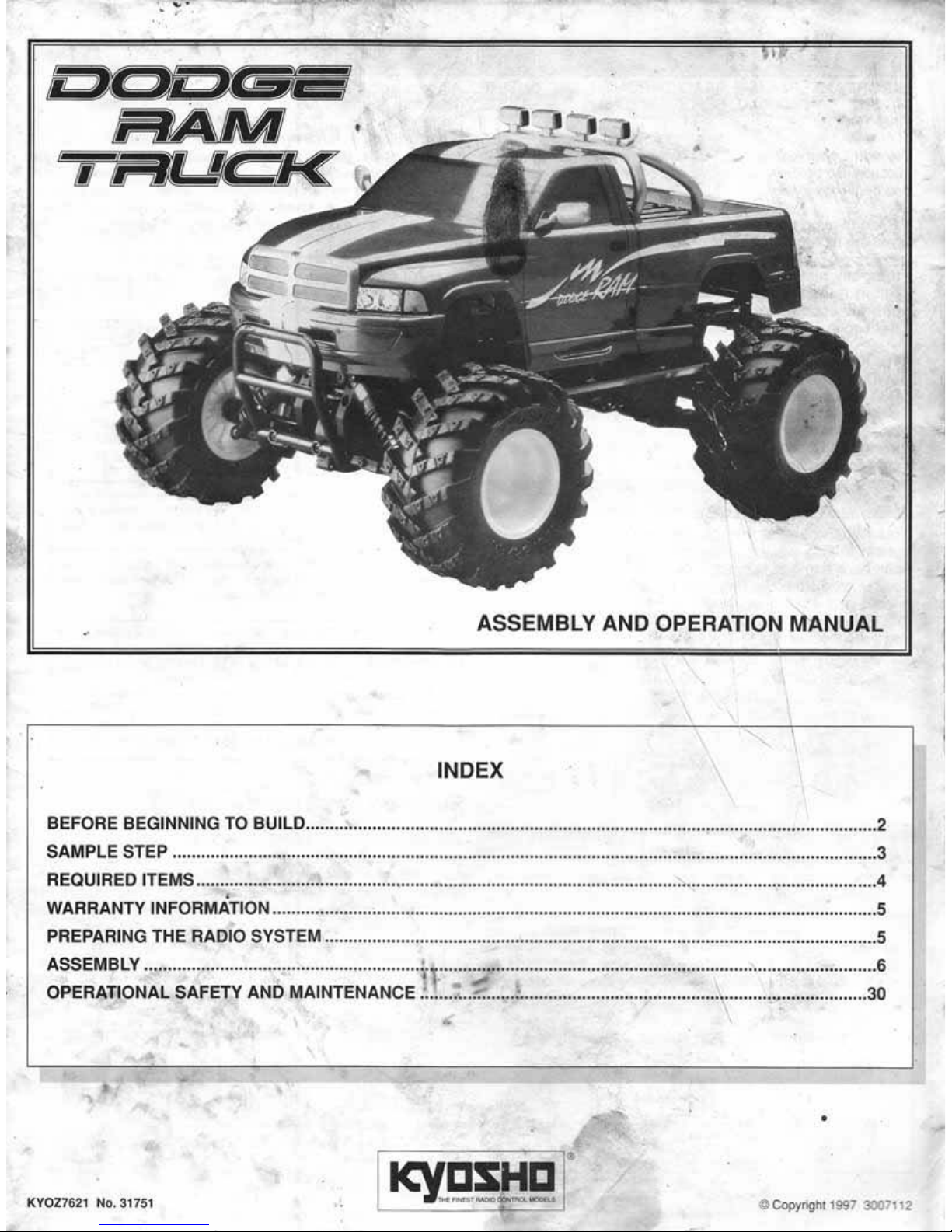

Kyosho dodge ram truck Assembly And Operation Manual

•

ASSEMBLY AND OPERATION

MANUAL

\ \

' I

INDEX

BEFORE BEGINNING TO BUILD ........................................................................................................................ 2

SAMPL.E s·TEP .................................................................................................................................................... 3

REQUIRED ITEMS ...................................................................... ........................................................................... 4

'

WARRANTY INFORMATION ............................................................................................................................... 5

PREPARING

THE

RADIO SYSTEM .................................................................................................................... 5

ASSEMBLY

···········································

·······

·····

···.fl····

···

-;;·

·················································································6

OPERATIONAL SAFETY AND MAINTENANCE : •.•....... ::: ..•... : ••.............................•.•....................................... 30

..

...

•

KYOZ7621 No. 31751

' .

c Copynghl 1997 3007112

•

IMP

ORT

ANT: PLEASE

READ

THROUGH THE

ENTIRE

INSTRUCTION MANUAL BEFORE BUILDING THE DODGE

RAM TRUCK.

We

want

your

experience

of

building

this

model

to be a

success. So before you remove any

parts from their packages

and begin assembly:

• Read through the entire manual carefully

to

make sure that

you are thoroughly acqualnled with the model.

•

II

lor

any reason you think this model may not be for you,

return It Immediately.

Please

Note

: Yo

ur

hobby dealer

cannot

accept a mo

del

kit

for return aft

er

assembly

has begun.

• The Kyosho Dodge Ram Truck is a sophisticated nitro-power

ed

4WD

monster

truck

with

a reversing transmission. Nitro-powered

RIC

vehicles are no more difficuH to build and operate than

electric RIC vehicles. They do require a

lew

different building

procedures than electrics. II you follow the directions closely,

the Kyosho Dodge Ram

Truck will provide many years

of

car

crushing enjoyment.

This

Kyosho

Instruction

manual

uses a cross-reference

system to help you locate all of the bagged parts. DO N

OT

open each bag and dump out the parts. Carefully remove the

header card from the bag a

nd

discard the staple. Slip the

header card into the bag or tape

it

to the outside of the bag so

that the bag number shows. This

will help you fi

nd

parts when

you need them.

REMOVE THE

HEADER

CARD

SLI

P CARD

I

NTO BAG

OR

TAPE

TO

OUTSIDE

PARTS IDENTIFICATION

A complete list of replacement and optional parts is included In

the pullout

section

of this manual. II you need to replace a

part, consult this guide f

or

the manufacturer

's

sto

ck

number

lor the

items

needed. In the left margin

of

each

page

of

instructions you will find a directory

of

small parts that will be

used in each step. For ease of identi

fi

cation, these parts are

shown actual

size, enabling you to place t

he

part directly

on

the picture to ensure you have selected the appropriate part.

Key Number

Part Name

Qua

ntity Used

2

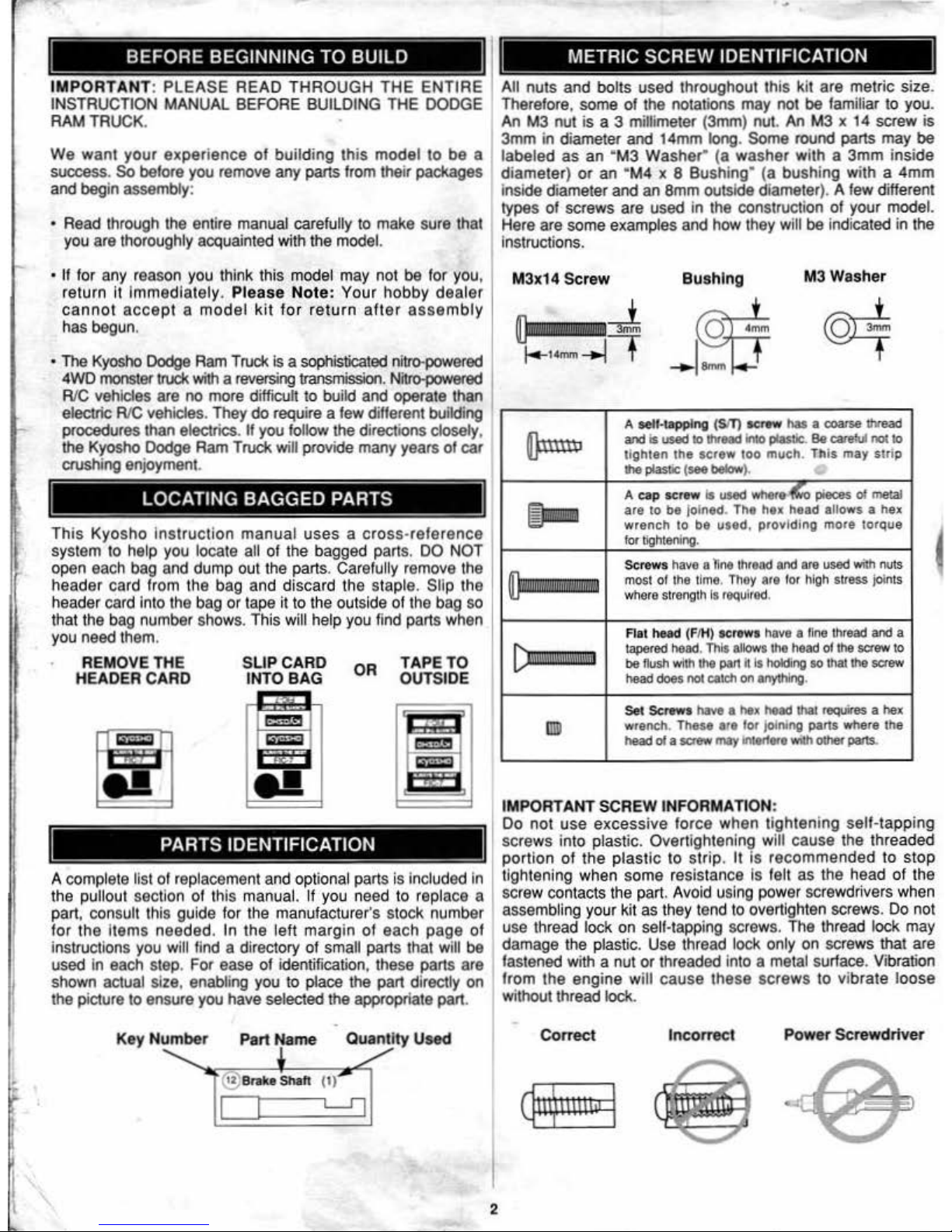

All

nuts

and bolts used throughout this kit are

metric

size.

Therefore, some

of

the notations may not be familiar to you.

An M3 nut

is

a 3 millimeter (3mm) nut. An M3 x

14

screw

is

3mm in diameter and 14mm long. Some round parts

may

be

labeled as an

"

M3

Washer" (a washer

with a 3mm inside

diameter) or an "

M4

x 8 Bush

ing'

(a bushing w

ith

a 4

mm

Inside diame

ter

and an Smm outside diameter). A few different

types of screws are used in the construction

of

your model.

Here are some examples and how they

will be indicated in the

Instructions.

M3x

14 Screw

Oa!NIIi!IMQIIM

Dfil!!b!!N!!!M!!!U!

d

Bush

ing

M3 Washer

A sell-tapping (SIT)

sc..w

has

a coarse

lh<oad

and

Is U$8d

10

lh<oad

Into pjaslic.

Be

care!\1

nolto

ti

ghten

the

screw

loo

much.

This

may

str

ip

lhe

JQ$1ic

(

see

below

).

A c:ap screw

Is

used

-•

pieces

of

melal

are to

be

joined. The hex head allows a hex

wrench to

be

used,

providing

more torque

for

tightening.

Screws

have

a line t

hread

and

are

used

with

nuts

most

of

the lime.

They

are

for

high stress join

ts

wtleca

strength Is

required

.

Rat head

(FIH)

scrowa

have a fine

thread

and

a

tlpllred

heed.

This

allows

the

head

of

the

screw

to

be

flush with the pan h Is holding

so

thai the

screw

head

does not

catCh

on anything.

Set Scrowo have

a hex head thai requires a hex

wrench. These

are

for

J

oinJ~

pans

where

the

head

of

a

screw

may

lnle<toro

with other pans.

IMPORTANT SCREW INFORMATION:

Do not

use

excess

ive

force when tightening sell-tapping

sc

rews into plast ic. Overtightening will cause the threaded

portion

of

the plas

tic

to

strip

. It

is

rec om

mended

to

stop

tightening when some resistance

Is felt

as

the head of the

screw contacts the part. Avoid using power screwdrivers when

assembling your kit as they tend to overtighten screws. Do not

use thread lock on self-tapping

sc

rews. The thread lock

may

damage the plastic. Use thread lock only

on screws that are

fastened with

a nut

or

threaded into a metal surface. Vibration

from

the

engine

will

cause

these

scre

ws

to

vibrate loose

without thread lock.

Correct

Incorrect

Power

Scre

wdriv

er

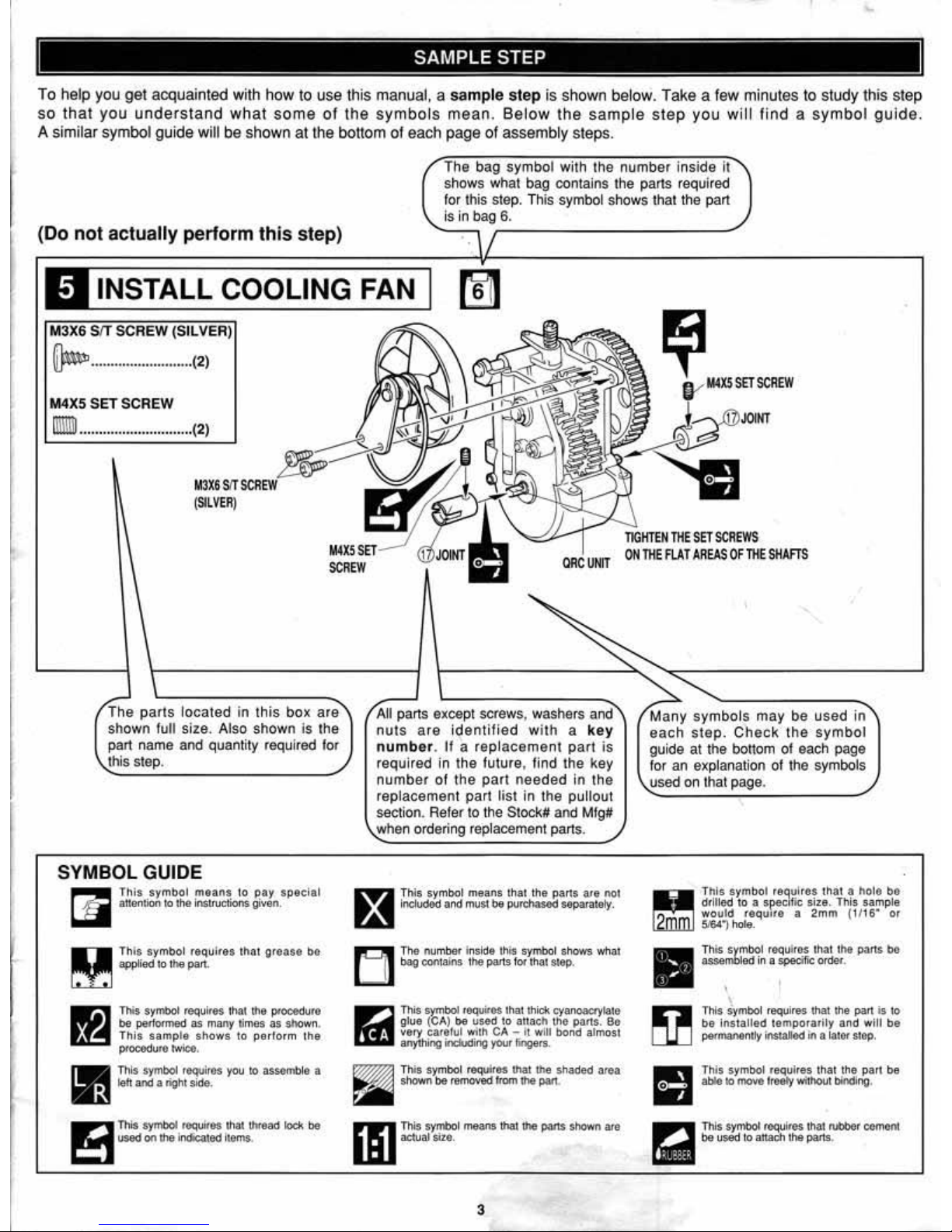

To he

lp

you get acquainted wi

th

how

to use this manual, a

samp

le

step

is

shown below. Take a few minut

es

to study th

is

step

so that

you

understand

what

some

of the symb

ols

mean. Be

low

the

samp

le

step

you

will find

a s

ymb

ol

guide

.

A

similar

symbol guide will be

shown

at

the bottom

of

each

page

of assembly steps.

(Do

not

actu

ally perform

thi

s step)

The bag symbol with the numb

er

insi

de

it

sh

ows

what bag oontains the parts

required

for this step. This symbol shows that

the

part

is

In

bag

6.

,-

--

-------------/

INSTALL COOLING FAN

M3X6

SIT

SCRE

W (SILVER)

~

.......................... (2)

M4X5

SET

SCREW

ll1ll11J

............................. (2)

M3X&

SIT

SCREW

(SI

LVER

)

The parts located

in this

box are

shown

fu

ll

size. Also shown

is

the

part name and qu

an

tity requi

red

for

this step.

SYMBOL GUIDE

~

Th

is

symbol means

to

pay special

~

attention to the Instructions given.

D This symbol requires thot grease be

m applied 10

the

part.

This symbol requires that the ptooeduro

be

perlormed as many times as shown.

This

samp

le

shows

to

perform the

ptOOOduro

twice.

-

This

symbol !&quires

you

to

assomb

le a

111,3

left

and

a right side.

All parts except sctews, washers and

n

uts

are ident

ifi

ed w

ith a key

number. If

a rep lacement

part

is

required in the future, find the key

number of the part needed

In the

replacement part

li

st

in the pullout

section. Refer to

the

Stock# and Mfg#

w

hen ord

ering replacement parts.

m

Th

is symbol

means

that

the

pans

are

no1

m

includOd

and

must

be

purchas.od

separatoly.

A The number inside this symbol shows whaJ

1-!J

~

con1ain~

t

he:

paris for that step.

This symbol roq

uifOS,

that thick cyanoacrylate

g.

lue

(CA)

be

u"Sed

to

auach

lhe

part$, sc

very

carelut

with

CA

- h

wil

l bond al

mo$1

anything incfuding your fingers.

This

symbol req

uires

that

the shaded area

shown

be

""""""

from

<he

pao.

Ill

This

syrri>ol

means

that the

p;II1S

shOwn

arc

actual

s1zo.

3

TIGHTEN

THE

SET

SCREWS

ON

THE FLAT

AREAS

OF

THE

SHAFTS

Many symbols may be used in

each

step.

Check the

symbol

guide at the bottom of each page

for

an

explanation of t

he

symbols

used on that page.

Th

is

sym

bol requhos

that a ho

lo

bo

drilled

to a spec•flc

size. This

sample

would requ

1t0

a

2mm

(1/1

6.

or

51641hote.

II

Th

is

$ymb01

r&quiros

tha

t t

he

parts

bO

assembled

in a specific order.

' I

This symbol requires that the

part

is to

be i

ns

talled

temporarily

and will

be

pori'I"'M8ntly inslalled

in

a

to:~tor

step,

- This

symbol requires that

the pan

be

1111:1

abl& ~ move fre

ely

v.iltiOut

binding

.

P.J

This

symbOl roqultOS that tubber cement

-

be

used

to attaoh the parts.

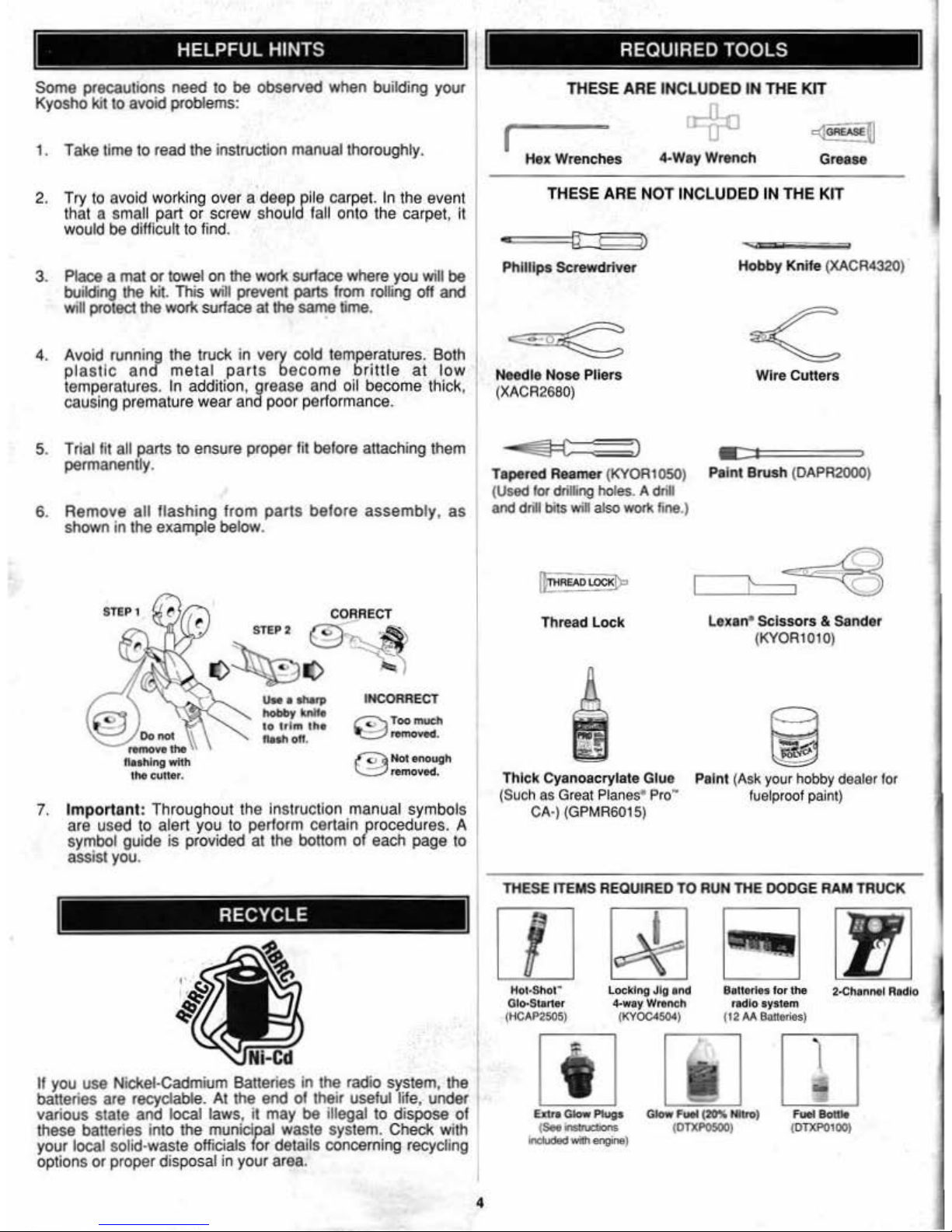

Some precauti

ons

need to

be

observed when building your

Kyosho

kit

to

avoid

problems:

1. Take time to read the instruction manual thoroughly.

2.

Try

to avoid working over a deep pile carp

el.

In

the

eve

nt

that a small part

or

screw shou ld fall onto t

he carpel, it

would

be

difficu

lt

to find.

3. Place a mat

or

towel

on

the work surface where you will

be

building

the

kit. This will prevent parts from rolling off and

will protect the work surface

a1

the

same

time

.

4. Avoid running the truck in very cold temperatures. Both

plastic

ancf meta

l parts

become brittle

at

low

temperatures. In addition, grease and oil b

eco

me thick,

causing premature w

ear

and

poo

r performance.

5. Trial fit

all

parts to ensure proper fit before attaching them

permanently.

6.

Remove

all

flashing

from

parts

before

assembly, as

shown in the examp

le

below.

STEP 1

®

Oono4

I

remove

the

1\

flashi

ng

with

l

ht

ev"er

.

UN

llhii'P

hobby Mite

to

trim

the

flllhoH

.

INCORRE

CT

~

Too

much

~.-.moved.

~

Not

enough

\...=;:/removed.

7.

Important

: Throughout the instruction manual symbols

are used to alert you to perform certain procedures. A

symbol guide is provi

ded

at

the bottom

of

each page to

assist you.

If you

use

Nickel-Cadmium Batteries in the radio system , the

batteries are recyclable.

At

the

end

of their useful life, under

various state

and

local laws, it

may

be

illegal to dispose

of

these batteri

es

into the municipal waste system. Check with

your local solid·waste officials for details concerning recycling

options

or

proper

dis

posal in your area.

4

TliESE

ARE INCLUDED

IN

THE KIT

c@§]l

(

Hex

Wrenches

4-Way Wrench

Grease

THESE ARE NOT INCLUDED

IN

THE

KIT

-

Phillips Screwdriver

Needle

Nose Pliers

(X

ACR2680)

~

:)

Tape

red

Reamer

(KYOR1050)

(

Used

for

dri!Dng holes. A drill

and dnll bits win also worl\ fi

ne

.)

IF

•EAD

LOCK[l:o

Thread Leek

Thick Cyanoacrylate Glue

(Such

as

Grea

t Planes•

Pro

·

CA

·) (GP

MR6

015)

.......

.

Hobby Knife (

XACR4320

)

Wire Cutters

• •

Paint

Brush (DAPA2000)

Lexa

n'

Scissors & Sander

(KY0Rt010)

Paint

(Ask

your hobby dealer

for

fuelproof p

aint)

TH

ESE ITEMS REQUI

RED

TO

RUN

THE

DODGE RA.M TRUCK

,

Hot-Shot"

Glo-S

tarter

(HC

AP250S

)

locking J

ig

and

4·way Wrtneh

(KYOC4504)

Extra

Gaow

Pl~s

(

SOo

..............

InCl

uded

Mh

engine)

Ballo

rte

s tor the

2-Chcmntl R

adi

o

radio

system

(1

2M

Batt&ri&s)

full8ottlt

(

OTXPOIOO

)

WARRANTY INFORMATION

-

--

•

For

90 days after

you

purchase

your

OOOGE

RAM

TRUCK.

Kyooho

will eith

er

rep:tlr

or

replaCe,

at

no

chrugo.

any

inoorr

OC11y

made

part

.

•

Make

"'re

you

SAVE

THE

RECEIPT

OR

INVOIC

'E you wert givvn

when

you

bough!

,.,... ,_,

11"1

,.,... proof

of

.,...-

•

and

we

"""t

oee ft bolore

we

ean

honor

me

w

3IT'IJI'tri

.

To

oond

Y'OUf

~Rom

Trud<

0\lor ._...-eel under

wwrar«y.

you

shoiAcl

send

your

truck

to

Ky

01110"o1Wtllotlzed

U.S. r.pair lacllly:

Hobby

So.vl*

1610 Intersta

te

Drive

Chin1>aign

. -

6t82t

Ml.SeMco~

Pnot>e

: (2t7)398-0007 9;

00..,._. 5:00• ....

Centrall'lmeM·F

For

detai

ls

on

your

telurn,

be

sure

to follow steps

1·4

under

tho

~Repa

ir

Sttvlees

Available

Anydme·

section.

Umh

of

01"

LlabMity

:

OUr

~

..-

tllio

Wlllfa/ty

Is

liritAod

10

the

repair

or

replacemerd

by

Hollby

SoMces of

defeetMO

patti

and

does

noc

1nc1u<1e

cos! ol

shipping

to

uo.

Hobby

Services

does

pay

!he

&hlpl)ing

expense

to"''"'"

warranty

items

to

you.

Ex

clu

sion

and/or

Voida

nce of

Warra

nty:

Th

is

warranty

doe$

not apply

to

damago

or

detects resulting

hom

misuse

.

- service.

damage

in

$hipmenl.

dalnlge

resulling

from

a

cnsh

01

damage

coiJSOd

by

the

banorieo.

The

warramy

Is

Wild

d

the

modol

ls

-.

allered

. 01

ropalrwcl

by

anyone -

111an

.-,.

SoMcos.

This

warranty

giws

you

spec

mc

legal

riGhts. and

you

may

have

ott'ler

rights

11\at

vary

from

state

to

&tate-

within

lhe

U.S. We are

sorry,

but

wo

cannot

be

responsib

le

for

crash dam

age and/o

r

resutdno tos.s

of

lhe truck.

onglne. radio. acce,SOl

les.

etc

.

Rep•lr

Seorvlcea

Available

AnytiiTlt':

After

1ho

904af

wam~nty

ho$

t>q>lrod,

you

can

s~

ll

hovo

your

Dodg

e Rllm

Truck

repaired lor a

lmal

chatgo

by

the

OJqlerts

at

Kyosho'& authorized U.S.

repa;r

ladlty

. Hollby

5eMces.

01

the

oddfe&&listod

under W""""'Yinlormalion.

•

To

speed

up

1ho

repair

procosa. please

follOw 111o

in&lrueli

o"' lslod

belOw

:

1.

Under

all

clrcums

tanoes. r&tum the ENTIRE

system

:

truck

and radio

.

2.

Make

su

re lho

transminer

is

wmod

oft

and

a1

baUOfles

are

d'osconnodod.

and

alluel

io

-!rom

lhe ,.,.,..,.,._

3.

Send

wriuen lnllr

uctfons wh

lch

include

: a list of

all

items

returned. a

THOROUGH explan'a.tion

ol the

prOblem

and tho

a.erv

iee

needed, and

your

phone

number

whefe

you

can

be r

eached

during

the

day.

II

you

expect

you

r

repa

ir

10

be

covered

under

warranty, be

sure

to

include

proof

of

date

of

purchase (your

51<>fe

,.,.,.,.,. « purcho5e

involc:e

).

4.

A/sQ-

yoour

lui

return

add<

....

Repa

ir ch<lrg"

and

postage

may

be

prepaid

or

billed C.O.D. All r

ep;ol

rs shipped

outside

the Unltod

States

must

be

prepaid

In U

.S. funds only.

Spedllcotlon

'""

DHaiptlon

Chango&

All pidutos, doscr1piJons

and

specillcalion$ lou>d 0\

tllio

inslruc1oon

manual

are

subiect

to

change without notice.

Kyosho

ma

ln~al

ns

no

responsibili

ty for

inadverte

n1

&f'rors

In

t.his

manu

al

• ,

----------·

------------------------------------ -------------------

~

a 4·

AA

Batteries

n Receiver

-

SWitch

Receiver Ba«ery Hold

er

fJ

Anlenna

Transmitter

8·AA Batteries

Servo

Arm

R

e<;eiver

Steering

Servo

IJ

II

lhe

servo

arm

Ia

no~

in

the

neutral

Pos

lli

on,

remove

the

scre

w

holding 'h,

lih

up

on

the

servo

arm

. and

relnslall

h in the

COtTlld

position.

.•

CORRE

CT

INCORRECT

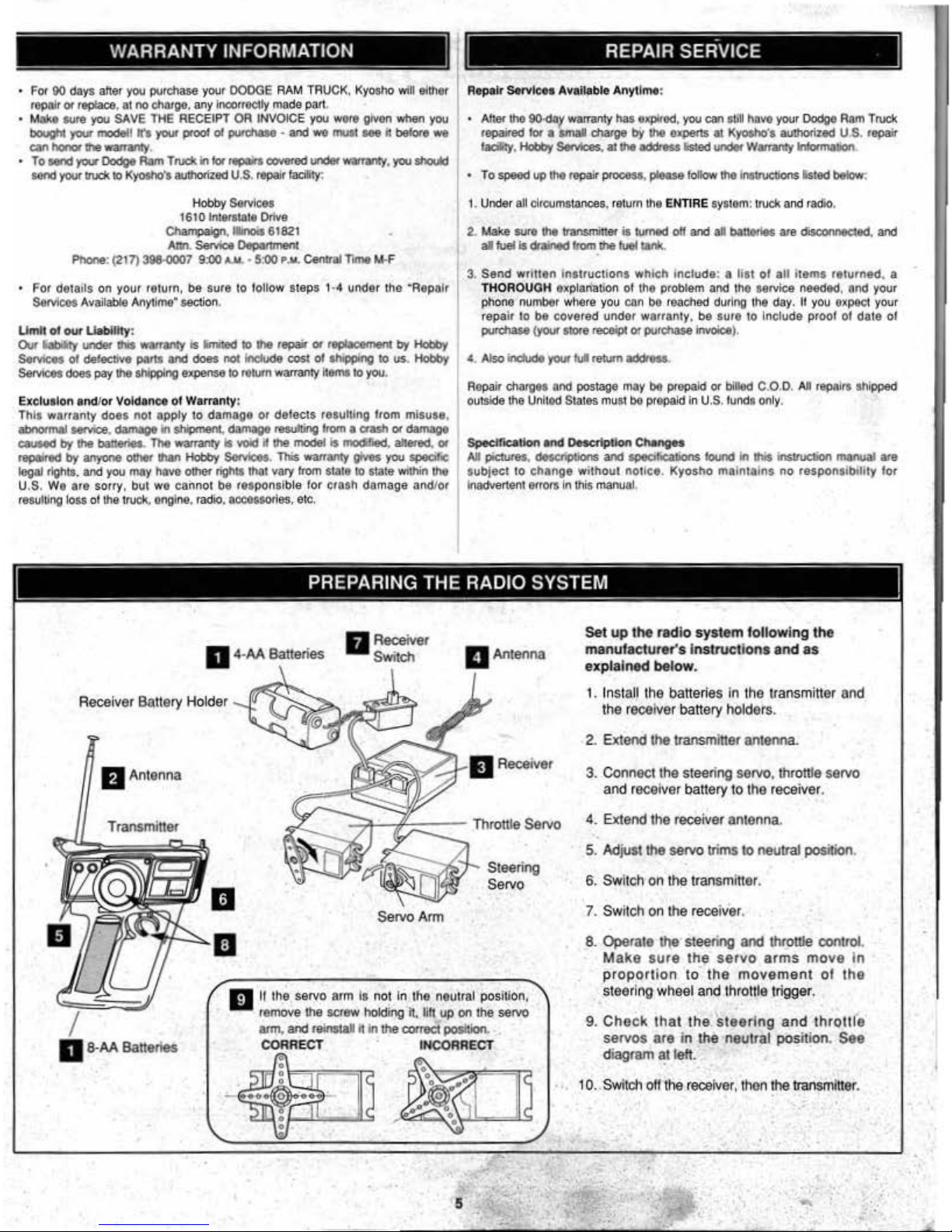

Set

up

the

radio

system following

the

manufacturer's

Instructions

and

a.s

explained

belo

w.

1.

Install the batteries In the transmitter and

the

receiver battery holders.

2. Extend the ttansmiher antenna.

3.

C<l

nnee1

the steering servo. throttle servo

and

receiver battery to the

re<:eiver

.

4.

Extend the receiver

antenna

5. Adjust

the

servo trims

to

neullal position.

6. Switch on lhe lransmltter.

7. Switch on

lhe

receiver.

8. Operate

tile

steering and throttle control.

Make sure

the

servo

arms

move

in

proportion

to

the

movement

ol

the

. steering wheel and throtlle trigger.

9.

Check

that

the steering

and

throtlle

servos

are

in

the

·neutral

position. See

diagram

at

left.

1

o.:

Switch

off the receiver, then the transmitter .

•

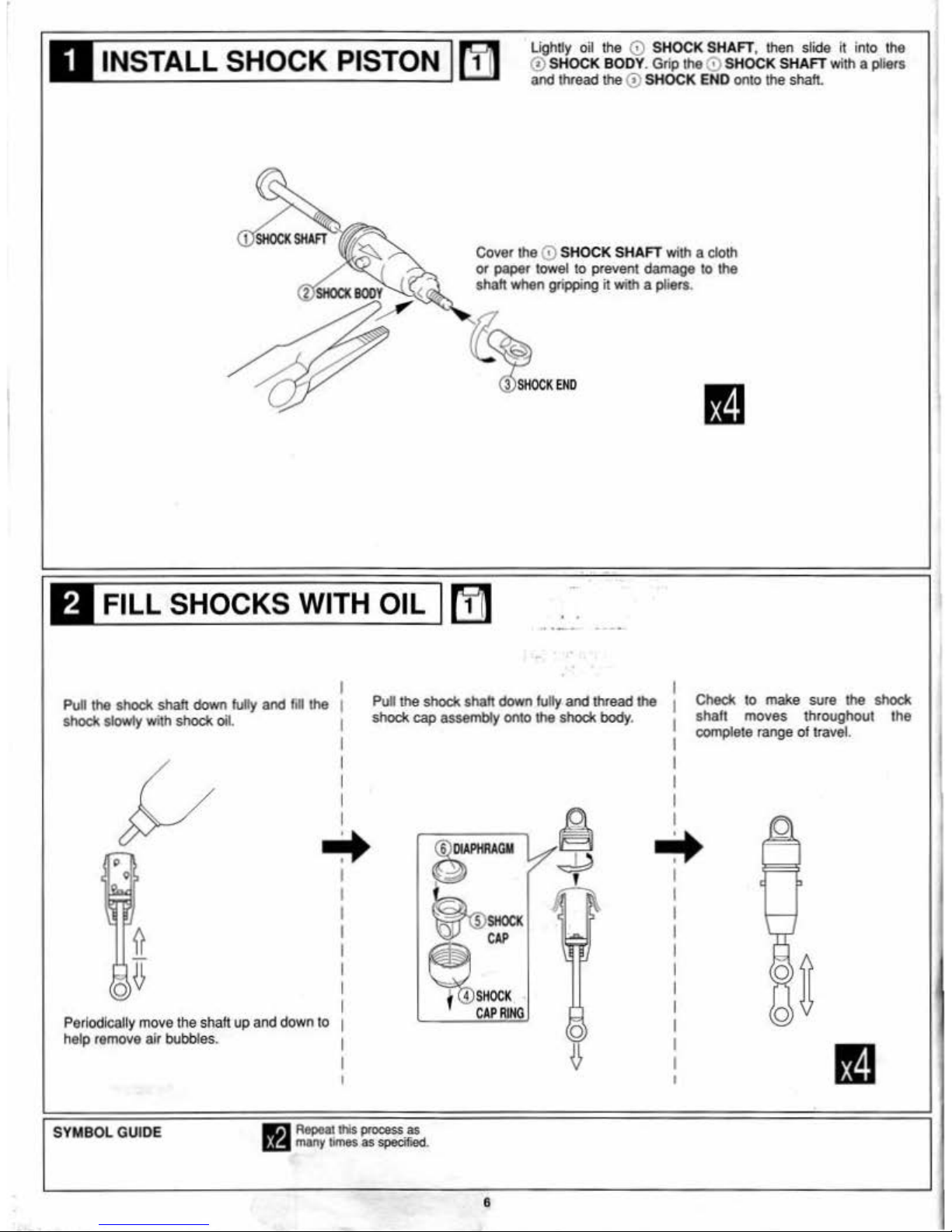

IJINSTALL

SHOCK PISTON I

[!J1

Llghdy oil the 0 SHOCK SHAFT, then slide it into the

<!)SHOCK BODY.

Grip

the0 SHOCK SHAFT with a

pliers

and

thread the

<!)

SHOCK END onto the shalt.

Cover the 0 SHOCK SHAFT with a cloth

or

paper towel to prevent damage to the

shah when gripping

it

with a pliers.

FILL SHOCKS WITH OIL

(!jl

• •

I

Pull the shock

shalt

down

tuly

and

fin

the 1

shock

slowly

with

shock oil. 1

I

I

I

I

I

-

I

Pul

the shock shah down

fully

and

thread the 1

shock cap assembly onto the

shock

body

.

1

I

I

I

I

I

Checl<

to make sure the shock

shaft

moves

throughout the

complete range

of

travel.

...

...

Periodlcall'y move the shah up and down to

help remove air

bubbles.

SYMBOL GUIDE

llil

Ropoatlhls process as

~if!

many

times

as

specified.

0

8

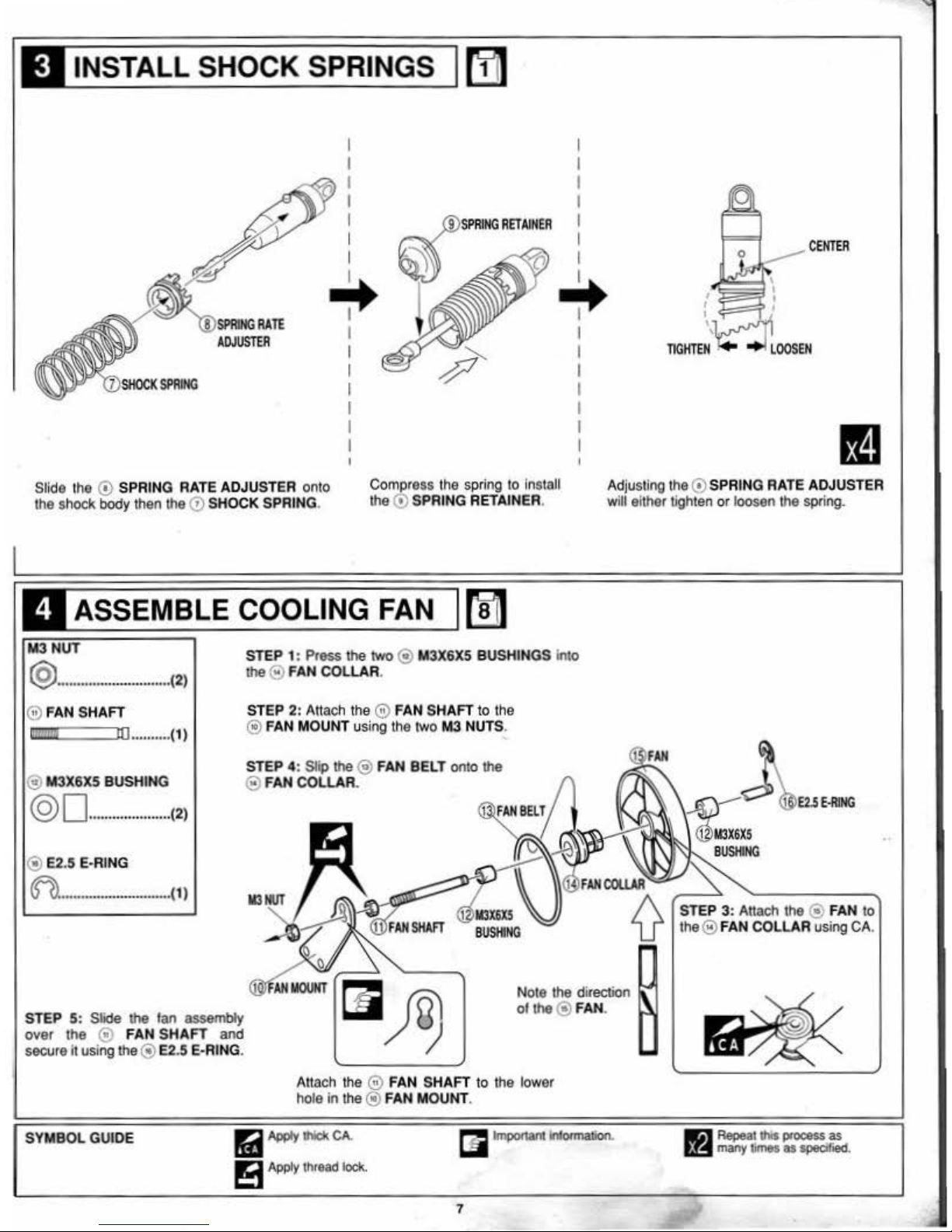

INSTALL SHOCK SPRINGS

[!J1

I I

I

I

I I

I I

I

I

I

I

CENTE.R

I I

~ ~

RATE

I I

ADJUSTER

I

I

I

I

I I

SI'RING

I

I

I I

I I

I I

Slide the

(!)

SPRING RATE ADJUSTER onto

the shock

body

then

lhe

0 SHOCK SPRING.

Compress

the spring

lo

Install

the

(!)

SPRING RETAINER.

Adjusting t

he

(!)

SPRING RATE ADJUSTER

will

e~her

tighten or loosen the spring.

ASSEMBLE COOLING FAN M

@

..............

..........

........

(2)

@ FAN SHAFT

c '

ru

..........

(1l

@ M3X6X5 BUSHING

@0

.....................

(2)

@ E2.5 E·RING

~o

ooooonoouoooo•ooooo.o.,ooo(

1 )

STEP 5: Slide lhe tan assembly

over

the

@ FAN

SHAFT

and

secure it using

lhe

® E2.5 E-RING.

STEP

1: Press

lhe

two

@ M3X6X5 BUSHINGS Into

lhe@ FAN COLLAR.

STEP

2: Altach the 0 FAN SHAFT to the

@ FAN MOUNT using the two

M3

NUTS.

STEP 4: Slip lhe@ FAN BELT onto lhe

@ FAN COLLAR.

Note the direction

ollhe

@ FAN.

Attach the 0 FAN SHAFT

to

lhe low

er

hole

In

the @ FAN MOUNT.

SYMBOL GUIDE

ra

AWY

-

CA.

!':t

Apply

thread

loc

k.

7

STEP 3: Attach

lhe

@ FAN

to

the@ FAN COLLAR using CA.

a

Repeat

lhis

-·as

t,;r:t

many

times

as

specified.

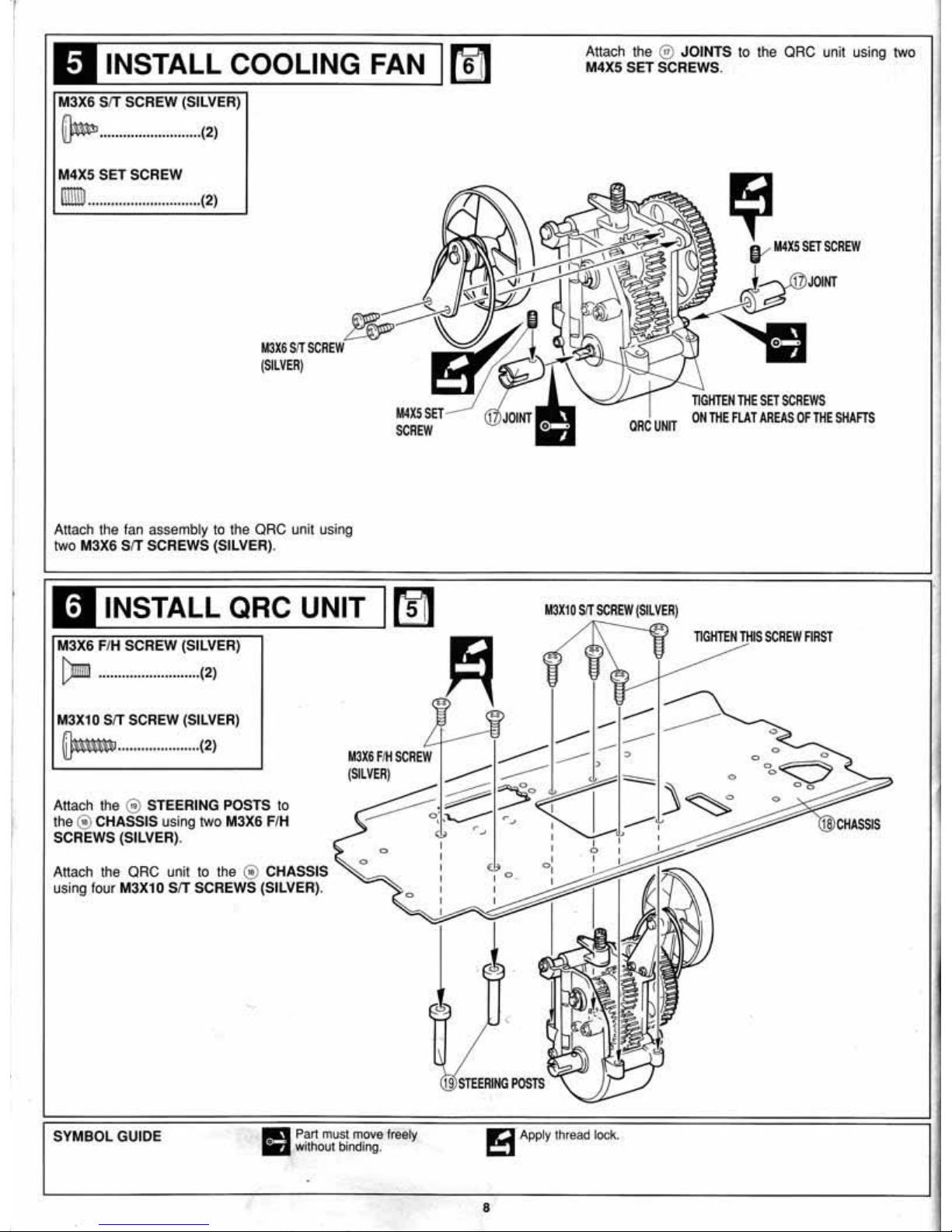

INSTALL COOLING FAN

(!jJ

Attach the

@>

JOINTS

to the QRC unit using two

M4X5

SET SCREWS.

M3X6 SIT SCREW (SILVER)

~

......................... . (2)

M4X5 SET SCREW

lllill1l

.............................

( 2)

Attach the fan assembly

to

the QRC unit using

two M3X6

SIT SCREWS (SILVER).

INSTALL QRC UNIT

rfl1

(::mm'a

..........................

(2)

M3X10 SIT SCREW (SILVER)

p

...

..................

(2)

Attach the @ STEERING POSTS to

the @ CHASSIS using two M3X6 F/H

SCREWS (SILVER).

M3X6 FIH

SCREW

(SILVER)

Attach the QRC unit to the @ CHASSIS

using four M3X10 SIT SCREWS (SILVER).

SYMBOL

GUIDE

Pa

rt

must move

fre

ety

w

ithout

binding

.

TIGIITEII

TilE

SET

SCREWS

ON

TilE

FLAT

AREAS

Of

THE

SHAFTS

1!!3

Appl

y lhread l

ock.

8

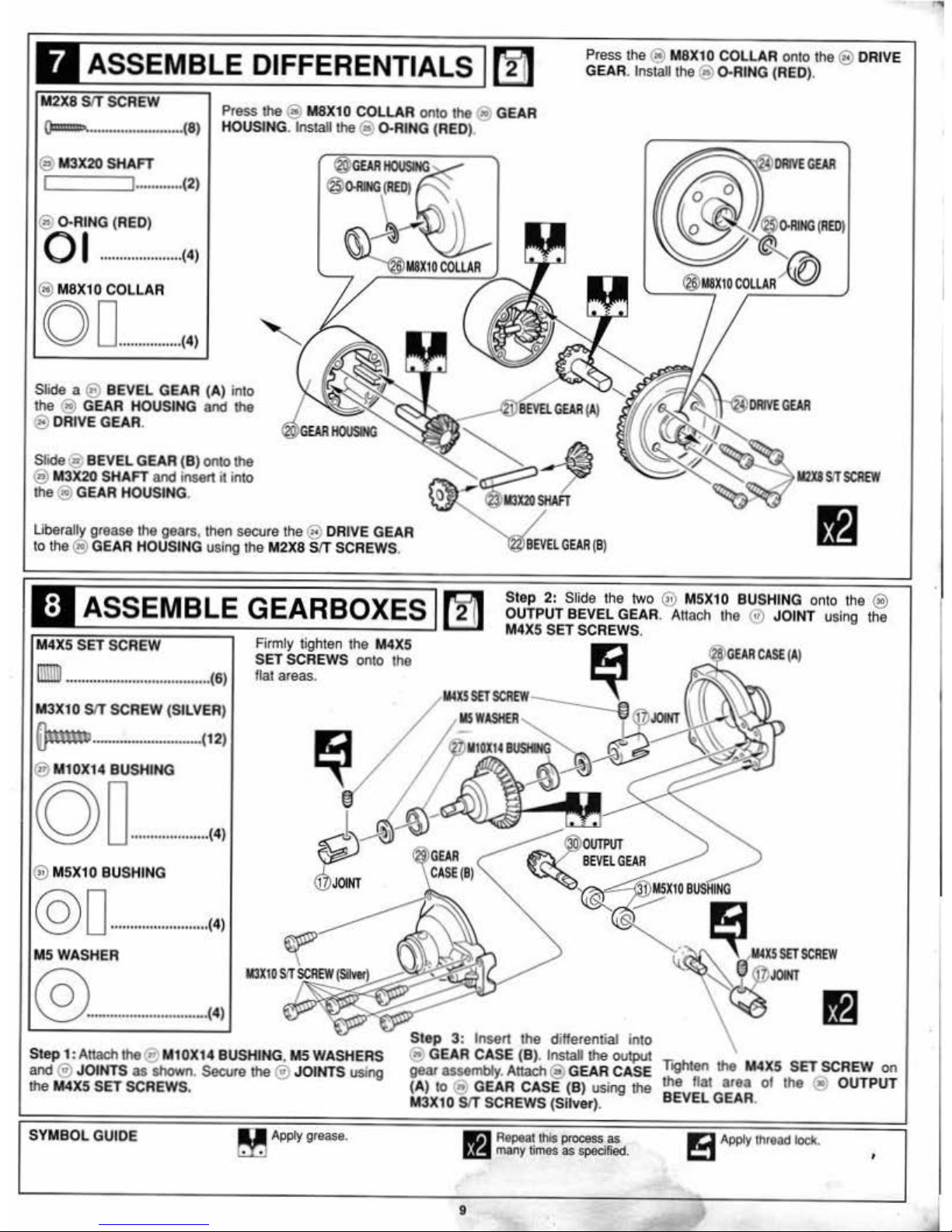

ASSEMBLE DIFFERENTIALS

~

Press the @

M8X1

0 COLLAR onro the @ DRIVE

GEAR. Install the@ D-RING (RED).

0

ffilf!!!!·

..........................

. (8)

@ M3X20 SHAFT

............. (2)

@)

D-RING (RED)

0 I

.....................

(4)

@ M8X10 COLLAR

0 0

................

(

4)

Press the @ M8X10 COLLAR onto the @ GEAR

HOUSING. lnslall the@ ().RING (RED).

Slide a @ BEVEL GEAR (A) into

the

@ GEAR HOUSING and the

@ DRIVE

GEAR.

Slide@ BEVEL GEAR (B) onto the

® M3X20 SHAFT and insert it into

the @ GEAR HOUSING.

Ube

ra

lly grease

the

gears. then secure

the® DRJVE

GEAR

to

th

e@ GEAR HOUSING using the M2X8

SfT

SCREWS.

ASSEMBLE GEARBOXES M

Step 2: Slide the two @ M

5X1

0 BUSHING onto the @

OUTPUT BEVEL GEAR. Attach the @ JOINT using the

M4X5

SET SCREWS.

lilliiil

......

.....

....

0

......................

( 6)

M3X10

SfT

SCREW (SILVER)

~

............................ (12)

@ M10X14 BUSHING

co

0

....................

(4)

@ M5X10 BUSHING

@ 0

.........................

(4)

M5WA

SHER

@

.....................

.

........

(4)

Firmly tighten the M4X5

SET SCREWS onto the

flat areas.

Step

1:Attachthe

@ M10X14 BUSHING,

M5

WASHERS

and® JOINTS

as shown. Secure the ® JOINTS using

the M4X5

SET SCREWS.

Step

3:

Insert the differential into

@ GEAR CASE (B). lnslall the

output

gear assembly. Attach@ GEAR CASE

(A) to

@ GEAR CASE (B) using the

M3X10

SfT

SCREWS (Sliver).

SYMBOL GUIDE

Apply

grease

.

9

Repea

t t

his

proeess

as

many times as

spedfled.

Toghten

the M4X5 SET SCREW

on

the flat area ot the

<!!;

OUTPUT

BEVEL

GEAR.

!3

Apply

thread

lock

.

'

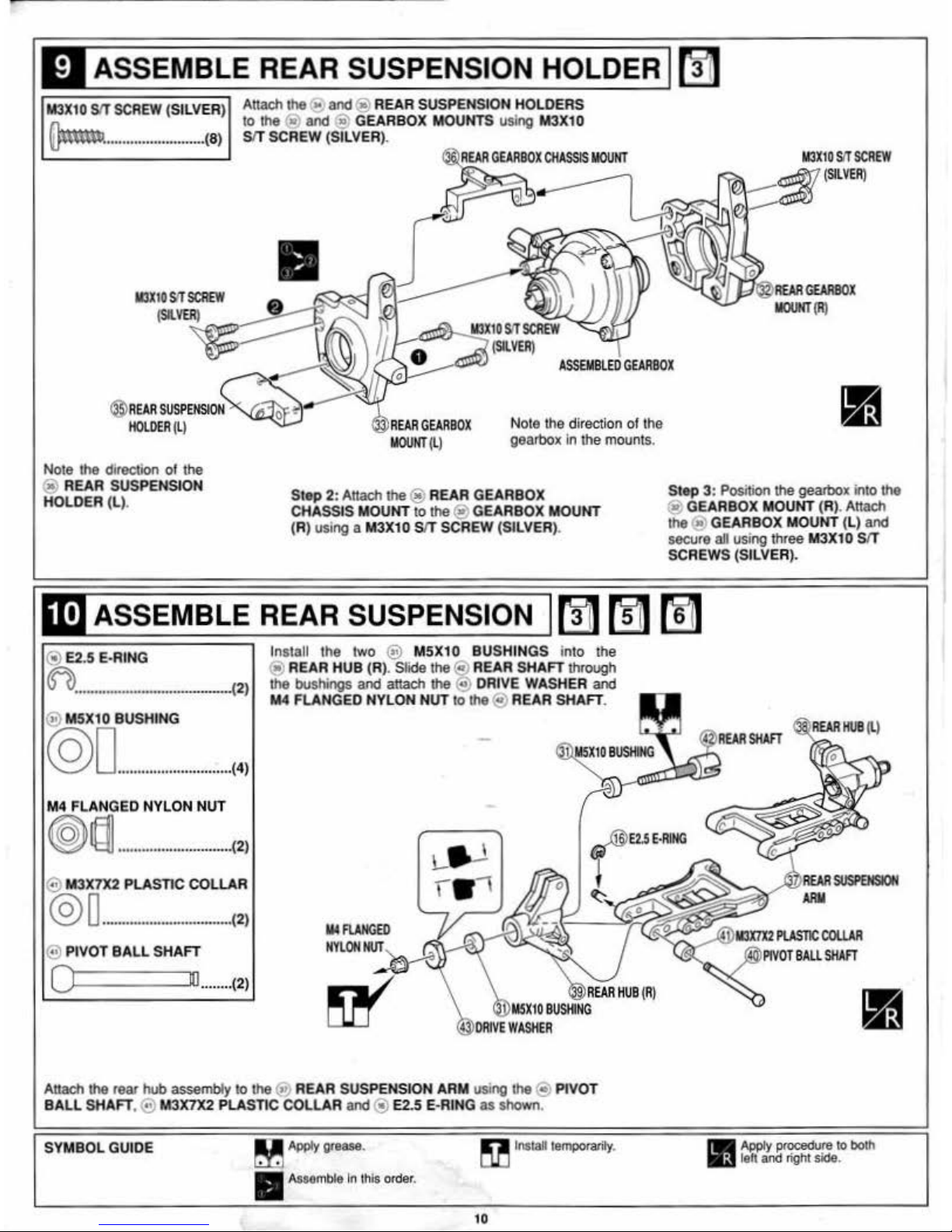

ASSEMBLE REAR SUSPENSION HOLDER

riJ1

M3X10

SIT

SCREW

(SILVER) Attach the " and@ REAR SUSPENSION HOLDERS

(1..-.

lo

lhe

@)

and @ GEARBOX MOUNTS using M3X10

llJ'"'""·

.......................

..

(8

) SIT SCREW (SILVER

).

113X

I D

SIT

SCREW

(SILVER)

II

•

113X

tD

SIT

SCREW

~(

SILVER

)

REAli

GEARBOX

IIOUHT

(R)

ASSEMBLED

GEARBOX

Nole lhe direction

of

the

® REAR SUSPENSION

HOLDER

(L).

Nole l

he

direction of

lhe

gearbox In lhe

mounls.

St

ep

2:

AHach

the® REAR GEARBOX

CHASSIS MOUNT

lo

lhe

® GEARBOX MOUNT

(R) using a M3X10 SIT SCREW (SILVER).

St

ep

3:

Position

lhe

gearbox into lhe

@ GEARBOX MOUNT (R). Attach

lhe

@1

GEARBOX MOUNT (L)

and

secure all using three M3X10 SIT

SCREWS (SILVER).

ASSEMBLE REAR SUSPENSION M

r!jJ

M

@ E2.5 E·RING

~

..........................................

.....

(2)

@ M

SX10

BUSHING

©0

..............

...............

(4)

M4 FLANGED NYLON NUT

@

1§1

.................

....

........

. (2)

@ M3X7X2 PLASTIC COLLAR

@ 0

....................

.

............

(2)

@ PIVOT

BALL

SHAFT

0

111

........ (2)

lnslall

lhe

two @ MSX10 BUSHINGS

inlo the

10)

RE.AR HUB (R). Slide the@ REAR

SHAFT

lhrough

lhe

bushings

and attach lhe @ DRIVE WASHER and

M4

FLANGED NYLON NUT

to

lhe

@ REAR

SHAFT

.

~

15XtD

BUSHING

Attach the rear hub assembly

lo

the@ REAR SUSPENSION ARM using the @ PIVOT

BA

LL SHAFT,@ M3X7X2 PLASTIC COLLAR

and

@ E2.5 E·RING

as

shown

.

SYM

BOL

GUIDE

M

AW:t

gtease.

~

Install

temporarily

.

A

sMmble

In this ord

er.

10

Apply

procedure

to

both

left

and

right side.

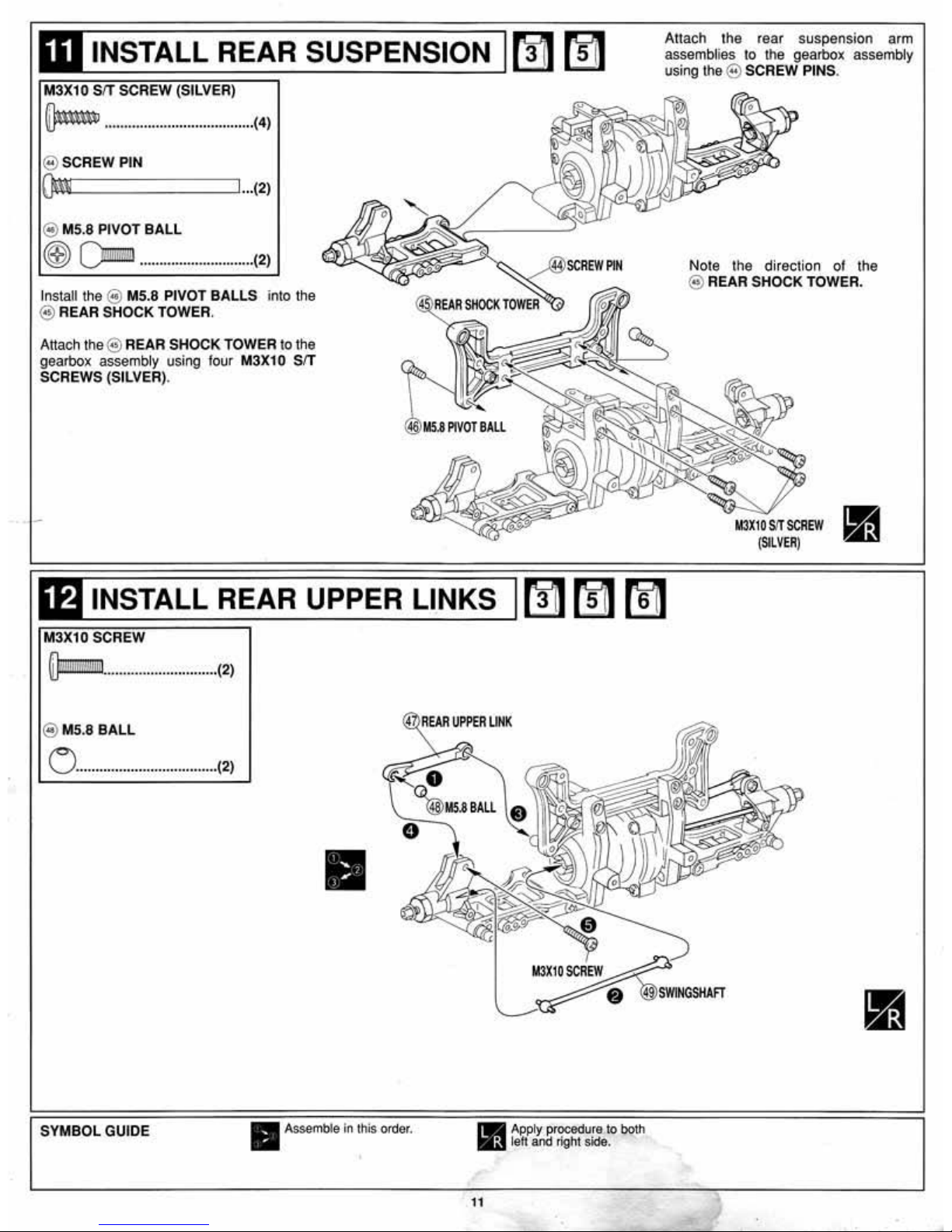

M3X10 SIT SCREW (SILVER)

~

........................................ (4)

@ SCREW PIN

{)mi$iic=c=c=c=

::::JI

...

(2)

@ M5.8 PIVOT

BALL

~

()mm

.............................

(2)

Install the @ M5.8 PIVOT BALLS into the

@)

REAR SHOCK TOWER.

Attach the@ REAR SHOCK TOWER

lo

the

gearbox assembly using four

M3X1 0 SIT

SCREWS (SILVER).

Attach t

he

rear

suspe nsion arm

assembli

es

to the gearbox assembly

using

the@ SCREW PINS.

Note the direction of the

@)

REAR SHOCK TOWER.

M3X10SJTSCREW

•

(SILVER(

lt11NSTALL REAR UPPER LINKS I M

[fll

M

@MS.8

BALL

0

....................................

(2)

SYMBOL GUIDE

@

llEAII

UPPER

UHK

11

Assemble

in

this

order

.

11

M3X10SCREW

Apply

proced

ure

to both

leh

and right

side.

Loading...

Loading...