Page 1

KÜPPERSBUSCH

After-Sales Service

Technical Information

Dishwasher Series 630

Models: IGVS 649.1

IGVS 659.1

IG S 669.1

IGSS 644.1

IGSS 659.1

GB

Page 2

Contents

1. GENERAL PRODUCT INFORMATION............. .. .. .. .. ................ .. .. .. .. ...............3

1.1 Intelligent washing technology .................................................................. 3

1.2 Operation and handling............... .............................................................. 5

1.3 Improved installation and connection.................................... .................... 7

1.4 Further techni cal inn ovatio ns..................... .............. .. .. .. .............. .. .. .. ..... 1 1

1.5 Technical Data......................................................................................... 17

2. GENERAL TECHNICAL DESCRIPTION............... .. .. .. .. .. ................ .. .. .. .. ....... 20

2.1 Structure.................................................................................................. 20

2.2 Housing parts..................... .. .. .. .............. .. .. .. .............. .. .. .. .............. .. .. .. ... 20

2.3 Rinse container ....................................................................................... 20

2.4 Inner door................................................................................................ 20

2.5 Tub .......................................................................................................... 23

2.6 Door spring adjuster .................... .. .. .............. .. .. .. .............. .. .. .. .............. .24

2.7 Height adjustmen t.......... .. .. .............. .. .. .. .............. .. .. .. .............. .. .. .. .........24

2.8 Spray system...........................................................................................25

2.9 Wash and pump syste m............... ............ .. .. . . .. .. . . .. .. . . .. .. . . .. .. . . .. .. . . .. .. . . .. .. .25

3. FUNCTION DESCRIPTION............................................................................. 29

3.1 Water inlet for models with heat exchanger and electronic control........29

3.2 Aqua Stop system................ .............. .. .. .............. .. ............................ .. ... 29

3.3 Safety function.........................................................................................29

3.4 Water inlet with heat exchanger prefill (VF1)

(models with electronic control only) ....................................................... 29

3.5 Explanation of wash commands.............................................................. 30

3.6 Water inlet without heat exchanger......................................................... 32

3.7 Regenerating with heat exchanger ......................................................... 32

3.8 Regenerating without heat exchanger .................................................... 32

3.9 Level sensor system for fill level..............................................................33

3.10 Safety level .............................................................................................33

3.11 Aqua Sensor .................... .. .............. .. .. .. .............. .. .. .. .............. .. .. .. .........40

3.12 Dispenser detergent/rinse aid ................................................................. 41

3.13 Operating panels.....................................................................................42

4. PROGRAMS/BUTTON FUNCTIONS E1 CONTROL ..................................... 42

5. FEATURES......................................................................................................43

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

1 For internal use only

Page 3

6. CONSUMPTION VALUES................ .. .. .. .............. .. .. .. .............. .. .. .. .............. .. .44

6.1 Electronic with heat exchanger................................................................44

6.2 Electronic without heat exchanger...........................................................44

7. SPECIAL PROGRAMS E1 CONTROL ...........................................................45

7.1 Button functions F-control with one 7-segment display...........................46

7.2 Button functions E-control and V-control

with two 7-segment displays....................................................................47

7.3 Special program "Function check", with heat exchanger ........................48

7.4 Customer Service check program - electronic dishwashers....................50

7.5 Check program with heat exchanger.......................................................51

7.6 Starting the Customer Service program ..................................................53

7.7 Fault numbers..........................................................................................53

7.8 Storage of fault numbers..........................................................................54

7.9 Remaining cycle time display...................................................................54

7.10 Operation - wash program .......................................................................54

7.11 Program sequence............ .. .. .............. .. .. .. .............. .. .. .. .............. .. .. .. .......55

7.12 Adjustment of regeneration steps............................................................62

8. POSSIBLE FAULT DISPLAYS AND EXPLANATION OF THE

NTC CHARACTERISTIC CURVE....................................................................64

8.1 Wiring diagrams.................................... .. .. .. .............. .. .. .. .............. .. .. .. .....64

8.2 Indications in the display and of the LEDs for electronic controls

with one 7-segment display .....................................................................65

8.3 Calling the Customer Service or function program................. .. .. .. .. .. .. .. .. .66

8.4 NTC characteristic curve..........................................................................67

9. WIRING DIAGRAMS............. .. .. .............. .. .. .. .............. .. .. .. .............. .. .. .. ...........68

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 2

Page 4

1. GENERAL PRODUCT INFORMATION

1.1 Intelligent washing technology

In the dishwasher series 630 all top and middle class dishwasher models are equipped with an

electronic control. Advantage for use: the appliances provide a number of functions during which

the

dishwasher "decides" itself. Thus the appliances are enabled to optimally fulfill their main task, i. e. to

wash and dry dishes that are more or less heavily dirtied while consuming the lowest possible amount of

water, current and chemicals. This performance is supported by the following features:

• Aqua Sensor

• Regeneration electronic

• Optimally differentiated wash programs

• Warm water detection

The Aqua Sensor

The essential component of the "Intelligent washing technology" is the Aqua Sensor: an optical

measuring system to measure the turbidity of the wash water. The Aqua Sensor consists of an

infrared light barrier located in the wash water circuit between recirculation pump and spray arms.

This light barrier serves to detect the contamination of the water by substances that have come off

like grease, oil, protein.

The Aqua Sensor is activated in all programs that contain a prewash cycle. If the wash water is still

"clean" at the end of the prewash cycle, i. e. the turbidity does not exceed a determined limit value,

the wash water will be used for the subsequent wash cycle. If the water is more heavily

contaminated, it will be drained and replaced by fresh water from the water supply. In this way the

water consumption in case of standard dirtying of the dis hes is reduced by 4.5 ltrs. S aving is always

realised, if the water has not been heavily dirtied during the prewash cyle, i. e. "has not yet fulfilled

its task". This applies to moderately dirtied dishes and to dishes to which the dirt sticks such heavily

that it could not be removed during prewash. Also in this case clean water is not unnecessarily

drained. A comparable system for optical checking of the water contamination has so far not been

used by any competitor in Europe. In general, the Aqua Sensor is included in the standard

equipment of appliances with 5 programs and more (see appliance range and features).

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

3 For internal use only

Page 5

Regeneration electronic

By means of the regeneration electronic the new dishwashers may regulate the consumption of

water and salt as required.

In contrast to mechanical dishwashers where a regeneration process is generally performed in any

wash program (regeneration of the softening system by means of a salt solution), the electronic

controls this regeneration process in accordance with the actual requirement. By means of the

water hardness preset at the dishwasher (see p. 13 - Softening system) the electronic counts the

number of wash baths that can be performed until the softening sy stem is "ex hausted". The number

of the actually performed wash baths is considered accordingly. When the highest-possible number

is reached, the regeneration process will be started.

Depending on the water hardness and the selected wash program regeneration may be performed

after every (31-50 dH) or only after the 30th wash program (0-3 dH). The regeneration electronic is

factory-set to level 5, i. e. 17-21 dH. W ith this presetting, regeneration is performed after 12 wash

baths, i. e. 3 standard programs (see p. 13 - Softening system). The advantage of this feature is that

only the amount of water and salt actually required for the respective water hardness will be used

for regeneration. The average salt consumption for each wash program is reduced by approx. 30%

from 25 g to 18 g.

The regeneration electronic is included in the standard equipment of dishwasher models with

electronic control.

Warm water detection

The electronic control reacts to the connection conditions of the appliance and thus enables the

unlimited use of all dishwasher models, with or without heat exchanger, in case of warm water

connection.

If the control recognises that the appliance has been connected to warm water supply (if the

measured temperature of the inlet water during the rinse cycle exceeds 45 °C), the heat exchanger

will not be filled for the drying cycle. In order to ensure the temperature difference required for

condensation, the temperature will be increased to 70 °C during the rinse cycle and thus the

inherent heat of the dishes increased.

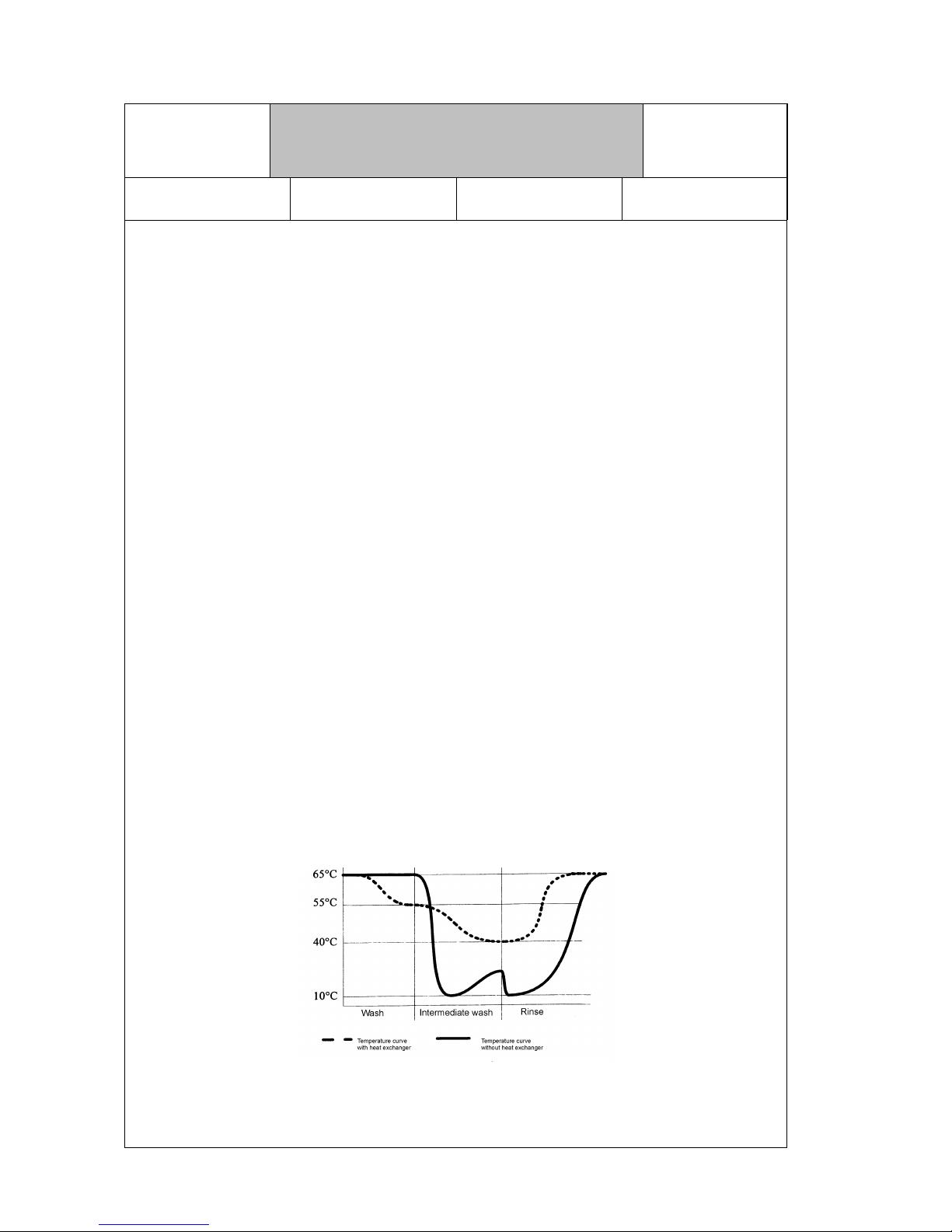

Smooth temperature transmissions due to heat exchanger

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 4

Page 6

1.2 Operation and handling

The design of the new dishwasher series 630 is especially characterised by easy operation and

activation of the most frequently used operating elements. Daily handling of the new dishwasher s is

convenient and user-friendly thanks to easily comprehensible operating sequences requiring only

little force. The most important elements are:

• Selection of all functions via short-stroke buttons

• Remaining cycle time display

• Detergent metering chamber

• Filter system

• Door brake

Depending on the equipment, delayed program start can be selected on some dishwasher models.

This start time preselection is possible up to 24 hour s in Top electronic models and up to 9 hours in

Comfort electronic models.

Also after the program sequence has been started changing to another program or operating mode

is still possible by pressing the respective button twice. This safety feature prev ents unintentional

changing during a running program. In case of an intentional program change, the running program

is interrupted and the sequence continued at the respective point in the newly selected program. As

soon as "0" is displayed in the figure panel, the dishwasher has returned to the initial position and

can be newly started.

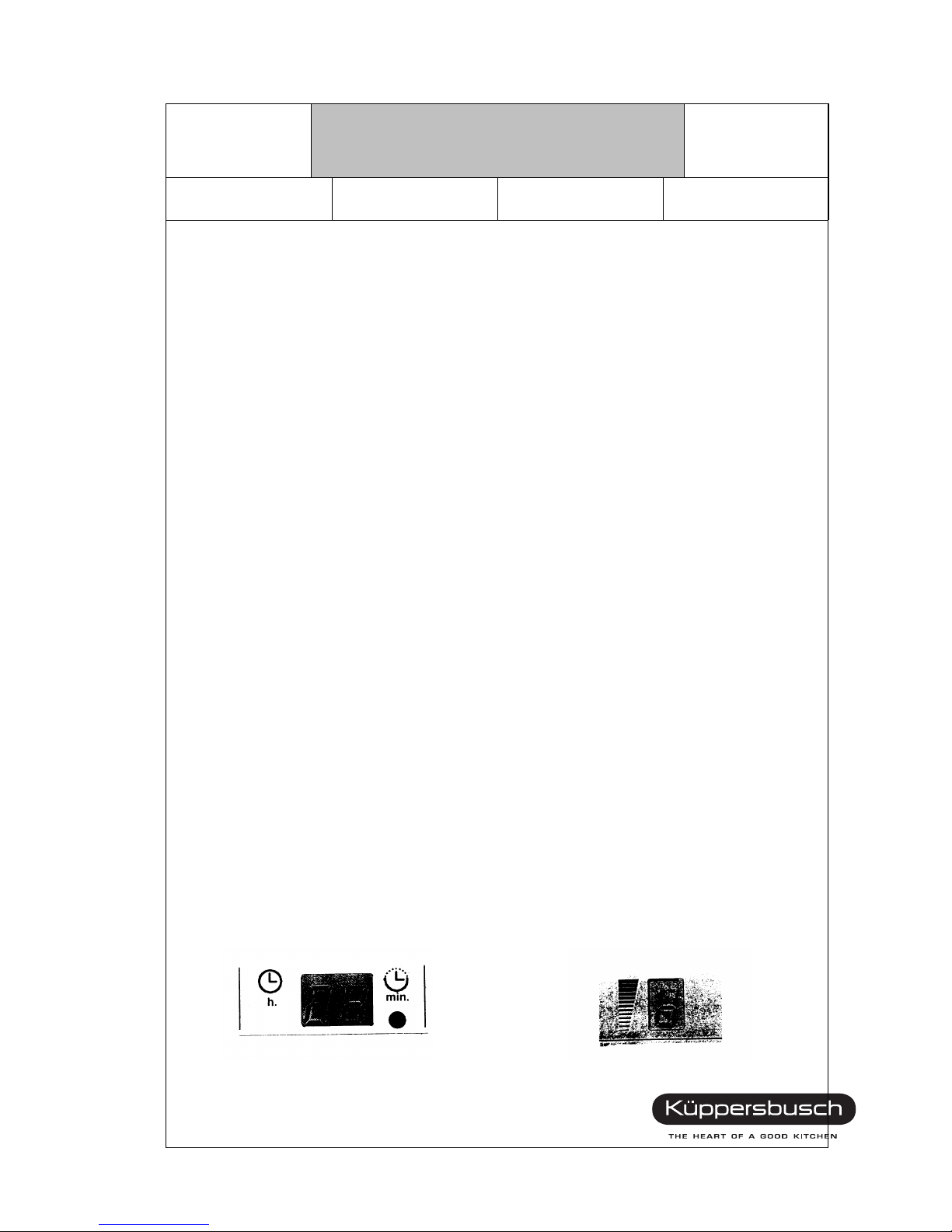

Remaining cyle time display

In case of dishwashers equipped with Top electronic the user is informed on the stage of the

running wash program: the remaining cycle time until program end (in minutes) is displayed on the

operating panel.

The remaining cycle time display is newly calculated and thus updated several times during the

program sequence. It mainly depends on the following factors: quantity and type of the dishes,

temperature of the inlet water as well as degree of dirtying of the dishes. For the initial calculation

after switching on of the dishwasher, always the values of the preceeding pogram are used. The

less the above-mentioned factors deviate, the less corrections are made as compared to the time

displayed first. The required correction amounts to approx. 10 minutes in the least favour able case.

The display is quartz-controlled and thus also reliable in case of deviations of the mains frequency.

In case of dishwashers equipped with Comfort electronic the program sequence display is

performed by means of an LED "bar", which indicates the individual phases of the wash program

(basically comparable to the program "indicator" of the previous series).

F

Remaining cyle time display Sequence display

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

5 For internal use only

Page 7

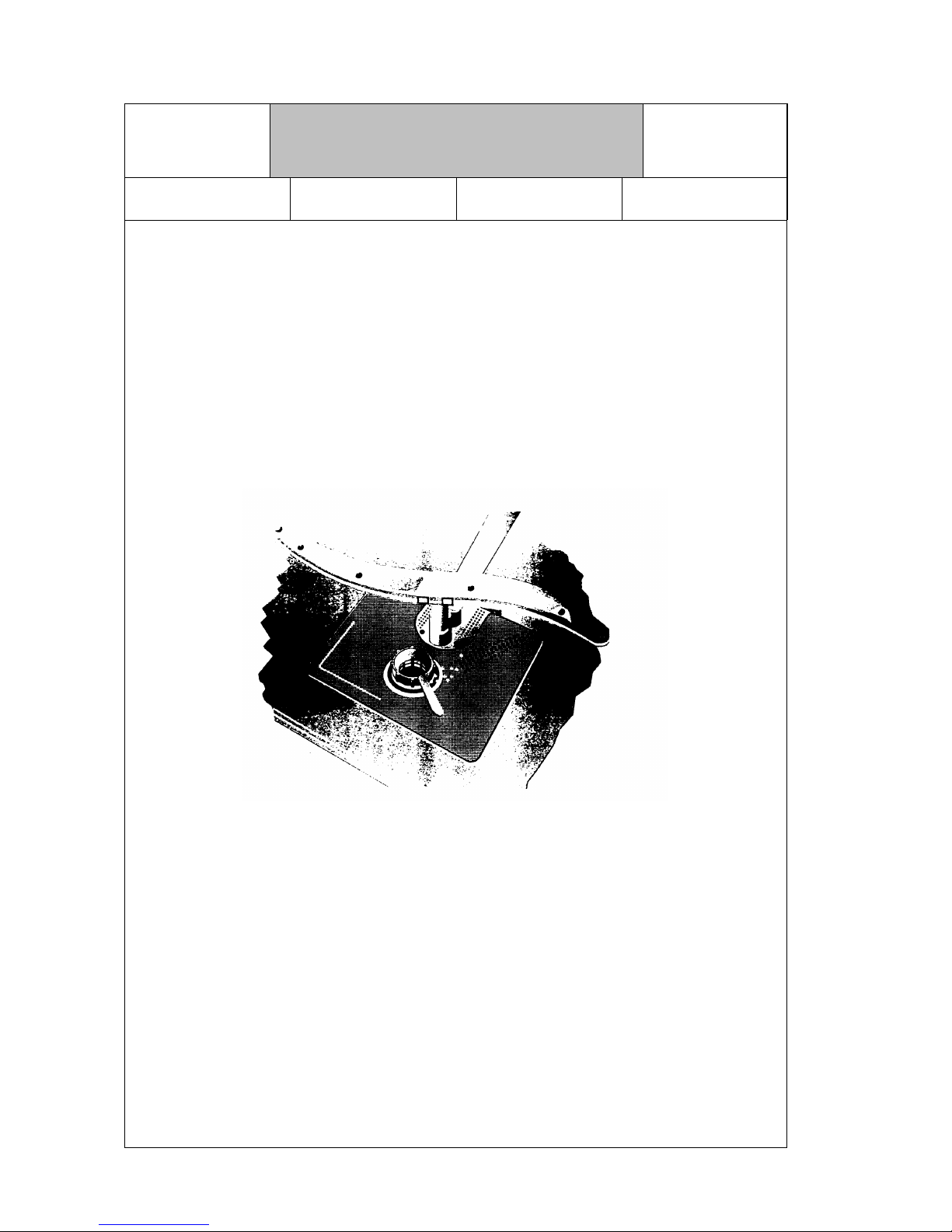

Filter system

The filter system consists of 3 parts: coarse, fine and micro-filter. The coarse and micro filter may be

taken out by means of of a joint handle, the fine filter is separately located in the container bottom.

Due to the surface increased by 30 % and the permanent cleaning during the wash cycle by means

of a special nozzle at the underside of the bottom spray arm, the fine filter has to be checked for

clogging only twice per year.

Furthermore, the newly designed coarse filter serves for improved self-cleaning. It is open towards

the drain pump and allows all foreign matters to pass thr ough that may be bor ne by the dr ain pump.

In this way it is ensured that the filter s ystem will not be clogged by left-overs of food. All larger

matters of dirt that cannot be transported by the drain pump are collected in the collection groove of

the coarse filter from where they can be easily removed.

Filter system

Door brake

In contrast to the dishwasher models of the previous series the door does not automatically fall

down but remains in any desired position. This feature allows to open the door only half the

way, e. g., when charging the upper basket or during filling of the detergent chamber and thus

enables the user to close the door without bending down.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 6

Page 8

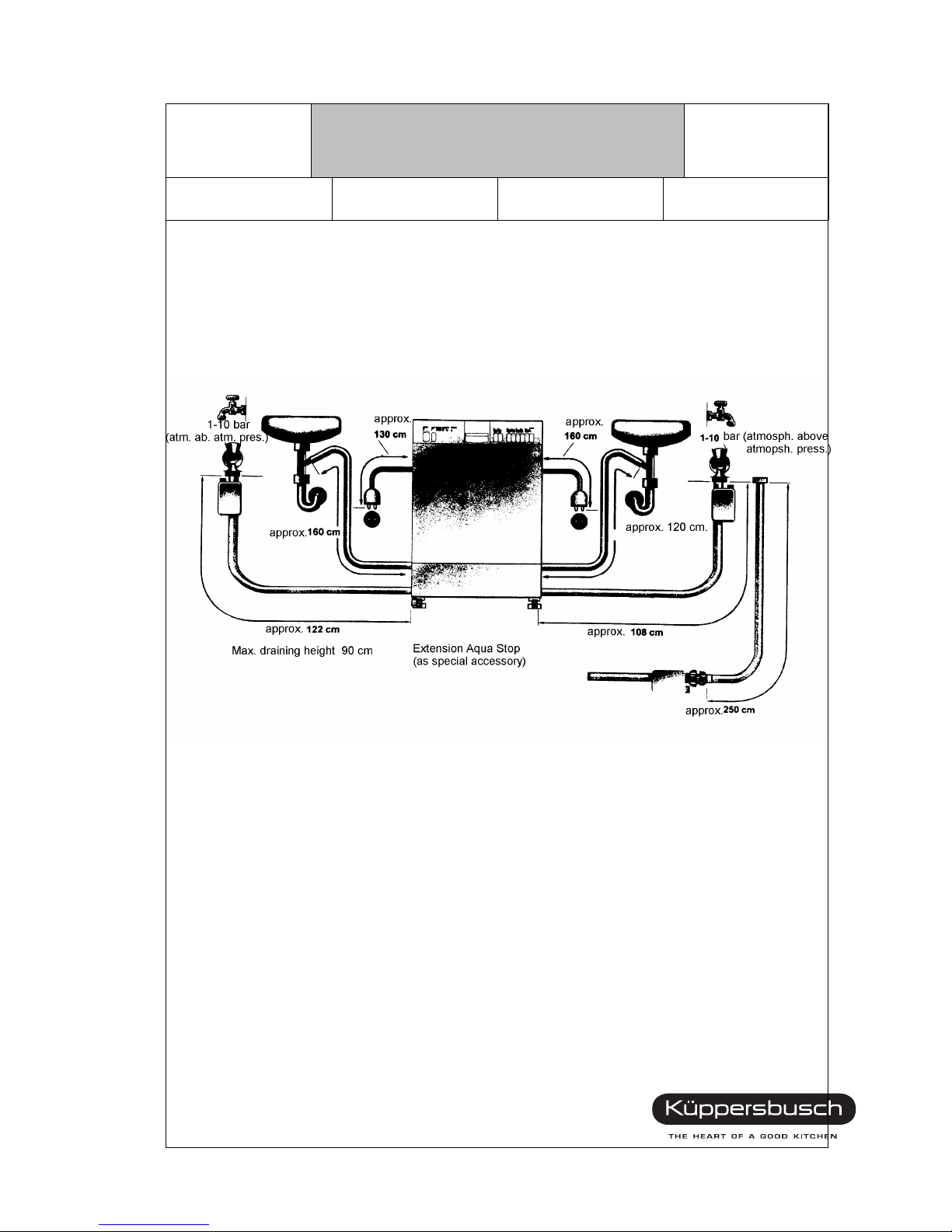

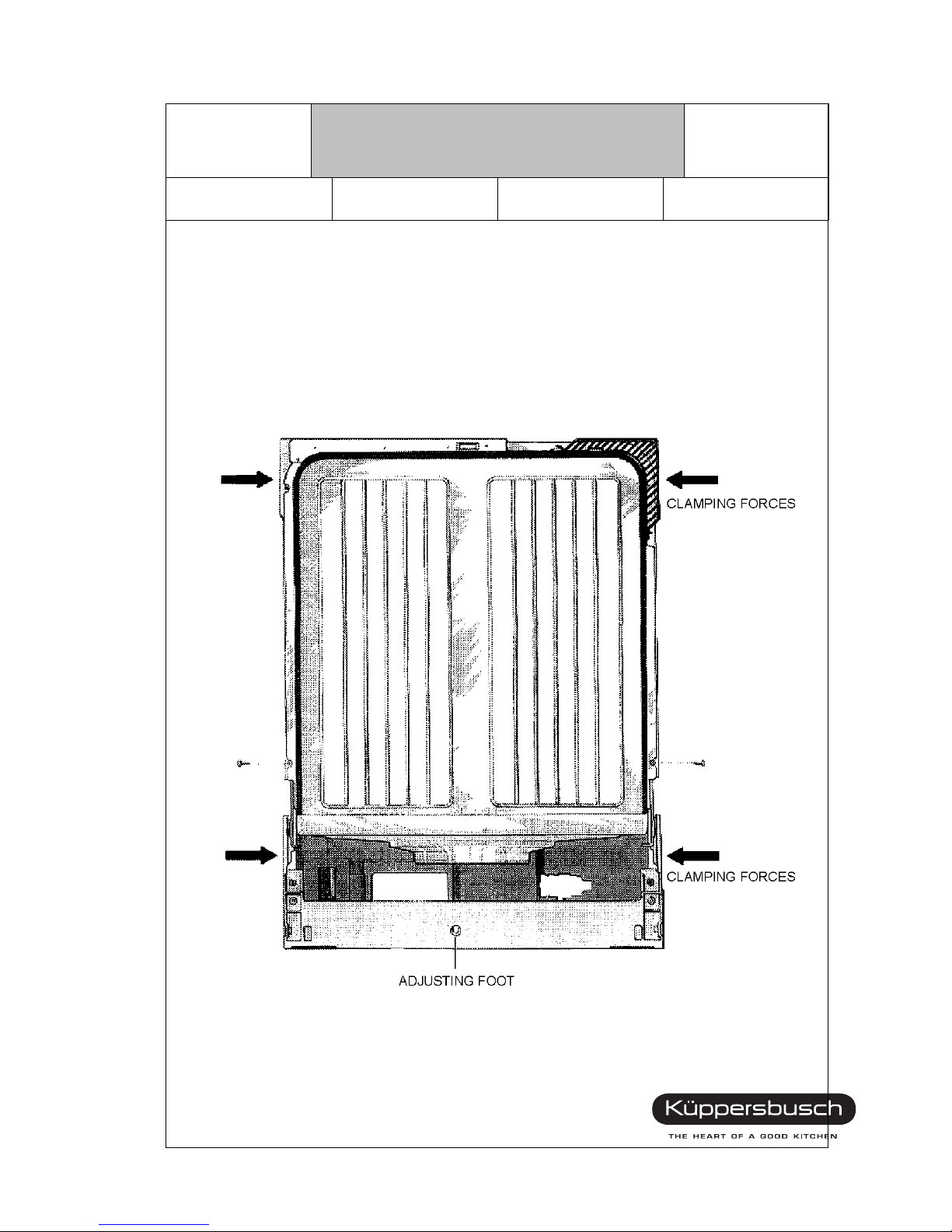

1.3 Improved installation and connection

Erection, installation and connection have been considerably facilitated for the dishwasher models

of the new series thus enabling the kitchen fitter and plumber to intergrate our dishwashers more

quickly and more easily into the kitchen. The following items are to be especially noted:

• Aqua Stop

• Installation reserve in the appliance height

• Adjustments from the front

• Infinite panel adaptation

Aqua Stop

Above all, the installation and handling of the Aqua Stop system has been facilitated by a number of

improvements. Inlet and outlet hose are separated from each other in any dishwasher model in

order to be more flexible in case of unfavourably located water connections. The Aqua Stop housing

is smaller althouhg its operativeness remains unchanged. In this way, installation thorugh the

bottom cupboards of the kitchen is facilitated .

A significant a dvantage of t he new Aqua S top is that it can be installe d in any desired pos ition,

also at an angle, hori zonally or, in extr eme cases, overhe ad. Besides that, the minimum height

for the inlet connection (0.3 m above the installation surface of the appliance) needs no longer

to be observed.

To this end, the valve system has been changed: the pneumatic valve in the Aqua Stop housing

has been replace d by a second magne tic valve. As the valves are dir ectly located on the water

tap and are c losed in d e-energiz ed condit ion, safety can be continually ensured i ndependent of

the mains. The Aqua Stop guarantee is of course also fully granted for the new dishwasher

models.

Furthermore, the discharge hose can be installed at any location on the dishwashers of the new

series, as the verti cal instal lati on tha t has been req uir ed so far is no longe r nece ssar y due to the

"hose bend". This has been rea lised by a vertic al installation and ventilation of the water outlet

already in the dishwasher itself. With respect to the appliance, it is thus ensured that no

malfunctions like emptying of the appliance or penetration of dirty water from clogged drain

pipes may occur.

In order to extend the inlet hose, acc. part no. 485 may be installed at the new dishwasher

models. The di scha rge h ose ca n be ex tended by means of a commerc ial plastic hose to

max. 4 m, if required .

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

7 For internal use only

Page 9

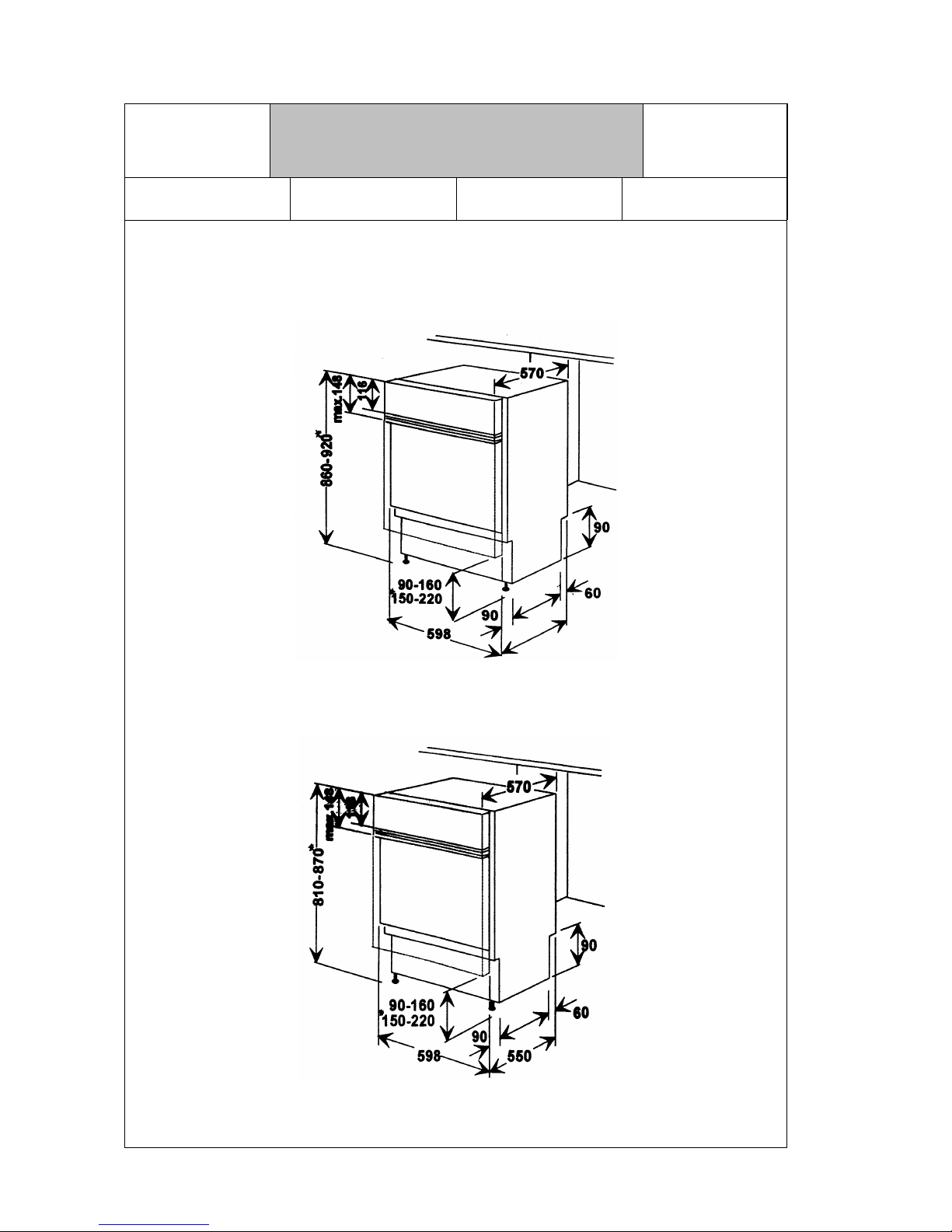

Installation reserve in the appliance height

To faciliate the installation the body height of all appliances of the new series, including stand-alone

and built-under models suitable for decoration, is reduced by 10 mm (see p. 18 - Installation

dimensions). This ensures, especially in case of replacement, easy installation also with narrow

niche conditions, e. g. unlevel ground, carpet, subsequently layed flooring materials. Furthermore,

the appliances can thus also be installed in kitchens with special niche dimensions (heights between

810 and 820 mm).

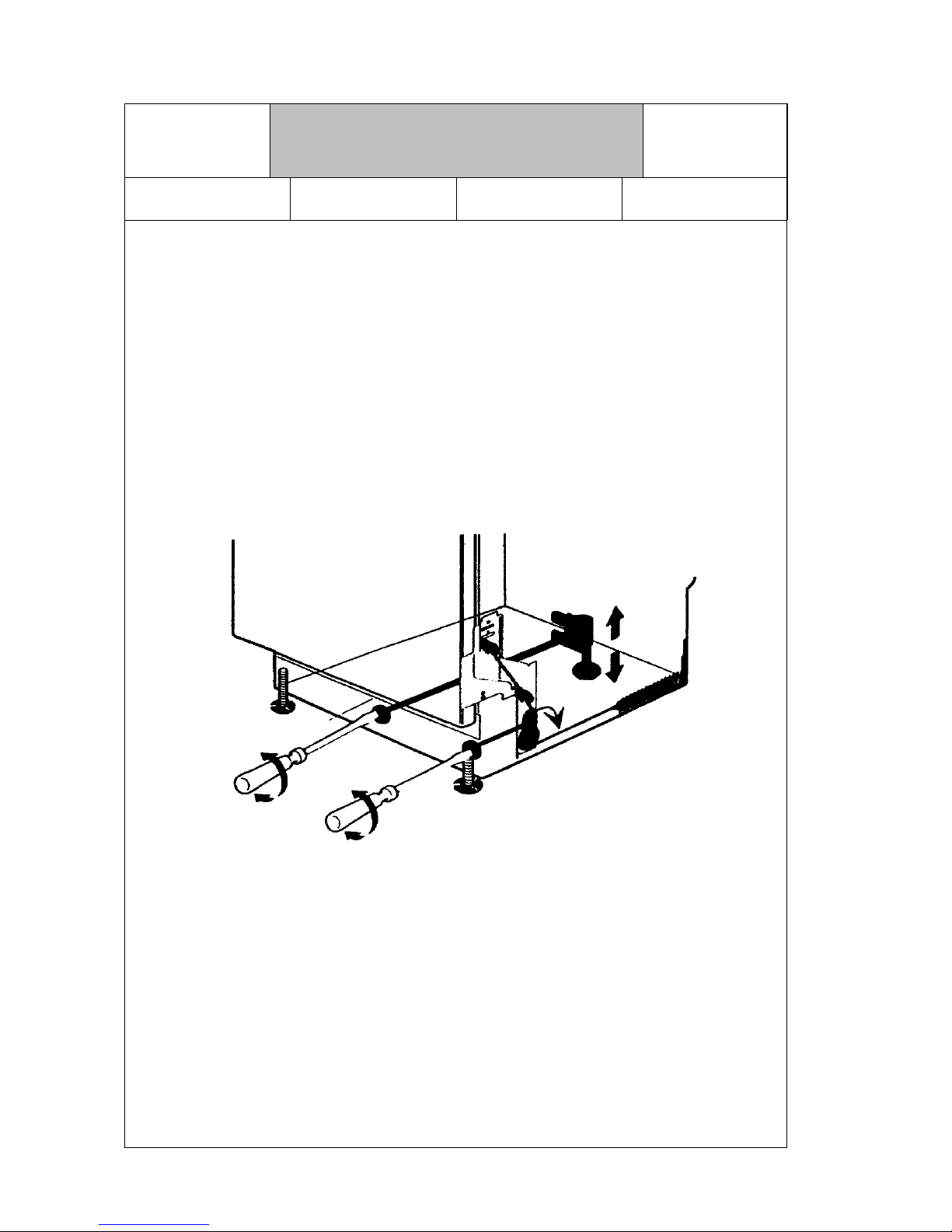

Adjustments from the front

The height of the rear foot as well as the prestr ess of the door springs (weight compensation of

furniture fronts) can be adjusted from the front at all intergrated and fully integrated dishwasher

models of the new series.

Adjustment of door springs and rear foot

Thus the appliance needs not to be repeatedly inserted and pulled out for alignment and

adjustment. All adjustments may be performed by means of the s crews loc ated in the base after the

appliance has been inserted into the niche.

At the same time, the design of the door springs has been changed in s uch a way that they are

suitable for furniture fronts of max. 10.5 kg in case of built-in appliances.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 8

Page 10

Infinite panel adaptation

In order to adapt the panel height to the drawer dimensions of the kitchen furniture a set of cover

strips with infinitely adjustable height is used for integrated appliances. This set consists of 4 strips

with a height of 8 mm each, which may be each telescoped into each other up to 3 mm. By means

of the complete set, a height difference of up to 32 mm may thus be compensated. The strips may

be assembled and disassembled without tool.

An exception are all appliances equipped with stainless steel operation panel. For these models 3

stainless strips are supplied, which may be used alternatively.

Spare part no. 42 67 44 up to 17.5 mm

42 66 11 up to 27.5 mm

42 66 10 up to 37.5 mm

Two further stainless steel strips may be supplied as accessory:

Spare part no. 42 67 45 up to 47.5 mm

42 67 46 up to 57.5 mm

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

9 For internal use only

Page 11

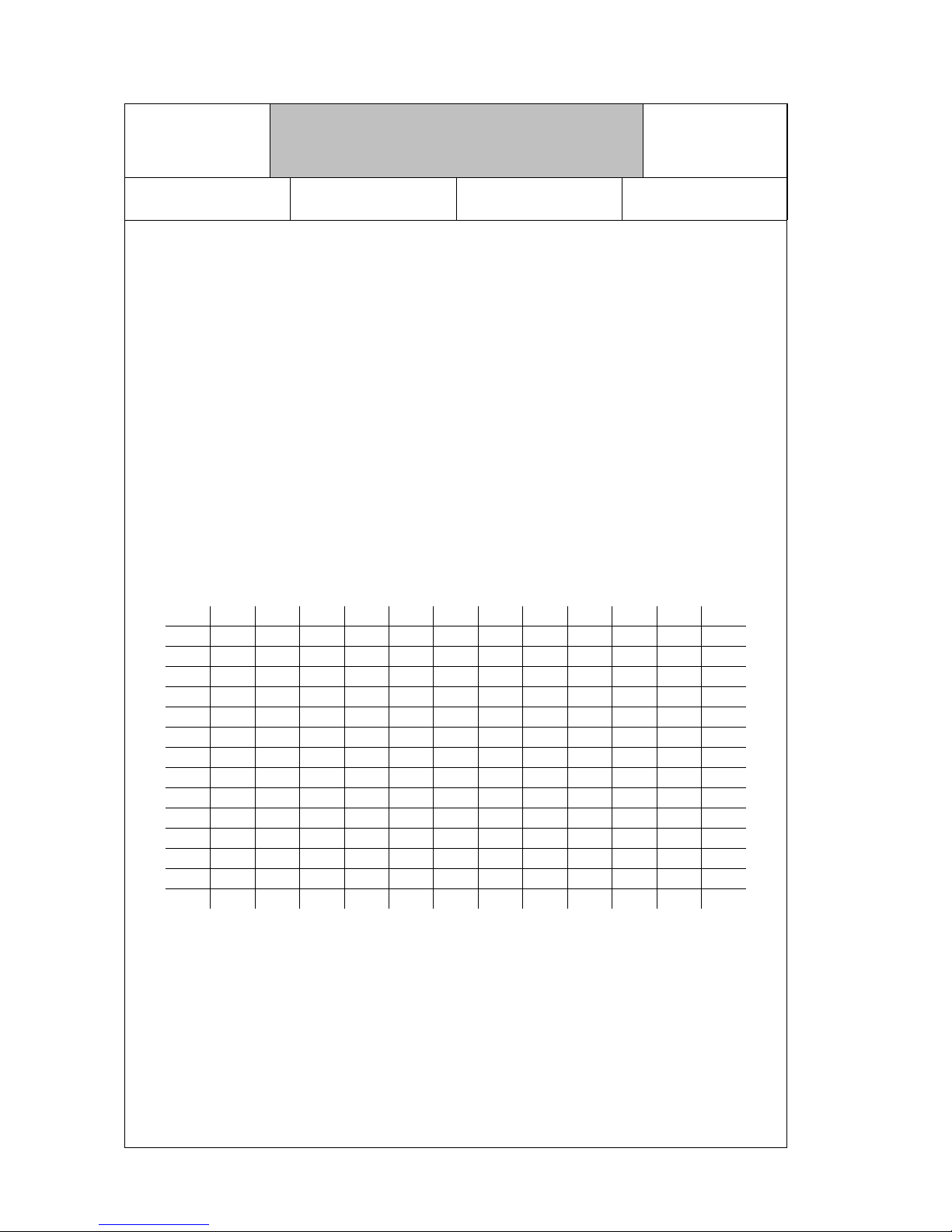

Appliance heights of 82 and 87 cm

In the kitchens, increased worktop heights tend to gain more and more acceptance for ergonomical

reasons. Today 55% of the new kitchens in Germany are already equipped with worktop heights of

91 cm and more. In Scandinavia, Great Britain and the Netherlands the proporotions of these height

dimensions are significantly higher.

Especially for those "high" kitchens, a further innovation is provided: dishwashers with a height

increased by 5 cm which ensure optimal utilisation of the available space. In contrast to

dishwashers with "normal" height these "extra-large" dishwashers offer an increased internal height

of 5 cm. These dishwashers are suitable for all kitchens with a niche height of at least 86 cm and a

body size (niche height minus base height) between 70 and 72 cm. In comparison with that: The

"normal" appliances are suitable for body sizes of 65 to 72 cm, with the minimum niche dimension

amounting to 81 cm.

In order to select the ideal appliance for a certain kitchen it is thus important to know the base

height in addition to the existing niche height, as the application of the dishwasher is determined by

the difference between them.

Niche height in mm

810 820 830 840 850 860 870 880 890 900 910 920

90

②❼

100

②② ❼❼

110

②②② ❼❼❼

120

②②②② ❼❼❼❼

130

②②②②②❼❼❼❼❼

140

②②②②②②❼❼❼❼❼❼

150

②②②②②②❼②❼❼❼❼❼❼

160

②②②②②②❼②❼❼❼❼❼❼

170

②②②②②②❼❼❼❼❼❼

180

②②②②②❼❼❼❼❼

190

②②②② ❼❼❼❼

200

②②② ❼❼❼

210

②② ❼❼

220

②❼

② dishwasher 82 cm ❼ dishwasher 87 cm

Possible installations in case of a niche height of 87 cm

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 10

Page 12

1.4 Further technical innovations

In the following chapters further innovations of the dishwasher series 630 are summarized and

explained. These modifications have also resulted in improved operation, performance, quality and

optical aspects of the appliance.

1.4.1 Wash system

The wash system of the dishwashers has been further developed with the aim to achieve an optimal

cleaning result with the lowest possible consumption of water and energy. The following appliance

components contribute to reach this aim:

Heat exchanger

The heat exchanger, which is still an exc lusive feature of Küppersbusch appliances, is also offered

in the new series. The heat exchanger offers a multitude of operating advantages like economical,

hygienic drying, gentle temperature guidance, no penetration of steam when the door is opened

after the program end. The heat exchanger is, above all, installed in top class dishwashers, partially

also in middle class appliances . Due to the warm water detection of the electronic sys tem a good

drying performance is also achieved in case of warm water connection.

Spray arms

An obvious characteristic feature of the new series is represented by the curved "wave-type spray

arms" that are exclusively installed in Küppersbusch dishwashers. The advantage of this design is

an improved spraying of the entire dishwasher interior, i. e. no more "dead angles" that are not

reached by the spray arms. All pieces of the dishes are thus reached by the spraying jets and

cleaned accordingly.

Both spray arms of the new dishwasher series - also the lower arm - are made of plastic. This

enables a more precise design and more exact alignment of the spraying nozzles as well as a lower

weight which results in a faster rotation of the spray arms and thus an improved distribution of the

water.

Water guidance

The entire water guidance from the pump casing to the spray arms and the top spray has been

newly designed and is now located in the inside of the rinse container. This leads to a reduction of

the inactive water quantity and thus to an improved washing result.

The water guidance to the upper spray arm is also new. The spray arm is connected to the supply

by means of a movable coupling and directly mounted at the upper basket. For this reason, no more

space-consuming funnel is required for any appliance. Thanks to this new coupling, height

adjustment and even removal of the upper basket with spray arm is now also possible without

funnel. In the latter case, the entire internal space of the appliance (51 or 56 cm, respectively) is

then available, for example for washing baking trays.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

11 For internal use only

Page 13

Flow heater

All appliances of whatever class belonging to the dishwasher series 630 are equipped with an

integrated flow heater to heat the water. Thus the new generation does not include appliances with

visible tubular heating any more. The complete range of advantages provided by the flow heater

(increased internal height, no damaging of plastic dishes, no carbonisation of remaining food) is only

provided in Küppersbusch appliances.

1.4.2 Dish baskets

In the new series two different types of dish baskets are used: standard baskets and universal

baskets.

The standard baskets are identical with those of the series 624 (dishwashers with heat exchanger).

The upper basket is suitable for up to 4 rows of glasses or cups and one row of small plates. The

lower basket is equipped with two rows of plates designed as fixed or removable inserts, depending

on the model (see "Appliance range and equipment"). In case of the appliances with removable

inserts the special accessory "Special glass basket" may be used.

The universal baskets are already known from the series 624 ( upper basket dishwashers). They

offer variable charging of the upper and lower basket and allow location of 6 standard dishes

including all parts like pots, bowls and pans only in the upper basket. The universal baskets are

included in the standard equipment of all upper basket dishwashers.

Furthermore, the new dishwasher models allow adjustment of the basket height for the upper

basket appliances which means a further improv ement of the flexible charging. The heights are factory-set to 26 cm at the top and 25 cm at the bottom. If required, this setting can be changed to 21

cm at the top and 30 cm at the bottom. Thus, these appliances are also suitable for pieces of dishes

up to a height of 30 cm (if arranged at an angle even up to 33 cm). Adjustment of the upper basket

has been facilitated: the basket is simply lifted of the guide rails and inserted in the second height

position.

The standard baskets are generally supplied with 21 cm top height and 30 cm bottom height. No

adjustment is possible here. The heights of the "high" appliance types amount to 26 cm at the top

and 30 cm at the bottom, no adjustment possible.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 12

Page 14

The heights of all appliance types are summarised in the following table:

Height 82 cm Height 87 cm

Standard

baskets

Universal

baskets

Standard

baskets

Universal

baskets

Height upper basket

- arranged at an angle

21 26

29

26

29

26

29

Height lower ba sket

- arranged at an angle

30

33

25

28

30

33

30

33

Adjustable to:

Height upper basket

- arranged at an angle

21

Height lower ba sket

- arranged at an angle

30

33

1.4.3 Softening system

The filling capacity of the salt container of the new dishwasher models amounts to 1.5 kg and is

sufficient for approx. 70 standard wash cycles with a water hardness of 5. After lighting up of the

salt refill indicator approx. 5 wash cycles can still be peformed before the salt container is

completely empty. The operation of the softening system depends on the respective control.

1.4.4 Noise

The appliances of the new series are equipped with 2 noise insulating stages: 48 dB and 45 dB.

These values always apply to the sound power dB (re 1 pW) for a built-under appliance.

Apart from some exceptions, all electronic appliances will be equipped with 48 dB. This v alue is so

low that it is not audible compared to the normal noise level in the r oom. This equipment enables us

to offer a large variety of low-noise dishwashers.

1.4.5 Turbo drying

The electronic appliances of the new dishwasher series enable the operator, if desired, to select a

more intensive drying function which, of course, results in an increased energy consumption.

In order to program this turbo drying, switch the dishwasher on while keeping the button

"Heavy-load 65°" depressed. The preset value "0" (= turbo drying off) will then be indicated in the

7-segment display. The function is actually activated by pressing the button "Heavy-load 65°" once

again. The value "1" (= turbo drying on) will be displayed. After switching off the appliance, the new

value is stored.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

13 For internal use only

Page 15

1.4.6 Connection value

All dishwashers of the new series have a heating capacity of 2150 W and thus a connection value of

2300 W; therefore a fuse protection of at least 10 A is required. Due to this feature, all dishwashers

may also be used at locations where no 16 A protection is available in the future. Special

low-protection variants, as are partially existing today, are no longer required.

1.4.7 Rinse aid metering chamber

The location, filling, metering adjustment and refill indicator of the rinse aid chamber have been

taken over from the acutal dishwasher models. Only the lid has been modified; it is now fixed to the

cabinet. Thus loss or misplacement of the lid is avoided.

The filling capacity of the rinse aid chamber amounts to 110 ml; in position 3, 3 ml are added per

wash program. Thus approx. 25 rinse cycles may be performed until the refill indicator lights up.

1.4.8 Ventilation

The inner container of the new dishwashers has no openings in the top, lateral and rear wall. The

only outlet for the produced steam is located in the inner door, integrated in the refill assembly for

detergent and rinse aid. The steam condenses in a separate channel in the inner door and is

recirculated below the door to the container bottom. In this way, the penetration of the steam

towards the top which results in the risk of a damaging of the worktops in this area is avoided.

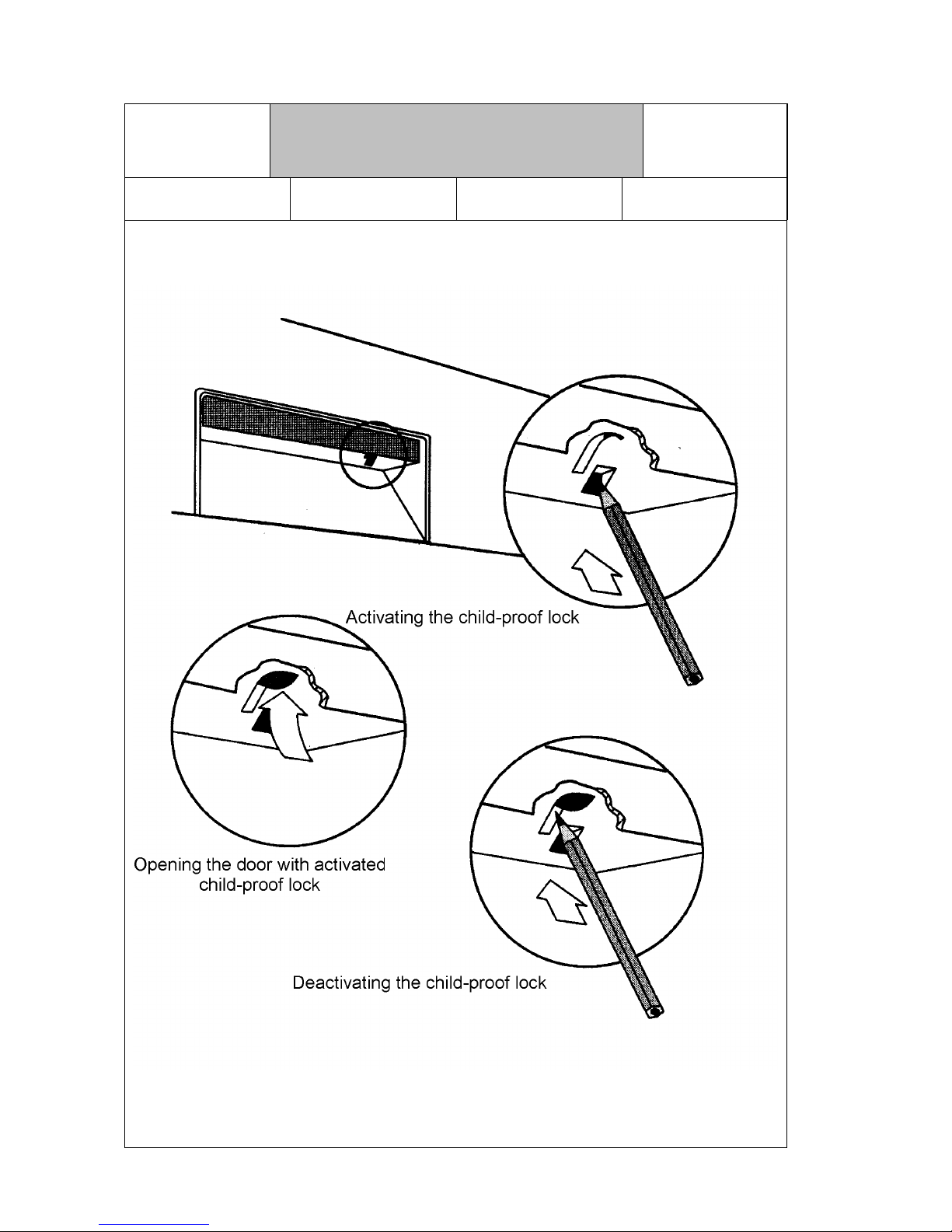

1.4.9 Operating safety

All appliances (except fully integrated appliances) are equipped with a safety device in case of

opening during the program sequence, i. e. a direct circuit-breaker which is operated when the door

opener is activated. When the appliance is opened, it will be immediately switched off via the mains

switch. After closing the door and switching on again, the program will be continued at the same

point. Besides that, all upper basket dishwashers are equipped with a child-proof loc k located in the

door handle to protect the appliance from being switched on unintentionally. When the child-proof

lock has been activated, the appliance can only be opened by pressing an additional pin in the

handle recess. If not required, the child-proof lock can be deactivated by means of a ballpen or

equivalent.

1.4.10 Salt refilling

The refilling of regeneration salt in the container bottom has been facilitated by shifting the filling

opening towards the front. Furthermore, a salt funnel is supplied with all appliances.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 14

Page 16

1.4.11 Feet and skids

The feet are made of plastic with extended foot plates in order to avoid damaging of flooring

materials. Stand-alone appliances and appliance suitable for decoration are equipped with four,

built-in appliances with three feet (two at the front, one at the rear in the middle) that ensure stable

standing on any ground.

The skids for easier sliding of the appliance into the furniture niche are integrated in the bottom tub.

In this way the installation of the appliances is even more faciliated.

1.4.12 Mounting at the kitchen furniture

For mounting the built-under appliances (suitable for decoration, integrated and fully integrated) at

the kitchen furniture two metal brackets to be inserted into the force sensors at the top of the

appliance are supplied. Each of the metal brackets has two fastening locations. In case mounting at

the worktop is not possible (e. g. stone or granite worktops), these brackets may als o be used for

lateral mounting at the furniture body.

In order to protect kitchen worktops against being damaged by emerging steam, for example when

opening the door during the program sequence, all built-under appliances are supplied with a s team

protection foil to be mounted at the underside of the worktop.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

15 For internal use only

Page 17

1.4.13 Child-proof lock

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 16

Page 18

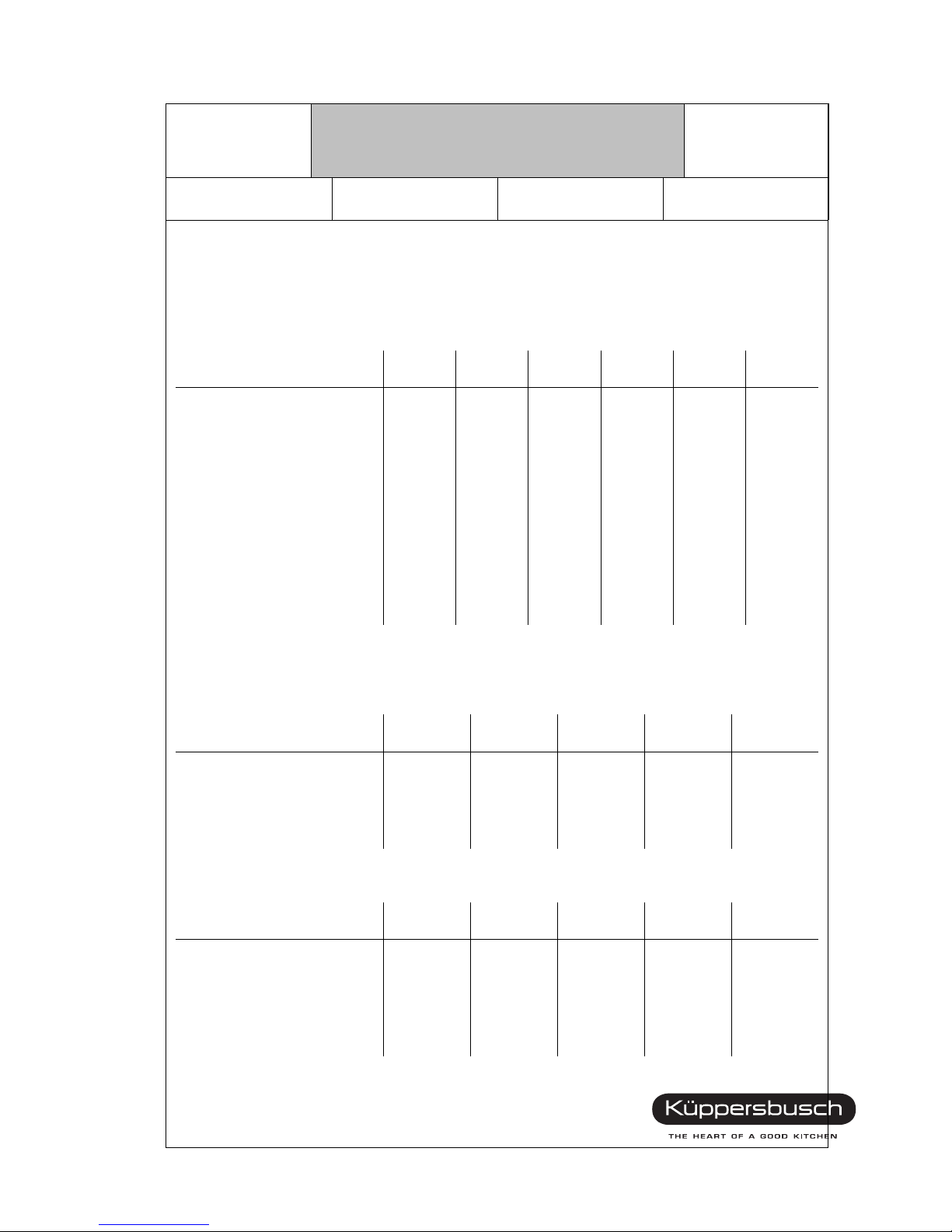

1.5 Technical Data

1.5.1 Consumption values

Electronic with heat exchanger

Programs 2 x 6

Prog.

5

Prog.

2 x 4

Prog.

Water

(ltr.)

Current

(kWh)

Time

(min.)

Pots 70 °C

upper basket

x 18 / 23*

14 / 18*

1,7 / 1,8*

1,2 / 1,3*

99

90

Heavy-load 65 °C

upper basket

x

x

xxx18 / 23*

14 / 18*

1,4

1,1

95

85

Normal 55 °C

upper basket

x

x

xxx14 / 18*

11 / 14*

1,2

0,9

90

82

Eco 55 °C

upper basket

x

x

xxx16

13

1,2

0,9

90

81

Glasses 40 °C

upper basket

x

x

14

11

0,9

0,7

58

52

Quick

upper basket

x

x

xxx12

10

1,0

0,8

30

25

* thanks to Aqua Sensor low value in case of standard dirtying

Electronic without heat exchanger

Program 5

Prog.

4

Prog.

Water

(ltr.)

Current

(kWh)

Time

(min.)

Heavy-load 65 °C x x 23 1,6 95

Normal 55 °C x x 18 1,4 90

Eco 55 °C x x 16 1,4 90

Glasses 40 °C x 14 1,1 58

Quick x x 12 1,0 30

Mechanic

Program 5

Prog.

4

Prog.

Water

(ltr.)

Current

(kWh)

Time

(min.)

Heavy-load 65 °C x x 25 1,6 95

Normal 65 °C x 20 1,5 95

Normal 55 °C x 20 1,4 92

Eco 55°C x 16 1,4 88

Energy saving x 17 1,3 75

Quick x 12 1,0 45

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

17 For internal use only

Page 19

1.5.2 Installation dimensions

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 18

Page 20

1.5.3 Connection dimensions

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

19 For internal use only

Page 21

2. GENERAL TECHNICAL DESCRIPTION

2.1 Structure

2.2 Housing parts

The lower edges of the side walls are inserted into the tub. Attachment is via 2 screws each at the

front and rear of the appliance. The outer door, which is screwed to the inner door, is attached

belo w th e a c c ess pa nel with brac ke ts in t he su ppor t. For sta nd-al one m odel s, t he ta ble t op is a tt ached

at the four supports. Built-under models have a divid ed, heig ht-ad justa ble oute r doo r for diff erent base s.

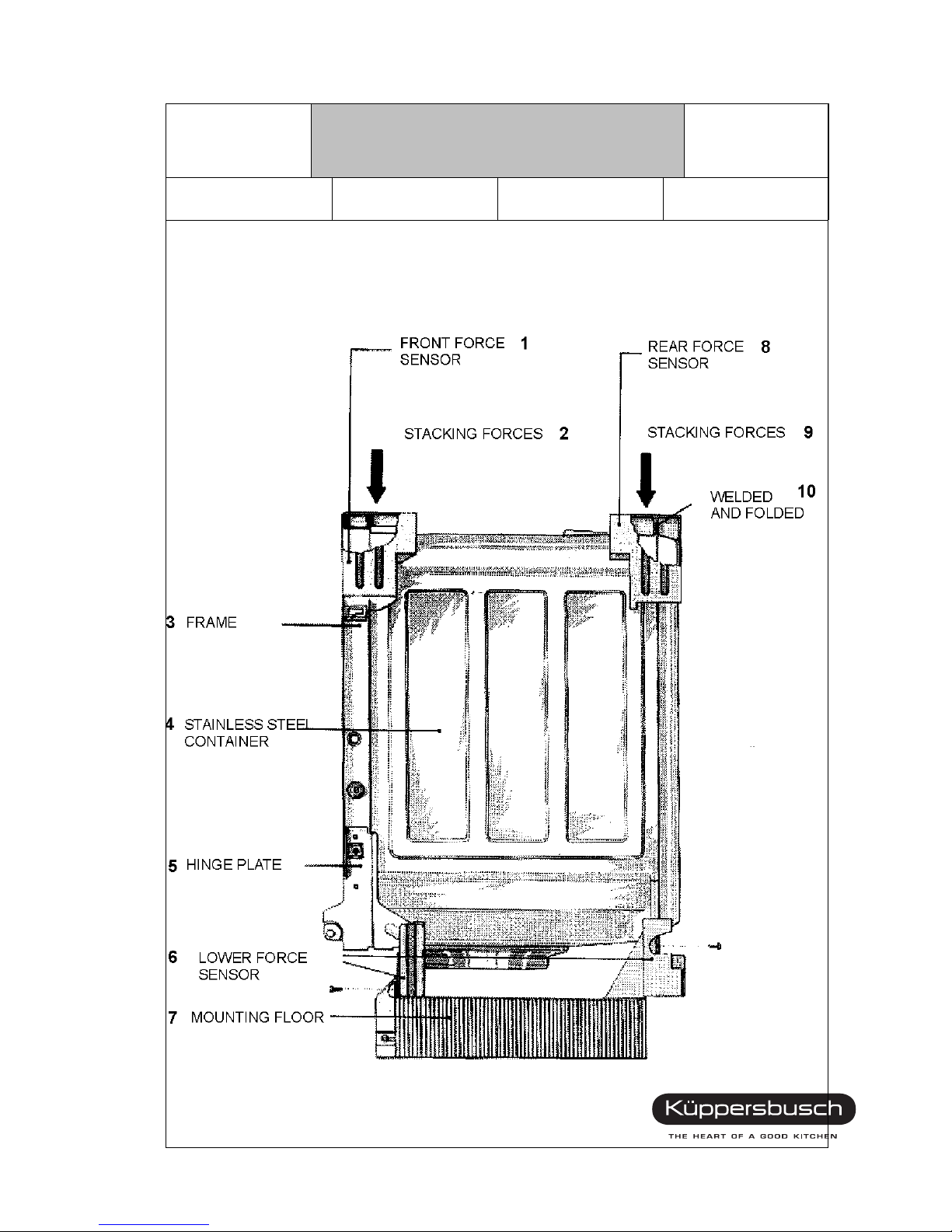

2.3 Rinse container

The bitumen coated stainless steel inner container has a U- channel around the door area which is

welded to the container. The welded rear wall is also double stacked on all four sides with the

container. These doubled and lock-seamed connections provide rigid and safe container edges. The

specially formed supports at the upper container corners, to which the housing parts are also

attached, absorb the load and clamping forces. The softening system is screwed down to the

container bottom. The heat exchanger with integrated water i nlet is att ache d at the le ft co ntai ner

wall with tw o rails . The connection between heat exchanger, softening system and level sensor

system is made via hoseless plug connections.

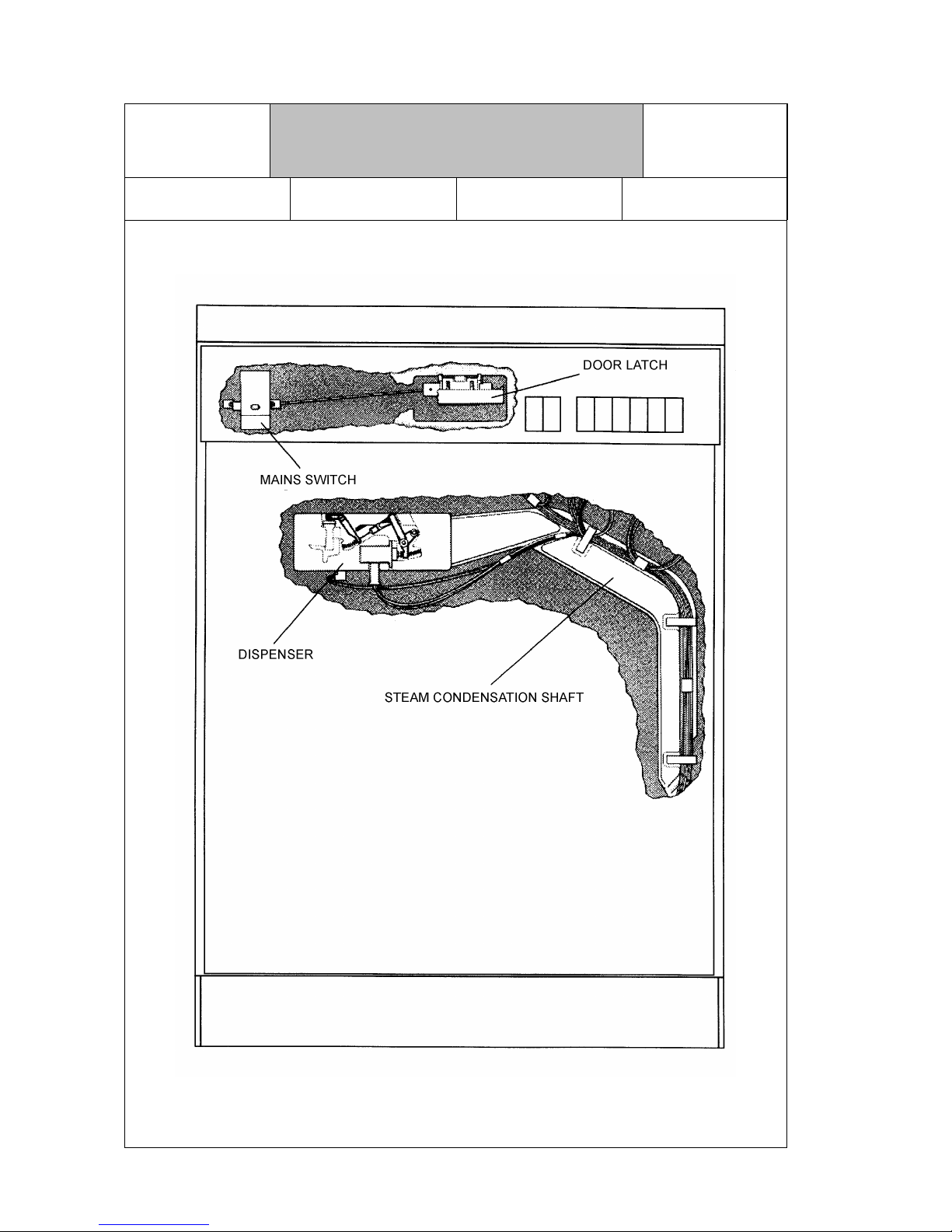

2.4 Inner door

The dispenser assembly is locked into the stainless st eel inner door, which is als o bitumen c oa te d .

The surge water seal is screwed to the inner door using the seal rail and snapped onto the

container edge. The edges of the inner door are doubled and lock-seamed for no sharp

edges. The container is vented through the housing of the dispenser assembly. A steam

condensation tube fitted into the housing between the inner and outer doors passes condensates

during the heating cycles or expansion peaks back into the container. The control, mains switch,

displays and door latch are attached to the support which is screwed to the inner door.

The access panel is fixed on the support.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 20

Page 22

RINSE CONTAINER

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

21 For internal use only

Page 23

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 22

Page 24

2.5 Tub

The plastic tub contains the pump system with flow heater, pump casing, drain and recirculation

pump, the level and safety system, as well as the float for shutting off when water is in the tub. The

drain and Aqua Stop hoses are brought in separately at the rear left of the tub. The electrical

connection with main filter is at the right rear.

The rear wall of the tub is formed such that it serves both as a support and attachment member for

the rinse container. The front support and attachment is made using the extended hinge plates of

the door hinges in the tub, which are screwed to the U-frame of the container.

TUB

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

23 For internal use only

Page 25

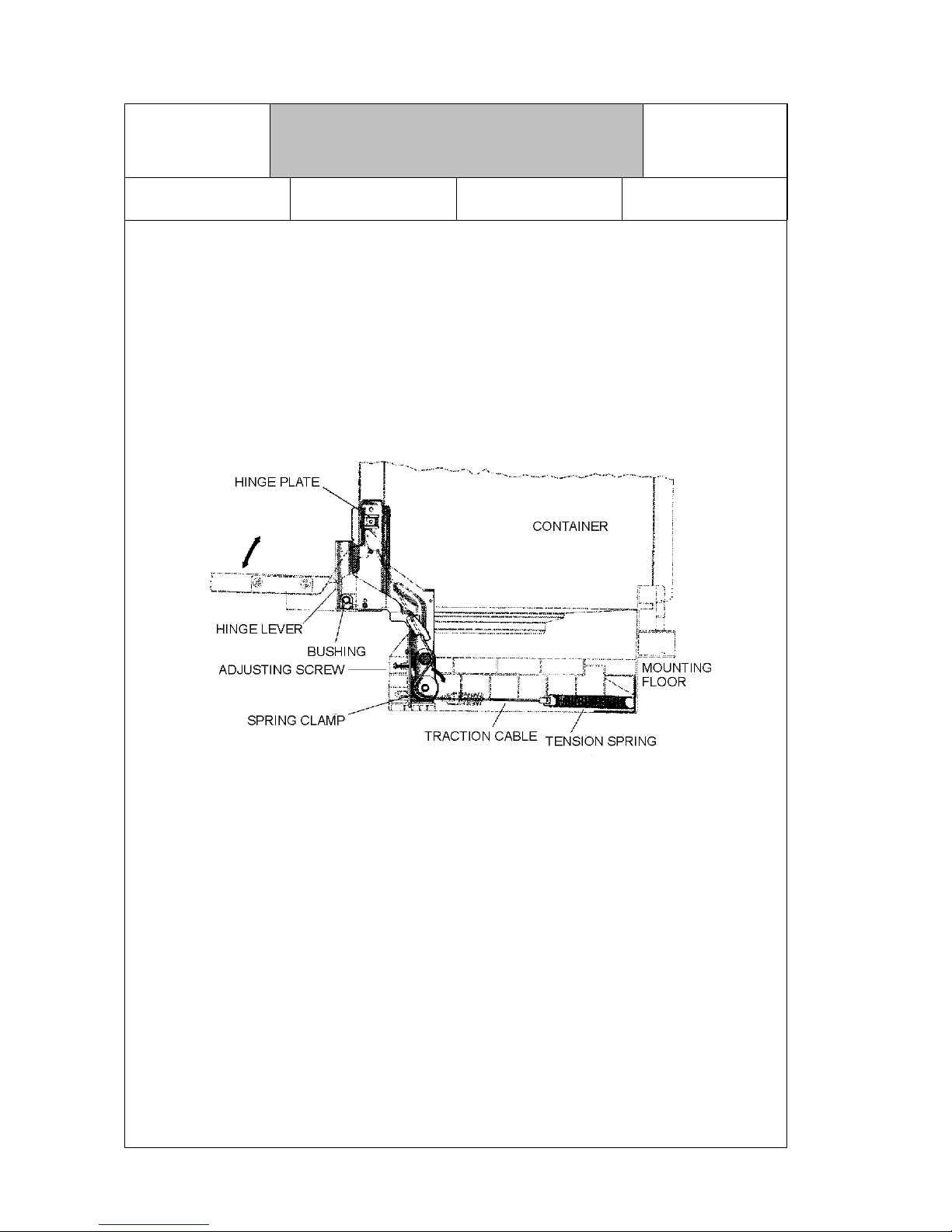

2.6 Door spring adjuster

The adjusting assembly consists of the tension spring, the cable, spring adjuster and adjusting

screw. The te nsi on s pr ing s ar e at ta c he d b el ow th e t ub at the rear wall u s in g b r ack e ts . The tension cable

is fed to the hinge plate over the spring adjuster, angled and hung into the hinge lever of the door.

DOOR HINGE WITH TENSION SPRING

2.7 Height adjustment

The integrable and built-under models have two adjusting feet in front and a rear foot which is

adjustable for height from the front. The stand-alone models have four identical adjusting feet, the

front ones in the base.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 24

Page 26

2.8 Spray system

The rotary spray system cons ists of three spray levels , the lower and upper spray arm and a top

spray .

The water supply to the upper spray arm and the top spray is brought through the inlet pipe

atta ched to t he inside of the co ntainer r ear wall . This pip e is conne cted by a direct connection

with the flow heater under the pump casing at one of its two outlets.

The upp e r sp r a y a rm i s di r e ct l y f as t e n ed w ith its in l et p ip e to t he u pp e r ba s k e t . The connection to

the inlet pipe is thro ugh a var i ab le cou pl in g. In mo dels w it h h ei gh t adj ust ab le uppe r basket, the water entry

is adapted to the spray arm using this variable coupling.

The connection to the inlet pipe is through a variable coupling. In models with height adjustable upper

basket, the water en tr y is adap te d to t he sp r ay ar m u sin g this var i ab le co up li ng .

The lower spray arm with its bearing is connected directly through the pump casing at the

second outlet of the flo w heat er.

The valve for the upper basket wash cycle is located in this outlet.

2.9 Wash and pump system

The switching mechanism with the permanent magnet and actuator is attached beneath the flow

heater. The recirculation and drain pump as well as the flow heater are attached to the pump casing

using plug connections. The flow heater is additionally screwed to the pump casing for pressure

resistance.

The pump casing is covered by the area fine filter. With the combined coarse and micro-filter, the

fine filter is attached to the floor of the pump casing using a bayonette mount. The washing liquid

accumulating in the pump casing is drawn by the recirculation pump and pressed into the flow

heater. At the appropriate pressure a flange membrane actuates the pressure switch for the heater

A series connected temperature controller with a turn-off temperature of 85 °C prevents

overheating.

This temperature switch is combined with an NTC resistor (Negative Temperature Coefficient)

(otherwise 55/88 °C) into a single component, and is only used in models with electronic control.

The NTC surface has direct contact with the wash liquid. At the outlet of the flow heater is the Aqua

sensor with its sensor in the flow current of the wash liquid for detecting turbidity of the water. With

the drain pump directly attached to the pump casing, the impeller and the check valve are

accessible after removing the cover in the rinse container.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

25 For internal use only

Page 27

SPRAY SYSTEM

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 26

Page 28

WASH AND PUMP SYSTEM

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

27 For internal use only

Page 29

FILTER SYSTEM

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 28

Page 30

3. FUNCTION DESCRIPTION

3.1 Water inlet for models with heat exchanger and electronic control

3.2 Aqua Stop system

The system consists of two series connected electrical solenoids, the fill solenoid and the safety

so le no id . The s olenoid combin ation is enclo sed in a housin g and attached at the water inlet ju nction.

From the sole n oid, the supply line is led to the integrated water inlet by the heat exchanger , and the

electrical control line for the solenoids is led into the tub through a leak water tube attached to the

solenoid housing.

3.3 Safety function

All leaks inside the appliance are collected in the tub, including leaks in the fill and safety solenoid

and the water supply line, which are led to the tub through the leak water tube. At a preset level in

the tub, the float actuates a switch lever for the safety switch on the level sensor, which electr ically

shuts off the fill and safety solenoid. Simultaneously the drain pump is turned on, the wash liquid is

removed from the rinse container, and the pump runs continuously.

Note: In models with electronic controls, the electronic system is turned off by a safety switch.

3.4 Water inlet with heat exchanger prefill (V F1)

(models with electronic control only)

After the fill solenoid is opened, the water flows to the integrated inlet over the fr ee flow line into the

softener and then as softened water into the heat exchanger. After the regeneration chamber is

filled the water flows through the overflow channel into the thredtle cup of the level sensor. The

pressure buildup in the pressure socket c auses the level switch to open the heat ex changer drain

valve.

The electronic determines the time between the open command of the fill solenoid and the closing

of the level switch (f1). From this time the additional fill time of the fill solenoid is calculated. At each

first filling of a wash cycle, 200 ml more water than the normal amount is filled. With this water

amount, for the first fill of the wash cycle the water loss is c ompensated which is caused by the

wetting of the dry dishes. Redation of the recirculation pump is ensured and in the following fill

operations water is saved. The recirculation pump is turned on time-delayed, the drain valve stays

open until the heat exchanger is fully emptied.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

29 For internal use only

Page 31

3.5 Explanation of wash commands

3.5.1 Filling process for models with heat exchanger (HE)

3.5.2 Filling process for models without heat exchanger (HE)

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 30

Page 32

FILL SYSTEM WITH HEAT EXCHANGER AND WATER SOFTENER

WATER INLET SOFTENING

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

31 For internal use only

Page 33

3.6 Water inlet without heat exchanger

After the fill sole noid op en s, w ater flo ws t o the in te gra te d i nl et acro ss th e fr ee fl ow li ne in to th e re ge ne rat io n

chamber. After the regeneration chamber is filled, the water flows over the overflow channel through

the softener, then as soft water into the level sensor and pump casing. After the static level is reached,

the output signal from the level pressure sensor is picked up the by the electroni c s and t h e r e c irculation

pump is turned on. When the rerecirculation pump starts, the level pressure switch is reset.

Dynamic filling continues until the level switch is activated again, which means the wash level has been

reached.

3.7 Regenerating with heat exchanger

The water quantities of the wash cycles which have already run are registered by the electronic and

determine the timing for regenerating of the softener. Before each regeneration step the electronic

system checks whether the capacity of the softener is still sufficient for a complete normal program

sequence. If not, another regeneration is done. During regeneration the regenerating valve on the

softener is opened. The reservoired quantity of water flows across the valve into the salt container ,

is enriched with salt, and flows as brine through the softener into the pump casing. To increase the

effect, another 360 ml are cycled. To this end the fill s olenoid is actuated for a short time with open

drain valve. To clear the dissolved hard ening agents, the softe ner is r insed through in two pha ses during

the drying cycle.

3.8 Regenerating without heat exchanger

The water quantities of the wash cycles which have already run are registered by the electronics

and determine the timing for regenerating of the softener. Before each regeneration step the

electronics checks whether the capacity of the softener is still suffic ient for a complete normal cycle.

If not, another regeneration is done. In regenerating the regenerating valve on the softener is opened.

The reservoired quantity of water flows across the valve into the salt reservoir container, is enriched

with salt, and flows as brine through the softener into the pump casing. To increase the effect,

another 360 ml are added. To this end the fill solenoid is actuated for a short time with open drain

val ve. To c lear the dissolv ed hardening agents, the softener is rinsed through in two phases at the

beginning of the ne xt cycle.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 32

Page 34

3.9 Level sensor system for fill level

After the heat exchanger and re generation chambe r are filled, the water flows over the drain chann el

into the level sensor housing to the level pressure chamber. The throttle cup under the pressure

chamber ensures that the level pressure chamber is filled first, until the corresponding pressure for

actuating the level switch is reached. The overflow water flows directly into the pump casing.

3.10 Safety level

If the fill solenoid does not shut off, filling continues until the level in the safety level chamber is

reac hed and the flo at act uate s t he s afet y switch. The safety level chamber is wired ahead of the

level chamber and is located between the level chamber and the drain to the pump casing.

The safety switch is used to turn the fill and safety solenoid off and the drain pump on.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

33 For internal use only

Page 35

FILL SYSTEM WITH HEAT EXCHANGER AND WATER SOFTENER

REGENERATING

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 34

Page 36

FILL SYSTEM WITHOUT HEAT EXCHANGER WITH WATER SOFTENER

WATER INLET REGENERATING

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

35 For internal use only

Page 37

FILL SYSTEM WITHOUT HEAT EXCHANGER WITH WATER SOFTENER

WATER INLET SOFTENING

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 36

Page 38

NORMAL LEVEL

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

37 For internal use only

Page 39

SAFETY LEVEL: OVERFILLING

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 38

Page 40

SAFETY LEVEL: TUB

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

39 For internal use only

Page 41

3.11 Aqua Sensor

The infrared LED and the phototransistor are located in a U-shaped, light-passing housing opposite

each other on a circuit board. The infrared diode sends its infrared light through the water which passes

between it and the phototransistor, whereby light which reaches the phototransistor switches it on.

If the water is excessively cloudy, the light intensity is not sufficient to switch the phototransistor.

The absence of a voltage signal is detected by the microcomputer, and the required water change is

carried out for cycles which include a prewash.

If the water remains clear enough, it is kept in the rinse container for use in the wash cycle.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 40

Page 42

3.12 Dispenser detergent/rinse aid

The release mechanism is controlled by a thermoactuator.

The first actuation causes the cover of the detergent dispenser to open, and at the same time the

release tab ratchets into the switch detent of the rinse aid lever, so that the next operation of the

actuator causes the metering plunger of the rinse aid to lift.

When repairs or inspections of the applianc e are done, the release mechanism must be reset to the

initial position by closing and opening the cover.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

41 For internal use only

Page 43

3.13 Operating panels

Built-under appliance/integrable

Fully-integrated appliance

4. PROGRAMS/BUTTON FUNCTIONS E1 CONTROL

2-

baskets

Upper

basket

Intensive70Heavy-

load

65

Normal

ECO

Energy

saving

55

Fine

40

Quick

30

S1 S2 S3 S4 S5 S6

Program interrupt Press S2 + S4 for approx. 3 seconds

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 42

Page 44

5. FEATURES

Control

E26 E24 E15 F15 F14 M4 R

Models

S/D/I S/I/V S/D/I/V S S/I/V S/D/I S/D/I

No. of programs

2 x 6 2 x 4 5 5 4 4 3

Upper basket

XX—————

Basket inserts

—— 2 2 ———

Drying cycle (heat exchanger / specific heat)

WWWE E E E

Aqua Sensor / autom. water saving device

X/X X/X X/X —/X —/X —/— —/—

Remaining cycle time display,

two-digit 7 segment display

X X X ————

Program sequence, one-digit 7 segment display

———X X——

Program sequence printed

—————X X

Time preselection via 7-segment display

X—*X**————

Water hardness range setting

electronic 0 - 7

XXXXX——

mechanical as usual 0 - 3

—————X X

Buttons / knobs

10 / 0 7 / 0 7 / 0 6 / 0 5 / 0 5 / 1 1 / 1

Operating pa nel wording

text symbols symbols symbols symbols symbols symbols

LED - for the selected program

64554——

LED - salt indication

XXXXXX—

LED - rinse aid indication

XXXX———

Consumption values water / current

Noise of built-under appliance in dB (re 1 pW)

48 48 48 48 48 51 54

* fully integrated with time preselection

** integrated without time preselection

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

43 For internal use only

Page 45

6. CONSUMPTION VALUES

6.1 Electronic with heat exchanger

Water*

calculated quantity Indica ti on

Current**

calculated quantity Indication

Time

calculated quantity Indication

Itr. kWh min.

Pots 70 °C 23,5 25,0 23 1,83 1,9 1,8 95 99 99

Heavy-load 65 °C 23,5 23,3 23 1,62 1,7 1,4 92 95 95

Normal 55 °C 19,0 20,8 18 1,42 1,5 1,2 94 95 95

Normal 55 °C A-S 14,5 14,8 14

Normal 55 °C (Upper basket) 14 1,08 0,9

Normal 55 °C (Upper basket, A-S) 11

ECO 55 °C 16,5 17,0 16 1,38 1,5 1,2 90 90 95

ECO 55 °C (Upper basket) 12,2 12 1,04 0,9

Glasses 40 °C 14,5 15,0 14 0,91 1,0 0,9 58 58

Quick 11,35 12,0 12 0,96 1 45 44 30

A-S = Aqua Sensor * =

Indications refer to 17° dH ** Indications correspoding to good

drying cycle (70 °C Rinse)

6.2 Electronic without heat exchanger

Water*

calculated quantity Indication

Current**

calculated quantity Indication

Time

calculated qua n ti ty Indication

Itr. kWh min.

Pots 70 °C 26 23 1,9 2 99

Heavy-load 65 °C 23 1,7 1,6 95

Normal 55 °C 18 1,4 95

Normal 55 °C, A-S 14

Normal 55 °C (Upper basket) 14 1,1

Normal 55 °C (Upper basket, A-S) 11

ECO 55 °C 18,5 16 1,5 1,4 95

ECO 55 °C (Upper basket) 12 1,1

Glasses 40 °C 14 0,9 58

Quick 12 12 1 30

A-S = Aqua Sensor *

Indications refer to 17°dH ** Indications correspondi ng to go od

drying cycle (70° RInse)

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 44

Page 46

7. SPECIAL PROGRAMS E1 CONTROL

Special cycle Call up Display

Hardness range S3 + HS

Setting: "0" to "7" with

button S3

To save: HV off

L3 blinks

Display: current setting

Function check S2 + S3 + HV

Start: S2 + S3

L2 + L3 blink

Display shows : 20 ,21

Overrun detected / cod e variant

as long as both buttons are pressed

Display fault no . se e be low

Customer serv ice S2 + S4 + HV

Start: S2 + S4

L2 + L4 blink

Display shows : 20 ,21

Overrun detected / cod e variant

as long as both buttons are pressed

Display fault no . se e be low

Special - Dry S2 + HV

Setting: "0" or "1" with

button S2

To store: HV off

L2 blinks

Display: current setting

Test (continuous running) S2 + S3 + S4 + HV

Start: Cycle Select

within 4 seconds

LEDs of the last run program blink

For manufacturing only

Program is restarted after a 20 min. bre ak

Electrical safety test

(high-voltage)

S3 + S4 + HV L3 + L4 blink

Buzzer (VI only) S4 + HV

Setting: "0" or "1" with

button S4

To save: HV off

L4 blinks

Display: current setting

Display information for special program "function check" and "customer service":

1 Turbidity sensor defective

2 Heating fault

4 Filling fault

8 NTC fault For multiple faults, the values are correspondingly added.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

45 For internal use only

Page 47

7.1 Button functions

F-control with one 7-segment display

Program buttons Function

S1 S2 S3 S4 S5 S6

Time

preselection

2-basket

washing

Up. basket

washing

Encoder

plug

---

001

Heavy-load

002

Normal

003

ECO

004

Glasses

005

Quick

no no no without

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

no no no red

---

001

Heavy-load

002

Normal

003

ECO

004

Glasses

--- no no no without

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

--- yes no no red

---

001

Heavy-load

002

Normal

003

ECO

006

Prewash

--- no no no blue

---

001

Heavy-load

002

Normal

003

ECO

006

Prewash

--- yes no no blue

---

001

Heavy-load

002

Normal

003

ECO

004

Glasses

005

Quick

yes no no without

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

006

Prewash

yes no no red

000

Pots

001

Heavy-load

002

Normal

003

ECO

004

Glasses

005

Quick

no no no without

---

001

Heavy-load

002

Normal

003

ECO

004

Glasses

--- yes no no without

000

Pots

001

Heavy-load

002

Normal

003

ECO

005

Quick

005

Quick

yes no no without

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

006

Prewash

no no no red

000

Pots

001

Heavy-load

002

Normal

003

ECO

005

Quick

006

Prewash

yes no no red

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

--- no no yes red

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

--- yes no yes red

000

Pots

002

Normal

003

ECO

005

Quick

--- --- no no no red

000

Pots

001

Heavy-load

002

Normal

003

ECO

004

Glasses

005

Quick

yes no yes without

---

001

Heavy-load

002

Normal

003

ECO

--- --- no no yes without

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 46

Page 48

7.2 Button functions

E-control and

V-control with two 7-segment displays

Program buttons Function

S1 S2 S3 S4 S5 S6

Time

preselection

2-basket

washing

Up. basket

washing

Encoder

plug

000

Pots

001

Heavy-load

002

Normal

003

ECO

004

Glasses

005

Quick

yes yes yes without

000

Pots

001

Heavy-load

002

Normal

003

ECO

005

Quick

yes yes yes red

000

Pots

001

Heavy-load

002

Normal

003

ECO

005

Quick

--- yes no no red

000

Pots

001

Heavy-load

002

Normal

003

ECO

005

Quick

--- no no no red

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

--- yes yes yes red

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

--- no yes yes red

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

--- no no no red

000

Pots

001

Heavy-load

002

Normal

003

ECO

006

Prewash

--- yes no no blue

000

Pots

001

Heavy-load

002

Normal

003

ECO

005

Quick

006

Prewash

yes no no red

000

Pots

001

Heavy-load

002

Normal

003

ECO

005

Quick

006

Prewash

yes yes yes red

000

Pots

001

Heavy-load

002

Normal

003

ECO

004

Glasses

005

Quick

yes no no without

---

001

Heavy-load

002

Normal

003

ECO

005

Quick

006

Prewash

yes no no red

Built-under appliance - integrable

Fully-integrated appliance

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

47 For internal use only

Page 49

7.3 Special program "Function check", with heat exchanger

Abbreviation Index

Type of

action

Function

Temperature Time (sec.) Sensor

P = Pump 0 6 P+OK 5

VF = Prefill 1 23 TR1+TR2+OK

F = Fill 2 5 VF+Z+OK F1

U = Recirculate 3 0 F+OK

H = Heat 4 3 U+VF F1

Z = Dispense 5 9 U+P 30

R = Regenerate 6 6 P 30

D = Rinse 7 0 F

A = Drain 8 13 U+H+Z 90

TR1+TR2 = Calibrating

turbidity sensor

9 14 U+H+R 60

10 25 H 5

11 12 U+H 55 °C

12 12 U+H 90

13 9 U+P 15

14 7 P+H 45

If buttons S2 and S3 are pressed while the appliance is turned on at the mains switch, the special

program "function check" will start.

The following is displayed on the panel:

- LED L2 and L3 blink.

- As long as both buttons, S2 and S3, are kept pressed after starting - provided that the overrun check is

successful - a designator for the vari ant code is displ ayed, e. g. 20 = Varia nt 0, 21 = Variant 1, etc.

- Pressing one of the program buttons causes the associated LED to come on.

- Pressing S3 causes in addition the display and the refill LEDs to come on.

- Pressing the time preselection button causes the minutes LED to come on.

- Pressing buttons S2 and S3 causes the function check program to start. Time preselection is

not possible here.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 48

Page 50

The following fault numbers may be displayed:

Fault no. One 7-segment display Two 7-segment displays

0 There is no fault There is no fault

1 Aqua Sensor system fault

Note: Fault display also if there is no sensor

Aqua Sensor system fault

2 Heating fault Heating fault

3 Combined fault: fault 1 + fault 2 Combined fault: fault 1 + fault 2

4 Filling fault Filling fault

5 Combined fault: fault 1 + fault 4 Combined fault: fault 1 + fault 4

8 NTC fault NTC fault

9 Combined fault: fault 1 + fault 8 Combined fault: fault 1 + fault 8

12 --- Combined fault: fault 4 + fault 8

13 --- Combined fault: fault 1 + fault 4 + fault 8

c Combined fault: fault 4 + fault 8 ---

d Combined fault: fault 1 + fault 4 + fault 8 ---

F Filling fault (from FD 7610 on)

(is only displayed in the normal program sequence)

Filling fault (from FD 7710 on)

is only displayed in the normal program sequence

The upper basket function is selected for the complete program sequence.

Pressing S3 allows you to skip to the nex t program step (

exception:

during the filling process, only

pressing the fill button F1 is effective).

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

49 For internal use only

Page 51

7.4 Customer Service check program - electronic dishwashers

The new dishwasher series corresponds to the state-of-the-art. It is not only characterised by the

completely new design structure but also by the great number of technical details with respect to

function and control. Special importance has been attached above all to even higher quality

standards.

The customer service is requested to participate in maintaining this quality standard in case of

failures by quick reaction and expertise. Any special matters are to be communicated to the

department VKS-H by written information and return of the relevant components.

IMPORTANT!

Reset the electronic after any customer service call.

- Switch on the mains switch.

- Press buttons S2 and S4 approx. 3 seconds (display: 0).

- Wait until the drain pump switches off (approx. 1 min.).

- Switch off the mains switch.

7.4.1 Button designations, e. g.

70 °C = S1, 55 °C = S4

Heavy-load 65 °C = S2, 40 °C = S5

Normal 55 °C = S3, 30 °C = S6

Note: Independent of the number of control buttons (acc. to model), the check program is always

started by simultaneously pressing button 65 °C and the next but one button.

7.4.2 Starting the check program

- Keep button S2 and S4 depressed.

- Switch on the mains switch.

Note: If the buttons are depressed, the model no. of the electronic will be indicated in the display

(e. g. 20, 21..., important as reference in case of queries).

- LEDs of buttons S2 and S4 flash.

7.4.3 LED check

- Press the associated button - LED lights up.

- If button S3 is pressed, the display and the LEDs of the refill indicators will light up.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 50

Page 52

7.5 Check program with heat exchanger

Abbreviation Index

Type of

action

Function

Temperature Time (sec.) Sensor

P= Pump 0 6 P 30

VF = Prefill 1 23 TR1+TR2

F= Fill 2 2 VF F1

U = Recirculate 3 0 F

H = Heat 4 13 U+H+Z 120

Z = Dispense 5 12 U+H 65 °C

R = Regenerate 6 14 U+H+R 120

D = Rinse 7 6 P 60

A = Drain 8 22 D+A 60

TR1+TR2 = Calibrating

turbidity sensor

97 P+A 30

If buttons S2 and S4 are pressed while the appliance is turned on at the mains switch, the special

program function check will start.

The following is displayed on the panel:

- LEDs L2 and L4 blink.

- As long as both buttons, S2 and S4, are kept pressed after starting - provided that the

overrun check is successful - a designator for the variant code is displayed,

for example 20 = Variant 0, 21 = Variant 1, etc.

- Pressing one of the buttons causes the associated LED to come on.

- Pressing S3 causes in addition the display and the fault LEDs to come on.

- Pressing the time preselection button causes the minutes LED to come on.

Pressing buttons S2 and S4 causes the function check program to start. Time preselection is not

possible here.

The function check program is terminated by switching off the appliance via the mains switch.

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

51 For internal use only

Page 53

The following fault numbers may be displayed:

Fault no. One 7-segment display Two 7-segment displays

0 There is no fault There is no fault

1 Aqua Sensor system fault

Note: Fault display also when there is no sensor

Aqua Sensor system fault

2 Heating fault Heating fault

3 Combined fault: Fault 1 + Fault 2 Combined fault: Fault 1 + Fault 2

4 Filling fault Filling fault

5 Combined fault: Fault 1 + Fault 4 Combined fault: Fault 1 + Fault 4

8 NTC fault NTC fault

9 Combined fault: Fault 1 + Fault 8 Combined fault: Fault 1 + Fault 8

12 --- Combined fault: Fault 4 + Fault 8

13 --- Combined fault: Fault 1 + Fault 4 + Fault 8

c Combined fault: Fault 4 + Fault 8 ---

d Combined fault: Fault 1 + Fault 4 + Fault 8 ---

F Filling fault (from FD 7610 on)

(is only displayed in the normal program sequence)

Filling fault (from FD 7710 on)

(is only displayed in the normal filling sequence

The upper basket function is selected for the entire program sequence. Pressing S3 allows you to

skip to the next program step (

exception

: during the filling process, only pressing the fill button F 1 is

effective).

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

For internal use only 52

Page 54

7.6 Starting the Customer Service program

- Start by simultaneously pressing the buttons S2 and S4 once again.

CAUTION! A figure between 0 and 15 is indidated in the display (0 = no fault).

The electronic system checks 4 functions and indicates faults that have occurred with the respective

fault numbers in the display. The fault numbers are displayed as follows:

1 Aqua Sensor defective

2 Heating fault

4 Filling fault (time fault or hardware fault)

8 NTC fault

For multiple faults, the values are added on!

The fault display is only extinguished after a repair, if a complete function check has been

performed afterwards, e. g. in case of a heating fault after the temperature has been reached.

The figure 1 which is indicated in the display shortly after the start (approx. 5 sec) is no fault no. but

rather caused by the calibration process of the Aqua Sensor.

The individual check positions are automatically switched.

Note: Keeping the button S3 depressed enables steps to be skipped, e. g. the step out of the

heating position. The skipped functions are displayed as fault number.

7.7 Fault numbers

Fault no. 1: Aqua Sensor

Failure during the calibration process at the Aqua Sensor, or no Aqua Sensor available

- electrical defect

- sensor contaminated / calcified

- contact fault

Fault no. 2: Heating fault

The max. heating time of 60 min. has been exceeded.

- heating defective

- pressure switch has no function

- 85° C thermo has no passage (electr. defect, temperature is exceeded)

- heating without voltage

- contact fault

The wash time in case of a defective heating amounts to 75 to 300 min. depending on the program.

Fault no. 4: Filling fault

The max. filling time of 10 min. has been exceeded.

- no water supply

- poor water pressure

- Aqua Stop valve defective

VKS-H

Technical Information

Dishwasher Series 630

H7-410-03-01

Responsible: Rutz Tel.: (0209) 401-733 Fax: (0209) 401-743 Date: 30.09.1998

53 For internal use only

Page 55

CAUTION! This step cannot be skipped by means of button 3. In case of intermittent filling and

draining (electronic can be switched off during draining depending on the model)

check the level switch.

Fault no. 8: NTC fault