l

i

Fully Automated FOB analyzer: HM-JACK series

FECAL OCCULT BLOOD TEST ANALYZER

For Professional Use only

Operation Manual(Rev.4)

Kyowa Medex Co., Ltd.

IVD

HM-JACKarc Operation Manual

Revision Record

ii

Rev.4

Revision Record

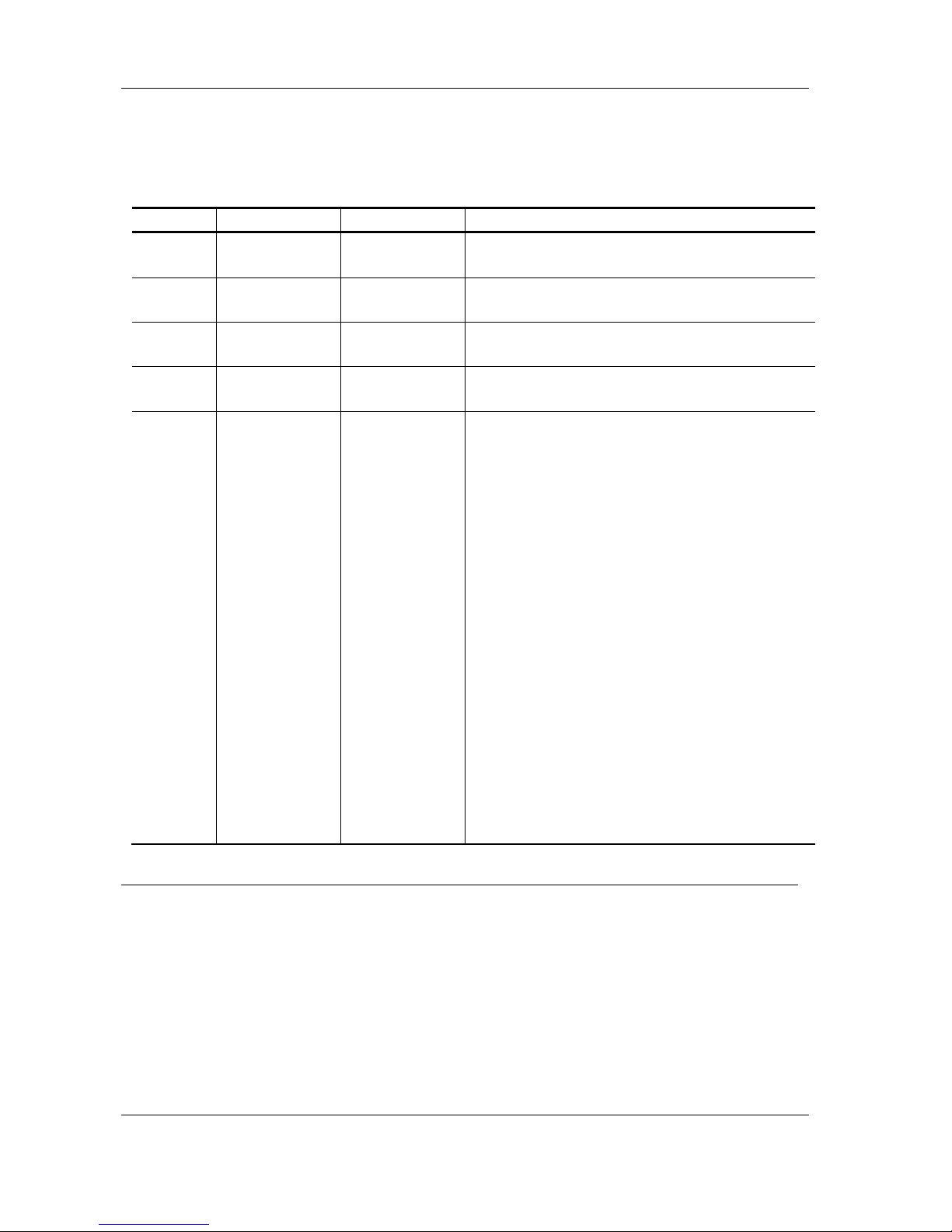

Manual Title : Fecal Occult Blood Analyzer HM-JACKarc Operation Manual

Edition

Printed Date

Revised Pages

Description

Rev.1

Dec. 2011 Newly Released

Rev.2

Jun. 2014

-

Wholly Revised

Updated to Main Program Ver.3.01

Rev.3

Feb.2016

6.3

Added some description to

“List of the Last three Digits of Error Codes”

Rev.4

Oct.2017

7.1

Added an item to specifications of Power supply

Fully Automatic Human Fecal Occult Blood Hemoglobin Analyzer HM-JACKarc Operation Manual

First edition published: December 2011

Written and edited by: Medical Instrument Department, Kyowa Medex Co., Ltd.

Published by: Kyowa Medex Co., Ltd.

1-8-10 Harumi, Chuo-ku, Tokyo 104-6004

HM-JACKarc Operation Manual

Contents

iii

Rev.4

Contents

1 Introduction ........................................................................................ 1-1

Warranty ................................................................................................................... 1-1

Disclaimers ............................................................................................................... 1-1

Applicable laws and standards ................................................................................. 1-2

Caution ..................................................................................................................... 1-2

Restrictions .............................................................................................................. 1-2

Prohibition of Modification ........................................................................................ 1-3

Contact ..................................................................................................................... 1-3

Other manuals .......................................................................................................... 1-3

Conventions employed in this Manual ..................................................................... 1-4

Ministry of Health and Welfare Guidelines on Medical Instruments .... 1-5

2 Safety Precautions ............................................................................ 2-1

2.1 Explanation of Alerting Symbol ...................................................................................... 2-1

2.2 Explanation of Warnings ................................................................................................ 2-1

2.3 Explanation of Warning Labels Affixed to the Analyzer ................................................. 2-2

2.4 Safety Precautions for Operators .................................................................................. 2-3

2.5 Safety Precautions for Maintenance .............................................................................. 2-5

2.6 Waste Materials Precautions. ........................................................................................ 2-6

2.7 Instrument Safety Device. ........................................................................................... 2-7

2.8 Noise Level of the Analyzer. ...................................................................................... 2-7

2.9 Note for Supplied Water and Detergent. ................................................................... 2-7

3 Outline of Analyzer ............................................................................ 3-1

3.1 Characteristics of the Analyzer ...................................................................................... 3-1

3.1.1 Outline .............................................................................................................. 3-1

3.1.2 Principles of Operation ....................................................................................... 3-2

3.1.3 Stool Samplers and Reagents ............................................................................ 3-4

3.2 Part Names .................................................................................................................... 3-5

Top ........................................................................................................................... 3-5

Right side ................................................................................................................ 3-5

Left side ................................................................................................................... 3-6

Back ........................................................................................................................ 3-6

3.3 Materials Required ....................................................................................................... 3-7

HM-JACKarc Operation Manual

Contents

iv

Rev.4

4 Function of Each Screen ................................................................ 4-1

4.1 Display and Operation Screen ................................................................................... 4-1

4.1.1 Startup screen (initial screen) ......................................................................... 4-1

4.1.2 Main Menu screen .......................................................................................... 4-1

4.1.3 Order .............................................................................................................. 4-4

4.1.4 Analysis .......................................................................................................... 4-7

4.1.5 Cell set .......................................................................................................... 4-10

4.1.6 Calibration .................................................................................................... 4-12

4.1.7 Result ........................................................................................................... 4-14

4.1.8 Reaction Data ............................................................................................... 4-16

4.1.9 QC ................................................................................................................ 4-17

4.2 System Menu Screen ............................................................................................ 4-19

4.3 Maintenance Menu Screen .................................................................................... 4-20

5 Analysis Operations ....................................................................... 5-1

5.1 Flow of Analysis Operations ....................................................................................... 5-1

5.2 Preparations for Starting Analysis .............................................................................. 5-2

5.2.1 Turning on the Analyzer ................................................................................. 5-2

Turning on manually ................................................................................ 5-2

Turning on automatically (from Sleep Mode) .......................................... 5-2

Logging in to the Analyzer ....................................................................... 5-3

5.2.2 Preparing Detergent in the Detergent Tank .................................................... 5-4

5.2.3 Preparing the Waste Tank .............................................................................. 5-5

5.2.4 Preparing the Reagent ................................................................................... 5-6

Setting the Reagent in place ................................................................... 5-6

Setting Reagent volume .......................................................................... 5-7

5.2.5 Preparing the Buffer ....................................................................................... 5-9

5.2.6 Preparing the Reaction Cell ......................................................................... 5-12

5.2.7 Registration of Master Curve and Calibration Card ..................................... 5-14

5.2.8 Preparation of Samples ................................................................................ 5-15

Definition of Racks ................................................................................ 5-15

Preparation of Calibrator ....................................................................... 5-15

Preparation of Control ........................................................................... 5-16

Preparation of Patient Sample .............................................................. 5-17

5.2.9 Loading the Racks to the Analyzer ............................................................... 5-19

Rack Orientation .................................................................................... 5-19

Loading Racks to the Analyzer .............................................................. 5-19

5.3 Analysis .................................................................................................................... 5-21

Adding samples during analysis ............................................................ 5-21

Next batch analysis ............................................................................... 5-21

Handling Results ................................................................................... 5-22

5.4 Shut Down Procedure ............................................................................................ 5-23

HM-JACKarc Operation Manual

Contents

v

Rev.4

5.4.1 Clearing up after completing analysis .......................................................... 5-23

5.4.2 Sleep Mode/Switch off.................................................................................. 5-24

■ Sleep Mode ........................................................................................... 5-24

Switching off .......................................................................................... 5-24

5.5 Supplemental Operations ........................................................................................ 5-25

5.5.1 Reading Barcodes with Handheld Scanner ................................................ 5-25

5.5.2 Inputting information and data manually..................................................... 5-26

■ Clearing input protect ............................................................................ 5-26

Inputting data for Calibrator ................................................................... 5-27

Inputting I.S.T of Master Curve ............................................................. 5-27

Inputting Expiration information of Master Curve .................................. 5-28

Inputting Lot information of Master Curve ............................................. 5-28

5.5.3 Setting the first position of picking up the Cell ............................................ 5-30

5.5.4 Setting Printer Paper .................................................................................. 5-31

5.5.5 Actions for Recovery from Emergency STOP ............................................ 5-33

6 Error Messages .............................................................................. 6-1

6.1 Structure of the Codes ............................................................................................... 6-1

6.2 List of the First Two Digits .......................................................................................... 6-2

6.3 List of the Last Three Digits of Error Codes ............................................................... 6-3

6.4 Trouble Shooting Actions (for trained personnel only) ............................................... 6-7

7 Miscellanea .................................................................................... 7-1

7.1 Specifications of the Analyzer .................................................................................... 7-1

7.2 Outline Dimensional Drawing..................................................................................... 7-2

7.3 Communication Specification ..................................................................................... 7-3

7.4 Tube Connection Diagram ....................................................................................... 7-4

7.5 Wiring Connection Diagram ....................................................................................... 7-5

HM-JACKarc Operation Manual

Introduction

1 - 1 Rev.4

1 Introduction

Thank you for choosing the Fully Automatic Human Fecal Occult Blood

Hemoglobin Analyzer HM-JACKarc (referred to below as the Analyzer

or HM-JACKarc).

The Operation Manual (referred to below as the Manual) is intended for

use by those who will operate and maintain the Analyzer.

Those intended should read the Manual thoroughly, and not perform

analysis operation and/or maintenance management of the Analyzer

until they fully understand its content.

Keep this Manual near the Analyzer. If you are unsure of the analysis

operation method for this Analyzer, read the Manual thoroughly before

proceeding with any operation or analysis.

Store this Manual carefully.

Warranty This Manual should be kept where it will be readily available to those

who use the Analyzer.

The content of the Manual and software is subject to change without

notice.

Warranty period Refer to local distributor.

Warranty coverage During the warranty period, all malfunctions due to manufacturing or

design faults will be repaired free of charge.

Exemptions The following are not covered by warranty even if they occur within the

warranty period.

1. Malfunctions due to disassembly or modifications not connected with

Kyowa Medex.

2. Malfunctions caused by operating methods not described in this

Manual.

3. Accidents caused by fire, lightning strike, earthquakes, wind, flooding,

riots, crime, war, or other force majeure.

4. Malfunctions caused by using parts or software not connected with

Kyowa Medex.

5. Malfunctions of consumable parts or using parts outside their period

of validity.

Disclaimers Kyowa Medex bears no liability in the event of losses to the customer or

any third party through the use of this Analyzer, or losses to the

customer or any third party through defects in this Analyzer that could

not be foreseen by the company.

HM-JACKarc Operation Manual

Introduction

1 - 2 Rev.4

Applicable laws and standards

This Analyzer falls under a medical analyzer as specified by the

Pharmaceutical Affairs Act of Japan.

Medical instrument manufacturing license number: 22B3X00004

With regard to the electrical safety test, this is a Class I device of Type

B as specified by JIS T1001 and IEC 61010-1, 2.

Caution This Manual should be kept where it will be readily available to those

who use this Analyzer.

The content of this Manual and software is subject to change without

notice.

In the event of any inconsistencies between this document and the

software, the software is to take precedence.

All other company names and product names used in this Manual

are trademarks or registered trademarks of their respective

companies.

Reproduction of all or part of this Manual without prior consent is

prohibited.

The content of this Manual is subject to change without notice.

While we have taken all possible precautions to ensure quality in the

content of this Manual, please contact your dealership or contact Kyowa

Medex Co., Ltd. if you find anything unclear, or any apparent errors or

omissions. Our contact details are stated on the last page of this

Manual.

This Manual is copyrighted by Kyowa Medex Co., Ltd.

2005 Kyowa Medex Co., Ltd. All Rights Reserved

Restrictions Copying of the HM-JACKarc application software without prior

consent is prohibited.

We do not warrant the functionality of the HM-JACKarc control

computer when used for other purposes.

Do not install any other application software on the HM-JACKarc

control computer. We do not warrant the functionality of the PC if any

other applications are installed.

Do not start any other application while the HM-JACKarc application

is running. We do not warrant the functionality if any other

application is running at the same time.

We do not warrant measurement data that is accidentally deleted.

Password-based restriction is provided for functions that are not

required in normal operation.

HM-JACKarc Operation Manual

Introduction

1 - 3 Rev.4

Prohibition of Modification For the safety of the operator, and to protect the Analyzer, handle the

Analyzer according to the instructions regarding safety precautions in

this Manual.

And please refrain from modifying this Analyzer.

Contact Kyowa Medex Co., Ltd.

1-8-10 Harumi, Chuo-ku, Tokyo Japan 104-6004

Tel: +(81)-3-6219-7605 Fax: +(81)-3-6219-7614 mxinter@kyowa-kirin.co.jp

Obelis S.A.

Boulevard Général Wahis 53, Brussels, BELGIUM 1030

Tel +(32)2.732.59.54 Fax +(32)2.732.60.03 e-mail: mail@obelis.net

Other manuals Other than this Manual read the following operation manuals thoroughly

and be sure to understand the information before performing analysis

operations or handling the reagent and other materials.

Keep the Manual near the Analyzer. If you are unsure of the analysis

operation method for this Analyzer, read this Manual thoroughly before

going on with operation and analysis.

Store this Manual carefully.

Operation Manuals packed with this Analyzer

CCD Touch Scanner FFTA10A Operation Manual

Corresponding codes: CODE39, ITF, Industrial 2 of 5, COOP2 of 5,

NW-7, CODE128, JAN

Instructions packed with other supplies indispensable

EXTEL HEMO・AUTO HS Instructions for Use

EXTEL HEMO・AUTO HS Calibrator Instructions for Use

EXTEL HEMO・AUTO MC Collection Picker Instructions for Use

HM-JACKarc Operation Manual

Introduction

1 - 4 Rev.4

Conventions employed in this Manual

Handling precautions: This Manual indicates information on precautions for handling the

Instrument as "Handling Precautions".

Carefully read the information following "Handling Precautions", and

handle the Analyzer accordingly.

: This Manual indicates information that the user should be particularly

aware of when performing analysis operation or maintenance

management tasks as "Request".

: Indicates section to reference in this Manual.

* : Provides supplementary information.

1. Numbers in italics in the text indicate the step numbers in procedures

and the sequences of operations. Perform operations and tasks

according to these numbers.

Request

HM-JACKarc Operation Manual

Introduction

1 - 5 Rev.4

Ministry of Health and Welfare Guidelines

on Medical Instruments

The attachment of this document, Precautions for the Use of Medical Electronic Instruments (for

Safety and Risk Prevention), to medical electronic instruments is required under Notification No. 495

from the Head of Pharmaceutical Affairs Bureau (June 1st, 1972). These precautions should be

observed to handle the Instrument correctly when it is in use.

Precautions for the Use of Medical Electronic Instruments

(for Safety and Risk Prevention)

1. Only the experienced staff are permitted to use the Instrument.

2. The following points must be observed when installing the Instrument.

(1) Install the Instrument in a location where it is not exposed to water.

(2) Install the Instrument in a location where there is no risk of adverse influence from

atmospheric pressure, temperature, humidity, drafts, sunlight, dust, air containing

substances such as salinity, sulfur, etc. or other environmental factors.

(3) Make sure the Instrument is safe from tilting, vibration and impact (including that during

movement).

(4) Do not install the Instrument in a location where chemical substances are stored or where

gas is generated.

(5) Pay close attention to the voltage and frequency of the power supply, and to the allowable

current (or consumption power).

(6) If battery-based power supply is used, check the status of the battery (depth of discharge

and polarity), etc.

(7) The Instrument must be correctly grounded.

3. The following points must be observed before using the Instrument.

(1) Check that the Instrument functions correctly.

(2) Check that all cables are connected correctly and securely.

(3) Be careful of using the equipment in combination with other instruments that can induce

errors in correct diagnoses and cause hazards.

(4) Check the battery power supply, if one is used.

HM-JACKarc Operation Manual

Introduction

1 - 6 Rev.4

4. The following points must be observed after using the Instrument.

(1) Follow the set procedure to return all control switches, dials to the same positions they

had before the Instrument was used, and then turn off the power.

(2) When you disconnect any cables, do not apply any excessive or inappropriate forces on

them, such as pulling them by the cable rather than by the plug.

(3) Pay attention to the following points regarding the storage location.

i) Store the Instrument in a location where it is not exposed to water.

ii) Store the Instrument in a location where there is no risk of adverse influence from

atmospheric pressure, temperature, humidity, drafts, sunlight, dust, air containing

salinity and/or sulfur or other environmental factors.

iii) Make sure the Instrument is safe from tilting, vibration and impact (including that

during movement).

iV) Do not store the Instrument in a location where chemical substances are stored or

where gas is generated.

(4) Clean the accessories, cables and probes.

(5) Be sure to keep the Instrument clean.

5. If the Instrument breaks down, do not attempt to fix it. Label it appropriately as "out of service" and

contact a specialist for repair.

6. Do not modify the Instrument.

7. Maintenance and inspections

(1) Inspect the Instrument and its components regularly.

(2) Before resuming use of the Instrument that has not been used for some time, be sure to

check that it operates correctly and safely.

8. In addition

The Instrument must be operated correctly, in accordance with the operation manuals.

HM-JACKarc Operation Manual

Safety Precautions

2 - 1 Rev.4

2 Safety Precautions

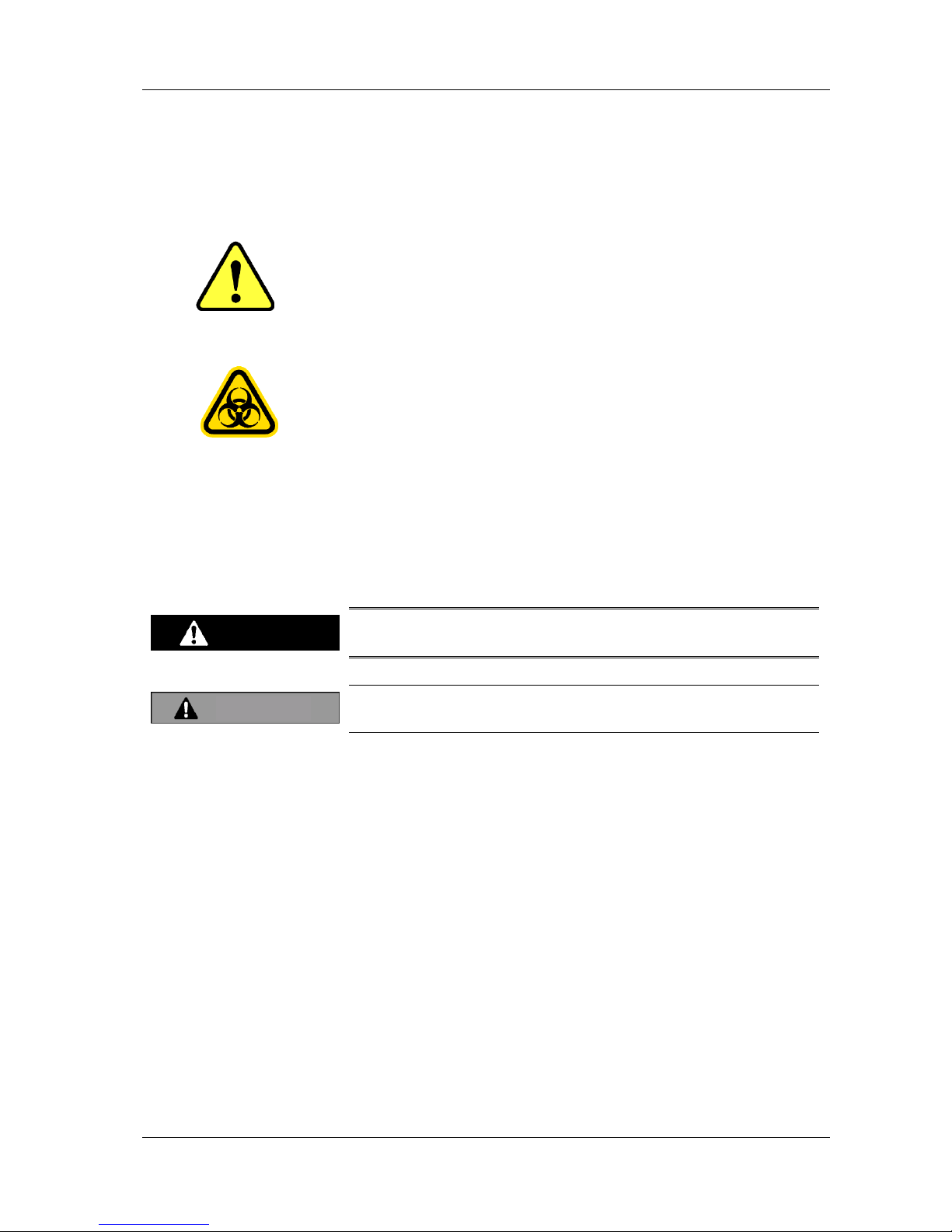

2.1 Explanation about Alert Symbols

The alert symbol on the left is used on this Instrument and in this

Manual to indicate potential dangers. This symbol represents

unspecified general risks and provides warnings and cautions. The

precautions stated after this symbol should be notified for safety

reasons.

The alert symbol on the left used on the Instrument and in this Manual

indicates potential dangers. This symbol represents infectious risk and

provides warnings and cautions. The precautions stated after this

symbol should be notified for safety reasons.

2.2 Explanation of Warnings

Two types of warning legends are used on the Instrument and in this

Manual. These warnings are used separately as described below to

indicate the degree (magnitude) of personal injury and property damage

which could occur.

This signal and the legend is used in situations in which

incorrect handling could result in serious injury to the user.

This signal and the legend is used in situations in which incorrect

handling could result in minor injury to the user.

Classifications and categories of damage and injury severity

The degrees of damage and injury used above are classified as follows:

Severe Injury: Loss of vision, wounds, burns (high or low

temperature), electric shock, bone fracture, poisoning,

infection etc. resulting in permanent after effects, or

requiring medical care involving hospitalization or

prolonged outpatient treatment.

Light injury: Injury other than the above, not requiring medical care

involving hospitalization or prolonged outpatient

treatment.

Warning

Caution

HM-JACKarc Operation Manual

Safety Precautions

2 - 2 Rev.4

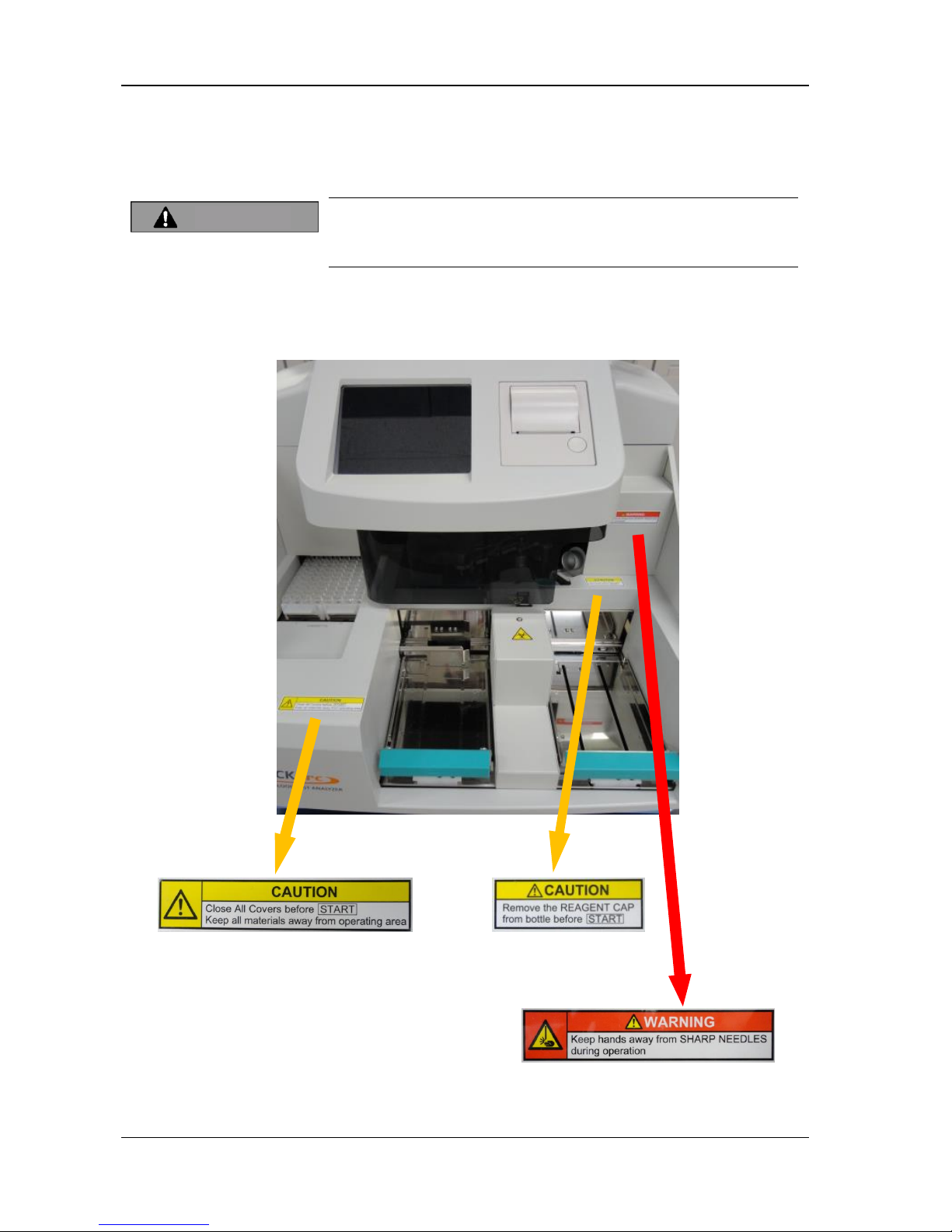

2.3 Explanation of Warning Labels Affixed to

the Analyzer

Make sure that warning labels are legible at all times. If a label peels

off, contact local distributor immediately.

Never peel warning labels off or modify them.

The warning labels shown below are affixed to warn operators of

potential hazards.

Caution

HM-JACKarc Operation Manual

Safety Precautions

2 - 3 Rev.4

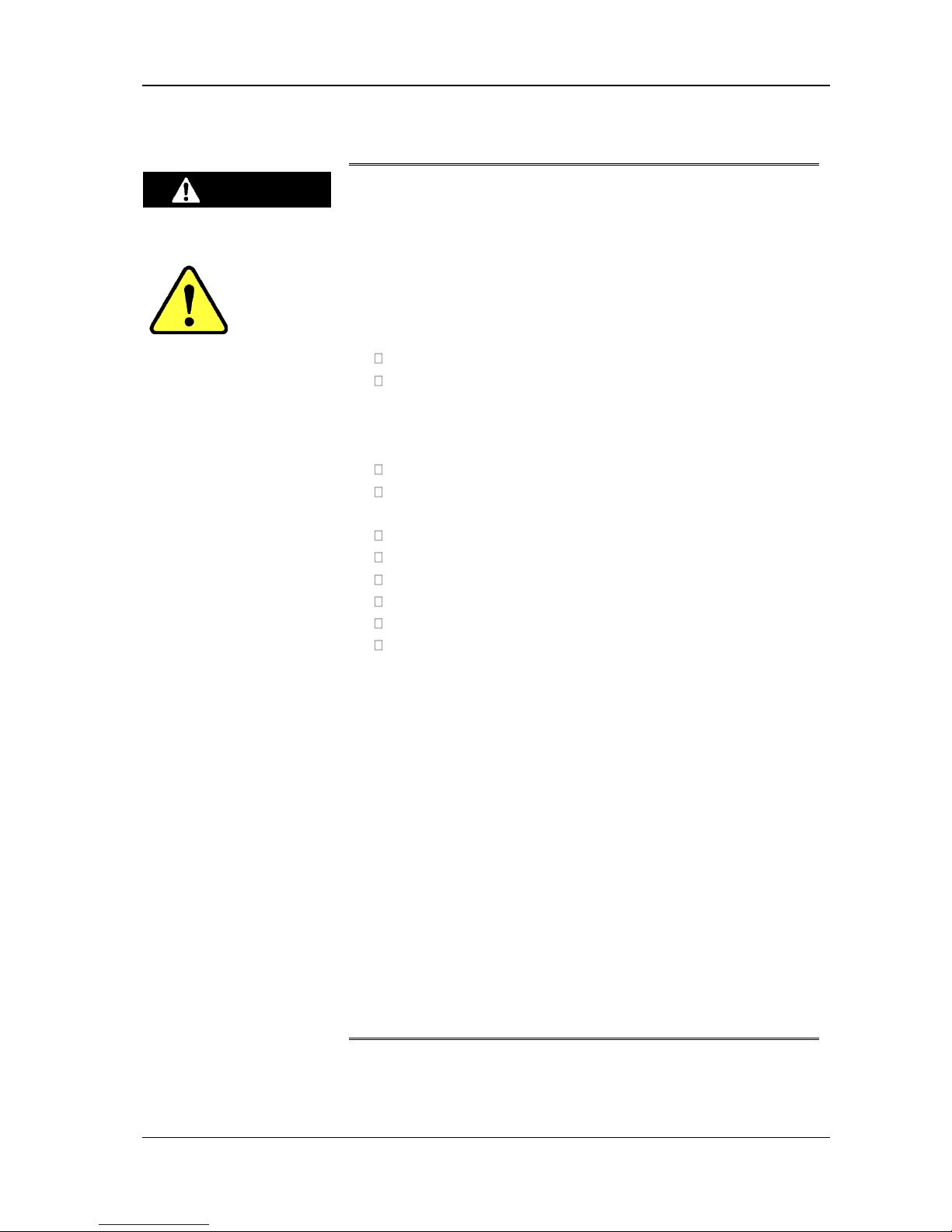

2.4 Safety Precautions for Operators

Before using this Instrument, make sure that the Instrument

was installed by authorized personnel.

If the Instrument is not installed correctly, it could break down

or cause fire, electric shock or injury.

Check the following points before starting operation. These

checks are necessary in order to prevent accidents and injuries.

the warning labels are legible

the ground connection is fully secured

A broken power cable could result in electric shock, fire, and

short circuit. Observe the following points.

the cable is not twisted

the cable is not caught by pressure between the Instrument

and the wall.

the cable is not bent too tight

nothing is put on the cable

the cable is not tied in a bundle

the cable is not modified

the cable is kept away from any heater.

the plug itself, not the cable, is gripped when unplugging the

cable

Dust accumulated on the power plug can start a fire. Check the

plug regularly and remove dust.

Insert the power plug firmly into the socket. Poor contact could

cause overheating, burn injuries and fires.

Do not get the power cable or plug wet, or electrical shock and

short circuit may result.

Never touch the power plug with wet hands, or electric shock

may result.

Using the power cable plug (plugging it in and unplugging it) to

turn the power on and off may cause the plug to overheat.

Always use the power switch (or the Main Breaker).

Warning

HM-JACKarc Operation Manual

Safety Precautions

2 - 4 Rev.4

Only use consumables and replacement parts (including

screws) that are specified by Kyowa Medex Co., Ltd.

Before cleaning the Instrument, turn the power off and be

sure to remove the power plug from the socket.

In the event of any malfunction of the Instrument, turn the

power switch off immediately and remove the power plug

from the socket. Leaving faults unattended can cause

accidents and fires.

Do not turn the power switch off and on repeatedly.

The Mixing Spatula, Sample Pipette and Reagent Pipette

attached to the injection assembly are sharp and could

cause injury.

The ends of the Mixing Spatula, Sample Pipette and Reagent

Pipette attached to the injection assembly come into direct

contact with Samples (stool samples) and Reagent. Incorrect

handling of those parts could cause infection with

pathogens or poisoning with Reagent. Wear medical rubber

gloves while working, and take extra care to avoid infection.

Warning

HM-JACKarc Operation Manual

Safety Precautions

2 - 5 Rev.4

2.5 Safety Precautions for Maintenance

Do not modify the Instrument without permission. Modification

could cause unexpected hazards.

Use consumables and replacement parts (including screws)

only specified by Kyowa Medex Co., Ltd.

Before servicing the Instrument or removing any of its parts

(fixing faults, replacing parts, inspecting, repairing, etc.), turn

the power switch off and be sure to disconnect the power plug

from the socket to avoid getting electric shock.

When disconnecting the power plug from the socket, always

grip and pull on the plug itself, not on the cable.

Use fuses of the only specified type. Use of non-specified fuses

could cause the Instrument to malfunction or, in some cases,

start a fire.

Using the power cable plug (plugging it in and unplugging it) to

turn the power on and off may cause the plug to overheat.

Always use the power switch (or the Main Breaker).

This Instrument weighs approximately 56 kg. Handle it with

extra care when moving. Note that moving the Instrument

should be done by two or more people.

The ends of the Mixing Spatula, Sample Pipette and Reagent

Pipette attached to the injection assembly are sharp and could

cause injury.

The ends of the Mixing Spatula, Sample Pipette and Reagent

Pipette attached to the injection assembly come into direct

contact with Samples (stool samples) and Reagents, so

incorrect handling of those parts could cause infection with

pathogens or poisoning with reagents. Wear medical rubber

gloves while working, and take extra care to avoid infection.

Warning

HM-JACKarc Operation Manual

Safety Precautions

2 - 6 Rev.4

2.6 Waste Materials Precautions

Samples could be contaminated with pathogens etc., so take

extra care to avoid infection when handling them, by wearing

medical rubber gloves etc.

Before handling sample containers, reagents and buffer, read

and understand the Instructions for Use. Handle them with care

to avoid accidents.

Any Mixing Spatula, Sample Pipette and Reagent Pipette which

has been detached or removed is sharp and dangerous. Handle

them with extra care.

The ends of the Mixing Spatula, Sample Pipette and Reagent

Pipette attached to the injection assembly come into direct

contact with samples (stool samples) and reagents. Incorrect

handling of those parts could cause infection with pathogens or

poisoning with reagents. Wear medical rubber gloves at all

times while working, and take extra care to avoid infection.

Here below is a list of Waste materials generated by regular analysis.

They should be handled as medical waste and disposed of by a

specialist contractor.

Liquid waste

Used cells

Reagents and reagent bottles

Buffer and buffer fluid bottles

Used stool sample containers

Hemoglobin standards before and after preparation

Hemoglobin standard containers

Used sample cups

Control samples before and after preparation

Control sample containers

The Instrument contains lithium battery. The local restriction or WEEE

should be applied when battery is wasted. Ask for local distributor for

more information.

Warning

Caution

Caution

HM-JACKarc Operation Manual

Safety Precautions

2 - 7 Rev.4

2.7 Instrument Safety Device

Overcurrent Protection

2 or more ampere of current (input voltage 220v) will be interrupted

immediately by internal breaker and the power will be shut down.

Transformer Secondary Fuses

A fuse is installed to protect Control PCBs (Main PCB, Power PCB) from

overcurrent.

Thetransformer is protected from overheating by a thermal fuse.

A fuse is installed to protect the lamp from overcurrent.

Outer Cover Opening Check Sensor

If the outer cover is open, the Analyzer does not start motion. If the outer

cover is opened while the Analyzer is in motion, an error occurs and the

Analyzer will stop sampling. There are 2 switches to secure the function.

2.8 Noise Level of the Analyzer

The maximum noise level is 70db.

2.9 Note for Supplied Water and Detergent

Temperature of supplied water

The temperature of supplied water for this Instrument should be in

20-30 ℃ . Lower temperature of water may cause malfunction of

instrument wash, and higher one may damage the tubing and lead to

leakage of water.

Amount of use of Detergent

The amount of use of Detergent (water include 0.1% of detergent) is

approximately 4.5mL per a test. It is also used in priming and wash. It is

necessary to keep enough amount of prepared Detergent during the run.

HM-JACKarc Operation Manual

Outline of Instrument

3 - 1 Rev.4

3 Outline of Analyzer

3.1 Characteristics of the Analyzer

3.1.1 Outline

This Analyzer measures the amount of human hemoglobin present in

a stool sample.

Compact and light analyzer designed for installation in a small space.

Barcode reading input is applied to register Sample ID, Calibration

Master Curve and Calibrator Information to make the operation easier

for operators.

A two-point calibration method is adopted to simplify the measurement

operation.

The measurement method is Latex Agglutination, which is quick and

achieves superior sensitivity.

Superior detection sensitivity realizes smaller volume of stool sample

and less smell.

The sample loading capacity of the Analyzer is 80.

Reaction Cells are replaced after use automatically.

The Sample Collection Picker achieves superior stability for human

hemoglobin, reduces the decline in the amount of human hemoglobin

and enables more accurate measurement.

Analysis results can be checked on the screen and printout. Also,

connection to a host computer enables data to be exported.

HM-JACKarc Operation Manual

Outline of Instrument

3 - 2 Rev.4

3.1.2 Principles of Operation

The Reagent Pipette aspirates the Latex Reagent, which then move to a

Cell on the Reaction Table, where it is dispensed together with the Buffer.

Next, the Reaction Table Rotates and the Cell containing the Reagent

moves to the sampling position. The Sample Pipette aspirates a Sample,

which is then dispensed to the Cell. The Mixing Spatula then turns

counterclockwise to mix the Reagent and the Sample together.

The Cell containing the Reagent and the Sample moves to the detection

position after a period of time set under the measurement conditions, and

the first photometric measurement (ISTT1) is performed. After another set

period of time, the second photometric measurement (ISTT2) is

performed.

The amount of change in the Integrating Sphere Turbidity of the two

photometric measurements (ΔIST=IST

T2

-ISTT1) is calculated by the

computer according to the calibration curve to output the measurement

result.

This series of actions is repeated to measure all samples placed in the

sample rack.

IST: Integrating Sphere Turbidity

HM-JACKarc Operation Manual

Outline of Instrument

3 - 3 Rev.4

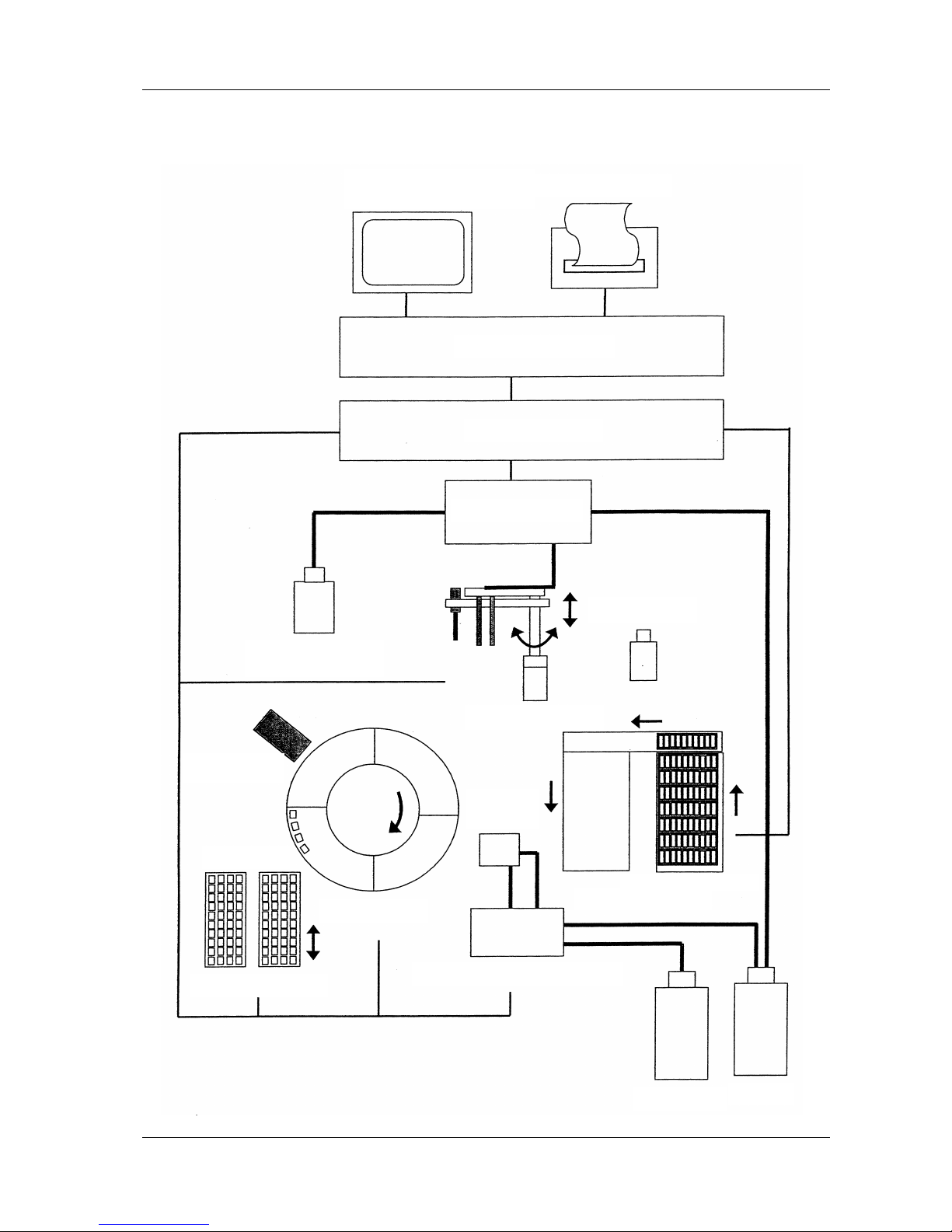

Operating Principle Diagram (Block Diagram)

Operation and Display Panel

(backlight color LCD panel)

Printer Paper

Microcomputer

Interface

Injector

Buffer Fluid

Latex Reagent

Injection Arm

Wash

Station

Turbidity Meter

Cell Cassette

Reaction Table

Cell Transportation

Supply and Waste Water Pump

Waste Liquid

Detergent

Sample Transportation

Sample Rack

HM-JACKarc Operation Manual

Outline of Instrument

3 - 4 Rev.4

3.1.3 Stool Samplers and Reagents

This Analyzer uses EXTEL HEMO・ AUTO HS as the measurement

reagent, together with the HEMO・ AUTO MC Collection Picker and

achieves:

Major improvement in reproducibility in range close to the cut-off

Large improvement in low-value reproducibility

By developing the HEMO・AUTO MC Collection Picker (patent applied

for), with the optimum reagent concentration to make the most of the

characteristics of the integrating sphere photometer, we have

achieved:

Optimization of the volume of stool sample by the two-step rotary

scraping method

Adoption of hexagonal stool sampling holes that improves both stool

holding and solubility

One-way collection of excess stool and easy check of whether stool

has been sampled

Time-saving by adopting integrated multifunction seals.

The features mentioned above enhance operability, accelerate

processing speed, and improves reproducibility of this Instrument.

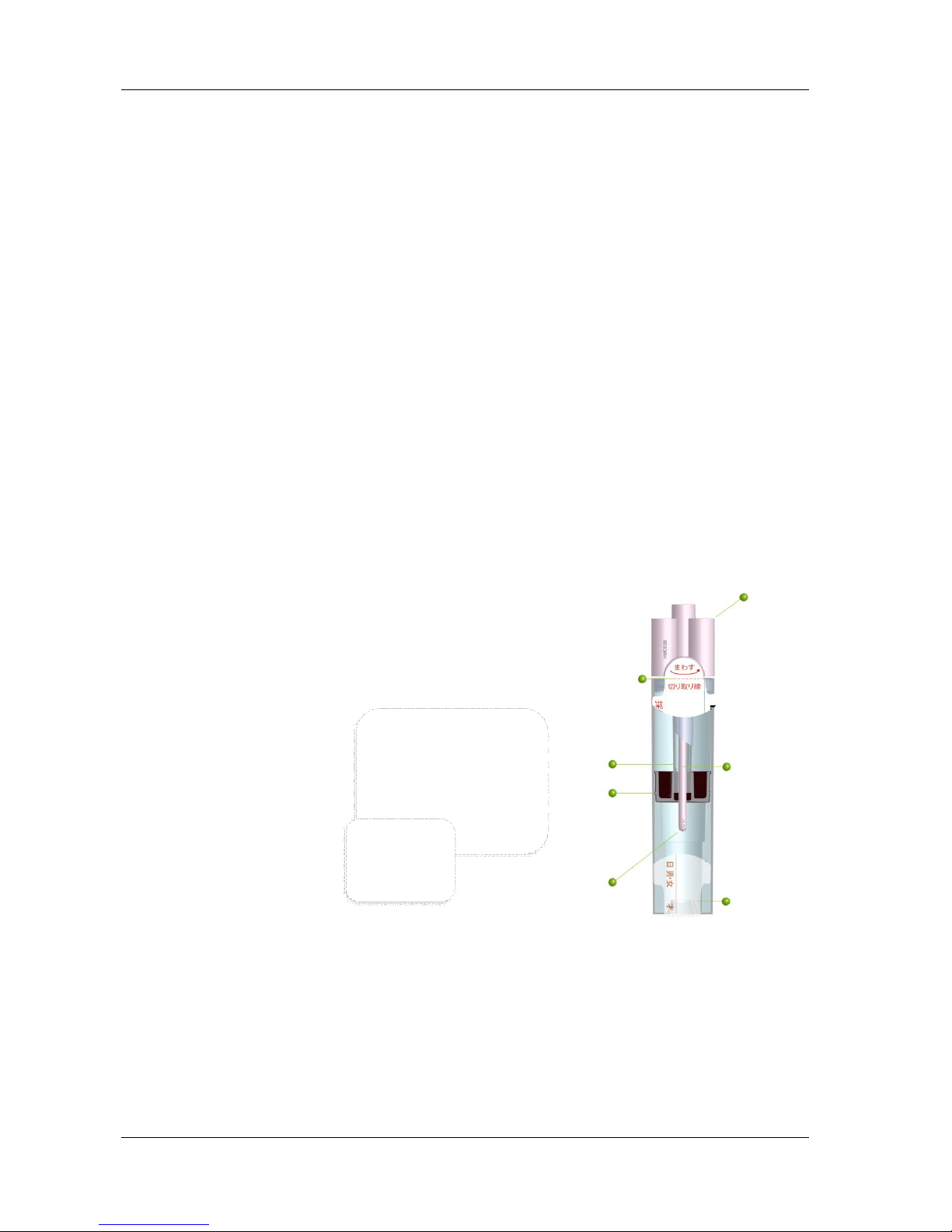

Piercer

Blending

Section

Stool

Collection

Rod

Tip of stool

collection rod

Separator

Stool

Collector

HEMO・AUTO

MC

Collection Picker

HM-JACKarc Operation Manual

Outline of Instrument

3 - 5 Rev.4

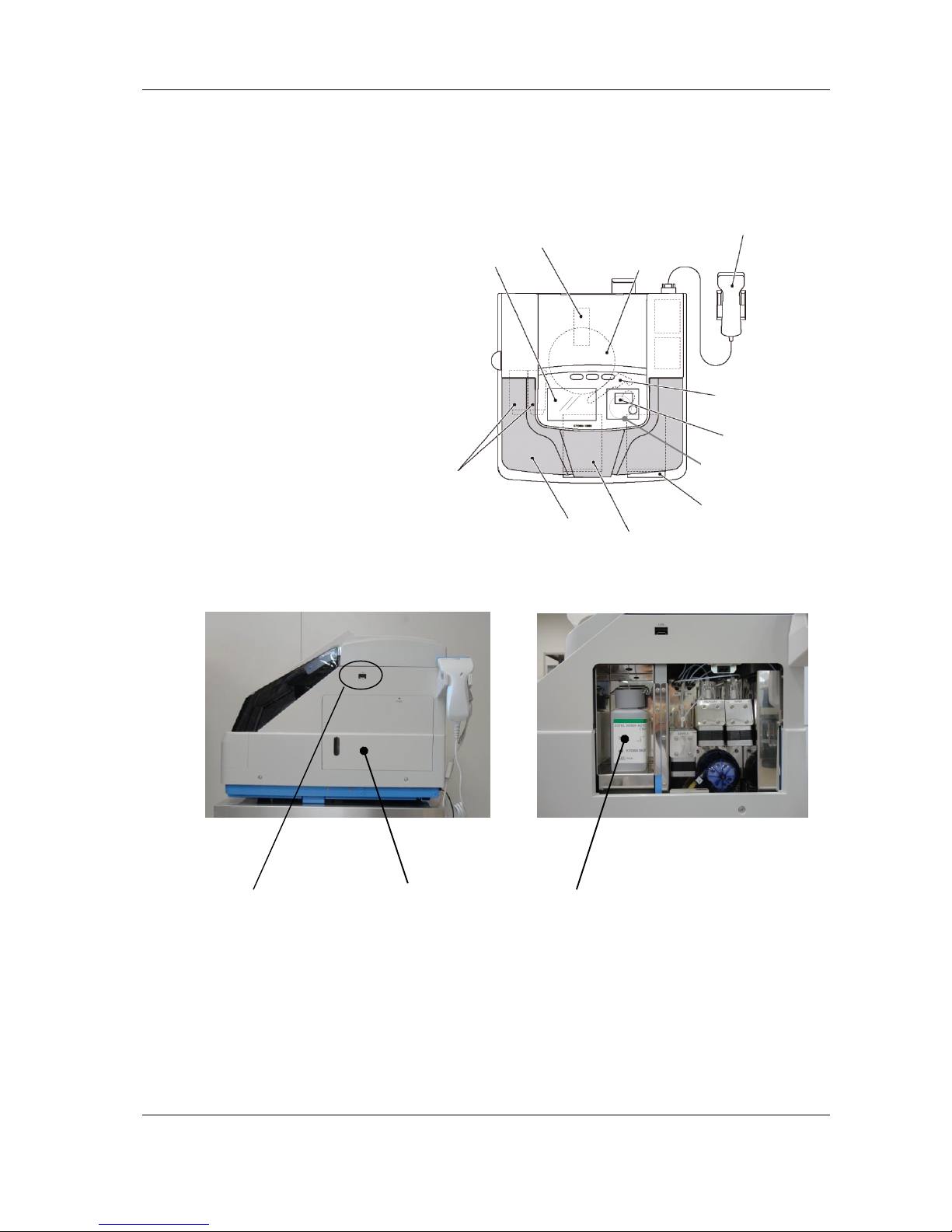

3.2 Part Names

The names of the parts of this Instrument are as follows:

Top

Right side

Display

Cell Cassette

(40 Reaction Cellsx2 (L, R))

Outer Cover

Sample Tray (eject)

Sample Tray (load)

Printer

Injection Arm

Handheld Scanner

Reaction Table

(Reaction Cell)

Integrating Sphere

Turbidity Meter

Buffer Reagent Cover

Latex

Buffer bottle

Inside the Cover

USB Slot

HM-JACKarc Operation Manual

Outline of Instrument

3 - 6 Rev.4

Left side

Back

Cell Waste Box

Cell Hand Cover

Handheld Scanner Connector

Cooling Fan

Lamp Replacement Panel

Breaker Switch

Power Cable Plug

Detergent sensor

Detergent tube

Waste tube

Connectors

HM-JACKarc Operation Manual

Outline of Instrument

3 - 7 Rev.4

3.3 Materials Required

Here below is the list of required materials other than parts provided with

the Analyzer.

EXTEL HEMO・AUTO HS Latex

EXTEL HEMO・AUTO Buffer

EXTEL HEMO・AUTO HS Calibrator

EXTEL HEMO・AUTO HS Control

EXTEL HEMO・AUTO MC Collection Picker

EXTEL HEMO・AUTO Reaction Cell

Please contact your local supplier to order the products.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 1 Rev.4

4 Functions of Each Screen

4.1 Display and Operation Screens

The names and functions of the various icons on the operation screen

are as follows:

4.1.1 Startup screen (Initial Screen)

This screen is displayed after the power is turned on.

Touch the screen to move to the Main Menu screen.

4.1.2 Main Menu screen

This screen is main screen to start operations. Touching any RETURN

key on each screen several times finally returns to this screen.

Applied Calibration

curve Number

Name of current

screen

Supplementary name of

current screen

Current versions of programs

(Main, Control and Detect)

USB Mark (if connected)

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 2 Rev.4

Analysis icon

Touch this icon to go to Order screen to start preparations for

measurement. See 4.1.3 Order for details.

Cell Set icon

Touch this icon to move to the Cell Set screen to display the status for

Cells on the Reaction Table. See 4.1.5 “Cell Set” for details.

Wash icon

Touch this icon to run a wash or prime the system.

After the initialization of the Injection Arm, the system performs priming to

fill the tube between the Sample Pipette and the Sample Syringe with

Detergent, and the tube between the Reagent Pipette and the Reagent

Syringe with the Buffer. Then the Analyzer stops.

When the Buffer or Detergent have been replaced or replenished, touch

this Wash icon to run a wash/prime cycle.

Home position icon

Touch this icon to return all moving parts to their home positions.

Calibration curve icon

Touch this icon to go to Calibration screen. Master Curve/Calibrator

registration are available from the screen.

See 4.1.5 “Calibration” for details.

Results icon

Touch this icon to display analysis results. The Results screen can be

used to display or print results, or send them to the host computer. To

display real time results, touch this icon during operation.

See 4.1.7 “Result” for details.

QC icon

Touch this icon to display analysis results for quality control.

X-R control diagrams and histograms are available from the menu.

See 4.1.8 QC for details.

Emergency STOP icon

Touch this icon to stop all movement immediately. Using this function

wastes all the processing measurement.

For actions after an emergency stop, refer to page 5-28 “Actions for

Recovery from Emergency STOP”.

Applied Calibration curve Number

The currently applied Calibration curve Number (No. 1 in this case) is

displayed.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 3 Rev.4

Name of current screen

The name of the current screen is displayed.

Supplementary name of current screen

The current operation status is displayed.

Sleep Mode button

Touch this button to go to screen to set up the date and time of the next

startup. See “Set Sleep Mode” on page 5-24 for details.

System button

From the menu various system parameters can be modified, but it is not

allowed to modify the parameters without permission.

Maintenance button

Touch this button to go to the Maintenance Menu screen.

Refer to the Service Manual for details.

USB Mark(if connected)

When a USB is inserted to the USB slot and recognized by the system,

the mark on the left appears. Touching this icon allows the USB stick to

be removed safely.

Feed button

Touch this icon to feed the printer paper.

H.Copy button

Touch this icon to print out the hardcopy of the screen.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 4 Rev.4

4.1.3 Order

When the Analysis icon is touched, Order screen appears. Analysis and

calibration can be started only from this screen.

Start Icon

Touch this icon to start measurement. See 4.1.4 “Analysis” for details.

Main Menu icon

Touch this icon to go back to the Main Menu screen.

Sample Stop icon

Touch this icon to stop sampling. Ongoing measurement still goes on

after sampling stop and will complete.

Home Position icon

Touch this icon to return all moving parts to their home positions.

Sample Status field

After starting measurement Sample Status will be displayed in this field.

See “Sample Status field” on page 4-7

ID column

(Not in Use)

Attribute field

(Not in Use)

Applied Calibration

curve Number

Name of current

screen

Sample Status field

Attribute field

USB Mark (if connected)

Supplementary name of

current screen

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 5 Rev.4

Barcode ID column

During the measurement, currently read sample barcode ID is displayed

in this column.

Latex column

Touch this column to input the volume of Latex Reagent. Available test

with the Latex Vial set to the Instrument is displayed and counted down

accordingly during measurement. See “Setting Reagent volume” on page

5 - 6 for details.

■Time Remained column

Estimated finish time is displayed.

Emergency Stop icon

Touch this icon to stop all movement immediately. Using this function

wastes all the processing measurement.

For actions after an emergency stop, refer to page 5-28 “Actions for

Recovery from Emergency STOP”.

Applied Calibration curve Number

The currently applied Calibration curve Number (No. 1 in this case) is

displayed.

Name of current screen

The name of the current screen is displayed.

Supplementary name of current screen

The current operation status is displayed.

System button

From the menu various system parameters can be modified, but it is not

allowed to modify the parameters without permission.

All Clear button

Touch this button to clear all the information displayed in Sample Status

field.

USB Mark (if connected)

When a USB is inserted to the USB slot and recognized by the system,

the mark on the left appears. Touching this icon allows the USB stick to

be removed safely.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 6 Rev.4

Feed button

Touch this icon to feed the printer paper.

H.Copy

Touch this icon to print out the hardcopy of the screen.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 7 Rev.4

4.1.4 Analysis

During the measurement, the screen below is displayed.

Sample stop icon

Touch this icon to stop further sampling. Ongoing measurement still goes

on after sampling stop and will complete. Touch Start icon to restart the

measurement again.

Main Menu icon

Touch this icon to go back the Main Menu screen.

■Rack Monitor

・Sampling

The sample rack Number and position Number being sampled at the

moment is displayed.

R: ID of the Rack is displayed

The position being sampled now is colored green.

・Sampling End

R: ID of ejected Rack is displayed.

Status and

operation

message

Applied calibration

curve number

Name of current

screen

Supplementary name of

current screen

Sample Status

field

Rack monitor

USB Mark (if connected)

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 8 Rev.4

Sample Status field

The status of each sample is displayed.

・Sel.:(Not in use)

・No.:Sample No.: 1-320

・Pos.:Attribute or Position Number

STD1 : Calibrator 1

STD2 : Calibrator 2

CTLL : Control L

CTLH : Control H

Cup : Sample Cup(as optional)

Samples : rrr-pp

rrr: Rack No. 001-999 (rack barcode)

pp: Position No. within rack No. 1-10

・ID CODE

When Sample barcode is enabled, Sample barcode for each

sample is displayed. When Sample barcode is disabled, User

ID is displayed.

・Av.:Attribute or repetition number is displayed.

Calibrator 1 and 2 = Average number of Calibration

(Set as an item parameter: 1-3)

Control L = Repetition number of Control L

(Set as an item parameter: 1-3)

Control H = Repetition number of Control H

(Set as an item parameter: 1-3)

Cup = Repetition number of Sample Cup(as optional)

(Set as an item parameter: 1-3)

Patient Samples (one-day method) = 1

Patient Samples (two-day method) = 1 (1st day), 2 (2nd day)

・Data:Results of the Sample is displayed.

・Alarm:If an event occurred for the Sample, a flag is displayed in this

column. Refer to Error List for details of the code.

■Status and Operation Message

The status of the analyzer and supplementary message is displayed

timely in this area during operation.

Latex column

Touch this column to input the volume of Latex Reagent. Available test

with the Latex Vial set to the Instrument is displayed and counted down

accordingly. See “Setting Reagent volume” on page 5 - 6 for details.

■Analysis end time

Estimated remaining time of the run is displayed in this column. This

column is not in use after finishing the run.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 9 Rev.4

Emergency Stop icon

Touch this icon to stop all movement immediately. Using this function

wastes all the processing measurement.

For actions after an emergency stop, refer to 5.1 “Actions for Recovery

from Emergency STOP”.

Applied calibration curve Number

The currently applied calibration curve (No. 1 in this case) is displayed

Name of current screen

The name of the current screen is displayed.

Supplementary name of current screen

The current operation status is displayed.

System button

Various parameters can be modified from this menu, but it is allowed to

enter this menu only when it is necessary to change input data for

Calibrator manually. Refer to ****** for details.

To Order button

Touch this button to start measurement after finishing previous one. Start

icon will appear.

USB Mark (if connected)

When a USB is inserted to the USB slot and recognized by the system,

mark on the left appears. Touching this icon allows the USB stick

removed safely.

Feed button

Touch this icon to feed the printer paper.

H.Copy button

Touch this icon to print out the hardcopy.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 10 Rev.4

4.1.5 Cell Set

This is the screen to control the Cells. It is not required to take care of

Cells as long as the Cassettes replaced as required. If required, touch

Cell Set icon on the Main Menu to go to Cell Set screen.

Main Menu icon

Touch this icon to go back the Main Menu screen.

Home position icon

Touch this icon to return all moving parts to their home positions.

■Position Status field

The status of each position of the Reaction Table is displayed in five

abbreviations as below.

・OK : A Cell is set and available

・MS : Measurement is ongoing

・NG : The position is checked but not available

・?? : The position is not checked yet

・( Blanc): No Cell is present

■All Changes icon

Touch this icon to replace all cells on the Reaction Table.

■Selective Change icon

Touch this icon to replace unavailable cells on the Reaction Table

recognized by the Analyzer.

Applied calibration

curve number

Name of current

screen

Supplementary name of

current screen

USB Mark (if connected)

Position Status field

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 11 Rev.4

■All OK icon

Touch this icon to change the status of all Reaction Table positions to OK.

■Cell Cassette icon

Touch this icon to go to the Cell Cassette screen.

Cell Cassette screen

・Cell Cassette Map

This map indicates presence of cells (1-40) on the cassettes (R and L) on

the Analyzer.

・White blocks : A Cell is present.

・Dark gray blocks : No Cell is present.

・Blue Block : The position will be picked up first. It can be

changed with touching another one.

・Start Position

The position picked up first is displayed.

・Cell Set icon

Touch this icon to go back to Cell Set screen.

Cell Cassette Map

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 12 Rev.4

4.1.6 Calibration

■No1./No2. Tub

The Analyzer can hold two Calibration data. Touch one of them to choose

Calibration data to view.

■Date of Master Curve registration

The date of Master Curve registration is displayed.

■Master Curve data field

Each I.S.T of registered Master Curve is displayed in I.S.T column. Backfit

will be displayed after calibration completed.

■Lot information field

Lot information of Master Curve and Calibrator is displayed.

■Master button

Touch this button to refer to the data input with registration of Barcodes or

to input data manually. Refer to ****** for procedure for manual input of the

data.

■Curve button

Touch this button to view the calibrated Master Curve.

■Barcode button

Touch this button to move to Barcode Registration mode. See 5.2.8

“Registration of Master Curve” for details.

Applied calibration

curve number

USB Mark (if connected)

Name of current

screen

No1/No2 Tub

Date of Master Curve

registration

Master Curve data

field

Lot information

field

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 13 Rev.4

■Curve 1⇔2 button

Touch this button to change Calibration data to apply. Confirmation window

will appear after touching this button. This is the only way to change

Applied Calibration between 1 and 2.

■RETURN button

Touch this button to go back to Main Menu.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 14 Rev.4

4.1.7 Result

■File name and Number of Data

The name of the file and number of Data inside the file is displayed.

■Results field

Below information is shown

・Avail : When this column is touched, X mark will be displayed and the

data of the row will be excluded from the target of Execution.

・Sel. : First, touch one of the commands at the bottom of the screen

to execute. Then touch this column to select as the target. ✔

mark will be displayed.

・No. : Sample number

・Pos : Rack ID and position number

・User ID : The number that the system applies to every sample following

a configuration in User Parameter.

・Barcode : Barcode of the Sample. Touch this area to view Reaction

Data. See 4.1.6 Reaction Data for reference.

・Av. : Number of repetition of Calibrator and Control

・Data : Result of the Sample(ng/mL)

・+/- : Qualitative Result

・Mark : Flag or Error Code

■File

Touch this button to display File List. Touch one of the files in the list to

display the detailed data.

Applied calibration

curve number

Name of current

screen

USB Mark (if connected)

Results field

File name and

Number of data

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 15 Rev.4

■Output button

Touch this button to output data. When this button is touched, Host and

Print button will appear. Touch one of them, select target result(s) with

touching Sel column and then touch Execute button.

・Host : Send the selected Result(s) to the Host Computer

・Print : Print out the selected Result(s)

■Calc button

Touch this button to calculate results again. When this button is touched,

two buttons will appear.

・Recalc :This button is effective only when the calibration data is revised.

The data can be calculated based on the new calibration data.

・CV : CV can be calculated from selected results. Touch sel column of

target data to select and touch Execute button. The Calculated

CV can be printed out afterwards. (CV: Coefficient of Variation)

■Avail button

(Not for Use)

■RETURN button

Touch this button to go back to the Main Menu.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 16 Rev.4

4.1.8 Reaction Data

■Measurement Information field

Information about Sample and Reagent is displayed.

■Reaction Data field

Reaction Data (I.S.T of each point) is displayed.

■Reaction Curve field

Reaction Curve of is displayed.

■Lot Info. button

Reaction Data field will be changed

to the information on the right.

■PREV. /NEXT button

Touch these buttons to view previous/next result.

Measurement

Information field

Reaction Data

field

Reaction Curve

field

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 17 Rev.4

4.1.9 QC

QC check functions are available from this screen. Touch one of menus

to enter the function.

CQ Menu screen

■Control X-bar Chart

X-bar chart is calculated from the control data and displayed. The

maximum number of calculated data is 31 from the start date. The data

plotted on the chart are average of each control result of a run.

・Date button : To direct the start date of the chart, touch these

buttons to display Numeric keys. Enter the start

date(yyyy/mm/dd) and touch Enter key.

・Information field : Statistic data are displayed.

・Chart : The Chart of each (Low/High) control

Date button

Information

field

Chart

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 18 Rev.4

・Low List button : Touch this button to exclude certain data from

the chart. List of the data will be shown, then

touch Avail and mark with X to exclude from the

Low chart.

・High List button : Touch this button to exclude certain data from

the chart. List of the data will be shown, then

touch Avail and mark with X to exclude from the

High chart.

■Histogram Result List

When the Histogram button is touched, the screen below is displayed.

Choose All, Today or touch Sel to target for execution.

・Sel column : Target Data with ✔ mark

・All button : Target All the data

・Today button : Target Data of current date

・Graph button : Tabulate the Graph including selected data

■Histogram

・Qualitative button : Show the Qualitative(+/-) tabulation

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 19 Rev.4

4.2 System Menu Screen

The System Menu is displayed when System button is touched. These

menus are for service personnel.

HM-JACKarc Operation Manual

Functions of Each Screen

4 - 20 Rev.4

4.3 Maintenance Menu Screen

The Maintenance Menu screen is displayed when the Maintenance button

is touched.

■Unit Control

Each moving unit can be operated separately from this menu. Also, some

configuration can be adjusted and the status of sensors can be checked.

This function is for service use.

■DETECT TEST

When this button is touched, DETECT screen is displayed. The scattering

light and transmitted light can be observed on the screen. This function is

for service use.

■Error History

Error History display can be seen from this menu.

■Maintenance

Touch this button to go to the Maintenance menu. This function is for

service use.

HM-JACKarc Operation Manual

Analysis Operations

5 - 1 Rev.4

5 Analysis Operation

5.1 Flow of Analysis Operation

Routine analysis operation follows the process described below.

1. Turn on the Analyzer (and Log in optional)

Turn the Analyzer on about an hour before the start of analysis, to allow

it to warm up.

Use of Sleep Mode can avoid the need for this warming-up period.

2. Prepare Detergent in the Wash Tank

3. Prepare the Waste Tank and Cell Dust Box

Empty the Waste Tank / Cell Dust Box if necessary.

4. Prepare the Reagent

Let the Latex Reagent warm to room temperature before use.

Set the reagent volume on the Sample Order screen, if necessary.

5. Prepare the Buffer

Let the Buffer warm to room temperature before use.

6. Prepare the Reaction Cells

If required, use the Cell Set screen to set the starting position for

picking up the cells and replacing used cells.

7. Prepare for calibration

When Latex lot is changed, register Master Curve. When the Calibrator

lot is changed, register barcodes of Calibrator Card.

8. Prepare the Calibrators (S1, S2)

If calibration is necessary, prepare the Calibrators.

9. Prepare the Controls (CL, CH)

10. Prepare the Patient Samples

Set the Patient Samples in Collection Picker or Sample Cup in the

Sample Racks.

10. Load Racks

Load Racks equipped with required materials.

11. Analysis

12. Completing Analysis

HM-JACKarc Operation Manual

Analysis Operations

5 - 2 Rev.4

5.2 Preparations for Starting Analysis

5.2.1 Turning on the Analyzer

There are two different ways to turn on the Analyzer.

Turning on manually

Before turning the power on, check that the power plug is

correctly inserted into the socket.

If the power plug is not connected correctly and securely, there

is the risk of overheating leading to fire and or electric shock.

It takes approximately one hour for the instrument to warm up and to be

ready for analysis after power is turned on. Turn it on in advance of

starting analysis.

Switch on the POWER on the left side of the Main Unit. The Start Up

screen will be displayed and touch anywhere of screen to go to Main

Menu.

Power switch (On)

Turning on automatically (from Sleep Mode)

When Sleep Mode is set after previous operation, the Analyzer starts up

automatically and the Start Up screen is displayed. Touch anywhere of

screen to return to Main Menu.

Warning

HM-JACKarc Operation Manual

Analysis Operations

5 - 3 Rev.4

Logging in to the Analyzer (as option)

Log in function is an option. For the configuration, contact local

distributor.

When Log in function is enabled, below screen will appear instead of

the Start Up screen after turning on.

To log in, touch each USER and PASS column. Then input User ID and

Password corresponding to the configuration from displayed key board.

Note that the input is case sensitive.

Current versions of programs

(Main, Control and Detect)

USER column

PASS column

HM-JACKarc Operation Manual

Analysis Operations

5 - 4 Rev.4

5.2.2 Preparing Detergent in the Wash Tank

The Detergent should be a 1:1000 dilution of Auto Detergent H.

When preparing the Wash solution, use purified water or deionized

water. Do not use water mixed with foreign substances or

contaminated with chemicals or tap water. Accurate analysis results

may not be obtained if the detergent is not prepared correctly.

When pouring detergent into the Wash Tank, take care to avoid

touching the tubes that enter the Wash Tank with your bare hands.

This Analyzer will stop sampling when the level of the Wash solution

becomes lower than a certain level. In that case, refill Wash solution

and touch Start on the screen to start sampling.

Caution

Medical rubber gloves

Wash solution (5L)

Wash Tank

Wash Tank

HM-JACKarc Operation Manual

Analysis Operations

5 - 5 Rev.4

5.2.3 Preparing the Waste Tank

This Analyzer will not stop when the Waste Tank becomes full. Be

sure to empty the Tank before starting analysis.

Waste should be handled as medical waste and disposed of by

recognized laboratory practices.

Waste in the Waste tank should be discarded.

Caution

HM-JACKarc Operation Manual

Analysis Operations

5 - 6 Rev.4

Reagent bottle

5.2.4 Preparing the Reagent

Set the bottle of EXTEL HEMOAUTO・HS Latex (referred to below as

"Reagent") in the Main Unit.

See "3.2 Part Names" for the names of the parts.

Read the Instructions for Use provided with the Reagent before

handling it.

Do not use Reagent that has expired, or under improper storage

condition or that is mixed with foreign substances or contaminated

with other chemicals. Accurate analysis results may not be obtained

if the Reagent is not prepared correctly.

Do not mix the Reagent from bottle to bottle in any case.

Setting the Reagent in place

Handling Precautions: Prepare sufficient volume of Reagent for the analysis to be performed.

1. Let the Reagent warm to room temperature, and then mix it well and

gently by repeated inversion.

Handling Precautions: Mix the Reagent by repeatedly inverting the bottle gently. If air bubbles

mix into the Reagent, accurate measurement results may not be

obtained.

2. Uncap the Reagent bottle and set the bottle in the Reagent Bottle

Holder next to the injection assembly.

Caution

Bottle Holder

Reagent Bottle

Reagent Bottle

HM-JACKarc Operation Manual

Analysis Operations

5 - 7 Rev.4

Handling Precautions: If measurement is not going to start immediately after the Reagent bottle

is set in the Reagent Bottle Holder, put the Reagent Bottle Lid on to

prevent evaporation (condensation) or contamination.

Open the Lid before starting measurement.

Setting Reagent volume

The Reagent volume must be revised when the Reagent Bottle is

replaced. To revise the volume, touch the Latex column and input the

volume of the Reagent from the numeric keypad.

1. Touch the Latex column. A numeric keypad will appear.

Reagent Bottle Lid

Latex column

Numeric keypad

HM-JACKarc Operation Manual

Analysis Operations

5 - 8 Rev.4

2. Using the numeric keypad input the Reagent volume (mL).

3. Press ENTER key to register. The number of available test count will be

calculated from the registered volume and displayed in the Latex

column.

:・The initial volume of each Reagent Vials is 18 (mL).

Note

HM-JACKarc Operation Manual

Analysis Operations

5 - 9 Rev.4

5.2.5 Preparing the Buffer

Set the bottle of EXTEL HEMO・AUTO Buffer (referred to below as

“Buffer”) in the Main Unit.

See "3.2 Part Names" for the names of the parts.

Be sure to read the Instructions for Use provided with the Buffer

before handling it.

Do not use Buffer that has passed its expiration date, kept under

improper storage condition or that is mixed with foreign substances or

contaminated with other chemicals. Accurate analysis results may not

be obtained if the Buffer is not prepared correctly.

Handling Precautions: Prepare a sufficient volume of Buffer for the measurement to be

performed. This Analyzer requires approximately 190ul of Buffer per

measurement.

1. Let the Buffer warm to room temperature, and then mix it gently by

repeated inversion.

Handling Precautions: Mixing of the Buffer should be done gently. If air bubbles mix into the

Buffer, accurate measurement results may not be obtained.

2. Open the Buffer Cover on the right side of the Main Unit.

Press and release the mark to open the cover, then lift it off.

Handling Precautions: The Buffer Cover is not hinged to the Main Unit. Handle the cover

carefully to avoid dropping it.

Caution

Buffer Bottle

Buffer Cover

Mark

HM-JACKarc Operation Manual

Analysis Operations

5 - 10 Rev.4

3. Uncap the Buffer Bottle and insert the Buffer Tube, which comes out of

the Bottle Head, inside the Main Unit into the bottle.

4. Insert the neck of the Buffer Bottle into the hole of the Bottle Head, then

lifting the Buffer Bottle together with the Bottle Head into the Main Unit,

set the bottle gently into its place.

5. Align the bottom of the Buffer Cover with the guide to attach it, and then

press on the mark to lock the cover to close it.

Right side of the Main Unit

Bottle Head

Buffer Tube

Buffer

Bottle

Right side of the Main Unit

Bottle Head

Buffer bottle

Right side of the Main Unit

HM-JACKarc Operation Manual

Analysis Operations

5 - 11 Rev.4

Handling Precautions: After setting or replacing a Buffer Bottle, touch the Wash icon on the

Main Menu screen to run a wash.

The Wash action removes air bubbles from inside the tube.

Do not touch the Buffer Tube by hand or Latex Glove to prevent

contamination of Reagent.

HM-JACKarc Operation Manual

Analysis Operations

5 - 12 Rev.4

5.2.6 Preparing the Reaction Cell

There are 40 Cells set in each Cell Cassette. Take a Cell Cassette out

of the package, and place it on the Cell Cassette Table. These

procedures are required every time when the Cells on the Cell Cassette

run out.

: Avoid touching the side-walls of Cells with bare hands or bringing

foreign object inside of Cell.

Use clean, new Cells. Accurate analysis results may not be obtained

if the Cells are soiled, scratched, or contaminated with other

chemicals.

1. Hold each Cell Cassette by its handle and align its groove on the

bottom to the rail on the center of the Cell Cassette Table. Then slide

the Cassette into place. The Cell Cassette Table has R and L sides, so

place a Cell Cassette onto the rail of each side.

2. Slide the Cell Cassette gently to the back of the Cell Cassette Table so

that their guide groove fit in the projections at the rear.

Pushing a Cell Cassette strongly could push it off position. Set the Cell

Cassettes gently.

3. Push the handle of each Cell Cassette down.

Push the handle of each Cell Cassette down gently until it stops. When

doing this, make sure that the Cell Cassette is fixed and not raised up.

Note

Handle

Groove

Cell Cassette

Guide

Groove

Projection

Rail

Cell Cassette Table

HM-JACKarc Operation Manual

Analysis Operations

5 - 13 Rev.4

In case the first picking up position is different, refer to 4.1.5 Cell Set for

setting the first position of picking up the Cell.

Correct positioning of Cell Cassette

HM-JACKarc Operation Manual

Analysis Operations

5 - 14 Rev.4

5.2.7 Registration of Master Curve and Calibration Card

Registration of Master Curve and Calibrator Card are required when

their lots are changed.

1. Touch the Calibration Curve icon to display the Calibration Curve

screen. (See 4.1.6 Calibration for reference)

2. Touch the Barcode button to display the Master Curve/Calibrator

Registration screen.

3. With above screen displayed, scan the barcodes.

When the Reagent lot is changed, register the barcodes on the Master

Curve card provided with the EXTEL HEMO・AUTO HS Latex in order

from the top. The Reagent lot number, the expiration date, and the Master

Curve parameters from 1 to 7 are input sequentially.

When the Calibrator lot is changed, register the barcodes on the Calibrator

Card provided with the EXTEL HEMO・AUTO HS Calibrator in order from

the top. The Master Curve, input data for Calibrators, lot number and

expiration date are input. (Refer to 5.5.1 Reading Barcodes with Handheld

Scanner)

Master Curve Card

Calibrator Card

HM-JACKarc Operation Manual

Analysis Operations

5 - 15 Rev.4

5.2.8 Preparation of Samples

○

It is mandatory to ensure results of Con

trol L and H are within

specified range provided by Instructions for Use of EXTEL HEMO

・

AUTO HS Control before proceeding with patient sample analysis.

Do not use the Calibrator that has expired, left uncapped, mixed with

foreign substances or contaminated with other chemicals. Accurate

calibration result may not be obtained if the Calibrator is not

prepared correctly.

Use new and clean Sample Cup. Using Sample Cup which is not

clean may cause incorrect result of calibration and control.

Definition of Racks

Racks are assigned exclusively to Calibrator, Control and Sample

Collection Picker. They can be identified with the colors and labels.

・White Rack with Red labels (STD) :for Calibrator

・White Rack with Yellow labels (CONT) :for Control

・Blue Rack :for Sample Collection Picker

・Green Rack(option) :for Adaptors with Cups

For Calibrator

For Sample Collection Picker

For Control

For Adaptors with Cups

HM-JACKarc Operation Manual

Analysis Operations

5 - 16 Rev.4

Preparation of Calibrator

1. Prepare the two concentrations of Calibrators and dispense the

necessary volume (200μ L as minimum) from the each vial into a

sample cup, using a pipette. Refer to Instructions for Use for how to

prepare Calibrators. Take care not to leave air bubbles inside the cup.

Handling Precautions: In case of using same pipette to dispense different concentrations of

Calibrators, take extra care to avoid cross mixing.

2. Set the cups containing the Calibrators into positions with red S1 and

S2 labels of the rack for measuring Calibrators. S1 is for Calibrator L

and S2 is for Calibrator H.

Handling Precautions: The cups with Calibrators cannot be identified visually. If they are placed

to wrong positions, correct calibration result cannot be obtained.

Preparation of Control

1. Prepare the two concentrations of Control and dispense the necessary

volume from the each vial into a sample cup, using a pipette. Refer to

The Instructions for Use for how to prepare Controls. Take care not to

leave air bubbles inside the cup.

2. Dispense the necessary volume (200μ L as minimum) of each, at

different concentration, of prepared Control solution from the vial into a

sample cup, using a pipette. When doing this, take care to leave no air

bubbles inside the cup.

Handling Precautions: When using the same pipette to handle Controls at different

concentrations, take extra care to avoid any cross mixing.

Rack with cups

HM-JACKarc Operation Manual

Analysis Operations

5 - 17 Rev.4

3. Place the cups with the dispensed Controls into positions with CL and

CH labels of the rack. CL is for Control L and CH is for Control H.

Preparation of Patient Sample

This Analyzer applies EXTEL HEMO・AUTO MC Collection Picker (or

Sample Cup as optional) as patient sample. Handle the Picker with

patient sample collected following the procedure below.

1. Check the sealing and orientation of the cap of the Sample Collection

Picker. Then mix thoroughly the buffer inside by repeated inversion.

After mixing, leave it with the cap at the bottom, so that any unexpected

bubbles rise to the top (the side opposite to the cap).

Handling Precautions: If bubbles remain at the bottom (the cap side) or midway in the Sample

Collection Picker, accurate measurement values might not be obtained.

If the seal covering the top of the Picker is exposed to possible

contaminant, accurate measurement values might not be obtained. In

this case peel the seal off before measuring.

2. Set each Sample Collection Picker to the Sample Rack with the cap at

the bottom and the sample barcodes of the Sample Collection Picker

face the side of the rack with rack ID.

Set all target Samples to the Rack in a correct way.

Handling Precautions: Set the Sample Collection Pickers securely in the Sample Rack and

push all the way down, taking care to avoid the barcode labels to be

turned up. Any damage, scratch or improper printing of barcode will

generate the barcode reading error.

Rack with cups

HM-JACKarc Operation Manual

Analysis Operations

5 - 18 Rev.4

Preparation of Cup Measurement Rack (option)

This rack is used to measure samples from Sample Cups. Set the

Adaptors (white blocks) on the Rack and place Sample Cups with

samples onto the Adaptors.

Replicate of individual Cup can be configured from 1 to 3 in Item

Parameter.

For manual mode, CUP needs to be chosen in attribution and the

position has to be selected to set the orders.

There is no special instruction required to Auto measurement mode but

Analyzer recognizes the Adaptor for presence of Cups. Remove the

unnecessary Adaptors prior to measurement.

Handling Precautions: If bubbles remain at the bottom (the cap side) or midway in the Sample

Collection Picker, accurate measurement values might not be obtained.

:The Adaptors should be placed with Cups with samples.

Rack barcode

Orientation of

sample barcode

Sample rack

Samples set on the Rack

Note

NG

(measured without

samples)

OK

(cups

measured)

OK

(not

measured)

Rack with Adaptors and Cups

HM-JACKarc Operation Manual

Analysis Operations

5 - 19 Rev.4

5.2.9 Loading the Racks to the Analyzer

After preparation of Calibrator and Control or Samples is complete,

Load the Racks to the Sample Tray.

■Rack Orientation

Racks must be loaded so that their Rack IDs can be seen from the front.

The notches fit into the Guide Plate of the Trays while they are

transferred towards.

■Loading Racks to the Analyzer

1. Loading Racks.

Place a Rack to the Handle side and slide so that the Notch fits into the