KYUNG-DONG NAVIEN KDB-200NHC, KDB-250NHC, KDB-350NHC, KDC-106M User Manual

1

Thank you for using our KYUNG-DONG NAVIEN boiler.

To use this boiler in the proper way, be sure to read this manual fully

before using it, and keep this manual with the warranty of the quality in

a safe place.

1. The structure and its description ------------------------- 2

2. How to install ------------------------------------------- 5

3. Before using the boiler ---------------------------------- 9

4. How to use -------------------------------------------- 11

5. Safety device ------------------------------------------- 14

6. Everyday checking ------------------------------------- 15

7. How to replace parts ------------------------------------ 18

8. How to locate troubles and to solve ---------------------- 19

9. The specification ---------------------------------------- 20

10. Electric wiring diagram ----------------------------------- 21

11. After sales service

CONTENTS

2

■ The Structure of the boiler (Model No : 200NHC, 250NHC, 350NHC)

■ Operation and display panel (KDC-106M)

HEATING TEMP. LED

INDICATE THE TEMP. OF HEATING

WATER, AND OCCURRENCE OF

TROUBLE DISPLAYED THE

FAILURE CODE.

01. OVERHEAT

02. LOW WATER LEVEL

03. MISFIRE

04. PSEUDO-FLAME

05. TEMP. SENSOR FAILURE

1. The structure and its description

3

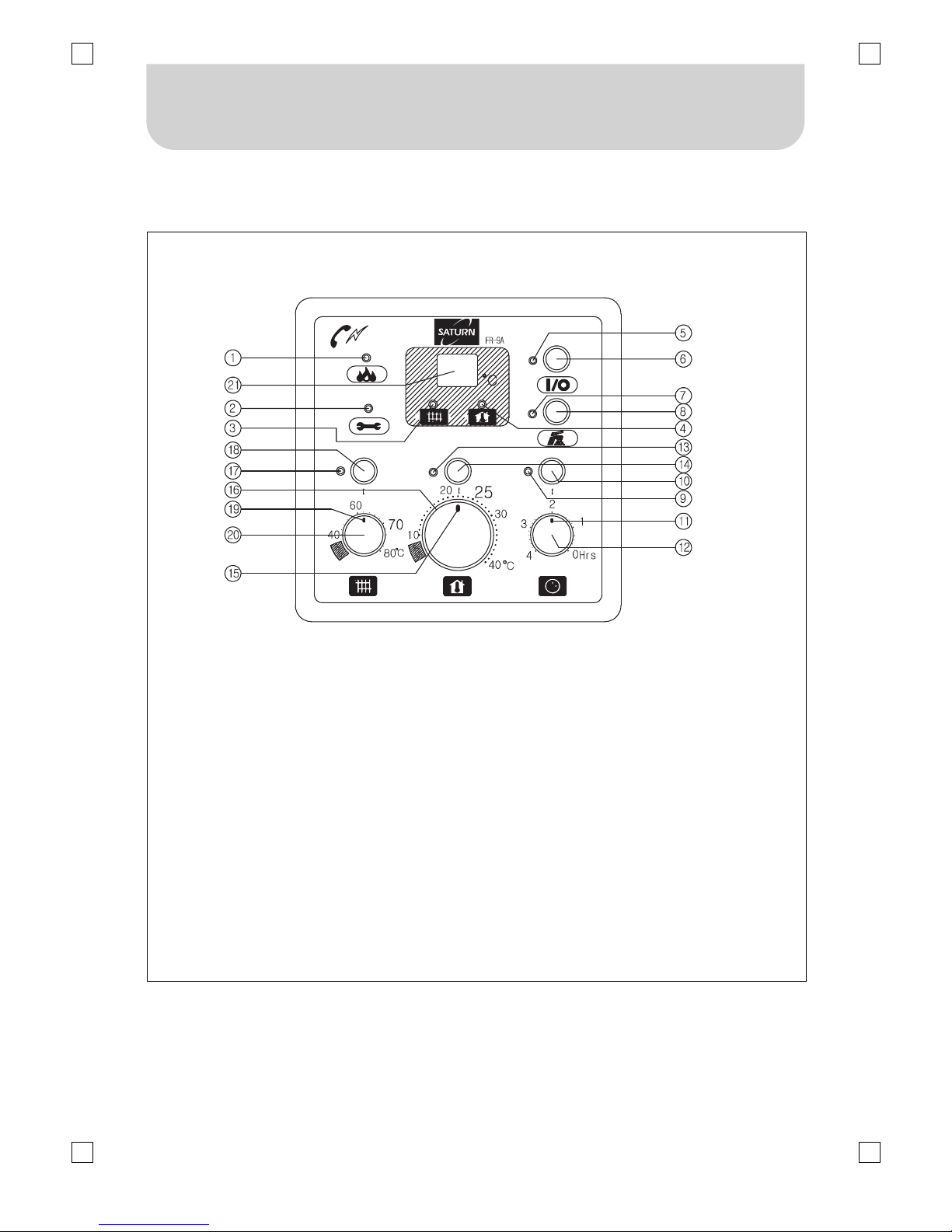

■ FR-9A Room controller(Model No : 200NHC, 250NHC, 350NHC)

DESCRIPTIONS AND FUNCTION OF EACH COMPONENT (USE GUIDELINE)

(1) RUN LAMP (12) REPEAT TIMER CONTROLLER

(2) CHECK LAMP (13) ROOM TEMP. LAMP

(3) HEATING WATER TEMP. LAMP (14) ROOM TEMP. BUTTON

(4) ROOM TEMP. LAMP (15) ROOM TEMP. INDICATION MARK

(5) POWER LAMP (16) ROOM TEMP. CONTROLLER

(6) POWER S/W (17) HEATING WATER TEMP. LAMP

(7) HOT WATER LAMP (18) HEATING WATER TEMP. BUTTON

(8) HOT WATER S/W (19) HEATING WATER TEMP. INDICATION MARK

(9) REPEAT TIMER LAMP (20) HEATIN WATER TEMP. CONTROLLER

(10) REPEAT TIMER BUTTON (21) TEMP. LED

(11) REPEAT TIMER INDICATION MARK

4

1. Power : when you sue to turn the controller on/off (in the state of “off” controller. The anti-freezing device is run)

- Press the power s/w(6), lamp(5) will on.

2. You can use hot water without heating room, in the temp. LED indicated room temperature on lighting lamp(4) on.

- Press the hot water s/w(8), lamp(7) will on.

3. Heating related to heating water temp. If the boiler operated by heating water temp. On lighting the lamp(3) on (temp. range : 4080

℃

)

- Press the heating water temp. controller(18), lamp(17) will on. If the heating water indication mark(19) located on higher point

than current heating water temp, the boiler operated but in the other way, the boiler not run

- If you set the temp. Of heating water below 40, the boiler not run.

4. Heating related to room temp; if the boiler operated by room temp. controller(16). In-the temp. Led indicated current room temp.

On lighting the lamp(4) on (temp. Range 10-40

℃

)

- Press the room temp. controller(14). Lamp(13) will on, if the room indication mark(15) located on higher point than current

room temp. The boiler operated but in the other way, the boiler not run.

- If you set the room temp. below 10. The boiler not run.

5. Heating related to repeat timer : use the boiler according to repeat timer. In the temp. LED(21) indicated current room temp. On

lighting lamp(4) on.

- Press the repeat timer button(10), lamp(9) will on.

- You can run the boiler according to the interval you set with timer.

- You set the time interval

“0” : the boiler run continuously.

“1” : run 20min, then stop for 60min

“2” : run 20min, then stop for 120min

“3” : run 20min, then stop for 180min

“4” : run 20min, then stop for 240min

6. Run lamp. temp will on when the boiler operate.

7. Check lamp : indicate the trouble of boiler (misfire, low water level, overheating, etc.)

8. Temp. LED : indicate the temp. of heating water or room in norman, but in occurrence of trouble displayed the failure code.

01 : overheat 02 : low water level

03 : misfire 04 : pseudo-flame

05 : heating sensor failure

9. Activation/suspension of boiler using telephone set

When you activate the boiler, it will operate at ‘high speed’ for 30 minutes, and will automatically switch to ‘out’ mode, and

‘operation lamp’ will light on during the operation. Using internal telephone set connected to the indoor temperature controller or

outside telephone set (telephone or mobile phone), you can activate or suspend operation of the boiler remotely, by presetting the

number of phone rings.

- When using outside telephone (telephone set or mobile phone), call the phone, When the call is connected to the boiler after

ringing the preset number of times, you will hear a ‘beep’ sound. Then, manipulate the buttons as described below.

- When using the telephone connected to the indoor temperature controller, hold the handset, and manipulate the buttons as

described below:

- Manipulation of buttons -

1) When activation the boiler [Press”#” button 3 times] : If you hear ‘beep-beep’ sound after pressing the “#” button three times,

hang up the phone.

2) When suspending the boiler [Press”*” button 3times] : If you hear ‘beep-beep-beep’ sound after pressing the “*” button three

times, hang up the phone.

3) When altering the number of ringing [Press “0” button 3 times] :

If you hear ‘beep-beep-beep-beep’ sound after pressing “0” button three times, press a button you select out of 5,6,7,8,9 and 0

three times.

When you hear ‘beep-beep-beep-beep-beep’ sound shortly after, hang up the phone.

4) Caution

4-1) If you don’t press any button for 10seconds or longer after pressing ‘#’ or ‘*’ button, the telephone will automatically hang up.

4-2) Make sure to hang up the phone after hearing activation signal(‘beep-beep’ or suspension signal(‘beep-beep-beep’)

4-3) When you use a mobile phone, use it where transmission sensitivity is stable.

4-4) If you don’t hear the ‘beep’ sound while using ROOMCON, manipulate it again slowly.

5

■ Choosing of the installation place

y For the place to install the boiler, choose the place possible to do the accompanying works, such as water

supply works or electric works.

y For the place to install, choose the place conformed to the installation standards of the boiler and the

construction act of the code of each city or municipality

y Install the boiler in the place as wide as possible for the maintenance and the fire prevention.

y Install the boiler in the place convenient for controlling and manipulation of the temperature.

y If there is no electric outlet in the proper position, do wiring by requesting to a company designated by the

electric power company.

y Around the installation place, there must be no place which stores and treats the combustibles and the

inflammables.

y There should be equipped drainage in the in stalling spot.

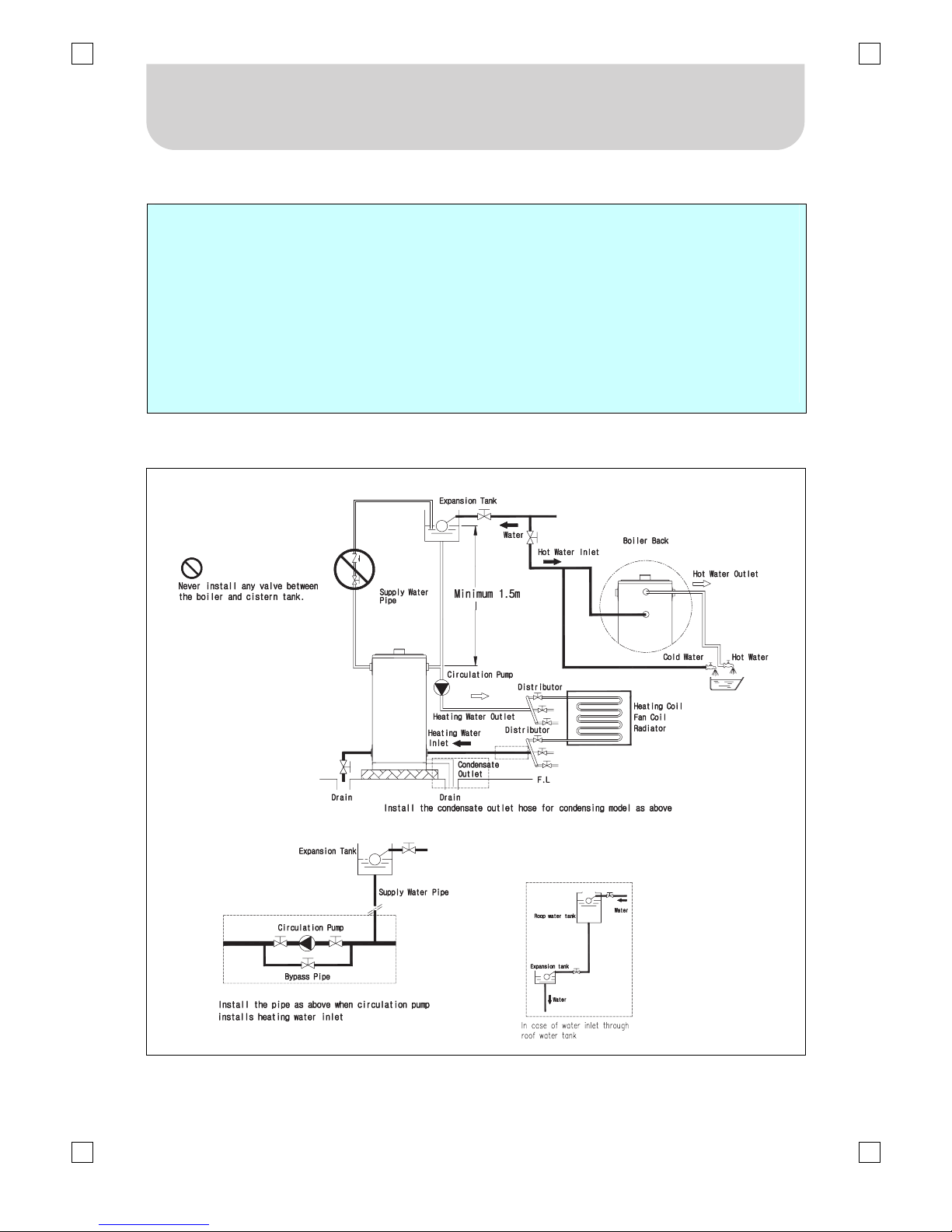

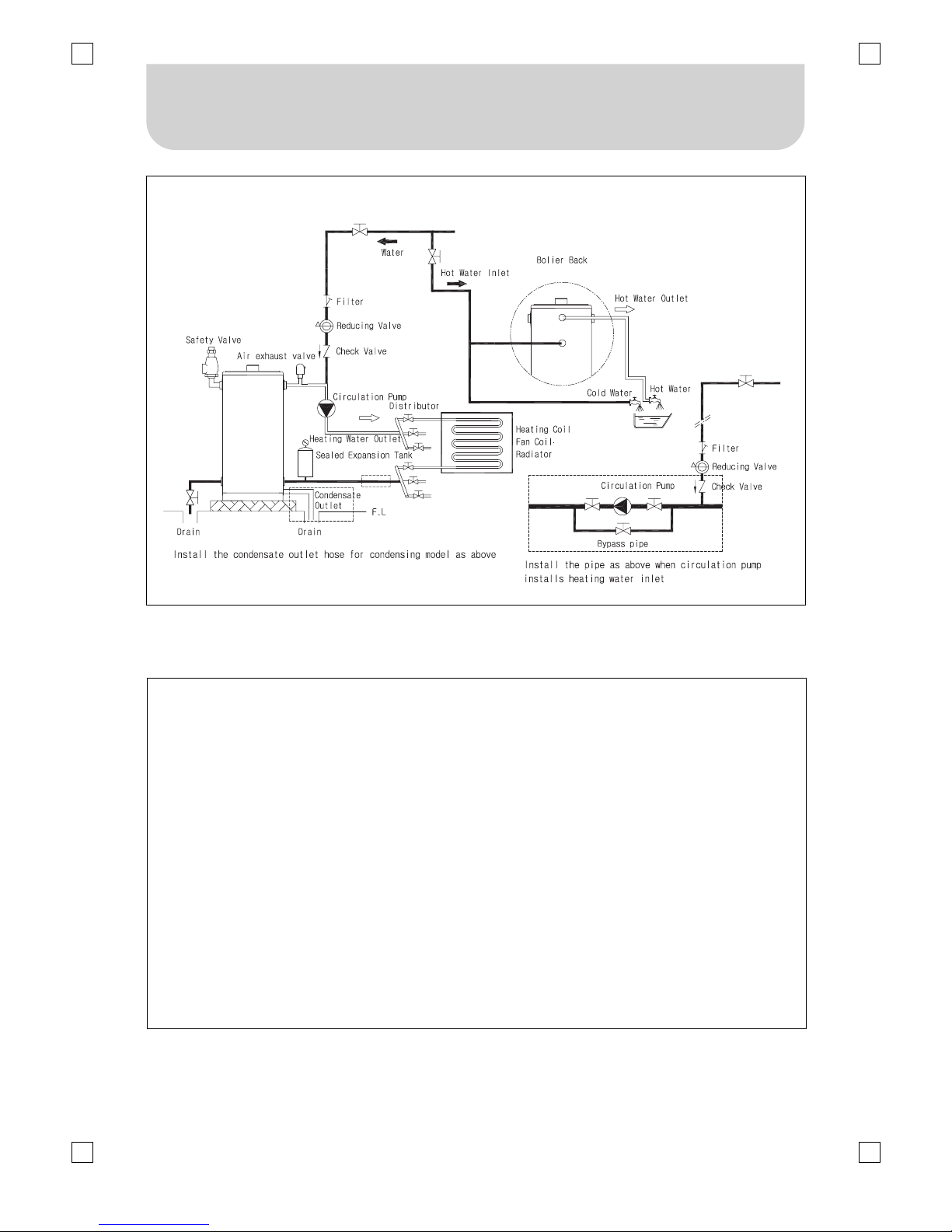

■ The diagram of the standard piping : Expansion tank install type

(Model No. : 200NHC, 250NHC, 350NHC)

2. How to install

6

<Sealed cistern tank>

■ Precautions

① The distributor on the return water distributor side should be placed lower than the

heating inlet.

② Connection should be made by installing a safety valve with 3.5kgf/cm

2

or lower

opening the discharge piping to the cistern tank.

③ The maximum operation pressure is 3.5kgf/cm

2

. Do not supply water at a higher

pressure or directly connect the water pipe having the pressure higher than.

④ Overflow of water during the heating to the cistern tank means short tank capacity.

Exchange it with a larger one.

⑤ Backflow of water during the running or stopping of the circulation pump to the cistern

tank is caused by too much air in the pipe. Remove air by opening valves on the

distributor, one at a time, while running the circulation pump.

⑥ Evaporation at the cistern tank means failure in the system. Contact your representative

to receive the check.

⑦ Never install any valve between the boiler and the cistern tank.

⑧ We will not be liable for any defect r breakdown caused by the failure to comply with

the above precautions.

7

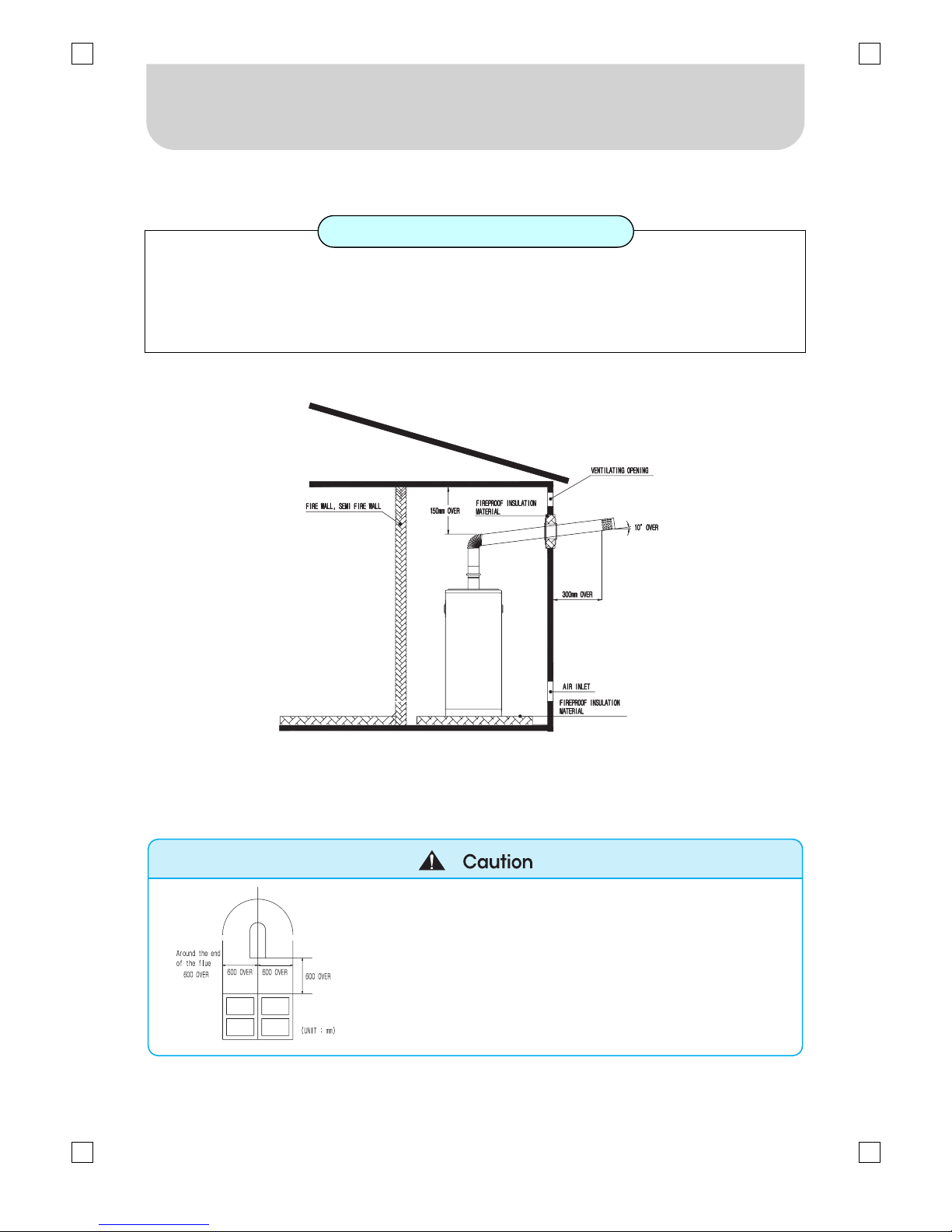

■ The example of a standard installation

■ It is recommend that the length of flue shall be less than 5 miters and the flexuosity shall be less than 2

point.(Except for the flexuosity at the end of the flue)

■ It is recommend that use the flue fitting in the connection caliber.

■ Be careful not to narrow down the flue. And please, maximize the radius of flexuosity when to work.

■ It is recommend that keeping the flue warm by using the noninflammable insulation.

■ Condensing boiler model : KDB-130/170/200/250/350NHC

■ When installing the flue, an angle of the flue shall be less than 10 degrees. Because the generated

condensate in the flue is exhausted through the inside.

If the angle of the flue should make more than 10 degrees, the rain will come into the inside of the boiler.

■ Material of flue must be used stainless steel or heat-corrosion resisting metal.

Flue Work of Forced Exhaust(FE)

It is imperative that there are no windows around the

end of the flue within 600mm.

●

If the waste gas should come into the room, you will suffer fro

m

the waste gas poisoning.

8

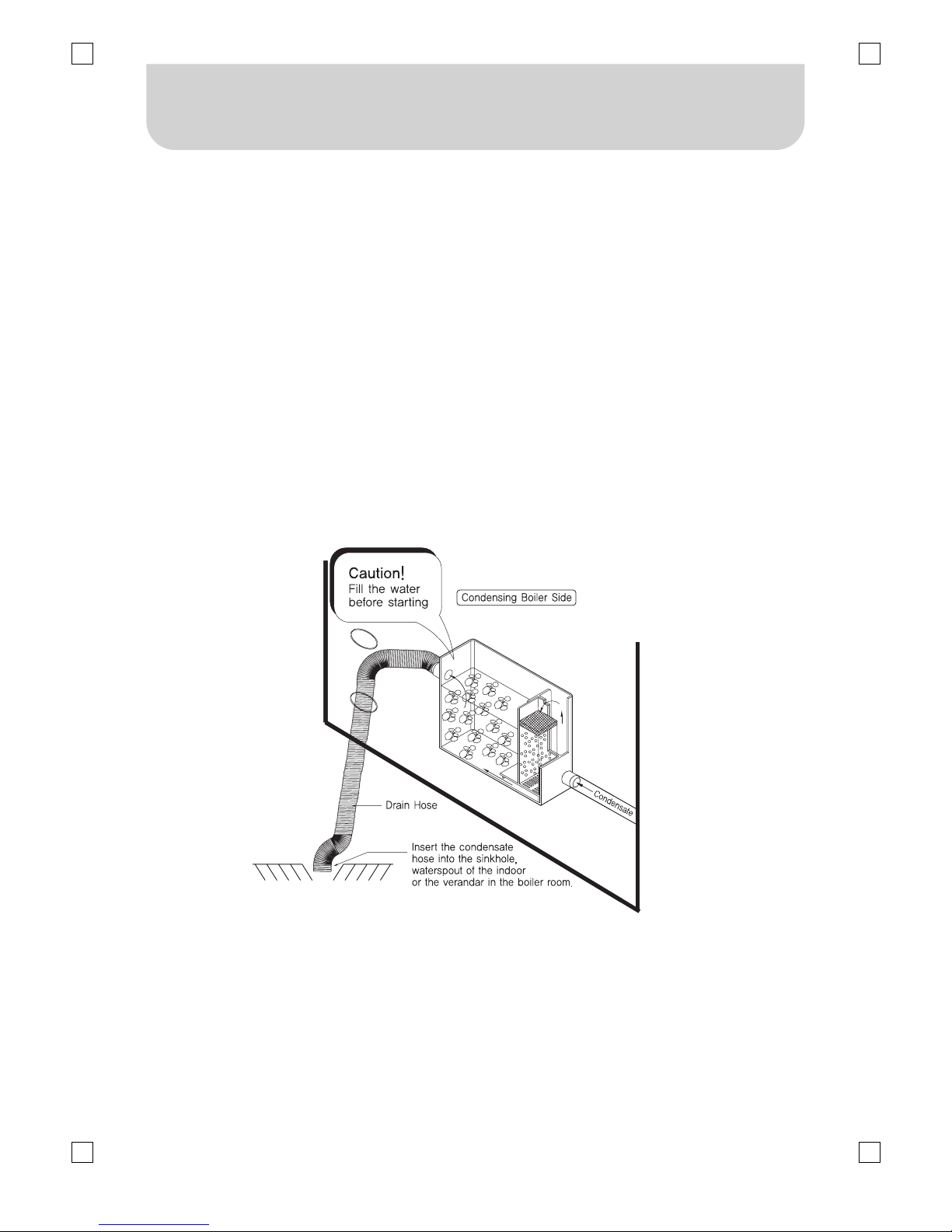

■ Condensate Drainage

1. Condensate is produced when condensing boiler is running and should be piped to the drainage

system.

2. Link the drain hose with the outlet of neutralization system located the bottom of boiler and then,

surely, connect the end of hose to a sink hole or ditch directly.

3. In case of using other drain hose which is not installed originally, it must be plastic and its inside

diameter should be more than ¢13

4. Please make sure that the neutralizer in the boiler should be filled with water, otherwise it must be

filled.

5. Condensate never be allowed for drinking or washing

6. Avoid from any frozen on the drain hose of N.W, insulation must be followed by installing the

hose.

(The additional device with anti-freeze function might be necessary for any sites are possibly

exposed at freezing temperature.)

Loading...

Loading...