Page 1

ELECTRIC

POWERED

RADIO

CONTROL

HIGH PERFORMANCE

SPORT BOAT

'

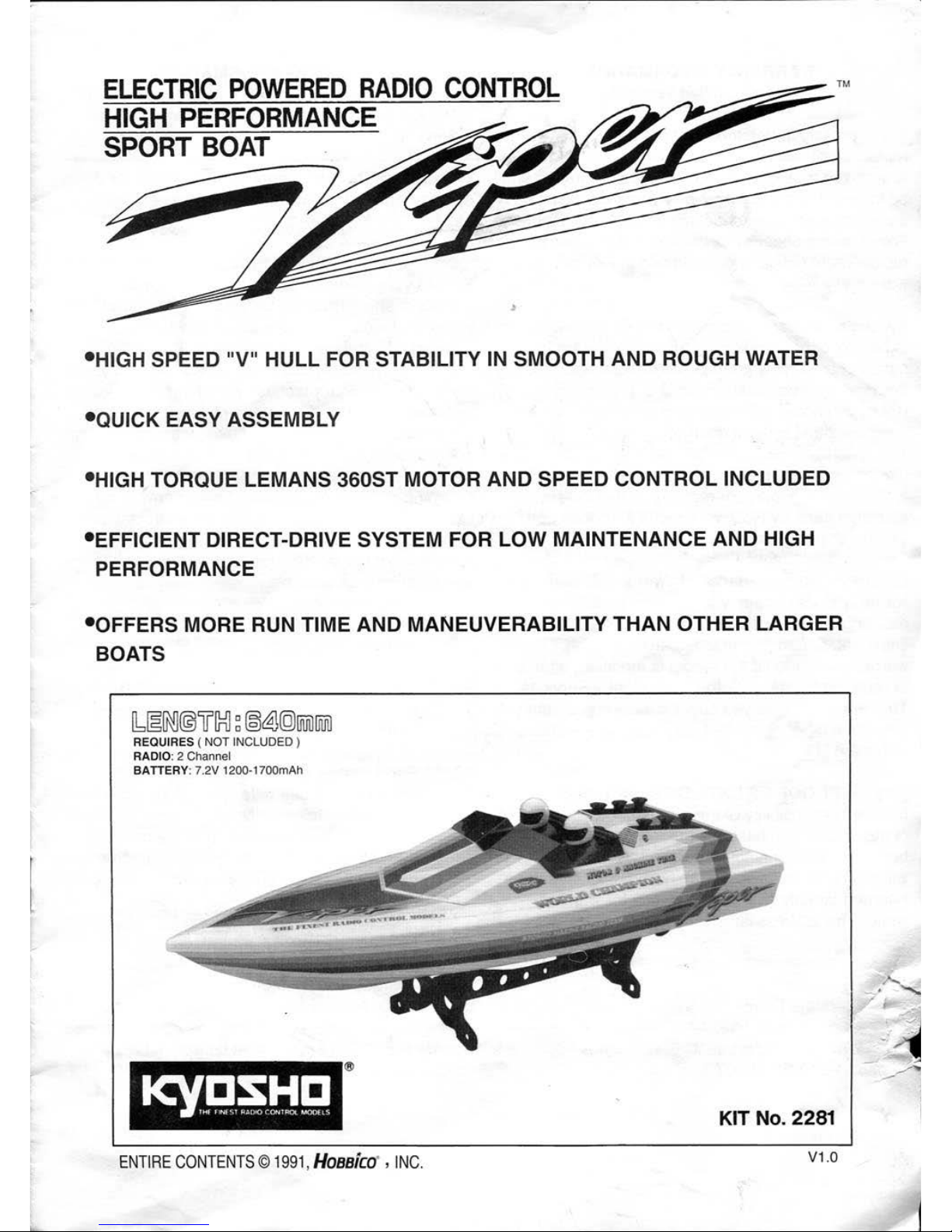

•HIGH

SPEED "V"

HULL

FOR STABILITY IN

SMOOTH

AND

ROUGH WATER

•QUICK

EASY

ASSEMBLY

•HIGH TORQUE

LEMANS

360ST MOTOR

AND

SPEED

CONTROL

INCLUDED

•EFFICIENT

DIRECT-DRIVE SYSTEM FOR

LOW

MAINTENANCE

AND

HIGH

PERFORMANCE

•OFFERS

MORE RUN TIME

AND

MANEUVERABILITY

THAN

OTHER

LARGER

BOATS

[b~!f!l®IJ'[}:D

g

~~@[iffi]

liiiiJ

REQUIRES (

NOT

INCLUDED )

RADIO:

2 Channel

BATTERY: 7.2V 1200·1700mAh

ENTIRE

CONTENTS© 1991

,

HOBBico

· , I

NC.

KIT No. 2281

V1.0

Page 2

WARRANTY INFORMATION

90

Day

Limited Warranty

It is expressly understood

that

the standard

replacement warranty

of

the seller, a

copy

of

which

is annexed to and made

part ·of

this agreement, shall

be in lieu

of

any and all other warranties, including

the warranties

of

merchantability and fitness

for

use.

The

so

le responsibility

of

the seller shall

be

in its

replacement obligations contained in this standard

warranty.

Kyosho's

" Viper " is warranted

to

the original

owner

to be free

of

defects in parts

or

workmanship

for

a

period

of

90

days from

the

date

of

purchase. During

this time Kyosho's authoriz

ed

U.S. repair facility,

Hobby Services,

will repair

or

replace

at

option

any

defective parts without charge.

Limit

of

our Liability:

Our

liability

under

this warranty

is limited to the repair

or

replacement

of

defect

or

defective parts

by

Hobby

Services and

does

not

include shipping expense.

Exclus ion and/or Voidance

of

Warranty: Th is

warranty does

not

apply to

damage

or

defects

resulting from misuse, abnormal service,

damage

in

shipment,

or

damage resulting from a crash.

The

warranty is voided if the model is modified, altered,

or

repaired

by

anyone other than

Hobby

Services.

This warranty gives

you

specific legal rights,

and

you

may have other rights that vary from state to state

within the U.S.

PROOF

OF

DATE

OF

PURCHASE

It is the responsibility

of

the purchaser to

show

proof

of

the date

of

purchase if a model's warranty is to

honored. Your original purchase invoice

or

receipt

will suffice

for

this. Your Kyosho " Viper " should

be

returned directly to

Hobby

Services

for

warranty

work. The address is:

_,-

1-Y'h

~,by

Services

10 Interstate Drive

.ampaign,

Illinois 61821

r.

n: Warranty Department

Phone:

1-217-398-0007

SHIPPING INFORMATION

Please follow steps 1 through 4 in

"Repair

Service"

when

returning a model to H

obby

Services. (See

Below).

We

are

sorry, but

we

cannot

be

responsible

for

crash

damage

and/or

loss

of

kits, engines, accessories ,

etc.

REPAIR SERVICE

Should

your

model

be

past

the

90

day

warranty

period,

or

should

your

kit

be

voided

or

excluded from

warranty coverage, repairs

are

available

for

a

nominal

cost

through

Kyosho

's authorized U.S.

repair facility, Hobby Services. Since

we

want

you to

be

happy

with

your

purchase

for

a long time,

Hobby

Services

employs

a full-time in-house service staff.

They

have

the professional knowledge and

the

sophisticated

equipment

and

parts available to

service

your

model

for

years

to

come

. When

return i

ng

your

model,

whether

for

warranty

or

repair

service, please

be

sure to follow the instructi

ons

listed below. This will

help

the

technician

troubleshoot

the

system , repair it, and return it

to

you

as

quickly

as

possible.

1.)

Under

all circumstances, return the

ENTIRE

system.

2.)

Disconnect

the

receiver battery switch

harness, and make sure

the

transmitter is

turned

off

.

3.) Send written instructions which include:

proof

of

purchase

date

(your store receipt

or

purchase invoice), a list

of

all items returned,

a

THOROUGH

exp

lanation

of

the

problem

and

the

service

needed

, and

your

phone

number

where

you can

be

reached during the

day.

4.)

Also

include

your

full return address.

R

epair

charges

and postage

may

be

prepaid

or

billed C.O.D. Additional postage charges will

be

applied

for

non

-warranty returns. All repairs

shipped

outside

the

United States

must

be

prepaid

in

U.S.

funds

only.

-2-

Page 3

Important! Before You Begin

Th

is

is a sophisticated model with a large number of moving parts. Before you 8.)

Avoid using power screwdrivers when assembling your kit.. They

tend

to

overtighten screws.

begin assembly, take a look through the box

and

these instructions carefully to

decide whether or

not

you

are

ready for this challenge!

If

you

do

not

think that

this type of model is for you,

it

may be returned to the dealer as long

as

it

is 9.)

Take your time and read the directions thoroughly.

It's not how fast

you can assemble the kit but

how

fast it goes once assembled.

NEW and UNUSED. UNDER

NO CIRCUMSTANCES CAN YOUR DEALER

ACCEPT A KIT FOR RETURN IF ASSEMBLY

HAS

ALR

EADY BEGUN! If this

is not what you bargained for, then

go

no further and return this kit to

the

dealer 1 0.)

Trial

fit

all

parts

to

ensure

proper lit

belore

attaching

them

permanently.

immed

ia

tely. BUT, if a little maintenance, doesn't bother you, and the thrill

of

high performance boating is for you, then don't hesitate another minute! IT IS

VERY

IMPORTANT TO

read

through

this

entire

manual

thoroughly

to 11.)

Do not

use

excessive Ioree when tighteni

ng

sell-tappi

ng

type

screws

into plastic. Overtightening will cause the threaded portion ol

the

plastic to strip.

It

is

recommended

to

stop tightening when some

resistance is felt after the threaded portion enters the plastic.

familiarize yourself with the parts and methods

of

construction used BEFORE

actually starting

to

build.

HOW

TO

USE THIS

MANUAL

On each page you will find a directory

of

small pans that will be used in each

step. For ease

of

identification, these parts are shown actual size enabling you

to place a screw directly

on

the

picture to ensure you

have

selected the

appropriate size.

TYPE

OF

SCREW

li

o;;

...............

;-;-:;iifl::i"i'<u«>CilJTi'j

\::::"1-

QUANTITY USED

SIZE OF

___

M3 x

10

SIT SCREW (2) IN THIS STEP

SCREW

~

On

Page 4 you will find a complete list

of

parts used in this kit including the part

number and total quantity supplied in

the kit and in whi

ch

step

it

is used. When

ordering replacement or optional parts. see page 4 for a

comp

lete listing of

parts and stock numbers.

HELPFUL TIPS

AND

PRECAUTIONS

Some precautions need to be observed when building your "Viper"

to

avoid

problems.

1.)

2.)

Use a muffin tin or egg carton to separate screws. nuts. washers. etc.

This will make

it

easier to locate the correct part.

Place a mat or towel

on

the work surface where you will be building

the

kit.

This will prevent parts from rolling

oH

and will protect the work

surface at the same time.

3.) Try to avoid working over a shag

carpet

In the event that a small

part or screw should

fall onto the carpet,

it

will

be

difficult to find.

4.)

5.)

Avoid getting products like engine cleaner

or

screw lock

on

the plastic

parts. They can have a serious effect

on

your model.

Avoid operating the

• Viper • in very oold temperatures. Both resin

and

metal parts become brittle

at

low

temperatures.

In

addition.

grease

and oil

become

very

thick

causing

premature

wear

and

deficient performance.

Remove

all flashing from the parts before assembly.

METRIC NUTS AND BOLTS

All nuts bolts used throughout this k

it

are metric size. Therefore. some ol

the

notations may not

be

familiar

to

you.

An

M3

nut

is

a 3 millimeter (3mm) nut.

An M3 x 15 screw is 3mm diameter and 15mm long. Some round parts

may

be labeled as a "4mm Washer"

(a

washer with a 4mm inside diameter) 'or a

"3mm Bushing"

(a

bushing with a 3mm inside diameter) . At various points

throughout the manual these parts are labeled and pictured in their actual

size

on

the left hand side of the the page. For your reference. 1 millimeter equals

approximately

.039 inches.

M3X

15SCREW

M4 WASHER

3mm

A few dilferent types

of

screws

are

used in

the

construction

of

your model.

He

re are some examples

and

how they will be indicated

in

the instructions

for

exampl

e.

Sell Tapping will simply be SIT screw.

SELF TAPPING (SfT)

Qiiiiii!IIBP

I " HAS A

TAPER

COARSE THREAD

SETSCREW

@))

SCREW

FINE

THREAD

When you see this symbol, there are steps that you

should

pay extra particul

ar

attention

to

when building this model.

-

~

.....

....

.....

-

-

Ensure that all parts are will lubricated where the instructions indicate

--~~~

th

~e~

us

_e_o_f_g_

re

_a_s_e_·--------------------------------------------------------------------------------

~~~

-

:-

These tools are

6.)

7.)

needed to assemble NEEDLE

NOSE PUERS

AWL

~

.,.

lheViper.

~

PHILUPS SCREWDRIVER

[

HOBBY

KNIFE

. 3 -

Page 4

'

,

b.

.

RADIO OPERATIONAL CHECK

Thoroughly read and follow the instructions supplied wilh your radio system.

The

following instructions are a general procedure for testing the oper

ation

of

your radio system.

An operational check of your complete radio system prior to installation is a

must. This check

will locate possible defective components BEFORE t

hey

are

installed in your model.

•

Gently plug the switch harness and servo connectors into the proper

receptacles

on

the

receiver. The connectors

are

polarized and will fit only one

way.

If they

do

not plug in easily, turn them around and try agai

n.

(DO NOT

FORCE

.)

Install the batteries I

nto

the battery holders f

or both

the transmitter

and receiver.

Unravel the receiver antenna wire and

tum

on

the transmitter, then tum

on

the

receiver switch. The servos may move a

little bit at this poi

nt

but this

is

normal.

Check to make

su

re that the transmitter is

on

when switched on. and if

it

is,

continue.

If it is

not

, recheck your installation

of

batteries. You should be able

to move the servos' a

rm

s using t

he

transmitter controls. Notice how the servos

move. They should move the same amount as you move t

he

controls. Also,

no

tice the direction of rotation of t

he

servos, then switch the servo reversing

switch

es,

if so equipped. See if the rotation

of

the servos change. They should

operate in the opposite direction

as

before.

Decide whether your radio is in prop

er

working order. If you decide that it is

defective, check the warranty procedures described in the r

ad

io instruction

manual. When turning off the system, always turn the receiver

off

first, then t

he

transmitter. This will prevent the receiver from responding to stray signals

which can cause damage.

NOTICE: Use only radio frequencies specifically allowed to operate "surface•

models such as RIC cars and boats. In the United States those frequencies fall

within the '75 MHz' or '

27 MHz' bands. Use of any other frequencies is both

ill

ega

l and dangerous.

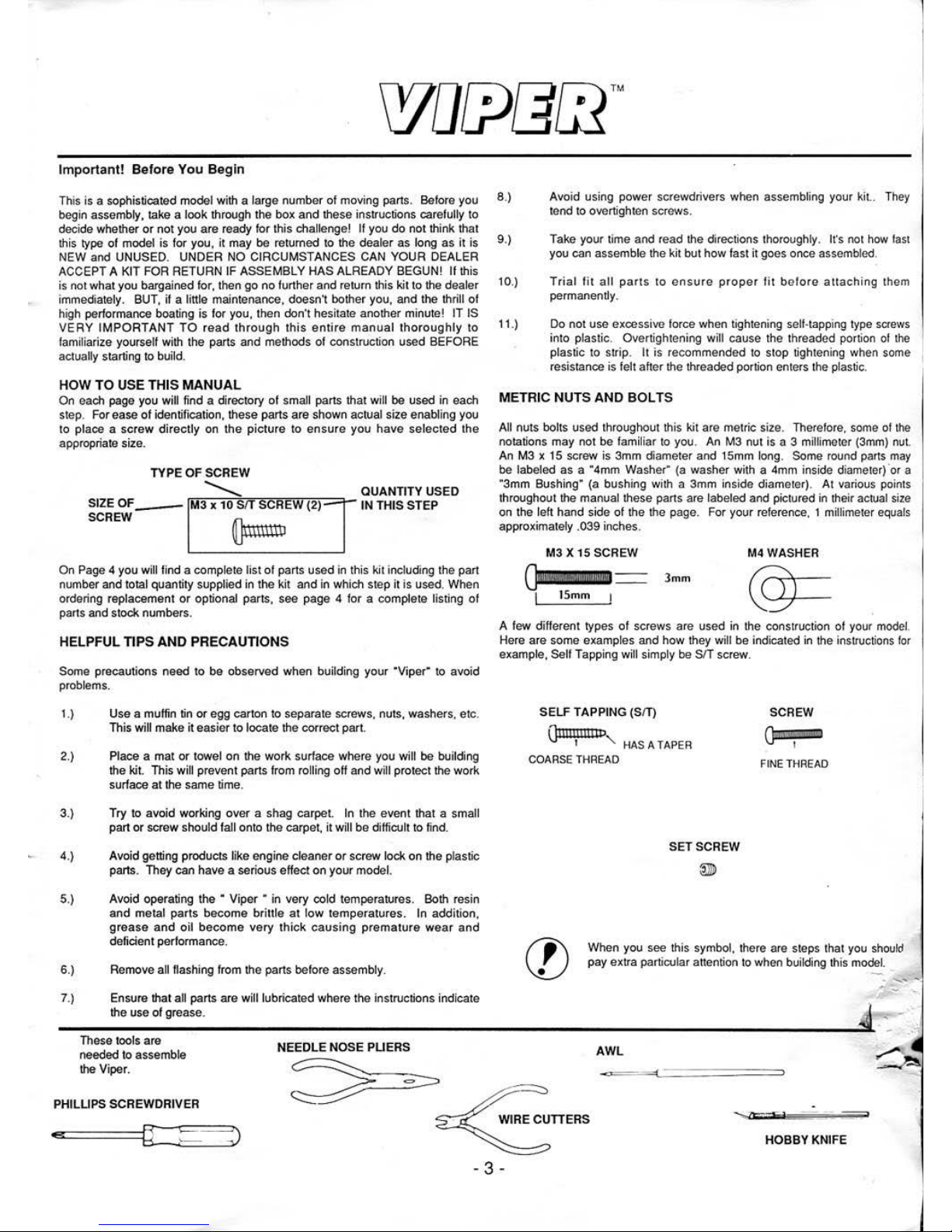

KEY NO.

1

2

s

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

PARTS

GUIDE

DESCRIPTION

Oty STEP USED IN

Hull

TOfl_

1

Hull Bottom 1

Hatch

Cover 1

Windshield 1 13

Radio

Co

mpartment

1

Compartment Cover

1

Mot

or

Stand 1

l!E2_er

Motor Bracket 1

Lower Motor Bracket 1

360 Motor 1

Shaft Connector 1

Brass Tube 1

Drive

Shaft 1

Brass Drive

Collar

1

3

Prop 1

3

Servo Tray 1

Speed Control

1

Hatch

Screw 1

Hatch

Nut 1

Rudder 1 4

Steerirlg_ Bracket 1

4

Rud der Bracket 1

Rud der Bracket Plate 1

Antenna Holder 1

Dri

ver

Head

2

12

Velocity

Stack A

2

12

Veloci

ty

Stack B

2 12

Veloci

ty

Stack C

2 12

St

eerirlg_

Rod 1 4

Speed Control Rod 1

9

Antenna Tube 1

6

Antennae~

1

6

Decal 1 1

Standj~

1 2

Stand (B) 1

2

Stand (C)

2 2

Double

Sided Tape 1

6

Double

Sided Tape (long

1 13

Rubber Boot 1 4

Ho

ok

and Loop 3 7 11

You

can purchase replaceme

nt

and

optiona

l parts for

you

r ki

t.

All

of the

parts ide

ntifi

ed

by

key numbers (s

ee

above

for

complete list)

are

usua

lly not

available

sing

ularly, but

we

offer these

parts

in convenient parts

"packs" which

can

be pur

chased

separately.

To figu

re

out which parts pack you

need,

find the

key number

for

that

part with

in

the manual. Th

en consu

lt

our

parts

pack gui

de below. When

referring to

the parts you

need, always

use

the

Parts

Pack

Numbe

r.

For

ins

tance, If

you

need a Decal

(Key

#33)

ask

your

dealer for

Kyosho

Parts

Pack VP-09

(Deca

l).

Check

NO. PARTS NAME

KEY

NO. AND OTY.

Check

NO. PARTS NAME KEY NO. AND OTY.

EBA

Y

VP-

01

Propeller

1

5x2

EB

AY

LA-41 Hook

and

Loop 40

x2

EBA

Y

VP-

02

Prop Shaft Set 1

1121314x1

EBAY

1840

Double Sided Tape

37x5

EBA

Y

VP-03

Rudder Set

20

21

22 23x1

EB

AY

1898 360ST Motor 10x1

EBAY

VP-04 Accessories set

4 18 19

24

31

32

38x1 OPTIONAL PARTS

25 26

27 28x2

EBAY

2461 AP 36L Motor

EBAY

VP-

05

Motor Bracket 8

9x1

EBAY

2326

Qu

ick

Charg_er

15 Minute

EBAY

VP-

06

Saeed Control 17x1

EB

AY

1849

Mu

lti-Charger If

Ac:lj_ustable

Charger

EBAY

VP-07 UnkaQe Set

29

30

39x1

EBAY

2246 FET Peak Charger P

eak

Cha!Q!lr

EB

AY

VP-08 Servo

Mount 6 16x1

.EBAY

. 4400H 1400mAh Flal Pack

6-Ceii7

.2V

EBAY

VP-

09

Decal

33x1

EBAY

2330B 1700mAh Fl

at

Pack 6·Ceii7.2V

EBAY

VP-10 Display Stand

34 35x1 36x2

EBAY

1700mAh SCR

7-Ceii8

.4V

. 4 .

Page 5

[I)

APPLYING THE DECALS

Cut-out the decals as close to

the Lines

as

possible. Tho

box

lid

and

photo below can

be

used for

Lhe

placement

of

the decals on the

Viper.

[Ij

ASSEMBLY OF BOAT STAND

Assemble

the

boat

stand

by sliding

the

slots in (

36

)

Stand C into

the

slots

in

(34)

Stan

d A

and

(35)

St

ond

B. Secw·e

A,

Band

C by placing a

few

drops of

cyanoacrylate g

lue on

the slots

.

[Ij

PROP INSTALLATION

MJ

Z"oPLASTIC NUT

©

(1)

SH

AKE PROOF

~

WASHER

'V

(1)

Check

that

the

bra

ss

tube

is

glued

in

.

lf

not, use o

water

proof glue

to

hold the

tube

.

Screw the

(14) Bn!SS Drive

Collar

onto

the

drive

s

han.

Slide

the

(

15)

Po·

op onto the

(

14)

Br

ass

Dri

ve

Collar

so

that

the slot in

the

Prop fi ts over the

Drive

Co

llar

.

'

Lnstall

the

Shake

Proof Washer

and

the

M3.5 plastic

Nut

Tighten

the M3.5 plasti c

Nut

secure!)'·

- 5 -

NOTE

: If

the

Viper will

be

painted

sec

pag

e

11

on

painting

before

appling

the

decals.

In

a pan

of warm

water

place a few drops

of

dish

soap.

Peel

th

e backing o

fT

of the

dccal

and

dip

it

in the water.

Place

the decal on

the

Viper.

The soap

and

wnter

will

allow

the

decal to

be

positioned. Remove

Lhc

excess

water

from

the

decal

(

dab

do

not rub )

and

allow

to

dry.

[H]

I

-

Page 6

•

I

(1]

RUDDER INSTALLATION

M2.6 x 10 SIT SCREW

~

(1)

1 I"' In

stall

the

{39)

Rubber

Boot

in

the

back

of

the

Hull . The Boot goes

to

the insi

de of

the

Hull

.

Cut

ond

remove I mm

(

1116

")

rrom

the

end

or

the

Boot.

lmm

lnstllllthc

(29)

Steering

Rod

so

that

the

large bend

is

outside

the

Hull.

[Ij RADIO INSTALLATION

•

a!'f'

~

.

Remove

the

8 screws

that

hold

the

radio

trny

cover and remove the cover.

lnstnllthe

two servos

as

shown

at

the

right. The

sides

of

the

holes in

the

se.r"o

tray

may

be

trimmed for

larger

servos.

Secure

the

sei"'OS

with

the

serews provided with

the

radio system.

Screw from

radio

system

.

I

nstall

the

{

21)

Steeri

ng

Bracket

on

the

(29)

Steering

RQd. Bend

lhe

end of

the rod 90 deg1·ees down.

The

Stee•·ing Rod

sho

uld

be

installed in

the

outside hole. Slide

the (20) Rudd

er

into

the

(22)

Rudder

Bracket

. Install

the

(2

1)

Steeri

ng

Brack

et

on

the (20) Rudder

.

Secure

the

Steering

Brockel wilh II

M2.6 X 10

srr Screw.

0

~

The

striped

area

~

may

be

trimmed

to

0

fit a

larger

servo.

0

1

•

0

(0

- 6 -

Page 7

L

[I) RECEIVER INSTALLATION

Cl

ean

the bottom

of

the receiver and the back

of

the

raruo

compartme

nt

with alcoho

l.

Place a piece

of

(37)

Double Sided

Tap

e on the bottom of the receiver

and

attach

it

to

the

back

of

the radio compartment.

/

Re~iv(

Louble

Sided Tape

o-

32 Antenna Cap

1----31

Antenna Tube

(f)

Wrap the

re~iver

in a plastic bag to

prevent moisture

from

damaging it.

Route the receiver

antenna

through the (24)

Antenna Hold

er

and

the

(3

1)

Antenna

Tube

. Place the

(3

2)

Antenna Cap over

the

(3

1)

Antenna

Tub

e.

DO

NOT

cut

the excess receiver antenna.

[I]

RECEIVER BATTERY INSTALLATION

Cl

ean

the side

of

the Receiver

Batte1-y

and

the

bottom right side

oflhe

hull beside

the

radio compartment with alcohol. Place a

piece

of

(40)

Hook

and

Loop material on

the Receiver

Battc•-y .

Remove

the paper backing from the oth

er

side

of

the Hook

and

Loop and

install

the

Receiver Battery and Hook and

Loop

to

the

bottom

rigbt

side

of

the

hull next

to

the

raruo

eompm·tment. This

will allow the Receiver

Battery to

be

removed when needed.

-7-

/

-

Page 8

[I) RUDDER CONTROL

Plug the Receiver Battery

and Servos

iniAl

the Receiver.

Turn

the

radio on and

set

the

servo trim levers

to neutral.

0

0

0

0

Trim

lhe

servo

arm

IAl

the shape

and

size shown.

In

sta

ll

the servo

arm

90 degrees

IAl

the

center

line

of

the servo.

The

(29) S

teering

Rod

should be

instal

led in

the

center

hole

NOTE: If more steering is needed

move the

(29)

steering

Rod

to

the outside hole on

the

servo arm.

By

extending

or

contracting

the

bend in the

(29)S

tee

ring Rod

adjust

the

length so

that

lhe

servo

arm

and

steering

bracket

are

parallel.

Install

th

e (30) Speed

Control Ro

d in

the hole 9/16

'"

from

the

center

of

the

servo arm, with the servo arm

in

lhe

neutral position

as

shown

at

the right.

0

By

moving

the

(3

0)

Spe

ed

Control

Rod out

one hole

on

the servo

arm,

\ m

o•·e

speed cont•·ol

~,

, mov7ment can

be

obtained.

'

'

,

'

---------------

~

, ' RIGHT TURN

•,

LE

FT

TURN

'

'

'

· - - -

---

-

r·

.~,

•

SPEED CONTROL MOVEMENT COMPARED TO STI

CK

MOVEMENT

...,

-

'

r

l

HIGH SPEED LOW SPEED NEUTRAL

REVERSE LOW SPEED REVERSE HIGH SPEED

- 8 -

Page 9

j1 ol RECEIVER SWITCH INSTA.LLATION

ST[

Install the receiver switch in

lhe

(6)

Compartm

ent

Cove~

us

ing

the

screws

provided with

the

receiver

switch.

STE 2. Route

the

receiver

antenna

and the receiver battery wire

through

lhe

indentat

ion

in

the radio compartment. rein

staU the

compartment

cover using the 8 screws.

·

ITIJ

BATTERY INSTALLATION

N

OTE: The

battery

will plug in only one

way.

DO

NOT

forc

e it.

S .

Put a strip

of

(40) Hook

and

Loop

ST

al

each end

of

the battery.

.. Remove the paper backing

from

the

(40)

Hook

and

Loop an

d in

sta

ll

the

battery

at

the left.

side of the radio

compartment on the bull bottom.

In

stall the

battery

toward the

front

of

the radjo compartment.

thjs will help balance

the

boat

in

the center.

lftlll£DCH

4iii'Pj(jjf

-

9-

Page 10

1

12

1 DRIVER AND STACK INSTALLATION

M3xa SIT SCREW

•

~

(2)

M3x6SCREW

o-

(6)

M3NUT

@ (6)

NOTE:

The

D1iver

Heads and the

Ve

locity

Stacks may

be

painted

with

a b

ru

sh-on

ena

mel

such

as

Kyosho"s Polyca

Paint.

'""C

. Install the two (

25)

Driv

er

Heads

with two

M3x8 S/1' Screws.

STE-

2. Install the

sLx

(26, 27, 28) Velocity

Stacks.

The

(28

)Velocity

Stack

B

(long) goes to

Lhc

rear.

Then

(27)

Velocity

Stack

A and (26)Veloci

ty

Stack

C (

short

) to

the

front. Use the

six M3x6

Screws

and

M3

Nuts.

1

13

1 WINDSHIELD INSTALLATION

\

•

STE" •. Remove

the

clear

protective covering

from

the

(4)

Windshield.

Sn':P

"'·

Install the long

stlip

of

(38) D

ouble

Sided

T

ape

along the

indentation in front of

the

dri

vcrs.

S,

~?

3. Attach the windshield

to

the

(3)

Hat

ch

Cover.

U is very important to

put

some

styrofoam

in

the hull a.nd the

under side

of

the hatch cover.

This

will all

ow

the

boat to float

should

an

accident occur.

~~~===~

~

-

10-

Page 11

l

Most types

of

paint

such as lacquer

or

epoxy can be

used. The

following is

an

example using lacquer.

SPRAY LACQUER SPRAY LACQUER

PRIMER COLOR

PLASTIC BODY

PUTTY

MASKI

NG

TAPE

THROTTLE

CJ

.

.

SA

ND

PAPEA(120. 240

AND 400 GAIT)

STEERING

FARTHEST

~HOLE

TIGHT

TURN

BATTERY TOO

FAR BACK

N

OSEHIG~

·

s:;:

'-

PAINTING THE VIPER

1.

Fill

any

dents

with

putty

and

sand

smooth.

4.

Spray

several light coats

of

paint

lo

prevent

the

paint

from running.

PUTTY

2.

Sand

using 120

grit

then

240 grit.

vo

·ver to avoid ovcr.spray.

5.Cover

the

area

not

lobe

painted with masking

tope.

Wet

the

surface while lightly

sanding

.

3. Priming

NEWSPAPER

6. Pin

striping

and decals can easily be applied

after

the

paint

has

dried.

<:z

--

··~

Cover

lo

avoid

.,.,.~·

~~

· ·

-#

over sprny.

Spray

with two coats

of

primer

and

allow

lo

dry. Wet

sand

with

400

grit

sand

paper

then

wash

and

dry.

ADJUSTMENTS

FAST FORWA

RD

SLOW FORWARD

NEUTRAL

NEUTRAL

REVERSE

RIGHT

TURN

STEERING TRIM

MIDDLE

HOLE

AVERAGE

TURN

BATTERY IN

MIDDLE

•

WIDE

TURN

BATTERY

TOO FAR

N

OSELEV

EL

~

s:;;;; ·-

N

~

AA

D

For

best

handling

the

boat

should

sit

level in

the

water.

If

the

battery is

too

far

forward ,

the

boat

will

not

get

up

on

plane

and

will be slow.

If

the

battery

is

too

far

back

the

front will bounce up and down, called porpoising.

If

the

boat

turns

too

sharp

it

may

spin

out,

and

the

back

of

the

boat

will flip

around.

- 11 -

-

'

...,.

Page 12

Loading...

Loading...