1

Thank you for using our KYUNG-DONG NAVIEN boiler.

To use this boiler in the proper way, be sure to read this manual fully

before using it, and keep this manual with the warranty of the quality in

a safe place.

1. The structure and its description ------------------------- 2

2. How to install ------------------------------------------- 5

3. Before using the boiler ---------------------------------- 9

4. How to use -------------------------------------------- 11

5. Safety device ------------------------------------------- 14

6. Everyday checking ------------------------------------- 15

7. How to replace parts ------------------------------------ 18

8. How to locate troubles and to solve ---------------------- 19

9. The specification ---------------------------------------- 20

10. Electric wiring diagram ----------------------------------- 21

11. After sales service

CONTENTS

2

■ The Structure of the boiler (Model No : 200NHC, 250NHC, 350NHC)

■ Operation and display panel (KDC-106M)

HEATING TEMP. LED

INDICATE THE TEMP. OF HEATING

WATER, AND OCCURRENCE OF

TROUBLE DISPLAYED THE

FAILURE CODE.

01. OVERHEAT

02. LOW WATER LEVEL

03. MISFIRE

04. PSEUDO-FLAME

05. TEMP. SENSOR FAILURE

1. The structure and its description

3

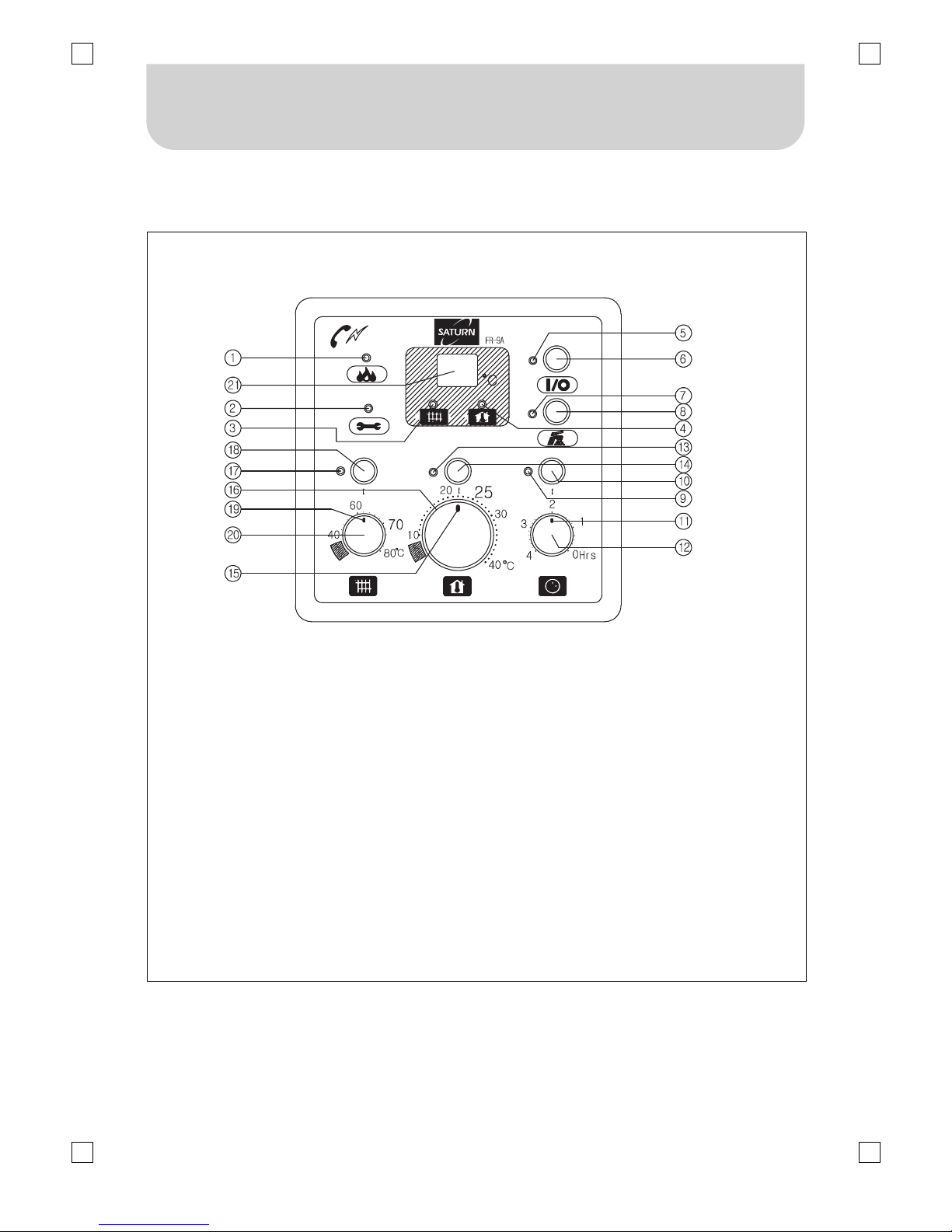

■ FR-9A Room controller(Model No : 200NHC, 250NHC, 350NHC)

DESCRIPTIONS AND FUNCTION OF EACH COMPONENT (USE GUIDELINE)

(1) RUN LAMP (12) REPEAT TIMER CONTROLLER

(2) CHECK LAMP (13) ROOM TEMP. LAMP

(3) HEATING WATER TEMP. LAMP (14) ROOM TEMP. BUTTON

(4) ROOM TEMP. LAMP (15) ROOM TEMP. INDICATION MARK

(5) POWER LAMP (16) ROOM TEMP. CONTROLLER

(6) POWER S/W (17) HEATING WATER TEMP. LAMP

(7) HOT WATER LAMP (18) HEATING WATER TEMP. BUTTON

(8) HOT WATER S/W (19) HEATING WATER TEMP. INDICATION MARK

(9) REPEAT TIMER LAMP (20) HEATIN WATER TEMP. CONTROLLER

(10) REPEAT TIMER BUTTON (21) TEMP. LED

(11) REPEAT TIMER INDICATION MARK

4

1. Power : when you sue to turn the controller on/off (in the state of “off” controller. The anti-freezing device is run)

- Press the power s/w(6), lamp(5) will on.

2. You can use hot water without heating room, in the temp. LED indicated room temperature on lighting lamp(4) on.

- Press the hot water s/w(8), lamp(7) will on.

3. Heating related to heating water temp. If the boiler operated by heating water temp. On lighting the lamp(3) on (temp. range : 4080

℃

)

- Press the heating water temp. controller(18), lamp(17) will on. If the heating water indication mark(19) located on higher point

than current heating water temp, the boiler operated but in the other way, the boiler not run

- If you set the temp. Of heating water below 40, the boiler not run.

4. Heating related to room temp; if the boiler operated by room temp. controller(16). In-the temp. Led indicated current room temp.

On lighting the lamp(4) on (temp. Range 10-40

℃

)

- Press the room temp. controller(14). Lamp(13) will on, if the room indication mark(15) located on higher point than current

room temp. The boiler operated but in the other way, the boiler not run.

- If you set the room temp. below 10. The boiler not run.

5. Heating related to repeat timer : use the boiler according to repeat timer. In the temp. LED(21) indicated current room temp. On

lighting lamp(4) on.

- Press the repeat timer button(10), lamp(9) will on.

- You can run the boiler according to the interval you set with timer.

- You set the time interval

“0” : the boiler run continuously.

“1” : run 20min, then stop for 60min

“2” : run 20min, then stop for 120min

“3” : run 20min, then stop for 180min

“4” : run 20min, then stop for 240min

6. Run lamp. temp will on when the boiler operate.

7. Check lamp : indicate the trouble of boiler (misfire, low water level, overheating, etc.)

8. Temp. LED : indicate the temp. of heating water or room in norman, but in occurrence of trouble displayed the failure code.

01 : overheat 02 : low water level

03 : misfire 04 : pseudo-flame

05 : heating sensor failure

9. Activation/suspension of boiler using telephone set

When you activate the boiler, it will operate at ‘high speed’ for 30 minutes, and will automatically switch to ‘out’ mode, and

‘operation lamp’ will light on during the operation. Using internal telephone set connected to the indoor temperature controller or

outside telephone set (telephone or mobile phone), you can activate or suspend operation of the boiler remotely, by presetting the

number of phone rings.

- When using outside telephone (telephone set or mobile phone), call the phone, When the call is connected to the boiler after

ringing the preset number of times, you will hear a ‘beep’ sound. Then, manipulate the buttons as described below.

- When using the telephone connected to the indoor temperature controller, hold the handset, and manipulate the buttons as

described below:

- Manipulation of buttons -

1) When activation the boiler [Press”#” button 3 times] : If you hear ‘beep-beep’ sound after pressing the “#” button three times,

hang up the phone.

2) When suspending the boiler [Press”*” button 3times] : If you hear ‘beep-beep-beep’ sound after pressing the “*” button three

times, hang up the phone.

3) When altering the number of ringing [Press “0” button 3 times] :

If you hear ‘beep-beep-beep-beep’ sound after pressing “0” button three times, press a button you select out of 5,6,7,8,9 and 0

three times.

When you hear ‘beep-beep-beep-beep-beep’ sound shortly after, hang up the phone.

4) Caution

4-1) If you don’t press any button for 10seconds or longer after pressing ‘#’ or ‘*’ button, the telephone will automatically hang up.

4-2) Make sure to hang up the phone after hearing activation signal(‘beep-beep’ or suspension signal(‘beep-beep-beep’)

4-3) When you use a mobile phone, use it where transmission sensitivity is stable.

4-4) If you don’t hear the ‘beep’ sound while using ROOMCON, manipulate it again slowly.

5

■ Choosing of the installation place

y For the place to install the boiler, choose the place possible to do the accompanying works, such as water

supply works or electric works.

y For the place to install, choose the place conformed to the installation standards of the boiler and the

construction act of the code of each city or municipality

y Install the boiler in the place as wide as possible for the maintenance and the fire prevention.

y Install the boiler in the place convenient for controlling and manipulation of the temperature.

y If there is no electric outlet in the proper position, do wiring by requesting to a company designated by the

electric power company.

y Around the installation place, there must be no place which stores and treats the combustibles and the

inflammables.

y There should be equipped drainage in the in stalling spot.

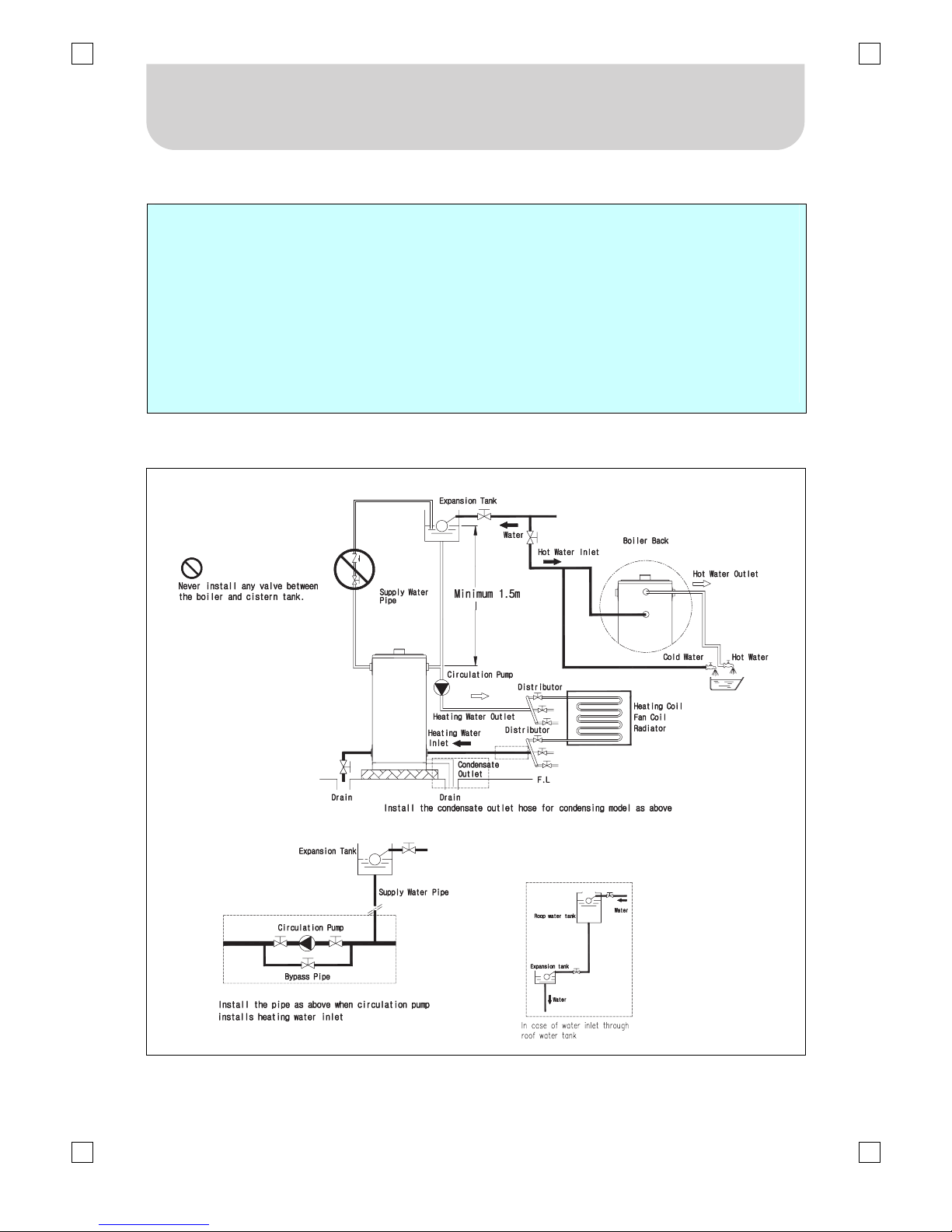

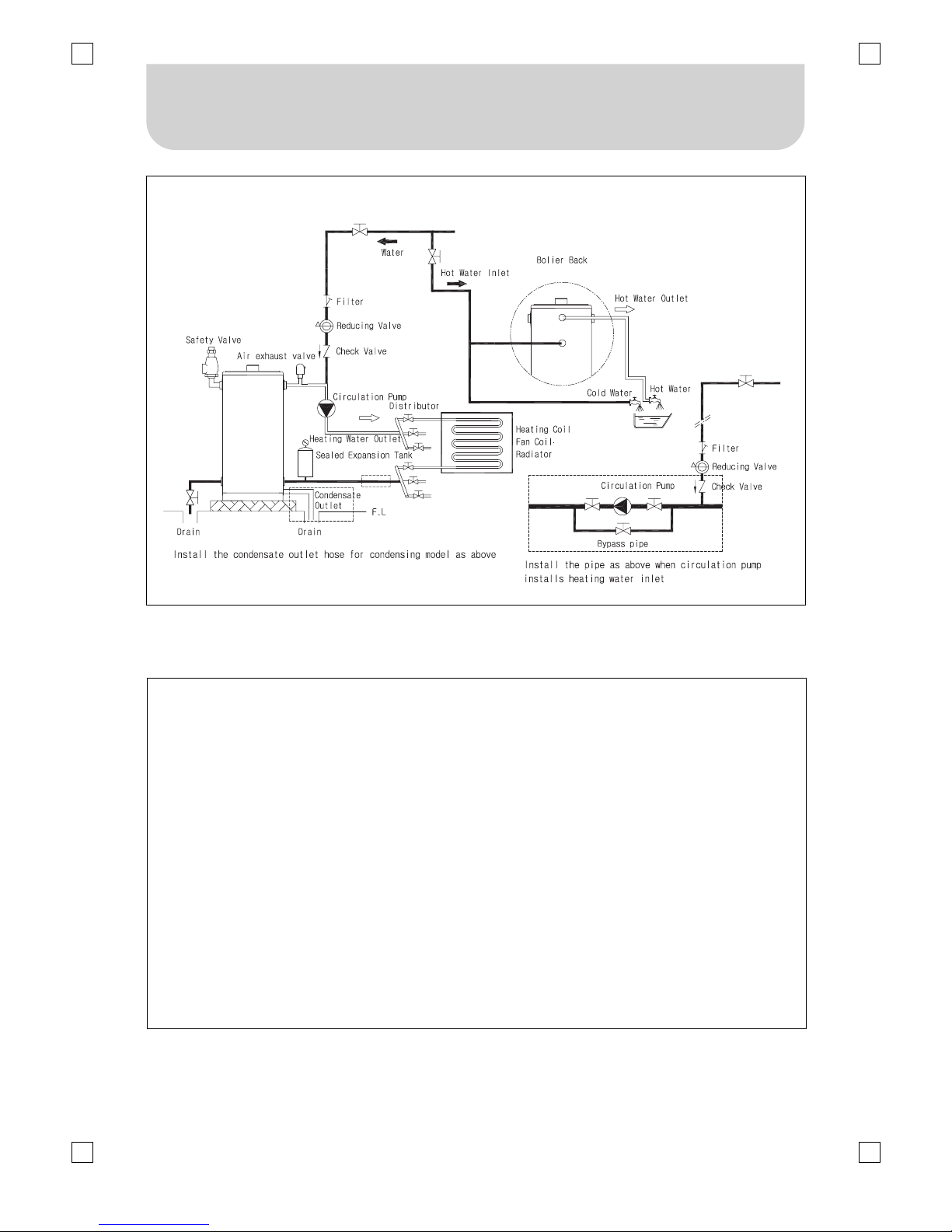

■ The diagram of the standard piping : Expansion tank install type

(Model No. : 200NHC, 250NHC, 350NHC)

2. How to install

6

<Sealed cistern tank>

■ Precautions

① The distributor on the return water distributor side should be placed lower than the

heating inlet.

② Connection should be made by installing a safety valve with 3.5kgf/cm

2

or lower

opening the discharge piping to the cistern tank.

③ The maximum operation pressure is 3.5kgf/cm

2

. Do not supply water at a higher

pressure or directly connect the water pipe having the pressure higher than.

④ Overflow of water during the heating to the cistern tank means short tank capacity.

Exchange it with a larger one.

⑤ Backflow of water during the running or stopping of the circulation pump to the cistern

tank is caused by too much air in the pipe. Remove air by opening valves on the

distributor, one at a time, while running the circulation pump.

⑥ Evaporation at the cistern tank means failure in the system. Contact your representative

to receive the check.

⑦ Never install any valve between the boiler and the cistern tank.

⑧ We will not be liable for any defect r breakdown caused by the failure to comply with

the above precautions.

7

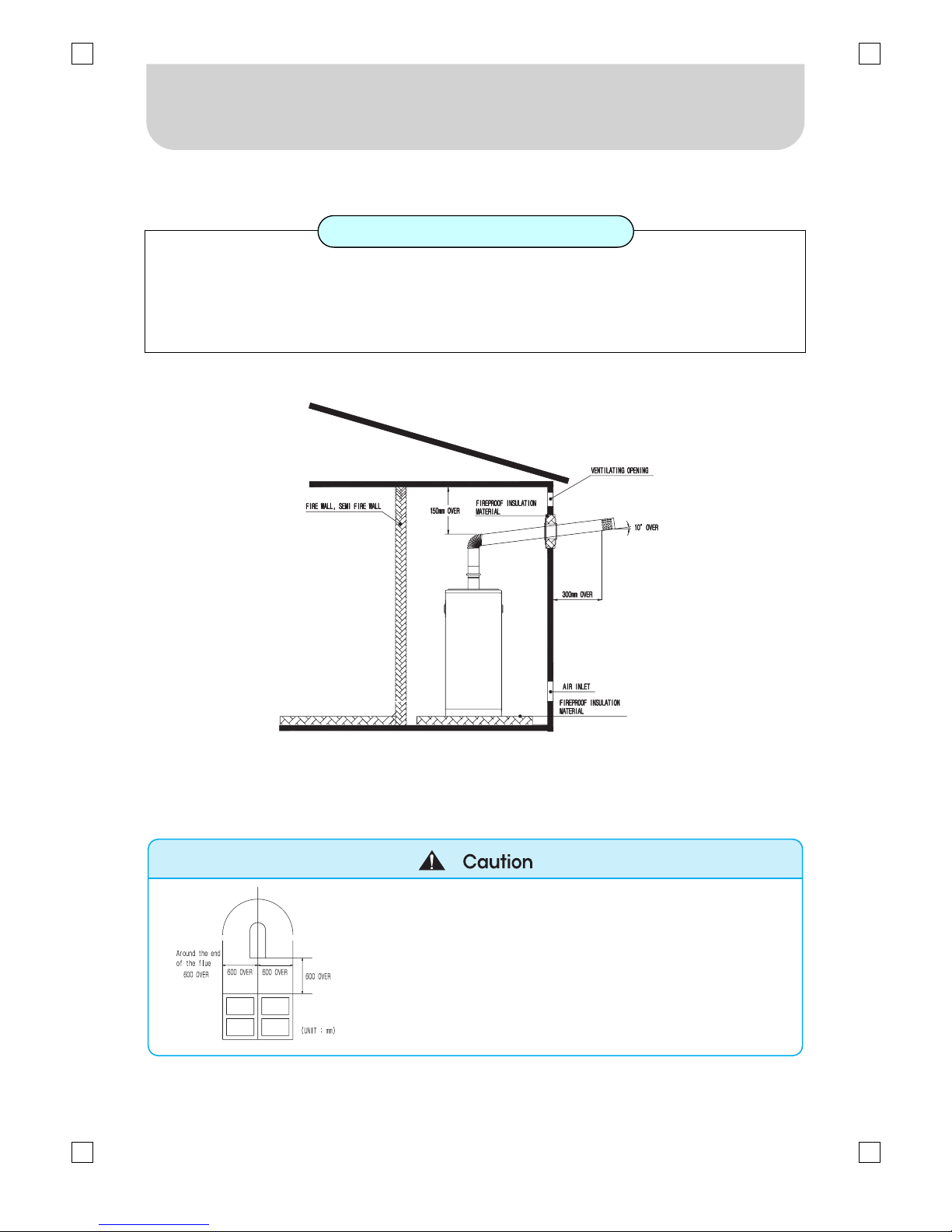

■ The example of a standard installation

■ It is recommend that the length of flue shall be less than 5 miters and the flexuosity shall be less than 2

point.(Except for the flexuosity at the end of the flue)

■ It is recommend that use the flue fitting in the connection caliber.

■ Be careful not to narrow down the flue. And please, maximize the radius of flexuosity when to work.

■ It is recommend that keeping the flue warm by using the noninflammable insulation.

■ Condensing boiler model : KDB-130/170/200/250/350NHC

■ When installing the flue, an angle of the flue shall be less than 10 degrees. Because the generated

condensate in the flue is exhausted through the inside.

If the angle of the flue should make more than 10 degrees, the rain will come into the inside of the boiler.

■ Material of flue must be used stainless steel or heat-corrosion resisting metal.

Flue Work of Forced Exhaust(FE)

It is imperative that there are no windows around the

end of the flue within 600mm.

●

If the waste gas should come into the room, you will suffer fro

m

the waste gas poisoning.

8

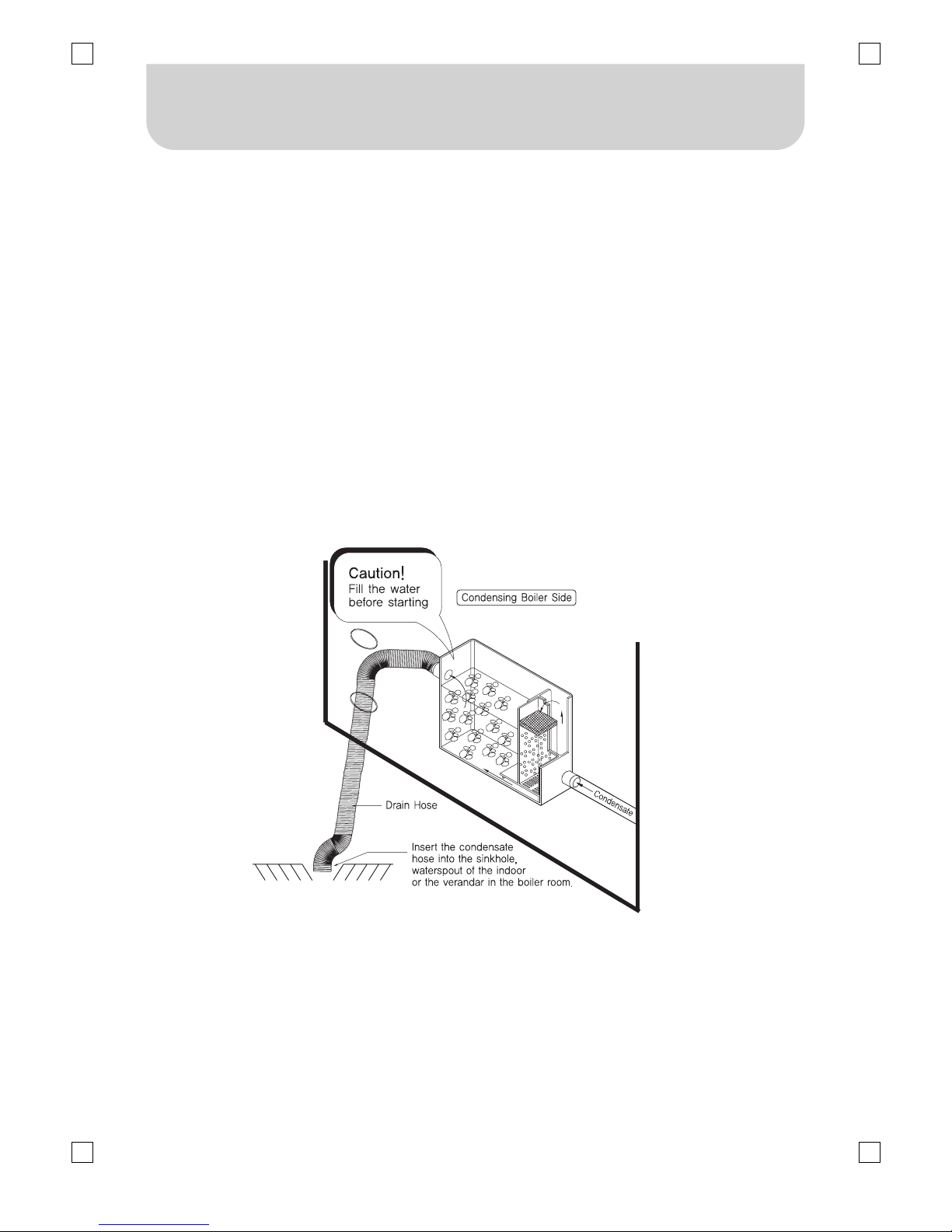

■ Condensate Drainage

1. Condensate is produced when condensing boiler is running and should be piped to the drainage

system.

2. Link the drain hose with the outlet of neutralization system located the bottom of boiler and then,

surely, connect the end of hose to a sink hole or ditch directly.

3. In case of using other drain hose which is not installed originally, it must be plastic and its inside

diameter should be more than ¢13

4. Please make sure that the neutralizer in the boiler should be filled with water, otherwise it must be

filled.

5. Condensate never be allowed for drinking or washing

6. Avoid from any frozen on the drain hose of N.W, insulation must be followed by installing the

hose.

(The additional device with anti-freeze function might be necessary for any sites are possibly

exposed at freezing temperature.)

9

y It is essential to use only kerosene or light oil.

(Don’t use gasoline, alcohol)

y It is better to use kerosene when the temperature

goes down below –5℃

y In winter, don’t use the light-oil for summer.

y Store in the place where there is no effect of oil,

fire, rain, and keep out of the sun.

y Pay attention that water or dust may not get in on

time of feeding oil.(Water or dust may cause the

combustion failure or shorten the boiler span.)

y Wipe off the oil spilled.

y Close the lid of the oil inlet without fail.

y Feed oil after turning the power off and locking the

tank valve.

y Check out if or not oil leaks in the connecting part

of the oil pipe.

3. Before using the boiler

Fuel

Checking points before starting up

10

y Check out that there is enough water in the body of

the boiler without failure.

y Expansion tank type-Check out if there is water in

the Expansion tank, and in case that there is no

water, please fill water in the body of the boiler.

y Open Expansion Tank type-check out if there is

water in the expansion tank, and in case that there

is no water, press the power button. Then, ‘Low

Water Level’ lamp turns on and water is supplied

automatically.

y Put the surroundings of the boiler in order and don’t

put the flammables near the boiler.

y Check out whether the ignition and the combustion

is normal.

(Checking through the flame inspection window)

y When the boiler is going to be not in use for a long

time, cut off the power.

(Don’t pull out the power cord when there is a

danger of freezing)

y If you pull out the power plug on time of thunder

and lightening, you can prevent the damage on the

boiler by the falling of the thunderbolts.

y Be careful not to get burned due to the high tem-

perature of the exhaust/inhale pipe(exhaust pipe).

y In case of emergency such as you may feel the ab-

normality of the boiler. cut off the power.

y Don’t use the hot water for food.

Notes when using

11

y Be careful that the oil tank may not run out of oil

completely.

In that case, even though oil is supplied, air may

get in. As a result, ignition failure or operation

failure may occurs.

y Untighten the screw for exhaust in the oil filter by a

screwdriver, the air goes out. When oil flows out,

please tighten it.

(This is possible only in case that the oil tank is

above the oil filter)

y If the oil tank is below the oil filter or the air flows

out enough like the above, lock the screw for

exhaust and remove the air with the exhaust valve.

y In such case, open the exhaust valve turn the power

on to operate the boiler. After about 6-7seconds, the

electronic pump exhaust the air off with noise, and

“CHECK” lamp on, the boiler stops.

4. How to use

How to exhaust

12

y Now press the power button on the panel repeatedly,

and thed oil flows out.

Lock the valve and press the power button again,

and the boiler gets ignited.

y In case that after removing air completely, the igni-

tion has failed repeatedly about three times, contact

the sales agency or the commercial agency.

y Open the drain valve, and check out whether there

is water in.

y Check out whether the pipes is filled with water.

y Check out that the boiler is grounded to earth.

(Don’t ground to the gas pipe or a lightening conductor)

y Plug the power plug in the outlet.(Checking if the

outlet power is 220V)

y Press the power button, and check out if

“RUN” lamp turns on a little later.

Preparation and checking befor

startin

g

to operate

Air vent valve

13

y Open the window door of the Operation and

Display Panel and set the thermostat to the position

you like.

y Pressing the power button starts fan motor. And the

boiler gets started,

turning the “COMBUSTION”

lamp on.

y

If ignition fails and the operation stops, “check”

lamp turns on. In this case, press the power

button on the panel.

y

In case that the ignition fails with pressing the

power button four or five times, contact the sales

agency or the commercial agency.

How to use

14

y When it doesn’t light even with the power button

“ON” or it gets extinguished due to running out of

oil, the FLAME Detector(CdS) gets to work and

stops the operation.

y If water is insufficient in the boiler, it interrupts the

operation of the boiler with the power cut off.

When water refills, the boiler starts again automatically.

y If the temperature of the boiler rises up too high, it

is dangerous. So, in such case, this device cut off

the power automatically.

y When the overheating preventer gets to operated

the combustion stops and “CHECK” lamp turn

on.

y

If the overhead temperature is fall “CHECK”

lamp turn off and “RUN” lamp turning on

automatically.

y

If the operation stop is repeated again, contact

the sales agency or the commercial agency.

y During the hard winter, the circulation pump or the

burner operates automatically to prevent the heating

circuit from freezing.

In winter, keep on plugging in the power cord and

turning the power button “ON”.(the insulation state

of the pipes must be normal)

y If the power gets off, oil gets blocked automatically

and the combustion stops.

5. Safety device

Combustion safety device

Low water level blocking device

Overheating preventer

Freezing preventer

Safety device on power-failure

15

y Check out whether the combustibles is near.

y Keep cleaning all the time and don’t let the dust

accumulated.

y Check out whether oil leaks from, is stacked on, or

soaks into the oil tank, oil pipes, the body of the

boiler, etc.

y Check out whether there is any water leakage from

the body of the boiler and the pipes.

y Open the drain plug of the oil tank regularly and

remove water.

6. Everyday Checking

Points to be checked once or more a year

16

y Much soot accumulated inside the boiler will reduce

the life and efficiency.

At least once a year, clean the boiler inside.

y In case that the oil filter gets dirty, stop operating,

lock the oil valve, and remove dust or rust accumulated below the oil cup.

y Detach the oil cup by rotating right and left.

y Pull down the filter.

y Wash the filter and the inside of the oil cup with

clean kerosene and light oil.

y Water may get mired in during feeding oil or get accu-

mulated naturally during the long period in the oil tank.

In this case, drain water off through the drain plug in

the oil tank, and when oil starts to get out, lock it.

Cleaning of boiler

Cleaning the oil filter

Cleaning the oil tank

17

y If the light-receiving surface(sensing surface) gets

darkened with soot, the bad sensitivity cause the

wrong automatic operation.

y You can pull out the flame detector(black) which is

attached in the lower part of the burner.

y Wipe the glassy surface of the flame detector with a

scrap and fix it in its position.

y At least once a year, check for any loose joints in

the discharge(piping and flue), clogging in flue,

corrosion or leak. If any abnormality is found,

contact out sales agency for checking up.(blocking

pipes or holes, and so on)

Cleaning the flame detector

Checking the exhaust pipe

18

y There is no parts which gets wear in a short period,

but when the replacement of the parts is needed,

consult to out sales agency or commercial agency.

y For the repair of the boiler, request to our sales

agency or commercial agency, or to the A/S center.

y Repairing the boiler by a man without qualification

cause another trouble, so never do that.

7. How to replace the parts

19

Happening

Cause Solution methods

1. Even with pressing the power

button, the motor doesn

’

t

work

1. The temperature in the boiler

is above the set temperature.

2. The room controller is off.

3. Others.

1.

This is not a trouble. When

the tem

p

erature of the boiler

goes down, get restarted.

2.

Set the room controller to

the operation condition.

3.

Contact the sales agency or

commercial agency.

2. The motor rotates, but the

boiler doesn

’

t ignite.

1. The oil valve is locked.

2. There is no oil in the tank.

3. There is air in pipes.

4. The oil filter is locked.

5. Others.

1. Open the valve.

2. Supply oil.

3. Drain off air.

4. Clean the boiler.

5. Contact the sales a

g

ency or

commercial agency.

3. The boiler ignites, but

immediately stops.

1. The oil in the oil tank is

insufficient.

2. The flame detector(CdS)

cannot sense.

3. The oil filter is locked.

4. There is mixed impure

materials in the oil.

5. Others.

1. Supply oil more.

2. Clean the flame detector.

3. Clean the oil filter.

4. Replace the oil with good oil.

5. Contact the sales a

g

ency or

commercial agency.

4. The electronic pump makes

big noise.

1. The oil filter is locked.

2. There is air in pipes.

3. Others.

1. Clean the oil filter.

2. Drain off air.

3. Contact the sales a

g

ency or

commercial agency.

5. On igniting, it backfires. 1. The wind flow back in the

exhaust pipe.

2. The ignition device is bad.

3. Others.

1. Contact the sales a

g

ency or

commercial agency.

2. ″

3. ″

6. The abnormal noise of the

combustion happens.

1. The air for combustion is

excessive.

2. The amount of oil feed is

excessive.

3. Others.

1. Contact the sales a

g

ency or

commercial agency.

2. ″

3. ″

7. Smoke and soot occurs. 1. The oil is bad or has impure

materials.

2.

The air for combustion is short.

3. Others.

1. Replace the oil.

2. Contact the sales a

g

ency or

commercial agency.

3. ″

8. Others. 1. The fuel pipes leaks.

2. The water pipes leaks.

1. Contact the sales agency or

commercial agency.

2. ″

※ Please contact your local shop and distributor for other unclean matters.

8. How to locate troubles and solve

20

9. The specification

CONDENSING OIL BOILER

MODEL

ITEM

UNIT

KDB-200NHC KDB-250NHC KDB-350NHC

kcal/ h

21,500 26,000 35,000

CONDENSING

(KJ/h)

(90,016) (108,857) (146,538)

kcal/ h

20,500 25,500 32,500

HEAT OUTPUT

NORMAL

(KJ/h)

(85,829) (106,763) (136,071)

kcal/ h

20,500 25,500 32,500

HOT WATER OUTPUT

(KJ/h)

(85,829) (106,763) (136,071)

FOR USE

HEATING AND HOT WATER

FUEL

KEROSENE, LIGHT-OIL

ROOM SIZE m2

Less than 132 Less than 165

Less than 234

kgf/cm2

MAXIMUM WORKING

PRESSURE

(kPa)

3.5

(343)

HEAT TRANSFERING SIZE m2

1.60 2.08

2.40

FUEL CONSUMPTION ℓ/h

2.52 3.12

4.03

TYPE OF AIR/EXHAUST GAS

FE

CONDENSING %

101 101

101

HEATING

EFFICIENCY

NORMAL %

95 95

95

HOT WATER EFFICIENCY %

95 95

95

ELECTRICITY

CONSUMPTION

COMBUSTION W

143 150

199

POWER V, Hz

220V, 50Hz

WATER STORAGE CAPACITY ℓ

34.0 41.0

48

W×L×H

EXTERNAL SIZE

(mm)

410

×665×1,031

444

×706×1,051

444

×706×1,186

WEIGHT kg

59 64

72.0

HEATING

CONNECTION

A

25

PIPING

HOT WATER

CONNECTION

A

15

DIAMETER OF FLUE φmm

EXHAUST : 75

※ The specification in this operating manual can be changed for improvement without prior notice.

21

■ MODEL NO : KDB-200NHC, 250NHC, 350NHC

10. Electric wiring diagram

22

23

MEMO

24

MEMO

Loading...

Loading...