April 2011

®

Woodloc

Float-In Installation 7mm, 10mm, 14mm, 15mm

Table of Contents

Jobsite

Subfloor Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Underlayments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Layout

Calculation Worksheet for Min. Board Width (U.S. Std.) . . . . . . . . . . . . . . . . . . . . . . 7

Calculation Worksheet for Min. Board Width (Metric) . . . . . . . . . . . . . . . . . . . . . . . . 8

Required Expansion Reference Chart (Metric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Required Expansion Reference Chart (U.S. Std.) . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tools & Techniques

Important Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Kährs Product Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Woodloc® Float-In Installation 7mm, 10mm, 14mm, 15mm . . . . . . . . . . . . . . . . . . . 14-18

Note: for Radiant Heat applications, see Radiant Heat Special Instructions at www.kahrs.

com

Follow Up

Recoating Your Floor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Approved Commercial Uses

Kährs flooring may be used as a floor covering in public or private business, educational or

religious buildings and offices.

Installation in any and all areas where food or drinks are consumed, or areas contiguous to outside

entrances must be coated with a compatible wood finish urethane, in accordance with the finish

manufacturers application procedures. Kährs recommends Bona Kemi or Bona Traffic in these

cases. Contact Bona Kemi for details (www.bona.com).

Kährs does not warranty the performance of any site-applied finish. Please contact the finish

manufacturer for suitable products, precedures, and warranty.

Maintenance

See Kährs Commercial Flooring Maintenance Procedures (Kährs Commercial Warranty) for

maintenance details (available at www.kahrs.com).

For prefinished oiled floors, please refer to Natural Oiled Floors Maintenance and Rennovation

Procedures at www.kahrs.com

Technical Support 1-800-ASK-KAHRS www.kahrs.com

Jobsite

April 2011

Subfloor Preparation

Note: Warranty coverage may be lost due to failure to strictly follow all installation instructions and

recommendations and/or the use of improper materials or tools.

READ ALL INSTRUCTIONS CAREFULLY!

Subfloor Specifications

A. The surface of the subfloor must be level to within 1/8” in an 8ft. radius. Check this by using the

edge of a Kährs or Linnea plank to find high/low spots. To fill excessive voids or variations in the

subfloor, use leveling compounds approved for your application. Consult the compound manufacturer

to be sure it is appropriate. Allow the compound to dry thoroughly before beginning wood floor

installation.

Fifteen-pound felt or roofing paper is also appropriate to level a floor for a float-in installation. Cut small

pieces to fit the shape of the depression and then stack as many sheets as necessary to level the area.

DO NOT us this method to correct extensive variations in concrete subfloors.

B. You must test concrete subfloors prior to installation by one of the following methods. Concrete subfloors

must not contain more than 3 lbs. moisture on a dry-weight basis (calcium chloride test). Subfloor must read

4.5 or less with Tramex meter. Follow ASTM2170 - subfloor relative humidity not to exceed 75% with in-situ

probe. Moisture content of wood subfloors must be less than 12% Moisture Content (MC). Document and

keep ALL test results. Subsequent excessive moisture after pre-installation documented testing is evidence

of moisture intrusion and will not be covered under Kährs warranty.

C. The subfloor must be clean.

D. Relative humidity at the job site must be, and remain, minimum 30%, maximum 60%. Temperature

setting must be, and remain, within 15º F of normal operating range.

Evaluation

Before installing a Kährs floor, inspect the job site thoroughly. With the help of the Installation

Environment Chart determine if grade, subfloor, and subfloor conditions are acceptable for the installa tion method you plan to use.

Exterior: Carefully inspect the outside surroundings for improper drainage and predictable or obvious

sources of moisture. The yard should be graded (at least 6” in 10 ft.) to slope away from the foundation.

Be sure that gutters and eaves sufficiently prevent rain from penetrating the foundation.

Under the house: In homes with crawl space or pier-beam foundations, foundation vents must provide

cross-ventilation with no dead air space. Vents should be located throughout the foundation with opening

area equal to 1-1/2% of the square-foot area within the crawl space (eg. a 1000sq. ft. crawl space must

have 15 sq. ft. of vents that remain open all year). If excessive moisture exists underneath the house,

you must lay a 6 mil black polyethylene moisture barrier on the ground in the crawl space

below the installation area.

Interior: Check the moisture content of the subfloor. See item “B” above as well as “Moisture” at the end

of this section. Room conditions can also indicate high moisture and relative humidity. Look for water

stains, peeled paint near windows and doors, and rusty metal, especially nails.

Preparation

Wood Subfloors: Moisture Content (MC) must be less than 12%. To prepare the subfloor for installation,

renail any loose areas with squeaks. Sand or plane any high spots and fill any low areas. The subloor should

not vary more than 1/8” in an 8’ radius. Check this by using the edge of a Kährs or Linnea plank to find any

high or low spots. See Installation Environmental Chart for Approved Subfloors.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

2

Jobsite

April 2011

Subfloor Preparation

Preparation (con’t.)

Preferred Subflooring: 3/4” (23/32”, 18.3 mm) CDX grade plywood subfloor/underlayment (Exposure 1)

4’ x 8’ sheets OR 3/4” (23/32” 18.3mm) OSB subfloor/underlayment grade, with joint spacing 19.2”

(475mm) on center joint construction or less. Direct Glue-Down installations: 2 layers 1/2” (11.9mm)

CDX plywood.

Minimum Subflooring: 5/8” (19/32”, 15.2mm) CDX plywood subfloor/underlayment (Exposure 1) 4’ x 8’

sheets, maximum 16” (400mm) on center joint construction. Direct Glue-Down installations: 2 layers 3/8”

(10mm) CDX plywood.

Follow panel manufacturer recommendations for spacing and fastening. Typical panel spacing for joint

systems is 1/8” (3.2mm) around perimeter and fastened every 6” (150mm) on bearing edges and every

12” (300mm) along intermediate supports.

Door casings should be notched or undercut to avoid difficult scribe cuts.

If nailing the floor, (Kährs 14, 15, 20 mm Traditional Tongue & Groove only) we suggest you cover the sub

floor with 15 lbs. or higher asphalt felt or rosin paper to retard moisture and to help alleviate variations in

the subfloor.

Concrete Subfloors: Lightweight (float-in only) and standard-density (float-in and glue-down) concrete

subfloors are ideal applications for a Kährs floor. Concrete subfloors are generally acceptable for float-in

installation if the subfloor appears to be dry (i.e. no standing water or discoloration of concrete) and

Kährs Combo System Underlayment is used and installed properly. Be sure that, as a minimum, any

concrete subfloor is at least 50-60 days old before installing a wood floor over it.

Moisture

To curb the adverse effects moisture will have on a Kährs wood floor and to determine the

source of moisture problems, use the following checklist:

1. Inspect the gutters, drains, and down spouts outside the house. Clear out any clogs caused by

leaves, dirt, or other substances. Down spouts are designed to transport water away from a

foundation.

2. Check the landscaping surrounding the home to be sure the yard is sloped away from the foundation

(at least 6” in 10 ft.).

3. Check windows and doors for proper drainage and waterproof caulking.

4. Inspect concrete subfloor for cracks or buckling. Sometimes the water table (water beneath the sur

face) may rise and force water up through the concrete floor with hydrostatic pressure.

5. Check the ventilation system in the crawl space, basement, and attic. Moisture will collect on walls

and floors if dead air (i.e. little or no ventilation) is present. As a rule, ventilation per sq. ft. should

equal 1-1/2% of the sq. ft. of the area in question.

6. Inspect pipes, water heater tank, dishwasher, and any other plumbing fixtures in the affected area.

7. Remember to take seasonal changes in relative humidity into consideration when installing a Kährs

floor.

8. Signs that the moisture content is too high include discolored (darker) concrete and evidence of

actual water droplets.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

3

Jobsite

April 2011

Subfloor Preparation

Moisture (con’t.)

Required moisture testing for ALL Kährs radiant heat installations and direct glue-down flooring:

Calcium Chloride test with a reading of 3 lbs. or less on a dry weight basis (2 lbs. or less for Radiant

Heat Installations). Testing kits are generally available through your distributor or call the NWFA at 800 422-4556 (or 800-848-8824 in Canada) for the source nearest you. Follow test kit manufacturer’s

instructions for conducting test and measuring results. If calcium chloride results read over 3 lbs. but

does not exceed 8 lbs. (and no obvious source of the moisture can be eliminated) you must use either

of the following approved moisture sealers before installing the floor for the Kährs Moisture Protection

Warranty to apply:

• DriTac MCS 7000 when used with DriTac 7600 or 7500 Adhesive (call 800-394-9310 for source

nearest to you).

• Dependable Cutdown (call 800-227-3434 for the source nearest you).

• Concrete Moisture Barrier System*

* If moisture is present an alternative is a barrier of inexpensive sheet vinyl or “slip sheet” (PVC). Use

the manufacturers recommended adhesive for a full spread application to completely adhere the vinyl

to the subfloor. Since Kährs cannot guarantee the bond of the vinyl to the subfloor, or subsequent per formance of the vinyl, a patch test is strongly advised. Install several 3” x 3” pieces of vinyl in different

areas of the installation. Wait 72 hours. Remove the vinyl. If the backing remains attached to the con-

crete, the subfloor should be acceptable for full spread vinyl installation.

Note: These concrete sealers are NOT approved for Radiant Heat installations.

All concrete sealer/vinyl manufacturer testing, documentation, and installation requirements MUST be

followed for Kährs Limited Warranty to apply.

Other Subfloors: Kährs floors can be installed directly over some existing floors (i.e. vinyl

and rubber tile, steel plates, terrazzo, and existing wood floors). The subfloor or existing floor must meet

the requirements listed in “Subfloor Specifications.” A Kährs floor installed over existing floors

must be installed with the float-in method.

Installation Environment Chart

I. Grade Type Glue** Nail* Float

A. Above Grade yes yes yes

B. On Grade yes yes yes

C. Below Grade no no yes

D. Over Radiant Subfloor no no yes

II. Subfloor Type Glue** Nail* Float

A. Concrete (701 lbs. cu. ft. density or higher) yes no yes

B. Light-weight concrete no no yes

C. Association-grade underlayment plywood yes yes yes

D. Association-grade underlayment particle board yes no yes

E. Stamped Underlayment Grade OSB (Oriented Strand Board) yes yes yes

F. Old wood floors - above grade only no no yes

(next page)

Technical Support 1-800-ASK-KAHRS www.kahrs.com

4

Jobsite

April 2011

Subfloor Preparation

Installation Environment Chart

II. Subfloor Type (con’t.) Glue Nail* Float

G. Asphalt tile no no yes

H. Inlaid linoleum *** no yes

I. Vinyl asbestos tile no no yes

J. Cushion vinyl no no yes

K. Rubber tile no no yes

L. Solid vinyl tile no no yes

M. Steel no no yes

N. Marble no no yes

O. Ceramic no no yes

P. Carpet no no no

*14mm, 15mm , 20mm T & G only

*** Check Kährs Technical Services Department: 1-800-ASK-KAHR

Technical Support 1-800-ASK-KAHRS www.kahrs.com

5

Jobsite

Underlayments

• Kährs Combo-System Underlayment

• Kährs QuietStride

April 2011

Combo Foam Underlayment System with Overlap:

The width of a row of Kährs Combo-System Underlayment

is comprised of 40” of underlayment plus an 8” overlap

flap. The overlap flap guards the flooring from moisture at

the seams, where the rows of underlayment are laid side

by side. The overlap flap has a peel and stick strip to aid

the installation process.

1. Layout 1st row of underlayment (logo side down,

blue side up) with the overlap flap facing the

starting wall. Allow the underlayment to wrap up

the wall, on the ends, approx. 2”.

2. Reach under and grab the overlap flap and pull

it up so it lies against the starting wall. Trim this

over lap flap back to leave approx. 2” of plastic

up the wall. (Use this cut off section to repair

damage in the underlayment as needed*, see

note below).

3. Lay 2nd row of underlayment flush to first. Make

sure the overlap flap is next to 1st row, and the

ends wrap up the walls. (If flooring installation

has already begun, make sure to stop the floor

ing approx. 8 inches from the side of the under-

layment to allow for the installation of the overlap

flap.)

4. Again, reach under and grab the overlap flap.

Pull the flap up and fold it back to expose the

peel and stick strip. Remove the white protective

cover from the adhesive strip. Lay overlap flap

across the 1st row of underlayment and press

into place.

5. Continue this procedure row by row until the

entire floor area is covered.

* Note: When connecting a new roll of underlayment to

the end of the roll you are working on, or for repairing

any tears or cuts in the underlayment; overlay the butt

joints or the damaged area with a spare piece of overlap

plastic. This spare piece should overlay by approx. 8”.

Hold the spare piece in place with tape. Do NOT overlap

underlayment. Overlap flap only.

Cover the entire floor area and run the underlayment up

the perimeter walls approximately 2”. This provides a

secure enclosure for the flooring. After the floor is installed

and before the installation of the baseboards, the excess

underlayment should be trimmed to the height of the

floor surface using a fine trimming blade. The use of the

Combo-System Underlayment is also approved for Radiant

Heat applications.

Kährs QuietStride:

Quiet Stride can be installed three different ways as a Kährs underlayment.

1. Float-in Installations: First install 6 mil polyethylene

plastic loose-laid, seams overlapped 8”. Run plastic up

the wall 2” (trim excess after installation, before

installing trim). Loose-lay QuietStride on top of plastic,

wall to wall, and butt all seams together (taping seams

preferred). Use of QuietStride with polyethylene plastic

is approved for float-in Radiant Heat applications.

2. Direct Glue-Down: Install QuietStride wall to wall, butt

all seams together (do not tape seams), directly adher-

ing to subfloor with QuietStride Adhesive* or a premium

multi-purpose adhesive. Fully adhere Kährs flooring to

underlayment using approved adhesive and trowel (see

Glue-Down Installation for details). Note: an approved

concrete sealer must be used if calcium chloride test

exceeds 3lbs. for Kährs Moisture Protection Warrany to

apply.

3. Direct Glue-Down over “float-in” underlayment: First

install 6 mil polyethylene plastic loose-laid, seams over lapped 8”. Run plastic up wall 2” (trim excess after

installation, before installing trim). Loose-lay QuietStride

on top of plastic, wall to wall, butt all seams together (do

not tape seams). Fully adhere Kährs flooring to under-

layment using approved adhesive and trowel (see Glue-

Down Installation for details). Note: an approved con-

crete sealer must be used if calcium chloride test

exceeds 3lbs. for Kährs Moisture Protection Warranty to

apply.

* QuietStride Adhesive has been developed for adhering

QuietStride Underlayment directly to the subfloor for use in

"double-stick" installations. The adhesive is a quick, inex pensive technique for affixing QuietStride Underlayment

to the subfloor, then gluing the Kährs flooring to the

QuietStride Underlayment with one of the approved Kährs

wood flooring adhesives.

• QuietStride Adhesive product ID #710248

• Sold in 1gallon pails

Important:

Kährs does not guarantee the performance of any nonKährs branded underlayment.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

6

Layout

April 2011

Calculation Worksheet for Min. Board Width - (U.S. Std.)

Purpose: To ensure last board of the installation (or long board at an obstruction) is not too narrow.

General Rule: Kährs requires that no board have a width less than 3” or .38” of a full board width.

Notes on Equation: This rule applies to boards with an original thickness of 5/8” x 3-strip wide. This equation should

be used when a board 4’ or more in length meets an obstruction.

WORKSHEET

Step 1

Measure width of connected area* from starting wall to finish

wall or obstruction, in inches. Round to the nearest 1/4”.

Step 1

Measure width of connected area* from starting wall to finish

wall or obstruction, in inches. Round to the nearest 1/4”.

EXAMPLE

Connected Area Width in inches

with fraction: __________________

Step 2

Convert “inches with Fraction” to “Inches with Decimal”. Use

conversion chart below.

Connected Area Width in inches

with decimal: __________________

Step 3

Multiply “Required Expansion Space” by 2. Use chart below.

Total Expansion Needed from above: __________________

Connected Area Width Expansion Total

(from Step 2) Space

Under 144” 1/4” x 2 = .50”

144” - 288” 1/2” x 2 = 1.0”

288” - 480” 3/4” x 2 = 1.5”

Step 4

Subtract Total Expansion Needed from Connected Area Width

to determine Actual Floor Width.

Total from Step 2: _____________._____”

Total from Step 3: - _____________._____”

Actual Floor Width in inches

with decimal: = _____________._____”

Step 5

Determine total # of rows of flooring needed.

Actual Floor Width (Step 4): _____________._____”

Board Width in Decimal - measure board and use chart below

to convert: ÷ _____________._____”

Total Rows of Flooring: = _____________.__rows

Step 6

If the result in Step 6 contains a decimal less than .38”, you

must rip the starting row in half to ensure proper width of the

last row.

Connected Area Width in inches

with fraction: 325-1/4”

Step 2

Convert “inches with Fraction” to “Inches with Decimal”. Use

conversion chart below.

Connected Area Width in inches

with decimal: 325.25”

Step 3

Multiply Required Expansion Space by 2. Use chart below.

Total Expansion Needed from above: 1.5”

Connected Area Width Expansion Total

(from Step 2) Space

Under 144” 1/4” x 2 = .50”

144” - 288” 1/2” x 2 = 1.0”

288” - 480” 3/4” x 2 = 1.5”

Step 4

Subtract Total Expansion Needed from Connected Area Width to

determine Actual Floor Width.

Total from Step 2: 325.25”

Total from Step 3: - 1.50”

Actual Floor Width in inches

with decimal: = 323.75”

Step 5

Determine total # of rows of flooring needed.

Actual Floor Width (Step 4): 323.75”

Board Width in Decimal - measure board and use chart below

to convert: ÷ 7.875”

Total Rows of Flooring: = 41.11 rows*

* The first board in this installation would be cut in half.

Step 6

If the result in Step 6 contains a decimal less than .38”, you

must rip the starting row in half to ensure proper width of the

last row. Ripping the starting row in half will increase the last board

width by .50 of a board. In this case the last board will end up being

.61 of a board or approx. 5”, instead of .11 or 1” wide.

*From Step 1 - Connected Area is defined as all areas connected without a break. If Room A and Room B both are to have flooring

installed and are directly connected, or connected by a hallway, without a t-molding, the connected area is the width of both Room A and

Room B, and the hallway (if applicable). Obstructions can include cabinets, islands, and the wall opposite the starting wall in the same

room, if the flooring continues to another room without a break. Multiple calculations may need to be made to best determine the amount

cut from the starting row.

Fraction to Decimal Conversion Chart

Fraction Decimal Equivalent

1/4” .25”

1/2” .50”

3/4” .75”

Board Width Decimal Eqivalent Chart

Board Width Decimal Equivalent

7-7/8" 7.875"

8-1/10" 8.100"

Technical Support 1-800-ASK-KAHRS www.kahrs.com

7

Layout

April 2011

Calculation Worksheet for Minimum Board Width - (Metric)

Purpose: To ensure last board of the installation (or long board at an obstruction) is not too narrow.

General Rule: Kährs requires that no board have a width less than 76mm or .38” of a full board width.

Notes on Equation: This rule applies to boards with an original thickness of 15mm x 3-strip wide. This equation

should be used when a board 120cm or more in length meets an obstruction.

WORKSHEET

Step 1

Measure width of connected area* from starting wall to finish

wall or obstruction, in inches. Round to the nearest 1/4”.

Total Area Width in mm: __________________

Step 2

Multiply Required Expansion Space by 2. Use chart below.

Required Expansion Space: ________________mm

X 2

Total Expansion = ________________mm

Step 3

Subtract Total Expansion from Total Area Width to determine

Actual Floor Width.

Total from Step 1: _____________.___mm

Total from Step 2: - _____________.___mm

Actual Floor Width: = _____________.___mm

Step 4

Determine total # of rows of flooring needed.

Actual Floor Width (Step 3): _____________.___mm

Board Width. Measure board. It will be

either 200 or 205mm. ÷ _____________.___mm

Total Rows of Flooring: = _____________.__rows

Step 5

If the result in Step 6 contains a decimal less than .38”, you

must rip the starting row in half to ensure proper width of the

last row.

EXAMPLE

Step 1

Measure width of connected area* from starting wall to finish

wall or obstruction, in inches. Round to the nearest 1/4”.

Total Area Width in mm: 8262mm

Step 2

Multiply Required Expansion Space by 2. Use chart below.

Required Expansion Space: 20mm

X 2

Total Expansion = 40mm

Step 3

Subtract Total Expansion from Total Area Width to determine

Actual Floor Width.

Total from Step 1: 8262mm

Total from Step 2: - 40mm

Actual Floor Width: = 8222mm

Step 4

Determine total # of rows of flooring needed.

Actual Floor Width (Step 3): 8222mm

Board Width. Measure board. It will be

either 200 or 205mm. ÷ 200mm

Total Rows of Flooring: = 41.11 rows*

*The first board in this installation would be ripped in half.

Step 5

If the result in Step 6 contains a decimal less than .38”, you

must rip the starting row in half to ensure proper width of the

last row. Ripping the starting row in half will increase the last board

width by .50 of a board. In this case the last board will end up being

.61 of a board or approx. 120mm, instead of .11 or 22mm wide.

* From Step 1 - Connected Area is defined as all areas connected without a break. If Room A and Room B both are to have flooring

installed and are directly connected, or connected by a hallway, without a t-molding, the connected area is the width of both Room A and

Room B, and the hallway (if applicable). Obstructions can include cabinets, islands, and the wall opposite the starting wall in the same

room, if the flooring continues to another room without a break. Multiple calculations may need to be made to best determine the amount

cut from the starting row.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

8

Layout

April 2011

Required Expansion Reference Chart - (Metric)

Purpose: To ensure proper expansion space around all walls, doors and obstructions for 7mm, 10mm, 14mm and

15mm flooring.

Required Expansion

Rules: (1) Kährs requires 1.5mm of expansion space for every 1m of Connected Area width or 2.5m of

Connected Area length (whichever is greater). This expansion space must be left around all

walls, doors and obstructions. Minimum expansion requirement is 12mm.

(2) No connected flooring can span greater than 12m in width or 36m in length.

Notes: (1) Connected area is defined as all areas connected without a break. If Room A and Room B

both are to have flooring installed and are directly connected, or connected by a hallway, with-

out a t-molding, the Connected Area is the width of both Room A and Room B, and the hall

way (if applicable). Obstructions can include cabinets, islands, and the wall opposite the start-

ing wall in the same room, if the flooring continues to another room without a break. Multiple

calculations may need to be made to best determine the amount cut from the starting row.

(2) The direction of the flooring must be determined prior to calculating the required expansion

space. The Connected Area width is parallel to the board width. The Connected Area length is

parallel to the board length.

Required Expansion Reference Chart

Connected Area Required Expansion Connected Area Required Expansion

Width Space* Length Space*

up to 750cm 12mm up to 2250cm 12mm

750cm-1200cm 20mm 2250cm-3600cm 20mm

* Determine the required expansion space for both width and length, then use the larger of the 2 on all

sides, and around all obstructions.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

9

Layout

April 2011

Required Expansion Reference Chart - (U.S. Standard)

Purpose: To ensure proper expansion space around all walls, doors and obstructions.

Required Expansion

Rules: (1) Kährs requires 1/16” of expansion space for every 3’ of Connected Area width or 9’ of

Connected Area length (whichever is greater). This expansion space must be left around all

walls, doors and obstructions. Minimum expansion requirement is 1/2”.

(2) No connected flooring can span greater than 40’ in width or 120’ in length.

Notes: (1) Connected area is defined as all areas connected without a break. If Room A and Room B

both are to have flooring installed and are directly connected, or connected by a hallway, with-

out a t-molding, the connected area is the width of both Room A and Room B, and the hall

way (if applicable). Obstructions can include cabinets, islands, and the wall opposite the start-

ing wall in the same room, if the flooring continues to another room without a break. Multiple

calculations may need to be made to best determine the amount cut from the starting row.

(2) The direction of the flooring must be determined prior to calculating the required expansion

space. The Connected Area width is parallel to the board width. The Connected Area length is

parallel to the board length.

Required Expansion Reference Chart

Connected Area Required Expansion Connected Area Required Expansion

Width Space* Length Space*

up to 24’ 1/2” up to 72’ 1/2”

24’-40’ 3/4” 72’-120’ 3/4”

* Determine the required expansion space for both width and length, then use the larger of the 2 on all

sides, and around all obstructions.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

10

Tools & Techniques

April 2011

Important Installation Notes

Please see our website - www.kahrs.com for Kahrs Floor Care Guide and Lifetime Guarantee.

Installation

Floating:

Maximum room dimensions for a floating floor are 40ft. across the boards or 120 ft. lengthwise. Floors exceeding

either of these dimensions require use of “T-Molding.”

A minimum of one butt seam is required in every row, regardless of width (e.g. hallways).

Never attach any permanent object through the flooring, affixing it to the subfloor. A float-in floor must be free to

expand and contract in all directions.

Glue down:

Installing Kährs floors with the Glue down method requires no expansion breaks in the floor and is not

limited in size. A 1/2” gap at perimeter walls is required to allow engagement of last boards.

Adhesive Tape on Kahrs Floors

The use of adhesive tape on any Kährs floor for any reason (i.e. to fasten temporary protection) is not recommend ed and is not covered in our warranty.

Kahrs Flooring is approved for installations in ½ bathrooms only (no bathrooms including showers or bath tubs)

Expansion in Large Areas

You may be able to attain the necessary added expansion by trimming the wallboard (i.e. sheetrock) or raising

baseboards before installing floor. This will allow the floor to expand underneath the wall. For complete information

please refer to Required Expansion Reference Charts on pages 8 and 9 in the Layout section of this Guide. A Kährs

floor requires 1/16” expansion for every 3’ across width and 1/16” expansion for every 9’ along length. For

example, a 28’ x 28’ space requires an expansion gap of 9/16” around the edge of the flooring.

Additional Finish Coating

For additional wear protection, a waterborne urethane finish is compatible with Kährs factory finishes. The following

products from Bona Kemi are recommended:

• Pacific Strong

• Traffic

Contact Bona Kemi USA, Inc. (1-800-574-4674). Follow manufacturers instructions for recoating a prefinished

wood floor. Kährs International, Inc. does not guarantee the performance and/or durability of these products.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

11

Tools & Techniques

April 2011

Installation

Do you have the tools and products you need to install a Kahrs floor?

Never start a job unprepared! Each installation method requires different tools and products. Use the chart below to

be sure you are fully prepared to begin your installation. For your convenience, product codes (SKU’s) are listed next

to each Kährs product name. Where appropriate, square footage and other important information is included as well.

KAHRS PRODUCT KEY

(LISTED BY INSTALLATION METHOD)

Product/Material SKU Float In Radiant Heat Glue Down Nail Down

Kàhrs 20mm Flooring - Tongue & Groove Various Yes Yes Yes Yes

Kährs 15mm Flooring - Woodloc Various Yes Yes Yes No

Kährs 15mm Flooring - Tongue & Groove Various Yes Yes Yes Yes

Kährs 14mm Flooring - Tongue & Groove Various Yes Yes Yes Yes

Kährs 14mm Flooring - Woodloc Various Yes Yes Yes No

Kährs 11mm Flooring - Tongue & Groove Various No No Yes Yes

Kährs 10mm Flooring - Woodloc Various Yes Yes Yes No

Kährs 7mm Flooring - Woodloc Various Yes Yes Yes No

Combo System Underlayment (subfloor) 710730CSU Yes Yes No Tar/Roofing

QuietStride Underlayment 710113 Yes Yes Yes No

QuietStride Adhesive 710248 No No Yes No

Prefinished Moldings Various Yes Yes Yes Yes

Landobond Adhesive; 239 sq.ft. per bottle 710225 Yes Yes Yes Yes

Woodloc 5S Lock/Unlock Tool 710559 Yes Yes Yes Yes

Knocking Block, T & G Float-In and Nail-Down, 14, 15mm 710202 Yes Yes No Yes

Knocking Block, T&G, Woodloc Glue-Down 14mm &15mm 710281 No No Yes No

Knocking Block, Glue Down 11mm 710290 No No Yes No

Woodloc Hand Block (Woodloc only) 710266 Yes Yes No No

Woodloc Installation Wedge (Woodloc only) 710267 Yes Yes No No

Last Board Puller (Jemmy) 710203 Yes Yes Yes Yes

Nail Plate Adapter 15mm for use with Bostitch Mach III 710268 No No No Yes

Nail Plate Adapter 14, 15mm for use with Bostitch Mach III 710269 No No No Yes

Expansion Shims 710283 Yes Yes Yes Yes

Recommended Mastic*** Taylor 2071, Dri Tac, Stauf Various No No Yes No

(continued next page)

* Tongue & Groove only

** Contact Kährs Customer Service

*** Alternative: any moisture cured urethane wood flooring adhesive. See Glue-Down sections for details.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

12

Tools & Techniques

April 2011

KAHRS PRODUCT KEY

(LISTED BY INSTALLATION METHOD)

Product/Material SKU Float In Radiant Heat Glue Down Nail Down

Spline - Kährs 11, 14, 15, 20 mm only - to change directions ** Yes Yes Yes Yes

Router Bit Kährs 11mm 710291S Yes Yes Yes Yes

Router Bit Kährs 14, 15mm 710291 Yes Yes Yes Yes

Kährs Wood Cleaner 710280 Yes Yes Yes Yes

Peel & Stick Floor Protectors 710287 Yes Yes Yes Yes

Touch Up Kits 710273-79 Yes Yes Yes Yes

Technical Support 1-800-ASK-KAHRS www.kahrs.com

13

Tools & Techniques

April 2011

Float-In Installation for Woodloc

®

Notes:

• For subfloor and environmental specifications and requirements, see

Jobsite / Subfloor Preparation section. Floating installation requires the use of

Kährs Approved Underlayment Systems. Refer to Underlayment section of this

Guide.

• Kährs flooring is covered by a Limited Lifetime Warranty. However, Warranty

coverage may be lost due to failure to strictly follow all installation instructions

and recommendations or the use of improper materials or tools. READ ALL

INSTRUCTIONS CAREFULLY.

IMPORTANT!

• Do not open packages until ready to begin installation! Inspect boards as you go.

Kährs flooring is sealed at the factory with a 7% moisture content. Opening cartons to

acclimate the flooring (as with some solid strip flooring) could result in a difficult

installation.

• As an installer, it is your responsibility to be aware of the grade, Relative Humidity of the

room, and moisture content of the subfloor. You should check that each plank is free of

damage or manufacturing defects. Any unusable boards should be set aside for later

replacement.

Tools and Materials Required

• Tape Measure

• Chalk Line

• Last Board Puller

• Hammer

• Woodloc

TM

Knocking Block

• WoodlocTM Installation Wedge

• Expansion Shims

• Floor Protectors

For SKU numbers see Kährs Product

Key in Tools & Techniques, page 12,

this Guide.

Step 1

Start in corner and lay first row with

tongue sides toward wall (Fig 1). Proper

expansion space can be achieved by

pulling floor away from wall once first

three rows have been installed (reference

Step 9). For proper expansion refer to

Calculation Worksheet, pages 9-10.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

14

Tools & Techniques

April 2011

Float-In Installation for Woodloc

Step 2

Hold next board against first board at approx. 45º angle and lay flat on floor (Fig. 2).

Continue in this manner for entire first row.

Step 3

Cut end board in first row to correct length and start second row with left-over piece

(if possible) as shown in Fig 4. End joints must be staggered by at least 12” for 7mm

and 10mm flooring, and 20” for 14mm and 15mm flooring. Butt seam must be placed in each

row regardless of width, e.g. hallways.

Step 4

Hold board at approx. 45º angle to board in front. Press forward to engage joint and lay

flat on floor (Fig. 4)

®

Step 5

Push in Kährs Wedge under short end of last board installed, as shown in Fig. 5.

Step 6

Engage short end of new board as in Step 2. Lay flat keeping long side in line with groove

of adjacent board (Fig. 6).

Technical Support 1-800-ASK-KAHRS www.kahrs.com

15

Tools & Techniques

April 2011

Float-In Installation for Woodloc

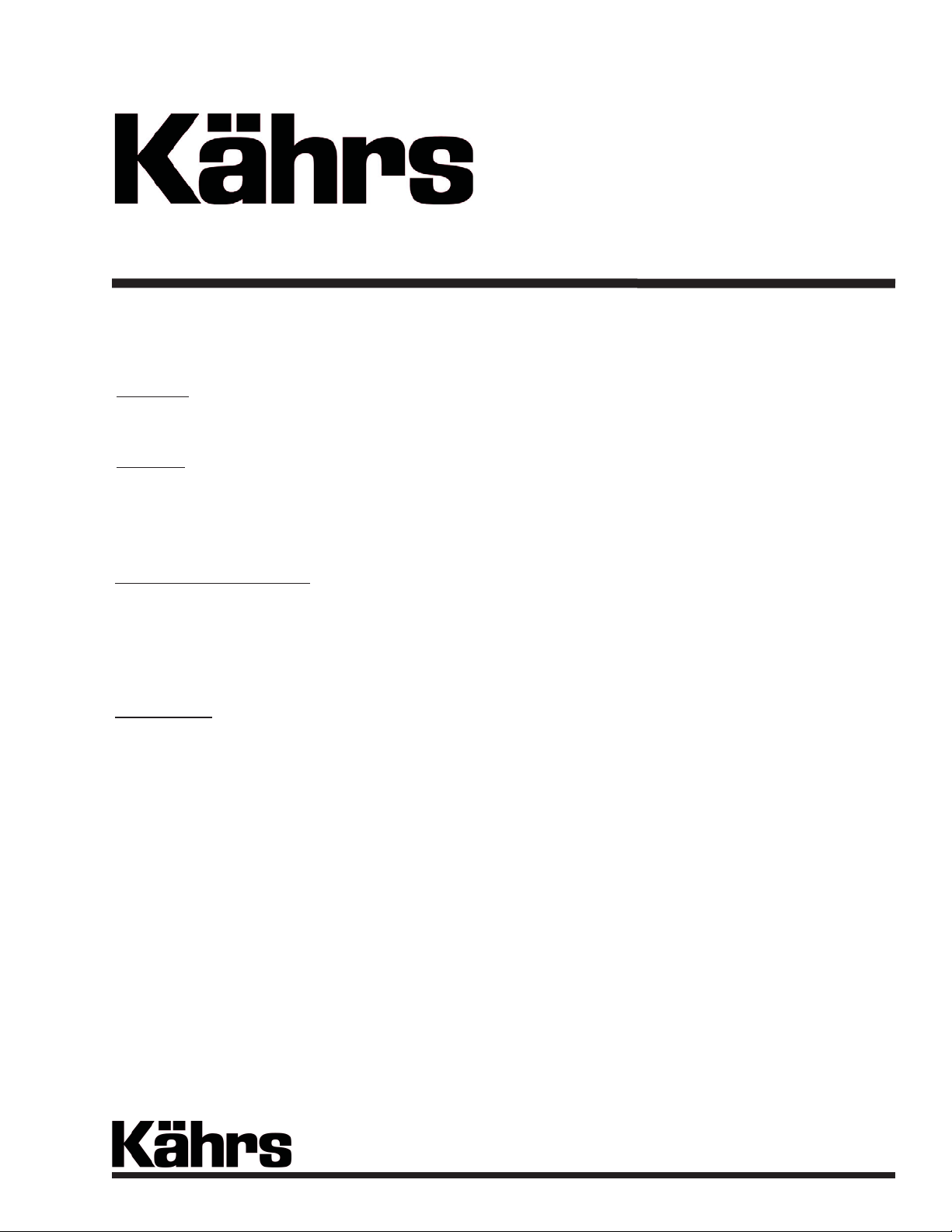

Step 7

Using Kährs knocking block, carefully tap long edges together until they are closed. DO

NOT tap too hard or over-engage (Fig.7). Never tap directly against wearlayer.

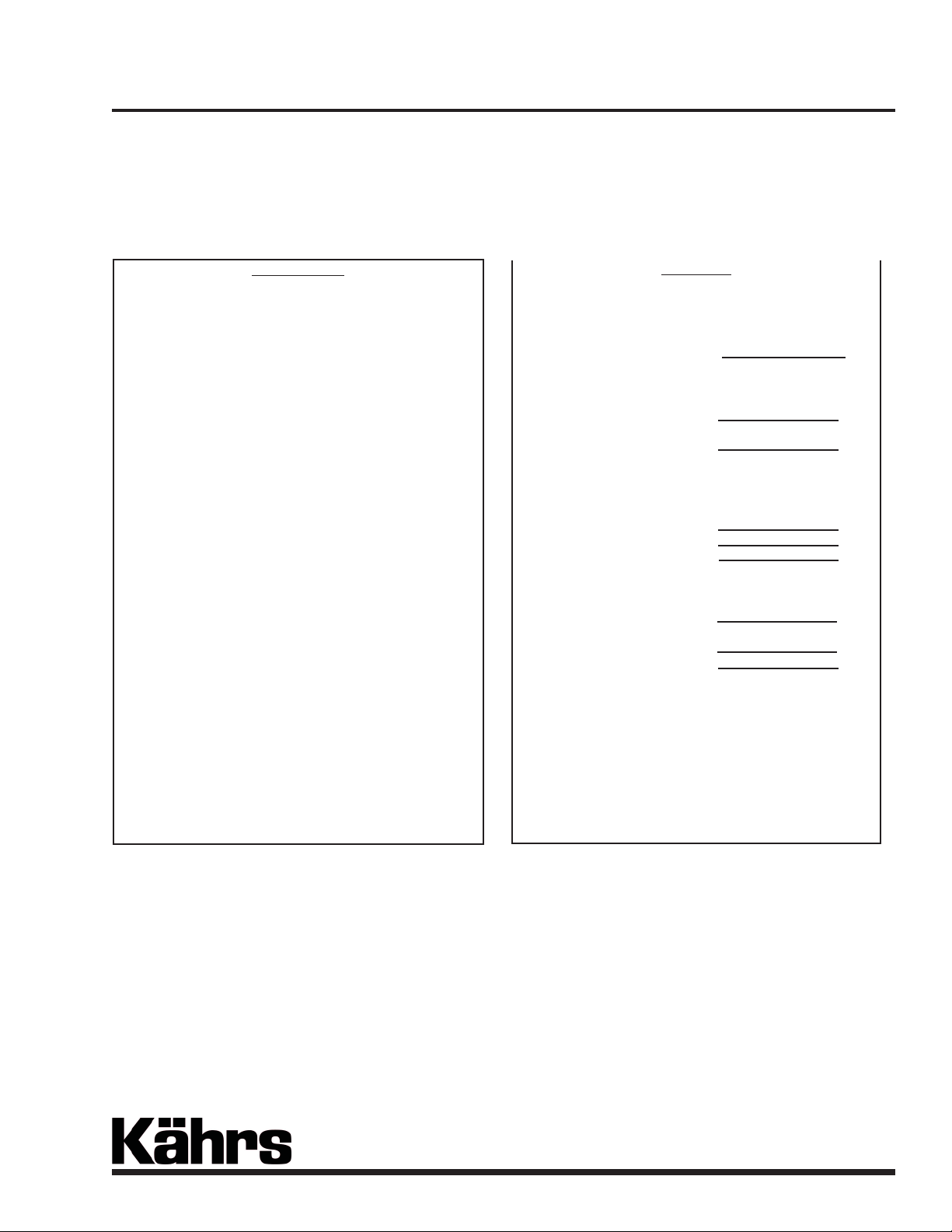

Step 8

Remove wedge and gently tap with knocking block along open long seam while applying

pressure downward, until board lays flat (Fig. 8). Board should fall easily into place.

®

Step 9

When three rows have been laid, pull floor away from starting wall until there is

proper amount of expansion space. Place shims between floor and wall to maintain

this space (Fig. 9).

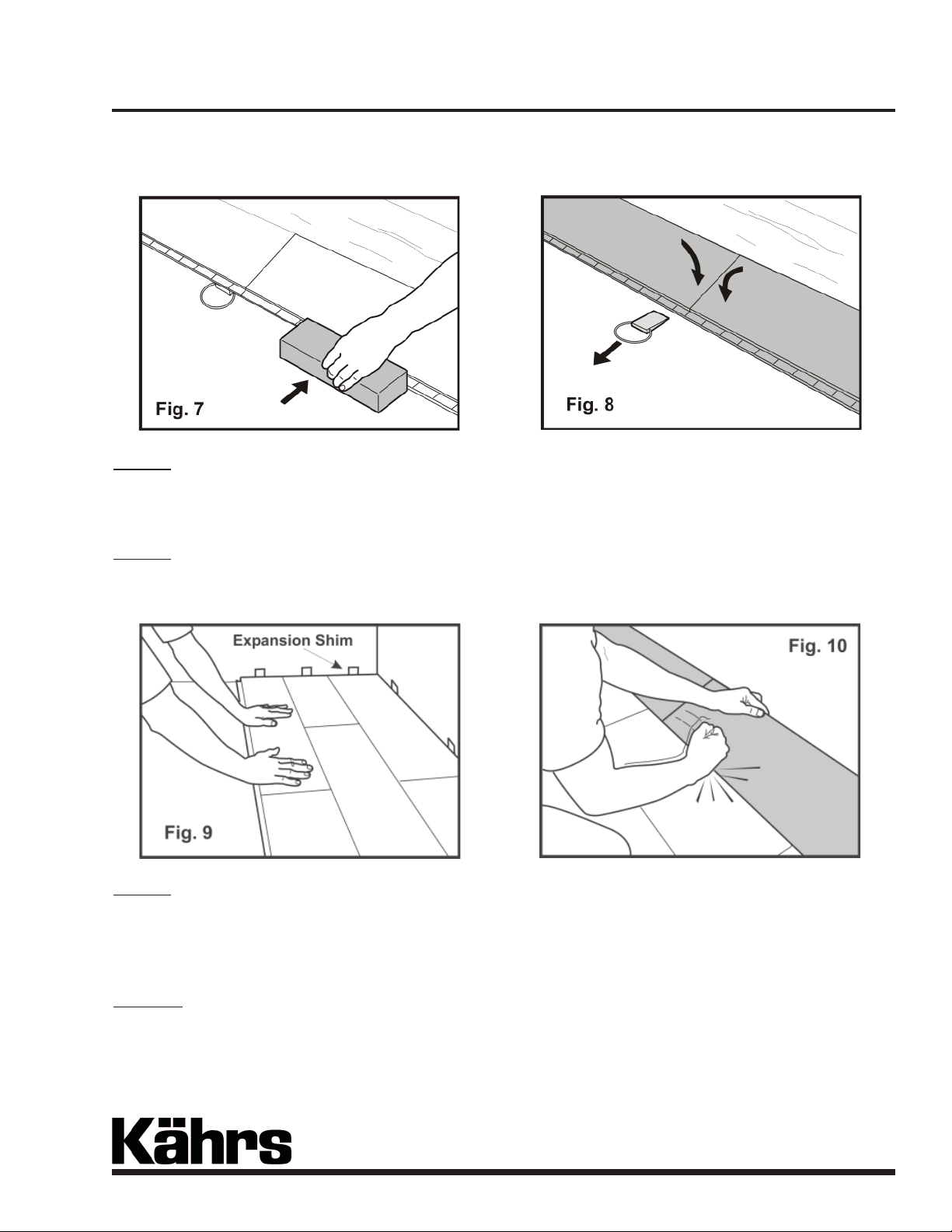

Step 10

If first row must be cut to match crooked wall, trace shape of wall on flooring,

making sure space is allowed for expansion (see Fig. 13). Disengage boards of first row

by gripping long side and pulling upward while simultaneously giving long joint a light

tap (Fig. 10). Saw to shape.

Technical Support 1-800-ASK-KAHRS www.kahrs.com

16

Tools & Techniques

April 2011

Float-In Installation for Woodloc

Step 11

Re-lay cut boards in first row and re-install 2nd and 3rd rows. Continue installation in

manner described above. Put shims between floor and wall (Fig. 11).

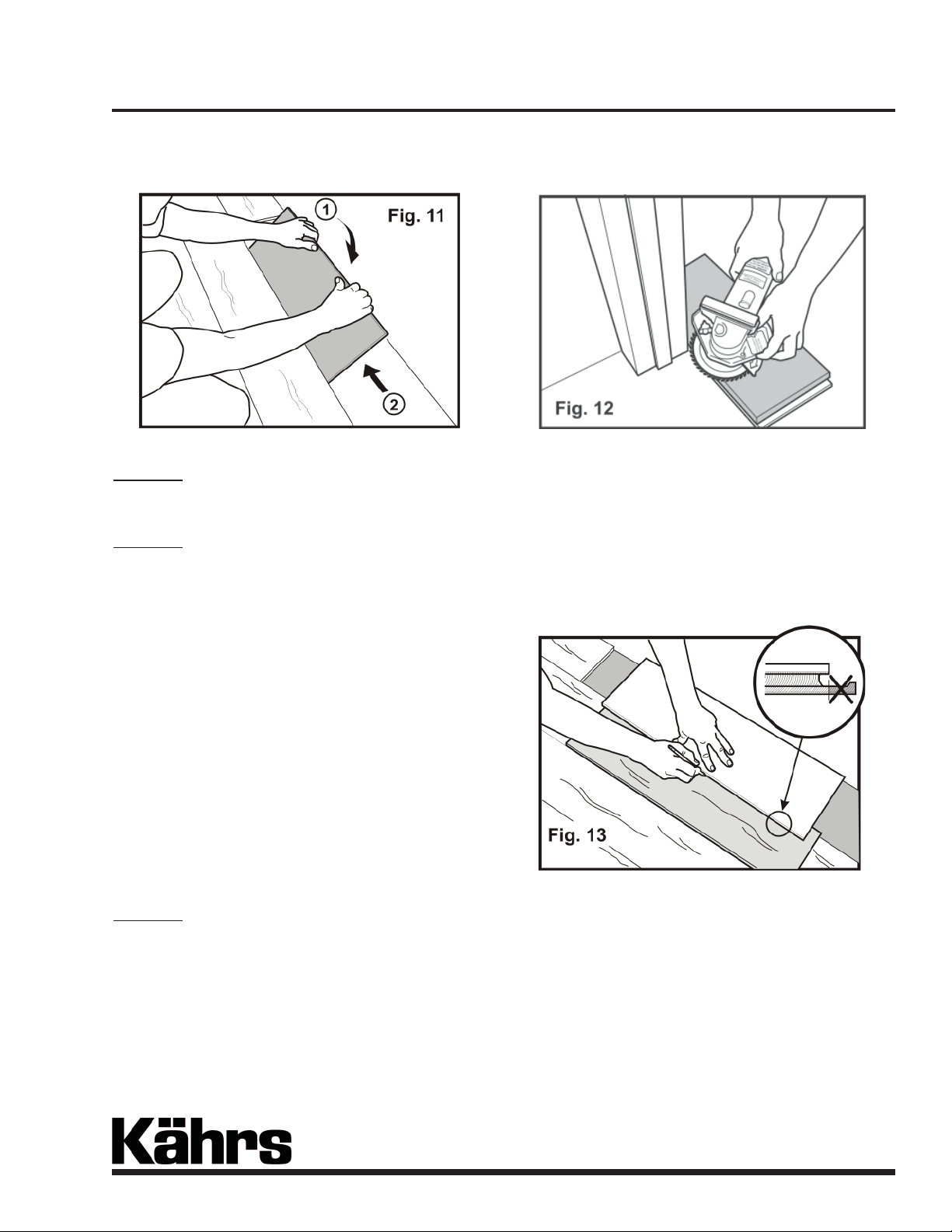

Step 12

If doorjamb (or similar) needs to be cut, use piece of board and piece of Combo

Underlayment to obtain correct height (Fig. 12). If new board must be tapped into place,

be sure to protect edges with scrap of wood before tapping with handblock.

®

Step 13

Saw last board to correct width. Place last board on top of second-to-last board. Mark

board with help of piece of board without locking edge (Fig. 13). No board should be less

than 3” in width (see Layout / Calculation Worksheet).

Technical Support 1-800-ASK-KAHRS www.kahrs.com

17

Tools & Techniques

April 2011

Float-In Installation for Woodloc

®

Step 14

Boards can be laid from all directions if

necessary. Woodloc® dismantles easily. This enables easier planning for

difficult installation areas. If boards cannot be easily angled under door frame

(or similar), do the following: cut away locking edge as shown in Fig. 14a. Then apply

LandobondTM Adhesive (sku 710225) and install board (Fig. 14b).

After Installation

• Remove expansion shims and use required Kährs moldings and/or trim pieces to cover

expansion space (Fig. 15). Always nail moldings to wall, never to flooring!

Clean Up

• Immediately clean any Landobond

TM

adhesive spilled on wood flooring during installation.

Maintenance

• Clean floor using dry dust mop or damp (lightly misted or well rung out) mop or cloth.

Regularly use Kährs Wood Floor Cleaner for best results. Do not use oil soap or

water-emulsion, self polishing waxes. NEVER wet mop floor. Place Peel & Stick Floor

Protectors on furniture legs to prevent damage. See Kährs Floor Care Guide & Lifetime

Guarantee for full details (available at

www.kahrs.com).

For prefinished oiled floors, please refer to

Natural Oiled Floors Maintenance and Rennovation

Procedures at www.kahrs.com

Fig. 15

Technical Support 1-800-ASK-KAHRS www.kahrs.com

18

Follow Up

April 2011

Recoating your Kährs Floor

Kährs floors can be renewed without removing the factory finish. As a floor ages, normal wear and tear will

cause a floor to lose its luster. This is natural - it happens to all wood floors. To renew the luster and extend

the wear layer of the Kährs floor, recoat with water based urethane coating.

Recoating should be done when necessary. Don’t wait until the finish has worn down. Call your

professional flooring contractor for recommendations as soon as you see a wear pattern developing.

Preparation:

Whether coating a floor upon installation or at a later date when it begins to show wear, the

following recoating procedures are recommended:

1. Kahrs recommends the BonaTech® Prep chemical bonding system for recoating all Kahrs floor.

Please contact Bona Kemi USA @ 1-800-574-4674 for product information, directions, and

qualified professionals in your area.

2. Do not use water based urethane over a floor that has been waxed or oiled. If unsure, wipe a

small section of the floor with a white rag dampened with mineral spirits to test for wax or coat a

test area to check adhesion prior to coating the entire floor. It is imperative, regardless of the age

of the floor, to test for adhesion.

Application:

Application of a waterborne finish should be done according to instructions on the product label.

Important factors to consider with any urethane are:

• Shake or Stir Bottle: There will also be a sitting time to consider before using.

• Coverage/Feet per Gallon : This will dictate how heavy or thin the finish is designed to be applied.

• Dry Time: Average time before a finish can be recoated.

• Curing Time: This includes time before a floor is walked on, time before normal use, and

complete cure time.

Note: To achieve a uniform look, coat the worn traffic areas first, followed by a coat over the entire

floor.

Recommended finishes from Bona Kemi:

• Pacific Strong

• Traffic

Call Kahrs Technical Line (1-800-ASK-KAHR) for other compatible floor finishes.

Note: For prefinished oiled floors please refer to Natural Oiled Floors Maintenance and

Rennovation Procedures at www.kahrs.com

Technical Support 1-800-ASK-KAHRS www.kahrs.com

19

Loading...

Loading...