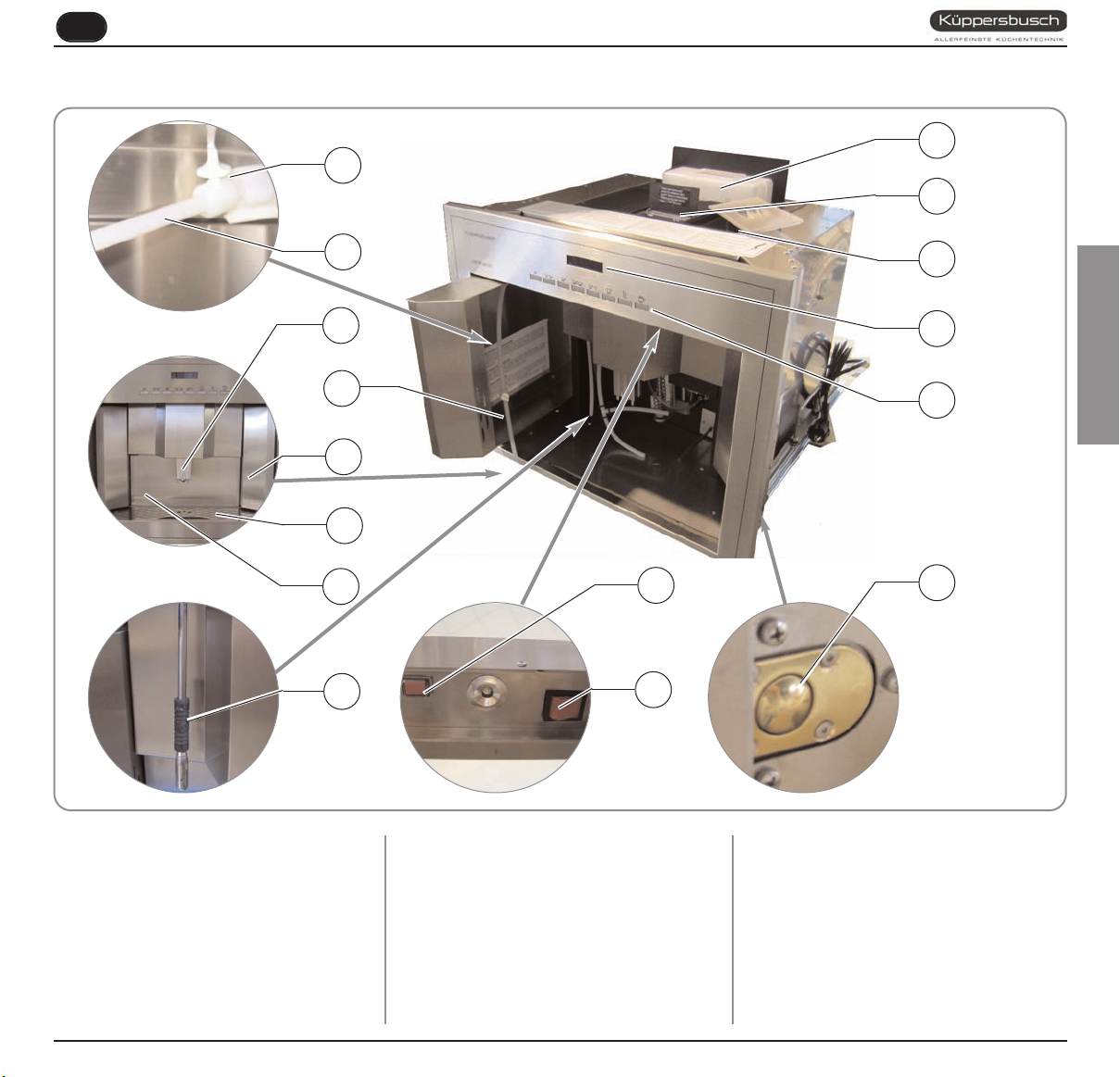

DESCRIPTION

16

1

15

2

14

ENGLISH

3

4

5

6

7

9

13

12

11

KEY

1 Adjustment valve

2 Milk suction tube

3 Coffee dispenser

4 Milk container compartment

5 Removable coffee cup compartment

6 Drip grille

8

7 Drawer for coffee grounds

8 Hot water pipe

9 LED lighting key

10 ON/OFF key

10

Fig. 1

13 Display

14 Coffee bean container

15 Ground coffee container

16 Water tank

11 Outer door release

12 Control panel

EKV 6800.1M

37

Page 5

UK

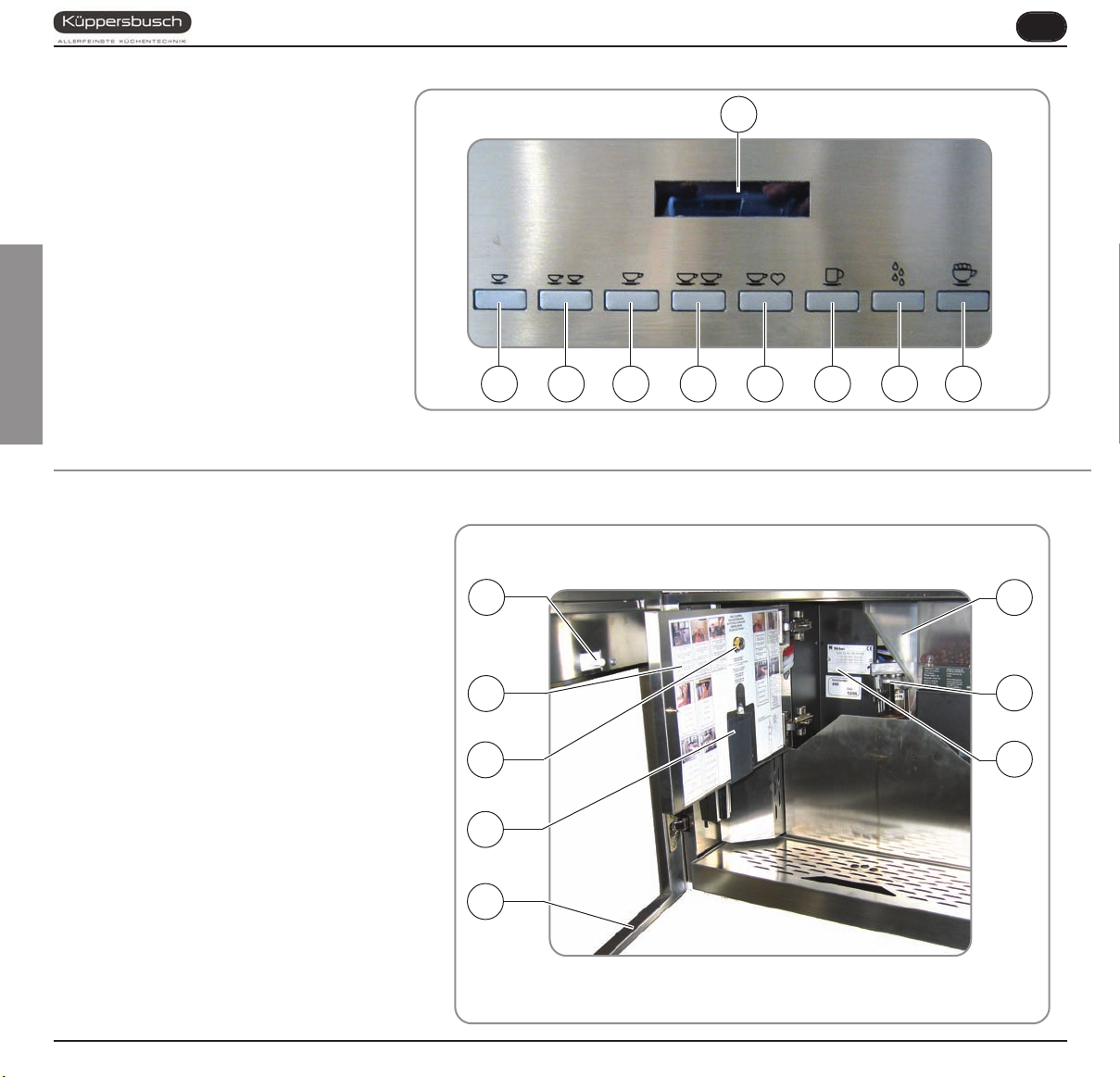

1.1

KEYBOARD

DESCRIPTION

(Standard configuration)

KEY

1

1 Espresso key

2 2 Espressos key

3 1 White coffee key

4 2 White coffees key

5 Decaffeinated coffee, Wash

cycle

6 Long coffee

7 Hot water dispensing

8 Cappuccino

ENGLISH

9 LCD display

1.2

EKV 6800. 1M INTERNAL DESCRIPTION

KEY

9

87654321

Fig. 2

1

6

1 Microswitch for outer door

2 Inside door open

3 Cappuccino maker air adjustment

4 Cappuccino maker with tubes

5 Outer door open

6 Ground coffee conveyor

7 Infusion group

8 Rating plate

38

EKV 6800.1M

2

3

4

5

7

8

Fig. 3

Page 6

UK

2.

☞

☞

SAFETY INSTRUCTIONS

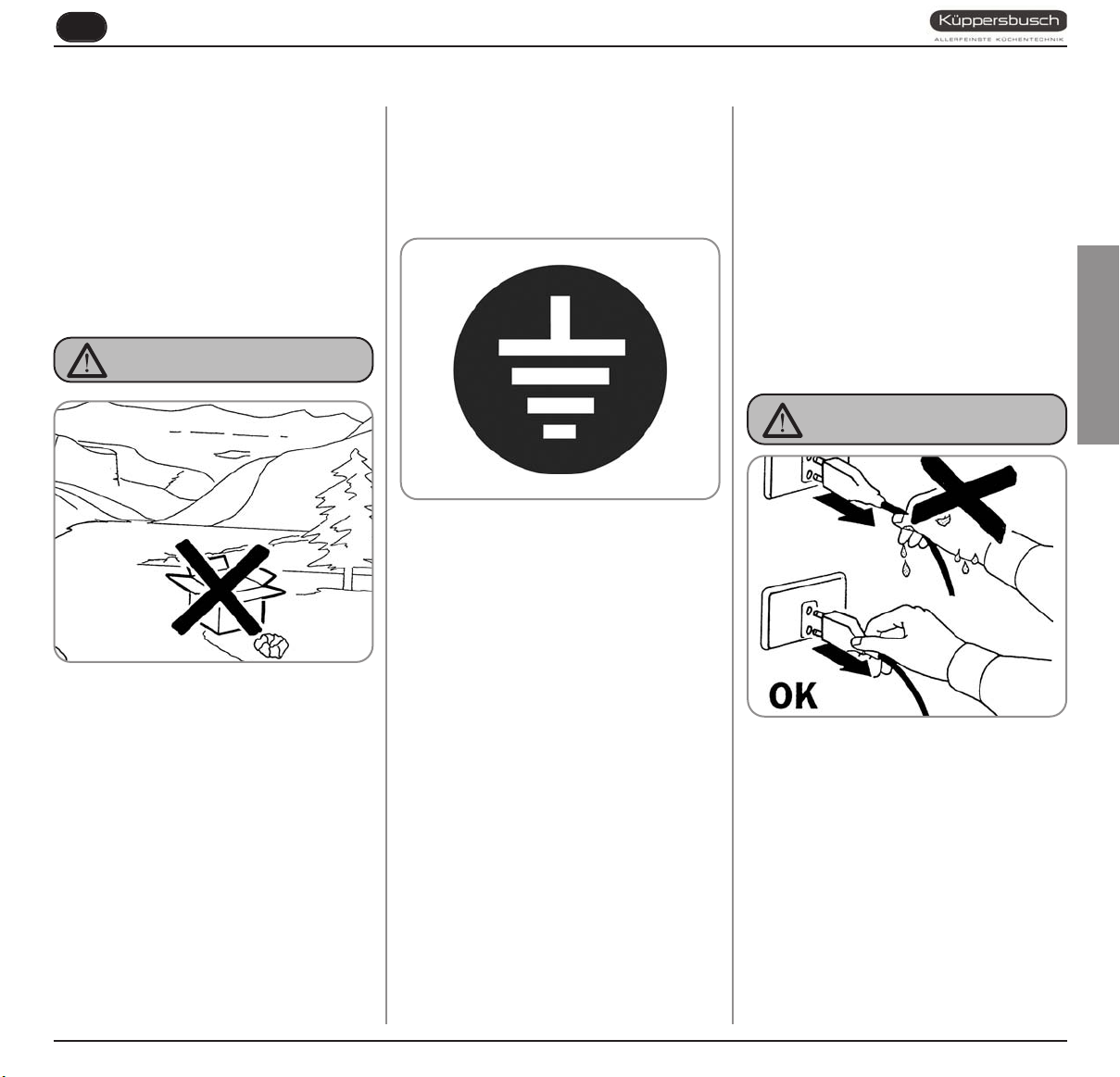

Parts of the packaging can be harmful to children. Danger of suffocation!

Keep packaging out of the reach of

children.

After unpacking, make sure the appliance is complete. In case of doubts,

do not use the appliance, but consult

a qualified technician.

RISK OF POLLUTION

ried out by a qualified electrician who

must ensure that the electric power

of the system is sufficient to absorb

the maximum power input stated on

the plate.

In particular you must ensure that the

size of the wiring cables is sufficient

☞

to absorb power input.

The use of adapters, multiple sockets

or extensions is strictly forbidden. If

they prove necessary, call a fully

qualified electrician.

Fig. 5

This appliance must only be used as

☞

described in this handbook. The

manufacturer shall not be liable for

any damage caused due to improper,

incorrect and unreasonable use.

Basic rules must be observed when

☞

using any electric appliance.

In particular:

• do not touch the appliance when

hands or feet are wet;

CAUTION

RISK OF ELECTRIC SHOCK

ENGLISH

Before connecting the appliance make sure the rating

☞

plate data correspond with the

mains. This plate is on the front panel

at the top right hand side of the appliance. The appliance must be

installed by qualified technicians in

accordance with current standards

and manufacturer’s instructions.

The manufacturer is not liable for any

damage caused due to failure to

ground the system. For the electrical

safety of the appliance, it is necessary to equip the system with the

proper grounding. This must be car-

Fig. 4

The machine must be installed

☞

according to the local standards in

force with regard to plumbing systems. For this reason, the plumbing

connections must be carried out by a

qualified technician.

Fig. 6

• do not use the appliance when

barefoot;

• do not use extensions in bath or

shower rooms;

• do not pull the supply cord out of

the socket to disconnect it from

the mains;

• do not leave the appliance

exposed to atmospheric agents

(rain, sun, etc.);

• do not let the appliance be used

by children, unauthorised staff or

staff who have not read and fully

EKV 6800.1M

39

Page 7

UK

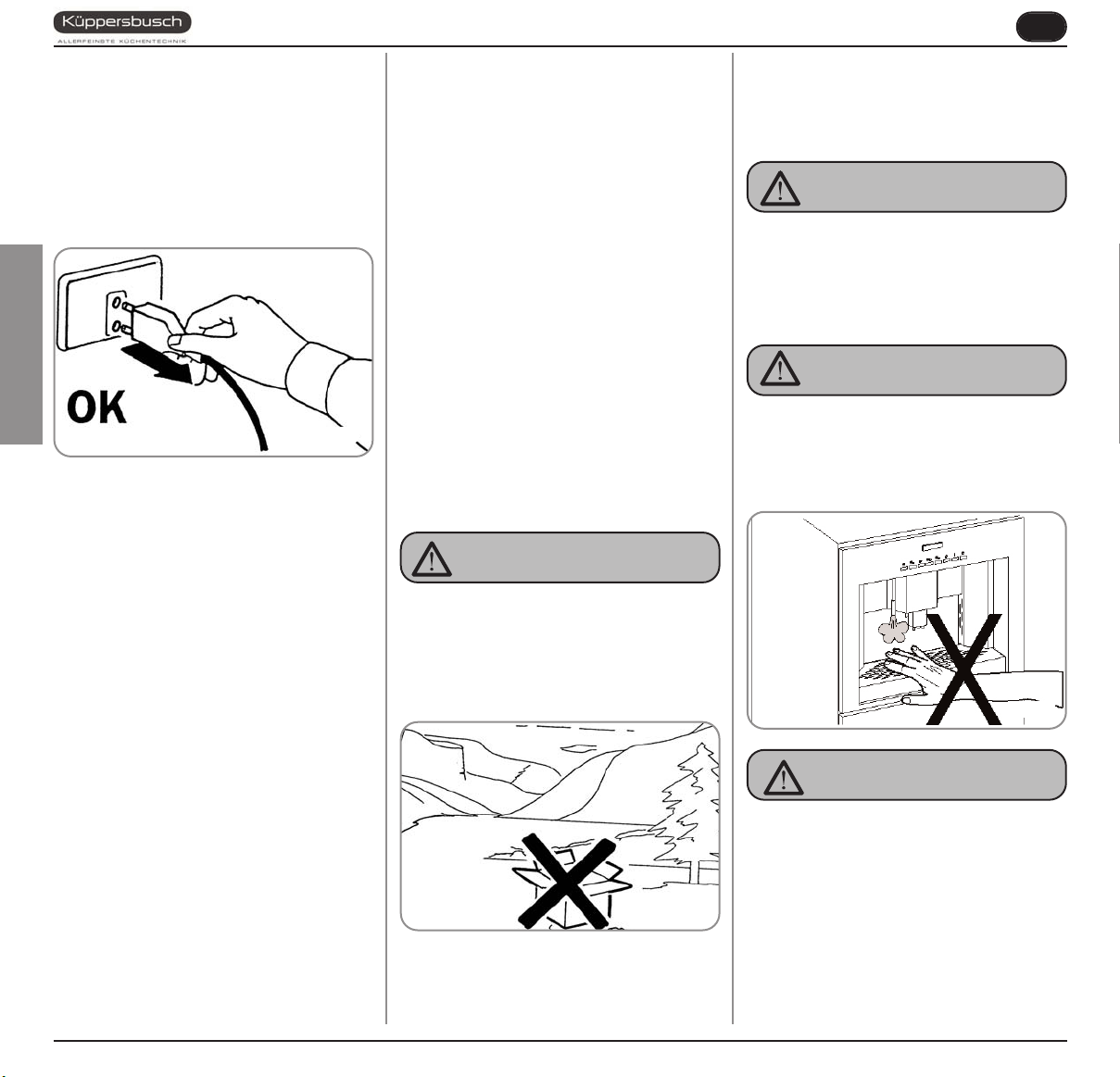

Before servicing the appliance, the

☞

authorised technician must first

switch off the appliance and remove

the plug.

ENGLISH

To clean the appliance, set the

☞

machine to the “0” energy level, that

is, “WITH THE MACHINE SWITCHED

OFF AND THE PLUG REMOVED

FROM THE MAINS” and follow the

instructions in this handbook.

If the appliance breaks down or fails

☞

to work properly, switch it off. Any

intervention is strictly forbidden.

Contact qualified experts only.

Repairs should only be made by the

manufacturer or authorized service

centres. Only original spare parts

must be used. Failure to observe the

above, could make the appliance

unsafe.

For installation, the qualified electri-

☞

cian must fit an omnipolar switch in

accordance with the safety regulations in force and with 3 (0,12) or

more mm (in) between contacts.

understood the contents of this

handbook.

Fig. 7

To avoid dangerous overheating,

☞

make sure the supply cord is fully

uncoiled.

Do not obstruct the suction and/or

☞

dissipation grilles.

The user must not replace the appli-

☞

ance supply cord. If the cord is damaged, switch off the appliance and

have a qualified technician change

the cord.

If no longer using the appliance, we

☞

recommend making it inoperative;

after removing the plug from the

mains electricity, cut the power supply cable.

CAUTION

RISK OF POLLUTION

Do not dispose of the machine in the

☞

environment: to dispose of the

machine, use an authorised centre,

or contact the manufacturer for relative information.

Fig. 8

To increase ventilation to the

☞

machine, make an opening of at least

300 x 100 mm in the back of the housing.

CAUTION

RISK OF INTOXICATION

Once a machine wash cycle has been

☞

started, do not interrupt it, as detergent residues may then be left inside

the delivery group.

CAUTION

RISK OF BURNS OR SCALDING

Use the steam nozzle with care and

☞

never place hands below the jet of

steam. Do not touch the nozzle immediately after use.

CAUTION

RISK OF CUTTING

When adding coffee beans, the

☞

machine operator must not place

his/her hands inside the container.

Fig. 9

40

EKV 6800.1M

Page 8

UK

3.

3.1

Always quote the machine serial number in all

communications to the manufacturer,

Küppersbusch.

TRANSPORT AND HANDLING

MACHINE

IDENTIFICATION

Ftg-Nr 702 148 N 02 010000 22

Fig. 10

3.2

The machine is transported on a pallet, inside

boxes which are secured to the pallet with ribs.

Prior to carrying out any transport or handling

operation, the operator must:

• put on work gloves and protective footwear,

as well as a set of overalls which must be

elasticated at the wrists and ankles.

The pallet must be transported using a suitable means for lifting (e.g., forklift).

TRANSPORT

3.3

During all handling operations, the operator

must ensure that there are no persons,

objects or property in the handling area.

The pallet must be slowly raised to a height

of 30 cm (11,8 in) and moved to the loading

area. After first ensuring that there are no

persons, objects or property, loading operations can be carried out.

Upon arrival at the destination and after

ensuring that there are no persons, objects

or property in the unloading area, the proper lifting equipment (e.g. forklift) should be

used to lower the pallet to the ground and

then to move it (at approx. 30 cm (11,8 in)

from ground level), to the storage area.

Before carrying out the following operation,

the load must be checked to ensure that it is

in the correct position and that, when the

supports are cut, it will not fall.

The operator, who must first put on work

gloves and protective footwear, will proceed

to cut the supports and to storing the product. To carry out this operation, the technical characteristics of the product

must be consulted in order to know the

weight of the machine and to store it

accordingly.

HANDLING

CAUTION

RISK OF IMPACT

OR CRASHING

CAUTION

RISK OF IMPACT

OR CRASHING

CAUTION

RISK OF POLLUTION

ENGLISH

Fig. 11

EKV 6800.1M

41

Page 9

UK

4.

Do not dispose of packaging in the environment.

PRELIMINARY OPERATIONS

CAUTION

RISK OF POLLUTION

ENGLISH

Before carrying out any installation and

adjustment operations you must read and

fully understand the SAFETY INSTRUCTIONS of this handbook.

The company cannot be held responsible

for damage to things or injury to persons

caused by failure to comply with the safety

instructions and installation and maintenance instructions contained in this handbook.

CAUTION

RISK OF SHORT CIRCUITS

Fig. 12

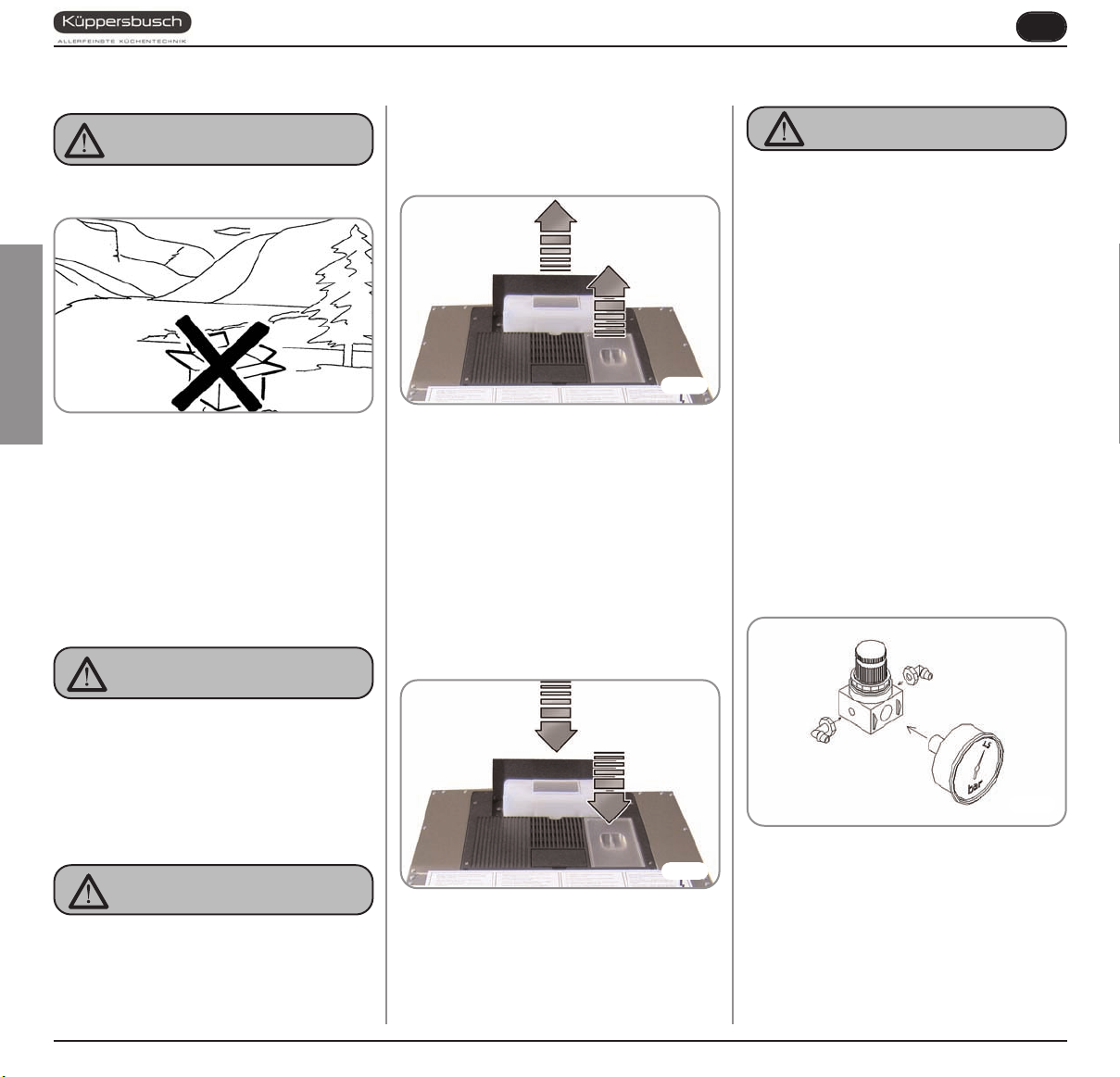

• Take the appliance out very slowly and in

order to guarantee maximum safety, make

sure that no people or things are below it.

Fig. 13

• Pull the water tank up and especially the

first time, wash it with soapy water; then

rinse it carefully, taking care to remove all

soap residues.

• Fill the tank with water (this does not apply

to the version connected to the water mains)

• In the same way, open the coffee bean container and pour in the coffee without reaching the maximum level; then refit the coffee

container lid.

WARNING

The water hardness must be less then

4° - 6° fr (french degree).

The chlorine contents is max 100 mg per

litre (0.00000361 lb/cu in).

Otherwise the conditions of guarantee of

the machine will expire.

4.2

MACHINEINSTALLATION

(VERSION FOR

DIRECT CONNECTION)

• Remove all parts from the box of accessories (Teflon tubes Ø 4 mm, 1 pressure

reducing valve, 3 snap-on connectors, 1

pressure gauge, 1 fastening bracket, 2

threaded connectors and two gaskets). Fit

the pressure gauge and 2 connectors to the

pressure reducing valve, as illustrated in the

drawing here below.

Before connecting the machine to the mains

power supply, please check that the supply

voltage corresponds to the machine voltage.

4.1

Switch off the machine before filling or

removing the water tank.

• Partially remove the machine from its seating.

42

FILLING THE

APPLIANCE

WARNING

EKV 6800.1M

Fig. 14

Fig. 15

• Use the relevant bracket to fit the previously assembled pressure reducing valve to the

nearest point to the water mains (see drawing below).

Page 10

UK

Fig. 16

• Connect one end of the Teflon pipe (diam. 4

mm) to the machine, inserting it firmly into

the snap-on connector. To make sure that

the connection has been made properly, pull

the tube outwards (see drawing).

• Cut the other end of the tube, first making

sure that the length is sufficient to connect it

to the pressure reducing valve.

Fig. 17

NOTE: The maximum outlet pressure from the

pressure reducing valve MUST NOT

exceed 1.5 bars.

Fig. 18

WARNING

The water hardness must be less then

4° - 6° fr (french degree).

The chlorine contents is max 100 mg per

litre (0.00000361 lb/cu in).

Otherwise the conditions of guarantee of

the machine will expire.

4.3

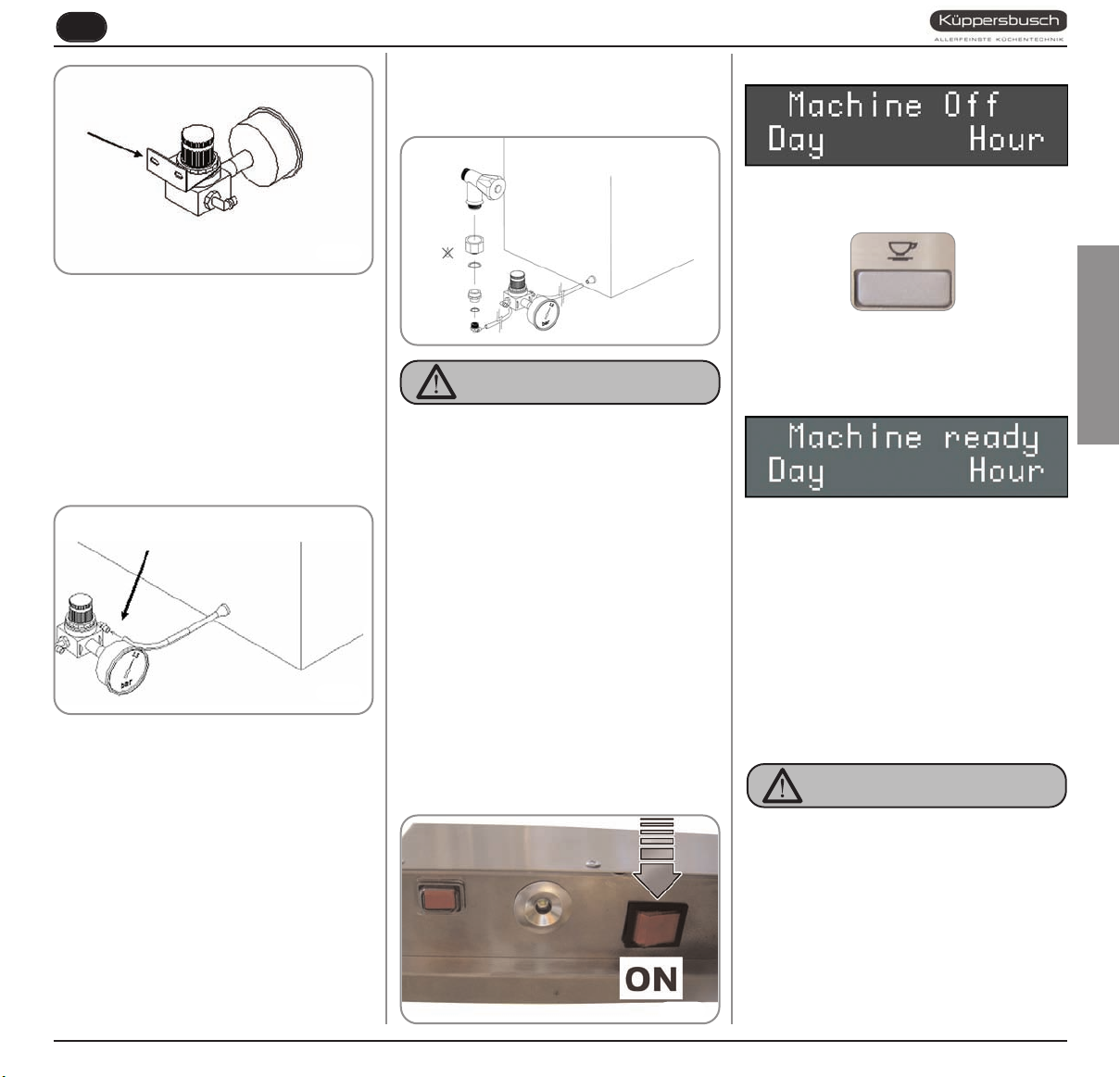

SWITCHING ON

NOTE: in case the following procedure should-

n't take effect, see the chapter on

"PROBLEMS AND SOLUTIONS".

The LCD will then light up and read as follows:

To switch the machine on definitively, press the

“ENTER” key:

ENGLISH

the machine automatically loads the heater with

water and begins heating operations. When the

desired temperature is reached the display will

show the following message:

NOTE: the starting time is about 3 minutes.

NOTA: The appliance is endowed with a secu-

rity system that will stop the machine

after about 1.5 minutes of constant

functioning of the pump (to avoid pump

overheating). In this case, switch off the

main switch of the machine and then

turn it on again.

• After finding the arrows that indicate the

direction of the water flow in the pressure

reducing valve, connect the tube to the

water outlet. Connect the remaining end of

the tube to the other connector (water inlet)

of the pressure reducing valve. After making

sure that you have shut off the stopcock,

proceed to install the connectors and the

relevant gaskets in the mains system.

Connect the free end of the tube to the previously fitted snap-on connector.

After the preliminary operations:

• Press the machine’s main switch and turn it

to “ON”.

Fig. 19

The machine is now ready to be used.

WARNING

When installing the machine for the first

time or after water heater unit maintenance,

press the button to dispense hot water

before dispensing any coffee. repeat this

operation as required and until there is an

even flow of water from the nozzle.

EKV 6800.1M

43

Page 11

UK

4.4

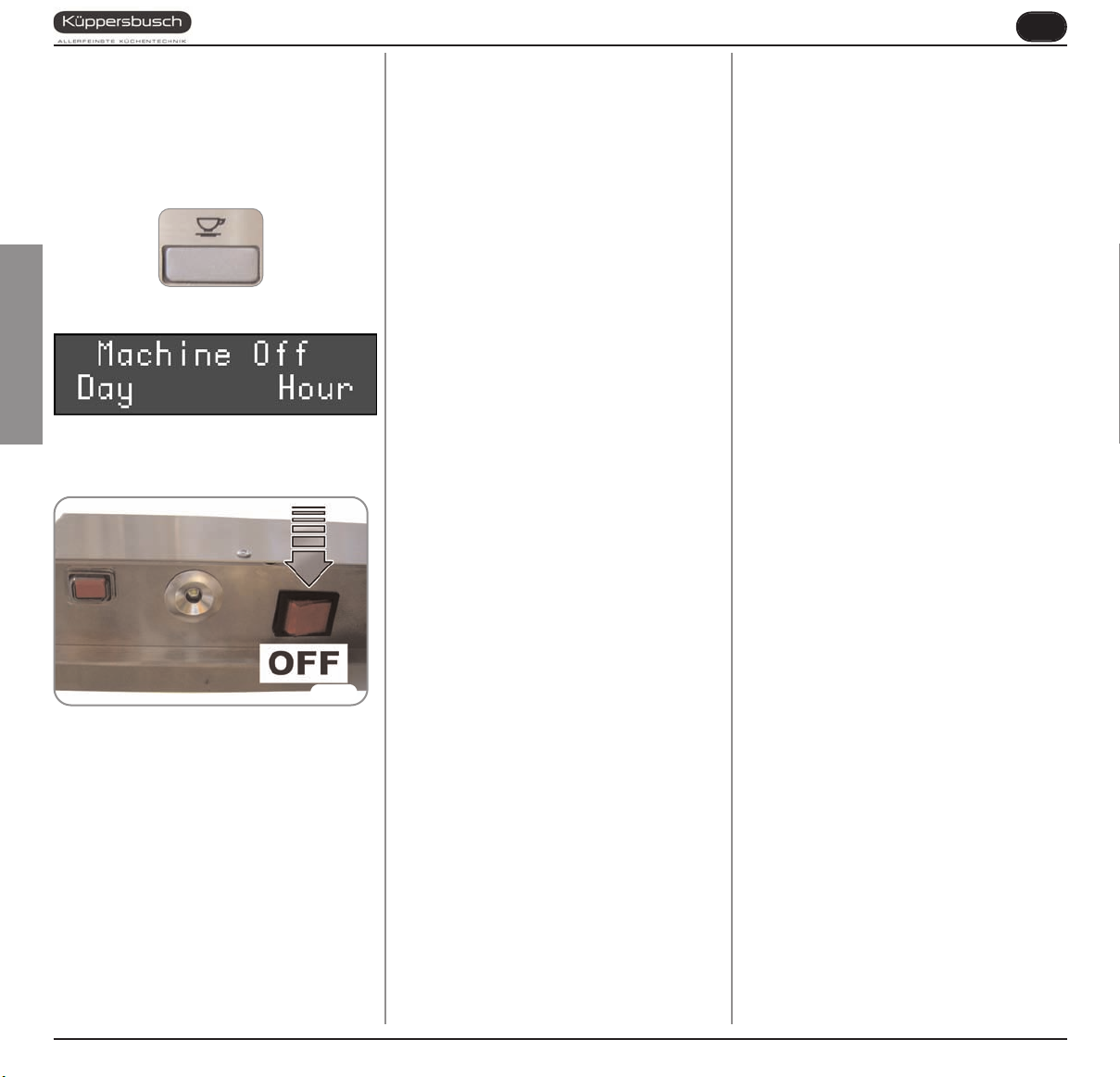

To switch off the machine, proceed as follows:

• Hold the “ENTER” key down for 5 seconds

with the machine switched on:

• The LCD will read as follows:

SWITCHING OFF

ENGLISH

• To switch the machine off fully, press the

main switch and turn it to the “OFF” position.

44

Fig. 20

EKV 6800.1M

Page 12

UK

5.

5.1

ASSEMBLY INSTRUCTIONS FOR QUALIFIED PERSONS

INSTRUCTIONS FOR

BUILT-IN ASSEMBLY

The company supplying this machine cannot

be held liable for any damage arising from

incorrect installation, insufficient or lack of

maintenance, or improper use of the appliance.

• Legal standards and connection instructions

from the local electricity supplier must be

respected.

• Before making electrical connections, make

sure that the electrical capacity of the system is suitable for the maximum power of

the appliance, as indicated on the rating

plate.

• When making connections or repairs, it is

necessary to disconnect the appliance from

the mains electricity.

• When the appliance is assembled, it must

not be possible to touch any insulated

cables enabling appliance operation.

• The unit housing the built-in coffee machine

must be suitably fixed to the floor or wall in

the room.

• To guarantee safe machine use, the unit

housing the machine must be structurally

sound and its guide attachment points must

be able to sustain a weight of three times

that of the coffee machine during the

removal phase.

5.2

EKV 6800 .1M BUILT-IN

UNIT DIMENSIONS

Fig. 21

• Place the metal plate in position in the top

part of the coffee machine housing so that it

meets with the back section of the unit.

ENGLISH

Fig. 22

• Tighten the four screws.

• Place the two corner pieces with guides on

the flat surface in the unit, fixing them into

place exactly 90 mm from the unit’s front

edge.

• The appliance is equipped to be connected

to a single plug socket, which must be fitted

in full compliance with the standards in

force. Only a qualified electrician may install

a plug socket or replace the power cord,

which must be performed in full respect of

the standards in force.

• If, after connection, it is no longer possible

to reach the plug, a separator with more

than one pole and a contact distance of at

least 3 mm must be fitted in order to comply

with safety regulations.

A 600 mm A 23,62 Inc

B da 562 a 568 mm

C 450 mm C 17,72 Inc

D da 16 a 19 mm D 063 - 075 Inc

5.3

BUILT-IN INSTALLA-

B 22,13 - 22,36 Inc

TION

• Remove the coffee machine from its packaging and make sure that it is not damaged

in any way. Should the machine show any

signs of damage, do not proceed with installation and contact the retailer.

Fig. 23

• Insert the screws into the holes of the corner

pieces, but do not tighten them.

Fig. 24

EKV 6800.1M

45

Page 13

UK

• The machine is supplied with 6 metal plates

(thickness 1 mm) that are to be placed

between the guide and the sides of the unit.

This is to fill any excess space in the event

that the unit is more than 562 mm wide.

5.4

NUMBER OF SPACER

PLATES

BUILT-IN HOUSING

ENGLISH

Width

(mm/inc)

Thick.

(mm/inc)

PLATES

562 / 22,13 19 / 0,748 0

564 / 22,2 18 / 0,708 1+1

566 / 22,28 17 / 0,669 2+2

568 / 22,36 16 / 0,629 3+3

• If necessary, insert the plates as described

above.

• Make sure that there is a distance (distance

B) of 558 mm between the corner pieces.

N°

• To prevent the machine from overheating,

make an opening in the back of the unit of at

least 300 mm x 100 mm, to allow air to circulate.

• Insert the coffee machine into the unit, fitting

the guides on the machine level into the

guides previously fixed on the unit.

The guides should slide telescopically when

a light pressure is exerted on the front of the

coffee machine; if this is not the case, it is

necessary to check the distance between

the guides again.

• When fitting into the unit, the appliance will

automatically hook onto the points A on the

guides.

A

Fig. 26

Open the lid in the top part; then remove and fill

the water tank and close the lid.

Powdered

or decaffeinated

coffee

WARNING

Only pour coffee beans into the container.

Any other type of coffee - ready ground for

example – will damage the grinder.

5.5

DISASSEMBLY

To remove the coffee machine from its housing,

it is first of all necessary to disconnect it from

the mains electricity by unplugging it.

Then press the relevant joints(B) in the guides

and remove the appliance, being sure to support it on the bottom.

B

Fig. 28

Fig. 25

• Fix the guides to the coffee machine housing, tightening all of the screws.

• Make sure that the power cord comes out

from the rear of the housing.

46

EKV 6800.1M

Fig. 27

Page 14

UK

5.6

COFFEE MACHINE CLASS I

RATED VOLTAGE 230V

ELECTRICAL

INPUT

CONNECTION

POWER CORD 1.2m / 47,24 inc

APPLIANCE

DIMENSIONS

(L X D X H)

COMPARTMENT

DIMENSIONS

(L X D X H)

NET WEIGHT 52Kg / 114Lb.

GROSS WEIGHT 63KG / 139Lb.

AMOUNT OF

WATER

TECHNICAL DATA

1800W

1.8KW (ready for connection)

594X440X464mm

23,39X17,32X18,27inc

560X550X450mm

22,05X21,65X17,72inc

5 Lt / 1,321gal.

• Classification of the control device accord-

ing to protection against electrical shocks:

incorporated into Class I equipment.

• Control device pollution levels: suitable for

use in ordinary or normal pollution environments.

• Category (Immunity against excess voltage)

CATEGORY I.

• Class and structure of software CLASS A.

• Control unit printed circuit: 100x180 mm.

ENGLISH

The card is built for use in temperature ranges

as indicated in the electrical characteristics.

Operation at temperatures over these levels is

not foreseen for the logic components in the

control unit and can therefore lead to malfunctioning.

Operation at voltages outside this range cannot

be guaranteed.

EKV 6800.1M

47

Page 15

UK

6.

6.1

ADJUSTMENTS TO BE MADE BY A QUALIFIED TECHNICIAN ONLY

GRINDING

ADJUSTMENT

WARNING

Always remove the drip compartment

before opening the outer door!

Always close the outer door and push the

drip compartment all the way in! Otherwise

the door and hinges could become damaged!

Open the outer door and then the inside one:

ENGLISH

Use the Allen wrench (supplied) on the relevant

screw:

Fig. 29

6.2

CAPPUCCINO MAKER

AIR ADJUSTMENT

(FOAM AMOUNT AND

DENSITY)

NOTE: this adjustment is possible even with

the machine switched on.

The amount of foam is factory set, but it can be

changed using the air adjustment dial on the

cappuccino maker. By making this adjustment,

which changes the density of the foam produced by the cappuccino maker, the result will

be a very creamy, a creamy or a slightly creamy

cappuccino.

• Open the outer door

• Open the inside door

• Turn the adjustment dial as shown on the

decal applied to the door to increase or

reduce air flow.

6.3

MILK FLOW ADJUSTMENT (Temperature

Regulation)

NOTE: this adjustment is possible even with

the machine switched on.

To adjust both the flow and the temperature of

the milk delivery, turn the adjusting tap as follows:

• Remove the left-hand compartment

• Insert the open milk carton and place the

milk suction tube inside it

NOTE: Always use normal pasteurised milk

with a fat content of 3.5%, or fresh milk.

• Turn the milk suction tap

CLOCKWISE/COUNTER-CLOCKWISE to

INCREASE/DECREASE the milk suction

and then DECREASE/INCREASE the temperature.

• Turn the tap until the milk reaches the

desired temperature.

Fig. 30

• turn clockwise for finer grinding or thicker

coffee;

• turn anticlockwise for coarser grinding or

more liquid coffee.

Close the doors after making these adjustments.

48

EKV 6800.1M

Fig. 31

To reduce the amount of foam, turn the dial

anticlockwise, while to increase it, turn the dial

clockwise.

• Close the doors after making these adjustments.

Fig. 32

Page 16

UK

7.

7.1

1 Dispenses 1 cup of espresso coffee

2 Dispenses 2 cups of espresso coffee

3 Dispenses 1 cup of white coffee

4 Dispenses 2 cups of white coffee

5 Dispenses 1 cup of decaffeinated coffee

6 Dispenses 1 cup of long coffee

7 Dispenses hot water

8 Dispenses 1 cup of cappuccino

USE

STANDARD CONFIGURATION

1

2

4

3

8765

Fig. 18

7.2

NOTE: in case the following procedure should-

After finishing the Preliminary Operations and

Installation processes:

• Press the main switch on the machine and

set it to “ON”. The LCD display will switch on

and read as follows:

SWITCHING ON

n't take effect, see the chapter on

"PROBLEMS AND SOLUTIONS".

• When the desired temperature is reached

the display will show the following message:

NOTE: The starting time is about 3 minutes.

NOTE: The appliance is endowed with a secu-

rity system that will stop the machine

after about 1.5 minutes of constant

functioning of the pump (to avoid pump

overheating). In this case, switch off the

main switch of the machine and then

turn it on again.

The machine is now ready to be used.

7.3

To switch off the machine, proceed as follows:

• Hold the “ENTER” key down for 5 seconds

with the machine switched on:

SWITCHING OFF

ENGLISH

IMPORTANT: Keys 1-2-3-4-6 (see 'DIS-

PLAY' description), can correspond to different drinks

according to taste and local

traditions (see PROGRAMMING and paragraph on

SELECTIONS CONFIGURATION).

• To switch the machine on definitively, press

the “ENTER” key:

The machine automatically loads the heater

with water and begins heating operations.

• The LCD will read as follows:

• To stop the machine completely, press the

main switch and turn it to the “OFF” position.

EKV 6800.1M

49

Page 17

UK

7.4

HEIGHT-ADJUSTABLE

COFFEE DISPENSER

To avoid spraying liquids, the height of the dispenser can be adjusted by hand to adapt it to

any type of cup. Carefully adjust to the required

position so as to limit the amount of space

between the dispenser and the cup.

ENGLISH

7.5

The method of preparation is the same as for

espresso and white coffee.

• Position a cup under the nozzles.

The beverages always flow from both nozzles.

HOW TO MAKE THE

COFFEE

’

Fig. 33

• Press the desired coffee delivery key once.

Fig.35

• The coffee is being made.

• According to the kind of coffee selected the

display will read.

O

Leave the cup beneath the nozzles until the

messages on the display disappear.

7.6

HOW TO MAKE TWO

COFFEES

• Position one cup under each nozzle.

Fig.36

• Press the desired coffee delivery key once.

Fig. 37

• The coffee is being made.

• According to the kind of coffee selected the

display will read.

50

O

Fig. 34

EKV 6800.1M

Page 18

UK

Leave the cup under the dispensers until the

message appears on the display.

7.7

HOW TO MAKE DECAFFEINATED COFFEE

USING GROUND COFFEE

• Partly remove the coffee machine from the

unit.

• Open the ground coffee conveyor hatch.

WARNING

Pour only ground coffee into the coffee

bean holder. Any other kind of coffee will

damage the coffee grinder.

Don't put caramelized, sugar coated, or similarly coated coffee beans, or instant coffee

or other sugary beverages because they will

harm the appliance.

Fig.38

• Insert only 1 dose of decaffeinated ground

coffee.

• Press the decaffeinated coffee key once

The display will read:

Then press the key for the type of coffee

required and the display will read as follows

(example):

Leave the cup beneath the nozzles until the

message on the display disappears.

7.8

PREPARING A LONG

COFFEE

NOTE: Use a larger cup than the one used for

white coffee.

• Place the cup under the coffee dispensers.

Beverages will always come out of both dispensers at the same time.

• press the dispensing key for the required

coffee once only.

• The display will read:

• The coffee is being made

Leave the cup under the dispensers until the

message appears on the display.

7.9

HOW TO MAKE

CAPPUCCINO

NOTE: Use a larger cup than the one used for

white coffee.

• Pull out the left-hand compartment and

insert the open milk carton.

Fig. 39

• Place the milk suction tube inside the carton.

• Use the valve on the tube to regulate the

amount of milk required.

• Place the cup under the coffee dispensers.

Beverages will always come out of both dispensers at the same time.

• Press the cappuccino dispensing key once

only.

ENGLISH

EKV 6800.1M

51

Page 19

UK

• The display will read as follows:

• the beverage is being prepared.

Leave the cup under the dispensers until the

message appears on the display.

ENGLISH

7.10

DDIISSPPEENNSSIINNGG HHOOTT

WWAATTEERR

This provides delivery of hot water for brewing

tea, chamomile-tea or herb teas.

WARNING

Before starting this operation, make sure

that there is water in the tank.

Place a suitable container beneath the hot

water nozzle.

Fig. 40

• Press the hot water delivery key once:

WARNING

RISK OF SCALDING

When hot water is being dispensed, never

allow the nozzle to come into contact with

parts of the body and never place your

hands under the nozzle. Always position the

nozzle so it is inclined downwards, towards

the cup grille.

52

• The display will read:

• Hot water will come out of the nozzle. When

you have the required amount, press the hot

water dispensing key again to interrupt hot

water delivery.

EKV 6800.1M

Page 20

UK

8.

8.1

1

2

4

3

PROGRAMMING

LEGENDA

1

ENTER key: used to enter menus

CURSOR keys: used to scroll through

RESET key: used to confirm and to

2

3

and/or to confirm values and pass on to the

next step.

the menus and to

increase / decrease

value settings.

return to the previous

step.

4

Fig. 41

LIST OF PROGRAMMABLE

FUNCTIONS

Functions that can be accessed from the USER

and TECHNICIAN modes.

1. TOT. COUNT

2. PRODUCT NAME

3. PROG. DOSES

4. PROG. GRINDER 1 S

5. MILK DOSE

6. DATE/TIME

7. PROGRAM. ON/OFF

8. ENERGY SAVING

9. LANGUAGE

Functions that can “ONLY” be accessed from

the TECHNICIAN mode.

This operation may ONLY be performed by a Specialist Technician.

Adjustments made by Unqualified

Technicians or other people may render the Guarantee null and void.

Additional functions that can be accessed from

the TECHNICIAN mode are:

10. PREINFUSION

11. TAMPING

12. GROUNDS NUMBER

13. MILK CLEAN WARN

14. CLEAN ALARM

15. SHUT DOWN CLEAN

16. GROUP SETTING

17. GRINDER SETTING

18. COFFEE TEMP.

19. STEAM TEMP.

20. PASSWORD

21. SMART CARD

22. WATER FILTER L

23. WATER HARDNESS SETTING

24 SCALE REMOVAL CYCLE

8.2

Entering the programming function gives

access to all of the USER and TECHNICIAN

mode functions.

NOTE: Can be performed with machine on.

NOTE: Always remove the drip compartment

To enter the programming mode, proceed as

follows:

• Partly remove the machine from its housing.

• Open the front door using the relevant button on the left-hand side of the machine.

• The display will read as follows:

• Press the ENTER key.

• Shut the door again

• The display will read:

The infusion group will then be positioned in

standby and the display will read as follows:

PROGRAMMING

before opening the outer door!

Always close the outer door and push

the drip compartment all the way in!

Otherwise the door and hinges could

become damaged.

ENGLISH

EKV 6800.1M

53

Page 21

UK

8.3

EXITING

PROGRAMMING

To quit the programming mode, it is sufficient to

open the door and close it again.

NOTE: Can be performed with machine on and

from any of the visualized functions.

• The display will read:

ENGLISH

• To switch the machine on definitively, press

the ENTER key.

alternatively, scroll through the functions using

the 4 key, until the display reads:

8.4

PROGRAMMING CYCLE

USER MODE

1. CUMULATIVE TOTAL

The submenus can be entered by pushing the ENTER key.

The quantity of doses delivered for each

kind of beverage will be displayed.

1 Total Ristretto

2 Total 2 Ristretto

3 Total Espresso

4 Total 2 Espresso

5 Total Cafee

6 Total 2 Cafee

7 Total Cafecream

8 Total Latte

9 Total Caffelatte

10 Total Macchiato

11 Total Cappuccino

12 Total Big Cappuccino

13 Total Deca

14 Total Cleaning

15 Total Litres

2. PRODUCT NAME:

A beverage name is assigned to each single

key (no. indicates the number of the relevant key.) The names are pre-set in the factory but it is possible to change them to suit

personal requirements. The individual setting will override the preset ones and influence all subsequent programming procedures.

Example:

In this case the beverage ‘Espresso’ is

assigned to key number 1.

The arrow keys 2 and 4 scroll the names of the

beverages on each key available in the agenda.

The RESET key is for exiting the submenu.

The ENTER key confirms the type of beverage

for the key number being taken into consideration, and then passes on to the beverage of the

next key.

The programmable keys are the following:

1

2 3 4

The machine is now ready to dispense beverages using the new stored settings.

54

EKV 6800.1M

Press the keys 2 and 4to scroll through the various totals relevant to all beverages.

Hold down the 4 key to view the total number of

doses dispensed by the machine.

In order to annul the counts, to press keys 2

and 4 at the same time.

The display will read as follows: “COUNTERS

RESET”.

The RESET key returns to the previous menu.

6

Fig. 42

Once the programming of the final key has

been completed, you pass on to the next menu

item.

NOTE: The keys can be programmed for milk-

based drinks and coffee. Keys 1 2 3

can only be programmed for coffee

drinks, while keys 4 6 and 8 can be

configured as coffee or milk-based

drinks.

8

Page 22

UK

3. WATER VOLUME CC

By pressing the ENTER key the submenus can be accessed.

The doses of water to be used for each

single drink can be programmed.

1 Water volume cc Ristretto

2 Water volume cc 2 Ristretto

3 Water volume cc Espresso

4 Water volume cc 2 Espresso

5 Water volume cc Coffee

6 Water volume cc 2 Coffee

7 Water volume cc CoffeCreme

8 Water volume cc caffelatte

9 Water volume cc macchiato

10 Water volume cc Cappuccino

11 Water volume cc Big Cappuccino

12 Water volume sec Tea

13 Maximum steam time

Keys 2 and 4 increase / reduce the amount of

water used to prepare the relevant beverage,

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

dose programming.

Press the ENTER key to scroll all the items on

the submenu and see confirmation of the dose

programmed.

5. MILK TIME

Press the ENTER key to access the submenu.

This allows you to program the milk delivery time.

1 Latte

2 Caffellatte

3 Macchiato

4 Cappuccino

5 Big Cappuccino

Keys 2 and 4 increase / reduce the amount of

time used to dispense the milk for the preparation of the relevant beverage.

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

grinding time set. Press the ENTER key to

scroll all the items on the submenu and see

confirmation of the set grinding time.

6. DATE/TIME

Press the ENTER key to access the submenu.

This is used to set the date and time to be

displayed on the machine.

1Day

2 Hour

3 Minutes

7. PROGRAM. ON/OFF

This is used to program the automatic

switching ON/OFF for the machine, only

with the machine switch in the ON position.

The default setting for the machine has all

days of the week set to “STANDBY” and

therefore, the main switch must be used

to switch the machine on and off.

Press the ENTER key to access the submenu and the display will read as follows:

Press the 2 and 4 keys to view the settings for

each day of the week.

Press RESET to set SUNDAY as the weekly

day off, which will de-activate the automatic on

and off function.

The display will read as follows:

ENGLISH

4. PROG.GRINDER 1 S

Press the ENTER key to access the submenu.

It is possible to set the grinding times for

each beverage.

1 Grind Time Ristretto

2 Grind Time 2 Ristretto

3 Grind Time Espresso

4 Grind Time 2 Epresso

5 Grind Time Coffee

6 Grind Time 2 Coffee

7 Grind Time CoffeCreme

8 Grind Time Caffellatte

9 Grind Time s. Macchiato

10 Grind Time s. Cappuccino

11 Grind Time s. Big Cappuccino

The 2 and 4 keys increase or decrease the values set for the relevant function.

The RESET key quits the submenu and returns

to the main menu without confirming the new

settings. The ENTER key scrolls through each

single item in the submenu and confirms the

new setting.

Once the date has been set, the function

returns to the main menu.

Press ENTER to reactivate the automatic on

and off function.

To confirm the setting, press the 2 key, which

will then pass to the settings for the following

day.

Press ENTER and the switch on timer will begin

to flash; use the 2 and 4 keys to increase /

decrease the time setting.

Once the required time has been set, press

ENTER to set the following day.

After SATURDAY, press the 4 key to return to

the previous menu.

EKV 6800.1M

55

Page 23

UK

8. ENERGY SAVING

This is used to set the time after which the

machine enables the energy-saving device,

while still keeping the water tank at working

temperature.

Press the ENTER key to access the submenu.

1 Hours:Minutes

Use the 2 and 4 keys to increase / decrease the

time after which the ENERGY-SAVING function

is enabled by 30-minute intervals. This function

is deactivated if the timer is left at zero.

Press the RESET to quit the submenu and

return to the main menu, confirming the new

ENGLISH

setting.

9. LANGUAGE

Press the ENTER key to access the submenu.

This sets the language for operatormachine interface, as shown on the display.

Press the 2 e 4 keys to select the required language.

The possible languages are as follows:

Italian, English, Spanish, German and French.

Press the RESET key to quit the submenu and

return to the main menu, confirming the new

setting.

8.5

TECHNICIAN MODE

PROGRAMMING CYCLE

To access the functions that can only be programmed using the TECHNICIAN MODE,

scroll through all of the functions that can be

accessed from the USER MODE until the display reads as follows:

Enter the correct password to view the first item

in the programming menu that can be accessed

from the TECHNICIAN MODE.

To access the functions reserved to the

service engineer, when entering this

mode for the first time, or if the password has not been changed, it is necessary to press the key (2) on the

machine button pad five times.

10. PREINFUSION

Press the ENTER key to access the submenu.

When keys 2 and 4 are pressed, this programs – for each single beverage – the

possibility to pre-infuse the coffee tablet

(YES or NO).

1 Preinfusion Ristretto

2 Preinfusion 2 Ristretto

3 Preinfusion Espresso

4 Preinfusion 2 Espresso

5 Preinfusion Coffee

6 Preinfusion 2 Coffee

7 Preinfusion CoffeeCreme

8 Preinfusion Caffelatte

9 Preinfusion Macchiato

10 Preinfusion Cappuccino

11 Preinfusion Big Cappuccino

Press the RESET key to quit the submenu and

return to the main menu, confirming the setting.

Press the ENTER key to scroll through each

single item in the submenu and confirm the settings.

11. PRESSING

Press the ENTER key to enter the submenu.

Press the keys 2 or 4 to program tablet

pressing (YES or NO) for each single beverage.

56

EKV 6800.1M

2

If an incorrect password is entered, the

machine will automatically quit the programming mode to enter the machine ready mode.

Fig. 43

The RESET key exits the sub-menu and

returns to the main menu, confirming the value

set.

The ENTER key scrolls through each single

item in the sub-menu and confirms the value

set.

Page 24

UK

12. GROUNDS NUMBER

Press the ENTER key to access the submenu. This allows you to program the

GROUNDS NUMBER. When the number

has been reached, a message will be displayed instructing you to empty the coffee

grounds drawer and the machine will stop

working to allow the procedure to be done

safely.

Press the keys 2 and 4 to set the number

of grounds reached before the message

to request emptying is displayed (max.

40).

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

grounds number programmed.

The ENTER key is disabled

13. MILK CLEAN WARN. H

Press the ENTER key to access the submenu. This allows you to program after

how many hours, following the last milk

delivery, the milk foamer cleaning warning

will be displayed.

Press the keys 2 and 4 to set the number

of hours after which a cappuccino maker

cleaning request is displayed.

NOTE: It is advisable to set this time to 2

hours.

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

number of hours programmed.

The ENTER key is disabled.

14. CLEAN WARNING

Press the ENTER key to access the submenu. This allows you to program the

number of cycles after which the group

clean warning will be displayed.

The arrow keys 2 and 4 increase/decrease the

amount of cycles for the display of the group

clean warning message.

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

number of cycles programmed.

The ENTER key is disabled

15. SHUT DOWNCLEAN

Press the ENTER key to access the submenu.

This programmes a cleaning cycle for the

dispenser group when the machine is

switched off.

Set to YES to enable this function.

If the function is enabled, 100 cm3(6.1024

cu in) of water will be dispensed.

Press the 2 and 4 keys to enable (YES) / deactivate (NO) cleaning at the end of service

16. GROUP SETTING

Press the ENTER key to access the submenu.

This allows you to program the group

repositioning.

The arrow keys 2 and 4 increase/decrease the

riascent of the motor.

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

programming.

The ENTER key is disabled.

17. GRINDER SETTING

Press the ENTER key to access the submenu.

This allow you to program the choice of

increasing grinding times by 0.1 seconds

every 250-1000 deliveries.

By setting the program at 0, the function is

disabled.

The arrow keys 2 and 4 increase/decrease the

number of deliveries, after which there will be

an increase in grinding time.

The available values are 0, 250,500, 750, 1000.

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

number of deliveries programmed.

The ENTER key is disabled.

18. COFFEE TEMPERAT.

Press the ENTER key to access the submenu.

This allow you to program the temperature of the coffee heater.

The arrow keys 2 e 4 increase/decrease the

temperature of the coffee heater.

La temperatura massima impostabile è 105°C

(221°F).

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

temperature programmed.

The ENTER key is disabled.

ENGLISH

EKV 6800.1M

57

Page 25

UK

19. STEAM TEMPERAT.

Press the ENTER key to access the submenu.

This allow you to program the temperature of the steam boiler.

The arrow keys 2 e 4 increase/decrease the

temperature of the steam boiler.

La temperatura massima impostabile è 130°C

(266°F).Press the RESET key to exit the submenu and go back to the main menu and to

confirm the temperature programmed.

The ENTER key is disabled.

20. PASSWORD

Press the ENTER key to access the sub-

ENGLISH

menu.

This programmes a new password to

access the functions that can be programmed in the TECHNICIAN MODE.

Enter a combination of 5 keys (from the 8

keys available on the keyboard) and set

the new required password.

Press the RESET key to quit the submenu and

return to the main menu without confirming the

setting.

Press the ENTER key to confirm the setting.

21. SMART CARD

Press the ENTER key to access the submenu.

This sets the SMART CARD reader to

enabled.

The function is enabled by setting the

parameter to YES.

Press the 2 and 4 keys to enable (YES) / deactivate (NO) the SMART CARD reader.

22. WATER FILTER

Press the ENTER key to access the submenu.

This allows you to program the number of

litres of water to be delivered for the display of the message clean water filter.

The arrow keys 2 e 4 increase/decrease the

number of litres of water delivered for the display of the message clean water filter.

Press the RESET key to exit the submenu and

go back to the main menu and to confirm the

number of litres programmed.

The ENTER key is disabled.

23. SETTING WATER

HARDNESS

It is possible to set water hardness according to

French degrees and therefore, an alarm for

performance of the de-scaling cycle.

• When the machine displays this message:

Press the ENTER key to enter the function.

The display will then read as follows:

Use the 2 e 4 è keys to set (increase/reduce)

the water hardness parameter.

Press the ENTER key to return to the main

menu and save the setting to memory.

Press the RESET key to return to the main

menu without saving the setting to memory.

The following table shows the correspondence

between the hardness setting and the number

of litres of water consumed after which the “DE-

SCALE” message appears.

WATER HARDNESS °FR

1-7

8-30

>31

_

00

NOTE:

The “DE-SCALE” alarm will not interrupt

machine operation and it will be reset as

soon as the de-scaling cycle has been completed, as will the litre counter.

If the set value is “00” the alarm will be disabled.

WATER LITRES (GAL)

1500

1000

500

Alarm disabled

24. DE-SCALING CYCLE

An automatic de-scaling cycle is performed on

the machine's boiler tanks.

• When the message:

Appears, press the ENTER key to begin the descaling cycle.

OPERATION:

• Before starting the de-scaling cycle, fill the

tank with a solution of water and de-scaling

product.

NOTE: Use at least 2 litres of solution.

• When the following message appears:

58

EKV 6800.1M

Page 26

UK

• Press the ENTER key;

• The machine will begin to suck up the solution from the tank and at the same time, to

expel hot water from the nozzle.

• The machine display will read as follows:

Once it has sucked up the first litre of solution,

the machine will stop for five minutes and then

it will start to suck up another litre of solution.

• At the end of this cycle, the display will read

as follows:

• Rinse out the tank and refill it with clean

water (without switch off the machine).

NOTE: Use at least 4 litres (1.06 gal) of solu-

tion, otherwise it will be necessary to

restart the cycle.

• Wait at least 5 minutes.

• At the end of this time, the display will read:

• When the machine has finished the 2 litres

(0,53 gal) taken from the container, the display will again read:

Press the ENTER key again for the machine to

start the second stage of the rinse cycle, taking

a further 2 litres(0,53 gal) on board from the

container. The machine display will then read:

• At the end of the rinse cycle, the machine

display will read as follows:

Leave the machine to heat up for a few minutes; at the end of this time, the machine will

return to its ready status.

WARNING

ENGLISH

• Press the ENTER key and the machine will

begin a rinse cycle, taking on board 2 litres

(0,53 gal) of water from the container and

then expelling it through the steam nozzle.

• During this stage, the machine display will

read as follows:

We advise using the steam dispensing function for a few minutes at the end of each descaling cycle.

WARNING

You may notice drops of water and steam

coming from the hot water nozzle during the

heating stage.

EKV 6800.1M

59

Page 27

UK

9.

9.1

This function allows you to reset the total

amount of water used.

Proceed as follows:

• Release voltage by turning the main switch

• Reinstate voltage by turning the main switch

SPECIAL MACHINE SCALING FUNCTIONS

RESETTING THE

CLEANING FILTER

LITRE COUNTER

off (OFF).

on (ON) and pressing down on the key:

ENGLISH

until the display reads:

until the display reads:

9.3

This function makes it possible to remove incorrect functioning data and to reinstate the

Standard Programming settings (see PRESET

SETTINGS chart).

Proceed as follows:

• Release voltage by turning the main switch

off (OFF).

• Reinstate voltage by turning the main

switch on (ON) and simultaneously pressing down on the keys ENTER and RESET;

RESETTING MACHINE

PARAMETRES

9.4

This function makes it possible to activate the

motor manually forming the automation of the

manual coffee delivery group. Proceed as follows:

• Release voltage by turning the main switch

off (OFF).

• Reinstate voltage by turning the main switch

on (ON) and simultaneously pressing down

on the arrow keys:

until the display reads:

HANDLING MANUAL

COFFEE DELIVERY

GROUP

Fig. 45

9.2

This function makes it possible to reset the total

number of washing cycles.

Proceed as follows:

• Release voltage by turning the main switch

off (OFF).

• Reinstate voltage by turning the main switch

on (ON) and pressing down on the key:

60

RESETTING WASHING

CYCLES

EKV 6800.1M

until the display reads:

Fig. 44

IMPORTANT: When the machine is switched

on, since the arrow key 4 is

used to access this site, the

piston will automatically start

to move downwards.

• Press the arrow key 4 to move the piston

DOWNWARDS.

• Press the arrow key 2 to move the piston

UPWARDS.

• Release and reinstate voltage using the

main switch to end the procedure.

Page 28

UK

10.

10.1

CLEANING AND MAINTENANCE

CLEANING THE OUTSIDE OF THE MACHINE

We recommend that you read this chapter with

care before using the appliance. The appliance

will remain in good condition if cleaned correctly and at regular intervals. Here we have listed

some suggestions about how to clean individual surfaces delicately and efficiently.

CAUTION

Before carrying out any cleaning operations, set the machine to the “O” energy

level, (machine switched off and plug

removed from the mains).

Fig. 46

CAUTION

CAUTION

RISK OF INTOXICATION.

Follow the instructions for use supplied

with all detergents.

These detergents can be ordered from the

Küppersbusch After-sales Service.

CLEANING THE CASING: Clean the casing

inside and out, using a soft damp cloth.

Clean the water-dispensing nozzle after every

use.

NEVER USE THE FOLLOWING UNDER ANY

CIRCUMSTANCES: Aggressive or whitening

products such as, for example, those containing active oxygen, chlorine or other corrosive

ingredients. Cleaning products that scratch,

such as wire wool, plastic scourers or other

items with abrasive surfaces.

CLEANING THE WATER TANK: Only appliances not connected to the mains water have a

water tank. This must be rinsed daily and

refilled with fresh water.

Only fill the tank with fresh, clean water. Never

put milk, sparkling water or other liquids into the

tank.

CLEANING THE WORK AREA:

• Remove the drip container.

• Remove the grille over the drip container.

• Release the outer door.

• Open the outer door and carefully clean the

steel, taking care not to scratch it.

• Open the inside door to make it easier to

remove the coffee grounds container.

• Remove the coffee grounds that have

deposited in the area of the dispenser.

• Remove the coffee grounds container and

clean it carefully, taking care not to scratch

the steel.

• Use a brush to remove any encrusted coffee

and residues from the gasket, piston and

infusion group area.

Fig.48

ENGLISH

Never use steam-cleaning or pressurised

appliances to clean the machine.

CAUTION

RISK OF BURNS OR SCALDING

Leave the machine to cool at least to its

average temperature before cleaning.

Fig. 47

EKV 6800.1M

61

Page 29

UK

10.2

CLEANING THE DELIVERY UNIT AND THE

MILK FOAMER

NOTE:Follow the instructions on the label

applied on the inside of the front door.

ENGLISH

NOTE:Before starting the washing cycle check

and refill the level of water in the water

tank.

The machine is equipped to wash the dispensing unit with special tablets (puly caff) and the

milk circuit with liquid detergent (puly milk).

The machine will begin a wash cycle that consists of hot water deliveries alternated with

pauses. The whole cycle lasts approximately 4

minutes.

Fig. 49

In order to execute the washing procedure proceed as follows:

• Position a container with water beside the

machine.

• Put the suction tube inside it.

• Add the specific cleaning product (20 ml

[0.005 Gal] of Puly Milk).

Fig. 50

• Press the following key:

• Keep pressing down on the key for about 5

seconds until the display reads:

• Press the following key:

The display will read:

WARNING

If the DECAFFEINATED key is not pressed,

after about 20 seconds the machine will

automatically continue the washing cycle.

NOTE:During the washing cycle the dose keys

are disabled.

• Afterwards the rinsing procedure will begin

and the display will read:

We recommend that you carry out a WASHING CYCLE at least once a day using special cleansers.

CAUTION

RISK OF INTOXICATION.

We remind you not to interrupt a washing

cycle using detergent tablets once started,

otherwise detergent residues may remain

inside the machine.

62

EKV 6800.1M

• Open the ground coffee conveyor hatch.

• Insert the cleanser tablet (puly Caff) and

close the hatch.

Fig. 51

Reposition a container only with water in it.

NOTE:During the washing and rinsing cycles

keeping a container under the delivery

unit is advisable or empty the water collector once the wash and rinse cycles

have been completed.

Page 30

UK

10.3

REINSTATING AN

INTERRUPTED WASH-

ING CYCLE

• Should the washing cycle be interrupted by

electricity failure, when the appliance is next

turned on the unit will be in rest position and

the display will read:

10.4

CLEANING THE MILK

FOAMER

NOTE:Follow the instructions applied on the

label on the inside of the front door too.

• Set the machine to the “O” energy level.

2

1

Fig. 53

• Disconnect all the tubes attached to it.

• Disassemble the milk foamer and wash it

carefully.

Fig. 54

ENGLISH

Fig. 52

• Open the door at the front and then the

inside door.

IMPORTANT: Proceed with caution.

• Remove the whole infusion group (1) (do

not pull it downwards).

• Extract the milk foamer from the delivery

group by sliding it upwards (2).

NOTE:If the pause between one cappuccino

and another is over one hour long, it is

advisable to wash the milk foamer by

fishing the milk suction tube in hot water

rather than in milk.

• To reassemble proceed inversely, attaching

the milk foamer tubes properly.

NOTE:To make the reassembling procedure

easier, an explanatory label has been

attached to the front door.

• Clean the drop collector (see paragraph

THE DROP COLLECTING TRAY GRID).

EKV 6800.1M

63

Page 31

UK

11.

ENGLISH

STANDARD SETTING TABLE

BEVERAGE WATER VOLUME GRINDING TIME MILK TIME PRE-BREWING TAMPING NUMBER

(cc) (sec) (sec)

Ristretto 40 7 No Yes

2 Ristretto 80 9 No No

Espresso 50 7 No Yes

2 Espresso 100 9 No No

Caffè 60 7 No Yes

2 Caffè 120 9 No No

Caffe Creme 100 7 No No

2 Caffe Creme 200 9 No No

Cappuccino 50 7 12 No Yes

Big Cappuccino 60 7 15 No Yes

Macchiato 50 7 12 No Yes

Caffellatte 60 7 12 No Yes

Milk 15

Hot Water 20

Steam 55

Grounds number 20

Milk cleaning warning 00

Clean warning 00

Group setting 1,8 (sec)

Coffee temperature 98 (°C)

Steam temperature 125 (°C)

Water filter 00

Grinder setting 00

Shut down clean No

Password

Smart Card No

Energy Saving 00

Water hardness°Fr 00

64

EKV 6800.1M

Page 32

UK

12.

MACHINE FUNCTIONS MESSAGES

DISPLAY CAUSA EFFECT SOLUTION NOTE

GROUNDS DRAWER FULL

GROUNDS DRAWER OUT

OF PLACE

Grounds drawer full. The

number of coffee grounds in

the drawer has reached the

number set during programming stage.

Grounds drawer out of place. Keys delivering coffee based

Keys delivering coffee based

drinks are blocked.

drinks are blocked.

Pull out the grounds drawer

and empty it into a garbage

bag. Put the drawer back into

place, when the display reads:

ENGLISH

Insert the grounds drawer

into its special slot.

Should this alarm turn on during the delivery of a coffee

based drink:

• up until brewing, the alarm

is displayed but the drink

will be delivered;

• after brewing, the cycle in

progress will be suspended.The coffee cycle will

recom-mence only when

the drawer has been put

back in its place.

FRONT PANEL POSITION

Front panel open. The machine functions are

blocked.

Should this alarm turn on during the group movement

phase:

• the movement will be

interrupted

When the drawer is back

in its place, the reset

group will be repeated.

Close the front panel.

EKV 6800.1M

65

Page 33

IDISPLAY CAUSE EFFECT SOLUTION NOTE

UK

WASHING CYCLE

IS NEEDEDGIO

WASHING THE MILK

CIRCUIT IS NEEDED

ENGLISH

SHUT DOWN CLEAN

The set number of cycles

programmed before washing,

has been exceeded.

The set number of hours programmed from time of last

milk based drink before

washing, has been exceeded.

An end of service wash was

set for the delivery unit during

the programming stage.

The message will appear on

the display but the machine

will continue to deliver drinks.

The message will appear on

the display but the machine

will continue to deliver drinks.

An end of service wash must

be performed before the

machine is switched off.

Do a washing cycle (see

paragraph WASHING THE

DELIVERY UNIT AND MILK

FOAMER).

Perform a washing cycle for

the milk foamer only. As in

the case of a complete

washing cycle, you must

keep the key pressed down

for 5 seconds without, however, inserting cleanser

tablets for this group’s washing. (See only points 1,2,3,4

of the paragraph ‘WASHING

THE DELIVERY UNIT AND

MILK FOAMER’).

Press the ENTER key as

shown on the display. The

machine will automatically

perform an end of service

wash, dispensing approx.

3

(3.0512 cu in) of water

50cm

and will then switch off.

NEED FOR DE-SCALING

CYCLE

66

EKV 6800.1M

The number of litres after

which a de-scaling cycle is

required has been exceeded.

This message is displayed

but the machine will continue

to dispense drinks.

Carry out a de-scaling cycle

(SEE the relevant section

entitled

"DE-SCALING CYCLE").

Page 34

UK

13.

MACHINE BLOCK ALARM MESSAGES

DISPLAY CAUSE EFFECT SOLUTION NOTE

UPPER PISTON MOTOR

GROUP ALARMORE

HEATER FILLING

ALARM

TURBINE ALARM

On registering the alarm, the

control unit will display a

message about the drink in

progress with the error message correspond-ing to the

function. For example:

During the group handling

phase, the upper piston

exceeded maximum set time

by 10 seconds before recognizing motor pickup.

The heater filling stage has

exceeded the 3 minute maximum time; the probe level is

uncovered.

The volume counter will not

send any impulses to the

control unit for 5 seconds.

The control unit will halt whatever cycle is on by turning off

both the movement actuator

and those for drink delivery;

the operator will not be able

to make selections on the

keyboard.

The machine will stop. If the alarm reappears

The delivery will continue for

up to 60 seconds or for as

long as any of the coffee

based drink keys are

pressed.

Open and close the machine

door.

Open and close the machine

door. The control unit will

repeat the machine starting

up procedure.

If the alarm reappears

after the second time of

taying, call the Service

Technician.

after the second time of

taying, call the Service

Technician.

In case the alarm persists, the machine can

be used as a manual

appliance.

• Press the selected

key to start the dosing;

• Once the desired

dose has been delivered in the cup,

press the same key

to halt the dose

being delivered.

Call the Service

Technician.

ENGLISH

WATER TANK EMPTY

ALARM

The water tank is empty.

ered and the dosing will be

halted while in progress.

Fill the water tank.The coffee will not be deliv-

Use the Hot Water key

to eliminate any air bubbles.

EKV 6800.1M

67

Page 35

DISPLAY CAUSE EFFECT SOLUTION NOTE

UK

CLEANING FILTER

ALARM

TEMPERATURE PROBE

MALFUNCTION ALARM

ENGLISH

COFFEE QUANTITY

ALARM

The volume counter has

reached the number of litres

of deliverable water set during programming phase.

One of the two temperature

probes is broken.

Too much coffee. Coffee will not be delivered

Coffee will not be delivered;

the dose will not be halted or

it is variable.

Coffee will not be delivered. Substitute the broken probe. This alarm blocks all

and an ejection cycle will be

effected.

Regenerate cleaning filter

salts. To erase the alarm see

paragraph on ‘RESETTING

CLEANING FILTER LITRE

COUNTER’.

Reduce the quantity of coffee.

This alarm will not halt

delivery. The cleaning

filter alarm can be eliminated by programming

the number of litres to

zero (see paragraph on

‘PROGRAMMING’).

deliveries.

68

EKV 6800.1M

Loading...

Loading...